Kenmore 3627361890, 3627361190 Owner’s Manual

CONT HT$

SAFE_

Important Safety Instructions ...........................2, 3, 17-20

Anti-Tip Device .................................................................2, 3, 12, 18

liNSTALLATION ....................................................2-t6

Dimensions and Clearances ..................................................2

Gas Pipe and Electric Outlet Locations ......................5, 6

Electrical Connections ..........................................................7, 8

Installing the Anti-Tip Device ...............................................I2

How to Convert the Range

for Use with LP Gas ..............................................................13-16

Kenmor'e

SERVICE

Minor Adjustments You Can Make ...................................45

Problem Solver ........................................................................46, 47

WARRANTY ....................................................... b_C k cover

MODELS:

73611,73618, 73619,

73915, 73919

@ @

WARN#,]G:if the informationin

this manual is not followed

exactly,a fire or explosionmay

resultcausingpropertydamage,

personalinjuryor death.

--Do not store or use gasoline or

other flammable vapors and li-

quidsinthevicinityof thisor any

otherappliance.

--WHAT TODOIFYOUSMELLGAS

oDo nottryto lightanyappliance.

RNSTALLATBONINSTRUCTIONS

Do not touch any electrical

switch;donot useany phonein

your building.

oimmediatelycall your gas sup=

plierfrom a neighbor's phone.

Follow the gas supplier's

instructions=

• If you cannot reach your gas

supplier,callthefire department.

--Installation and service must be

performedbya qualifiedinstaller,

serviceagencyorthegassupplier.

BEFORE YOU BEGnN

Read these instructions completely and

carefully.

IMPORTANT: Save these instructions for the

local electrical inspector's use.

INSTALLER: Leave these instructions with the

appliance after installation is completed.

OWNER: Keep this Use and Care Guide and

the Installation Instructions for future use.

This appliance must be properly grounded.

CAUTION

Do not attempt to operate the oven of this

range during a power failure.

IMPORTANT

Remove all packing material and literature

from oven before connecting gas and electri-

cal supply to range.

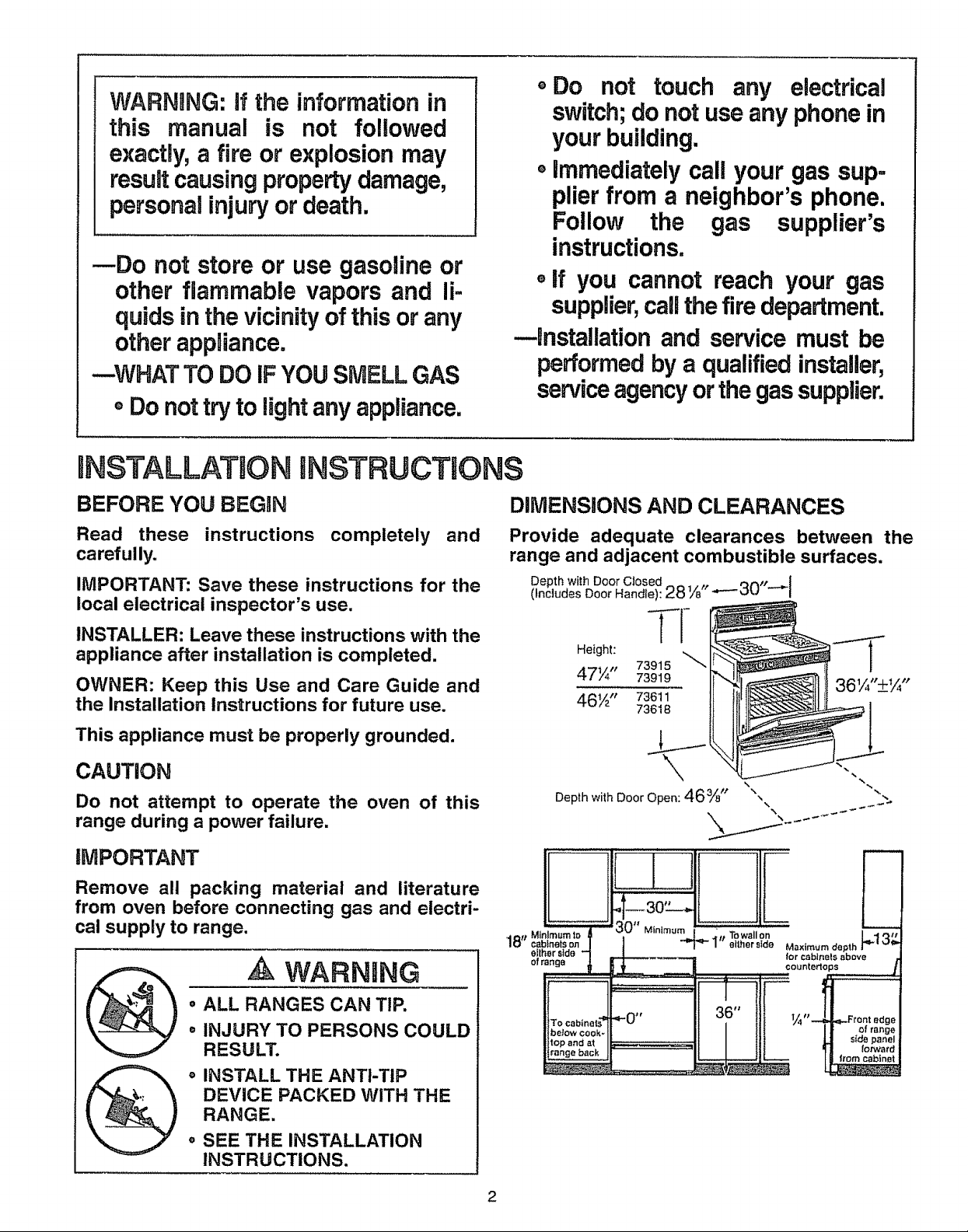

DIMENSIONS AND CLEARANCES

Provide adequate clearances between the

range and adjacent combustible surfaces.

Depth with Door Closed tt ,_^_t ..I

(Includes Door Handle): 28'A ---_u i

TI-

Height:

47¼" 73919

46½" 73611

Depthwith Door Open: 46%" ",

73915

73618

%

A WARNING

• ALL RANGES CAN TIP.

• INJURY TO PERSONS COULD

RESULT.

INSTALL THE ANTI-TIP

DEVICE PACKED WITH THE

RANGE.

, SEE THE INSTALLATION

INSTRUCTIONS.

TO cabinet_,= ._0 *r l_lJ Front edge

filth °'°°°°topand at _:::

2

lVlPORTANT SAFETY INSTRUCTIONS

_lnstallation of this range must conform with local

__ codes, or in the absence of local codes, with the

National Fuel Gas Code, ANSi Z223, latest edition.

This range has been design-certified by the American

_i Gas Association according to ANSI Z21.1, latest edF

tion. As with any appliance using gas and generating

heat, there are certain safety precautions you should

:follow. You will find these precautions at the beginning

:of the Use and Care section of this book Read them

carefuilyo

e Have your range installed by a qualified installer or

service technician.

, "(our range must be electrically grounded in accor-

dance with local codes or, in the absence of local

codes, in accordance with the National Electrical

Code (ANSI/NFPA 70, latest edition) See Electrical

Connections in this section

o Before installing your range on linoleum or any other

synthetic floor covering, make sure the floor covering

can withstand 180°R without shrinking, warping or

discoloring. Do not install the range over carpeting

unless a sheet of l/4-inch4hick plywood or similar

insulator is placed between the range and carpeting.

o Make sure the wall coverings around the range can

withstand heat generated by the range up to 200°R

o Avoid placing cabinets above the ranger To reduce

the hazard caused by reaching over the open flames

of operating burners, install over the range a ventila-

tion hood that projects forward at least 5 inches

beyond the front of the cabinets

The ventilating hood must be constructed of sheet

metal not less than 040122 inch thick. Install above

the cooking top with a (_tearance of not less than 1/4

inch between the hood and the underside of the

combustible material or metal cabinet. The hood

must be at least as wide as the appliance and cen-

tered over the appliance° Clearance between the

cooking surface and the ventilation hood surface

MUST NEVER BE LESS THAN 24 INCHES.

o if cabinets are placed above the range, allow a mini-

mum clearance of 30 inches between the cooking

surface and the bottom of unprotected cabinets.

° if a 30-inch clearance between cooking surface and

overhead combustible material or metal cabinets

cannot be maintained, protect the underside of the

cabinets above the cooking top with not less than

1/4-inch insulating millboard covered with sheet

metal not less than 0.0122 inch thick.

o Clearance between the cooking surface and protect-

ed cabinets MUST NEVER BE LESS THAN 24

INCHES, The vertical distance from the plane of the

cooking surface to the bottom of adjacent overhead

cabinets extending closer than 1 inch to the plane of

the range sides must not be less than 18 inches.

(Se e Dimensions and Clearances in this section.)

° Caution: items of interest to children should not be

stored in cabinets above a range or on the back-

splash of a range--children climbing on the range to

reach items could be seriously injured

WARNaNG

All ranges can tip and injury could

result. To prevent accidental tipping

of the range, attach an approved

Anti-Tip device to the wail. (See

Installing the Anti-Tip Device in this

section..) To check if the device is

installed and engaged properly,

carefully tip the range forward° The

Anti-Tip device should engage and

prevent the range from tipping over,.

if you pull the range out from the wall for any reason,

make sure the Anti-Tip device is engaged when you

push the range back against the wall

o For your safety, never use your range for warming

or heating the room Your oven and cooktop are not

designed to heat your kitchen. Top burners should

not be operated without cookware on the grates.

