Kenmore 625348702, 625348302, 625348202 Owner’s Manual

OWNERS

..-MANUAL

MODEL NOS.

625.348202

MEDIUM CAPACITY

-, ._|

625.348302

.HIGH CAPA CIIT-_Y

625.348702

EXTRA HIGH

CAPACITY

CAUTION

Read All Safety

Guides Before

You Start to

Install Your

Softener

Kenmore

-- HOW TO INSTALL

-- HOW IT WORKS-

- CARE OF --

-- SPECIFICATIONS -

-- REPAIR PARTS--

SAVE THIS MANUAL

PRINTED IN U S A

l TABLE OF CONTENTS /

PAGE NO. PAGE NO

Safety Guides ................................ 3

Before You Install ......................... 3-5

Tools and Materials Needed ................. 4

Plans to Install Your Softener ............. 5-8

Sweat Soldering Tips ........................ 7

Step by Step Guides to install Softener .. 9-14

WARRANTY /

SEARS RESIDENTIAL AUTOMATIC WATER SOFTENER

FULL ONE YEAR WARRANTY ON WATER SOFTENER

For one year from the date of purchase, when this water softener is installed and

maintained in accordance with our instructions. Sears will repair, free of charge, defects

in material or workmanship in this water softener.

FULL TEN YEAR WARRANTY AGAINST LEAKS

For ten years from the date of purchase. Sears will furnish and install a new current

model water softener tank or salt storage drum. free of charge, if either the tank or drum

develop a leak.

TO OBTAIN WARRANTY SERVICE, SIMPLY CONTACT THE NEAREST

SEARS SERVICE CENTER THROUGHOUT THE UNITED STATES. THIS WAR-

RANTY APPLIES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED

STATES.

Setting the Timer .......................... 1,

How Your Softener Works .............. 15-1

"Fine-Tuning'" Your Softener ........... 18-2:

Care of Your Softener ................... 23-2:

Dimensions and Specifications ............ 2_

Repair Parts ............................. 27-3

This warranty gives you specific legal rights, and you may have other rights

which vary from state to state.

Sears, Roebuck and Co., Dept. 698/731A, Sears Tower, Chicago, IL 60684

If you want your water softener professionally installed, talk to your Sears Salesperson who will ar-

range a prompt, quality installation by Sears Authorized Installers.

SEARS INSTALLATION POLICY

All installation labor arranged by Sears shall be

performed in a neat, workmanlike manner in

accordance with generally accepted trade prac-

tices.Further,all installations shall comply with all

local laws. codes, regulations and ordinances.

Customer shall also be protected, during installa-

tion, by insurance relating to Property Damage,

Workman's Compensation and Public Liability.

SEARS INSTALLATION WARRANTY

In addition to any warranty extended to you or

the Sears merchandise involved, which warran

ty becomes effective the date the merchandis_

is installed, should the workmanship of an!

Sears arranged installation prove faulty withir

one year, Sears will, upon notice from you

cause such faults to be corrected at no addi

tional cost to you.

• Read all steps, guides and rules carefully

before installing and using your new water

softener. Follow all steps exactly to correctly

install. Failure to follow them could cause

personal injury or property damage. Read-

ing this book will also help you to get all of the

benefits from your water softener.

• Your water softener will remove hardness

minerals and "clear water" iron from water,

up to the limits shown on page 26. It will not

remove other types of iron, acids, tastes and

odors, etc. It will not purify polluted water or

make it safe to drink.

When you see this sign in the book, • something could be damaged, or someone hurt, if the guide

is not followed exactly.

Check with your local public works depart-

ment for plumbing, electric and sanitation

codes. You must follow their guides as you

install your softener.

• Protect the softener and piping from freez-

ing. Damage from freezing voids the softener

warranty.

• Be sure the electric outlet for the softener

is grounded the right way to protect the

user from injury or possibly fatal shock.

BEFORE YOU START TO

HELPFUL INFORMATION

if you know little about plumbing skills, we sug-

gest you get a book on the subject. There are

many good books for do-it-yourselfers on the

basics of plumbing. You can get a low cost book

from Sears Plumbing and Heating departments

that will help you. Some basic sweat soldering

tips are on page 7 of this manual.

WATER SYSTEM TESTS

HAS YOUR WATER SUPPLY HAD A

CHEMICAL ANALYSIS? Sears has many kinds

of water treating units (see page 4) to correct

different water problems. To know the kind

and size of unit you need, you must first know

what elements are in your house water supply.

A chemical analysis shows the type and

amounts of elements in water. If your water

needs analysis, call or write your nearest

Sears store for help.

CHECK YOUR WATER PRESSURE-- For your

softener to work right, a water pressure of no

lower than 20 pounds per square inch (psi) is

needed in the house water pipes. The highest

A pressure allowed in the water pipes is 120 psi. If

pressure iS over 120 psi. buy and install a pres-

sure reducing valve in the water inlet pipe to the

softener. NOTE: If water pressure during the

day is 100 psi or more, pressure during the

night may go over 120 psi.

if you have a well water system, look at the

pressure gauge to find the water pressure. Call

your local water department if you have city

water. They will tell you what the water

pressure is where you live.

CHECK YOUR WATER FLOW RATE - A water

flow of at least 3 gallons per minute is needed.

A lower flow will keep your softenerfrom work-

ing as well as it should. To make an easy

check of your flow rate, do the following. You

will need a 1 gallon container (can, jar, pail,

etc.).

1. Fully open 2 cold water faucets close to the

point water enters the house.

2. With both faucets open, fill the gallon con-

tainer at 1 faucet while looking at a watch or

clock to see how many seconds it takes.

3. Empty the container and go the second

faucet (be sure BOTH faucets are still on).

Fill the gallon container at the second

faucet and see how many seconds it takes.

