Kenmore 25591589010 Owner’s Manual

rf_

¢9

BEER COOLER

Model: 91589

CAUTION:

BEFORE USE. PLEASE READ AND FOLLOW ALL SAFETY RULES AND OPERATING INSTRUCTIONS.

Sears Brands Management Corporation, ltoffman Estates, IL 60179 U.S.A.

www.sears.com

SAFETY PRECAUTIONS .................................................................. 1

General Safety .................................................................................... 1

Warranty ............................................................................................. 2

CO2 (Carbon Dioxide) Gas Safety ..................................................... 3

UNPACKING AND ACCESSORIES INVENTORY ........................... 3

PARTS AND FEATURES ................................................................... 3

PROPER LOCATION ......................................................................... 4

ELECTRICAL CONNECTIONS ......................................................... 4

ASSEMBLY INSTRUCTIONS ........................................................... 4

Installing the Casters ......................................................................... 4

Installing the Guardrail ........................................................................ 4

Installing the Beer Tap ...................................................................... 5

Tapping the Beer Keg (Single-Valve Type Barrel) ............................ 5

Important Safety Message for Draft Beer Dispensing ......................... 6

OPERATING YOUR BEER DISPENSER ........................................ 6

Dispensing the Beer............................................................................ 6

Understanding Beer Temperature ....................................................... 6

Understanding the Temperature Control Setting ................................ 6

Normal Operating Sounds ................................................................. 6

BEER SERVING GUIDE .................................................................. 7

Beer Serving Tips.............................................................................. 7

What a 1/2 Barrel Keg (Full Keg) of Beer Gives You ......................... 7

Tips for Cleaning Beer Glasses ......................................................... 7

2 Simple Tests for Cleaning Beer Glasses ........................................ 7

ENERGY SAVING TIPS .................................................................. 7

PROPER CARE AND CLEANING OF THE BEER DISPENSER ....7

Installing the Cleaning Kit.............................................................. 7

Cleaning and General Maintenance .................................................... 7

TROUBLESHOOTING GUIDE ........................................................... 8

WARRANTY ................................................................................... 12

Thank you for purchasing our Kenmore product. This easy-to-

use manual will guide you in getting the best use of your beer

dispenser. Remember to record the model and serial number.

They are on a label in back of the unit.

Model number

Serial number

Ib'dId

Read all of the instructions before using this

appliance. When using this appliance, always

exercise basic safety precautions, including the

following:

1. Use this appliance only for its intended purpose as

described in this operation manual.

2. This appliance must be properly installed in

accordance with the installation instructions before it is

used. See the installation section for more details.

3. This appliance must be connected to a proper

electrical outlet with the correct electrical supply.

Proper grounding must be ensured to reduce the risk

of shock and fire.

4. Do not cut or remove the grounding plug? tf you do not

have a three-prong electric receptacle outlet in the

wall, have a certified electrician install the proper

outlet. The wall receptacle must be properly grounded.

5. Never unplug your appliance by pulling on the power

cord. Always grasp the plug firmly and pull straight out

from the outlet.

6. Immediately replace worn power cords, loose plugs

and power outlets.

7. To reduce the risk of electric shock or fire, do not use

extension cords or adapters to connect the unit to an

electrical power source.

8. Unplug your appliance before cleaning or making any

repairs.

9. We suggest that a certified technician perform the

service if for any reason this product requires service.

10. If your old appliance is being discarded, we

recommend that you remove the door and leave the

helves in place. This will reduce the possibility of

danger to children.

11. This appliance should not be recessed or built into an

enclosed cabinet. It is designed for freestanding

installation only.

12. Do not operate your appliance inthe presence of

explosive fumes.

13. Do not tamper with the controls.

14. Do not operate this appliance unless all enclosure

panels are properly in place.

15. Do not operate this appliance when parts are missing

or broken.

16. Do not use this appliance for commercial use.

17. This appliance is designed for indoor use only and

should not be used outdoors.

18. To reduce the risk of injury, do not allow children to

play in or on the appliance. Close supervision is

necessary when the appliance is used near children.

19. The appliance door must be closed during operation.

Do not leave the door open when children are near the

dispenser.

Date of purchase

Warranty Statement

When installed, operated and maintained according to all instructions supplied with the

product, if this appliance fails due to a defect in material and workmanship within one year from

the date of purchase, call 1-800-4-MY-HOME® to arrange for free repair.

If this appliance is ever used for other than private family purposes, this warranty applies for

only 90 days from the date of purchase.

This warranty covers only defects in material and workmanship. Sears will NOT pay

for:

1. Expendable items that can wear out from normal use,including but not limited to filters,

belts, light bulbs, and bags.

2. A service technician to instruct the user in correct product installation, operation or

maintenance.

3. A service technician to clean or maintain this product.

4. Damage to or failure of this product if it is not installed, operated or maintained according

to the all instructions supplied with the product.

5. Damage to or failure of this product resulting from accident, abuse, misuse or use for other

than its intended purpose.

6. Damage to or failure of this product caused by the use of detergents, cleaners, chemicals

or utensils other than those recommended in all instructions supplied with the product.

Z Damage to or failure of parts or systems resulting from unauthorized modifications made

to this product.

Disclaimer of implied warranties; limitation of remedies

Customer's sole and exclusive remedy under this limited warranty shall be product repair as

provided herein. Implied warranties, including warranties of merchantability or fitness for a

particular purpose, are limited to one year or the shortest period allowed by taw. Sears shall

not be liable for incidental or consequential damages. Some states and provinces do not allow

the exclusion or limitation of incidental or consequential damages, or limitation on the duration

of implied warranties of merchantability or fitness, so these exclusions or limitations may not

apply to you.

This warranty applies only while this appliance is used in the United States or Canada.

