Kenmore 3851788180 Owner’s Manual

Kenmope

SEWING MACHINE 17881

OWNER'S MAN1

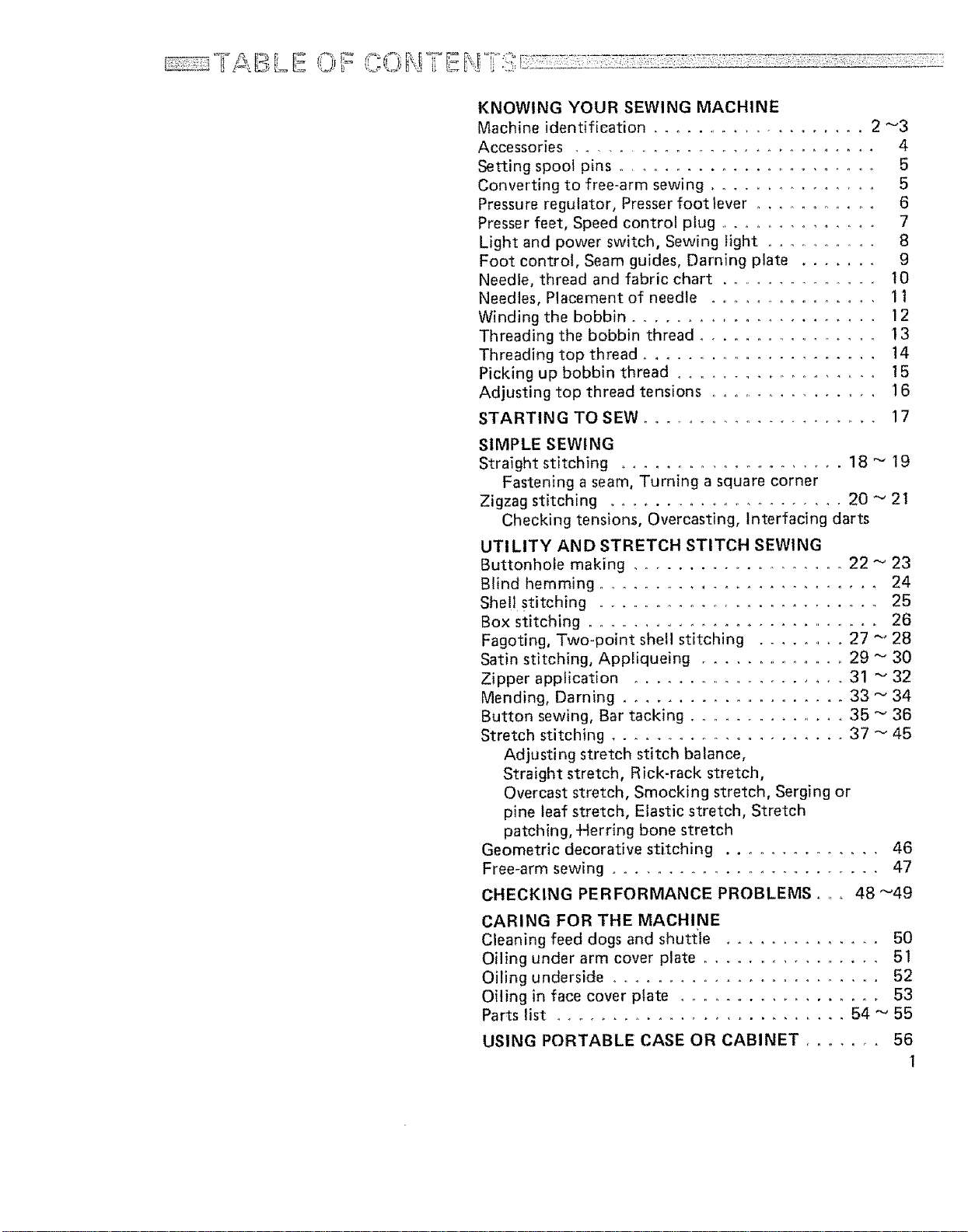

KNOWING YOUR SEWING MACHINE

Machine identification ...................... 2 _3

Accessories .............................. 4

Setting spool pins ........................... 5

Converting to free-arm sewing ............... 5

Pressure regulator, Presser foot lever ........... 6

Presser feet, Speed control plug ................ 7

Light and power switch, Sewing light ............ 8

Foot control, Seam guides, Darning plate ....... 9

Needle, thread and fabric chart ................ t0

Needles, Placement of needle ................. 11

Winding the bobbin ...................... 12

Threading the bobbin thread .................. 13

Threading top thread ........................ 14

Picking up bobbin thread .................... 15

Adjusting top thread tensions ................ 16

STARTING TO SEW ....................... 17

SIMPLE SEWING

Straight stitching ..................... 18 _" 19

Fastening a seam, Turning a square corner

Zigzag stitching ......................... 20 *" 21

Checking tensions, Overcasting, Interfacing darts

UTI LITY AND STRETCH STITCH SEWING

Buttonhole making ..................... 22 _ 23

Blind hemming ......................... 24

Shell stitching .......................... 25

Box stitching .................................. 26

Fagoting, Two-point shell stitching ......... 27 "_ 28

Satin stitching, Appliqueing ................ 29 _ 30

Zipper application ..................... 31 _" 32

Mending, Darning ..................... 33 "_ 34

Button sewing, Bar tacking ............... 35 _ 36

Stretch stitching ...................... 37 _ 45

Adjusting stretch stitch balance,

Straight stretch, Rick-rack stretch,

Overcast stretch, Smocking stretch, Serging or

pine leaf stretch, Elastic stretch, Stretch

patching, Herring bone stretch

Geometric decorative stitching .............. 46

Free-arm sewing ......................... 47

CHECKING PERFORMANCE PROBLEMS .... 48 _49

CARING FOR THE MACHINE

Cleaning feed dogs and shuttle .............. 50

Oiling under arm cover plate ................ 51

Oiling underside ........................ 52

Oiling in face cover plate .................. 53

Parts list ........................... 54 _ 55

USING PORTABLE CASE OR CABINET ....... 56

Face Cover Plate

Threading Chart

Bobbin Winder

Ex tension Table/,

Thread Spool Pins

Hand Wheel

Push-Pull Clutch

Stretch Stitch Adjuster

Light and Power Switch

Electric Cord Receptacle

/

Presser Foot Thumb Screw

Needle Plate

Nomenclature Plate

Thread Guide

Thread Guide

Needle

Clamp Screw

Bobbin Cover

Plate

Presser Foot Lever

Free Arm

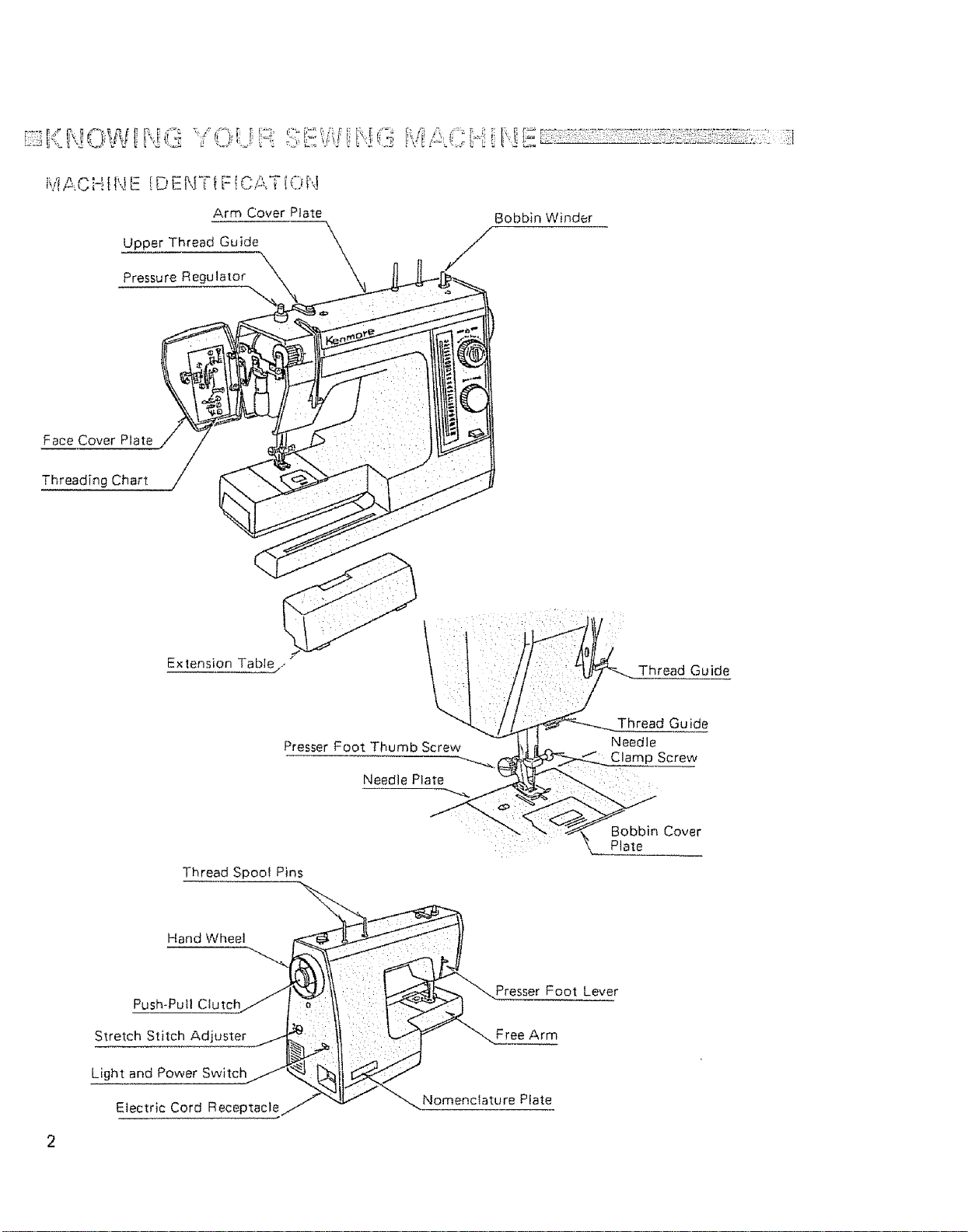

2. StitchWidthControt

3÷

Stitch Length Controt

Stitch Seiector

[IN

/

"_5. Reverse Stitch Lever

This control regulates the length of the

stitch you select. _ i

The diaf is calibrated in stitches per inch.

