Kenmore 41747102700 Installation Guide

®

Installation

instructions

lnstrucciones

para la instalacion

Before beginning installation, carefully read these instructions. This will simplify the installation and ensure the washer is installed

correctly and safely. Leave these instructions near the washer after installation for future reference.

NOTE: The electrical service to the washer must conform with local codes and ordinances and the latest edition of the National

Electrical Code, ANSI/NFPA 70 or in Canada, CSA C22.1 Canadian Electrical Code Part 1.

Antes de comenzar la instalacion, lea estas instrucciones con atencion. Le facilitaran la instalacion y aseguraran que la lavadora sea

instalada correctamente y de manera segura. Guarde estas instrucciones cerca de la lavadora una vez terminada la instalacion para

referirse a elias en el futuro.

NO TA: el suministro el#ctrico de su lavadora debe estar conf orme con los codigos y ordenanzas Iocales y la edicion m#s reciente del

National Electrical Code (Codigo El#ctrico Nacional), ANSI/NFPA 70, o en Canada, la edicion m#s reciente del Canadian Electrical Code

(Codigo El#ctrico de Canada).

_For your safety the information inthis manual must be followed to minimize the risk of fire or explosion or to prevent

property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable vapors and liquid in the vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Clear the room, building or area of all occupants.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas suppliers instructions.

• If you cannot reach your gassupplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

Para su seguridad, siga la informacion contenida en este manual para minimizar el riesgo de incendio o explosion

o para evitar daflos materiales, lesiones personales o la rnuerte.

No guarde ni utilice gasolina u otros vapores y liquidos inflamables en las cercanias de este ni cualquier otro electrodomestico.

- QUEHACERSI NOTA UNOLORA GAS:

No trate de encender ningun electrodomestico.

No toque ningL]n interruptor electrico; no use ningun telefono de su edificio.

Haga que todo el mundo salga del cuarto, edificio o area.

Llame inmediatamente al proveedor del gas desde el telefono de un vecino. Siga las instrucciones del proveedor del gas.

Si no puede ponerse en contacto con el proveedor del gas, Ilame a los bomberos.

La instalacion y el servicio deben set hechos pot un instalador capacitado, una agencia de servicios o el proveedor del gas.

Save These Instructions

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Printed in U.S.A. P/N 134837600 (0611)

Contents

SUBJEC T PAGE

Pre-lnstallation Requirements 2

Electrical Requirements 2

Grounding Requirements 2

Water Supply Requirements 2

Drain Requirements 2

Rough-In Dimensions 3

Location Of Your Washer 3

Unpacking 3

Installation 4

Replacement Parts 4

PRE-INSTALLATION REQUIREMENTS

Tools Required for Installation:

1. 1/4 in. nut driver

2. 3/8 in. socket with ratchet.

3. 3/8 in. open end wrench.

4. 7/16 in. socket with ratchet.

5. 9/16 in. open end wrench.

6. Channel-lock adjustable pliers.

7. Carpenter's level.

ELECTRICAL REQUIREMENTS

CIRCUIT- Individual, properly polarized and grounded

15 amp. branch circuit fused with 15 amp. time delay

fuse or circuit breaker.

POWER SUPPLY- 2wire, with ground, 120 volt, single

phase, 60 Hz, Alternating Current. NOTE: The use of

this washer with power created by gas powered

generators, solar powered generators, wind powered

generators or any other generator other than the local

utility company is not recommended.

into an appropriate, copper wired receptacle that is

properly installed and grounded in accordance with

all local codes and ordinances or in the absence of

local codes, with the National ElectricalCodes, ANSI/

NFPA70 (latest edition). If in doubt, call a licensed

electrician. DO NOTcut off or alter the grounding

prong on the power supply cord. In situations where

a two-slot receptacle is present, it is the owner's

responsibility to have a licensed electrician replace

it with a properlygroundedthree prong grounding

type receptacle.

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUST be installed within

42 inches (107 cm) of your washer's water inlet. The

faucets MUST be 3/4 inch (1.9 cm) garden hose type

so inlet hosescan be connected. Water pressure MUST

be between 10 and 120 pounds per square inch

(maximum unbalance pressure, hot vs. cold, 10 psi.)

