Kenmore 41797912702, 41797912704, 41797962701, 41797962703 Installation Guide

27" (69 cm) Wide

LAUNDRY CENTER

Washer- Dryer

Installation Instructions

CENTRO DE LAVANDERiA

de 27" (69 cm) de ancho

Lavadora - Secadora

Instrucciones para la instalaci6n

J

I

i

\

Table Of Contents

S UBJECT PAGE

Pre-lnstallation Requirements ............................... 2

Electrical Requirements .......................................... 3

Water Supply Requirements .................................... 3

Drain Requirements ................................................. 3

Exhaust System Requirements ................................. 4-5

Gas Supply Requirements ........................................... 5

Location ................................................................... 5

Rough-In Dimensions ............................................. 6

Mobile Home Installation ........................................... 7

Unpacking .............................................................. 7

Electrical Installation ................................................. 8

Grounding Requirements ......................................... 8

3 & 4-Wire Connections ............................................ 9

Installation ....................................................... 10-11

Replacement Parts ................................................. 11

PIN 134809300C (0904)

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A. www.sears.com

Indice

MA TERIA PA GINA

Requerimientos de instalacion preliminares .................... 12

Requerimientos electricos ........................................... 13

Requerimientos del sumin istro de agua .......................... 13

Requenmlentos de desagOe .......................................... 13

Requerimientos del sistema de escape ..................... 14-15

Requerimientos del suministro de gas............................. 15

Ubicacidn ....................................................................... 15

Dimensiones para la instalaci6n ..................................... 16

Instalaci6n en casas m6viles ........................................ 17

Desembalaje ........................................................................ 17

Instalaci6n electrica ..................................................... 18

Requerimientos para la puesta a tierra ........................... 18

Conexi6nes electricas - trifilares y tetrafilares .......... 18-19

Instalaci6n .............................................................. 19-20

Repuestos ................................................................... 20

_This isthe safety alert symbol. This symbol alerts you to hazards that can kill or hurt you or others. All safety messages will

be preceded by the safety alert symbol and the word "DANGER" or "WARNING ". Thesewords mean:

You can be killed or seriously injured if you don't immediately follow instructions.

You can be killed or seriously injured if you don't follow instructions.

All safety messages will identify the hazard, tell you how to reduce the chance of injury, and tell you what can happen if the

instructions are not followed.

Foryour safety the information in this manual must be followed to minimize the risk of fire or

explosion or to prevent property damage, personal injury or loss of life. Do not store or use gasoline or other flammable vapors

and liquid in the vicinity of this or any other appliance.

Readall of the following instructions before installing and using this appliance.

• Destroy the carton and plastic bags after the Laundry Center is unpacked. Children might use them for play. Cartons

covered with rugs, bedspreads, or plasic sheets can become airtight chambers causing suffocation. Placeall materials in a

garbage container or make materials inaccessible to children.

Installations must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or license by the state,

province, or region where this appliance is being installed.

Before beginning installation, carefully read these instructions. Thiswill simplify the installation and ensure the Laundry Center

is installed correctly and safely. Leave these instructions near the Laundry Center after installation for future reference.

The electrical serviceto the Laundry Center must conform with local codes and ordinances and the latest edition of the National

Electrical Code, ANSI/NFPA70, or in Canada, the Canadian electrical code C22.1 part 1.

The gas serviceto the Laundry Center must conform with local codes and ordinances and the latest edition of the National Fuel

GasCode ANSI Z223.1, or in Canada, CAN/ACG B149.1-2000.

The Laundry Center isdesigned under ANSI Z 21.5.1 or ANZl/UL 2158 - CAN/CSA C22.2 No. 112 (latest editions) for HOME

USEonly. This Laundry Center is not recommended for commercial applications such as restaurants or beauty salons, etc.

Do not install a Laundry Center with flexible plastic venting materials. Flexibleventing materials are known to collapse, be

easily crushed and trap lint. These conditions will obstruct clothes dryer airflow and increase the risk of fire.

Your safety and the safety of others isvery important. We have provided many important safety messages in the

Installation Instructions / Use & Care Guide and on your appliance. Always read and obey all safety messages.

The instructions in this manual and other literature included with this dryer are not meant to cover every possible condition and

situation that may occur. Good safe practice and caution MUST be applied when installing, operating and maintaing any

appliance.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

Clear the room, building or area of all occupants.

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

If you cannot reach your gas supplier, call the fire department.

Tools and Materials Required for Installation:

Adjustable pliers.

