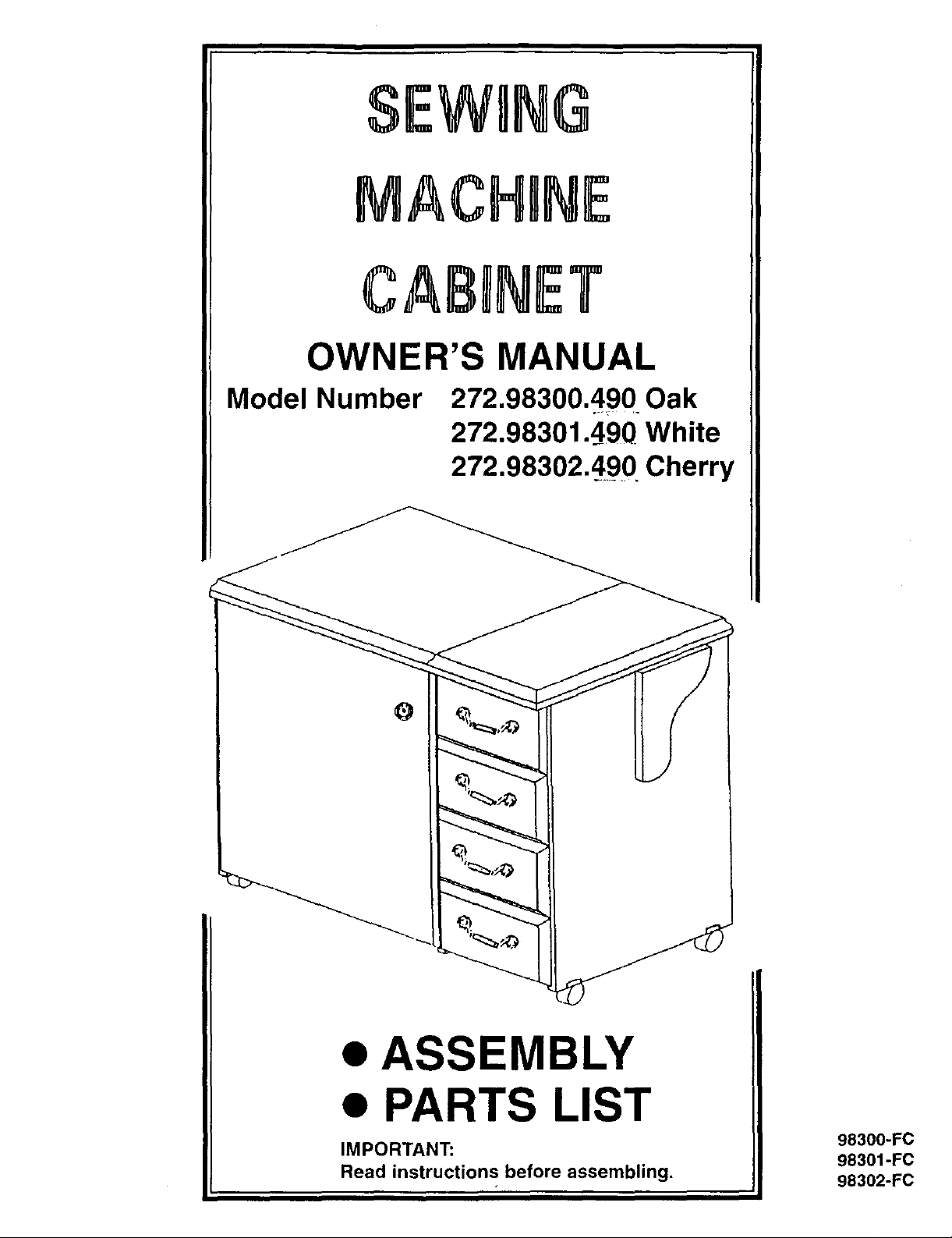

Kenmore 27298302490, 27298301490, 27298300490 Owner’s Manual

SEWING

MACHINE

CABINET

OWNER'S MANUAL

Model Number 272.98300.490 Oak

272.98301.4_90 White

272.98302.490 Cherry

ASSEMBLY

PARTS LIST

IMPORTANT:

Read instructions before assembling.