4. Turn off both faucets. Now add the number

of seconds it took to fill the container at

both faucets.

.

A total of 90 seconds, or less, means the

3

system flow rate is good.

• BEFORE YOU START TO I L YOUR SOFTENER

I

I

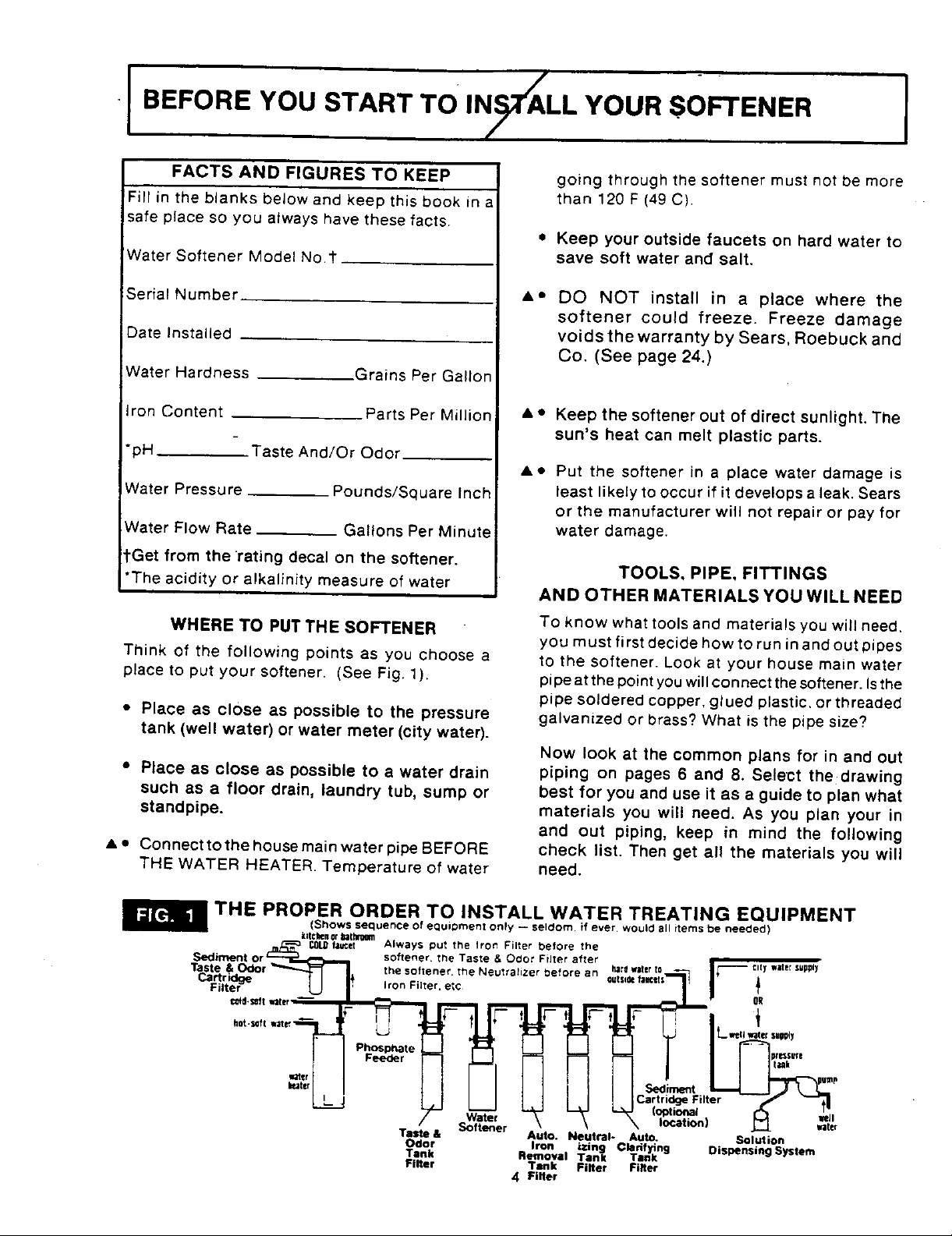

FACTS AND FIGURES TO KEEP

Fill in the blanks below and keep this book in

safe place so you always have these facts.

Water Softener Model No.!"

Serial Number

Date Installed

Water Hardness Grains Per Gallon

Iron Content Parts Per Million

"pH Taste And/Or Odor

Water Pressure __ Pounds/Square Inch

Water Flow Rate ____ Gallons Per Minute

t'Get from the rating decal on the softener.

"The acidity or alkalinity measure of water

WHERE TO PUT THE SOFTENER

Think of the following points as you choose a

place to put your softener. (See Fig. 1).

• Place as close as possible to the pressure

tank (well water) or water meter (city water).

= Place as close as possible to a water drain

such as a floor drain, laundry tub, sump or

standpipe.

• • Connect to the house main water pipe BEFORE

THE WATER HEATER. Temperature of water

going through the softener must not be more

than 120 F (49 C).

= Keep your outside faucets on hard water to

save soft water and salt.

• o DO NOT install in a place where the

softener could freeze. Freeze damage

voids the warranty by Sears, Roebuck and

Co. (See page 24.)

A#b

Keep the softener out of direct sunlight. The

sun's heat can melt plastic parts.

•e

Put the softener in a place water damage is

least likely to occur if it develops a leak. Sears

or the manufacturer will not repair or pay for

water damage.

TOOLS, PIPE, FITTINGS

AND OTHER MATERIALS YOU WILL NEED

TO know what tools and materials you will need.

you must first decide how tO run in and out pipes

to the softener. Look at your house main water

pipe at the point you wilt connect the softener, is the

pipe soldered copper, glued plastic, or threaded

galvanized or brass? What is the pipe size?

