Kenmore 596.50012100 User Manual [en, es, fr]

' ÊéTÆM'm MM jffjai''

Side-by-Side Refrigerator

Use & Care Guide

ORDER # 67003379

Refrigerador Dúpiex

Guía para el Uso y Cuidado

Réfrigérateur à Compartiments Juxtaposés

Guide D’utilisation et D’entretien

Models:

596.53462301, 596.53463301, 596.53464301,596.53469301,

596.52672201, 596.52673201,596.52674201, 596.52679201,

596.50002100, 596.50003100, 596.50004100, 596.50009100,

596.50012100, 596.50013100, 596.50014100, 596.50019100

m

Z

O

$

O

>

M

Part Na. 12S91320

Form A/04/O3

Sears, Roebuck and Co,, Hoffman Estates, (L 60179 U.S.A

Sears Canada, Inc, Toronto, Ontario, Canada MSB 2B8

Au Canada,

(A

S

wwwsears.com

www.searsxa

WH A T Y O U H E E D T O K N O W AB O U T S A E E T Y

Warning and important Safety

insirucfions appearing In this manoai are

not meanl to cover al! possible

conditions and situations that may occur.

Common sense, caution, and care must

be exercised when installing,

maintaining, or operating refrigerator.

Always contact your deaier, distributor,

service agent, or manufacturer about

problems or conditions you do not

understand

RECOGNIZE SAFETY

SYMBOLS, WORDS,

LABELS

ADANGER

DANGER - immediate hazards

which WILL result in severe personal

injury Of death. : :

A WARNING

WARNING “ Hazards or unsafe

practices which COULD result in

severe persona! injury or death.

ACAUTION

CAUTION *- Hazards or unsafe

practices which COULD result in

minor personal injury.

A DANGER

To reduce risk of injury or death,

follow basic precautions, fncluding

the followingi

IMPORTANT: Child entrapment and

suffocation are not problems of the;

past. Junked or abandoned ■ , ■

refrigerators are still dangerous even if they sit out for “just a few : ,

days ” If you are getting rid of your

old refrigerator, please follow the,

instructions below to help prevent

accidents.-

Before you throw away your old

refrigerator or freezer: .

>- Take off the doors^

>■ Leave the shelves in

..............................

place so children

may not easily climb

inside. -

.

A WARNING

To reduce risk of fire, electric shock, serious injury or death when using your refrigerator, follow these basic

precautions, including the following: ^ ^ ^ ^ ^ ^

I. Read all instructions before using the refrigerator.

; 2. Observe ail local coifes and ordinances, ^ , ;

3. Be sure to Idlow grounding instructions, .

, 4. Check with a qualified electrician if you are not sure this

: . - appliance is properly grounded. ■ v ' ... ' . : ,

5; DO NOT ground to'a gas line.' .' .

6, DO NOT ground to a cold-water pipe.

•7. Refrigeratofis designed to dperate bn a separate 103 to ■

126 volt, 15 amp., 60 cycle line, DO NOT modify plug on

power cord. If plug does not fit electrical outlet, have i

proper outlet insiailed by a qualified electrician.

8. DO NOT use a two-prong adapter, extension cord or .

power strip;.'- . ' 1'

9. DO NOT remove warning tag fronj power cord.

10. DO NOT tamper with refrigerator controls. ; .

II. DO NOT service or replace any part of refrigerator unless

.. / specifically recxjmmended in Use & Cars Guide or published

user-repair instructions DO NOT attempt service if

■ instfUcBons are not understood or if they are beyond personal

skill level,. ; ' . ; , . , ,

12. Always disconnect refrigeratorirom electricai supply

before attempting any service. Disconnect power cord by

■ grasping the plug, not the cord. . :

13. install refrigerator according to installation Instructions. Ail

connections for water, electrical power and grounding .

must compiy with focai codes and be made by licensed personnel when required. ;

14. Keep your refrigerator in good condition. Bumping or .

dropping refrigerator can damage refrigerator or cause

refrigerator to malfunction or leak If damage occurs, have

refrigerator checked by qualified service technician.

15. Replace worn power cords and/or loose plugs.

16. Always read and follow manufacturer’s storage and idest

environment instructions for items being stored in

'refrigerator.-'.■ •.

PROTÍ CT IOH Á6ÍEMÍ HIS

MASMPROTiaiOK

штъ

IN THE U.S.A.

Congratulations on making a smart

purchase, Your new Kenmore®

appliance is designed and manufactured

for years of dependable operation. But

like all products, it may require

preventive maintenance or repair from

time to time. That is when having a

Master Protection Agreement can save

you money and aggravation,,

Purchase a Master Protection

Agreement now and protect yourself

from unexpected hassle and expense

The Master Protection Agreement also

helps extend the life of your new

appliance. Here is what is included in

the agreement:

> Expert service by our 12,000

professionai repair specialists

> Unlimited service and no charge for

parts and labor on all covered

repairs.

"No-lemon" guarantee -■ replacement

of your covered product if more than

three product failures occur within

twelve months.

>- Product replacement II your covered

product cannot be fixed,

>■ Annual Preventive Maintenance

Check at your request - rio extra

charge.

>- Fast help by phone ~ non-techrrical

and instructional assistance on

products repaired in your home, plus

convenient repair scheduling

Power surge protection against

electrical damage due to power

ftuctuations

Rental reimbursement if repair of

your covered product takes longer

than promised.

Once you purchase the Agreement, a

simple phone call is aii that it takes for

you to schedule service, You can call

anytime day or night, or schedule a

service appointment online.

Sears has over 12,000 professional

repair specialists, who have access to

over 4 5 million quaiity parts and

accessories, That is the kind of

professionalism you can count on to

help prolong the life of your new

purchase for years to come Purchase

your Master Protection Agreement

today!

Some limitations and exclusions apply.

For prices and additional information,

call 1-800-827-6655

Sears Installation Service

For Sears guaranteed professional

installation of home appliances and

items like garage door openers and

wafer heaters, in the U S.A cail

1-BQO-MY-HOME®

Mmma mms

IN CANADA

Your purchase has added value because

you can depend on Sears HomeCentraP

for service. With over 2,400 Service

Technicians and access to over 900,000

parts and accessories, we have the

tools, parts, knowledge and skills to

ensure our pledge: We Service What

We SellYour Kenmore* appliance is designed,

manufactured and tested to provide

years of dependable operation. Yet any

major appliance may require service

from time to time. The Sears

Maintenance Agreement offers you an

outstanding service program, affordably

priced

Sears Maintenance Agreement

> Is your way to buy tomorrow's service

at today’s price

> Eliminates repair bills resulting from

normal wear and tear.

5=^ Provides for non-technica! and

instructional assistance,

>■ Even if you don't need repairs,

provides an annua! Preventive

Maintenance Check, at your request,

to ensure that your appliance is in

proper running condition,

Some limitations apply For information

concerning Sears Canada Maintenance

Agreements, call 1-800-361-6665,

m

z

&

5)

X

i

Full One Year Warranty on

Refrigerator

Fot one year from the dale of purchase,

when this refrigerator is operated and

maintained according to instructions

attached to or furnished with it, Sears

will repair it, free of charge, if defective

in material or workmanship,

Fuil Five Year Warranty on Sealed

Refrigeration System

For five years from the date of purchase,

when this refrigerator is operated and

maintained according to instructions

attached to or furnished with it, Sears

will repair the sealed system (consisting

of refrigerant, connecting tubing and

compressor motor) free of charge, if

defective in material or workmanship,

The above warranty coverage applies

only to refrigerators which are used for

storage of food for private household

purposes It excludes original and

replacement Kerimore ice & wafer filter

cartridges. Original and repfacement

cartridges are warranted for 30 days,

parts oniy, against defects in material or

workmanship

In the space below record the model

and serial numbers and purchase date

of your refrigerator You will find the

model and serial number sticker inside

the refrigerator section on the left wall.

Model Number; 596.

Serial Number:.

Purchase Date;

Keep this booklet and your Sears

sales receipt in a safe place for future

Warranty service is available by

contacting 1-800-4-yY-HOME®

(1-800-469*4663)

This warranty applies only while this

product is in use in the United States.

This wananty gives you specific legal

rights, and you may also have other-

rights, which vary from state to state

Sears, Roebuck and Co., Dept, 817WA,

Hoffman Estates, 1L60179

NOTE: Some Reverse Osmosis home

water systems cause low water

pressure. Low water pressure can affect

the water and ice dispensing system by

causing small or hollow ice cubes and

slow water flow from the dispenser.

Service problems related to the home’s

Reverse Osmosis water system are not

covered by the warranty.

4

CONf fiN ÎS

important Safety Information

What You Need to Know About Safety instructions

Protection Agreements

Master Protection Agreements - U S A

Maintenance Agreemertts - Canada ,

Warranty

Product Record

Installing Your Refrigerator

Settirtg and Maintaining Proper Temperatures

About Your Water Fiiter

Fresh Food Features..

Freezer Features.

Dispenser Features

Hints and Care

Normal Operating Sounds

Troubleshooting

Français

Español...

Service

.......

.........................

........... ..........

Measuring the Opening ......

Transporting Your Refrigerator

Selecting the Best Location

How to Install and Remove Handles.

Removing the Doors and Hinges .,

Replacing the Doors ...........................

Howio Install and Remove Panels.,,

How to Connect the Water Supply.,,

How to Level Your Refrigerator

Dial Temperature Gontrois.

Electric Temperature Controls

Fresh Food Storage... ..

Frozen Food Storage ...............................

Water Filter Installation and Removal,,....

Water Fiiter Data...........

interior Shelves,..-,.........................................................

Door Storage-

Climate-Controlled Drawers.

Storage Drawers...........

Automatic Ice Maker,

Interior Shelves.

Storage Drawers

Door Storage...

Dispenser Light

Dispenser Pad

Removable Tray

Water Dispenser Operatiorr

Five-Button Control Features

Electronic Corrtrol Features

Hidden Electronic Control Features.,,,

How to Clean Your Refrigerator.

How to Remove Odors from Refrigerator

Energy Saving ideas.......

How to Remove and Replace Light Bulbs

Operation.................... , „

Ice and Water.,,,,

................................

......—..................

.............

.......

.......

......

...........

-------- -

.........

....................

...........

............

.......

.............................................................................................................

............

...... .

.......... ......

.................. „ . ... ............

.............

....

.....

....................... —.................................

................................................................................

.....

.

......................................................................................... ,,.,,17

-

.........................

.............

.......... ,...........

.......................

..................

...................................................—.......................Back Cover

............... . ........

.

..........

.

................

..........

..................................... , .

..............................

............................ ........................................

.........................

...........

..................,..

........................................................... 13

.........................................................

........

................................................................ ,16

................................

.

......

................................................................. 17

....................................................................... 17

......................-......................................................

..........

.................................-............................18-22

.

............................................................................

..............................................................................18

...........

...............................................

............................................................................

......

.......................................

.........

...................... ......

................................ ....

.......

...............

..........

....................

...............

—..............................

..............................................—.............. 24

..........

....

...................................

......

...............................................................................

.....

............. .................

-................................

...................

...................

...................

.....................3

...................

.....................4

,

..........

.............................

.....

........................

.............................6

.......................

...........................-.....................

..............................................

............

.

...................10

.......

.... ,.,,11

...

............

.........................

.................

...

..................

..............

.................., .............................

.........................

......

...................................

..........

....

...... ,

....................... .

.....

.......

..........

..................12

.......................... . ..12

...............

.....,.............................,19

..................................

........................................

......................

.................................

........................................

.........

......................

.............................

..........................

..........................

15

..................

............. .20-21

.....................

................

..........

...........

..................

3

3

.....

6-10

.........9

„12

.......

...12

........ ,.12

13-14

14

15-16

15

15

17

18

18

18

..........

22

.,23-24

.....

23

24

24

...

.25

26-27

.26

..27

29

57

2

2

Rl

6

6

7

8

.8

Z

o

V)

5

INS TAL LI NG YO UR R fTR

Thsse instructions were provided to aid

you in the instaltation of your

refrigeralot-

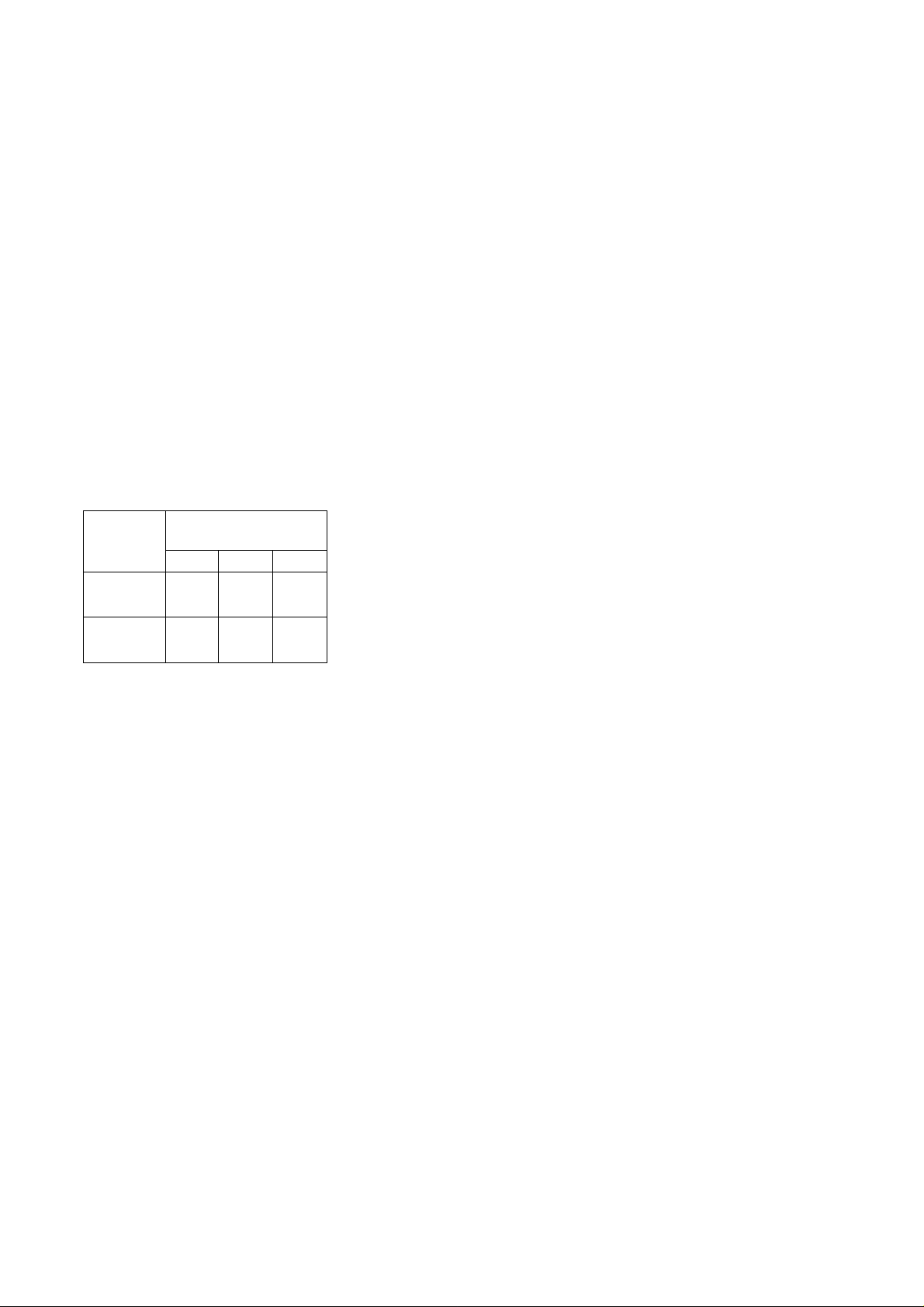

St l l C T I H G T H E B E S T

When installing your refrigerator, please

reference chart below for clearance

requirements-

Subflooring or fioor coverings fi e.

carpet, tile, wood floors, rugs) may make

your opening smaller than anticipated.