98300-FC

98301-FC

98302-FC

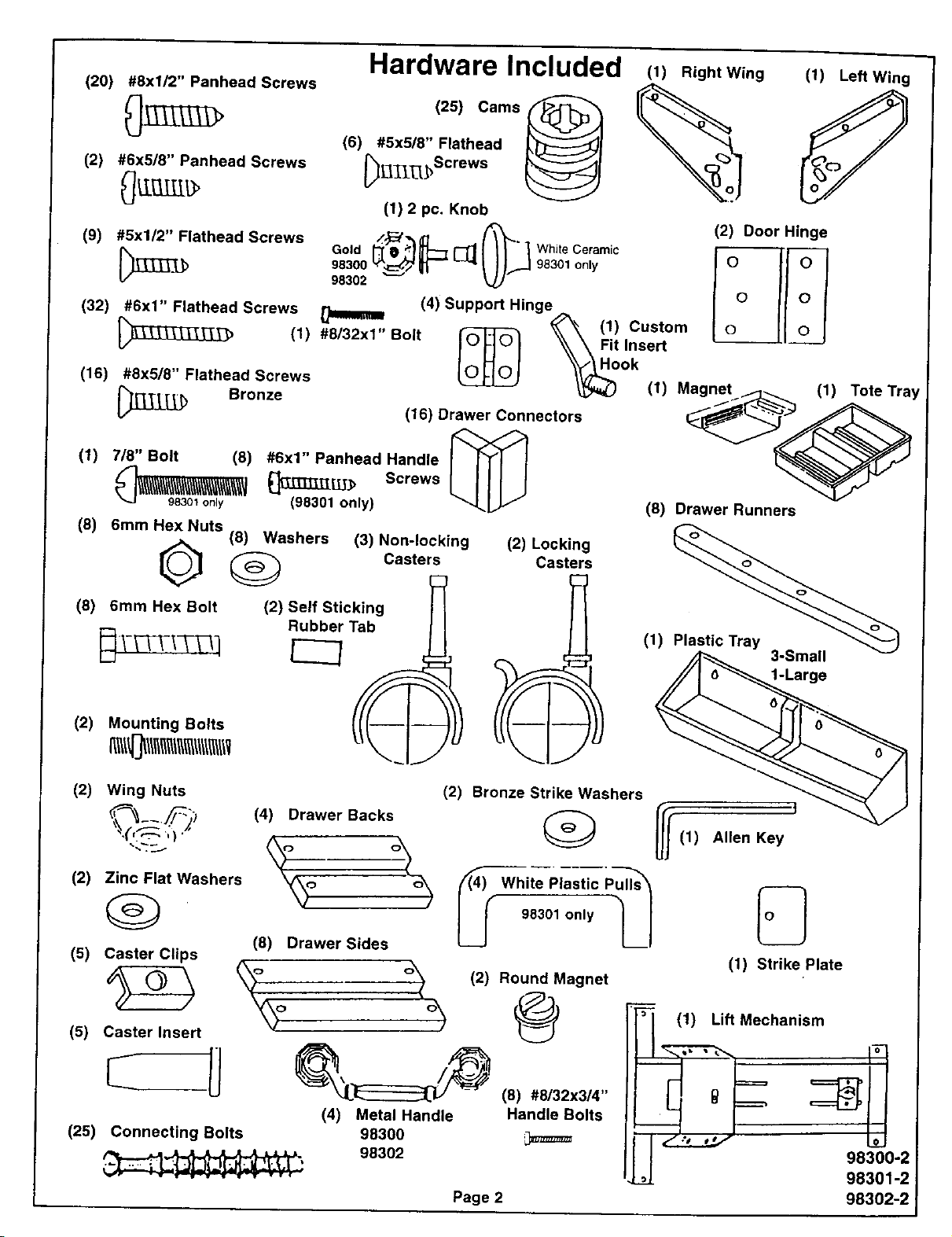

(20) #8xl/2" Panhead Screws

Hardware Included

,o,

(1) Right Wing

(1) Left Wing

(2) #6x5/8" Panhead Screws

(1) 2 pc. Knob

(9) #5x1/2" Flathead Screws Gold t_/F_ P,_L-- _ (_" _ Wh te Ceramic H

%

(2) Door Hinge

983o0%j_ IM,030,on,, I° IIoI

98302 _j' I II 0 I

(32) #8x1" Flathead Screws ,, _ '_'_ (1) Custom o___l O_

_"_'T_:> (1) #9/32xl Bolt IOJ_]© I _x_ Fitlnsert

(16) #8x5/8" Flathead Screws _ _ (1) Magnet (1)

