Kenmore Best

Owner's Manual

r

Sears Service Is At Your Service

Your Kenmore has added value when

you consider that Sears has nationwide

service units staffed by Sears-trained

technicians...professional technicians

specifically trained to service SEARS

appliances, having the parts, tools and

equipment to insure that we meet our

pledge to you... "We Service What

We Sell."

ADD TO THE VALUE OF YOUR

KENMORE, BUY A SEARS

MAINTENANCE AGREEMENT

Sears Kenmore refrigerators are

designed, built and tested for years of

dependable use. Yet any modern

appliance may need service from time

to time. The Sears warranty plus the

Sears maintenance agreement give pro-

tection from unexpected repair bills.

Contact your salesman or nearest ser-

vice center for details.

For future use, please record

the model number,serial

number and the date you

purchased your Kenmore

refrigerator in the spaces

provided below:

Model Number

Serial Number

Date Purchased

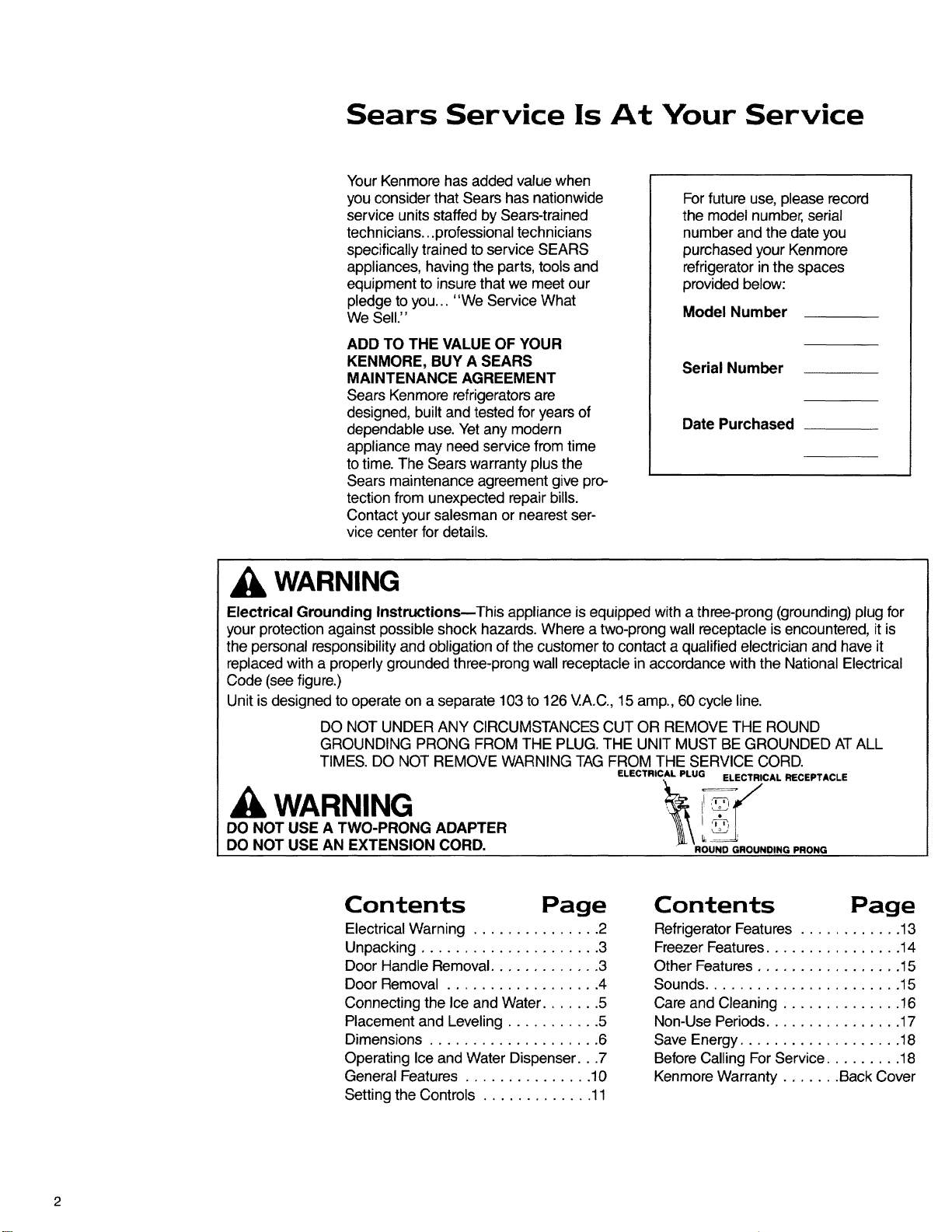

WARNING

Electrical Grounding Instructions--This appliance is equipped with a three-prong (grounding) plug for

your protection against possible shock hazards. Where a two-prong wall receptacle is encountered, it is

the personal responsibility and obligation of the customer to contact a qualified electrician and have it

replaced with a properly grounded three-prong wall receptacle in accordance with the National Electrical

Code (see figure.)

Unit is designed to operate on a separate 103 to 126 V.A.C., 15 amp., 60 cycle line.

DO NOT UNDER ANY CIRCUMSTANCES CUT OR REMOVE THE ROUND

GROUNDING PRONG FROM THE PLUG. THE UNIT MUST BE GROUNDED AT ALL

TIMES. DO NOT REMOVE WARNING TAG FROM THE SERVICE CORD.