Phillips, straight, & square bit screwdrivers.

Adjustible wrench.

Pipe wrench for gas supply (gas dryer).

LP-resistant thread tape (for natural

gas or LPsupply, gas dryer)

Carpenter's level.

External vent hood.

Rigid or semi-rigid metal 4 inch

(10.2 cm) exhaust duct work.

3-wire or 4-wire 240 volt corg kit

(electric dryer).

4 in. (10.2 cm) clamp.

Gas line shutoff valve (gas dryer).

1/2NPTunion flare adapters (x2) and

flexible gas supply line (gas dryer).

Metal foil tape not (duct tape).

[

CIRCUIT- Individual 30 amp. branch circuit fused with 30

amp. time delay fuses or circuit breakers.

Use separately fused circuits for washers and dryers, and DO

NOToperate a washer and a dryer on the same circuit.

POWER SUPPLY- 3 wire or 4-wire, 240 volt, single phase, 60

Hz, Alternating Current.

POWER SUPPLYCORD KIT- 3 wire - the dryer MUSTemploy

a 3-conductor power supply cord NEMA 10-30 type SRDTrated

at 240 volt AC minimum, 30 amp., with 3 open end spade lug

connectors with upturned ends or closed loop connectors and

marked for use with clothes dryers. See ELECTRICAL

CONNECTIONSFORA 3-WIRE SYSTEM.

4 wire - The dryer MUSTemploy a 4-conductor power supply

cord NEMA 14-30 type SRDTor ST(as required) rated at 240

volt AC minimum, 30 amp., with 4 open end spade lug

connectors with upturned ends or closed loop connectors and

marked for use with clothes dryers. See ELECTRICAL

CONNECTIONSFORA 4-WIRE SYSTEM.

(Canada - 4-wire power supply cord is installed on dryer.)

WARNING- Risk of Shock. Appliance grounded to neutral

conductor through a link. Grounding through the neutral link is

prohibited for (1) New branch circuit installations (2) mobile

homes; (3) recreational vehicles; and (4) areaswhere local codes

do not permit grounding through the neutral, (1) disconnect the

link from the neutral, (2) use grounding terminal or lead to

ground appliance in accordancewith localcodesand (3)connect

neutral terminal or lead to branch circuit neutral in usual manner

(if the appliance is to be connected by means of a cord kit, use

4-conductor cord for this purpose). USECOPPERCONDUCTOR

ONLY.

OUTLET RECEPTACLE- NEMA 10-30R receptacle to be located

so the power supply cord is accessible when the dryer is in the

installed position. (Canada - NEMA 14-30R receptacle.)