Some clearance rnay be gained by

using the leveling procedure under

How to Level Your Refrigerator

(page 11),

Recommended

Unit Tot^l

Volume

Less than

23 cu ft

Greater than

23 cu ft

IMPORTANT: if refrigerator is to be

instaiied into a recess where top of

refrigerator ts completely covered, use

dimensions from floor to top of hinge

cap to verify proper clearance

Clearance

Top

N/A

Sides

14" N/A

Rear

N/A '//

'/i"

Follow these tips when moving the

refrigerator to final location;

>■ NEVER transprt refrigerator on its

side If an upright position is not

possible, lay refrigerator on its back,

Allow refrigerator to sit upright for

approximately 30 minutes prior to

plugging refrigerator in to assure oil

returns to the compressor. Plugging

refrigerator in immediately may cause

damage to internal parts.

> Use an appliance dolly when moving

refrigerator, ALWAYS truck

refrigerator from its side or backNEVER from its front.

> Protect outside finish of refrigerator

during transport by wrapping cabinet

in blankets or inserting padding

betweert the refrigerator and dolly

Secure religerator to doily firmly with

straps or bungee cords, TTiread sfiaps

through handles when possible, DO NOT

overtighten. Overfightenlng resfralnts may

derst or damage outside finish

Observe these points when choosing the

final location for your refrigerator:

>- DO NOT install refrigerator near

oven, radiator or other heat source If

not possible, shield refrigerator with

cabinet material

> DO NOT install where temperature

falis below 55“ F (13“ C) Malfunction

may occur at this temperature

> To assure proper door closure, follow

the leveling instructions in the

section, How to Level Your

Refrigerator (page 11).

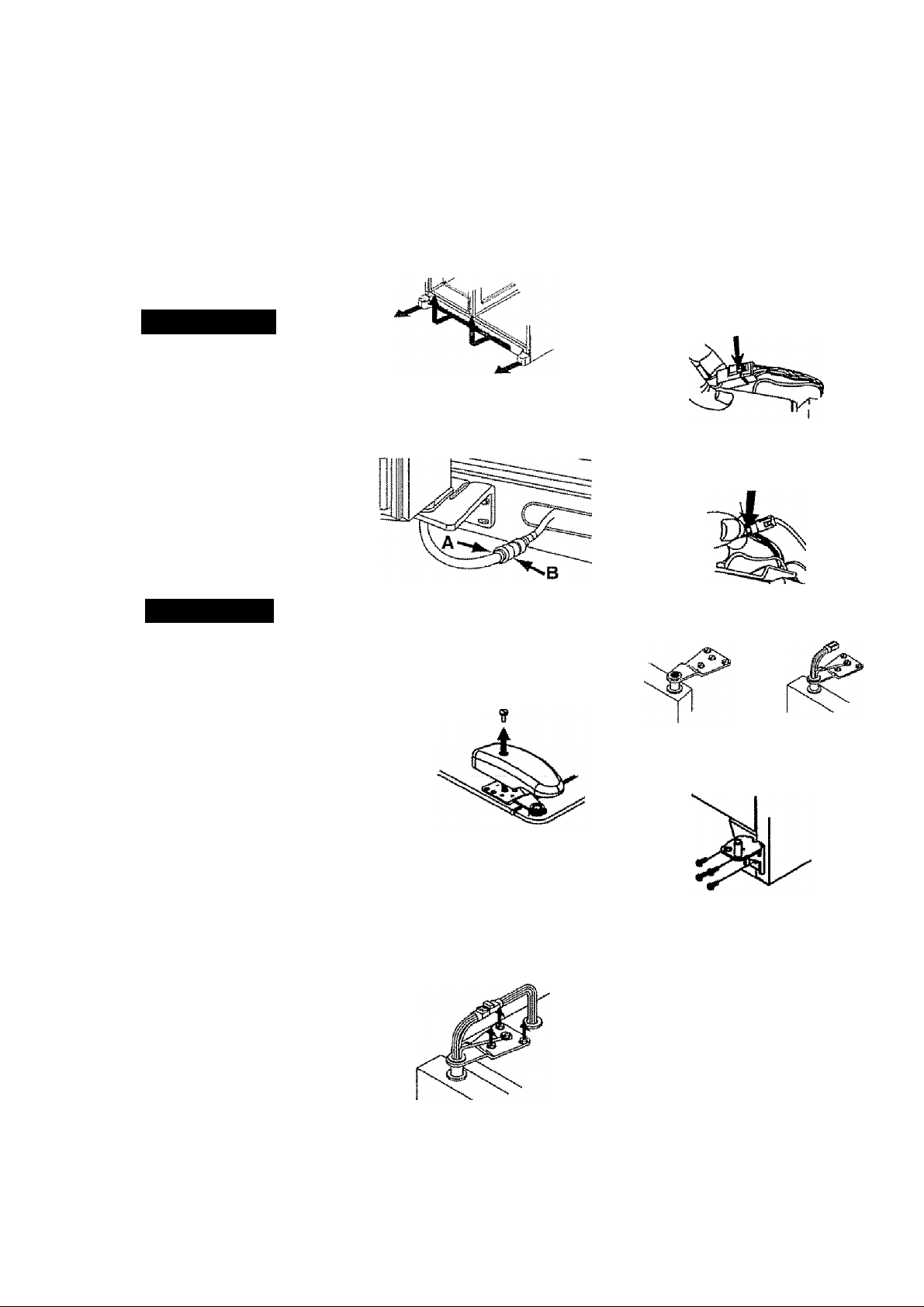

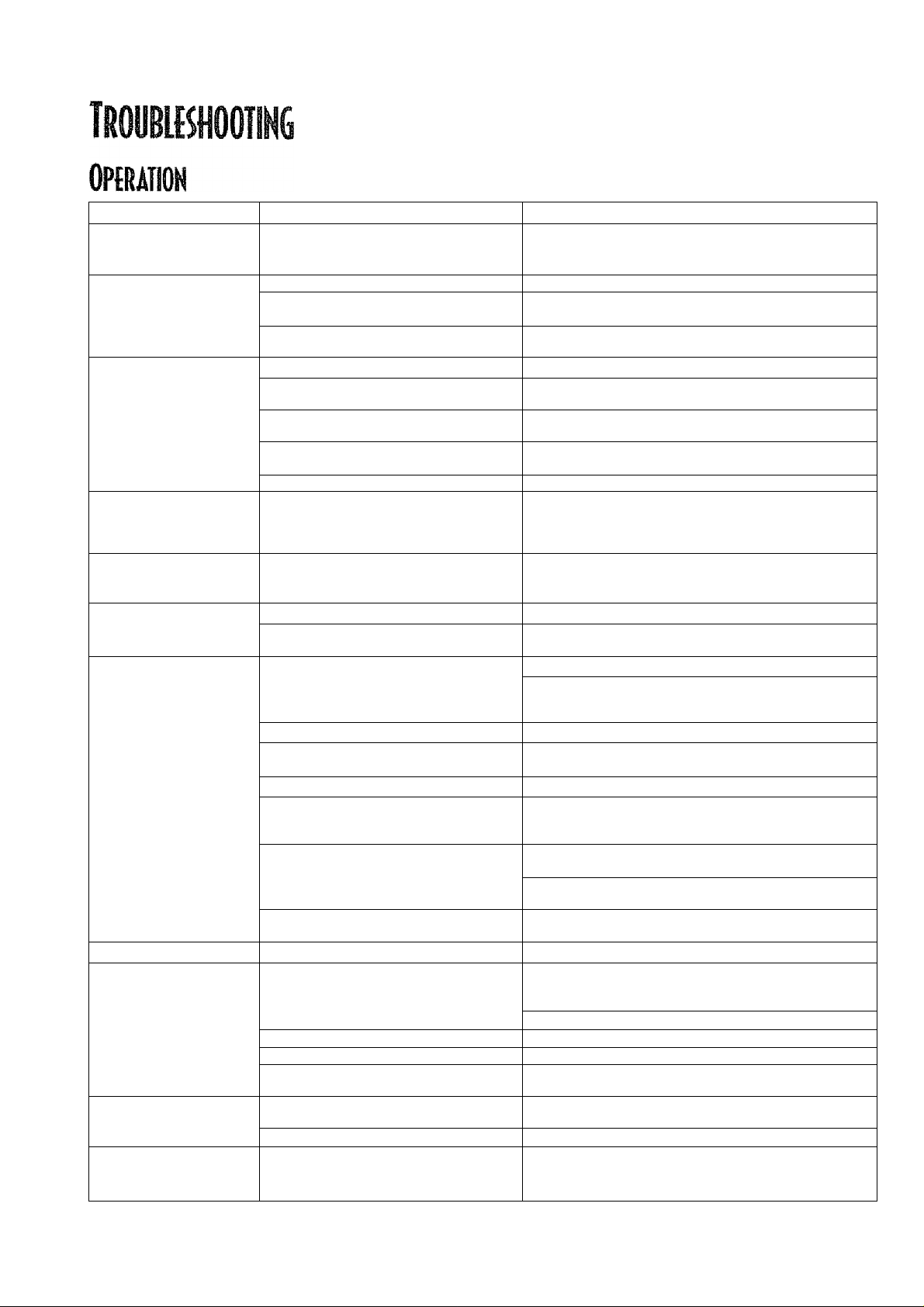

tíow

TO I H S T A I L Á K D

Rf M O V Í M A N D l f S

For easier installation, some

refrigerators may have been delivered

with the handles off Please see the

interior of the fresh food section to

locate the handle assembly, In case

future transport of the refrigerator is

necessary, the removal instructions have

been included here for your

convenience

Handle design may vary from

refrigerator fo refrigerator Please

reference the instructions for the

appropriate handle design below/

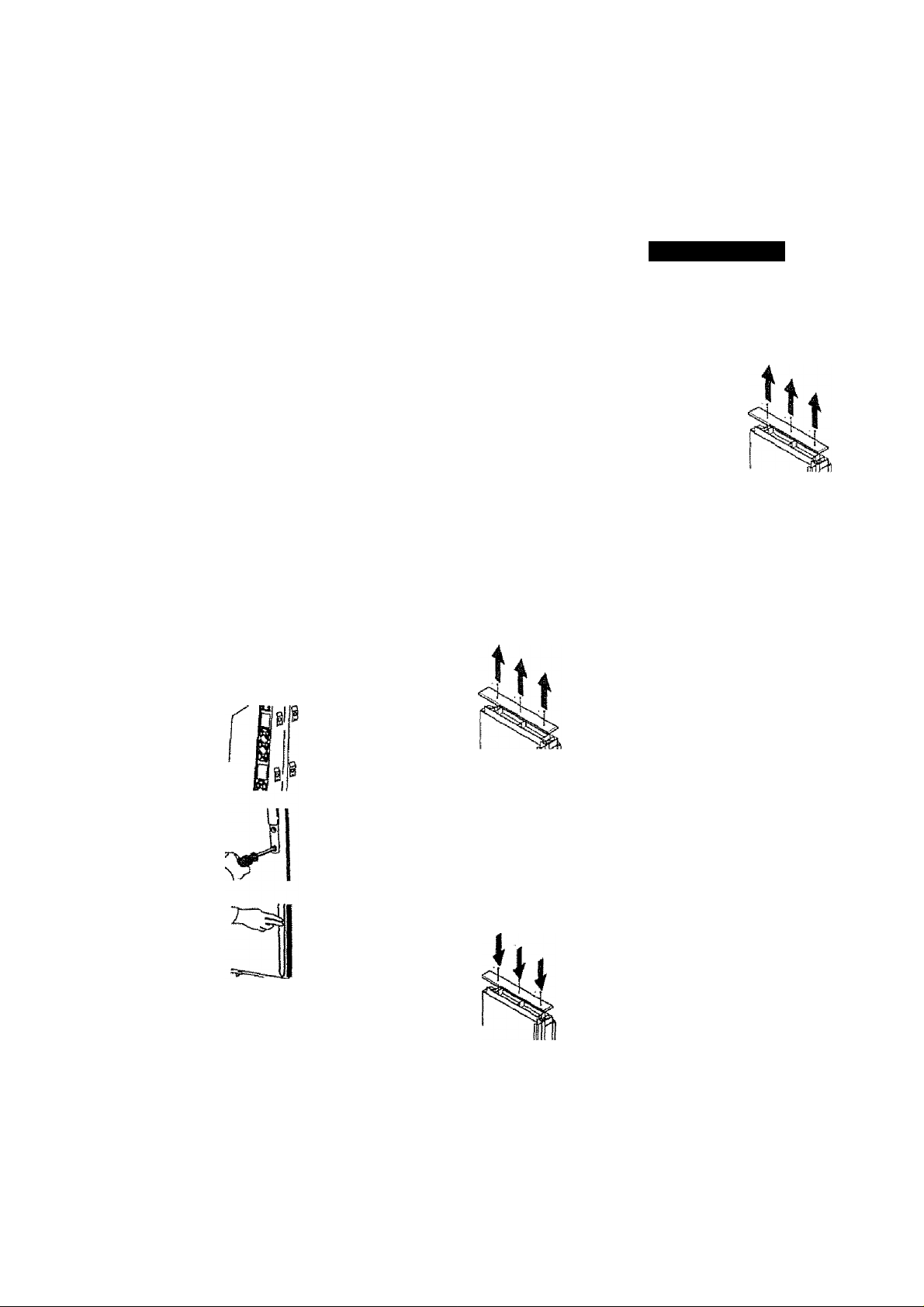

INSTALLING FRONT-

MOUNTED HANDLES

1 Remove two'/4“ hex nut screws from

bottom of door.

2, Align door handle with

top and bottom sets of

door clips, and slide

down until screw holes

on bottom of handle

match with door screw

holes,

3 Insert ’/4" hex nut screws

previously removed into

screw holes at bottom of

handle section,

4. Snap trim over bottom

portion of handle and

retainer on bottom door

5. Repeat instructions 1-4

to install other handle.

REMOVING FRONTMOUNTED HANDLES

1, Remove handle trim with a very small

ilat-biade screwdriver

IMPORTANT: Wrap blade of

screwdriver with masking tape to

avoid damaging refrigerator

4-j

Remove two handle

base screws

3, Pull handle up and

out to release from

refrigerator. Fit may

be tight,

4 Repeat instructions 1-3 to remove

other handle.

INSTALLING FULLLENGTH EXTRUDED

HANDLES

1. Release top door

trim by removing

Phillips screws from

top of fresh food

door

>' Retain PhlHlps screws for later

replacement

2. Aftgn notches on back of handle with

retaining clips on doors, insert dtps

into notches

and slide

handle down

until it contacts

bottom trim,

3 Replace top door trim

with Phillips screws

retained from trim

removal

4. Repeat instructions

1-3 to install other

handie.

REMOVING FULL-LENGTH

EXTRUDED HANDLES

A WARNING

To avoid possible injury and damage

to property, tape decorative panels

(some models) securely into place

before removing door handles.

1. Release top door trim

by removing Phillips

screws from top of

fresh food door

Retain Phillips

screws for later

replacement

2- Grasp handle firmly

with both hands and

slide handle upward

approximately to

release.

3. Repeat instructions

1-3 to remove other handie.

1h

m

z

n

w

7

STAL LI NG YO UR R EN ámc oK T.

Re m o v i n g t h e d o o r s

AN I

Some instaliations require door removal

to get refrigerator to final tocatioo

.........

* •

,. ■

.........

ÀWARNLNG

To avoid severe personal injury or

death, observe the foilowing:

■ Disconnect power to refrigerator

before removing doors. Connect

power only after replacing doors.