Now look at the common plans for in and out

piping on pages 6 and 8. Select the drawing

best for you and use it as a guide to plan what

materials you will need. As you plan your in

and out piping, keep in mind the following

check list. Then get all the materials you will

need.

THE PROPER ORDER TO INSTALL WATER TREATING EQUIPMENT

(Shows sequence of equipment only _ seldom, if ever would all items be needed)

kit_'ken_ Ut htom_

Sediment or_:_--*.,_ softener the Taste & O0or Filte after

Taste & O_or_ he sot ener he Neu rahzer before an _ tl wile _ |_'_ .

ri ' outs=detaacets II

C_!.Df_et Always put the Iron Filter before _he

I I r, ,rooFlI,erefc / I

,ot-.tl.,t_-=l ? ', ', _ _Ir _ _ _ LJ IL-.,,_,.,.._,

I L ] t , I I I I I I ! ICsrtridgeFilter f

/ Water \ \ \ location) _=ter

_ /. _ Softener ' , " -_ _'t'

Taste & -" Auto. Neutcal- Auto. Solution

Odor Iron |zing Clarifying Dispensing System

T_k RemovRI Tank Tamk

Filter Tank FilteT Filter

4 Filter

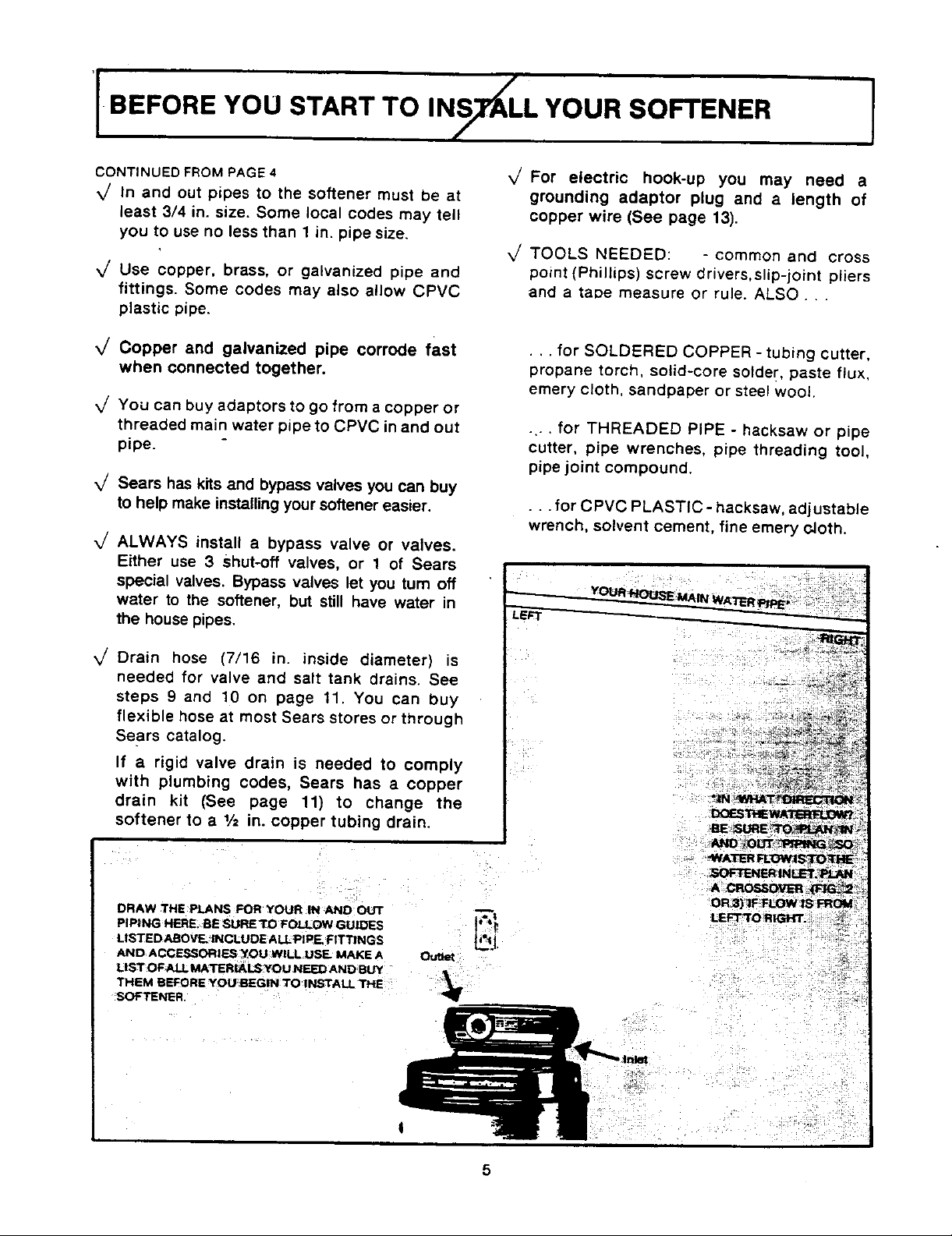

IoE o.oYousT..TTo You.so o.o.

CONTINUED FROMPAGE4

In and out pipes to the softener must be at

least 3/4 in. size. Some local codes may tell

you to use no less than 1 in. pipe size.

_/ Use copper, brass, or galvanized pipe and

fittings• Some codes may also allow OPVC

plastic pipe.

_/ Copper and galvanized pipe corrode fast

when connected together.

k/ You can buy adaptors to go from a copper or

threaded main water pipe to CPVC in and out

pipe.

x/ Sears has kits and bypass valves you can buy

to help make installing your softener easier.

•,/ ALWAYS install a bypass valve or valves.

Either use 3 shut-off valves, or 1 of Sears

special valves. Bypass valves let you turn off

water to the softener, but still have water in

the house pipes.

For electric hook-up you may need a

grounding adaptor plug and a length of

copper wire (See page 13).

