Page 1

BEER D1SPE9ISER

OW№R’S INSTRVCnOlVS

Kenmore

MODEL 564.8815022

Биш rms book:

' ItaMill tpll vni I hnw tn npprptp япН care for your beer dispenser. It also offers tips on how to get the

best, as well as lowest cost, performance.

_ ^~

When ordering raplarpmRnt_parts use For parts or service information, call

the part number. Do not use the illustra- your nearest Sears store or Service

tion number. Center, give the complete model num

ber listed above.

ice provided below the model number and serial number

nee. They are located on the model number plate on the

FEEE 0№TEAR

WARRABiTT OIV BEER DISPEIVSER

For one year from the date of purchase, when this beer dispenser is operated and maintained according to owner's in

structions attached to or furnished with the product. Sears will repair this beer dispenser, free of charge, if defective in

material or workmanship. ’

FEEE FIVE-YEAR WARRAIVIT

OIV SEALED REFRIOERAHOAT SYSTEM

For five years from the date of purchase, when this beer dispenser is operated and maintained according to owner’s

instructions attached to or furnished with the product. Sears will repair the sealed system (consisting of refrigeranf, con

necting tubing and compressor motor), free of charge, if defective in material or workmanship.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS

STORE OR SERVICE CENTER THROUGHOUT THE UNITED STATES. "

This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 698/731A, Sears Tower, Chicago, IL 60684

Part No. 302104

SEARS, ROEBUCK AND CO.. U.S.A.

Page 2

Read and understand these instructions thoroughly before installing

beer dispenser.

ASSEMBLY

1. Carton Inventory

Unpack aruJ inspect the parts. Make sure all items are present

and in good condition.

1 Draft arm assembly (Package includes 1 gasket for

draft arm and 1 washer for connection to keg tapper)

1 CO2 regulator

1 CO2 cylinder

1 Keg tapper (Sankey type)

1 Cleaning kit

1 Pressure tube

2 Hose clamps

2 Keg supports (wooden plates)

1 CO2 cylinder retainer (spring)

1 Guard rail

1 Drip tray

4 Wheel casters

4 Hex head screws (5mm dia x 15mm long)

16 Machine screws (5mm dia x 12mm long)

8 Small screws (5mm dia x 10mm long)

2. Install casters

a. Empty the cabinet and then lay down the beer dispenser

sideways so that the door hinge side comes to the top. Be

careful not to cause dents or scratches on the cabinet.

Placing outer carton underneath the cabinet is

recommended.

b. Install casters to the four bottom corners of the cabinet

with the four machine screws (5mm dia x 12mm long) for

each caster.

c. Stand the cabinet upright.

