Page 1

Use & Care Guide

Manual de Uso y Cuidado

Guide d’utilisation et d’entretien

English / Español / Français

Models/Modelos/Modèles: 253.7034*, 7041*, 7042*, 7044*

Kenmore

®

French Door Bottom Freezer

Congelador Inferior de Puerta Doble

La Porte-fenêtre Congélateur Inférieur

* = Color number, número de color, le numéro de couleur

P/N A05963501 (1611)

Sears Brands Management Corporation

Homan Estates, IL 60179 U.S.A.

www.kenmore.com

www.sears.com

Sears Canada Inc.

Toronto, Ontario, Canada M5B 2C3

www.sears.ca

®

Page 2

Record Model/Serial

Numbers

Important Safety

Instructions

Please read and save these

instructions.

This Use & Care Guide provides specic

operating instructions for your model. Use

your unit only as instructed in this guide.

These instructions are not meant to cover

every possible condition and situation

that may occur. Common sense and

caution must be practiced when installing,

operating, and maintaining any appliance.

Please record your model and serial

numbers below for future reference. This

information is found on the serial plate

located inside the refrigerator compartment.

Model Number:

Serial Number:

Purchase Date:

253.

IMPORTANT

Use only soap and water to clean serial plate.

Table of Contents

Record Model/Serial Numbers ................ 2

Important Safety Instructions ............... 2-4

Warranty Information ............................ 5

Master Protection Agreements ................ 6

Features at a Glance ..............................7

Installation ..................................... 8-10

Door Removal Instructions ............... 11-12

Installing Door Handles ....................... 13

Connecting the Water Supply ............ 14-15

Controls ........................................ 16-20

Automatic Ice & Water Dispenser ...... 21-23

Storage Features ............................ 24-27

Storing Food and Saving Energy ............ 28

Normal Operating Sounds .................... 29

Changing the Filter ......................... 30-31

Care & Cleaning ............................. 32-33

Before You Call .............................. 34-38

Safety Precautions

Do not attempt to install or operate

your unit until you have read the safety

precautions in this manual. Safety items

throughout this manual are labeled with

a Danger, Warning, or Caution based on

the risk type.

Denitions

This is the safety alert symbol. It is

used to alert you to potential personal

injury hazards. Obey all safety messages

that follow this symbol to avoid possible

injury or death.

DANGER

DANGER indicates an imminently

hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING

WARNING indicates a potentially

hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

CAUTION indicates a potentially

hazardous situation which, if not avoided,

may result in minor or moderate injury.

IMPORTANT

Indicates installation, operation, or

maintenance information which is

important but not hazard-related.

2

Page 3

Important Safety Instructions

WARNING

Please read all safety instructions

before using your new appliance.

For your Safety

DO NOT store or use gasoline, or other

ammable liquids in the vicinity of this or

any other appliance. Read product labels

for warnings regarding ammability and

other hazards.

DO NOT operate the refrigerator in the

presence of explosive fumes.

Avoid contact with any moving parts of

automatic ice maker.

Remove all staples from the carton.

Staples can cause severe cuts, and also

destroy nishes if they come in contact

with other appliances or furniture.

Child Safety

Destroy or recycle the carton, plastic

bags, and any exterior wrapping material

immediately after the refrigerator is

unpacked. Children should never use these

items to play. Cartons covered with rugs,

bedspreads, plastic sheets or stretch wrap

may become airtight chambers, and can

quickly cause suocation.

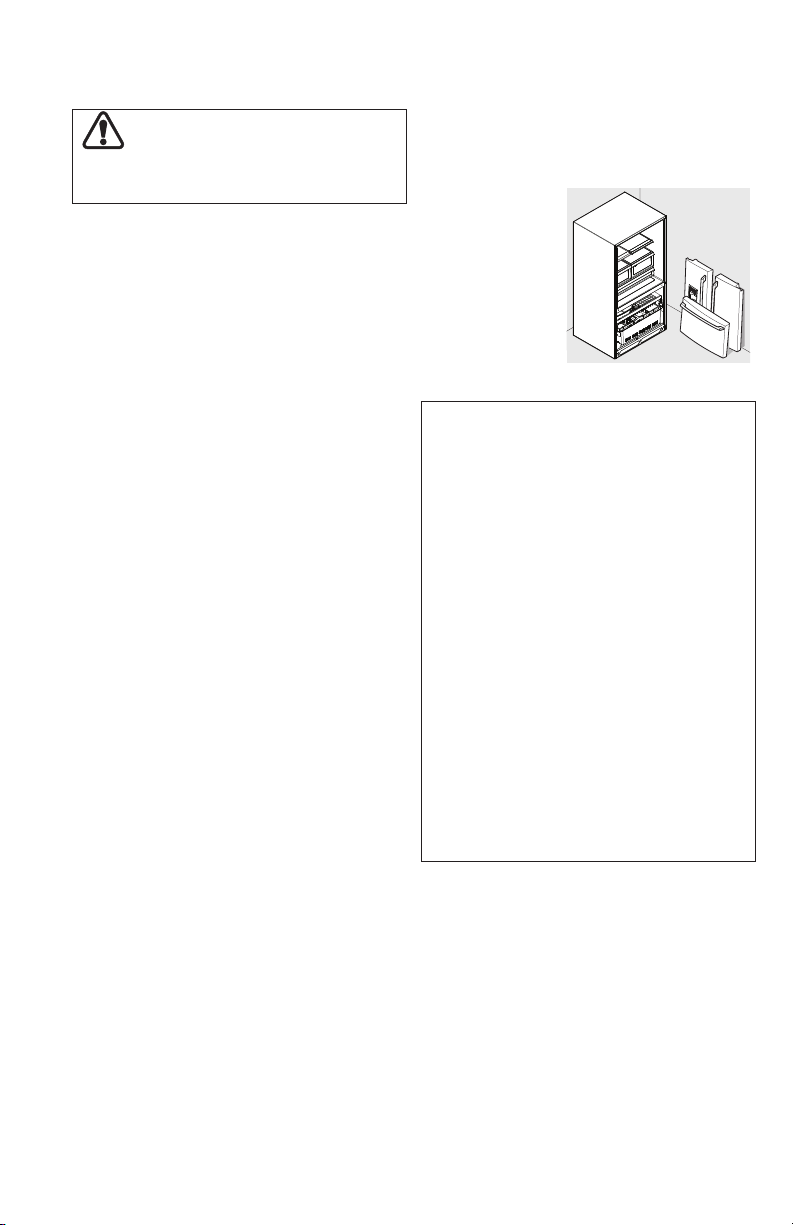

Proper Disposal of your

Refrigerator or Freezer

Risk of child entrapment

Child entrapment and suocation are not

problems of the past. Junked or abandoned

refrigerators or freezers are still dangerous

– even if they will sit for “just a few days”. If

you are getting rid of your old refrigerator

or freezer, please follow the instructions

below to help prevent accidents.

We strongly encourage responsible

appliance recycling/disposal methods.

Check with your utility company or

visit www.energystar.gov/recycle for

more information on recycling your old

refrigerator.

Before you throw away your old

refrigerator/freezer:

Remove doors.

Leave shelves in

place so children

may not easily

climb inside.

Have refrigerant

removed by a

qualied service

technician.

IMPORTANT

CFC/HCFC Disposal

Your old refrigerator may have

a cooling system that used CFCs

or HCFCs (chlorouorocarbons or

hydrochlorouorocarbons). CFCs

and HCFCs are believed to harm

stratospheric ozone if released to the

atmosphere. Other refrigerants may

also cause harm to the environment if

released to the atmosphere.

If you are throwing away your old

refrigerator, make sure the refrigerant

is removed for proper disposal by a

qualied technician. If you intentionally

release refrigerant, you may be subject

to nes and imprisonment under

provisions of environmental legislation.

3

Page 4

Grounding type wall receptacle

Power cord with

3-prong grounded plug

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

Important Safety Instructions

Electrical information

The refrigerator must be plugged into its

own dedicated 115 Volt, 60 Hz., 15 Amp,

AC only electrical outlet. The power cord

of the appliance is equipped with a threeprong grounding plug for your protection

against electrical shock hazards. It must

be plugged directly into a properly

grounded three prong receptacle.

The receptacle must be installed in

accordance with local codes and

ordinances. Consult a qualied electrician.

Avoid connecting refrigerator to a Ground

Fault Interrupter (GFI) circuit. Do not use

an extension cord or adapter plug.

If the power cord is damaged, it should

be replaced by an authorized service

technician to prevent any risk.

Never unplug the refrigerator by pulling

on the power cord. Always grip the

plug rmly, and pull straight out from

the receptacle to prevent damaging the

power cord.

Unplug the refrigerator before cleaning

and before replacing a light bulb to avoid

electrical shock.

Performance may be aected if the

voltage varies by 10% or more. Operating

the refrigerator with insucient power can

damage the compressor. Such damage is

not covered under your warranty.

Do not plug the unit into an electrical

outlet controlled by a wall switch or pull

cord to prevent the refrigerator from

being turned o accidentally.

IMPORTANT

Pressing and holding the On/O

button for three seconds, located on the

temperature control panel, will disable

your refrigerator’s cooling system

but does not disconnect the power

to the light bulb and other electrical

components. To turn o power to your

refrigerator you must unplug the power

cord from the electrical outlet.

CAUTION

To avoid personal injury or property

damage, handle tempered glass

shelves carefully. Shelves may break

suddenly if nicked, scratched, or

exposed to sudden temperature

change.

4

Page 5

Warranty Information

KENMORE LIMITED WARRANTY

FOR ONE YEAR from the date of sale this appliance is warranted against defects

in material or workmanship when it is correctly installed, operated and maintained

according to all supplied instructions.

WITH PROOF OF SALE, a defective appliance will receive free repair or replacement

at option of seller.

For warranty coverage details to obtain free repair or replacement, visit the web page:

www.kenmore.com/warranty

This warranty applies for only 90 DAYS from the sale date in the United States, and

is void in Canada, if this appliance is ever used for other than private household

purposes.

This warranty covers ONLY defects in material and workmanship, and will NOT pay

for:

1. Expendable items that can wear out from normal use, including but not limited to

lters, belts, bags or screw-in base light bulbs.

2. A service technician to clean or maintain this appliance, or to instruct the user in

correct appliance installation, operation and maintenance.

3. Service calls to correct appliance installation not performed by Sears authorized

service agents, or to repair problems with house fuses, circuit breakers, house

wiring, and plumbing or gas supply systems resulting from such installation.

4. Damage to or failure of this appliance resulting from installation not performed

by Sears authorized service agents, including installation that was not in accord

with electrical, gas or plumbing codes.

5. Damage to or failure of this appliance, including discoloration or surface rust, if it

is not correctly operated and maintained according to all supplied instructions.

6. Damage to or failure of this appliance, including discoloration or surface rust,

resulting from accident, alteration, abuse, misuse or use for other than its intended

purpose.

7. Damage to or failure of this appliance, including discoloration or surface rust,

caused by the use of detergents, cleaners, chemicals or utensils other than those

recommended in all instructions supplied with the product.

8. Damage to or failure of parts or systems resulting from unauthorized

modications made to this appliance.

9. Service to an appliance if the model and serial plate is missing, altered, or cannot

easily be determined to have the appropriate certication logo.

Disclaimer of implied warranties; limitation of remedies

Customer’s sole and exclusive remedy under this limited warranty shall be product

repair or replacement as provided herein. Implied warranties, including warranties

of merchantability or tness for a particular purpose, are limited to one year on the

appliance and ve years on the sealed system, or the shortest period allowed by

law. Seller shall not be liable for incidental or consequential damages. Some states

and provinces do not allow the exclusion or limitation of incidental or consequential

damages, or limitation on the duration of implied warranties of merchantability or

tness, so these exclusions or limitations may not apply to you.

This warranty applies only while this appliance is used in the United States or

Canada*.

This warranty gives you specic legal rights, and you may also have other rights which

vary from state to state.

* In-home repair service is not available in all Canadian geographical areas, nor will this

warranty cover user or servicer travel and transportation expenses if this product is located

in a remote area (as dened by Sears Canada Inc.) where an authorized servicer is not

available.

Sears Brands Management Corporation, Homan Estates, IL 60179

Sears Canada Inc., Toronto, Ontario, Canada M5B 2C3

5

Page 6

Master Protection Agreements

Congratulations on making a smart purchase. Your new Kenmore® product is designed

and manufactured for years of dependable operation. But like all products, it may

require preventive maintenance or repair from time to time. That’s when having a

Master Protection Agreement can save you money and aggravation.

The Master Protection Agreement also helps extend the life of your new product. Here’s

what the Agreement* includes:

Parts and labor not just for repairing defects, but to help keep products operating

properly under normal use. Our coverage goes well beyond the product warranty.