Such abuse could result in fire and damage to your

range and will void your warranty.

o Do not store or use combustible materials, gasoline

or other flammable vapors and liquids in the vicinity

of this or any other appliance. Explosions or fires

could result°

, Do not use oven for a storage area° Items stored in

the oven can ignite,

o Do not let cooking grease or other flammable mate-

rials accumulate in or near the range,

nnstaUgationinstructions

GENERAL

• See the Dimensions and Clearances section for all

rough-in and spacing dimensions,. These dimensions

must be met for safe use of your range. The location

of the electrical outlet and pipe opening (see Gas

Pipe and Electric Outlet Locations) may be adjusted

to meet specific requirements.

oThe range may be placed with 0" clearance (flush)

at the back wall and side walls of the range.

LOCATION

Do not locate the range where it may be subject to

strong drafts. Any openings in the floor or wall behind

the range should be sealed. Make sure the openings

around the base of the range that supply fresh air for

combustion and ventilation are not obstructed by car-

peting or woodwork.

PROTECT YOUR FLOOR

Your range, like many other household items, is heavy

and can settle into soft floor coverings such as cush-

ioned vinyl or carpeting. Use care when moving the

range on this type of flooring° it is recommended that

the following simple and inexpensive instructions be

followed to protect your floor..

The range should be installed on a sheet of plywood

(or similar material)., When the floor covering ends at

the front of the range, the area that the range wilt rest

on should be built up with plywood to the same level

or higher than the floor covering, This will allow the

range to be moved for cleaning or servicing,

MODEL AND SERIAL NUMBER LOCATION

Depending on your range, you'll find the model and

serial numbers on a label on the front frame of the

range, behind the storage drawer, broiler drawer or

kick panel.

TOOLS YOU WiLL NEED

• Phillips and flat-blade screwdrivers

• Pencil and ruler

° Two pipe wrenches (one for backup)

o 1%" open-end or adjustable wrench

• Nut drivers or wrenches: 3/16" and 1/4"

ADDITIONAL MATERIALS YOU MAY NEED

- Gas line shut-off valve

° Pipe joint sealant or UL-approved pipe thread tape

with Teflon* that resists action of natural and LP

gases

. Flexible metal appliance connector (1/2" I.D,). A 5-

foot length is recommended for ease of installation

but other lengths are acceptable° Never use an old

connector when installing a new range.

oFlare union adapter for connection to gas supply fine

(3/4" or 1/2" NPT x 1/2" !,,D,)

° Flare union adapter for connection to pressure regu-

lator on range (t/2" NPT x 1/2" IoD,)

"Teflon: Registered trademark of DuPont

PREPARATION

• Remove all tape and packaging. Lift up the cooktop

(on models with dual burners) and remove any pack-

ing material under it..Make sure the dual burners are

properly seated and level.

. Remove plastic film that covers some chrome parts

(around oven door, side trim)_

° Take the accessory pack out of the oven..

• Check to be sure that no range parts have come

loose during shipping.

4

Step t

Provide Adequate Gas Supply

Your range is designed to operate at a pressure of

4" of water column on natural gas or, if designed for

LP gas (propane or butane), 10" of water column°

Make sure you are supplying your range with the type

of gas for which it is designed. This range is convert-

ible for use on natural or propane gas, if you decide to

use this range on a different type of gas, conversion

adjustments must be made by a service technician or

other qualified person before attempting to operate

the range on that gas.

