Kenmore 229965570, 229965560, 229965550, 229965540, 229965530 Owner’s Manual

...

Electronic Ignition

Gas-Fired

Hot Water

Induced Draft

Boiler

• Installation

• Operation

• Repair Parts

WARNING: Improper installation, adjustment, alteration,

service or maintenance can cause injury or property

damage. Refer to this manual. For assistance or

information consult a qualified installer, service agency

or the gas supplier. Natural gas boilers are not to be

converted to Propanr gas.

Warranty..........................................................2

RulesforSafe Installationand Operation.......3

BoilerRatingsand Capacities.........................4

BeforeYou Start..............................................5

Locatingtheboiler..........................................6

FreshAirforCombustion ................................7

Installation-SystemPiping.................................9

Chimney and VentPipeConnection...............11

HorizontalVenting...........................................14

Gas Supply Piping ........................................ 20

Electrical Wiring/Sequence of Operation ....... 21

Wiring Diagram ............................................. 22

Equipment and Optional Accessories - What

They Do ........................................................ 23

Checking and Adjusting ................................. 27

Maintaining "Your Boiler ................................ 28

Service Hints ................................................. 30

Repair Parts ................................................ 31

SEARS

KENMORE CAST IRON BOILERS

FULL ONE YEAR WARRANTY ON HOT WATER AND GAS STEAM CAST IRON BOILERS

For one (1) year from the date of installation, when this boiler is installed and maintained inaccordance

with our instructions. Sears will repair defects inmaterial or workmanship in the boiler, free of charge.

LIMITED 12 YEAR WARRANTY ON STEAM CAST IRON BOILERS

After one (1)year and thoughtwelve(12) yearfrom the dateofinstallation,Sears willfumish a replacement

heat exchange, ifthe heat exchanger inthe boiler isdefective. YOU PAYFOR LABOR.

LIMITED 20 YEAR WARRANTY ON HOT WATER CAST IRON BOILERS

After one (1) year and through twenty (20) years from the date of installation,Sears willfurnisha

replacement heat exchanger in the boiler is defected YOU PAY FOR LABOR.

SEARS INSTALLATION WARRANTY

In addition to any warranty extended to you on the Sears merchandise involved, which warranty becomes

effective the date the merchandise is installed, should the workmanship of any Sears arranged installation

prove faulty with one year, Sears will, upon notice from you, cause such faults to be corrected at no

additional cost to you.

FOR WARRANTY SERVICE, SIMPLY CONTACT THE NEAREST SEARS STORE OR

SERVICE CENTER THROUGHOUT THE UNITED STATES. This warranty gives you specific

legal rights, and you may also have other rights which vary from state to state.

IMPORTANT

The following are the responsibilities of the user

and are cover by the Warranty.

1. Filter clearing or replacement.

2. Damage to unit or unsatisfactory operation

due to improper cleaning or use of unit in

corrosive atmosphere.

3. Damage to unit or unsatisfactory operation

due to blown fuses or inadequate or interrupted

electrical protective devices.

4. Damage to unit caused by _e use of components

or other accessories not compatible with the unit:

5. If the unit is removed from the place it was

originally installed, this Warranty becomes void.

6. Damage to the unit caused by accident, abuse,

negligence, misuse, riot,fire, flood,or acts of God.

SEARS ROEBUCK AND COMPANY

D/817WA

Hoffman Estates, IL 60179

2

1. Readthe Owner's Manualfor SaleOperation

carefully. Failure to follow the rules for safe

operation and the instructions can cause a

malfunction of the boiler and result in death,

serious bodily in jury, and/or property damage.

2. Check your local codes and utility requirement

before installation. The installation must be in

accordance with their directives.

3. Before servicing, allow boiler to cool. Always

shut off any electricity and gas to boiler

when working on it. This will prevent any

electrical shocks or burns.

4. Never test for gas leaks with an open flame.

Use soap and check all connections. This

will avoid any possibility of fire or explosion.

5. Be certain your boiler will be using the

correct gas. Overfiring will result in

premature failure of the boiler sections and

cause dangerous operation.

6. Never vent this boiler into an enclosed

space. Always vent to the outside. Never

vent to another room or inside a building.

7. Be sure there is adequate air supply for

complete combustion.

8. Follow a regular service and maintenance

schedule for efficient and safe operation.

TOOLS

Pipe Wrench

Screwdriver

Tin Snips

6 foot tape or folding rule

Hack Saw

LP Torch, if you have copper piping

Pipe cutter and threading tools

(for iron pipe systems)

The following booklets will help you in making the installation:

Electrical Wiring -Available at Sears from the Plumbing, Heating or Electrical Departments at

nominal cost.

Pipe joint compound suitable for natural and propane gas.

Iron or copper pipe for the water lines.

Black pipe for the gas lines.

Miscellaneous fittings.

Solder and flux if you have copper piping.

MATERIALS

American National Standards, Installation of Gas Appliance and Gas Piping, National Fuel

Gas Code ANSIZ223.1 - latest revision.

Obtain from American Gas Association, 1515 Wilson Boulevard, Arlington (Roslyn), VA 22209

