Kenmore 59679279990, 59679277990, 59679272993, 59679272990, 59679147990 Owner’s Manual

...

Use and Care Guide

®

Manual de Uso y Cuidado

Guide d'Utilisation et

d'Entretien

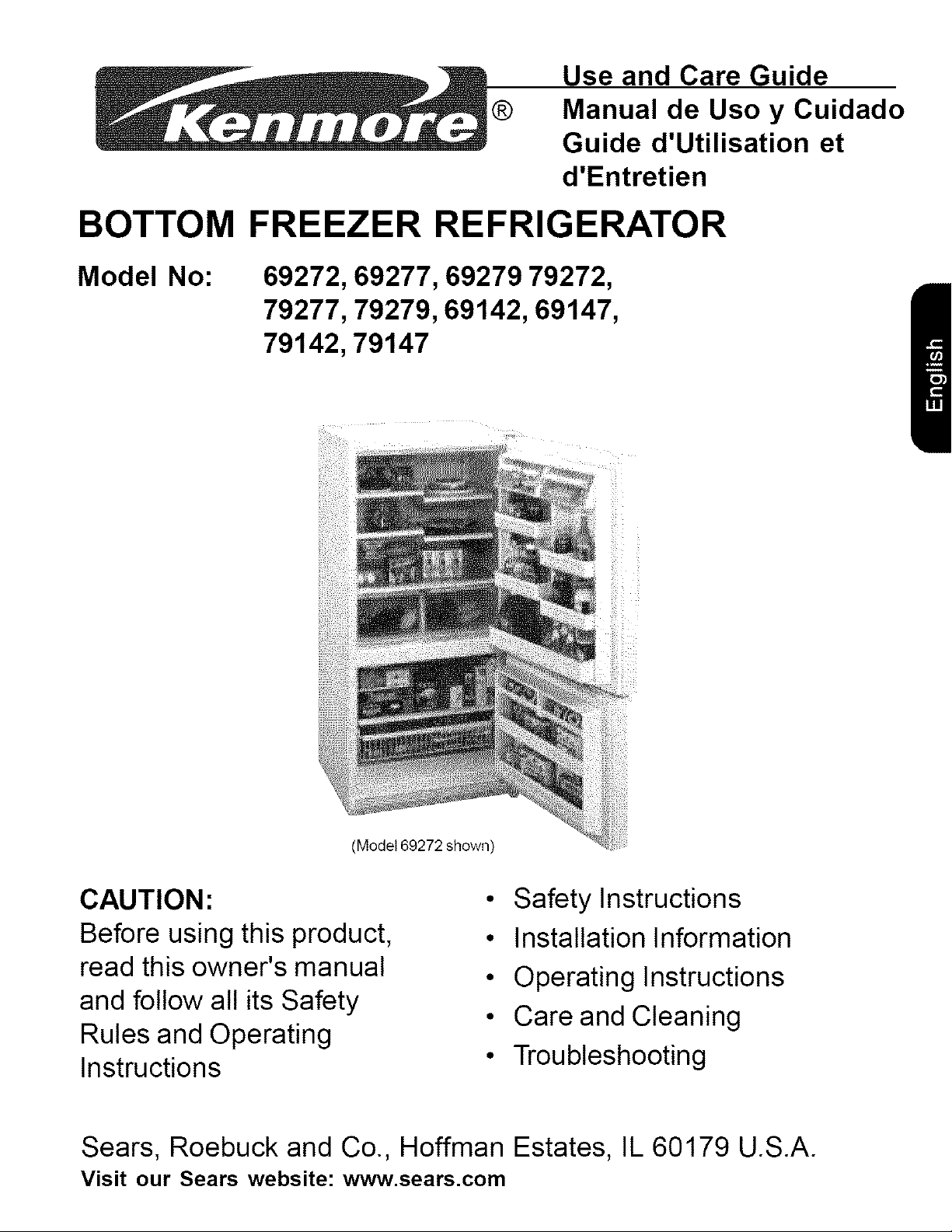

BOTTOM FREEZER REFRIGERATOR

Model No:

69272,69277,69279 79272,

79277,79279,69142,69147,

79142,79147

(Model 69272 shown

CAUTION:

Before using this product,

• Safety Instructions

• Installation Information

read this owner's manual

• Operating Instructions

and follow all its Safety

• Care and Cleaning

Rules and Operating

Instructions

• Troubleshooting

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Visit our Sears website: www.sears.com

Electrical Requirements

,_Recognize this symbol as a safety precaution.

_WARNING

Electrical Grounding Instructions--This refrigerator isequipped with a three-prong (grounding)

plug for protection against possible shock hazards. Ifyou encounter a two-prong receptacle,

contact a qualified electrician and have the two-prong wall receptacle replaced with a properly

grounded three-prong wall receptacle in accordance with the National Electrical Code.

Refrigerator is designed to operate on a separate 103 to 126 volt, 15 amp., 60 cycle line.

Do not under any circumstances cut or remove the round grounding prong from i

the plug. Refrigerator must be grounded at all times. Do not remove warning tag from power cord.

_lb WARNING

Do not use a two-prong adapter. Do not use an extension cord.

WARNING

Proper Disposal of Your Refrigerator

IMPORTANT: Child entrapment and suffocation are not problems of the past. Junked

or abandoned refrigerators are still dangerous--even if they will sit for"just a few

days". Ifyou discard an old refrigerator, please follow the instructions below to help

prevent accidents.

BEFORE YOU THROW AWAY YOUR OLD REFRIGERATOR OR

FREEZER:

• Take off the doors.

Leave the shelves in place so children may not easily climb inside.

LJ

Warranty

Full One Year Warranty on Refrigerator

For one year from the date of purchase, when this refrigerator is operated and maintained according to

instructions attached to or furnished with it, Sears wili repair it, free of charge, if defective in material or

workmanship.

Full Five Year Warranty on Sealed Refrigeration System

For five years from the date of purchase, when this refrigerator is operated and maintained according to

instructions attached to or furnished with it, Sears will repair the sealed system (consisting of refrigerator,

connecting tubing and compressor motor) free of charge, if defective in material or workmanship.

The above warranty coverage applies only to refrigerators which are used for storage of food for private

household purposes.

Warranty Service is available by contacting 1-800-4-MY-HOME (1-800-469-4663).

This warranty applies only while this product is in use in the United States.

This Warranty gives you specific legal rights, and you may also have other rights, which vary from state to

state.

Sears, Roebuck and Co, Dept 817WA, Hoffman Estates, IL 60179

Read and Save These Instructions

Record in the space provided below the model and seriai numbers found on the serial plate located on the top left wall

of the refrigerator compartment.

Model Number:596.

Serial Number:

Purchase Date:

Contents

Electrical Requirements ........................................... 2

Proper Disposal ofYour Refrigerator ......................... 2

Warranty .................................................................. 3

Installation Checklist ................................................ 3

Read and Save These Instructions ........................... 3

Installation Instructions ............................................ 4

Space Requirements ............................................. 4

Leveling Refrigerator ............................................. 4

Door Reversal ....................................................... 4

Connect ice maker water supply line

(some models) ...................................................... 6

Controls ................................................................... 7

Refrigerator and Freezer Controls .......................... 7

Setting Controls .................................................... 7

Refrigerator Features ............................................... 8

Refrigerator Shelves ............................................. 8

Crisper Drawers .................................................... 8

Temperature Controlled Meat Drawer

(some models) ...................................................... 9

Bottle Rack (some models) ................................. 10

Covered Utility Bin (some models) ...................... 10

Dairy Compartments (some models) ................... 10

Door Buckets ...................................................... 10

Tall Package Retainer (some models) ................. 11

Door Shelves ...................................................... 11

Adjustable Divider (some models) ....................... 11

Bottle Holder (some models) ............................... 11

Freezer Features .................................................... 12

Frost-Free System .............................................. 12

Automatic Ice Maker (some models) .................. 12

Ice Service Rack (some models) ........................ 12

Slideout Shelf (some models) ............................. 12

Vertical Shelf Divider (some models) .................. 13

Fixed Wire Shelf (some models) ......................... 13

Wire Basket ........................................................ 13

Ice Bin (some models) ........................................ 13

Care and Cleaning .................................................. 14

General Cleaning ................................................ 14

Adhesives ........................................................... 14

Door Gaskets ..................................................... 14

Condenser Coils ................................................. 14

Glass Shelves .................................................... 14

Odor Removal ..................................................... 14

Light Bulb Replacement ...................................... 15

Vacation Tips ......................................................... 15

EnergyTips ............................................................ 15

Normal Operating Sounds ...................................... 16

Before Calling For Service ..................................... 17

Espan61.................................................................. 21

Francais ................................................................. 42

Installation Checklist

Verify the following has been completed to ensure proper

operation of your refrigerator.

Doors

Handles are solidly attached

Handle side of door is %" higher than hinge side of

door. (See installation instructions page 6.)

Doors seal completely to refrigerator cabinet.

Leveling

Refrigerator is tilted W' (6 mm) from front to rear and

level side to side.

Ice Maker (some models)

Water supply to refrigerator is attached and turned on.

Water leaks are not present at connection between

household water supply and refrigerator. (After 24

hours check connection for water leaks.)

Ice maker arm is in on position for ice production. (It

may take up to 24 hours for first harvest of ice.)

Electrical

Properly ground 3-prong wall receptacle is used to

plug in refrigerator.

Note:

Translation may sometimes cause variations in meaning.

In all cases where meaning varies, the most accurate

meaning wiii be the English version of this document.

3

Installation Instructions

Proper installation will ensure this refrigerator operates

most efficiently.

Space Requirements

[ WARNING

Keep flammable materials and vapors, such as

gasoline, away from refrigerator. Failure to do so can

resu t n death, expos on, fre, or burns.

Toensure proper ventilation for your refrigerator, allow

for a 1"(2.5 cm) space at the top of your refrigerator.

If your refrigerator has an ice maker, make sure you

leave some extra space at the back to allow for the

water line connection. The refrigerator can be flush

with the back wail if you do not have an ice maker

installed.