The higher the number, the shorter the

stitch.

Fabric will not be fed when the dial is set at

"0 't"

The desired stitch will be obtained by

turning this Stitch Selector until the stitch

is indicated by the red line on the indicator

panel.

Note: To select a stitch, be sure needle :is

out of fabric at its highest position.

When reverse stitching iS needed, push down the lever and

hold there during sewing.

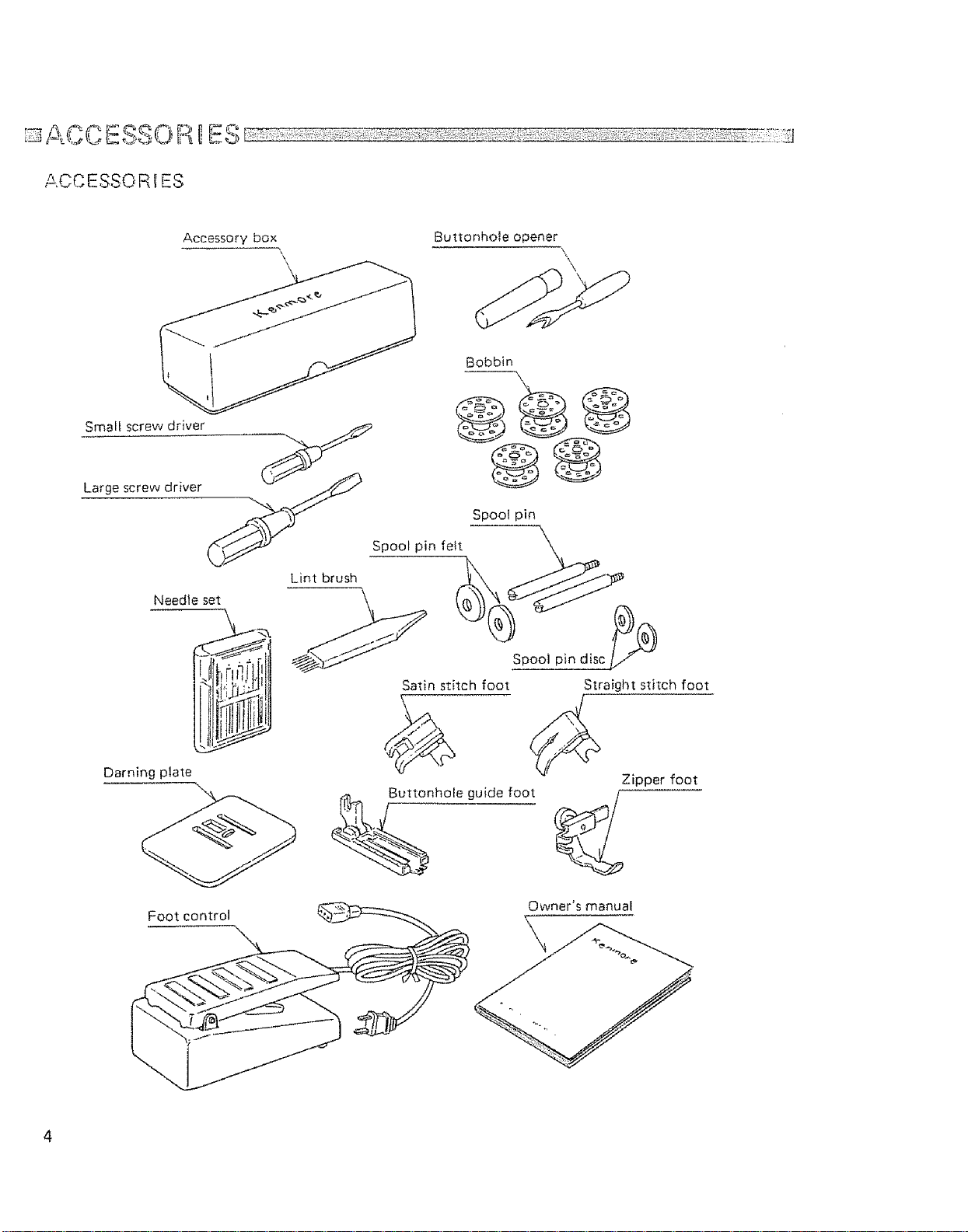

ACCESSORI ES

Small screw driver

Large screw driver

Accessory box

h

Lint brush

Buttonhole opener

.\

Bobbin

Spool pin

Spool pin fett

Spool pin disc

Straight stitch foot

Darning plate

Foot control

Buttonhole guide foot

Zipper foot

Owner's manual

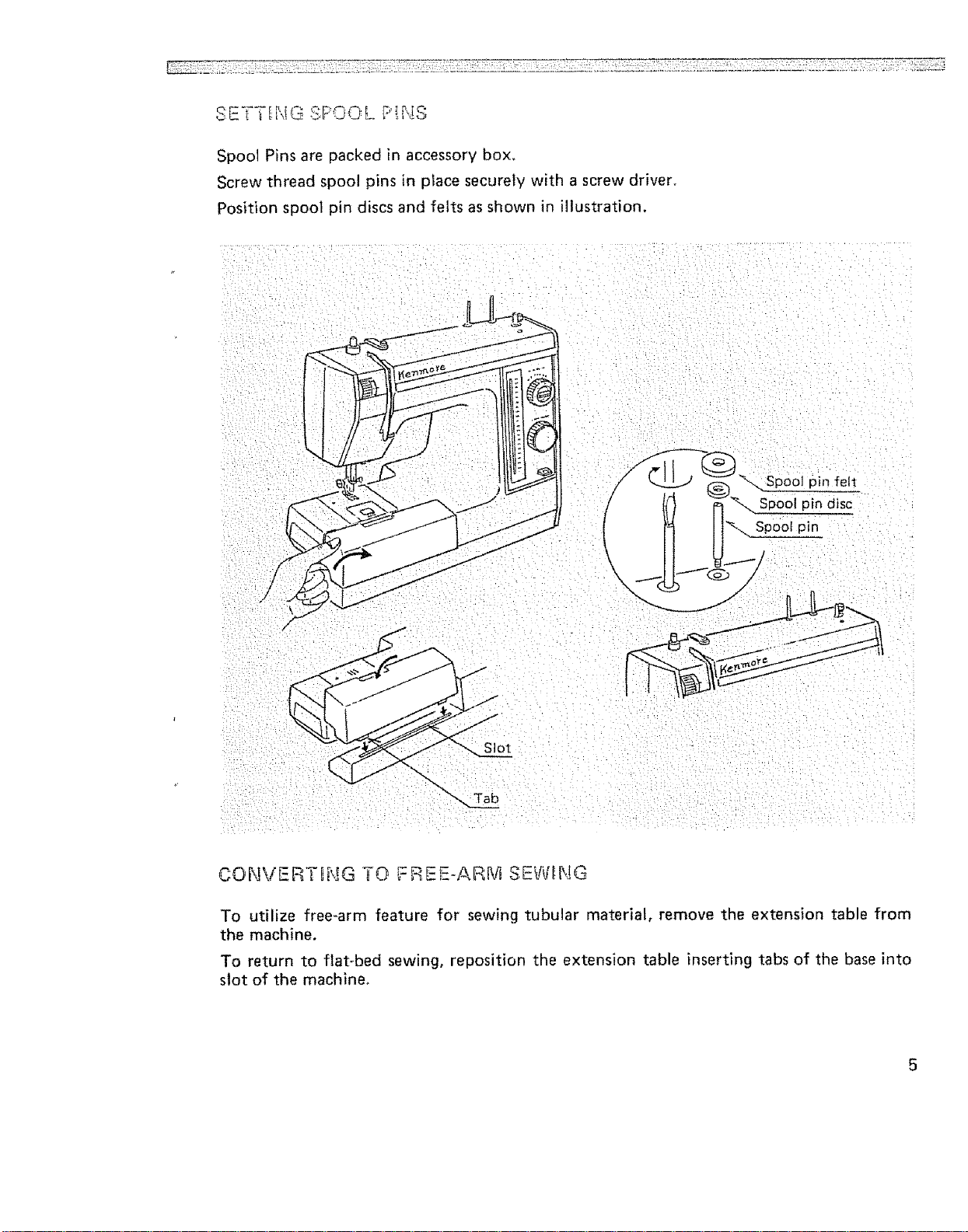

SETTING SI:'OO L P'!NS

Spool Pins are packed in accessory box,

Screw thread spool pins in place securely with a screw driver.

