Kenmore 6127995483, 6127995423, 6127995383, 6127995323, 6127995183 Owner’s Manual

...

OWNER'S MANUAL

Model Nos.

612.7995383-115V

612.7995483-230V

612.7995183-GAS

ASSEMBLY, INSTALLATION, AND

OPERATION INSTRUCTIONS

612.7995323-115V

612.7995423-230V

612.7995123-GAS

KENMORE

READ THIS BOOK! IT WILL TELL YOU HOW TO SAFELY ASSEMBLE AND INSTALL

YOUR COMPACT KITCHEN. IT WILL ALSO GIVE YOU HINTS ON HOW TO OBTAIN

THE MOST EFFICIENT OPERATION. RECORD IN SPACE PROVIDED BELOW THE

SERIAL NUMBER AND MODEL NUMBER OF THIS APPLIANCE. THEY ARE LOCATED

ON THE SERIAL PLATE ON THE TOE BASE.

SERIAL # MODEL #

FULL ONE YEAR WARRANTY

ON COMPACT KITCHEN

For one year from the date of purchase, we will repair

this COMPACT KITCHEN free of charge,

if defective in material or Workmanship.

FULL FIVE YEAR WARRANTY ON

SEALED REFRIGERATION SYSTEM

For five years from the date of purchase, we will repair the sealed system

(consisting of refrigerant, co.nnecting tubing and compressor motor)

free of charge, if defective in material or workmanship

Service under these warranties is available by simply contacting your nearest

Sears store or Service Center throughout the United States

SEARS, ROEBUCK AND CO.

_art No. 1300000 SEARS, ROEBUCK AND CO., U.S.A.

GENERAL INFORMATION

LOCAL CODES

The installation of the Compact Kitchen Unit must be

in accordance with these instructions and all local

plumbing and electrical codes and Underwriter's

Laboratories Requirements.

SAFETY

This unit is approved for a permanent electrical con-

nection. It is extremely important that the correct wire

size is being used and that the unit is properly ground-

ed. See Wiring Diagrams Fig. 7 and 8 and Note under

Step 1 for the total power requirements. Name plate on

right side of base has the maximum power require-

ments also.

INSPECTION

Sears Compact Kitchen Units are carefully inspected

and cartoned to protect against shipping damage. If

there is damage or missing parts, the transportation

company agent should make a notation to that effect

on the bill. Send the bill to Sears, Roebuck and Co.

location from which the Company Kitchen Unit was

purchased with reference to the parts list in the "Repair

Parts Manual" and advise what parts are missing or

damaged. If available, give the invoice number on all

order bills. Following this procedure will enable Sears

to quickly ship the needed parts without further incon-

venience.

WATER PIPING INSTALLATION

The easiest method of connecting a faucet to water

supply pipes is the use of corrugated tubing designed

specifically for this procedure. However, in some areas

local plumbing codes may permit the use of copper

tubing. If so, the dimensions listed in Table 6 would be

appropriate for copper tubing. Compression fittings

and compression nuts would have to be purchased in

addition to the copper tubing. Shut off valves for cor-

rugated tubing are used with copper tubing. In some

areas, iron pipe is the only approved plumbing. Table 5

lists plumbing needed for iron pipe use. Table 6 lists

plumbing needed for corrugated tubing use.

ELECTRICAL INSTALLATION

The easiest method for electrical installation is the

use of armored cable. However, in some areas local

electrical codes do not permit the use of armored

cable. Some local electrical codes permit the use of

rigid conduit only. Table 2A lists the electrical supplies

needed involving armored cable or rigid conduit. Elec-

trical connections should be made by a licensed

electrician.

PREPARATION FOR INSTALLATION

Tools Needed

• 5/16 in. Nut Driver

• Hack Saw

• Screwdriver

• Pliers

• Adjustable Wrench

• Pipe Wrench - 8 in.

• Hammer

Purchased Parts Needed

• Plumbing: Refer to Table 2A and Table 5 or Table6

• Electrical: Refer to Table 2A

Parts Included With Unit

• Sink Faucet

• Basket Strainer

Unit Preparation

Remove side compartment panel by removing the two

hex head screws at the bottom of the panel and pulling

panel straight down. Test run refrigerator before per-

manent installation. An electrical outlet is located on

the left wall of the compartment. A three-wire power

cord is plugged into this outlet. Remove the plug and

attach to an extension cord. Plug the extension cord

into an electrical outlet. The compressor for the re-

frigerator will be turned on. Run the refrigerator for

1/2 hour. Check the freezer section. If the section is

cold, the refrigerator is operating properly.