ELECTRICAL PLUG ELECTRICAL RECEPTACLE

WARNING

DO NOT USE AN EXTENSION CORD. ROUNO_----=_GROUNDINGPRONG

Contents Page

Electrical Warning ............... 2

Unpacking ..................... 3

Door Handle Removal............. 3

Door Removal .................. 4

Connecting the Ice and Water ....... 5

Placement and Leveling ........... 5

Dimensions .................... 6

Operating Ice and Water Dispenser...7

General Features ............... 10

Setting the Controls ............. 11

Contents Page

Refrigerator Features ............ 13

Freezer Features................ 14

Other Features ................. 15

Sounds ....................... 15

Care and Cleaning .............. !6

Non-Use Periods ................ 17

Save Energy ................... 18

Before Calling For Service ......... 18

Kenmore Warranty ....... Back Cover

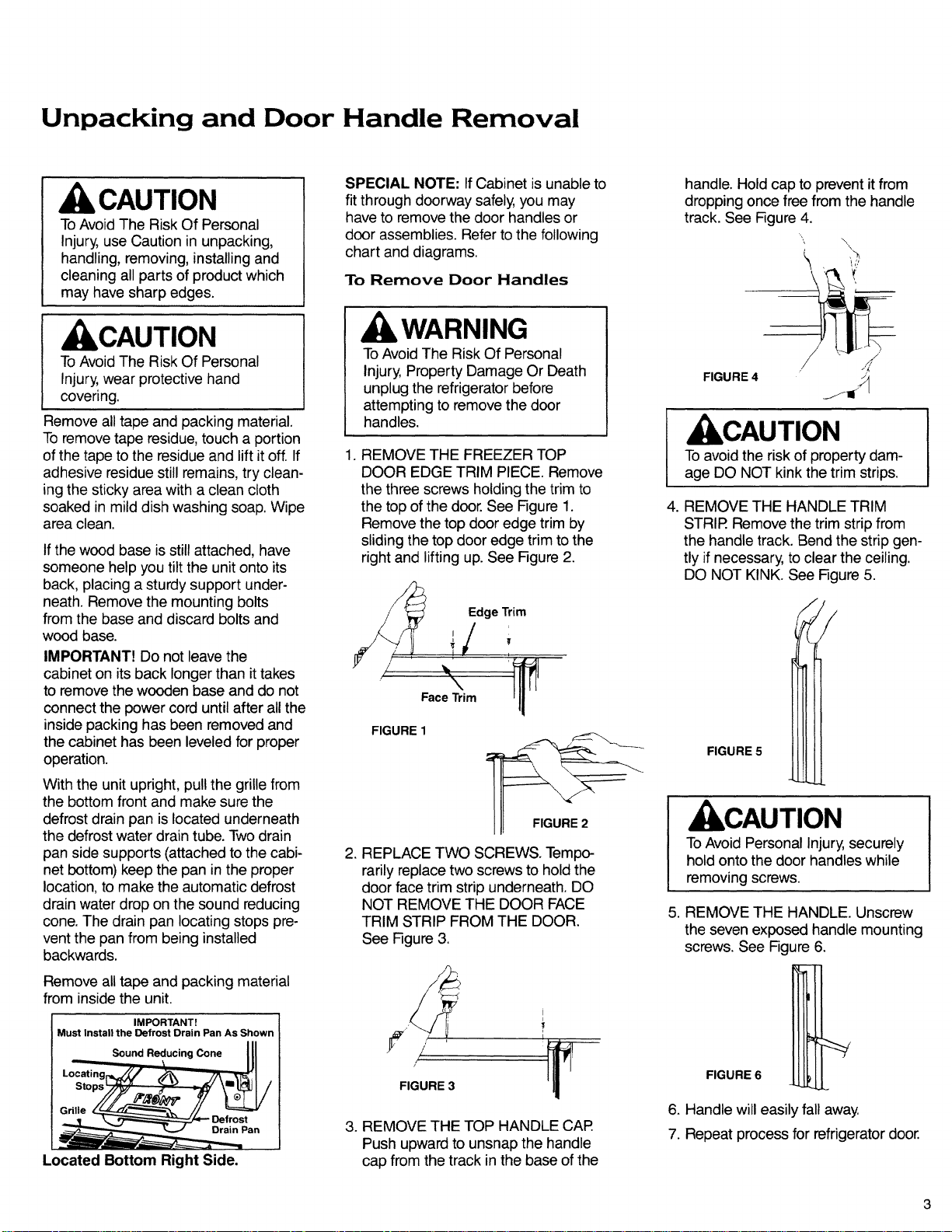

Unpacking and Door Handle Removal

, CAUTION

ToAvoid The Risk Of Personal

Injury, use Caution in unpacking,

handling, removing, installing and

cleaning all parts of product which

may have sharp edges.

CAUTION

To Avoid The Risk Of Personal

Injury, wear protective hand

covering.

Remove all tape and packing material.

To remove tape residue, touch a portion

of the tape to the residue and lift it off. If

adhesive residue still remains, try clean-

ing the sticky area with a clean cloth

soaked in mild dish washing soap. Wipe

area clean.

If the wood base is still attached, have

someone help you tilt the unit onto its

back, placing a sturdy support under-

neath. Remove the mounting bolts

from the base and discard bolts and

wood base.

IMPORTANT! Do not leave the

cabinet on its back longer than it takes

to remove the wooden base and do not

connect the power cord until after all the

inside packing has been removed and

the cabinet has been leveled for proper

operation.

With the unit upright, pull the grille from

the bottom front and make sure the

defrost drain pan is located underneath

the defrost water drain tube. Two drain

pan side supports (attached to the cabi-

net bottom) keep the pan in the proper

location, to make the automatic defrost

drain water drop on the sound reducing

cone. The drain pan locating stops pre-

vent the pan from being installed

backwards.

SPECIAL NOTE: If Cabinet is unable to

fit through doorway safely, you may

have to remove the door handles or

door assemblies. Refer to the following

chart and diagrams.

To Remove Door Handles

WARNING

ToAvoid The Risk Of Personal

Injury, Property Damage Or Death

unplug the refrigerator before

attempting to remove the door

handles.

. REMOVE THE FREEZER TOP

DOOR EDGE TRIM PIECE. Remove

the three screws holding the trim to

the top of the door. See Figure 1.

Remove the top door edge trim by

sliding the top door edge trim to the

right and lifting up. See Figure 2.

Edge _im

Face Trim

FIGURE 1

2. REPLACE TWO SCREWS. Tempo-

rarily replace two screws to hold the

door face trim strip underneath. DO

NOT REMOVE THE DOOR FACE

TRIM STRIP FROM THE DOOR.

See Figure 3.

handle. Hold cap to prevent itfrom

dropping once free from the handle

track. See Figure 4.

CAUTION

Toavoid the risk of property dam-

age DO NOT kink the trim strips.

.

REMOVE THE HANDLE TRIM

STRIP. Remove the trim strip from

the handle track. Bend the strip gen-

tly if necessary, to clear the ceiling.

DO NOT KINK. See Figure 5.

FIGURE 5

CAUTION

ToAvoid Personal Injury, securely

hold ontothe door handles while

removing screws.

.

REMOVE THE HANDLE. Unscrew

the seven exposed handle mounting

screws. See Figure 6.

Remove all tape and packing material

from inside the unit.

[ IMPORTANT! 1

Must install the Defrost Drain Pan As Shown

Sound Reducing Cone

Located Bottom Right Side.

