Kenmore 41797812700, 41797812704, 41797822700, 41797822701, 41797912700 Installation Guide

...

27" (69 cm) Wide

LAUNDRY CENTER

Washer- Electric Dryer

CENTRO DE LAVANDERiA

de 27" (69 cm) de ancho

Lavadora - Secadora electrica

\

iii

P/N 134809300 (0610) Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A. www.sears.com

SUBJECT PA GE

Contents

Pre-lnstallation Requirements .......................................... 2

Electrical Requirements ................................................... 2

Water Supply Requirements ........................................... 2

Drain Requirements .......................................................... 3

Exhaust System Requirements .................................. 3-4

Gas Supply Requirements ................................................ 4

Location ............................................................................ 4

Rough-In Dimensions ....................................................... 4

Mobile Home Installation ................................................. 5

Unpacking ......................................................................... 5

Electrical Installation ........................................................ 6

Grounding Requirements ................................................ 6

3 & 4-Wire Connections ........................................... 6-7

Installation .................................................................... 7-8

Replacement Parts........................................................... 8

Before beginning installation, carefully read these instructions.

This will simplify the installation

and ensure the laundry center is installed correctly and safely.

Leave these instructions near the

laundry center after installation for future reference.

NOTE: The electrical service to the laundry center must con-

form with local codes and ordinances and the latest edition of

the National Electrical Code, ANSI/NFPA 70, or in Canada, the

Canadian Electrical Code, CSA C22.1

NOTE: The gas service to the laundry center must conform with

local codes and ordinances and the latest edition of the National

Fuel Gas Code ANSIZ223. I/NFPA 54, or in Canada, the Canadian

Natural Gas andPropane Installation Code, CSA B149. 1.

NOTE: The laundry center is designed under ANSI Z21.5.1 or

ANSI/UL 2158- CAN/CSA C22.2 No. 112 (latest edition) for HOME

USE only. This laundry center is not recommended for commer-

cial applications such as restaurants or beauty salons, etc.

For your safety the information in this manual must

be followed to minimize the risk of fire or explosion or to prevent

property damage, personal injury or loss of life.

- Do not store or use gasoline or other flammable vapors and

liquid in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in

your building.

Clear the room, building or area of all occupants.

Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

If you cannot reach your gas supplier, call the fire

department.

Installation and service must be preformed by a qualified installer,

service agency or the gas supplier.

ELECTRICAL REQUIREMENTS

ELECYRICLaundry Center

Circuit- Individual 30 amp branch circuit fused with 30 amp minimum

time delay fuses or circuit breakers.

POWER SUPPLY - 3-wire or 4-wire, 240 volt, single phase, 60 Hz,

Alternating Current.

POWER SUPPLY CORD KIT- The laundry center MUST employ a 3-

condutor power supply cord NEMA 10-30 type SRDT rated at 240

volt AC minimum, 30 amp, with 3 open end spade lug connectors

with upturned ends or closed loop connector OR a 4-condutor power

supply cord NEMA 14-30 type SRDT or ST (as required) rated at 240

volt AC minimum, 30 amp, with 4 open end spade lug connectors

with upturned ends or closed loop connectors and marked for use

with clothes dryers. If being installed in a new branch circuit

installation, manufactured (mobile) home, recreational vehicle or area

which prohibits grounding through the neutral conductor, the laundry

center MUST employ a 4-condutor power supply cord NEMA 14- 30

type SRDT or ST (as required) rated at 240 volt AC minimum, 30 amp,

with 4 open end spade lug connectors with upturned ends or closed

loop connectors and marked for use with clothes dryers. See

ELECTRICAL CONNECTIONS. (Canada - 4-wire power supply cord is

installed on laundry center.)