No deductibles, no functional failure excluded from coverage— real protection.

Expert service by a force of more than 10,000 authorized Sears service

technicians, which means someone you can trust will be working on your product.

Unlimited service calls and nationwide service, as often as you want us, whenever

you want us.

“No-lemon” guarantee – replacement of your covered product if four or more

product failures occur within twelve months.

Product replacement if your covered product can’t be xed.

Annual Preventive Maintenance Check at your request – no extra charge.

Fast help by phone – we call it Rapid Resolution – phone support from a Sears

representative on all products. Think of us as a “talking owner’s manual.”

Power surge protection against electrical damage due to power uctuations.

$250 Food Loss Protection annually for any food spoilage that is the result of

mechanical failure of any covered refrigerator or freezer.

Rental reimbursement if repair of your covered product takes longer than

promised.

25% discount o the regular price of any non-covered repair service and related

installed parts.

Once you purchase the Agreement, a simple phone call is all that it takes for you to

schedule service. You can call anytime day or night, or schedule a service appointment

online.

The Master Protection Agreement is a risk free purchase. If you cancel for any reason

during the product warranty period, we will provide a full refund. Or, a prorated

refund anytime after the product warranty period expires. Purchase your Master

Protection Agreement today!

Some limitations and exclusions apply. For prices and additional information in the

U.S.A. call 1-800-827-6655.

* Coverage in Canada varies on some items. For full details call Sears Canada at

1-800-361-6665.

Sears Installation Service

For Sears professional installation of home appliances, garage door openers, water

heaters, and other major home items, in the U.S.A. call 1-844-553-6667, and in

Canada call 1-800-469-4663.

6

Page 7

Features At A Glance

*LED

*Features may vary according to model

*Fresh Food

Ice Maker

*1/4 Shelf

*LED

Cluster

Light

Deli

Drawer

Adjustable Hinges

*Ice Bin

Cluster Lights

Flipper

Guide

*Water

Filter

*Dairy

Compartment

*Door Bin

*Air

Filter

Flipper

Mullion

Spill-Proof

Shelf

Spill-Proof

Shelf

Crisper

Drawer

®

®

*Freezer Ice

Maker

*Removable

Ice Bin

Freezer Baskets

*Toe Grille

7

Page 8

Installation

Top Hinge

Cover Front

Screw

Top Hinge

Cover Rear

Screw

Lower

Hinge

Screw

Top

Hinge

Screw

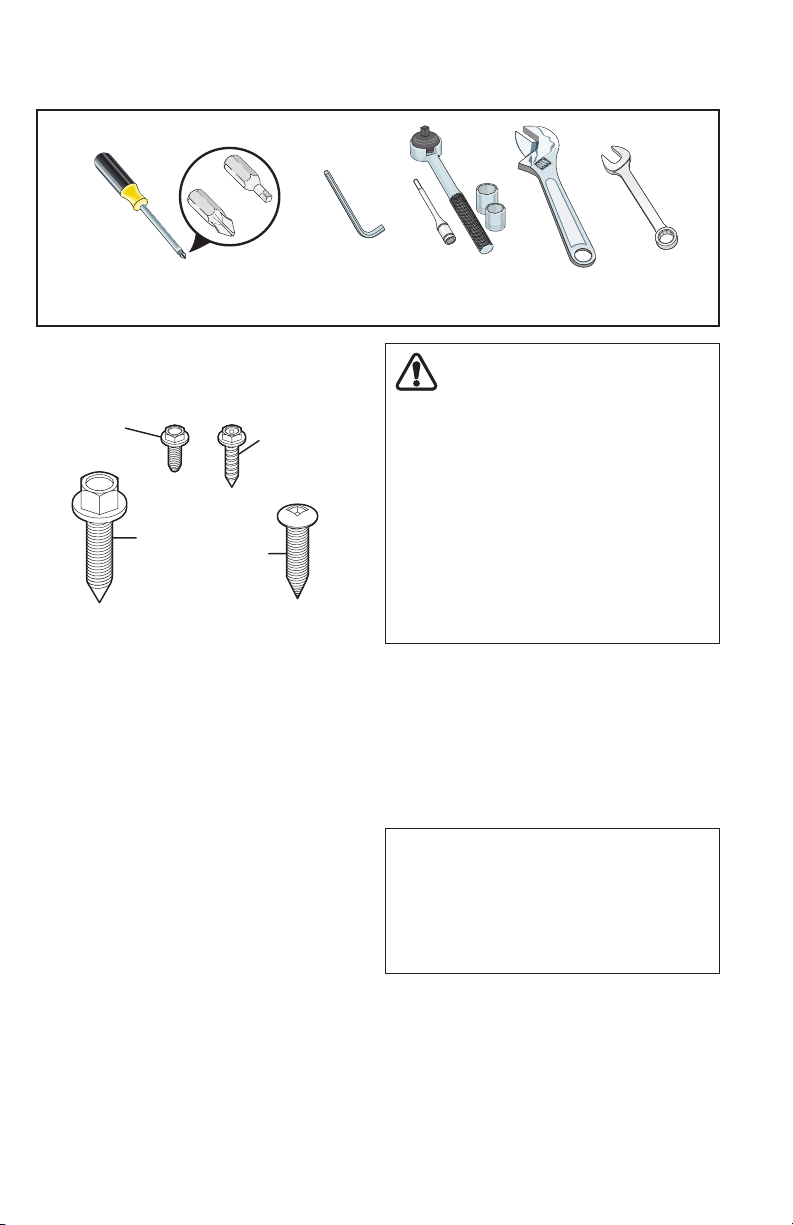

Components Provided:

Tools Necessary:

Quadrex Head

Screwdriver

Wrench

Wrench

Fixed

Wrench

Allen Wrench

(OR)

Phillips Head

or

6mm

This Use & Care Guide provides general

installation and operating instructions

for your model. We recommend using a

service or kitchen contracting professional

to install your refrigerator. Use the

refrigerator only as instructed in this

Use & Care Guide. Before starting the

refrigerator, follow these important rst

steps.

ANDAND

OR

⅜" and ¼"

Socket

OR

Adjustable

⅜"

CAUTION

Do Not install the refrigerator where

the temperature will drop below 55°F

(13°C) or rise above 110°F (43°C).

The compressor will not be able to

maintain proper temperatures inside

the refrigerator.

Do Not block the toe grille on the lower

front of your refrigerator. Sucient air

circulation is essential for the proper

operation of your refrigerator.

Installation

Allow the following clearances for ease

of installation, proper air circulation, and

plumbing and electrical connections:

Sides & Top ⅜ inch (9.5 mm)

Back 1 inch (25.4 mm)

Location

Choose a place that is near a grounded,

non-GFCI, electrical outlet. Do Not use an

extension cord or an adapter plug.

If possible, place the refrigerator out of

direct sunlight and away from the range,

dishwasher, or other heat sources.

The refrigerator must be installed on a

oor that is level and strong enough to

support a fully loaded refrigerator.

Consider water supply availability for

models equipped with an automatic ice

maker.

NOTE

If your refrigerator is placed with the

door hinge side against a wall, you may

have to allow additional space so the

door can be opened wider.

Door opening

Your refrigerator should be positioned

to allow easy access to a counter

when removing food. For best use of

refrigerator drawers and freezer baskets,

the refrigerator should be in a position

where both can be fully opened.

8

Page 9

Installation

Toe Grille Must

CAUTION

Do Not loosen or remove these 3 hex

screws.

DO NOT

Loosen

or

Remove

These 3

Hex

Screws

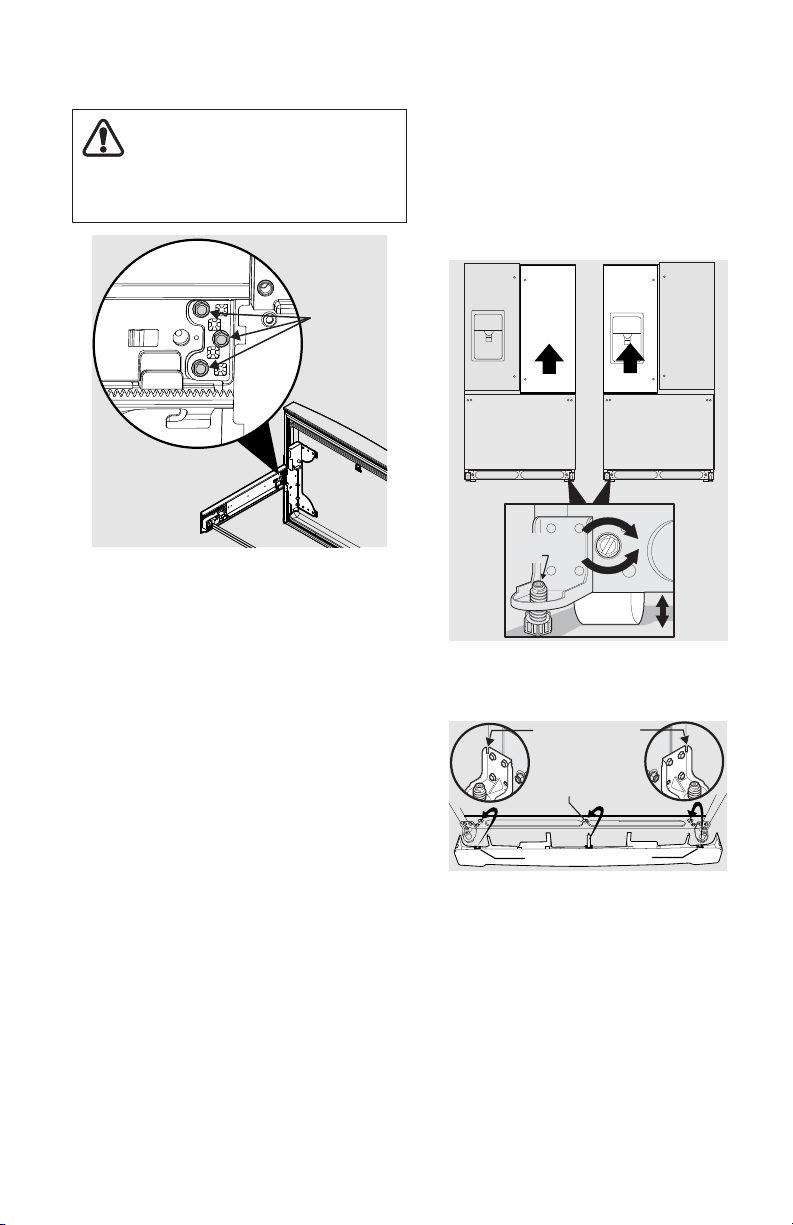

Cabinet Leveling & Refrigerator

Door Alignment (if necessary)

Guidelines for nal positioning of your

refrigerator:

All four corners of the cabinet must rest

rmly on the oor.

The front should be slightly elevated to

ensure that doors close and seal properly.

Doors should align with each other and

be level.

Most of these conditions can be met by

raising or lowering the adjustable front

rollers.

To level the cabinet using the front rollers:

1 Slightly open freezer drawer if the

toe grill is installed. Lift the toe grille

and gently pull forward.

2 Make initial cabinet adjustments by

using the front roller height adjusting

screws. Use a 3/8 inch socket wrench

to turn the adjustment screws (1 per

side).

To raise: turn adjustment screw clockwise.

To lower: turn adjustment screw

counterclockwise.

3 Ensure both doors are bind-free with

their seals touching the cabinet on all

four sides and that cabinet is stable.

4 After unit is leveled, lower anti-tip leg

using a 3/8 inch socket wrench until it

rmly contacts the oor.

Door

Anti-tip

Leg

Door

Raise

Lower

5 Install the toe grille by tting into

place.

Fit in Slot on

Anti-tip Bracket

Screw/Washer

Assembly

(3) Retaining Clips

9

Page 10

Installation

To make nal door height adjustments:

1. Open freezer drawer to make lower

hinge visible.

2. Insert 6mm Allen wrench into the

shaft of the lower hinge.

3. Adjust the height by turning clockwise

or counterclockwise. Turning

clockwise will lower the door. Turning

counterclockwise will raise the door.

Default setting is to the lowest height

when you receive your appliance.

Raise

To adjust the ipper mullion:

1 Loosen the screw located on the

ipper mullion hinge.

Flipper

Mullion

Screw

Flipper

Mullion

Hinge

Adjusting Flipper Mullion Screw

2 Adjust ipper mullion height. For

proper connection with the ipper

mullion guide, there should be a

separation about the thickness of

a coin (0.060 inches, or 1.5 mm)

between the guide and ipper

mullion.