I

f '/

FIGURE 3

3. REMOVE THE TOP HANDLE CAP

Push upward to unsnap the handle

cap from the track in the base of the

FIGURE 6

6. Handle willeasily fall away.

7. Repeat process for refrigeratordoor.

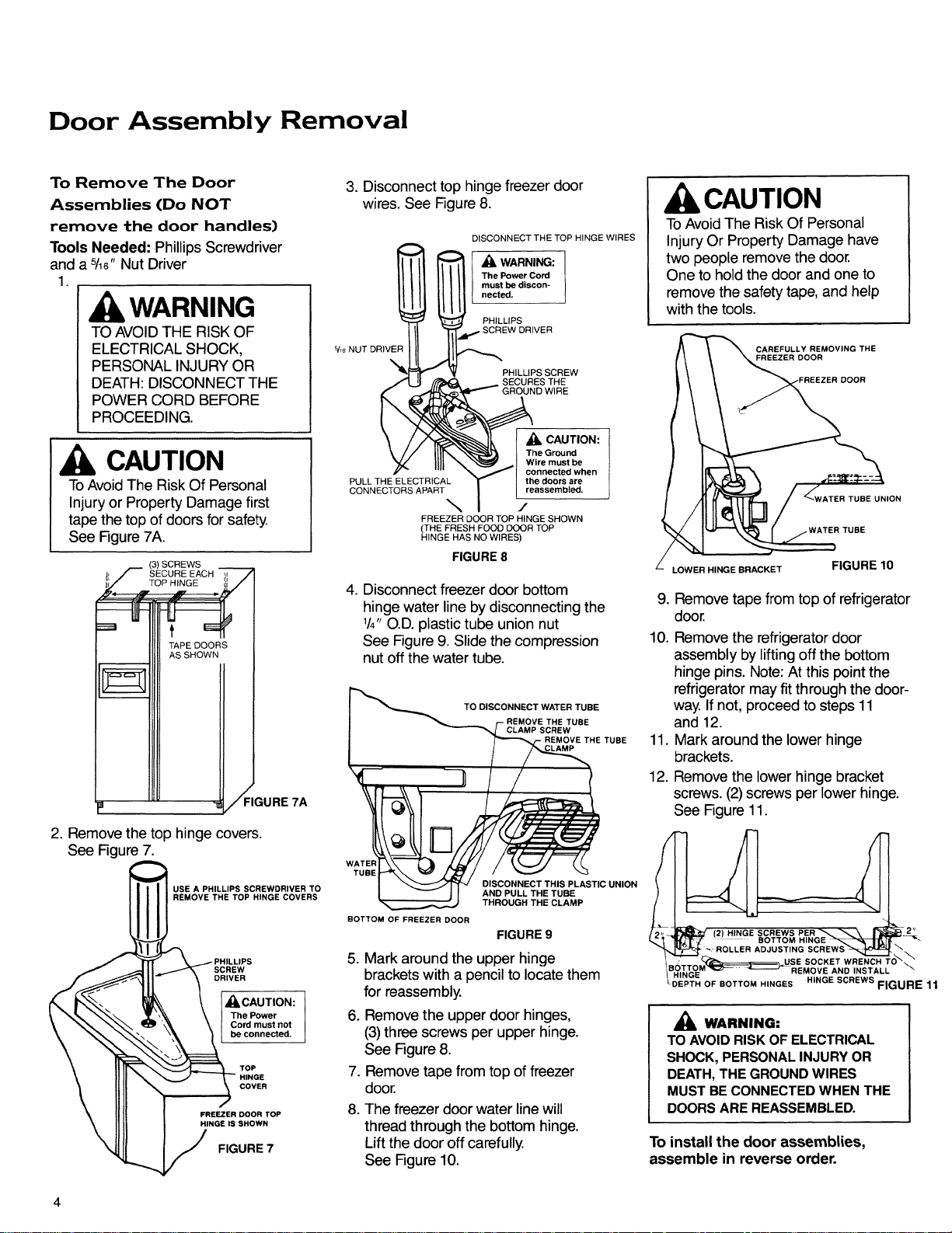

Door Assembly Removal

To Remove The Door

Assemblies (Do NOT

remove the door handles)

Tools Needed: Phillips Screwdriver

and a 5118"Nut Driver

1.

WARNING

TO AVOID THE RISK OF

ELECTRICAL SHOCK,

PERSONAL INJURY OR

DEATH: DISCONNECT THE

POWER CORD BEFORE

PROCEEDING.

CAUTION

ToAvoid The Risk Of Personal

Injury or Property Damage first

tape the top of doors for safety

See Figure 7A.

(3) SCREWS

t!' / SECURE EACH ,,i /

IGURE 7A

2. Remove the top hinge covers.

See Figure 7.

3. Disconnect top hinge freezer door

wires. See Figure 8.

DISCONNECT THE TOP HINGE WIRES

The Power Cord

must be discon-

WARNING: j

nected.

PHILLIPS

sheNUT DRIVER

PHILLIPS SCREW

SECURES THE

GROUND WIRE

_lh CAUTION:

The Ground

Wire must be

PULL THE ELECTRICAL the doors are

CONNECTORS APART reassembled.

connected when

\ /

FREEZER DOOR TOP HINGE SHOWN

(THE FRESH FOOD DOOR TOP

HINGE HAS NO WIRES)

FIGURE 8

4. Disconnect freezer door bottom

hinge water line by disconnecting the

tl4" O.D. plastic tube union nut

See Figure 9. Slide the compression

nut off the water tube.

TO DISCONNECT WATER TUBE

- REMOVE THE TUBE

CLAMP SCREW

REMOVE THE TUBE

CAUTION

ToAvoid The Risk Of Personal

Injury Or Property Damage have

two people remove the door.

One to hold the door and one to

remove the safety tape, and help

with the tools.

FREEZER DOOR

LOWER HINGE BRACKET

9. Remove tape from top of refrigerator

door.

10. Remove the refrigerator door

assembly by lifting off the bottom

hinge pins. Note: At this point the

refrigerator may fit through the door-

way. If not, proceed to steps 11

and 12.

11. Mark around the lower hinge

brackets.

12. Remove the lower hinge bracket

screws. (2)screws per lower hinge.

See Figure 11.

REMOVING THE

TUBE UNION

WATER TUBE

FIGURE 10

DISCONNECT THIS PLASTIC UNION

AND PULL THE TUBE

THROUGH THE CLAMP

BOTTOM OF FREEZER DOOR

FIGURE 9

5. Mark around the upper hinge

brackets with a pencil to locate them

for reassembly

6. Remove the upper door hinges,

(3)three screws per upper hinge.

See Figure 8.

Remove tape from top of freezer

door.

The freezer door water line will

t_ "_,_t_" ....................... BOTTOM HINGE _-_--1_ _

_'_1_ ROLLER ADJUSTING SCREWS _

I _--_-__ USE SOCKET WRENCH TO_. _

IBOTTOM_------J_-REMOVE AND INSTALL

(2) HINGE SCREWS PER_ _\

HINGE

_,"_"_9_, .,NGESCREWS

DEPTHOFBOTTOMHINGES FIGURE 11

,_ WARNING:

TO AVOID RISK OF ELECTRICAL

SHOCK, PERSONAL INJURY OR

DEATH, THE GROUND WIRES

MUST BE CONNECTED WHEN THE

DOORS ARE REASSEMBLED.

threadthrough the bottom hinge.

Lift the door off carefully

See Figure 10.

4

To install the door assemblies,

assemble in reverse order.

Connecting the Ice and Water Dispenser

Connect the ice and Water

System to Cold Water

Supply.

Refer to the instructions on the back of

the cabinet.

Placement and Leveling

,CAUTION

Toavoid cross threading and

water leaks, you must start all the

water tube fittings several turns

by hand before tightening with

wrenches. DO NOT OVER-

TIGHTEN. Also be sure to double

check for water leaks after turning

on the water pressure to the

refrigerator.