ELECTRICLaundry Center

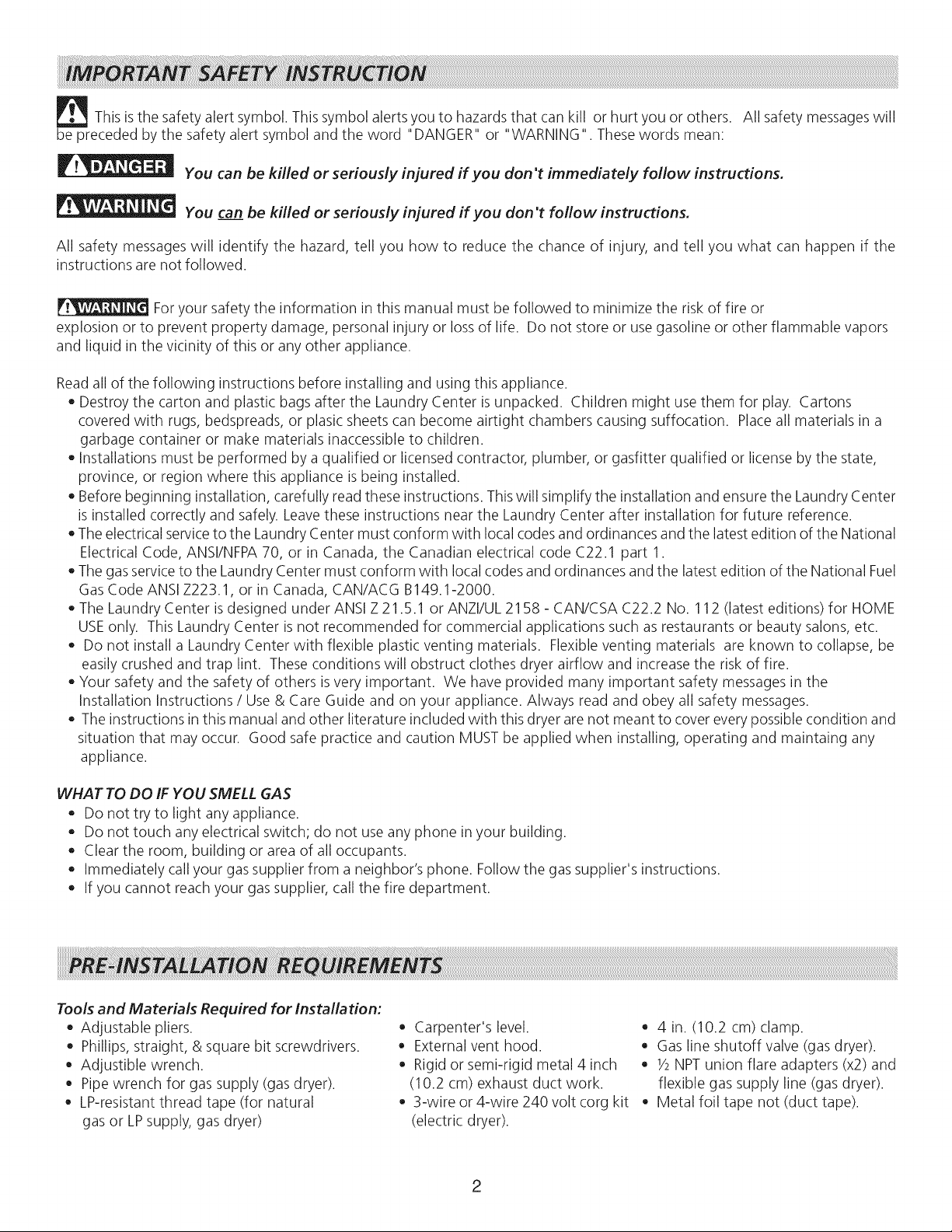

NOTE:Do not under

any circumstances

remove grounding

]

prong from plug.

\

Grounding Prong

Hot and cold water faucets MUSTbe installed within 42 inches

(106.68 cm) of your laundry center's water inlet. The faucets

MUSTbe 3/4 inch (1.9 cm) garden hose type soinlet hoses can

be connected. Water pressure MUST be between 10 and 120

pounds per square inch (maximum unbalance pressure, hot vs.

cold, 10 psi). Your water department can advise you of your

water pressure.