• Green ground wire must be

attached to top hinge while

performing door removal and

- replacement. - ■ , , ' - '

• Tape'decorative panels (select

models) securely into place before

removing door handles. , , ; .,

ACAUtlON

To avoid property damage, observe;

the following:: ,

> Protect soft vinyl or other flooring

with cardboard, rugs or other

protective material, prior to moving

refrigerator.,. : , , . , , .,

> To avoid damage or breakage to.

.....

'adju sting bolt, W hot lisi'power'

tools to correct leveiing.

1. Remove toe grille and bottom hinge

covers

Open both doors 180 degrees, or

as wide as possible to remove

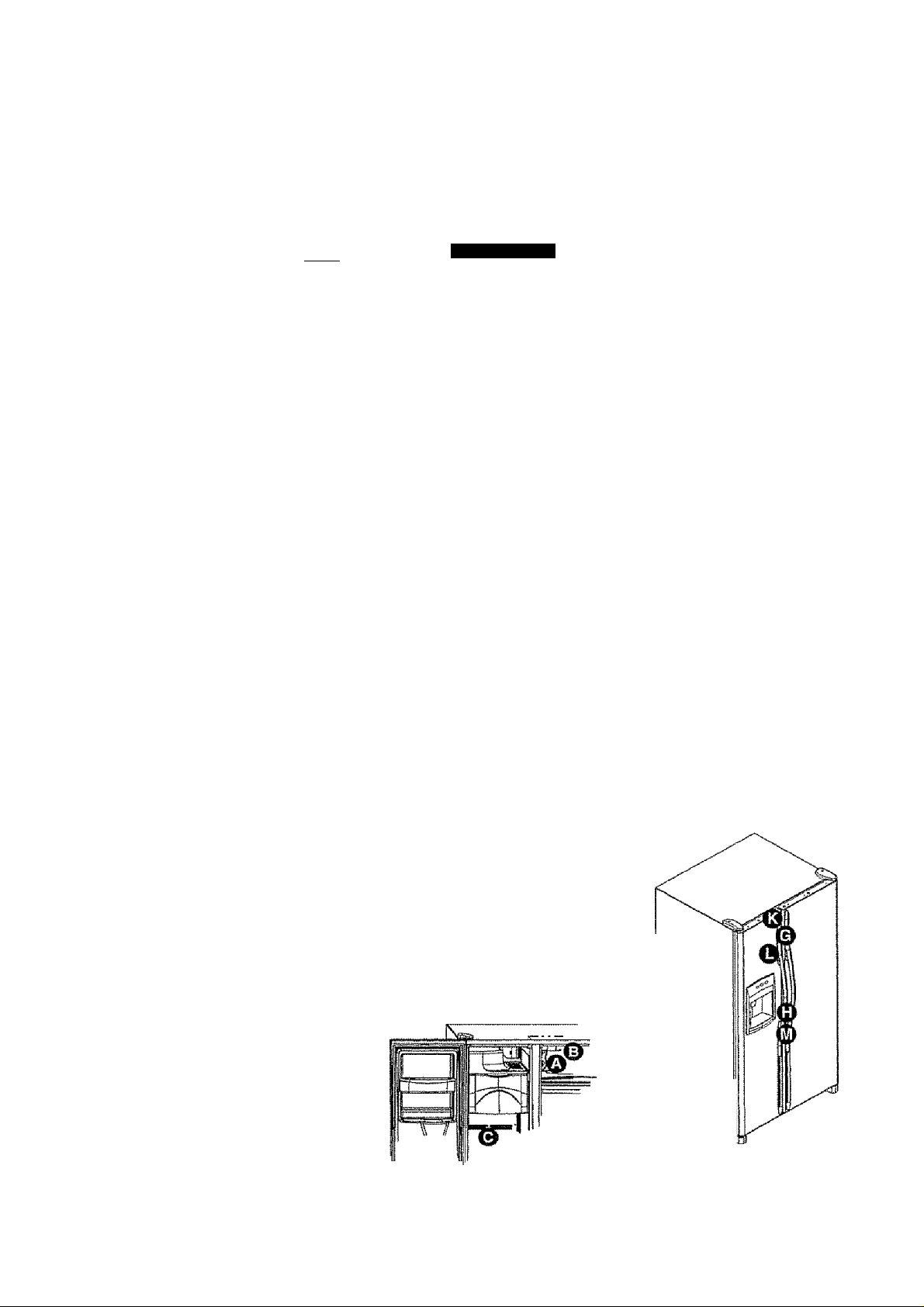

2, While pinching white collar (A) to the

blue connector (B), pull water line

from connector

iiyiPORTANT: When reconnecting water

line, cut off tubing at first available

scored line before inserting into

connector collar

3 Remove top hinge cover by removing

Phillips screw.

6,, Detach main wire connector harness

and red wire harness

>■ To detach main wire harness, use

a flat biade screwdriver or finger

nail to press junction point

between two connectors to

release.

To detach red wire harness, press

tab on underside of connector to

release.

7, Remove top hinges along with doors

8. Remove bottom hinges with a hex

head driver.

> DO NOT adjust refrigerator to be

any shorter than 68'/i” tall (minus

. hinge and cap). Doing so may;. ,

; damage underside components

8

4. Close doors,

5, Unscrew hex head screws from

top hinges

• DO NOT remove either green

ground wire or wire connecting

center screw.

RE P L A C I N G T H E D O O R S

> To replace the doors, follow the steps

in Removing the Doors and Hinges

in reverse order.

IMPORTANT: When reconnecting water

line, cut off tubing at first available

scored line before inserting into

connector collar.

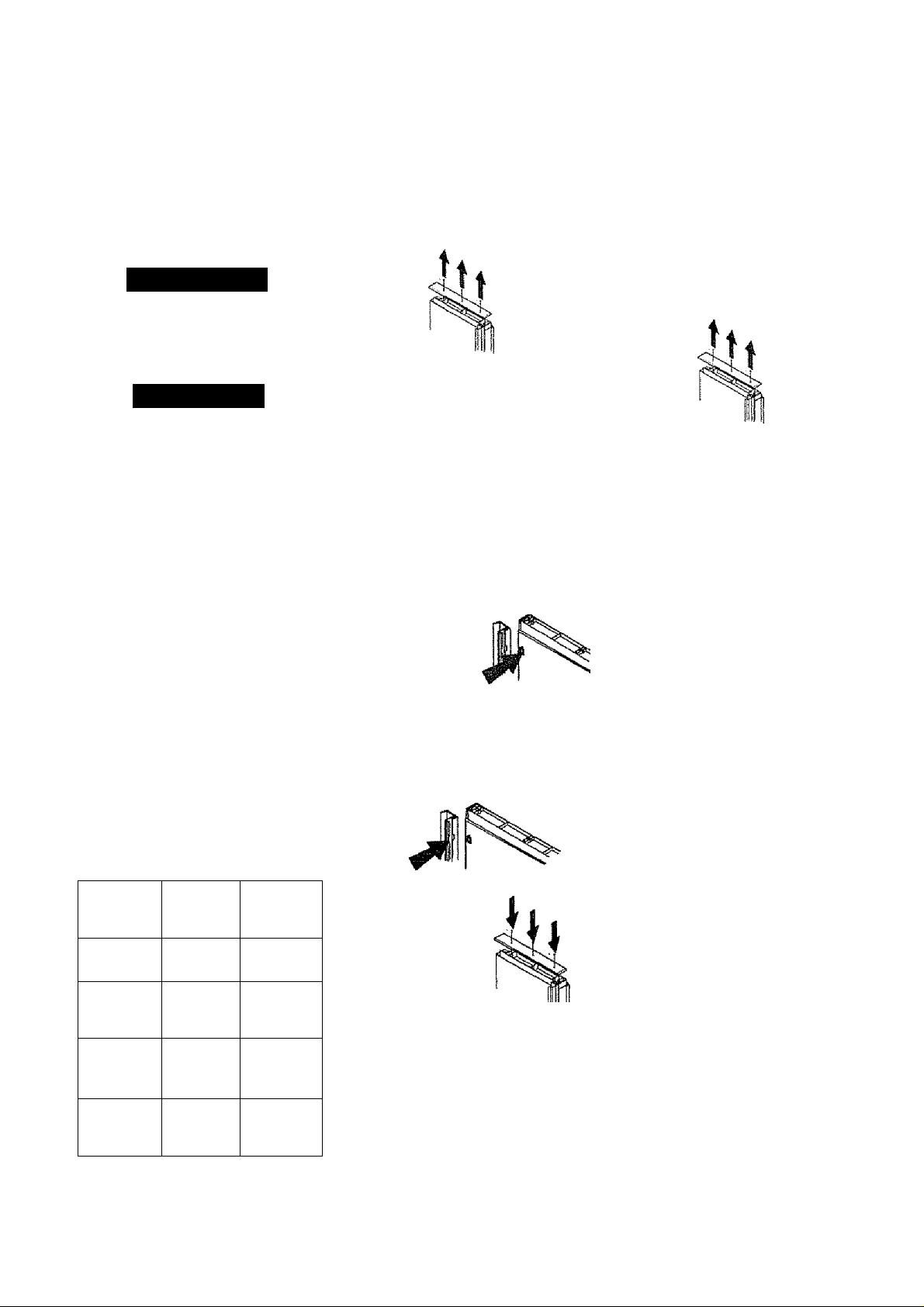

fl o w T O I N S T A L L A N D

MM O V E P A N E S

INSTALLING PANELS

1Remove top trim screws with a

Phillips screwdriver and remove top

trim.

REMOVING PANELS

1 Remove top trim screws with a

Phillips screwdriver and remove top

trim

Jk WARNING

To avoid possible injury and damage

to property, tape decorative panels

{some models) securely into place

when door handles are removed.

A CAUTION

To avoid personal injury or

property damagef observe the

foSlowing;

> Refrigerator panels should not

weigh more than 30 pounds |14

kiiograms) and freezer panels

should not weigh more than 15

pounds (7 kilograms),

> Protect soft vinyl or other flooring

with cardboard, rugs or other

protective material.

> Protect hands and arms by

wearing gloves,.

NOTE:

5» To protect door surfaces from being

scratched, cover back edges of

decorator panels by placing masking

tape along back edges

Save all screws and reuse in origina!

locations.

Slide handle upward until

loose. Remove handle

from door

Remove door

retainer dips with

a '/7' hex head

driver.

4. Slide bottom of panels into bottom

door trim until hinge side of decorator

pane! rests under hinge side trim.

IMPORTANT: Tape tops of panels to

door to prevent panels from failing

5. Reinstall door

retainer clips with

a H" hex head

driver,

6 Reinstall handle by inserting retaining

dips on door into notches on back of

handle.

> Slide handle down until it contacts

bottom trim.

ih

IMPORTANT: Tape tops of panels to

door to prevent panels from falling, m

Slide handle upward until

loose. Remove handle

from door

Remove door

retainer ciips with

a K" hex head

driver.

4. Remove tape to slide panels out of

door trim

5 Refer to steps 5, 6 and 7 of

Instating Panels to install handles

and trim,

1

^

O

(6 mm) Panel Dimensions

Extended

Door

Panel

Fresh food

door

Upper

dispensing

freezer door

Lower

dispensing

freezer door

Non

dispensing

freezer door

Panai

Height

66 74"

(169 5 cmj

18'/."

(46 cm)

32

(81 5 cm)

66 77

(169 5 cm)

Panel

Width

ta ’7«’’

(46,1 cm)

13 '7.7

(35 ,4 cm)

13 '7,."

(35 4 cm)

13 ’7."

(35 4 cm)

7. Remove tape from

tops of panels

before reinstalling

top door trim with

Phillips screws

removed in step 1

9

INS TAL LI NG YO UR R EFR IG ER ATO R,

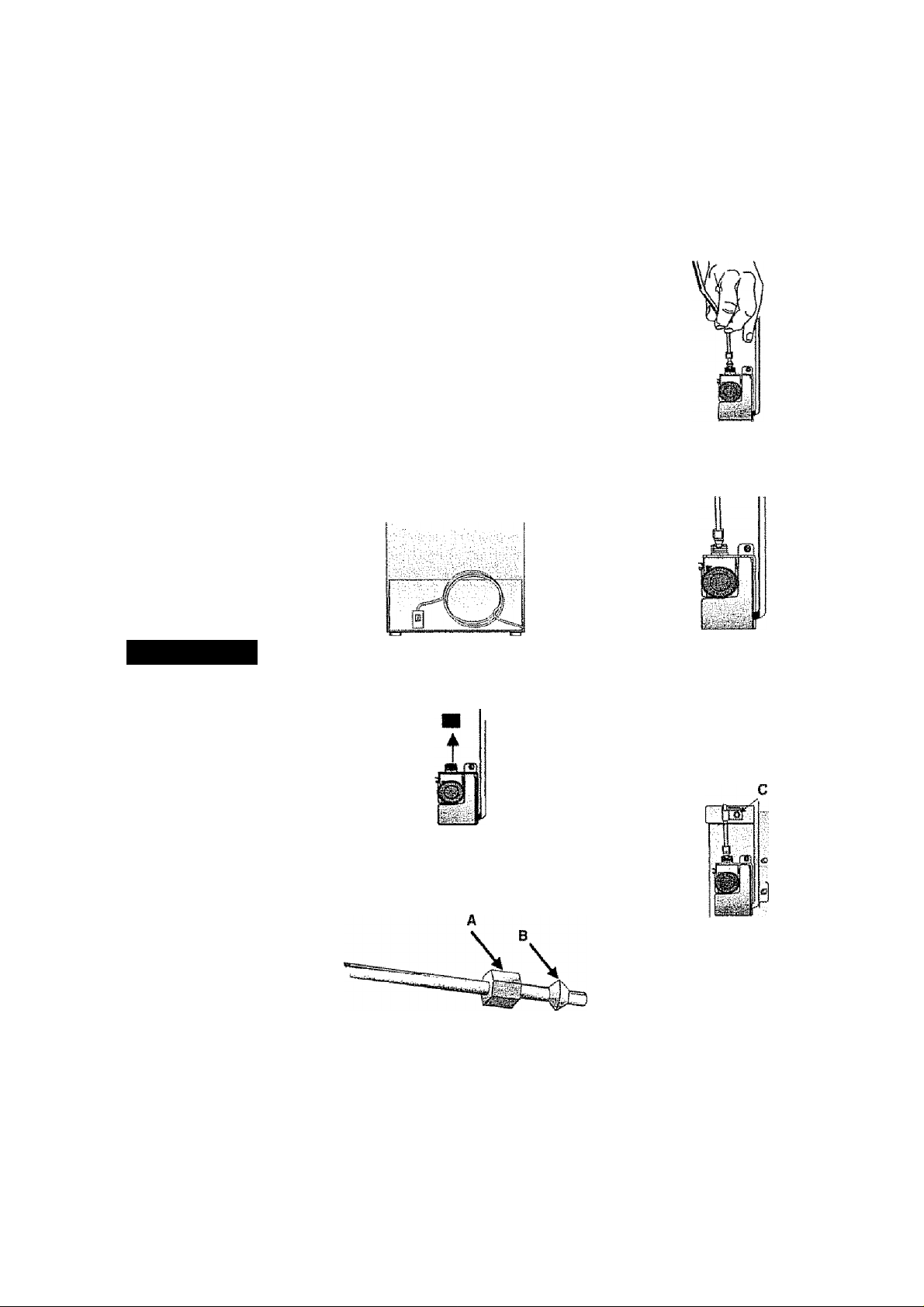

HO V f T O C O N N E C T T H E WA T E R S Ü P P I Y

To redyes the risk of injury or

death, follow baste precautions,

including the following:

Read all insiructions before

installing device.:

> DO NOT attempt installation if

instructions are net understood or

if they are beyond personal skill

level.' V f;', ; _ ■;

> Observe all local codes and \ .