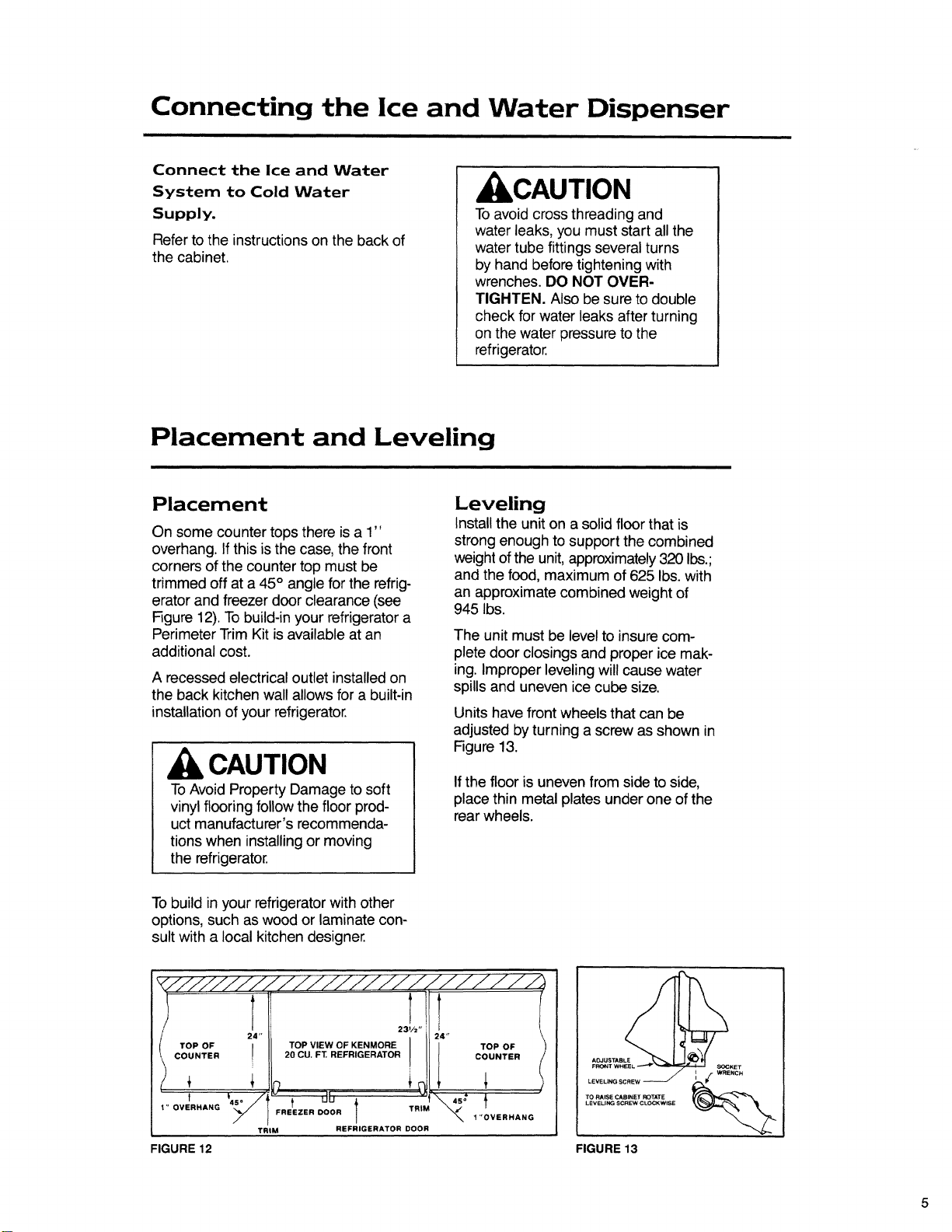

Placement

On some counter tops there is a 1"

overhang. If this isthe case, the front

corners of the counter top must be

trimmed off at a 45° angle for the refrig-

erator and freezer door clearance (see

Figure 12). Tobuild-in your refrigerator a

Perimeter Trim Kit is available at an

additional cost.

A recessed electrical outlet installed on

the back kitchen wall allows for a built-in

installation of your refrigerator.

CAUTION

ToAvoid Property Damage to soft

vinyl flooring follow the floor prod-

uct manufacturer's recommenda-

tions when installing or moving

the refrigerator.

To build in your refrigerator with other

options, such as wood or laminate con-

sult with a local kitchen designer.

Leveling

Install the unit on a solid floor that is

strong enough to support the combined

weight of the unit, approximately 320 Ibs.;

and the food, maximum of 625 Ibs. with

an approximate combined weight of

945 lbs.

The unit must be level to insure com-

plete door closings and proper ice mak-

ing. Improper leveling will cause water

spills and uneven ice cube size.

Units have front wheels that can be

adjusted by turning a screw as shown in

Figure 13.

If the floor is uneven from side to side,

place thin metal plates under one of the

rear wheels.

TOP OF !

COUNTER

÷ l

" OVERHANG

FIGURE 12

23V2" f

t

///////.

24"

///)s).-Ty////

TOP VIEW OF KENMORE I | TOP OF

24"

20 CU. FT. REFRIGERATOR ! ! COUNTER

FREEZER DOOR TRIM 1 "OVERHANG

TRIM

REFRIGERATOR DOOR

TO RA_E CABINET ROTATE

LEVEUNG SCREW CLOCKWISE

FIGURE 13

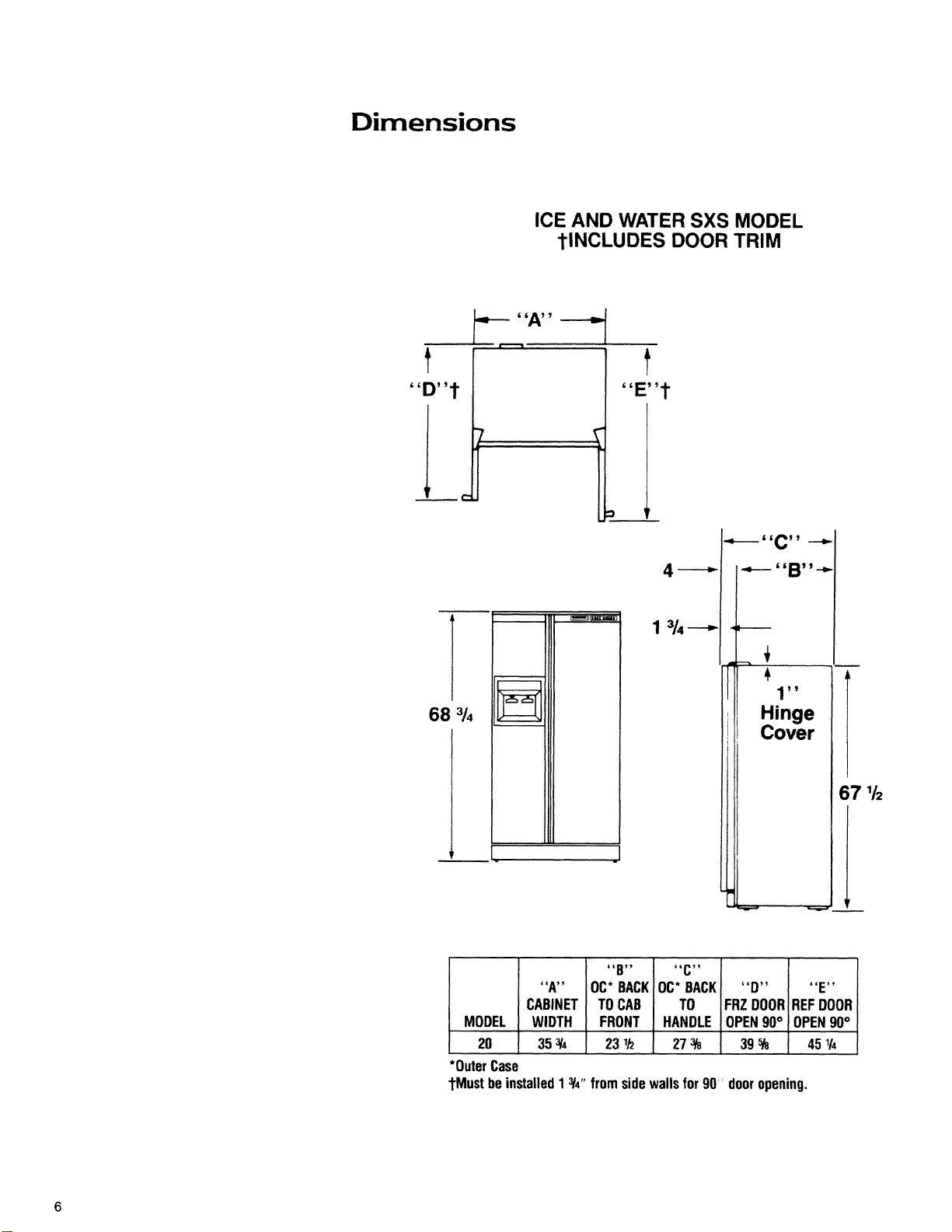

Dimensions

ICE AND WATER SXS MODEL

"['INCLUDES DOOR TRIM

' 'A' '

1¾--_

68 3/4

"B.... C"

"A" OC*BACKOC*BACK "D .... E"

CABINET TOCAB TO FRZDOORREFDOOR

MODEL

20

*OuterCase

tMust beinstalled13/4"fromsidewallsfor90 dooropening.