If you are installing your refrigerator next to a fixed

wail, leave 2 V2"minimum on hinge side (depending

on your model) to allow for the door to swing open

90°

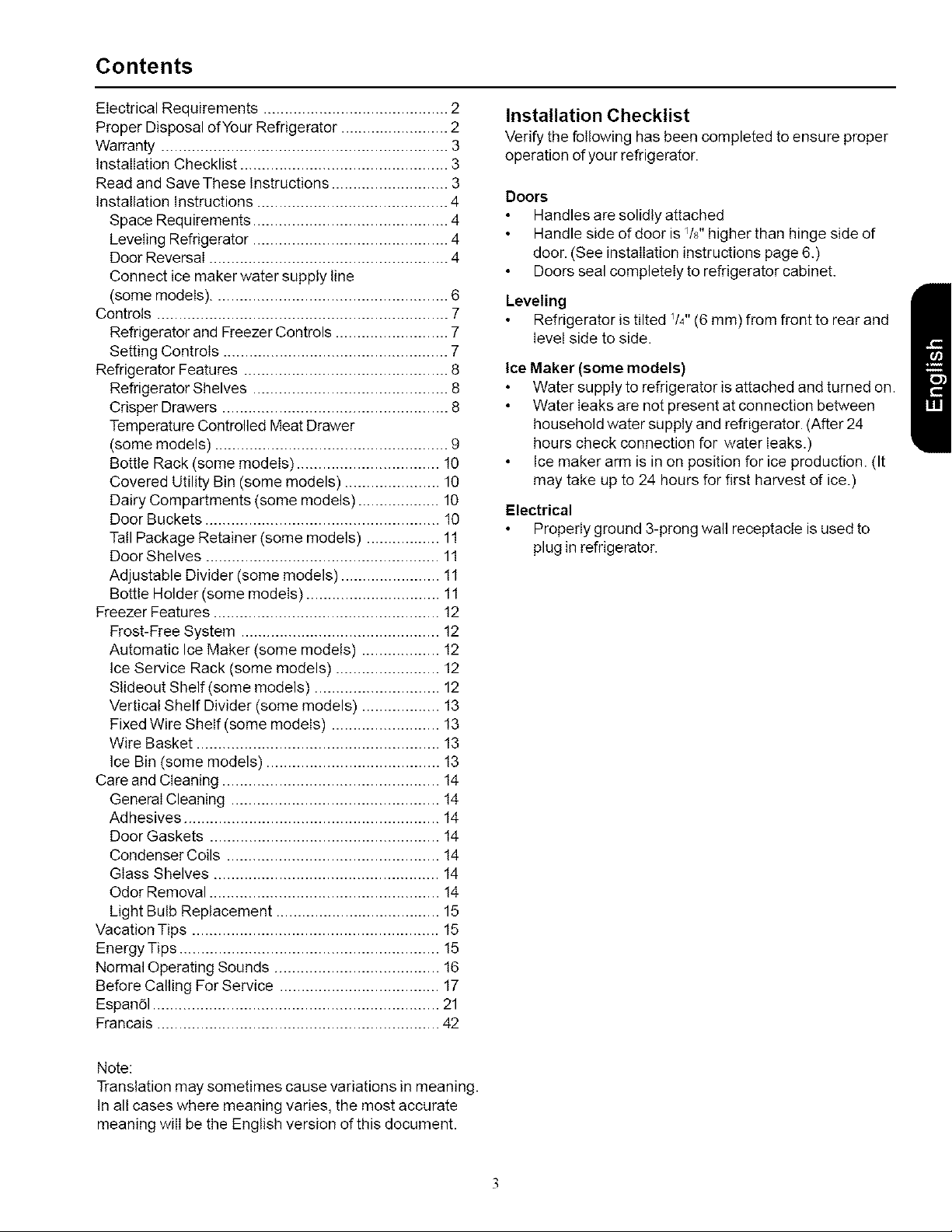

adjustment

screw

t

Bottom hinge Stabilizing leg

cover (some models)

Door Reversal

NOTE: Do not install the refrigerator near an oven,

radiator, or other heat source. Do not install the

refrigerator in a location where the temperature will fail

below 55°F (13°C).

Leveling Refrigerator

Some installations may require door reversal to achieve

full door swing. If so, proceed to "Door Reversal" section

before leveling your refrigerator.

If your refrigerator requires ice maker water supply

connection, proceed to "Connect ice maker water supply"

section on page 6 before leveling your refrigerator.

f.

Plug in power cord.

2.

Move refrigerator into final location.

3.

Level refrigerator using a level placed on top of the

refrigerator.

• RemovetoegriIle. Remove bottom hinge cover if

refrigerator has a stabilizing leg.

• Turn roller adjustment screws to raise or lower

refrigerator cabinet. Front of refrigerator must be

V4"(6 mm), or V=bubble on your level, higher than

the back of your refrigerator.

• Make sure refrigerator cabinet is level from side to

side by adjusting left and right roller adjustment

screw.

• Turn stabilizing leg (some models) clockwise until

firmly against floor.

Protect soft vinyl or other flooring with cardboard, rugs

I CAUTION I

or other protective material to avoid property damage.

Some installations may require door reversal to achieve

full door swing. To reverse door swing direction perform

the following steps:

Tools Required

Putty knife (blade covered by masking tape)

s/_6"hex nut driver

3/8"hex nut driver

/4" hex nut driver

Phillips screwdriver

Blade screwdriver

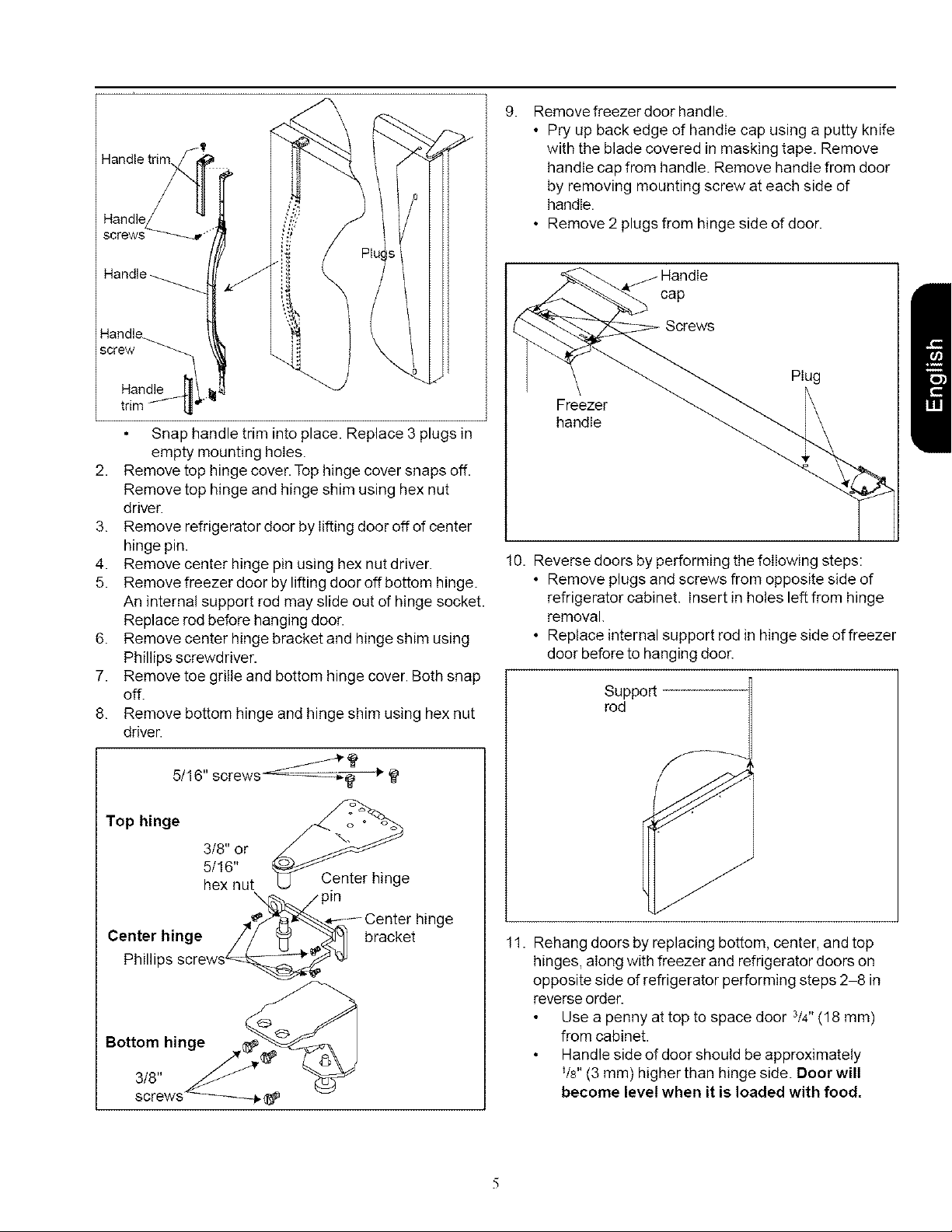

I. Remove and reverse refrigerator handle.

IMPORTANT: For plug removal requiring use of flat blade

screwdriver or putty knife, blade of tool must be

covered with masking tape to avoid damage to

refrigerator finish. For plugs using a screwdriver- or nut

driver- style head, use appropriate tool to avoid damage

to plugs.

• Remove handle screw from top handle trim. Pry

up edge of handle trim using a putty knife with the

blade covered with masking tape. Remove handle

from door by removing 1remaining mounting screw

at each end of handle.

• Remove 1plug from top hinge side of door and 2

from front hinge side of door. Mount handle on

opposite side of door using mounting screws

removed in previous step.

Handle_

SO_'ew

Handle

trim

Snap handle trim into place. Replace 3 plugs in

empty mounting holes.

2. Remove top hinge cover. Top hinge cover snaps off.

Remove top hinge and hinge shim using hex nut

driver.

3. Remove refrigerator door by lifting door off of center

hinge pin.

4. Remove center hinge pin using hex nut driver.

5. Remove freezer door by lifting door off bottom hinge.

An internal support rod may slide out of hinge socket.

Replace rod before hanging door.

6. Remove center hinge bracket and hinge shim using

Phillips screwdriver.

7. Remove toe grille and bottom hinge cover. Both snap

off.

8. Remove bottom hinge and hinge shim using hex nut

driver.

g. Remove freezer door handle.

• Pry up back edge of handle cap using a putty knife

with the blade covered in masking tape. Remove

handle cap from handle. Remove handle from door

by removing mounting screw at each side of

handle.

• Remove 2 plugs from hinge side of door.

Handle

cap

ws

Plug

10.

Reverse doors by performing the following steps:

• Remove plugs and screws from opposite side of

refrigerator cabinet. Insert in holes left from hinge

removal.

• Replace internal support rod in hinge side of freezer

door before to hanging door.

Suppo_

_d

5/16 screws__ _"9

Top hinge

3/8" or

5/16"

hex nut L_ center hinge

_pin

_f"_'_-.._Z-,--Center hinge

Center hinge // _'_1 bracket

Phillips screws_ _

Bottom hinge

3/8"

screws

11. Rehang doors by replacing bottom, center, and top

hinges, along with freezer and refrigerator doors on

opposite side d refrigerator performing steps 2-8 in

reverse order.