■ ordinances. ^ -

>- DO NOT service device unless

specifically recommended in

owner’s manual or published

user-repair instructions,

> Disconnect power to refrigerator

prior to Installing device. ,

>■ Va outer diameter flexible copper

tubing

>■ Brass compression nut and sleeve for

ki" outer diameter copper tubing,

>■ Shut-off valve ^requires a ’/f hole to

be drilled into water supply before

valve attachment)

>• Adjustable wrench

>- '/4" hex nut driver

NOTE: Add 8' to tubing length needed to

reach water supply for creation of

service loop.,

1. Create service loop with tubing using

care to avoid kinks in tubing.

CONI

4, Place end of copper tubing into water

valve inlet port,. Shape tubing slightly -

DO NOT KfNK - so that tubing feeds

straight into inlet port.

5, Slide brass riut over sleeve and

screw nut into inlet port Tighten nut

with wrench .

A CAUTION

To avoid property damage of

possible injury, foliow basic

precautions, including the

following:

> Consult a plumber to connect

~ copper tubing to ^ household';. :.

plumbing to assure compliance ■

with local codes and ordinances;

> Confirm water pressure to water

valve Is between 20 and 100

pounds per square inch. If water

■, filter is installed, water pressure to

water valve must be á minimum of

35 pounds per square inch.

> DO NOT use a self'■piercing, or fm"

saddle valve! Both reduce water ;

flow, become clogged with time,

-- ' and may cause leaks if repair is ííttprnntpd .

> Tighten nuts by hand to prevent ;

cross threading. Finish tightening ;

nuts with pliers and wrenches; DO

V . NOT overtighten - : ■ ' - . ■

> Wait 24 hours before placing .

refrigerator into final position to

check and correct any water leaks

2 Remove plastic cap from water valve

Inlet port.

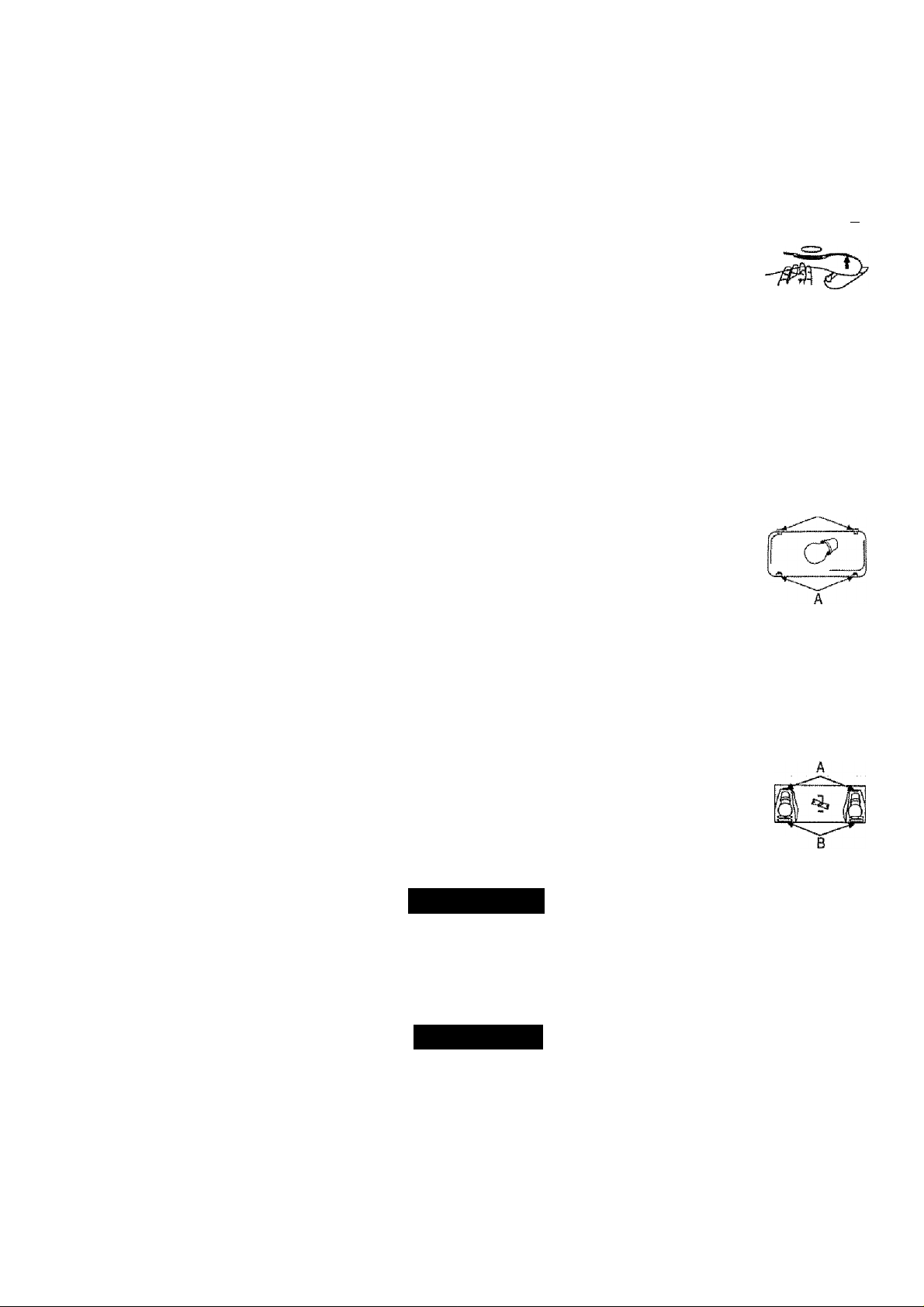

3 Place brass nut (A) and sleeve (B) on

copper tube end as illustrated

IMPORTANT: DO NOT overtighten,

Cross threading may occur.

6, Pull on tubing to confirm connection

is secure. Connect tubing to frame

with water tubing damp (C) and turn

on water supply Check for leaks and

correct, if present.

7 Monitor water connection for 24

hours Correct leaks, if necessary.

10

HO W T O L t V i l Y O U R

RE F R I G E R A T O R

II your refrigerator requires an ice mater

water supply connection, refer to How

to Connect the Water Supply

10) before leveling your refrigerator

A CAUTION

To protect personal property or

refrigerator from damage, observe

the following:

> Protect soft vinyl or other flooring

with cardboard, rugs, or other

protective material.

DO NOT use power tools when

performing leveling procedure.

(page

MATERIALS NEEDED

>■ %" hex head driver

>■ Level

1, Remove toe grille and bottom bracket

covers (see previous instructions),

2 Turn both front adjustment screws (A)

clockwise to raise and counter

clockwise to lower

3. Turn both rear adjustment screws

clockwise to raise and

counterclockwise to iower.

4, Using a level, make sure front of

refrigerator is '// (6 mm) or % bubble

higher than back of refrigerator. See

leveling step 3 for assistance.

B)

if required, correct rocking of

refrigerator by turning rear

adjustment screw clockwise to raise

rocking corner If doors are

uneven,..

Determine which door needs to be

raised,

>• Turn front roller adjustment screw

clockwise to raise front corner of

door.

>■ if the refrigerator has reached the

Umit of its adjuslment range, and

doors are still not level-lower

opposite door by turning roller

adjustment screw

counterclockwise,

>- Check with level to verify 'ff till to

the back for proper door closure

m

o

bÔ

X

> if refrigerator is aligned and stable,

replace toe grille and hinge

covers

11

This refrigerator is designed to operate at a househoid temperature of 55“ to 100° F (13° to 43“ C).

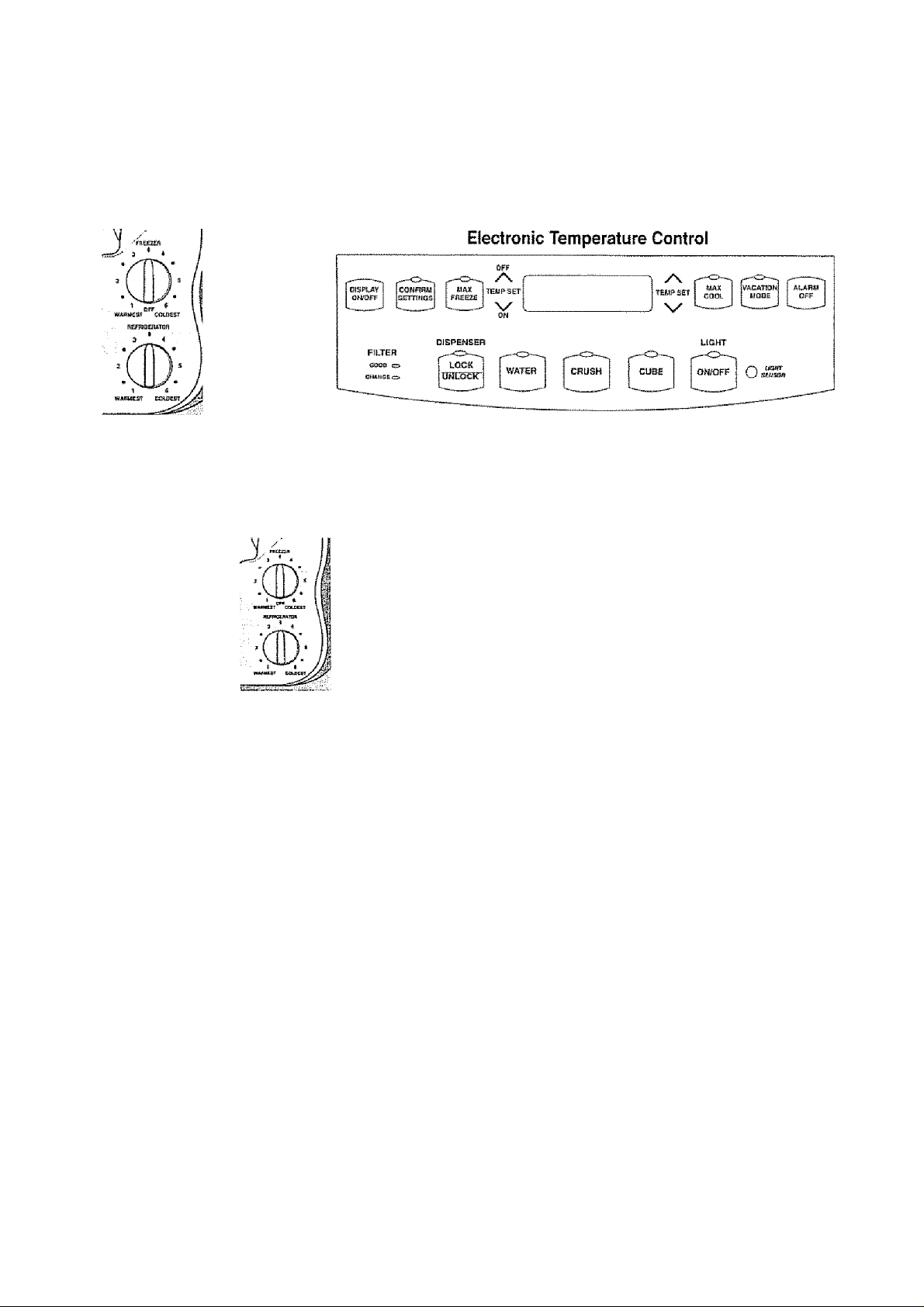

Dial

Temperature

Control

DIAL CONTROLS

1. Locate refrigerator

and freezer corrtrol

on upper-left wali of

fresh food section

2. The manufacturer's

rficommendalion

setting for both

compartmerits is

3 Let the refrigerator rurs at feast 8 to

12 hours before adding food

4. Allow 24 hours for temperature to

stabilize.

Z'L

ELECTRONIC CONTROLS

1, To set temperature of the freezer, use

the""“" buttons next to the

button.

>• Use thè ^ to raise thè

temperature of thè freezer section,

or thè tofowerii.

Press the

the settings

2. To set temperature of the fresh food

section, use the buttons next to

the L!ìtJ button.

button to confirm

Use the ^ button to raise the

temperature of the fresh food

section, or the button to tower it

Press the t

the settings.

3 Allow 24 hours for temperatures to

stabiiizs.

NOTE:

> The temperature display orr the LED

screen may fluctuate after being set

as the refrigerator cycles to maintain

the set temperature.

After 24 hours from adding food, you

may decide that one or both

compartments should be colder or

warmer. Follow the instructions below

for proper temperature adjustment

NOTE:

> Due to design of refrigerator, always

start temperature adjustments with

freezer section

>• DO NOT change either control more

than one number at a time,

> Allow 5-8 hours for temperatures to

stabilize

> Changing either control wll! have

some effect on the temperature of the

other compartment.

button to confirm

If freezer or refrigerator is too cold;

> Change control to next lowest number

If freezer or teftigerator is too warm:

> Change control to next highest

number

FRESH FOOD STORAGE

> Tire fresh food compartment of a

refrigerator should be kept between

34“ F and 40“ F with an optimum

temperature of 37“ F To check the

temperature, place an appliance

thermometer in a glass of water and

place in the center of the refrigerator.

Check after 24 hours If the

temperature is above 40“ F adjust the

control,

FROZEN FOOD STORAGE

> The freezer compartment of a

refrigerator should be kept at

approximately 0“ R, To check the

temperature, place an appliance

thermometer between the frozen

packages and check after 24 hours If

the temperature is above 0® F, adjust

the control

12

ÀBOiT ïûUB mm fira...

WA T i R f l U f R I M Ï Ï A I I A T I O N

AH D M M O V A L

ifìk WARNING

To avoid serioiis lliness or death, DO

NOT use refrigerator where water is

unsafe or of unknowri quality without

adequate disinfection before or after

use of filter.

A CAUTION

Bypass cartridge DOES NOT filter

water. Be sure to have

repiacement cartridge available

when filter change is required,

> If water filtration system has been

allowed to freeze, replace filter

cartridge. ;

> If system has not been used for

several months, and water has an

unpleasant taste or odor, flush

system by dispensing 2-3 glasses

of wafer. If linpieasant taste or

odor persists, change filter

cartridge.

INSTALLING

WATER FILTER

1 Remove blue bypass cap and retain

for possible later use

2 Remove sealing label from end of

filter and insert into filter head,

3, Rotate gently clockwise until filter

stops, and snap filter cover closed.

4- Reduce water spurts by flushing air

from system. Run water continuously

for 2 minutes through dispenser until

water runs steady,

> Additional flushing may be

required in some households

where water is of poor quality,

RERLACING

WATER FILTER

IS/IPORTANT: Air trapped in system

may cause water and cartridge to eject.

Use caution when removing.

1 Turn fiiter counterctockwise until it

releases from filter head

2 Drairi water from filter into sink, and

dispose in normal household

garbage

WHEN DO I CHANGE THE

WATER FILTER?

The dispenser features a water filter

change indicator For instructions on

how to operate and reset this feature,

refer to the Dispenser Features section

(page 18)

IMPORTANT: Condition of water and

amount used determines life span of

water filter cartridge If water use is

high, or if water is of poor qualify,

replacement may need to lake place

more often,

HOW DO f ORDER A

REPLACEMENT FILTER

CAnlFfiUutr

Kenmore'^ replacement water filter

cartridge model 9005 is available

through Sears dealers and servicers.

You may also order through Sears by

using the information on the back cover

¡‘^ jf^YING TO DISPENSE

WATER TO FLUSH THE

SYSTEM. WHERE’S THE

During initial use, allow about a 1 to 2

minute delay in water dispersal to allow

internal water tank to fill.

hjp’ ji

TO USE THE WATER

FILTRATION SYSTEM?

Dispenser feature may be used without

water filter cartridge. It you choose this

option, replace filter with blue bypass

cap.

