Page 1

Installation Instructions

Instrucciones de instalación

Instructions d’installation

English/Español/Français

Kenmore®

Gas Range

Estufa a gas

Cuisinière à gaz

P/N W10884766A

Sears Brands Management Corporation

Hoffman Estates, IL 60179 U.S.A.

www.kenmore.com

www.sears.com

Sears Canada Inc.

Toronto, Ontario, Canada M5B 2C3

www.sears.ca

Page 2

TABLE OF CONTENTS

RANGE SAFETY ....................................................................2

INSTALLATION REQUIREMENTS ..........................................4

Tools and Parts .................................................................................4

Location Requirements ...................................................................4

Electrical Requirements ..................................................................6

Gas Supply Requirements ..............................................................6

INSTALLATION INSTRUCTIONS ........................................... 8

Unpack Range .................................................................................8

Install Anti-Tip Bracket ...................................................................8

Adjust Leveling Legs .......................................................................9

Level Range .................................................................................... 10

Make Gas Connection ..................................................................10

Verify Anti-Tip Bracket IsInstalledandEngaged ..................... 11

Electronic Ignition System ............................................................. 11

Remove/Replace Drawer ............................................................. 12

Oven Door...................................................................................... 12

Complete Installation .................................................................... 13

GAS CONVERSIONS .......................................................... 14

LP Gas Conversion ........................................................................ 14

Natural Gas Conversion ...............................................................17

Adjust Flame Height .................................................................... 20

RANGE SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

follow instructions.

You

can be killed or seriously injured if you don't

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

instructions.

follow

WARNING: If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or death.

– Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

– WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

•

Do not touch any electrical switch.

•

Do not use any phone in your building.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

•

instructions.

If you cannot reach your gas supplier, call the fire department.

•

– Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

2

Page 3

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the “What to do if you smell gas” instructions.

IMPORTANT: Do not install a ventilation system that blows air downward toward this gas cooking appliance. This type of

ventilation system may cause ignition and combustion problems with this gas cooking appliance resulting in personal injury or

unintended operation.

In the State of Massachusetts, the following installation instructions apply:

■ Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

■ If using a ball valve, it shall be a T-handle type.

■ A flexible gas connector, when used, must not exceed 3 feet.

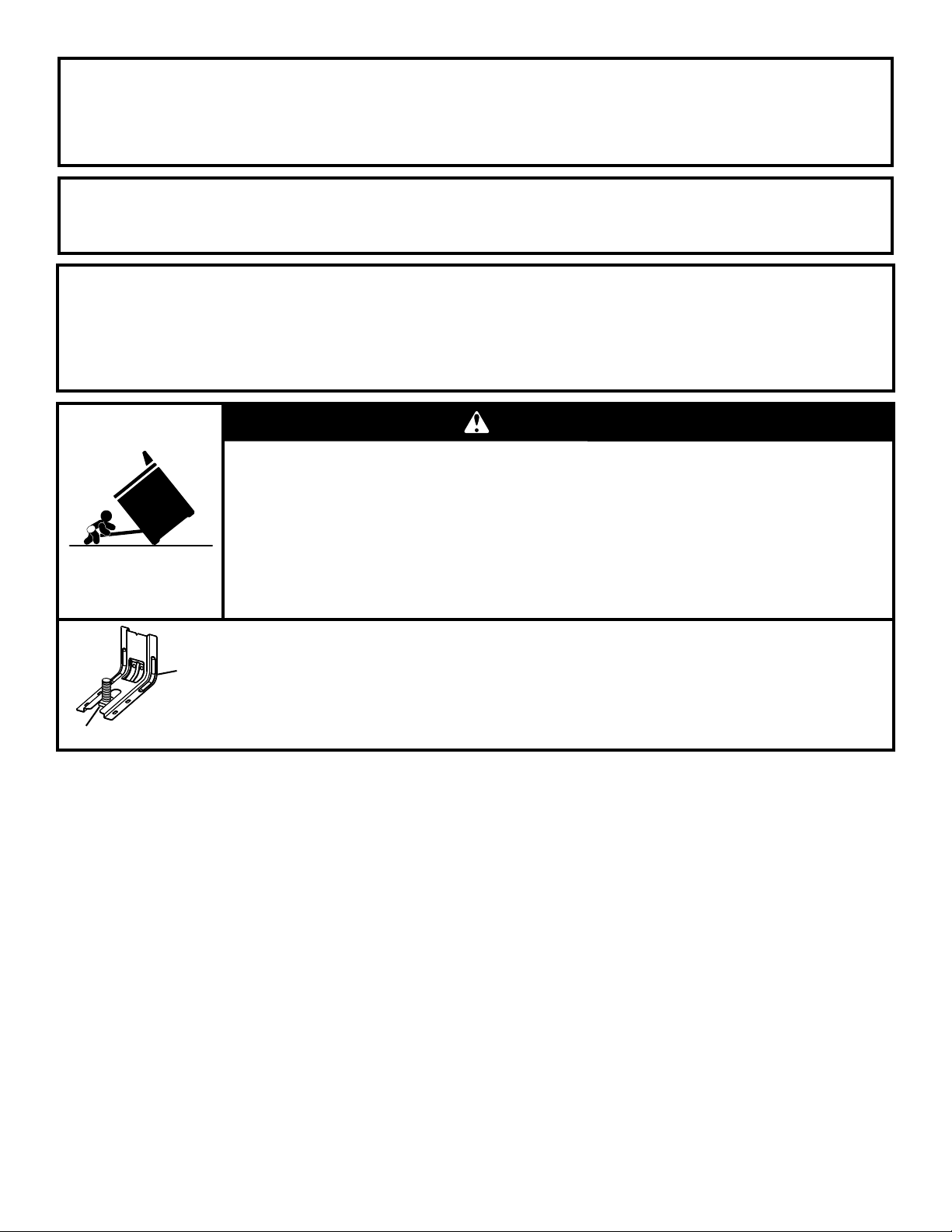

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation instructions.

Slide range back so rear range foot is engaged in the slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed and engaged.

Failure to follow these instructions can result in death or serious burns to children and adults.

Range Foot

Anti-Tip

Bracket

To verify the anti-tip bracket is installed and engaged:

• Slide range forward.

• Look for the anti-tip bracket securely attached to floor or wall.

• Slide range back so rear range foot is under anti-tip bracket.

• See installation instructions for details.

3

Page 4

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools

listedhere.

Tools Needed

■ Tape measure

■ Phillips screwdriver

■ Flat-blade screwdriver

1

■

/8" (3 mm) at-blade

screwdriver

■ Level

■ Drill

■ Wrench or pliers

■ Pipe wrench

15

■

/16" (2.4 cm) combination

wrench

1

■

/8" (3.2 mm) drill bit

(forwood oors)

■ Marker or pencil

Parts Supplied

Check that all parts are included.

■ LP/Natural Gas Conversion Kit

■ #10 x 1

5

/8" (4.1 cm) screws

(for mounting anti-tipbracket)(2)

■ Anti-tip bracket (inside oven cavity)

Anti-tip bracket must be securely mounted to the back wall

or floor. Thickness of flooring may require longer screws

to anchor bracket to subfloor. Longer screws are available

from your local hardware store.

Parts Needed

Check local codes and consult gas supplier. Check existing gas

supply and electrical supply. See the “Electrical Requirements”

and “Gas Supply Requirements” sections.

■ Pipe-joint compound

resistant to LP gas

3

■

/16" (4.8 mm) carbidetipped masonry drill bit

(for concrete/ceramic

oors)

■ Noncorrosive leak-

detection solution

For LP/Natural Gas

Conversions

5

■

/8" (1.6 cm) combination

wrench

3

■

/8" (1 cm) nut driver

9

■

/32" (7 mm) nut driver

■ Masking tape

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

Donot obstruct ow of combustion and ventilation air.

■ It is the installer’s responsibility to comply with installation

clearances specied on the model/serial/rating plate. The

model/serial/rating plate is located behind the oven door

on the top left-hand side of the oven frame.

■ The range should be located for convenient use in the

kitchen.

■ Recessed installations must provide complete enclosure

ofthe sides and rear of the range.

■ To eliminate the risk of burns or re by reaching over the

heated surface units, cabinet storage space located above

the surface units should be avoided. If cabinet storage

is to be provided, the risk can be reduced by installing a

range hood or microwave hood combination that projects

horizontally a minimum of 5" (12.7 cm) beyond the bottom

of the cabinets.

■ All openings in the wall or oor where range is to be

installed must be sealed.

■ Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

■ The anti-tip bracket must be installed. To install the anti-tip

bracket shipped with the range, see the “Install Anti-Tip

Bracket” section.

■ Grounded electrical supply is required. See the “Electrical

Requirements” section.

■ Proper gas supply connection must be available. See the

“Gas Supply Requirements” section.

■ Contact a qualied oor covering installer to check that the

oor covering can withstand at least 200°F (93°C).

■ Use an insulated pad or

range if installing range over carpeting.

IMPORTANT: To avoid damage to your cabinets, check

with your builder or cabinet supplier to make sure that the

materials used will not discolor, delaminate, or sustain other

damage. This oven has been designed in accordance with the

requirements of UL and CSA International and complies with

the maximum allowable wood cabinet temperatures of 194°F

(90°C).

1

/4" (0.64 cm) plywood under

4

Page 5

Mobile Home - Additional Installation Requirements

The installation of this range must conform to the

Manufactured Home Construction and Safety Standard,

Title24 CFR, Part 3280 (formerly the Federal Standard for

Mobile Home Construction and Safety, Title 24, HUD Part

280). When such standard is not applicable, use the Standard

for Manufactured Home Installations, ANSI A225.1/NFPA 501A

or local codes.

In Canada, the installation of this range must conform with

thecurrent standards CAN/CSA - A240-latest edition or with

local codes.

Mobile Home Installations Require:

■ When this range is installed in a mobile home, it must be

secured to the oor during transit. Any method of securing

the range is adequate as long as it conforms to the

standards listed above.

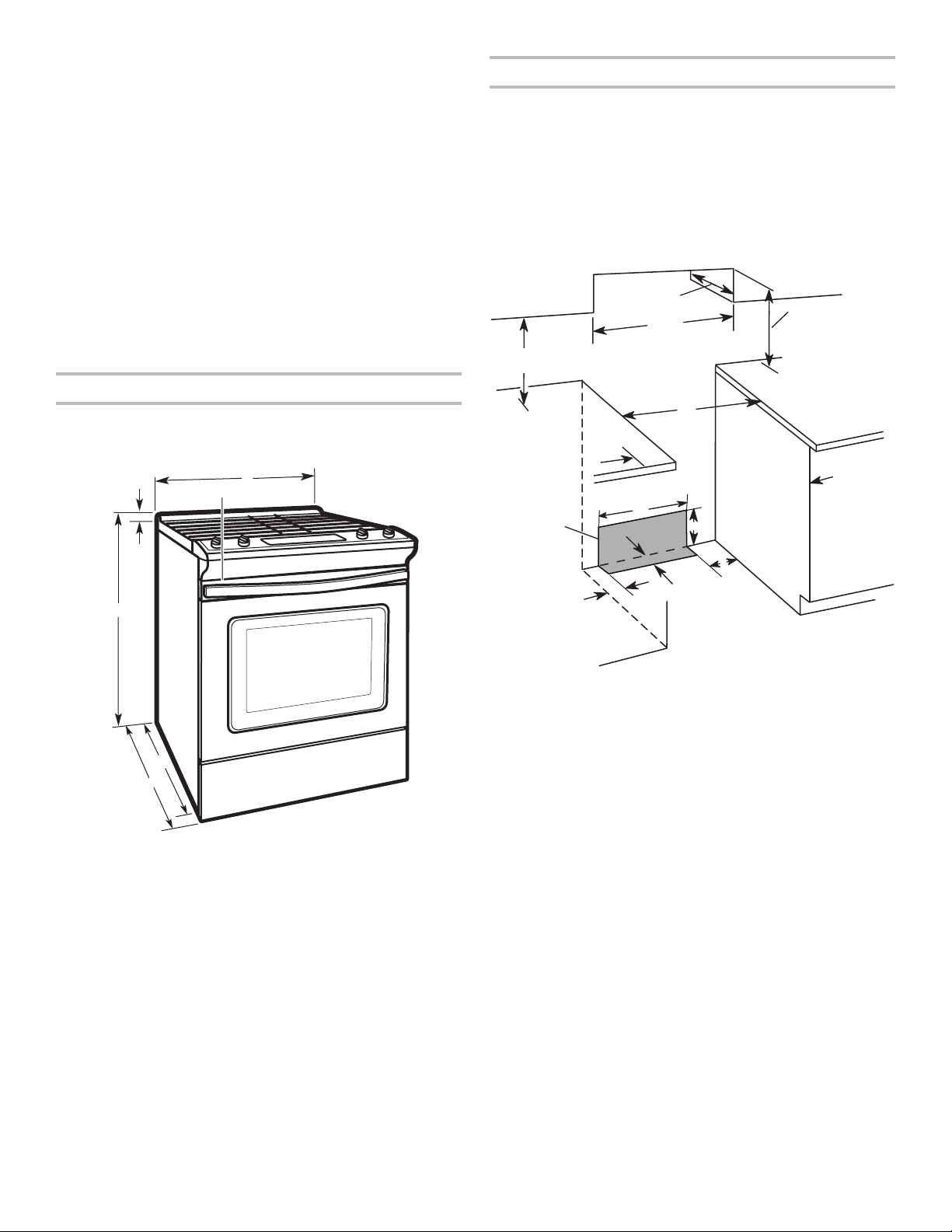

Product Dimensions

This manual covers several models. Your model may appear

dierent from the models depicted. Dimensions given are

maximum dimensions across all models.

A

B

C

Cabinet Dimensions

Cabinet opening dimensions shown are for 25" (64.0 cm)

countertop depth, 24" (61.0 cm) base cabinet depth, and

36"(91.4 cm) countertop height.

IMPORTANT: If installing a range hood or microwave hood

combination above the range, follow the range hood or

microwave hood combination installation instructions for

dimensional clearances above the cooktop surface.

Range may be installed next to combustible walls with zero

clearance.

