Service Manual

®

ROOMAIRCONDITIONER

Model: 79053/79056/79074/79122

79184/79188

• PREFACE

• DISASSEMBLY INSTRUCTIONS

• INSTALLATION

• TROUBLESHOOTING GUIDE

• CIRCUIT DIAGRAM

• EXPLODED VIEW AND SERVICE PARTS LIST

CAUTION

- BEFORE SERVICING THE UNIT, READ THE

"SAFETY PRECAUTIONS" IN THIS MANUAL.

- ONLY FOR AUTHORIZED SERVICE

PERSONNEL.

Sears, Roebuck and Co., Hoffman Estates, IL. 60179 U.S.A.

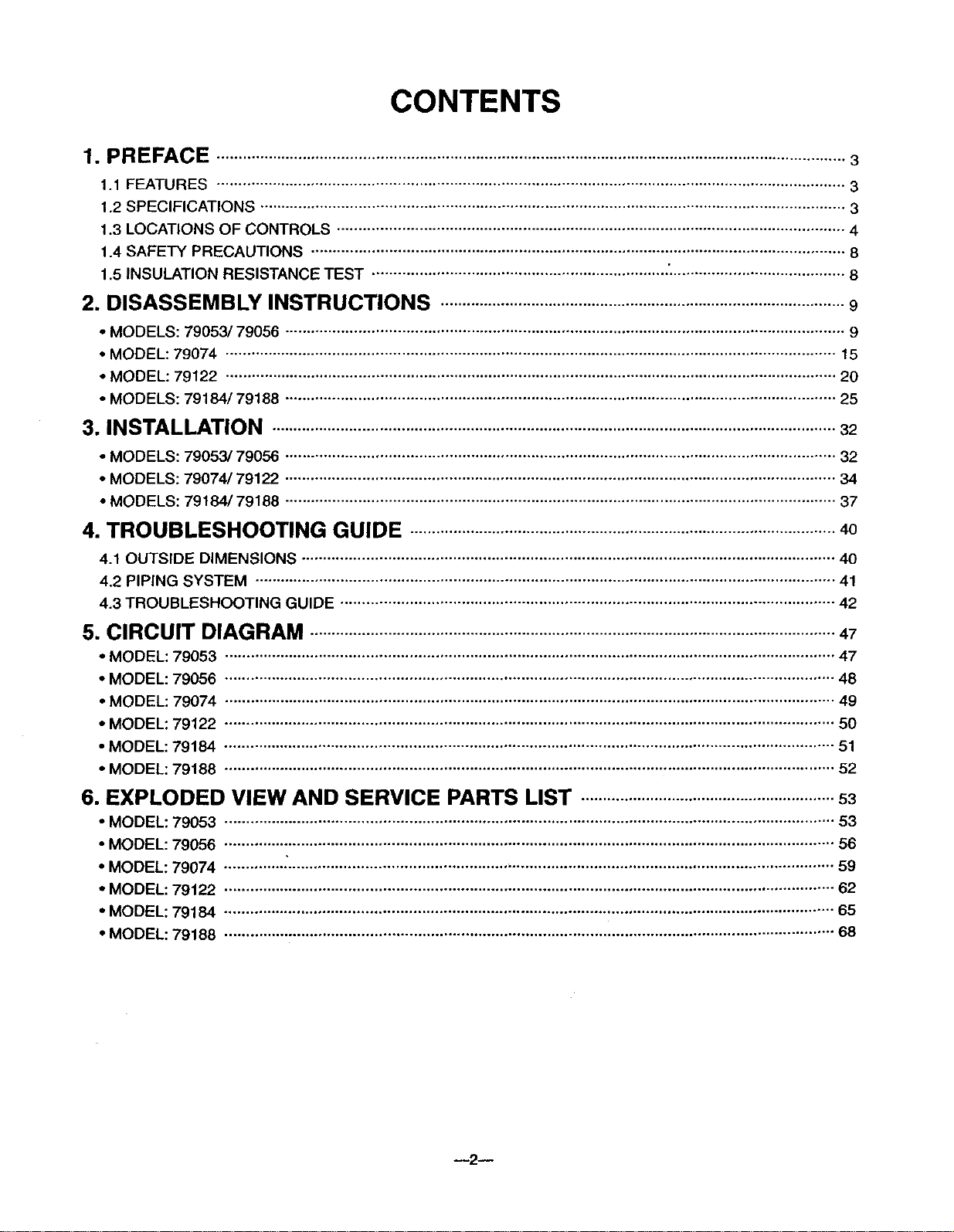

CONTENTS

1. PREFACE ..................................................................................................................................................3

1.1 FEATURES .................................................................................................................................................. 3

1.2 SPECIFICATIONS ........................................................................................................................................ 3

1.3 LOCATIONS OF CONTROLS ...................................................................................................................... 4

1.4 SAFETY PRECAUTIONS ............................................................................................................................ 8

1.5 INSULATION RESISTANCE TEST ..................................................................... "......................................... 8

2. DISASSEMBLY INSTRUCTIONS ..............................................................................................9

• MODELS: 79053/79056 .................................................................................................................................. 9

• MODEL: 79074 .............................................................................................................................................. 15

• MODEL: 79122 .............................................................................................................................................. 20

• MODELS: 79184/79188 ................................................................................................................................ 25

3. INSTALLATION ...................................................................................................................................32

• MODELS: 79053/79056 ................................................................................................................................ 32

• MODELS: 79074/79122 ................................................................................................................................ 34

• MODELS: 79184/79188 ................................................................................................................................ 37

4. TROUBLESHOOTING GUIDE ...................................................................................................40

4.1 OUTSIDE DIMENSIONS ............................................................................................................................ 40

4.2 PIPING SYSTEM ....................................................................................................................................... 41

4.3 TROUBLESHOOTING GUIDE ................................................................................................................... 42

5. CIRCUIT DIAGRAM ..........................................................................................................................47

• MODEL: 79053 .............................................................................................................................................. 47

• MODEL: 79056 .............................................................................................................................................. 48

• MODEL: 79074 .............................................................................................................................................. 49

• MODEL: 79122 .............................................................................................................................................. 50

• MODEL: 79184 .............................................................................................................................................. 51

• MODEL: 79188 .............................................................................................................................................. 52

6. EXPLODED VIEW AND SERVICE PARTS LIST ...........................................................53

• MODEL: 79053 .............................................................................................................................................. 53

• MODEL: 79056 .............................................................................................................................................. 56

• MODEL: 79074 .............. "............................................................................................................................... 59

• MODEL: 79122 .............................................................................................................................................. 62

• MODEL: 79184 .............................................................................................................................................. 65

• MODEL: 79188 .............................................................................................................................................. 68

--2--

1. PREFACE

This service manual provides various service information, including the mechanical and electrical parts, etc.

This room air conditioner was manufactured and assembled under a strict quality control system.

The refrigerant is charged at the factory. Be sure to read the safety precautions prior to servicing the unit.

1.1 FEATURES

• DESIGNED FOR COOLING ONLY

• POWERFUL AND INCREDIBLE COOLING

• THE SIMPLE INSTALLATION AND SERVICE

• BUILT-IN ADJUSTABLE THERMOSTAT

• WASHABLE ONE-TOUCH FILTER

• COMPACT SIZE

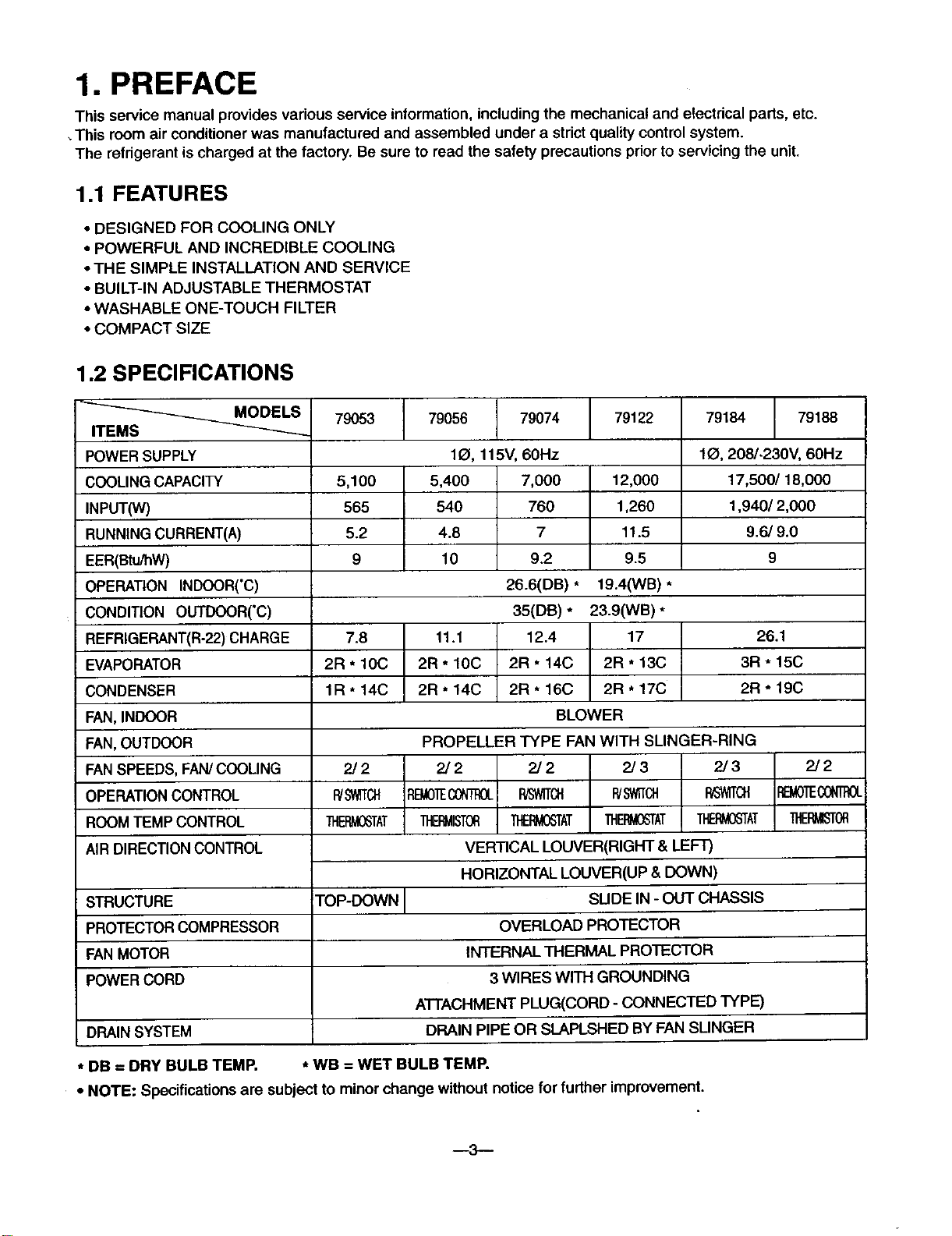

1.2 SPECIFICATIONS

__ MODELS

ITEMS

POWER SUPPLY

COOLING CAPACITY

INPUT(W)

RUNNING CURRENT(A)

EER(Btu/hW)

OPERATION INDOOR('C)

CONDITION OUTDOOR('C)

REFRIGERANT(R-22) CHARGE

EVAPORATOR

CONDENSER

FAN,INDOOR

FAN,OUTDOOR

FANSPEEDS, FAN/COOLING

OPERATIONCONTROL

ROOM TEMP CONTROL

AIR DIRECTION CONTROL

STRUCTURE TOP-DOWN

PROTECTOR COMPRESSOR

FAN MOTOR

POWER CORD

DRAIN SYSTEM

79053 79056 79074 79122

5,100

565

5.2

9

7.8

2R * 10C

1R * 14C

2/2

R/St_T_

THERMOSTAT

79184 79188

1(_, 115V,

5,400

540

4.8

10

11.1

2R * 10C

2R * 14C

PROPELLER TYPE FAN WITH SLINGER-RING

2/2 2/2 2/3 2/3

P,B/_)]Ecokr'_OL RISWlTCH R/SWITCH R_'WlTCH

11"IE_ISTOB _IEEV_3_rAT THE!_'TAT _AT

VERTICAL LOUVER(RIGHT & LEFT)

HORIZONTAL LOUVER(UP & DOWN)

INTERNAL THERMAL PROTECTOR

ATTACHMENT PLUG(CORD - CONNECTED TYPE)

DRAIN PIPE OR SLAPLSHED BY FAN SLINGER

60Hz

7,000

760

7

9.2

26.6(DB) *

35(DR) *

12.4

2R * 14C

2R * 16C

BLOWER

OVERLOAD PROTECTOR

3 WIRES WITH GROUNDING

12,000

1,260

11.5

9.5

19.4(WB) *

23.9(WB) *

17

2R * 13C

2R * 17C

SUDE IN - OUT CHASSIS

10, 208/-230V, 60Hz

17,500/18,000

1,940/ 2,000

9.6/9.0

26.1

3R "15C

2R "19C

2/2

REMOTECON]t_OL

]HER_ISTOR

* DB = DRY BULB TEMP. * WB = WET BULB TEMP.

• NOTE: Specifications are subject to minor change without notice for further improvement.