Position spool pin discs and felts as shown in illustration.

/ t4 _ _. spoolpin,_i_o

( 11 II'" s_'°O'_'° "

Slot

CONVERTING TO FREE-ARM SEWING

To utilize free-arm feature for sewing tubular material, remove the extension table from

the machine.

To return to flat-bed sewing, reposition the extension table inserting tabs of the base into

slot of the machine.

? _-_ESSU R E R I:._aU L s "i-} i_

y_

/

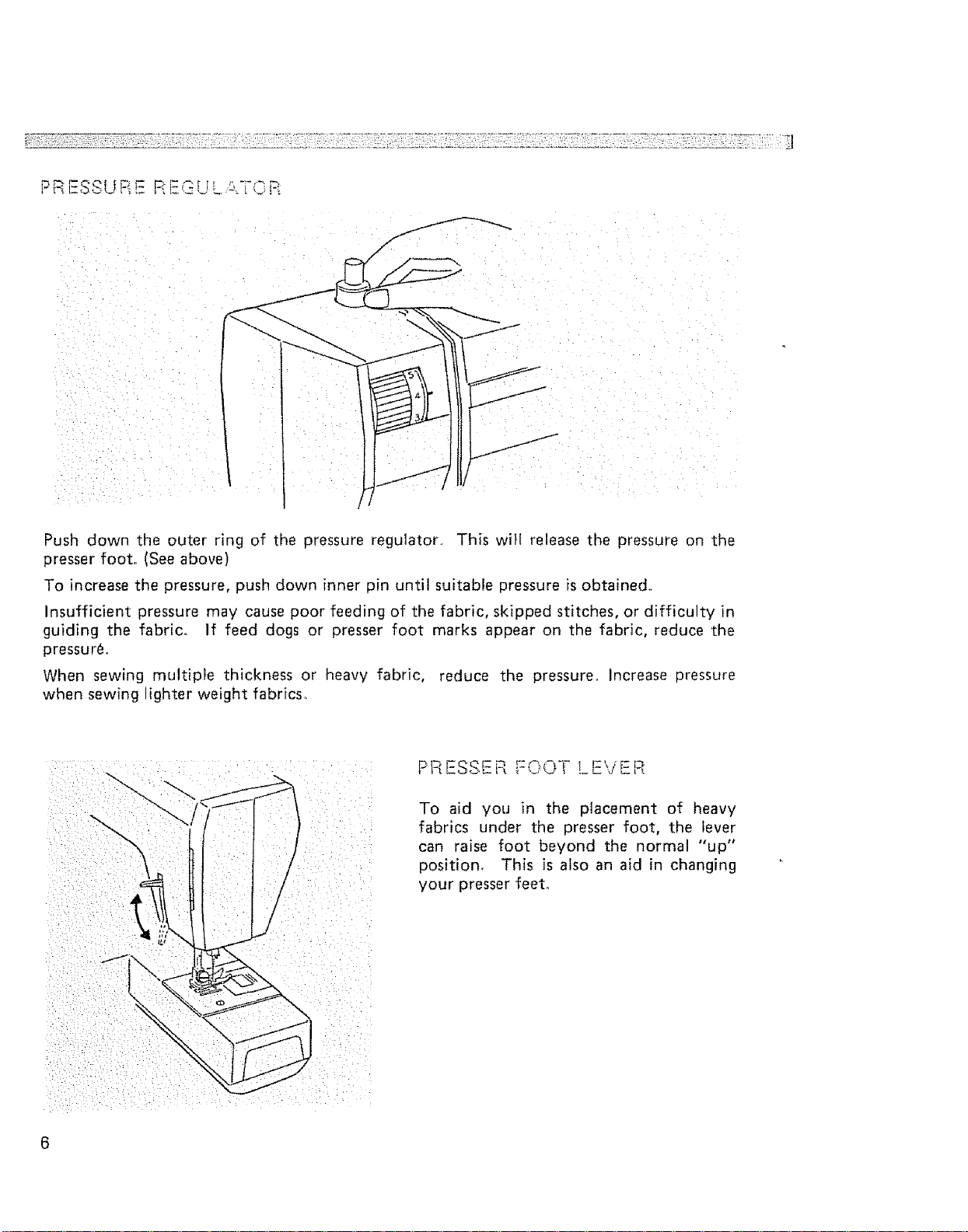

Push down the outer ring of the pressure regulator.. This will release the pressure on the

presser foot.. (See above)

To increase the pressure, push down inner pin until suitable pressure is obtained..

Insufficient pressure may cause poor feeding of the fabric, skipped stitches, or difficulty in

guiding the fabric_ If feed dogs or presser foot marks appear on the fabric, reduce the

pressure.

When sewing multiple thickness or heavy fabric, reduce the pressure.. Increase pressure

when sewing lighter weight fabrics,.

PRESSER FOOT LEVER

To aid you in the placement of heavy

fabrics under the presser foot, the lever

can raise foot beyond the normal "up"

position, This is also an aid in changing

your presser feet,,

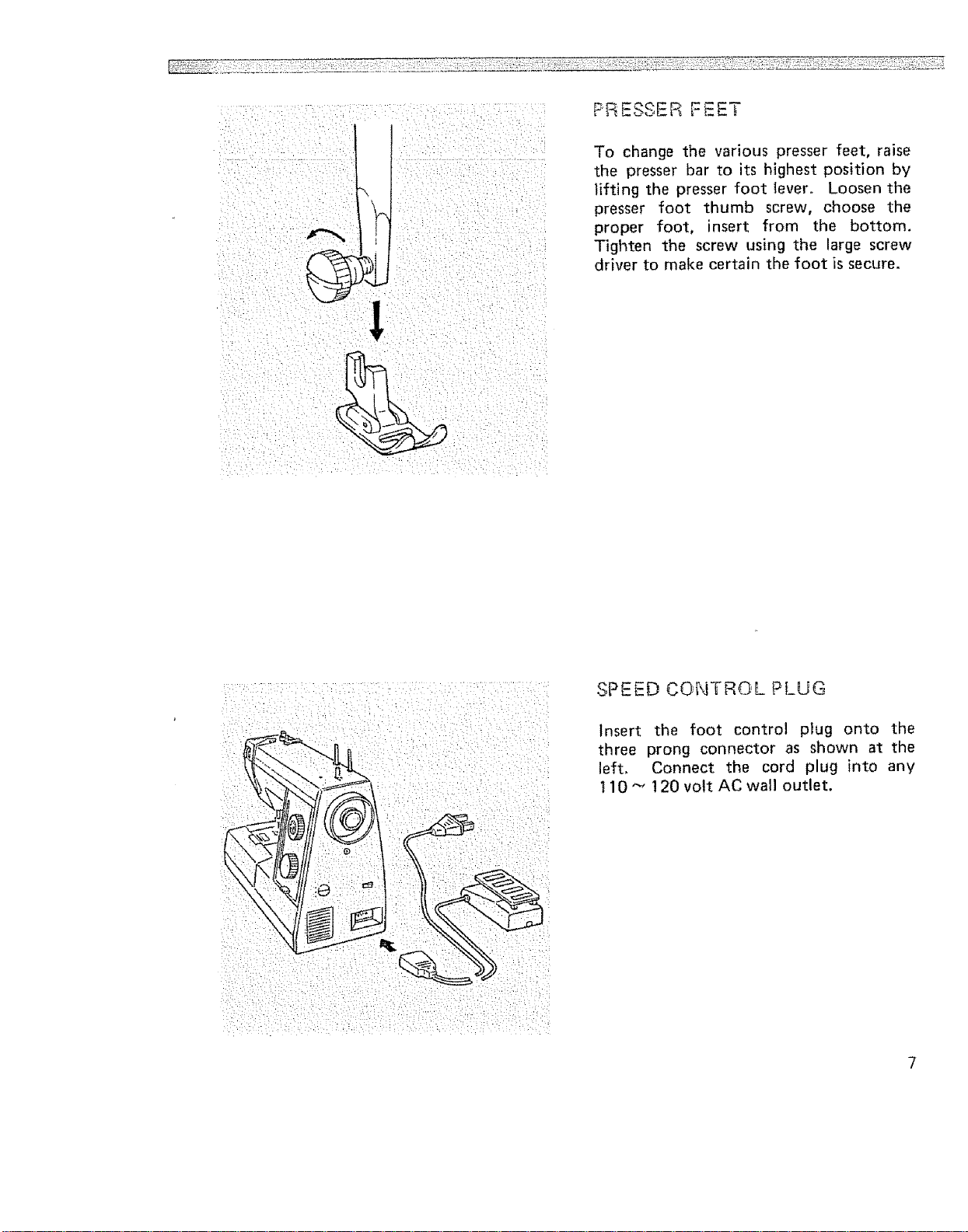

PRESSER FEET

To change the various presser feet, raise

the presser bar to its highest position by

\

lifting the presser foot levero Loosen the

presser foot thumb screw, choose the

proper foot, insert from the bottom.

Tighten the screw using the large screw

driver to make certain the foot is secure.

SPEED CONTROL PLUG

Insert the foot control plug onto the

three prong connector as shown at the

left, Connect the cord plug into any

t 10 "" 120 volt AC wall outlet.