WIDTH FRONT HANDLE OPEN90° OPEN90°

35 3/4 231/2 273/8 39 5/8 45tl4

Hinge

Cover

1 _

67 1/2

Operating the Ice and Water Dispenser

Water taste and odor.

, CAUTION

ToAvoid the Possibility of Per-

sonal Injury, Never Attempt to

Operate the Ice Dispenser with

the Door Open.

Separate dispenser bars control the

release of ice cubes and water. They are

located in a recessed alcove for safety

and convenience. The dispenser bars

are sculptured to fit the contours of an

ordinary drinking glass. Depress the

appropriate dispenser bar to activate

the dispensing mechanism.

Small spills will be caught in the sump

area below the dispenser. The sump

cover grille is easily removed for

cleaning.

NOTE: There is no drain in the sump

so water should not purposely be

poured into it.

Do not add ice to ice bin.

Do not try to speed ice dispensing by

adding cubes of ice that you may have

purchased or made in some other way

The unit has been "matched" to the

automatic ice maker and will not oper-

ate properly with different shaped or

sized cubes.

Water Dispenser

There are many variables which can

affect the taste and odor properties of

the water that is being dispensed from

your Ice and Water model such as:

1. Iron and other mineral deposits nor-

mally found in water.

2. Type of tubing (copper, galvanized,

plastic, etc.) used in the household

water supply system, as well as the

type of tubing used to connect your

unit to your household water supply

3. Is the water "fresh" or has it been

left standing unused in the storage

reservoir and/or water supply line for

any length of time?

Tominimize taste and odor problems, it

is recommended that the following

steps be taken:

1.Thoroughly rinse out the system after

it has been connected to the house-

hold water supply This can be

accomplished by throwing away the

first 10-14 eight-ounce glasses of

water that are obtained from the unit.

2. If the water dispensing system is not

used frequently, the entire water res-

ervoir and system should be flushed.

This will ensure a fresh supply of

water at all times.

If the above suggestions do not

entirely eliminate an undesirable

taste or odor condition in your water,

your problem is most likely a water

problem. It is recommended that you

contact your local water treatment

company for its specialized kind of

help in solving your problem.

To operate, press glass against the

water dispenser bar. Releasing pres-

sure shuts the water off.

After the unit is connected to an active

household cold water line, it is advisable

to fill and throw out the first 10-14

glasses of water. This will cleanse the

lines of impurities.

How The Water Dispenser

Works

The water reservoir is located in the

refrigerator behind the crisper pan. The

water line to the dispenser bar is routed

in a special way to prevent freeze-ups.

The water dispensing lever energizes

the water line solenoid valve to add

water to the water reservoir.

The water is forced by household water

pressure through the tubing and out the

water dispenser.

Operating the Ice and Water Dispenser

you use it. At first, your family will be

WATERLINE

TO THE

ICE MAKER

HOW THE WATER DISPENSER WORKS

This water is cooled in the water reser-

voir. Some water remains in the water

line to the dispenser, causing the first

glass of water to be somewhat warmer

than the following glasses.

Ice Dispenser

using it quite frequently

To help meet this demand, you can

speed ice production by turning the

freezer control to a colder setting.

For best overall operation of the

unit, be sure to return the freezer

control to its previous position as

soon as possible.

If you use very little ice over a period of

a week or so -- or if you use none at all

for that period -- the ice cubes may

freeze into a solid mass and the unit will

not dispense ice. You must then remove

the ice bin (follow instructions on next

page), thaw the ice, and throw it away

Overload. If you hold the dispenser bar

in the ON position for approximately 4-5

minutes, the dispenser motor may trip

out on overload. This could occur if you

were trying to fill a large container with

ice. The overload will reset automatically

in approximately 3 minutes, after which

ice can again be dispensed.

IMPORTANT! UNDER NO CIRCUM-

STANCE SHOULD YOU USE AN ICE

PICK OR SIMILAR SHARP INSTRU-

MENT TO BREAK THE ICE. Todo this

could cause damage to the ice bin and/

or ice auger.

To operate apply pressure against the

dispenser bar with a glass or other con-

tainer. This activates the ice auger and

ice wheel which automatically delivers

ice to the glass.

Release pressure on the dispenser

bar before glass is full. Do not re-

move the glass until the last of the

cubes fall.

Normal Operation. Allow 4 to 12 hours

after installation for the first ice harvest.

The time required will depend on the

freezer temperature and the amount of

food in the unit.

The ice storage bin takes about three or

four days to fill, depending on how often

How the Ice Dispenser Works

Safety. All the icemaking and dispens-

ing mechanisms are enclosed within

their own compartment for safety and

for maximum storage space in the

freezer section.

Whenever the freezer door isopened,

the ice dispenser mechanism is inter-

rupted. This prevents the dispensing of

ice and also insures that you can ser-

vice the ice bucket safely

Water is automatically measured into

the ice maker. When the water freezes,

a sensor initiates the ejector blades that

dump the cubes into the U-shaped har-

vester bin, where they are held in stor-

age for delivery. When you push the

dispenser bar, a large auger gently, but

firmly, moves cubes from the bin. See

Figure 14A.

Operating the Ice and Water Dispenser

WATER SUPPLY

TUBE

ICE MAKER

SHUT-OFF ARM

SHUT-OFF ARM

EXTENSION

! AUGER

_ _I WATER DISPENSER

U_"_P? _lCE =SPENSER

-- ;' BAR

Servicing The Ice Dispenser

Certain conditions will require you to

service the ice maker and dispenser.

The unit has been designed so that you

can do such servicing with a minimum

of effort.

Cold dry air has to circulate in the

freezer to maintain a safe freezing tem-

perature. Thus, cubes stored in the bin

will tend to evaporate and flow together

if not used regularly.

You should remove the bin and

empty the contents:

• After the first few harvests of ice have

been made by a newly installed unit.

This will allow any impurities in the

line to be flushed out.

• Ifyou are going to be gone for longer

than a week. Raise the ice maker

shut-off arm to stop ice production

and prevent the cubes from freezing

into a mass around the ice auger.

• Ifthe ice cubes become frozen to

each other and around the ice auger.

• Ifthe ice cubes become frozen

together on the back ledge of the ice

bin. Periodic cleaning of the ice bin

may alleviate this occurrence. Clean

with warm water and dry before

replacing bin. Do not use an ice pick

to break apart ice.

Ice maker control arm. The wire con-

trolarm on the automatic ice maker has

2 functions:

1. Normal Operation: the wire arm is

in the down position; ice willbe

made. (See Fig. 14).

HARVEST BIN

OAR

FIGURE 14A

\ I! ...w,..,.,,oo...oo,+,o.

\ _-"q---SHUT-OFF ARM

k "EXTENSION

AUTOMATIC SHUT-OFF ARM FIGURE 14

.

To stop ice production or to remove

the ice bin: take hold of wire arm

near black housing, and lift up. There

will be an audible "click" when ice

maker shuts off. The wire arm stays

in the upper position. (See Fig. 15).

As long as the arm is in this position,

ice will not be made. The unit will

continue to dispense cubes from the

ice bin until all have been used.