--3--

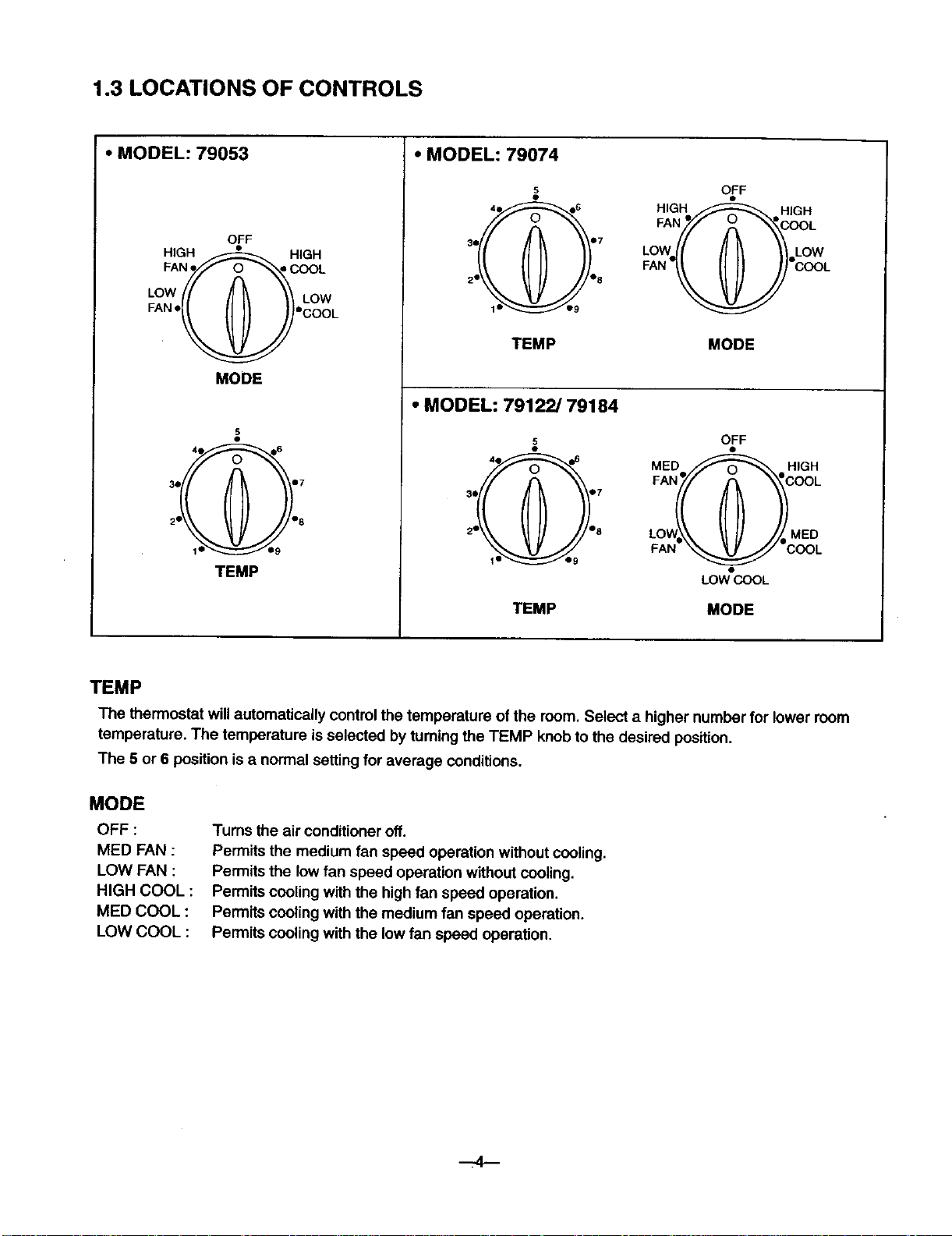

1.3 LOCATIONS OF CONTROLS

• MODEL: 79053

OFF

HIGH F-_--------_-._ HIGH

FANFF" -oooL

LOW /r I LOW

FAN'I _ ( !"cOOL

MODE

3• 4e •6 •7

TEMP

• MODEL: 79074

s OFF

FAN "gOOOL

HIGH_ HIGH

i ,. ow

2• _ % FAN 3 _i I r COOL

TEMP MODE

• MODEL: 79122/79184

5

3• •7 FAN e///f _ _'COOL

2 % LOW•_\ J_ / I MED

s OFF

MED _ HIGH

FAN _ COOL

LOW COOL

TEMP MODE

TEMP

The thermostat will automatically control the temperature of the room. Select a higher number for lower room

temperature. The temperature is selected by turningthe TEMP knob to the desired position.

The 5 or 6 position is a normal setting for average conditions.

MODE

OFF :

MED FAN :

LOW FAN :

HIGH COOL :

MED COOL :

LOW COOL :

Turns the air conditioner off.

Permits the medium fan speed operation without cooling.

Permits the low fan speed operation withoutcooling.

Permits cooling with the high fan speed operation.

Permits cooling with the medium fan speed operation.

Permits cooling with the low fan speed operation.

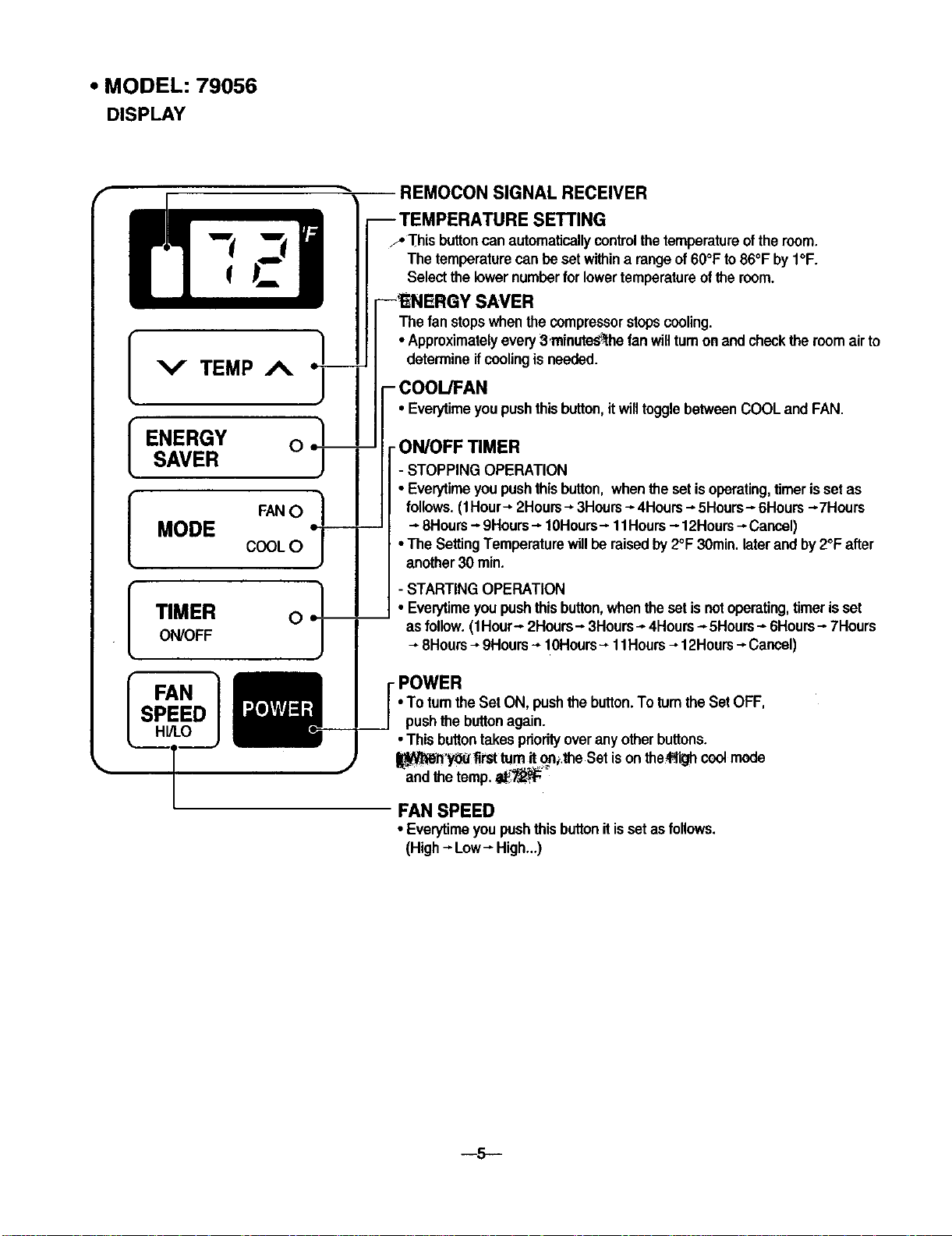

• MODEL: 79056

DISPLAY

REMOCON SIGNAL RECEIVER

-- TEMPERATURE SETTING

y' Th s buttoncan automaticay controthetemperatureoftheroom.

The temperaturecan be setwithina rangeof 60°F to86°F by I°F.

Selectthe lowernumberforlowertemperatureofthe room.

The fan stopswhenthe compressorstopscooling.

• Approximatelyevery3 minute_the fan willturnonand checkthe roomairto

determineifcoolingis needed.

--INERGY SAVER

OOUFAN

[ENERGY O _._._ I :I_:F_e_M;R shthisbutt°n'itwillt°gglebetweenCOOLandFAN"

_ SAVER _N OO_ I: STOPPING OPERATION

( T"T'_MER O ! ] ; STeArRtTImNGO:pEut_iONbutt°n,whentheset is n°t °perking ,umeris set

L ON/OFF_ [ as_lo°W__ HHUru"rs2H_JoHou3HlUlHo4H°urs"5H°urs 6H°urs 7H°urs

• To turn the Set ON, pushthe button.To rumthe Set OFF,

pushthe buttonagain.

-

• Thisbuttontakespriorityoveranyotherbuttons.

_jN_rl'y_ _irsttum it_the Set is onthe_gh coolmode

andthe temp._"

FAN SPEED

• Everytimeyoupushthis buttonitissetas follows.

(High--Low-- High...)

- 12Hours--_Cancel)

--5--

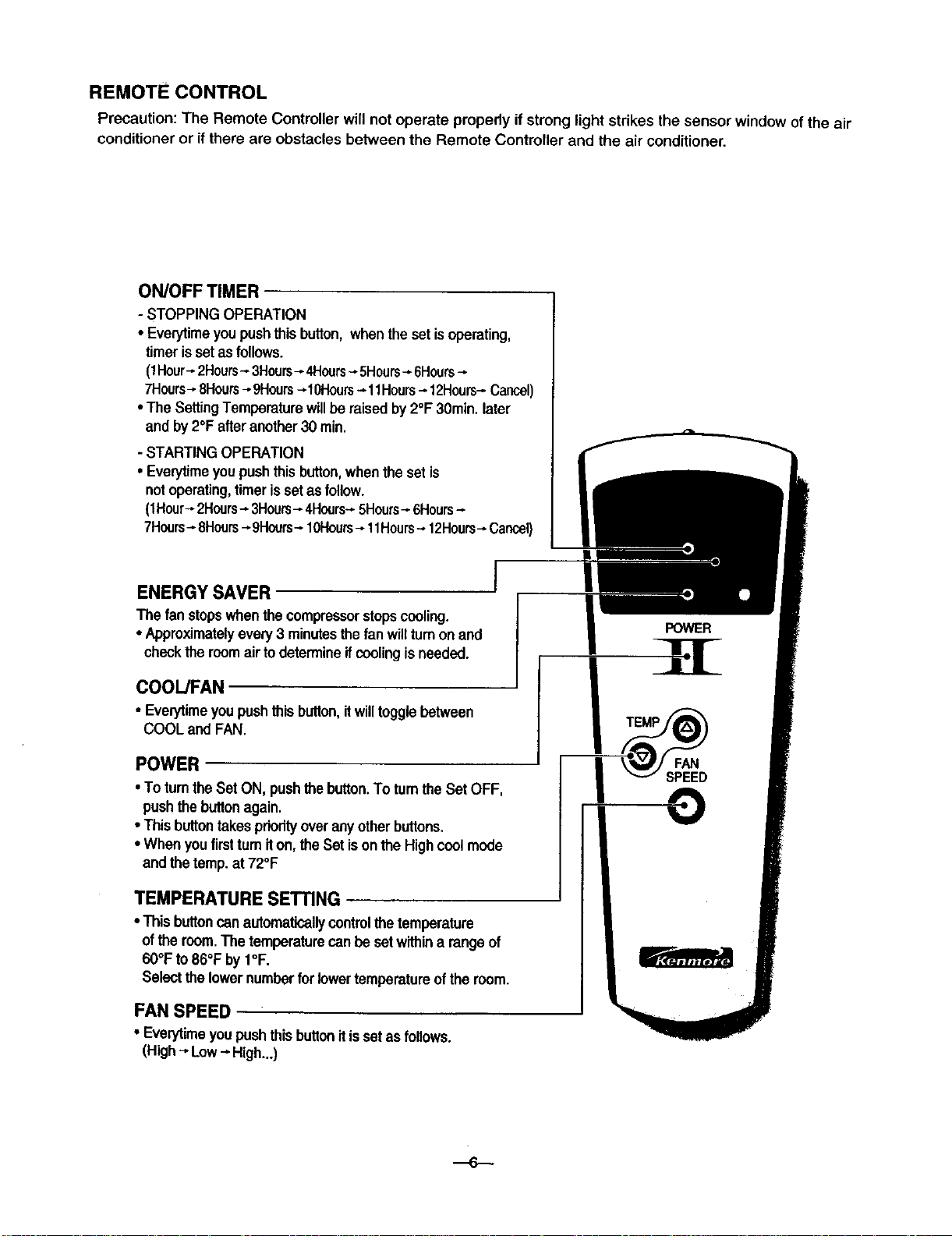

REMOTE CONTROL

Precaution: The Remote Controller will not operate propedy ifstrong light strikes the sensor window of the air

conditioner or if there are obstacles behveen the Remote Controller and the air conditioner.

ON/OFF TIMER

- STOPPING OPERATION

• Everytimeyou push this button, when the set isoperating,

timer is set as follows.

(1Hour=.2Hours- 3Hours- 4Hours- 5Hours-- 6Hours

7Hours-8Hours_-9Hours-10Hours_ 11Hours--12Hours_Cancel)

•The SettingTemperaturewillbe raisedby 2°F 30rain.later

and by2°F afteranother 30 rain.

- STARTING OPERATION

• Even/timeyou pushthis button,whenthe setis

not operating, timer is set as follow.

(1Hour_2Hours-*3Hours_ 4Hours-_5Hours_6Hours-

7Hours- 8Hours_-9Hours_ 10Hours_ 11Hours-_12Hours- Cancel)

ENERGY SAVER

The fan stopswhenthe compressorstopscooling.

• Approximatelyevely 3 minutesthe fan willtumon and

checkthe roomairto determineifcoolingisneeded.

COOL/FAN

• Eve_time youpushthis button,itwilltogglebetween

COOL and FAN.