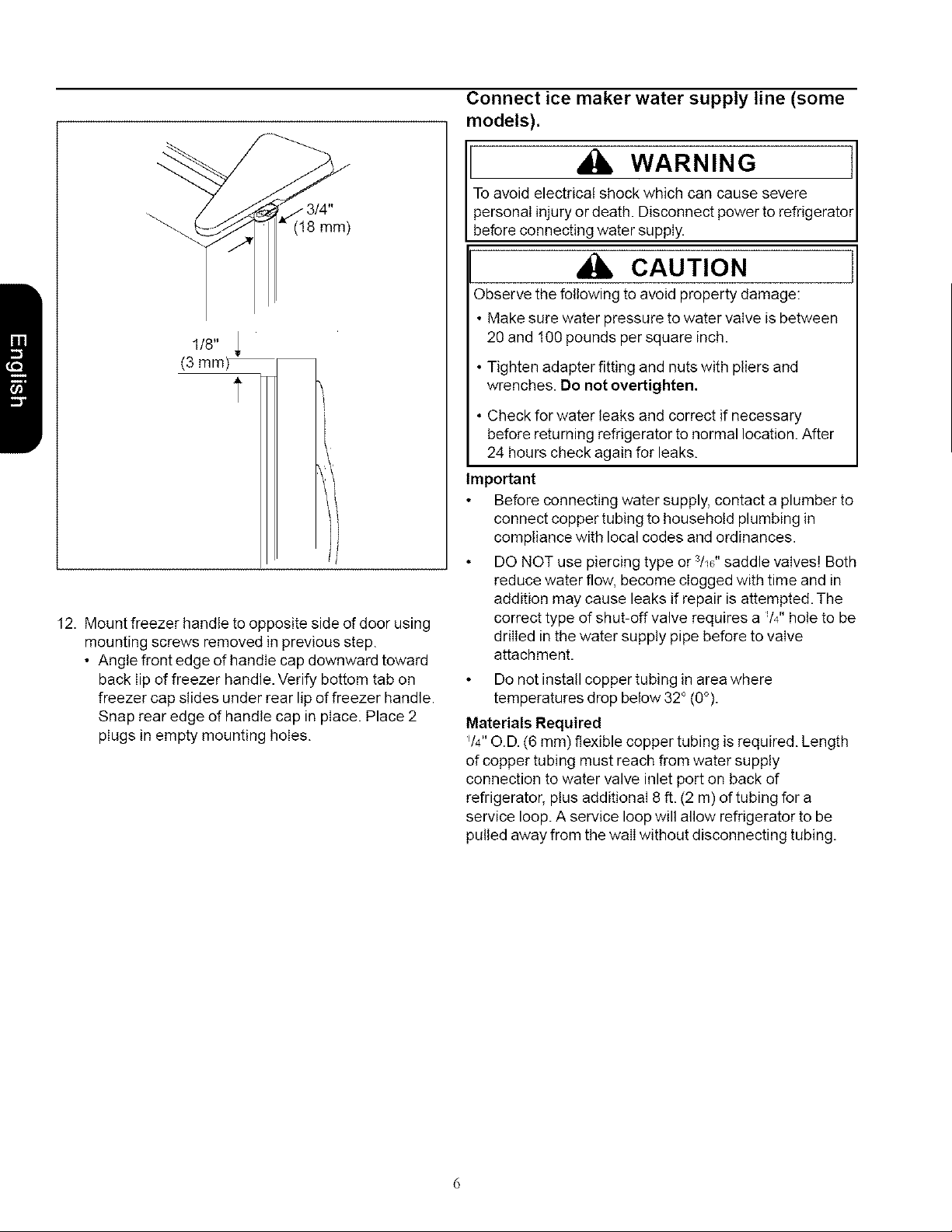

Use a penny at top to space door 3/4"(18 mm)

from cabinet.

Handle side of door should be approximately

_/8"(3 mm) higher than hinge side. Door will

become level when it is loaded with food.

5

12. Mount freezer handle to opposite side of door using

mounting screws removed in previous step.

• Angle front edge of handle cap downward toward

back Iip of freezer handle. Verify bottom tab on

freezer cap slides under rear lip of freezer handle.

Snap rear edge of handle cap in place. Place 2

plugs in empty mounting holes.

Connect ice maker water supply line (some

models).

I WARNING I

To avoid electrical shock which can cause severe

personal injury or death. Disconnect power to refrigerator

before connect ngwater supp y.

CAUTION

Observe the following to avoid property damage:

• Make sure water pressure to water valve is between

20 and 100 pounds per square inch.

• Tighten adapter fitting and nuts with pliers and

wrenches. Do not overtighten.

• Check for water leaks and correct if necessary

before returning refrigerator to normal location. After

24 hours check again for leaks.

Important

Before connecting water supply, contact a plumber to

connect copper tubing to household plumbing in

compliance with local codes and ordinances.

DO NOT use piercing type or 3h6"saddle valves! Both

reduce water flow, become clogged with time and in

addition may cause leaks if repair is attempted. The

correct type of shut-off valve requires a El4"hole to be

drilled in the water supply pipe before to valve

attachment.

Do not install copper tubing in area where

temperatures drop below 32 °(0°).

Materials Required

_/4"O.D. (6 mm) flexible copper tubing is required. Length

of copper tubing must reach from water supply

connection to water valve inlet port on back of

refrigerator, plus additional 8 ft. (2 m) of tubing for a

service loop. A service loop will allow refrigerator to be

pulled away from the waII without disconnecting tubing.

Controls

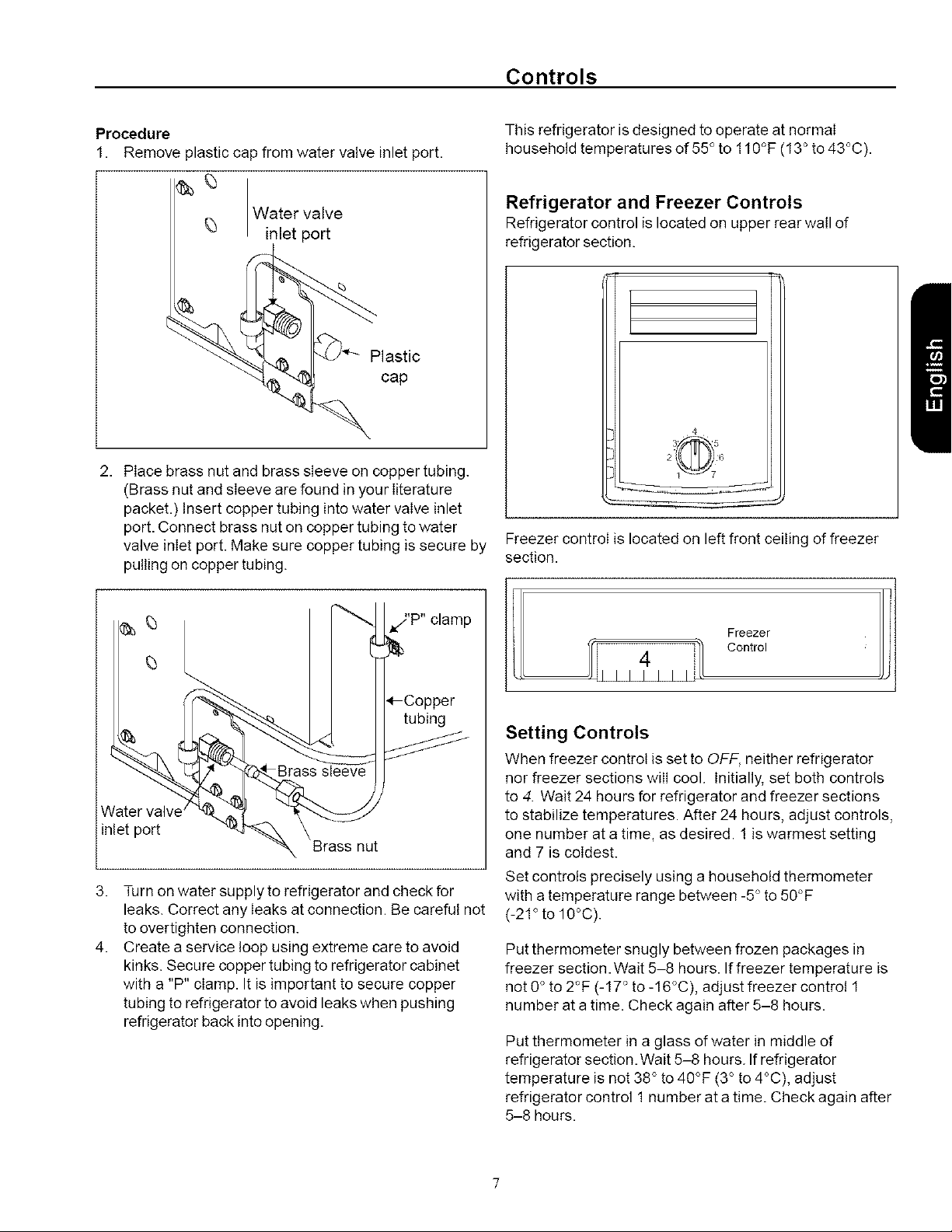

Procedure

1. Remove plastic cap from water valve inlet port.

%

Water valve

% inlet port

Plastic

cap

2. Place brass nut and brass sleeve on copper tubing

(Brass nut and sleeve are found in your literature

packet.) Insert copper tubing into water valve inlet

port. Connect brass nut on copper tubing to water

valve inlet port. Make sure copper tubing is secure by

pulling on copper tubing.

This refrigerator is designed to operate at normal

household temperatures of 55°to 110°F (13° to 43°C).

Refrigerator and Freezer Controls

Refrigerator control is located on upper rear wall of

refrigerator section.

4

3 5

2"QI 6

Freezer control is located on left front ceiling of freezer

section.

_i'P" clamp

_-Copper

tubing

Water valve /

inlet port

3.

Turn on water supply to refrigerator and check for

leaks. Correct any leaks at connection. Be careful not

to overtighten connection.

4.

Create a service loop using extreme care to avoid

kinks. Secure copper tubing to refrigerator cabinet

with a "P" clamp. It is important to secure copper

tubing to refrigerator to avoid leaks when pushing

refrigerator back into opening.

Freezer

4 Control

IIIIII

Setting Controls

When freezer control is set to OFF, neither refrigerator

nor freezer sections will cool. Initially, set both controls

to 4. Wait 24 hours for refrigerator and freezer sections

to stabilize temperatures. After 24 hours, adjust controls,

one number at a time, as desired. 1 is warmest setting

and 7 is coldest.

Set controls precisely using a household thermometer

with a temperature range between -5° to 50°F

(-21° to 10°C).

Put thermometer snugly between frozen packages in

freezer section. Wait 5-8 hours. Iffreezer temperature is

not 0° to 2°F (-17° to -16°C), adjust freezer control 1

number at a time. Check again after 5-8 hours.

Put thermometer in a glass of water in middle of

refrigerator section. Wait 5-8 hours. Ifrefrigerator

temperature is not 38 °to 40°F (3° to 4°C), adjust

refrigerator control 1 number at a time. Check again after

5-8 hours.

Refrigerator Features

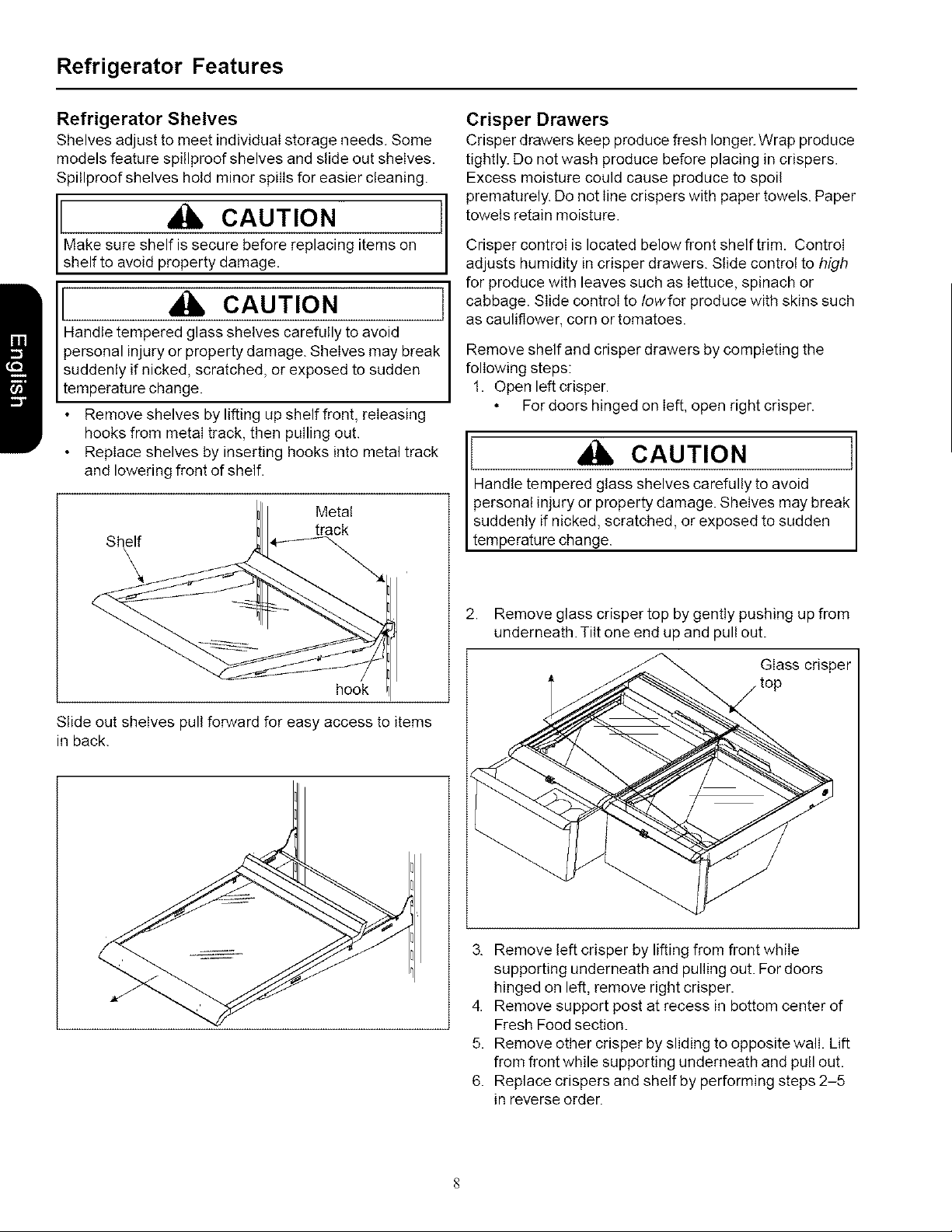

Refrigerator Shelves

Shelves adjust to meet individual storage needs. Some

models feature spillproof shelves and slide out shelves.