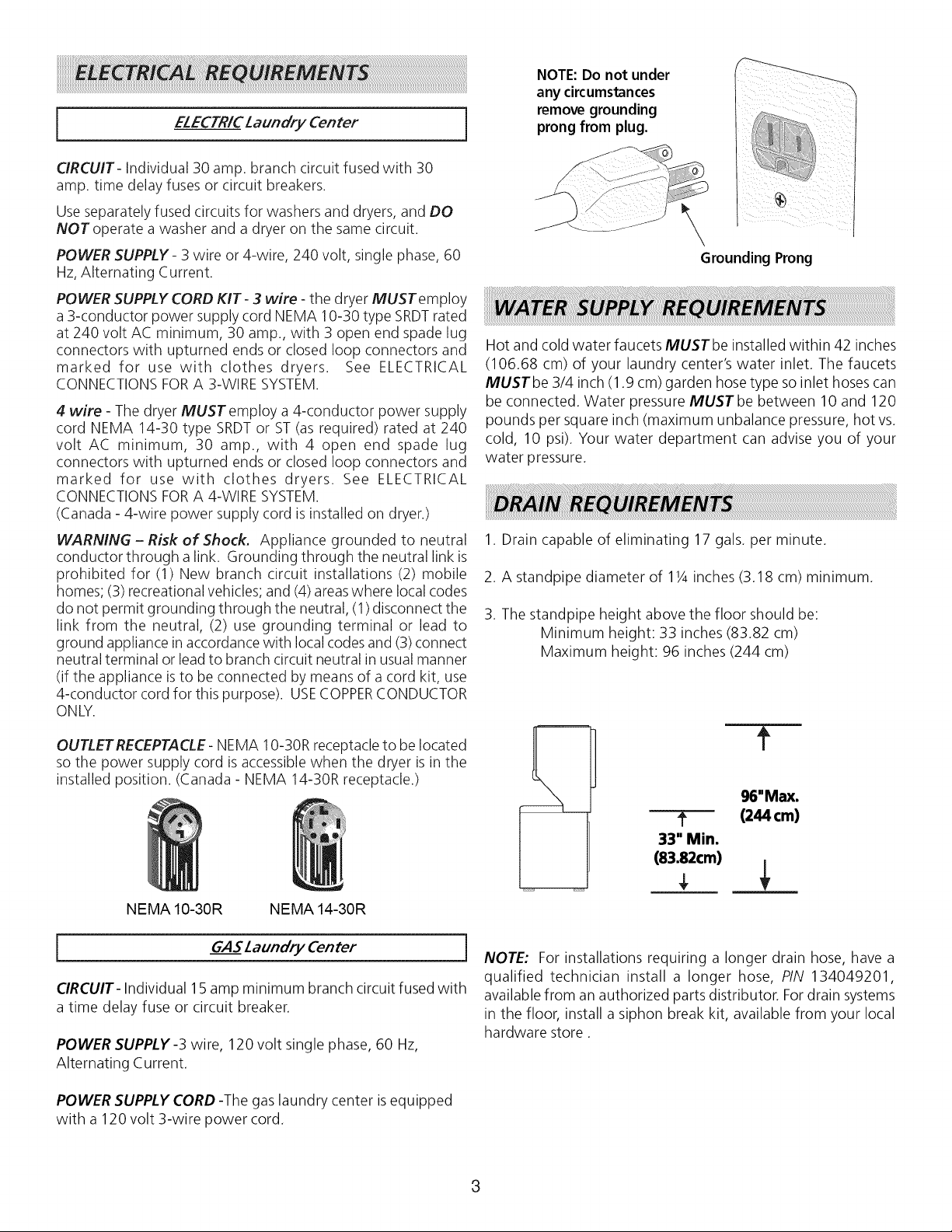

1. Drain capable of eliminating 17 gals. per minute.

2. A standpipe diameter of 11/4inches (3.18 cm) minimum.

3. The standpipe height above the floor should be:

Minimum height: 33 inches (83.82 cm)

Maximum height: 96 inches (244 cm)

m

f

96"Max.

? (244cm)

33" Min.

(83.82cm)

NEMA 10-30R NEMA 14-30R

[ GASLaundryCenter ]

CIRCUIT- Individual 15 amp minimum branch circuit fused with

a time delay fuse or circuit breaker.

POWER SUPPLY-3 wire, 120 volt single phase, 60 Hz,

Alternating Current.

POWER SUPPLY CORD -The gas laundry center is equipped

with a 120 volt 3-wire power cord.

NOTE: For installations requiring a longer drain hose, have a

qualified technician install a longer hose, PIN 134049201,

available from an authorized parts distributor. Fordrain systems

in the floor, install a siphon break kit, available from your local

hardware store.

3

Use only 4 inch (10.2 cm) diameter (minimum) rigid or flexible

metal duct and approved vent hood which has a swing-out

damper(s) that open when the dryer is in operation. When the

dryer stops, the dampers automatically close to prevent drafts

and the entrance of insects and rodents. Toavoid restricting the

outlet, maintain a minimum of 12 inches (30.5 cm) clearance

between the vent hood and the ground or any other obstruction.

The following are specific requirements for

proper and safe operation of your dryer. Failure to follow

these instructions can create excessive drying times and

fire hazards.

Do not install a dothes dryer with flexible

plastic venting materials. If your present system is made up

of plastic duct or metal foil duct, replace itwith a rigid or flexible

metal duct. Flexible venting materials are known to collapse,

be easily crushed and trap lint. These conditions will obstruct

clothes dryer airflow and increase the risk of fire. Ensure the

present duct is free of any lint prior to installing dryer

duct.

L

Do not allow combustible materials (for

example: dothing, draperies/curtains, paper) to come in

contact with exhaust system. The dryer MUST NOT be

exhausted into a chimney, a wall, a ceiling, or any concealed

space of a building which can accumulate lint, resulting in a fire

hazard.

Exceeding the length of duct pipe or number

of elbows allowed in the "MAXIMUM LENGTH" charts can

cause an accumulation of lint in the exhaust system. Plugging

the system could create a fire hazard, aswell as increase drying

times.

Do not screen the exhaust ends of the vent

system, nor use any screws, rivets or other fastening means

that extend into the duct and catch lint to assemble the

exhaust system. Lint can become caught in the screen, on the

screwsor rivets,clogging the duct work and creating a fire hazard

aswell as increasing drying times. Use an approved vent hood

to terminate the duct outdoors, and seal all joints with duct

tape. All male duct pipe fittings MUSTbe installed downstream

with the flow of air.