POWER

• To turnthe Set ON, pushthe button.Totumthe Set OFF,

pushthe button again.

• Thisbuttontakespriorityoveranyotherbuttons,

• Whenyoufirstturniton, the Set ison the Highcoolmode

and thetemp. at72°F

TEMPERATURESETTING

• This buttoncanautomatically control thetemperature

of the room.The temperature can beset withina rangeof

60°Fto 86°F by I°F.

Selectthe lower number for lower temperature of the room.

FAN SPEED

• Everytimeyoupush thisbuttonitis set as follows.

(High--,Low-_High...)

POWER

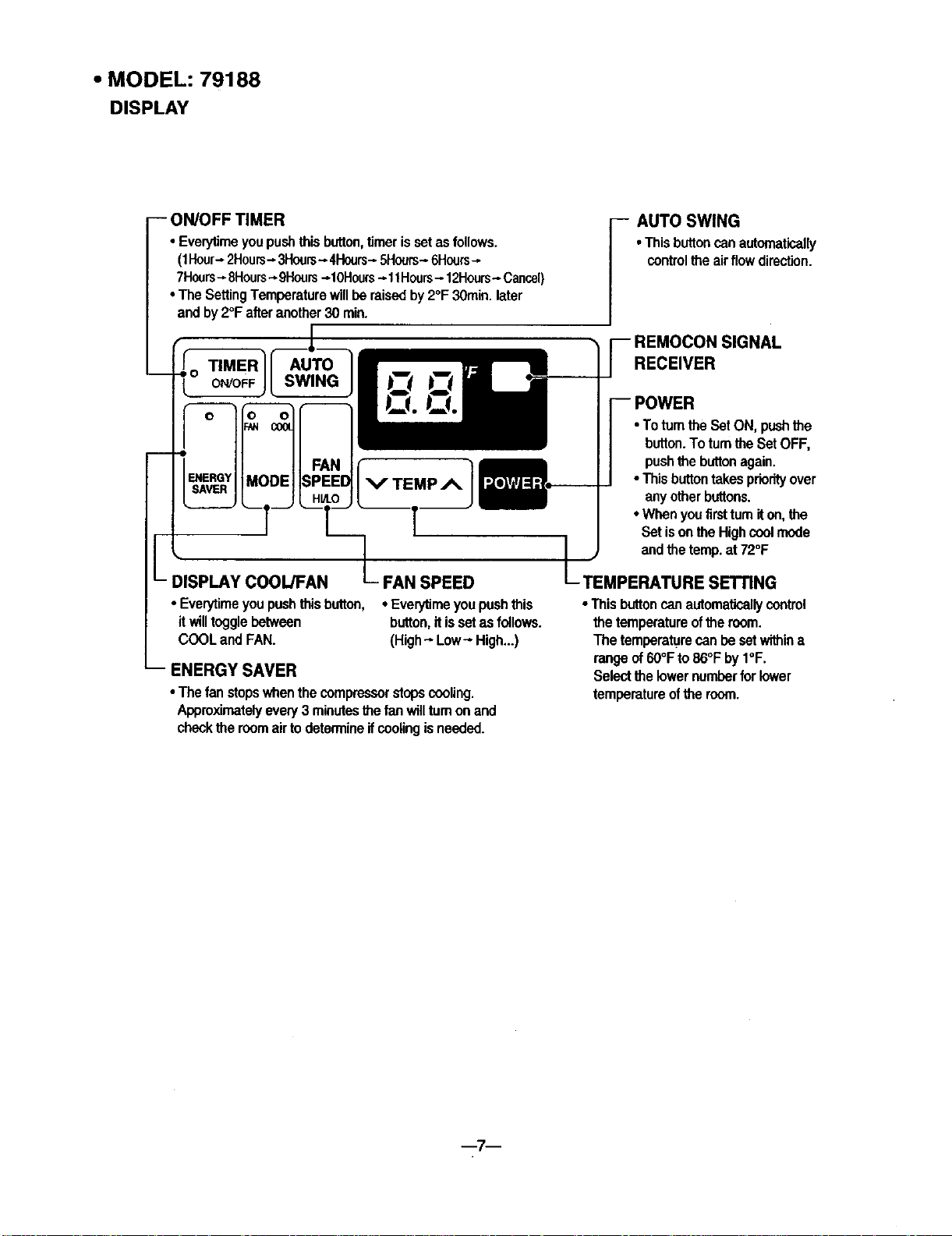

• MODEL: 79188

DISPLAY

-- ON/OFF TIMER

• Everyfimeyoupushthisbutton,timerissetasfollows,

(1Hour-2Hours- 3Hours-*4Hours_5Hours-6Hours-

7Hours_8Hours-*9Hours-*10Hours-*11Hours- 12Hours-Cancel)

• TheSettingTemperaturewillberaisedby2°F 30rain.later

andby2°F afteranother30 rain,

•This buttoncan automatically

controltheairflowdirection.

I UTO SWING

TIMER AUTO

L

,-0

FAN SPEED

• Everytimeyoupushthisbutton,

itwilltogglebetween

COOLandFAN.

ENERGY SAVER

•Thefanstopswhenthecompressorstopscooling.

Approximatelyevery3minutesthe fanwilltumonand

checkthe roomair todetermineif coolingis needed.

• EverylJmeyoupushthis

button,it issetasfollows,

(High_ Low- High...)

RECEIVER

•To turntheSetON, pushthe

button.TotumtheSetOFF,

pushthebuttonagain.

•This buttontakespriorityover

anyotherbuttons.

•Whenyoufirsttumiton, the

Setisonthe Highcoolmode

andthetemp.at72°F

TEMPERATURESETTING

• Thisbuttoncanautomatloailycontrol

thetemperatureoftheroom.

Thetemperaturecan be setwithine

rangeof60°Fto86°FbyI°F.

Selectthe lowernumberfor lower

temperatureoftheroom.

m7m

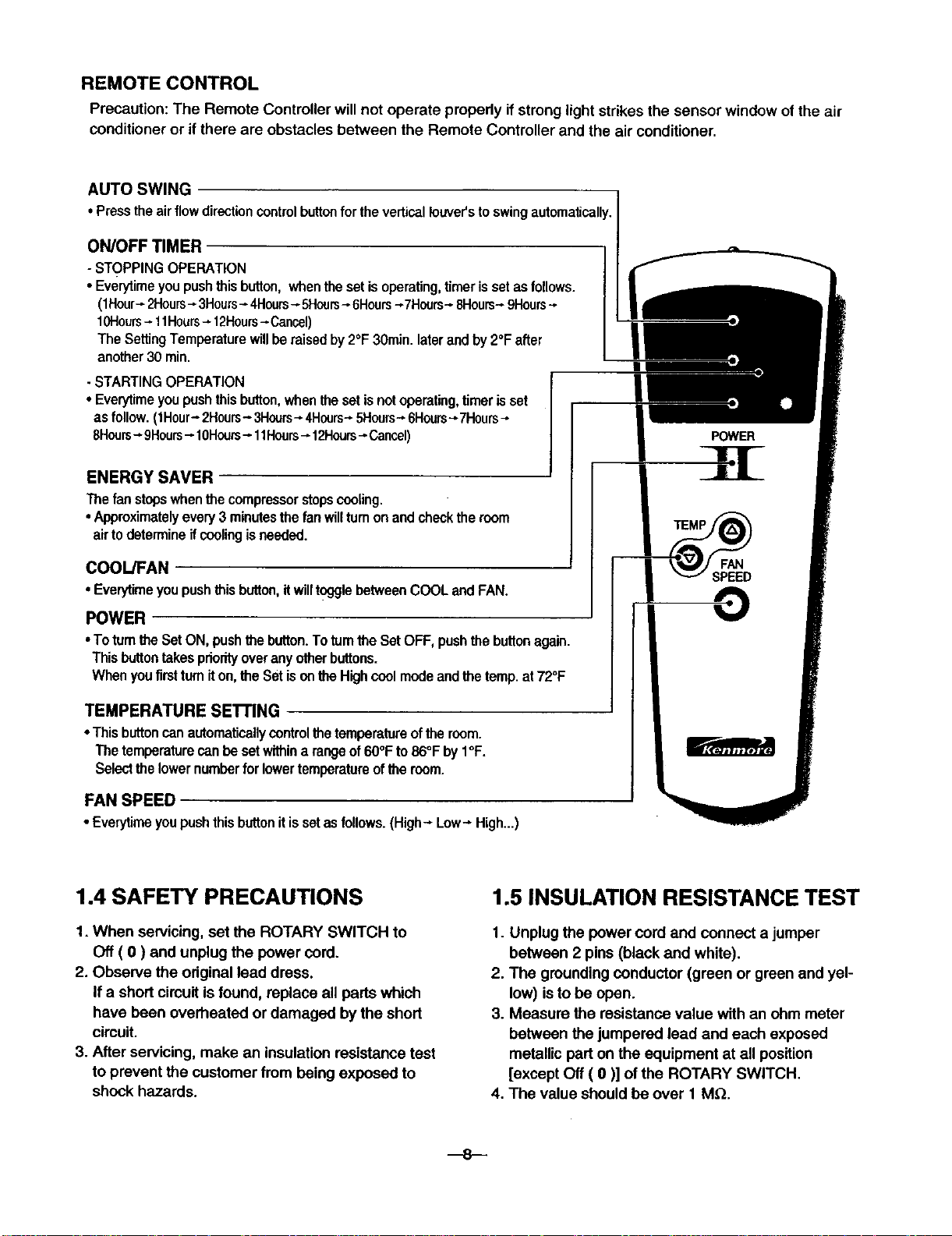

REMOTE CONTROL

Precaution: The Remote Controller will not operate properly if strong light strikes the sensor window of the air

conditioner or if there are obstacles between the Remote Controller and the air conditioner,

AUTO SWING

• Presstheairflowdirectioncontrolbuttonforthe verticalIouver'stoswingautomatically,

ON/OFF TIMER

- STOPPINGOPERATION

• Ever/timeyoupushthisbutton,whenthesetisoperating,timeris setasfollows.

(1Hour_2Hours_3Hours- 4Hours-5Hcers_ 6Hours--_7Hours-8Hours-9Hours-*

10Hours-11Hours-12Hours-Cancel)

TheSettingTemperaturewillberaisedby2°F 30rain.laterandby2°Fafter

another30 min.

- STARTINGOPERATION

• Everytimeyoupushthisbutton,whenthesetisnotoperating,timer isset

asfollow.(1Hour-2Hours- 3Hours-4Hours-5Hours-6Hours-_7Hours

8Hours-, 9Hours_ 10Hours_ 11Hours--12Hours--Cancel)

POWER

ENERGY SAVER

Thefanstopswhenthecompressorstopscooling,

•Approximatelyevery3minutesthe fanwillturnonandchecktheroom

airtodetermineifcoolingis needed.

COOL/FAN

• Everytimeyoupushthisbutton,itwilltogglebetweenCOOLandFAN.

FAN

SPEED

POWER

•To turntheSetON, pushthebutton.Totumthe SetOFF, pushthe buttonagain.

Thisbuttontakespriorityoveranyotherbuttons.

Whenyoufirstturniton,theSetis onthe Highcoolmodeandthe temp.at72°F

TEMPERATURE SEI"rlNG

• This buttoncanautomaticallycontrolthe temperatureofthe room.

The temperaturecanbe setwithina rangeof60°Fto86°F byI°F.

Selectthelowernumberforlowertemperatureofthe room.

FAN SPEED

• Everytimeyoupushthisbuttonit issetasfollows.(High---Low---High..,)

1.4 SAFETY PRECAUTIONS

1. When servicing, set the ROTARY SWITCH to

Off ( O ) and unplug the power cord.

2. Observe the original lead dress.

If a short circuit is found, replace all parts which

have been overheated or damaged by the short

circuit.

3. After servicing, make an insulation resistance test

to prevent the customer from being exposed to

shock hazards.

1.5 INSULATION RESISTANCE TEST

1. Unplug the power cord and connect a jumper

2. The grounding conductor (green or green and yel-

3. Measure the resistance value with an ohm meter

4. The value should be over 1 M_.

---8--

between 2 pins (black and white).

low) is to be open.

between the jumpered lead and each exposed

metallic part on the equipment at all position

[except Off ( 0 )] of the ROTARY SWITCH.

