Kenmore 25377185410, 25377185412 Installation Guide

For Medium (15-18.5K) + Heavy duty (22-28.5K) Air Conditioner

READ BEFORE INSTALLING UNIT

To avoid risk of personal injury, property damage, or product damage due to the weight of this device and sharp

edges that may be exposed:

Air conditioners covered in this manual pose an excessive weight hazard. Two or more people are needed to

move and install the unit. To prevent injury or strain, use proper lifting and carrying techniques when moving unit.

Carefully inspect location where air conditioner will be installed. Be sure it will support the weight of the unit over

an extended period of time.

Handle air conditioner with care. Wear protective gloves whenever lifting or carrying the unit. AVOID the sharp

metal fins of front and rear coils.

Make sure air conditioner does not fall during installation.

If a new electrical outlet is required, have the outlet installed by a qualified electrician before installing unit.

NOTE: DO NOT USE ANY SCREWS OTHER THAN THOSE SPECIFIED HERE.

Preliminary instructions:

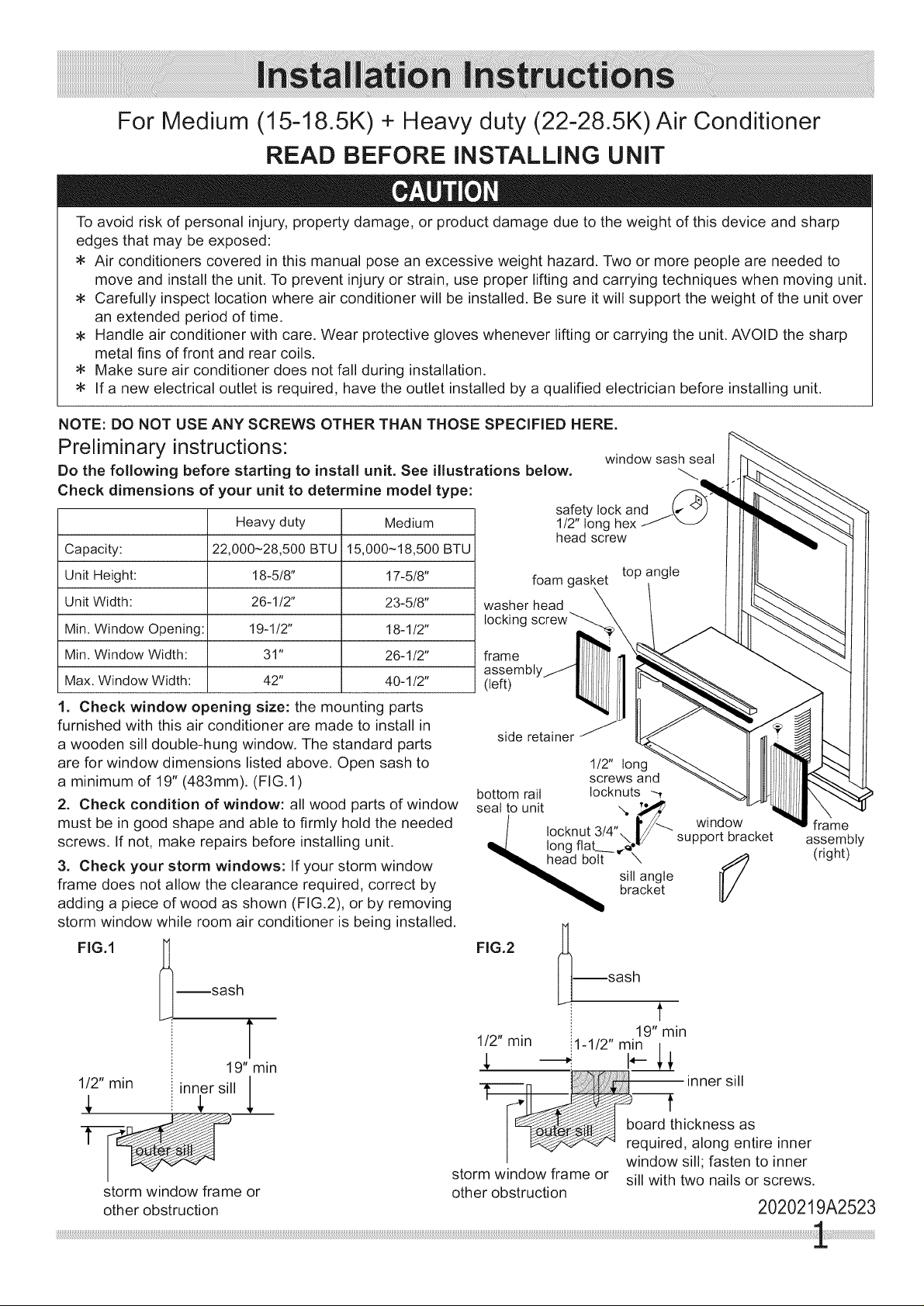

Do the following before starting to install unit. See illustrations below.

Check dimensions of your unit to determine model type:

Heavy duty Medium

Capacity: 22,000-28,500 BTU 15,000-18,500 BTU

Unit Height: 18-5/8" 17-5/8"

Unit Width: 26-1/2" 23-5/8"

Min. Window Opening: 19-1/2" 18-1/2"

Min. Window Width: 31" 26-1/2"

Max. Window Width: 42" 40-1/2"

1. Check window opening size: the mounting parts