_____ Bronze (16) Drawer Connectors

(1) 7/8" Bolt (8) #6x1" Panhead Handle [_X_[

_'_ i\_\\_\_ _LU._ Screws

".J 98301 only (98301 only)

(8) 6mm HexNuts

(8) Washers (3) Non-locking (2) Locking

0

(8) 6mm Hex Bolt

(2) Self Sticking [I

Tab

(4) Support Hinge _ I 0 /[ /

loHol _?_ook

(8) Drawer Runners

Casters Casters

(1)

3-Small

1-Large

Tote Tray

(2) Mounting Bolts

(2) Wing Nuts

(2) Zinc Flat Washers

(g)

(5) Caster Clips

(5) Caster Insert

(25) Connecting Bolts

Rubber[_ _

(2) Bronze Strike Washers

(4) Drawer Backs

\o o\

_ White_,astic___

U 98301 only

(8) Drawer Sides

(2) Round Magnet

\o % @

(4) Metal Handle Handle Bolts

98300 ,_

98302

Page 2

I

(1) Allen Key

(1) Strike Plate

_,_(1) Lift Mechanism

98300 2

98301-2

98302-2

I

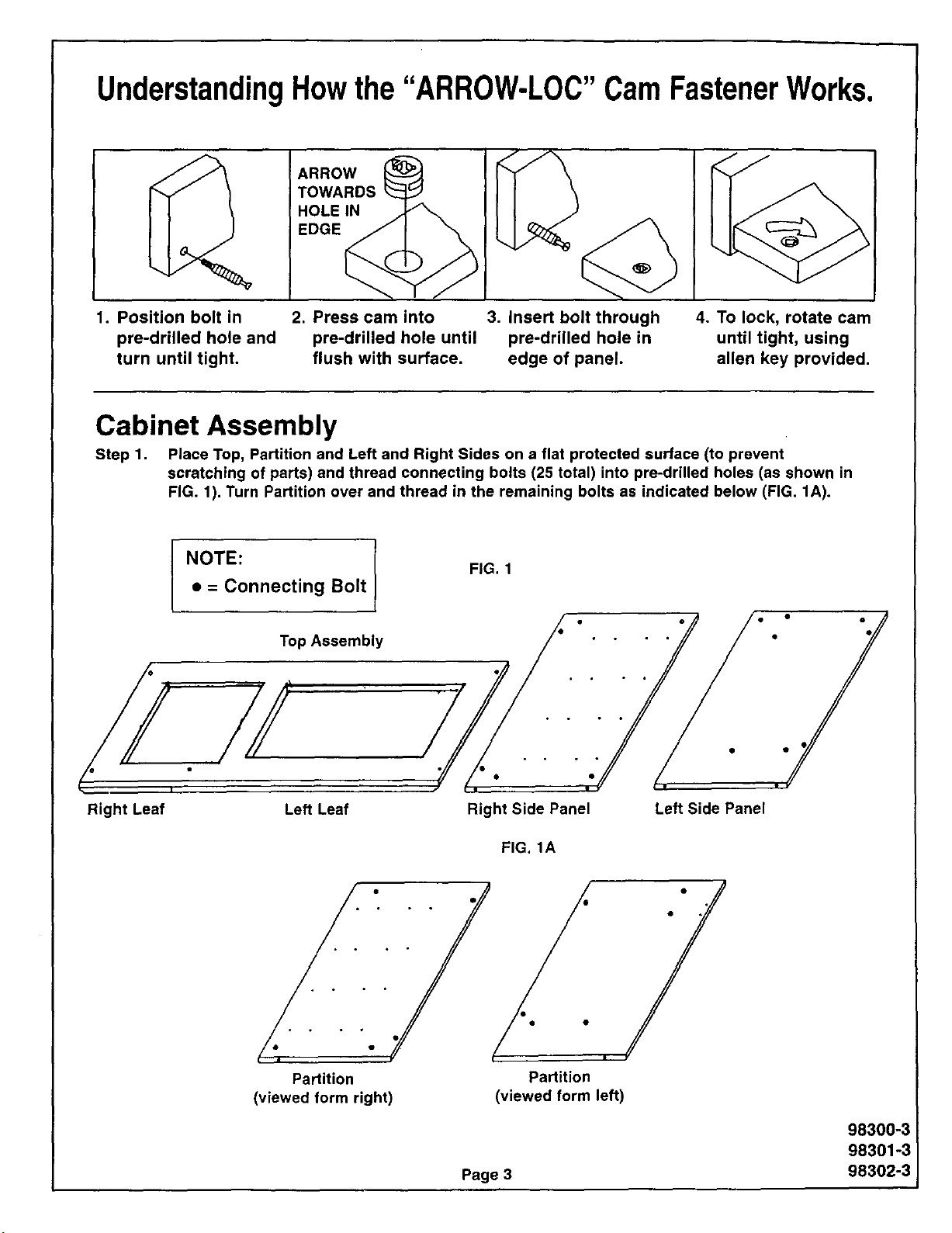

UnderstandingHowthe"ARROW-LOC"CamFastenerWorks.

TOWARDS

ARROW

HOLEIN

EDGE

1. Position bolt in 2. Press cam into 3. Insert bolt through

pre-drilled hole and pre-drilled hole until pre-drilled hole in

turn until tight, flush with surface, edge of panel.

4. To lock, rotate cam

until tight, using

allen key provided.

Cabinet Assembly

Step 1. Place Top, Partition and Left and Right Sides on a flat protected surface (to prevent

scratching of parts) and thread connecting bolts (25 total) into pre-drilled holes (as shown in

FIG. 1). Turn Partition over and thread in the remaining bolts as indicated below (FIG. 1A).

NOTE:

• = Connecting Bolt

Top Assembly

FIG. 1

Right Leaf

Left Leaf

Partition Partition

(viewed form right) (viewed form left)

Right Side Panel

FIG. 1A

• • • • 4"