3

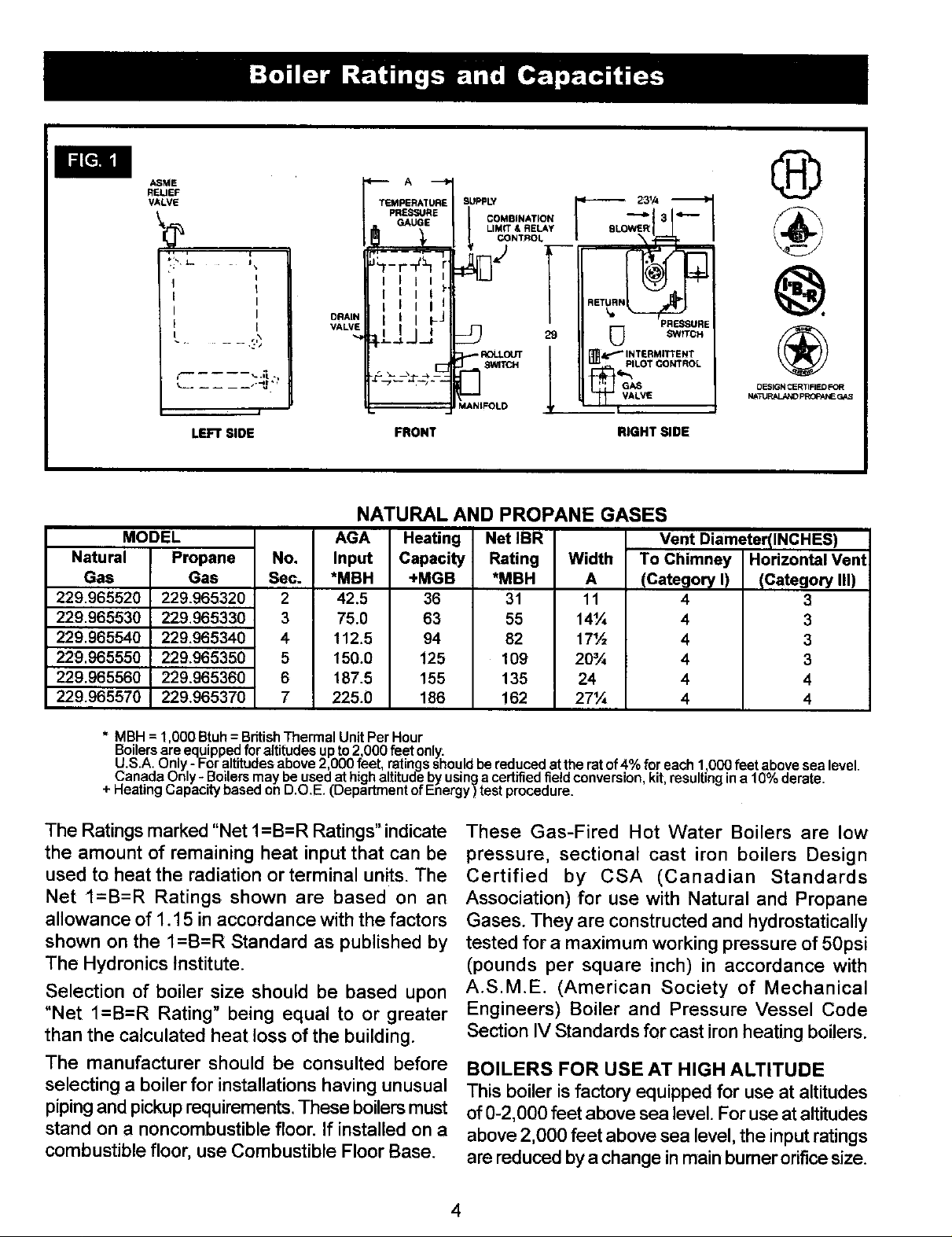

ASME

RELIEF

VALVE

TEMPERATURE

PRESSURE

LiMrr & RELAY

CONTROL

23111

®

3 <-'--

LEFT SIDE

MODEL

Natural Propane

Gas Gas

229.965520 229.965320

229.965530 229.965330

229.965540 229,965340

229.965550 229.965350

229.965560 229.965369

229.965570 229,965370

I

I

I

I

I

No. Input

Sec. *MBH

2 42,5

3 75.0

4 112.5

5 150.0

6 167.5

7 225.0

I I I I

t I I

DRAII_

VALVE

AGA Heating

I I

I I I-

I I I

Swrm_

IANIFOLD 2

FRONT RIGHT SIDE

NATURAL AND PROPANE GASES

Net IBR Vent Diameter(INCHES)

Capacity

+MGB

36

63

94

125

155

186

Rating

*MBH

31

55

82

109

135

162

Width

14¼

17%

20¾

24

27¼

U _tTCH

[_ _,_" INTERMnTEHT

_ILOT CONTROL

L

To Chimney

A

11

(Category I)

@

®

DESIGN CER11FIED FOR

NA_nJp_,LAND pRGPANE GA_

Horizontal Vent

(Category III)

4

4

4

4

4

4

3

3

3

3

4

4

* MBH = 1,000 Btuh = British Thermal Unit Per Hour

Boilers are equipped foraltitudes upto2,000 feet only: o

U.S.A. Only -For altitudes above 2,000 feet, ratings should be reduced at the rat of4 _ for each 1,000 feet above sea level.

Canada Only - Boilers may be used at highaltitude by using a certified field conversion, kit,resulting in a 10% derate.

+ Heating Capacity based on D.O.E. (Department of Energy}test procedure.

The Ratings marked "Net 1=B=R Ratings" indicate

the amount of remaining heat input that can be

used to heat the radiation or terminal units. The

Net I=B=R Ratings shown are based on an

allowance of 1.15 in accordance with the factors

shown on the I=B=R Standard as published by

The Hydronics Institute.

Selection of boiler size should be based upon

"Net I=B=R Rating" being equal to or greater

than the calculated heat loss of the building.

The manufacturer should be consulted before

selecting a boiler for installations having unusual

piping and pickup requirements. These boilers must

stand on a noncombustible floor. If installed on a

combustible floor, use Combustible Floor Base.

These Gas-Fired Hot Water Boilers are low

pressure, sectional cast iron boilers Design

Certified by CSA (Canadian Standards

Association) for use with Natural and Propane

Gases. They are constructed and hydrostatically

tested for a maximum working pressure of 50psi

(pounds per square inch) in accordance with

A.S.M.E. (American Society of Mechanical

Engineers) Boiler and Pressure Vessel Code

Section IV Standards for cast iron heating boilers.

BOILERS FOR USE AT HIGH ALTITUDE

This boiler is factory equipped for use at altitudes

of 0-2,000 feet above sea level. For use at altitudes

above 2,000 feet above sea level, the input ratings

are reduced by a change in main burner orificesize.

4

Checktobesureyouhavethe rightsizeboilerbefore

startinathe installation.Seeratingandcapacitytable

onpreviouspage.Also besurethe newboilerisfor

the type of gas you are using. Check the rating

plate onthe rightside of the boiler.

You must see that the boiler is suppliedwith the

correcttypeofgas,fresh airfor combustion,and a

suitable electrical supply. Also, the boiler must be

connected to a suitable chimney or horizontal venting

system and an adequate piping system. Finally, a

thermostat, properly located, is needed for control

of the heating system. If you have any doubts as to

the various requirements, check with localauthorities

and obtain professional help where needed. Take

the time to complete all of the steps for SAFE and

PROPER operation of the heating system.