B

C

A

E

F

G

H

I

D

M

D

E

F

A. 13/16" (3.0 cm) height from

cooktop to top of vent

B. 297/8" (75.9 cm)

C. Model/serial/rating plate

(located behind the oven

door on the top left-hand

side of the oven frame)

D. 36" (91.4 cm) height to

top of cooktop edge with

leveling legs screwed in all

the way*

E. 2825/64" (72.1 cm) max.

depth from front of console

to back of range

F. 291/64" (73.7 cm) max.

depth from handle to back

of range

IMPORTANT: Range must be level after installation. Follow the

instructions in the “Level Range” section. Using the cooktop as

a reference for leveling the range is not recommended.

* Range can be raised approximately 1" (2.5 cm) by adjusting

the leveling legs.

L

J

A. 18" (45.7 cm) upper side cabinet to countertop

B. 13" (33 cm) max. upper cabinet depth

C. 30" (76.2 cm) min. opening width

D. For minimum clearance to top of cooktop, see NOTE.

E. 30" (76.2 cm) min. opening width

F. 3" (7.6 cm) min. clearance from both sides of range to side wall

orother combustible material

G. The shaded area is recommended for installation of rigid gas pipe

and grounded outlet.

H. 131/8" (33.3 cm)

I. 711/16" (19.5 cm)

J. 413/16" (12.2 cm)

K. 311/16" (9.4 cm)

L. 12" (30.5 cm)

M. Cabinet door or hinges should not extend into the cutout.

K

NOTE: 24" (61.0 cm) minimum when bottom of wood or

metal cabinet is shielded by not less than 1/4" (0.64 cm)

ame-retardant millboard covered with not less than No.28

MSG sheet steel, 0.015" (0.4 mm) stainless steel, 0.024"

(0.6mm) aluminum or 0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance between the top of the

cooking platform and the bottom of an uncovered wood

ormetal cabinet.

5

Page 6

Electrical Requirements

Gas Supply Requirements

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

IMPORTANT: The range must be electrically grounded in

accordance with local codes and ordinances, or in the absence

of local codes, with the National Electrical Code, ANSI/NFPA

70 or Canadian Electrical Code, CSA C22.1.

This range is equipped with an electronic ignition system that

will not operate properly if plugged into an outlet that is not

properly polarized.

If codes permit and a separate ground wire is used, it is

recommended that a qualied electrical installer determine

that the ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

■ A 120-volt, 60 Hz., AC-only, 15-amp fused, grounded, and

polarized electrical circuit is required. A time-delay fuse

or circuit breaker is also recommended. It is recommended

that a separate circuit serving only this range be provided.

■ Electronic ignition systems operate within wide voltage

limits, but proper grounding and polarity are necessary.

Check that the outlet provides 120-volt power and is

correctly grounded.

■ This gas range is not required to be plugged into a GFCI

(Ground-Fault Circuit Interrupter) outlet. It is recommended

that you not plug an electric spark ignition gas range or

any other major appliance into a GFCI wall outlet as it

maycause the GFCI to trip during normal cycling.

■ Performance of this range will not be aected if operated

on a GFCI-protected circuit. However, occasional nuisance

tripping of the GFCI breaker is possible due to the normal

operating nature of electronic gas ranges.

■ The tech sheet and wiring diagram are located on the back

of the range in a plastic bag.

NOTE: The metal chassis of the range must be grounded

in order for the control panel to work. If the metal chassis

of the range is not grounded, no keypads will operate.

Check with a qualified electrician if you are in doubt as

towhether the metal chassis of the range is grounded.

6

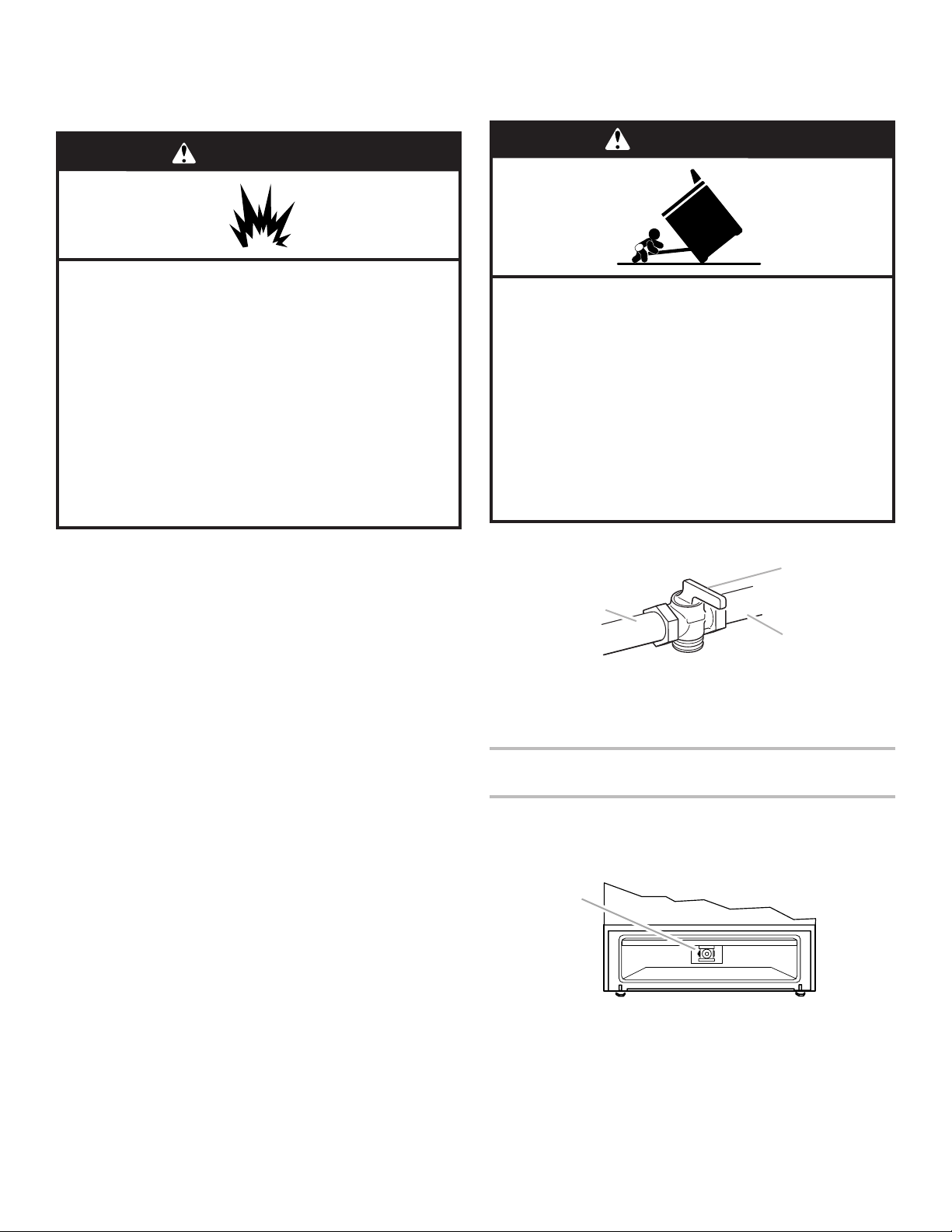

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Observe all governing codes and ordinances.

IMPORTANT: This installation must conform with all local

codes and ordinances. In the absence of local codes,

installation must conform with American National Standard,

National Fuel Gas Code ANSI Z223.1 - latest edition or

CAN/CGA B149 - latest edition.

IMPORTANT: Leak testing of the range must be conducted

according to the manufacturer’s instructions.

Type of Gas

Natural Gas:

This range is factory set for use with Natural gas. See the “Gas

Conversions” section. The model/serial/rating plate located on

the oven frame behind the top left-hand side of the oven door

has information on the types of gas that can be used. If the

types of gas listed do not include the type of gas available,

check with the local gas supplier.

LP Gas Conversion:

Conversion must be done by a qualied service technician.

No attempt shall be made to convert the appliance from the

gas specied on the model/serial/rating plate for use with a

dierent gas without consulting the serving gas supplier. See

the “Gas Conversions” section.

Gas Supply Line

■ Provide a gas supply line of

range location. A smaller size pipe on longer runs may

result in insucient gas supply. With LP gas, piping or

tubing size can be 1/2" (1.3 cm) minimum. Usually, LP gas

suppliers determine the size and materials used in the

system.

NOTE: Pipe-joint compounds that resist the action of LP gas

must be used. Do not use TEFLON®† tape.

†®TEFLON is a registered trademark of Chemours.

3

/4" (1.9 cm) rigid pipe to the

Page 7

Flexible Metal Appliance Connector:

A

C

■ If local codes permit, a new CSA design-certied,

4to5 ft (122 to 152.4 cm) long, 1/2" or 3/4"

(1.3or1.9cm) I.D. (inside diameter), exible metal

appliance connector may be used for connecting

rangeto the gassupply line.

1

■ A

/2" (1.3 cm) male pipe thread is needed for

connection to the female pipe threads of the

inlettotheappliance pressure regulator.

■ Do not kink or damage the exible metal tubing

whenmoving the range.

■ Must include a shut-o valve:

The supply line must be equipped with a manual shut-off

valve. This valve should be located in the same room but

external to the range opening, such as an adjacent cabinet.

It should be in a location that allows ease of opening and

closing. Do not block access to shut-off valve. The valve is

for turning on or shutting off gas to the range.

B

Gas Pressure Regulator

The gas pressure regulator supplied with this range must be

used. The inlet pressure to the regulator should be as follows

for proper operation:

Natural Gas:

Minimum pressure: 6" WCP

Maximum pressure: 14" WCP

LP Gas:

Minimum pressure: 11" WCP

Maximum pressure: 14" WCP

Contact local gas supplier if you are not sure about the inlet

pressure.

Burner Input Requirements

Input ratings shown on the model/serial/rating plate are for

elevations up to 2,000 ft (609.6 m).

For elevations above 2,000 ft (609.6 m), ratings are reduced

at a rate of 4% for each 1,000 ft (304.8 m) above sea level

(not applicable for Canada).

Gas Supply Pressure Testing

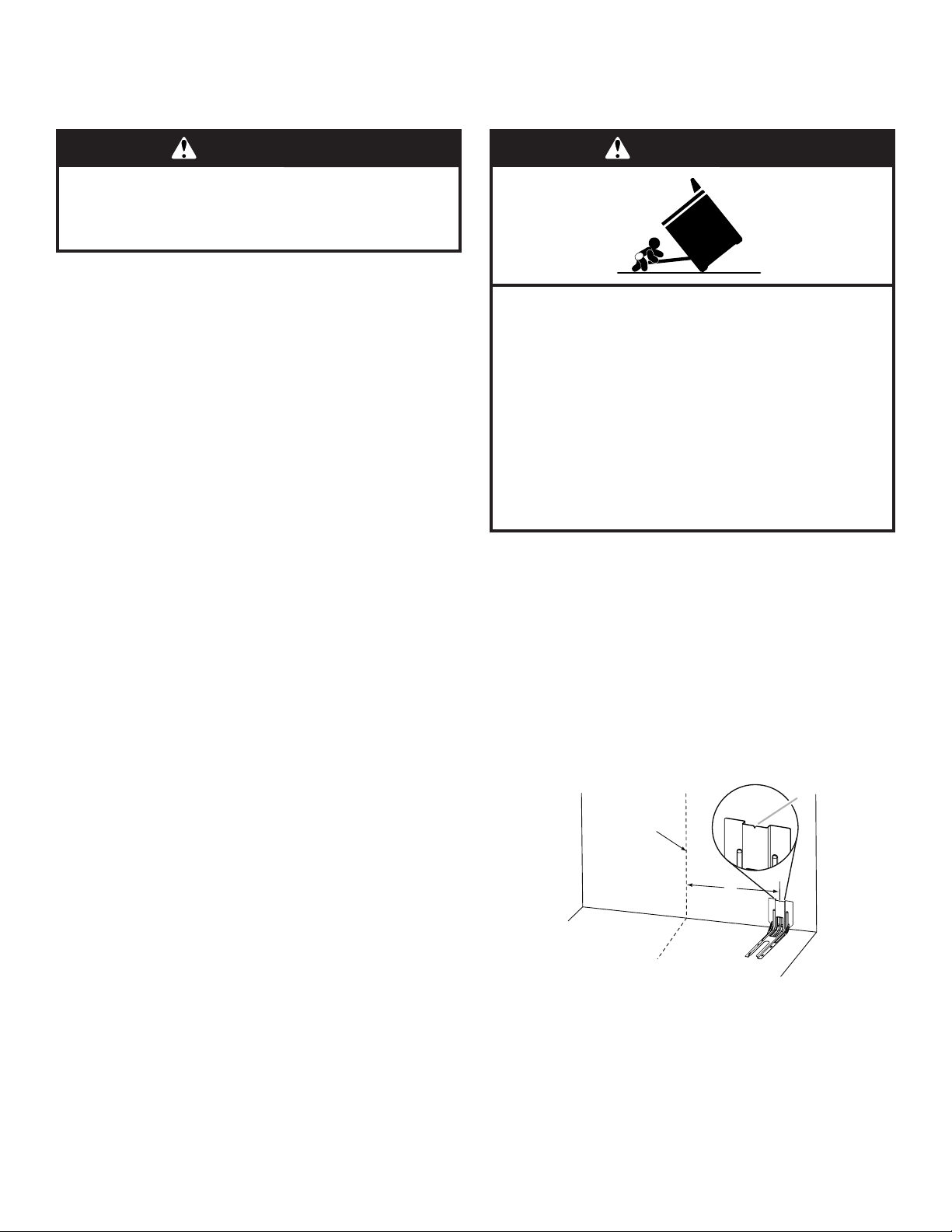

A. Gas supply line

B. Shut-off valve open position

C. To range

Gas supply pressure for testing regulator must be at least 1"

water column pressure above the manifold pressure shown on

the model/serial/rating plate.

Line Pressure Testing Above 1/2 psi Gauge (14" WCP)

The range and its individual shut-o valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1

/2psi (3.5 kPa).

Line Pressure Testing at 1/2 psi Gauge (14" WCP) or Lower

The range must be isolated from the gas supply piping

system by closing its individual manual shut-o valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.5 kPa).

7

Page 8

INSTALLATION INSTRUCTIONS

WARNING

WARNING

Unpack Range

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

1. Remove shipping materials, tape, and lm from the range.

Keep cardboard bottom under range. Do not dispose of

anything until the installation is complete.

2. Remove oven racks and parts package from oven and

shipping materials.