INSTALLATION INSTRUCTIONS

This Compact Kitchen Unit has limited space on the

back wall for plumbing and electrical service access.

The plumbing (water supply and drain pipe) must

come out of the wall. The electrical junction box must

be located in the area specified in Figure 1 to avoid

interference when the unit is set in place. The proper

sequence of service connections is important to make

installation as trouble free as possible, as follows:

• Water Supply Connections

• Drain Pipe Connection

• Electrical Connection

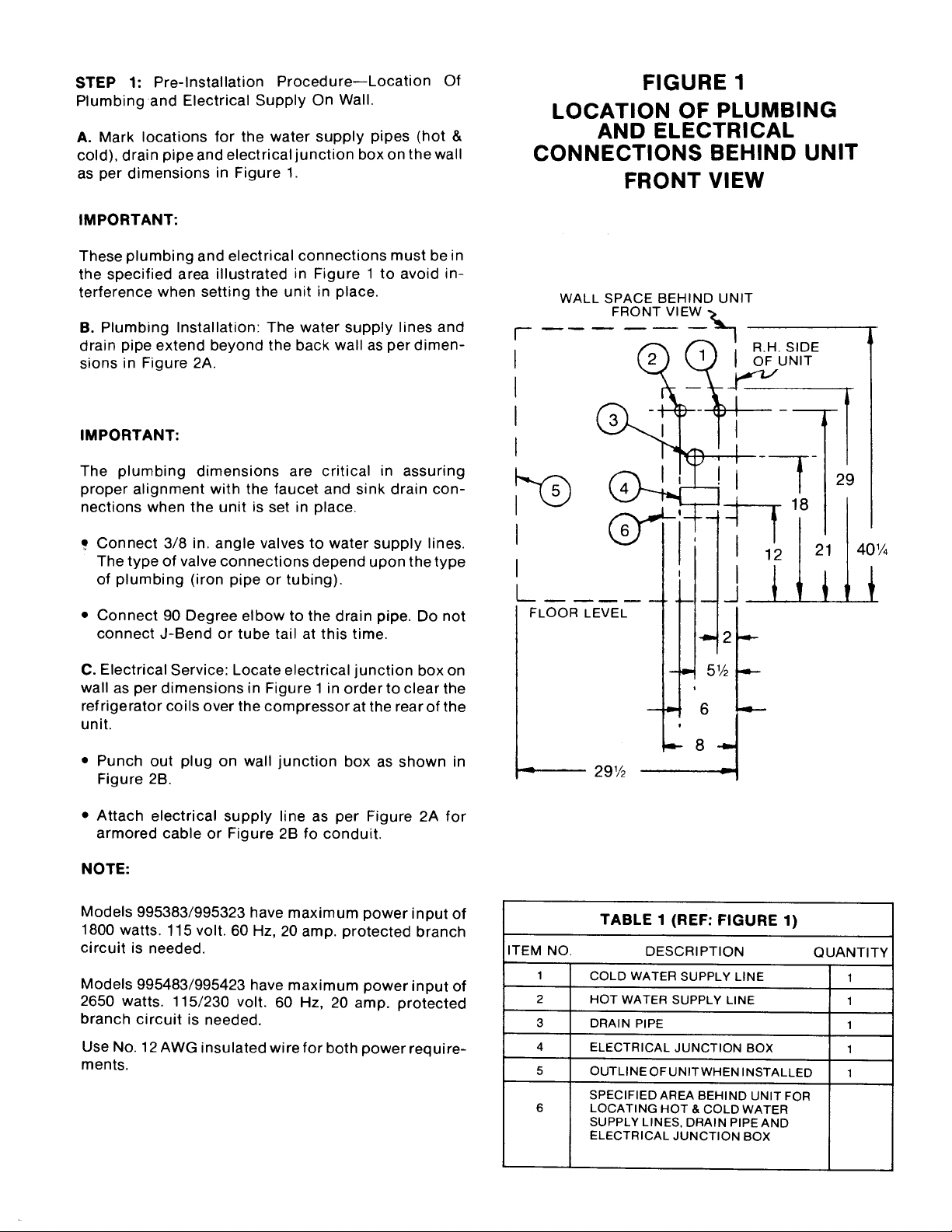

STEP 1: Pre-lnstallation Procedure--Location Of

Plumbing and Electrical Supply On Wall.

A. Mark locations for the water supply pipes (hot &

cold), drain pipe and electrical junction box on the wall

as per dimensions in Figure 1.

IMPORTANT:

These plumbing and electrical connections must be in

the specified area illustrated in Figure 1 to avoid in-

terference when setting the unit in place.

