Gas-Fired

CastIron

HOTWATER

BOILER

• Installation

• Operation

• RepairParts

WARNING: Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage. Refer to this

manual. For assistance or additional information consult a qualified

installer, service agency or the gas supplier.

PRINTED IN U,S,A. FORM 608-500-1/01-56519

KENNMORE CAST IRON BOILERS

FULLONEYEARWARRANTYONHOTWATERANDGASSTEAMCASTIRONBOILERS

For one (1) year from the date of installation, when this boiler is installed and maintained in accordance

with our instructions. Sears will repair defects in material or workmanship in the boiler,free of charge.

LIMITED 12 YEAR WARRANTY ON STEAM CAST IRON BOILERS

After one (1}year and through twelve (12) years from the date of installation,Sears willfurnish a replacement

heat exchanger, if the heat exchanger in the boiler is defective. YOU PAY FOR LABOR.

LIMITED 20 YEAR WARRANTY ON HOT WATER CAST IRON BOILERS

After one (1)year and through twenty (20) yearsfrom the date of installation,Searswillfurnish a replacement

heat exchanger ifthe heat exchanger in the boiler is defective. YOU PAYFOR LABOR.

SEARS INSTALLATION WARRANTY

In addition to any warranty extended to you on the Sears merchandise involved,which warranty becomes

effective the date the merchandise is installed,should the workmanship of any Sears arranged installation

prove faulty within one year, Sears will, upon notice from you, cause such faults to be corrected at

no additional cost to you.

FOR WARRANTY SERVICE, SIMPLY CONTACT THE NEAREST SEARS STORE OR SERVICE

CENTER THROUGHOUT THE UNITED STATES. This warranty gives you specific legal rights, and

you may also have other rights which vary from stateto state.

IMPORTANT

The following are the responsibilities of the user and are not

covered by the Warranty

1. Filter clearing or replacement.

2. Damage to unit or unsatisfactory operation due to improper

cleaning or use of unit in corrosive atmosphere.

3. Damage to unit or unsatisfactory operation due to blown fuses

or inadequate or interrupted electrical protective devices.

4. Damage to unit caused by the use of components or other

accessories not compatible with the unit.

1. Read the Owner's Manual for Safe Operation carefully Failure

to follow the rules for safe operation and the instructions can

cause a malfunction of the boiler and result in death, serious

bodily injury,and/or property damage.

2. Check your local codes and utility requirements before

installation. The installation must be in acordance with their

directives.

3. Before servicing, allow boiler to cool. Always shut off any

electricity and gas to boiler when working on it.This will prevent

any electrical shocks or burns.

4. Never test for gas leaks with an open flame. Use soap and

5. ifthe unit is removed from the place it was originally installed,

this Warranty becomes void.

6. Damage to the unit caused by accident, abuse, negligence,

misuse, riot,fire, flood, or acts of God.

SEARSROEBUCKAND COMPANY

D/817WA

Hoffman Estates,IL 60179

check all connections. This will avoid any possibility of fire

or explosion.

5. Be certain your new boiler will be using the correct gas.

Overfiring will result in premature failure of the boiler sections

and cause dangerous operation.

6. Never vent this boiler into an enclosed space. Always vent

to the outside. Never vent to another room or inside a building.

7. Be sure there isadequate air supply for complete combustion.

8. Followa regular service and maintenance schedule forefficient

and safe operation.

2

ASME

RELIEF VENT DAMPER

VALVE

TEMR/PRESS.GAUGE

!/

,_ A _, I7," SUPP_

AQUASTAT

_I ['--

-- -- --]-._._

I rV/NPT I \\ CH"

T

231/4

L____

iL

_ -I /

1'/4" RETURN

d

I__

DRAIN VALVE

LEFT SIDE

ROLLOLIT GAS 1

SWITCH VALVE

FRONT

IN]_ PILOT CONTROL

RIGHT SIDE

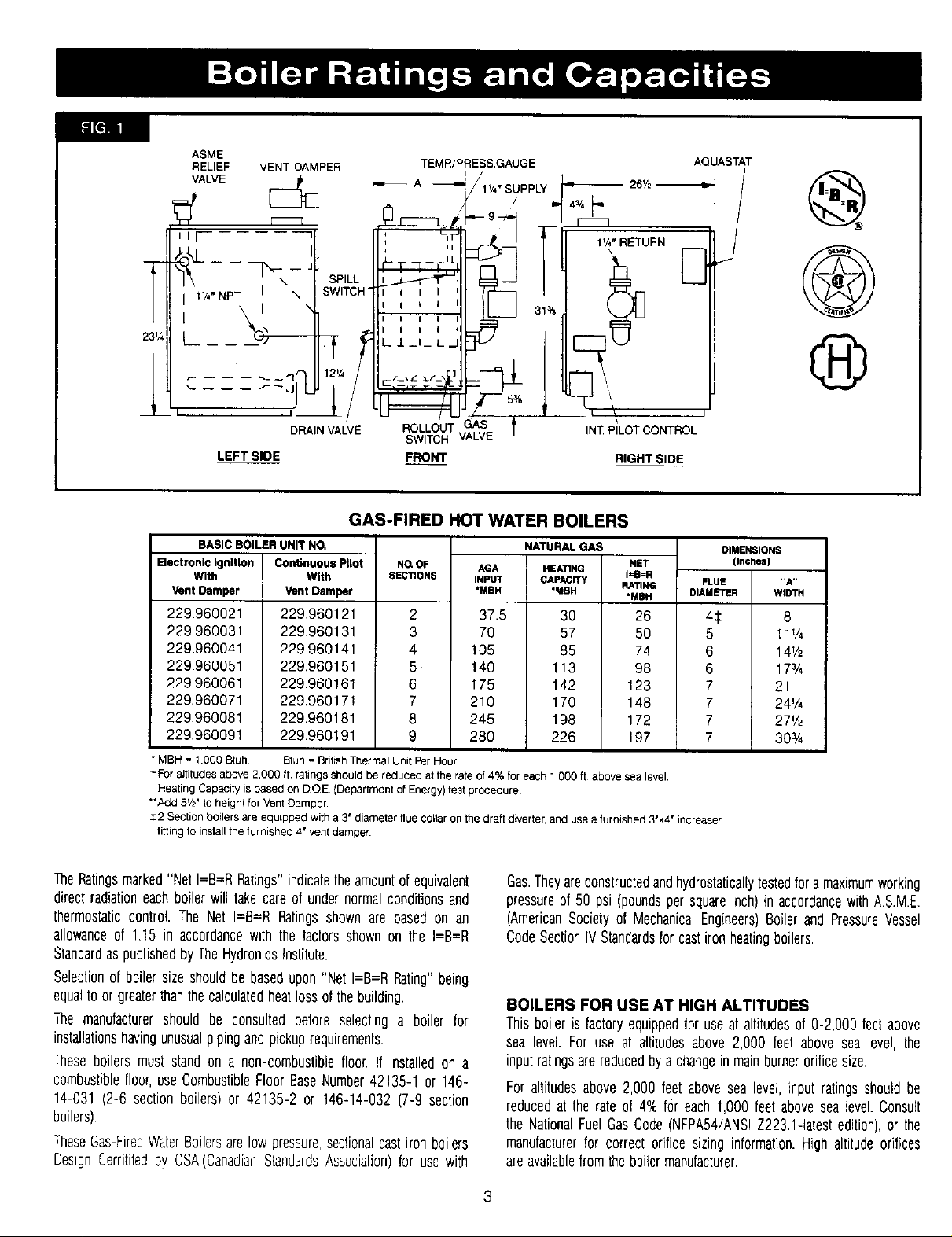

GAS-FIRED HOT WATER BOILERS

BASICBOILER UNIT N(_ NATURALGAS

Electronic Ignition

With

Vent Damper

229.960021

229.960031

229960041

229.960051

229.960061

229,960071

229.960081

229.960091

* MBH - 1,000 Stuh Btuh - British Thermal Unit Per Hour

t For aJtitudes above 2,000 ft ratings should be reduced at the rate of 4% for each 1,000 ft above sea level