Z

O

(Â

X

3- Wipe up excess water in filter cover

and continue with Installing Water

Filter, steps 2 and 3,,

ABNI fOUB №nn File..., am

MBKHIU

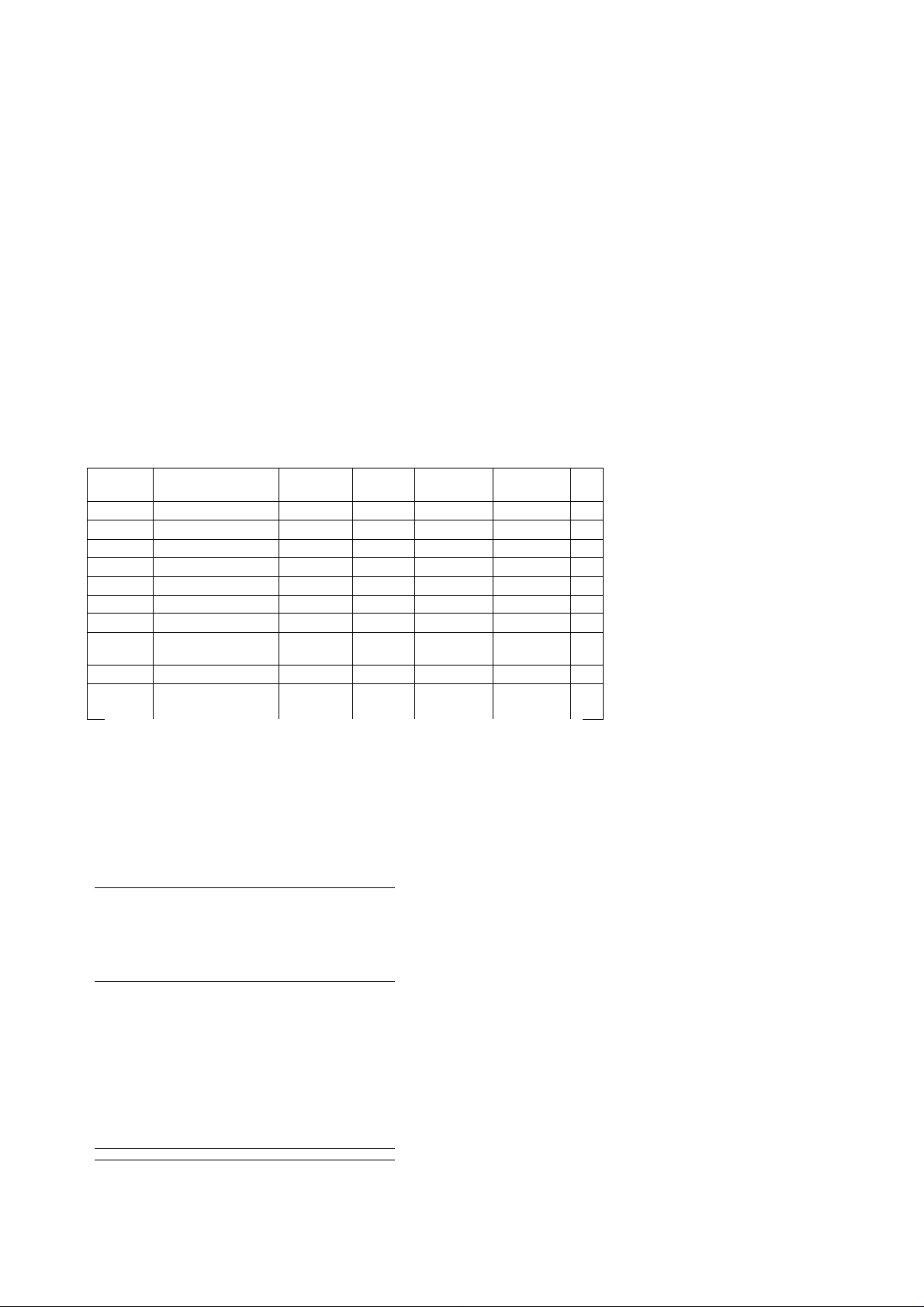

SYSTEM SPECIFICATION AND PERFORMANCE DATA

SHEET REFRIGERATOR WATER FILTER CARTRIDGE

MODEL 900S

Specifications

Service Row Rate (maximum)

Rated Service Life Model 9005 (maximum)

Maximum Operating Temperature ...................

Minimum Operating Temperature

Minimum Pressure Requirement

Maximum Operating Pressure

........................

.............................0,75 GPM (2 63 L/min)

......

..........................

...........................

500 galbns/1892 liters

100® F/38® C

..... .... ................................ ,„33® F/1 ® C

.........................................

........................

.............................120 psi/827 kPa

35 psi/138 kPa

PERFORMANCE DATA

Substance

Lead

L0sd

Cyst

Concentration

0.15nig/L+/-10%

0.1S rtig/L+/-10%

MiramUm 50,000/L Icount/ffli

Turbidity 11+A1 NTU

Influent Chaltenge

Lindane

Attazitte

0,002 mg/L+M0%

0.009 mg/L +/-10%

Chlorine 2.Oni0/L+/-1Q%

Particulate*“

at least 10,000

pariicles/mL

2,4-D

Q.21Q mg/L+/-10%

Asbestos 10' to IC ftersl: fibsts greater

te 10 mioomatere in tsegift

Tested using a flow rats o! 0 75 QPM (2 S3 L/min) and a maxmum pressure of 120 psl (327 kPa)

under standard laboratory condilians, however, actual performance may vary Health Claim

PartonrianGe tested and certified by NSF International

Particte size range ciassiffeation of test. Particles used were Q: 5 -1 miorons. ‘ ‘

Sut£ Qf CrtlaJamu

Water Fraalment Device

Certificate Number

QI"i4Sâ

№iÉ fuuct.

üns-tîiiJWsj: iitmh W, 5003

ïiïiasiiitôlafüJjeEcaiilsit

wFis-wisna

WTîiwriJæ . , ■

Wr»StWjjlR ; ■ .

witiiafcjvijcu ■ ■ ■

nwrîft-wüat - ' '

СРМГЗОТАХ» ..

TM »№£«»( bc*<ltu4e&<ei:Sttecr>q(iU«mBi«

JlfâZtii najSâirtl ЕГДЙ tili btiWbn1aatil<anunM№iÈti ,

Стш

A-tiSUUI« '

fliadartratel thaiwiu

wfM' '■

; . -ts-яхп- .

■ '.-''М-дай- ', ' " ■

OWTS3 ' - ■ . .

^ , . AiSHSHi#. _ ■

' 1 •rJ. .

Efltoent

Average

0.001 mg/L

Average %

Reduction

93.33%

0.002 ragfl. 98.66%

99.99%

0,12 NTU

98.98%

0,00005 mg/L 97.62%

0.0002 mg/L 97.93%

o.osmg/L

95.26%

900 counS/mL Э9 68%

45.46 ug/L 84.43%

0,16 MFL/mL

■ ■■ ■

SMiJjS£»tir

503

K>3tâi

JOQiSt

Ы Sfdkn 11

99,96%

Maximum

EHIuent

0.001 fttg/L

0.003 mg/L

3 caunt/mL

Min. Required

Reduction

0.010 mg/L

0.010 mg/L a.s

> 99.95%

0.18 NTU 0.5 NTU

Q.OODQ5 mg/L

Q.000S mg/L

0.00002 mg/L NA

0.003 mg/L NA

0.17 mg/L a7S%

2400 counl/fflL

й35% NA

100 ug/L 0.0017 mg/L NA

016 MFL/mL 99%

Tested and certilisd by NSF tfflemtitanal aaainst AMSr/NSF Standards A2 end S3 in

ntûdaîs WFSO.KN)300 and WFSO-KWiSdO lor the redudian at:

Standant No 42: Aasihaitc Eltects

Teste and Odor Reductian

Chiarifta Reduction

Mschanlrat Fftraiion Unit

Particuiate Reduotion Class 1

intet

pH

3.5

NA

NA

NA

NA

GENERAL USE CONDITIONS

Read this Perfotmancs Data Sheet and

compare the capabilities of this

refrigerator with your actual water

treatment needs

DO NOT use this product where water

is microbioiogicaHy unsafe or of

unknown quality without adequate

disinfection installed before or after

filtration system. Systems certified

for cyst reduction may be used on

disinfected water that may contain

filterable cysts.

Use only with cold water supply.

Check tor compliance with the state

and local laws and regulations.

The refraotabie wafer filtration system

uses a 9005 replacement cartridge (see

Sears contact information at the back of

yout Use and Care Guide to order)

Timely replacement of filter cartridge is

essential for performance satisfaction

from this fiitration system. Please refer

to the applicable section in this Use and

Care Guide for general operation,

maintenance requirements and

troubleshooting.

This system has been tested according

to ANSI/NSF 42 and 53 for reduction of

the substances listed below. The

concentration of the indicated

substances in water entering the system

was reduced to a concentration less than

or equal to the permissible limit for water

leaving the system, as specified in

ANSI/NSF 42 and 53.

Standard Ka. S3: Health Stfscts

Ghemteal Hadtiaian Unit

Lead, AlrazifiB, Lindane and 2,4-0 Reduction

Machanicat Filtraliori Unit

Cyst, Turbidity and Asbestos Reduction

Uttcd Itawi Q.TS

PentaPure

ШЕИГТХЙЛТ ( 1}

1000 Apollo Road

Eagan, Minnesota U.S.A

EPA EST #35917-MN-1

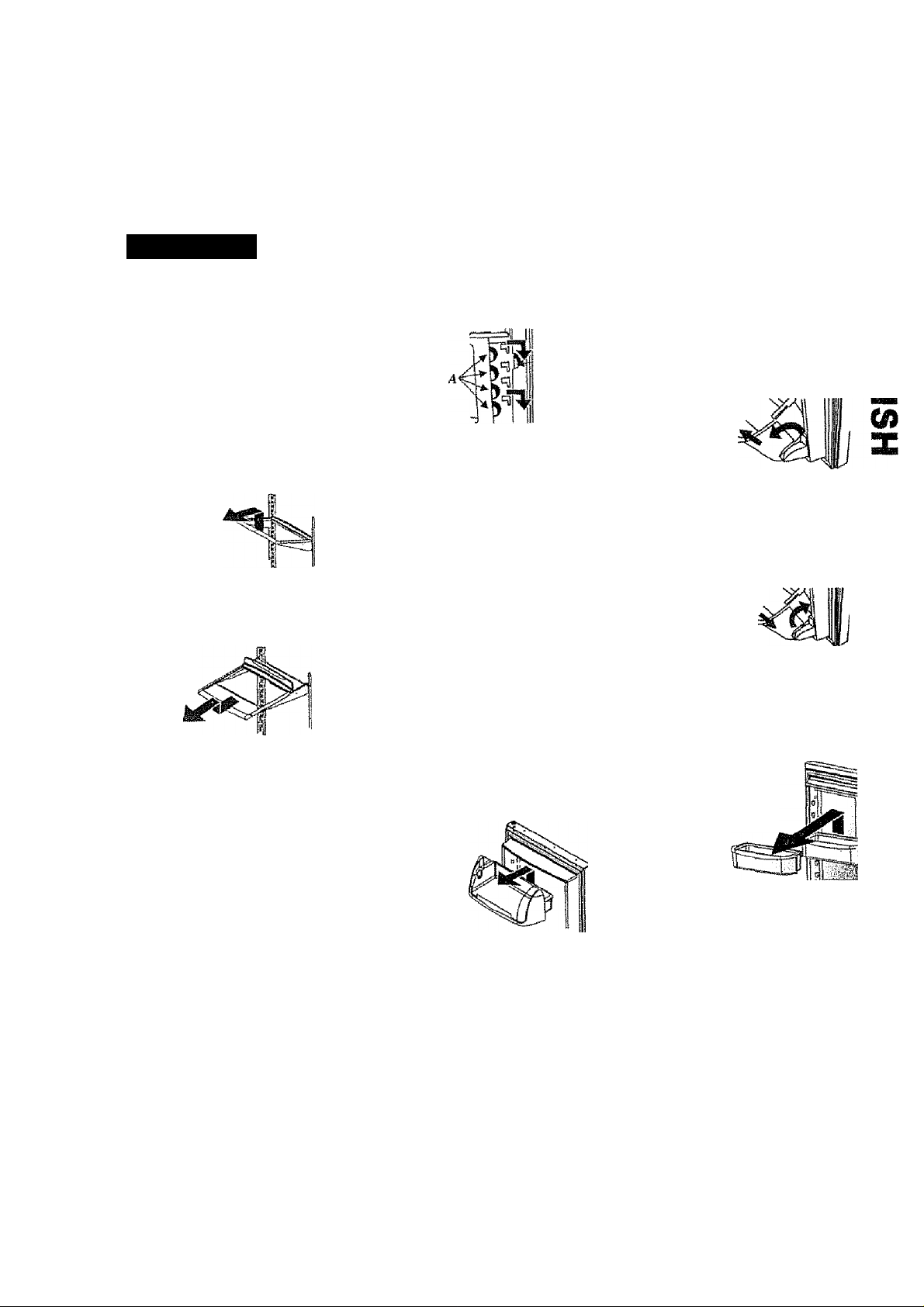

м m mm

l«W ЯШ

^CAUTION

To avoid personal injury or property

damage, observe the iollowing:

3> Confirm shelf is secure before

placing items on shelf.

> Handle tempered glass shelves

carefully. Shelves may break

suddenly it nicked, scratched, or

exposed to sudden temperature

change>

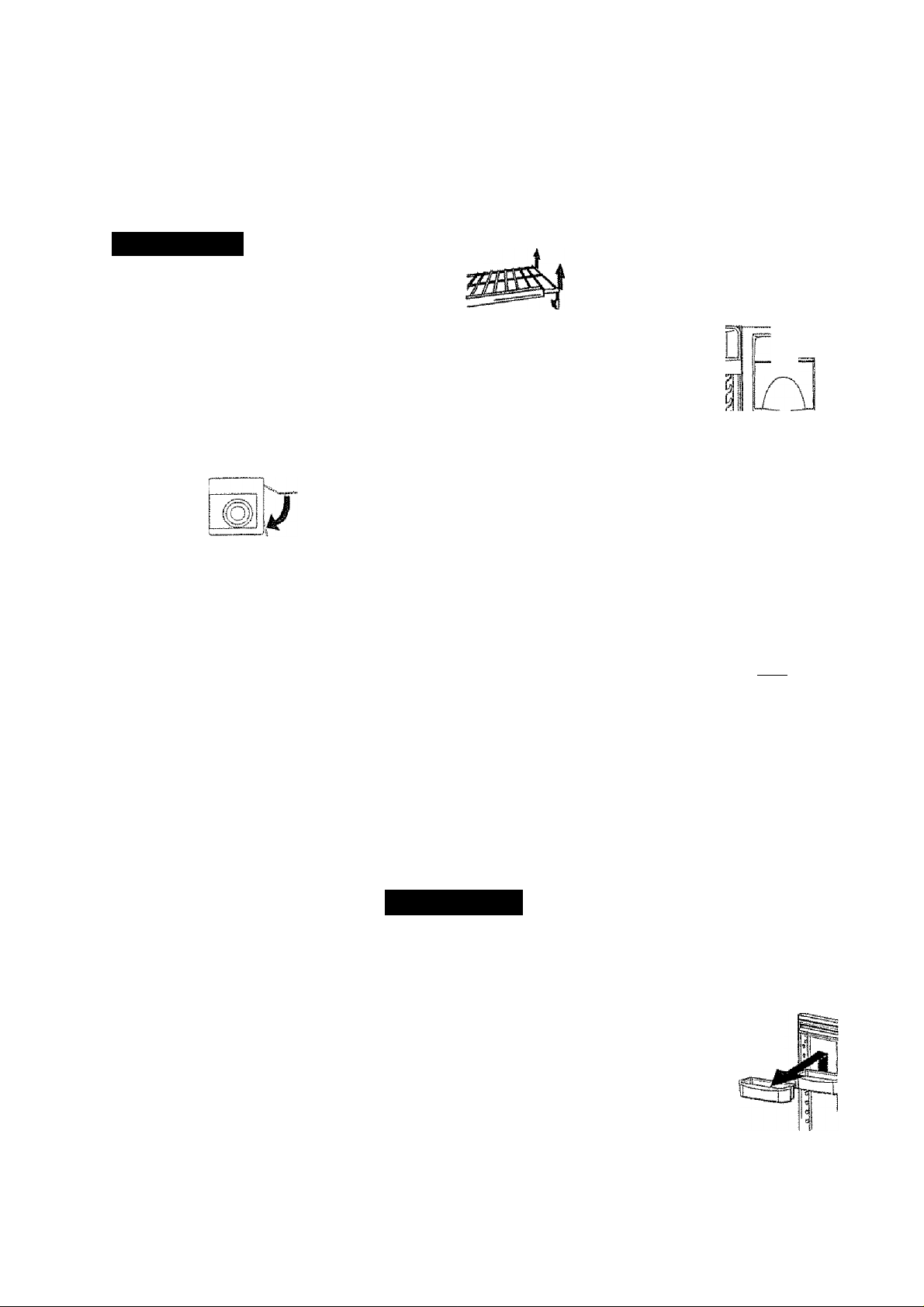

SPILLPROOF SHELVES

Splllproof Shelves hold

simple spills for easier

cleaning

> To remove shelves, lift

up and out

> To install shelves, reverse above

procedure.