TOOLS NEEDED: -common and cross

point (Phillips) screw drivers, slip-joint pliers

and a taoe measure or rule. ALSO...

• .. for SOLDERED COPPER- tubing cutter,

propane torch, solid-core solde[, paste flux,

emery cloth, sandpaper or steel wool.

.... for THREADED PiPE - hacksaw or pipe

cutter, pipe wrenches, pipe threading tool,

pipe joint compound.

•.. for OPVC PLASTIC- hacksaw, adjustable

wrench, solvent cement, fine emery cJoth.

_/ Drain hose (7/16 in. inside diameter) is

needed for valve and salt tank drains. See

steps 9 and 10 on page 11. You can buy

flexible hose at most Sears stores or through

Sears catalog.

If a rigid valve drain is needed to comply

with plumbing codes, Sears has a copper

drain kit (See page 11) to change the

softener to a 1/= in. copper tubing drain.

DRAW THE PLANS FOR YOUR IN ,AND OUT

PIPING HERE. BE SURE 1"0 FOLLOW GUIDES

LISTEDABOVF-_CLUDE ALLPIPE FITTINGS

AND ACCESSORIES YOU WILL USE. MAKE A Outlet

U ST OFALL MATERIALS YOU NEED AND BUY

THEM BEFORE YOU BEGIN "TO INSTALL THE '_L.

SOFTENER 41'

I

5

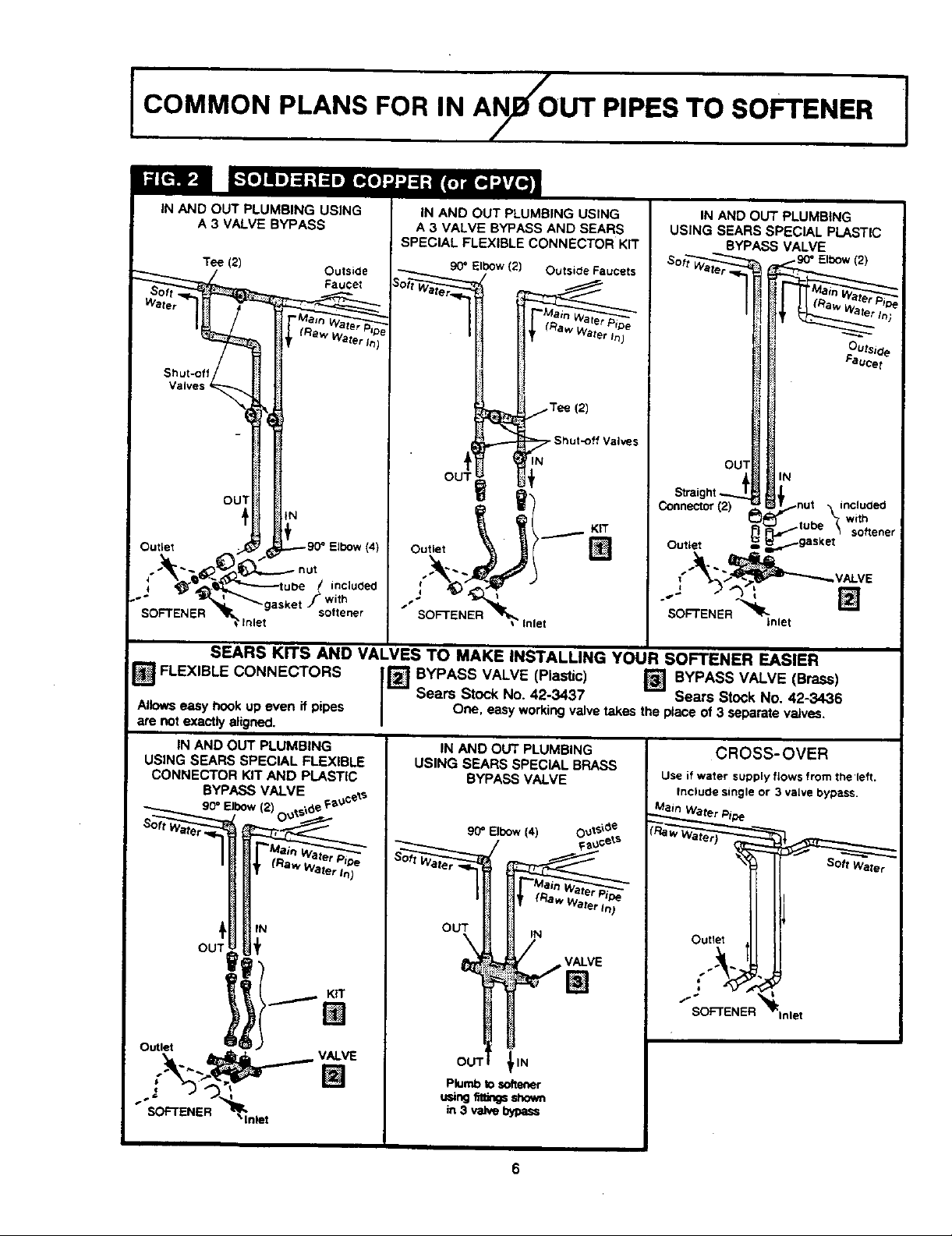

IN AND OUT PLUMBING USING

A 3 VALVE BYPASS

Tee (2)

/ Outsi_e

_ ,-..._ _Faucet

! Water _ _

IN AND OUT PLUMBING USING

A 3 VALVE BYPASS AND SEARS

SPECIAL FLEXIBLE CONNECTOR KIT

90• Elbow(2) OutsideFaucets

IN AND OUT PLUMBING

USING SEARS SPECIAL PLASTIC

BYPASS VALVE

eter . i

S°ftWa_" i _ 90* Elbow(2)

J,_._;;er,2

(Raw Water/nD) e

S ut-o

I Shut-off Valves

, _ oui ,.