For proper operation, the pressure of natural gas sup-

plied to the regulator must be between 4" and 13" of

water column. For LP gas, the pressure supplied must

be between 10" and t3" of water column.. When

checking for proper operation of the regulator, the inlet

pressure must be at least 1" greater than the operat-

ing (manifold) pressure as given above. The pressure

regulator located at the inlet of the range manifold

must remain in the supply line regardless of whether

natural or LP gas is being used,. A flexible metal appli-

ance connector used to connect the range to the gas

supply line should have an I.,Doof 1/2" and be 5 feet in

length for ease of installation,

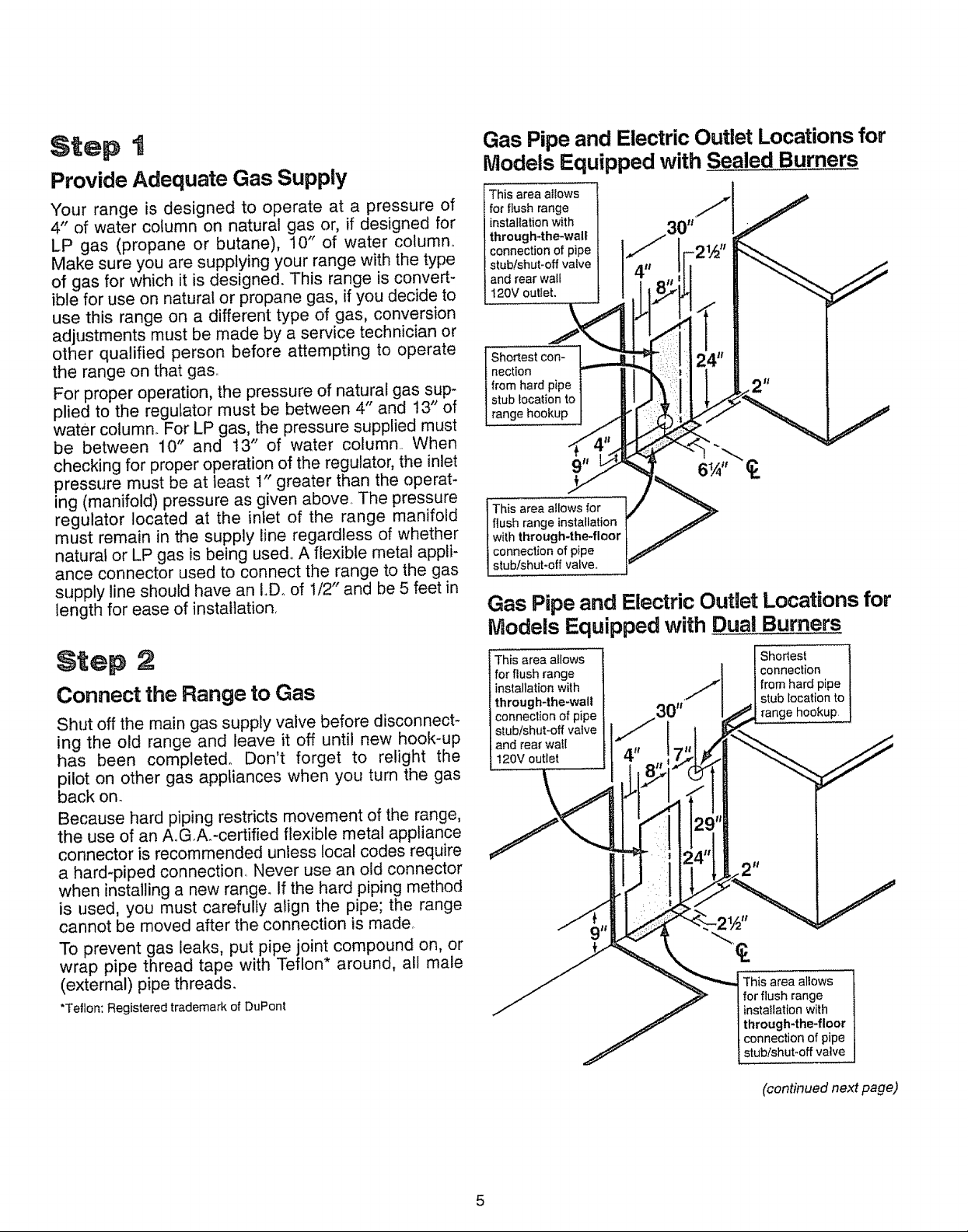

Gas Pipe and ElectricOutlet Locations for

Models Equipped with Sealed Burners

This area abws

for flush range

installation with

through-the-walt

connection of pipe

stub/shut-off valve

and rear walt

t20V outiet,

I Shortest con-

nection

from hard pipe

stub location to

range hookup

This area abws for

I flush range installation

I with through-the-floor

conneclion of pipe

1stub/shut-off valve,

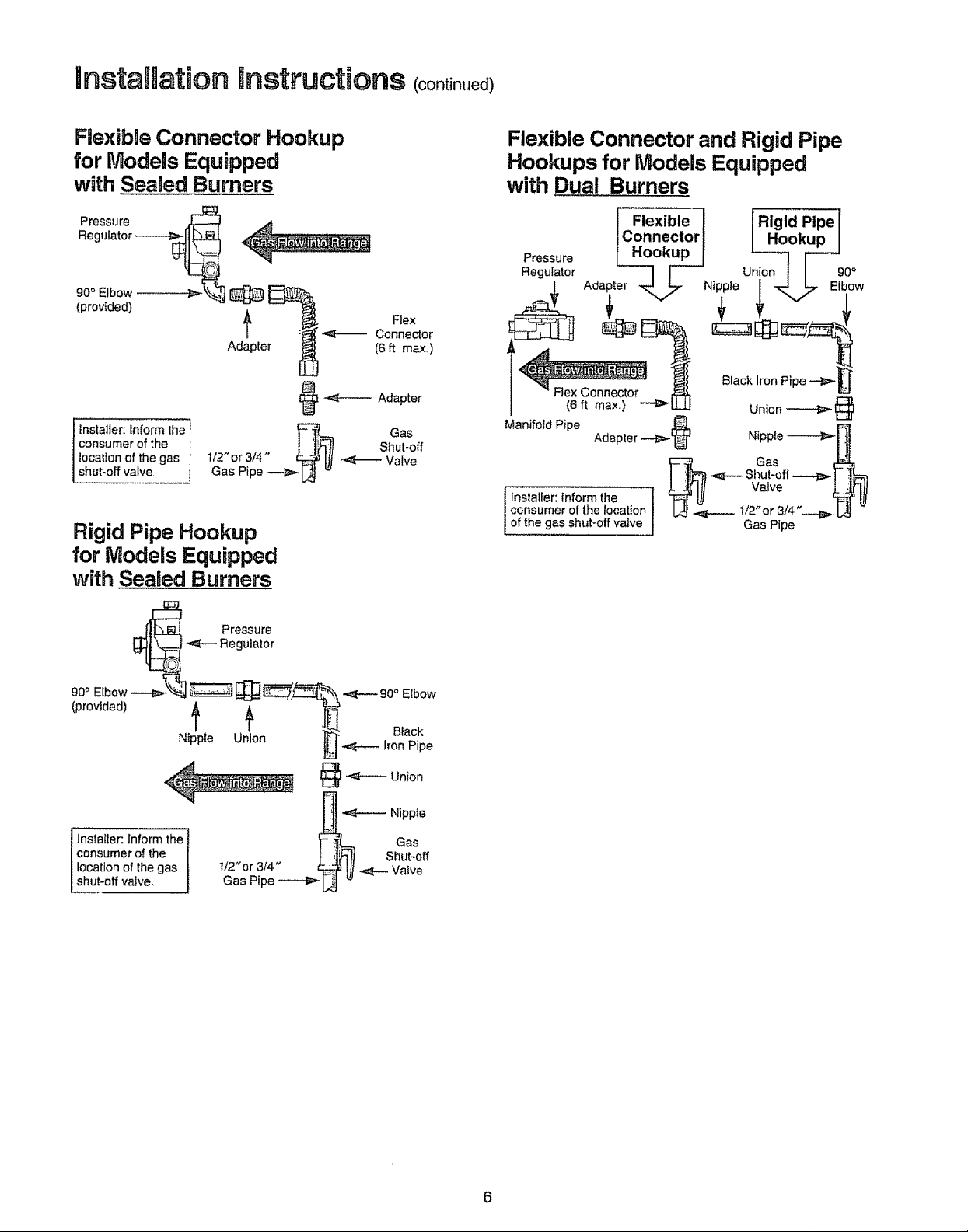

Gas Pipe and Electric Outlet Locations for

Models Equipped with Dual Burners

Step 2

Connect the Range to Gas

Shut off the main gas supply valve before disconnect-

ing the old range and leave it off until new hook-up

has been completed° Don't forget to relight the

pilot on other gas appliances when you turn the gas

back on.

Because hard piping restricts movement of the range,

the use of an AoGA:certified flexible metal appliance

connector is recommended unless local codes require

a hard-piped connection,. Never use an old connector

when installing a new range_ If the hard piping method

is used, you must carefully align the pipe; the range

cannot be moved after the connection is made,

To prevent gas leaks, put pipe joint compound on, or

wrap pipe thread tape with Teflon* around, all male

(external) pipe threads.

*Teflon: Registered trademark of DuPont

This area allows

for flush range

installation with

through-the-walt

connection of pipe

stub/sh_Jt-off vatve

and rear wail

120V outlet

Shortest 1

connection J

from hard pipe J

stub location to J

range hookup j

This area allows

for flush range

installation with

through-the-floor

connection of pipe

stub/shut-off valve

(continued next page)

5

instanUation Bnstructions (continued)

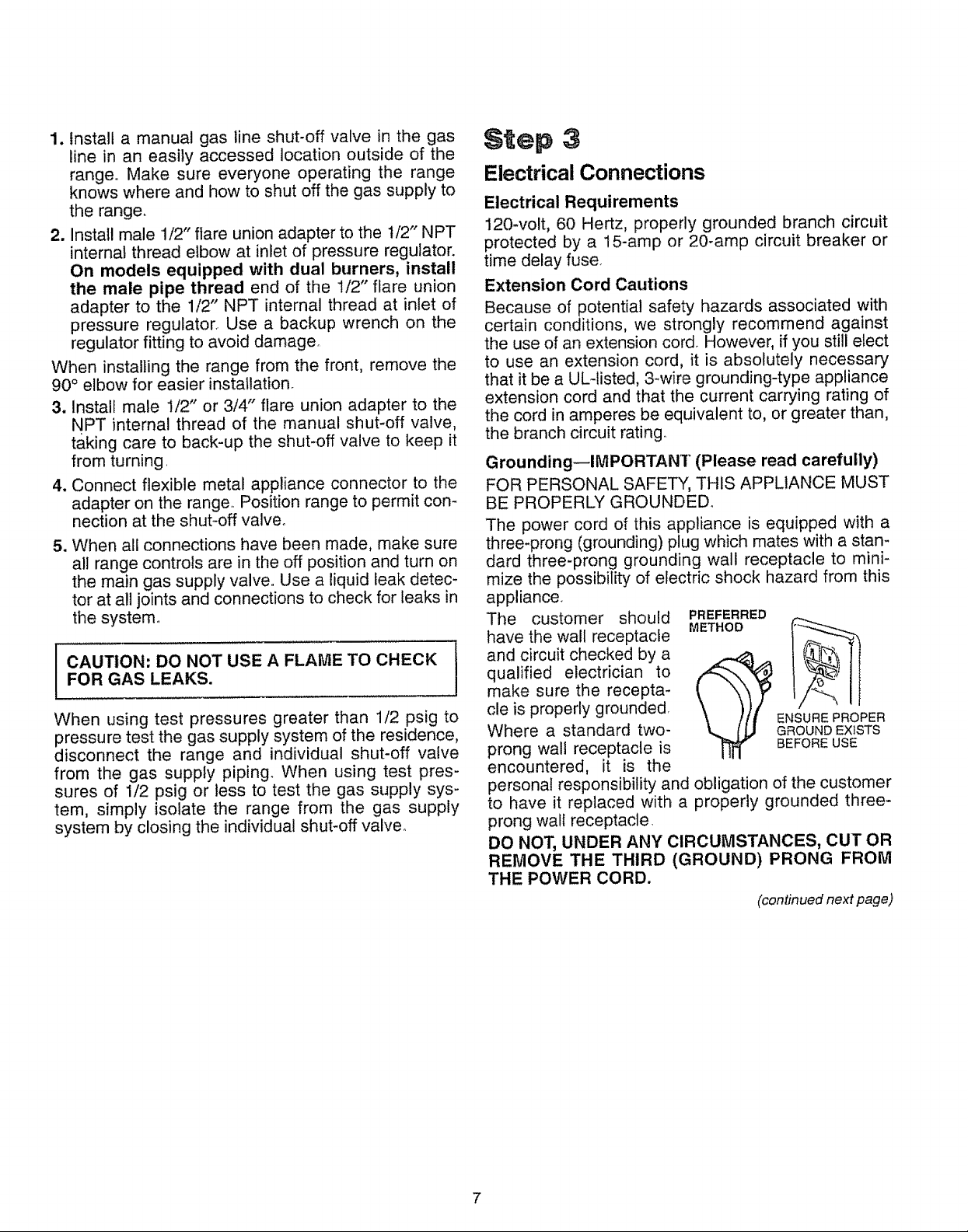

Flexible Connector Hookup

for Models Equipped

with Sealed,Burners

Regulator

90=Elbow

(provided) _ Flex

Adapter (6 ft max,)

@ -.,_----- Adapter

I fnstalter: Informthe

consumer of the

localion of the gas

,shut-off valve

I/2" or 3/4"