furnished with this air conditioner are made to install in

a wooden sill double-hung window. The standard parts

are for window dimensions listed above. Open sash to

a minimum of 19" (483mm). (FIG.l)

2. Check condition of window: all wood parts of window

must be in good shape and able to firmly hold the needed

screws. If not, make repairs before installing unit.

3. Check your storm windows: If your storm window

frame does not allow the clearance required, correct by

adding a piece of wood as shown (FIG.2), or by removing

storm window while room air conditioner is being installed.

washer head

frame

bottom rail Iocknuts --_

seat to unit %

foam gasket

locking screw_

(left)

side retainer

/ Iocknut 3/4"\ _ _

long flat__.._. ,'_

head bolt \

"_ bracket

safety lock and

1/2" long hex

head screw

window sash seal

top angle

1/2" long

screws and

window frame

support bracket assembly

sill angle

(right)

FIG.1 _--sash

19" min

1/2" min inner sill |

storm window frame or

other obstruction

t

FIG.2 _--sash

t

19" min

1/2" min _:1-1/2"mint

-- inner sill

...............................t

_'_oard thickness as

I _ required, along entire inner

window sill; fasten to inner

storm window frame or sill with two nails or screws.

other obstruction

2020219A2523

4. Check for anything that could block airflow

Check area outside of window for things such as shrubs, trees, or awnings. Inside, be sure furniture, drapes, or blinds

will not stop proper air flow.

