Kenmore 40289032010, 40289032011, 40289032012, 40299032010, 40299032011 Installation Guide

...Page 1

Size : 420 X 297 (ram)

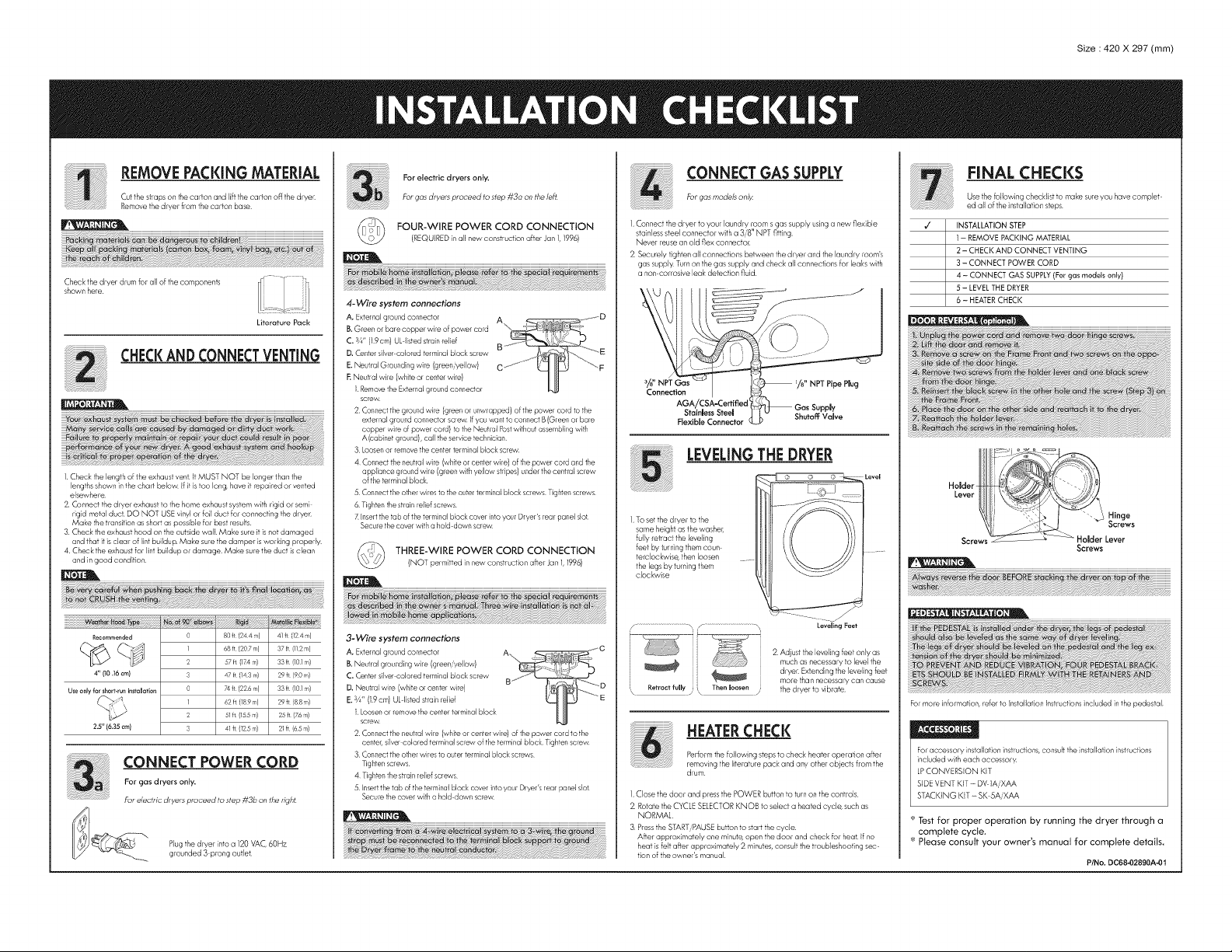

REMOVEPACKINGMATERIAL

Cut the straps oil he carton and lift the carton off the drye*

Remove the dryer from the carton base

Check the dryer drum for all of the componen%

shown here

Literature Pack

CHECKAND CONNECTVENTING

1 Check the length of the exhaust vent it MUST NOT be longer than the

lengths shown in the chart below If it is too long, have it repaired or vented

elsewhere

2 Connect the dryer exhaust to the home exhaust system with rigid or semi

rigid metal duct DO NOT USE vinyl or foil duct for connecting the dryel

Make the transition as short as possible for best results

3 Check the exhaust hood on the outside wall Make sure it is not damaged

and that it is clear of lint buildup Make sure the damper is working properly

4 Check the exhaust for lint buildup or damage Make sure the duct is clean

and in good condition

Reeemm_ded 0 80 it 1244 m) 41 fl (124 m)