Gas Pipe --.4_,1_ _

Connector

Shut-off

.,,=_t_-__Valve

Rigid Pipe Hookup

for Models Equipped

with Sealed Burners

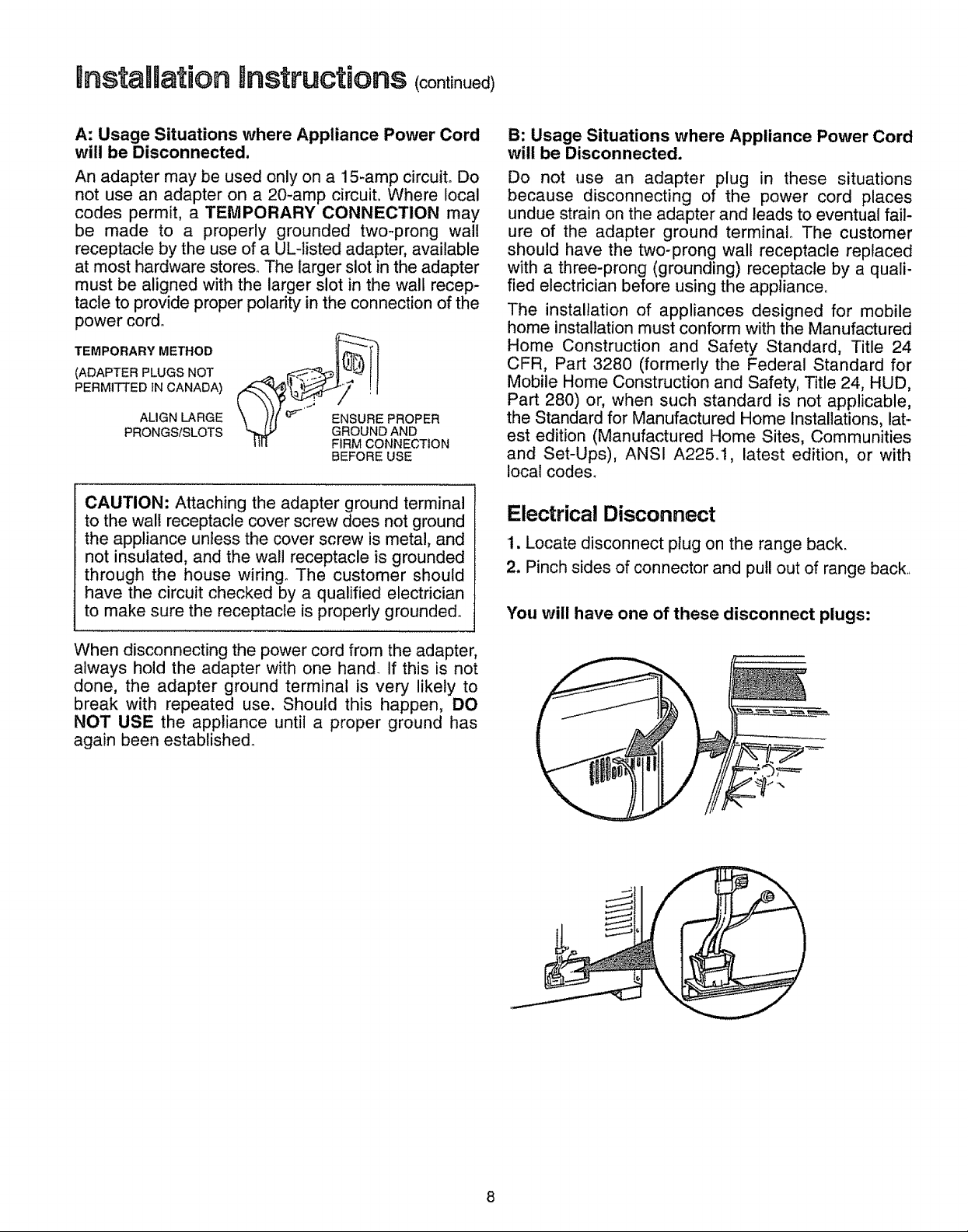

Flexible Connector and Rigid Pipe

Hookups for Models Equipped

with Dual Burners

Gas

__ Pressure

Regulalor

,0.o.,0o0,€ g

Nipple Union _.f_ IronPipe

.I_-,,_---_ Nipple

Installer: Inform the _ Gas

consumer of the f ;l_ll Shut-off

location of the gas t/2"or 3/4" b._ I]I _ Valve

shut-off valve, Gas Pipe _ L_ "

6

1. Install a manual gas line shut-off valve in the gas

line in an easily accessed location outside of the

range_ Make sure everyone operating the range

knows where and how to shut off the gas supply to

the range.

2. Instalt male 1/2" flare union adapter to the 1/2" NPT

internal thread elbow at inlet of pressure regulator.

On models equipped with dual burners, install

the male pipe thread end of the !/2" flare union

adapter to the 1/2" NPT internal thread at inlet of

pressure regulator Use a backup wrench on the

regulator fitting to avoid damage

When installing the range from the front, remove the

90 ° elbow for easier installation

3. Install male 1/2" or 3/4" flare union adapter to the

NPT internal thread of the manual shut-off valve,

taking care to back-up the shut-off valve to keep it

from turning

4. Connect flexible metal appliance connector to the

adapter on the range_ Position range to permit con-

nection at the shut-off valve.

5. When all connections have been made, make sure

all range controls are in the off position and turn on

the main gas supply valve. Use a liquid leak detec-

tor at a!l joints and connections to check for leaks in

the system.

CAUTION: DO NOT USE A FLAME TO CHECK

FOR GAS LEAKS.

When using test pressures greater than 1/2 psig to

pressure test the gas supply system of the residence,

disconnect the range and individual shut-off valve

from the gas supply piping. When using test pres-

sures of 1/2 psig or less to test the gas supply sys-

tem, simply isolate the range from the gas supply

system by closing the individual shut-off valve.

Step 3

Electrical Connections

Electrical Requirements

120-volt, 60 Hertz, properly grounded branch circuit

protected by a 15-amp or 20-amp circuit breaker or

time delay fuse

Extension Cord Cautions

Because of potential safety hazards associated with

certain conditions, we strongly recommend against

the use of an extension cord° However, if you still elect

to use an extension cord, it is absolutely necessary

that it be a UL-listed, 3-wire grounding-type appliance

extension cord and that the current carrying rating of

the cord in amperes be equivalent to, or greater than,

the branch circuit rating°

Grounding--IMPORTANT (Please read carefully)

FOR PERSONAL SAFETY, THIS APPLIANCE MUST

BE PROPERLY GROUNDED°

The power cord of this appliance is equipped with a

three-prong (grounding) plug which mates with a stan-

dard three-prong grounding wall receptacle to mini-

mize the possibility of electric shock hazard from this

appliance

The customer should

have the wall receptacle

and circuit checked by a

qualified electrician to

make sure the recepta-

cle is properly grounded

Where a standard two-

prong wall receptacle is

encountered, it is the

personal responsibility and obligation of the customer

to have it replaced with a properly grounded three-

prong wall receptacle

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD (GROUND) PRONG FROM

THE POWER CORD.

PREFERRED

METHOD

ENSURE PROPER

GROUND EXISTS

BEFORE USE

(continued next page)

InstanUationSnsttuctions <contin.ed>

A: Usage Situations where Appliance Power Cord

will be Disconnected.

An adapter may be used only on a 15-amp circuit° Do

not use an adapter on a 20-amp circuit. Where local

codes permit, a TEMPORARY CONNECTION may

be made to a properly grounded two-prong wall

receptacle by the use of a UL-listed adapter, available

at most hardware stores_ The larger slot in the adapter

must be aligned with the larger slot in the wall recep-

tacle to provide proper polarity in the connection of the

power cord.

(ADAPTER PLUGS NOT

TEMPORARY METHOD ._ ___

PERMITTED IN CANADA) _--_ ,_"

PRONGS/SLOTS

BEFORE USE

CAUTION: Attaching the adapter ground terminal

to the wall receptacle cover screw does not ground

the appliance unless the cover screw is metal, and

not insulated, and the wall receptacle is grounded

through the house wiring. The customer should

have the circuit checked by a qualified electrician

to make sure the receptacle is properly grounded.

N

B: Usage Situations where Appliance Power Cord

will be Disconnected.

Do not use an adapter plug in these situations

because disconnecting of the power cord places

undue strain on the adapter and leads to eventual fail-

ure of the adapter ground terminal° The customer

should have the two-prong wall receptacle replaced

with a three-prong (grounding) receptacle by a quali-

fied electrician before using the appliance°

The installation of appliances designed for mobile

home installation must conform with the Manufactured

Home Construction and Safety Standard, Title 24

CFR, Part 3280 (formerly the Federal Standard for

Mobile Home Construction and Safety, Title 24, HUD,

Part 280) or, when such standard is not applicable,

the Standard for Manufactured Home installations, lat-

est edition (Manufactured Home Sites, Communities

and Set-Ups), ANSI A225ol, latest edition, or with

local codes.

Electrical Disconnect

1. Locate disconnect plug on the range back.

2. Pinch sides of connector and putl out of range back,,

You will have one of these disconnect plugs:

When disconnecting the power cord from the adapter,

always hold the adapter with one hand_ If this is not

done, the adapter ground terminal is very likely to

break with repeated use. Should this happen, DO

NOT USE the appliance until a proper ground has

again been established°

8

Step 4

Seal the Openings

Seal any openings in the wall behind the range and

in the floor under the range when hookups are

completed,

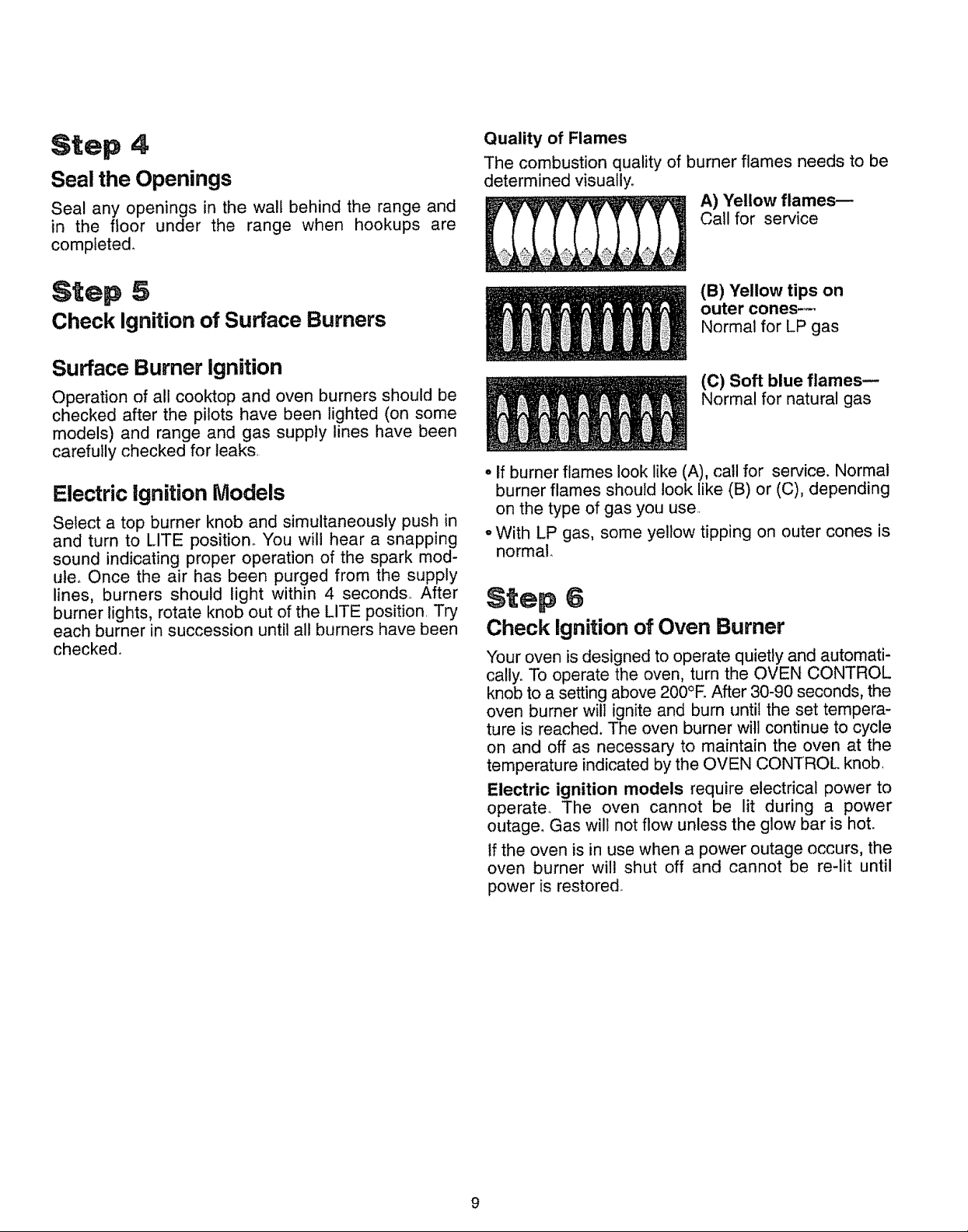

Quality of Flames

The combustion quality of burner flames needs to be

determined visually,

A) Yellow flames--

Call for service

Step 5

Check Ignition of Surface Burners

Surface Burner Ignition

Operation of all cooktop and oven burners should be

checked after the pilots have been lighted (on some

models) and range and gas supply lines have been

carefully checked for leaks,

Electric ignition Models

Select a top burner knob and simultaneously push in

and turn to LITE position. You will hear a snapping

sound indicating proper operation of the spark mod-

ute, Once the air has been purged from the supply

lines, burners should light within 4 seconds, After

burner lights, rotate knob out of the LITE position Try

each burner in succession until all burners have been

checked.

(B) "fellow tips on

outer cones---

Normal for LP gas

(C) Soft blue flames--

Normal for natural gas

• if burner flames look like (A), call for service. Normal

burner flames should look like (B) or (C), depending

on the type of gas you use

oWith LP gas, some yellow tipping on outer cones is

normal.

Step 6

Check Ignition of Oven Burner

Your oven is designed to operate quietly and automati-

cally. To operate the oven, turn the OVEN CONTROL

knob to a setting above 200°R After 30-90 seconds, the

oven burner will ignite and bum until the set tempera-

ture is reached. The oven burner witl continue to cycle

on and off as necessary to maintain the oven at the

temperature indicated by the OVEN CONTROL knob,

Electric ignition models require electrical power to

operate_ The oven cannot be lit during a power

outage. Gas will not flow unless the glow bar is hot.

if the oven is in use when a power outage occurs, the

oven burner will shut off and cannot be re-lit until

power is restored

9

RnstaURationInstructions (continued)

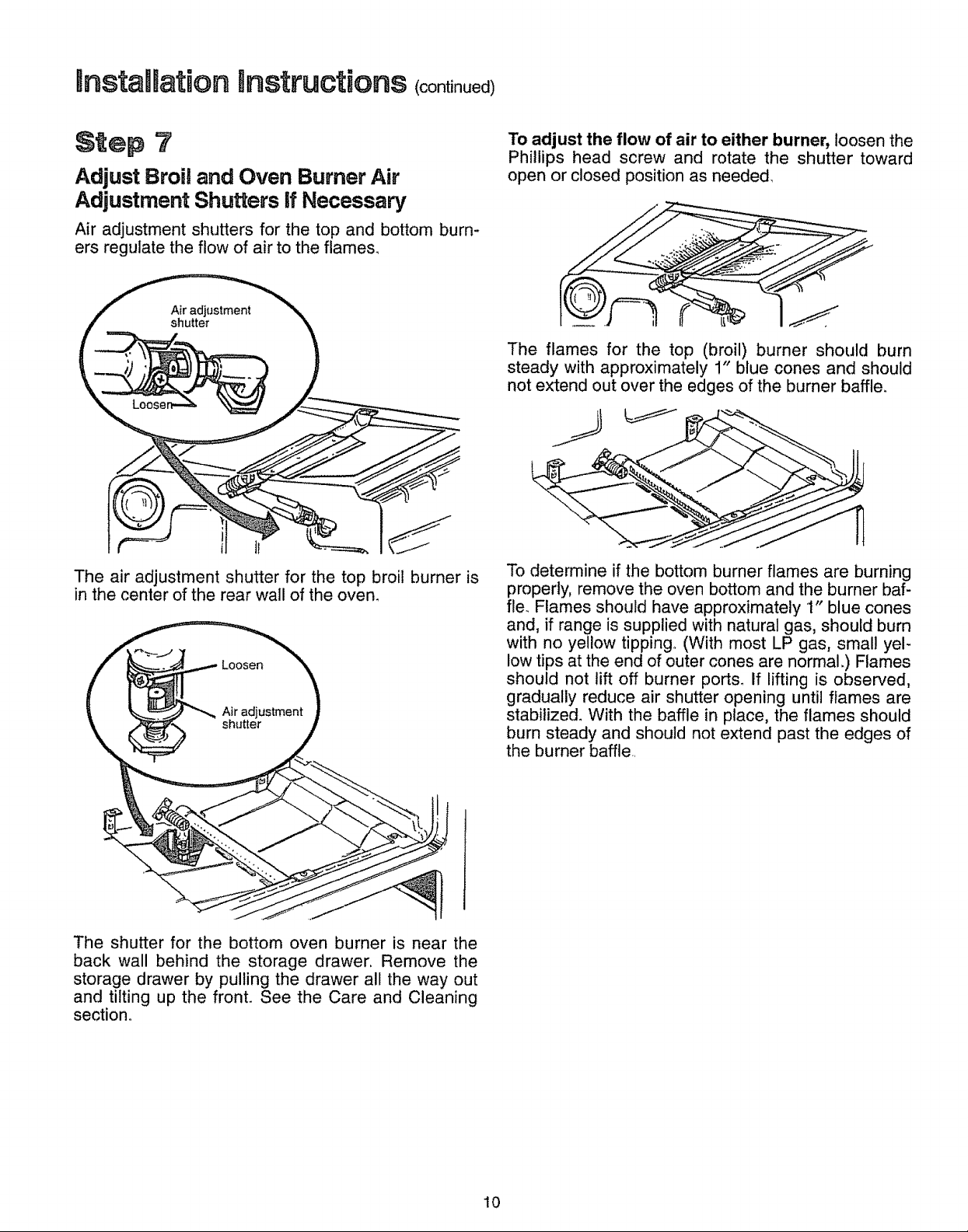

$tep 7

Adjust Broit and Oven Burner Air

Adjustment Shutters If Necessary

Air adjustment shutters for the top and bottom burn-

ers regulate the flow of air to the flame&

l

The air adjustment shutter for the top broil burner is

in the center of the rear wall of the oven.

To adjust the flow of air to either burner, loosen the

Phillips head screw and rotate the shutter toward

open or closed position as needed,

The flames for the top (broil) burner should burn

steady with approximately 1" blue cones and should

not extend out over the edges of the burner baffle.