3. To remove cardboard bottom, rst take 4 cardboard

corners from the carton. Stack one cardboard corner on

top of another. Repeat with the other 2 corners. Place them

lengthwise on the oor behind the range to support the

range when it is laid on its back.

4. Using 2 or more people, rmly grasp the range and gently

lay it on its back on the cardboard corners.

5. Remove cardboard bottom.

The leveling legs can be adjusted while the range is on its

back. See the “Adjust Leveling Legs” section.

NOTE: To place range back up into a standing position, put a

sheet of cardboard or hardboard on the oor in front of range

to protect the ooring. Using 2 or more people, stand range

back up onto the cardboard or hardboard.

Install Anti-Tip Bracket

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Remove the anti-tip bracket from the inside of the oven.

2. Determine which mounting method to use: oor or wall.

If you have a stone or masonry floor, you can use the

wallmounting method. If you are installing the range in

amobile home, you must secure the range to the floor.

This anti-tip bracket and screws can be used with wood

ormetal studs.

3. Determine and mark centerline of the cutout space. The

mounting bracket can be installed on either the left-hand

orright-hand side of the cutout. Position mounting bracket

against the wall in the cutout so that the V-notch of the

bracket is 121/2" (31.8 cm) from centerline, as shown.

B

Centerline

A

A. 121/2" (31.8 cm)

B. Bracket V-notch

8

Page 9

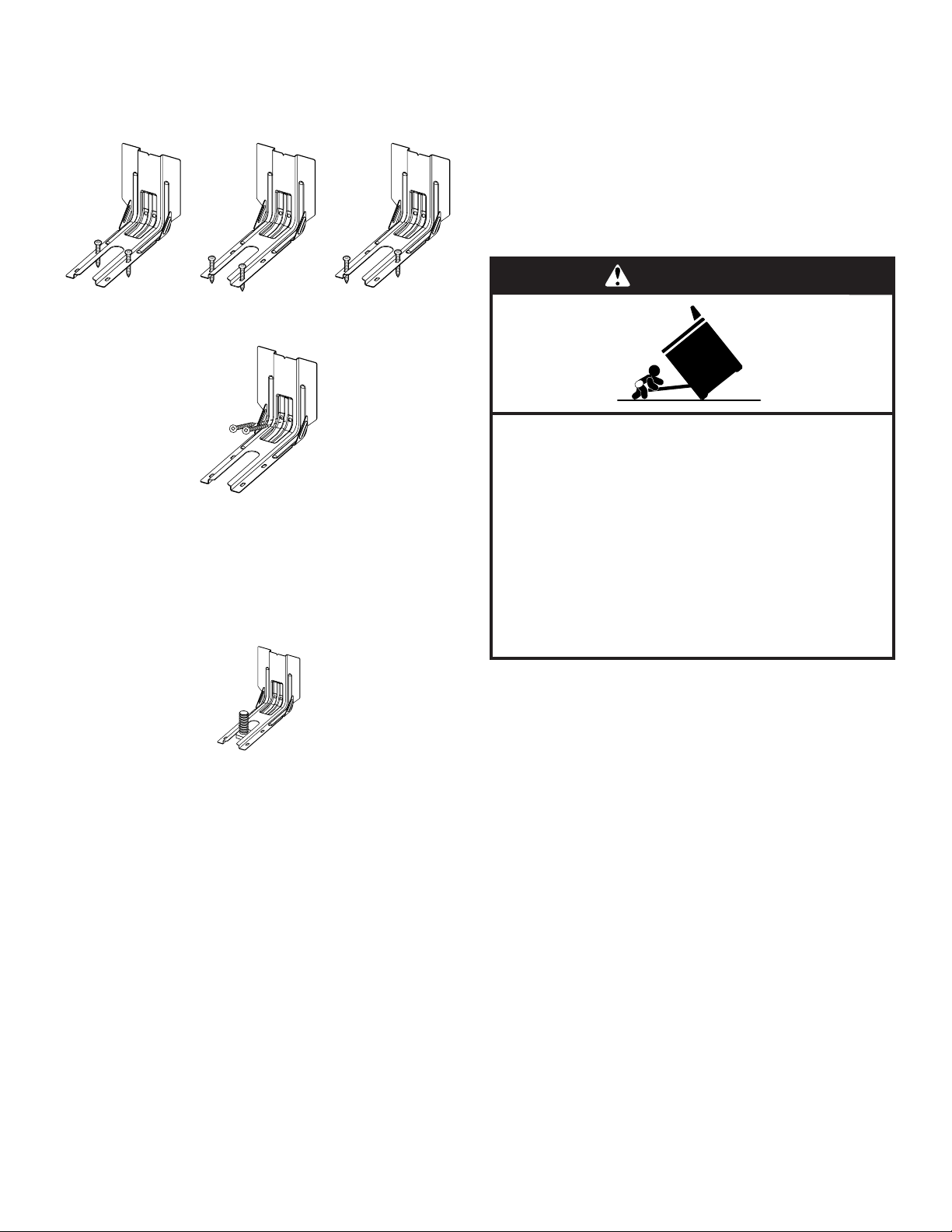

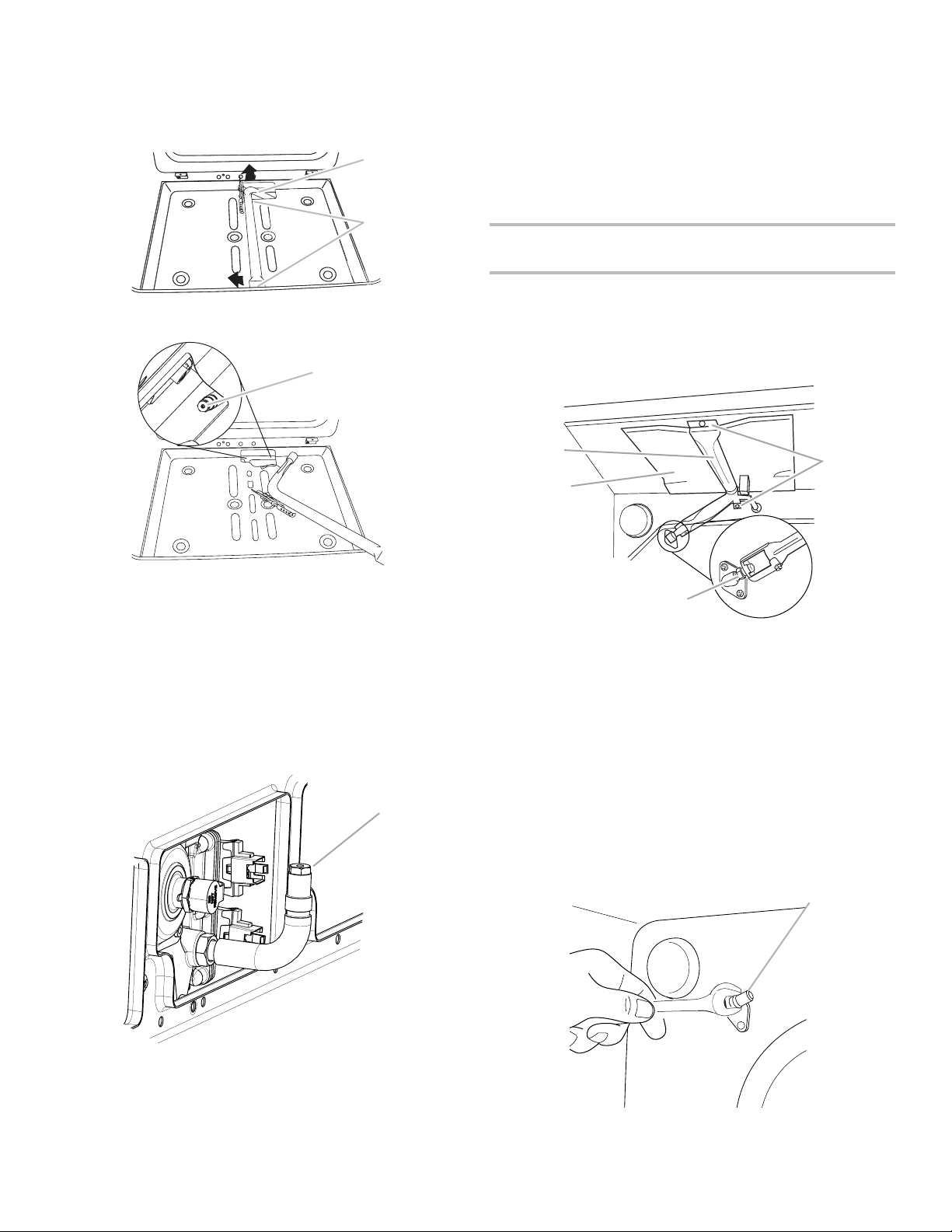

4. Drill two 1/8" (3 mm) holes that correspond to the bracket

WARNING

holes of the determined mounting method. See the

following illustrations.

Floor Mounting

Rear position Front position Diagonal (2 options)

Wall Mounting

5. Using the two #10 x 15/8" (4.1 cm) Phillips-head screws

provided, mount anti-tip bracket to the wall or oor.

6. Move range close enough to opening to allow for nal

electrical connections. Remove shipping base, cardboard,

or hardboard from under range.

7. Move range into its nal location, making sure rear leveling

leg slides into anti-tip bracket.

Adjust Leveling Legs

1. If range height adjustment is necessary, use a wrench

orpliers to loosen the 4 leveling legs.

This may be done with the range on its back or with the

range supported on 2 legs after the range has been placed

back to a standing position.

NOTE: To place range back up into a standing position, put

a sheet of cardboard or hardboard in front of range. Using

2 or more people, stand range back up onto the cardboard

or hardboard.

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

8. Move range forward onto shipping base, cardboard,

or hardboard to continue installing the range, using the

following installation instructions.

2. Measure the distance from the top of the counter to the

oor.

3. Measure the distance from the top of the cooktop to the

bottom of the leveling legs. This distance should be the

same. If it is not, adjust the leveling legs to the correct

height. The leveling legs can be loosened to add up to

a maximum of 1" (2.5 cm). A minimum of 3/16" (5 mm)

isneeded to engage the anti-tip bracket.

NOTE: If height adjustment is made when range is standing,

tilt the range back to adjust the front legs, and then tilt

forward to adjust the rear legs.

4. When the range is at the correct height, check that there

is adequate clearance under the range for the anti-tip

bracket. Before sliding range into its nal location, check

that the antitip bracket will slide under the range and onto

the rear leveling leg prior to anti-tip bracket installation.

NOTE: If a Trim Kit will be used, the top of the cooktop

should be higher than the counter. See the Installation

Instructions included with the Trim Kit for the correct height.

9

Page 10

Level Range

A

FG

A

A

B

1. Place level on the oven bottom, as indicated in one of the

2gures below, depending on the size of the level. Check

with the level side to side and front to back.

2. If range is not level, use a wrench or pliers to adjust leveling

legs up or down until the range is level.

Make Gas Connection

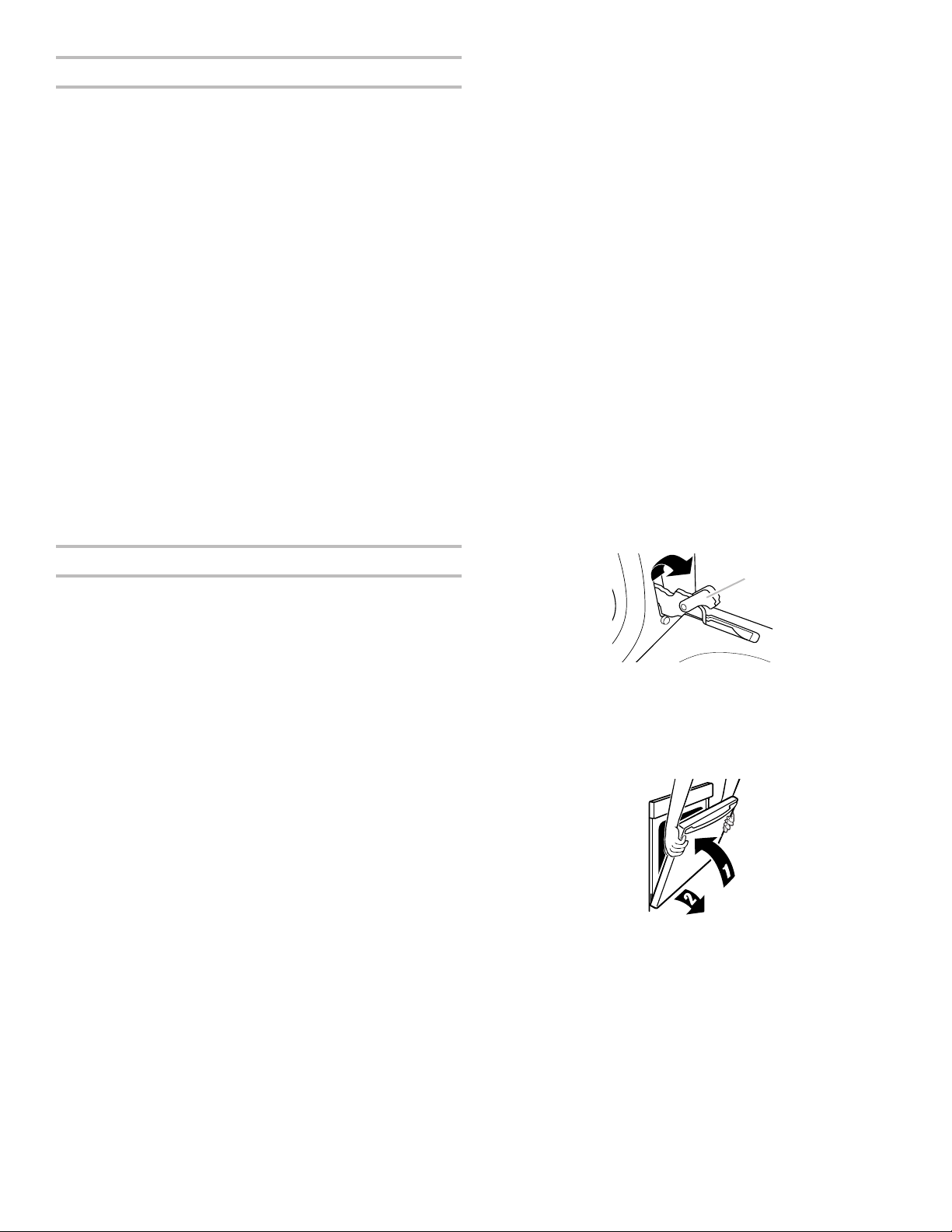

3. Use a 15/16" (2.4 cm) combination wrench and an adjustable

wrench to attach the exible connector to the adapters.