2. DISASSEMBLY INSTRUCTIONS

• MODEL: 79053/79056

2.1 MECHANICAL PARTS

2.1.1 FRONT GRILLE

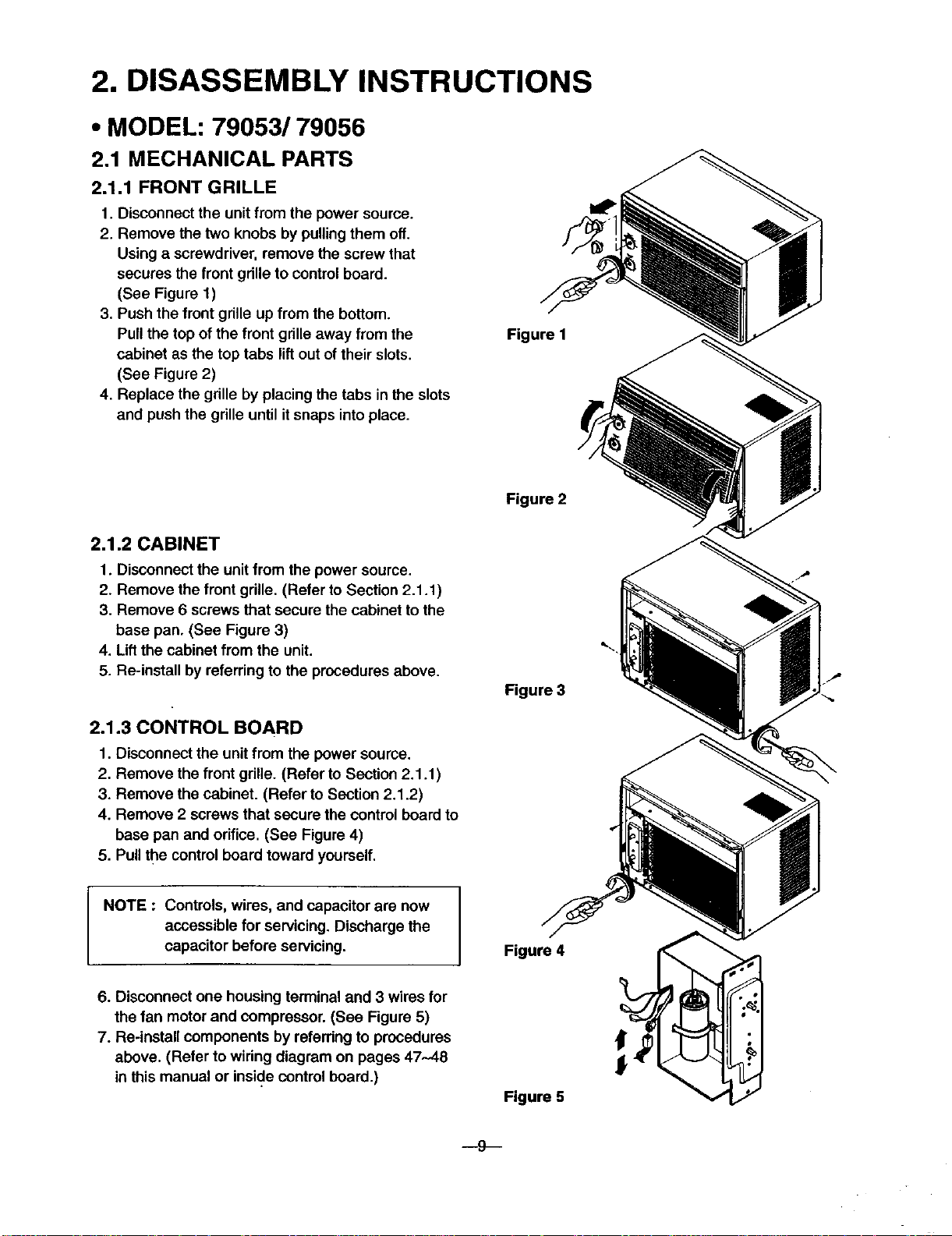

1. Disconnect the unit from the power source.

2. Remove the two knobs by pullingthem off.

Using a screwdriver, remove the screw that

secures the front grille to control board.

(See Figure 1)

3. Push the front grills up from the bottom.

Pull the top of the front grille away from the

cabinet as the top tabs lift out of their slots.

(See Figure 2)

4. Replace the grille by placing the tabs in the slots

and push the grille until itsnaps into place.

Figure 1

Figure 2

2.1.2 CABINET

1. Disconnect the unit from the power source.

2. Remove the front grille. (Refer to Section 2.1.1)

3. Remove 6 screws that secure the cabinet to the

base pan. (See Figure 3)

4. Lift the cabinet from the unit.

5. Re-install by referring to the procedures above.

2.1.3 CONTROL BOARD

1. Disconnect the unit from the power source.

2. Remove the front gdlle. (Refer to Section 2.1,1)

3, Remove the cabinet. (Refer to Section 2.1.2)

4. Remove 2 screws that secure the control board to

base pan and orifice, (See Figure 4)

5. Pull the control board toward yourself,

NOTE : Controls, wires, and capacitor are now

accessible for servicing. Discharge the

capacitor before servicing.

Figure 3

6. Disconnect one housing terminal and 3 wires for

the fan motor and compressor. (See Figure 5)

7. Re-install components by referring to procedures

above. (Refer to wiring diagram on pages 47-48

in this manual or inside control board.)

Figure 4 :_

Figure 5

--9---

2.2 AIR HANDLING PARTS

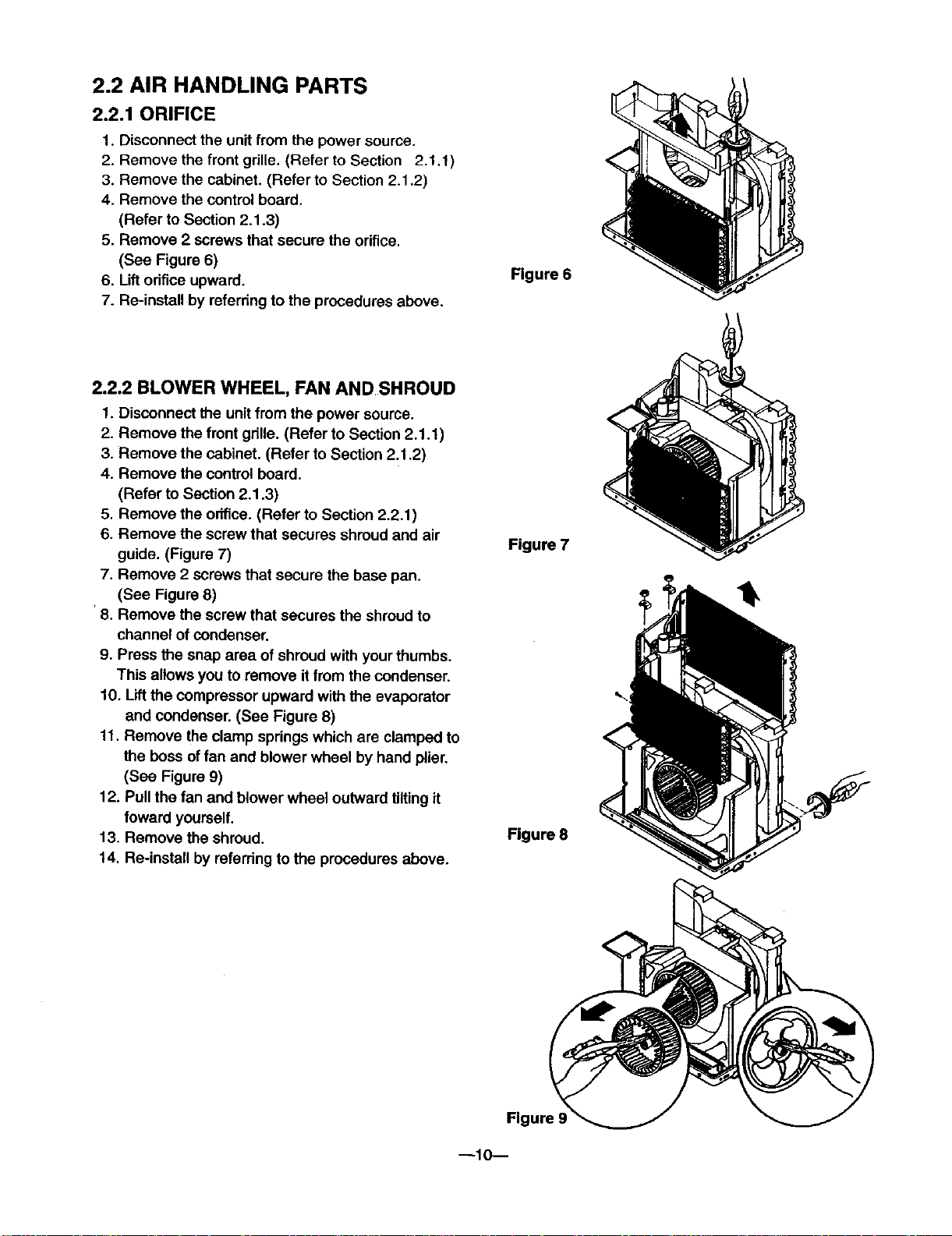

2.2.1 ORIFICE

1. Disconnect the unit from the power source.

2. Remove the front gdlle. (Refer to Section 2.1.1)

3. Remove the cabinet. (Refer to Section 2.1.2)

4. Remove the control board.

(Refer to Section 2.1.3)

5. Remove 2 screws that secure the orifice.

(See Figure 6)

6. Uft orifice upward.

7. Re-install by referring to the procedures above.

2.2.2 BLOWER WHEEL, FAN AND SHROUD

1. Disconnect the unit from the power source.

2. Remove the front gdlle. (Refer to Section 2.1.1)

3. Remove the cabinet. (Refer to Section 2.1.2)

4. Remove the control board.

(Refer to Section 2.1.3)

5. Remove the orifice. (Refer to Section 2.2.1)

6. Remove the screw that secures shroud and air

guide. (Figure 7)

7. Remove 2 screws that secure the base pan.

(See Figure 8)

8. Remove the screw that secures the shroud to

channel of condenser.

9. Press the snap area of shroud with your thumbs.

This allows you to remove it from the condenser.

10. Lift the compressor upward with the evaporator

and condenser. (See Figure 8)

11. Remove the clamp springs which are clamped to

the boss of fan and blower wheel by hand plier.

(See Figure 9)

12. Pull the fan and blower wheel outward tilting it

foward yourself.

13. Remove the shroud.

14, Re-install by referring to the procedures above.

Figure 6

Figure 7

Figure 8

--10--

Figure 9

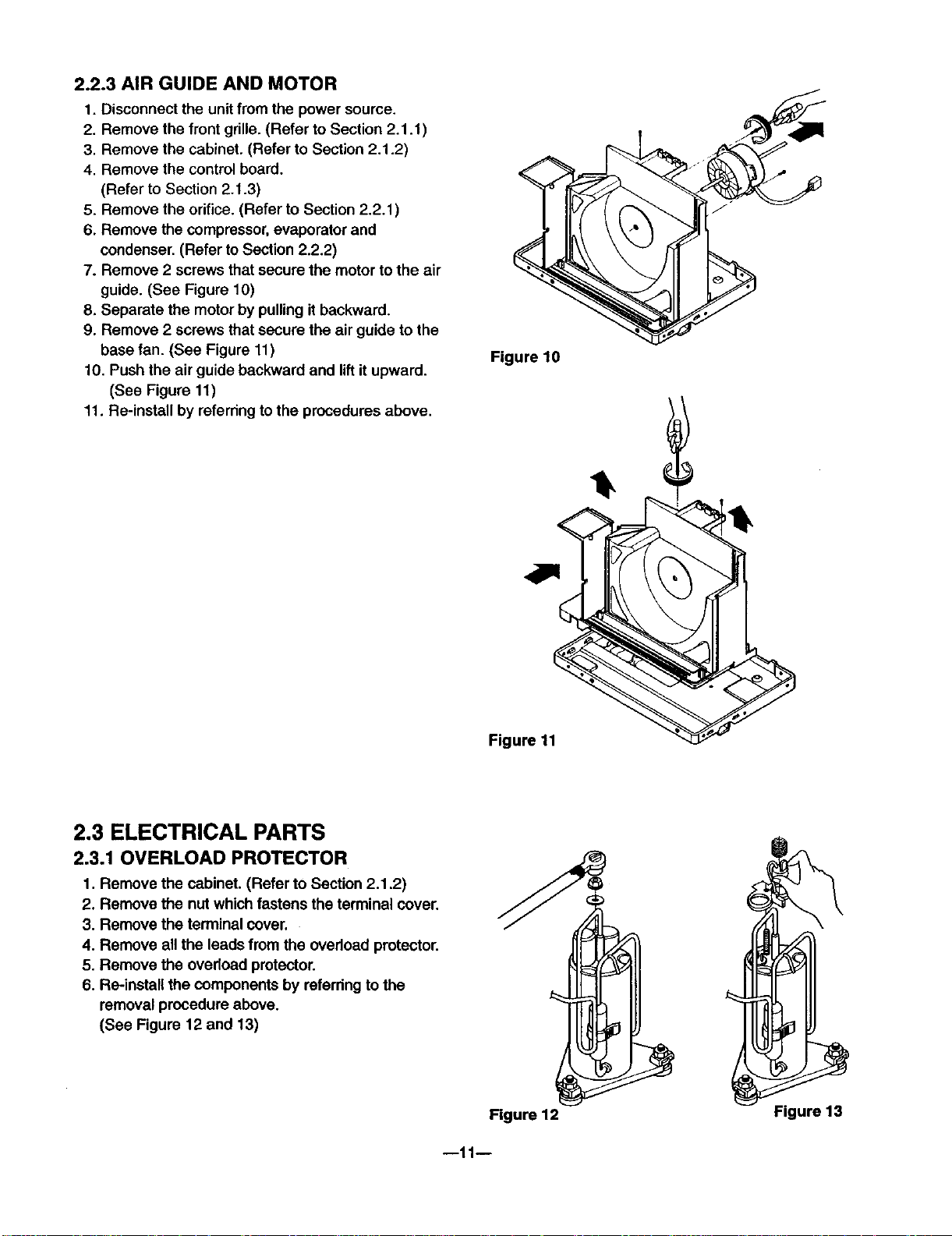

2.2.3 AIR GUIDE AND MOTOR

1. Disconnect the unit from the power source.

2. Remove the front grille. (Refer to Section 2.1.1)

3. Remove the cabinet. (Refer to Section 2.1.2)

4. Remove the control board.

(Refer to Section 2.1.3)

5. Remove the orifice. (Refer to Section 2.2.1 )

6. Remove the compressor, evaporator and

condenser. (Refer to Section 2.2.2)

7. Remove 2 screws that secure the motor to the air

guide. (See Figure 10)

8. Separate the motor by pulling it backward.

9. Remove 2 screws that secure the air guide to the

base fan. (See Figure 11)

10. Push the air guide backward and lift it upward.

(See Figure 11)

11. Re-install by referring to the procedures above.

Figure 10

2.3 ELECTRICAL PARTS

2.3.1 OVERLOAD PROTECTOR

1. Remove the cabinet. (Refer to Section 2.1,2)

2. Remove the nut which fastens the terminal cover.

3. Remove the terminal cover.

4. Remove all the leads from the overload protector.

5. Remove the ovedoad protector.

6. Re-install the components by referring to the

removal procedure above.