Were required by the authority having jurisdiction,

the installation must conform toAmerican Society

of Mechanical Engineers Safety Code for Controls

and Safety Devices for Automatically Fired

Boilers, No. CSD-I*

The installation must conform to the requirements

of the authority having jurisdiction or, in the

absence of such requirements, to the National

Fuel Gas Code, ANSI Z223. l-latest revision.

The following steps are all necessary for proper

installation and safe operation of your boiler.

1. LOCATING THE BOILER

2. FRESH AIR FOR COMBUSTION

3. SYSTEM PIPING

4. CHIMNEY & VENT PIPE CONNECTION

5. GAS SUPPLY PIPING

6. ELECTRICAL WIRING

7. CHECKING &ADJUSTING

KEEP BOILERAREA CLEAN AND FREE FROM COMBUSTIBLE MATERIALS, GASOLINE I

AND OTHER FLAMMABLE VAPORS AND LIQUIDS

I

I

If your boiler is part of a planned heating system,

locate it where shown on your plan. If boiler isto

be part of an existing system, it is usually best to

put itwhere the old one was. !f you plan to change

location, you will need additional materials as well

as an adequate base. The following rules apply:

1. The boiler must be level. Metal shims may be

used under base legs for final leveling.

2. Use a raised base iffloor can become wet or damp.

3. The vent pipe connection should be as short

as possible.

4. Additional clearances for service may exceed

clearances for fire protection. Always comply

with the minimum fire protection clearances

shown on the boiler.An 18 inch clearance should

be maintained on any side where passage is

required to access another side for cleaning,

servicing, inspection or replacement of any part

that may need attention. An 18 inch clearance is

recommended on the control side for servicing.

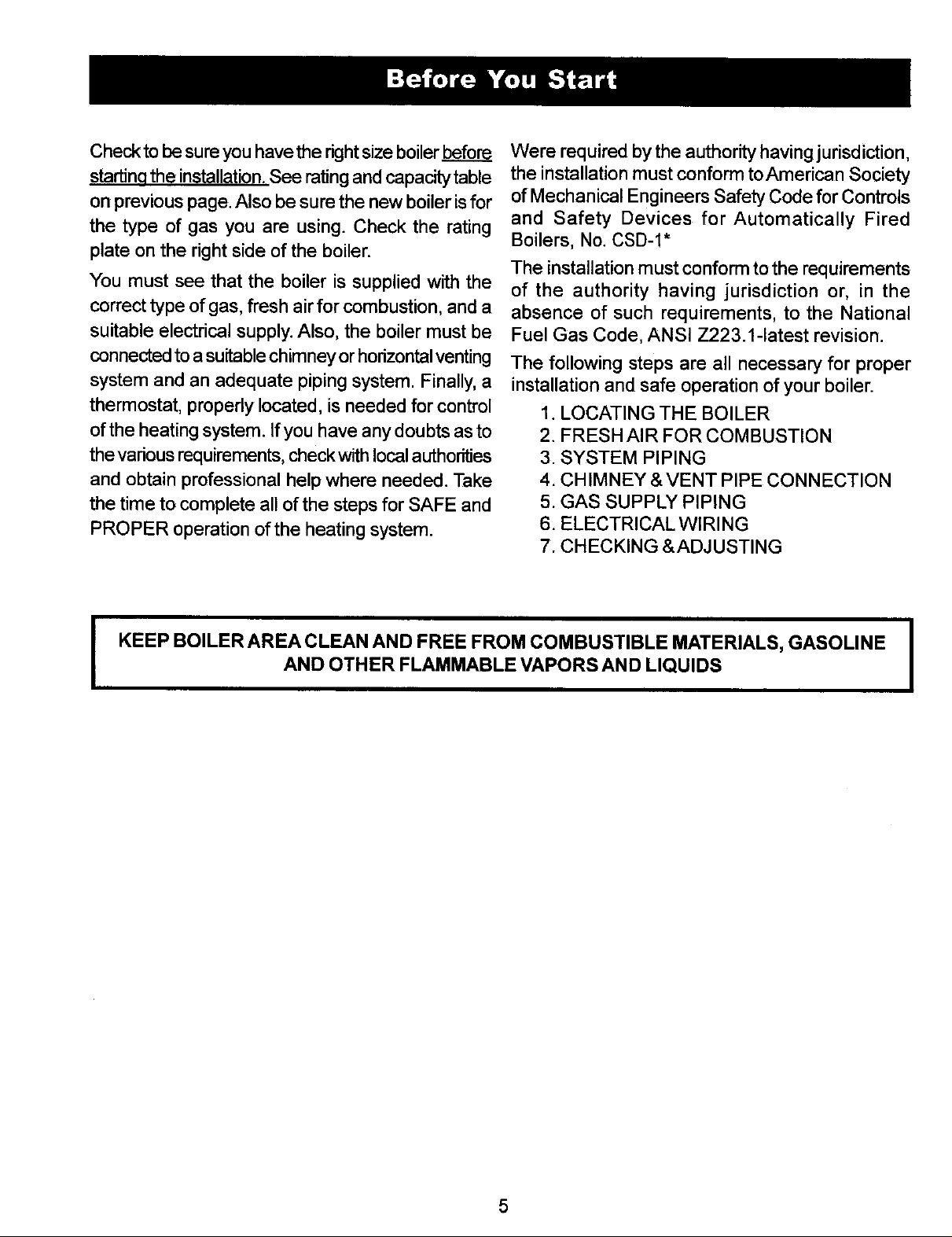

Figure 2 shows minimum clearances to

combustible construction. Rooms that are large

in comparison with the size of the boiler are

defined as rooms having a volume equal to or

greater than 16 times the volume of the boiler.

Where the actual ceiling height of a room is

greater that 8', the volume of a room shall be

figured on the basis of a ceiling height of 8'.

Determination of room size should be based

on the total volume of all gas fired equipment

installed in theroom. Consult section 6.3.1 of

the National Fuel Gas Code for further

information, including approved methodes for

reducing clearances in large room.

5. Equipment shall be installed in a location in

which the facilities for ventilation permit

satisfactory combustion of gas, proper venting,

and maintenance of ambient temperature at

safe limits under normal conditions of use.

Equipment shall be located so as not to interfere

with proper circulation of air. When normal

infiltration does not provide the necessary air,

outside air shell be introduced (See Page 4 -

"Fresh Air for Combustion").