IMPORTANT: All connections must be wrench-tightened. Do

not make connections to the gas regulator too tight. Making

the connections too tight may crack the regulator and

cause a gas leak. Do not allow the regulator to turn when

tightening fittings.

B

C

D

E

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

This range is factory set for use with Natural gas. To use this

range with LP gas, see the “Gas Conversions” section before

connecting this range to the gas supply. Gas conversions from

Natural gas to LP gas or from LP gas to Natural gas must be

done by a qualied installer.

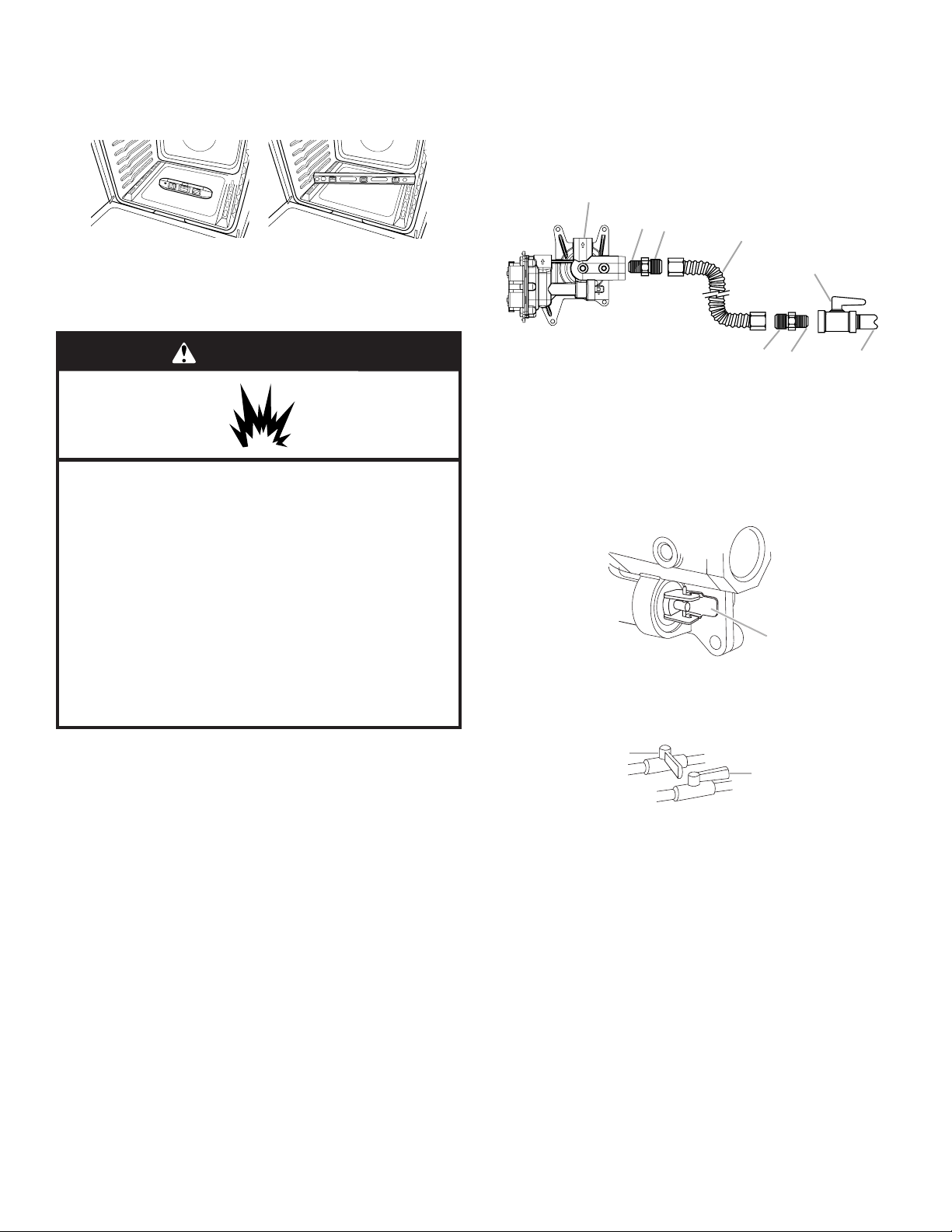

Typical Flexible Connection

1. Apply pipe-joint compound made for use with LP gas to the

smaller thread ends of the exible connector adapters. See

B and G in the following illustration.

2. Attach 1 adapter to the gas pressure regulator and the

other adapter to the gas shut-o valve. Tighten both

adapters, being certain not to move or turn the gas

pressureregulator.

H

A. Gas pressure regulator

B. Use pipe-joint compound.

C. Adapter (must have 1/2"

[1.3cm] male pipe thread)

D. Flexible connector

E. Manual gas shut-off valve

F. 1/2" (1.3 cm) or 3/4" (1.9 cm)

gas pipe

G. Use pipe-joint compound.

H. Adapter

Complete Connection

1. Check that the gas pressure regulator shut-o valve

isintheOn position.

A. Gas pressure regulator shut-off

valve shown in the On position

2. Open the manual shut-o valve in the gas supply line. The

valve is open when the handle is parallel to the gas pipe.

A. Closed valve

B. Open valve

3. Test all connections by brushing on an approved

noncorrosive leak-detection solution. If bubbles appear,

aleak is indicated. Correct any leak found.

4. Remove cooktop burner caps and bases from package

containing parts.

5. Align the gas tube opening in the burner base with the

orice holder on the cooktop and the igniter electrode

withthe notch in the burner base.

10

Page 11

A

D

A

Verify Anti-Tip Bracket

IsInstalledandEngaged

B

C

E

1. Slide range into nal location, making sure rear leveling

legslides into anti-tip bracket.

2. Remove the storage drawer. See the “Remove/Replace

Drawer” section.

3. Use a ashlight to look underneath the bottom of

therange.

4. Visually check that the rear range foot is inserted into

theslot of the anti-tip bracket.

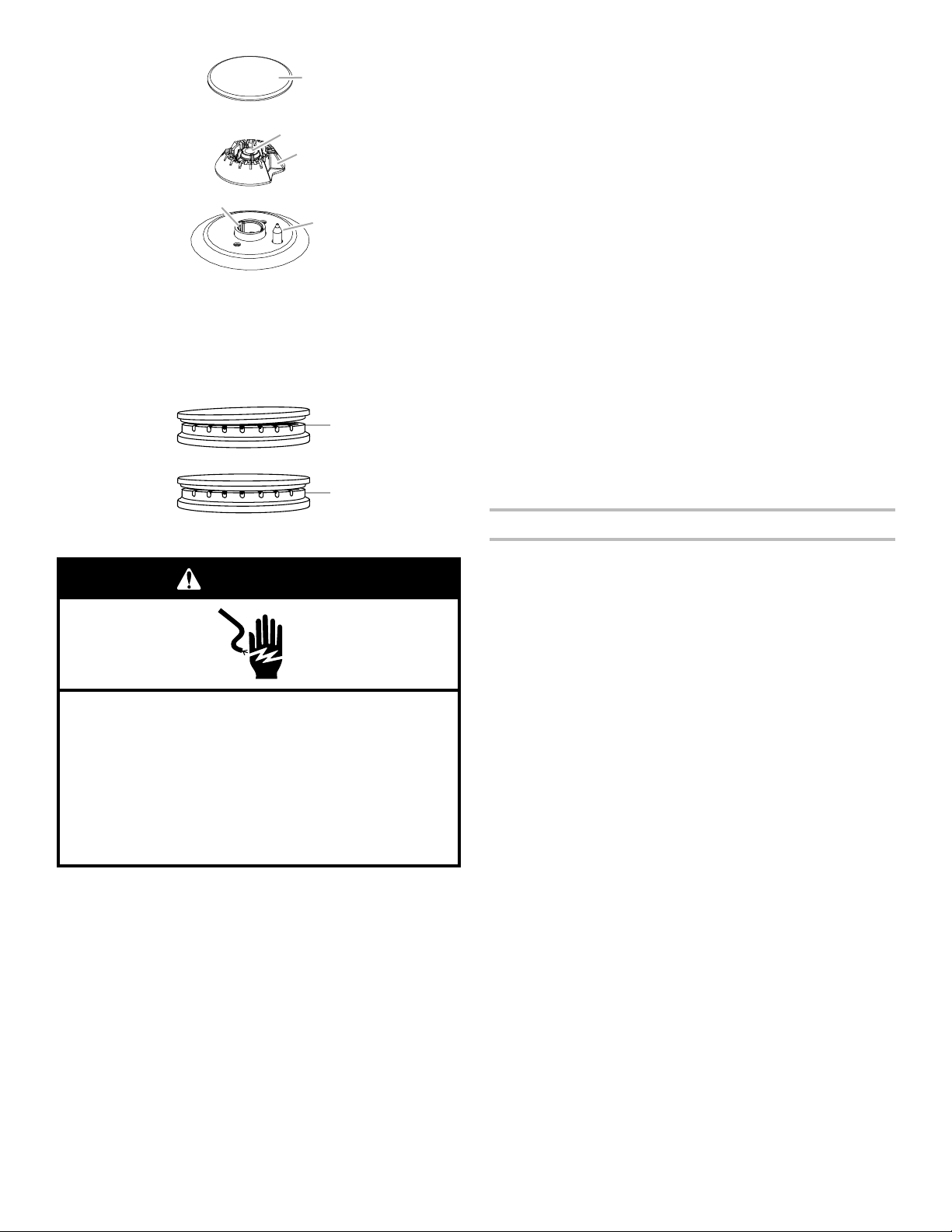

A. Burner cap

B. Gas tube opening

C. Burner base

D. Igniter electrode

E. Orifice holder

Burner caps should be level when properly positioned. If

burner caps are not properly positioned, surface burners

will not light. The burner cap should not rock or wobble

when properly aligned.

B

A. Incorrect

B. Correct

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

6. Plug into a grounded 3 prong outlet.

Electronic Ignition System

Initial Lighting and Gas Flame Adjustments

Cooktop and oven burners use electronic igniters in place of

standing pilots. When the cooktop control knob is turned to

the Lite position, the system creates a spark to light the burner.

All cooktop burners will spark, but only the burner with the

control knob turned to the Lite position will produce a ame.

This sparking continues as long as the control knob is turned

totheLite position.

When the oven control is turned to the desired setting,

sparking occurs and ignites the gas.

Check Operation of Cooktop Burners

Standard Surface Burners

Push in and turn each control knob to the Lite position.

The ame should light within 4 seconds. The rst time a burner

is lit, it may take longer than 4 seconds to light because of air

in the gas line.

If Burners Do Not Light Properly:

■ Turn cooktop control knob to the O position.

■ Check that the range is plugged into a grounded 3 prong

outlet. Check that the circuit breaker has not tripped or

thehousehold fuse has not blown.

■ Check that the gas shut-o valves are set to the open

position.

■ Check that burner caps are properly positioned on burner

bases.

Repeat startup. If a burner does not light at this point, turn the

control knobs to the O position and contact your dealer or

authorized service company for assistance. Please reference

the back cover of the Use & Care Guide to contact service.

If the cooktop low burner ame needs to be adjusted for any

of the burners, see the “Adjust Flame Height” section.

11

Page 12

Check Operation of Oven Bake Burner

1. Press BAKE.

2. Press the Start keypad.

The oven burner should light within 8 seconds. The first

timea burner is lit, it may take longer than 8 seconds

tolight because of air in the gas line.

3. After 2 minutes, open the oven door and check that the

oven is warm.

If Burner Does Not Light Properly:

■ Press the Cancel keypad.

■ Check that the range is plugged into a grounded 3 prong

outlet. Check that the circuit breaker has not tripped or the

household fuse has not blown.

■ Check that the gas shut-o valves are set to the open

position.

Repeat steps 1 through 3. If the burner does not light at this

point, press the Cancel keypad and contact your dealer or

authorized service company for assistance. Please reference

the back cover of the Use & Care Guide to contact service.

If the bake burner ame needs to be adjusted, see the “Adjust

Flame Height” section.

Refer to the Use & Care Guide for proper operation of the

oven controls.

Check Operation of Oven Broil Burner

1. Close the oven door.

2. Press BROIL.

3. Press the Start keypad.

The oven burner should light within 8 seconds. The first time

a burner is lit, it may take longer than 8 seconds to light

because of air in the gas line.

4. After 2 minutes, open the oven door and check that the

oven is warm.

If Burner Does Not Light Properly:

■ Press the Cancel keypad.

■ Check that the range is plugged into a grounded 3 prong

outlet. Check that the circuit breaker has not tripped or the

household fuse has not blown.

■ Check that the gas shut-o valves are set to the open

position.

Repeat steps 1 to 3. If the burner does not light at this

point, press the Cancel keypad and contact your dealer or

authorized service company for assistance. Please reference

the back cover of the Use & Care Guide to contact service.

If the broil burner ame needs to be adjusted, see the “Adjust

Flame Height” section.

Refer to the Use & Care Guide for proper operation of the

oven controls.