Flipper

Mullion

Adjusting Flipper Mullion Height

3 Re-tighten screw.

10

Mullion

Guide

Thickness

of a Coin

Page 11

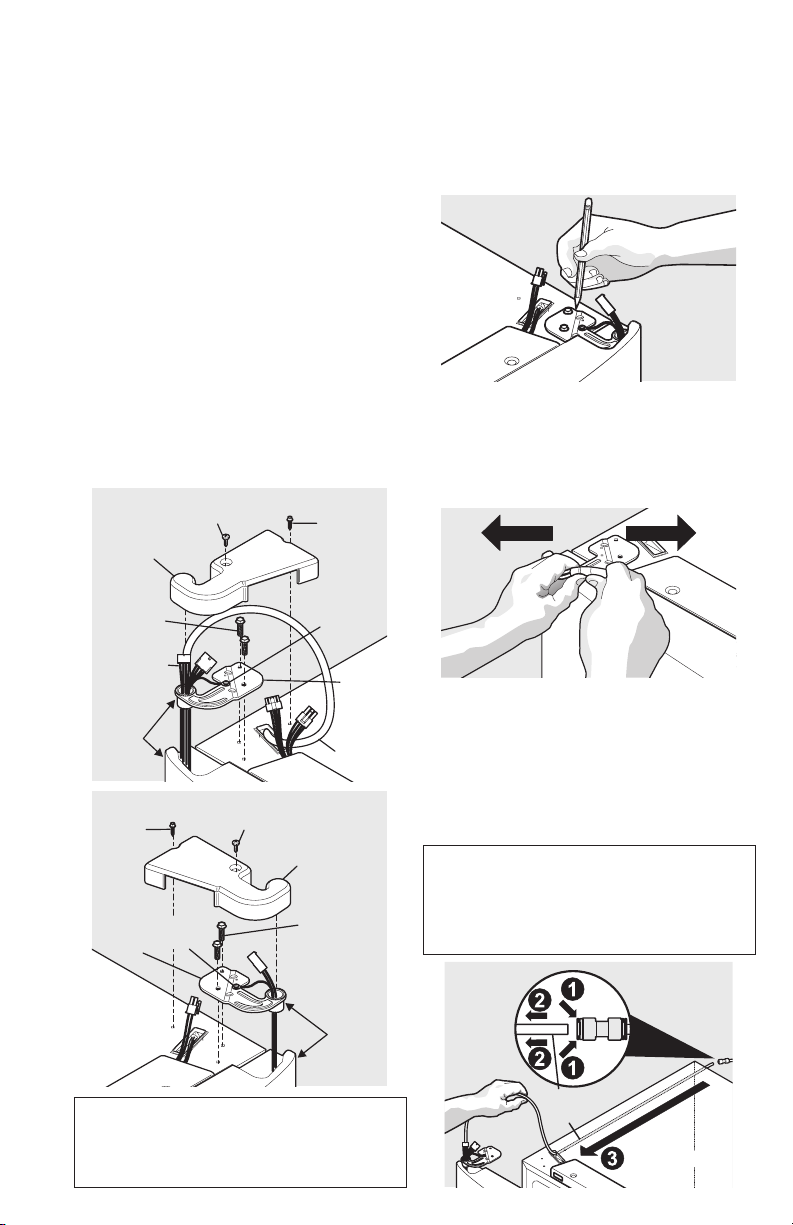

Door Removal Instructions

Front

Getting through narrow spaces

If your refrigerator will not t through an

entrance area, you can remove the doors.

Check rst by measuring the entrance.

To prepare for removing the doors:

1 Make sure the electrical power cord

is unplugged from the wall outlet.

2 Open the freezer drawer and remove

the toe grille (see Installation section).

3 Remove any food from the door

shelves and close the doors.

To remove the top hinge covers:

1 Remove the two screws from each

cover over the top door hinges.

2 Lift inside edge of hinge cover and

tilt back.

Rear

Cover

Screw

Ground

Screw

Top

Hinge

Water

Line

Top Hinge

Cover

Hinge

Screws

Top Hinge

Cover

Multi-wire

Cables

Leave

Hinge

With

Door

Rear

Cover

Screw

Top

Hinge

Hinge

Screws

Cover Screw

Front

Cover Screw

Ground

Screw

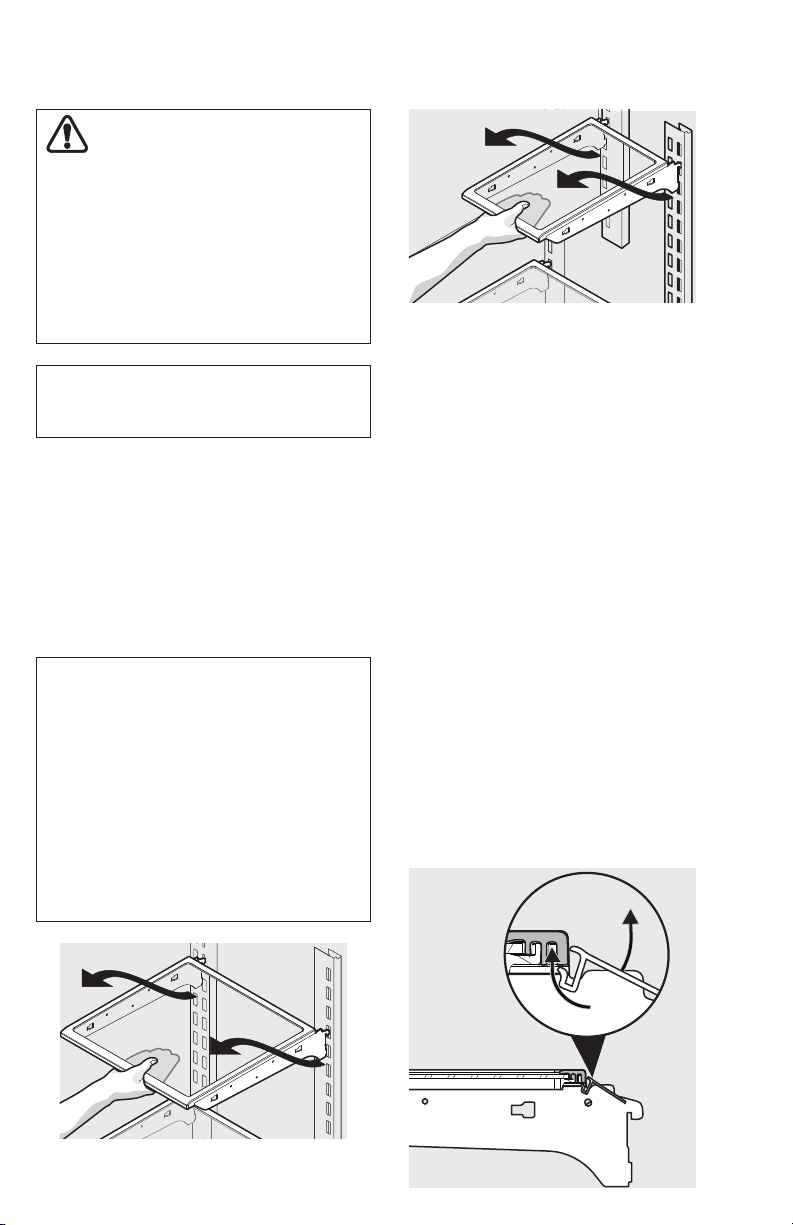

To remove the refrigerator doors

1 Trace lightly around the door’s top

hinges with a pencil. This makes

reinstallation easier.

2 Disconnect the harness by grasping

both sides of the connector rmly,

depress the latch, and pull apart.

Remove the two screws from the top

hinge. Lift the door o of the bottom

hinge and set it aside.

3 Detach the water tube from the

connector located behind the refrigerator

and pull the tube back out to the front

of the unit. The connector releases when

you press inward on the outer sleeve while

pushing the tube toward the connector

then while continuing to hold in the sleeve,

pull the tube away.

NOTE

Use care while pulling the water tube

from the unit to be sure that you do not

kink the tube.

Leave

Hinge

With

Door

NOTE

DO NOT remove the ground screw from

hinge.

Press

Press

Water

Line

Approximately

5 feet

11

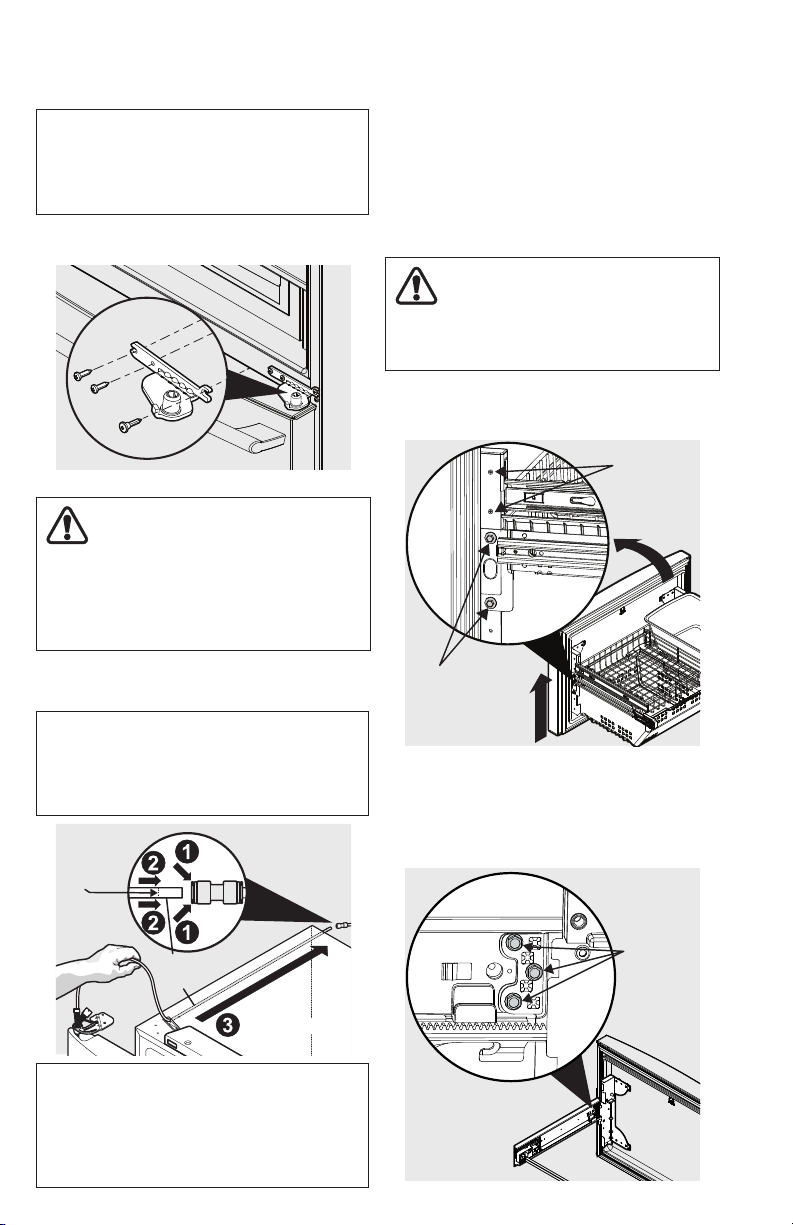

Page 12

Door Removal Instructions

NOTE

You will be pulling approximately ve feet of

water tube from the back of the refrigerator.