Page 3

Left Side Panel

98300-3

98301-3

98302-3

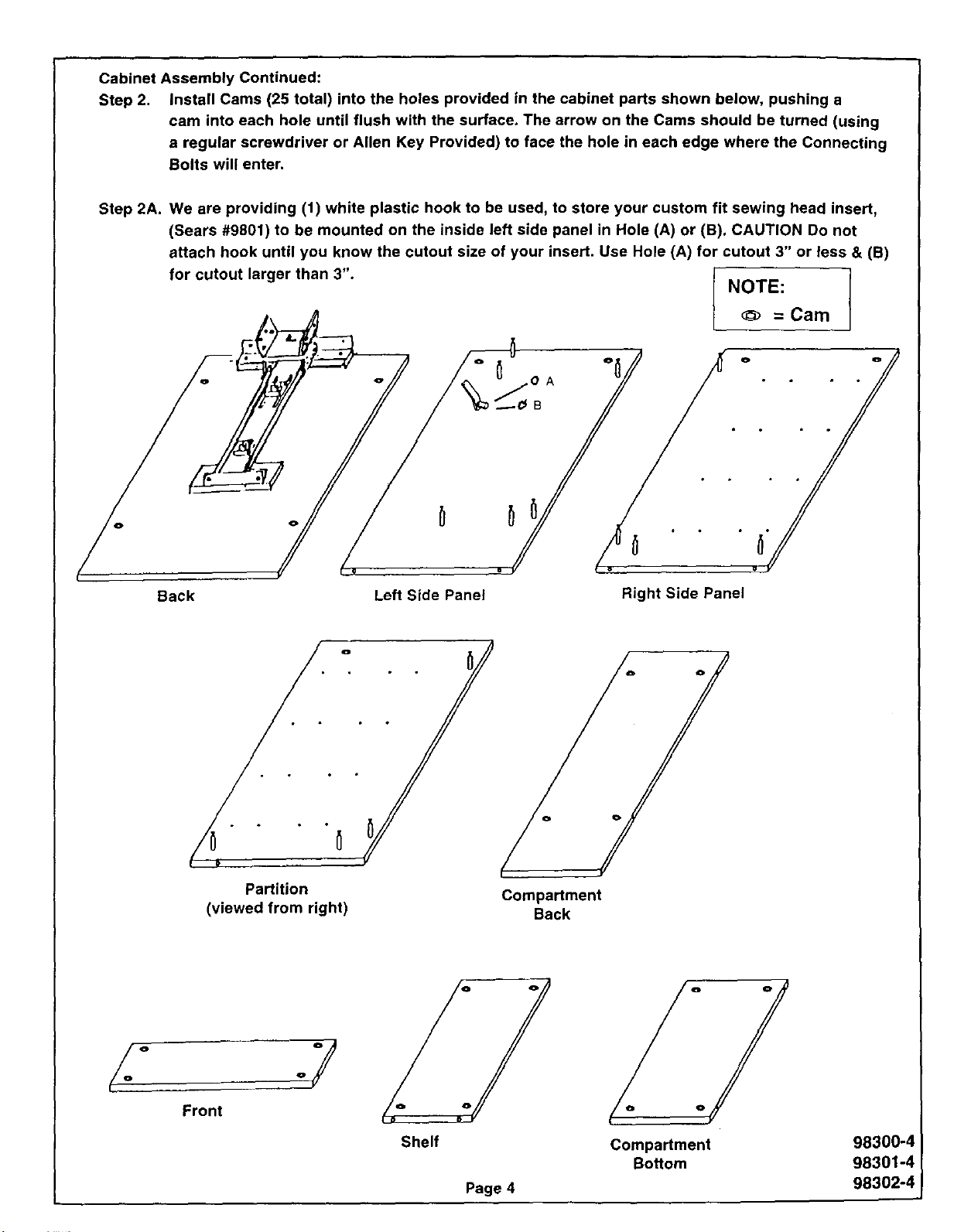

Cabinet Assembly Continued:

Step 2. Install Cams (25 total) into the holes provided in the cabinet parts shown below, pushing a

cam into each hole until flush with the surface. The arrow on the Cams should be turned (using

a regular screwdriver or Allen Key Provided) to face the hole in each edge where the Connecting

Bolts will enter.

Step 2A. We are providing (1) white plastic hook to be used, to store your custom fit sewing head insert,

(Sears #9801) to be mounted on the inside left side panel in Hole (A) or (B). CAUTION Do not

attach hook until you know the cutout size of your insert. Use Hole (A) for cutout 3" or less & (B)

for cutout larger than 3". NOTE:

= Cam

Back Left Side Panel Right Side Panel

°

"o° _ • o°

Partition

(viewed from right)