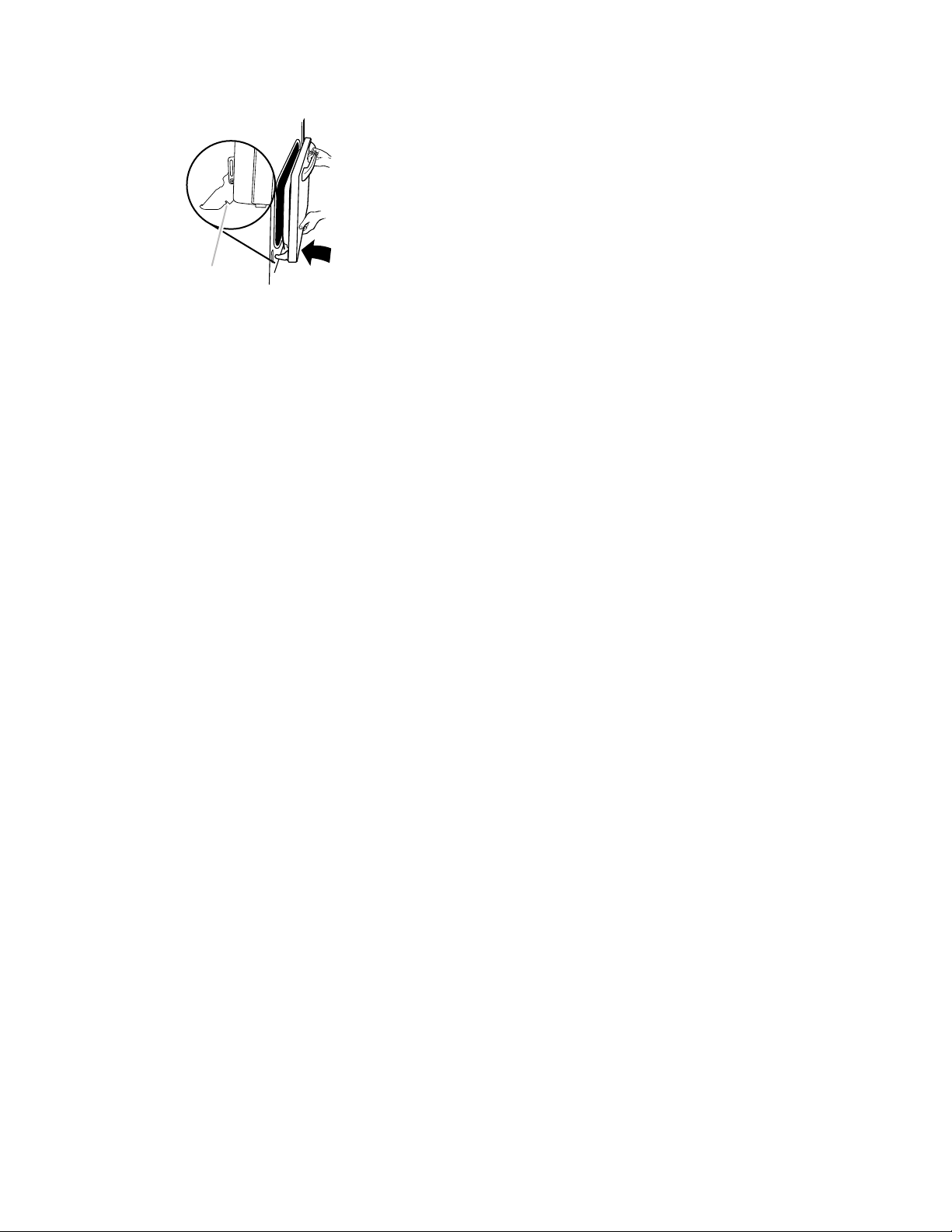

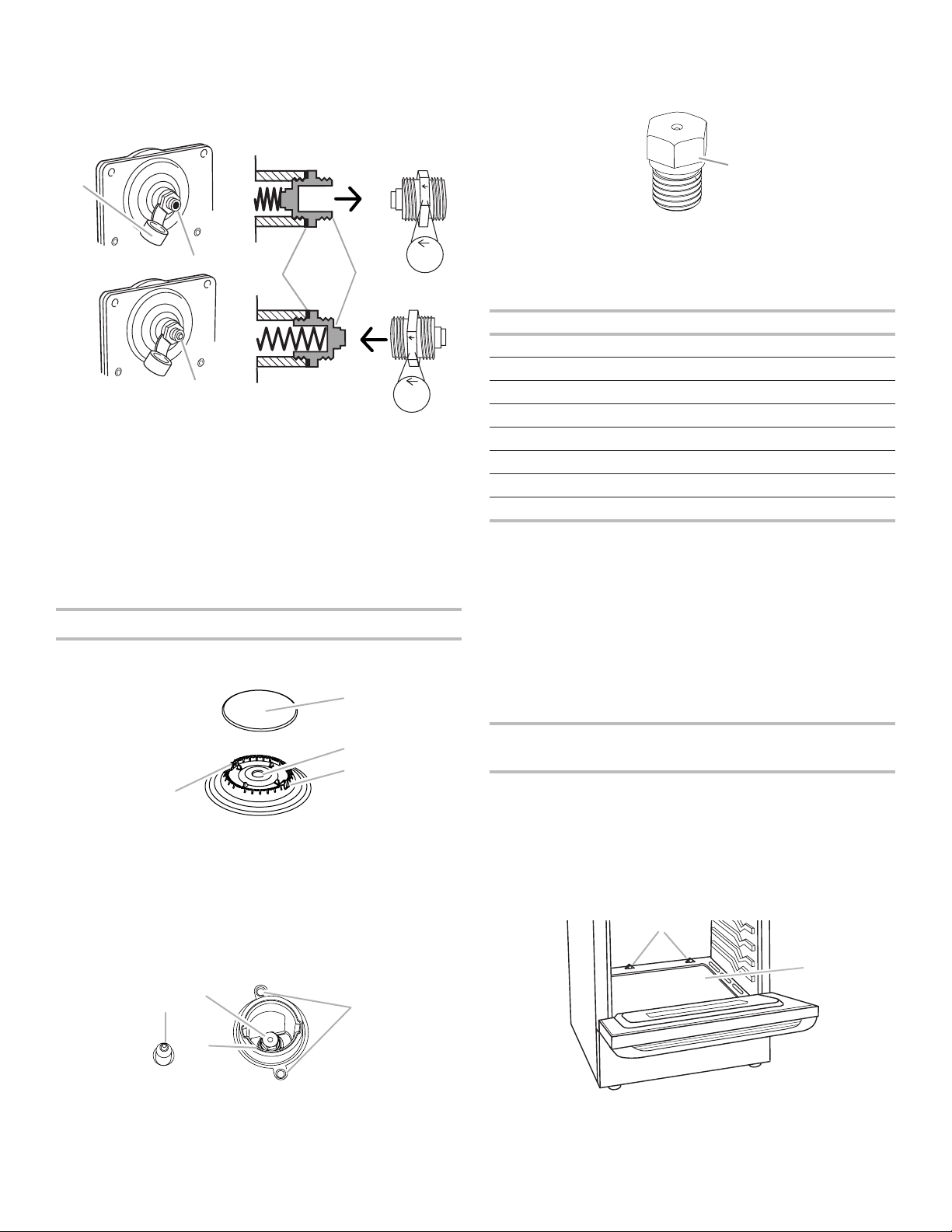

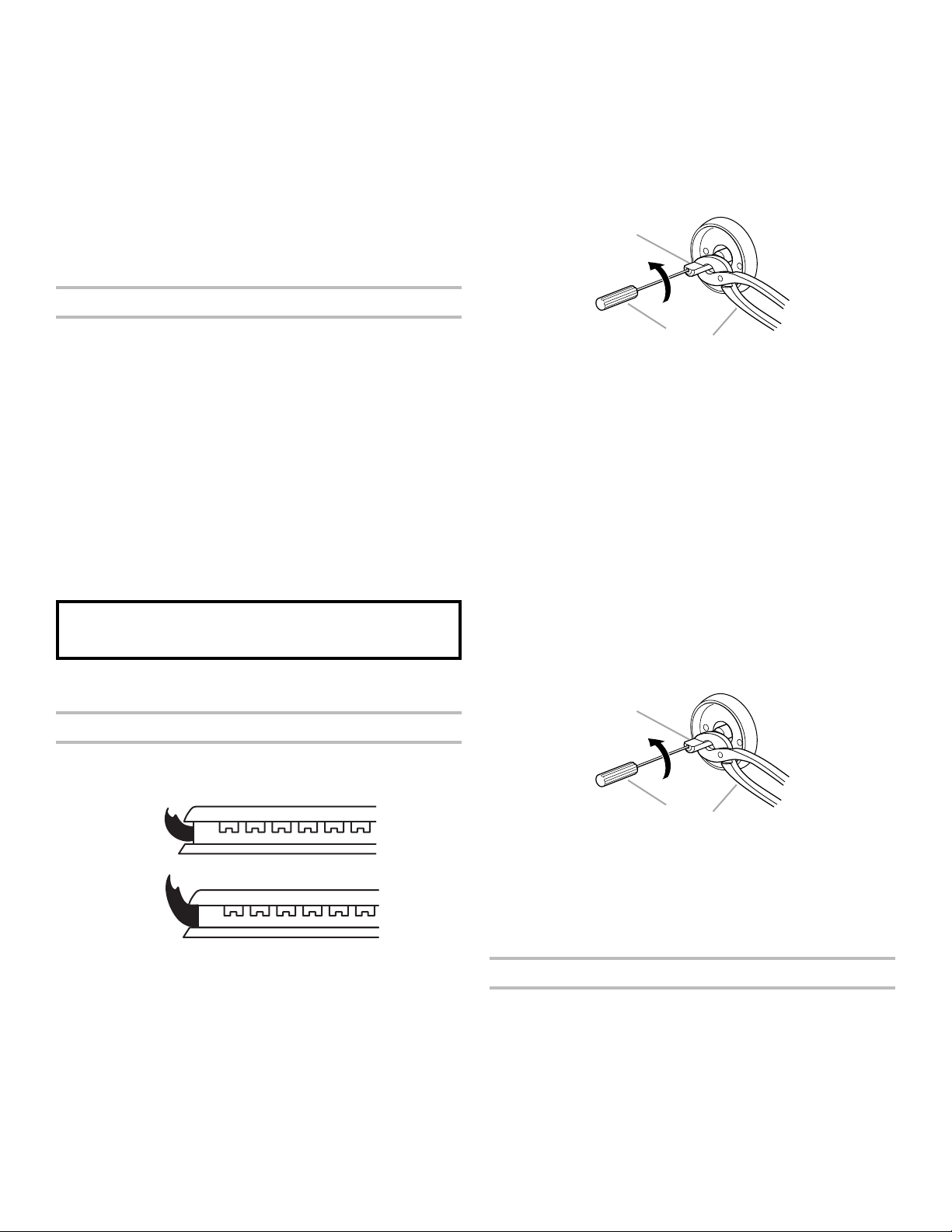

Remove/Replace Drawer

Remove all items from inside the storage drawer, and then

allow the range to cool completely before attempting to

remove the drawer.

To Remove:

1. Open the drawer to its fully open position.

2. Raise the front edge and then lift out.

To Replace:

1. Align the forward drawer notches with the notches in the

drawer rails on both sides. Place the rear alignment tabs

into the drawer rails on both sides.

2. Push the drawer in all the way.

3. Gently open and close the drawer to ensure it is seated

properly on the rails on both sides.

Oven Door

For normal range use, it is not suggested to remove the oven

door. However, if removal is necessary, make sure the oven

isOFF and cool. Then, follow these instructions. The oven

dooris heavy.

To Remove:

1. Open oven door all the way.

2. Pinch the hinge latch between 2 ngers and pull forward.

Repeat on other side of oven door.

A

A. Hinge latch

3. Close the oven door as far as it will shut.

4. Lift the oven door while holding both sides.

Continue to push the oven door closed and pull it away

from the oven doorframe.

12

Page 13

To Replace:

1. Insert both hanger arms into the door. Be sure that the hinge

notches are engaged in the oven doorframe.

A

A. Hinge notch

2. Open the oven door.

The door should be able to open all the way.

3. Move the hinge levers back to the locked position.

Checkthat the door is free to open and close and is

levelwhile closed. If it is not, repeat the removal and

installation procedures.

Complete Installation

1. Check that all parts are now installed. If there is an

extrapart, go back through the steps to see which step

wasskipped.

2. Check that you have all of your tools.

3. Check that you have all of the range accessories,

especiallyoven racks. These accessories may be

intherange packaging.

4. Dispose of/recycle all packaging materials.

5. Check that the range is level. See the “Level Range” section.

6. Use a mild solution of liquid household cleaner and warm

water to remove waxy residue caused by shipping material.

Dry thoroughly with a soft cloth. For more information, see

the “Range Care” section of the Use & Care Guide.

7. Read the Use & Care Guide.

8. Turn on surface burners and oven. See the Use & Care

Guide for specic instructions on range operation.

NOTE: Odors and smoke are normal when the oven

isusedthe first few times.

If Range Does Not Operate, Check the Following:

■ Household fuse is intact and tight or circuit breaker

hasnottripped.

■ Gas pressure regulator shut-o valve is in the open position.

■ Range is plugged into a grounded 3 prong outlet.

■ Electrical supply is connected.

9. When the range has been ON for 5 minutes, check for

heat. If the range is cold, turn o the range and check that

the gas supply line shut-o valve is open.

■ If the gas supply line shut-o valve is closed, open it

and then repeat the 5-minute test as outlined above.

■ If the gas supply line shut-o valve is open, close it,

and contact a qualied technician.

If You Need Assistance or Service:

Please reference the back cover of the Use & Care Guide

tocontact service.

13

Page 14

GAS CONVERSIONS

A

B

C

A

Gas conversions from Natural gas to LP gas or from LP gas

toNatural gas must be done by a qualied installer.

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

LP Gas Conversion

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Turn the manual shut-o valve to the closed position.