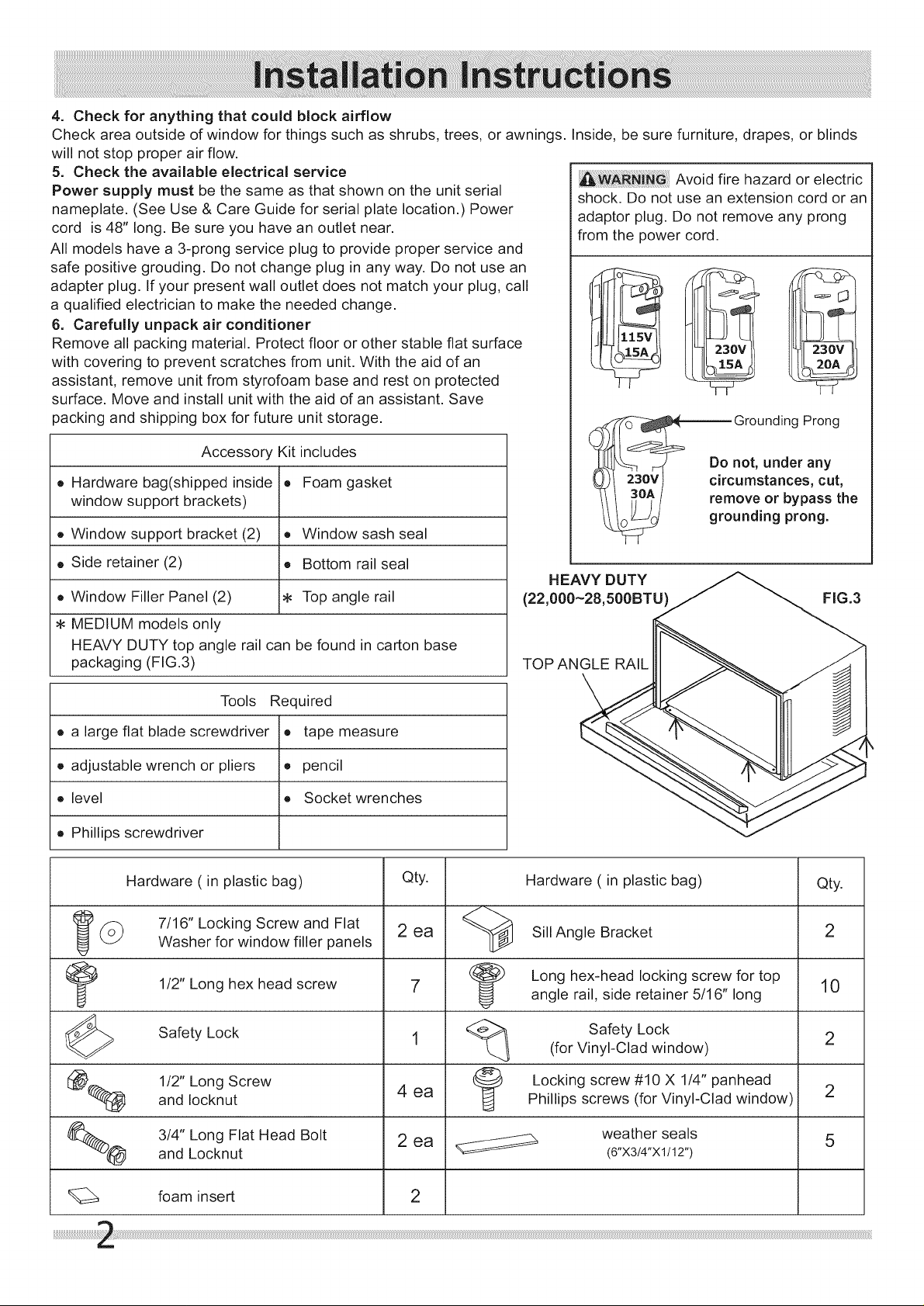

5. Check the available electrical service

Power supply must be the same as that shown on the unit serial

nameplate. (See Use & Care Guide for serial plate location.) Power

cord is 48" long. Be sure you have an outlet near.

All models have a 3-prong service plug to provide proper service and

safe positive grouding. Do not change plug in any way. Do not use an

adapter plug. If your present wall outlet does not match your plug, call

a qualified electrician to make the needed change.

6. Carefully unpack air conditioner

Remove all packing material. Protect floor or other stable flat surface

with covering to prevent scratches from unit. With the aid of an

assistant, remove unit from styrofoam base and rest on protected

surface. Move and install unit with the aid of an assistant. Save

packing and shipping box for future unit storage.

Accessory Kit includes

• Hardware bag(shipped inside • Foam gasket

window support brackets)

shock. Do not use an extension cord or an

adaptor plug. Do not remove any prong

from the power cord.

__ rounding Prong

o.vt ciroumstances,cot,

/// i1"t/ remove.orbyp s the

Avoid fire hazard or electric

not, under any

• Window support bracket (2) • Window sash seal

• Side retainer (2) e Bottom rail seal

• Window Filler Panel (2) _ Top angle rail

MEDIUM models only

HEAVY DUTY top angle rail can be found in carton base

packaging (FIG.3)

Tools Required

• a large flat blade screwdriver o tape measure

• adjustable wrench or pliers • pencil

• level • Socket wrenches

• Phillips screwdriver

Qty.

2 ea

7

?

Hardware ( in plastic bag)

7/16" Locking Screw and Flat

Washer for window filler panels

1/2" Long hex head screw

?

o_ grounding prong.