Your water department can advise you of your water

pressure.

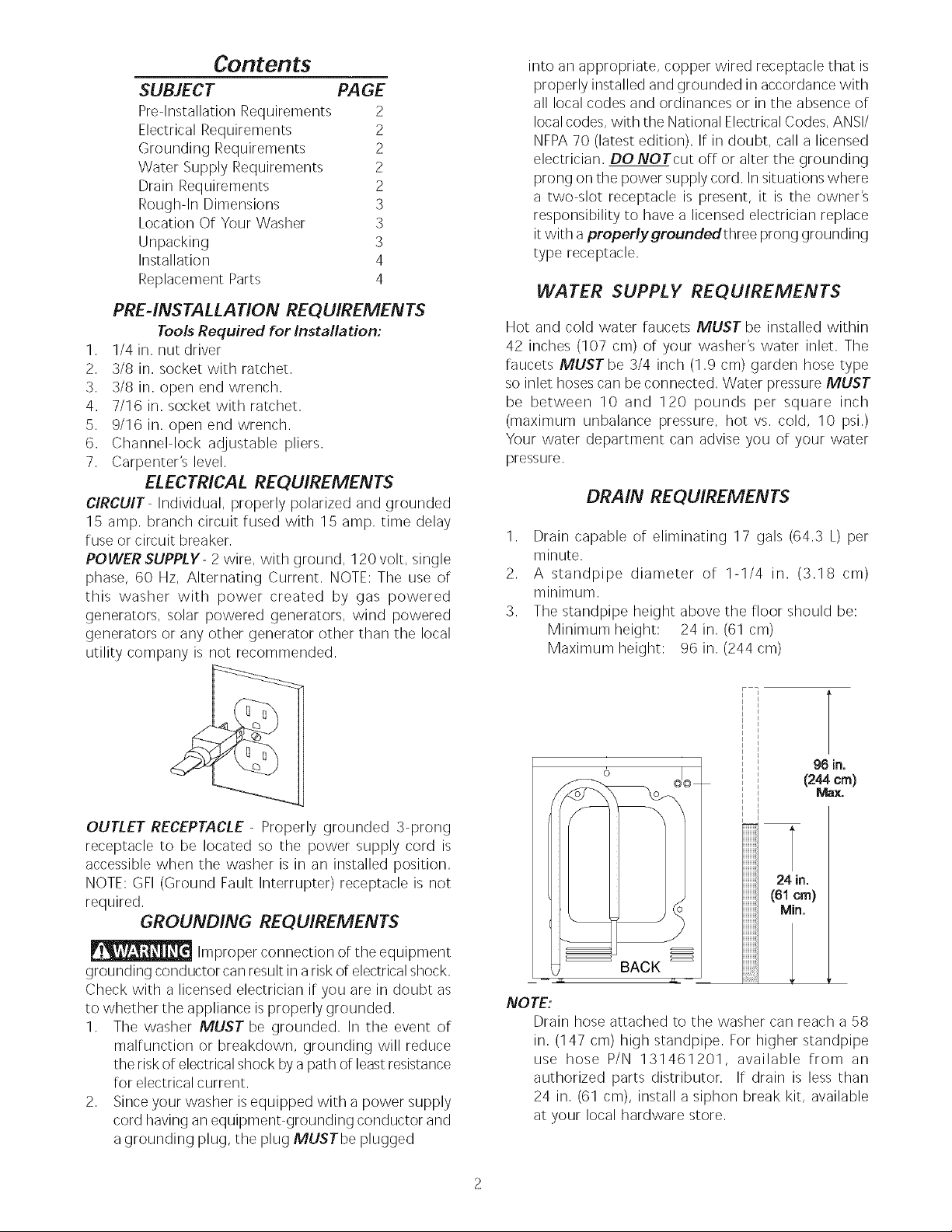

DRAIN REQUIREMENTS

1. Drain capable of eliminating 17 gals (64.3 L) per

minute.

2. A standpipe diameter of 1-1/4 in. (3.18 cm)

minimum.