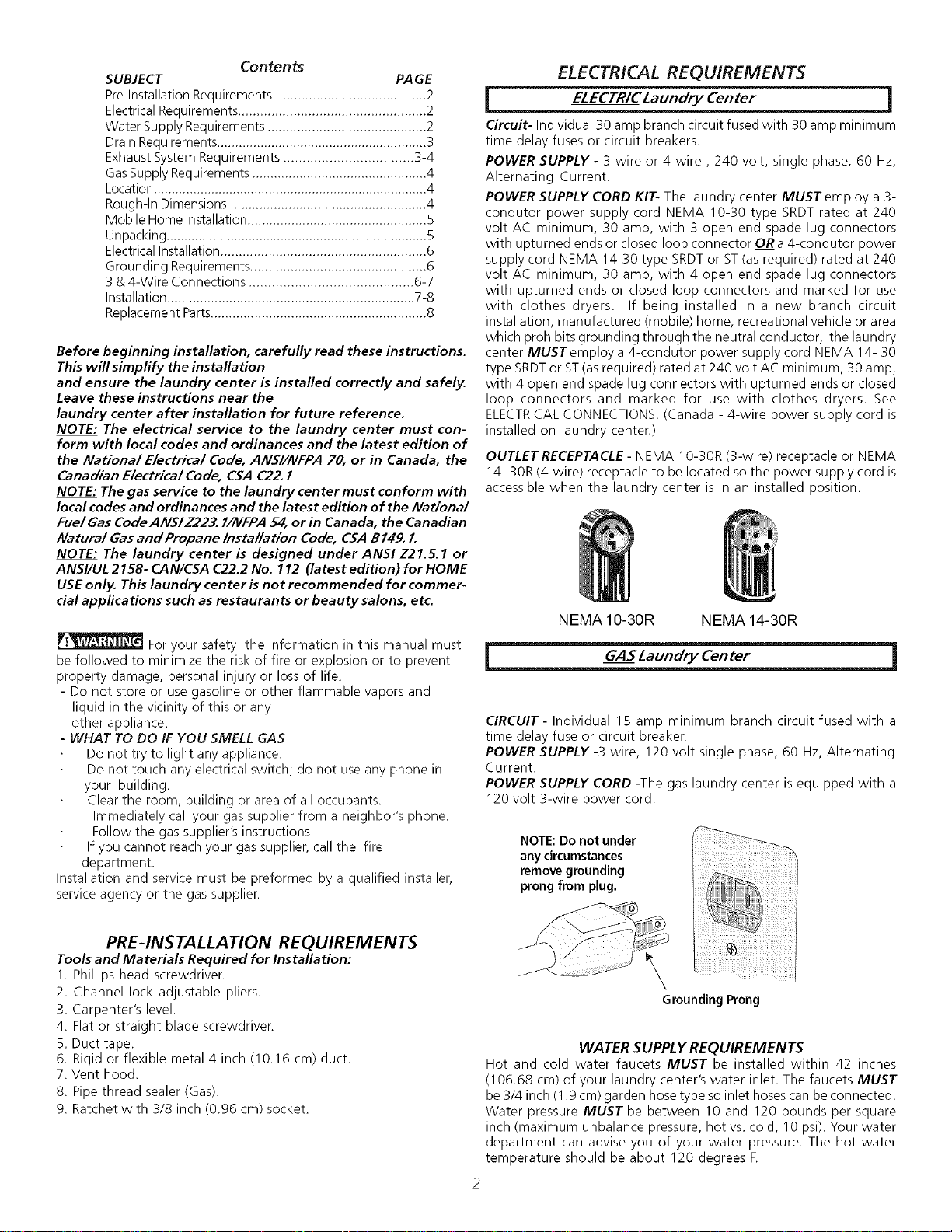

OUTLET RECEPTACLE- NEMA 10-30R (3-wire) receptacle or NEMA

14- 30R (4-wire) receptacle to be located so the power supply cord is

accessible when the laundry center is in an installed position.

NEMA 10-30R NEMA 14-30R

GAS Laundry Center

CIRCUIT - Individual 15 amp minimum branch circuit fused with a

time delay fuse or circuit breaker.

POWER SUPPLY -3 wire, 120 volt single phase, 60 Hz, Alternating

Current.