(See Figure 12 and 13)

Figure 11

Figure 12 Figure 13

--11--

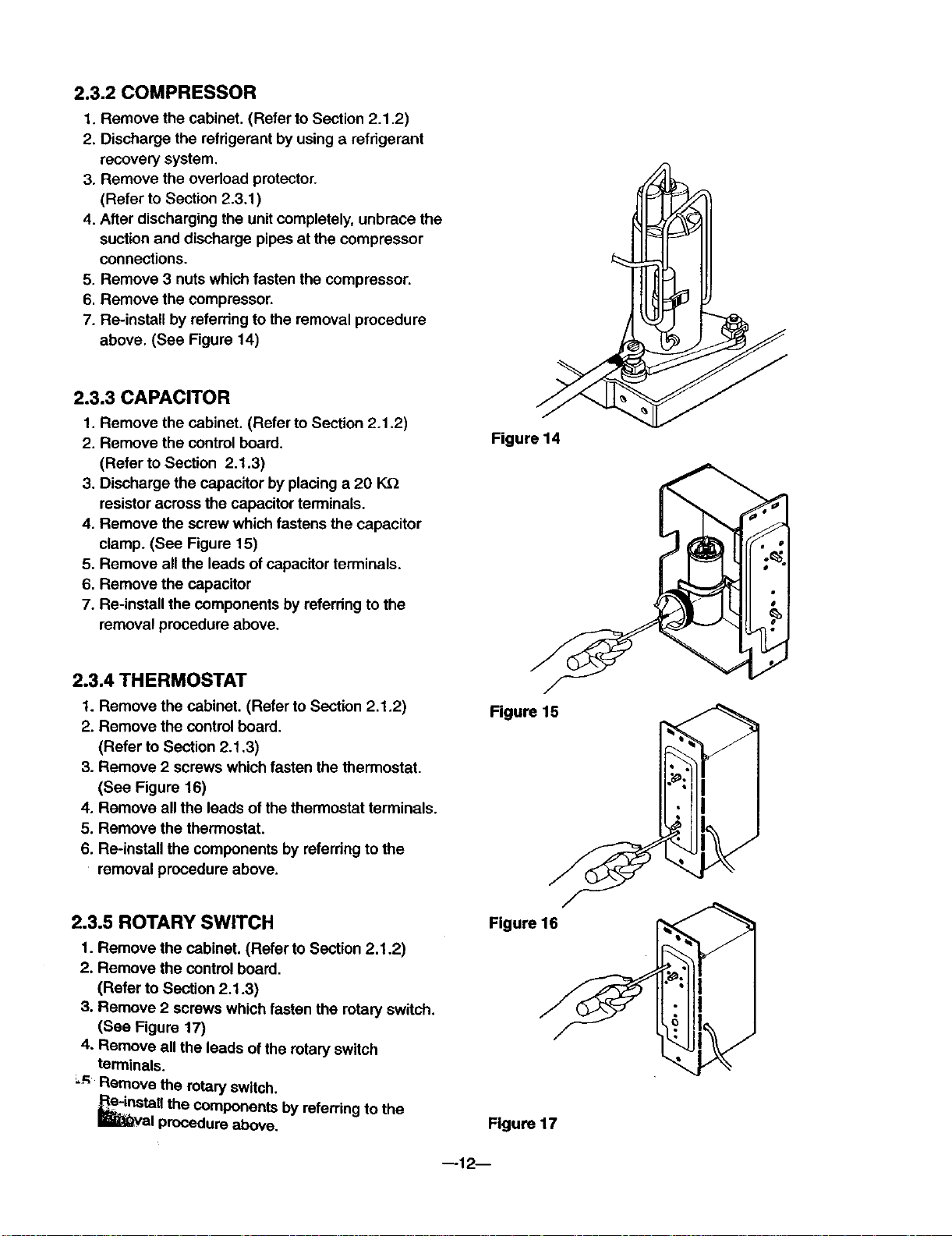

2.3.2 COMPRESSOR

1. Remove the cabinet. (Refer to Section 2.1.2)

2. Discharge the refrigerant by usinga refrigerant

recovery system,

3. Remove the overload protector.

(Refer to Section 2.3.1)

4. After discharging the unit completely, unbrace the

suction and discharge pipes at the compressor

connections.

5. Remove 3 nuts which fasten the compressor.

6. Remove the compressor.

7. Re-install by referring to the removal procedure

above, (See Figure 14)

2.3.3 CAPACITOR

1. Remove the cabinet. (Refer to Section 2.1.2)

2. Remove the control board.

(Refer to Section 2.1.3)

3. Discharge the capacitor by placing a 20 K.Q

resistor across the capacitor terminals.

4. Remove the screw which fastens the capacitor

clamp. (See Figure 15)

5. Remove all the leads of capacitor terminals.

6. Remove the capacitor

7. Re-install the components by referring to the

removal procedure above.

Figure 14

2.3.4 THERMOSTAT

1. Remove the cabinet. (Refer to Section 2.1.2)

2. Remove the control board.

(Refer to Section 2.1.3)

3. Remove 2 screws which fasten the thermostat.

(See Figure 16)

4. Remove all the leads of the thermostat terminals.

5, Remove the thermostat.

6. Re-install the components by referring to the

removal procedure above.

2.3.5 ROTARY SWITCH

1. Remove the cabinet, (Refer to Section 2,1.2)

2. Remove the control board.

(Refer to Section 2.1.3)

3. Remove 2 screws which fasten the rotary switch.

(See Figure 17)

4. Remove all the leads of the rotary switch

terminals.

_-_ Remove the rotary switch.

_!nstaU the components by referring to the

R_;_val procedure above.

Figure 15

Figure 16

Figure 17

--12 D

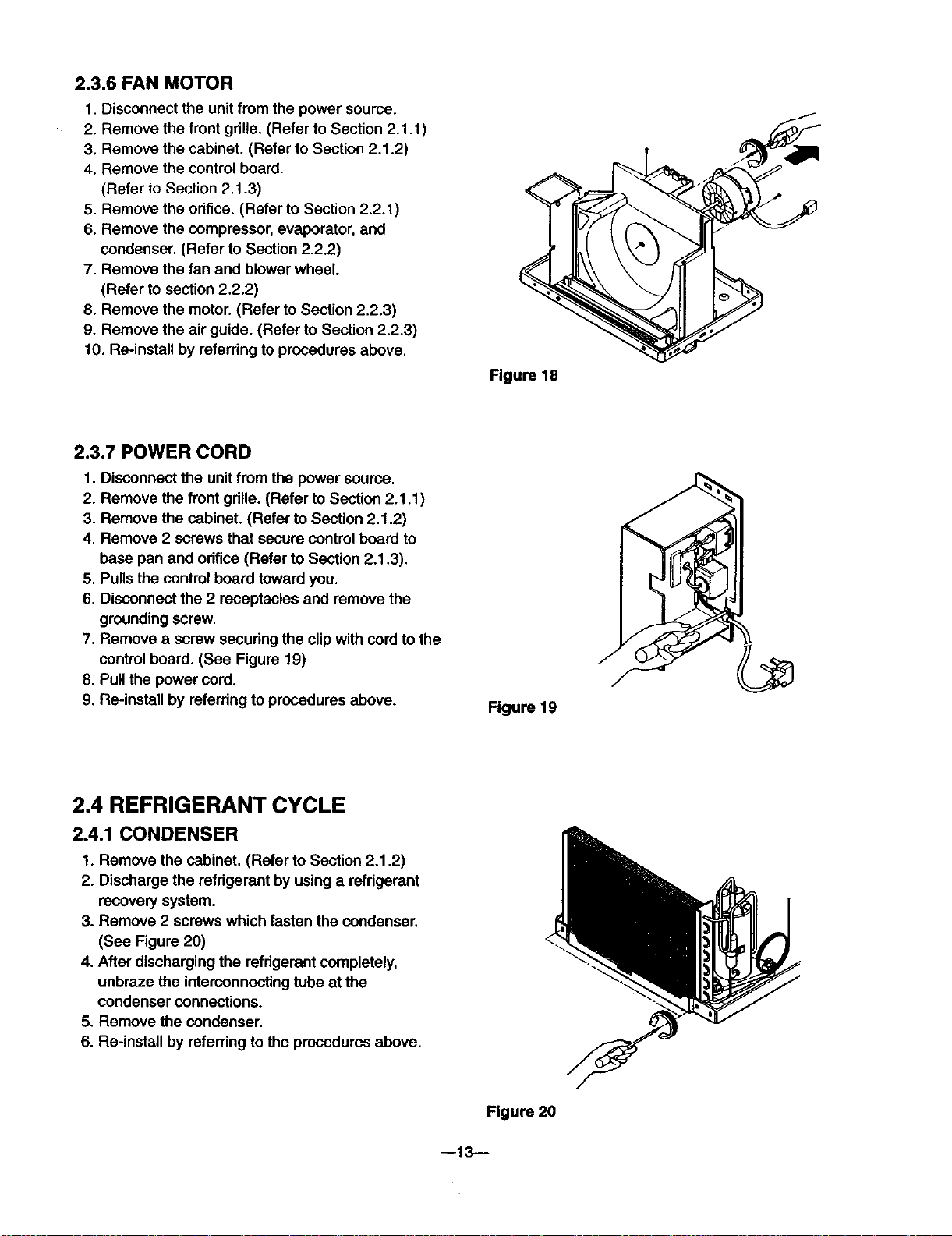

2.3.6 FAN MOTOR

1. Disconnect the unit from the power source.

2. Remove the front grille. (Refer to Section 2.1.1 )

3. Remove the cabinet. (Refer to Section 2.1.2)

4. Remove the control board.

(Refer to Section 2.1.3)

5. Remove the orifice. (Refer to Section 2.2.1)

6. Remove the compressor, evaporator, and

condenser. (Refer to Section 2.2.2)

7. Remove the fan and blower wheel.

(Refer to section 2.2.2)

8. Remove the motor. (Refer to Section 2.2.3)

9. Remove the air guide. (Refer to Section 2.2.3)

10. Re-install by referring to procedures above.

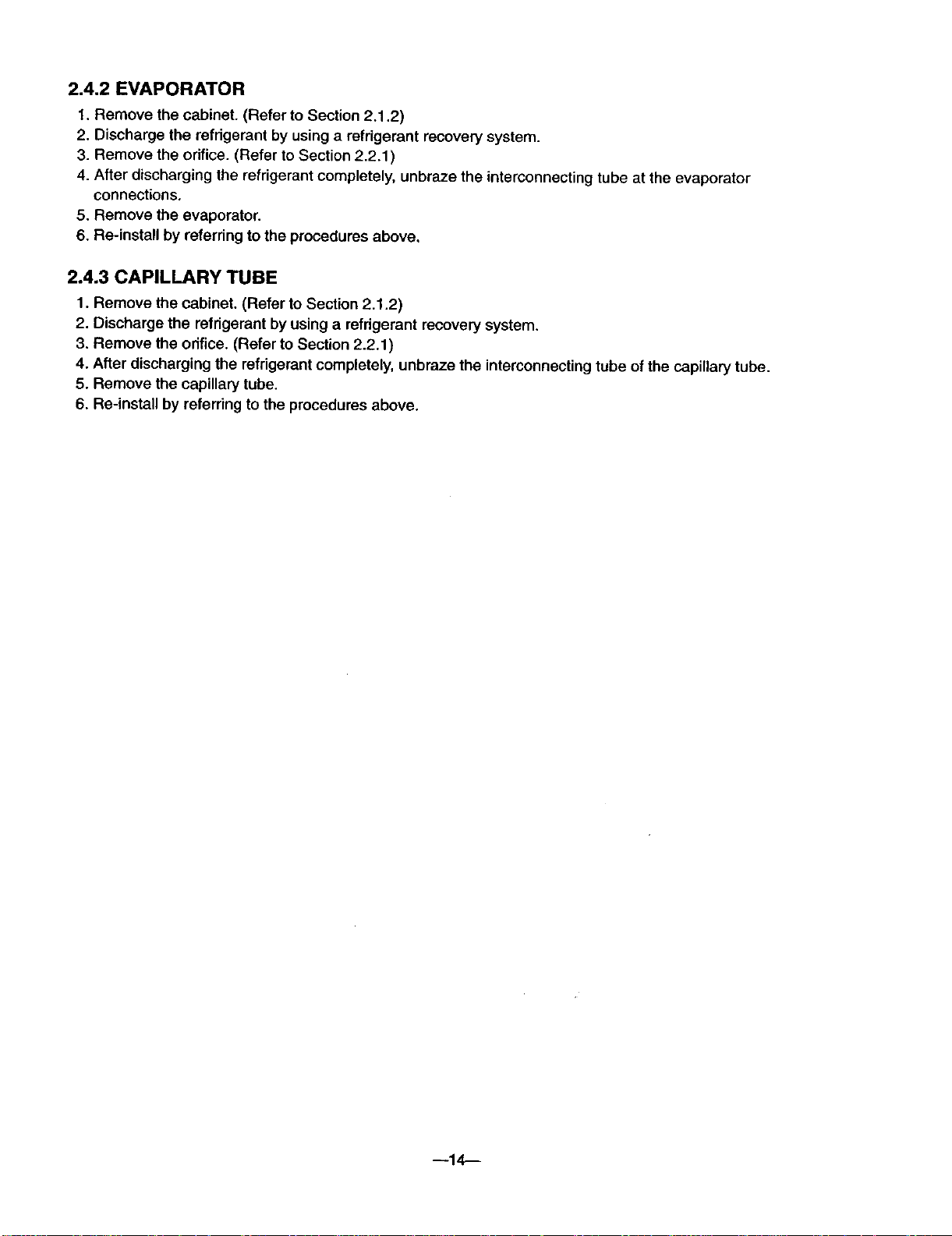

2.3.7 POWER CORD

1. Disconnect the unit from the power source.

2. Remove the front grille. (Refer to Section 2.1.1 )

3. Remove the cabinet. (Refer to Section 2.1.2)

4. Remove 2 screws that secure control board to

base pan and orifice (Refer to Section 2.1.3).

5. Pulls the control board toward you.

6. Disconnect the 2 receptacles and remove the

grounding screw.