6. Advise owner to keep air passages free of

obstructions. Ventilating and combustion air

must enter boiler room without restrictions.

boiler on Combustible Floor Base No 14614031

for 2-5 section boilers, or No. 14614032 for 6-7

section boilers. We use a 2" cloudlet pad as a

combustible floor base. These are available from

your Iocalsupplier. Use 24" x 30" pad for 2-5

section boilers, and a minimum 30" x 30" pad for

6-7 sections boilers. The boiler must be centered

on the combustible floor base.

8.The boiler shall be installed such that the automatic

gas ignition system components are protected

from water (dripping, spraying, rain, etc.) during

appliance operation and service(circulator

replacement, control replacement, etc..)

Alcove, or

Room Not Large Room Large

In Comparison In Comparison

With Boiler With Boiler

Top 6" 6"

Rear 6" 6"

Control Side 8" 8"

Opposite Side 6" 6"

Front 18" 18"

FlueNent Connector 6" 6"

Near Boiler Piping 1" 1"

Minimum Room

Boiler Boiler Volume Required

Size Volume To Be Large

(Cu. Ft.) Room (Cu. Ft)*

2 sect. 4.3 68.7

3 sect. 5.6 89

4 sect. 6.8 109.3

5 sect. 8.1 129.5

6 sect. 9.4 149.8

7 sect. 10.6 170.1

THIS UNIT MUST BE SET ON A CONCRETE OR OTHER

NONCOMBUSTIBLE MATERIAL BASE OR FLOOR. IT MUST NOT

BE INSTALLED ON CARPETING

I

I

7.The floor supporting the boiler must be

noncombustible. If it is combustible, place the

6

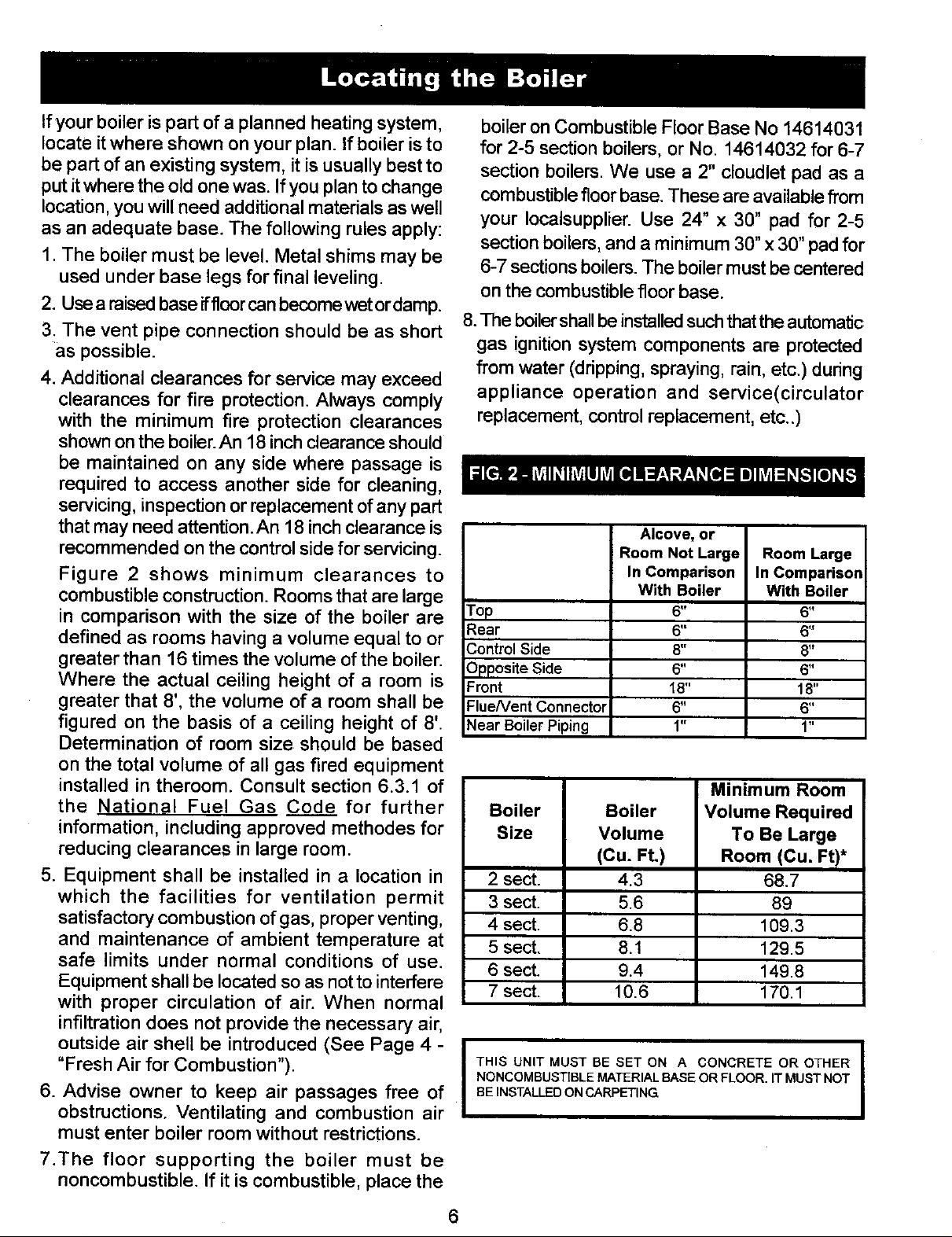

Combustion and Ventilation, of the National fuel Gas Code, ANSI Z223.1-latest revision, or

I Provision for combustion and ventilation air must be in accordance with Section 5.3, Air for I

applicable provisions of the local building codes.

I

WARNING

Be sure provide enough fresh airfor combustion.

Enough air insures proper combustion and

assures that hazard will develop due to the

lack oxygen.

You must provide for enough fresh air to assure

proper combustion. The fire in the boiler uses

oxygen. It must have a continuous supply. The air

in a house contains only enough oxygen to supply

the burner for a short time. Outside air must enter

the house to replace that used bythe burner. Study

following examples I and 2 to determine your fresh

air requirements.

EXAMPLE 1: Boiler Located in Unconfined Space

An unconfned space is defined as a space whose

volume is not less than 50 cubic feet per 1,000

Btu per hour ofthe total input rating of allappliances

installed in that space.