POWER SUPPLY CORD -The gas laundry center is equipped with a

120 volt 3-wire power cord.

NOTE: Do not under

any circumstances

remove grounding

prong from plug.

PRE-INSTALLATION REQUIREMENTS

Tools and Materials Required for Installation:

1. Phillips head screwdriver.

2. Channel-lock adjustable pliers.

3. Carpenter's level.

4. Flat or straight blade screwdriven

5. Duct tape.

6. Rigid or flexible metal 4 inch (10.16 cm) duct.

7. Vent hood.

8. Pipe thread sealer (Gas).

9. Ratchet with 3/8 inch (0.96 cm) socket.

Grounding Prong

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUST be installed within 42 inches

(106.68 cm) of your laundry center's water inlet. The faucets MUST

be 3/4 inch (1.9 cm) garden hose type so inlet hoses can be connected.

Water pressure MUST be between 10 and 120 pounds per square

inch (maximum unbalance pressure, hot vs. cold, 10 psi). Your water

department can advise you of your water pressure. The hot water

temperature should be about 120 degrees E

DRAIN REQUIREMENTS

1. Drain capable of eliminating 17 gals. per minute.

2. A standpipe diameter of 1¼ inches (3.18 cm) minimum.

3. The standpipe height above the floor should be:

Minimum height: 33 inches (83.82 cm)

Maximum height: 96 inches (244 cm)

f

96"Max.

--T--

33" Min.

(83.82cm)

NOTE: For installations requiring a longer drain hose, have a qualified

technician install a longer hose, PIN 134049201, available from an

authorized parts distributor. For drain systems in the floor, install a

siphon break kit, available from your local hardware store.

EXHAUST SYSTEM REQUIREMENTS

Use only 4 inch (10.16 cm) diameter (minimum) rigid or flexible

metal duct and approved vent hood which has a swing-out

damper(s) that opens when the dryer is in operation. When the

dryer stops, the damper(s) automatically closes to prevent drafts

and the entrance of insects and rodents. To avoid restricting the

outlet, maintain a minimum of 12 inches (38,5 cm) clearance

between the vent hood and the ground or any other

obstruction.

The following are specific requirements for proper

and safe operation of your laundry center. Failure to follow these

instructions can create excessive drying times and fire hazards.

Do not use plastic flexible duct or metal foil to

exhaust the dryer. Excessive lint can build up inside the exhaust

system and create a fire hazard and restrict air flow. Restricted air

flow will increase drying times. If your present system is made up of

plastic duct or metal foil duct, _lace it with a rigid or flexible metal

duct. Ensure the present duct is free of any lint prior to installing

laundry center dryer duct.

If the dryer is not exhausted outdoors some fine

lint will be expelled into the laundry area. An accumulation of lint in

any area of the home can create a health and fire hazard. The dryer

exhaust system MUST be exhausted to the outside of the

dwelling!

Do not allow combustible materials (for example:

clothing,draperies/curtains, paper) to come in contact with the

exhaust system. The dryer MUST NOT be exhausted into a chimney,

a wall, a ceiling, or any concealed space of a building which can

accumulate lint, resulting in a fire hazard.

Do not exceed the length of duct pipe or number of

elbows allowed in the" EXHAUST DUCT LENGTHS" chart. Lint can

accumulate in the system, plugging the system and creating a fire

hazard, as well as increasing drying times.

_Do not the exhaust ends of the vent

nor use any screws or rivets to assemble the exhaust system. Lint can

become caught in the screen, on the screws or rivets, clogging the

exhaust system and creating a fire hazard as well as increasing drying

times. Use an approved vent hood to terminate the duct outdoors,

and seal all joints with duct tape. All male duct pipe fittings MUST

be installed downstream with the flow of air. 3

screen

(244 cm)

system,

Explosion hazard, Do not install the laundry center

where gasoline or other flammables are kept or stored.If the laundry

center is installed in a garage, it must be a minimum of 18 inches

(45.7 cm) above the floor. Failure to do so can result in death, explosion,

fire or burns. The exhaust system back pressure MUST not exceed

0.6 inches (1.52 cm) of water column, measured with an inclined

manometer at the point the exhaust connects to the dryer. The

exhaust system should be inspected and cleaned a minimum of

every two years with normal usage. The more the dryer is used, the

more often you should check the exhaust system and vent hood for

proper operation.