OUT Connector{2) _ = _1.not _included

tN r_ zq- tube "_with

i, , ----_ oo,,e,_-_oe"''s°".°.'

oo,,., ou,,.t

FLEXIBLE CONNECTORS !_ BYPASS VALVE (Plastic) [] BYPASS VALVE (Brass)

Allows easy hook up even ff pipes One, easy working valve takes the place of 3 separate valves.

are not exactly aligned.

USING SEARS SPECIAL FLEXIBLE

CONNECTOR KIT AND PLASTIC

Soft Water : ,_

" ube included _,_

_'trite1 SOFTENER-_ inlet Inlet

SEARS KITS AND VALVES TO MAKE INSTALLING YOUR SOFTENER EASIER

Sears Stock No. 42-3437 Sears Stock No, 42-3436

IN AND OUT PLUMBING

BYPASS VALVE cede

90"Elbow(2) _..:_deF_'_

IN AND OUT PLUMBING

USING SEARS SPECIAL BRASS

BYPASS VALVE

90=Elbow(4) O'J_'s_de

CROSS-OVER

Use if water supply flows from the left.

IncluOe single or 3 valve bypass,

_MainWaterPi_e

Outsi<l e

Fauce t

T (Raw Water Ir_)

ter Pipe

IN

OUT_

o=,.t t,_L) VALVE

SOFTENER • Inlet

,_

=!

OUT IN

Out_e_ 1

";O._._.'S,n,e.

o

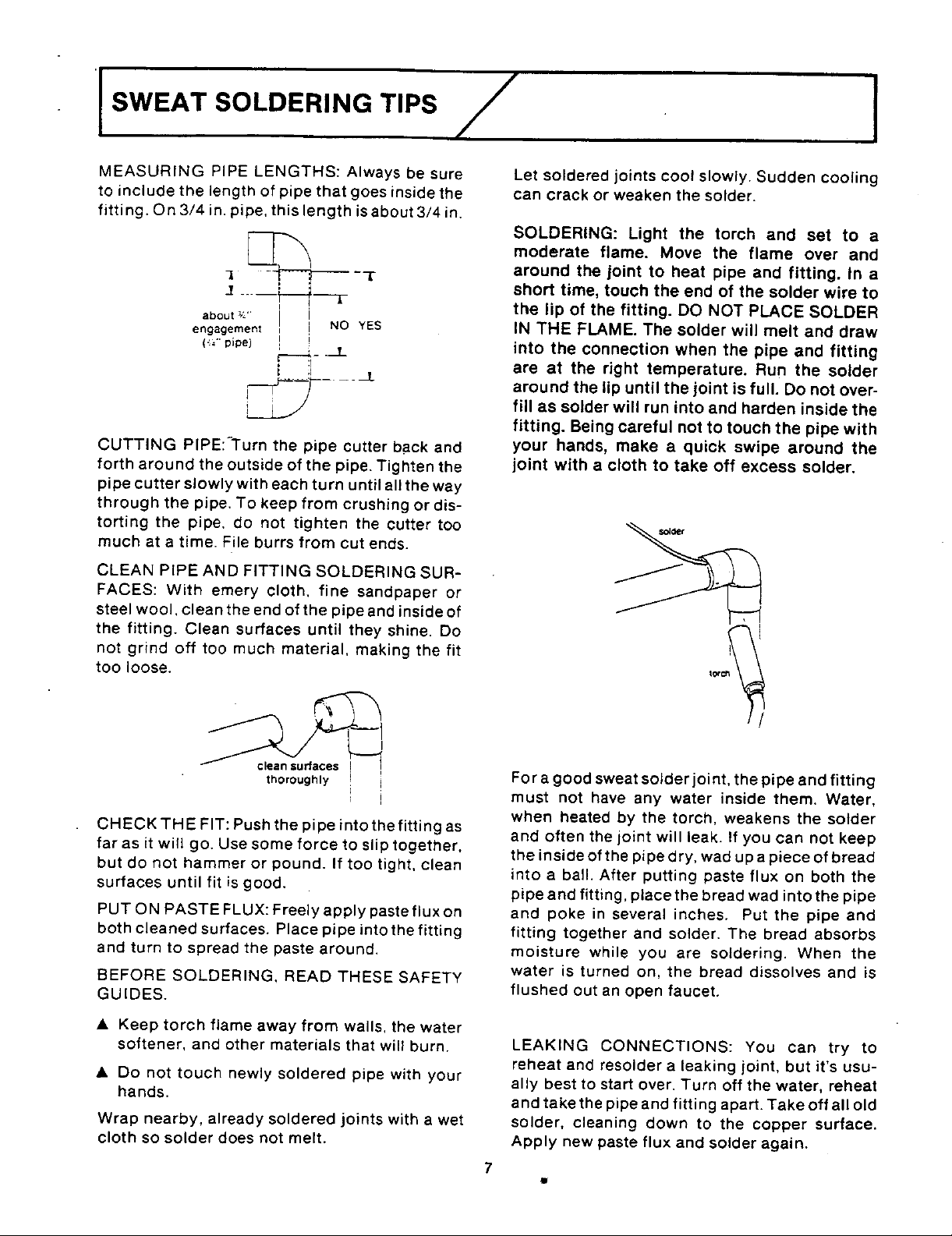

SWEAT SOLDERING TIPS /

I

MEASURING PIPE LENGTHS: Always be sure

to include the length of pipe that goes inside the

fitting, On 3/4 in. pipe, this length is about 3/4 in.

CUTTING PIPE:-Turn the pipe cutter back and

forth around the outside of the pipe. Tighten the

pipe cutter slowly with each turn until all the way

through the pipe. To keep from crushing or dis-

torting the pipe, do not tighten the cutter too

much at a time. File burrs from cut ends.