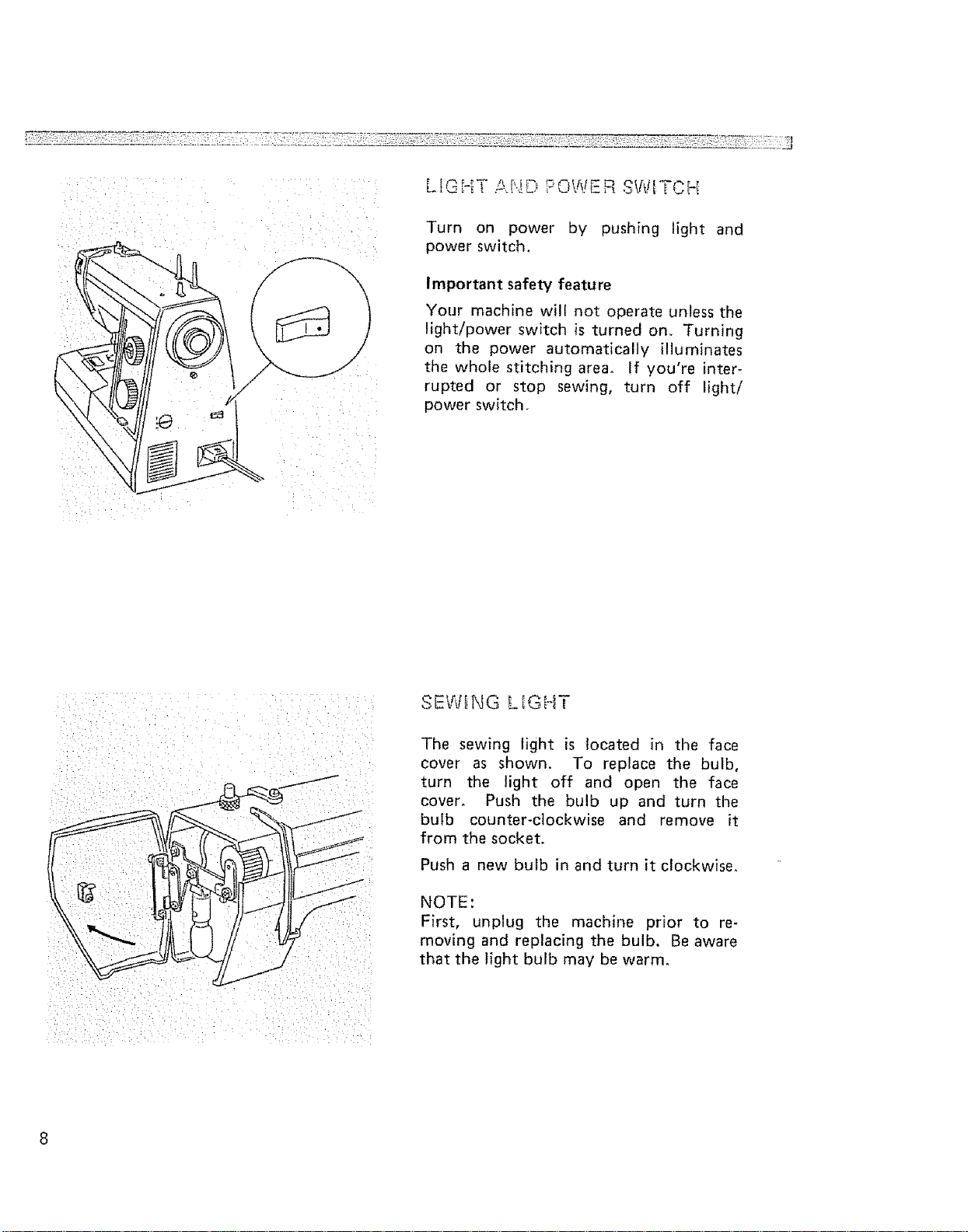

LIGHT :-,^.r'_D_POWER SWI _CH

Turn on power by pushing light and

power switch,

Important safety feature

Your machine will not operate unless the

light/power switch is turned on,, Turning

on the power automatically illuminates

the whole stitching area. If you're inter-

rupted or stop sewing, turn off light/

power switch.

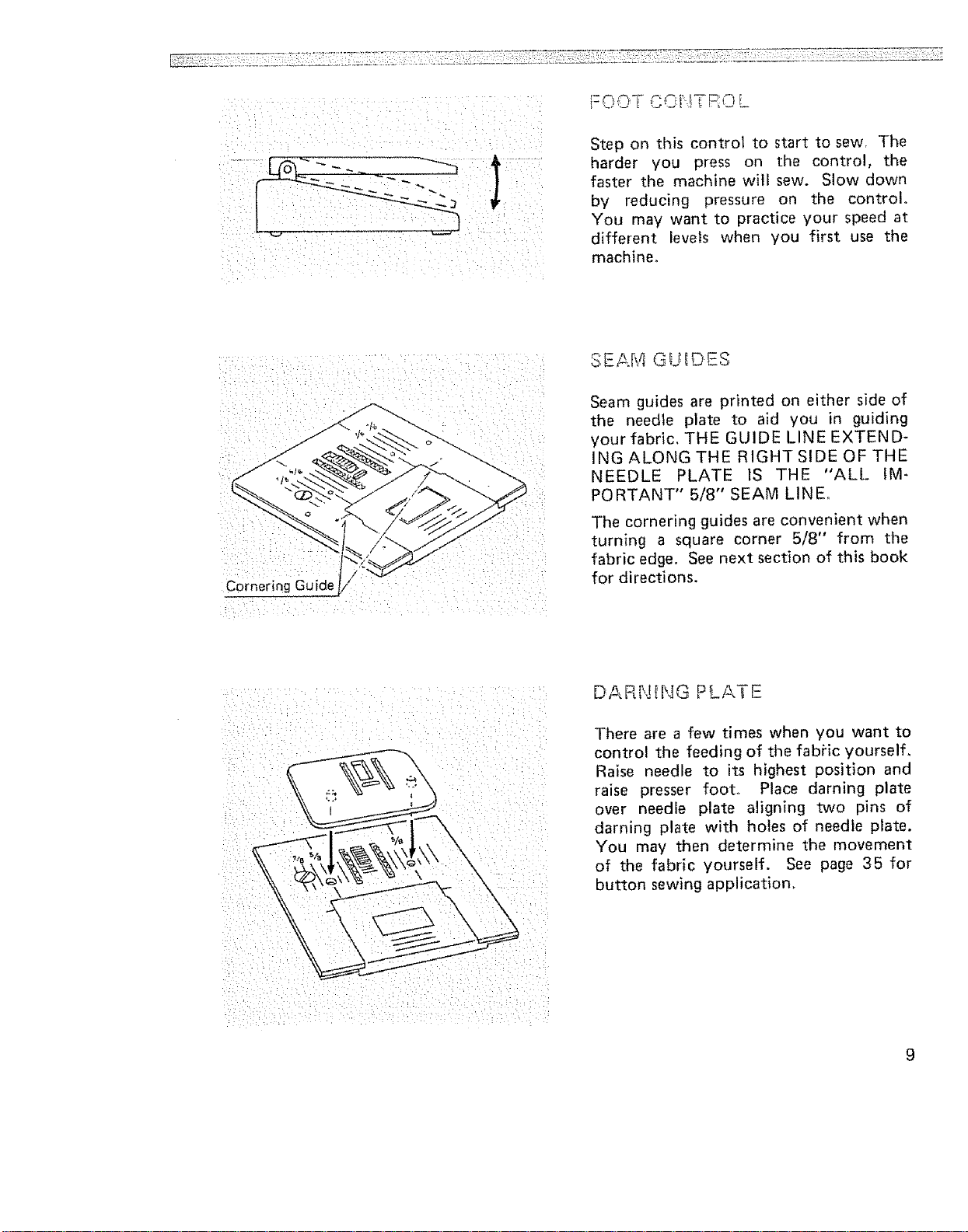

SEWING L_GHT

The sewing light is located in the face

cover as shown. To replace the bulb,

turn the light off and open the face

cover. Push the bulb up and turn the

bulb counter-clockwise and remove it

from the socket.

Push a new bulb in and turn it clockwise.

NOTE :

First, unplug the machine prior to re-

moving and replacing the bulb, Be aware

that the light bulb may be warm.