Heating Capacity is based on DOE {Debarirnent of Energy) test procedure

**Add 5½" to height for Vent Damper

:_2 Section boilers are equipped with a 3" diameter flue collar on the draft diverter, and use a furnished 3'x4" increaser

fitting to install the furnished 4" vent damper

Continuous Pilot

With

Vent Damper

229.960121

229.960131

229.960141

229.960151

229.960161

229,960171

229.960181

229.960191

NQ OF AGA HEATING

SECTIONS

2

3

4

5

6

7

8

9

INPUT

*MBH

37.5

7O

105

140

175

210

245

280

CAPACITY

"MBH

3O

57

85

113

142

170

198

226

NET (Inches)

I=B=R

RATING FLUE

*MBN DIAMETER

26 4_

50 5

74 6

98 6

123 7

148 7

172 7

197 7

DIMENSIONS

,,A-

WIDTH

8

11%

14'/2

173/4

21

2474

271/2

303_

®

TheRatingsmarked"Net I=B=RRatings"indicatetheamountof equivalent

directradiationeachboilerwill takecareof undernormalconditionsand

thermostaticcontrol. The Net I=B=R Ratingsshownare basedon an

allowanceof 1.15 in accordancewith the factorsshownon the I=B=R

Standardaspublishedby TheHydronicsInstitute.

Selectionof boilersizeshouldbe basedupon"NetI=B=RRating"being

equalto or greaterthanthecalculatedheatlossof thebuilding.

The manufacturershould be consulted before selectinga boiler for

installationshavingunusualpipingandpickuprequirements.

Theseboilersmusl standon a non-combustiblefloor•If installedon a

combustiblefloor,useCombustibleFloor BaseNumber42135-1 or 146-

14-031 (2-6 sectionboilers) or 42135-2 or 146-14-032 (7-9 section

boilers)•

TheseGas-FiredWaterBoilersarelowpressure,sectionalcastironboilers

DesignCerritifedby CSA(CanadianStandardsAssociation)for usewith

Gas.Theyareconstructedandhydrostaticallytestedfora maximumworking

pressureof 50 psi(poundspersquareinch)in accordancewithA.SM.E.

(AmericanSocietyof MechanicalEngineers)Boilerand PressureVessel

CodeSectionIVStandardsfor castironheatingboilers.

BOILERS FOR USE AT HIGH ALTITUDES

This boileris factoryequippedfor use at altitudesof 0-2,000 feetabove

sea level. For use at altitudesabove2,000 feet abovesea level, the

inputratingsarereducedbyachangein mainburnerorificesize.

Foraltitudesabove2,000 feet abovesea level,inputratingsshouldbe

reducedatthe rate of 4% for each1,000feet abovesealevel.Consult

the NationalFuelGasCode(NFPA54/ANS!Z223.1-1atestedition),or the

manufacturerfor correct orifice sizing information.Highaltitudeorifices

areavailablefromtheboilermanufacturer.

3

Checkto besureyouhavetherightsizeboilerbeforestartingthe installation.

Seeratingandcapacitytableonpreviouspage.Alsobesurethenewboileris

forthetypeof gasyouareusing.Checktheratingplateontherightsideofthe

boiler.

Youmuslseethattheboileris suppliedwiththecorrecttypeofgas,freshair

forcombustion,andasuitableelectricalsupply.Also,theboilermustbecon-

nectedtoasuitableventingsystemandanadequatepipingsystem.Finaily,a

thermostat,properlylocated,is neededforcontroloftheheatingsystem.Ifyou

haveanydoubtsastothevariousrequirements,checkwithlocalauthorities

andobtainprofessionalhelpwhereneeded.Takethetimeto completeall of

thestepsfor SAFEandPROPERoperationoftheheatingsystem.

Ifthisboilerisinstalledinabuildingunderconstruction,specialcaremustbe

takentoinsureacleancombustionairsupplyduringtheconstructionprocess.

Airborneparticulatessuchasfromdrywalldustandfromfiberglassinsulation

canclogtheburnerportsandcauseincompletecombustionandsootfng.

KEEP BOILER AREA CLEAN AND FREE FROM COMBUSTIBLE MATERIALS,

GASOLINE AND OTHER FLAMMABLE VAPORS AND LIQUIDS

Whererequiredbytheauthorityhavingjurisdiction,theinstallationmustcon-

formtoAmericanSocietyof MechanicalEngineersSafetyCodeforControls

andSafetyDevicesfor AutomaticallyFiredBoilers,No.CSD-1.

Theinstallationmustconformto therequirementsof the authorityhaving

jurisdictionor, intheabsenceofsuchrequirements,to theNationalFuelGas

Code,ANSIZ223.1-1atestrevision.

In Canada,theboilershall be installedaccordingto CSA-B149.1and.2,

InstallationCodeforGasBurningAppliancesandEquipment.

Installers- Followlocalregulationswith respectto installationofCO

detectors.Followmaintenancerecommendationsin this instruction

manual.

Techniciens- Veuillezvousconformer_ lardgiementationenvigueur

concernantI" installationdesdetecteursd'oxydedecarbone.Suivrelos

consignesd'entretienfigurantdenslemanueldinstructioncijeint.

1. Selectlevellocationascentralizedwithpipingsystem,andasnearchim-

ney,as possible.

2. Placecratedboiler at selectedlocation,removecratebypullingcrate

sidesfromtopandbottomboards.Combustiblefloors:Whenboileristo

beinstalledonacombustiblefloor,a SpecialBasePlatemustbeused-

146-14-031(2-6Section)or 146-14-032(7-9 Section).Thisboilermust

notbeinstalledon carpeting.

3. Boileris tobe level.Metalshimsmaybeusedunderbaselegsforfinal

leveling.