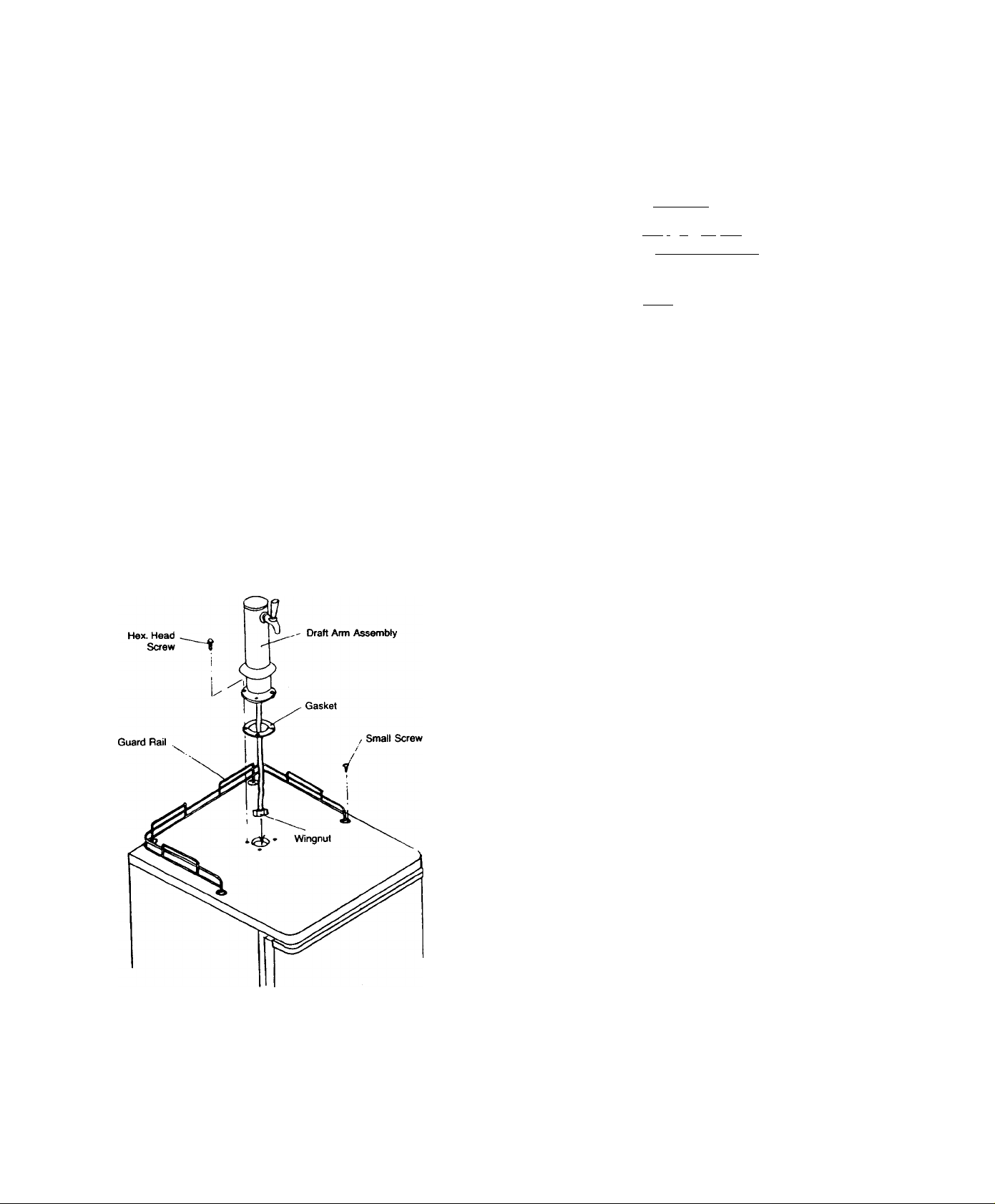

3. Install Draft Arm Assembly (See Fig. 1).

a. Slide gasket over wingnut on bottom of draft arm assem

bly beer tube. Slide gasket up beer tube to draft arm base.

b. Push wingnut and beer tube of draft arm assembly

through hole in top of cabinet until draft arm is resting on

cabinet top.

c. Align holes in draft arm base with holes in gasket and pilot

holes in cabinet top, then secure draft arm to cabinet top

with four hex head screws (5mm dia x 15mm).

4. Install Guard Rail (See Fig. 1).

a. Place guard rail on cabinet top and secure guard rail with

eight small screws.

‘ ■ '

INSTALLATION ^ ’

1. Install beer dispenser on strong, igYfjlutlO^'^ Avoid direct sun

light, hearsdOfcesanS moisture. .

2. Connect to42OVr60*Hz7-l9 Al IfirgrOOf¡31^ TXToutlet. Do not

use extension cord. Use three-prong Dlua^adlh three-prong

grounded waTSuflefT“ . .

WARNING: Unless the atSCiie'groundrng method is followed,

you are not protegtptL .against severe or lethal

shock in the event of a short circuit of an electrical

cpmponenLor-wirittg of beer dispenser.

TEMPERATURE CONTROL

1. Control is located on rear. First set the control at NORMAL pos

ition. Wait for 24 hours to check the temperature then adjust

temperature control, if needed.

DEFROST

1. Beer dispenser will not require much defrosting since the

door opening is at a minimum. Defrost when % inch frost is

built up on the cold plate. The best time to defrost is when

the keg is changed. To defrost, set temperature control at

OFF position and leave door open until ice melts. Defrost

water will accumulate at the bottom of interior cabinet

which can be absorbed with a sponge or towel. Do nofuse

heating devices or sharp objects to speed defrosting

as this could damage cabinet iiner of cold plate. Reset

temperature control after defrosting is completed.

Figl.

INSTALLATION OF BEER SYSTEM

1. Installing CO2 Cylinder and C02 Regulator

WARNING: COj GAS CAN BE DANGEROUS

Read front pages of “Draught Beer Facts” book in

cluded in your cleaning kit for safety precautions

before installaing the CO2 cylinder.

OPERATING INSTRUCTIONS FOR COj CYLINDERS

Do not operate valve control unless cylinder is completely

installed and connected.

TURN HANDWHEEL FULLY COUNTERCLOCKWISE

AS FAR AS IT WILL GO»

IMPORTANT: If valve is not fully opened the stem may not

seal properly against the upper packing washer and the

valve may leak. If leak occurs when fully opened, tighten

down packing nut urKler handwheel then open and dose

valve fully several times. Replacement packing washer

must be ordered directly from valve manufacturer whose

name is stamped on valve.