(:!i _ Y : : : i i _:

cornering Guide

:: !71

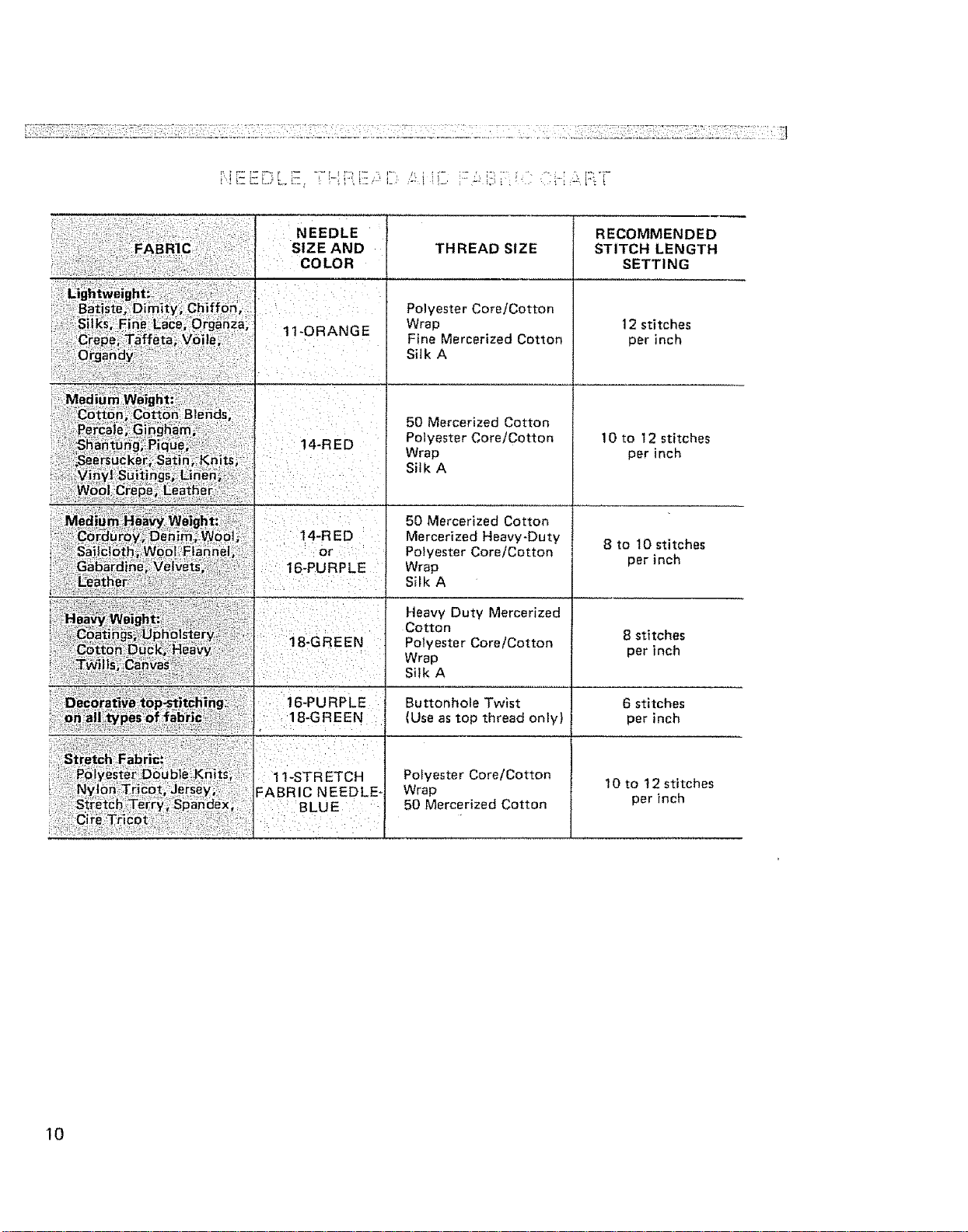

FOOT L_C4 P_j L

Step on this control to start to sew, The

harder you press on the contro!, the

faster the machine will sew. Slow down

by reducing pressure on the control°

You may want to practice your speed at

different levels when you first use the

machine°

SEAM GUIDES

Seam guides are printed on either side of

the needle plate to aid you in guiding

your fabric, THE GUIDE LINE EXTEND-

ING ALONG THE RIGHT SIDE OF THE

NEEDLE PLATE IS THE "ALL IM-

PORTANT" 5/8" SEAM LINEo

The cornering guides are convenient when

turning a square corner 5/8" from the

fabric edge. See next section of this book

for directions.

_" _ i _ _ _ _ _ _7 •

• : :i I

DARNING PLATE

There are a few times when you want to

control the feeding of the fabric yourself,

Raise needle to its highest position and

raise presser foot,, Place darning plate

over needle plate aligning two pins of

darning plate with holes of needle plate.

You may then determine the movement

of the fabric yourself. See page 35 for

button sewing application,

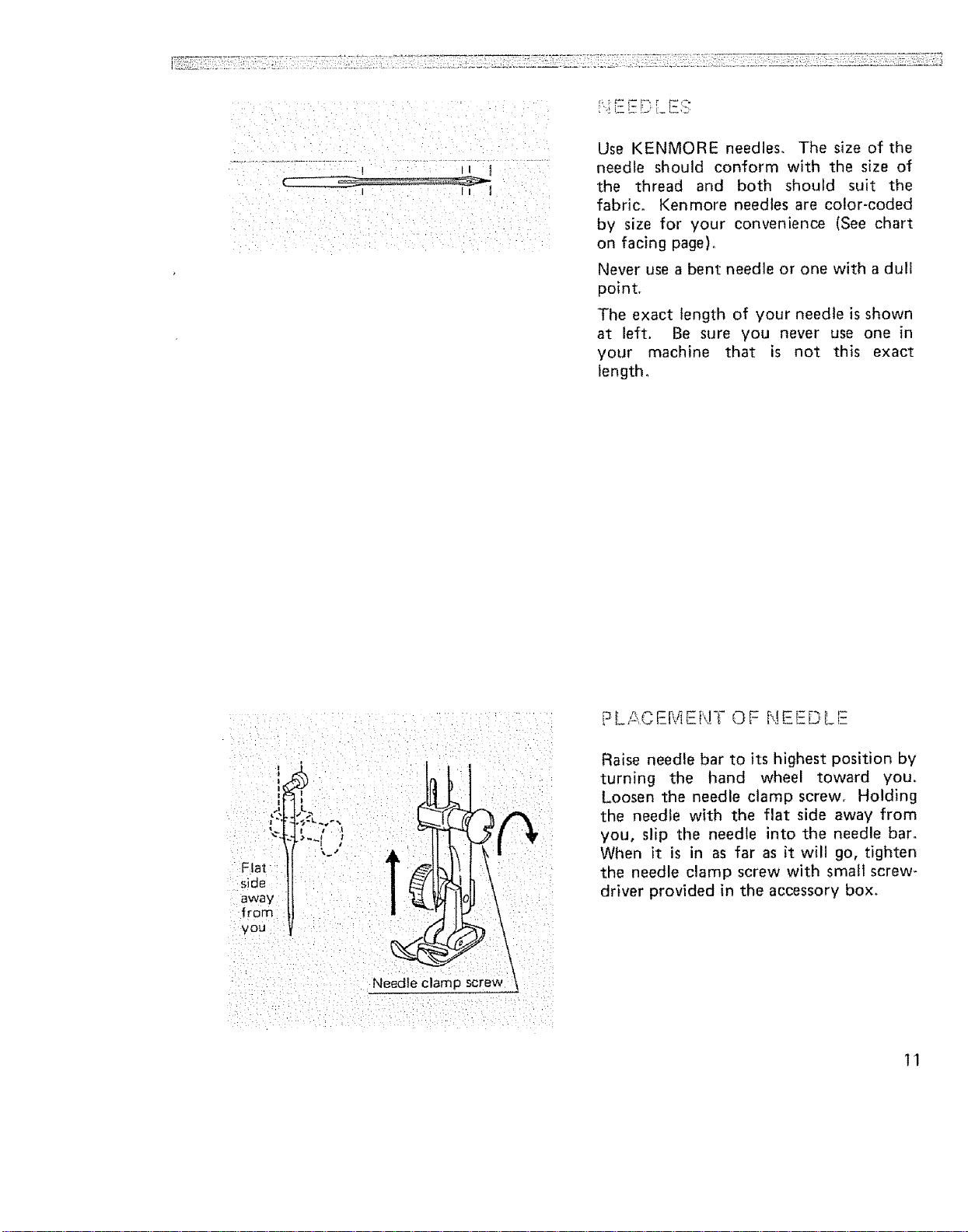

NEEDLE

SIZE AND

COLOR

THREAD SIZE

RECOMMENDED

STITCH LENGTH

SETTING

Polyester Core/Cotton

11-ORANGE

14-RED

14-RED

or

16-PURPLE

18-GREEN

16-PURPLE Buttonhole Twist 6 stitches

18-GREEN (Use as top thread only) per inch

Wrap

Fine Mercerized Cotton

Silk A

50 Mercerized Cotton

Polyester Core/Cotton

Wrap

Silk A

50 Mercerized Cotton

Mercerized Heavy-Duty

Polyester CoreiCotton

Wrap

Sitk A

Heavy Duty Mercerized

Cotton

Polyester CoretCotton

Wrap

Silk A

12 stitches

per inch

10 to 12 stitches

per inch

8 to t0 stitches

per inch

8 stitches

per inch

1 !-STR ETCH

FABRIC NEEDLE-

;::BLUE i

Polyester Core/Cotton

Wrap

50 Mercerized Cotton

10 to 12 stitches

per inch

Use KENMORE needles. The size of the

needle should conform with the size of

the thread and both should suit the

fabric. Kenmore needles are color-coded

by size for your convenience (See chart

on facing page)°

Never use a bent needle or one with a dull

point.

The exact length of your needle is shown

at left. Be sure you never use one m

your machine that is not this exact

length.

Flat

side

away

from

you

PLACEI_,_EHT OF NEEDLE

Raise needle bar to its highest position by

turning the hand wheel toward you,

Loosen the needle clamp screw. Holding

the needle with the flat side away from

you, slip the needle into the needle bar.