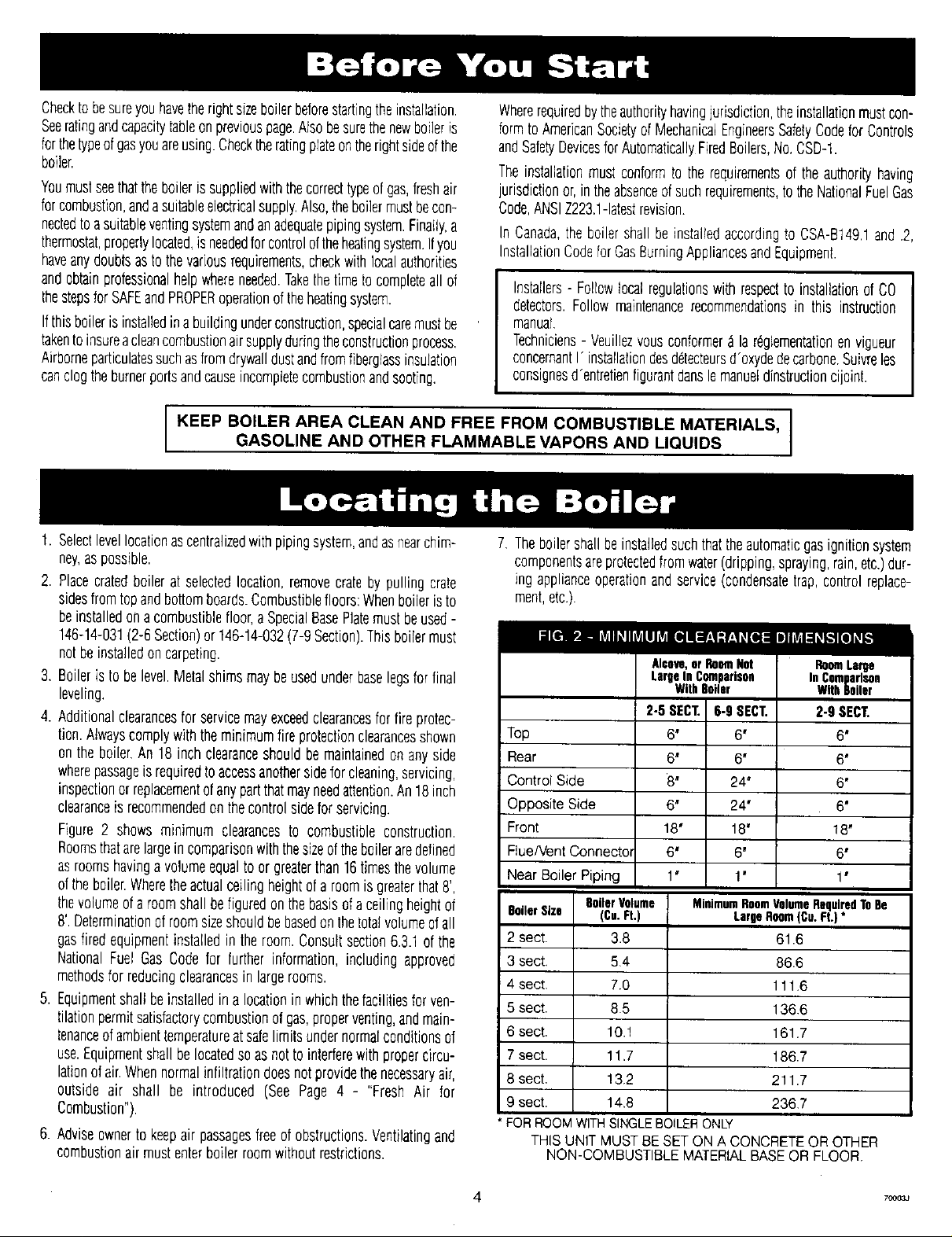

4. Additionalclearancesfor servicemayexceedclearancesforfire protec-

tion.Alwayscomplywiththeminimumfireprotectionclearancesshown

onthe boiler,An 18 inchclearanceshouldbe maintainedonany side

wherepassageisrequiredtoaccessanothersideforcleaning,servicing,

inspectionorreplacementofanypartthatmayneedattention.An18inch

clearanceis recommendedonthecontrolsideforservicing.

Figure2 shows minimum clearancesto combustibleconstruction.

Roomsthatarelargeincomparisonwiththesizeoftheboileraredefined

asroomshavinga volumeequalto or greaterthan16timesthevolume

ofthe boiler.Wheretheactualceilingheightofa roomis greaterthat8',

thevolumeof aroomshallbefiguredonthebasisofaceilingheightof

8'.Determinationofroomsizeshouldbebasedonthetotalvolumeof all

gasfired equipmentinstalledinthe room.Consultsection6.3.1ofthe

NationalFuelGas Codefor further information,including approved

methodsfor reducingclearancesin largerooms.

5. Equipmentshallbeinstalledina locationinwhichthefacilitiesforven-

tilationpermitsatisfactorycombustionofgas,properventing,andmain-

tenanceofambienttemperatureatsafelimitsundernormalconditionsof

use.Equipmentshallbelocatedsoasnot tointerferewithpropercircu-

lationofair.Whennormalinfiltrationdoesnotprovidethe necessaryair,

outside air shall be introduced (See Page 4 - "Fresh Air for

Combustion"),

6. Adviseownerto keepair passagesfreeofobstructions.Ventilatingand

combustionair mustenterboilerroomwithoutrestrictions.

7. Theboilershallbeinstalledsuchthattheautomaticgasignitionsystem

componentsareprotectedfromwater(dripping,spraying,rain,etc.)dur-

ing applianceoperationandservice(condensatetrap,controlreplace-

ment,etc.).

Alcove,orRoomNot

LargeInComparison

WithBoiler

2-5 SECT` 6-9 SECT,

Top

Rear

Control Side

Opposite Side

Front

Flue/Vent Connector

Near Boiler Piping

BoilerVolume

BoilerSize (Cu.Ft,)

2 sect. 3.8

3 sect, 54

4 sect, 7.0

5 sect. 85

6 sect. 10.1

7 sect. 11.7

8 sect, ! 3.2

9 sect. 14.8

* FOR ROOMWITHSINGLEBOILERONLY

THIS UNIT MUST BE SET ON A CONCRETE OR OTHER

NON-COMBUSTIBLE MATERIAL BASE OR FLOOR.

6' 6'

6' 6"

8" 24"

6" 24"

18" 18'

6" 6"

1" 1'

MinimumRoomVolumeRequiredToBe

LargeRoom(Cu.Ft.)*

RoomLarge

InCompedsoo

2-9 SECT,

61.6

86.6

111.6

136.6

161.7

186.7

211.7

2367

WithBoiler

6'

6'

6'

6'

18'

6'

1'

4 70{)032

Provisionfor combustionand ventilation air must be in accordance with Section 5.3, Air forCombustionand Ventilation, of

the National Fuel Gas Code, ANSI Z223.1-1atest revision, or applicable provisionsof the local building codes.

WARNING

Be sure to provide enough fresh air for combustion.

Enough air insures proper combustion and assures that

no hazard will develop due to the lack of oxygen.

Youmustprovideforenoughfreshairto assurepropercombustion.Thefire

in theboilerusesoxygen,it musthaveacontinuoussupply.Theair in a

housecontainsonly enoughoxygento supplytheburnerfora shorttime.

Outsideair mustenterthehouseto replacethatusedbytheburner.Study

followingexamples1and2 to determineyourfreshairrequirements.

EXAMPLE1: Boiler Locatedin UnconfinedSpace

An unconfinedspaceis definedasa spacewhosevolumeis notlessthan

50cubicfeetper!,000 Btuperhourofthetotalinputratingofallappliances

installedinthatspace.

Ifyourboileris inan openarea(unpartitionedbasement)inaconventional

house,theairthatleaksthroughthecracksarounddoorsandwindowswill

usuallybeadequateto provideairforcombustion.Thedoorsshouldnotfit

tightly.Donotcaulkthecracksaroundthewindows.

Equipmentlocatedinbuildingsofunusuallytightconstructionshallbepro-

videdwithair for combustion,ventilation,anddiMion offluegasesusing

themethodsdescribedin example2Bor shallbespeciallyengineered.The

authorityhavingjurisdictionmustapprovespeciallyengineeredinstalla-

tions.

EXAMPLE2: BoilerLocatedin ConfinedSpace

A.All Air from Inside the Building:Theconfinedspaceshall bepro-

videdwithtwopermanentopeningscommunicatingdirectlywithanaddi-

tionalroom(s)of sufficientvolumeso thatthecombinedvolumeofall

spacesmeetsthecriteriafor anunconfinedspace.Thetotalinputofall

gasutilizationequipmentinstalledin thecombinedspaceshallbecon-

sideredinmakingthis determination.Eachopeningshall haveamini-

mumfreeareaofonesquareinchper1,000Btuperhourof thetotalinput

ratingolall gasutilizationequipmentin theconfinedspace,butnotless

that100squareinches.Oneopeningshallbewithin12inchesofthetop

andonewithin12 inchesof thebottomoftheenclosure.Theminimum

dimensionofairopeningsshallnotbelessthan3 inches.

B,All Airfrom Outdoors:Theconfinedspaceshallcommunicatewiththe

outdoorsinaccordancewithmethods1or 2.Theminimumdimensionof

air openingsshall notbelessthan3 in.Whereductsareused,theyshall

beofthe samecross-sectionalareaas thefreeareaof theopeningsto

whichtheyconnect.

1.Twopermanentopenings,onecommencingwithin 12 inchesofthe

top,andonecommencingwithin12inchesolthebottom,oftheenclo-

sureshallbeprovided.Theopeningsshallcommunicatedirectly,orby

theducts,withthe outdoorsorspaces(crawlorattic)thatfreelycom-

municatewith theoutdoors,

a)Wheredirectlycommunicatingwiththeoutdoorsor wherecommu-

nicatingto theoutdoorsthroughverticalducts,eachopeningshall

haveaminimumfreeareaof 1 sq.in.per4000Btuperhouroftotal

inputratingofagequipmentin theenclosure.(SeeFigure3A.)

b)Wherecommunicatingwiththe outdoorsthroughhorizontalducts,

eachopeningshallhaveaminimumfreeareaof 1 sq, in.per2000

Btuperhourof totalinputratingol all equipmentintheenclosure.