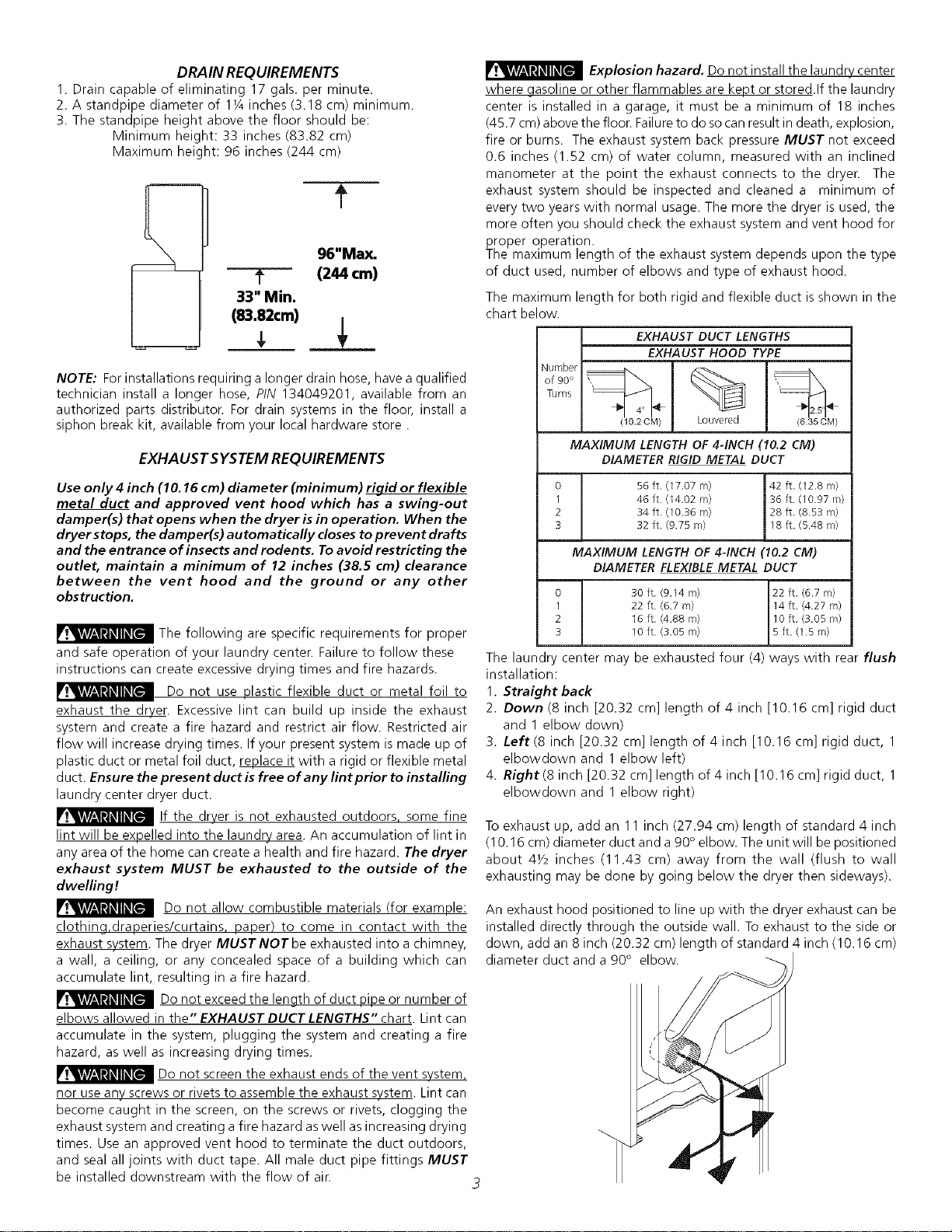

The maximum length of the exhaust system depends upon the type

of duct used, number of elbows and type of exhaust hood.