When it is in as far as it will go, tighten

the needle clamp screw with small screw_

driver provided in the accessory box,

Needte clamp

11

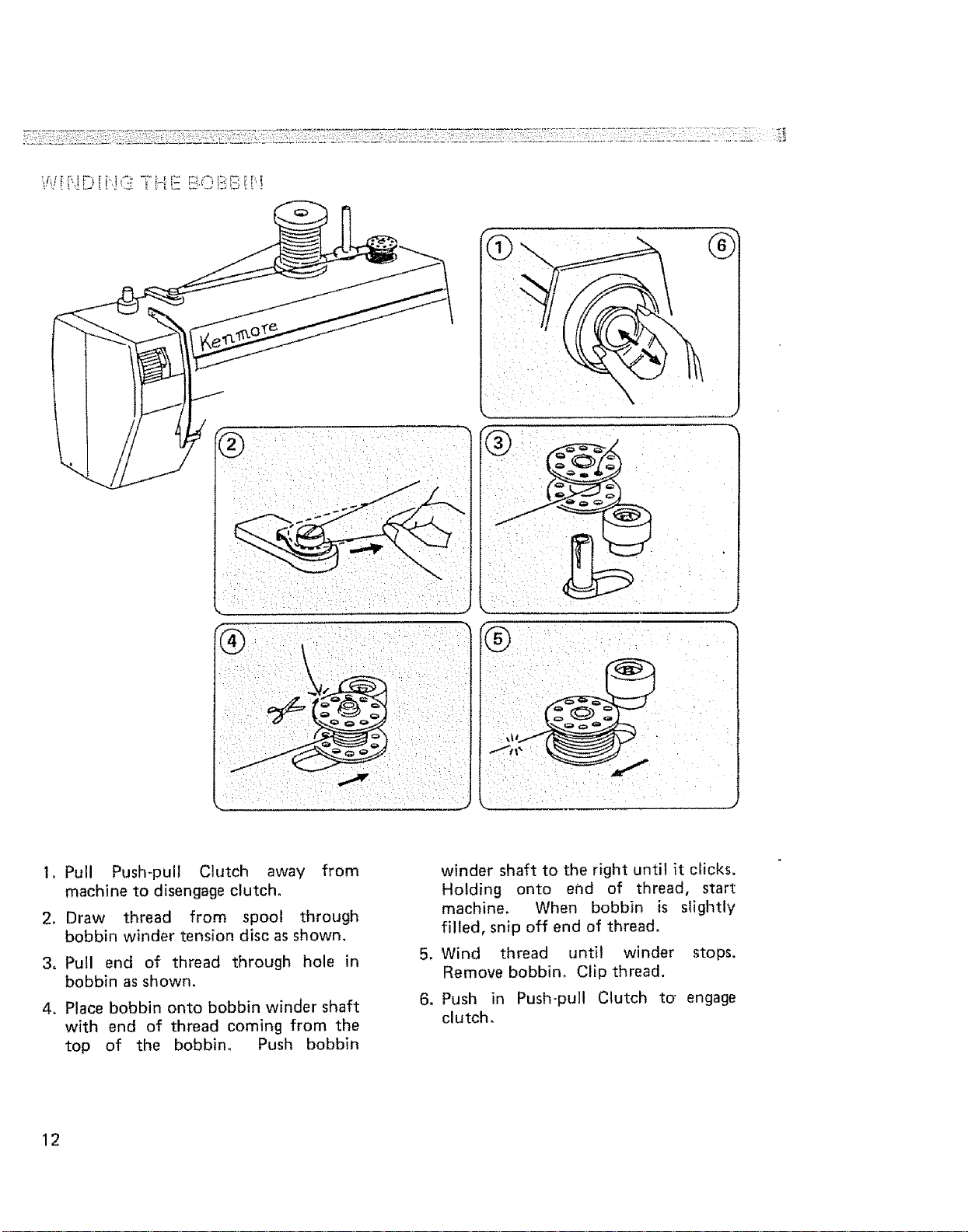

1. Pull Push-pull Clutch away from

machine to disengage clutch,

2. Draw thread from spool through

bobbin winder tension disc as shown,

3, Pull end of thread through hole in

bobbin as shown,

4, Place bobbin onto bobbin winder shaft

with end of thread coming from the

top of the bobbin. Push bobbin

12

winder shaft to the right until it clicks,

Holding onto end of thread, start

machine. When bobbin is slightly

filled, snip off end of thread.

5, Wind thread until winder stops,

Remove bobbin. Clip thread.

6. Push in Push-pul! Clutch to" engage

clutch.

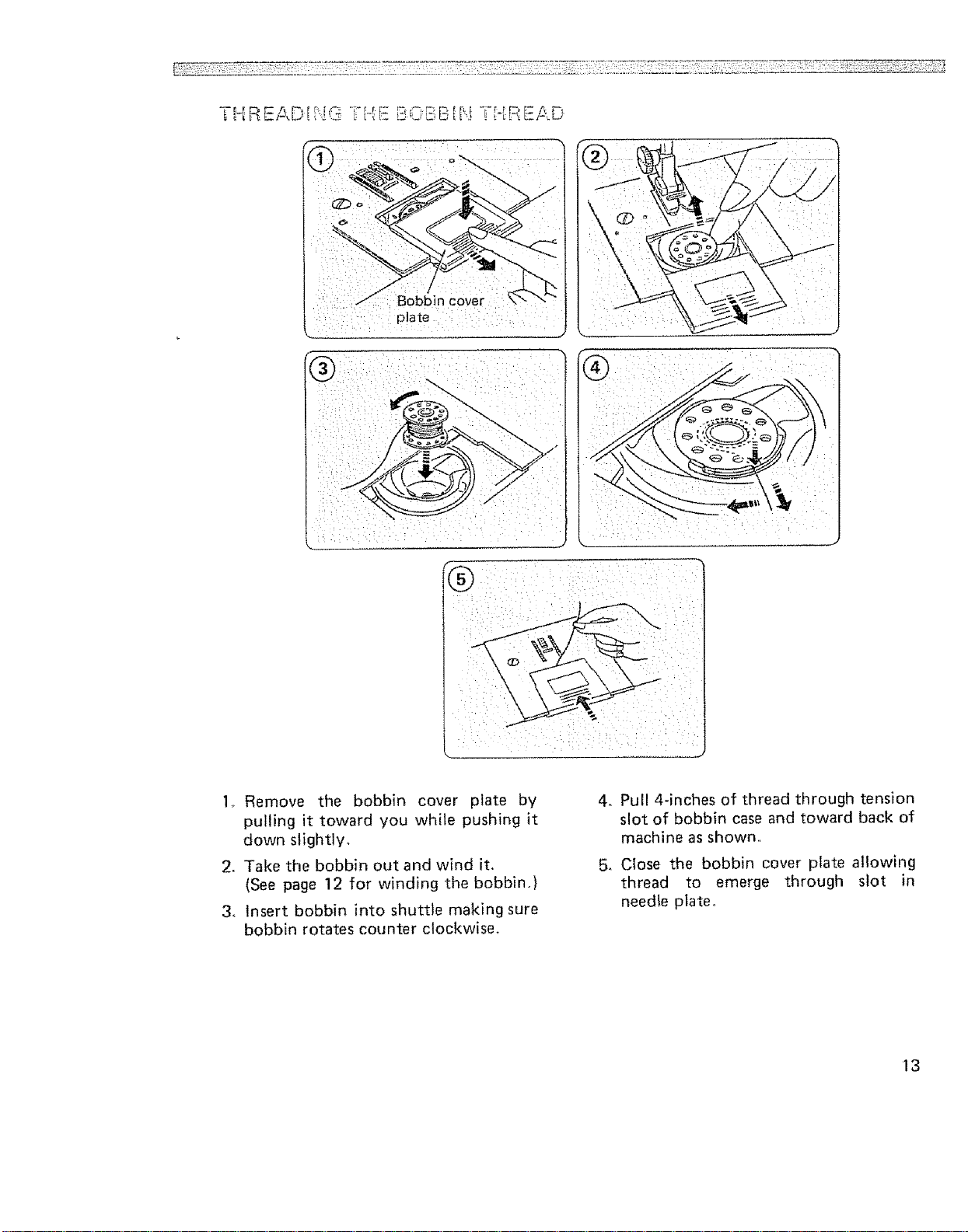

Bobbin cover

p ate

O

1_ Remove the bobbin cover plate by

pulling it toward you while pushing it

down stightlv.

2. Take the bobbin out and wind it,

(See page 12 for winding the bobbin.)