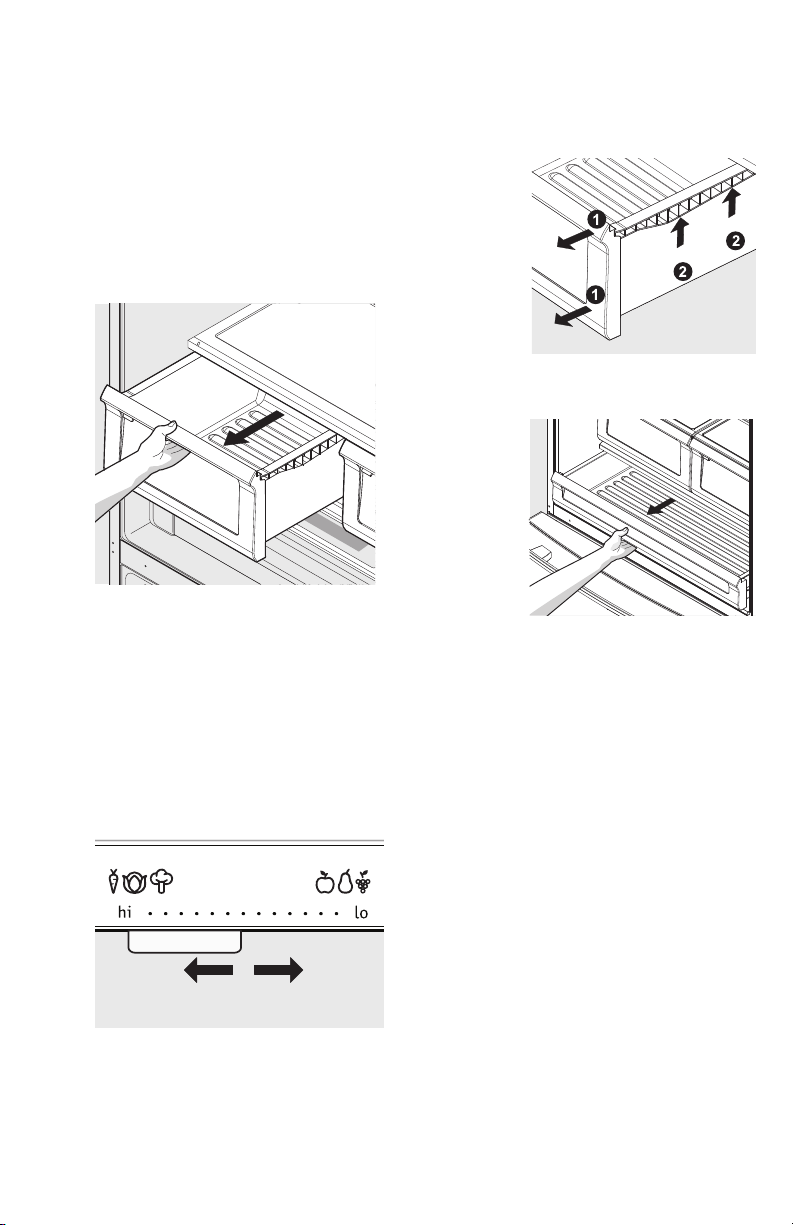

4 Unscrew the three lower hinge screws

and slide the hinge inwards.

Lower Hinge Removal

CAUTION

Be sure doors are set aside in a secure

position where they cannot fall and

cause personal injury, or damage to

the doors or handles.

To reinstall the refrigerator doors:

Reverse the above steps.

NOTE

Upon replacement, the tube needs to be

fully inserted up to the marking line.

Insert tube

up to the

marking

line

Water

Line

Press

Press

Approximately

5 feet

Once both doors are in place, ensure they

are aligned with each other and level

(Please see the Installation section for

more details), and replace the top hinge

cover.

Removing Freezer Drawer

CAUTION

Drawer is heavy. Use caution when

lifting.

1 Remove 4 hex head drawer screws.

2 Lift up drawer to remove.

DO NOT

Remove

Other

Screws

Remove

Hex Head

Drawer Screw

Replacing Freezer Drawer

1 Lower drawer back into place.

2 Replace 4 hex head drawer screws

and tighten.

DO NOT

Loosen

or

Remove

These 3

Hex

Screws

NOTE

When reinserting the water tube and

replacing the top hinge cover, use care

to be sure you do not kink the tube.

12

Page 13

Installing Door Handles

Door Handle Mounting Instructions

CAUTION

Wear gloves and safety goggles. Use extreme CAUTION when installing these

handles. The rounded end of the handles may be sharp.

1. Remove handles from carton and any other protective packaging.

2. Position fresh food handle end over upper and lower pre-installed shoulder bolts

(A) that are fastened into the doors ensuring the holes for the set screws are facing

towards the opposite door.

3. While holding handle rmly against door, fasten upper and lower Allen set screws (B)

with supplied Allen wrench.

4. Repeat steps two and three to install opposite handle. Ensure the holes for the set

screws are facing towards the rst door.

5. Position freezer handle end over left and right pre-installed handle mounts that are

fastened to the door, ensuring the holes for the set screws are facing down.

6. While holding handle rmly against door, loosely tighten far right Allen set screw (B)

with supplied Allen wrench until there is no gap between handle and door.

7. Still holding the handle rmly to the door, rmly tighten far left Allen set screw (B) with

supplied Allen wrench.

8. Return to the far right Allen set screw (B) and rmly tighten with supplied Allen wrench.

NOTE

All set screws should be tightened so that the screw is below the surface of the handle.

The handles should be drawn tight to freezer and refrigerator doors with no gaps.

Opening the opposite door while tightening the Allen screw makes installation easier.

The door handle may loosen over time. If this happens, tighten the set screws on

the handles.

Mounting Freezer HandlesMounting Refrigerator Handles

13

Page 14

Connecting the Water Supply

A water supply line made of ¼inch

WARNING

To avoid electric shock, which can

cause death or severe personal injury,

disconnect the refrigerator from

electrical power before connecting a

water supply line to the refrigerator.

CAUTION

To Avoid Property Damage:

Copper or Stainless Steel braided

tubing is recommended for the water

supply line. Water supply tubing made

of ¼ inch plastic is not recommended

to be used. Plastic tubing greatly

increases the potential for water leaks,

and the manufacturer will not be

responsible for any damage if plastic

tubing is used for the supply line.

DO NOT install water supply tubing in

areas where temperatures fall below

freezing.

Chemicals from a malfunctioning

water softener can damage the ice

maker. If your home has a water

softening system, ensure the softener is

maintained and working properly.

IMPORTANT

Ensure that your water supply line

connections comply with all local

plumbing codes.

Before Installing The Water Supply Line,

You Will Need:

Basic Tools: adjustable wrench, at-blade

screwdriver, and PhillipsTM screwdriver

Access to a household cold water line with

water pressure between 30 and 100psi.

(6.4mm) OD, copper or stainless steel

tubing. To determine the length of tubing

needed, measure the distance from the

ice maker inlet valve at the back of the

refrigerator to your cold water pipe. Then

add approximately 7feet (2.1meters),

so the refrigerator can be moved out for

cleaning (as shown).

A shuto valve to connect the water

supply line to your household water

system. DO NOT use a self-piercing type

shuto valve.

Do not re-use compression tting or use

thread seal tape.

A compression nut and ferrule (sleeve) for

connecting a copper water supply line to

the ice maker inlet valve.

To Connect Water Supply Line To Ice

Maker Inlet Valve

1 Disconnect refrigerator from electric

2 Place end of water supply line into sink

3 Remove plastic cap from water valve

4 If you use copper tubing - Slide brass

NOTE

Check with your local building authority

for recommendations on water lines and

associated materials prior to installing

your new refrigerator.

power source.

or bucket. Turn ON water supply and

ush supply line until water is clear.

Turn OFF water supply at shuto valve.

inlet and discard cap.

compression nut, then ferrule (sleeve)

onto water supply line. Push water

supply line into water valve inlet as far

as it will go (¼inch/6.4mm). Slide

ferrule (sleeve) into valve inlet and nger

tighten compression nut onto valve.

Tighten another half turn with a wrench;

DO NOT over tighten. See Figure 1.

14

Page 15

Connecting the Water Supply

Steel

If you use braided exible stainless steel

tubing - The nut is already assembled on

the tubing. Slide nut onto valve inlet and

nger tighten nut onto valve. Tighten

another half turn with a wrench; DO

NOT over tighten. See Figure 2.

5 With steel clamp and screw, secure

water supply line to rear panel of

refrigerator as shown.

6 Coil excess water supply line (copper

tubing only), about 2½turns, behind

refrigerator as shown and arrange coils

so they do not vibrate or wear against

any other surface. Do not kink tubing.

7 Turn ON water supply at shuto valve

and tighten any connections that leak.

8 Reconnect refrigerator to electrical

power source.

9 To turn ice maker on, lower wire signal

arm (freezer ice maker) or set the ice

maker’s On/O power switch to the

“On” position (fresh food ice maker).

NOTE

These instructions do not cover

after market ice maker installation.

Instructions in after market ice maker kit

should be used.

IMPORTANT

After connecting the water supply, refer

to “How to Prime the Water Supply

System” for important information

about priming an empty water supply

system.

Your refrigerator’s water supply system

includes several tubing lines, a water

lter, a water valve, and a water tank.

To ensure that your water dispenser

works properly, this system must be

completely lled with water when your

refrigerator is rst connected to the

household water supply line.

Plastic Water

Tubing to Ice

Maker Fill

Tube

Copper water line

from household

(Include enough tubing in loop to allow

moving refrigerator out for cleaning.)

Clamp

Brass

Compression

Water Valve

Water Valve

water supply

Nut

Ferrule

(Sleeve)

Copper

water line

Bracket

Valve Inlet

Figure 1

Plastic Water Tubing

to Ice Maker

Fill Tube

6 ft (1.8 Meters) Stainless Steel

water line from household

water supply

(Include enough tubing in loop to allow

moving refrigerator out for cleaning.)

Steel

Clamp

Stainless

Steel

water Line

Water Valve

Bracket

Valve Inlet

Water Valve

Figure 2

15

Page 16

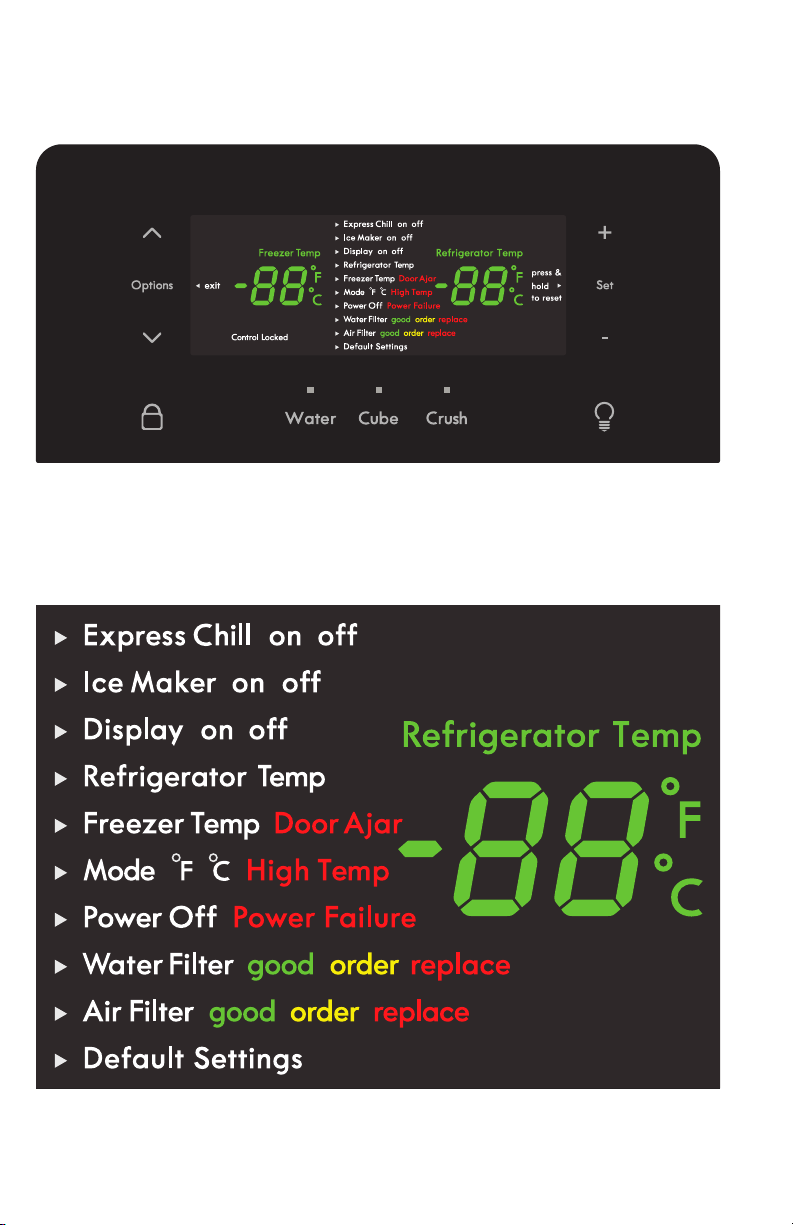

Controls - Dispenser Models

User Interface (options may vary)

Enlarged view of user interface display menu (options may vary)

16

Page 17

Controls - Dispenser Models

Options May Vary

options

(∧ or ∨)

exit Toggles the options and run

control

locked

express

chill on

o

ice maker

on o

display

on o

refrigerator

temp

freezer

temp

mode

°F °C

light Toggles dispenser light On

power o Press and hold for three

water

lter

air lter Displays the current status of

Used to enter and exit the

options menu and make

selections.

modes.

While in the locked state, you

will not be able to change

any settings on the display nor

dispense ice and water. The

“Control Locked” indicator

will ash and an audible

warning tone is played.

Activates a faster rate for

freezing food and increases

ice production in the freezer.