3. The standpipe height above the floor should be:

Minimum height: 24 in. (61 cm)

Maximum height: 96 in. (244cm)

OUTLET RECEPTACLE- Properly grounded 3-prong

receptacle to be located so the power supply cord is

accessible when the washer is in an installed position.

NOTE: GFI (Ground Fault Interrupter) receptacle is not

required.

GROUNDING REQUIREMENTS

Improper connection of the equipment

grounding conductor can result in a riskof electricalshock,

Check with a licensed electrician if you are in doubt as

to whether the appliance isproperly grounded,

1. The washer MUST be grounded, In the event of

malfunction or breakdown, grounding will reduce

the risk of electricalshock by a path of leastresistance

for electrical current,

2. Sinceyour washer is equipped with a power supply

cord having an equipment-grounding conductor and

a grounding plug, the plug MUSTbe plugged

))

24 in.

(61 cm)

Min.

BACK

NOTE:

Drain hose attached to the washer can reach a 58

in. (147 cm) high standpipe. For higher standpipe

use hose P/N 131461201, available from an

authorized parts distributor. If drain is less than

24 in. (61 cm), install a siphon break kit, available

at your local hardware store.

96 in,

(244 cm)

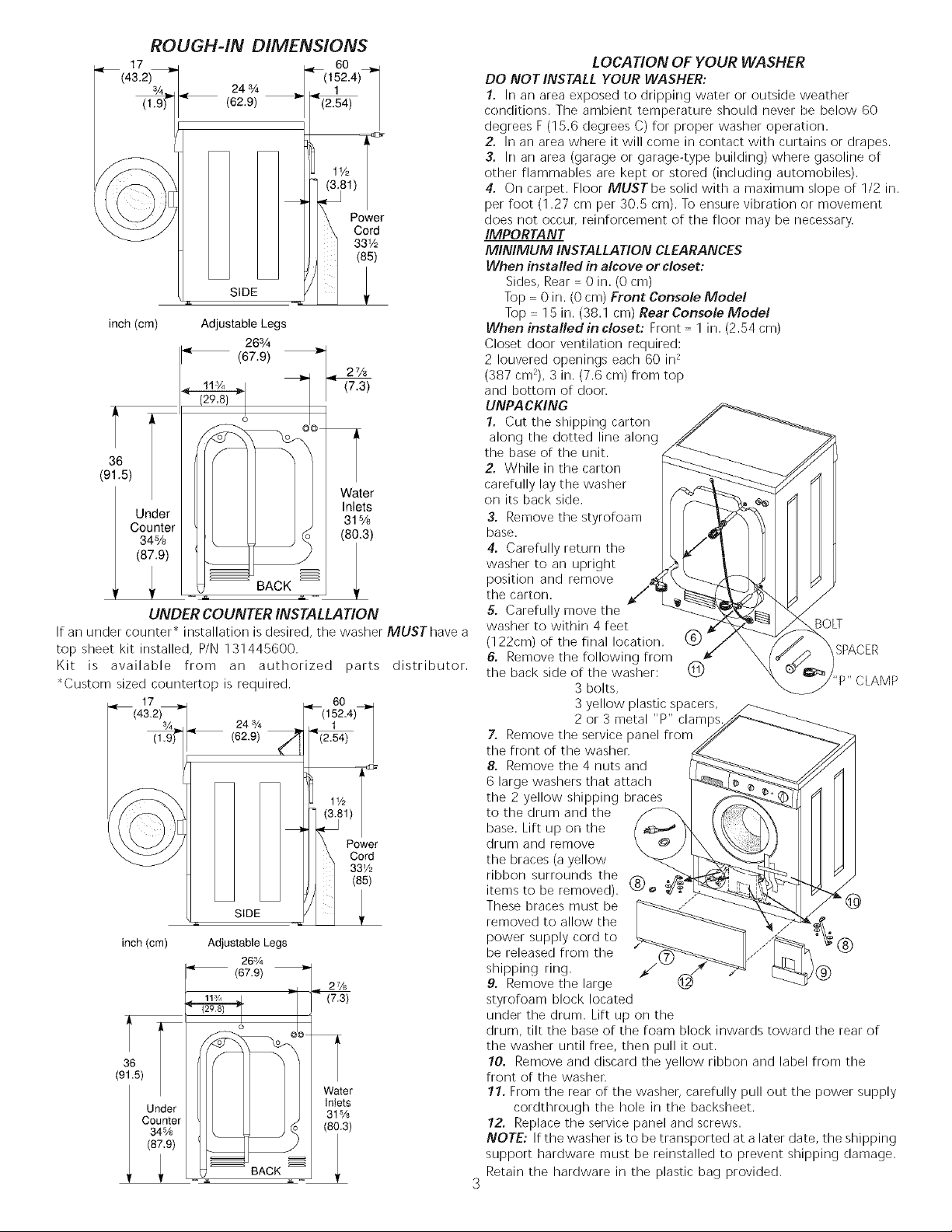

ROUGH-IN DIMENSIONS

< 17_

(43"2)3/`

3/4_,< 24 3A

(1.9) (62.9)

SIDE

inch (cm) Adjustable Legs

< (67.9)

36

(91.5)

Under 31%

Counter (80.3)

34%

(87.9) 1

! ,_ BACK ,,

26%

o

UNDER COUNTER INSTALLATION

If an under counter" installation is desired, the washer MUST have a

top sheet kit installed, P/N 131445600.

Kit is available from an authorized parts distributor.

"Custom sized countertop is required.

24s/4

(62.9)

inch (crn) Adjustable Legs

"_' (67.9)

._ _ BACK _ ._

263/4

o o @@

<60

(152.4)

(2.54)

1½

Water

2¼

(7.3)

Wate

Intet_

31sA

(8i'3

Power

Cord

331/2

(85)

2%

(7.3)

Inlets

Power

Cord

33_/2

(85)

LOCATION OF YOUR WASHER

DO NOT INSTALL YOUR WASHER:

1. In an area exposed to dripping water or outside weather

conditions. The ambient temperature should never be below 60

degrees F (15.6 degrees (3) for proper washer operation.

2. In an area where it will come in contact with curtains or drapes.