Explosion hazard. Do not install the dryer

where gasoline or other flammables are kept or stored. If

the dryer is installed in a garage, it must be a minimum of 18

inches (45.7 cm) above the floor. Failure to do so can result in

death, explosion, fire or burns. The exhaust systembackpressure

MUST not exceed 0.6 inches (1.52 cm) of water column,

measured with an inclined manometer at the point the exhaust

connects to the dryer. The exhaust system should be inspected

and cleaned a minimum of every 18 months with normal

usage. The more the dryer is used, the more often you should

check the exhaust system and vent hood for proper operation.

7

- Risk of Fire - A clothes dryer must be

exhausted outdoors. Do not exhaust dryer into a chimney, a

wall, a ceiling, an attic, a crawl space or any concealed space

of a building A clothes dryer produces combustible lint. If the

dryer is not exhausted outdoors some fine lint will be expelled

into the laundry area. An accumulation of lint in any area of the

home can create a health and fire hazard. The dryer must be

connected to an exhaust outdoors. Regularly inspect the

outdoor exhaust opening and remove any accumulation of lint

around the outdoor exhaust opening and in the surrounding

area.

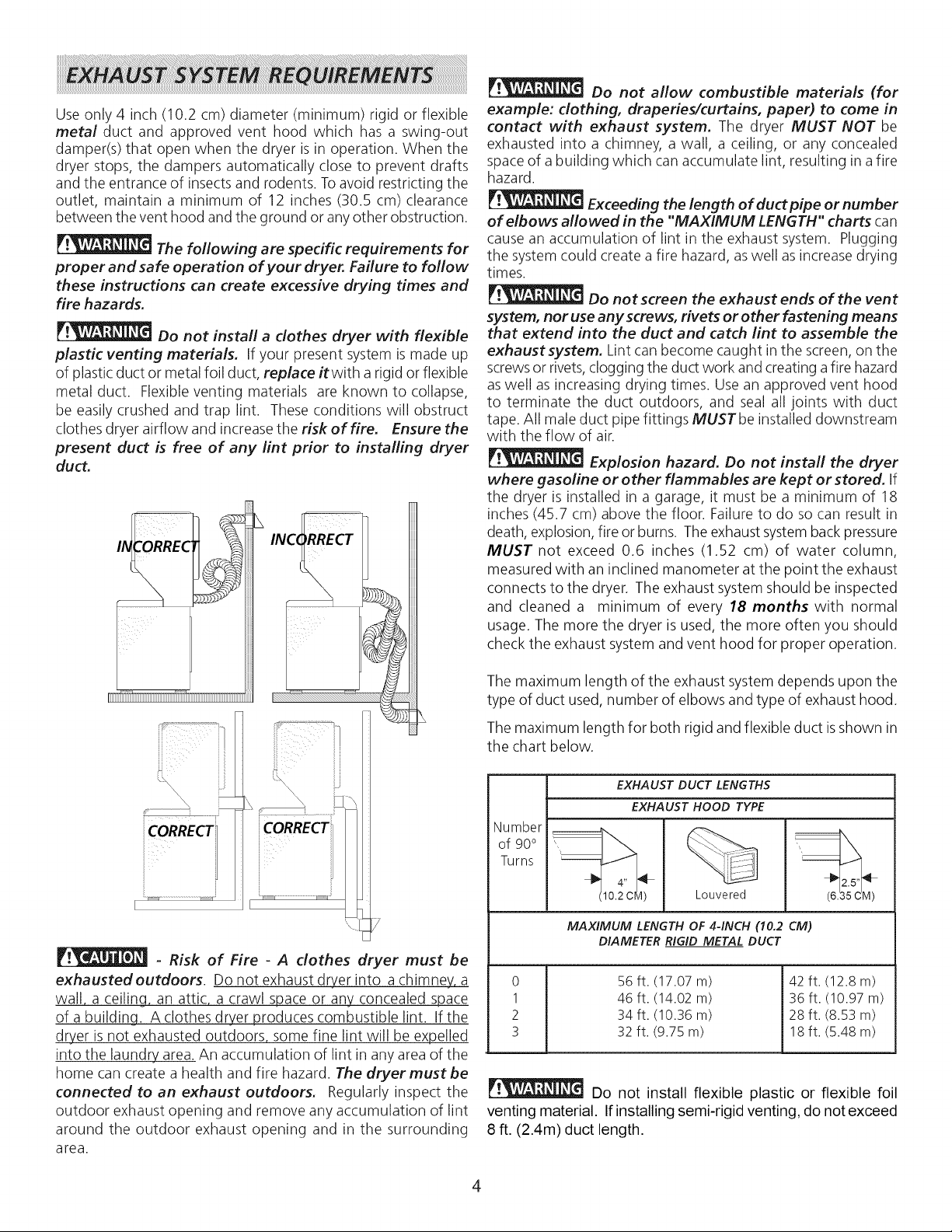

The maximum length of the exhaust system depends upon the

type of duct used, number of elbows and type of exhaust hood.

The maximum length for both rigid and flexible duct is shown in

the chart below.

EXHAUST DUCT LENGTHS

EXHAUST HOOD TYPE

Number

of 90°

Turns

_ 2.5"

(10.2 CM) Louvered

MAXIMUM LENGTH OF 4-INCH (10.2 CM)

DIAMETER RIGID METAL DUCT

0

1

2

3

56 ft. (17.07 m)

46 ft. (14.02 m)

34ft. (10.36 m)

32 ft. (9.75 m)

(6_

42 ft. (12.8 m)

36 ft. (10.97 m)

28 ft. (8.53 m)

18 ft. (5.48 m)

Do not install flexible plastic or flexible foil

venting material. If installing semi-rigid venting, do not exceed

8 ft. (2.4m) duct length.