Deactivates after 12 hours.

Toggles the ice maker in the

refrigerator compartment

“ON” or “OFF”. In the “O”

state, the indicator will blink

when ice is dispensed.

Toggles the display of the

temperature settings On

and O.

Allows the temperature setpoints to be adjusted. Control

temperatures range from +33°F

/ +1°C to +47°F / +8°C.

Allows the temperature setpoints to be adjusted. Control

temperatures range from

-6°F / -21°C to +6°F / -15°C.

Toggles display from

Fahrenheit to Celsius.

and O.

seconds to turn o the

cooling system. It also turns

o the ice maker and all

dispenser functions. The

display will read “powero”.

Displays the current status of the

water lter (Good, Order, or

Replace). To reset the lter status

to “Good”, press and hold the

“set” key for three seconds.

the air lter (Good, Order, or

Replace). To reset the lter status

to “Good”, press and hold the

“set” key for three seconds.

default

settings

set

(+ or -)

water Press the “water” key to

cube Press the “cube” key to select

crush Press the “crush” key to select

While in the default option,

press and hold the “set” key

for three seconds to reset all

refrigerator settings to their

factory default settings.

Selects the current menu

selection option.

select water. An indicator

light will be illuminated

above the active feature.

cubed ice. An indicator light

will be illuminated above the

active feature.

crushed ice. An indicator light

will be illuminated above the

active feature.

Setting cooling temperatures

(options may vary)

NOTE

The recommended settings for a product

installed in a kitchen is 37˚F for the fresh

food compartment and 0˚F for the freezer.

IMPORTANT

If your product has food freezing in the

fresh food compartment, increase the

temperature setting 1 or 2 degrees.

IMPORTANT

If you place food within 1 inch in front

of the air ports, there may be the

chance of freezing food.

Air Port

17

Page 18

Controls - Dispenser Models

NOTE

Control features and alarms may vary

by model.

Alarms

Power Failure

In the event of a power failure, the power

fail alert will be illuminated. Press set to

acknowledge the alarm. Other modes

may be turned o until the alarm is

acknowledged. While a power fail alert is

displayed on the control panel, the unit will

continue normal operation. The power fail

alert on the control panel will be removed

once in the user acknowledges the power

fail condition by pressing any key on the

control panel. The high temp alarm may

also be illuminated until a safe operating

range temperature has been reached.

Freezer Temp

If the freezer temperature reaches 26°F

or greater, the alarm will sound and the

temperature will ash. You can disable

the alarm by pressing the set key but the

“High Temp” indicator will illuminate until

the temperature goes below 26°F.

Fresh Food Temp

If the fresh food temperature reaches

55°F or greater, the alarm will sound and

the temperature will ash. You can disable

the alarm by pressing the set key but the

“High Temp” indicator will illuminate until

the temperature goes below 55°F.

Door Ajar

If the freezer or fresh food doors have been

left open for ve minutes or more, an alarm

will sound and the door ajar indicator will

illuminate on the display. Press the set key to

reset any system alarms.

Flapper

When “Cube” or “Crush” is selected, if the

apper (or ice chute door) is being held

open by a jammed ice cube, an alarm will

sound for two minutes. The alarm will reset

after two minutes or when the ice cube is

removed and the set key is pressed to reset.

Sabbath Mode

The Sabbath Mode is a feature that

disables portions of the refrigerator and its

controls in accordance with observance of

the weekly Sabbath and religious holidays

within the Orthodox Jewish community.

Sabbath Mode is turned ON and OFF

by simultaneously pressing and holding

both the “∨” and “+” for ve seconds. The

display shows “Sb” while in Sabbath mode.

In the Sabbath Mode, the High Temp alarm

is active for health reasons. For example, if

the door is left ajar the High Temp alarm

is activated. The refrigerator will function

normally once the door is closed, without

any violation of the Sabbath/Holidays. The

High Temp alarm is permitted when cabinet

temperature is outside the safe zone for 20

minutes. The alarm silences itself after 10

minutes while the High Temp icon stays lit

until the Sabbath mode is exited.

For further assistance, guidelines for

proper usage and a complete list of

models with the Sabbath feature,

please visit the web at

http:\\www.star-k.org.

NOTE

While in Sabbath Mode, neither the

lights, dispenser, nor the control panel will

work until Sabbath Mode is deactivated.

Refrigerator stays in Sabbath Mode

after power failure recovery. It must

be deactivated with the buttons on the

control panel.

NOTE

Although you have entered the Sabbath

Mode, the ice maker will complete the

cycle it had already initiated. The ice

cube compartment will remain cold

and new ice cubes can be made with

standard trays.

18

Page 19

Controls - Non-Dispenser Models

A red indicator light will be illuminated above most active

features.

Touch the icon to activate the options below.

quick ice Increases the production of ice

water lter Press and hold for three seconds to reset

after lter change.

C/F Touch to toggle display from Fahrenheit to

Celsius.

default settings Resets all refrigerator settings such as temp,

temp display and tones to their factory

default settings.

Power on-off Press and hold for three seconds to turn off

the cooling system to clean the refrigerator.

It also turns off the ice maker. The temperature displays will read OFF.

alert reset Tones emitted by each key press can be

turned off based on user preference. The

sounds are muted when the red indicator is

lit. Warning signals will stay active.

IMPORTANT

Pressing the power on/o icon does not turn o power to

your refrigerator. You must unplug the power cord from the

wall outlet.

Setting Cooling Temperatures

Press the “∧” or “∨” indicator to adjust the temperature to

the desired setting.

The temperature display will begin to blink with the rst

touch. The display will time out after 10 seconds and return

to the basic display.

19

Page 20

Controls - Non-Dispenser Models

Alarms

Door Ajar If the door has been left open for

an extended period of time, an

alarm will sound and the door

ajar indicator will display on the

bottom display of the control

panel. The alarm is turned off by

closing the door. The mute sounds

key will blink to prompt the reset

of any active alarms. Press this

key to reset any system alarms.

High Temp In the event of a high tempera-

ture condition, the temperature

display will blink and display

“HI”. After 20 minutes, the

alarm will sound and the high

temp indicator will be red on the

bottom of the control panel. The

mute sounds icon will illuminate

until pressed, acknowledging the

alarm, at which time the highest

temperature reached will be

displayed and the refrigerator

will resume normal operation. In

case the high temp alarm is not

acknowledged at the rst alarm

sound time out, when the door

is rst opened, the alarm sound

will be repeated.

Power Fail In the event of a power failure,

the power fail alert will be

displayed and the temperature

display will blink until the mute

sounds icon is pressed, acknowledging the alarm. Other

modes may be turned off until

the alarm is acknowledged.

The power fail alert is turned

off and the refrigerator will

resume normal operation. The

high temp alarm may also be

illuminated until a safe operating range temperature has been

reached.

Sabbath Mode

The Sabbath Mode is a feature that

disables portions of the refrigerator and its

controls in accordance with observance of

the weekly Sabbath and religious holidays

within the Orthodox Jewish community.

Sabbath Mode is turned ON and OFF by

simultaneously pressing and holding both

the freezer “∨” and refrigerator “ ∧ ”

indicators for ve seconds. The display

shows “Sb” while in Sabbath mode.

In the Sabbath Mode, the High Temp

alarm is active for health reasons. For

example, if the door is left ajar the High

Temp alarm is activated. The refrigerator

will function normally once the door

is closed, without any violation of the

Sabbath/Holidays. The High Temp alarm

is permitted when cabinet temperature

is outside the safe zone for 20 minutes.

The alarm silences itself after 10 minutes

while the High Temp icon stays lit until the

Sabbath mode is exited.

For further assistance, guidelines for

proper usage and a complete

list of models with the Sabbath

feature, please visit the web at

http:\\www.star-k.org.

NOTE

While in Sabbath Mode, neither the

lights, nor the control panel will work

until Sabbath Mode is deactivated.

Refrigerator stays in Sabbath Mode

after power failure recovery. It must

be deactivated with the buttons on the

control panel.

NOTE

During the Sabbath Mode, the automatic

ice maker will continue to work and must

be manually turned o to be compliant

with the Sabbath observances.

20

Page 21

Automatic Ice & Water Dispenser (select models)

Counter Depth model, the ice bin will hold

CAUTION

For proper dispenser operation,

recommended water supply pressure

should fall between 30psi and 100psi.

Excessive pressure may cause the

system to malfunction.

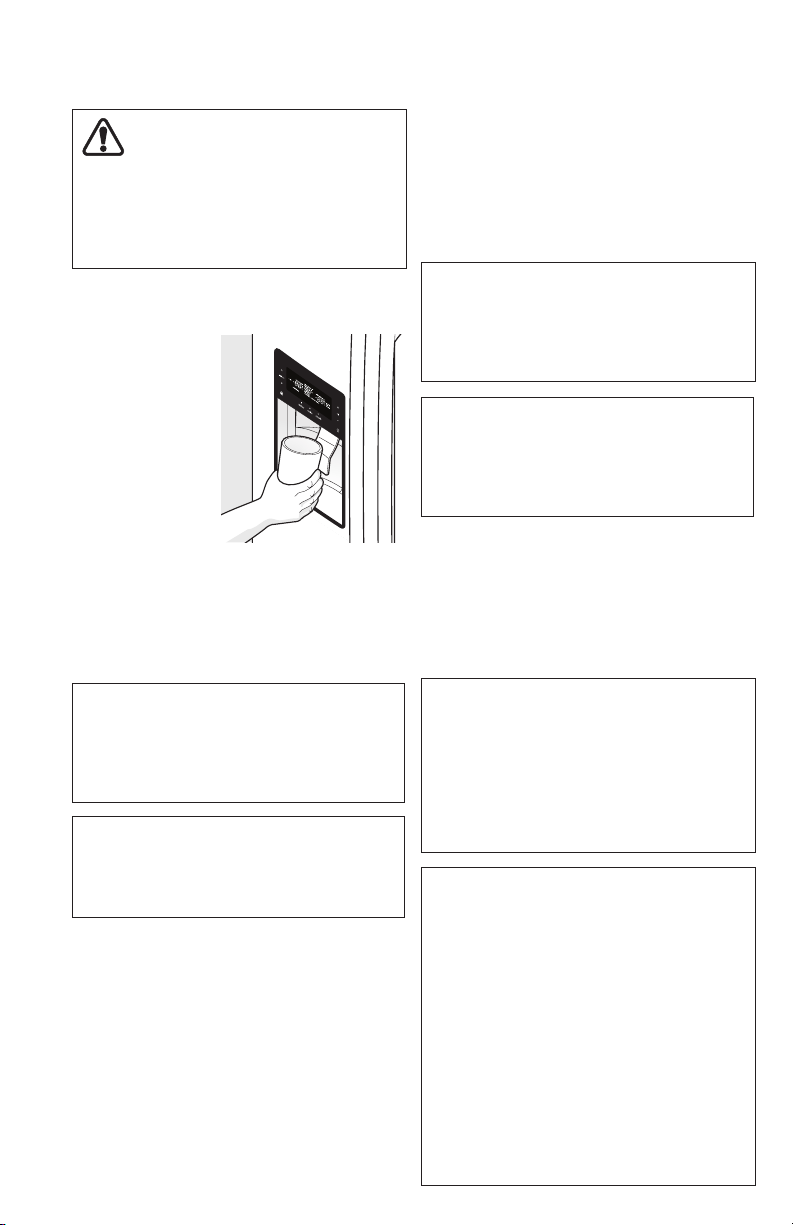

Priming the water supply system

1 Begin lling the system by pressing

and holding

a drinking

glass against

the water

dispenser

paddle.

2 Keep the

glass in this

position until

water comes

out of the

dispenser.

It may take

about 1½

minutes.

3 Continue dispensing water for about four

minutes to ush the system and plumbing

connections of any impurities (stopping to

empty the glass as necessary).

Dispenser (varies by

model)

about 4 pounds of ice.

Turning the fresh food ice maker on and o

Ice production is controlled by the ice

maker’s On/O feature on the control

panel. Pressing the On/O feature turns

the ice maker on & o.

IMPORTANT

Turning o the ice maker simply

disables ice making. You will still be

able to dispense existing ice, and you

will still be able to dispense water.

NOTE

The ice maker also has a built-in plastic signal

arm that automatically stops ice production

when the ice bin is full. This signal arm should

not be used to manually stop the ice maker.

Using the ice maker after installation

Before making ice for the rst time, be sure

to prime the water supply system. Air in new

plumbing lines can result in two or three

empty ice maker cycles. Furthermore, if the

system is not ushed, the rst ice cubes may

be discolored or have an odd avor.

NOTE

The water dispenser has a built-in device that

shuts o the water ow after three minutes

of continuous use. To reset this shuto device,

simply release the dispenser paddle.