Spillproof Slide-out

Shelves feature the

convenience of

easy cleaning

with a pullout

design to reach

items in the back. For ease of cleaning,

glass shelf may be removed by pulling

to full extension and lifting out of frame

DO O R S I O R A f i l

BEVERAGE

COMPARTMENT

(SOME MODELS)

The temperature-controlled beverage

compartment keeps beverages and

other items colder than the rest of the

fresh food section. Air inlet allows air

from the freezer section to pass to the

beverage compartment

Controls

The control is located on the left wall of

the fresh food section. Control adjusts

amount of air circulating in the beverage

compartment. Turn control clockwise for

colder temperature

To remove and install the beverage

compartment:

> if located directly above the beverage

compartment, dairy center or door

bucket may need to be removed.

Refer to appropriate Instructions and

remove item.

Slide the

beverage

compartment

assembly up

and pull

straight out,

> To install, align one of the cold air

intake holes (A) with one of the two

air Wets (B) in door liner Push

assembly down onto door liner

retainer until it stops,

IMPORTANT: The beverage

compartment will not operate properly if

air intake holes are not aligned with air

inlet in door liner.

DAIRY CENTER

The Dairy Center provides convenient

storage for items such as butter, yogurt,

cheese, etc

This compartment is an adjustable

feature located in the door It can be

moved to several different locations to

accommodate storage needs.

To remove and install bln:

To remove,

slide dairy

center up and

pull out.

> To install, slide

assembly in

above desired door liner retainer and

push down until it stops

To remove and install dairy door;

> To remove, press in sides of dairy

door and pull out

> To install, slide sides of dairy door

inside dairy center until hinge points

snap into place.,

TILT-OUT DOOR BUCKETS

(SOME MODELS)

The TilLOut Bucket assembly consists

of a bucket and frame, providing

adjustable, convenient storage for food

items in door. The bucket assembly tilts

forward for easy access of items, and

lifts out for ease in cleaning and

adjusting.

To remove and install bucket:

>■ To remove

bucket, tip bucket

forward and pull

straight out to

remove

> To install bucket, slide bucket into

bucket frame and push bucket

upright.

To adjust bucket frame:

Remove bucket per

above instructions,

> Lift frame off door

support and place in

desired door location

DOOR BUCKETS

Door Buckets adjust to meet individual

storage needs.

> To remove, slide bucket

up and pull straight out,

>■ To install,

reverse above

procedure

Z

О

15

ШМ А Т Е - C O N T R O L L t D

HUMIDITY-CONTROLLED

The Humidity-Controlted Crisper

keeps produce fresh longer by providing

an environment with ad|ustable humidity.

Controis

The humidity-controlled crisper controls

regulate the amount of humidity in the

crisper drawer. Use the /ow setting for

non-leafy produce Use the high setting

for leafy produce.

To remove and instai! drawer:

> To remove, pull drawer out to full

extension. Tilt up front of drawer and

pull straight out,

> To instali, guide drawer into frame

and push back until drawer is flush

with rear wall.

To remove and install shelf:

>■ To remove, lift sheif

from wall supports,

>• To install, lower

shelf onto wall

supports and push

in until shelf is flush

with rear wall

PRODUCE STORAGE TIPS

Please observe the following rules when

storing produce in humidity-controlled

crisper drawers:

>■ DO NOT wash produce before

placing in crispers. Any additional

moisture added to the drawers may

cause produce to prematurely spoil,

> DO NOT line crispers with paper

towels,. Towels will retain moislute

> Follow control instructions carefully.

Not setting controis correctly may

damage produce

\

See below for correct humidity drawer

control settings:

tow • cauliflower

• corn

■ zucchini

• cucumbers

HIGH • lettuce

' spinach

• celery

• fresh sprouts

• apples

• oranges

• grapes

• asparagus

• broccoli

• fresh herbs

TEMPERATURECONTROLLED DRAWER

The Temperature-Coniroiled Drawer

provides a drawer with a variable

temperature control that keeps the

compartment colder than refrigerator

temperature. This drawer can be used

for deli storage or additional produce

storage,

NOTE: Cold air directed to the

temperature-controlled meat drawer car:

lower refrigerator temperature.

Refrigerator control may need to be

adjusted.

Controls

Located on the wail to the left of the

drawer, the climate controls regulate ttie

ait temperature in the temperaturecontrolled drawer. Set control level to

соШ to provide normarrefrigerator

temperature for non-leafy produce. Use

the coldest setting for meats or other

deli items

To remove and instaf! drawer:

>- To remove, pull

drawer out to full

extension, Tilt up

front of drawer and

pul! straight out

> To install, guide

drawer into frame

and push back until drawer is flush

with rear wall,

WHAT SETTINGS SHOULD

I USE FOR ITEMS IN THE

TEMPERATURECONTROLLED DRAWER?

You should not store lettuce or other

leafy produce in this drawer.

COLD

■ cauliflower

• cucumbers

• zucchini

dpjJicjb

" corn

• oranges

• grapes

COLDEST

’ steaks

• hard cheeses

■ cold cuts

• bacon

• hot dogs

ST O R A G E D m S

SNACK DRAWER

{SOME MODELS)

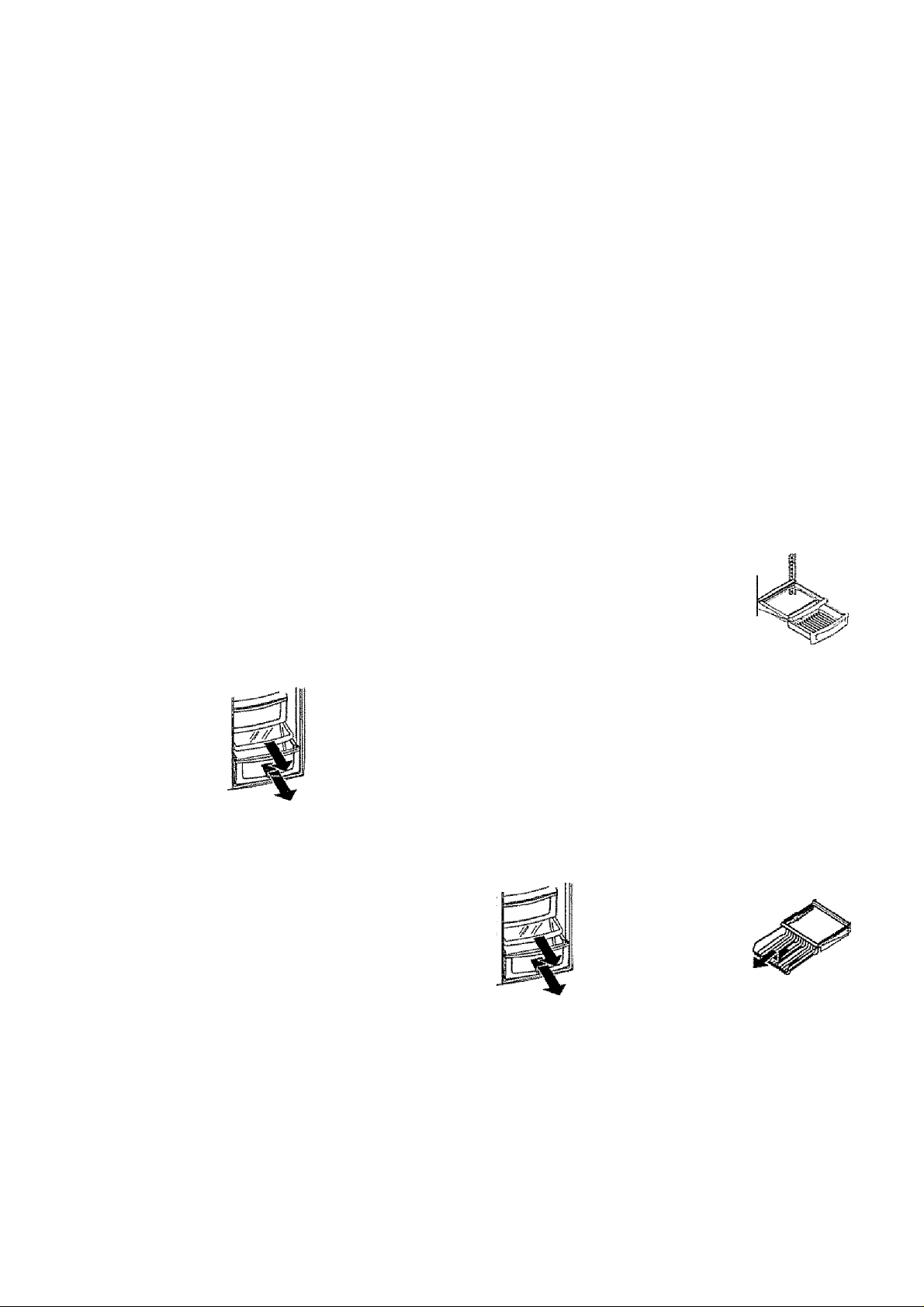

The Snack Drawer

car! be used for

storage of

miscellaneous items or

extra produce.

Controls {some models)

The conirols regulate the amount of

humidity in the drawer. Use the low

setting for non-leafy produce. Use the

high setting for leafy produce

To remove and instali drawer:

>• To remove, puli drawer out to full

extension. Tilt up front of drawer and

pull straight out.

> To instali, guide drawer Into frame

and push back until drawer is flush

with rear wall.

CAN RACK

{SOME MODELS)

The Can Rack slides

out from underneatfi

the spillproof

stationary sheif. The can rack holds up

to twelve 12-ounce beverage cans.

To remove and install can rack:

>• To remove, empty contents of can

rack, Pull carr rack forward to full

extension and lift front to release from

shelf rail. Pull str aight out to remove.

>- To install, reverse above procedure

16

m№ HiJUREÌ

ilUOMKKIMAKI

A CAUTION

•To avoid properly damage, observe ■;

theio!iowmgr:V ■-

> PO NOT force ice maker arm

;: down or up. ^ ' '

> DO NOT place or store anything in

ice storage bin. : .

This ice maker creates the ice used in

the dispensing system.

Using Ice Maker for the First Time

> Confirm ice bin is in

place and ice maker

arm is down.

> After freezer section reaches

between 0“ to 2“F (-18= to -17= C).

ice maker fills with water and begins

operating.

> Ailow approximately 24 hours after

installation to receive first harvest of

ice.

>■ Discard ice created within first 12

hours of operation to verify system is

hushed of impurities

Operating Instructions

>- Confirm ice bin is in place and ice

maker arm is down.

> After freezer section reaches 0” to

a=F (-18® to -I?" C), ice maker fiiis

with water arid begins operating. You

wiil have a compists harvest of ice

approximately every 3 hours

Stop ice production

by raising ice maker

arm untii click Is

heard.

> Ice maker will remain in the off

position until arm is pushed down.

IMPORTANT; Ice Cream Shelf should

not be installed if ice maker arm is in

“off position

>

INKRIOR mm

wmmrLwmKmmmmmw^ r*

freezer shelf

To remove and install

cilp*mounted

shelves:

>- To remove, pui! sheif from wall

mounting dips and pull ieft side of

sheif out of wail mounting Notes.

> To instali, place shelf in mounting hole

arrd attach to wall mounting clips.

To remove and install rail-mounted

shelves:

> To remove, snap

right side of shelf

from cabinet railing

and remove from wal! mounting clips,

> To install, replace shelf in wali

mounting clips. Be sure back edge of

shelf is flush with back of cabinet and

snap shelf into cabinet railing.

tCE CREAM SHELF

Ice Cream Shelf

provides a space for

items to be chilled or

frozen quickly

> To remove, lift ice cream sheif from

ice bin rails and pull straight out,

To install, fit shelf over top of ice

maker and lower onto ice bucket rails.

IMPORTANT: Ice Cream Shelf should

not be installed if ice maker arm is in

“off position.

A WARNING

To avoid possible injury, including

Clc^c|l.i Lie# I iLfli ^rdL«vj 11^ IE F iL#w

cream shelf. Glass objects may

shatter or explode if exposed to

extreme cold. '

ST O R A G E D R A ^ R S

FREEZER BASKET

To remove and instati

basket:

>■ To remove, lift

front of basket

strtH niiii niit tn ite full extension

Lift lip front of basket and remove

To instali, slide basket into rails at

bottom of freezer section., Lit up front

of basket, and slide to the back of

refrigerator

ICE STORAGE BIN

The tee Storage

Bin is located below

the automatic

dispensing ice

maker.

To remove and Instatl Ice storage bin:

> To remove bin. remove ice cream

shell

> Raise Ice maker arm to deactivate ice

maker Lift front of bin and pull out to

its full extension, Lift up front of bin

and remove

> To instali, slide bin into rails below ice

maker until bin locks Into place. Drop

ice maker arm to activate ice maker,

diFU itípidLt; tüti Clcditl bncMi<

IMPORTANT; Ice bin must be iocked in

nmnpf filricp fr>r r—

proper ice |(SI

dispensing H [Qli ■*

freezer door

does not dose, bin is not in proper

location. Turn auger driver

counterclockwise (as shown) to properly

align ice bin with back of refrigerator.

Ice Storage

/ Bin

........

DO O R S T O R A G E

ADJUSTABLE DOOR

BUCKETS

Door Buckets adjust to meet individual

storage needs.