_ _# 1 68 fl (207 m) 37 Jt ill 2"n)

4" (10.16 era) 3 47it (14 3 m) 29 fl (90 m)

Use only for short-run installation 0 74 it (226 m) 33 it (101 m)

25" (6.35 ¢m) 3 41 fl (125 m) 21 fl (6 5 m)

2 5711 (]Z4 m) 33fl ri0]m)

1 6211 f189m) 29fl (88m)

2 51ft 1155 m) 251t 176m)

CONNECT POWER CORD

For gas dryers only.

#or electric dryers proceed to step #3b on the right

Plug the dryer into a 120 VAC, 60Hz

grounded 3 prong outlet

For electric dryers only.

For gas dryers proceed to step #30 on the IdL

FOUR-WIRE POWER CORD CONNECTION

(REQUIREDinall new constructionafter Jan 1,19%)

4-Wire system connections

B. Greet, or bare copper wire of power cord

C. _f_" (]9 cm} UL listed strain relief

A. External ground connector

D. Center silver colored terminal block screw B

E. Neutral Grounding wire (green yellow} C J _ _ F

E Neutral wire (white or center wire}

i Remove the External ground connector

screw

2 Connect the ground wire (green or unwrapped} of the power cord to the

external ground connector scre_ If you want to connect B(Green or bare

copper wire of power cord} to the Neutral Post without assembling with

A(cabinet ground}, call the service technician

3 Looser,or remove the center terminal block screw

4 Connect the neutral wire (white or center wire} of the power cord and the

appliance ground wire (greet, with yellow stripes} under the cenhal screw

of the terminal block

5 Connect the other wires to the outer terminal block screws Tighter, screws

B Tighten the strain relief screws

X [nsed the tab of the terminal block cover into your Dryer's rear panel slot

Secure the cover with a hold dowr, screw

A _ D

U

THREE-WIRE POWER CORD CONNECTION

(NOT permitted in newconstructionafterJan1,19%)

3-Wire system connections

A. External ground connector

B. Neutral grounding wire (green/yellow)

C. Cer,ter silver colored terminal block screw

D. Neuhal wire (white or center wire}

E. s/4_' (19 cm} UL listed strain relid

] Looser,or remove the center terminal block

screw

2 Connect the neutral wire (white or center wire} of the power cord to the

centel, silver colored terminal screw of the terminal block Tighter, screw

3 Connect fl:e other wires to outer terminal block screws

fighter, screws

4 Tighter, the strain relief screws

5 Insert fi:e tab of the terminal block cover into your DryeFs rear par,el slot

Secure the cover with a hold dowr, screw

CONNECT GAS SUPPLY

For gos mode_ only

1Connect the dryer to your laundry room s gas supply using a new flexible

stainless steel connector with a 3/8" NPT fitting

Never reuse an old flex connecto_

2 Securely tighten all connections be+ween the dryer and he laundry room's

gas supply Turn on the gas supply and check all connections for leaks with

a non corrosive leak detection fluid

E

3/8" NPT Gas /8" NPT Pipe Plug

Connection

AGA!CSA-42ertifled

Stainless Steel Shutoff: Valve

Flexible Connector

LEVELINGTHE DRYER

1To set the dryer to the

same height as the washel,

fully retract the leveling

feet by t_urning them coun

terclockwise, then loosen

the legs by turning them

clockwise

2 Adiust the leveling feet only as

much as necessary to level the

dryec Extending the leveling fee+

more than necessary can cause

the dryer to vibra'e

HEATERCHECK

Perform the following steps to check heater operation after

removing the literature pack and any other obiects from the

drum

1Close the door and press the POWER button to turn oil the controls

2 Rotate the CYCLE SELECTOR KNOB to select a hea'ed cycle, such as

NORMAL.