WIRE

SHUT-OFF ARM

TO STOP THE

ICE MAKER

To remove ice bin assembly: Lift up

the ice bin assembly /4 ,then pull out.

1 /!

The Automatic Shut-off stops ice

making by raising the control arm when

the ice bin is removed. (See Fig. 16.)

_I_WIRE SHUT-OFF ARM IS

IN OFF POSITION

THE AUTOMATIC SHUT-OFF IS SHOWN

IN THE OFF POSITION (WHEN

THE ICE STORAGE BIN HAS

BEEN REMOVED).

AUTOMATIC SHUT.OFF

FIGURE 15

FIGURE 16

General Features

Refrigerator/Freezer

Controls

First to Freeze Shelf

Removable Door Dikes

Removable

Freezer Door

Shelf

Ice and Water

Dispenser

Ice Bin

Egg Storage

'and

Handi Bin

///

Compartments

Adjustable Glass

Refrigerator

Shelves

Meat Drawer

_Adjustable

Refrigerator

Door Shelves

Adjustable Freezer

Door Shelves

/

Glide-out

Basket

*Features may vary from model to model. Your refrigerator may not have all of

the features shown.

Defrost Drain Pan

and Condenser

(Behind Toe Grille)

Adjustable

Humidity

Drawer Controls

Adjustable Humidity

Controlled Crispers

Toe Grille

10

Setting the Controls

Freezer Temperature

FREEZER TEMPERATURE

OFF

Freezer Control

The controls are located on the upper

back wall of the refrigerator compart-

ment. The Freezer Control is the main

Refrigerator Temperature

FRESH FOOD TEMPERATURE

LDER

Thermostatic Refrigerator

Control

This control, operates independently of

the freezer control. A hidden thermosta-

tic sensor measures refrigerator air tem-

control. If it isturned OFF, neither the

Freezer nor the Refrigerator will cool. All

of the electrical circuits remain ener-

gized except for the compressor and

fan motors. The control has settings,

from "1" (the warmest) to "4" (the cold-

est). Start by setting the dial on "2V2".

Load food in freezer. Allow 24 hours for

the freezer to cool after the unit is

installed, before checking food tempera-

tures.

Check Food temperature as instructed

on page 12. Adjust the control as

needed, one number at a time. The

best temperature for frozen food storage

is in the 0° to + 2° F range.

perature constantly, and automatically

lets in more cold air if temperature rises

as little as 1 1/2° F from your setting.

The control has settings, from "1" (the

warmest) to "4" (the coldest). The best

food storage temperature is in the 38°

to 40° F range. Start by setting the dial

on 2V2.Load food in the refrigerator.

Place a glass of water in the middle of

the refrigerator section, making sure

that air can flow around it. (This will be

used later to check food temperature.)

After the unit is installed, allow 24 hours

for the refrigerator to cool. Check food

temperature as instructed on the next

page. Adjust the control as needed,

one number at atime.

11

Setting the Controls (cont.)

Checking Food Temperature

Twenty-four hours after the unit is

installed, check the food temperature in

the refrigerator and freezer sections.

Use a quality thermometer that can reg-

ister below zero temperatures.

FREEZER: Place the thermometer in

the center of the freezer, surrounded by

frozen packages. Wait 5 to 8 hours,

then check the reading. If temperature

is not within 0° to + 2° F,adjust control

as needed, one number at a time and

check temperature again after 4 to

6 hours. See Figure 17.

REFRIGERATOR: Place the thermom-

eter in a glass of water and place the

glass in the middle of the refrigerator

section. Be sure air can flow around it.

Wait 3 to 4 hours, check the tempera-

ture and adjust the control as needed

one number at a time to achieve the

38° to 40° F range. Wait 3 to 4 hours

and check the temperature again. See

Figure 18.

FROZEN FOOD PACKAGES

FIGURE 17

GLASS OF WATER _

FIGURE 18

Power Miser Control

The 2-Position Power Miser Control lets

you save energy by adjusting refrigera-

tor operation to humidity level in your

house. During hot, humid weather, any

refrigerator/freezer will form moisture

around the doors, similar to the way

condensate forms on a glass of ice

water.The cabinet has special heaters

to minimize this condensation. The

Power Miser Control lets you turn these

heaters higher or lower.

The upper position is for periods of

high humidity.

The lower position is for maximum

energy savings. Use for periods of low

humidity.

A minimum amount of condensation is

normal. During extreme high humidity,

condensate may also form on the cabi-

net sides and doors. This is normal and

will disappear when climatic conditions

return to normal.

POWER MISER

REDUCES

MOISTURE

SAVES

ENERGY

12

Refrigerator Features

Adjustable Cantilever Glass Shelves.

These shelves attach to metal tracks in

the back of the interior.To remove, tap

upwards at rear of shelf hooks. Lift shelf

and pull out. Toinstall, tilt shelf and

engage upper hooks indesired track

slots. Lower shelf front and tap down-

wards near the tracks until shelf hooks

are securely seated and shelf is level.

The Meat Storage Drawer -- and

shelf to which it attaches -- can be relo-

cated within the Fresh Food compart-

ment. The sealed drawer retains high

humidity for convenient storage of

unwrapped meats, cheese, bacon, hors

d'oeuvres, spreads and snacks.

CAUTION:

ToAvoid Personal Injury Or Prop-

erty Damage test for proper instal-

lation by exerting some pressure

downward on the front edge. Shelf

should not move.

Drawer Removal

Drawers stop before coming all the

way out, to help prevent contents from

spilling onto the floor. Drawers can be

removed easily by tilting up slightly and

pulling past "stop" location.

Nice 'N Fresh Drawers have acontrol

to regulate humidity inside. Set high

humidity for leafy vegetables such as

cabbage and lettuce, and set low

humidity for produce with skins such as

apples and tomatoes.

Slide to the left for high humidity and to

the right for low humidity.

Crisper Drawers can be pulled out fully,

even when door is opened at minimum

of 90° angle.

To remove the crisper drawer when the

fresh food compartment door cannot be

opened fully,first, remove food and the

lower door shelves. Empty the drawers

and remove them. Then lift the drawer

cover up and out.

13

Refrigerator Features (cont.)

Refrigerator Door

Egg Storage. A removable take-to-

counter egg bucket. To clean wash in

soapy water. Store the egg bucket in

either the door or on a shelf.

Butter storage. Foods stored in the

door include butter inthe dairy compart-

ment. For your convenience, there is a

sturdy butter dish that can be taken to

the table. It is dishwasher safe. (Recom-

mended placement: top rack of

dishwasher.)

Freezer Features

TO REMOVE

ROTATE TO RELEASE

Door Shelves. Door shelves can be

moved up or down to fit storage needs.

Toremove, loosen shelf by tapping

upwards gently underneath both ends.

Lift shelf slightly, then rotate bottom out

and up to release mounting hooks from

door slots. Toinstall, tilt shelf and insert

upper hooks into any two door slots as

shown. Rotate shelf bottom towards

door and insert bottom hooks into door

slots. Hold shelf against door and tap

down gently on both ends until shelf is

seated securely.

1

Freezer Door Shelves

The freezer door has three adjustable

shelves (some models). To remove,

gently tap both ends up, then )ull out.

Large Glide-out Freezer

Basket

Stores odd-shaped,bulky food items.

Automatic Ice and Water

Dispenser

See instructions beginning on page 6

14

Removable Door Dike

Designed for kitchens when space lim-

itations restrict opening of door to 90° .