3o Insert bobbin into shuttle making sure

bobbin rotates counter clockwise°

4_ Pull 4-inches of thread through tension

slot of bobbin case and toward back of

machine as shown,,

5o Close the bobbin cover plate allowing

thread to emerge through slot in

needle plate°

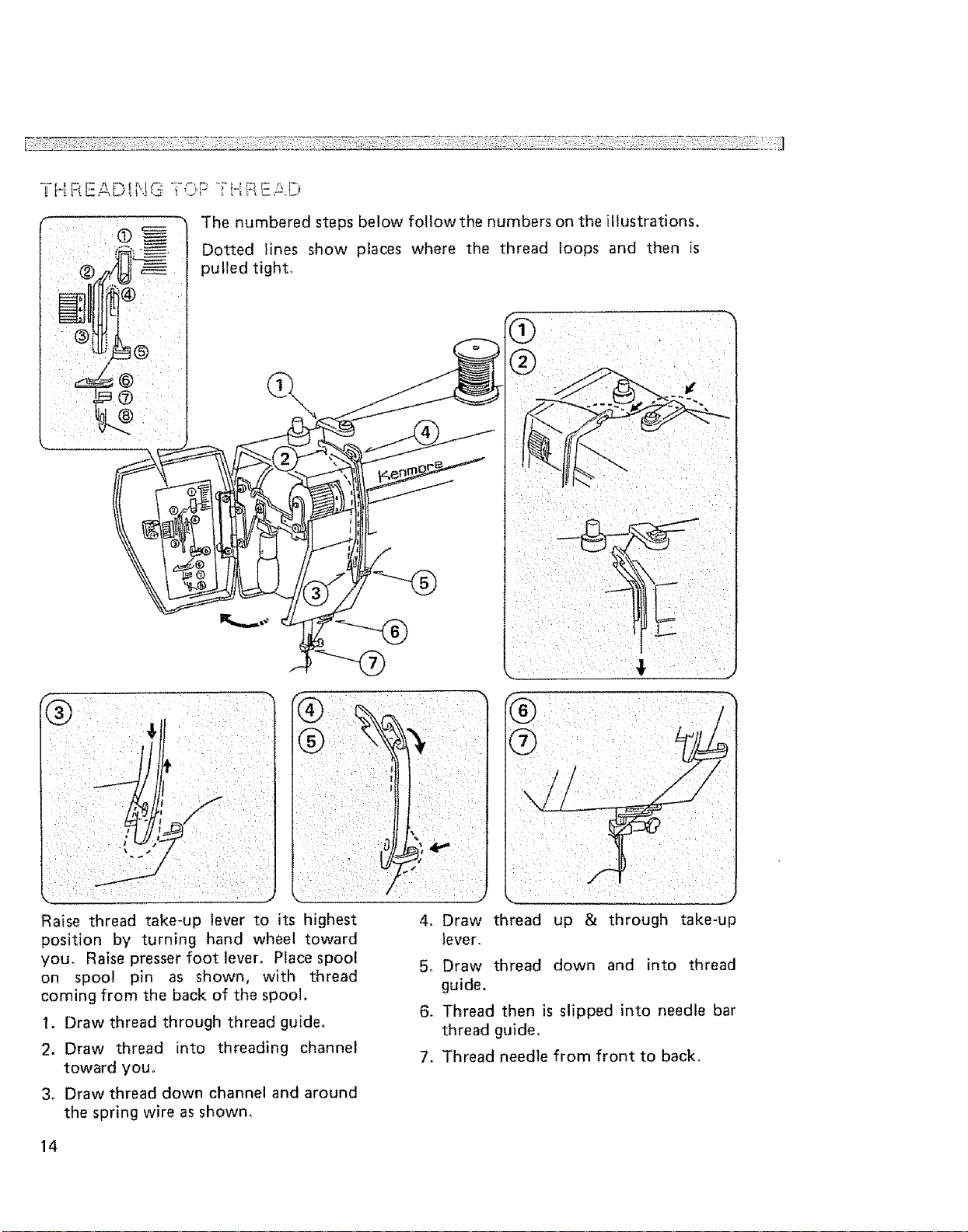

Thenumberedstepsbelowfollow thenumbersontheillustrations.

Dotted lines show placeswhere the thread loops and then is

3ulledtight,

®

1. Drawthreadthroughthreadguide.

2. Draw thread into threading channel

towardyou.

3, Drawthreaddownchannelandaround

thespringwireasshown.

14

4, Draw thread up & through take-up

lever,

5, Draw thread down and into thread

guide.

6. Thread then is slipped into needle bar

thread guide.

7o Thread needle from front to back.

®

®

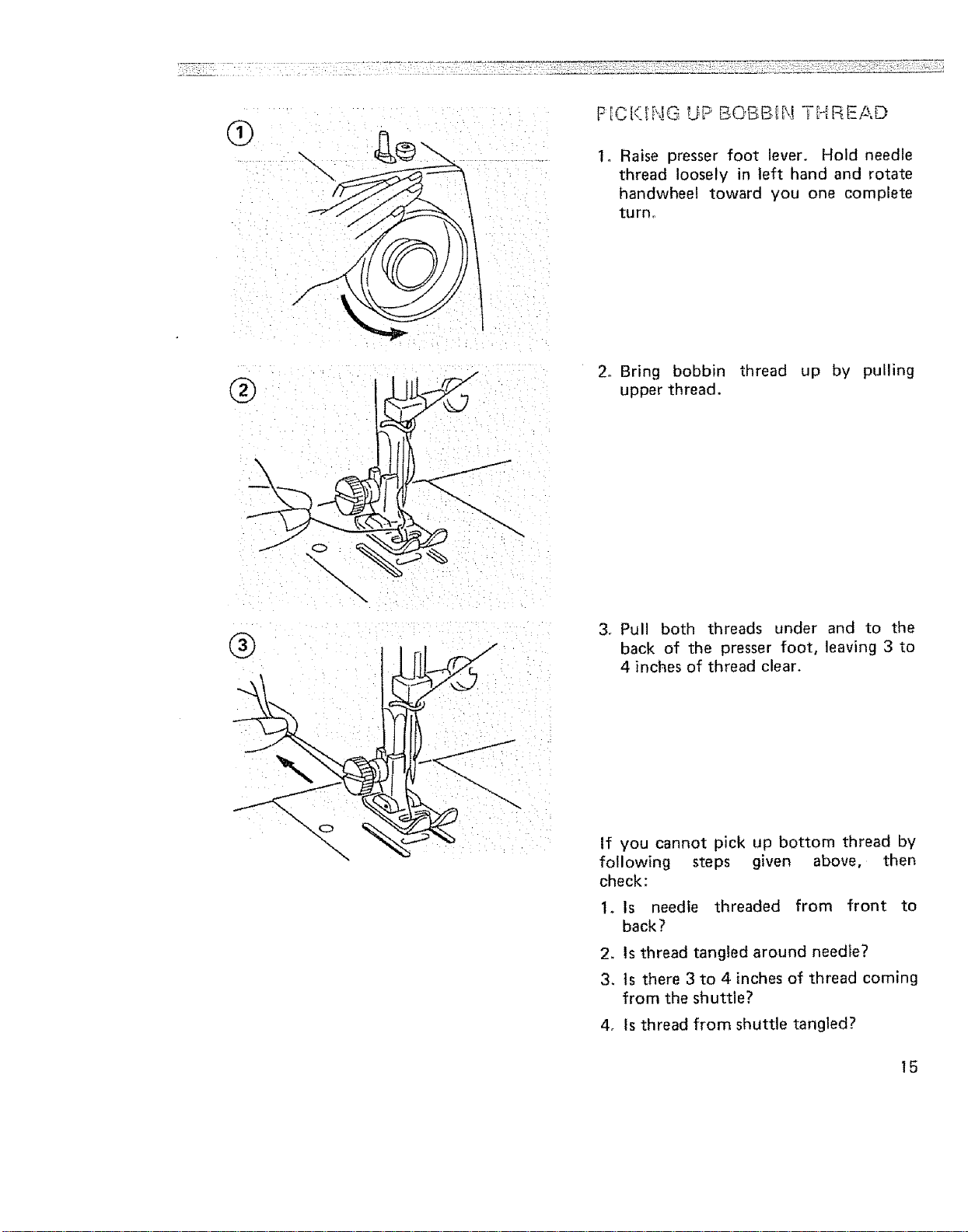

PICkiNG UP BOBBIB_ TI4READ

1, Raise presser foot lever. Hold needle

thread loosely in left hand and rotate

handwheel toward you one complete

turn°

2. Bring bobbin thread up by pulling

upper thread.

\

®

3. Pull both threads under and to the

back of the presser foot, leaving 3 to

4 inches of thread clear.

If you cannot pick up bottom thread by

following steps given above, then

check:

t. Is needle threaded from front to

back?

2. Is thread tangled around needle?

3, ls there 3 to 4 inches of thread coming

from the shuttle?