B. Plumbing Installation: The water supply lines and

drain pipe extend beyond the back wall as per dimen-

sions in Figure 2A.

IMPORTANT:

The plumbing dimensions are critical in assuring

proper alignment with the faucet and sink drain con-

nections when the unit is set in place.

FIGURE 1

LOCATION OF PLUMBING

AND ELECTRICAL

CONNECTIONS BEHIND UNIT

FRONT VIEW

WALL SPACE BEHIND UNIT

FRONT VI

I

I

I

I

I

I

• Connect 3/8 in. angle valves to water supply lines.

The type of valve connections depend upon the type

of plumbing (iron pipe or tubing).

• Connect 90 Degree elbow to the drain pipe. Do not

connect J-Bend or tube tail at this time.

C. Electrical Service: Locate electrical junction box on

wall as per dimensions in Figure 1 in order to clear the

refrigerator coils over the compressor at the rear of the

unit.

• Punch out plug on wall junction box as shown in

Figure 2B.

• Attach electrical supply line as per Figure 2A for

armored cable or Figure 2B fo conduit.

NOTE:

Models 995383/995323 have maximum power input of

1800 watts. 115 volt. 60 Hz, 20 amp. protected branch

circuit is needed.

Models 995483/995423 have maximum power input of

2650 watts. 115/230 volt. 60 Hz, 20 amp. protected

branch circuit is needed.

Use No. 12 AWG insulated wire for both power require-

ments.

I

J

FLOOR LEVEL

0

•.=_ 291/2

TABLE 1 (REF: FIGURE 1)