The removable door dike (closest to

hinge) will snap out to allow removal of

freezer basket and ice bucket. Simply

grasp door dike with both hands and

firmly snap door dike out. To replace

door dike align the four push clips to the

holes on the freezer door. Snap in until

the door dike is locked into place.

Freezer Shelves

1 To remove,tap shelf gently upward

on the right side and slide out.

2. Reverse procedure to install.

Other Features

Automatic Frost Free

Operation

The freezer and refrigerator sections are

completely frost-free. The evaporator

coil in the back wall of the freezer sec-

tion collects the frost. Under normal

operating conditions, you'll never have

to defrost the unit, because it's

automatic.

Sounds

Air Circulation

Air to cool the condenser is drawn in the

grille, at the bottom front, passes over

the condenser, and is then exhausted

through the same grille. Therefore, the

unit is designed to be enclosed com-

pletely at the top, back and sides for the

total built-in look. Do not block airflow

through the toe grille at bottom front

of unit.

Your new unit may be replacing a

smaller refrigerator of different design

and/or a product which operated less

efficiently. We have taken steps in prod-

uct design and operation which will con-

tinue to provide our customers the

highest quality product, one which is

energy efficient and operates as eco-

nomically as possible. With this new

design, you may hear sounds which are

unfamiliar to you, yet quite normal.

Polyurethane foam insulation, while a

much better insulator, does not have the

sound-absorbing characteristic of

fiberglass insulation. Sounds may be

amplified further by the wall and/or floor

acting as a sounding board.

Because your product is designed to

provide greater efficiency, the com-

pressor operates at a much higher

speed than previously. This results in a

high speed hum which will be more

noticeable than the sound produced by

a slower speed compressor. In addition,

the compressor's increased torque may

cause some vibration during start up or

shut down of the unit.

The refrigerant flowing through the

refrigeration tubing may create "water

running" or "gurgling" sounds during

operation and shortly after shut down.

You may also hear the ice falling out of

the automatic Ice Maker or the activa-

tion of the water solenoid valve during

an ice making cycle.

Periodically, your refrigerator will auto-

matically defrost. When this happens,

you may hear "dripping water" and

"sizzling" sounds.

None of these sounds are unusual, and

will soon become familiar. They indicate

the unit isoperating and performing as

designed.

15

Care & Cleaning

I=CAUTION

ToAvoid The Risk Of Personal

Injury, use Caution in unpacking,

handling, removing, installing and

cleaning all parts of product which

may have sharp edges.

(1 I

WARNING

TO AVOID THE RISK OF ELECTRICAL SHOCK OR DEATH

UNPLUG THE POWER CORD BEFORE REPLACING A

BURNED OUT LIGHT BULB OR BEFORE CLEANING.

Remove all food and special compart-

ments from the freezer and refrigerator

sections.

Exterior. Wash with warm, soapy water,

rinse and dry. Use appliance polish or

wax periodically to keep the exterior

looking like new.

Door Gaskets. Clean at least twice a

year with mild soap and water. Rinse

and dry Apply a light film of petroleum

jelly to the gaskets on the hinge side to

keep them soft and pliable, and prevent

rolling.

Interior. Wash the liner with warm,

soapy water. Rinse and dry. Interior

components such as shelves and

drawers may be washed with 4 table

spoons baking soda dissolved in

1 quart of warm water to "sweeten"

these parts. Rinse and dry thoroughly

Interior and Exterior. DO NOT USE

abrasive, heavy-duty powders such as

AJAX cleanser, COMET cleanser, etc.

when cleaning the interior or exterior of

the refrigerator. These can scratch and

dull the surface, depending on their

abrasiveness and the cleaning pressure

applied. Avoid metal pads and abrasive

impregnated plastic, nylon and cloth

pads such as CHORE-BOY _'and

KURLY KATE"_pot cleaners, BRILLO®

metal cleaning pads, SCOTCH-BRITE _

and PADDY®soap pads, etc. These can

scratch the baked enamel exterior and

interior surfaces.

Do not use concentrated liquid dish-

washing detergent (dissolve in warm

water before using), abrasive cleaners,

solvents or polishing agents on plastic

parts. These cleansers may cause

cracking or discoloration.

Do not wash plastic parts in an auto-

matic dishwasher. They may warp. (The

butter dish can be washed in a dish-

washer if placed on the top rack.)

Ice Maker. If your water has a high min-

eral content, the ice maker may require

,CAUTION

ToAvoid The Risk Of Personal Injury,wear protective

hand covering.

periodic cleaning. Contact your local

water treatment dealer for cleaning

instructions. An in-line water filter may

also be necessary.

Clean Defrost Drain Pan. The pan is

located underneath the unit behind the

toe grille. Pull the toe grille forward to

remove. Every three months, remove

the drain pan, wash it with warm soapy

water, rinse and dry. When replacing the

pan, make sure it is directly underneath

the defrost water tube that extends from

the back of the unit.

Clean Condenser Coil. The condenser

coil is located behind the toe grille. Use

a long-handled bottle brush and a vac-

uum cleaner to remove dust and lint

from the coil. Dust and lint act as an

insulator and prevent the coil from

expelling heat taken from inside the

unit. Failure to keep the coil clean will

reduce cooling performance and

efficiency

16

Care and Cleaning (cont.)

Reconnect Power Cord. After clean-

ing, reconnect the power cord.

Odors. If an offensiveodor appears to

be lingering in the refrigerator or freezer,

the following procedures may eliminate

the problem. Always begin with Method

I. Use Method II only if the odor persists.

Method I

1. Unplug the unit.

2. Remove all food.

3. Thoroughly wash the inside of the

unit, includingall shelves, drawers,

accessories and gaskets with a mix-

ture of 4 tablespoons of baking soda

dissolved in 1 quart of warm water.

Pay special attention to any corners_

crevices or grooves intowhich odor-

causing liquid may have seeped. Dry

thoroughly.

4. Return food to unit washing off all

bottles, jars and containers before

placing them into the refrigerator and

freezer.

5. Plug in the unit. Wait 24 hours before

checking to see if the odor has been

eliminated. If the odor is still present,

proceed with Method II.

Method II

1. Unplug the unit.

2. Remove all food, making arrange-

ments for food storage. (The insideof

the unit should already have been

washed as instructed in Method I.)

3. Place crisper drawers on the top

shelf of the refrigerator section.

4. Lightly crumple single sheets of

newspaper. Loosely pack and fill

entire refrigerator and freezer interior

with newspapers including, door

shelves, drawers and compartments.

5. Randomly place charcoal briquettes

throughout both compartments on

the crumpled newspaper.

6. Close the doors and let stand for

24 to 48 hours.

7. Remove the charcoal briquettes

and newspapers. Wash and dry

the inside of the unit as described

in Method I.

8. Plug in the unit. Wait for 24 hours

before checking to see ifthe odor

has been eliminated, then replace the

food.

Non-Use Periods

Vacation Time. If you will be away for

vacation, remove perishable foods from

the unit. Shut off the ice maker by turn-

ing off the water supply to the refrigera-

tor and moving the icemaker wire arm

to its uppermost position.

Extended periods of non-use. If you

are going to be away for longer periods,

empty and unplug the unit. This will

reduce needless operation and assure

that food will not be spoiled if electrical

service is interrupted. Just clean the

unit as instructed in this manual and

prop open the doors so air can circulate

inside. Leave the unit unplugged. If the

refrigerator has an automatic icemaker,

turn off the water supply to the

refrigerator.