HEAVY DUTY

(22,000-28,500BTU) FIG.3

TOP ANGLE RAIL

Hardware ( in plastic bag)

Sill Angle Bracket

Long hex-head locking screw for top

angle rail, side retainer 5/16" long

Qty.

2

10

©

%

%

Safety Lock

1/2" Long Screw

and Iocknut

3/4" Long Flat Head Bolt

and Locknut

foam insert 2

4 ea

2 ea

1

Locking screw #10 X 1/4" panhead

Phillips screws (for Vinyl-Clad window)

Safety Lock

(for Vinyl-Clad window)

weather seals

(6"X3/4"X1/12")

2

5

Window Mounting

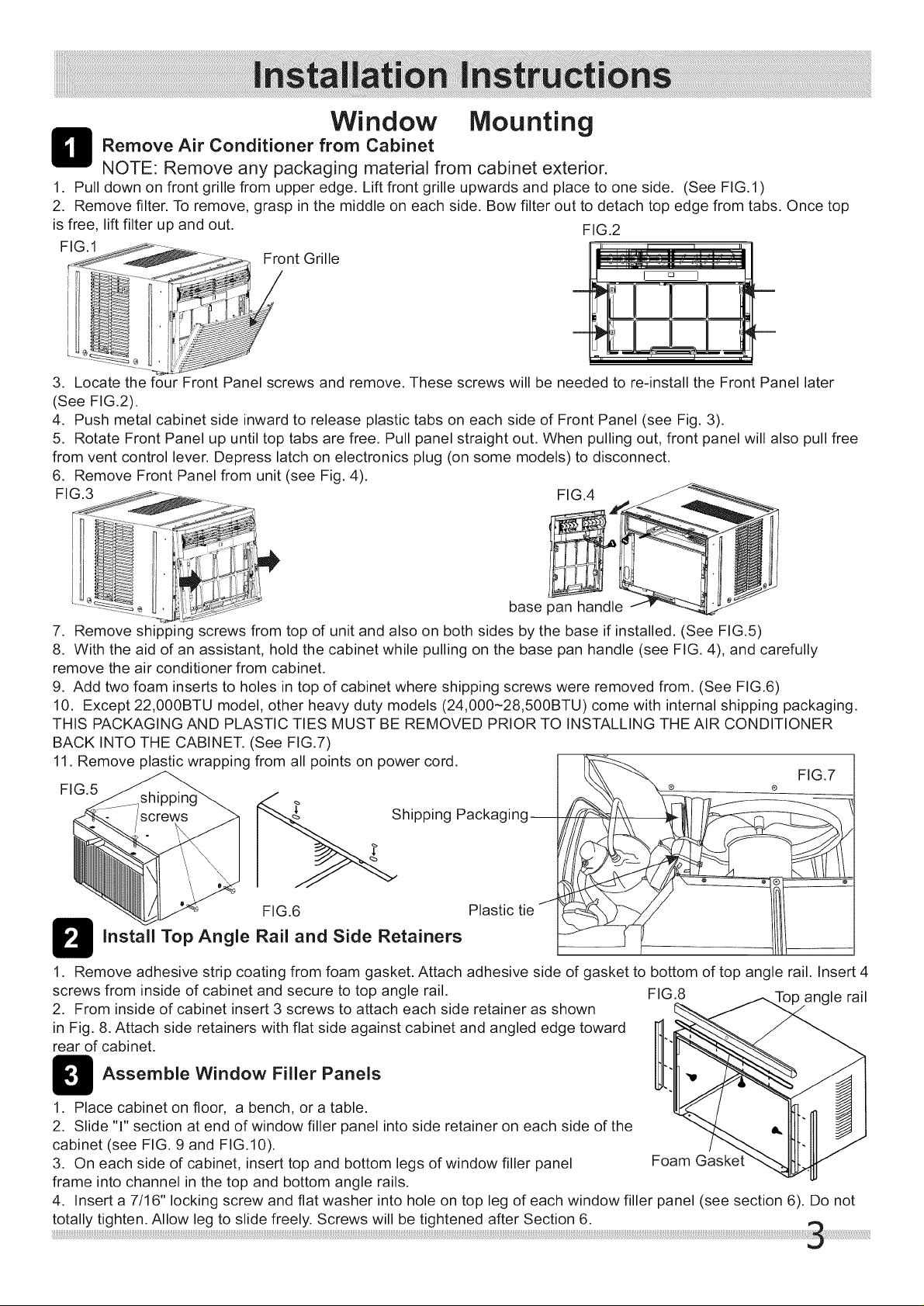

Remove Air Conditioner from Cabinet

NOTE: Remove any packaging material from cabinet exterior.