-2-

Page 3

• Do not remove valve from CO2 cylinder.

Pressure Vessel

• C02 cylinder should be handled only by trained, experi

enced personnel and in accordance with the safe handl

ing practices recommended by the current C.G.A. pam

phlet P-1* *.

• Keep out of reach of children.

• Visually inspect monthly or more frequently. If cylinder

shows evidence of corrosion or mechanical damage, it

should be inspected and tested in accordance with the

current C.G.A. pamphlets C-1* or C-6* or it should be

replaced.

CHARGE ONLY WITH DRY CARBON DIOXIDE

• Do not charge with carbon dioxide unless the pressure

rating stamped on COj cylinder is 1800 PSI or greater.

• When charged with carbon dioxide do not exceed a fill

density of 68%. (Fill density is a percent ratio of the

weight of gas in the cylinder to the weight of water that

the cylinder will hold at 60°F).

• If cylinder has been exposed to temperatures in excess

of 350°R, it must be destroyed.

Improper use of cylinder could cause serious bodily injury

or property damage.

• C.G.A. pamphlets are published by the Compressed

Gas Association, 500 5th Ave., New York, N Y.

a. Your C02 cylinder is shipped empty to avoid any possible

accident during transportation. When you purchase the

first keg of beer, get CO2 cylinder filled by your beer

distributor.

b. Follow the procedure on the inside front cover page of

“Draught Beer Facts" book for installation of CO2 regulator

to CO2 cylinder.

NOTE: Shutoff valve on CO2 cylinder may be different in

shape. Do not open shutoff valve until pressure

tube, keg tapper and beer keg are connected to

COj regulator.

c. Connect pressure tube (clear plastic tube) to CO^ reg

ulator at nipple. Secure connection with hose clamp. To do

this, place hose clamp over tube and squeeze both ends

of hose clamp so that locking teeth will mate.