3. In an area (garage or garage-type building) where gasoline of

other flammables are kept or stored (including automobiles).

4. On carpet. Floor MUSTbe solid with a maximum slope of 1/2 in.

per foot (1.27 cm per 30.5 cm). To ensure vibration or movement

does not occur, reinforcement of the floor may be necessary.

IMPORTANT

MINIMUM INSTALLATION CLEARANCES

When installed in alcove or closet:

Sides, Rear = 0 in. (0 cm)

Top = 0 in. (0 cm) Front Console Mode!

Top = 15 in. (38.1 cm) Rear Console Model

When installed in closet: Front = 1 in. (2.54 cm)

Closet door ventilation required:

2 Iouvered openings each 60 in 2

(387 cm2), 3 in. (7.6 cm) from top

and bottom of door.

UNPA CKING

1. Cut the shipping carton

along the dotted line along

the base of the unit.

2. While in the carton

carefully lay the washer

on its back side.

3. Remove the styrofoam

base.

4. Carefully return the

washer to an upright

position and remove

the carton.

5. Carefully move the

washer to within 4 feet BOLT

(122cm) of the final location. (_)

6. Remove the following from SPACER

the back side of the washer: (_)

3 bolts,

3 yellow plastic spacers,

2 or 3 metal "P" clamps

7. Remove the service panel from

the front of the washer.

8. Remove the 4 nuts and

6 large washers that attach

the 2 yellow shipping braces

to the drum and the

base. Lift up on the

drum and remove

the braces (a yellow

ribbon surrounds the

items to be removed). (_

These braces must be (_

removed to allow the

power supply cord to

be released from the

shipping ring. )@

9. Remove the large

styrofoam block located

under the drum. Lift up on the

drum, tilt the base of the foam block inwards toward the rear of

the washer until free, then pull it out.

10. Remove and discard the yellow ribbon and label from the

front of the washer.

11. From the rear of the washer, carefully pull out the power supply

cordthrough the hole in the backsheet.

12. Replace the service panel and screws.

NOTE: If the washer is to be transported at a later date, the shipping

support hardware must be reinstalled to prevent shipping damage.

Retain the hardware in the plastic bag provided,

Loading...

Loading...