Spillproof shelves hold minor spills for easier cleaning.

Make sure shelf is secure before replacing items on

I' ,,C UT.O.11

shelf to avoid property damage.

I A CAUTION I

Handle tempered glass shelves carefully to avoid

personal injury or property damage. Shelves may break

suddenly if nicked, scratched, or exposed to sudden

temperature change.

Remove shelves by lifting up shelf front, releasing

hooks from metal track, then pulling out.

Replace shelves by inserting hooks into metal track

and lowering front of shelf.

Metal

track

Crisper Drawers

Crisper drawers keep produce fresh longer.Wrap produce

tightly. Do not wash produce before placing in crispers.

Excess moisture could cause produce to spoil

prematurely. Do not line crispers with paper towels. Paper

towels retain moisture.

Crisper control is located below front shelf trim. Control

adjusts humidity in crisper drawers. Slide control to high

for produce with leaves such as lettuce, spinach or

cabbage. Slide control to Iowfor produce with skins such

as cauliflower, corn or tomatoes.

Remove shelf and crisper drawers by completing the

following steps:

1. Open left crisper.

For doors hinged on left, open right crisper.

Handle tempered glass shelves carefully to avoid

personal injury or property damage. Shelves may break

suddenly if nicked, scratched, or exposed to sudden

temperature change.

CAUTION

hook

Slide out shelves pull forward for easy access to items

in back.

2. Remove glass crisper top by gently pushing up from

underneath. Tilt one end up and pull out.

Glass crisper

3. Remove left crisper by lifting from front while

supporting underneath and pulling out. For doors

hinged on left, remove right crisper.

4. Remove support post at recess in bottom center of

Fresh Food section.

5. Remove other crisper by sliding to opposite walI. Lift

from front while supporting underneath and pull out.

6. Replace crispers and shelf by performing steps 2-5

in reverse order.

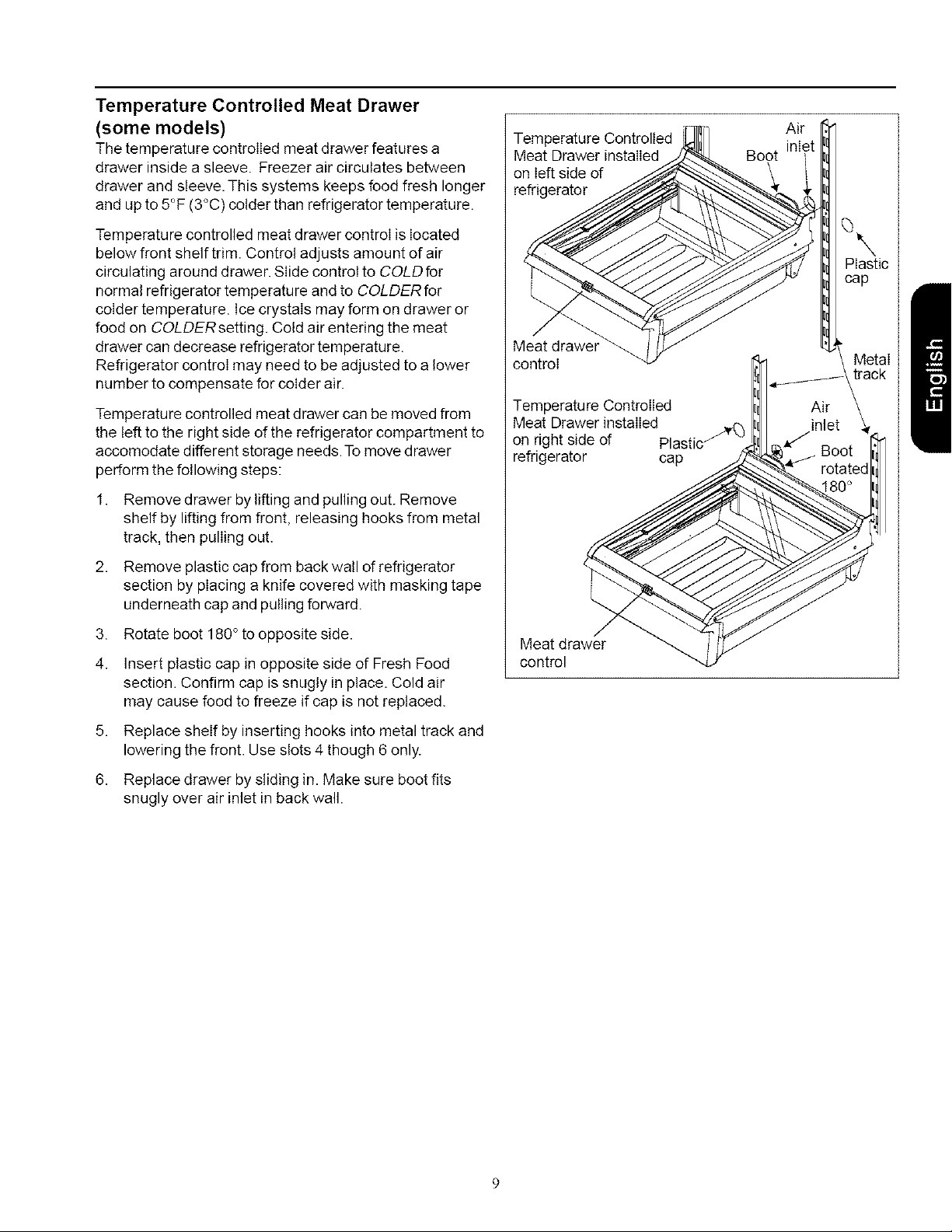

Temperature Controlled Meat Drawer

(some models)

The temperature controlled meat drawer features a

drawer inside a sleeve. Freezer air circulates between

drawer and sleeve. This systems keeps food fresh longer

and up to 5°F (3°C) colder than refrigerator temperature.

Temperature controlled meat drawer control is located

below front shelf trim. Control adjusts amount of air

circulating around drawer. Slide control to COLD for

normal refrigerator temperature and to COLDER for

colder temperature. Ice crystals may form on drawer or

food on COLDERsetting. Cold air entering the meat

drawer can decrease refrigerator temperature.

Refrigerator control may need to be adjusted to a lower

number to compensate for colder air.

Temperature controlled meat drawer can be moved from

the left to the right side of the refrigerator compartment to

accomodate different storage needs. To move drawer

perform the following steps:

1. Remove drawer by lifting and pulling out. Remove

shelf by lifting from front, releasing hooks from metal

track, then pulling out.

Temperature Controlled

Meat Drawer installed

on left side d

refrigerator

Meat drawer

control

Temperature Controlled

Meat Drawer installed

on right side of

refrigerator cap

Boot

Air

inI

2. Remove plastic cap from back wall of refrigerator

section by placing a knife covered with masking tape

underneath cap and pulling forward.

3. Rotate boot 180° to opposite side.

4. Insert plastic cap in opposite side of Fresh Food

section. Confirm cap is snugly in place. Cold air

may cause food to freeze if cap is not replaced.

5. Replace shelf by inserting hooks into metal track and

lowering the front. Use slots 4 though 6 only.

6. Replace drawer by sliding in. Make sure boot fits

snugly over air inlet in back wall.

Meat drawer

control

9

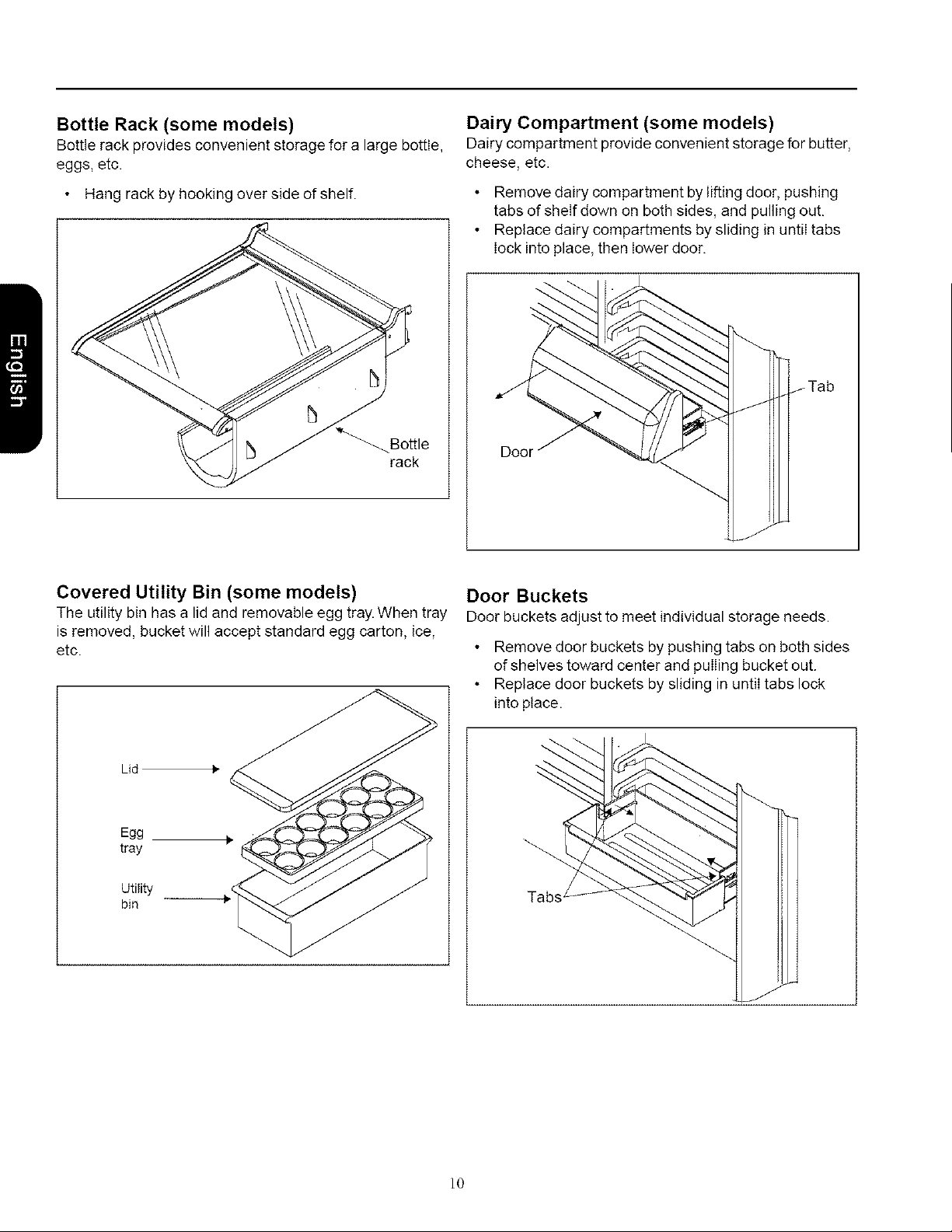

Bottle Rack (some models)

Bottle rack provides convenient storage for a large bottle,

eggs, etc.