(SeeFigure3B.)

2. Onepermanentopeningcommencingwith 12inchesofthe topof the

enclosure,shall bepermittedwheretheequipmenthasclearanceof at

NOTE

If you use a fireplace or a kitchen or bathroom exhaust

fan, you should install an outside air intake. These

devices will rob the boiler and water heater of combus-

tion air.

least1 inchfromthesidesandbackand6inchesfromthefrontofthe

appliance,Theopeningshaddirectlycommunicatewith theoutdoors

or shallcommunicatethroughaverticalor horizontalductto theout-

doorsorspaces(crawlorattic)thatfreelycommunicatewith theout-

doors,andshallhaveaminimumfreeareaof:

a)1 sq,inchper3000Btuperhourofthetotalinpulol allequipment

locatedintheenclosure(SeeFigure4),and

b)Notlessthanthesumof theareasofall venlconnectorsinthecon-

finedspace.

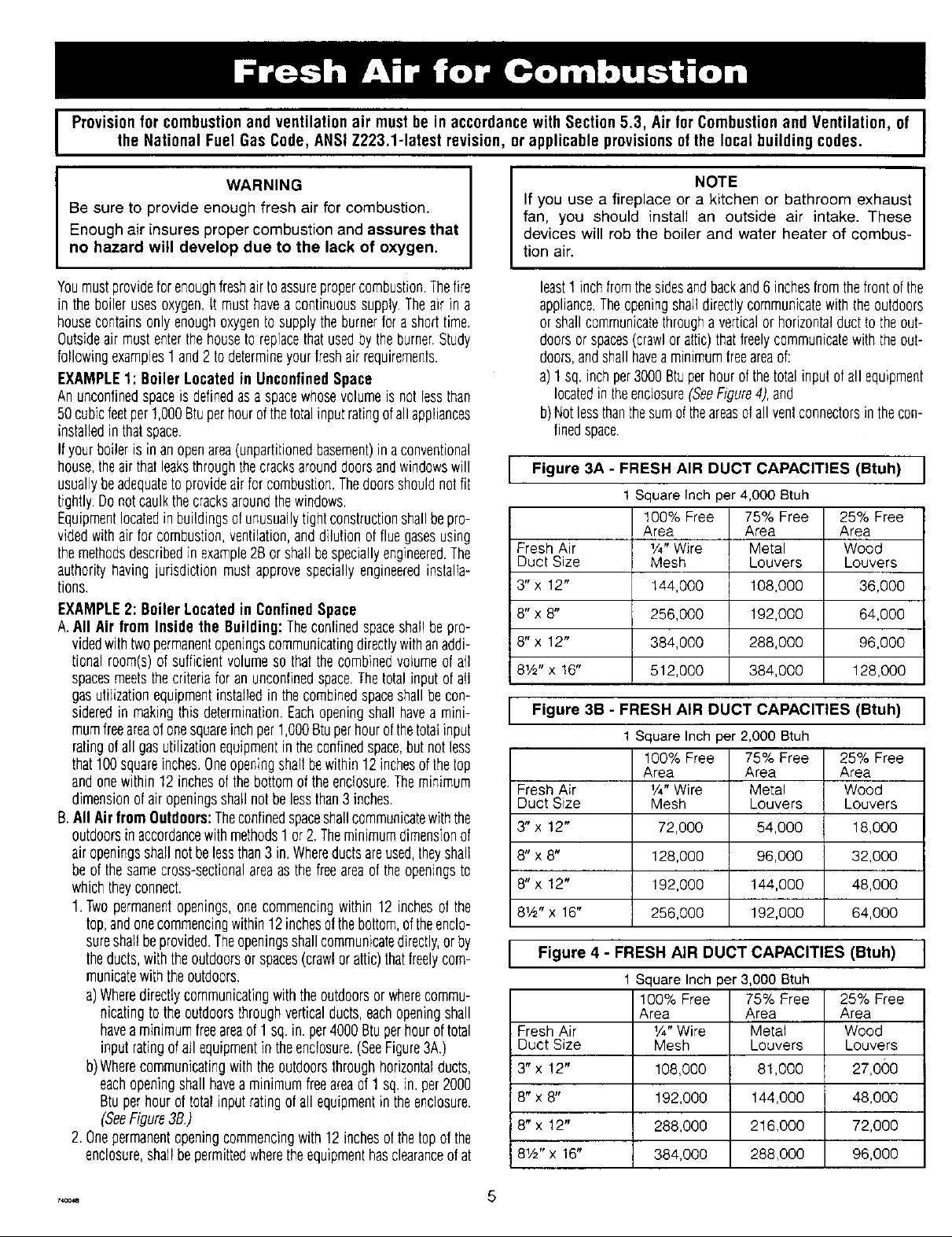

I Figure 3A - FRESH AIR DUCT CAPACITIES (Btuh)

1 Square Inch per 4,000 Btuh

100% Free 75% Free 25% Free

Area Area Area

Fresh Air 1/4"Wire Metal Wood

Duct Size Mesh Louvers Louvers

3" x 12" 144,000 108,000 36,000

8" x 8" 256,000 192,000 64,000

8" x 12" 384,000 288,000 96,000

81/2"x 16" 512,000 384,000 128,000

I Figure 3B - FRESH AIR DUCT CAPACITIES (Btuh)

1 Square Inchper 2,000 Btuh

100% Free 75% Free 25% Free

Area Area Area

Fresh Air 1/4"Wire Metal Wood

Duct Size Mesh Louvers Louvers

3" x 12" 72,000 54,000 18,000

8" x 8" 128,000 96,000 32,000

8" x 12" 192,000 144,000 48,000

81/2"x 16" 256,000 192,000 64,000

I Figure 4 - FRESH AiR DUCT CAPACITIES (Btuh)