If your boiler is in an open area (unpartitioned

basement) in a conventional house, the air that

leaks through the cracks around doors and

windows will usually be adequate to provide air

for combustion. The doors should not fit tightly.

Do not caulk the cracks around the windows.

Equipment located in buildings of unusually tight

construction shall be provided with air for

combustion, ventilation, and dilution of flue gases

using the methods described in example 2B or

shall be specially engineered. The authority having

jurisdiction must approve specially engineered

installations.

EXAMPLE 2: Boiler Located in Confined Space

A. All Air from Inside the Building: The confined

space shall be provided with two permanent

openings communicating directly with an additional

room(s) of sufficient volume so that the combined

volume of all spaces meets the criteria for an

unconfined space. The total input of all gas

utilization equipment installed in the

NOTE

If you use a fireplace or a kitchen or bathroom

exhaust fan, you should install an outside air

intake. These devices will rob the boiler and

water heater of combustion air.

combined space shall be considered in making this

determination. Each opening shall have a

minimumfree area of one square inch per 1,000 Btu

per hour of the total input rating of all gas utilization

equipment in the confined space, but not less that

100 square inches. One opening shall be within 12

inches of the top and one within 12 inches of the

bottom of the enclosure. The minimum dimension of

air openings shall not be less than 3 inches.

B. All Air from Outdoors: The confined space

shall communicate with the outdoors in accordance

with methods 1 or 2. The minimum dimension of

air openings shall not be less than 3 in. Where

ducts are used, they shall be of the same cross-

sectional area as the free area of the openings to

which they connect.

1.Two permanent openings, one commencing

within 12 inches of the top, and one commencing

within 12 inches of the bottom, of the enclosure

shall be provided. The openings shall

communicate directly, or by the ducts, with the

outdoors or spaces (crawl or attic) that freely

communicate with the outdoors.

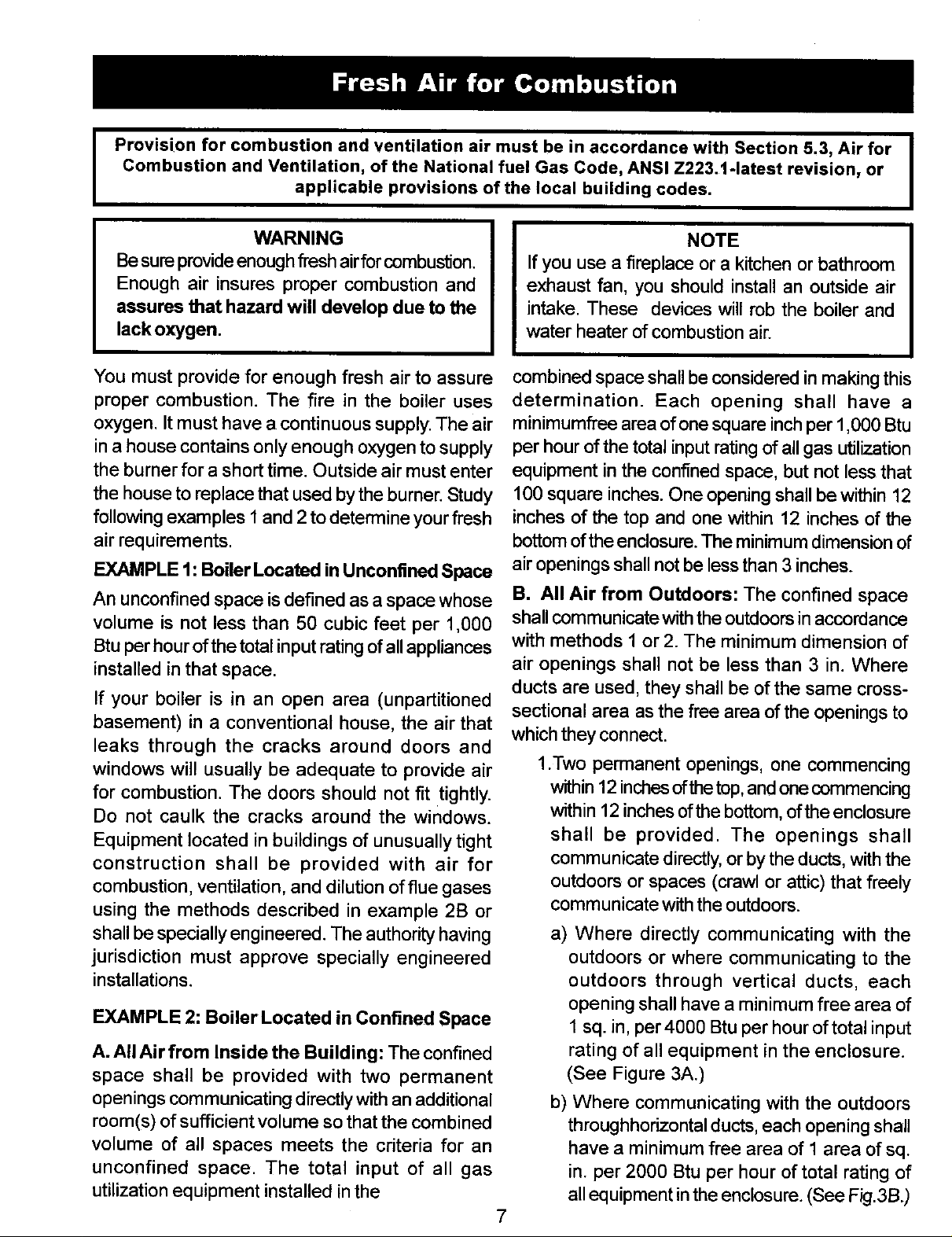

a) Where directly communicating with the

outdoors or where communicating to the

outdoors through vertical ducts, each

opening shall have a minimum free area of

1 sq. in, per 4000 Btu per hour oftotal input

rating of all equipment in the enclosure.

(See Figure 3A.)

b) Where communicating with the outdoors

throughhorizontal ducts, each opening shall

have a minimum free area of 1 area ofsq.

in. per 2000 Btu per hour of total rating of

all equipment in the enclosure. (See Fig.3B.)