Compartment

Back

Front

.y

Shelf

Page 4

Compartment

Bottom

98300-4

98301-4

98302-4

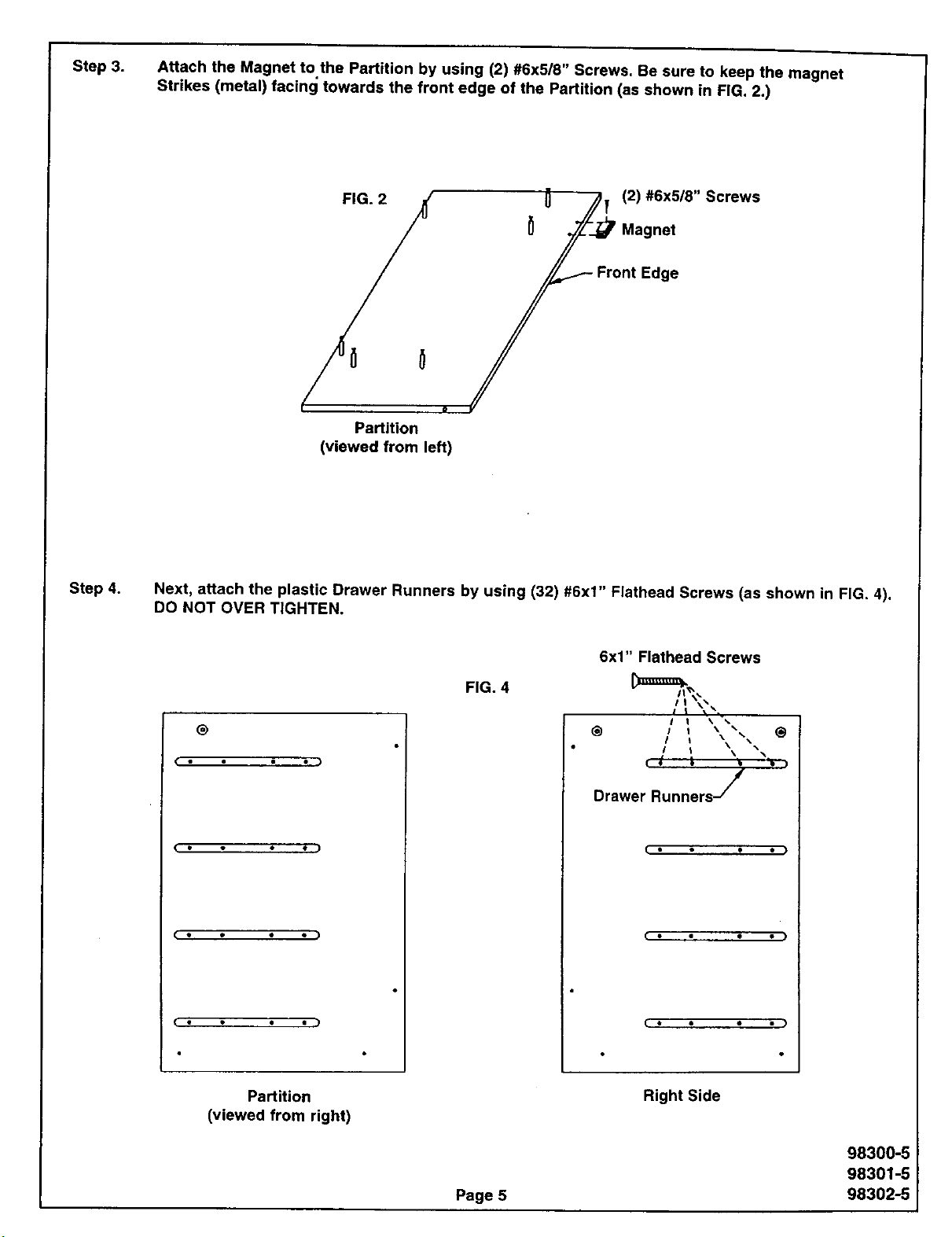

Step 3. Attach the Magnet to.the Partition by using (2) #6x5/8" Screws. Be sure to keep the magnet

Strikes (metal) facing towards the front edge of the Partition (as shown in FIG, 2.)

FIG. 2 .4_ 0 ./_y (2) #6x5/8" Screws

/ _ f__Magnet

/°°/

Partition

(viewed from left)

Step 4.

Next, attach the plastic Drawer Runners by using (32) #6x1" Flathead Screws (as shown in FIG. 4).

DO NOT OVER TIGHTEN.

6x1" Flathead Screws

FIG. 4

®

( • • • )

(. • • ./

@ / I

Drawer Runners /

I • • • • )

Partition

(viewed from right)