1 Square Inch per 3,000 6tuh

100% Free 75% Free 25% Free

Area Area Area

Fresh Air %" Wire Metal Wood

Duct Size Mesh Louvers Louvers

3" x !2" 108,000 81,000 27,000

8" x 8" 192,000 144,000 48,000

8" x 12" 288,000 216,000 72,000

81/2"x 16" 384,000 288,000 96,000

7,_4 5

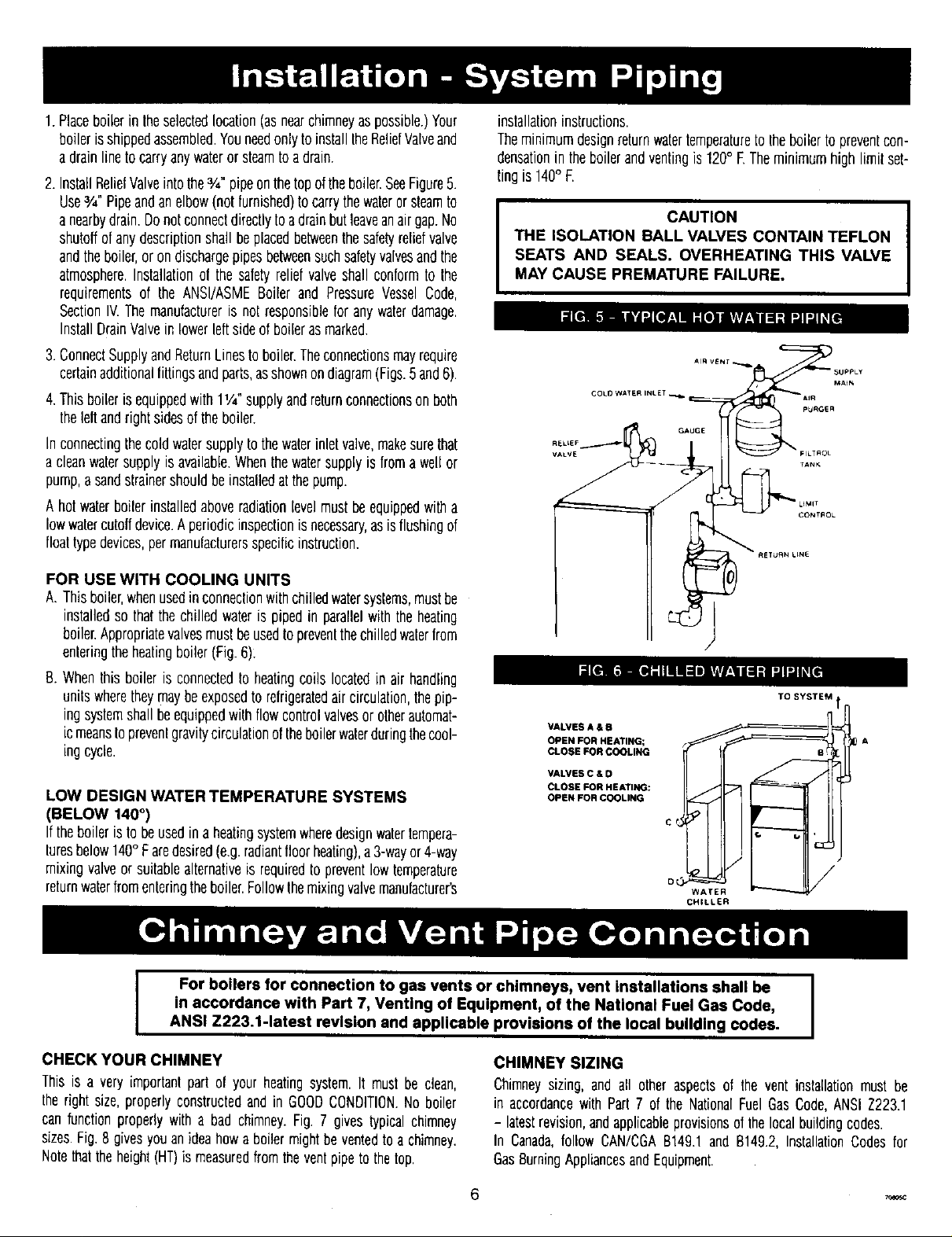

1.Placeboilerinlhe selectedlocation(asnearchimneyas possible.)Your

boilerisshippedassembled.Youneedonlyto installIheBeliefValveand

a drainlinetocarryanywateror steamtoadrain.

2. InstallRebelValveintothe3/+,,pipeonthetop oftheboiler.SeeFigure5.

Use3/4"Pipeandanelbow(notfurnished)tocarrythewaterorsteamto

a nearbydrain.Donotconnectdirectlytoadrainbutleaveanairgap.No

shutoffofanydescriptionshallbeplacedbetweenthesafetyreliefvalve

andtheboiler,or ondischargepipesbetweensuchsafetyvalvesandthe

atmosphere.Installationol thesafetyrelief valveshallconformto lhe

requirementsof the ANSI/ASMEBoiler and PressureVesselCode,

SectionIV.Themanufactureris notresponsibleforany waterdamage.

InstallDrainValvein lowerleftsideof boilerasmarked.

3.ConnectSupplyandReturnLinestoboiler.Theconnectionsmayrequire

certainadditionalfittingsandparts,asshownondiagram(Figs.5and6).

4.Thisboileris equippedwith 11/4"supplyandreturnconnectionsonboth

thelelt andrightsidesof theboiler.

Inconnectingthecoldwatersupplyto thewaterinlelvalve,makesurethat

a cleanwatersupplyisavailable.Whenthewatersupplyisfromawellor

pump,a sandstrainershouldbeinstalledatthe pump.

A hotwaterboilerinstalledaboveradiationlevelmustbeequippedwitha

lowwatercutoffdevice.A periodicinspectionisnecessary,asisflushingof

floatlypedevices,permanufacturersspecificinstruction.

installationinstructions.

Theminimumdesignreturnwatertemperaturetotheboilertopreventcon-

densationin theboilerandventingis 120° E Theminimumhighlimit set-

tingis140° E

THE ISOLATION BALL VALVES CONTAIN TEFLON

SEATS AND SEALS. OVERHEATING THIS VALVE

I CAUTION

MAY CAUSE PREMATURE FAILURE.

COLD WATER INLET --

RELLEFJ[

FOR USE WITH COOLING UNITS

A.Thisboiler,whenusedinconnectionwithchilledwatersystems,mustbe

installedsothatthe chilledwateris pipedin parallelwiththeheating

boiler.Appropriatevalvesmustbeusedtoprevenlthechilledwaterfrom

enteringtheheatingboiler(Fig.6)_

B.Whenthis boiler is connectedto heatingcoils locatedin air handling

unitswheretheymaybeexposedto relrigeratedair circulation,thepip-

ingsystemshallbeequippedwithflowcontrolvalvesor otherautomat-

icmeanstopreventgravitycirculationoftheboilerwaterduringthecool-

ingcycle.

LOW DESIGN WATER TEMPERATURE SYSTEMS

(BELOW 140+)

If theboileris to beusedina heatingsystemwheredesignwalertempera-

luresbelow140° Faredesired(e.g.radiantfloorheating),a3-wayor4-way

mixingvalveor suitablealternativeis requiredto preventlowtemperature

returnwaterfromenteringtheboiler.Followthemixingvalvemanufacturer's

in accordance with Part 7, Venting of Equipment, of the National Fuel Gas Code,

For boilers for connection to gas vents or chimneys, vent installations shall be

ANSI Z223.1-1atest revision and applicable provisions of the local building codes.

VALVES A & B

OPEN FOR HEATING;

CLOSE FOR COOLING

VALVES C & D

CLOSE FOR HEATING:

OPEN FOR COOLING

TO SYSTEM

IDA

CHILLER

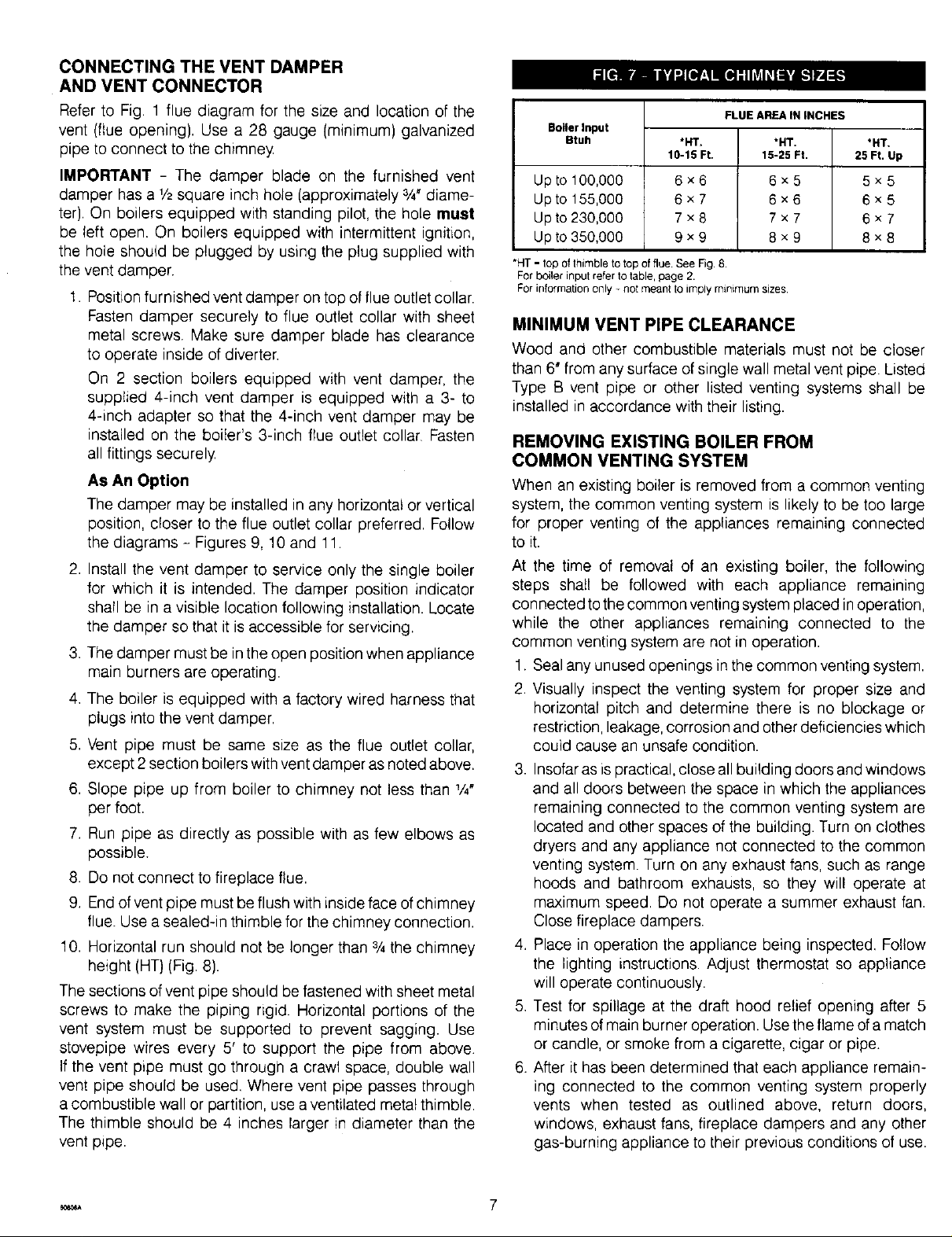

CHECK YOUR CHIMNEY

This is a very importantpart of your heatingsystem.It mustbe clean,

the right size,properlyconstructedandin GOODCONDITION.No boiler

canfunctionproperlywith a bad chimney.Fig.7 givestypicalchimney

sizes.Fig.8 givesyouanideahowa boilermightbe ventedto a chimney.

Notethatthe height(HT)is measuredfromtheventpipetothetop.

CHIMNEY SIZING

Chimneysizing, and all otheraspectsof the vent installationmustbe

in accordancewith Part 7 of the NationalFuelGasCode,ANSIZ223.1

- latestrevision,andapplicableprovisionsofthelocalbuildingcodes.

In Canada,follow CAN/CGAB149.1and B149.2,InstallationCodesfor

GasBurningAppliancesandEquipment.

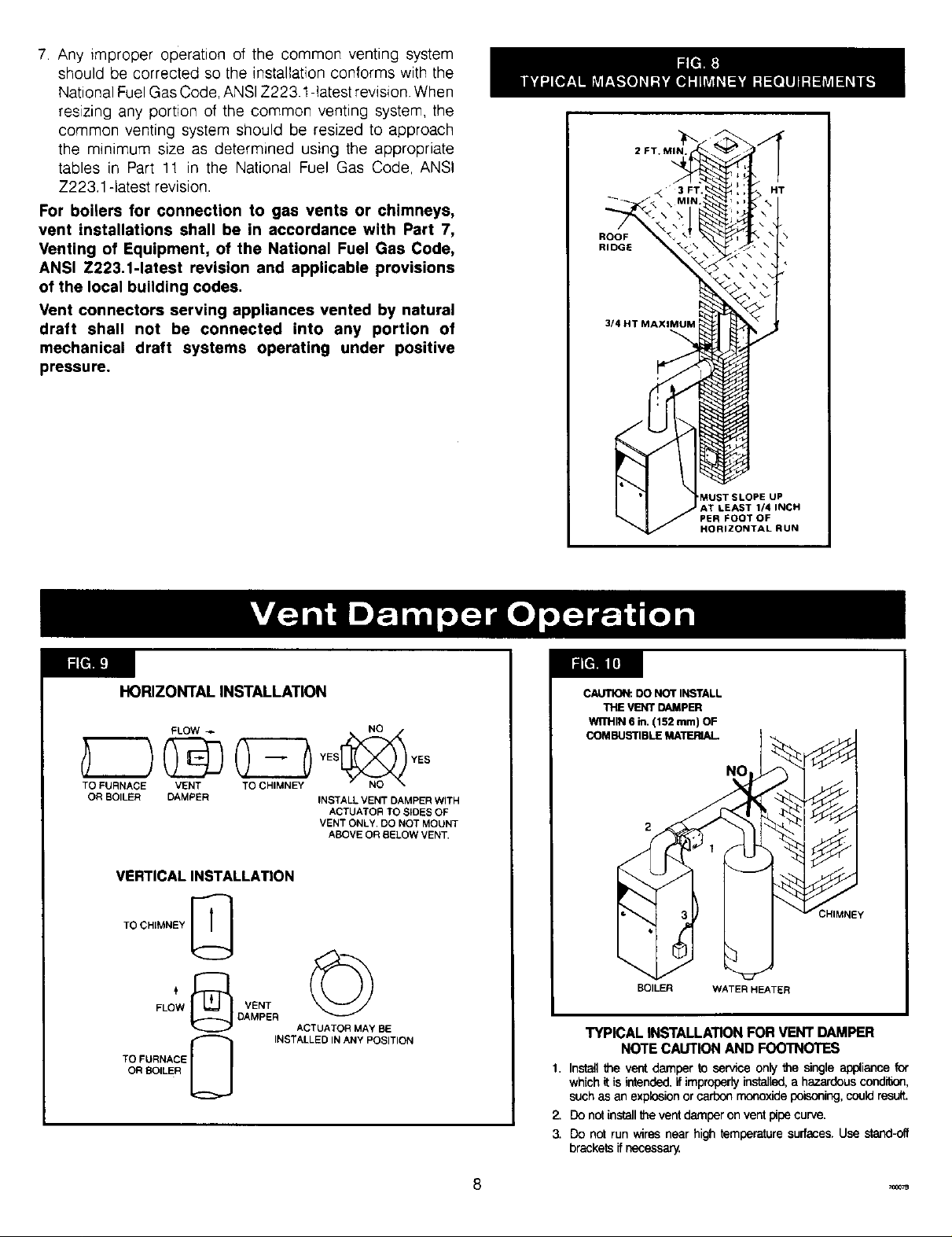

CONNECTING THE VENT DAMPER

AND VENT CONNECTOR

Refer to Fig. 1 flue diagram for the size and location of the

vent (flue opening). Use a 28 gauge (minimum) galvanized

pipe to connect to the chimney

IMPORTANT - The damper blade on the furnished vent

damper has a V2square inch hole (approximately 3/4"diame-

ter). On boilers equipped with standing pilot, the hole must

be teft open. On boilers equipped with intermittent ignition,

the hole should be plugged by using the plug supplied with

the vent damper.

1. Position furnished vent damper on top of flue outlet collar.

Fasten damper securely to flue outlet collar with sheet

metal screws. Make sure damper blade has clearance

to operate inside of diverter.

On 2 section boilers equipped with vent damper, the

supplied 4-inch vent damper is equipped with a 3- to

4-inch adapter so that the 4-inch vent damper may be

installed on the boiler's 3-inch flue outlet collar Fasten

all fittings securely

As An Option

The damper may be installed in any horizontal or vertical

position, closer to the flue outlet collar preferred. Follow

the diagrams - Figures 9, 10 and 11.

2. Install the vent damper to service only the single boiler

for which it is intended. The damper position indicator

shall be in a visible location following installation. Locate

the damper so that it is accessible for servicing.

3. The damper must be in the open position when appliance

main burners are operating.

4, The boiler is equipped with a factory wired harness that

plugs into the vent damper.

5. Vent pipe must be same size as the flue outlet collar,

except 2 section boilers with vent damper as noted above.

6. Slope pipe up from boiler to chimney not less than 1/4"

per foot.

7. Run pipe as directly as possible with as few elbows as

possible.