Dairy Compartment (some models)

Dairy compartment provide convenient storage for butter,

cheese, etc.

Hang rack by hooking over side of shelf.

_.Bottle

rack

Covered Utility Bin (some models)

The utility bin has a lid and removable egg tray. When tray

is removed, bucket will accept standard egg carton, ice,

etc.

Remove dairy compartment by lifting door, pushing

tabs of shelf down on both sides, and pulling out.

Replace dairy compartments by sliding in until tabs

lock into place, then lower door.

Door

Door Buckets

Door buckets adjust to meet individual storage needs.

Remove door buckets by pushing tabs on both sides

of shelves toward center and pulling bucket out.

Replace door buckets by sliding in until tabs lock

into place.

Lid

Egg _,

tray

Utility

bin

]0

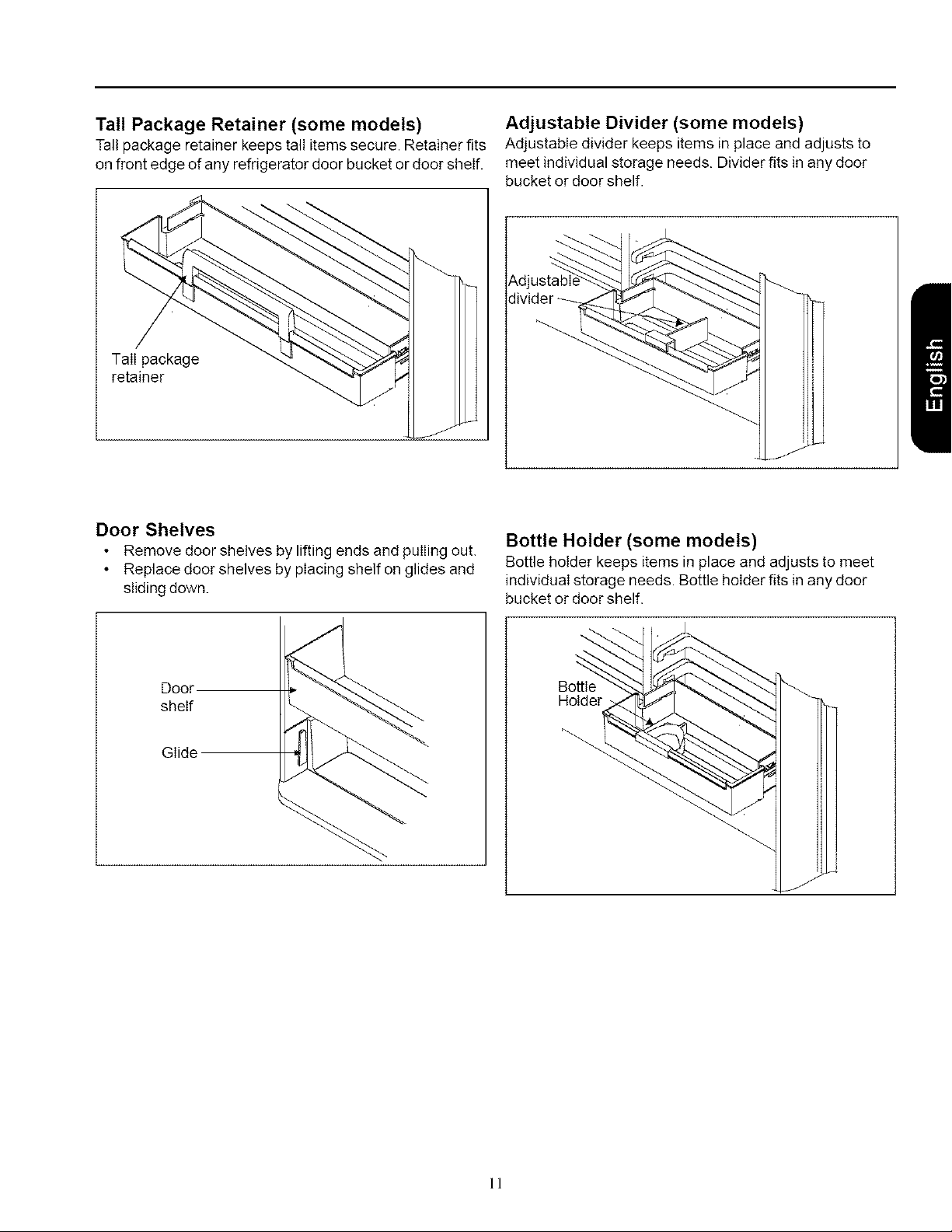

Tall Package Retainer (some models)

Tall package retainer keeps tall items secure. Retainer fits

on front edge of any refrigerator door bucket or door shelf.

Tail package

retainer

_J

Adjustable Divider (some models)

Adjustable divider keeps items in place and adjusts to

meet individual storage needs. Divider fits in any door

bucket or door shelf.

Door Shelves

• Remove door shelves by lifting ends and pulling out.

• Replace door shelves by placing shelf on glides and

sliding down.

Door

shelf

Glide

Bottle Holder (some models)

Bottle holder keeps items in place and adjusts to meet

individual storage needs. Bottle holder fits in any door

bucket or door shelf.

Bottle

Holder

]]

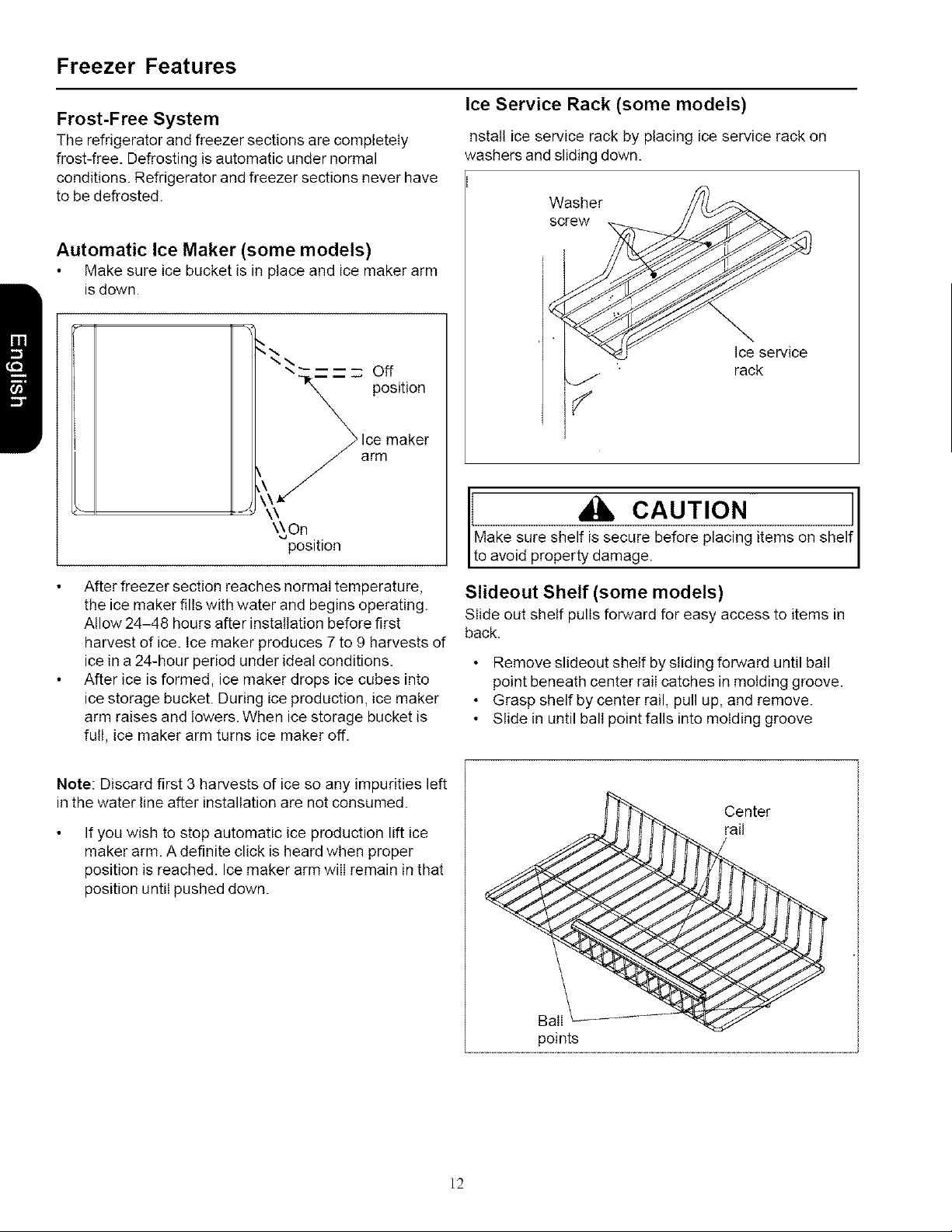

Freezer Features

Frost-Free System

The refrigerator and freezer sections are compteteIy

frost-free. Defrosting isautomatic under normal

conditions. Refrigerator and freezer sections never have

to be defrosted.

Automatic Ice Maker (some models)

Make sure ice bucket is in place and ice maker arm

is down.

Ice Service Rack (some models)

nstall ice service rack by placing ice service rack on

washers and sliding down.

Washer

screw

>...

-%

__ Off

position

>Ice maker

arm

-_, \\

\k On

position

After freezer section reaches normal temperature,

the ice maker fills with water and begins operating.

Allow 24-48 hours after installation before first

harvest of ice. Ice maker produces 7 to 9 harvests of

ice in a 24-hour period under ideal conditions.

After ice is formed, ice maker drops ice cubes into

ice storage bucket. During ice production, ice maker

arm raises and lowers. When ice storage bucket is

full, ice maker arm turns ice maker off.

Note: Discard first 3 harvests of ice so any impurities left

in the water line after installation are not consumed.

If you wish to stop automatic ice production lift ice

maker arm. A definite click is heard when proper

position is reached. Ice maker arm will remain in that

position until pushed down.

Ice service

rack

Make sure shelf is secure before placing items on shel

[ cAuz,o. Jl

to avo d property damage.

Slideout Shelf (some models)

Slide out shelf pulis forward for easy access to items in

back.

Remove slideout shelf by sliding forward until bail

point beneath center rail catches in molding groove.

Grasp shelf by center rail, pull up, and remove.