Page 5

Right Side

98300-5

98301-5

98302-5

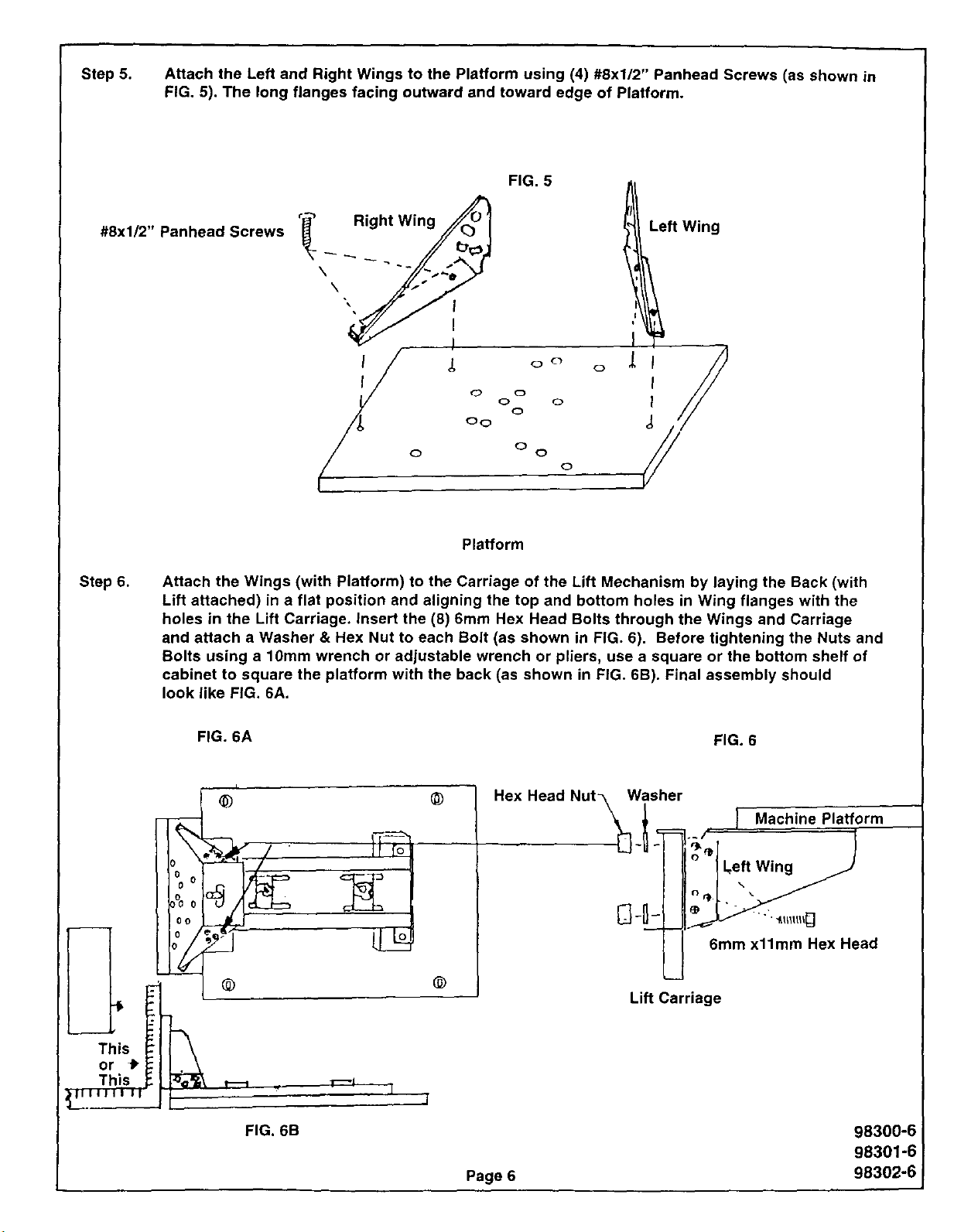

Step 5. Attach the Left and Right Wings to the Platform using (4) #8xl/2" Panhead Screws (as shown in

FIG. 5). The long flanges facing outward and toward edge of Platform.

FIG. 5

#8xl/2" Panhead Screws

Step 6.

Attach the Wings (with Platform) to the Carriage of the Lift Mechanism by laying the Back (with

Lift attached) in a flat position and aligning the top and bottom holes in Wing flanges with the

holes in the Lift Carriage. insert the (8) 6mm Hex Head Bolts through the Wings and Carriage

and attach a Washer & Hex Nut to each Bolt (as shown in FIG. 6). Before tightening the Nuts and

Bolts using a 10mm wrench or adjustable wrench or pliers, use a square or the bottom shelf of

cabinet to square the platform with the back (as shown in FiG. 6B). Final assembly should

look like FiG. 6A.

",,//// i

°cl

Platform

Left Wing

0 0

0

0

0

o

Ii

0

I

I

3

This

or _"

This

FIG. 6A FIG. 6

@

Left Wing

6mm x11mm Hex Head

@

Lift Carriage

FIG. 6B

Page 6

Machine Platform

•"f.l_lllll_]