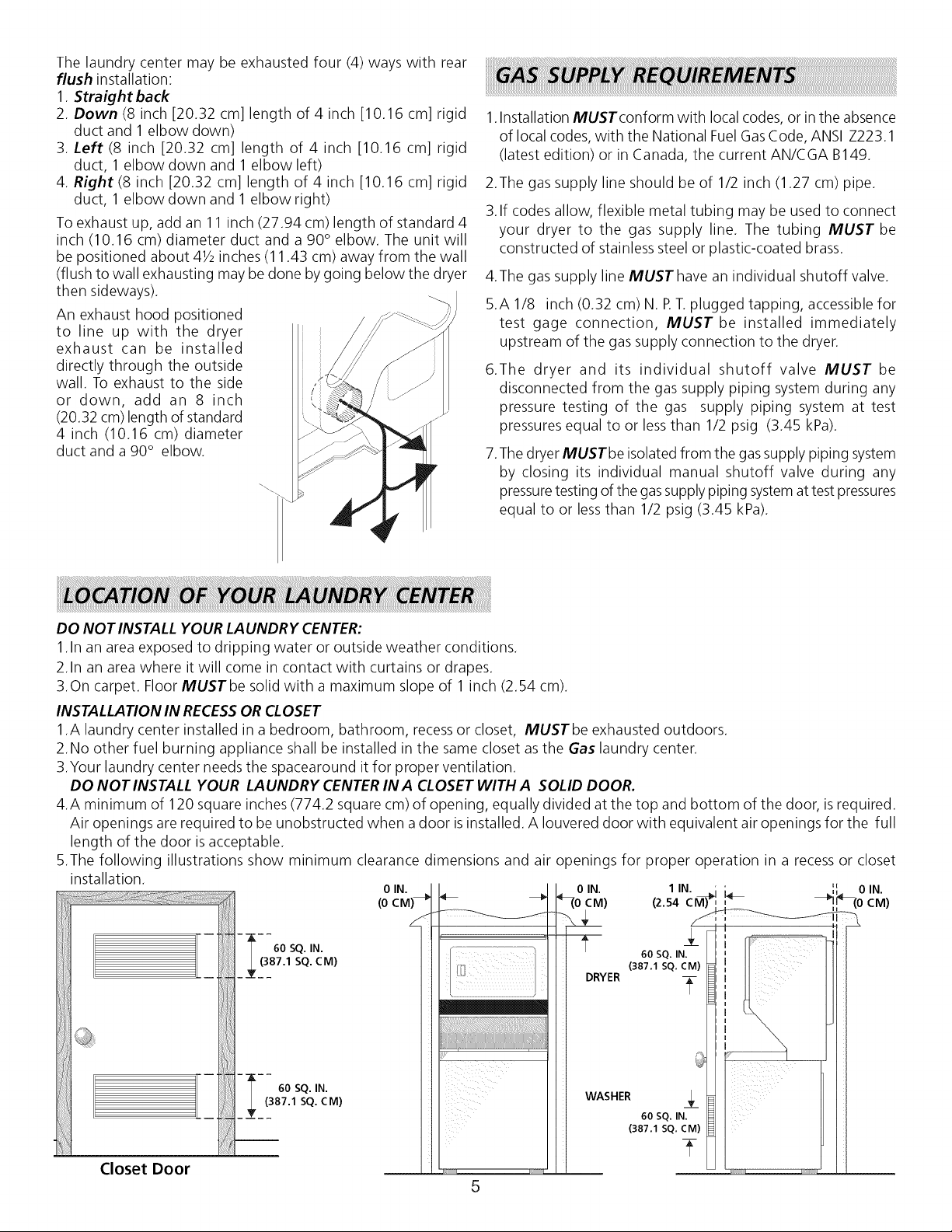

Thelaundrycentermaybeexhaustedfour(4)wayswithrear

flushinstallation:

1.Straight back

2. Down (8 inch [20.32 cm] length of 4 inch [10.16 cm] rigid

duct and 1 elbow down)

3. Left (8 inch [20.32 cm] length of 4 inch [10.16 cm] rigid

duct, 1 elbow down and 1 elbow left)

4. Right (8 inch [20.32 cm] length of 4 inch [10.16 cm] rigid

duct, 1 elbow down and 1 elbow right)

To exhaust up, add an 11 inch (27.94 cm) length of standard 4

inch (10.16 cm) diameter duct and a 90° elbow. The unit will

be positioned about 41/2inches (11.43 cm) away from the wall

(flush to wall exhausting may be done by going below the dryer

then sideways).

An exhaust hood positioned

to line up with the dryer

exhaust can be installed

directly through the outside

wall. To exhaust to the side

or down, add an 8 inch

(20.32 cm) length of standard

4 inch (10.16 cm) diameter

duct and a 90° elbow.

......

1.Installation MUST conform with local codes, or in the absence

of local codes, with the National Fuel GasCode, ANSI Z223.1

(latest edition) or in Canada, the current AN/CGA B149.

2.The gas supply line should be of 1/2 inch (1.27 cm) pipe.

3.If codes allow, flexible metal tubing may be used to connect

your dryer to the gas supply line. The tubing MUST be

constructed of stainless steel or plastic-coated brass.

4.The gas supply line MUSThave an individual shutoff valve.

5.A 1/8 inch (0.32 cm) N. F T.plugged tapping, accessible for

test gage connection, MUST be installed immediately