The maximum length for both rigid and flexible duct is shown in the

chart below.

EXHAUST DUCT LENGTHS

Number

of 90 °

Turns

MAXIMUM LENGTH OF 4-INCH (10.2 CM)

0

1

2

3

MAXIMUM LENGTH OF 4-INCH (10.2 CM)

DIAMETER FLEXIBLE METAL DUCT

0

1

2

3

EXHAUST HOOD TYPE

(10.2 CM) Louvered (635 CM)

DIAMETER RIGID METAL DUCT

56 ft. (17.07 m) 42 ft. (12.8 m)

46 ft. (14.02 m) 36 ft. (10.97 m)

34 ft. (10.36 m) 28 ft. (8.53 m)

32 ft. (9.75 rn) 18 ft. (5.48 m)

30 ft. (9.14 m)

22 ft. (6.7 rn)

16 ft. (4.88 m)

10 ft. (3.05 m)

22 ft. (6.7 m)

14 ft. (4.27 rn)

10 ft. (3.05 m)

5 ft. (1.5 m)

The laundry center may be exhausted four (4) ways with rear flush

installation:

1. Straight back

2. Down (8 inch [20.32 cm] length of 4 inch [10.16 cm] rigid duct

and 1 elbow down)

3. Left (8 inch [20.32 cm] length of 4 inch [10.16 cm] rigid duct, 1

elbowdown and 1 elbow left)

4. Right (8 inch [20.32 cm] length of 4 inch [10.16 cm] rigid duct, 1

elbowdown and 1 elbow right)

To exhaust up, add an 11 inch (27.94 cm) length of standard 4 inch

(10.16 cm) diameter duct and a 90 ° elbow. The unit will be positioned

about 41/2 inches (11.43 cm) away from the wall (flush to wall

exhausting may be done by going below the dryer then sideways).

An exhaust hood positioned to line up with the dryer exhaust can be

installed directly through the outside wall. To exhaust to the side or

down, add an 8 inch (20.32 cm) length of standard 4 inch (10.16 cm)

diameter duct and a 90 ° elbow.

GASSUPPLYREQUIREMENTS ROUGH-IN DIMENSIONS

1. Installation MUST conform with local codes, or in the absence of

local codes, with the National Fuel Gas Code, ANSI Z223.1 (latest

edition) or in Canada, the current AN/CGA B149.

2.The gas supply line should be of 1/2 inch (1.27 cm) pipe.

3. If codes allow, flexible metal tubing may be used to connect your

dryer to the gas supply line. The tubing MUST be constructed of

stainless steel or plastic-coated brass.

4. The gas supply line MUST have an individual shutoff valve.

5. A 1/8 inch (0.32 cm) N. R T. plugged tapping, accessible for test

gage connection, MUST be installed immediately upstream of

the gas supply connection to the dryen

6.The dryer and its individual shutoff valve MUST be disconnected

from the gas supply piping system during any pressure testing of

the gas supply piping system at test pressures equal to or less

than 1/2 psig (3.45 kPa).

7.The dryer MUSTbe isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure

testing of the gas supply piping system at test pressures

equal to or less than 1/2 psig (3.45 kPa).

LOCATION OF YOUR LAUNDRY CENTER

DO NOT INSTALL YOUR LAUNDRY CENTER:

1.In an area exposed to dripping water or outside weather

conditions.

2. In an area where it will come in contact with curtains or drapes.

3. On carpet. Floor MUST be solid with a maximum slope of 1 inch

(2.54 cm).