.

Pull down on front grille from upper edge. Lift front grille upwards and place to one side. (See FIG.l)

2.

Remove filter. To remove, grasp in the middle on each side. Bow filter out to detach top edge from tabs. Once top

is free, lift filter up and out.

FIG_ ..__

rn _:_ ................. /

3. Locate the four Front Panel screws and remove. These screws will be needed to re-install the Front Panel later

(See FIG.2).

4. Push metal cabinet side inward to release plastic tabs on each side of Front Panel (see Fig. 3).

5. Rotate Front Panel up until top tabs are free. Pull panel straight out. When pulling out, front panel will also pull free

from vent control lever. Depress latch on electronics plug (on some models) to disconnect.

6. Remove Front Panel from unit (see Fig. 4).

FIG.3

Front Grille

FIG.2

FIG.4

......_---_ _ base pan handle

7. Remove shipping screws from top of unit and also on both sides by the base if installed. (See FIG.5)

8. With the aid of an assistant, hold the cabinet while pulling on the base pan handle (see FIG. 4), and carefully

remove the air conditioner from cabinet.

9. Add two foam inserts to holes in top of cabinet where shipping screws were removed from. (See FIG.6)

10. Except 22,000BTU model, other heavy duty models (24,000~28,500BTU) come with internal shipping packaging.

THIS PACKAGING AND PLASTIC TIES MUST BE REMOVED PRIOR TO INSTALLING THE AIR CONDITIONER

BACK INTO THE CABINET. (See FIG.7)

11. Remove plastic wrapping from all points on power cord.

FIG.5

Shipping Packaging--

t

FIG.6 Plastic tie

/

FIG.7

Install Top Angle Rail and Side Retainers

1. Remove adhesive strip coating from foam gasket. Attach adhesive side of gasket to bottom of top angle rail. Insert 4

screws from inside of cabinet and secure to top angle rail. FIG.8 le rail

2. From inside of cabinet insert 3 screws to attach each side retainer as shown

in Fig. 8. Attach side retainers with flat side against cabinet and angled edge toward

rear of cabinet.

Assemble Window Filler Panels

1. Place cabinet on floor, a bench, or a table.

2. Slide "1" section at end of window filler panel into side retainer on each side of the

cabinet (see FIG. 9 and FIG.10).

3. On each side of cabinet, insert top and bottom legs of window filler panel Foam

frame into channel in the top and bottom angle rails.

4. Insert a 7/16" locking screw and flat washer into hole on top leg of each window filler panel (see section 6). Do not

totally tighten. Allow leg to slide freely. Screws will be tightened after Section 6.