This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

Sears, Roebuck and Co., Hoffman Estates_ IL 60179

Sears Canada inc., Toronto, Ontario, Canada M5B 2B8

2

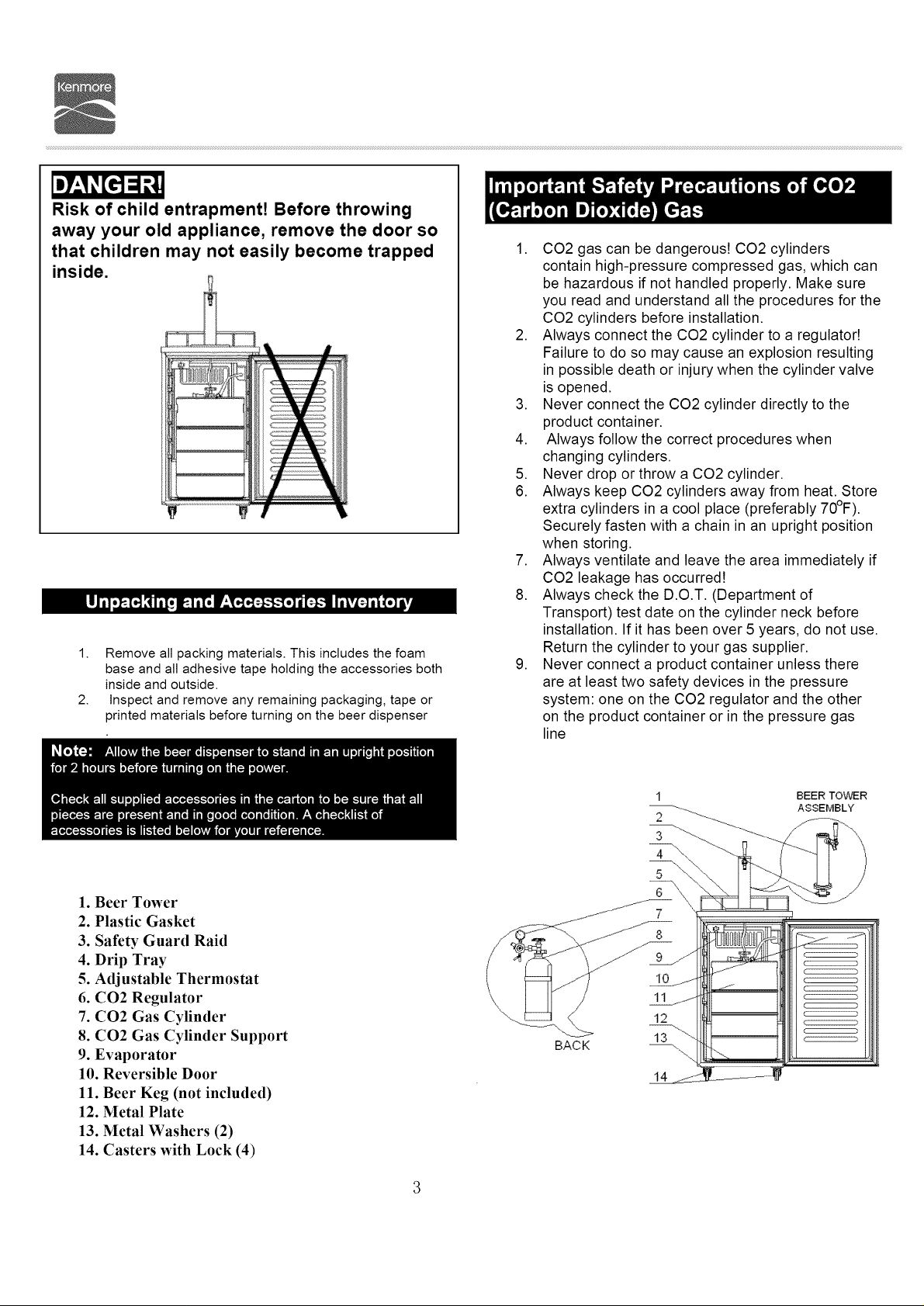

Risk of child entrapment! Before throwing

away your old appliance, remove the door so

that children may not easily become trapped

inside,

1. Remove all packing materials. This includes the foam

base and all adhesive tape holding the accessories both

inside and outside.

2. Inspect and remove any remaining packaging, tape or

printed materials before turning on the beer dispenser

1. CO2 gas can be dangerousf CO2 cylinders

contain high-pressure compressed gas, which can

be hazardous if not handled properly. Make sure

you read and understand all the procedures for the

CO2 cylinders before installation.

2. Always connect the CO2 cylinder to a regulatod

Failure to do so may cause an explosion resulting

in possible death or injury when the cylinder valve

is opened.

3. Never connect the CO2 cylinder directly to the

product container.

4. Always follow the correct procedures when

changing cylinders.

5. Never drop or throw a CO2 cylinder.

6. Always keep CO2 cylinders away from heat. Store

extra cylinders in a cool place (preferably 70°F).

Securely fasten with a chain in an upright position

when storing.

7. Always ventilate and leave the area immediately if

CO2 leakage has occurredY

8. Always check the D.O.T. (Department of

Transport) test date on the cylinder neck before

installation. If it has been over 5 years, do not use.

Return the cylinder to your gas supplier.

9. Never connect a product container unless there

are at least two safety devices in the pressure

system: one on the CO2 regulator and the other

on the product container or in the pressure gas

line

1. Beer Tower

2. Plastic Gasket

3. Safety Guard Raid

4. Drip Tray

5. Adjustable Thermostat

6. CO2 Regulator

7. CO2 Gas Cylinder

8. CO2 Gas Cylinder Support

9. Evaporator

10. Reversible Door

11. Beer Keg (not included)

12. Metal Plate

13. Metal Washers (2)

14. Casters with Lock (4)

1

3

4 \_

14

BEER TOWER

ASSEMBLY

I::1

• To ensure that your beer dispenser works at the

maximum efficiency it was designed for, install it in a

location where there is proper air circulation,

plumbing and electrical connections.

• Choose a location where the beer dispenser will be

away from heat and will not be exposed to direct

sunlight.

• This beer dispenser is designed for indoor use only

and should not be used outdoors.

• This beer dispenser is a freestanding design and

should not be placed in a built-in or recessed area.

The following dimensions are the recommended clearances

around the beer dispenser.

Sides ...................... 3/4" (19mm)

Back ........................... 1" (25mm)

Read carefully and understand all installation instructions

before installing the beer dispenser. If after completing the

process you are still unsure whether the beer dispenser has

been properly installed, we recommend that you contact a

qualified installer.