7

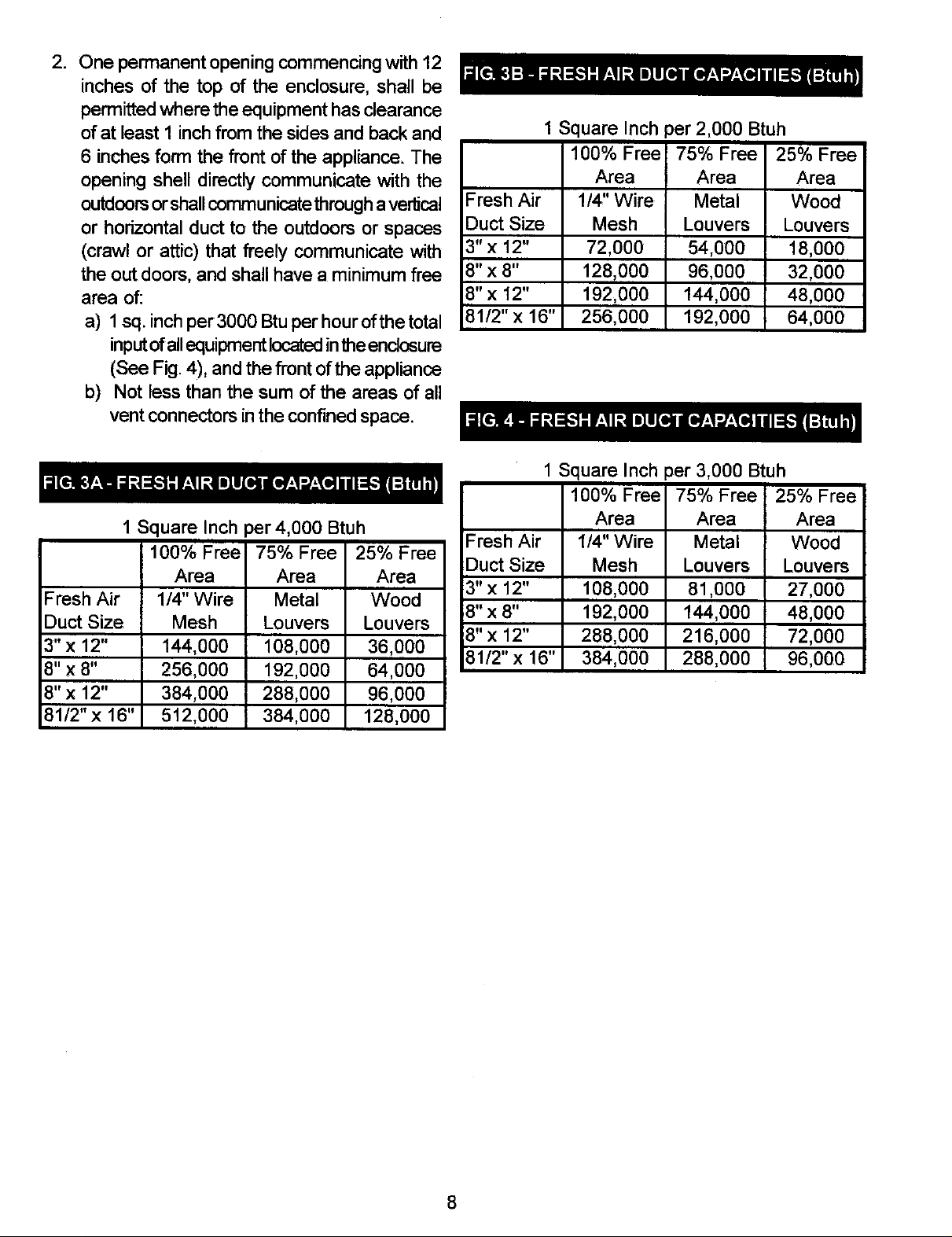

2, One permanentopeningcommencingwith 12

inches of the top of the enclosure, shall be

permitted where the equipment has clearance

of at least 1 inch from the sides and back and

6 inches form the front of the appliance. The

opening shell directly communicate with the

outdoorsor shallcommunicate through avertical

or horizontal duct to the outdoors or spaces

(crawl or attic) that freely communicate with

the outdoors, and shall have a minimum free

area of:

a) 1sq. inch per3000 Btu per hour ofthe total

inputof allequipment locatedinthe enclosure

(See Fig. 4), and the front of the appliance

b) Not less than the sum of the areas of all

vent connectors in the confined space.