NOTE

Dispensed water is not chilled. For

colder water, add ice to cup or

container before dispensing water.

Ice maker operation & care

After the refrigerator is installed properly and

has cooled for several hours, the ice maker can

produce ice within 24hours. The ice maker will

ll the ice bin from the rear. You must dispense

some ice to force the ice forward in the bin.

This will allow the bin to ll completely.

Ice Maker and Storage Bin Capacity

This ice maker should produce 2.5 to 3

pounds of ice per 24 hours.

In a Standard Depth model, the ice bin

will hold about 6.5 pounds of ice. In a

IMPORTANT

Your ice maker is turned on at the factory

so it can work as soon as you install your

refrigerator. If you cannot connect a water

supply, set the ice maker’s On/O feature

to O; otherwise, the ice maker’s ll valve

may make a loud chattering noise when it

attempts to operate without water.

IMPORTANT

On occasion, unusually small ice cubes may

be noticed in the bucket or in dispensed ice.

This could occur in normal operation of the

ice maker. If you start seeing these more

frequently, it may be an indication of low

water pressure or the water lter needs to

be replaced. As the water lter nears the

end of its useful life and becomes clogged

with particles, less water is delivered to the

ice maker during each cycle. Remember, if

it’s been six months or longer since you last

changed your water lter, replace the water

lter with a new one. Poor quality household

water may require the lter to be changed

more frequently.

21

Page 22

Automatic Ice & Water Dispenser (select models)

Ice maker/dispenser tips

If your refrigerator is not connected to a

water supply or the water supply is turned

o, turn o the ice maker as described in

the previous section.

The following sounds are normal when the

ice maker is operating:

- Motor running

- Ice dropping into ice bin

- Water valve opening or closing

- Running water

If you need a large quantity of ice at one time,

it is best to get cubes directly from the ice bin.

Ice cubes stored too long may develop an odd

avor. Empty the ice bin as explained below.

When dispensing cubed ice, it is normal

to have a small quantity of little pieces

along with the whole cubes.

To avoid splashing, dispense ice into your

container before adding liquids.

It is normal for ice to ll to the top of the ice bin.

CAUTION

If the water supply to your refrigerator is

softened, be sure the softener is properly

maintained. Chemicals from a water

softener can damage the ice maker.

Cleaning the ice maker

Clean the ice maker and ice bin at regular

intervals, especially prior to vacation or moving.

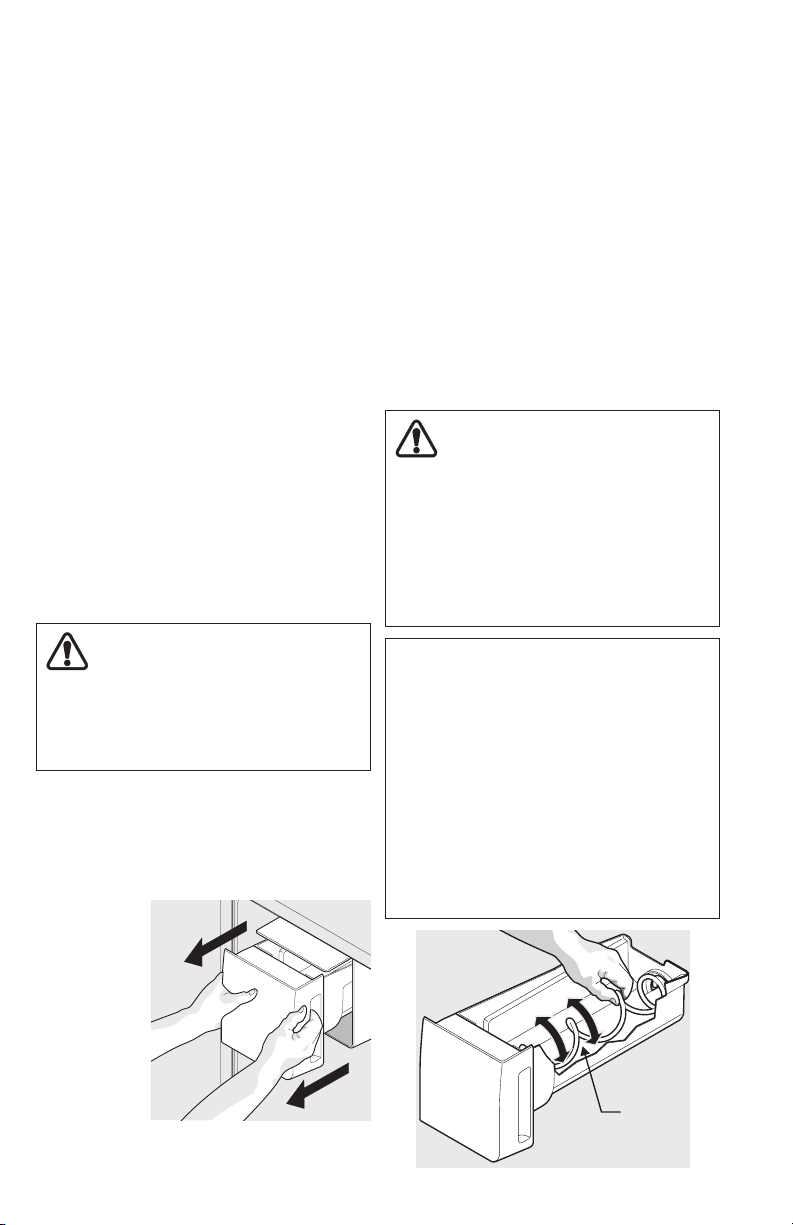

1 Turn o the ice maker.

2 Remove

the ice bin

by pulling

straight

out.

3 Empty

and

carefully

clean the

ice bin

with mild

detergent.

Do not

use harsh or abrasive cleaners. Rinse

with clear water.

Removing Ice Bin

4 Allow the ice bin to dry completely

before replacing in the freezer.

5 Replace the ice bin. Turn the ice maker on.

Remove and empty the ice bin if:

An extended power failure (one hour or

longer) causes ice cubes in the ice bin to

melt and refreeze together after power is

restored, jamming the dispenser mechanism.

You do not use the ice dispenser frequently.

Ice cubes will freeze together in the bin,

jamming the dispenser mechanism.

Remove the ice bin and shake to loosen

the cubes or clean as explained above.

CAUTION

NEVER use an ice pick or similar

sharp instrument to break up the ice.

This could damage the ice bin and

dispenser mechanism.

To loosen stuck ice, use warm water.

Before replacing the ice bin, make sure

it is completely dry.

IMPORTANT

When removing or replacing the ice bin,

avoid rotating the auger in the ice bin. If

the auger is accidentally rotated, you must

realign the auger by turning it in 45degree

turns (see below) until the ice bin ts

into place with the drive mechanism. If

the auger is not properly aligned when

replacing the ice bin, the refrigerator will

not dispense ice. The fresh food door also

may not close properly causing warm air

to leak into the fresh food compartment.

Auger

Adjusting Ice Bin Auger

22

Page 23

Automatic Ice Maker - Freezer (select models)

Operation & Care of the Freezer

Ice Maker (select models)

After the refrigerator is installed properly,

the ice maker can produce ice within

24hours. When using the ice maker for

the rst time, and in order for it to work

properly, it is necessary to clear air from

the water tubing and the lter. Furthermore,

if the system is not ushed, the rst ice

cubes may be discolored or have an odd

avor. Once the ice maker begins making

ice, allow the bin to ll completely, then

discard the rst FULL bin of ice on a

Standard Depth model, and the rst TWO

FULL bins of ice on a Counter Depth model.

Ice Maker and Storage Bin Capacity

This ice maker should produce between 2 and

2.5 pounds of ice per 24 hours depending on

usage conditions. In a Standard Depth model,

the ice bin will hold about 12 pounds of ice. In

a Counter Depth model, the ice bin will hold

about 7 pounds of ice.

IMPORTANT

Your ice maker is turned on at the

factory so it can work as soon as you

install your refrigerator. If you cannot

connect a water supply, lift the ice

maker’s wire signal arm to turn it o.

Otherwise, the ice maker’s ll valve may

make a loud chattering noise when it

attempts to operate without water.

Turning the ice maker on and o

The ice maker is turned o and on by

lifting/lowering

the ice maker’s

wire signal arm.

To gain access

to the ice

maker, pull the

freezer drawer

out. Lift the

wire signal arm

to turn the ice

maker OFF and

lower the wire signal arm to turn it ON.

OFF

Wire

Signal Arm

ON

Ice maker tips

The following sounds are normal when the

ice maker is operating:

- Motor running

- Ice dropping into ice bin

- Water valve opening or closing

- Running water

Ice cubes stored too long may develop an odd

avor. Empty the ice bin as explained below.

CAUTION

If the water supply to your refrigerator is

softened, be sure the softener is properly

maintained. Chemicals from a water

softener can damage the ice maker.

Express Chill Function

Your refrigerator is equipped with a

Express Chill Function for freezing food

at a faster rate, but it can also increase

ice production. This function terminates

automatically after 12 hours. This function

aects only the ice maker in the freezer.

NOTE

For Non Dispenser models choose the

Quick Ice Function.

Cleaning the ice maker

Clean the ice maker and ice bin at regular

intervals, especially prior to vacation or moving.

1 Turn o the ice maker.

2 Remove the ice bin.

3 Empty and carefully clean the ice bin

with mild detergent. Do not use harsh or

abrasive cleaners. Rinse with clean water.

4 Allow the ice bin to dry completely

before replacing in the freezer.

5 Replace the ice bin. Turn the ice maker on.

Remove and empty the ice bin if an

extended power failure (one hour or longer)

causes ice cubes in the ice bin to melt and

refreeze together after power is restored.

Remove the ice bin and shake to loosen

the cubes or clean as explained above.

CAUTION

NEVER use an ice pick or similar sharp

instrument to break up the ice. This

could damage the ice bin.

To loosen stuck ice, use warm water.

Before replacing the ice bin, make sure

it is completely dry.

23

Page 24

Storage Features

CAUTION

To avoid personal injury or property

damage, handle tempered glass

shelves carefully. Shelves may break

suddenly if nicked, scratched, or

exposed to sudden temperature

change. Allow the glass shelves to

stabilize to room temperature before

cleaning. Do not wash in dishwasher.

Half Spill-ProofTM Shelf

NOTE

Features may vary according to model.

Your refrigerator includes Spill-ProofTM

glass shelves that are designed to catch

and hold accidental spills.

You can easily adjust shelf positions

in the fresh food compartments to suit

your needs. The shelves have mounting

brackets that attach to slotted supports at

the rear of each compartment.

IMPORTANT

Be aware of the air seal located at

the rear of the shelf. Shelves located

on the left side should have the air

seal mounted on the far left side.

Shelves located on the right side should

have the air seal mounted on the far

right side. This is to ensure there is no

interference with the large air tower on

the back wall of the cabinet. This also

applies to the crisper shelves.

Change the Position of a Shelf

1 Remove all food from shelf.

2 Lift the front edge up and pull the

shelf out.

3 Replace by inserting the mounting bracket

hooks into the desired support slots.

4 Lower the shelf and lock into position.

Reposition the Air Seal

For slide-out shelves & crisper shelves:

1 Remove air seal by pushing down on

the ap with a downward rotation.

2 Position the air seal towards the outside

end of the shelf to avoid the air tower

when shelf is pushed back into place.

3 Install seal by sliding lower tab of seal

up into bottom rear slot of shelf with

seal at a downward angle then pulling

up on seal ap until seal sits snug on

back of shelf and ap sits at about a

10 degree angle from shelf surface.

Full Spill-ProofTM Shelf

24

Page 25

Storage Features

Drawers

Your refrigerator includes a variety of

storage drawers.

Crispers

Crisper drawers are designed for storing

fruits, vegetables, and other fresh produce.