3 Pressthe START/PAUSE button to start the cycle

After approximately one minute, open the door and check for hea" if no

heat is felt after approximately 2 minutes, consuft the troubleshooting sec

tion of the owner's manual

Leveling Feet

FINAL CHECKS

Use the following checklist to ma ke sure you have complet

ed all of the installation steps

INSTALLATION STEP

1- REMOVE PACKING MATERIAL

2 - CHECK AND CONNECT VENTING

3 - CONNECT POWER CORD

4 - CONNECT GAS SUPPLY (For gas models only)

5- LEVEL THE DRYER

6 - HEATER CHECK

.evel

For more information, refer to Installation Instructions included in the pedestal

For accessory installation instructions, consult the ins:allafion instructions

included with each accessory

LP CONVERSION KiT

SiDE VENT KIT - DV ]A XAA

STACKING KIT- SK 5AXAA

Test for proper operation by running the dryer through a

complete cycle.

Please consult your owner's manual for complete details.

Screws

P/No. DC68-O289gA-O1

Page 2

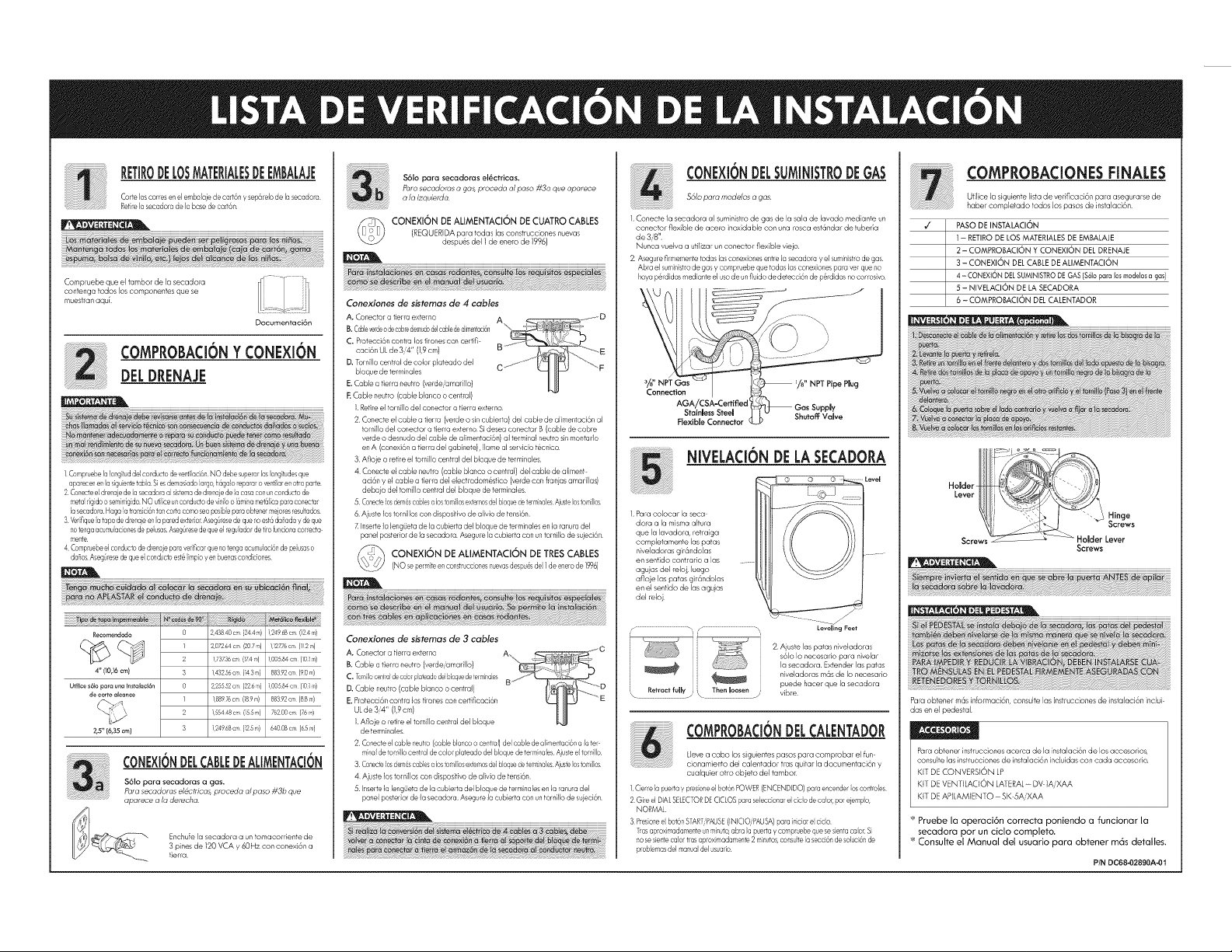

RETIRODELOSMATERIALESDEEMBALAJE

Carte bs coes e:/e] embalaje de cartTn y sep6relo de b secede a

Rete la secede a de la base de cart6n

Compruebe que el lamber de la secadora

contenga redes los componentes que se

muestran aqul

Documentaci6n

COMPROBACIONY CONEXION

DELDRENAJE

ii i i

1Compruebe =ao%tud de',condudo devent ac@ NO debe superaras =0%tudes que

ape ecer, er, a s_guer,tetaba S es demas adeago,:,%ao epaa o ver,t a er,ot:a pate

2 Cor,ectee der,aje de a secede a a sstemade d er,ajede a case con unconducto de

mete ',gdeo semk::_gde NO uf:ice un conducto de vqo o @mhamet6 ice pea conecta

a secede a Hagaa 'TO'ISc6fi te aCo_¢acoma sea p'osbe pea obter,e mejo esesutades

3 Verfique a tape de d er,aje er,a paed exter:or Aseg0rese de que <1oestad@ada y de que

'io ter,ga acurvJc onesde pe usesAseg0resede que e eguade deto tuncone co ecta

met,re

4 Comprueoe e conducto de d er,ajepea vefica que <1oter,ga acurrlUac @ de pe useso

d@os Ase@rese deque e Co+lductoestT'mpio y er,buer,as condc ones

$61o pare secadoras el6ctricas.

Pare secadoras a gas, precede al paso #3o que aparece

a la izquierda

CONEXION DE AL(MENTACION DE CUATRO CABLES

(REQUERIDA para odas las cons rucciones nuevas

despu6s del 1 de enero de 1996)

Conexiones de sistemas de 4 cables