1 Square Inch

100% Free

Area

Fresh Air 1/4, Wire

Duct Size Mesh

3" x 12" 72,000

8" x 8" 128 000

8"x 12" 192,000

81/2"x 16" 256,000

)er 2,000 Btuh

75% Free 25% Free

Area Area

Metal Wood

Louvers Louvers

54,000 18,000

96,000 32,000

144,000 48,000

192,000 64,000

1 Square Inch )er 4,000 Btuh

100% Free 75% Free 25% Free

Area Area Area

Fresh Air 1/4" Wire Metal Wood

Duct Size Mesh Louvers Louvers

3"x 12" 144,000 108,000 36,000

8" x 8" 256,000 192,000 64,000

8" x 12" 384,000 288 000 96,000

81/2" x 16" 512,000 384,000 128,000

1 Square Inch

100% Free

Area

Fresh Air 1/4" Wire

Duct Size Mesh

3" x 12" 108,000

8" x 8" 192,000

8" x 12" 288,000

81/2"x 16" 384,000

oer 3,000 Btuh

75% Free 25% Free

Area Area

Metal Wood

Louvers Louvers

81,000 27,000

144,000 48,000

216,000 72,000

288,000 96,000

8

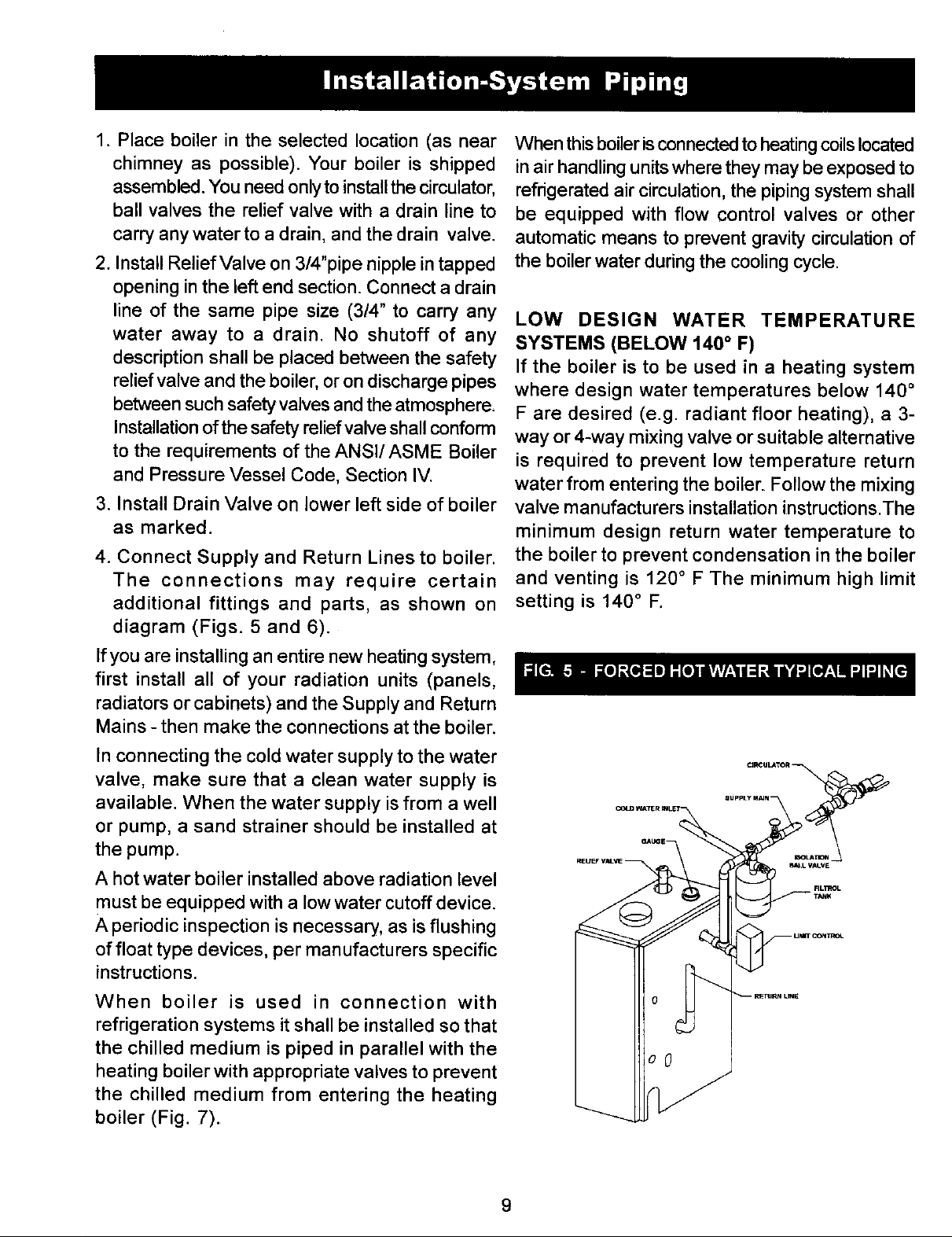

1. Place boiler in the selected location (as near

chimney as possible). Your boiler is shipped

assembled.Youneedonlyto installthecirculator,

ball valves the relief valve with a drain line to

carryanywater to a drain, andthe drain valve.

2. Install ReliefValve on 3/4"pipenippleintapped

openinginthe leftend section. Connecta drain

line of the same pipe size (3/4" to carry any

water away to a drain. No shutoff of any

descriptionshall be placed betweenthe safety

reliefvalveand theboiler,or ondischargepipes

betweensuchsafetyvalvesandtheatmosphere.

Installationofthe safetyreliefvalveshallconform

to the requirements of the ANSI/ASME Boiler

and PressureVessel Code,Section IV.

3. Install Drain Valve on lower left side of boiler

as marked.