INSTALLATION IN RECESSOR CLOSET

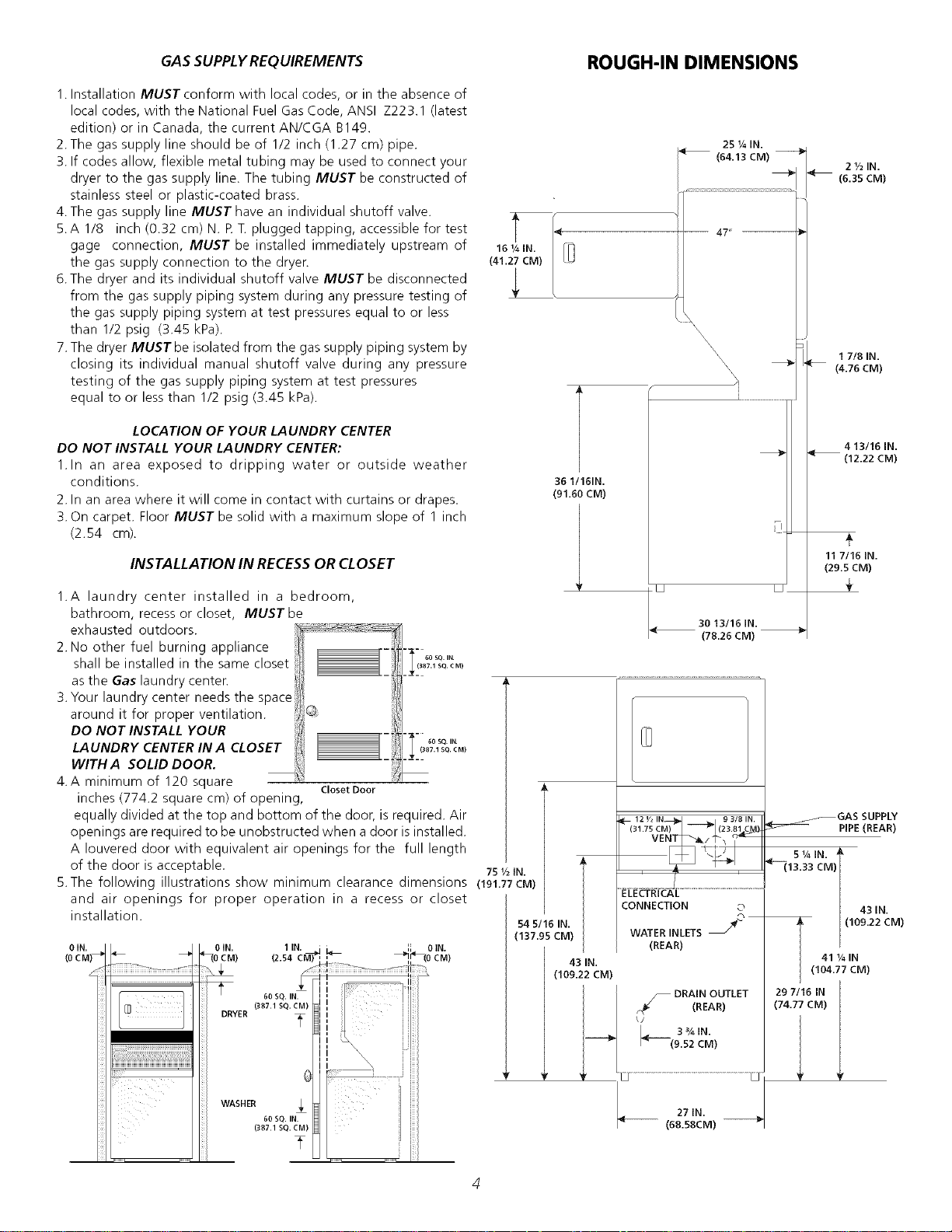

16 I/4 IN.

(41.27 CM)

36 1!161N.

(91.60 CM)

25 ¼IN.

i (64.13 CM)

_\\\\\\\

(

2½IN.

(6.3SCM)

17/8 IN.

[_ (4.76CM)

4 13/16 iN.

(12.22 CM)

+

11 7116 IN.

(29.5 CM)

1.A laundry center installed in a bedroom,

bathroom, recess or closet, MUST be

exhausted outdoors.