FIG.9 Top window filler

panel leg

WINDOW FILLER

PANEL

FIG.10

TOP VIEW

AIR CONDITIONER

Bottom windov

filler panel leg

,SIDE RETAINER

"1"SECTION

WINDOW

FILLER

PANEL

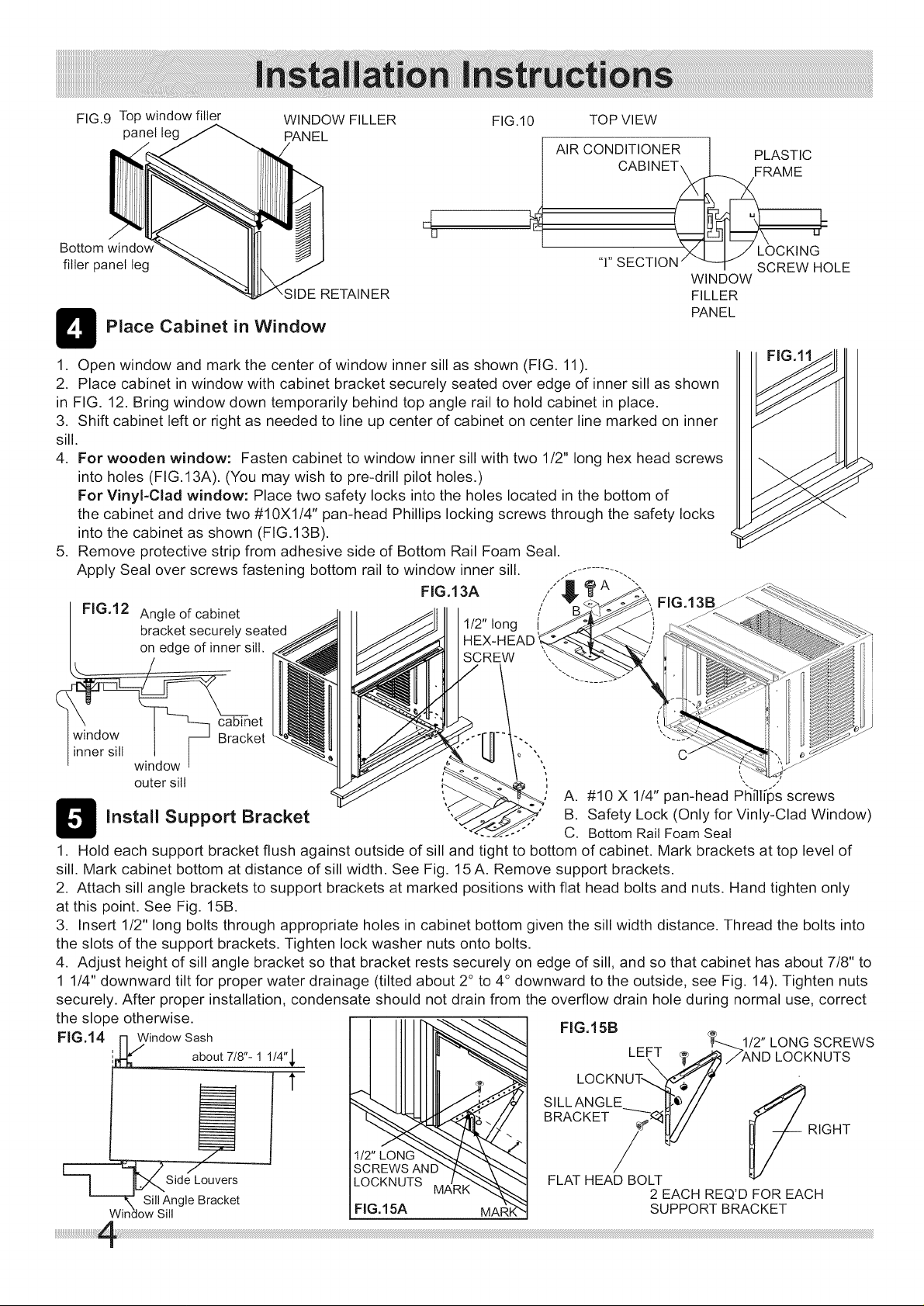

Place Cabinet in Window

1. Open window and mark the center of window inner sill as shown (FIG. 11).

2. Place cabinet in window with cabinet bracket securely seated over edge of inner sill as shown

in FIG. 12. Bring window down temporarily behind top angle rail to hold cabinet in place.

3. Shift cabinet left or right as needed to line up center of cabinet on center line marked on inner

sill.

4. For wooden window: Fasten cabinet to window inner sill with two 1/2" long hex head screws

into holes (FIG.13A). (You may wish to pre-drill pilot holes.)

For Vinyl-Clad window: Place two safety locks into the holes located in the bottom of

the cabinet and drive two #10Xl/4" pan-head Phillips locking screws through the safety locks

into the cabinet as shown (FIG.13B).

5. Remove protective strip from adhesive side of Bottom Rail Foam Seal.

Apply Seal over screws fastening bottom rail to window inner sill .............. .

FIG.13A ,""i _ A _

/' _B__ , FIG.13B

FIG.12 Ang_ketfsCacbuindtyseated

on edge of inner sill.