To remove buckets:

> Lift the door bucket up until

it dears the retainers on the

door liner, then puli the

door bucket

straight out

To reinstall buckets:

> Slide bucket in above desired door

liner retainer and push down until

bucket stops |J[

m

Q

CÔ

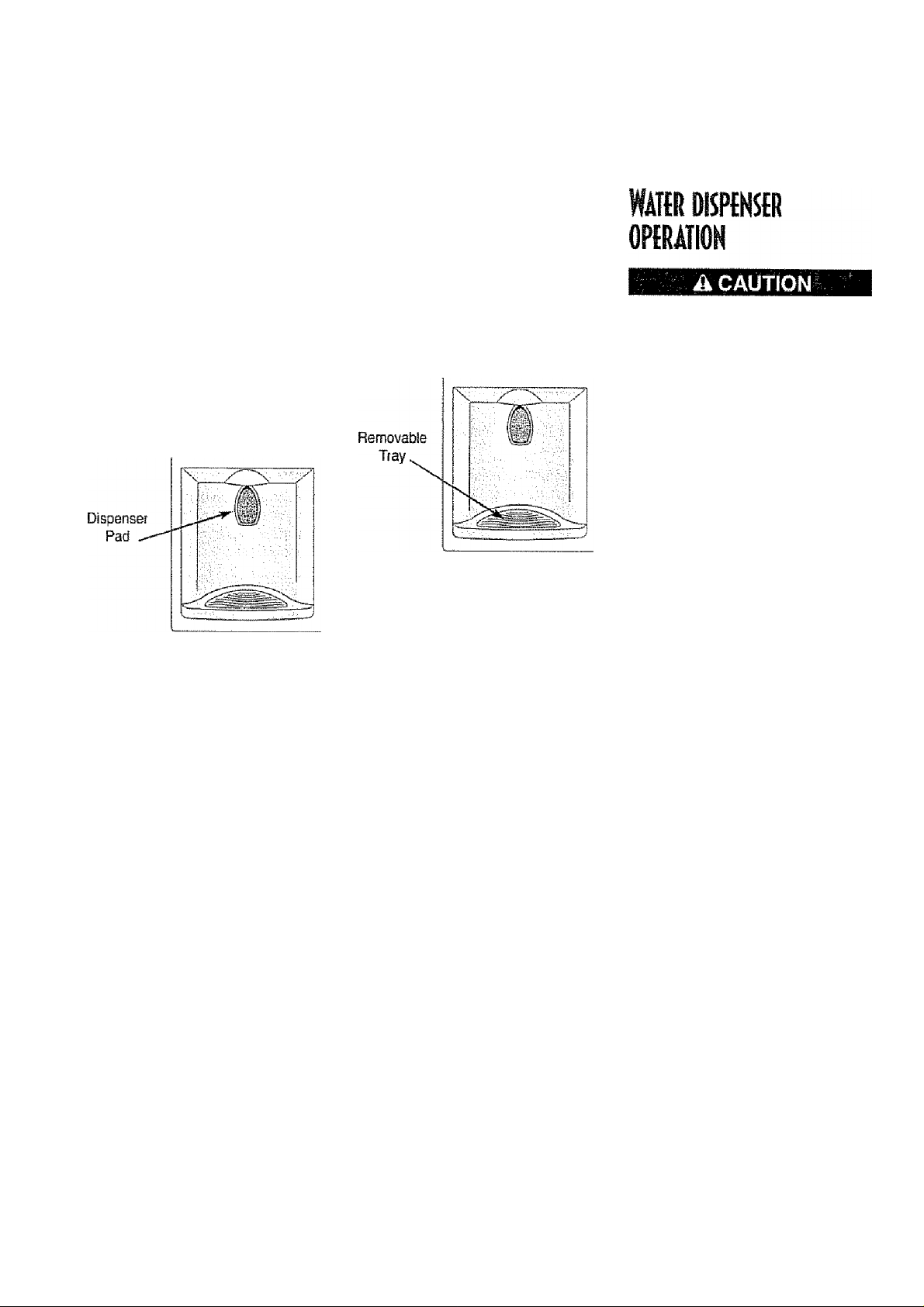

A light activates within the dispenser

area at full power when dispensing ice

or water.

The dispenser pad is located on the

back wali of the dispensing area. When

the dispenser pad is pressed, the

selection chosen on the dispenser

control panel will dispense

The removable tray at the bottom of the

dispenser area is designed to collect

smati spills and may be easily removed

for cleaning and emptying purposes

IMPORTANT: Removable tray does not

drain. Continuous water running into tray

will cause tray to overflow

To avoid personal in|uryor

property damage, observe the

following: :

>■ DO NOT piit fingers, hands or any

foreign object info dispenser opening.

> DO NOT use sharp objects to

break ice. : ,

s- DO NOT dispense ice directly into

thin glass, fine china or delicate

crystal. -- '

NOTE:

> During initial use of water dispenser,

there wili be a 1- to 2-minute delay

while water tank fills before water

dispenses. Discard first 10-14

containers of water after initially

connecting refrigerator to household

water supply and after extended

periods of nonuse.

To use dispenser pad:

>- Choose water selection from

dispenser control panel,

>■ Press sturdy, wide-mouthed container

against dispenser pad. When

dispensing crushed ice, hold

container as close to chute as

possible to reduce spraying.

Release pressure on dispenser pad

to stop water from dispensing. A

small amount of water may continue

to dispense and collect in dispenser

tray. Large spills should be wiped dry

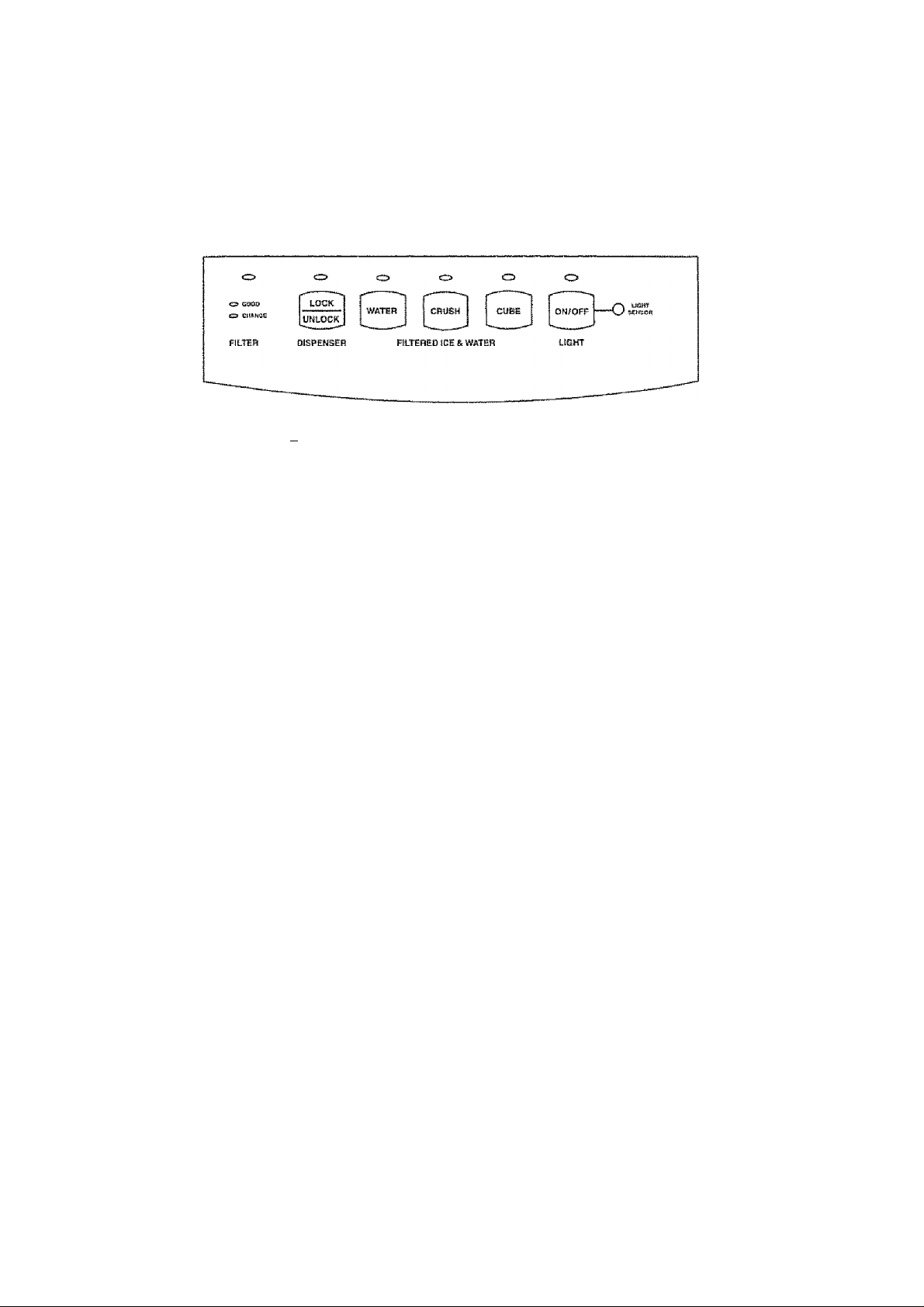

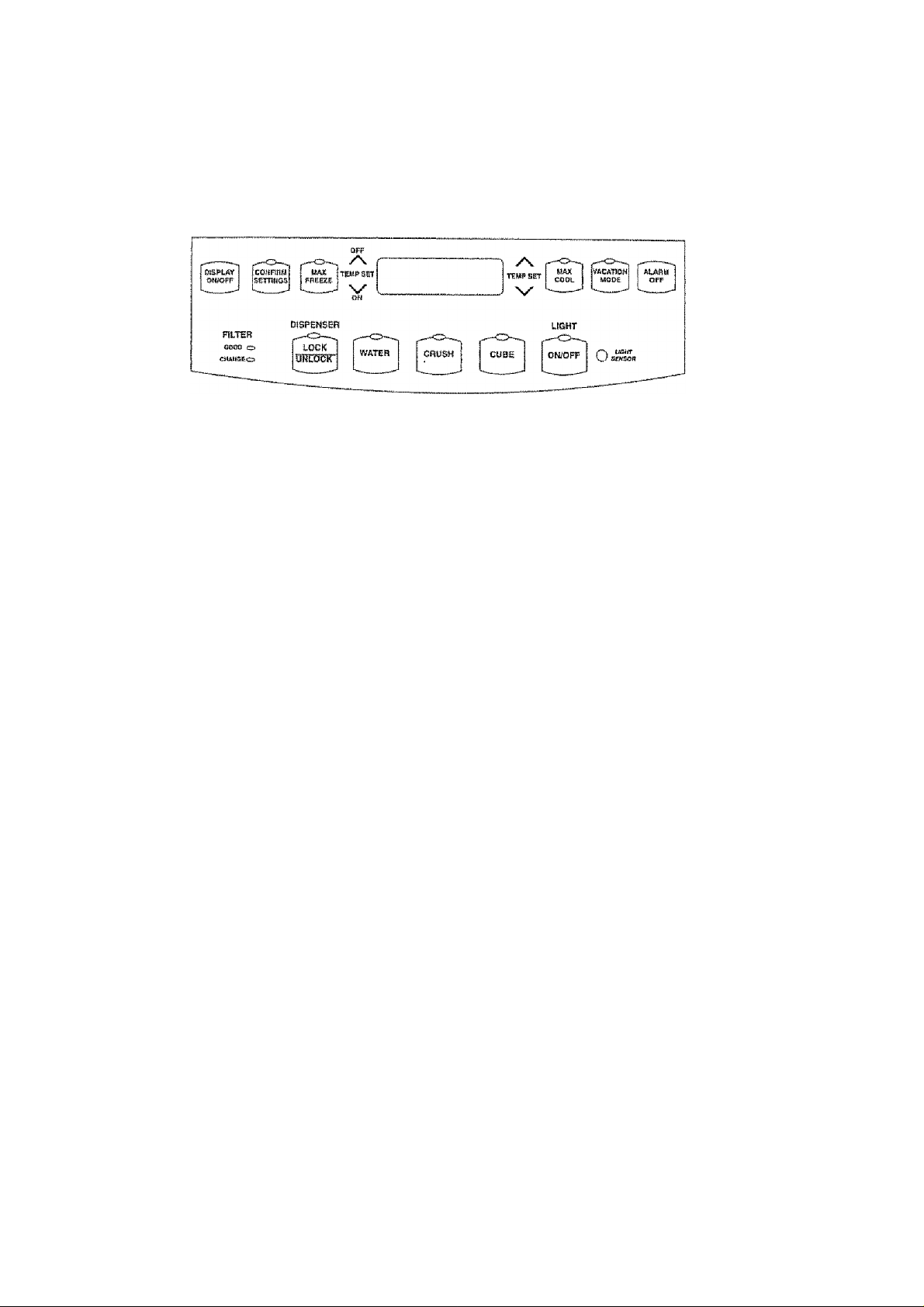

fl V t - B Ü T T O M C O N T R O l f E Á U J i S

O

dispenser

r ~i r~~i

WATírt CítteSií

I—II II—.

OPERATION

To dispense:

> Setect CUBE, CRUSH or WATER

mode by pushing button on dispenser

control panel. A green indicator light

above button shows mode selection

>* Press container against dispenser

pad Sefectfon mode may not be

changed while ice dispenser is in

operation.

NOTE: if water dispenser is

continuously active for more than 5

minutes, an automatic lock out sensor

wiil shut down power to dispenser area

For instructions on how to unlock your

dispenser, see the section entitied

Dispenser lock beiow

DISPENSER LOCK g|

This feature prevents ice or

water from being dispensed

To lock and unlock dispenser:

> To lock dispenser, press artd hold

LOCK/UNIOCK button for 3

seconds, A green indicator light

above button confirms dispenser is

locked.

> To unlock dispenser, hold

LOCKAJNLOCK button for 3

seconds Green Indicator light above

button will go out

.........

I

FILTER STATUS INDICATOR LIGHT

The filter status indicator light

serves as a reminder to

replace the water filter, A green light

indicates that the filter is in good

condition A red light indicates the filter

should be changed Once light turns red,

it will remain red until function is reset.

To reset indicator:

> Press and hold both LOCKAJNLOCK

and WATER buttons simuitaneously

for 4 seconds. The green filter status

indicator light wilt flash 3 times when

the function has successfuliy reset

AUTO LIGHT

The auto light function

offers the ability to activate the

dispenser light at haif-power when the

LIGHT SENSOR detects that the tight

levels in room are low

To activate and deactivate auto light:

>- To activate, press ON/OFF button

located on control panel, A green

indicator light above button displays

to show that sensor is active.

>• To deactivate, press ON/OFF button

Green Indicator light witi go out

NOTE: Dispenser light wiil operate

whether or not auto light is selected

RLTEfl

SABBATH

MODE

This mode is intended to deactivate

power to the LED and dispenser tights,

whiie aliowing the controls to remain

operationalTo activate and deactivate Sabbath

Mode:

> To activate, press and hold both

LOCKAJNLOCK and ON/OFF

buttoris simultaneously for 3 to 4

seconds. After 3 to 4 seconds, the

LED and dispenser lights wiil turn off.

Oispenser light will not activate

during dispensing while in this

mode.

I

>• To deactivate, press and hold both

LOCKAJNLOCK and ON/OFF

buttons simultaneously lor 3 to 4

seconds. After 3 to 4 seconds, the

LED and dispenser lights wilt

activate

NOTE: in the event that power is

interrupted while the Sabbath Mode is

active, the control will remain in Sabbath

Mode when power returns

j-y

X

19

{L K I R O N i C C O N T R O L

MM

DISPENSER i ,

{ annuii ( cus£ I

OPERATION J ^ ^

To dispense water:

>■ Select the WATER button. ^

>- Press containef against dispenser

pad.

To dispense ice:

> Select the CUBE button for

cubed !G8

> Press the CRUSH button for

crushed ice.

> Press container against dispenser

pad.

NOTE: If wafer dispenser is

continuously active for more than 2

minutes, an automatic lock out sensor

will shut down power to dispenser area.

For instructions on how to unlock your

dispenser, see the section entitled

Dispenser Lock below,

DISPENSER LOCK

This feature prevents ice or

water from being disperrsed

To lock and unlock dispenser:

> To lock dispenser, press and hold the

LOCK/UNLOCK button for 3

seconds. A green indicator light

above button confirms dispenser is

locked,

LIGHT FUNCTION r ,

The light function offers two ^

settings: OFF and AUTO,

The OFF setting will turn off the

dispenser cavity light

The AUTO setting allows ttre SENSOR

to measure the surrounding light levels

and adjust the power of the cavity light

accordingly. When the sensor registers

lower light levels (night time, darkened

kitchen), the cavity light will respond at

50% power When the sensor registers

high light levels (lighted kitchen, direct

sunlight), tfie cavity light will not activate.

NOTE; Dispenser light will operate at

full power when ice or water functions

3f8 in USS,

To activate auto setting:

> Press the ON/OFF button iocated on

control panel Wherr the green

indicator light above the button

display is on, the cavity dispenser

light will use the AUTO setting.