7. Remove a screw secudng the clip with cord to the

control board. (See Figure 19)

8. Pull the power cord.

9. Re-install by referring to procedures above.

Figure 18

Figure 19

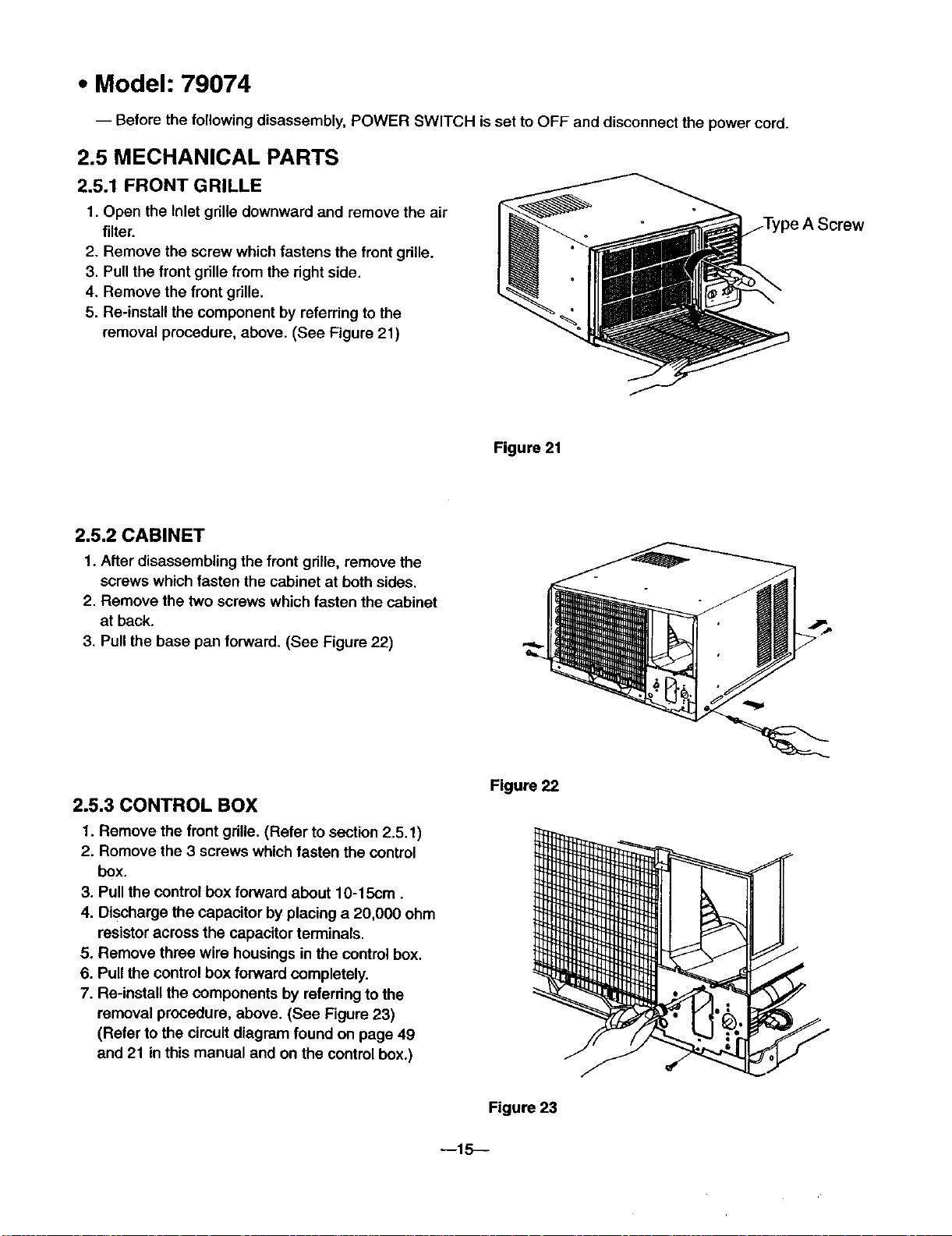

2.4 REFRIGERANT CYCLE

2.4.1 CONDENSER

1. Remove the cabinet. (Refer to Section 2.1.2)

2. Discharge the refdgerant by using a refdgerant

recovery system.

3. Remove 2 screws which fasten the condenser.

(See Figure 20)

4. After discharging the refrigerant completely,

unbraze the interconnecting tube at the

condenser connections.

5. Remove the condenser.

6. Re-install by referring to the procedures above.

Rgure 20

--13--

2.4.2 EVAPORATOR

1. Remove the cabinet. (Refer to Section 2.1.2)

2. Discharge the refrigerant by using a refrigerant recovery system.

3. Remove the orifice. (Refer to Section 2.2.1)

4. After discharging the refrigerant completely, unbraze the interconnecting tube at the evaporator

connections,

5. Remove the evaporator.

6, Re-install by referring to the procedures above,

2.4.3 CAPILLARY TUBE

1. Remove the cabinet. (Refer to Section 2.1.2)

2. Discharge the refrigerant by using a refrigerant recovery system.

3. Remove the orifice. (Refer to Section 2.2.1 )

4. After discharging the refrigerant completely, unbraze the interconnecting tube of the capillary tube.

5. Remove the capillary tube.

6. Re-install by referring to the procedures above.

--14--

• Model: 79074

-- Before the following disassembly, POWER SWITCH is set to OFF and disconnect the power cord.

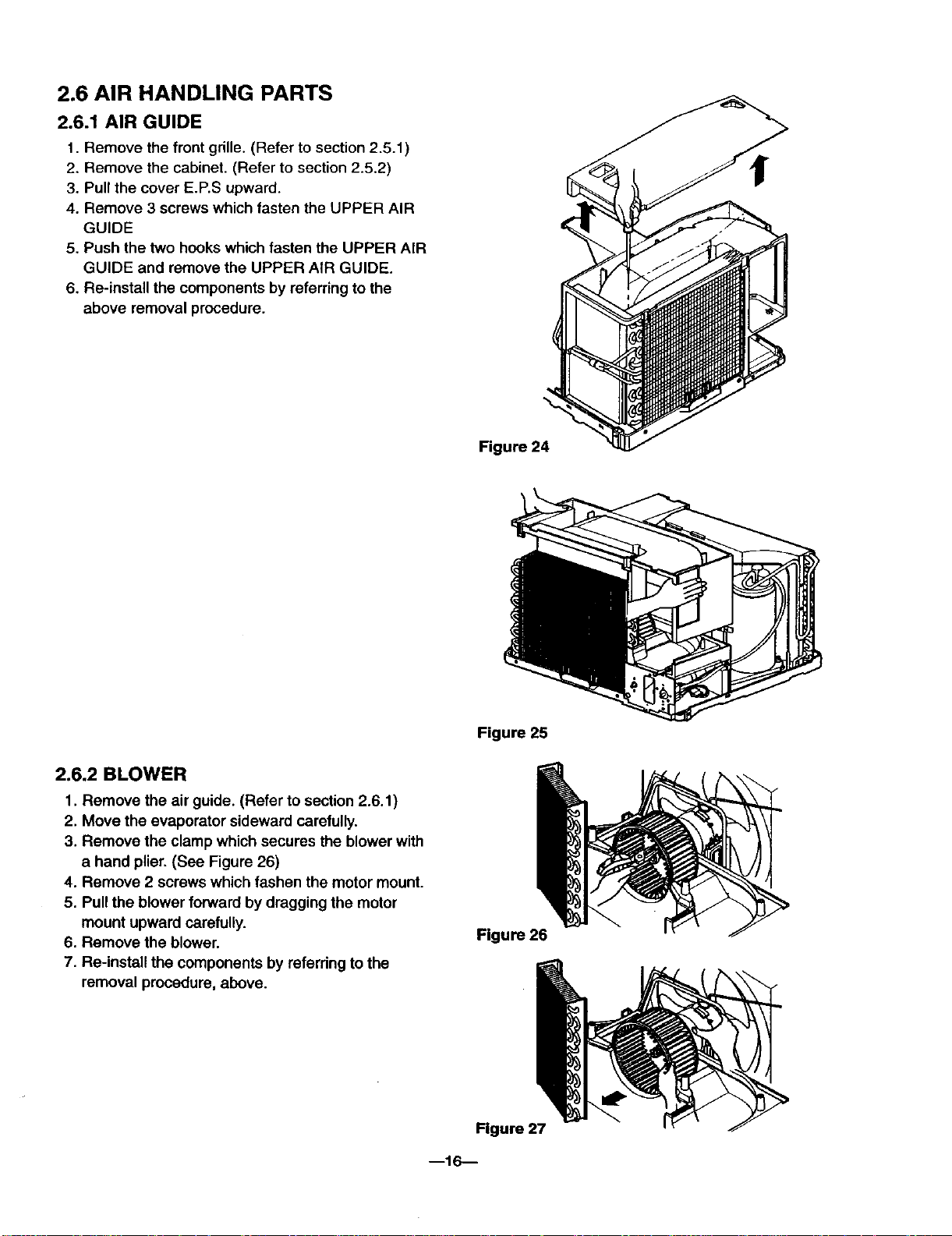

2.5 MECHANICAL PARTS

2.5.1 FRONT GRILLE

1. Open the Inlet grille downward and remove the air

filter.

2. Remove the screw which fastens the front grille.

3. Pull the front grille from the right side.

4. Remove the front grille.

5. Re-install the component by referring to the

removal procedure, above. (See Figure 21)

Figure 21

2.5.2 CABINET

1. After disassembling the front gdile, remove the

screws which fasten the cabinet at both sides.

2. Remove the two screws which fasten the cabinet

at back.

3. Pull the base pan forward. (See Figure 22)

2.5.3 CONTROL BOX

1. Remove the front grille. (Refer to section 2,5.1)

2. Romove the 3 screws which fasten the control

box.

3. Pull the control box forward about 10-15cm.

4, Discharge the capacitor byplacing a 20,000 ohm

resistoracross the capacitor terminals,

5. Remove three wire housings in the control box.

6. Pullthe control box forward completely.

7, Re-install the components by referring to the

removal procedure, above. (See Figure 23)

(Refer to the circuit diagram found on page 49

and 21 in this manual and on the control box.)

Figure22

--15_

Figure 23

2.6 AIR HANDLING PARTS

2.6.1 AIR GUIDE

1. Remove the front grille. (Refer to section 2.5.1)

2. Remove the cabinet. (Refer to section 2.5.2)

3. Pull the cover E.P.S upward.

4. Remove 3 screws which fasten the UPPER AIR

GUIDE

5. Push the two hooks which fasten the UPPER AIR

GUIDE and remove the UPPER AIR GUIDE.

6. Re-install the components by referring to the

above removal procedure.

Figure 24

2.6.2 BLOWER

1. Remove the air guide. (Refer to section 2.6.1)

2. Move the evaporator sideward carefully.

3. Remove the clamp which secures the blower with

a hand plier, (See Figure 26)

4. Remove 2 screws which fashen the motor mount.

5. Pull the blower forward by dragging the motor

mount upward carefully.

6. Remove the blower.

7. Re-install the components by referring to the

removal procedure, above.

Figure 25

Figure 26

Figure 27

--16---

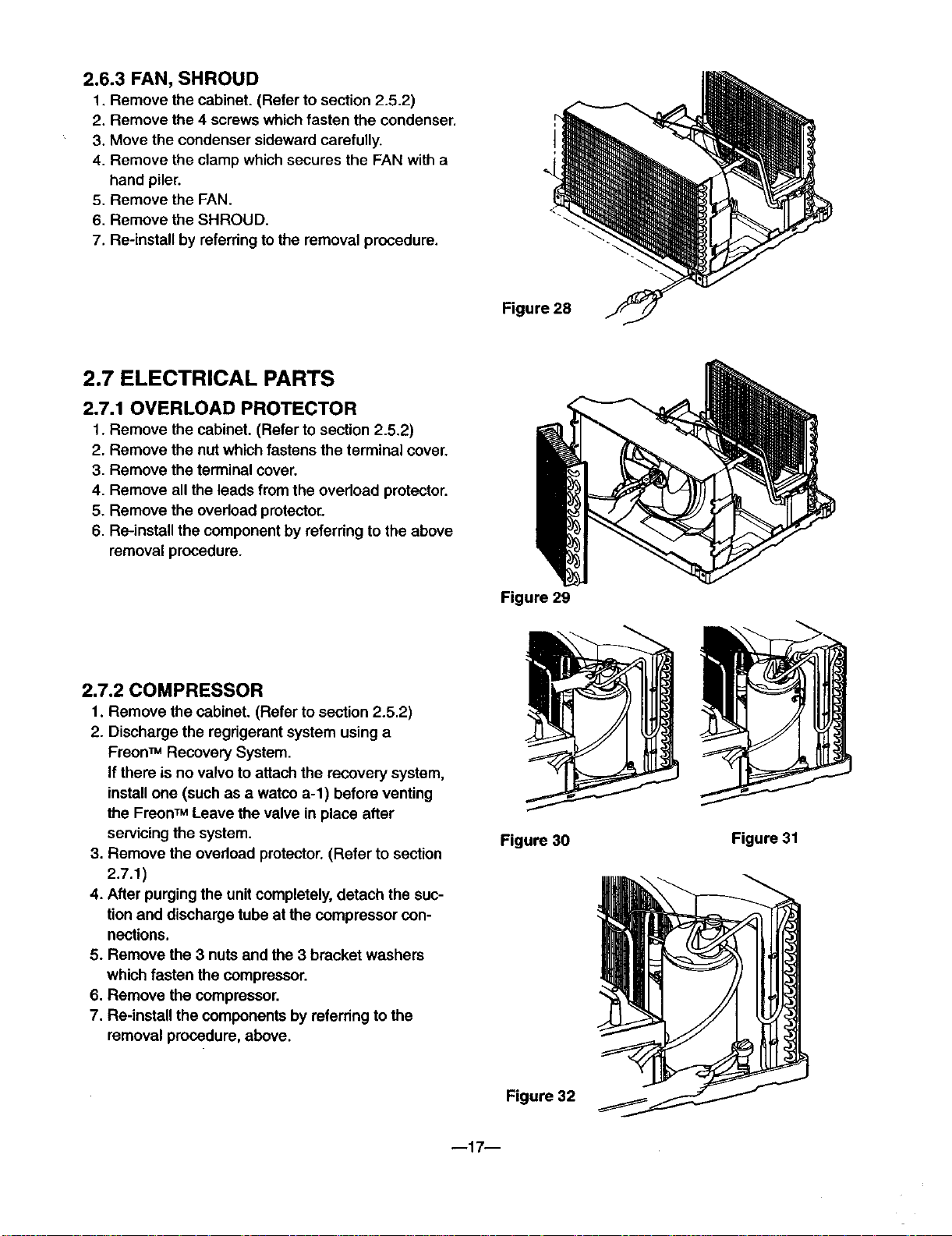

2.6.3 FAN, SHROUD

1. Remove the cabinet. (Refer to section 2.5.2)

2. Remove the 4 screws which fasten the condenser,

3. Move the condenser sideward carefully.

4. Remove the clamp which secures the FAN with a

hand plier.