A. Gas supply line

B. Manual shut-off valve closed position

C. To range

2. Unplug range or disconnect power.

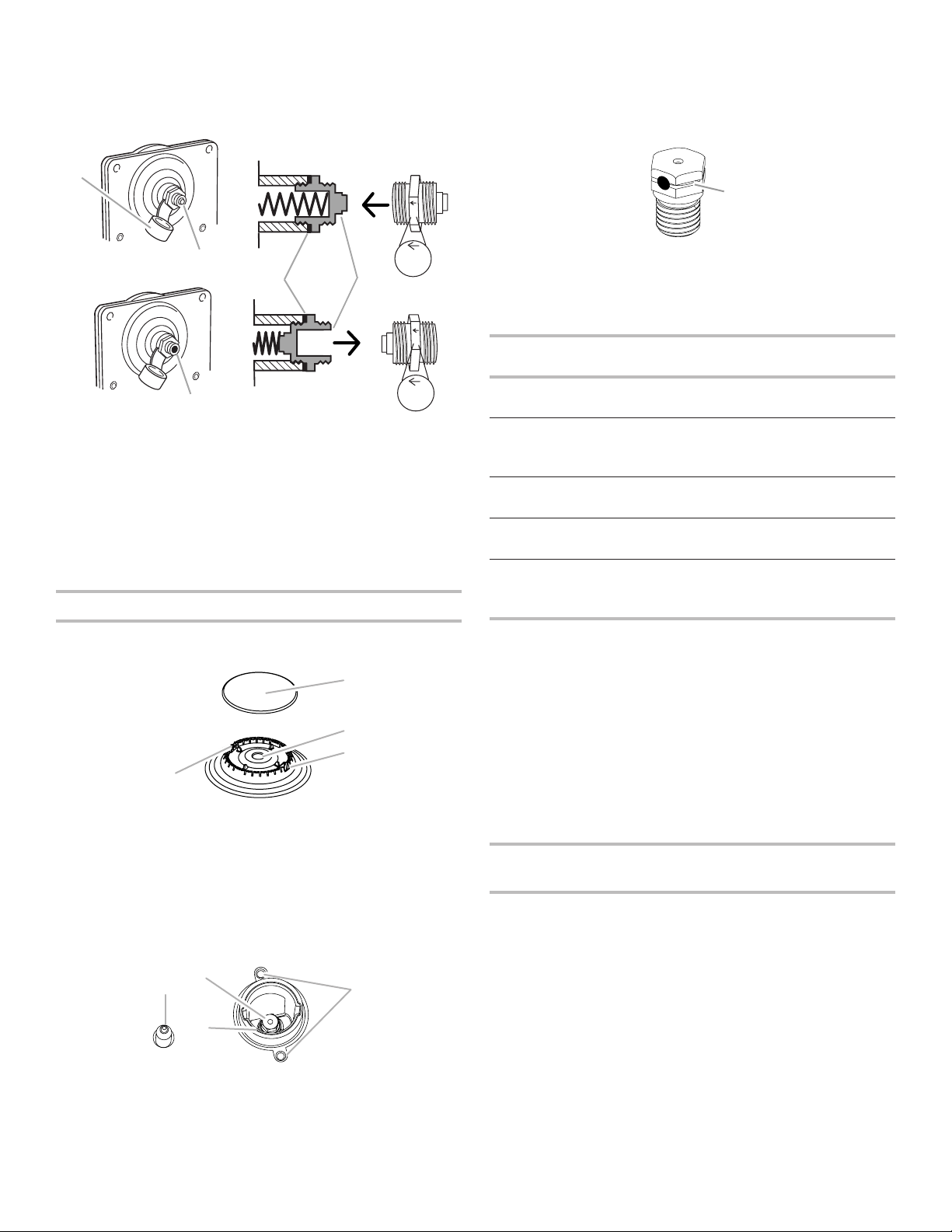

To Convert Gas Pressure Regulator (Natural Gas

toLP Gas)

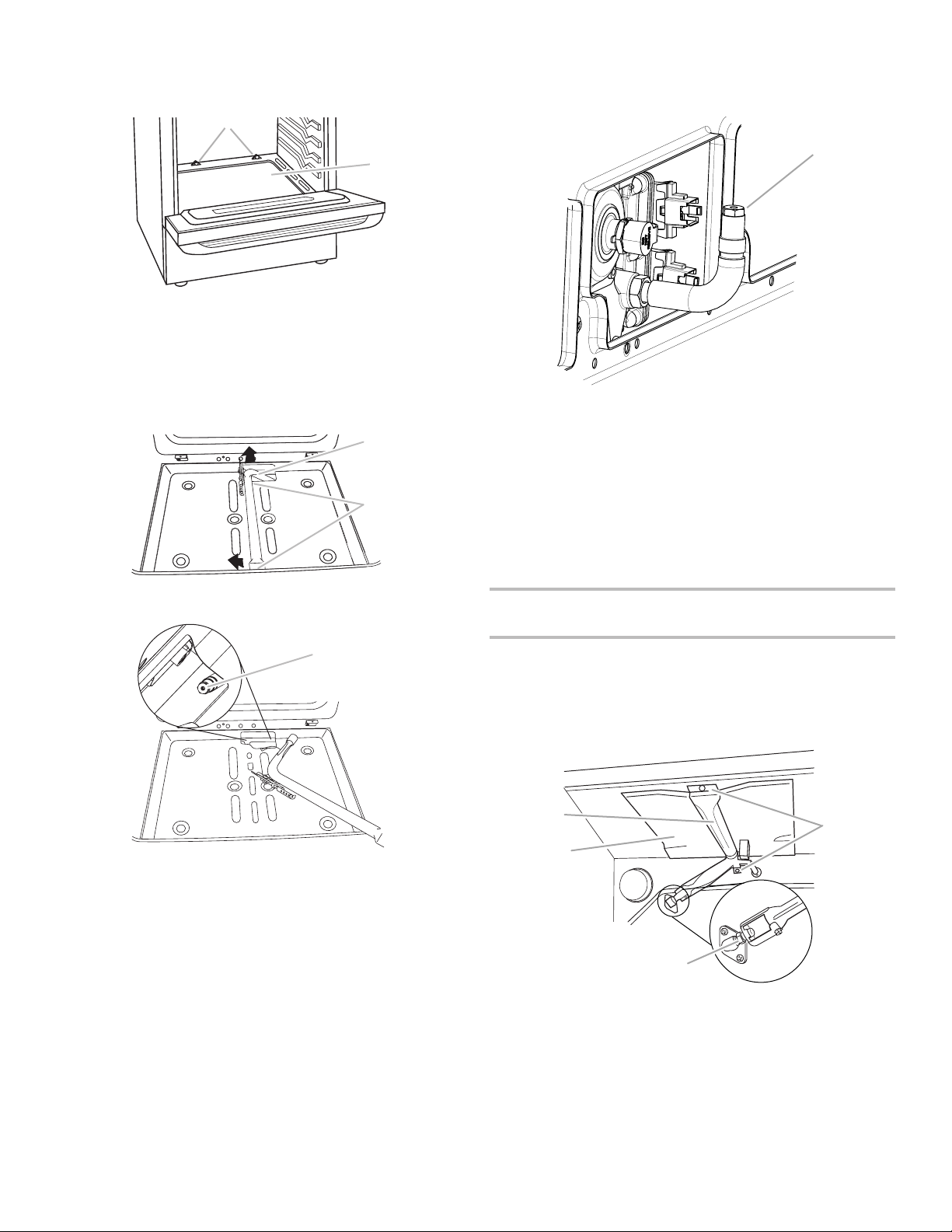

1. Remove the storage drawer. See the “Remove/Replace

Drawer” section.

2. Locate gas pressure regulator at rear of the drawer

compartment.

A. Gas pressure regulator

IMPORTANT: Do not remove the gas pressure regulator.

14

Page 15

3. Remove plastic cover from gas pressure regulator cap.

A

C

D

A

B

D

A

4. Turn gas pressure regulator cap counterclockwise with

a5/8" (1.6 cm) combination wrench to remove.

NOTE: Do not remove the spring beneath the cap.

Side view before

NG

4. Remove the orice spuds shipped in the literature package

in the oven. Gas orice spuds are stamped with a number,

marked with 1 or 2 color dots, and have a groove in the hex

area. Replace the Natural gas orice spud with the correct

LP gas orice spud.

B

D

NG

E

Refer to the following chart for correct LP gas orifice spud

A. LP groove

ratings and to spud holder card for proper placement.

LP

LP

Side view after

A. Plastic cover

B. Gas pressure regulator cap with solid end facing out

C. Gas pressure regulator cap with hollow end facing out

D. Washer

E. Gas pressure regulator cap

5. Turn over the gas pressure regulator cap and reinstall on

regulator so that the hollow end faces out and the marking

“ê LP” is facing the direction shown in the above drawing.

6. Replace plastic cover over gas pressure regulator cap.

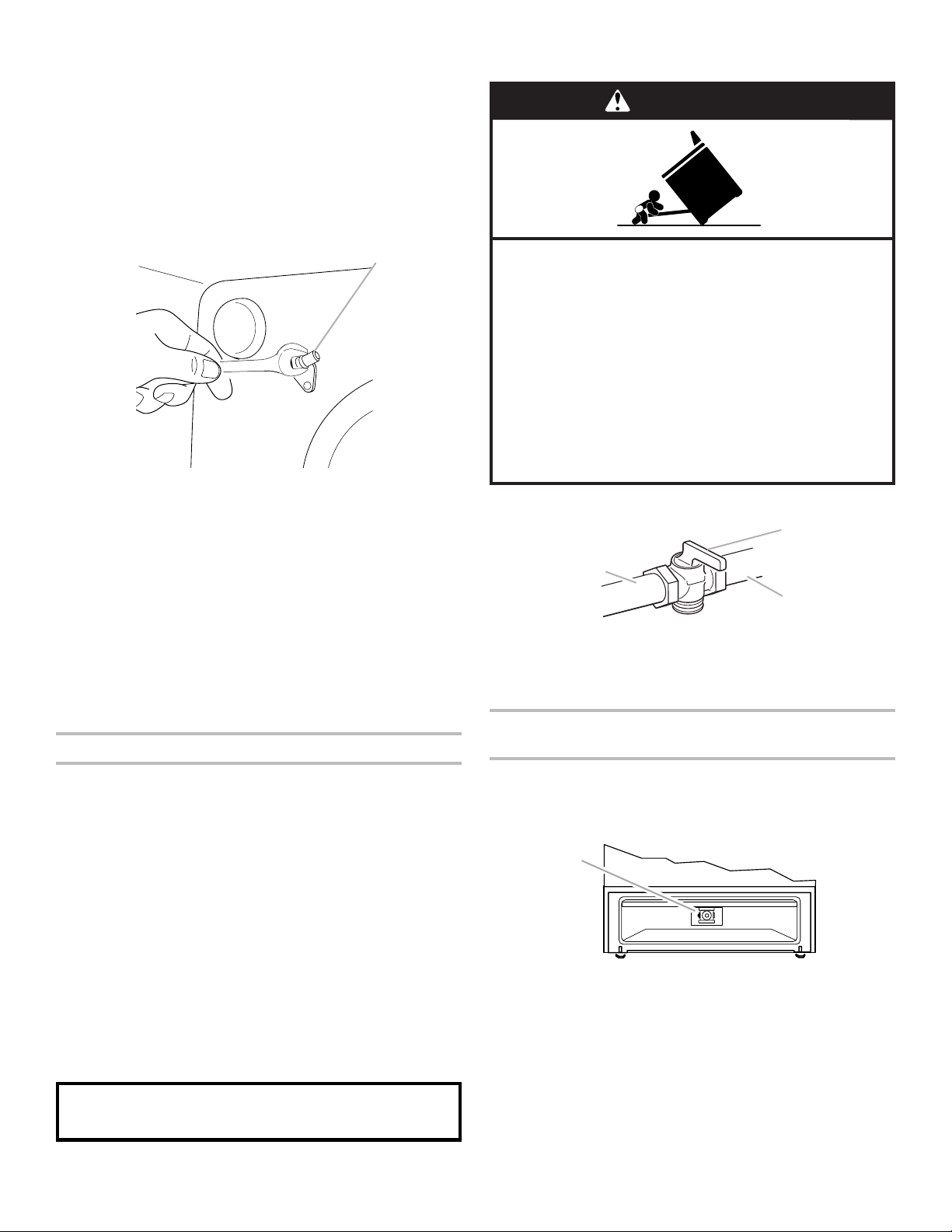

To Convert Surface Burners (Natural Gas to LP Gas)

1. Remove burner cap.

2. Remove the burner base.

LP Gas Orifice Spud Chart for Surface Burners

Burner

Rating/Type

15,000 BTU/

Stacked*

14.200

BTU/Ultra/

Stacked*

8.000 BTU/

Semi

5,000 BTU/

Auxi

1,200 BTU/

Stacked/

Simmer*

* Not in all kits/models

NOTE: Refer to the model/serial/rating plate located on the

Color Size

(mm)

Silver

Black/Orange

1.05

0.32

ID

number

L105

L32

Placement

LF

Silver 1.05 L105 LF/RF

Red/Orange 0.85 L85 RR/CTR

Red/Blue 0.65 L65 LR

Black/Orange 0.32 L32 LF

(Simmer)

oven frame behind the top left-hand side of the oven door for

proper sizing of spuds for each burner location.

5. Place Natural gas orice spuds in the orice spud bag.

C

IMPORTANT: Keep the Natural gas orifice spuds in case

ofreinstallation with Natural gas.

6. Replace the burner base.

7. Replace burner cap.

A. Igniter electrode

B. Burner cap

C. Gas tube opening

D. Burner base

3. Apply masking tape to the end of a 9/32" (7 mm) nut driver

to help hold the gas orice spud in the nut driver while

changing it. Press nut driver down onto the gas orice spud

and remove by turning it counterclockwise and lifting out.

Set gas orice spud aside.

B

A

8. Repeat steps 1 through 7 for the remaining burners.

To Convert Oven Bake Burner (Natural Gas

toLPGas)

1. Remove the oven racks and the oven door. See the “Oven

Door” section.

2. Remove 2 screws and washers at the rear of the oven

bottom.

C

A. Igniter electrode

B. Orifice spud

C. Orifice spud holder

D. Screws

15

Page 16

3. Lift the rear of the oven bottom up and back until the front

A

A

A

C

A

of the panel is away from the front frame. Remove from

oven and set it aside on a covered surface.

B

A. Screws

B. Oven bottom

4. Remove 2 screws from the bake burner.

5. Slide the front of the bake burner to the side to remove tab

from front of oven. Lift the back of the bake burner o the

oven orice and set the bake burner aside. Do not

disconnect the wire.

B

7. Replace the “47” spud with a “56” spud. Install the LP gas

bake burner orice spud, turning it clockwise until snug.

IMPORTANT: Do not overtighten.

A. Orifice spud

8. Position the back of the bake burner over the oven orice,

and then align the holes for the screws.

9. Reattach the bake burner with 2 screws.

10. Position the front of the oven bottom panel toward the

frontframe, and then lower the rear of the oven bottom

panel into the oven.

11. Reattach the oven bottom panel with 2 screws and

2washers.

A. Bake burner

B. Screws

To Convert Oven Broil Burner (Natural Gas

toLPGas) (on some models)

A

A. Oven orifice

6. Apply masking tape to the end of a 3/8" (1 cm) nut driver

to help hold the gas orice spud in the nut driver while

changing it. Press nut driver down onto the gas orice spud

and remove by turning the Natural gas bake burner orice

spud counterclockwise to remove. The spud will be stamped

with a “47.”

1. Remove the 1 screw from the broil burner.

2. Remove the ame spreader.

3. Remove the broil burner from the broil burner orice hood.

NOTE: The broil burner will hang in the back of the oven

while you are changing the orifice hood.