Opening Crisper Drawer

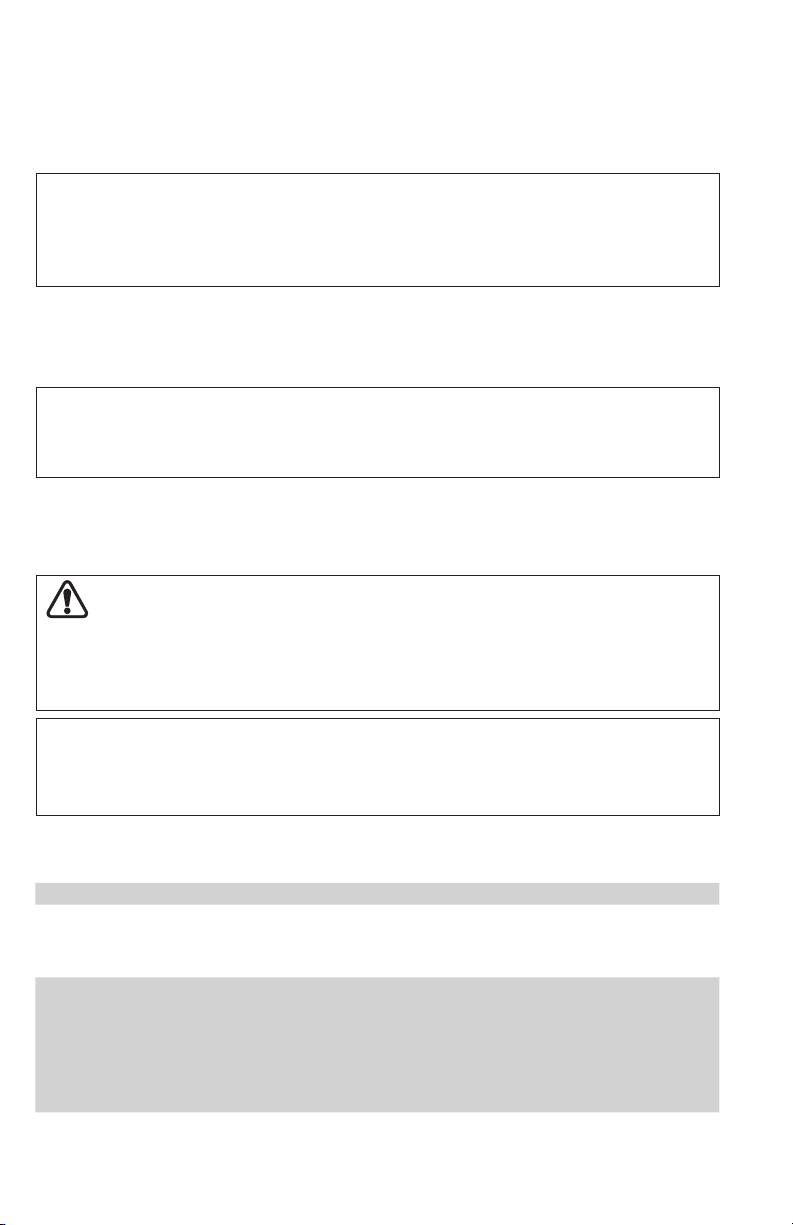

Crisper humidity control

Crisper drawers include a sliding control

for adjusting the humidity inside the crisper.

Leafy vegetables keep best when stored with

the Humidity Control set on Higher Humidity.

Fresh fruits keep best when stored with the

Humidity Control set on Lower Humidity.

To remove the Crisper Drawer for

cleaning:

1 Pull the

drawer

out until

it stops.

2 Lift the

front

slightly

and

remove

the

drawer.

Removing Crisper Drawer

Deli

drawer

Ideal for

storage of

deli meats

and cheese.

Doors

Storage bins

The doors to your fresh food compartment

use a system of modular storage bins.

All of these bins are removable for easy

cleaning. Some of them have xed

positions, while others can be adjusted to

your needs.

humidity control

Higher

Humidity

Adjusting Crisper Humidity

Lower

Humidity

25

Page 26

Storage Features

Door bins are ideal for storing jars, bottles,

cans, and large drink containers. They also

enable quick selection of frequently used items.

To change the position of an adjustable

door bin:

1 Remove all

food from

door bin.

2 Grip the bin

rmly with

both hands

and lift it

upward.

3 Remove the

bin.

4 Place the bin

just above

desired position.

5 Lower the bin onto supports until locked

in place.

Adjustable Door Bin

Accessories

(varies by

model)

Dairy

compartment

Use the dairy

compartment,

at the top of

the fresh food

compartment door, for short-term storage

of cheese, spreads, or butter. The dairy

compartment is designed to be warmer than

the open area and includes a lift-up cover and

a dairy divider (select models).

Dairy Compartment

Freezer Features (varies by model)

Clip

Freezer Baskets

To Remove Upper Freezer Basket

1 Find the side where the basket frame is

aligned to the clip opening. The basket

frame should be aligned to both front

and rear clips on the same side (either

left or right side).

2 If the basket frame is not aligned to

the left or right side, push the basket

sideways (to either side) until it is aligned.

3 By grabbing the basket wire frame close to

the frontal clip, pull up to take the basket

frame out.

4 Grab the basket frame close to the

rear clip and pull up until it comes out

of the clip.

5 Once one side of the basket is o

the clips or retainers, slide the basket

sideways until the other side of the

frame is aligned with the clip openings

on the opposite side of the freezer.

6 In the same way, pull up the basket

frame from the frontal and rear clips

until it is out of the clips.

7 Remove the basket.

Reverse the steps to reinstall the basket.

NOTE

If basket is not resting on stabilizer bar retainer

clips, the drawer will not close properly.

26

Page 27

Storage Features

Removing Freezer Basket Instructions

1 Locate the basket clips in the rear corners

of the basket and pull them out to remove.

2 Open fresh food doors completely.

3 Lift the basket up and remove.

Replacing Freezer Basket

Instructions

1 Place freezer basket back inside the

freezer drawer.

2 Replace clips by sliding them back

into the slots.

Location of

basket clip.

One each side.

Dividers Removal

Lift up on the front of the upper divider

and pull out.

Upper Basket

Divider

Retainers

Stabilizer

Bar

Upper Basket Divider

Squeeze handle and lift up in the center

of the divider to move it side-to-side. (The

divider cannot be removed.)

Lower Basket

Divider

Pull to Remove

Push to Replace

Plastic Lower Basket Divider

Tilt Wire Shelf

The freezer tilt wire shelf (located on

the inside of the freezer drawer) is not

designed to be removed.

27

Page 28

Storing Food and Saving Energy

Ideas for storing foods

Fresh food storage

• Keep the fresh food compartment

between 34°F and 40°F with an

optimum temperature of 37°F.

• Avoid overcrowding the refrigerator

shelves, which reduces air circulation

and causes uneven cooling.

• Avoid placing food in front of air ports.

(See Controls Section for illustration.)

Fruits and vegetables

• Store fruits and vegetables in crisper

drawers, where trapped moisture helps

preserve food quality for longer time

periods.

• Wash items and remove excess water.

• Wrap any items that have strong odors

or high moisture content.

Meat

• Wrap raw meat and poultry separately

and securely to prevent leaks and

contamination of other foods or surfaces.

• Use the deli drawer to store meat/poultry

for short-term storage. Any meat to be kept

longer than two days should be frozen.

Frozen food storage

• Keep the freezer compartment at 0°F or

lower.

• A freezer operates most eciently when

it is at least ⅔ full.

Packaging foods for freezing

• To minimize food dehydration and quality

deterioration, use aluminum foil, freezer

wrap, freezer bags, or airtight containers.

Force as much air out of the packages as

possible and seal them tightly. Trapped air

can cause food to dry out, change color,

and develop an o-avor (freezer burn).

• Wrap fresh meats and poultry with

suitable freezer wrap prior to freezing.

• Do not refreeze meat that has

completely thawed.

Loading the freezer

• Prior to grocery shopping, activate

“Express Chill” (some models) so that on

your return you can ensure your newly

purchased food designated for the freezer

will be preserved as quickly as possible.

• Activating “Express Chill” (some models)

also will help your freezer more eciently

maintain the selected temperature after

placing new purchases with pre-existing

frozen foods.

• Avoid adding too much warm food to the

freezer at one time. This overloads the

freezer, slows the rate of freezing, and

can raise the temperature of frozen foods.

• Leave a space between packages, so

cold air can circulate freely, allowing

food to freeze as quickly as possible.

Ideas for saving energy

Installation

• Locate the refrigerator in the coolest

part of the room, out of direct sunlight,

and away from heating ducts or

registers.

• Do not place the refrigerator next to heatproducing appliances such as a range, oven,

or dishwasher. If this is not possible, a section

of cabinetry or an added layer of insulation

between the two appliances will help the

refrigerator operate more eciently.

• Level the refrigerator so that the doors

close tightly.

Temperature settings

• Refer to the “Controls” section for

procedures on temperature settings.

Food storage

• Avoid overcrowding the refrigerator or

blocking cold air vents. Doing so causes

the refrigerator to run longer and use

more energy.

• Cover foods and wipe containers dry

before placing them in the refrigerator.

This cuts down on moisture build-up

inside the unit.

• Organize the refrigerator to reduce

door openings. Remove as many items

as needed at one time and close the

door as soon as possible.

• Do not place a hot container directly

on a cold shelf. Remember, such an

extreme temperature change may

damage the glass.

28

Page 29

Normal Operating Sounds and Sights

Understanding the sounds you

may hear

Your new, high-eciency refrigerator

may introduce unfamiliar sounds. These

sounds normally indicate your refrigerator

is operating correctly. Some surfaces on

oors, walls, and kitchen cabinets may

make these sounds more noticeable.

The following is a list of major

components in your refrigerator and the

sounds they can cause:

A Evaporator - Refrigerant through the

evaporator may create a boiling or

gurgling sound.

B Evaporator fan - You may hear air

being forced through the refrigerator

by the evaporator fan.

C Defrost heater - During defrost

cycles, water dripping onto the

defrost heater may cause a hissing

or sizzling sound. After defrosting, a

popping sound may occur.

D Automatic ice maker - When ice

has been produced, you will hear

ice cubes falling into the ice bin. Ice

maker fan, water valve activation,

and refrigerant gas uid may create

sounds from its operation.

E Electronic control & automatic

defrost control - These parts can

produce a snapping or clicking sound

when turning the cooling system on

and o.

F Condenser fan - You may hear air

being forced through the condenser.

G Compressor - Modern, high-eciency

compressors run much faster than

older models. The compressor may

have a high-pitched hum or pulsating

sound.

H Water valve - Makes a buzzing sound

each time it opens to ll the ice maker.

I Drain pan (not removable) - You may

hear water dripping into the drain

pan during the defrost cycle.

J Condenser - May create minimal

sounds from forced air.

L Ice dispensing paddle - When

dispensing ice, you will hear a

snapping, clicking, or popping sound.

M Motorized damper - May produce a

light humming during operation.

NOTE

Energy ecient foam in your

refrigerator is not a sound insulator.

NOTE

During automatic defrost cycle, a red

glow in the back wall vents of your

freezer compartment is normal.

Features vary by model

29

Page 30

Changing the Filter

Air lter (select models)

The air lter is located under the utility bin.

Replacing your KenmorecleanTM

air lter

To ensure optimal ltering of refrigerator

odors, you should change the air lter

every six months (the lter status light on

the Touch Panel prompts you to replace

the lter after six months).

1 Open the air lter door.

2 Remove the old lter and discard it.

3 Unpack the new lter and slide it into

the housing. The open face of the lter

should be installed facing downward.

4 To close the air lter door, push the top

and bottom to lock the door closed.

5 Press and hold the Air Filter Reset

button on the control panel for three

seconds. When the display changes

from “Replace” to “Good,” the status

has been reset.

6 The Air Filter Reset will turn itself o

after a few seconds.

Ordering replacement lters

Order new lters through the dealer

where you bought your refrigerator. You

may want to consider ordering extra lters

when you rst install your refrigerator.

Air Filter Replacement cartridge,

part #9920

30

Page 31

Changing the Filter

Filter Cartridge

Locating the Filters

Your refrigerator is equipped with water

ltering system. The water lter system lters

the water used to produce ice.

Water Filter

The water lter is located at the top right

side of the fresh food compartment.

Replacing the Water Filter

In general, you should change the water

lter every six months to ensure the highest

possible water quality. Water Filter Status

on the user interface prompts you to replace

the lter after a standard amount of water

(200 gallons/757 liters for Kenmorepure!TM)

has owed through the system.

If your refrigerator has not been used

for a period of time (during moving

for example), change the lter before

reinstalling the refrigerator.

Ordering Replacement Filters

To order your replacement lters, please

visit the dealer where you purchased your

refrigerator. Sears recommends that you

order extra lters when you rst install your

refrigerator, and that you replace your lters

at least once every six months.

Here is the product number to request

when ordering:

Kenmorepure!TM Water Filter

Part #046-9999

NOTE

When ordering your replacement lter,

please reorder the same lter type that is

currently in your refrigerator.

More about your Advanced Water Filter

The Kenmorepure!TM ice and water

lter system is tested and certied to

NSF/ANSI Standards 42 and 53 for

the reduction of claims specied on

the performance data sheet.

Do not use with water that is

microbiologically unsafe or of unknown

quality without adequate disinfection before

or after the system. Systems certied for

cyst reduction may be used on disinfected

waters that may contain lterable cysts.