B. Cableverdeodecobredesnu@del cablededimentaci6n <

C. Protecci@_ cor_tra los tiror, es car, certifi

A. Correcter a tierra externo

caci6r_ UL de 34" (1,9cm} B

D. Tarnillo cer_tral de color plateado del

bloque de terminales O " _ x F

E. Cable a tierra r_eutro (verde/amarillo}

E Cable r_eutro (cable blanco o cer_tlal}

i Retire el tornillo del correcter a tierra externo

2 Cor_ecte el cable a tie_ra (verde o sin cubierta) del cable de abmer_tacide al

tornillo del correcter a fierra externo Si desea cor_ectar B (cable de cobre

verde o desr,udo del cable de alimerCaci@_) al terminal neutro sinmor_tarlo

er_A (conexi6r_ a flerra del gabinetd, Ilame al servicio tTcr_ico

3 Afloje o retire el tomillo cer_tlal del bloque de terminales

4 Cor_ecte el cable r,eutro (cable blanco o cer_hal} del cable de alimer_t

aci@_y el cable a tierra de] electlodom@stico (verde cor_frar_as amadllas)

debajo del tomillo cer_tlal del bloque de terminales

5 Conede as aem6scabes a ostorrd ase£ernosde hague ae terminaiesAJusleostornlos

6 Ajuste los families car, dispositivo de alivio de ter_side

Z Inserte la lerlgJeta de la cubierta del bloque de terminales erl la rarlura del

panel posterior de la secadora Asegure la cubierta con Urltornillo de s,;jeci6n

CQNEXION DE ALIMENTAClON DE TRES CABLES

(NO sepermie e: co:slrucc onesn,;evasdespu@ de 1de e:'e_o de 1996)

A _ D

CONEXlONDELSUMINISTRODEGAS

561o pare modelos a gas

1Conecte la secadora al suministlo de gas de la sala de lavado mediante un

conector flexible de acero inoxidable con una rosca estTndar de tuberTa

de 3/8"

Nunca vuelva a utilizar un conector flexible viejo

2 Asegure firmemente todas las cortex ones entre la secadera y el sumnistro de gas

Abra el sumnistro de gas y compruebe que todas las corlexiones pare vet que no

haya p@d desreed ante elusa de un @ida de detecci6n de _6rddes nocorrosive

E

3/8" NPT Gas /8" NPT Pipe Plug

Connection

AGA!CSA-Certifled

Stainless Steel Shutoff Valve

Flexible Connector

NIVELACIONDELASECADORA

1 Para colocar la seca

dora a la rqsma alfura

que la lavadora, retraiga

completamente las paras

niveladoras gir6ndolas

en sentido contrario a las

agujas del relo], luego

afloje las paras gir6ndolas

en el senfido de las agujas

del relo]