8. Do not connect to fireplace flue.

9. End of vent pipe must be flush with inside face of chimney

flue. Use a sealed-in thimble for the chimney connection.

10. Horizontal run should not be longer than 3/4the chimney

height (HT) (Fig. 8).

The sections of vent pipe should be fastened with sheet metal

screws to make the piping rigid. Horizontal portions of the

vent system must be supported to prevent sagging. Use

stovepipe wires every 5' to support the pipe from above.

If the vent pipe must go through a crawl space, double wall

vent pipe should be used. Where vent pipe passes through

a combustible wall or partition, use a ventilated metal thimble.

The thimble should be 4 inches larger in diameter than the

vent p_pe.

Boiler Input

Btuh

10-15 Ft.

Up to 100,000

Up to 155,000

Up to 230,000

Up to 350,000

*HT - top of thimble to fop of flue See Fig 8

For boiler input refer to table, page 2.

For information only - not meant to imply mm_rnurn sizes

6x6

6x7

7x8

9x9

FLUE AREA IN INCHES

*HT.

*HT.

15-25 Ft.

6x5

6x6

7x7

8x9

*HT,

25 Ft. Up

5x5

6x5

6x7

8x8

MINIMUM VENT PiPE CLEARANCE

Wood and other combustible materials must not be closer

than 6' from any surface of single wall metal vent pipe. Listed

Type B vent pipe or other listed venting systems shall be

installed in accordance with their listing.

REMOVING EXISTING BOILER FROM

COMMON VENTING SYSTEM

When an existing boiler is removed from a common venting

system, the common venting system is likely to be too large

for proper venting of the appliances remaining connected

to it.

At the time of removal of an existing boiler, the following

steps shall be followed with each appliance remaining

connected to the common venting system placed in operation,

while the other appliances remaining connected to the

common venting system are not in operation.

1. Seal any unused openings in the common venting system.

2. Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other deficiencies which

could cause an unsafe condition.

3. Insofar as ispractical, close all building doors and windows

and all doors between the space in which the appliances

remaining connected to the common venting system are

located and other spaces of the building. Turn on clothes

dryers and any appliance not connected to the common

venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will operate at

maximum speed. Do not operate a summer exhaust fan.

Close fireplace dampers.

4. Place in operation the appliance being inspected. Follow

the lighting instructions. Adjust thermostat so appliance

will operate continuously.

5, Test for spillage at the draft hood relief opening after 5

minutes of main burner operation. Use the flame of a match

or candle, or smoke from a cigarette, cigar or pipe.

6. After it has been determined that each appliance remain-

ing connected to the common venting system properly

vents when tested as outlined above, return doors,

windows, exhaust fans, fireplace dampers and any other

gas-burning appliance to their previous conditions of use.

_._ 7

7.Any_mproperoperationofthecommonventingsystem

shouldbecorrectedsotheinstallationconformswiththe

NationalFuelGasCode,ANSIZ2231-latestrevisionWhen

resizinganyportionofthecommonventingsystem,the

commonventingsystemshouldberesizedto approach

theminimumsizeasdeterminedusingtheappropriate

tablesin Part11 in theNationalFuelGasCode,ANSI

Z223.1-latestrevision.

For boilers for connection to gas vents or chimneys,

vent installations shall be in accordance with Part 7,

Venting of Equipment, of the National Fuel Gas Code,

ANSI Z223.1-1atest revision and applicable provisions

of the local building codes.

Vent connectors serving appliances vented by natural

draft shall not be connected into any portion of

mechanical draft systems operating under positive

pressure,

ROOF

RIDGE

3/4 HT MAXIMUM

HT

MUSTSLOPEUP

AT LEAST 1/41NCH

PER FOOT OF

HORIZONTAL RUN

HORIZONTAL INSTALLATION

TO FURNACE VENT TO CHIMNEY

OR BOILER DAMPER INSTALL VENT DAMPER WITH

ACTUATOR TO SIDES OF

VENT ONLY. DO NOT MOUNT

ABOVE OR BELOW VENT.

VERTICAL INSTALLATION

TO CHIMNEY

FLOW VENT

'6 ©

TO FURNACE N INSTALLED IN ANY POSITION

OR BOILER

DAMPER

ACTUATOR MAY BE

U

CAUTION: DO NOT INSTALL

THE VENT DAMPER

WmHIN 6 in. (152 ram) OF

COMBUSTIBLE MATERIAL

3HIMNEY

BOILER WATER HEATER

TYPICAL INSTALLATION FOR VENT DAMPER

NOTE CAUTION AND Foo'rNOTES

1. Installthe vent damper to ser,Ace only the single appliance for

which it is intended,if improperlyinstalled, a hazardous condition,

such as an explosion or carbon monoxide poisoning,could result.

2. Do not install _e vent damper on vent pipe curve.

3, Do not run wires near high temperature surfaces. Use stand-off

brackets if necessary

7o0o_

For safe, efficient operation, the vent damper and all flue

product carrying areas of the appliance must be checked

annually by you, with particular attention given to deterioration

from corrosion or other sources. If you see corrosion or other

deterioration, contact your heating contractor for repairs.

Check vent damper operation as follows:

1. When the boiler is off, check that the vent damper position

indicator points to the closed position, Fig. 11.

2. Turn the thermostat or controller up to call for heat and

check that the vent damper indicator points to the open

position, Fig. 11.

3. Turn the thermostat or controller down again and check

that the vent damper position indicator returns to the closed

position.

MANUAL OPERATION OF THE VENT DAMPER

The Effikal vent damper may be placed in the open position

to permit burner operation by using the "HOLD DAMPER

OPEN" switch, located on the damper controller. The

thermostat will control the burner firing as before, while the

damper will remain open. DO NOT turn damper open manu-

ally or motor damage will result. Set switch to "AUTOMATIC

OPERATION" to close vent damper during burner off cycle.

Forfurther information, and for a vent damper troubleshooting

guide, refer to the Effikal manual that was packaged with

the vent damper.

The vent damper must be inspected at least once a

year by a trained, experienced service technician. The

name of the person who originally installed your vent

damper is shown on the installation label.

DAMPER CLOSED DAMPER OPEN

SHOWING OPEN AND CLOSED POSITION

CHECK GAS SUPPLY

The gas pipe to your boiler must be the correct size for the

length of the run and for the total Btu per hour input of all

gas utilization equipment connected to it. See Fig. 12 for

the proper size. Be sure your gas line complies with local

codes and gas company requirements.

The boiler and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess

of V2psig (3.5 kPa).

The boiler must be isolated from the gas supply piping system

by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than V2psig (3.5 kPa).

NATURAL GAS

Length of Includes Fittings

Pipe - Ft.

Pipe Capacity - BTU Per Hour Input

112" 3/4" 1" 111+"

20 92,000 190,000 350,000 625,000

40 63,000 130,000 245,000 445,000

60 50,000 105,000 195,000 365,000

The length of pipe or tubing should be measured from the gas meter

CONNECTING THEGASPIPING

Refer to Fig. 13 for the general layout at the boiler. It shows

the basic fittings you will need. The gas line enters the boiler

from the right side.

The following rules apply:

1. Use only those piping materials and joining methods

listed as acceptable by the authority having jurisdiction,

or in the absence of such requirements, by the National

Fuel Gas Code, ANSI Z223.1-latest revision.

2. Use pipe joint compound suitable for LP gas on male

threads only.

3. Use ground joint unions.

4. Install a sediment trap upstream of gas controls,

5. Use two pipe wrenches when making the connection

to the gas valve to keep it from turning.

6. Install a manual shut-off valve in vertical pipe about 5

feet above floor.

7. Tighten all joints securely

CHECKING THE GAS PIPING

Upon completion of piping, check immediately for gas leaks.

Open the manual shut-off valve. Test for leaks by applying

soap suds (or a liquid detergent) to each joint. Bubbles

forming indicate a leak. CORRECT EVEN THE SMALLEST

LEAK ATONCE.