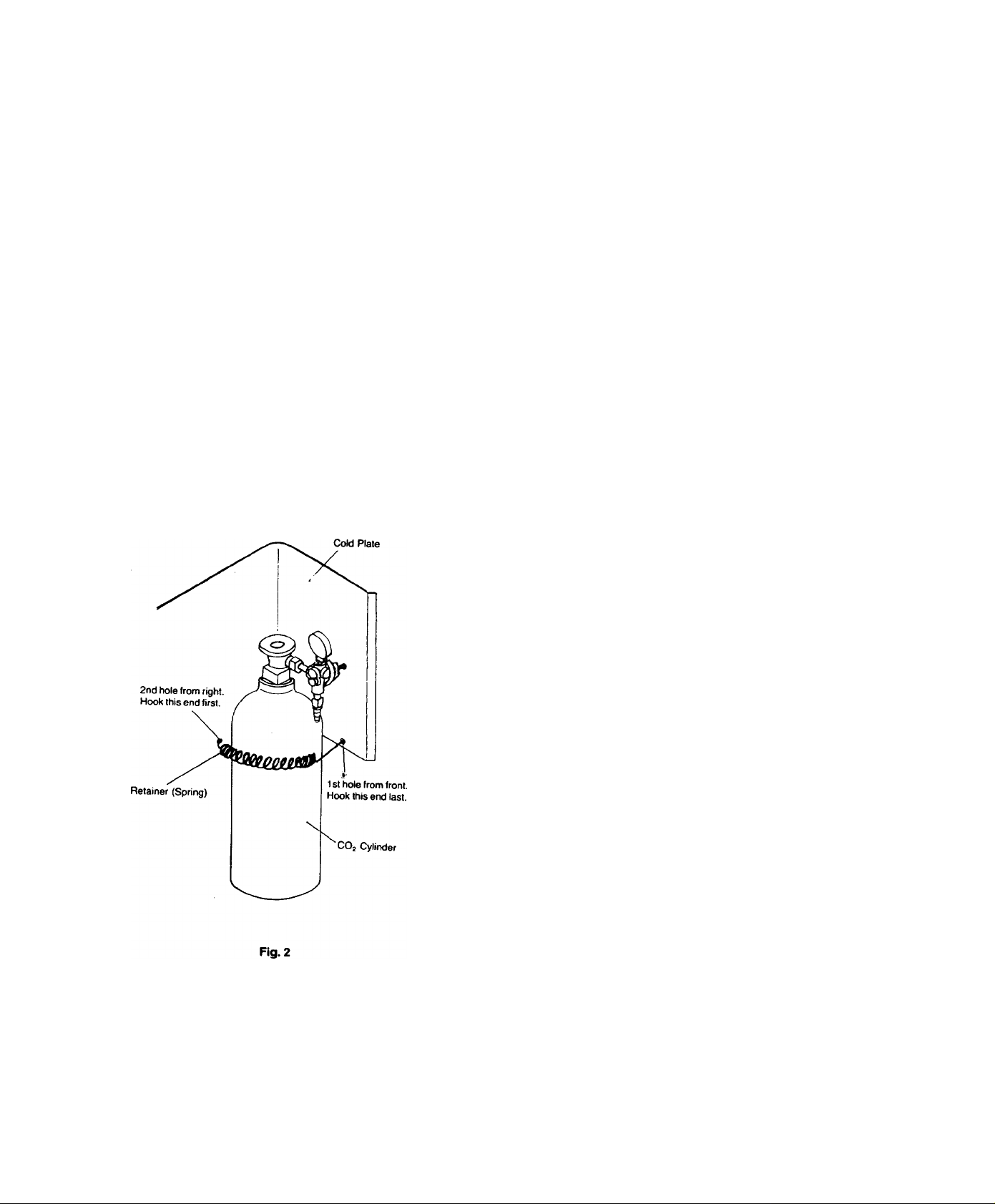

d. Place COj cylinder at right rear corner inside beer dis

penser cabinet in upright position. Fasten CO2 cylinder

with COj cylinder retainer (spring) provided. Hook both

ends of retainer to holes in cold plate. (See Fig. 2.)

WARNING: To avoid personal injury and/or property dam

age, always secure COj cylinder with re

tainer to prevent it from falling. Should CO2

cylinder valve become accidentally damaged

or broken off, C02 cylinder can become an

unguided missile.

2. Installing Keg Tapper and Beer Keg.

a. The Sankey type keg tapper supplied with beer dispenser

is the most widely used in the United States. However,

some other type keg tappers, such as Golden-Gate, Euro

pean Sankey or Hoff-Stevens are still being used. Before

installing keg tapper, check with your beer distributor to

make sure that the Sankey type keg tapper can be used.

If you need a keg tapper other than Sankey type, it is rec

ommended to purchase the tapper you need from your

beer distributor keeping the Sankey type keg tapper for fu

ture use because the Sankey system is becoming more

widely used.

If you wish to have the Sankey type keg tapper exchanged

with another type keg tapper, please return collect the

Sankey type keg tapper to the address below specifying

the type of keg tapper you need:

Sanyo E & E Corp.

2001 Sanyo Avenue

San Diego. California 92173

ATTN: Customer Service Dept.

b.

Make sure shutoff valve on CO^ regulator is in closed posi

tion. Connect pressure tube to nipple of keg tapper (use

hose clamp). Connect beer tube from draft arm to keg tap

per (fasten securely with washer and wingnut).

Make sure that beer faucet and keg tapper are in closed

position, then tap a keg. Open keg tapper valve. (For more

detailed procedures for Items B and C, refer to attached

leaflet.)

Make sure the keg is properly tapped, then open shutoff

valve on CO2 regulator. To install beer keg into cabinet fol

low the steps below (see Fig. 3). —

• Wet the surface of keg supports (wooden plates)

• Lean keg supports on the front bottom edge of

cabinet.

• Place keg on supports supportir>g keg by hands.

• Push the upper part of keg to stand in upright position

then slide keg supports into cabinet.

• Make sure that keg and beer tube do not touch cold

plate and that keg and keg supports are properly

positioned not to interfere with door closing.

Release air caught in draft arm assembly by opening beer

faucet until foam appears. Now dispenser is ready to us.

-3-

Page 4

REPLACING EMPTY KEG

Close shutoff valve on CO2 regulator then remove keg tappei

from empty keg. To tap a new keg, follow the procedures C, D

and E of "Installing Keg Tapper and Beer Keg.”

OPERATION

Place drip tray under beer faucet. To dispense beer, open beer

faucet quickly all the way. I< you have any trouble with beer, refer to

"Draught Beer Facts” book.

The recommended pressure for the C02 system is 8-10 lbs.

CLEANING

1. To maintain good-tasting beer, periodical cleaning of beer

system is required. Complete cleaning kit is provided for

your convenience. Refer to the instructions included in

cleaning kit.

2. To clean cabinet inside and outside, mix 2 tablespoons baking

soda with 1 quarter warm water, or use mild soap. Never use

strong cleanser, scouring powder or pads.

Do not put the drip tray in dishwasher, it is not dishwasher safe.

Vacuum the tubing on outside back twice a year.