ITEM NO. QUANTITY

1 1

2 1

3 1

4 1

5 1

COLD WATER SUPPLY LINE

HOT WATER SUPPLY LINE

DRAIN PIPE

ELECTRICAL JUNCTION BOX

OUTLINE OF UNITWHEN INSTALLED

SPECIFIED AREA BEHIND UNIT FOR

LOCATING HOT & COLD WATER

SUPPLY LINES, DRAIN PIPE AND

ELECTRICAL JUNCTION BOX

DESCRIPTION

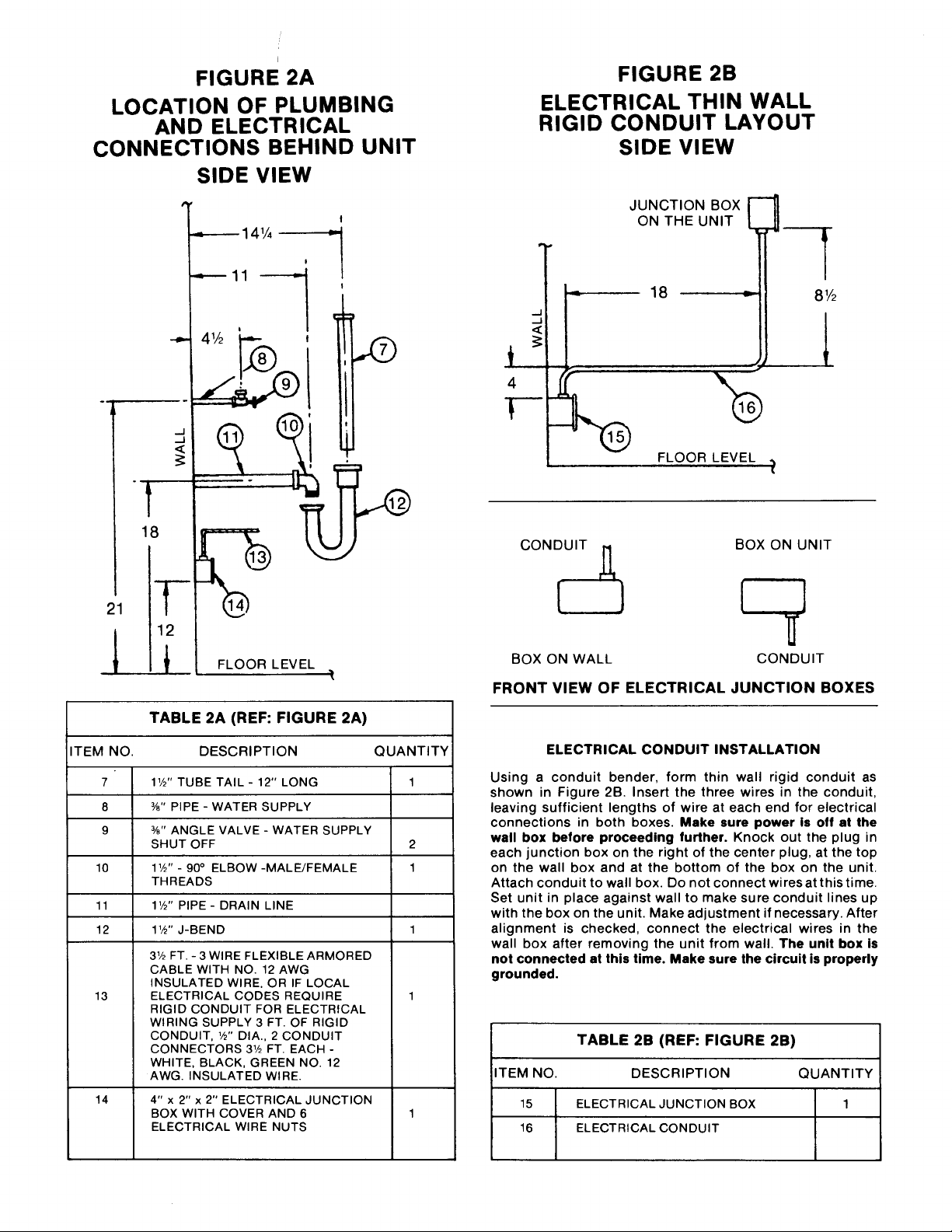

FIGURE 2A

LOCATION OF PLUMBING

AND ELECTRICAL

CONNECTIONS BEHIND UNIT

SIDE VIEW

._---- 141/4

FIGURE 2B

ELECTRICAL THIN WALL

RIGID CONDUIT LAYOUT

SIDE VIEW

JUNCTION BOX

ON THE UNIT

18

..j,.

..J

.J

<c

21

FLOOR LEVEL

TABLE 2A (REF: FIGURE 2A)

ITEM NO. DESCRIPTION QUANTITY

7 11/2'' TUBE TAIL - 12" LONG 1

8 %" PIPE - WATER SUPPLY

9 %" ANGLE VALVE - WATER SUPPLY

10 11/2"- 90° ELBOW -MALE/FEMALE 1

11 11/2'' PIPE- DRAIN LINE

12 11/2'' J-BEND 1

13

14

SHUT OFF 2

THREADS

31/2 FT. - 3 WIRE FLEXIBLE ARMORED

CABLE WITH NO. 12 AWG

INSULATED WIRE. OR IF LOCAL

ELECTRICAL CODES REQUIRE

RIGID CONDUIT FOR ELECTRICAL

WIRING SUPPLY 3 FT. OF RIGID

CONDUIT, 1/_,,DIA., 2 CONDUIT

CONNECTORS 31/2 FT. EACH -

WHITE, BLACK, GREEN NO. 12

AWG. INSULATED WIRE.

4" x 2" x 2" ELECTRICAL JUNCTION

BOX WITH COVER AND 6

ELECTRICAL WIRE NUTS

<

<

FLOOR LEVEL

CONDUIT N BOX ON UNIT

I ]

BOX ON WALL CONDUIT

FRONT VIEW OF ELECTRICAL JUNCTION BOXES

ELECTRICAL CONDUIT INSTALLATION

Using a conduit bender, form thin wall rigid conduit as

shown in Figure 2B. Insert the three wires in the conduit,

leaving sufficient lengths of wire at each end for electrical

connections in both boxes. Make sure power is off at the

wall box before proceeding further. Knock out the plug in

each junction box on the right of the center plug, at the top

on the wall box and at the bottom of the box on the unit.

Attach conduit to wall box. Do not connect wires at this time.

Set unit in place against wall to make sure conduit lines up

with the box on the unit. Make adjustment if necessary. After

alignment is checked, connect the electrical wires in the

wall box after removing the unit from wall. The unit box is

not connected at this time. Make sure the circuit is properly

grounded.

TABLE 2B (REF: FIGURE 2B)