1 .,oo0

HEX-HEAD'_

SCREW ",

PLASTIC

FRAME

,,k

OCKING

CREW HOLE

_net

w'n_r°_, 1 winldow F Bracket

outer silt

\

A. #10 X 1/4" pan-head Ph'HT[psscrews

Install Support Bracket

B. Safety Lock (Only for Vinly-Clad Window)

C. Bottom Rail Foam Seal

1. Hold each support bracket flush against outside of sill and tight to bottom of cabinet. Mark brackets at top level of

sill. Mark cabinet bottom at distance of sill width. See Fig. 15 A. Remove support brackets.

2. Attach sill angle brackets to support brackets at marked positions with flat head bolts and nuts. Hand tighten only

at this point. See Fig. 15B.

3. Insert 1/2" long bolts through appropriate holes in cabinet bottom given the sill width distance. Thread the bolts into

the slots of the support brackets. Tighten lock washer nuts onto bolts.

4. Adjust height of sill angle bracket so that bracket rests securely on edge of sill, and so that cabinet has about 7/8" to

1 1/4" downward tilt for proper water drainage (tilted about 2° to 4° downward to the outside, see Fig. 14). Tighten nuts

securely. After proper installation, condensate should not drain from the overflow drain hole during normal use, correct

the slope otherwise. FIG.15B

FIG.14 Window Sash LEFT I_1/2" LONG SCREWS

" about 7/8"-1 1/4"J, _ _/AND LOCKNUTS

LOCKNUT_ _ /_"