To determine if the bottom burner flames are burning

properly, remove the oven bottom and the burner baf-

fle._ Flames should have approximately 1" blue cones

and, if range is supplied with natural gas, should burn

with no yellow tipping.. (With most LP gas, small yel-

low tips at the end of outer cones are normal.) Flames

should not lift off burner port& If lifting is observed,

gradually reduce air shutter opening until flames are

stabilized° With the baffle in place, the flames should

burn steady and should not extend past the edges of

the burner baffle

The shutter for the bottom oven burner is near the

back wall behind the storage drawer, Remove the

storage drawer by pulling the drawer all the way out

and tilting up the front. See the Care and Cleaning

section°

10

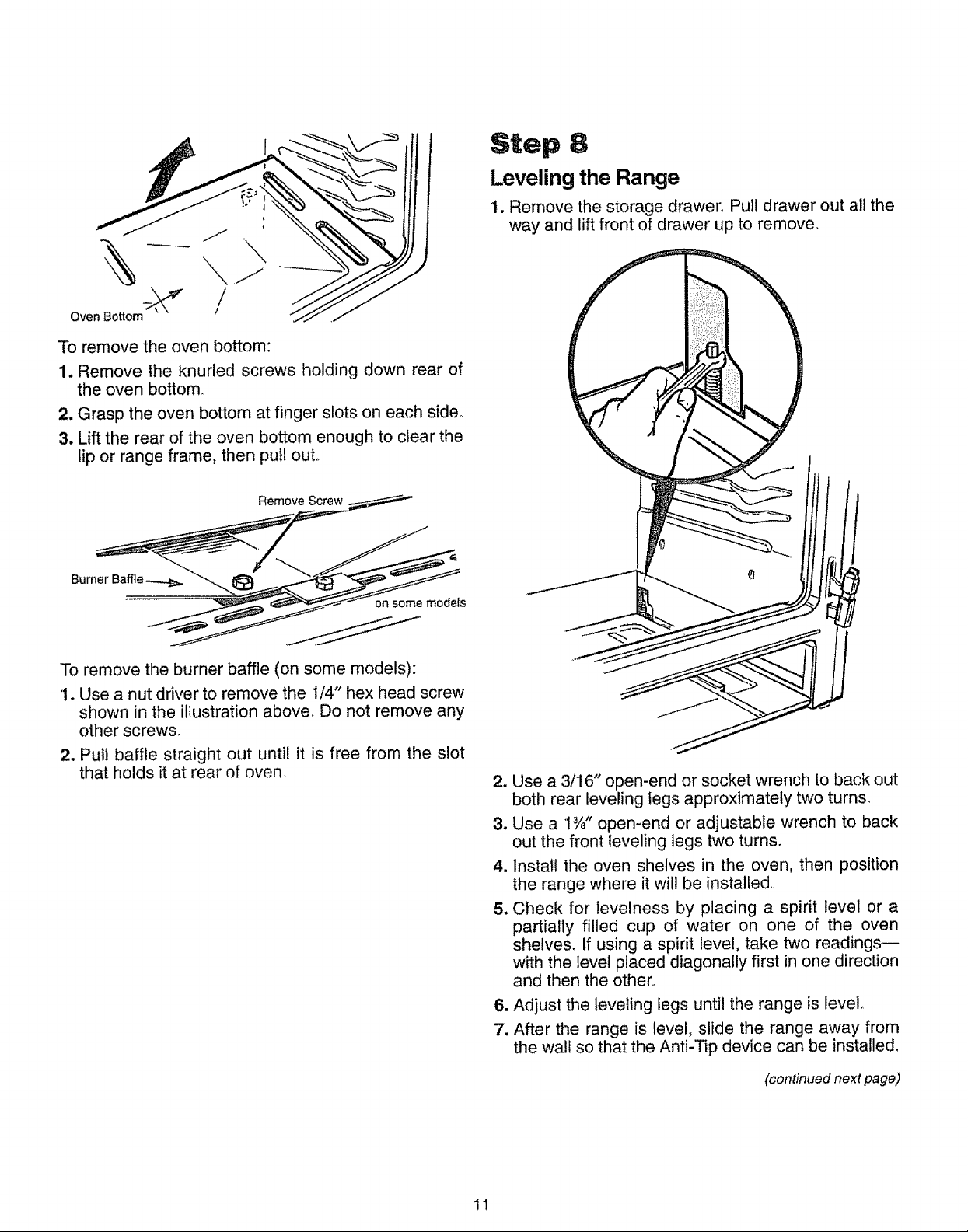

Oven Bottom

To remove the oven bottom:

1. Remove the knurled screws holding down rear of

the oven bottom.

2. Grasp the oven bottom at finger slots on each side°

3. Lift the rear of the oven bottom enough to clear the

lip or range frame, then pull out.

Remove Screw

Step 8

Leveling the Range

1. Remove the storage drawer_ Pull drawer out all the

way and lift front of drawer up to remove.

on some models

To remove the burner baffle (on some models):

1. Use a nut driver to remove the t/4" hex head screw

shown in the illustration above. Do not remove any

other screws.

2. Pull baffle straight out until it is free from the slot

that holds it at rear of oven_

2. Use a 3/16" open-end or socket wrench to back out

both rear leveling legs approximately two turns.

3. Use a t%" open-end or adjustable wrench to back

out the front leveling legs two turns.

4. Install the oven shelves in the oven, then position

the range where it will be installed.

5. Check for levelness by placing a spirit level or a

partially filled cup of water on one of the oven

shelves, if using a spirit level, take two readings--

with the level placed diagonally first in one direction

and then the other..

6. Adjust the leveling legs until the range is level_

7. After the range is level, slide the range away from

the wall so that the Anti-Tip device can be installed_

11

(continued next page)

mnstaaRationQnstructions (cont n ed)

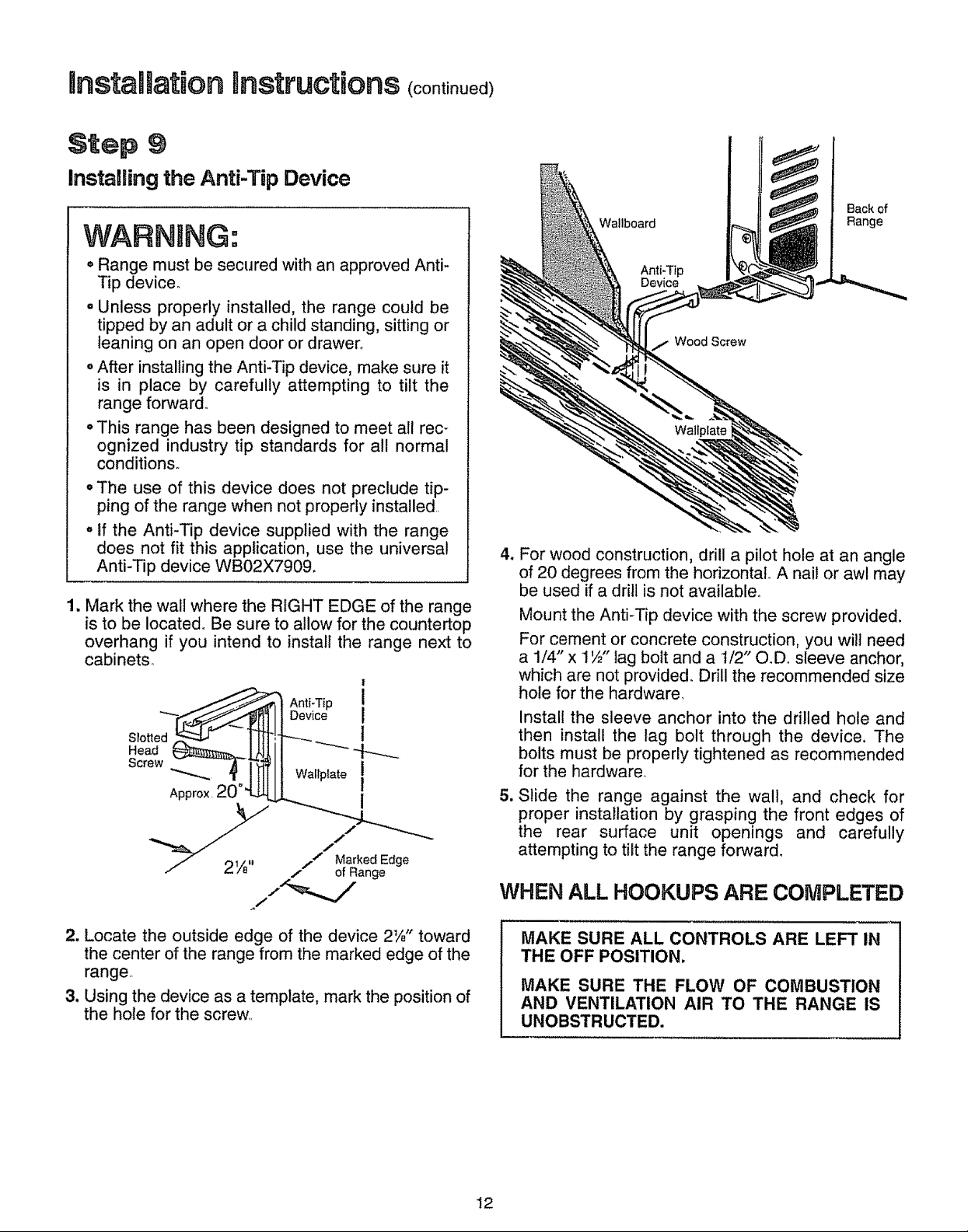

Step 9

Installing the Anti-Tap Device

WARNING:

Wallboard

Back of

Range

• Range must be secured with an approved Anti-

Tip device.

. Unless properly installed, the range could be

tipped by an adult or a child standing, sitting or

leaning on an open door or drawer_

• After installing the Anti-Tip device, make sure it

is in place by carefully attempting to tilt the

range forward,,

o This range has been designed to meet all rec-

ognized industry tip standards for all normal

condition&

oThe use of this device does not preclude tip-

ping of the range when not properly installed,,

. If the Anti-Tip device supplied with the range

does not fit this application, use the universal

Anti-Tip device WB02X7909.

1. Mark the wall where the RIGHT EDGE of the range

is to be located° Be sure to allow for the countertop

overhang if you intend to install the range next to

cabinets,,

!

Anti-Tip I

IOev ooI

/ 2W' / o"1_kaedeEdge

J

Anti-Tip

Device

Wood Screw

4_

For wood construction, drill a pilot hole at an angle

of 20 degrees from the horizontal. A nail or awl may

be used if a drill is not available°

Mount the Anti-Tip device with the screw provided.