98300-6

98301-6

98302-6j

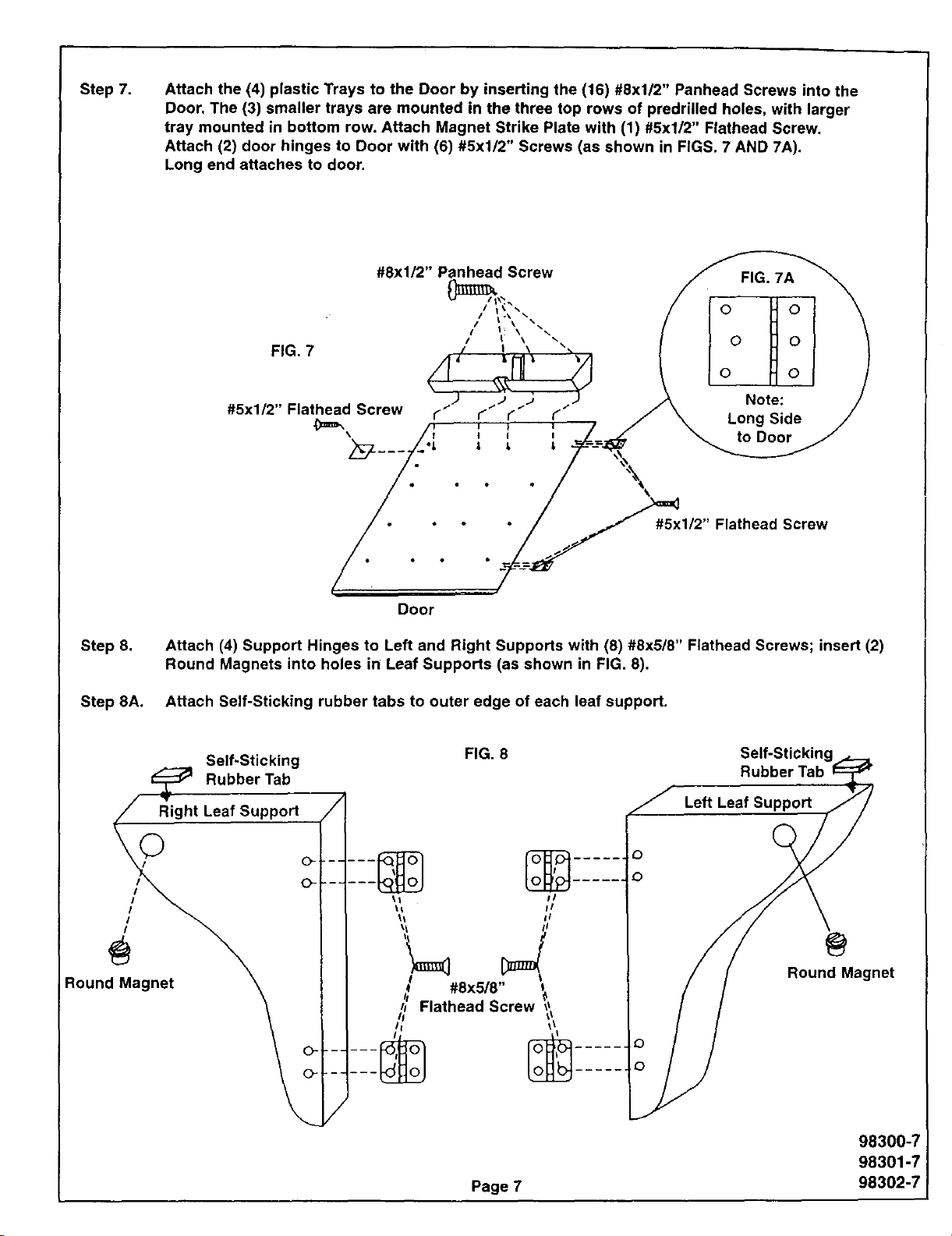

Step 7. Attach the (4) plastic Trays to the Door by inserting the (16) #8xl/2" Panhead Screws into the

Door. The (3) smaller trays are mounted in the three top rows of predrilled holes, with larger

tray mounted in bottom row. Attach Magnet Strike Plate with (1) #5xl/2" Flathead Screw.

Attach (2) door hinges to Door with (6) #5xl/2" Screws (as shown in FIGS. 7 AND 7A).

Long end attaches to door.

#8xl/2" Panhead Screw FIG. 7A

Step 8.

Step 8A.

FIG. 7

t I \ 0 0

0

#5x1/2" Flathead Screw ¢I)¢.. J / Note:

l" Long Side

_'=_ I i , to Door

#5xl/2" Flathead Screw

Door

Attach (4) Support Hinges to Left and Right Supports with (8) #8x5/8" Flathead Screws;

Round Magnets into holes in Leaf Supports (as shown in FIG. 8).

Attach Self-Sticking rubber tabs to outer edge of each leaf support.

Self-Sticking

FIG. 8 Self-Sticking

Rubber Tab

Rubber Tab

pport

Left Leaf Support

insert (2)

I I _1 Flathead Screw t_t

R°undMagnet __ _ #8X5/8'' '

Page 7

II

iI

i I

@

Round Magnet

98300-7

98301-7

98302-7

Loading...

Loading...