To deactivate auto setting:

>• Press the ON/OFF button located on

controi panel. Green indicator light

above button will go out.

filter STATUS ™

INDICATOR

LIGHT

The filter status indicator light serves as

a reminder to repface the water filter A

green light indicates that the filter is in

good condition A red light indicates the

filter should be changed Once light

tur ns red, it will remain

red until function is

reset

To reset indicator:

Press and hold both the LOCK/

UNLOCK and the WATER buttons

simultaneously for 4 seconds The

green filter status indicator light will

flash 3 times when the function ^

has successfully reset,

^ HAIER j

TEMPERATURE KEYS

These keys will lower or raise the

freezer or fresh food compartment

temperature,

NOTE; See the section How to Adjust

the Temperature Controls (page 12)

for instructions on how to set food

compartment temperatures.

“V

> To unlock dispenser, hold the

LOCK/UNLOCK button for 3

seconds. Green indicator light above

button will go out.

20

f L E C Í R0NI C C O H T R O l f t A T O R E S ,

coni.

m

z

Q

r

MAX COOL

This function causes the fresh

food temperature to drop to the

minimum refrigerator temperature setting

avallabte - This setting remains in effect

for approximately 10 hours.

To activate and deactivate Max Cool;

> To activate, press the MAX COOL

button. The green fight above the

button will indicate active status

> To deactivate, press the MAX COOL

button. The green light above the

button will go out

NOTE: The temperature setting cannot

be changed if Max Cool or Max Freeze

setting is active.

MAX freeze

This function causes the freezer

temperature to drop to the minimum

freezer temperature setting available

This setting remains in effect for

approximately 24 hours.

To activate and deactivate Max

Freeze:

DISPLAY ON/OFF

The Display Ort/Off switch

controls power to the LED display

To activate and deactivate display:

5=» To activate, press the DISPLAY

ON/OFF button The display will light

> To deactivate, press the DISPLAY

ON/OFF button. The display will go

out

VACATION MODE

This key, if enabled, causes less

frequent defrost cycles. This conserves

energy.

To activate and deactivate Vacation

Mode:

> To activate, press the VACATION

MODE button, The green light above

the button will indicate active status,

> To deactivate, press the VACATION

MODE button, or open either

refrigerator door

ALARM OFF

This key is used to turn the HI

TEMP Warning Indicator and audio

alarm, as well as the OPEN DOOR

audio alarm off This will also deactivate

alarms presently in progress.

To turn the alarm off;

> Press the ALARM OFF button

ÍaukmI

X

> To activate, press the MAX FREEZE

button. The green light above the

button will indicate active status,

>• To deactivate, press the MAX

FREEZE button. The green light

above the button will go out

NOTE: The temperature setting cannot

be changed if Max Cool or Max Freeze

setting is active.

?

SABBATH

MODE

This mode is intended to deactivate

power to the LED and dispenser iighls,

while allowing the controls to remain

operationaL No visual or audio alarms

will be available while in this mode

To activate and deactivate Sabbath

Mode:

>- To activate, press and hold both the

LOCK/UNLOCK and ON/OFF

buttons simultaneously for 3 seconds.

After 3 seconds, the LED and

dispenser lights will turn off

Dispenser light wlil not activate

during dispensing while in this

mode.

> To deactivate, press and hold both

LOCK/UNLOCK and ON/OFF

buttons simultaneously for 3 seconds.

After 3 seconds, the LED and

dispenser lights will activate

NOTE: In the event that power is

interrupted while the Sabbath Mode is

active, the control will remain in Sabbath

Mode when power returns

I tOCK Í

I tfflLOSK I

AUTO DISPLAY

The auto display controls the illumination

of the LED display based on the light

readings received from the SENSOR. If

the SENSOR indicates low light levels,

the display will be dimmer than if

displaying during welHit periods.

To set the power level of the display:

> Press and hold both the

ON/OFF button and the

freezer 's/ button for 3 seconds The

current active state will sftow In the

display by using AL 0 for on, AL A

for auto

>■ Use the refrigerator button to

scroll through the display states

> Activate the chosen setting by pSsi

pressing the CONFIRM

SETTINGS button

NOTE: The letters AL will always show

in freezer temperature display while in

this mode

or*

jemperature

CONVERSION MODE

This mode is available to change

the temperature display between

Fahrenfteit and Celsius,

To change current temperature

reading:

>- Press the DISPLAY ON/OFF and X

buttons simultaneously for 3 seconds

HIDDEN LOCKOUT FOR

yppgp^ КЕУРДР

The purpose of this mode is to prevent

tampering with the upper set of

dispenser conirois, This includes the

Display On/Off, Max Freeze, Max Cool,

Vacation Mode, and Temperature Set

functions

To activate and deactivate Hidden

Dispenser Lockout:

>■ To activate, press the LOCK/

UNLOCK and DISPLAY OFF buttons

simultaneously for 3 seconds,

> To deactivate, press the LOCK/

UNLOCK and DISPLAY OFF buttons

simultaneously for 3 seconds

ON/OFF FUNCTION

The ON/OFF function turns off coolirtg to

the fresh food and freezer sections while

allowing the lights and electronic display

to stay on The dispenser functions will

not be available while in this mode.

To deactivate and activate refrigerator:

> To deactivate, press the freezer ^

button until the readout registers

beyond the maximum allowable

freezer temperature. At this point, the

- LEO will read OFF. Press the

CONFIRM SETTINGS button to Ы

confirm the saieciion ,

>■ To reactivate, press the freezer ^

button. Press the CONRRM

SETTINGS button to confirm the

selection.

22

NOTE: After reactivation, the display

wiil show temperature setting previously

in use. See the section How to Adjust

the Temperature Controls (page 12)

for instructions on how to set food

compartment temperatures,

To avoid electrical shock which can

:' cause seYere personal injury or .

death, DO NOT perform maintenance

or service on refrigerator'unless ■'

refrigerator is unplugged. :

NIKIS m URE

MioauHveuRnKisuioi!

A WARNING

To avoid electrical shock which can

cause severe personal injury or ,

death, disconnect power to

refrigerator before cieaning. After

cleaning, connect power.

PART

Textured Doors

and Exterior

Cabinet Interior

Stainless Stee! Doors

and Exterior*

HVtPORTANTr Damage

to stainless steei finish

due to improper USB of

cleaning products or

non-recommended

products is not covered

under this product's

warranty.

Door Gaskets

DO NOT USE

>• Abrasive or harsh cleaners

>• Ammonia

S' Chlorine bieach

s- Concentrated detergents or

solvents

>* Metal Of plastic-textured

scouring pads

S' Abrasive or harsh cleaners

> Ammonia

> Chiorine bieach

> Concentrated detergents or

solvents

> Metai or plastic-textured

scouring pads

> Vinegar-based products

> Cifriis-based cleaners

> Abrasive or harsfi cleaners

> Metai or plastic-textured

scouring pads

A CAUTION

To avoid persona! injury or property damage, observe the fohowfng:

• Read and foiiow manufacturer's directions for all cieaning products.

• DO NOT place buckets, shelves or accessories in dishwasher Cracking or

warping of accessories may resutl.

DO

>- Use 4 tablespoons of baking soda dissoived in 1 quart

(1 liter) warm soapy water,

>• Rinse surfaces with clean warm water and dry immediately

to avoid water spots.

>- Use warm, soapy water and a soft, clean cloth or sponge

> Rinse surfaces with ciean warm water and dry immediately

to avoid water spots

in

z

o

(A

X

Condenser Coil

Remove base grille to

access

Condenser Fan Outlet

Grille

See back of refrigerator

Accessories Shelves,

buckets, drawers, etc

> A dishwasher

>■ Use a vacuum cleaner hose nozzle.

> Use a vacuum cleaner hose nozzle with brush attachment

> Follow removal and installation instructions from appropriate

feature section

>• Allow Hems to adjust to room temperature

> Dilute mild detergent and use a soft ciean cloth or sponge

(or cleaning.

> Use a plastic bristle brush to get into crevices

> Rinse surfaces with clean warm water.

> Dry glass and clear items immediately to avoid spots.

A stainless steel cleaner has been included inside the refrigerator for your use. To purchase additional cleaner, please contact

Sears using the Information on the back o1 your manual

B

HO W т о M M O V t O D O R S

1, Remove all food,

2 Disconnect refrigerator,

3, Glean the following items-paying

special attention to crevices-using

the appropriate instructions in How to

Clean Your Refrigerator:

■ Wails, floor, and ceiling of cabinet

interior,

* Drawers, shelves, and gaskets

4 Wash and dry all bottles, containers,

and jars. Discard spoiled or expired

items

5, Wrap or store odor-causing foods ir>

tightly-sealed containers to preverri

reoccurring odors

6 Connect power to refrigerator and

return food.,

7 After 24 hours, check if odor has

been eliminated.

If odor is still present...

1, Remove drawers and place on top

shelf of refrigerator,

2, Pack refrigerator and freezer

sections-including doors-with

crumpled sheets of bfack and white

newspaper.

3 Place charcoal briquettes randomly

on crumpled newspaper in both

freezer and refrigerator

Gompartments.

4, Close doors and let stand 24-48 hours.

5, Repeat steps 5 through 7 above.

If odor was not eliminated, contact

Sears Service Center. Refer to back of

manual for phone number;.

№G Y W I N G I D E A S

> Avoid overcrowding refrigerator

shelves. This reduces effectivity of air

circulation around food and causes

refrigerator to run longer..

>- Avoid addirrg too much warm food to

refrigerator at one time. This

overloads compartments and slows

rate of cooling

24

>■ DO NOT use aluminum foil, wax paper,

or paper toweling as shelf liners This

decreases air flow and causes

refrigerator to run less efficiently,

> A freezer that is % full runs most

efficiently

>■ Locate refrigerator in coolest part of

room. Avoid areas of direct sunlight,

or near heating ducts, registers, or

other heat producing appliances, if

this is not possible, isolate exterior by

using a section of cabinet or an

added layer of insulation,

> Refer to section in Use and Care

Guide on temperature controls for

recommended control settings

>“ Clean door gaskets every three

months according to use arrd care

guide instructions This will assure

that door seals properly and

refrigerator runs efficiently

>■ Take time to organize stems in

refrigerator to reduce time that door

is open,

> Be sure your doors are closing

securely by leveling refrigerator as

instructed in your use and care guide,

>■ Glean condenser coils off as

indicated in the Use and Care Guide

every 3 months. This wlil increase

energy efficiency and cooling

performance.

HO W T O R E M O V E A N D

RE P L A C E L I G H T B U L B S

A WARNING

To avoid eiectrica! shock which can

; cause sevère personal irtjury or death,

disconnect power to refrigerator

before replacing light bulb. After

■ replacing light bulb, coririect power.

A CAUTION

To avoid personal injury or property

damage, observe the following:

>■ Aiiow'light bulb to cooi.

>■ Wear gloves when repiacing light

bulb.

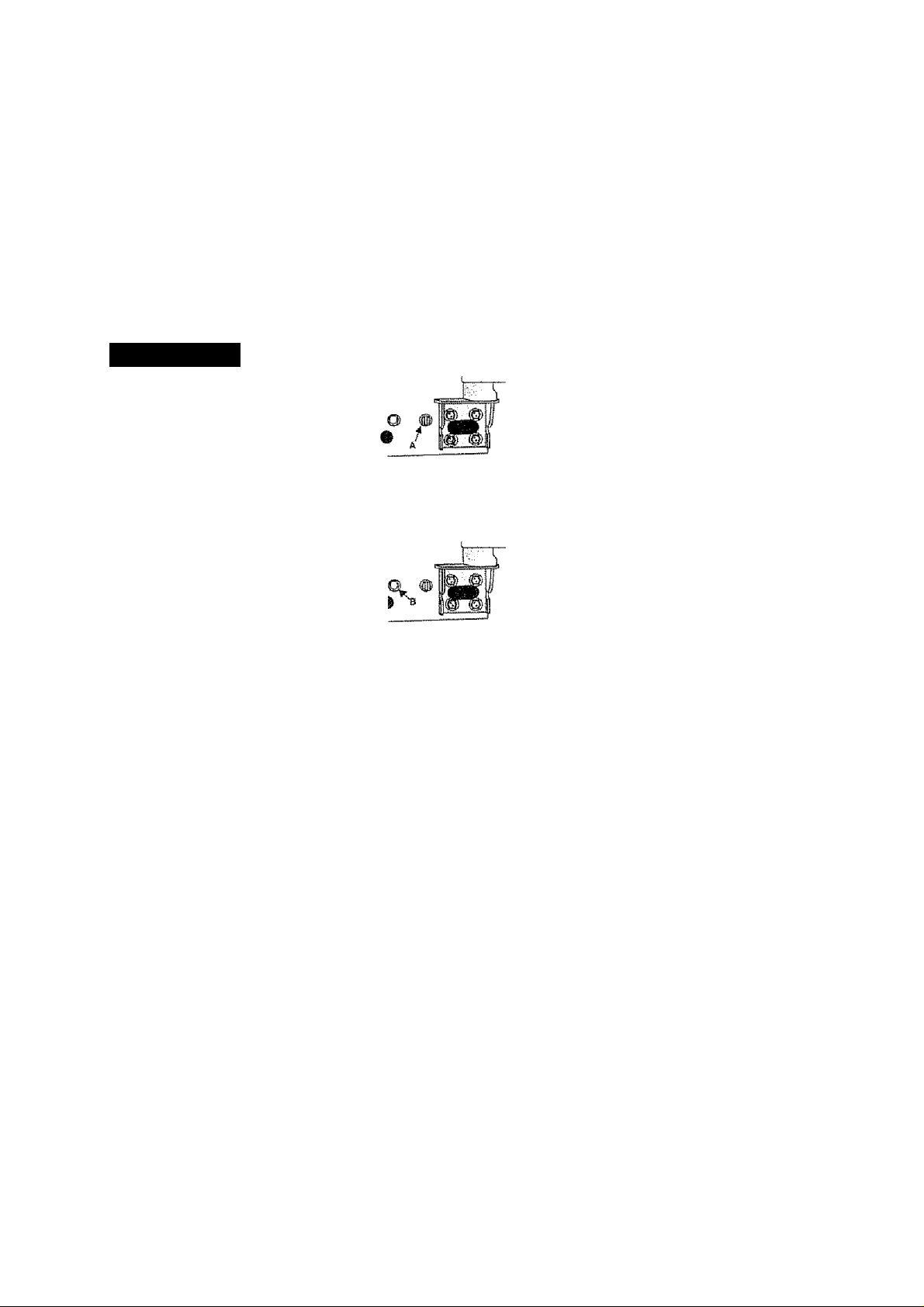

UPPER FRESH FOOD

Section []

1 Locale finger

gaps on each -r

side of clear light

shield- Insert

fingers and press in on each side of

shield. Pull shield down and remove

2 Remove light bulbs

3 Replace with appliance bulbs no

greater than 40 watts.

4 Replace light buib cover by inserting

front tabs of light shield into slots

directly in front of light assembly

LOWER FRESH FOOD

SECTION B

1. Pinch bottom tabs

(A) on light cover

and pull straight

out

2. Remove light bulb

3 Replace bulb with appliance bulb no

greater than 40 waffs.

4 Insert top tabs (0) of light cover into

liner slots and snap bottom portion

over light assembly,

FREEZER SECTION

1 Remove ice bin by

lifting front of bin

and pulling out

2 Remove tight bulb

cover by pinching top tab

(A) and pulling cover out,

3. Remove light bulb Replace with

ai^liance bulb no greater Own 40 watts.

4. Insert bottom tab (B) of light cover

into liner slots and snap top portion

over light assembly

5 Replace Ice bin by sliding in until bin

locks irrto place

ICE AND WATER DISPENSER

1 Locate light bulb inside top edge of

dispenser frame, Unscrew to remove.

2 Replace light buib with a

7-watt, 120 volt bulb

OTOve.

i

NOR MAL O PER AT IN G S OU ND S

Today’s refrigerators use foam insulation and are more energy efficient than refrigerators of the past- However, foam insulation is