2. No other fuel burning appliance

shall be installed in the same closet

60 SQ. IN.

(387.1 SQ. CM)

as the Gas laundry centen

3. Your laundry center needs the space

around it for proper ventilation.

DO NOT INSTALL YOUR

LAUNDRY CENTER IN A CLOSET

60 SQ. IN.

(387.1 SQ. CM)

WITH A SOLID DOOR.

4. A minimum of 120 square

inches (774.2 square cm) of opening,

Closet Door

equally divided at the top and bottom of the door, is required. Air

openings are required to be unobstructed when a door is installed.

A louvered door with equivalent air openings for the full length

of the door is acceptable. 751/2(N.

5.The following illustrations show minimum clearance dimensions (191.77 CM)

and air openings for proper operation in a recess or closet

installation.

54 5/16 IN.

(137.95 CM)

12 I/2 IN._ 9 3/8 IN.

(31.75 CM_ (23.81 C_4)

VENT_.._ / -1_\ _,_

ELECTRICAL

CONNECTION ©

WATERINLETS _2_

(REAR)

43 IN.

(109.22 CM)

._,_ (REAR)

\J

3%1N.

_:---(9.52 CM)

,m_ _ DRAINOUTLET

30 13/16 IN.

(78.26 CM)

f--GAS SUPPLY

PIPE (REAR)

s 1/4mN.

_13.33 CM)

1 43 IN.

/(109.22 CM)

411/4IN

I (104.77 CM)

29 7116 IN

(74.77CM)

"!

27 IN.

(68.58CM)

MOBILE HOME INSTALLATION

1.Dryer MUST be exhausted outside (outdoors, not beneath the mobile

home) using metal ducting that will not support combustion. Metal

ducting must be 4 inches (10.16 cm) indiameter with no obstructions.

Rigid metal duct is preferred.

2.If dryer isexhausted through the floor and area beneath the mobile

home is enclosed, the exhaust system MUSTterminate outside

the enclosure with the termination securely fastened to the mobile

home structure.

3.Refer to page 3 for other important venting requirements.

ii i

4.When installing a gas dryer into a mobile home, a provision must be

made for outside make up air. This provision isto be not lessthan twice

the area of the dryer exhaust outlet.

_iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

5.Installation MUSTconform to current Manufactured Home Construction

& Safety Standard (which is a Federal Regulation Title 24 CFR-Part 32-

80) or when such standard is not applicable, with American National

Standard for Mobile Homes. In Canada, the CSA Z240 is applicable.

_1__ The laundry center is designed under ANSI Z 21.5.1for HOME USE only.

UNPACKING

1. Using the four shipping carton corner posts (two on each

side), carefully lay the laundry center on its left side and

remove foam shipping base.

Excessive weight. Use two or more people

to move Laundry Center.

2. Using a ratchet with 3/8 inch (0.96 cm) socket, remove the

mechanism shipping bolt and plastic spacer block from the

center of the base.

NOTE: If the laundry center is to be transported at a later

date, the tub blocking pad, shipping bolt, and plastic

spacer block should be retained.

3. Return laundry center to an upright position.

4. Remove:

(a) foam tub blocking pad.

(b) foam shipping blocks from rear of unit.

(c) tape from dryer door.

(d) foam dryer support pads.

(e) inlet hoses.

(f) enclosure package.

5. From the back of the washer, remove the wire shipping

clips securing the drain hose and power cord (if equipped).

Plastic clamps secure the drain hose to the right side of

the washer backsheet. These clamps form a standpipe to

prevent water syphoning. DO NOT REMOVE THESE

CLAMPS.

6. Carefully move the laundry center to within 4 feet (1.22 m)

of the final location to begin the installation.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

PLASTIC SPACER

MECHANL €

SHIPPING

BOLT

FOAM

SHIPPING

PAD

CARTON CORNER POSTS

POWER CORD

(IF EQUIPPED)

DRAIN HOSE

Loading...

Loading...