.evel

COMPROBACIONES FINALES

Utilice la siguiente lista de vedficaci6n para asegurarse de

haber completado redes los pasos de instalaci@/

PASO DE INSTALACI6N

1- RETIRe DE LOS MATERIALES DE EMBALAJE

2-COMPROBACION Y CONEXION DEL DRENAJE

3 - CONEXION DEL CABLE DE ALIMENTACION

4 - CONRXION DRL SUMINISTRODR GAS (561opare los modelos a gas)

5 - NIVELACION DE LASECADORA

6 - COMPROBACION DEL CALENTADOR

Screws

Recamendado 8 243840 c'n (244"n) i24R68c'_11i24rrl)

4"(10,16 cm) 3 i43256c'n (43<n) 88392cm (90m)

Utilice s61opareu_ instdaci6n 8 225552 c'n (226<n) 108584cm 1i01m)

decarte alcance

2,5" (6,35 cm)

2 i73Z%c'n (Z4<n) i%584cm 1i0im)

1 i88976cm (89rs) 88392cm I88rn)

2 i55448cm (55m) 762%cm (16m)

3 i24968c'n (25<n) 648 % c'_1 (65r+1)

CONEXIONDELCABLEDEALIMENTACION

S6lo para secadoras a gas.

Pare secadoras eldctricas, precede al paso #3b que

aparece a la derecha

__ Enchde la secadora a un tomacordente de3 pines de 120 VCA y 60Hz con conexi6n a

tierra

Conexianes de sistemas de 3 cables

A. Correcter a tierra externo

B. Cable a tierra r_eutro (verde amarillo)

C. Tomi_ cer-ra de coor p!aleadode L';oquedeterrlinae_

D. Cable r_e,;tlo (cable blar_co o cer_tlal)

E. Piotecci6r_ cor_tla los tiror_es cor_certificacide

UL de 34 +' (1,9cmJ

i Afloje o retire d tomillo cer_tral del bloque

de terminales

2 Conecte el cable neutro (cable blanco o cent'al) del cable de al _e_'tac 6:,a la're

renal de to Iio ce_'tral de cdo plaleado del bloque de te m_abs A;usie el to Iio

3 Conede as aerl,_scabes a iostorrdasexternos@ hague geterminaies Ajusteostorrd as

4 Ajuste los tornillos cor_dispositivo de alivio de ter_side

5 Insertela lengdeta de la cub erta del bloque de term hales en la ranura del

panel poster or de la secadora Asegure la cubierta con untornillo de su;eci6n

ii

ii

ii

\ Retract fully / _ Then loosen /

Leveling Feet

2 Ajuste las patas niveladoras

sTIo Io necesario para nivelar

la secadora Extender las paras

niveladoras rots de Io necesario

puede hacer que la secadora

vibre

COMPROBACIONDELCALENTADOR

Lleve a cabo los siguientes pasos para comprobar el fun

cionamiento del calentador tras quiar la documentaci6n y

cualquier otto objeto del fambo_

1Cerre a pueda y presbne d bo16nPOWER {ENCENDIDO) pare encender as co _t<oes

2 G_e d DIALSELECTORD_ CICLOSpare se ecconar d cco de cao_, par e;empo,

NORMAL

3 Presone e bo16nSTART/PAUSE(INICIO PAUSA)pare ncar e cco

_as aprox madamerle unmnulq aba a pueda y compruebe que sese:'ta cao_ S

nose serle caor 1'asaprox madem÷qe 2mhulas,consu'3e',asecc 6nde so uci6n de

probemas dd manua de usuaro

Para obtener mas in$ormaci6n, consulfe las [nsfrucciones de inCalaci6n inclui

des en el pedestal

Para obtener ins rucciones acerca de la ins alaci@l de los accesodos,

consulle las instrucciones de instalaci6n induidas con cada accesodo.

KIT DE CONVERSION LP

KIT DE VENTILACiON LATERAL- DV ]AXAA

KIT DE APILAMIENTO SK 5AXAA

Pruebe la operaci6n correcta poniendo a funcionar la

secadora par un ciclo complete.

Consulte el Manual del usuario para obtener m6s detalles.

PIN DC68-O289OA=01

Loading...

Loading...