5. Remove the FAN,

6. Remove the SHROUD.

7. Re-install by referring to the removal procedure.

2.7 ELECTRICAL PARTS

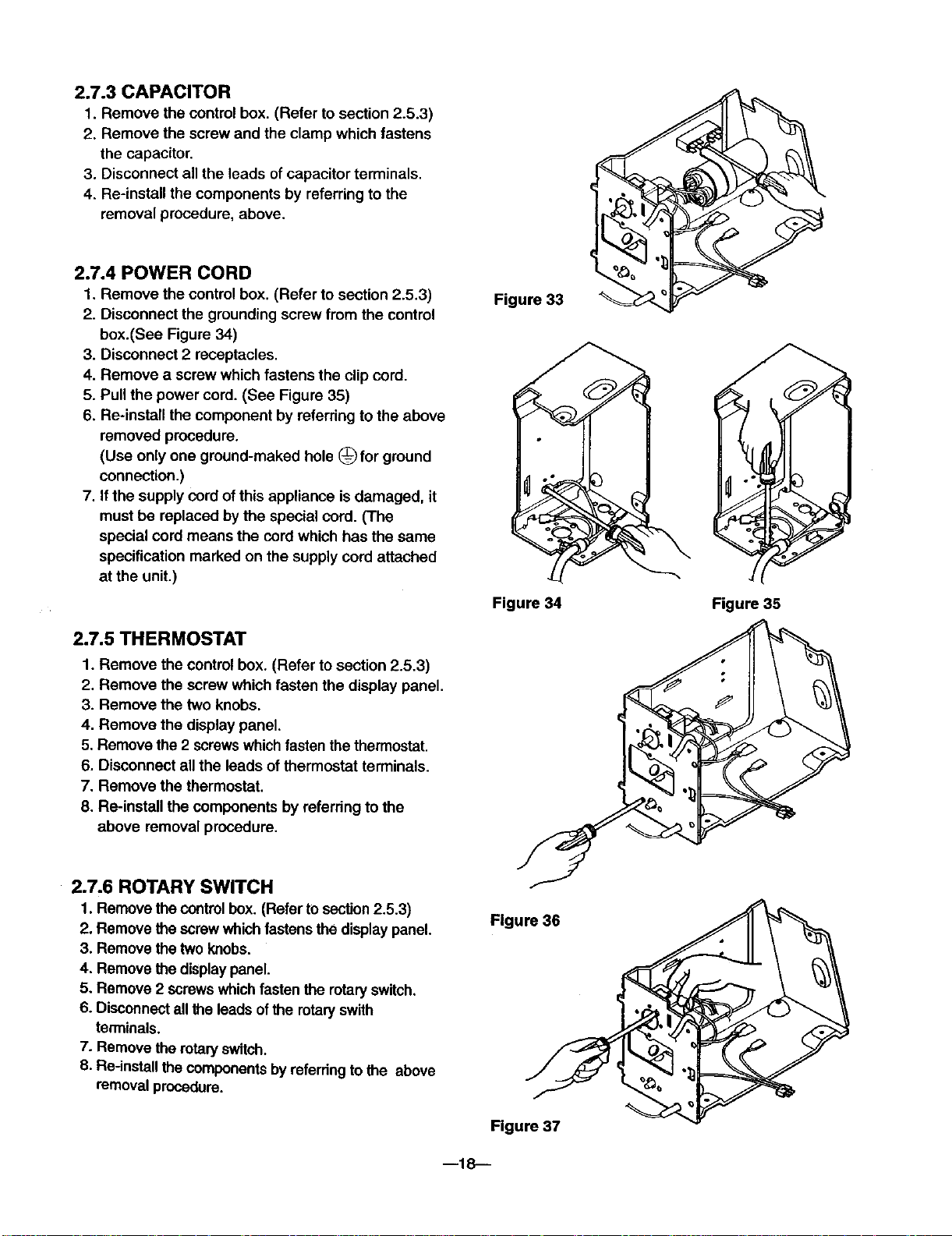

2.7.1 OVERLOAD PROTECTOR

1. Remove the cabinet. (Refer to section 2.5.2)

2. Remove the nut which fastens the terminal cover.

3. Remove the terminal cover.

4. Remove all the leads from the overload protector.

5. Remove the overload protecto_

6. Re-install the component by referring to the above

removal procedure.

Figure 28

2.7.2 COMPRESSOR

1. Remove the cabinet. (Refer to section 2.5.2)

2. Discharge the regdgerant system using a

FreonTM Recovery System.

If there is no valvo to attach the recovery system,

install one (such as a watco a-l) before venting

the FreonTM Leave the valve in place after

servicingthe system.

3. Remove the ovedoad protector. (Refer to section

2.7.1)

4. After purging the unit completely, detach the suc-

tion and discharge tube at the compressor con-

nections.

5. Remove the 3 nuts and the 3 bracket washers

which fasten the compressor.

6. Remove the compressor.

7. Re-install the components by referring to the

removal procedure, above.

Figure 29

Figure 30

Figure 31

m17--

Figure 32

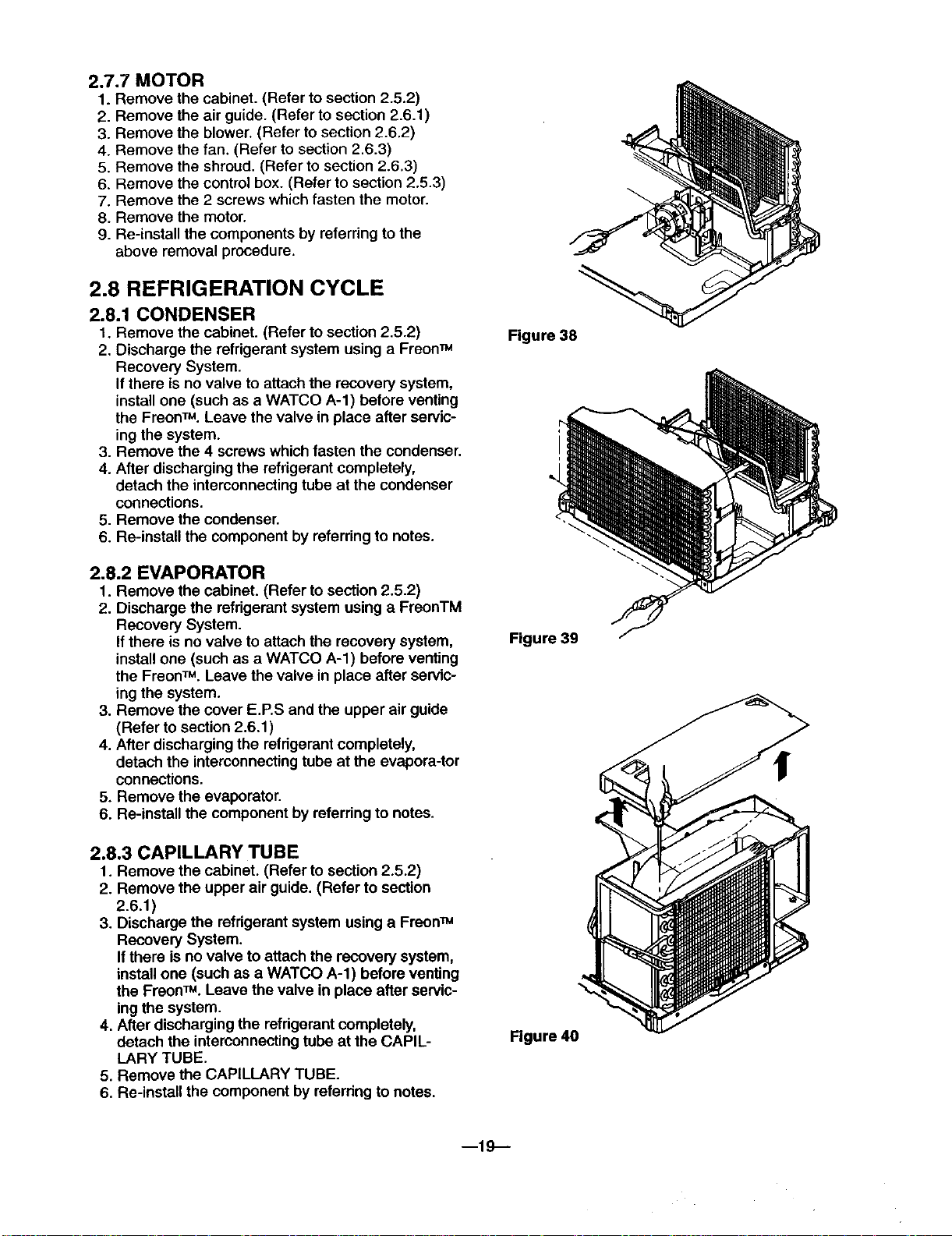

2.7.3 CAPACITOR

1. Remove the control box. (Refer to section 2.5.3)

2. Remove the screw and the clamp which fastens

the capacitor.

3. Disconnect all the leads ofcapacitor terminals.

4. Re-instan the components by referring to the

removal procedure, above.

2.7.4 POWER CORD

1. Remove the control box. (Refer to section 2.5.3)

2. Disconnect the grounding screw from the control

box.(See Figure 34)

3. Disconnect 2 receptacles.

4. Remove a screw which fastens the clip cord.

5. Pull the power cord. (See Figure 35)

6. Re-install the component by referring to the above

removed procedure.

(Use only one ground-maked hole (_ for ground

connection.)

7. If the supply cord of this appliance is damaged, it

must be replaced by the special cord. (The

special cord means the cordwhich has the same

specification marked on the supply cord attached

at the unit.)

Figure 33

Figure 34

Figure 35

2.7.5 THERMOSTAT

1. Remove the control box. (Refer to section 2.5.3)

2. Remove the screw which fasten the display panel.

3. Remove the two knobs.

4. Remove the display panel.

5. Remove the 2 screws whichfasten the thermostat.

6. Disconnect all the leads ofthermostat terminals.

7. Remove the thermostat.

8. Re-install the components by referring to the

above removal procedure.

2.7.6 ROTARY SWITCH

1. Remove the controlbox. (Refer to section2.5.3)

2. Remove the screw which fastensthe display panel.

3. Remove the two knobs.

4. Remove the displaypanel.

5. Remove 2 screws whichfastenthe rotaryswitch.

6. Disconnect all the leads ofthe rotaryswith

terminals.

7. Remove the rotaWswitch.

8. Re-install the componentsby referringto the above

removal procedure.

Figure 36

m18--

Figure 37

2.7.7 MOTOR

1. Remove the cabinet. (Refer to section 2.5.2)

2. Remove the air guide. (Refer to section 2.6.1)

3. Remove the blower, (Refer to section 2.6.2)

4. Remove the fan. (Refer to section 2.6.3)

5, Remove the shroud. (Refer to section 2.6.3)

6, Remove the control box. (Refer to section 2.5.3)

7, Remove the 2 screws which fasten the motor.

8. Remove the motor.

9. Re-install the components by referring to the

above removal procedure,

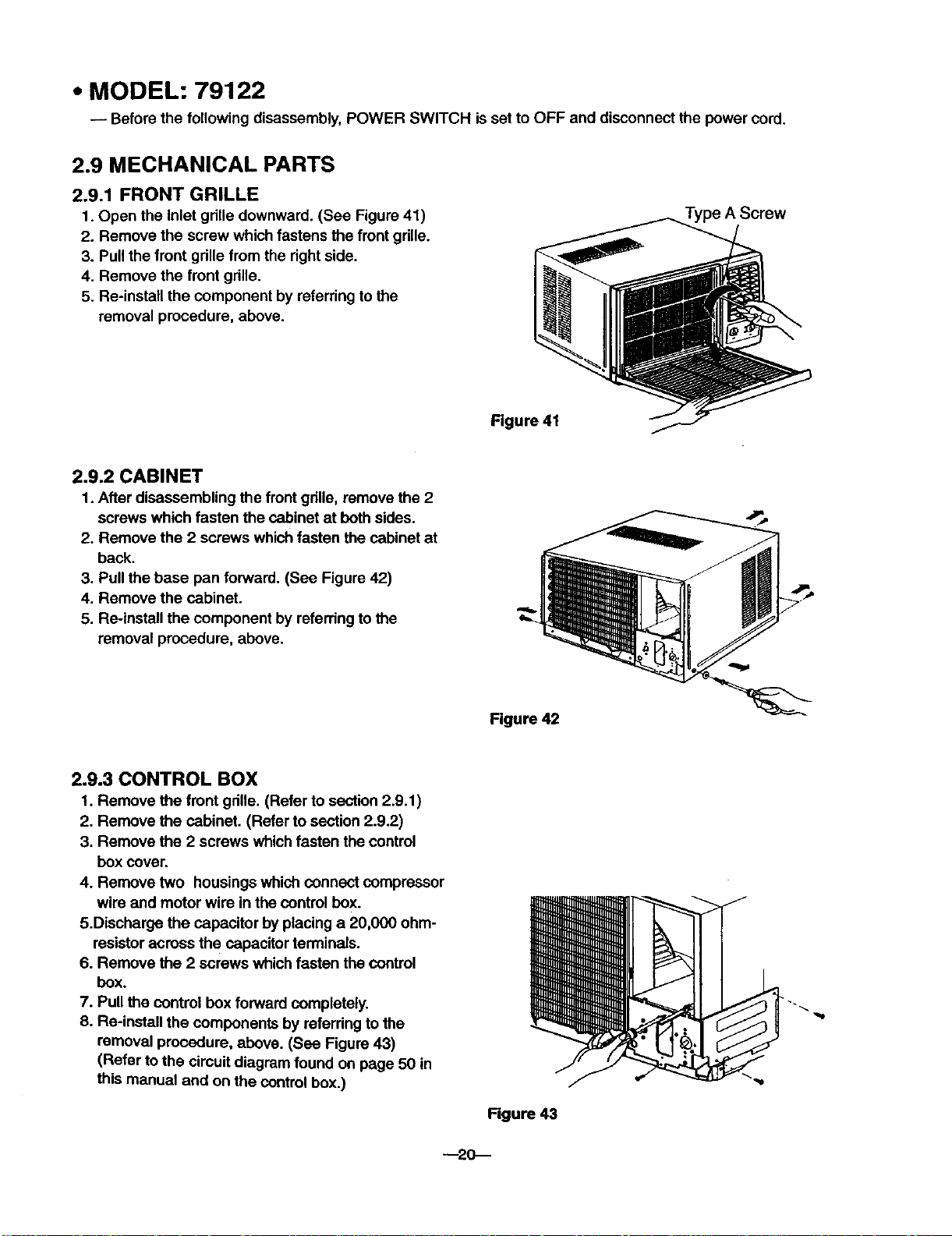

2.8 REFRIGERATION CYCLE

2.8.1 CONDENSER

1. Remove the cabinet. (Refer to section 2.5.2)

2. Discharge the refrigerant system using a Freon_

Recovery System.