When You Move. Unplug the unit and

clean it. Use strapping tape or masking

tape to secure all trays, shelves and

other parts to prevent damage during

shipment. Do not leave the unit closed

for an extended period of time.

CAUTION

ToAvoid Property Damage do

NOT use tape that has "perma-

nent" type adhesive.

if the Refrigerator Will Be

Stored.

If the refrigerator will be stored or

remain unused in a sub-freezing envi-

ronment, remove the water and protect

the water valve from damage as follows:

1. Disconnect the refrigerator from the

electrical power source.

2. Shut off the refrigerator water supply.

This can be done at the saddle valve

where the 114"copper supply tubing

joins the household water line. Refer

to illustration on back of cabinet.

TYPICAL WATER VALVE COUPLING

Dual solenoid coil

is shown

Hose

Fitting

V4" Plastic

Tube With

Anti-Kink

Spring

Adaptor

Fitting

Brass

Sleeve Brass

Nut

1/4,r

17

Non-Use Periods

valve coupling. Place a small con-

CAUTION

To guard against possible

water damage. Ifthe refrigerator

willbe unattended,raisethe ice

maker wireshut offarm and close

thewater shutoff valve for the

refrigerator.

.

Remove the compressor compart-

ment cover from the bottom rear of

the refrigerator to reveal the water

You Can Help Save Energy!

tainer under the valve to catch water

spills. Remove the brass hose fitting

from the valve. Label the two plastic

tubes attached to the valve. Unscrew

the compression nuts from the tubes

and push the ends of the tubes away

from their valve fittings.

.

Blow the water out of the water dis-

penser plastic tubing with com-

pressed air.

Your New RefrigeratodFreezer is

designed to operate efficiently You can

help reduce energy consumption by fo!-

lowing these suggestions:

Power Miser Control. This control reg-

ulates special heaters that help reduce

condensation during periods of high

humidity. Reduce energy consumption

by setting the control according to cur-

rent climatic conditions.

Controls. Set the freezer and refrigera-

tor controls so the compartments are

not colder than recommended. See

page 11 for details.

Doors. Make sure the door gaskets do

not become blocked, dirty or worn. Air

leaks will cause the unit to operate more

often.

Location. Installthe unit away from

heating equipment or direct sunlight.

Keep the Condenser Coil Clean. A

dirty condenser coil will cause the unit

to operate more than necessary See

Care and Cleaning section.

Before Calling For Service

Unnecessary service calls may be

avoided by checking for the following

common sources of difficulty The fol-

lowing items are considered customer

replaceable: defrost drain pan, door and

cabinet shelves and drawers, butter

dish, light bulbs, egg bucket, and

accessories.

If product does not appear to be

operating:

• Does the light work? A dim light indi-

cates low voltage or a weak bulb.

• Iscord plugged in?

• Isa fuse or circuit breaker open?

Check by plugging in another

appliance or lamp at the same wall

outlet.

• Has either of the doors been left

open? Make certain food items stored

within the refrigerator are not obstruct-

ing proper door closure. Check level-

ing of unit. (See page 5.)

If the lights work and the freezer con-

trol is on, but the fan and compressor

are not operating, the unit is likely in

the defrost cycle. Wait 30 minutes to

see if the unit will restart. If it does

not, remove the toe grille. The defrost

timer is located behind the grille. Turn

the timer knob clockwise until you

hear a click. The refrigerator should

begin running.

If the unit still won't operate:

• Be sure you have completed the

steps listed above.

• Takethe steps necessary to preserve

the food stored in the unit. Dry ice

may be placed in the freezer section

of the unit to preserve food until the

unit can be serviced. Doors should be

left closed until the unit has been

repaired.

• Call your nearest authorized service

center.

18

Before Calling For Service

If food temperature appears to be

warm in the freezer section:

• See prior sections.

• Have you recently added a large load

of food? Allow adequate time for the

food to reach freezing temperature.

• Are any shelves covered with foil or

plastic, preventing proper air flow?

• Isthe condenser area clean?

(See page 16.)

• Adjust freezer control. (See page 11.)

If refrigerator section is too warm:

• See prior sections.

• Adjust refrigeratorcontrol.

(See page 11.)

• Adjust freezer controlto a colder set-

ting.(See page 11.)

If refrigerator section temperature is

too cold:

• Adjust refrigeratorcontrol. (See

page 11.)

• Adjust freezer controlto warmer set-

ting. Allow several hoursfortempera-

ture to change.

• Iscondenser area clean?

(See page 16.)

• Check to see that the air deflectoris

in place in the tunnel located in the

leftside wall of the fresh food

compartment.

If the unit runs too much or too

frequently:

• It may be normal to maintain an even

temperature.

• Is condenser area clean?

(See page 16.)

• Have doors been opened frequently

or for an extended period of time?

• Isfreezer running too cold? Adjust

freezer control. (See page 11.)

• Check door alignment and gasket

seal for proper closure.

If the unit makes unfamiliar sounds

such as popping or cracking; tap-

ping, gurgling, boiling or bubbling;

rumbling or rattling on shutdown:

! These may be normal operating

sounds. Refer to page 15 for informa-

tion on sounds the unit may make.

If you hear running water in the unit:

• This is normal when the icemaker fills.

• This is normal when the unit defrosts

and water enters the condensate pan.

If you hear periodic buzzing:

• This is normal in cabinets with an

automatic icemaker. The water valve

will buzz when energized to refill the

icemaker.

If condensate forms on the inside of

the unit:

• This isnormal during periods of high

humidity

If condensate forms on the outside

of the unit:

• Is Power Miser Control on highest set-

ting? Thiswill help reduce

condensate.

• Check door alignment and gasket

seal for proper closure.

If Crisper or Meat Keeper drawers do

not close freely.

• Check for package obstructing proper

closure.

• Check to confirm drawer is in proper

position in assembly

• Apply thin layer of petroleum jelly to

slide channels.

If there is an odor in the unit or

ice cubes.

• Clean product. (See pages 16-17).

• Cover allfoods tightly.

• Use freezer containersor

freezer wrap.

If ice forms in the inlet tube to the

ice maker.

• Indicates sedimentin solenoid valve

which has notallowedthe valveto

close.An in-line waterfilter should be

added. If problempersiststhe

solenoid valve willneed to be cleaned

or changed.

If light bulb needs replacing.

• Unplug unit from wall outlet to avoid

electricalshock. A pairof gloves

should be worn as a precaution

against broken glass.

19

SEARS

For one year from the date of purchase, when this refrigerator is operated and maintained according to instructions attached

to or furnished with the product, Sears will repair this refrigerator, free of charge, if defective in material or workmanship,

For five years from the date of purchase, when this refrigerator is operated and maintained according to instructions

attached to or furnished with the product, Sears will repair the sealed system (consisting of refrigerant, connecting tubing

and compressor motor) free of charge, if defective in material or workmanship.

The above warranty coverage applies only to refrigerators which are used for storage of food for private household

purposes,

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS SERVICE CENTER/DEPARTMENT

IN THE UNITED STATES.

This warranty applies only while this product is in use in the United States.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

FULLON EYEARWARRANTY

ON REFRIGERATOR

FULL FIVE-YEARWARRANTY

ON SEALEDREFRIGERATIONSYSTEM

SEARS, ROEBUCK AND CO., D/731 CR-W, Sears Tower, Chicago, IL 60684

10062604

Printed in U.S.A.

Loading...

Loading...