Ili'b__ iiiJ[,iI i1_1._'_:-_(=]i--_

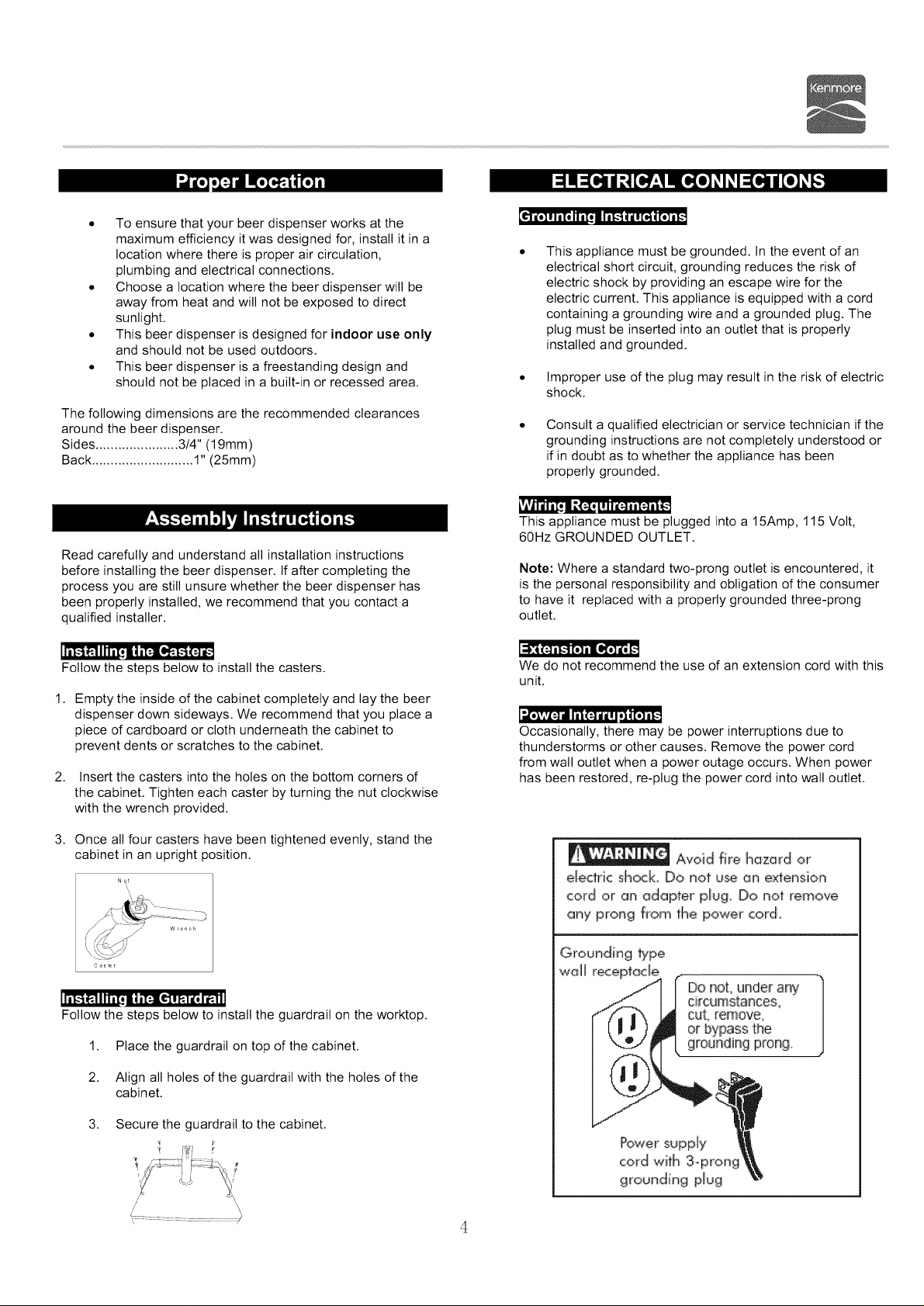

Follow the steps below to install the casters.

1.

Empty the inside of the cabinet completely and lay the beer

dispenser down sideways. We recommend that you place a

piece of cardboard or cloth underneath the cabinet to

prevent dents or scratches to the cabinet.

2. Insert the casters into the holes on the bottom corners of

the cabinet. Tighten each caster by turning the nut clockwise

with the wrench provided.

[e] I[O].! I iTJ ] IiTo I f_'_ | IL! [o',]_l[o] i[,--"]

This appliance must be grounded. In the event of an

electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the

electric current. This appliance is equipped with a cord

containing a grounding wire and a grounded plug. The

plug must be inserted into an outlet that is properly

installed and grounded.

• Improper use of the plug may result in the risk of electric

shock.

Consult a qualified electrician or service technician if the

grounding instructions are not completely understood or

if in doubt as to whether the appliance has been

properly grounded.

ivlvji-/iiT,ii r,_[;tii0til;-]ii[;] il _,.1

This appliance must be plugged into a 15Amp, 115 Volt,

60Hz GROUNDED OUTLET.

Note: Where a standard two-prong outlet is encountered, it

is the personal responsibility and obligation of the consumer

to have it replaced with a properly grounded three-prong

outlet.

We do not recommend the use of an extension cord with this

unit.

[o],VAvl:t II I"_ (:]II | I Io] _ [o] j]

Occasionally, there may be power interruptions due to

thunderstorms or other causes. Remove the power cord

from wall outlet when a power outage occurs. When power

has been restored, re-plug the power cord into wall outlet.

3. Once all four casters have been tightened evenly, stand the

cabinet in an upright position.

caster

II'i¥':-t_ I JiiT,hillil'_i_ uP.l,[,_ I

Follow the steps below to install the guardrail on the worktop.

1. Place the guardrail on top of the cabinet.

2. Align all holes of the guardrail with the holes of the

cabinet.

3. Secure the guardrail to the cabinet.

_ Avoid fire hazard or'

dectric shock° Do not use an extension

cord or an adapter plJug Do not remove

any prong from the power cord.

wdil rece

Do not, under any

cilrcumsta_ces_

cut_remove0

or bypass the

grounding prong

Power supply

cord with 3oprong

grounding plug

Il ':4llb']ll ill'i IB1L IBlllI

, e_.-i_ Ihe[onh'T:_ll"_:_:4i _.l,1

Follow the steps below to install the beer tap.

1. First, remove the cabinet tap hole cover located on the

worktop. Firmly grasp cover, twist and pull upward.

Note: Store this plug in a safe place as it will be required when

converting the beer dispenser into a beverage center.

2. Remove the top plug by twisting and pulling out. Save plug

for later use if you decide to convert the unit to an all

refrigerator u nit.

3. Unravel the beer line (clear hose) from the tower and insert

the beer line and nut through the uncovered hole on the top

of the unit.

4.

Lock the beer tower assembly to the top and make sure to

position the beer faucet so it is aligned with the cabinet front

(6 o'clock position). You accomplish this by aligning the

bottom of the beer tower to the 3 grooves on the top cabinet

and tighten by hand clockwise to properly lock.

Note: Your C02 cylinder is shipped empty to avoid any

possible accidents during transportation. When you purchase

the first keg of beer, have your C02 cylinder filled by your

local compressed gas supplier. (See Welding Supply in

Yellow Pages)