Test & Certication Results:

• Rated Capacity - 200 gallons/757 liters

for Kenmorepure!TM ice and water lter

• Rated service ow - .50 gallons per minute

• Operating Temp.: Min. 33°F, Max. 100°F

• Maximum Rated Pressure - 100 pounds

per square inch

• Recommended Minimum Operating

Pressure: 30 pounds per square inch

To Replace your Kenmorepure!TM

Water Filter:

It is not necessary to turn the water supply

o to change the lter. Be ready to wipe up

any small amounts of water released during

the lter replacement.

1. Turn O ice maker.

2. Remove the lter by pushing on the end/

face of the lter.

3. Slide the old water lter cartridge straight

out of the housing and discard it.

4. Unpackage the new lter cartridge. Using

the alignment guide, slide it gently into the

lter housing until it stops against the snapin connector at the back of the housing.

5. Push rmly until the cartridge snaps into

place (you should hear a click as the

cartridge engages the snap-in connector).

6. Turn On ice maker.

7. To reset the water lter on your IQ-Touch

control, press and hold the water lter

icon for three seconds. When the display

changes from Red to Green, the status

has been reset.

31

Page 32

Care & Cleaning

Protecting your investment

Keeping your refrigerator clean maintains its appearance and prevents odor build-up. Wipe up

any spills immediately and clean the freezer and fresh food compartments at least twice a year.

NOTE

Do not use abrasive cleaners such as window sprays, scouring cleansers, ammable

uids, cleaning waxes, concentrated detergents, bleaches, or cleansers containing

petroleum products on plastic parts, interior doors, gaskets, or cabinet liners. Do not

use paper towels, scouring pads, or other abrasive cleaning materials.

• Never use metallic scouring pads, brushes, abrasive cleaners, or strong alkaline

solutions on any surface.

• Never use CHLORIDE or cleaners with bleach to clean stainless steel.

• Do not wash any removable parts in a dishwasher.

• Always unplug the electrical power cord from the wall outlet before cleaning.

NOTE

If you set your temperature controls to turn o cooling, power to lights and other

electrical components will continue until you unplug the power cord from the wall outlet.

• Remove adhesive labels by hand. Do not use razor blades or other sharp instruments

which can scratch the appliance surface.

• Do not remove the serial plate. Removal of your serial plate voids your warranty.

• Before moving your refrigerator, raise the anti-tip brackets so the rollers will work

correctly. This will prevent the oor from being damaged.

CAUTION

Pull the refrigerator straight out to move it. Shifting it from side to side may damage

ooring. Be careful not to move the refrigerator beyond the plumbing connections.

Damp objects stick to cold metal surfaces. Do not touch refrigerated surfaces with

wet or damp hands.

IMPORTANT

If you store or move your refrigerator in freezing temperatures, be sure to completely drain

the water supply system. Failure to do so could result in water leaks when the refrigerator is

put back into service. Contact a service representative to perform this operation.

Refer to the guide on the next page for details on caring and cleaning specic areas

of your refrigerator.

Vacation and moving tips

Occasion Tips

Short

Vacations

Long

Vacations

Moving • Remove all food and ice.

• Leave refrigerator operating during vacations of three weeks or less.

• Use all perishable items from refrigerator compartment.

• Turn automatic ice maker o and empty ice bucket, even if you will

only be gone a few days.

• Remove all food and ice if you will be gone one month or more.

• Turn the cooling system o (see “Controls” section for location of On/

O button) and disconnect power cord.

• Turn water supply valve to closed position.

• Clean interior thoroughly.

• Leave both doors open to prevent odors and mold build-up. Block

doors open if necessary.

• If using a handcart, load from the side.

• Adjust rollers all the way up to protect them during sliding or moving.

• Pad cabinet to avoid scratching surface.

32

Page 33

Care & Cleaning

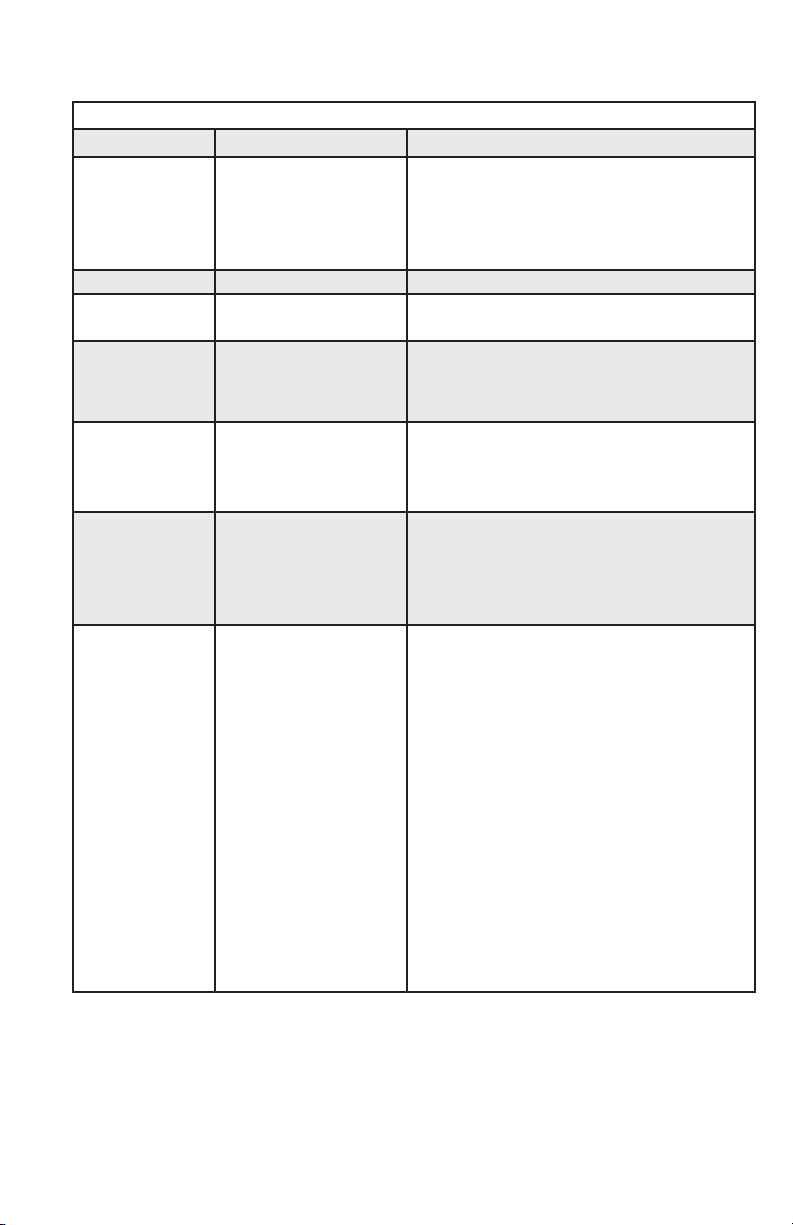

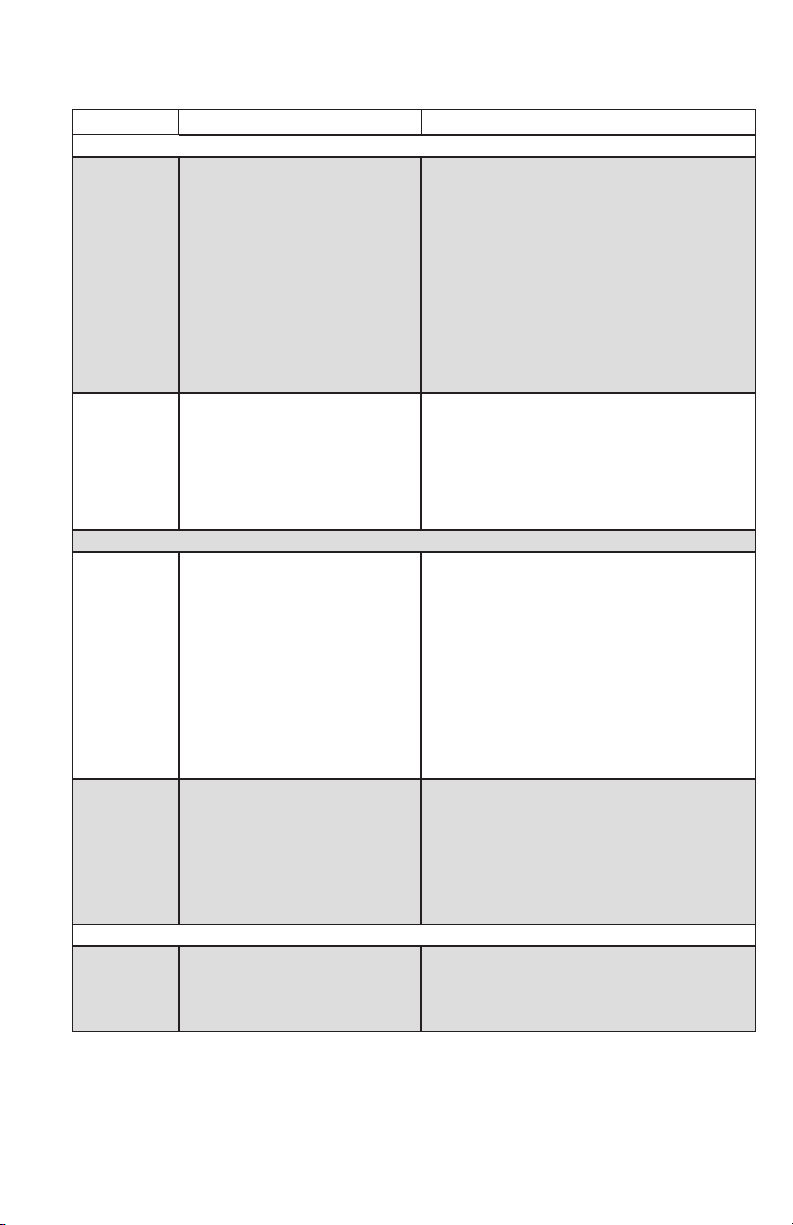

Care & Cleaning Tips

Part What To Use Tips and Precautions

Interior & Door

Liners

Door Gaskets • Soap and water • Wipe gaskets with a clean soft cloth.

Drawers & Bins • Soap and water • Use a soft cloth to clean drawer runners

Glass Shelves • Soap and water

Toe Grille • Soap and water

Exterior &

Handles

Exterior &

Handles

(Stainless Steel

Models Only)

• Soap and water

• Baking soda and

water

• Glass cleaner

• Mild liquid sprays

• Mild liquid sprays

• Vacuum attachment

• Soap and water

• Non Abrasive Glass

Cleaner

• Soap and water

• Stainless Steel

Cleaners

• Use two tablespoons of baking soda

in one quart of warm water. Be sure to

wring excess water out of sponge or

cloth before cleaning around controls or

any electrical part.

and tracks.

• Allow glass to warm to room

temperature before immersing in warm

water.

• Vacuum dust from front of toe grille.

Remove toe grille (see Installation

Instructions). Vacuum backside, wipe with

sudsy cloth or sponge. Rinse and dry.

• Do not use commercial household

cleaners containing ammonia, bleach

or alcohol to clean handles. Use a soft

cloth to clean smooth handles. DO NOT

use a dry cloth to clean smooth doors.

• Never use CHLORIDE or cleaners with

bleach to clean stainless steel.

• Clean stainless steel front and handles with

non-abrasive soapy water and a dishcloth.

Rinse with clean water and a soft cloth.

Use a non-abrasive stainless steel cleaner.

These cleaners can be purchased at most

home improvement or major department

stores. Always follow manufacturer’s

instructions. Do not use household cleaners

containing ammonia or bleach.

• NOTE: Always clean, wipe and dry with

the grain to prevent scratching. Wash

the rest of the cabinet with warm water

and mild liquid detergent. Rinse well,

and wipe dry with a clean soft cloth.

33

Page 34

Before You Call

Concern Potential Cause Common Solution

Automatic Ice Maker

Ice maker is

not making

any ice.

• Ice maker is turned o.

• Refrigerator is not

connected to water line or

water valve is not open.

• The water supply line is

kinked.

• The water lter is not

seated properly.

• The water lter may be

clogged with foreign

material.

• Freezer ice maker wire

signal arm is being held

up by an item not allowing

it to go in the on or down

position.

• Turn on ice maker. For the fresh food

ice maker, press ice maker on-o once.

For the freezer ice maker, lower the

arm to turn the ice maker on, or raise

it and snap it in its upper position to

turn the ice maker o.

• Connect the unit to the household

water supply and ensure the water

valve is open.

• Ensure that the supply line does not

kink when the refrigerator is pushed

into place against the wall.