To provide protective care of the painted finish:

Regular applications of wax or polish provide vital protection against

rust. Waxing cleans the surface and seals out moisture and other

contaminants.

Use a wax or polish that is suitable for appliances.

Apply the wax or polish when the refrigerator is new and then at

least twice a year.

Between waxings, clean the cabinet with the same polish or

with a CLEAN soft cloth dampened with a mild household de

tergent. Rinse with a CLEAN lightly dampened cloth and DRY

thoroughly.

Page 5

PARTS LIST

MODEL 564.8815022

CAUTION: Use Kenmore part number on ail orders, not the illustration number.

Ulus.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9. 300752 Evap. Bracket (4)

10.

11.

12. 300459 Bolt

13.

14.

15. 300756

16. 300757

17.

18.

19. 300308 Tapping Screw

20.

21.

22.

23.

24.

25.

26. 300762

27.

28.

29. 300308 Tapping Screw

30.

31.

32.

33. 300766 Guard Rail

34. 300767

35. 300768 Draft Arm Assembly

36,

37.

38. 300771

39. 300308

40. 300772 Table Top

41.

42.

43.

44.

45.

Part

No. Description

300746

300747

300748

300308 Tapping Screw

300749 Hinge, Upper

300459 Bolt

300750

300751 BeerTube Sleeve

300140 Machine Screw

300753 Hinge, Lower

300754

300755

300758 Cord Bushing

300759

300760

300165

300463

300308 Tapping Screw

300308 Tapping Screw

300761 Back Cover

300141

300308

300763

300764

300308

300765 Back Cover Support

300769 Small Screw

300770 Drip Tray

300103 Plate, Support (4)

300308

300096

300100

300479

Door Liner

Door Gasket

Door

BeerTube Insulation

Wheel Caster (4)

Machine Screw

Cabinet Assembly

Power Supply Cord

Clamp

Thermostat

Bracket, Thermostat

Machine Screw

Cold Control Dial

Control Knob

Tapping Screw

Bracket, Top Rear Right

Bracket, Top Rear Left

Tapping Screw

Hex Head Screw

Bracket, Top Front (2)

Tapping Screw

Tapping Screw

Condenser

Dryer

Clamp, Thermostat Bulb

Ulus.

No.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

Part

No.

300773

300480

300494

300475

301957

301956

300736 PTC Thermistor

302017

300430 Grommet (4)

300413 Bolt

302016

Description

Evaporator Assembly

Machine Screw

Tapping Screw

Insulation, Tube

Retainer, Relay Cover

Relay Cover

Compressor

Overload Protector

PARTS NOT ILLUSTRATED

Part

No.

300774

300775

300776

300777

300778

300779

300780

300781

302015

302104

300784

Description

CO2 Cylinder

CO2 Regular (consists of the following)

740 Regulator

624 Pressure Gauge

1600c Air Cock

CO2 Cylinder Retainer

Keg Tapper, Sankey

Cleaning Kit (consists of the following)

584P Pump

1841 -1A Cap and Jar Assembly (including tubing)

905W Faucet Brush

904A Hose Brush

4350 Faucet Wrench

1000-1 Cleaning Compound (1 lb.)

DBF Draught Beer Facts Book

JK Cleaning Instructions

Pressure Tube

Hose Clamp (2)

Keg Support (2)

Owner's Instruction Manual

Technical Sheet

Use & Care Label

OPTIONAL KEG TAPPERS (Not Included)

300786 European Sankey

300787 Golden Gate, Vent

300788 Golden Gate, Key Tap

300789 Hoff-Stevens

-5-

Page 6

Page 7

Page 8

TR" DRAUGHT ARM PARTS

4318 4322

4324 4328

Part No. Description

D-19-60AC

Beer Tube Assembly

759 Washer

D-2 Coupling Nut

D-5N Shank

D-6

D7P

D-8

D9R

D-10

Outside Flange

Inside Flange

Lock Nut

Gland

Inverted Flare Nut

4301 Black Knob

4302 Knob Lever Collar

4306 Knob Lever Bonnet

4308

4311

4312

4313

4316

4318

4322

4324

Friction Washer

Ball Washer

Brass Lever

Stainless Steel Lever

Body

Coupling Gasket

T-R Shaft

T-R Valve Seat

4326 T-R Shaft^Nut

4328 Snap Ring

4330 Sleeve

D12-2P Cap

D12-1 Cap 0-Ring

D-15-2P

D14-9

Flange Cover

Cylinder

D-16 Gasket

D17-8

Cylinder Insulation

4326

4330

-8-

8336 4119 51702

Loading...

Loading...