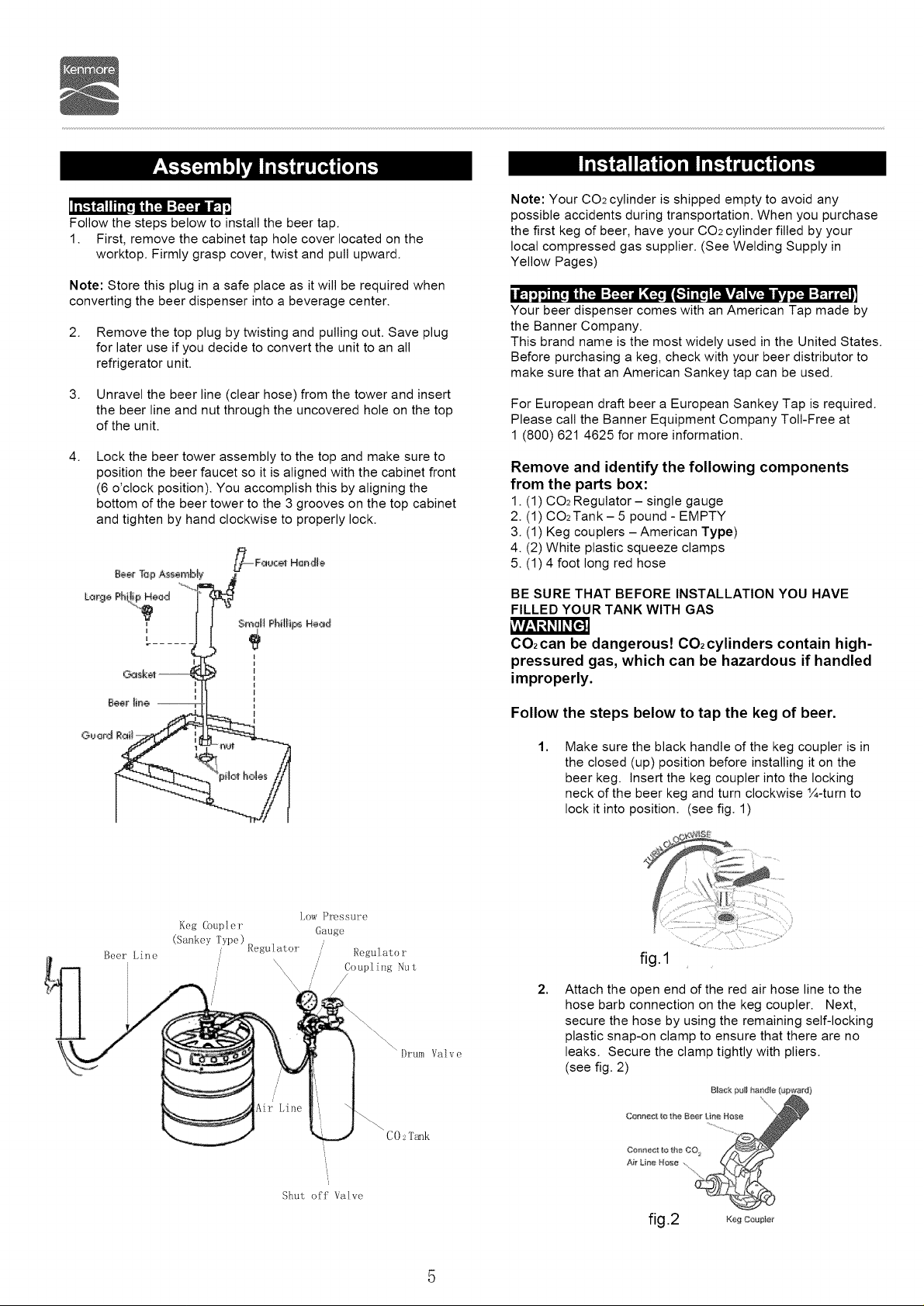

i I_.1Ij*] II1. I I I[:1 :I:[:.] I _[:.[*Ill,."lJII1.I['_llj_ lvt:ll I_*I_ 1_1d1_t]

Your beer dispenser comes with an American Tap made by

the Banner Company.

This brand name is the most widely used in the United States.

Before purchasing a keg, check with your beer distributor to

make sure that an American Sankey tap can be used.

For European draft beer a European Sankey Tap is required.

Please call the Banner Equipment Company Toll-Free at

1 (800) 621 4625 for more information.

Remove and identify the following components

from the parts box:

1. (1) CO2 Regulator- single gauge

2. (1) CO2Tank- 5 pound - EMPTY

3. (1) Keg couplers- American Type)

4. (2) White plastic squeeze clamps

5. (1) 4 foot long red hose

BE SURE THAT BEFORE INSTALLATION YOU HAVE

FILLED YOUR TANK WITH GAS

CO2can be dangerous! CO2cylinders contain high-

pressured gas, which can be hazardous if handled

improperly.

Beer Line

Low P_ssure

Gauge

Regulator / Regulator

\\ //' Coupling Nut

/

/

C0;Tank

Val v e

Follow the steps below to tap the keg of beer.

1,

Make sure the black handle of the keg coupler is in

the closed (up) position before installing it on the

beer keg. Insert the keg coupler into the locking

neck of the beer keg and turn clockwise %-turn to

lock it into position. (see fig. 1)

fig. 1

2,

Attach the open end of the red air hose line to the

hose barb connection on the keg coupler. Next,

secure the hose by using the remaining self-locking

plastic snap-on clamp to ensure that there are no

leaks. Secure the clamp tightly with pliers.

(see fig. 2)

Shut; off' Valve

fig.2 Ko_co,_to,-

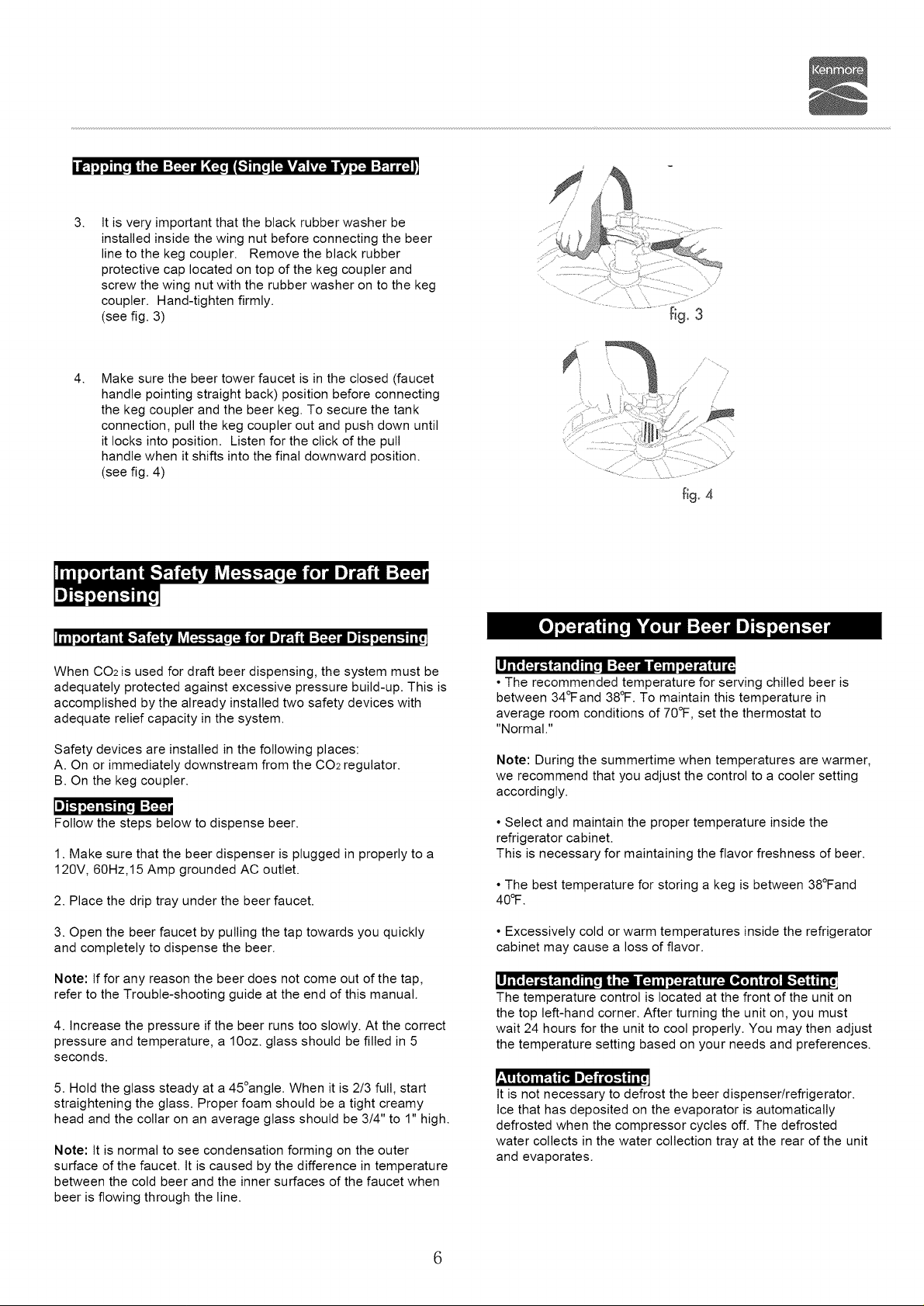

/ i_.1 Ij,] II[i I _I[:1 :[:_;11 _,:_i|_'_ I i[i I _Y_ L'{:I |vj oI:l -'_| i {;t | 1

3.