B

D

A. Broil burner

B. Flame spreader

C. Screws

D. Orifice hood

16

Page 17

4. Apply masking tape to the end of a 3/8" (1 cm) nut driver

A

A

B

C

A

to help hold the gas orice spud in the nut driver while

changing it. Press nut driver down onto the gas orice

spud and remove by turning the Natural gas broil burner

orice hood counterclockwise to remove. The hood will be

stamped with a “155.”

5. Replace the “155” hood with a “100” hood. Install the

LPgas broiler burner orice hood, turning it clockwise

untilsnug.

IMPORTANT: Do not overtighten.

x.xx

A. Orifice hood

Natural Gas Conversion

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

6. Place the broil burner on the broil burner orice hood.

Insertthe broil burner ceramic igniter in the hole in the

rearof the oven.

7. Replace the ame spreader with all 4 tabs facing up

andthe notches toward the rear of the oven.

8. Position the broil burner against the top of the oven

andattach it with 1 screw.

9. Replace storage drawer. See the “Remove/Replace

Drawer”section.

10. Replace the oven door. See the “Oven Door” section.

11. Replace the oven racks.

Complete Installation (Natural Gas to LP Gas)

1. Refer to the “Make Gas Connection” section for proper

connection of the range to the gas supply.

2. Refer to the “Electronic Ignition System” section for proper

burner ignition and operation.

3. Refer to the “Adjust Flame Height” section for burner

ameadjustments.

IMPORTANT: You may have to adjust the low setting for

each cooktop burner.

Checking for proper cooktop flame is very important. The

small inner cone should have a very distinct blue flame

1

/4" to 1/2" (0.64 to 1.3 cm) long. The outer cone is not as

distinct as the inner cone. LP gas flames have a slightly

yellow tip.

4. Refer to “Complete Installation” in the “Installation

Instructions” section of this manual to complete this

procedure.

1. Turn the manual shut-o valve to the closed position.

A. Gas supply line

B. Manual shut-off valve closed position

C. To range

2. Unplug range or disconnect power.

To Convert Gas Pressure Regulator (LP Gas

toNatural Gas)

1. Remove the storage drawer. See the “Remove/Replace

Drawer” section.

2. Locate gas pressure regulator at rear of the drawer

compartment.

A. Gas pressure regulator

IMPORTANT: Do not remove the gas pressure regulator.

IMPORTANT: Make sure to save the orifices that have

just been replaced in the conversion.

17

Page 18

3. Remove plastic cover from gas pressure regulator cap.

A

Side view before

D

A

B

D

A

A

4. Turn gas pressure regulator cap counterclockwise with

a5/8" (1.6 cm) combination wrench to remove.

NOTE: Do not remove the spring beneath the cap.

B

D

E

LP

LP

4. Gas orice spuds are stamped with a number on the side.

Replace the LP gas orice spud with the correct Natural

gas orice spud.

XXX

A. Stamped number

Refer to the following chart for the correct Natural gas

orifice spud placement.

Natural Gas Orifice Spud Chart

NG

C

A. Plastic cover

B. Gas pressure regulator cap with hollow end facing out

C. Gas pressure regulator cap with solid end facing out

D. Washer

E. Gas pressure regulator cap

Side view after

NG

5. Turn over the gas pressure regulator cap and reinstall

onregulator so that the solid end faces out and the

marking “ê NG” is facing the direction shown in the

abovedrawing.

6. Replace plastic cover over gas pressure regulator cap.

To Convert Surface Burners (LP Gas to Natural Gas)

1. Remove burner cap.

2. Remove the burner base.

C

Burner Rating Color Size (mm) ID Number

19,000 BTU (ST) White/Gray 1.84 184

18,000 BTU Blue 1.94 194

17,000 BTU (ST) N/A 1.75 175

17,000 BTU White/Blue 1.90 190

9,200 BTU White/Black 1.35 135

8,000 BTU White/Yellow 1.25 125

5,000 BTU White/Orange 1.00 100

1,200 BTU Black 0.52 52

NOTE: Refer to the model/serial/rating plate located on the

oven frame behind the top left-hand side of the oven door for

proper sizing of spuds for each burner location.

5. Place LP gas orice spuds in the orice spud bag.

IMPORTANT: Keep the LP gas orifice spuds in case

ofreinstallation with LP gas.

6. Replace the burner base.

7. Replace burner cap.

8. Repeat steps 1 through 7 for the remaining burners.

To Convert Oven Bake Burner (LP Gas

toNaturalGas)

1. Remove the oven racks and the oven door. See the “Oven

Door” section.

A. Igniter electrode

B. Burner cap

C. Gas tube opening

D. Burner base

3. Apply masking tape to the end of a 9/32" (7 mm) nut driver

2. Remove 2 screws and washers at the rear of the oven

bottom.

3. Lift the rear of the oven bottom up and back until the front

of the panel is away from the front frame. Remove from

oven and set it aside on a covered surface.

to help hold the gas orice spud in the nut driver while

changing it. Press nut driver down onto the gas orice spud

and remove by turning it counterclockwise and lifting out.

Set gas orice spud aside.

18

B

A

C

A. Igniter electrode

B. Orifice spud

C. Orifice spud holder

D. Screws

B

A. Screws

B. Oven bottom

Page 19

4. Remove 2 screws from the bake burner.

A

A

C

A

A

5. Slide the front of the bake burner to the side to remove tab

from front of oven. Lift the back of the bake burner o the

oven orice and set the bake burner aside. Do not

disconnect the wire.

B

A. Bake burner

B. Screws

A

8. Position the back of the bake burner over the oven orice,

and then align the holes for the screws.

9. Reattach the bake burner with 2 screws.

10. Position the front of the oven bottom panel toward the front

frame, and then lower the rear of the oven bottom panel

into the oven.

11. Reattach the oven bottom panel with 2 screws and

2washers.

To Convert Oven Broil Burner (LP Gas

toNaturalGas) (on some models)

1. Remove 1 screw from the broil burner.

2. Remove the ame spreader.

3. Remove the broil burner from the broil burner orice hood.

NOTE: The broil burner will hang in the back of the oven

while you are changing the orifice hood.

B

A. Oven orifice

6. Apply masking tape to the end of a 3/8" (1 cm) nut driver

to help hold the gas orice spud in the nut driver while

changing it. Press nut driver down onto the gas orice spud

and remove by turning the LP gas bake burner orice spud

counterclockwise to remove. The spud will be stamped with

a “56.”

7. Replace the “56” spud with a “47” spud. Install the Natural

gas bake burner orice spud, turning it clockwise until snug.

IMPORTANT: Do not overtighten.

D

A. Broil burner

B. Flame spreader

C. Screws

D. Orifice hood

4. Apply masking tape to the end of a 3/8" (1 cm) nut driver

to help hold the gas orice spud in the nut driver while

changing it. Press nut driver down onto the gas orice spud

and remove by turning the LP gas broil burner orice hood

counterclockwise to remove. The hood will be stamped with

a “100.”

5. Replace the “100” hood with a “155” hood. Install the

Natural gas broiler burner orice hood, turning it clockwise

until snug.

IMPORTANT: Do not overtighten.

x.xx

A. Orifice spud

A. Orifice hood

19

Page 20

6. Place the broil burner on the broil burner orice hood.

A

B

C

C

Insertthe broil burner ceramic igniter in the hole in the

rearof the oven.

7. Replace the ame spreader with all 4 tabs facing up

andthe notches toward the rear of the oven.

8. Position the broil burner against the top of the oven

andattach it with 1 screw.

9. Replace the storage drawer. See the “Remove/Replace

Drawer” section.

10. Replace the oven door. See the “Oven Door” section.

11. Replace the oven racks.

Complete Installation (LP Gas to Natural Gas)

If the “Low” Flame Needs to Be Adjusted:

1. Light 1 burner and turn to lowest setting.

2. Remove the control knob.

Hold the knob stem with a pair of pliers. Use a small

flat-blade screwdriver to turn the screw located in the

center of the control knob stem until the flame is the proper

size. Turning the screw clockwise will increase the flame size

and counterclockwise will decrease the flame size.

A

1. Refer to the “Make Gas Connection” section for proper

connection of the range to the gas supply.

2. Refer to the “Electronic Ignition System” section for proper

burner ignition and operation.

3. Refer to the “Adjust Flame Height” section for burner ame

adjustments.

IMPORTANT: You may have to adjust the low setting

foreach cooktop burner.

Checking for proper cooktop, bake, and broil burner

flameis very important. Natural gas flames do not

haveyellow tips.

4. Refer to “Complete Installation” in the “Installation

Instructions” section of this manual to complete

thisprocedure.

IMPORTANT: Make sure to save the orifices that have

just been replaced in the conversion.

Adjust Flame Height

Adjust Surface Burner Flame

Adjust the height of top burner ames. The cooktop “low”

burner ame should be a steady blue ame approximately

1

/4" (0.64 cm) high. LP gas ames have a slightly yellow tip.

B

A. Control knob stem

B. Screwdriver

C. Pliers

3. Replace the control knob.

4. Test the ame by turning the control from the low position

to the high position, checking the ame at each setting.

5. Repeat the previous steps for each burner.

To Adjust Double Burner (on some models):

1. Light burner and turn to lowest setting where both inner

andouter burners are lit.

2. Remove the control knob.

3. Insert a 1/8" (3 mm) at-blade screwdriver into the

adjustment locations shown in the following illustration

andengage the slotted screw. Turn the screw until the

ameis the proper size. Turning the screw clockwise

willincrease the ame size and counterclockwise will

decrease the ame size.

A

B

A. Control knob stem

B. Screwdriver

C. Pliers

4. Replace the control knob.

5. Test the ame by turning the control from the low position

to the high position, checking the ame at each setting.

A. Low flame

B. High flame

To Adjust Standard Burner:

The ame can be adjusted using the adjustment screw in the

Check Operation of Oven Bake Burner

Refer to the Use & Care Guide for proper operation of the

oven controls.

center of the valve stem. The valve stem is located directly

underneath the control knob.

20

Page 21

Adjust Oven Bake Burner Flame (if needed)

A

A

A

B

A

1. Remove the storage drawer (see the “Remove/Replace

Drawer” section).

2. Locate gas pressure regulator at rear of the drawer

compartment.

A. Gas pressure regulator

IMPORTANT: Do not remove the gas pressure regulator.

3. Check the oven bake burner for proper ame.

a. Remove the oven racks.

b. To remove the oven bottom: Remove 2 screws at the

rear of the oven bottom. Lift the rear of the oven

bottom up and back until the front of the panel is away

from the front frame. Remove from oven and place on

a covered surface.

4. If the oven bake ame needs to be adjusted, locate the

airshutter near the center rear of the drawer cavity

behindthe access panel. Loosen the locking screw and

rotate the air shutter until the proper ame appears.

Tighten locking screw.

A. Locking screw

B. Air shutter

5. Push the Cancel keypad when nished.

6. Reinstall the oven bottom and the storage drawer (see the

“Remove/Replace Drawer” section).

Adjust Oven Broil Burner Flame (if needed)

B

A. Screws

B. Oven bottom

c. Press BAKE.

d. Press the Start keypad.

The oven bake burner should light within 8 seconds. Under

certain conditions, it may take the burner up to 50 to

60seconds to light.

Electronic igniters are used to light the bake and

broilburners.

This flame should have a 1/2" (1.3 cm) long inner cone of

bluish-green with an outer mantle of dark blue and should

be clean and soft in character. No yellow tips, blowing, or

lifting of flame should occur.

Press BROIL, and then press the Start keypad. Look through

theoven window to check broil burner for proper ame.

Thisame should have a 1/2" (1.3 cm) long inner cone of

bluish-green with an outer mantle of dark blue and should

beclean and soft in character. No yellow tips, blowing, or

lifting of ame should be present.

If Flame Needs to be Adjusted:

1. Press the Cancel keypad. Let the oven cool.

2. Loosen the lock screw on the air shutter located at the rear

of the broil burner.

3. Adjust the air shutter as needed.

4. Tighten lock screw.

B

A. Lock screw

B. Air shutter

5. Close the oven door. Press BROIL, and then press the Start

keypad. Look through the oven window to check broil

burner for proper ame. If ame needs to be adjusted,

repeat steps 1 through 5.

21

Page 22

ÍNDICE

SEGURIDAD DE LA ESTUFA ................................................ 22

REQUISITOS DE INSTALACIÓN ..........................................24

Herramientas y piezas ................................................................. 24

Requisitos de ubicación ............................................................... 24

Requisitos eléctricos ..................................................................... 26

Requisitos del suministro de gas ................................................ 26

INSTRUCCIONES DE INSTALACIÓN ................................... 28

Desempaque la estufa ................................................................ 28

Instalación del soporte antivuelco ............................................. 28

Regule las patas niveladoras ..................................................... 29

Nivelación de la estufa ............................................................... 30

Conexión del suministro de gas ................................................. 30

Verique que el soporte antivuelco

estéinstaladoyenganchado ...................................................... 31

Sistema de encendido electrónico ............................................. 31

Retire/vuelva a colocar el cajón ................................................32

Puerta del horno ............................................................................32

Finalización de la instalación......................................................33

CONVERSIONES DE GAS ...................................................34

Conversión a gas LP ..................................................................... 34

Conversión de gas natural ...........................................................38

Cómo regular la altura de la llama ........................................... 41

SEGURIDAD DE LA ESTUFA

Su seguridad y la seguridad de los demás es muy importante.

Hemos incluido muchos mensajes importantes de seguridad en este manual y en su electrodoméstico. Lea y obedezca siempre

todos los mensajes de seguridad.

Este es el símbolo de alerta de seguridad.

Este símbolo le llama la atención sobre peligros potenciales que pueden ocasionar la muerte o una lesión a

usted y a los demás.

Todos los mensajes de seguridad irán a continuación del símbolo de advertencia de seguridad y de la palabra

“PELIGRO” o “ADVERTENCIA”. Estas palabras significan:

PELIGRO

ADVERTENCIA

Todos los mensajes de seguridad le dirán el peligro potencial, le dirán cómo reducir las posibilidades de sufrir una lesión y lo que

puede suceder si no se siguen las instrucciones.

Si no sigue las instrucciones de inmediato, usted puede

morir o sufrir una lesión grave.

Si no sigue las instrucciones, usted puede morir o sufrir

una lesión grave.