upstream of the gas supply connection to the dryer.

6.The dryer and its individual shutoff valve MUST be

disconnected from the gas supply piping system during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.45 kPa).

7.The dryer MUSTbe isolated from the gassupply piping system

by closing its individual manual shutoff valve during any

pressuretesting of the gas supply piping systemat test pressures

equal to or less than 1/2 psig (3.45 kPa).

DO NOT INSTALL YOUR LAUNDRY CENTER:

1.In an area exposed to dripping water or outside weather conditions.

2.In an area where it will come in contact with curtains or drapes.

3.On carpet. Floor MUSTbe solid with a maximum slope of 1 inch (2.54 cm).

INSTALLATION IN RECESSOR CLOSET

1.A laundry center installed in a bedroom, bathroom, recess or closet, MUSTbe exhausted outdoors.

2.No other fuel burning appliance shall be installed in the same closet asthe Gas laundry center.

3.Your laundry center needs the spacearound it for proper ventilation.

DO NOT INSTALL YOUR LAUNDRY CENTER IN A CLOSET WITH A SOLID DOOR.

4.A minimum of 120 square inches (774.2 square cm) of opening, equally divided at the top and bottom of the door, is required.

Air openings are required to be unobstructed when a door isinstalled. A Iouvered door with equivalent air openings for the full

length of the door is acceptable.

5.The following illustrations show minimum clearance dimensions and air openings for proper operation in a recess or closet

installation.