It is very important that the black rubber washer be

installed inside the wing nut before connecting the beer

line to the keg coupler. Remove the black rubber

protective cap located on top of the keg coupler and

screw the wing nut with the rubber washer on to the keg

coupler. Hand-tighten firmly.

(see fig. 3)

4.

Make sure the beer tower faucet is in the closed (faucet

handle pointing straight back) position before connecting

the keg coupler and the beer keg. To secure the tank

connection, pull the keg coupler out and push down until

it locks into position. Listen for the click of the pull

handle when it shifts into the final downward position.

(see fig. 4)

fig. 3

fig. 4

When 002 is used for draft beer dispensing, the system must be

adequately protected against excessive pressure build-up. This is

accomplished by the already installed two safety devices with

adequate relief capacity in the system.

Safety devices are installed in the following places:

A. On or immediately downstream from the CO2 regulator.

B. On the keg coupler.

Ik] [:1 ol:_ i1.11i[i I :[:_:_ i

Follow the steps below to dispense beer.

1. Make sure that the beer dispenser is plugged in properly to a

120V, 60Hz,15 Amp grounded AC outlet.

2. Place the drip tray under the beer faucet.

3. Open the beer faucet by pulling the tap towards you quickly

and completely to dispense the beer.

Note: tf for any reason the beer does not come out of the tap,

refer to the Trouble-shooting guide at the end of this manual.

4. Increase the pressure if the beer runs too slowly. At the correct

pressure and temperature, a 10oz. glass should be filled in 5

seconds.

5. Hold the glass steady at a 45°angle. When it is 2/3 full, start

straightening the glass. Proper foam should be a tight creamy

head and the collar on an average glass should be 3/4" to 1" high.

Note: It is normal to see condensation forming on the outer

surface of the faucet. It is caused by the difference in temperature

between the cold beer and the inner surfaces of the faucet when

beer is flowing through the line.

LI_ [:_ I_'_ _.l l[O I I l[O I _[:1:_ II 1:_ Iil o[:] I_.i_l I _

• The recommended temperature for serving chilled beer is

between 34°Fand 38°F. To maintain this temperature in

average room conditions of 70°F, set the thermostat to

"Normal."

Note: During the summertime when temperatures are warmer,

we recommend that you adjust the control to a cooler setting

accordingly.

• Select and maintain the proper temperature inside the

refrigerator cabinet.

This is necessary for maintaining the flavor freshness of beer.

• The best temperature for storing a keg is between 38°Fand

40°F.

• Excessively cold or warm temperatures inside the refrigerator

cabinet may cause a loss of flavor.

LIr_ [:_/,,.-__l n[oh nTol _nT-_1:.]U l oI:.]_llu I_[_o] n|{'_';II[_,_ | _InTo

The temperature control is located at the front of the unit on

the top left-hand corner. After turning the unit on, you must

wait 24 hours for the unit to cool properly. You may then adjust

the temperature setting based on your needs and preferences.

It is not necessary to defrost the beer dispenser/refrigerator.

Ice that has deposited on the evaporator is automatically

defrosted when the compressor cycles off. The defrosted

water collects in the water collection tray at the rear of the unit

and evaporates.

6

Lll'_I_[;] I-t _l el,II a[_i _[,] di'*_! i[el,[;-] _i41 a[_I_-"[,]lI el, k't

• Bubbling or gurgling sounds and slight vibrations are the result

of the refrigerant circulating through the cooling coils.

• Sizzling or popping sounds occur during the automatic defrost

cycle.

• Dripping sounds occur as ice melts from the evaporator and

flows into the water collection tray during the automatic defrost

cycle.

• Cracking or popping sounds are caused by the expanding

and/or contracting of the cooling coils during the automatic defrost

cycle.

1) 1/4 barrel kegs

2) 1/6 barrels kegs (narrow)

3) 1/4 barrel (slim) keg

4) 1/2 barrel keg

Follow the energy-saving tips below for optimum efficiency.

• Limit the opening and closing of the door on hot and humid

days. When you open the door, close it quickly to prevent hot

air from entering.

• Check regularly for proper air circulation around the unit to

make sure that the unit receives sufficient airflow.

• Keep the door gasket clean and straight to ensure a proper

seal. If the door gasket is not sealed properly, hot air may

easily enter into the unit, making the interior temperature

warmer. The compressor must then run continuously to keep

the unit cool, thus making the energy consumption very high

and inefficient.

Beer Serving Tips

The following tips will help you serve the perfect beer.

Before serving beer from the tap, check for the following:

• Cleanliness • Temperature • 002 pressure

Tips for C_eaming Beer G_asses

For the freshest flavor, it is important to serve beer in clean

glasses. For your convenience, the following tips explain how to

properly clean beer glasses before serving beer.

• Do not wash beer glasses together with glasses that have

contained milk or any other fatty substance.

film on the glasses, which may cause flat beer.

• Wash glasses thoroughly with a good detergent to remove all

fatty substances (i.e. lipstick).

• Do not use soap.

• Do not wipe glasses dry. Allow glasses to air-dry by placing

them on a wire rack or on corrugated metal.

• Rinse in fresh cold water just before serving beer. It is best to

serve beer in a wet glass.

Note: Replace a damaged door gasket to restore energy

efficiency.

kvAv/_,1_,1_I1_It..]

To avoid electric shock, always unplug your beer

dispenser before cleaning. Failure to do so may result

in possible death or injury.

[_:_lJl i [o]_i

Before using cleaning products, always read and

follow the manufacturer's instructions and warnings to

avoid personal injury and product damage.

_ [_l*l I*1_ IF_4*[, I[L'I;]*[;] _! II iVi_] I*i(;]*_l*[_• An excessive amount of germicide build-up will also leave a fatty

General

Note: Do not use harsh chemicals, abrasives, ammonia, chlorine

bleach, concentrated detergents, solvents or metal scouring pads.

Some of these products may dissolve, damage and/or discolor

the cabinet finish.

Interior and Exterior Cabinet Cleaning

1.

Prepare a cleaning solution of 3-4 tablespoons of baking

soda mixed with warm water. Use a sponge or soft cloth

dampened with the cleaning solution to wipe down the

interior and exterior surfaces of the cabinet.

2. Rinse with clean, warm water and dry with a soft cloth.

1. Wash the glasses using your usual method. Immerse the glass

heel first in clean water. Empty the glass, tf water droplets cling

to the glass or if spots appear on the glass while pouring, the

glass has not been cleaned properly. A clean glass should air-

dry crystal clear.

2. Again, wash the glass using your usual method. Pour out the

water and then shake salt into the wet glass, tf salt does not

cling to the entire inside wall of the glass and clear unsalted

spots remain, the glass is not clean.

,Z.Z.]4t/_,'{_l_[mlllll

1. Clean the door gasket with a damp cloth every three

months. The gasket must be kept clean and pliable to

ensure a proper seal.

2. Petroleum jelly applied lightly to the hinge side of the

gaskets will keep the gasket pliable and ensure a good

seal.

We recommend that you clean the rear of the refrigerator at least

twice a year.

Note: Some operating environments may require more frequent

cleaning.

Use a vacuum or a brush to clean the coils.