Slide in until ball point falls into molding groove

Center

rail

Bail

points

]2

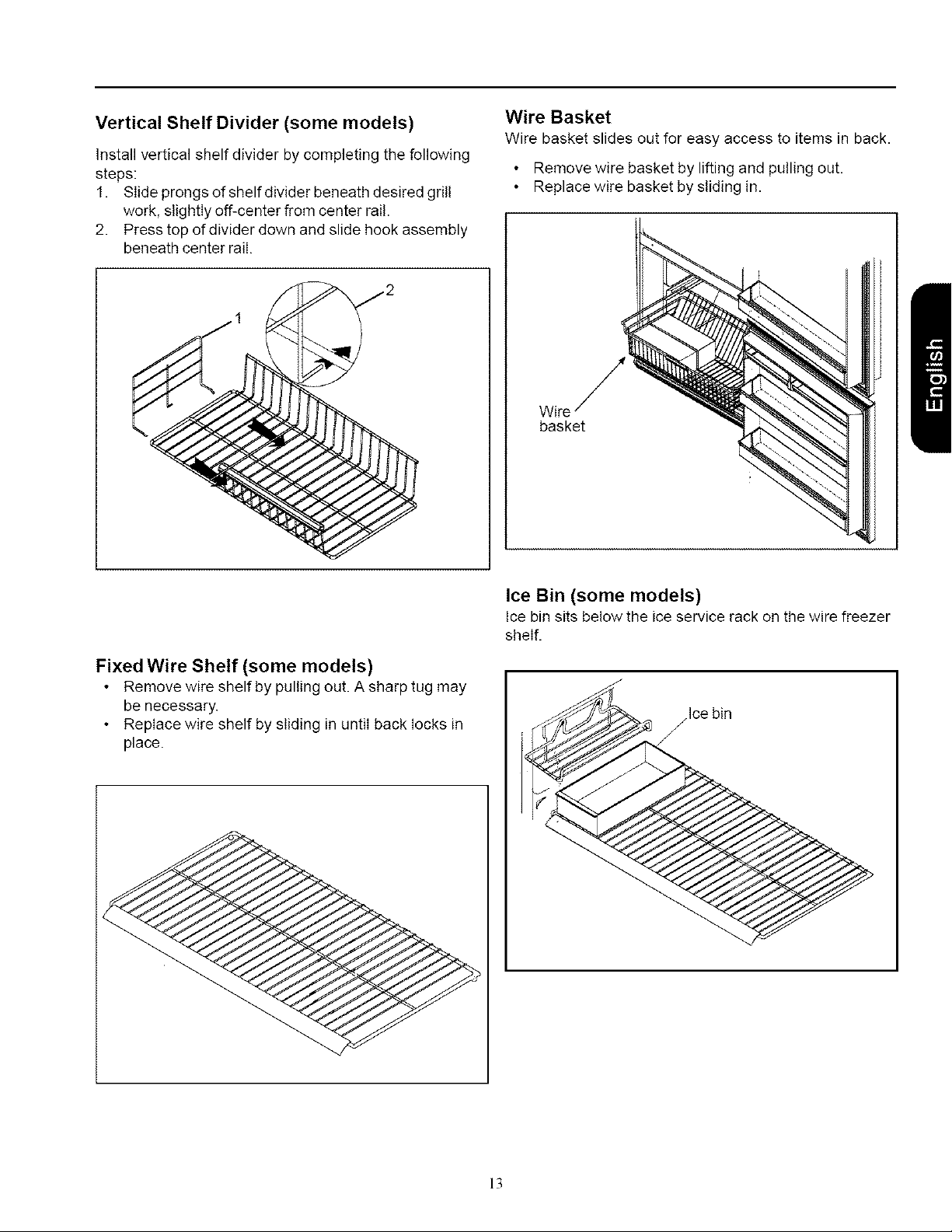

Vertical Shelf Divider (some models)

Install vertical shelf divider by completing the following

steps:

1. Slide prongs of shelf divider beneath desired grill

work, slightly off-center from center rail.

2. Press top of divider down and slide hook assembly

beneath center raiI.

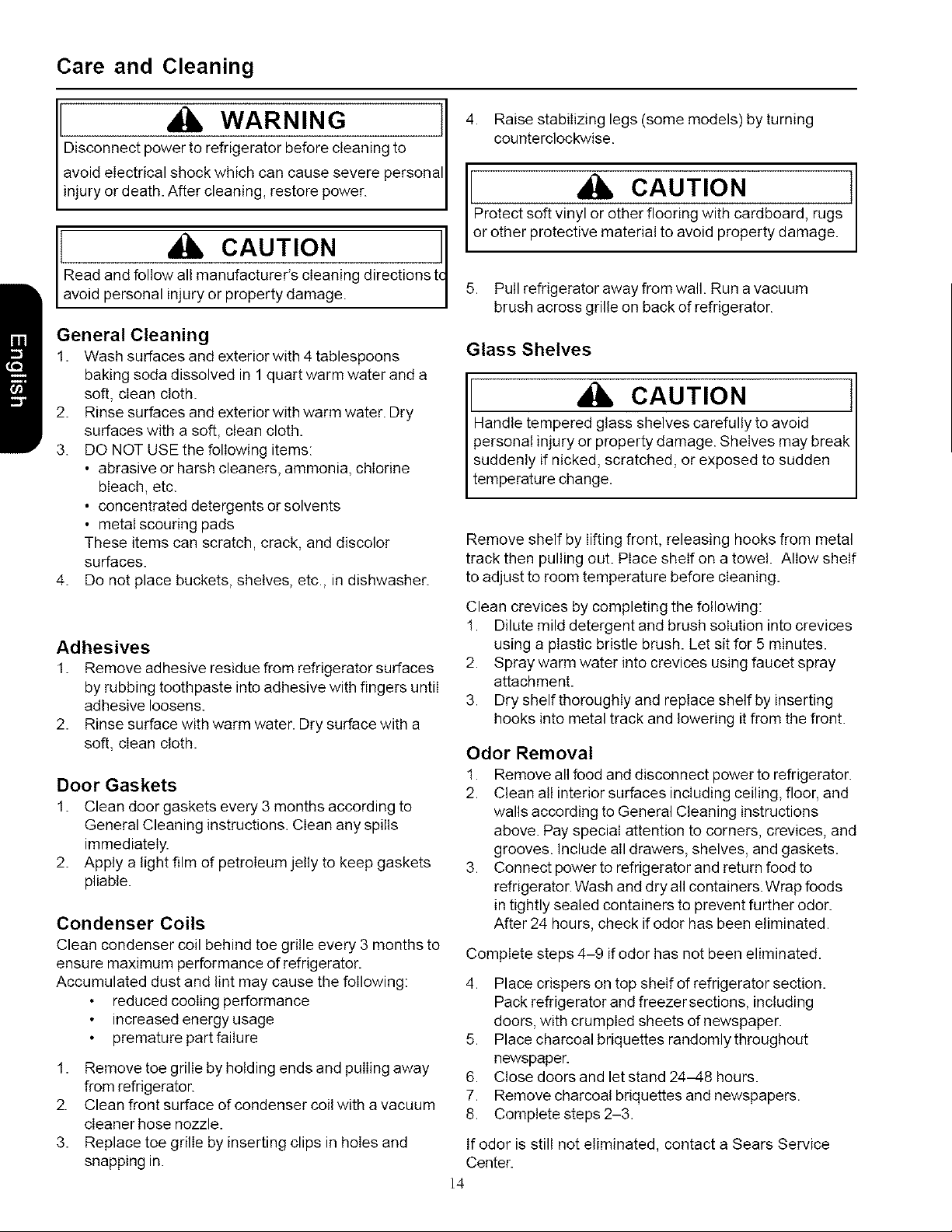

Wire Basket

Wire basket slides out for easy access to items in back.

Remove wire basket by lifting and pulling out.

Replace wire basket by sliding in.

Wire

basket

Fixed Wire Shelf (some models)

• Remove wire shelf by pulling out. A sharp tug may

be necessary.

• Replace wire shelf by sliding in until back locks in

place.

Ice Bin (some models)

Ice bin sits below the ice service rack on the wire freezer

shelf.

Ice bin

]3

Care and Cleaning

WARNING

Disconnect power to refrigerator before cleaning to

avoid electrical shock which can cause severe personal

injury or death. After cleaning, restore power.

Read and follow all manufacturer's cleaning directions tcI

avoid personal injury or property damage. J

General Cleaning

1. Wash surfaces and exterior with 4 tablespoons

baking soda dissolved in 1 quart warm water and a

soft, clean cloth.

2. Rinse surfaces and exterior with warm water. Dry

surfaces with a soft, clean cloth.

3. DO NOT USE the following items:

• abrasive or harsh cleaners, ammonia, chlorine

bleach, etc.

• concentrated detergents or solvents

• metal scouring pads

These items can scratch, crack, and discolor

surfaces.

4. Do not place buckets, shelves, etc., in dishwasher.

Adhesives

1. Remove adhesive residue from refrigerator surfaces

by rubbing toothpaste into adhesive with fingers until

adhesive loosens.

2. Rinse surface with warm water. Dry surface with a

soft, clean cloth.

Door Gaskets

1. Clean door gaskets every 3 months according to

General Cleaning instructions. Clean any spills

immediately.

2. Apply a light film of petroleum jelly to keep gaskets

pliable.

Condenser Coils

Clean condenser coil behind toe grille every 3 months to

ensure maximum performance of refrigerator.

Accumulated dust and lint may cause the following:

reduced cooling performance

increased energy usage

premature part failure

1. Remove toe grille by holding ends and pulling away

from refrigerator.

2. Clean front surface of condenser coil with avacuum

cleaner hose nozzle.

3. Replace toe grille by inserting clips in holes and

snapping in.

4. Raise stabilizing legs (some models) by turning

counterclockwise.

Protect soft vinyl or other flooring with cardboard, rugs

I _ CAUTION I

or other protect ve mater a to avo d property damage.

5. Pull refrigerator away from wall. Run a vacuum

brush across grille on back of refrigerator.

Glass Shelves

CAUTION

Handle tempered glass shelves carefully to avoid

personal injury or property damage. Shelves may break

suddenly if nicked, scratched, or exposed to sudden

temperature change.

Remove shelf by lifting front, releasing hooks from metal

track then pulling out. Place shelf on a towel. Allow shelf

to adjust to room temperature before cleaning.

Clean crevices by completing the following:

I. Dilute mild detergent and brush solution into crevices

using a plastic bristle brush. Let sit for 5 minutes.

2. Spray warm water into crevices using faucet spray

attachment.

3. Dry shelf thoroughly and replace shelf by inserting

hooks into metal track and lowering it from the front.

Odor Removal

1. Remove all food and disconnect power to refrigerator.

2. Clean all interior surfaces including ceiling, floor, and

walls according to General Cleaning instructions

above. Pay special attention to corners, crevices, and

grooves. Include all drawers, shelves, and gaskets.

3. Connect power to refrigerator and return food to

refrigerator. Wash and dry all containers. Wrap foods

in tightly sealed containers to prevent further odor.

After 24 hours, check if odor has been eliminated.

Complete steps 4-9 if odor has not been eliminated.

4. Place crispers on top shelf of refrigerator section.

Pack refrigerator and freezer sections, including

doors, with crumpled sheets of newspaper.

5. Place charcoal briquettes randomly throughout

newspaper.

6. Close doors and let stand 24-48 hours.

7. Remove charcoal briquettes and newspapers.

8. Complete steps 2-3.

If odor is still not eliminated, contact a Sears Service

Center.