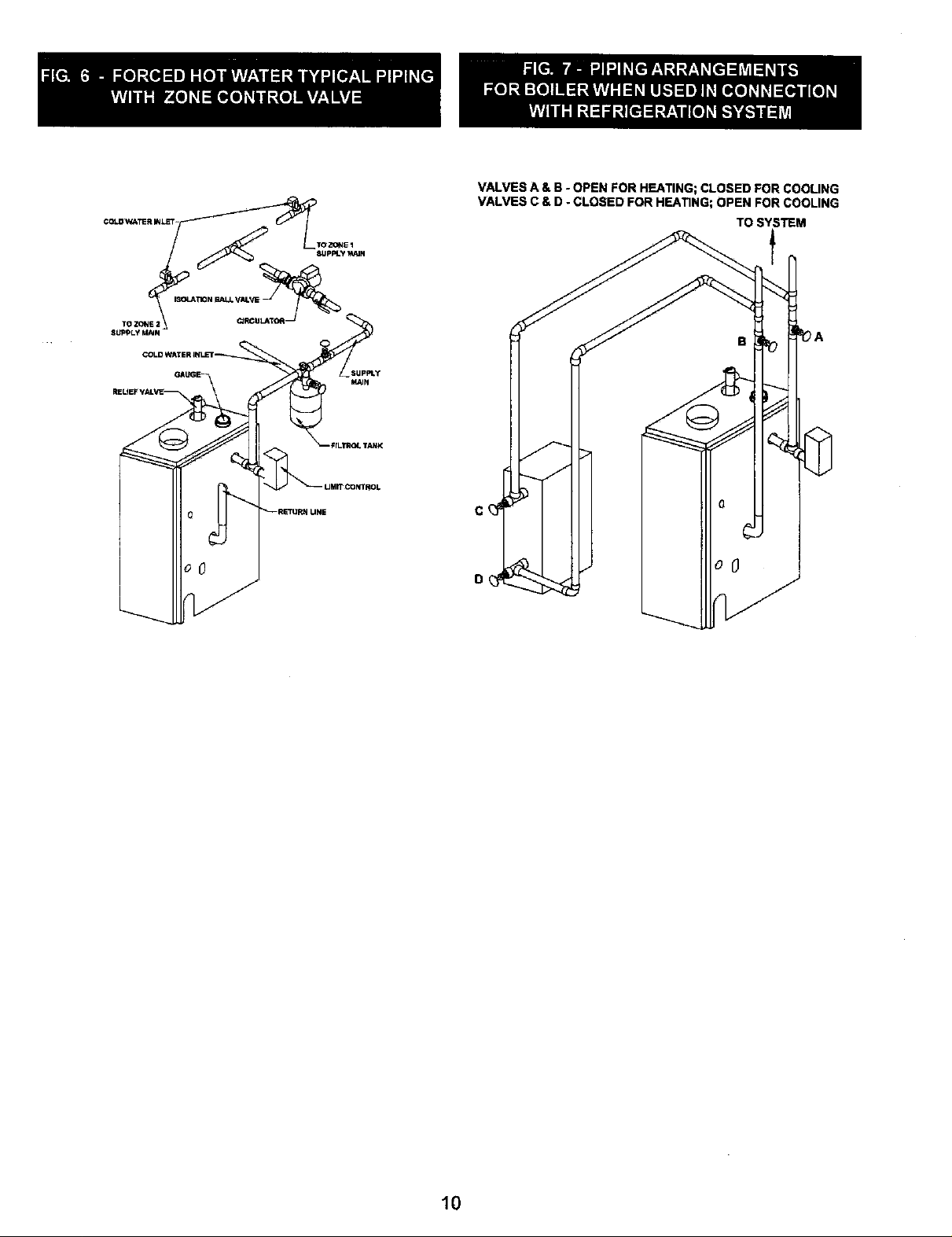

4. Connect Supply and Return Lines to boiler.

The connections may require certain

additional fittings and parts, as shown on

diagram (Figs. 5 and 6).

When this boiler isconnected to heating coils located

in air handling units where they may be exposed to

refrigerated air circulation, the piping system shall

be equipped with flow control valves or other

automatic means to prevent gravity circulation of

the boiler water during the cooling cycle.

LOW DESIGN WATER TEMPERATURE

SYSTEMS (BELOW 140 ° F)

If the boiler is to be used in a heating system

where design water temperatures below 140 °

F are desired (e.g. radiant floor heating), a 3-

way or 4-way mixing valve or suitable alternative

is required to prevent low temperature return

water from entering the boiler. Follow the mixing

valve manufacturers installation instructions.The

minimum design return water temperature to

the boiler to prevent condensation in the boiler

and venting is 120 ° F The minimum high limit

setting is 140 ° F.

Ifyou are installing an entire newheatingsystem,

first install all of your radiation units (panels,

radiatorsor cabinets) and the Supply and Return

Mains- then make the connections atthe boiler.

Inconnecting the cold water supply to the water

valve, make sure that a clean water supply is

available. When the water supply isfrom a well

or pump, a sand strainer should be installed at

the pump.

A hot water boiler installed above radiation level

must beequipped with a lowwater cutoff device.

Aperiodic inspection is necessary,as isflushing

of float type devices, per manufacturers specific

instructions.

When boiler is used in connection with

refrigeration systems it shall be installed so that

the chilled medium is piped in parallel with the

heating boiler with appropriate valves to prevent

the chilled medium from entering the heating

boiler (Fig. 7).

9

VALVES A & B - OPEN FOR HEATING; CLOSED FOR COOLING

VALVES C & D - CLOSED FOR HEATING; OPEN FOR COOLING

TO SYSTEM

B

10

with Part 7, Venting of Equipment, of the National Fuel Gas Code, ANSI Z223.l-latest issue

I For boilers for connection to gas vents or chimneys, vent installations shell be in accordance

and applicable provisions of the local building codes.

CHECK YOUR CHIMNEY

5. Outside chimneys should not be used unless

This is a very important part of your heating system.

Itmust be clean, the right size, properly constructed

and in GOOD CONDITION. No boiler can function

properly with a bad chimney.

1. Use local codes for installation or National Fuel

Gas Code Z223.1-1atest issue. In Canada,

follow CSA 13149.1 or .2 Installation Codes. It

is very important to properly size the venting

system for induced draft appliances. Consult

the Vent Sizing Tables, in the National Fuel

Gas Code ANSI Z223.1-1atest revision for

correct sizing information In Canada, consult

the Vent Sizing Tables, Amendment #1 to CSA-

13149.1 and .2 Installation Codes.

2. The boiler's induced draft blower has a 3" outlet.

A 3" X 4" increaser fitting isincluded in the parts

bag. Locate the increaser fitting on the outlet

of the induced draft blower, and secure gastight

with a bead of the furnished silicone sealant.

The increaser fitting is required on this boiler

for Category I venting, and 4" is the minimum

permissible vent diameter. This does not imply

that the vent connector is intended to be 4"

diameter pipe. The vent connector shall be sized

according to the appropriate venting tables in

the National Fuel Gas Code or the Canadian

Installation Codes, and may be required to be

larger than 4" diameter.

they are either:

a. enclosed in a chase, or

b. lined with Type B vent pipe, or listed flexible

vent liner, or other certifEEI chimney lining system.

6. The vent connector from the boiler to the

chimney should run as directly as possible with

as few elbows as possible.

7. Where possible, itis recommended to common

vent the water heater and boiler. Consult the

appropriate Vent Sizing Tables in either the

National Fuel Gas Code, or the Canadian

Installation Codes for specific requirements

of multiple appliance venting.

8. If the boiler is the only appliance connected to

the vent, Type B vent pipe is recommended

for the vent connector.

9. Slope pipe up from boiler to chimney not less

than 1/4" per foot.

10. End of vent pipe must be flush with the inside

face of the chimney flue. Use a sealed-in

thimble for the chimney connection.

11. The sections of vent pipe should be fastened

with sheet metal screws to make the piping

rigid. Use stovepipe wires to support the pipe

from above.

12. Do not connect to fireplace flue.

13. Do not install a damper on this boiler.

The boiler installation for chimney venting

is not complete unless the 3" x 4" increaser

fitting is located and secured.

3. These are high efficiency boilers with a low stack

or exhaust temperature.

4. Ifventing into a masonry chimney without a liner,

line the chimney from top to bottom with either:

a, listed Type B vent pipe

b. listed fexible vent liner

c. poured ceramic liner.

MINIMUM VENT PIPE CLEARANCE

if the vent pipe must go through a crawl space,

Type B vent pipe should be used. Where vent

pipe passes through a combustible wall or

partition, use a ventilated metal thimble. The

thimble should be 4 inches larger in diameter than

the vent pipe.

11

Loading...

Loading...