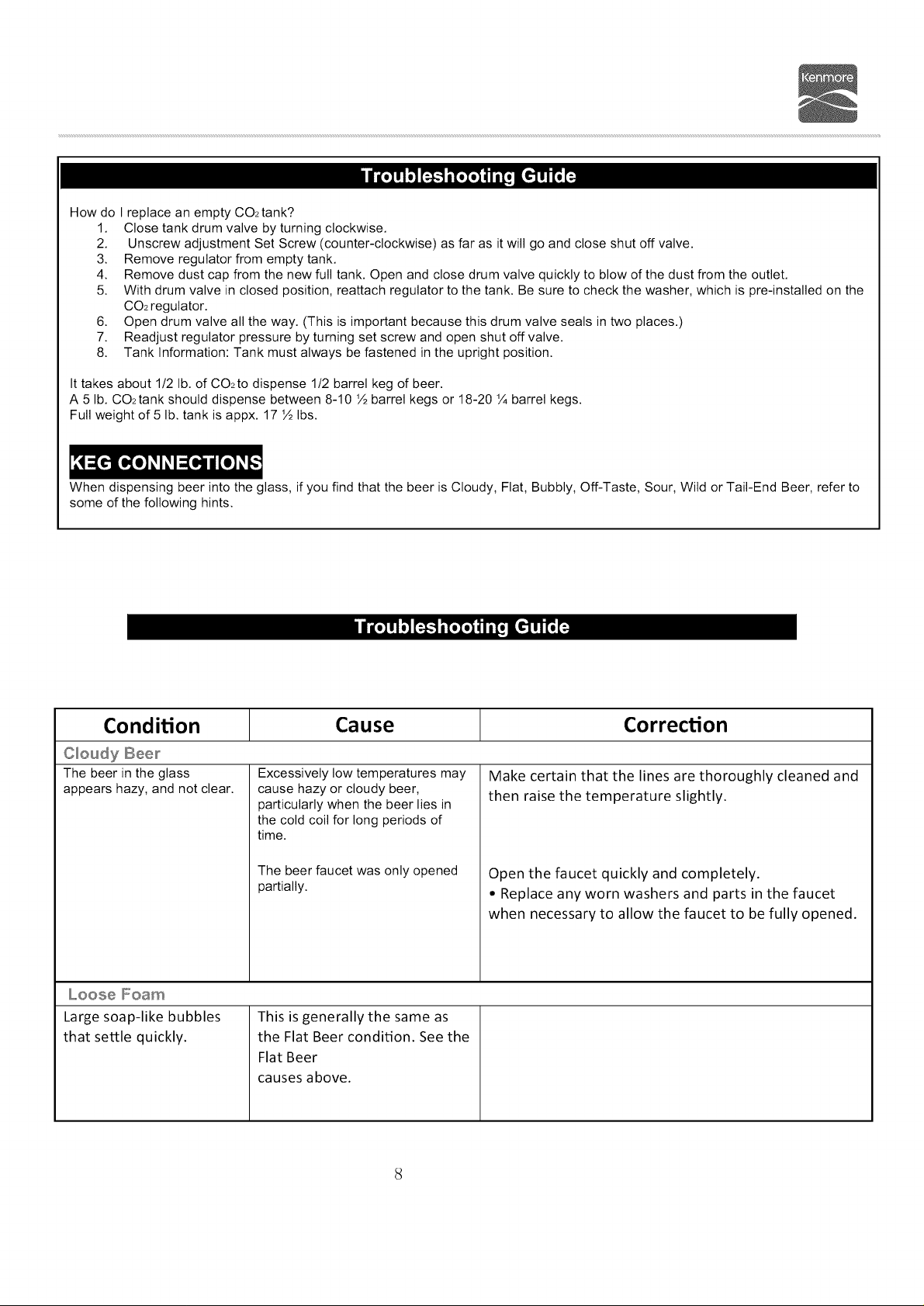

How do

I replace an empty CO2tank?

1.

Close tank drum valve by turning clockwise.

2.

Unscrew adjustment Set Screw (counter-clockwise) as far as it will go and close shut off valve.

3.

Remove regulator from empty tank.

4.

Remove dust cap from the new full tank. Open and close drum valve quickly to blow of the dust from the outlet.

5.

With drum valve in closed position, reattach regulator to the tank. Be sure to check the washer, which is pre-installed on the

CO2 regulator.

6.

Open drum valve all the way. (This is important because this drum valve seals in two places.)

7.

Readjust regulator pressure by turning set screw and open shut off valve.

8.

Tank Information: Tank must always be fastened in the upright position.

It takes about 1/2 lb. of CO2to dispense 1/2 barrel keg of beer.

A 5 lb. CO2tank should dispense between 8-10 ½ barrel kegs or 18-20 1¼barrel kegs.

Full weight of 5 lb. tank is appx. 17 ½ Ibs.

When dispensing beer into the glass, if you find that the beer is Cloudy, Flat, Bubbly, Off-Taste, Sour, Wild or Tail-End Beer, refer to

some of the following hints.

Condition

C_o_dy Bee_

The beer in the glass

appears hazy, and not clear.

IIIoose Foam

Large soap-like bubbles

that settle quickly.

Cause Correction

Excessively low temperatures may

cause hazy or cloudy beer,

particularly when the beer lies in

the cold coil for long periods of

time.

The beer faucet was only opened

partially.

This is generally the same as

the Flat Beer condition. See the

Flat Beer

causes above.

Make certain that the lines are thoroughly cleaned and

then raise the temperature slightly.

Open the faucet quickly and completely.

• Replace any worn washers and parts in the faucet

when necessary to allow the faucet to be fully opened.