For cement or concrete construction, you wilt need

a 1/4" x 1½" lag bolt and a 1/2" O.Do sleeve anchor,

which are not provided. Drill the recommended size

hole for the hardware,

Install the sleeve anchor into the drilled hole and

then install the lag bolt through the device. The

bolts must be properly tightened as recommended

for the hardware_

5_

Slide the range against the walt, and check for

proper installation by grasping the front edges of

the rear surface unit openings and carefully

attempting to tilt the range forward.

WHEN ALL HOOKUPS ARE COMPLETED

2. Locate the outside edge of the device 2W' toward

the center of the range from the marked edge of the

range

3. Using the device as a template, mark the position of

the hote for the screw

MAKE SURE ALL CONTROLS ARE LEFT IN

THE OFF POSITION.

MAKE SURE THE FLOW OF COMBUSTION

AND VENTILATION AIR TO THE RANGE IS

UNOBSTRUCTED.

12

How to Convert the Range for Usewith LP Gas or Natural Gas

Prepare Range for Conversion

Tools Required:

T_I 0 Torxdriver (for sealed burners)

CAUTION--Before converting the range:

(1) Turn off gas supply at the wall and

(2) Turn off the electrical power to the range.

If range has not yet been connected to gas supply,

or if flexible connection was made, range may be

pulled out from the wall to make conversion easier°

WARNING: Do not remove the pressure regulator from the range.

1/2" and 3/4" open-end wrench

Fiat blade screwdriver (small)

Nut drivers or wrenches: 7mm or 5/16"

(depending on the size of the spuds)

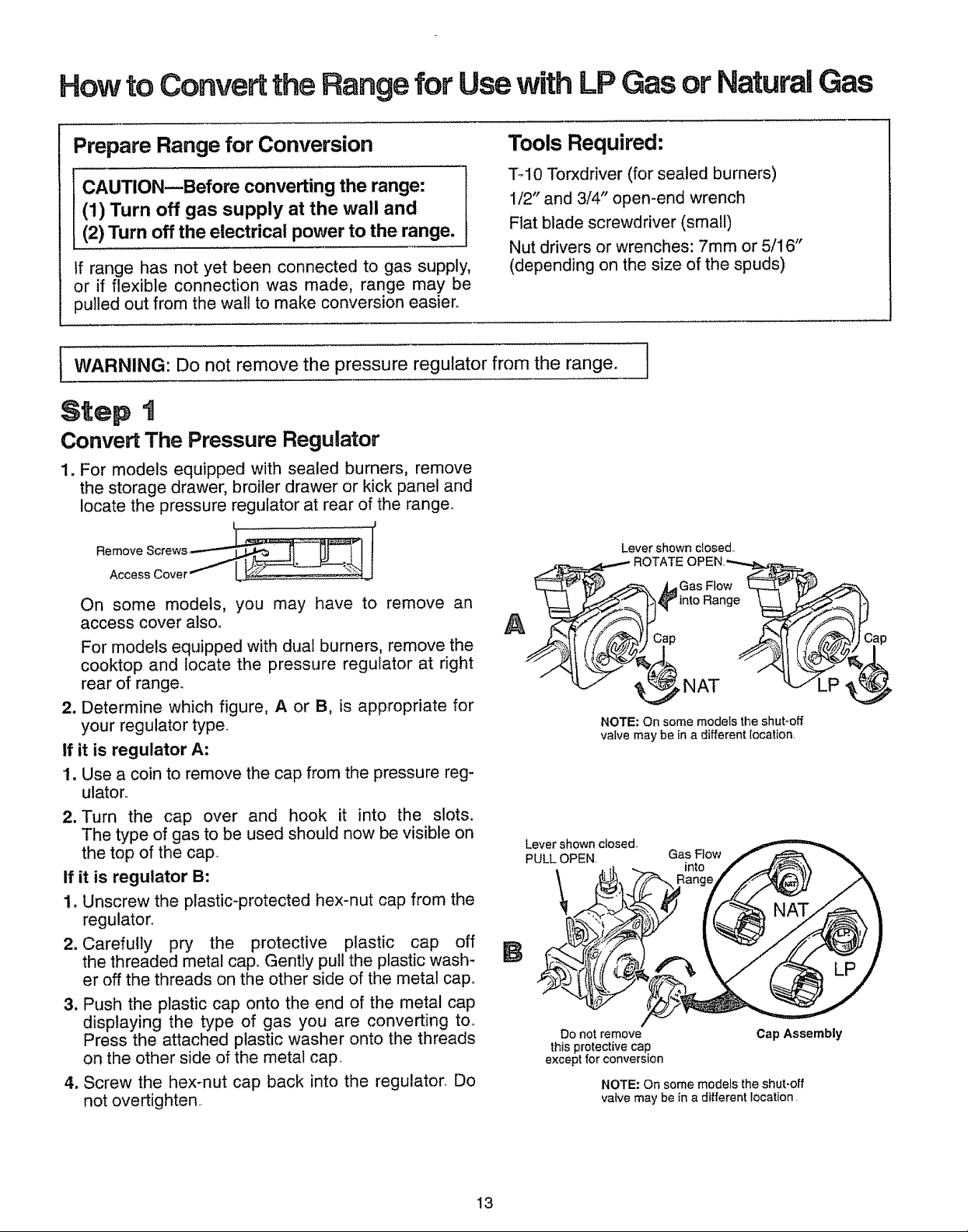

Step t

Convert The Pressure Regulator

1. For models equipped with sealed burners, remove

the storage drawer, broiler drawer or kick panel and

locate the pressure regulator at rear of the range_

Lever shown dosed,

On some models, you may have to remove an

access cover atsoo

For models equipped with dual burners, remove the

cooktop and locate the pressure regulator at right

rear of range.

2. Determine which figure, A or B, is appropriate for

your regulator type.

If it is regulator A:

1. Use a coin to remove the cap from the pressure reg-

ulatoro

2. Turn the cap over and hook it into the slots.

The type of gas to be used should now be visible on

the top of the cap

If it is regulator B:

1. Unscrew the plastic-protected hex-nut cap from the

regulator.

2. Carefully pry the protective plastic cap off

the threaded metal caF Gently pull the plastic wash-

er off the threads on the other side of the metal cap.

3. Push the plastic cap onto the end of the metal cap

displaying the type of gas you are converting to.

Press the attached plastic washer onto the threads

on the other side of the metal cap.

4. Screw the hex-nut cap back into the regulator_ Do

not overtighten.,

Lever shown closed,,

PULL OPEN.

\

B

Do not remove

this protective cap.

except for conversion

)Cap _tf ////,_"_lJ Cap

_NAT _JLP

NOTE: On some models the shut-off

vatve may be in a different location.

Gas Flow

into

Cap Assembly

NOTE: On some models the shut-off

valve may be in a different location

!3

Howto Convertthe Rangefor Usewith LPGasor NaturalGas oootJno )