ITEM NO. DESCRIPTION QUANTITY

15 ELECTRICAL JUNCTION BOX 1

16 ELECTRICAL CONDUIT

SINK TOP

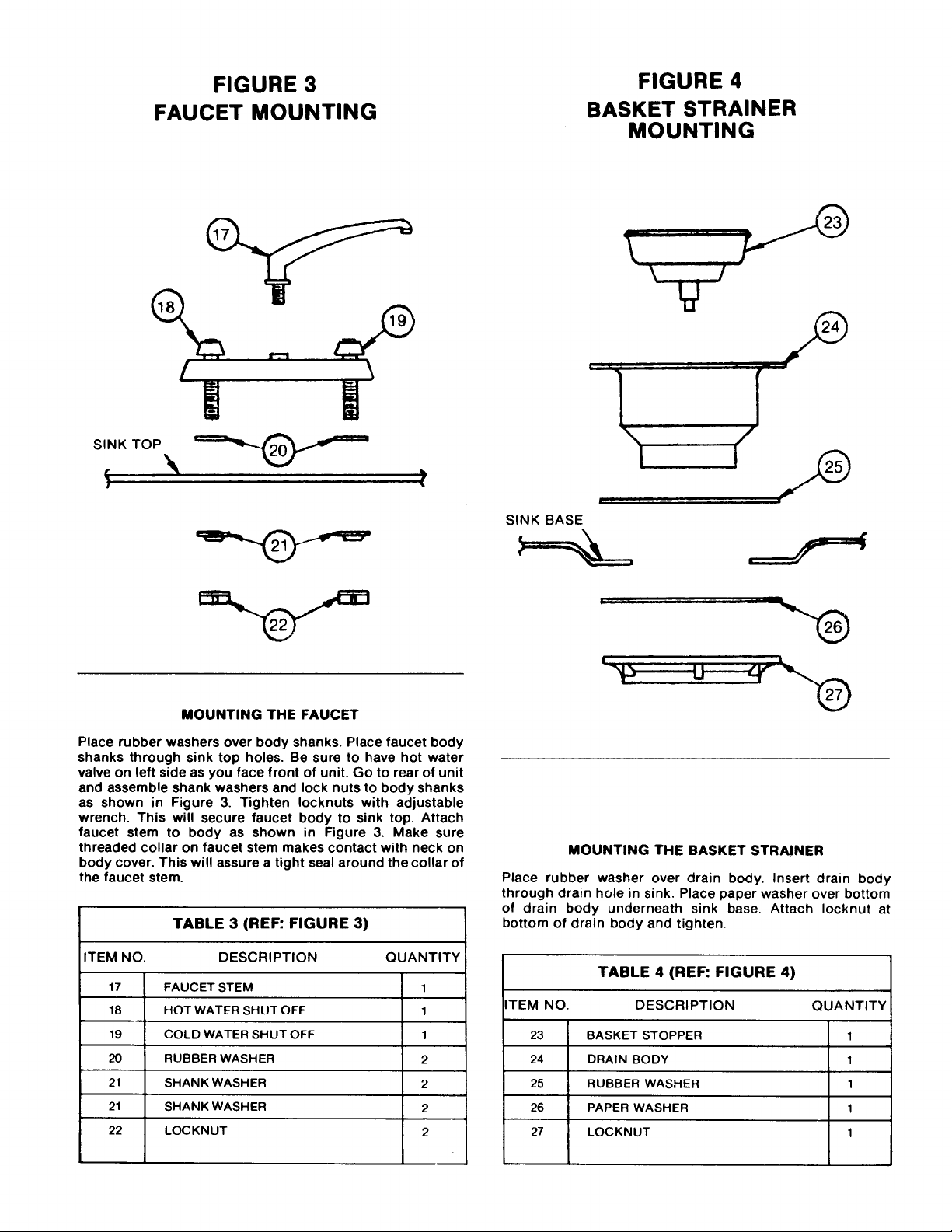

FIGURE 3

FAUCET MOUNTING

\ ,,

SINK BASE

FIGURE 4

BASKET STRAINER

MOUNTING

i

! i ,

| i

MOUNTING THE FAUCET

Place rubber washers over body shanks. Place faucet body

shanks through sink top holes. Be sure to have hot water

valve on left side as you face front of unit. Go to rear of unit

and assemble shank washers and lock nuts to body shanks

as shown in Figure 3. Tighten Iocknuts with adjustable

wrench. This will secure faucet body to sink top. Attach

faucet stem to body as shown in Figure 3. Make sure

threaded collar on faucet stem makes contact with neck on

body cover. This will assure a tight seal around the collar of

the faucet stem.

TABLE 3 (REF: FIGURE 3)

ITEM NO. DESCRIPTION QUANTITY

17 FAUCET STEM 1

18 HOT WATER SHUT OFF 1

19 COLD WATER SHUT OFF 1

20 RUBBER WASHER 2

21 SHANK WASHER 2

21 SHANK WASHER 2

22 LOCKNUT 2

MOUNTING THE BASKET STRAINER

Place rubber washer over drain body. Insert drain body

through drain hole in sink. Place paper washer over bottom

of drain body underneath sink base. Attach Iocknut at

bottom of drain body and tighten.

TABLE 4 (REF: FIGURE 4)

ITEM NO. DESCRIPTION QUANTITY

23 BASKET STOPPER 1

24 DRAIN BODY 1

25 RUBBER WASHER 1

26 PAPER WASHER 1

27 LOCKNUT 1

Loading...

Loading...