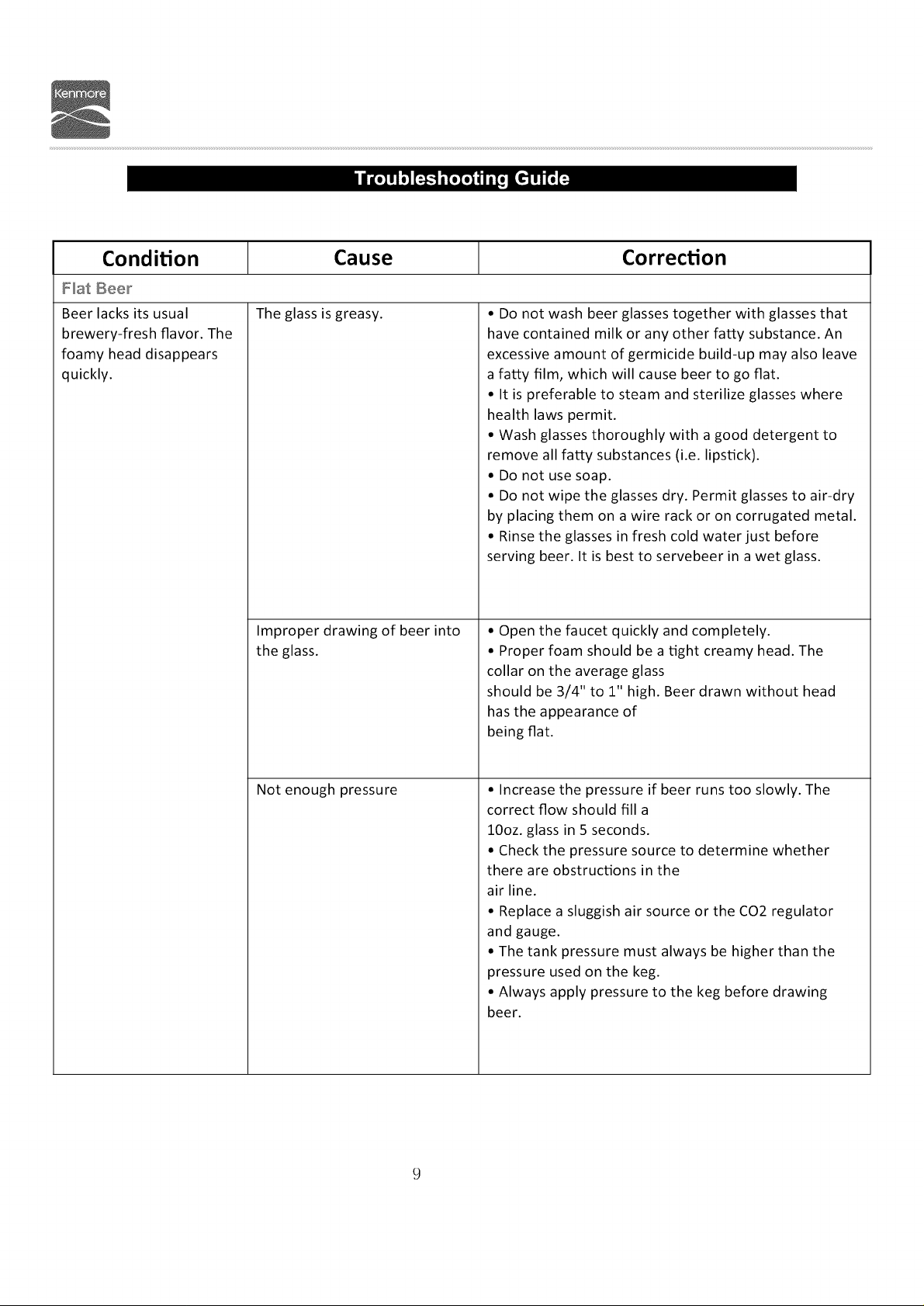

Condition Cause Correction

F_at Beer

Beer lacks its usual

brewery-fresh flavor. The

foamy head disappears

quickly.

The glass is greasy.

• Do not wash beer glasses together with glasses that

have contained milk or any other fatty substance. An

excessive amount of germicide build-up may also leave

a fatty film, which will cause beer to go fiat.

• It is preferable to steam and sterilize glasses where

health laws permit.

• Wash glasses thoroughly with a good detergent to

remove all fatty substances (i.e. lipstick).

• Do not use soap.

• Do not wipe the glasses dry. Permit glasses to air-dry

by placing them on a wire rack or on corrugated metal.

• Rinse the glasses in fresh cold water just before

serving beer. It is best to servebeer in a wet glass.

Improper drawing of beer into

the glass.

Not enough pressure

• Open the faucet quickly and completely.

• Proper foam should be a tight creamy head. The

collar on the average glass

should be 3/4" to 1" high. Beer drawn without head

has the appearance of

being flat.

• Increase the pressure if beer runs too slowly. The

correct flow should fill a

lOoz. glass in 5 seconds.

• Check the pressure source to determine whether

there are obstructions in the

airline.

• Replace a sluggish air source or the C02 regulator

and gauge.

• The tank pressure must always be higher than the

pressure used on the keg.

• Always apply pressure to the keg before drawing

beer.

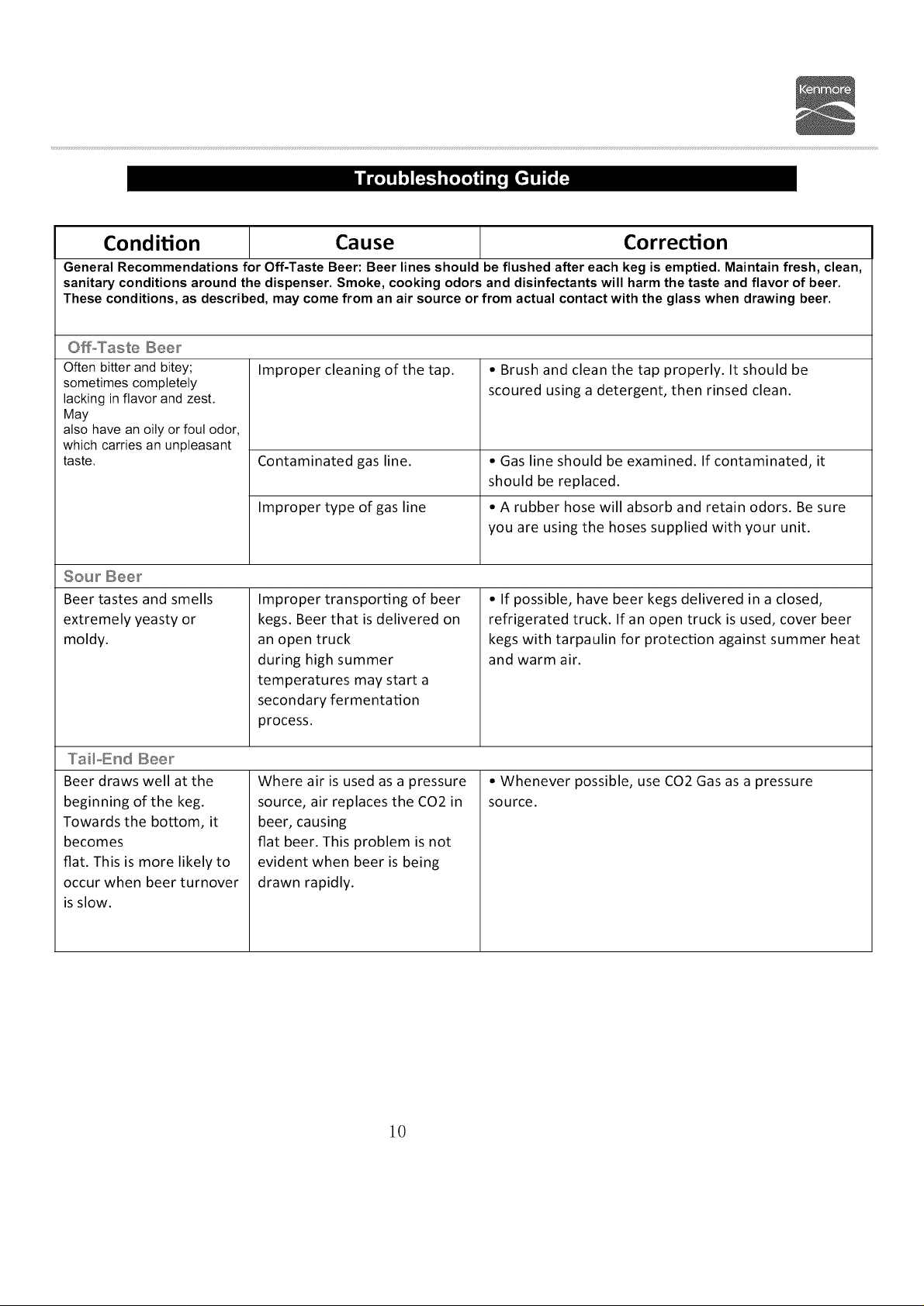

hrz'cr],' ,j

Condition J Cause Correction

General Recommendations for Off-Taste Beer: Beer lines should be flushed after each keg is emptied. Maintain fresh, clean,

sanitary conditions around the dispenser. Smoke, cooking odors and disinfectants will harm the taste and flavor of beer.