CLEAN PIPE AND FITTING SOLDERING SUR-

FACES: With emery cloth, fine sandpaper or

steel wool, clean the end of the pipe and inside of

the fitting. Clean surfaces until they shine. Do

not grind off too much material, making the fit

too loose.

Let soldered joints cool slowly. Sudden cooling

can crack or weaken the solder.

SOLDERING: Light the torch and set to a

moderate flame. Move the flame over and

around the joint to heat pipe and fitting. In a

short time, touch the end of the solder wire to

the lip of the fitting. DO NOT PLACE SOLDER

IN THE FLAME. The solder will melt and draw

into the connection when the pipe and fitting

are at the right temperature. Run the solder

around the lip until the joint is full. Do not over-

fill as solder will run into and harden inside the

fitting. Being careful not to touch the pipe with

your hands, make a quick swipe around the

joint with a cloth to take off excess solder.

solOer

clean surfaces !

thoroughly

i

CHECK THE FIT: Push the pipe into the fitting as

far as it will go. Use some force to slip together,

but do not hammer or pound. If too tight, clean

surfaces until fit is good.

PUT ON PASTE FLUX: Freely apply paste flux on

both cleaned surfaces. Place pipe into the fitting

and turn to spread the paste around.

BEFORE SOLDERING, READ THESE SAFETY

GUIDES.

• Keep torch flame away from walls, the water

softener, and other materials that will burn.

• Do not touch newly soldered pipe with your

hands.

Wrap nearby, already soldered joints with a wet

cloth so solder does not melt.

l/

For a good sweat solder joint, the pipe and fitting

must not have any water inside them, Water,

when heated by the torch, weakens the solder

and often the joint will leak. If you can not keep

the inside of the pipe dry, wad up a piece of bread

into s ball. After putting paste flux on both the

pipe and fitting, place the bread wad into the pipe

and poke in several inches. Put the pipe and

fitting together and solder. The bread absorbs

moisture while you are soldering. When the

water is turned on, the bread dissolves and is

flushed out an open faucet.

LEAKING CONNECTIONS: You can try to

reheat and resolder a leaking joint, but it's usu-

ally best to start over. Turn off the water, reheat

and take the pipe and fitting apart. Take off all old

solder, cleaning down to the copper surface,

Apply new paste flux and solder again.