If there is no valve to attach the recovery system,

install one (such as a WATCO A-l) before venting

the FreonTM. Leave the valve in place after servic-

ing the system.

3. Remove the 4 screws which fasten the condenser.

4. After discharging the refrigerant completely,

detach the interconnecting tube at the condenser

connections.

5. Remove the condenser.

6. Re-install the component by referring to notes.

Figure 38

2.8.2 EVAPORATOR

1. Remove the cabinet. (Refer to section 2.5.2)

2. Discharge the refrigerant system using a FreonTM

Recovery System.

If there is novalve to attach the recovery system,

install one (such as a WATCO A-l) before venting

the FreonTM. Leave the valve in place after servic-

ing the system.

3. Remove the cover E,P.S and the upper air guide

(Refer to section 2.6.1)

4. After discharging the refrigerant completely,

detach the interconnectingtube at the evaporator

connections.

5. Remove the evaporator.

6. Re-install the component by referring to notes.

2.8.3 CAPILLARY TUBE

1. Remove the cabinet. (Refer to section 2.5.2)

2. Remove the upper air guide. (Refer to section

2.6.1)

3. Discharge the refrigerant system using a Freon_

Recovery System.

Ifthere is no valve to attach the recovery system,

install one (such as a WATCO A-l) before venting

the FreonTM. Leave the valve in place after servic-

ingthe system.

4. After discharging the refrigerant completely,

detach the interconnecting tube at the CAPIL-

LARY TUBE.

5. Remove the CAPILLARY TUBE.

6. Re-install the component by referring to notes.

Figure 39

Figure 40

m19--

• MODEL: 79122

-- Before the following disassembly, POWER SWITCH is set to OFF and disconnect the power cord.

2.9 MECHANICAL PARTS

2.9,1 FRONT GRILLE

1. Open the inlet gdlle downward. (See Figure 41)

2. Remove the screw which fastens the front gdlle.

3. Pull the front gdlle from the right side.

4. Remove the front gdlle.

5. Re-install the component by referring to the

removal procedure, above.

Figure 41

2.9.2 CABINET

1. After disassembling the frontgdlle, remove the 2

screws which fasten the cabinet at both sides.

2. Remove the 2 screws which fasten the cabinet at

back.

3. Pull the base pan forward. (See Figure 42)

4. Remove the cabinet.

5. Re-install the component by referring to the

removal procedure, above.

Type A Screw

2.9.3 CONTROL BOX

1. Remove the front gdlle. (Refer to section 2.9.1 )

2. Remove the cabinet. (Refer to section 2.9.2)

3. Remove the 2 screws whichfasten the control

box cover.

4. Remove two housings which connect compressor

wire and motor wire in the control box.

5.Discharge the capacitor by placing a 20,000 ohm-

resistor across the capacitor terminals.

6. Remove the 2 screws which fasten the control

box.

7. Pull the control box forward completely.

8. Re-install the components by referring to the

removal procedure, above. (See Figure 43)

(Refer to the circuit diagram found on page 50 in

this manual and on the controlbox.)

Figure 42

Rgure 43

--20--

2.10 AIR HANDLING PARTS

2.10.1 AIR GUIDE AND BLOWER

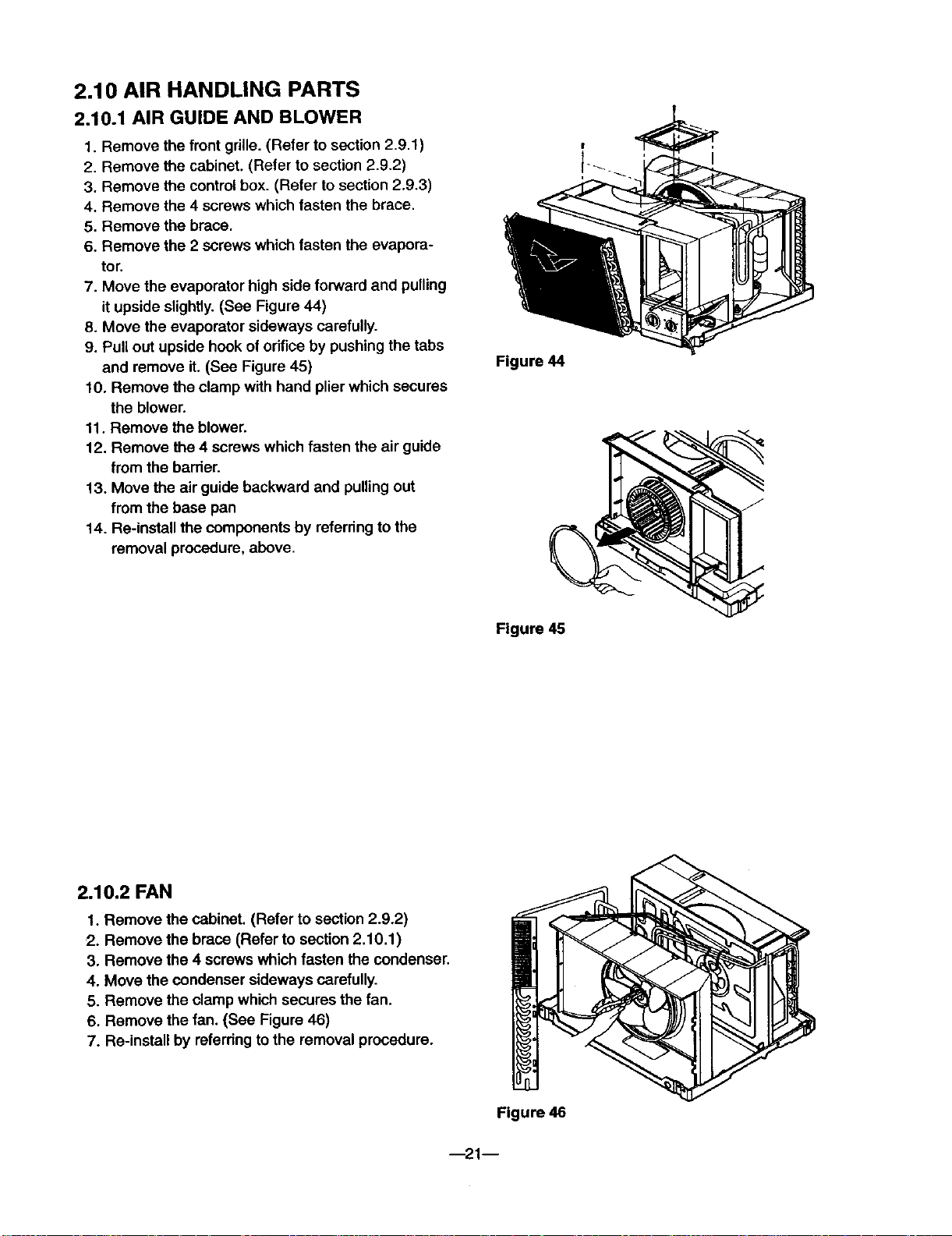

1, Remove the front grille. (Refer to section 2.9.1)

2. Remove the cabinet, (Refer to section 2.9.2)

3. Remove the control box. (Refer to section 2.9,3)

4. Remove the 4 screws which fasten the brace,

5. Remove the brace.

6. Remove the 2 screws which fasten the evapora-

tor.

7. Move the evaporator high side forward and pulling

it upside slightly. (See Figure 44)

8. Move the evaporator sideways carefully.

9. Pull out upside hook of orifice by pushing the tabs

and remove it. (See Figure 45)

10. Remove the clamp with hand plier which secures

the blower.

11. Remove the blower.

12. Remove the 4 screws which fasten the air guide

from the barrier.

13. Move the air guide backward and pulling out

from the base pan

14. Re-install the components by referdng to the

removal procedure, above.

Figure 44

/

2.10.2 FAN

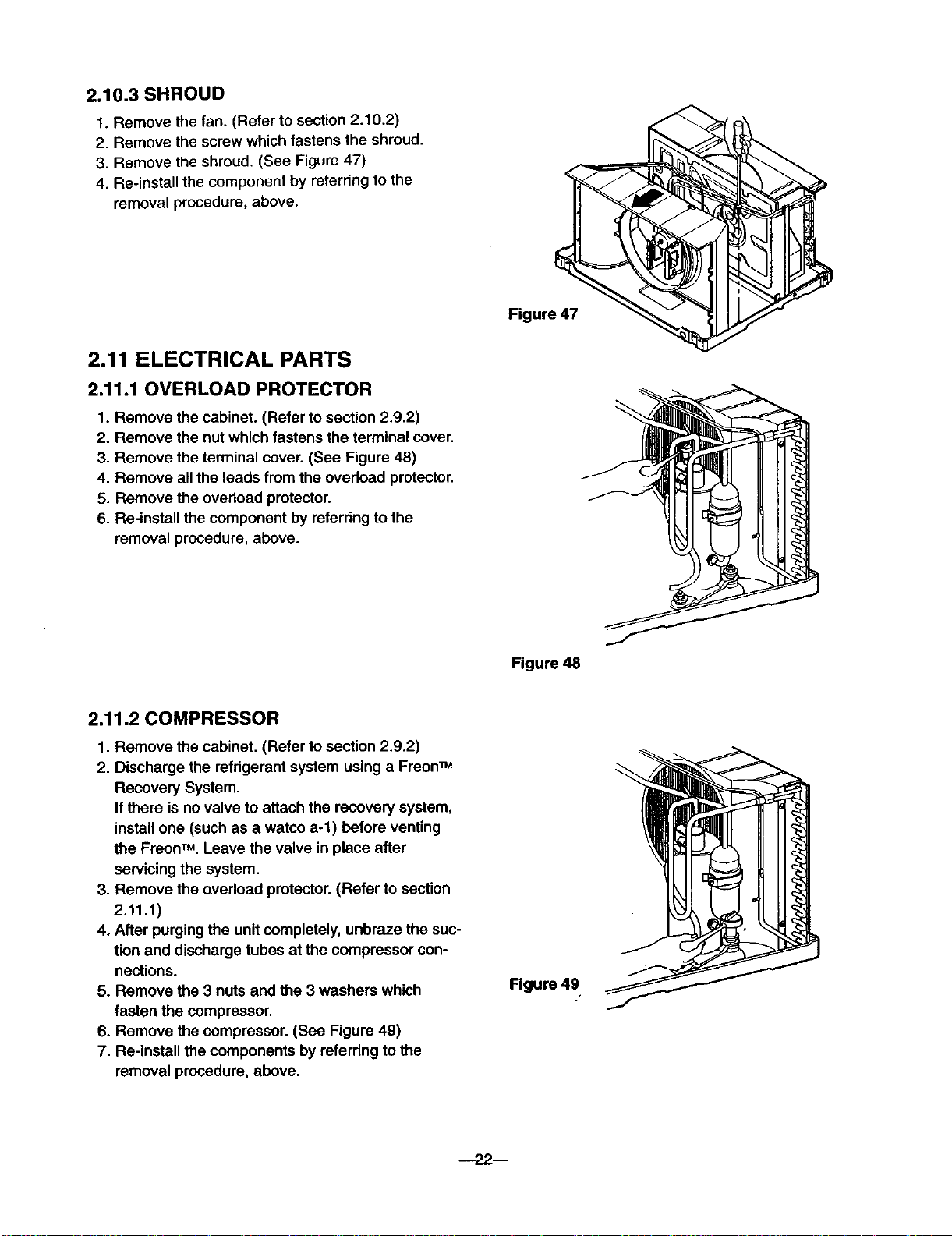

1. Remove the cabinet. (Refer to section 2.9.2)

2. Remove the brace (Refer to section 2.10.1)

3. Remove the 4 screws which fasten the condenser.

4. Move the condenser sideways carefully.

5. Remove the clamp which secures the fan.

6, Remove the fan. (See Figure 46)

7. Re-install by referdng to the removal procedure.

Figure 45

--21--

Figure 46

2.10.3 SHROUD

1. Remove the fan. (Refer to section 2.10.2)

2. Remove the screw which fastens the shroud.

3. Remove the shroud. (See Figure 47)

4. Re-install the component by referring to the

removal procedure, above.

2.11 ELECTRICAL PARTS

2.11.1 OVERLOAD PROTECTOR

1. Remove the cabinet. (Refer to section 2.9.2)

2. Remove the nut which fastens the terminal cover.

3. Remove the terminal cover. (See Figure 48)

4. Remove all the leads from the ovedoad protector.

5. Remove the overload protector.

6. Re-install the component by referring to the

removal procedure, above.

Figure 47

2.11.2 COMPRESSOR

1. Remove the cabinet. (Refer to section 2.9.2)

2. Discharge the refrigerant system using a Freon_

Recovery System.

If there is no valve to attach the recovery system,

install one (such as a watco a-l) before venting

the FreonTM.Leave the valve in place after

servicing the system.

3. Remove the overload protector. (Refer to section

2.11.1)

4. After purging the unit completely, unbraze the suc-

tion and discharge tubes at the compressor con-

nections.

5. Remove the 3 nuts and the 3 washers which

fasten the compressor.

6. Remove the compressor. (See Figure 49)

7. Re-install the components by referring to the

removal procedure, above.

Figure 48

Figure 49

--22D

Loading...

Loading...