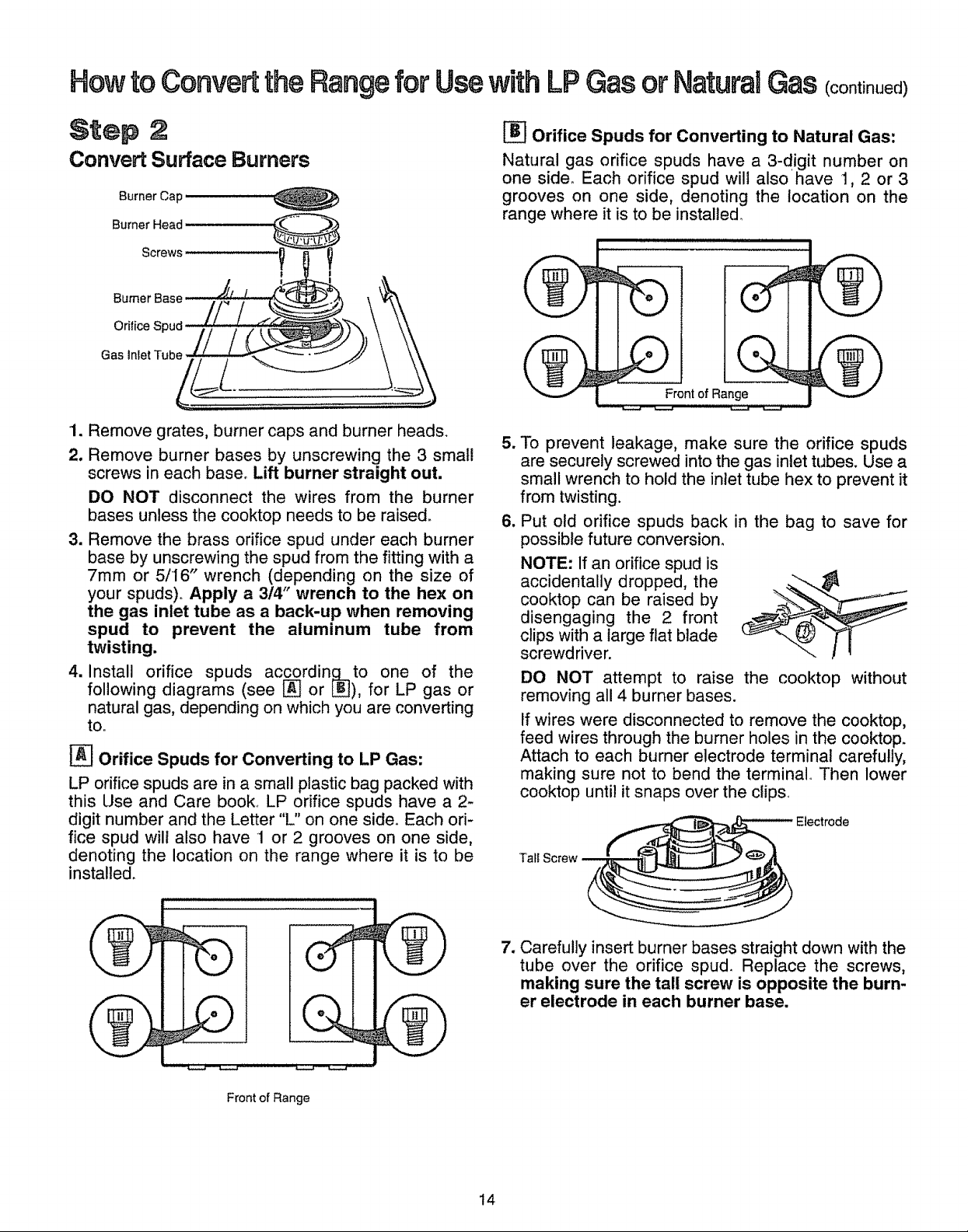

Step 2

Convert Surface Burners

Burner Cap

Burner Head

Screws

Burner Base

Orifice Spud

Gas Inlet Tube

1. Remove grates, burner caps and burner heads.

2. Remove burner bases by unscrewing the 3 small

screws in each base° Lift burner straight out.

DO NOT disconnect the wires from the burner

bases unless the cooktop needs to be raised.

3. Remove the brass orifice spud under each burner

base by unscrewing the spud from the fitting with a

7ram or 5/16" wrench (depending on the size of

your spuds)° Apply a 314" wrench to the hex on

the gas inlet tube as a back-up when removing

spud to prevent the aluminum tube from

twisting.

4. Install orifice spuds accordin_to one of the

following diagrams (see L_J or LBJ), for LP gas or

natural gas, depending on which you are converting

to.

[_ Orifice Spuds for Converting to LP Gas:

LP orifice spuds are in a small plastic bag packed with

this Use and Care book LP orifice spuds have a 2-

digit number and the Letter "L" on one side. Each ori-

fice spud will also have 1 or 2 grooves on one side,

denoting the location on the range where it is to be

installed.

Orifice Spuds for Converting to Natural Gas:

Natural gas orifice spuds have a 3-digit number on

one side° Each orifice spud will also have t, 2 or 3

grooves on one side, denoting the location on the

range where it isto be installed°

Front of Range

w

To prevent leakage, make sure the orifice spuds

are securely screwed into the gas inlet tubes. Use a

small wrench to hold the inlet tube hex to prevent it

from twisting.

=

Put old orifice spuds back in the bag to save for

possible future conversion_

NOTE: If an orifice spud is

accidentally dropped, the

cooktop can be raised by

disengaging the 2 front

clips with a large flat blade

screwdriver.

DO NOT attempt to raise the cooktop without

removing all 4 burner bases.

If wires were disconnected to remove the cooktop,

feed wires through the burner holes in the cooktop.

Attach to each burner electrode terminal carefully,

making sure not to bend the terminal Then lower

cooktop until it snaps over the clips

| a i

v

A

%- -

....... _._11 i //i J_._j_--3_._ ///

Front of Range

7. Carefully insert burner bases straight down with the

tube over the orifice spud. Replace the screws,

making sure the tall screw is opposite the burn-

er electrode in each burner base.

t4

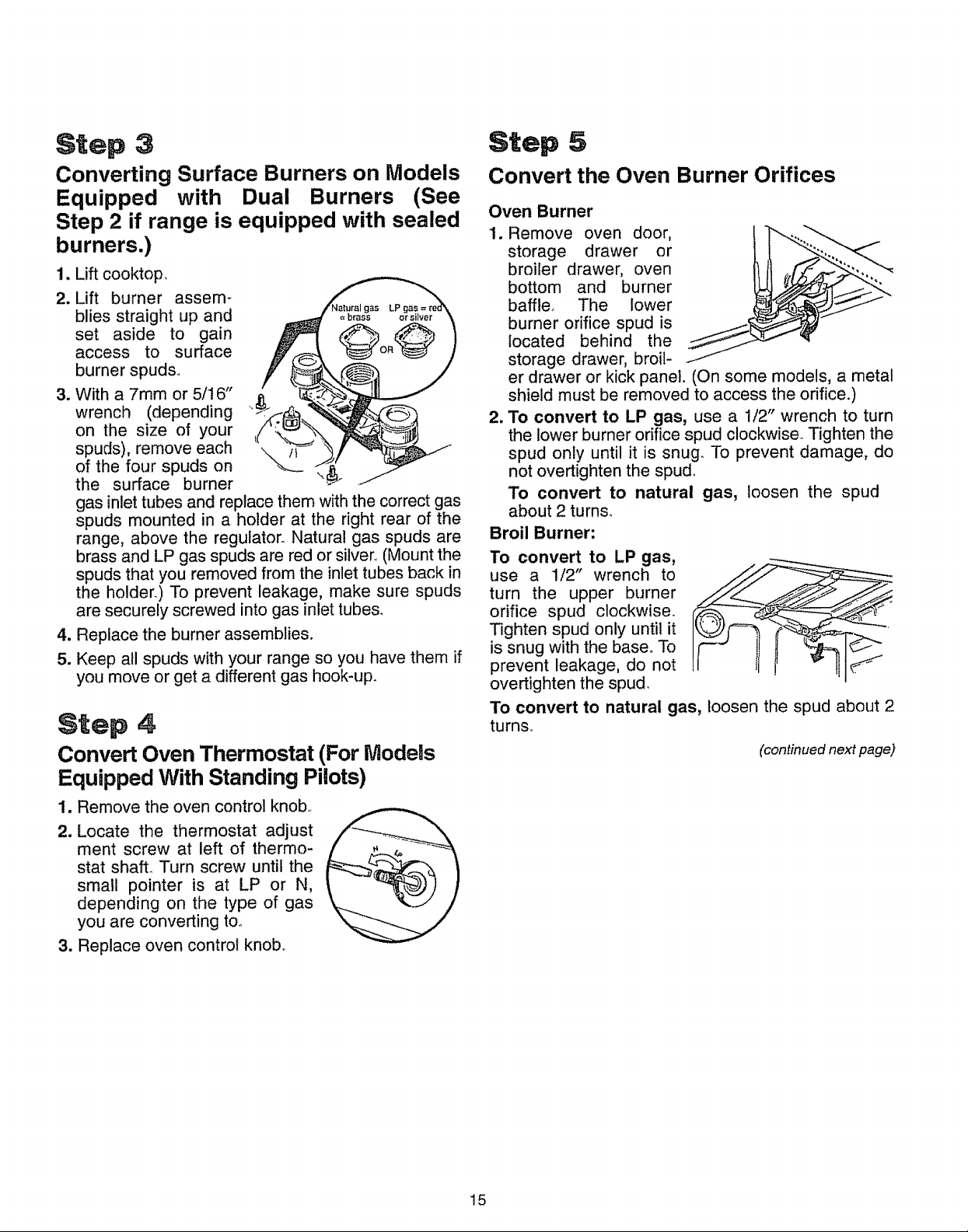

Step :3

Step 5

Converting Surface Burners on Models

Equipped with Dual Burners (See

Step 2 if range is equipped with sealed

burners.)

1. Lift cooktop.

2, Lift burner assem-

blies straight up and

set aside to gain

access to surface

burner spuds

3. With a 7ram or 5/16"

wrench (depending

on the size of your

spuds), remove each

of the four spuds on

the surface burner

gas inlet tubes and replace them with the correct gas

spuds mounted in a holder at the right rear of the

range, above the regulator. Natural gas spuds are

brass and LP gas spuds are red or silver (Mount the

spuds that you removed from the inlet tubes back in

the holder..) To prevent leakage, make sure spuds

are securely screwed into gas inlet tubes.

4. Replace the burner assemblies.

5. Keep all spuds with your range so you have them if

you move or get a different gas hook-up.

Step 4

Convert Oven Thermostat (For Models

Equipped With Standing Pilots)

1. Remove the oven control knob,,

2, Locate the thermostat adjust

ment screw at left of thermo-

stat shaft° Turn screw until the

small pointer is at LP or N,

depending on the type of gas

you are converting to.

3. Replace oven control knob,

Convert the Oven Burner Orifices

Oven Burner

I. Remove oven door,

storage drawer or

broiler drawer, oven

bottom and burner

baffler The lower

burner orifice spud is

located behind the

storage drawer, broil-

er drawer or kick panel. (On some models, a metal

shield must be removed to access the orifice.)

2. To convert to LP gas, use a 1/2" wrench to turn

the lower burner orifice spud clockwise. Tighten the

spud only until it is snug. To prevent damage, do

not overtighten the spud°

To convert to natural gas, loosen the spud

about 2 turns.

Broil Burner:

To convert to LP gas,

use a 1/2" wrench to

turn the upper burner

orifice spud clockwise.

Tighten spud only until it

is snug with the base° To

prevent leakage, do not

overtighten the spud.

To convert to natural gas, loosen the spud about 2

turns.

(continued next page)

!5

Loading...

Loading...