7

I

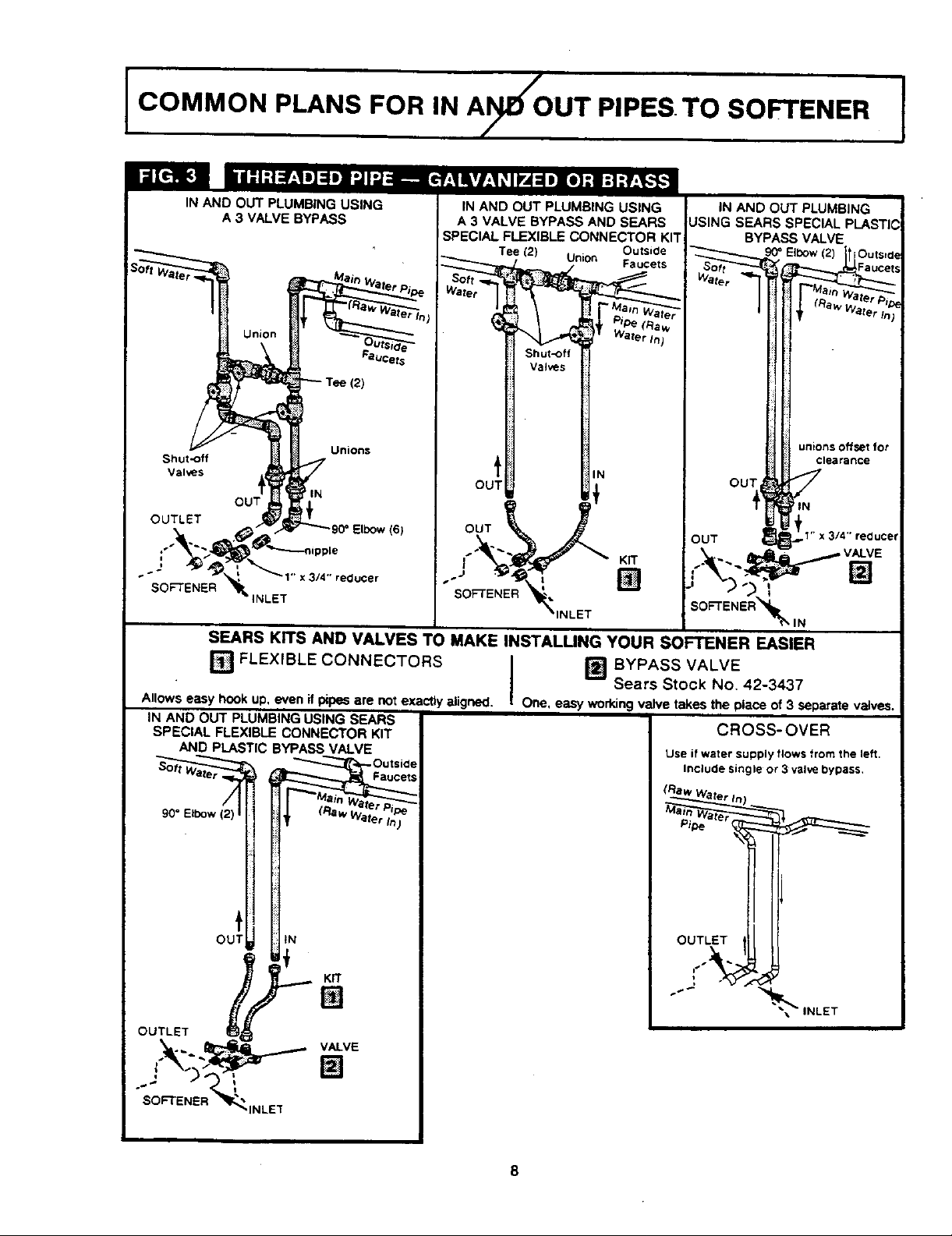

IN AND OUT PLUMBING USING

A 3 VALVE BYPASS

Unions

OUTLET

-" x 3/4" reClucer

• SOFTENER

INLET

FaUCets

IN AND OUT PLUMBING USING

! A 3 VALVE BYPASS AND SEARS

I SPECIAL FLEXIBLE CONNECTOR KIT

wator I

SEARS KITS AND VALVES TO MAKE INSTALUNG YOUR SOFTENER EASIER

[]FLEXIBLE CONNECTORS

Allows easy hook up, even if pipes are not exactly aligned.

IN AND OUT PLUMBING USING SEARS

SPECIAL FLEXIBLE CONNECTOR KIT

AND PLASTIC BYPASS VALVE

IN AND OUT PLUMBING

USING SEARS SPEC AL PLASTIC

Tee (2) Union Faucets

Shut-off

Valves

One, easy workingvalve takes the place of 3 separate valves.

Outsioe

tN

OUT 1" x 3/4" reducer

B BYPASS VALVE

Sears Stock No. 42-3437

BYPASS VALVE

90=Elbow(2)

unions OffSet for

clearance

Oul

IN

CROSS-OVER

Use if water supply flows from the left,

Include single or 3 valve bypass,

OUTLET _i_

._. _ v,J.VE

SOFTENER "_F._IN LE. T

Pi_e ater

OUT!ET !

_ _ % INLET

8

Close the shut-off valve on the house main

• ]. water pipe, near the water meter or pres-

sure tank, to turn off the water.

Shut off the gas or electric supply to the

• 2. water heater.

INSTALLING INLET SCREEN,

AND THE INLET AND OUTLET

ADAPTORS

Open the highest and lowest water faucets

I"i

• _. in your house to let water drain from the

pipes. Close faucets after water has

drained.

4. If not already done, remove all cardboard or

plastic packing pieces from inside the

softener. Take the bag with small parts.

Remove parts and lay out neatly so you can

find them when needed.

INSTALL THE INLET SCREEN, AND THE

5, INLET AND OUTLET ADAPTORS OR

SEARS BYPASS VALVE, STOCK NO.

42-3437.

a. INLET SCREEN - The inlet screen (Fig. 4 or 5)

is with the small parts bag items. This screen,

put in the softener valve inlet, stops dirt and

other sediments from getting inside the

softener. To install it, put it into the valve inlet

with the pointed end facing outward, toward in

coming water.

b. INLET AND OUTLET ADAPTORS (Do not use

if you will install the bypass valve) - Push the

adaptors into the valve inlet and outlet ports

(Fig. 4) as far as they will go. Both adaptors are

the same and fit either valve port. SNAPTHE 2

LARGE HOLDING CLIPS INTO PLACE, FROM

THE TOP DOWN AS SHOWN. BE SURE THEY

SNAP FIRMLY INTO PLACE SO THE ADAP-

TORS CAN NOT PULL OUT.

INLET I / ./"

-"'_ Screen

tn4et #

Adaptors

INSTALLING INLET SCREEN

AND BYPASS VALVE

\, / _ _ _'/ RemoveInner

•"_-_-./ .//O-Ring Seals

Bypass Valve _

Stock No, 42-3437

BYPASS VALVE TURNED

DOWNWARD

UPSIDE DOWN TO

CONNECT TO FLOOR

O_UT LEVEL PLUMBING

IN

3 VALVE

c. BYPASS VALVE, STOCK NO. 42-3437 - If the

bypass valve has 4 o-ring seals on it, remove

the inner one on both sides (Fig. 5). Push the

bypass valve into the softener valve as far as it

will go (Fig. 5 or 6). SNAP THE 2 LARGE

HOLDING CLIPS INTO PLACE, FROM THE

TOP DOWN AS SHOWN. BE SURE THEY

SNAP FIRMLY IN PLACE SO THE BYPASS

VALVE CAN NOT PULL OUT.