]4

Vacation Tips

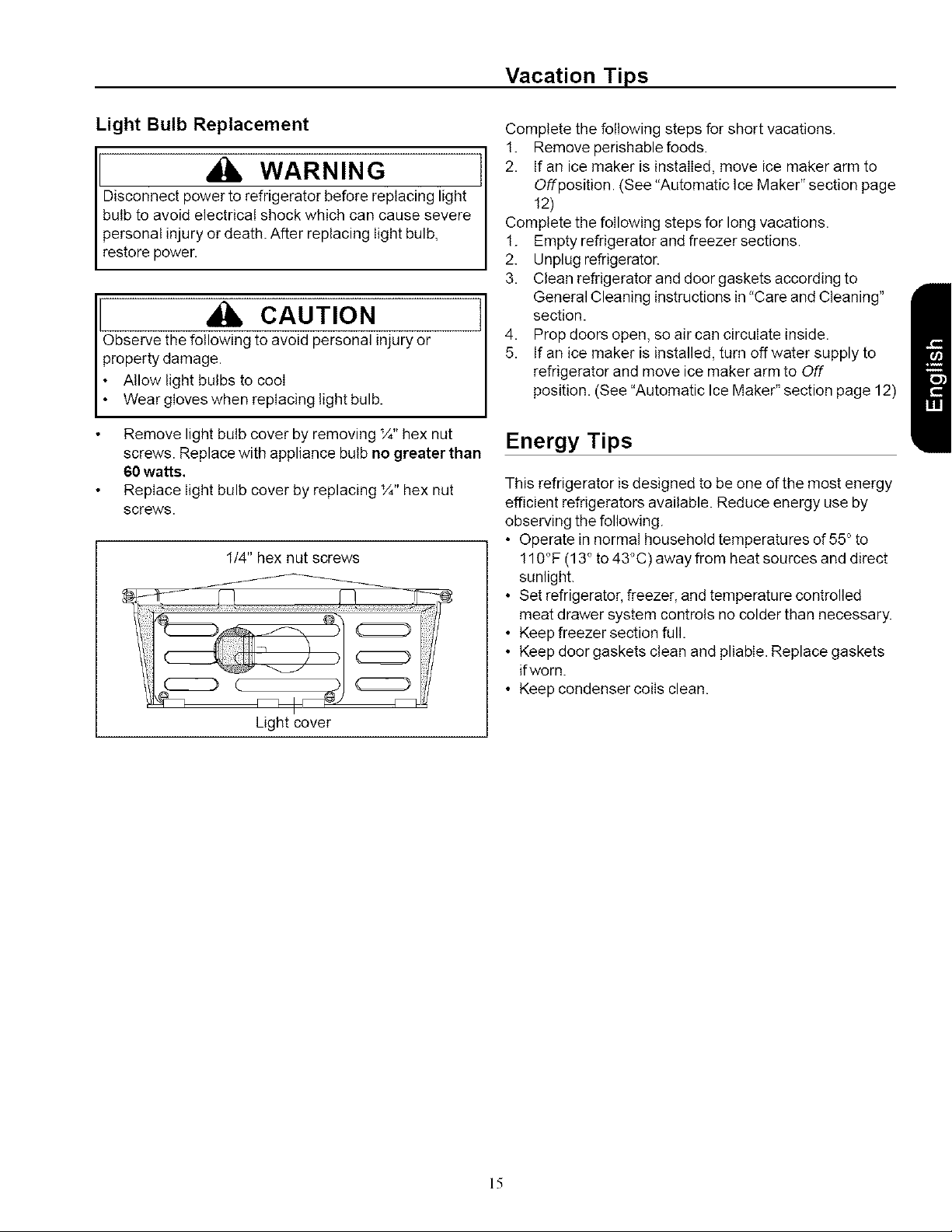

Light Bulb Replacement

WARNING

Disconnect power to refrigerator before replacing light

bulb to avoid electrical shock which can cause severe

)ersonat injury or death. After replacing light bulb,

restore power.

CAUTION

Observe the following to avoid personal injury or

property damage.

Allow light bulbs to cool

Wear gloves when replacing light bulb.

Remove light bulb cover by removing ¼" hex nut

screws. Replace with appliance bulb no greater than

60 watts,

Replace light bulb cover by replacing ¼" hex nut

screws.

1/4" hex nut screws

_ZZ)_- __,..... @)_ (ZZ_ _t/

Complete the following steps for short vacations.

1. Remove perishable foods.

2. If an ice maker is installed, move ice maker arm to

Offposition. (See "Automatic Ice Maker" section page

I2)

Complete the following steps for long vacations.

1. Empty refrigerator and freezer sections.

2. Unplug refrigerator.

3. Clean refrigerator and door gaskets according to

General Cleaning instructions in "Care and Cleaning"

section.

4. Prop doors open, so air can circulate inside.

5. If an ice maker is installed, turn off water supply to

refrigerator and move ice maker arm to Off

position. (See "Automatic Ice Maker" section page 12)

Energy Tips

This refrigerator is designed to be one of the most energy

efficient refrigerators available. Reduce energy use by

observing the following.

• Operate in normal household temperatures of 55° to

110°F (13° to 43°C) away from heat sources and direct

sunlight.

• Set refrigerator, freezer, and temperature controlled

meat drawer system controls no colder than necessary.

• Keep freezer section full.

• Keep door gaskets clean and pliable. Replace gaskets

ifworn.

• Keep condenser coils clean.

Light cover

]5

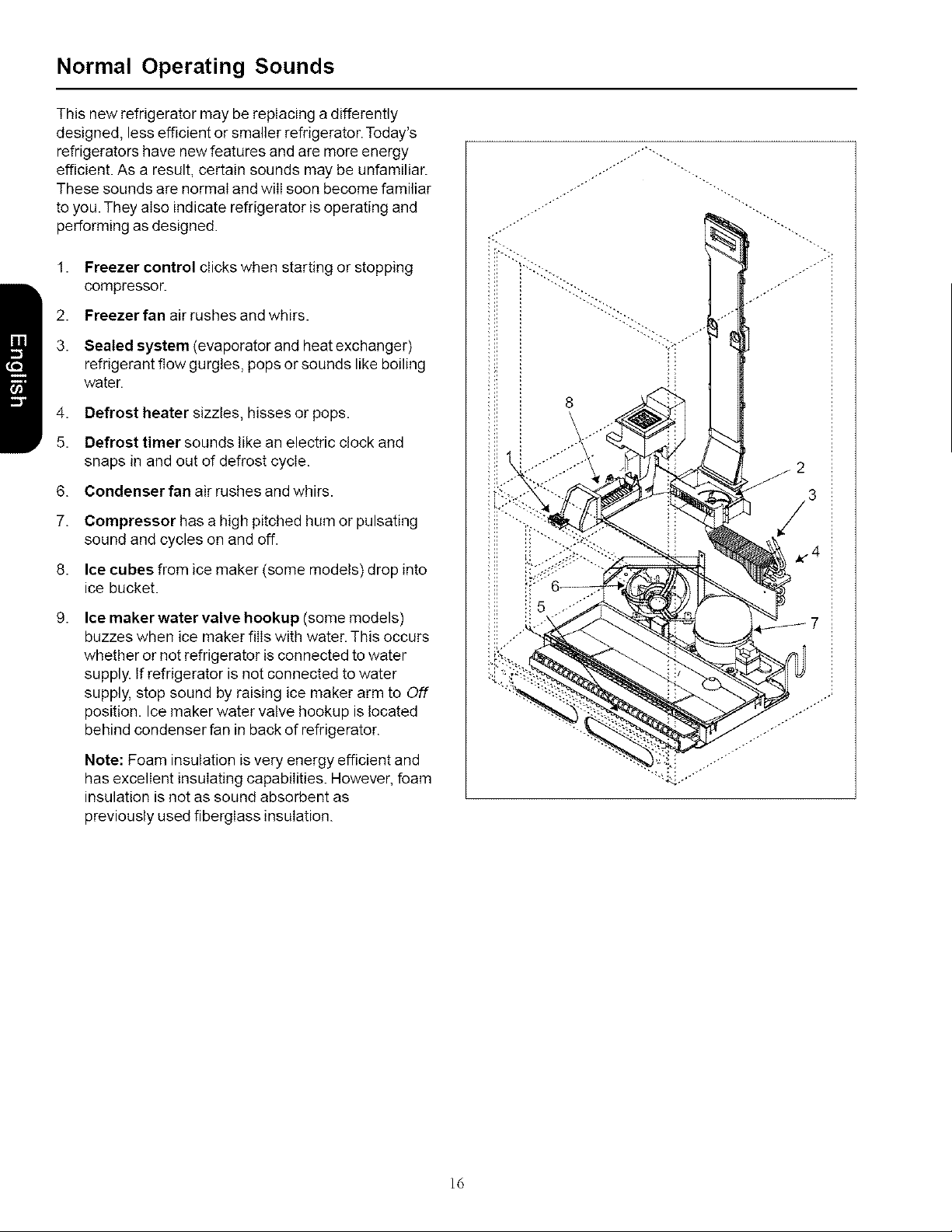

Normal Operating Sounds

This new refrigerator may be replacing a differently

designed, less efficient or smaller refrigerator. Today's

refrigerators have new features and are more energy

efficient. As a result, certain sounds may be unfamiliar.

These sounds are normal and will soon become familiar

to you. They also indicate refrigerator is operating and

performing as designed.

1. Freezer control clicks when starting or stopping

compressor.

2. Freezer fan air rushes and whirs.

3. Sealed system (evaporator and heat exchanger)

refrigerant flow gurgles, pops or sounds like boiling

water.

4. Defrost heater sizzles, hisses or pops.

5. Defrost timer sounds tike an electric clock and

snaps in and out of defrost cycle.

6. Condenser fan air rushes and whirs.

7. Compressor has a high pitched hum or pulsating

sound and cycles on and off.

8. Ice cubes from ice maker (some models) drop into

ice bucket.

g.

Ice maker water valve hookup (some models)

buzzes when ice maker fills with water. This occurs

whether or not refrigerator is connected to water

supply. If refrigerator is not connected to water

supply, stop sound by raising ice maker arm to Off

position. Ice maker water valve hookup is located

behind condenser fan in back of refrigerator.

Note: Foam insulation is very energy efficient and

has excellent insulating capabilities. However, foam

insulation is not as sound absorbent as

previously used fiberglass insulation.