60 SQ.iN. 60SQ._N.

(387.1 SQ. CM) (387.1 SQ. CM) I_ II III

0 IN.

(0 _(0 c

0 IN. 1 IN. ; ; ',', 0 IN.

M) (2.54CM)'I,,_ _(0 CM)

Closet Door

(387.1 SQ. CM)

60 SQ. IN. _ I

5

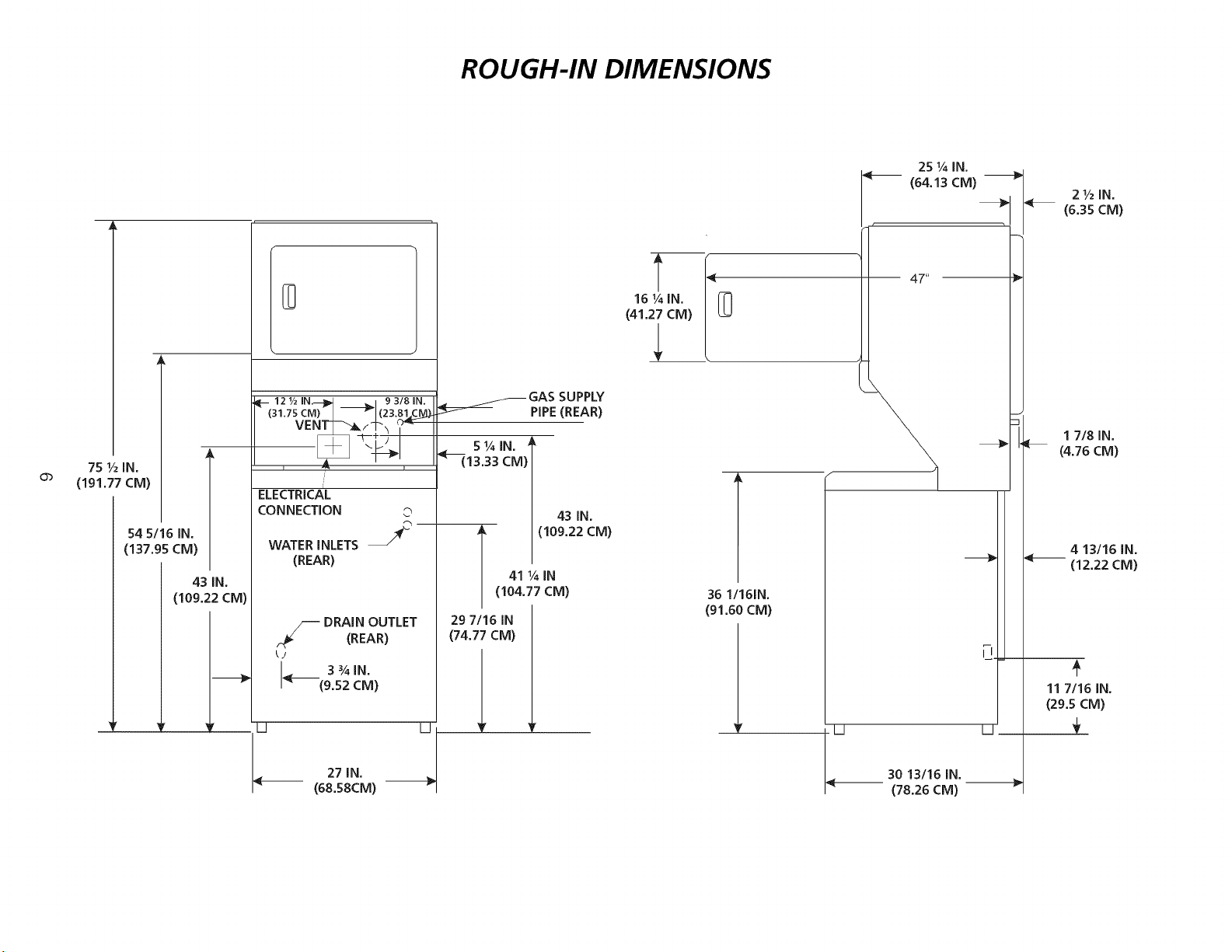

ROUGH-IN DIMENSIONS

75 1/2IN,

(191,77 CM)

54 5/16 IN,

(137.95 CM)

43 IN.

(109.22 CM)

D

II-- 121/2 IN.--]II_I _ , 93181N.

(31.75 CM) _ _1(23"81_C_

VENT_I_ _,_'_

ELECTRICAL

CONNECTION ©

WATER INLETS J_

(REAR)

_._/_ DRAIN OUTLET

<__ 3%1N,

II D

(REAR)

(9,52 CM)

_.____._ GAS SUPPLY

13.33 CM)

A (109.22 CM)

29 7/16 IN

(74.77 CM)

PIPE(REAR)

43 IN.

41 ¼ IN

(104.77 CM)

16 ¼ IN,

(41,27 CM)

U

l

36 1/161N.

(91.60CM)

II

27 IN.

(68,58CM)

30 13116 IN.

(78.26 CM)

Loading...

Loading...