These conditions, as described, may come from an air source or from actual contact with the glass when drawing beer.

OffoTaste Beer

Often bitter and bitey;

sometimes completely

lacking in flavor and zest.

May

also have an oily or foul odor,

which carries an unpleasant

taste.

Sour Beer

Beer tastes and smells

extremely yeasty or

moldy.

Improper cleaning of the tap.

• Brush and clean the tap properly. It should be

scoured using a detergent, then rinsed clean.

Contaminated gas line. • Gas line should be examined. If contaminated, it

should be replaced.

Improper type of gas line • A rubber hose will absorb and retain odors. Besure

you are using the hoses supplied with your unit.

Improper transporting of beer

kegs. Beer that is delivered on

an open truck

during high summer

temperatures may start a

secondary fermentation

process.

• If possible, have beer kegs delivered in a closed,

refrigerated truck. If an open truck is used, cover beer

kegs with tarpaulin for protection against summer heat

and warm air.

qr°aiFEnd Beer

Beer draws well at the

beginning of the keg.

Towards the bottom, it

becomes

flat. This is more likely to

occur when beer turnover

is slow.

Where air is used as a pressure

source, air replaces the CO2 in

beer, causing

fiat beer. This problem is not

evident when beer is being

drawn rapidly.

]0

• Whenever possible, use CO2 Gas as a pressure

source.

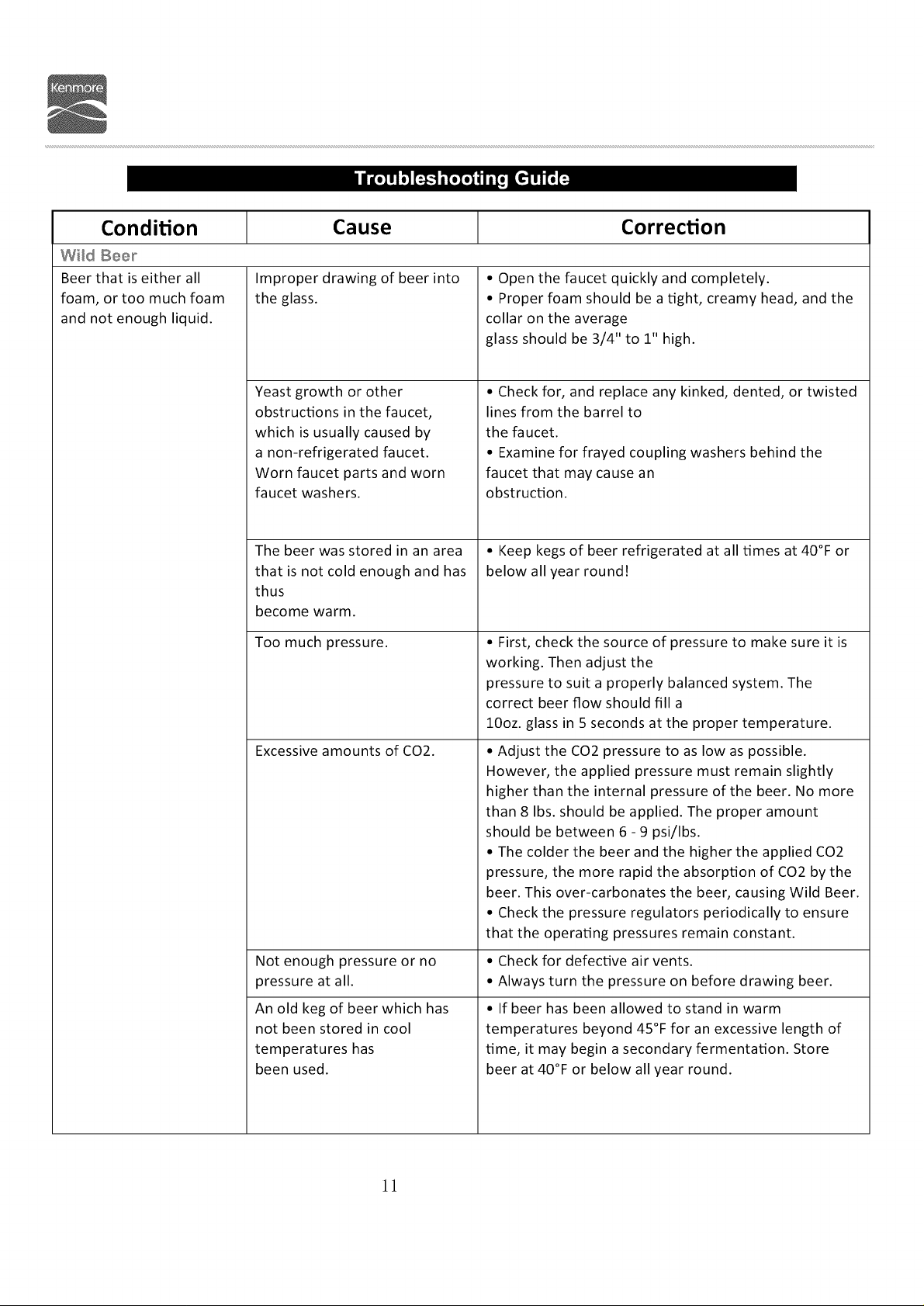

hrza'r],'L ,j

Condition

Wi_d Bee_

Beer that is either all

foam, or too much foam

and not enough liquid.

Cause Correction

Improper drawing of beer into

the glass.

Yeast growth or other

obstructions in the faucet,

which is usually caused by

a non-refrigerated faucet.

Worn faucet parts and worn

faucet washers.

The beer was stored in an area

that is not cold enough and has

thus

become warm.

Too much pressure.

Excessive amounts of CO2.

Not enough pressure or no

pressure at all.

An old keg of beer which has

not been stored in cool

temperatures has

been used.

• Open the faucet quickly and completely.

• Proper foam should be a tight, creamy head, and the

collar on the average

glass should be 3/4" to 1" high.

• Check for, and replace any kinked, dented, or twisted

lines from the barrel to

the faucet.

• Examine for frayed coupling washers behind the

faucet that may cause an

obstruction.

• Keep kegs of beer refrigerated at all times at 40°F or

below all year round!

• First, check the source of pressure to make sure it is

working. Then adjust the

pressure to suit a properly balanced system. The

correct beer flow should fill a

10oz. glass in 5 seconds at the proper temperature.

• Adjust the CO2 pressure to as low as possible.

However, the applied pressure must remain slightly

higher than the internal pressure of the beer. No more

than 8 Ibs. should be applied. The proper amount

should be between 6 - 9 psi/Ibs.

• The colder the beer and the higher the applied CO2

pressure, the more rapid the absorption of CO2 by the

beer. This over-carbonates the beer, causing Wild Beer.

• Check the pressure regulators periodically to ensure

that the operating pressures remain constant.

• Check for defective air vents.

• Always turn the pressure on before drawing beer.

• If beer has been allowed to stand in warm

temperatures beyond 45°F for an excessive length of

time, it may begin a secondary fermentation. Store

beer at 40°F or below all year round.

11

Loading...

Loading...