]d

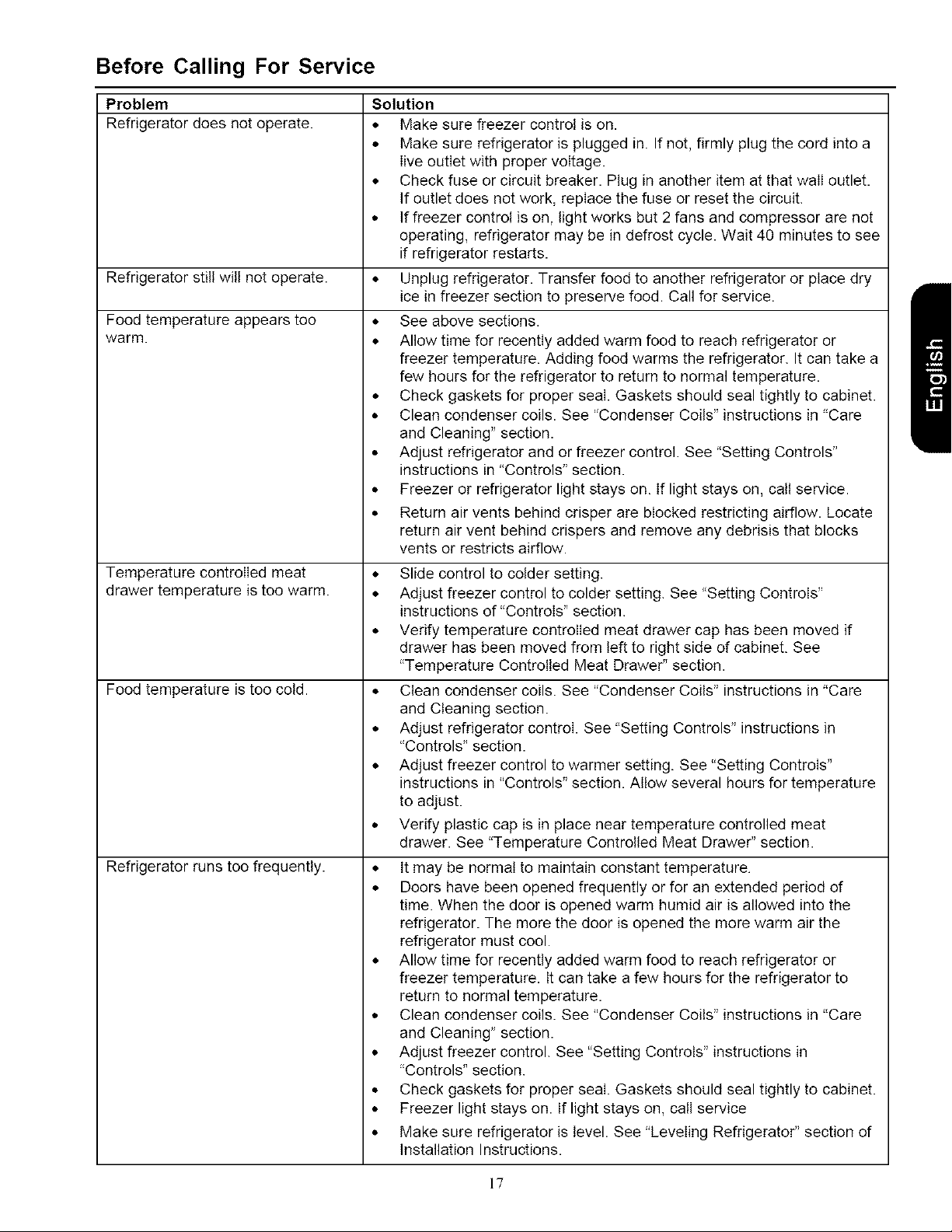

Before Calling For Service

Problem

Refrigerator does not operate.

Refrigerator still will not operate. • Unplug refrigerator. Transfer food to another refrigerator or place dry

Food temperature appears too

warm.

Solution

• Make sure freezer control is on.

• Make sure refrigerator is plugged in. If not, firmly plug the cord into a

live outlet with proper voltage.

• Check fuse or circuit breaker. Plug in another item at that wail outlet.

If outlet does not work, replace the fuse or reset the circuit.

• If freezer control is on, light works but 2 fans and compressor are not

operating, refrigerator may be in defrost cycle. Wait 40 minutes to see

if refrigerator restarts.

ice in freezer section to preserve food. Call for service.

• See above sections.

• Allow time for recently added warm food to reach refrigerator or

freezer temperature. Adding food warms the refrigerator. It can take a

few hours for the refrigerator to return to normal temperature.

• Check gaskets for proper seal. Gaskets should seal tightly to cabinet.

• Clean condenser coils. See "Condenser Coils" instructions in "Care

and Cleaning" section.

• Adjust refrigerator and or freezer control. See 'Setting Controls"

instructions in "Controls" section.

• Freezer or refrigerator light stays on. If light stays on, call service.

• Return air vents behind crisper are blocked restricting airflow. Locate

return air vent behind crispers and remove any debrisis that blocks

vents or restricts airflow.

Temperature controlled meat

drawer temperature is too warm.

Food temperature is too cold.

Refrigerator runs too frequently.

• Slide control to colder setting.

• Adjust freezer control to colder setting. See "Setting Controls"

instructions of "Controls" section.

• Verify temperature controlled meat drawer cap has been moved if

drawer has been moved from left to right side d cabinet. See

"Temperature Controlled Meat Drawer" section.

• Clean condenser coils. See "Condenser Coils" instructions in "Care

and Cleaning section.

• Adjust refrigerator control. See"Setting Controls" instructions in

"Controls" section.

• Adjust freezer control to warmer setting. See "Setting Controls"

instructions in "Controls" section. Allow several hours for temperature

to adjust.

• Verify plastic cap is in place near temperature controlled meat

drawer. See "Temperature Controlled Meat Drawer" section.

• It may be normal to maintain constant temperature.

• Doors have been opened frequently or for an extended period of

time. When the door is opened warm humid air is allowed into the

refrigerator. The more the door is opened the more warm air the

refrigerator must cool.

• Allow time for recently added warm food to reach refrigerator or

freezer temperature. It can take a few hours for the refrigerator to

return to normal temperature.

• Clean condenser coils. See "Condenser Coils" instructions in "Care

and Cleaning" section.

• Adjust freezer control. See "Setting Controls" instructions in

'Controls" section.

• Check gaskets for proper seal. Gaskets should seal tightly to cabinet.

• Freezer light stays on. If light stays on, call service

• Make sure refrigerator is level. See "Leveling Refrigerator" section of

Installation Instructions.

]7

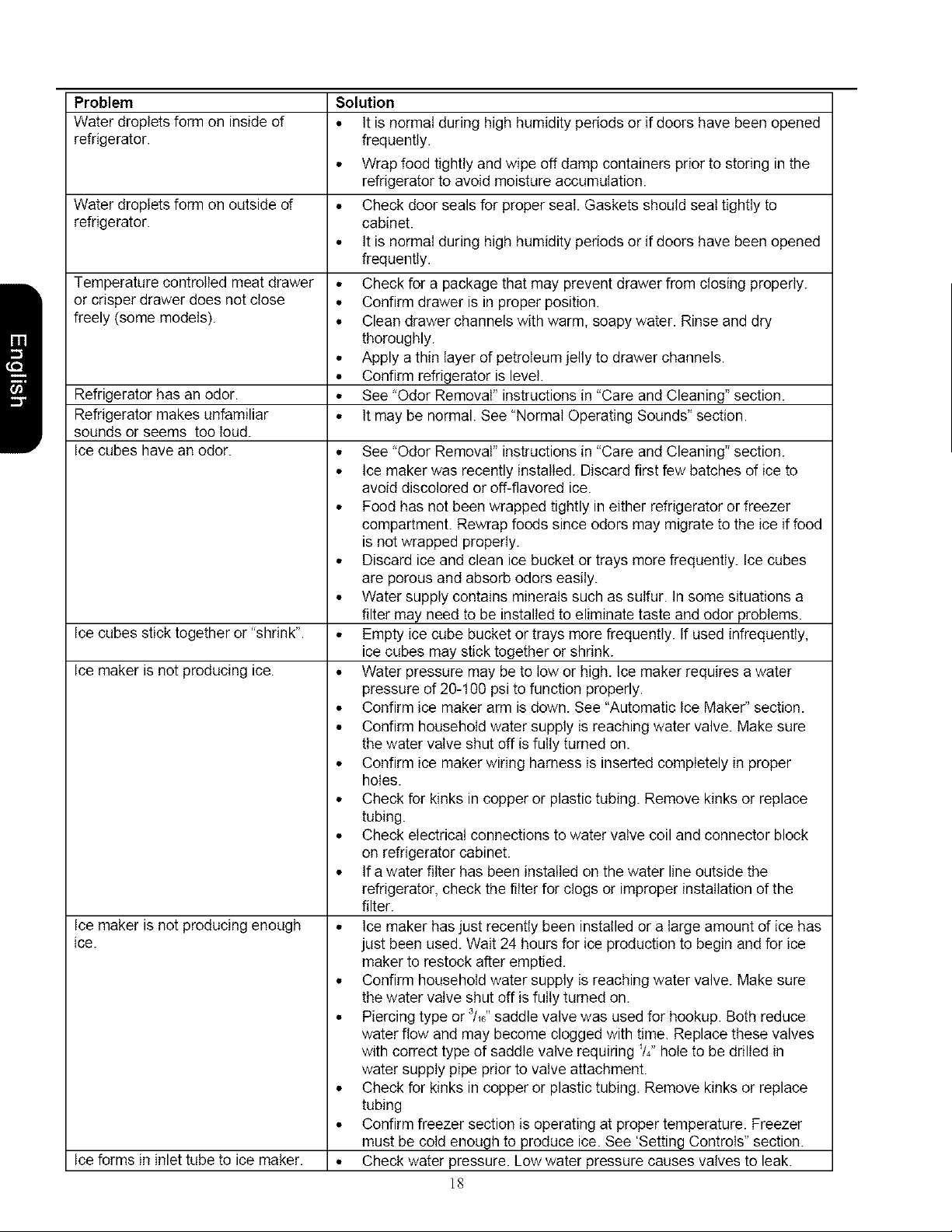

Problem Solution

Water droplets form on inside of • It is normal during high humidity periods or if doors have been opened

refrigerator, frequently.

• Wrap food tightly and wipe off damp containers prior to storing in the

refrigerator to avoid moisture accumulation.

Water droplets form on outside of • Check door seals for proper seal. Gaskets should seal tightly to

refrigerator, cabinet.

• It is normal during high humidity periods or if doors have been opened

frequently.

Temperature controlled meat drawer • Check for a package that may prevent drawer from closing properly.

or crisper drawer does not close • Confirm drawer is in proper position.

freely (some models). • Clean drawer channels with warm, soapy water. Rinse and dry

thoroughly.

• Apply a thin layer of petroleum jelly to drawer channels.

• Confirm refrigerator is level.

Refrigerator has an odor. • See "Odor Removal" instructions in "Care and Cleaning" section.

Refrigerator makes unfamiliar • It may be normal. See "Normal Operating Sounds" section.

sounds or seems too loud.

Ice cubes have an odor. •

Ice cubes stick together or "shrink".

Ice maker is not producing ice.

Ice maker is not producing enough

ice.

Ice forms in inlet tube to ice maker.

See "Odor Removal" instructions in "Care and Cleaning" section.

Ice maker was recently installed. Discard first few batches of ice to

avoid discolored or off-flavored ice.

• Food has not been wrapped tightly in either refrigerator or freezer

compartment. Rewrap foods since odors may migrate to the ice if food

is not wrapped properly.

• Discard ice and clean ice bucket or trays more frequently. Ice cubes

are porous and absorb odors easily.

• Water supply contains minerals such as sulfur. In some situations a

filter may need to be installed to eliminate taste and odor problems.

• Empty ice cube bucket or trays more frequently. If used infrequently,

ice cubes may stick together or shrink.

• Water pressure may be to low or high. Ice maker requires a water

pressure of 20-100 psi to function properly.

• Confirm ice maker arm is down. See "Automatic Ice Maker" section.

• Confirm household water supply is reaching water valve. Make sure

the water valve shut off is fully turned on.

• Confirm ice maker wiring harness is inserted completely in proper

holes.

• Check for kinks in copper or plastic tubing. Remove kinks or replace

tubing.

• Check electrical connections to water valve coil and connector block

on refrigerator cabinet.

• If a water filter has been installed on the water line outside the

refrigerator, check the filter for clogs or improper installation of the

filter.

• Ice maker has just recently been installed or a large amount of ice has

just been used. Wait 24 hours for ice production to begin and for ice

maker to restock after emptied.

• Confirm household water supply is reaching water valve. Make sure

the water valve shut off is fully turned on.

• Piercing type or _/_G"saddle valve was used for hookup. Both reduce

water flow and may become clogged with time. Replace these valves

with correct type of saddle valve requiring W' hole to be drilled in

water supply pipe prior to valve attachment.

• Check for kinks in copper or plastic tubing. Remove kinks or replace

tubing

• Confirm freezer section is operating at proper temperature. Freezer

must be cold enough to produce ice. See 'Setting Controls" section.

• Check water pressure. Low water pressure causes valves to leak.

]81920

Loading...

Loading...