IF YOU DO NOT USE SEARS BYPASS VALVE, STOCK NO. 42-3437, DO STEP 6. IF YOU DID INSTALL

THIS BYPASS VALVE, SKIP STEP 6 AND GO TO STEP 7°

9

t STEP BY STEP GUIDES TO I ALLYOUR SOFTENER

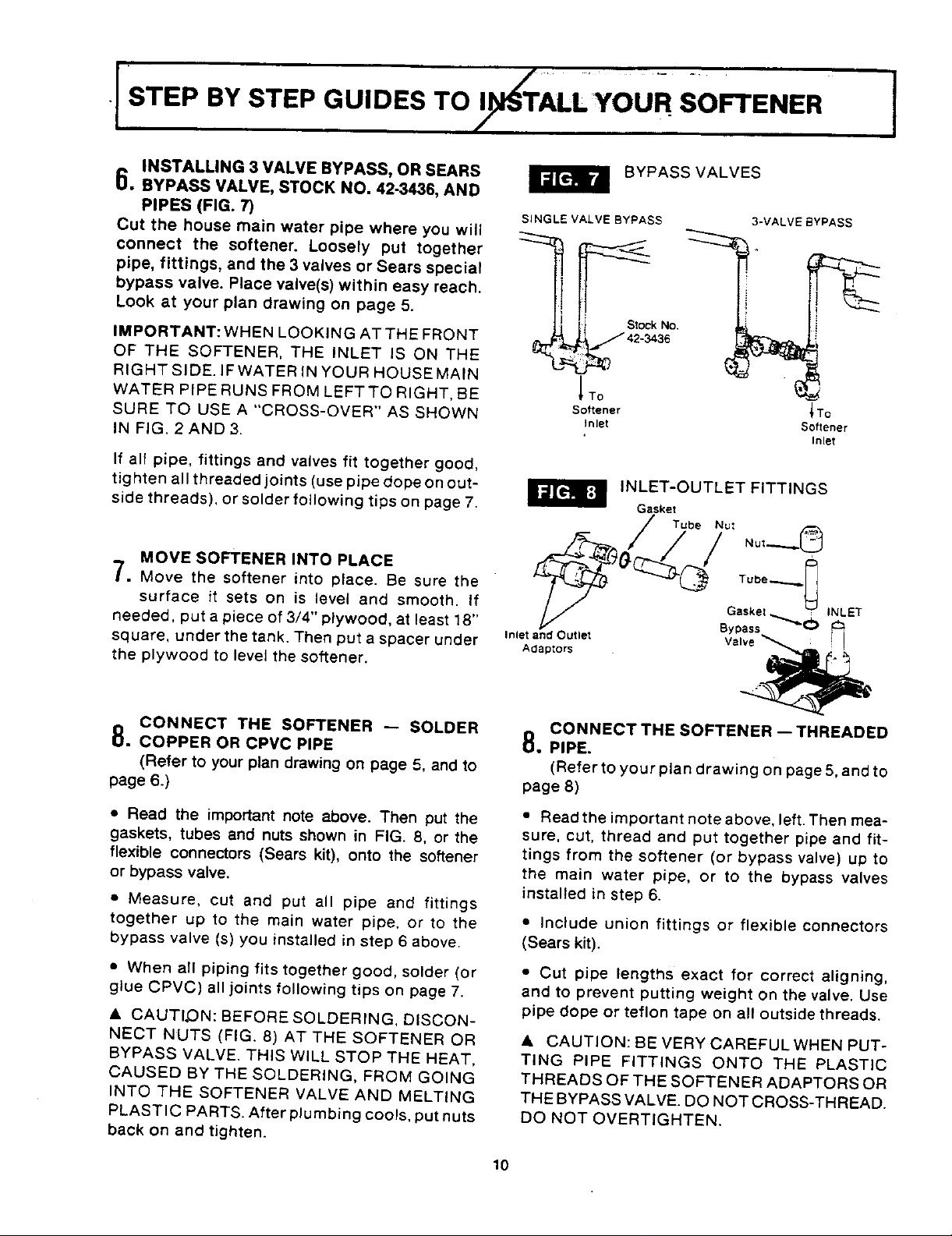

INSTALLING 3 VALVE BYPASS, OR SEARS

6, BYPASS VALVE, STOCK NO. 42-3436, AND

PIPES (FIG. 7)

Cut the house main water pipe where you will

connect the softener. Loosely put together

pipe, fittings, and the 3 valves or Sears special

bypass valve. Place valve(s) within easy reach.

Look at your plan drawing on page 5.

IMPORTANT:WHEN LOOKING ATTHE FRONT

OF THE SOFTENER, THE INLET iS ON THE

RIGHT SIDE. IF WATER IN YOUR HOUSE MAIN

WATER PIPE RUNS FROM LEFT TO RIGHT, BE

SURE TO USE A "CROSS-OVER" AS SHOWN

IN FiG. 2 AND 3.

If all pipe, fittings and valves fit together good,

tighten all threaded joints (use pipe dope on out-

side threads), or solder following tips on page 7.

MOVE SOFTENER INTO PLACE

. Move the softener into place. Be sure the

surface it sets on is level and smooth. If

needed, put a piece of 3/4" plywood, at least 18"

square, under the tank. Then put a spacer under

the plywood to level the softener.

SINGLE VALVE BYPASS

_ 42-3436

ITo

Softener

Inlet

Inlet and Outlet

Adaptors

BYPASS VALVES

3-VALVE BYPASS

Stock No.

_To

Softener

Inlet

CONNECT THE SOFTENER -- SOLDER

ft

0. COPPER OR CPVC PIPE

(Refer to your plan drawing on page 5, and to

page 6.)

• Read the important note above. Then put the

gaskets, tubes and nuts shown in FIG. 8, or the

flexible connectors (Sears kit), onto the softener

or bypass valve.

• Measure, cut and put all pipe and fittings

together up to the main water pipe, or to the

bypass valve (s) you installed in step 6 above.

• When all piping fits together good, solder (or

glue CPVC) all joints following tips on page 7.

• CAUTLON: BEFORE SOLDERING, DISCON-

NECT NUTS (FIG. 8) AT THE SOFTENER OR

BYPASS VALVE. THIS WILL STOP THE HEAT,

CAUSED BY THE SOLDERING, FROM GOING

INTO THE SOFTENER VALVE AND MELTING

PLASTIC PARTS. After plumbing cools, put nuts

back on and tighten.

CONNECT THE SOFTENER -- THREADED

8, PIPE.

(Refer to your plan drawing on page 5, and to

page 8)

• Read the important note above, left. Then mea-

sure, cut, thread and put together pipe and fit-

tings from the softener (or bypass valve) up to

the main water pipe, or to the bypass valves

installed in step 6.

• Include union fittings or flexible connectors

(Sears kit).

• Cut pipe lengths exact for correct aligning,

and to prevent putting weight on the valve. Use

pipe dope or teflon tape on all outside threads.

• CAUTION: BE VERY CAREFULWHEN PUT-

TING PIPE FITTINGS ONTO THE PLASTIC

THREADS OF THE SOFTENER ADAPTORS OR

THE BYPASS VALVE. DO NOT CROSS-THREAD.

DO NOT OVERTIGHTEN.

10

Loading...

Loading...