S,LL . L "Ig//

L__

. Side Louvers LOCKNUTS FLAT HEAD BOLT

-- Sill Angle Bracket 2 EACH REQ'D FOR EACH

Win FIG.15A SUPPORT BRACKET

1/2" LONG BRACKET __:_[_ / [FRIGHT

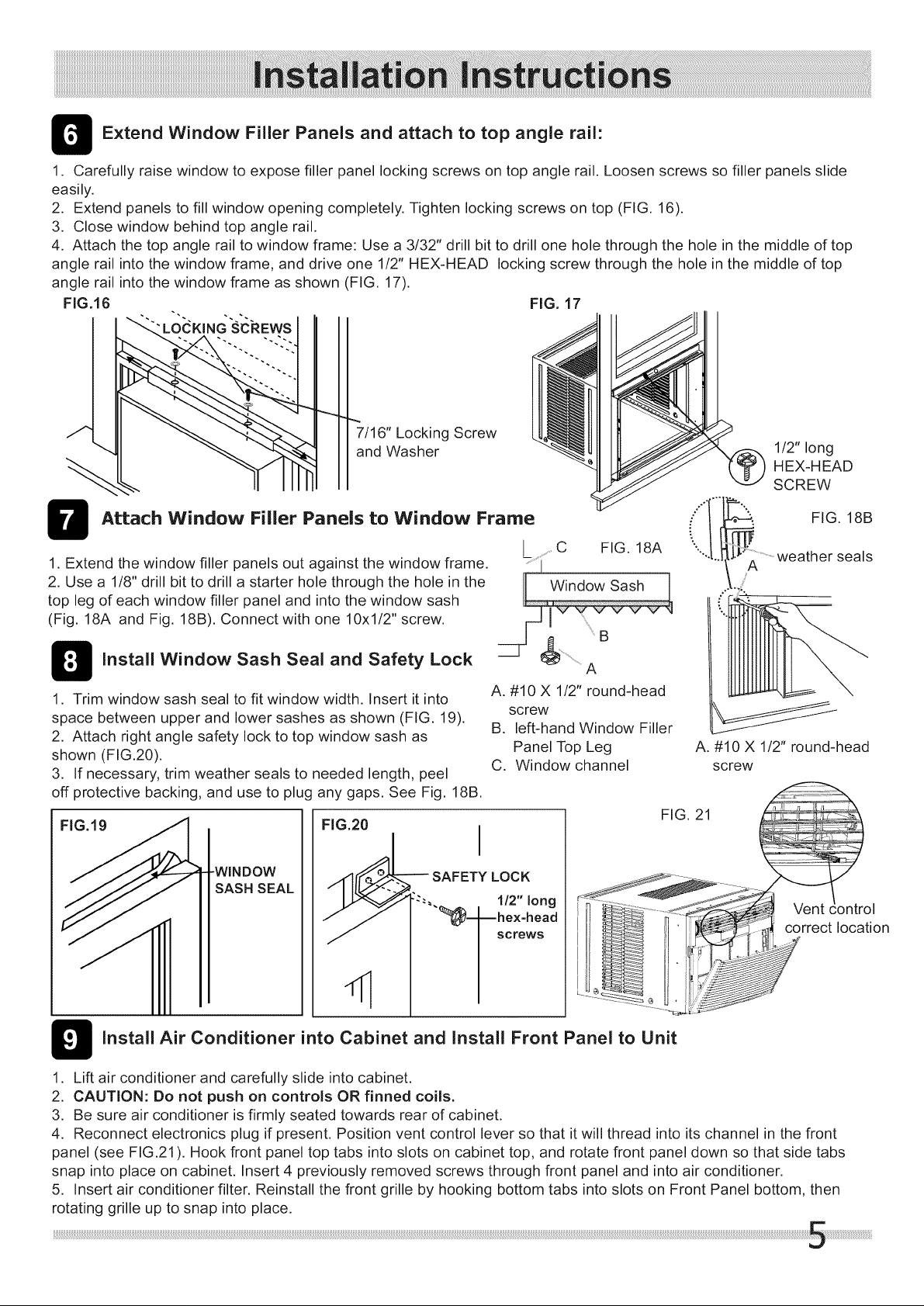

Extend Window Filler Panels and attach to top angle rail:

1. Carefully raise window to expose filler panel locking screws on top angle rail. Loosen screws so filler panels slide

easily.

2. Extend panels to fill window opening completely. Tighten locking screws on top (FIG. 16).

3. Close window behind top angle rail.

4. Attach the top angle rail to window frame: Use a 3/32" drill bit to drill one hole through the hole in the middle of top

angle rail into the window frame, and drive one 112" HEX-HEAD locking screw through the hole in the middle of top

angle rail into the window frame as shown (FIG. 17).

FIG.16

7/16" Locking Screw

and Washer

FIG. 17

1/2" longHEX-HEAD

SCREW

Attach Window Filler Panels to Window Frame

1. Extend the window filler panels out against the window frame.

2. Use a 1/8" drill bit to drill a starter hole through the hole in the

top leg of each window filler panel and into the window sash

(Fig. 18A and Fig. 18B). Connect with one 10x1/2" screw.

Install Window Sash Seal and Safety Lock

1. Trim window sash seal to fit window width. Insert it into

space between upper and lower sashes as shown (FIG. 19).

2. Attach right angle safety lock to top window sash as

shown (FIG.20).

3. If necessary, trim weather seals to needed length, peel

off protective backing, and use to plug any gaps. See Fig. 18B.

FIG.20

SAFETY LOCK

SASH SEAL

L c FIG. 18A

A. #10 X 1/2" round-head

screw

B. left-hand Window Filler

Panel Top Leg

C. Window channel

IG. 21

1/2" long

screws

I _ _4

II _ !] tion

_-_±_ , ....

"/...."I'-_\" FIG. 18B

....................weatheseas

A. #10 X 1/2" round-head

screw

k!l !1 1

........->_-_® _ • !/__

Install Air Conditioner into Cabinet and Install Front Panel to Unit

1. Lift air conditioner and carefully slide into cabinet.

2. CAUTION: Do not push on controls OR finned coils.

3. Be sure air conditioner is firmly seated towards rear of cabinet.

4. Reconnect electronics plug if present. Position vent control lever so that itwill thread into its channel in the front

panel (see FIG.21 ). Hook front panel top tabs into slots on cabinet top, and rotate front panel down so that side tabs

snap into place on cabinet. Insert 4 previously removed screws through front panel and into air conditioner.

5. Insert air conditioner filter. Reinstall the front grille by hooking bottom tabs into slots on Front Panel bottom, then

rotating grille up to snap into place.

Loading...

Loading...