4. Is thread from shuttle tangled?

15

ADJUSt _[_GTOP Lr_Rsr',m_.=_

TENSIONS

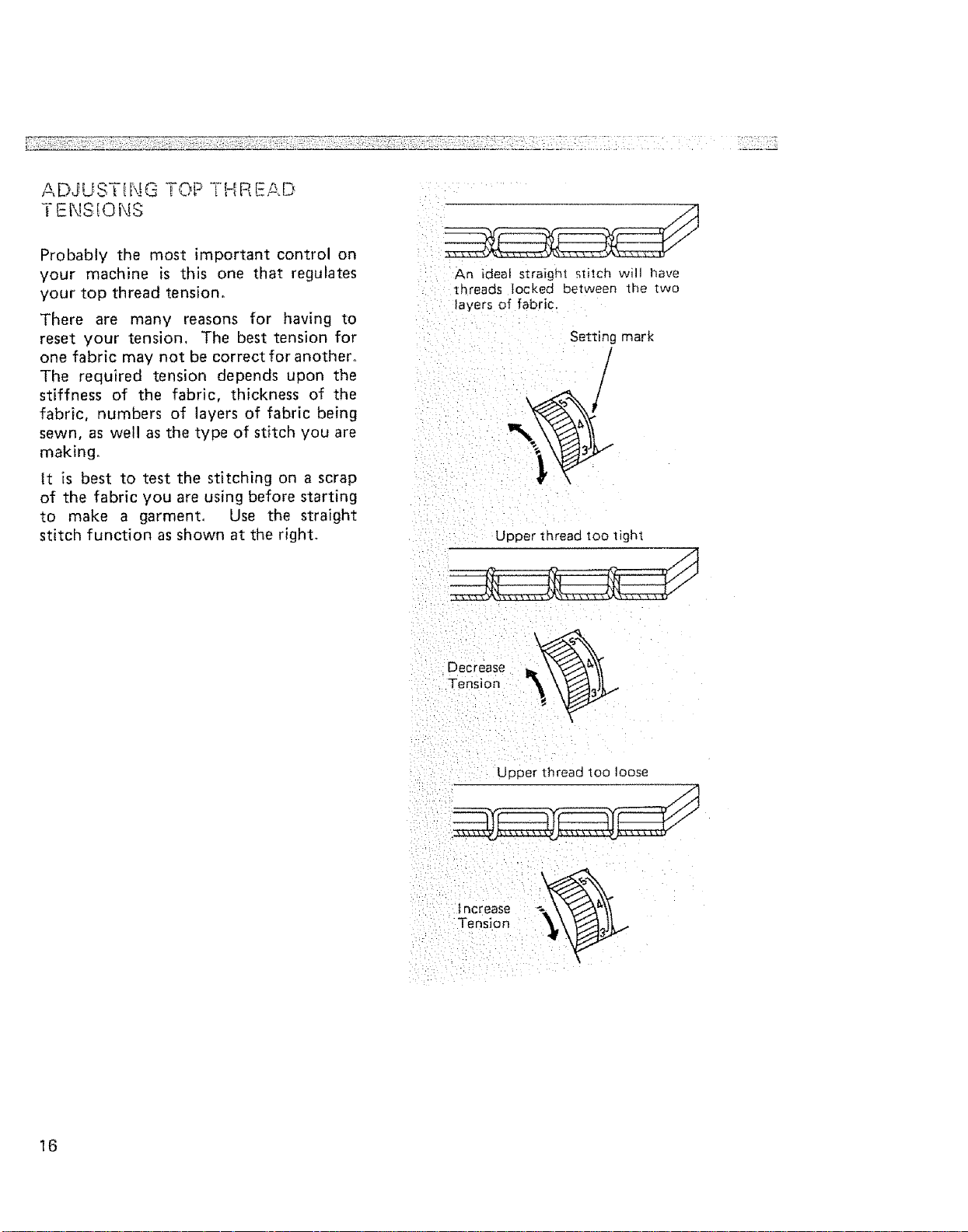

Probably the most important control on

your machine is this one that regulates

your top thread tension.

There are many reasons for having to

reset your tension. The best tension for

one fabric may not be correct for another°

The required tension depends upon the

stiffness of the fabric, thickness of the

fabric, numbers of layers of fabric being

sewn, as well as the type of stitch you are

making,

It is best to test the stitching on a scrap

of the fabric you are using before starting

to make a garment,, Use the straight

stitch function as shown at the right°

An ideal straight stitch will have

threads locked between the two

layers of fabric.

Setting mark

/

Upper thread too tight

Decrease __

Tension _ \ _;¢:::_j_

U Dper thread 1oo loose

Tension

1ncrease -_

\

16

Now that you are familiar with the controls on your machine and with the accessories

provided for the machine, you are ready to start to sew with your new Kenmore sewing

machine. Below are some good habits to follow each time you sit down to sew:

Test the needle.. It should be straight, properly set and sharp on the point° It should be

the correct size for the fabric and thread being used Do not be afraid to change your

needle frequently° Many of the new fabrics made of synthetic blends tend to dull the

needles more easily than fabrics made of natural fibers,,

2o Before placing the material on the machine, see that the ends of the threads have been

drawn about 4 inches to the rear of the machine° Hold on to threads during the sewing

of the first 3 or 4 stitches of the seam,

3o Test the machine stitch on a scrap of fabric you plan to use, The fabric should be

double thickness, Adjust the machine for the length of stitch and tension suitable to

your fabric°

4, Fabric should be placed under the presser foot with the bulk of the material to the left

of the needle and the right edge of the material placed on the 5/8" seam marking on

the needle plate when making a simple seam,

5, Run the machine at a slow even speed, The more pressure you put on the foot control,

the faster the machine will sew,,

6, Fasten each seam by back tacking at the beginning and end of the seam.

7,, Always finish sewing each seam with the needle at its highest point°

8_ Guide the fabric gently with your hand in front of the needle. Never pull or hold the

fabric in such a way that the normal feeding is altered.

9. When turning the hand wheel manually, always turn it toward you°

17

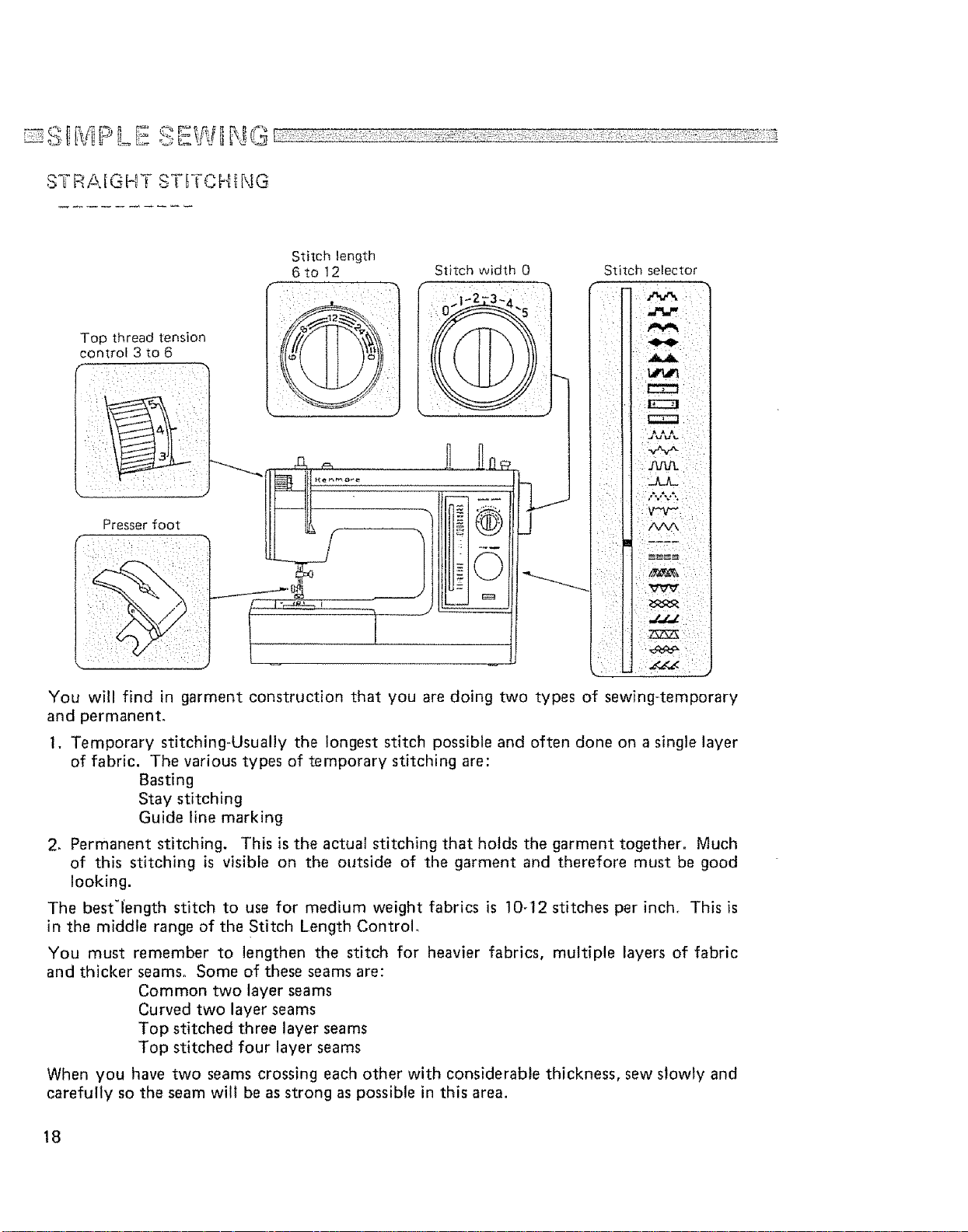

STRiAtGFIT STITCHING

Stitch length

6to 12

Top thread tension

control 3 to 6

Presser foot

Stitch width 0 Stitch selector

7_

J

i

::Vml_

You will find in garment construction that you are doing two types of sewing-temporary

and permanent.

1. Temporary stitching-Usually the longest stitch possible and often done on a single layer

of fabric. The various types of temporary stitching are:

Basting

Stay stitching

Guide line marking

2. Permanent stitching. This is the actual stitching that holds the garment together° Much

of this stitching is visible on the outside of the garment and therefore must be good

looking.

The best_[ength stitch to use for medium weight fabrics is 10-12 stitches per inch° This is

in the middle range of the Stitch Length Control.

You must remember to lengthen the stitch for heavier fabrics, multiple layers of fabric

and thicker seams° Some of these seams are:

Common two layer seams

Curved two layer seams

Top stitched three layer seams

Top stitched four layer seams

When you have two seams crossing each other with considerable thickness, sew slowly and

carefully so the seam will be as strong as possible in this area.

18

Loading...

Loading...