ADVERTENCIA: Si la información en este manual no se sigue con exactitud, podría

ocurrir un incendio o una explosión, lo que causaría daños a propiedades, heridas

personales o la muerte.

– No almacene o use gasolina u otros líquidos y vapores inflamables cerca de este u otro

aparato electrodoméstico.

– PASOS QUE USTED DEBE SEGUIR SI HUELE A GAS:

No trate de encender ningún aparato electrodoméstico.

•

No toque ningún interruptor eléctrico.

•

No use ningún teléfono en su casa o edificio.

•

Llame inmediatamente a su proveedor de gas desde el teléfono de un vecino.

•

Siga las instrucciones de su proveedor de gas.

Si usted no puede comunicarse con su proveedor de gas, llame al departamento

•

de bomberos.

– La instalación y el servicio deben ser efectuados por un instalador calificado, una

agencia de servicio o por el proveedor de gas.

22

Page 23

ADVERTENCIA: Las pérdidas de gas no siempre se pueden detectar por el olfato.

Los proveedores de gas recomiendan que usted use un detector de gas aprobado por UL (Laboratorio de normalización) o

CSA (Asociación canadiense de seguridad).

Para obtener más información, póngase en contacto con su proveedor de gas.

Si se detecta una fuga de gas, siga las instrucciones de “Pasos que usted debe seguir si huele a gas”.

IMPORTANTE: No instale un sistema de ventilación que sople aire hacia abajo dirigido hacia este aparato de cocción a gas.

Este tipo de sistema de ventilación puede ocasionar problemas de encendido y combustión con este aparato de cocción a gas,

resultando en heridas a personas o en un funcionamiento no deseado del aparato.

En el estado de Massachusetts se aplican las siguientes instrucciones de instalación:

■ Las instalaciones y reparaciones se deben efectuar por un contratista, plomero o gasista calificado o licenciado por el estado

de Massachusetts.

■ Si se usa una válvula de bola, debe ser un tipo de manigueta T.

■ Si se usa un conector de gas flexible no debe exceder de 3 pies.

ADVERTENCIA

Peligro de Vuelco

Un niño o un adulto puede volcar accidentalmente la estufa y resultar muerto.

Instale el soporte anti-vuelco al piso o a la pared según las instrucciones de instalación.

Deslice la estufa hacia atrás de modo que la pata trasera quede enganchada en la ranura del

soporte anti-vuelco.

Si traslada de lugar la estufa, vuelva a asegurar el soporte anti-vuelco.

No ponga a funcionar la estufa sin tener el soporte anti-vuelco instalado y asegurado.

No seguir estas instrucciones puede ocasionar la muerte o quemaduras graves en niños y

adultos.

Pata de la estufa

Soporte

anti-vuelco

Para verificar que el soporte anti-vuelco esté instalado y asegurado:

• Deslice la estufa hacia adelante.

• Verifique que el soporte anti-vuelco esté bien sujeto al piso o a la pared.

• Deslice la estufa hacia atrás de modo que la pata trasera quede debajo del soporte

anti-vuelco.

• Consulte las instrucciones de instalación para ver más detalles.

23

Page 24

REQUISITOS DE INSTALACIÓN

Herramientas y piezas

Reúna las herramientas y las piezas necesarias antes de

comenzar la instalación. Lea y siga las instrucciones provistas

con todas las herramientas que se enumeran.

Herramientas necesarias

■ Cinta métrica

■ Destornillador Phillips

■ Destornillador de hoja

plana

■ Destornillador de hoja

plana de 1/8" (3mm)

■ Nivel

■ Taladro

■ Llave o pinza

■ Llave para tubos

■ Llave de combinación

de15/16" (2,4cm)

■ Broca de

1

/8" (3,2mm)

(para pisos de madera)

■ Marcador o lápiz

Piezas suministradas

Verique que estén todas las piezas.

■ Juego para conversión a gas natural/LP

■ 2 tornillos n.° 10 x 1

5

/8" (4,1cm) (para montar el soporte

anti-vuelco)

■ Soporte antivuelco (dentro de la cavidad del horno)

El soporte antivuelco debe estar montado firmemente a

la pared posterior o al piso. Según el espesor del piso, es

posible que sea necesario utilizar tornillos más largos para

sujetar el soporte al contrapiso. Puede conseguir tornillos

más largos en su ferretería local.

Piezas necesarias

Verique los códigos locales y consulte con el proveedor de

gas. Verique el suministro de gas y el suministro eléctrico

existentes. Vea las secciones “Requisitos eléctricos” y

“Requisitos del suministro de gas”.

■ Compuesto para unión de

tuberías resistente a gas LP

■ Broca para albañilería con

punta de carburo de 3/16"

(4,8mm) (para pisos de

hormigón/cerámica)

■ Solución para detectar

fugas no corrosiva

Para las conversiones

degas natural/LP

■ Llave de combinación

de5/8" (1,6cm)

■ Sacatuercas de

■ Sacatuercas de

(7mm)

■ Cinta adhesiva protectora

3

/8" (1cm)

9

/32"

Requisitos de ubicación

IMPORTANTE: Respete todos los códigos y las ordenanzas

vigentes. No obstruya el ujo de aire para la combustión y la

ventilación.

■ Es responsabilidad del instalador cumplir con los espacios

de instalación especicados en la placa que indica

modelo/serie/valores nominales. La placa que indica

modelo/serie/valores nominales está detrás de la puerta

del horno, en la parte superior del lado izquierdo del marco

del horno.

■ La estufa debe ubicarse en un lugar de la cocina

conveniente para su uso.

■ Las instalaciones empotradas deben dejar completamente

encerrados los lados y la parte posterior de la estufa.

■ Para eliminar el riesgo de quemaduras o incendio al

tocar unidades con la supercie demasiado caliente,

deberá evitarse el uso de armarios de almacenamiento

encima de las unidades. Si van a proveerse armarios de

almacenamiento, puede reducir el riesgo instalando una

campana de ventilación o una combinación de microondas

y campana que se proyecte horizontalmente un mínimo de

5" (12,7cm) más allá de la base de los armarios.

■ Todas las aberturas en la pared o en el piso en donde se

instalará la estufa deben estar selladas.

■ Deben usarse las dimensiones de la abertura del armario

que se muestran. Las dimensiones proporcionadas son los

espacios mínimos.

■ Debe instalarse el soporte antivuelco. Para instalar el

soporte antivuelco que se envía con la estufa, vea la

sección “Instalación del soporte antivuelco”.

■ Se requiere un suministro eléctrico conectado a tierra.

Consulte la sección “Requisitos eléctricos”.

■ Debe haber una conexión adecuada de suministro de gas.

Vea la sección “Requisitos del suministro de gas”.

■ Póngase en contacto con un instalador de revestimiento de

pisos competente para vericar que el revestimiento del

piso pueda soportar por lo menos 200 °F (93 °C).

■ Use una almohadilla aislante o una madera laminada de

1

/4" (0,64cm) debajo de la estufa si va a instalar la estufa

sobre una alfombra.

IMPORTANTE: Para evitar daños a los armarios, verique con

el constructor o el distribuidor de los armarios para asegurarse

de que los materiales empleados no cambien de color, no

desprendan el laminado ni sufran ningún otro tipo de daño.

Este horno se ha diseñado de acuerdo con los requisitos de UL

y CSA International y cumple con las temperaturas máximas

permitidas para armarios de madera de 194 °F (90 °C).

24

Page 25

Requisitos de instalación adicionales para casas rodantes

La instalación de esta estufa debe ajustarse a la Norma para

la construcción y la seguridad de casas fabricadas, título 24

CFR, parte 3280 (antes Norma federal para la construcción

y la seguridad de casas rodantes, título 24, HUD parte 280).

Cuando esa norma no sea aplicable, use la Norma para

instalaciones en casas fabricadas, ANSI A225.1/NFPA 501A

olos códigos locales.

En Canadá, la instalación de esta estufa debe cumplir con

lasnormas vigentes CAN/CSA-A240, edvición más reciente,

ocon los códigos locales.

Las instalaciones en casas rodantes requieren lo siguiente:

■ Cuando se instale esta estufa en una casa rodante, deberá

asegurarse al piso durante el transporte. Cualquier método

de jación es adecuado en tanto cumpla con las normas

indicadas arriba.

Dimensiones del armario

Las dimensiones de la abertura del armario que se muestra

son para una profundidad de mostrador de 25" (64,0cm),

unaprofundidad del armario de la base de 24" (61,0cm) y

una altura del mostrador de 36" (91,4cm).

IMPORTANTE: Si va a instalar una campana para estufa o

una combinación de microondas y campana sobre la estufa,

siga las instrucciones de instalación incluidas con la campana

para estufa o la combinación de microondas y campana para

ver las medidas de los espacios sobre la supercie de cocción.

La estufa puede instalarse próxima a paredes combustibles

con una separación cero.

B

D

C

Dimensiones del producto

Este manual abarca varios modelos; la apariencia de su

modelo puede diferir de los que se ilustran. Las dimensiones

que se indican son las dimensiones máximas entre todos los

modelos.

A

D

E

F

A. 13/16" (3,0cm) de altura

desde la superficie de cocción

hasta la parte superior de la

ventilación

B. 297⁄8” (75,9cm)

C. Placa que indica modelo/

serie/valores nominales (detrás

de la puerta del horno, en

la parte superior del lado

izquierdo del marco del horno)

IMPORTANTE: La estufa debe ser nivelada después de la

instalación. Siga las instrucciones de la sección “Nivelación

de la estufa”. No se recomienda usar la supercie de cocción

como referencia para nivelar la estufa.

* La estufa se puede elevar aproximadamente 1" (2,5 cm)

mediante la regulación de las patas niveladoras.

B

C

D. 36" (91,4cm) de altura hasta

la parte superior del borde

de la superficie de cocción

con las patas niveladoras

completamente atorrnilladas*

E. 2825/64" (72,1cm) de

profundidad máx. desde el

frente de la consola hasta la

parte posterior de la estufa

F. 291/64" (73,7 cm) de

profundidad máx. desde la

manija hasta la parte posterior

de la estufa

A

E

F

M

G

J

A. 18" (45,7 cm) del armario lateral superior al mostrador

B. 13" (33 cm) de profundidad máx. del armario superior

C. 30" (76,2cm) de ancho mínimo de la abertura

D. Para ver el espacio mínimo hasta la parte superior de la superficie

decocción, consulte la NOTA.

E. 30" (76,2 cm) de ancho mínimo de la abertura

F. 3" (7,6 cm) de espacio desde ambos lados de la estufa hasta

laparedlateral u otro material combustible

G. Se recomienda esta área sombreada para la instalación de

latuberíade gas rígida y el tomacorriente con conexión a tierra.

H. 131/8" (33,3cm)

I. 711/16" (19,5cm)

J. 413/16" (12,2cm)

K. 311/16" (9,4cm)

L. 12" (30,5cm)

M. La puerta o las bisagras del armario no deben extenderse dentro

delárea del recorte.

H

I

L

K

NOTA: 24" (61,0cm) como mínimo cuando la base del

armario de madera o de metal esté protegida por madera

moldeada retardante de llama de al menos 1/4" (0,64cm),

cubierta con una lámina de acero no inferior a N.° 28 MSG,

acero inoxidable de 0,015" (0,4mm), aluminio de 0,024"

(0,6mm) o cobre de 0,020" (0,5mm).

30" (76,2cm) de espacio mínimo entre la parte superior de la

plataforma de cocción y la parte inferior de un armario de

madera o metal sin revestimiento.

25

Page 26

Requisitos eléctricos

IMPORTANTE: La estufa debe tener una conexión de

electricidad a tierra de acuerdo con los códigos y las

ordenanzas locales o, en ausencia de códigos locales, con el

Código nacional de electricidad (National Electrical Code),

ANSI/NFPA 70 o el Código canadiense de electricidad

(Canadian Electrical Code), CSA C22.1.

Esta estufa está equipada con un sistema de encendido

electrónico que no funcionará correctamente si se enchufa en

un tomacorriente que no esté polarizado de forma correcta.

Si los códigos lo permiten y se emplea un cable de conexión

atierra separado, es recomendable que un instalador eléctrico

competente determine si la ruta de conexión a tierra es

adecuada.

Puede obtener una copia de las normas de los códigos arriba

indicadas en:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

■ Se requiere un circuito eléctrico de 120 voltios, 60 hertzios,

CA solamente, con fusible de 15 amperios y polarizado.

También se recomienda usar un fusible retardador o

un cortacircuitos. Se recomienda el uso de un circuito

independiente que preste servicio únicamente a este

aparato.

■ Los sistemas de encendido electrónico funcionan dentro

de límites de tensión amplios, pero se debe tener una

conexión a tierra y la polaridad correctas. Verique que el

tomacorriente tenga una capacidad para 120 voltios y que

esté debidamente conectado a tierra.

■ No es necesario enchufar esta estufa en un tomacorriente

con GFCI (disyuntor diferencial). Se recomienda no

enchufar una estufa con encendido con chispa eléctrica

ni ningún otro electrodoméstico importante en un

tomacorriente de pared con GFCI ya que puede causar la

desconexión del GFCI durante el funcionamiento normal.

■ El rendimiento de esta estufa no se verá afectado si

funciona en un circuito protegido con un GFCI. Sin

embargo, se puede producir el inconveniente de la

desconexión ocasional del GFCI debido a la naturaleza del

funcionamiento normal de las estufas de gas electrónicas.

■ La hoja con especicaciones técnicas y el diagrama de

cableado se encuentran en la parte posterior de la estufa,

en una bolsa plástica.

NOTA: el armazón de metal de la estufa deberá

conectarse a tierra para que funcione el panel de control;

si no se lo conecta a tierra, ningún botón funcionará.

Verifique con un electricista competente si tiene dudas

acerca de si el armazón de la estufa está conectado a

tierra.

Requisitos del suministro de gas

ADVERTENCIA

Peligro de Explosión

Use una línea de suministro de gas nueva con

aprobación de CSA International.

Instale una válvula de cierre.

Apriete firmemente todas las conexiones de gas.

Si se conecta a un suministro de gas LP, la presión no

debe exceder una columna de agua de 36 cm (14") y

debe ser verificada por una persona calificada.

Ejemplos de una persona calificada incluyen:

personal de servicio del sistema de calefacción con

licencia,

personal autorizado de la compañía de gas, y

personal autorizado para dar servicio.

No seguir estas instrucciones puede ocasionar

la muerte, explosión o incendio.