MANUAL

SHUT'OFF

VALVE

AUTOMATIC

GAS

VALVE

GROUND

MANIFOLD UNION

FLOOR

LINE

JOINT

SEDIMENT TRAP

WARNING

I

Never use a match or open flame to test for leaks.

0 _I]A

All electrical work must conform to local codes as well as

the National Electrical Code, ANSI/NFPA-70, latest revision.

a vertically mounted outlet box. Itshould be sensing average

room temperature, so avoid the following:

ELECTRIC POWER SUPPLY

Run a separate 120 volt circuit from a separate overcurrent

protective device in the electrical service entrance panel.

This should be a 15 ampere circuit. Locate a shut-off switch

at the boiler. It must be turned off during any maintenance.

Connect 120 volt power supply to aquastat terminals LI (HOT}

and L2.

The boiler, when installed, must be electrically grounded in

accordance with the requirements of the authority having

jurisdiction or, in the absence of such requirements, with the

National Electrical Code, ANSI/NFPA No. 70-latest revision.

Run a 14 gauge or heavier copper wire from the boiler to

a grounded connection in the service panel or a properly

driven and electrically grounded ground rod.

WARNING

Turn off electric power at fuse box before making any

I

line voltage connections. Follow local electrical codes.

INSTALL YOUR THERMOSTAT

The thermostat location has an important effect on the

operation of your boiler system. BE SURE TO FOLLOW THE

INSTRUCTIONS INCLUDED WITH YOUR THERMOSTAT.

DEAD SPOTS:

Behind doors

Corners and alcoves

HOT SPOTS:

Concealed pipes

Fireplace

TV sets

Radios

Lamps

Direct sunlight

Kitchens

COLD SPOTS:

Concealed pipes or ducts

Stairwells - drafts

Doors - drafts

Unheated rooms on other side of wall

Set heat anticipator at .2 amps.

I

VENT DAMPER WIRING

The boiler is equipped with a factory wired harness with 4

pin molex plug, that plugs into a 4 pin molex receptacle

inside the vent damper operator.

The vent damper must be connected for the boiler to

operate.

Locate the thermostat about five feet above the floor on an

inside wall. It may be mounted directly on the wall or on

Wiring diagrams follow for the various different models.

CAUTION

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after

servicing.

..... 11

INTERMITTENT IGNITION

I-"_Z • L8148E

I //--AQUASTAT

r L

W_RE COOE

FJ:x"?;_':IT'P':_IDAMPER CABLE

l_:z_ ICNIT}ON CABLE

--LINE VOLTAGE

--LOW VOLTAGE

-- --LOW VOLTAGE

FIELD WIRING

COLOR COOE

BK-BLACK

BR-BROWN

O -ORANGE

Y -YELLOW

R -RED

BT-BLACK WITH WHITE TRAX_ER

W -WHITE

B -GREEN

_i? r? _?;........

LelIK _,r

_,: il F"_ I..............

I i\_-,'_ LF--;_!! i !_-°'! _ / ,,_-

i IiiIi!T ?il II

t .1.o I _-_=111 i I!! i !

"° _ _ "°l _ I : "_-_ T I I,':',__: : [ ==="='_,_'_

Br-B_ W_ V_ TR_FR

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THIS APPLIANCE MUST BE REPLACED,

IT MUST BE REPLACED WITH TYPE 105° C THERMOPLASTIC WIRE OR ITS EQUIVALENT,

1_ 70011A

STANDING PILOT

WIRE CODE

F_';'Pr_DAMPER CABLE

C_=:zzZ_ICNITrON CABLE

--LINE VOLTAGE

--LOW VOLTAGE

-- --LOW VOLTAGE

FIELO WIRING

COLOR CODE

BK-BLACK

BR-BROWN

0 -ORANGE

Y -YELLOW

R -RED

BT-BLACK WITH WHITE TRACER

W -WHIT[

G -GREEN

_ [ ' r ................................. •

14 ; '

, I

II !',_-' I f-:-! t_ 7_'', _ ( _J I ',

II Y -o

II I_?, ?! li, ,,_ ,,",,

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THIS APPLIANCE MUST BE REPLACED,

IT MUST BE REPLACED WITH TYPE 105 ° C THERMOPLASTIC WIRE OR ITS EQUIVALENT.

,,., : ,,, ,,,,-L_I@'_..__'

.... II , ,

---,U { ..... :.... ,,

RELIEF VALVE

You must have a relief valve on your boiler. Water expands

as it is heated. If there is no place for the water to expand

into, water pressure will build up inside the boiler and system.

Should this happen, the relief valve will automatically open

at a pre-determined pressure. This wi(I relieve the strain on

the boiler and system. Run a pipe from the relief valve outlet

(pipe must be same size as outlet and the open end must

not be threaded} to an open drain, tub or sink, or other suitable

drainage point not subject to freezing. Failure to do so may

cause water damage or injury should relief valve release.

EXPANSION TANK

In a properly assembled system, the expanding water flows

into an expansion tank. This tank should be of the correct

size.

The tank is filled with air. As the water expands it compresses

the air inthe tank to form an air pressure cushion. This "spring-

like" cushion serves to maintain correct operating water

pressure regardless of water temperature. This assures a

"full measure" of water, even in the highest radiation unit

of the system. It also prevents blowing off of the relief valve.

The air in the tank in the beginning (with system filled with

cold water) is sufficient for proper operation. The tank also

serves as a trap for excess air in the system. The air would

cause gurgling in the pipes and inefficient circulation in the

radiators if left in the system.

It is possible for a tank to become "water-logged" (filled with

water). It can also become overfilled with air. This can happen

after filling the system with new water. Fittings provided on

the tank and in the line to the tank are for bleeding off excess

water or air.

When installing this tank, it is important: 1} That the tank be

higher than the boiler top. 2) That the pipe to the tank

continuously rises up to the tank (so that air can "bubble"

up to it).

AIR ELIMINATING FITTING (AIR PURGER)

An air purger is used to remove excess air from the system.

It is installed in the supply line. It will eliminate air from the

water before it reaches the radiators and bleed off this air.

MAIN AIR VENT FOR DOWN FLOW SYSTEMS OR

DIAPHRAGM TYPE EXPANSION TANK

Before a system is filled with water, there is air in the pipes

and radiation units. Some of it will be trapped as the system

is filled. It is possible to eliminate most of this air through

the air vents on the radiation units. A main air vent will speed

and simplify this. It should be installed on the highest point

in the supply main when all radiation is below top of boiler.

AUTOMATIC FILL VALVE

For safe, efficient operation, a hot water system must be

completely tilled with water. Adding new water, when

needed can be done manually (by use of a hand valve in

the water supply line}. This requires regular attention to the

system's needs. An automatic fill valve accomplishes this

without attention. It is installed in the supply line on hot water

boilers only The valve operates through water pressure

differentials. It does not require an electrical connection.

DRAIN VALVE

This manual valve provides a means of draining all water

from the boiler and system. It is often installed in the 3A,

tapping at the bottom of the end boiler section. Or it can

be installed in a tee where the return line enters the boiler.

WATER TEMPERATURECONTROL

The water temperature limit control in the relay is adjustable

and may be set as necessary. It may be set as low as 140°

E, or as high as 240 ° E This depends on the type and amount

of radiation involved and weather conditions.

DIAPHRAGM TYPE EXPANSION TANK

The diaphragm type expansion tank (EX-TROL} takes the

place of the conventional expansion tank. Carefully read the

instructions packed with your EX-TROL tank assembly

The EX-TROL tank comes to you with a 10-12 pounds per

square inch air charge. This is the same as the pressure

produced in the system by the automatic fill valve. When

the system is first filled, the EX-TROL tank will contain little

or no water.

As the water is heated its pressure increases. It expands

into the EX-TROL tank, compressing the air in the tank. This

compressed air cushion permits the water in the system to

expand as the temperature changes.

The diaphragm type tank can be mounted on the air purger

fitting or at any other convenient place in the supply or return

line.

,_,_, 14

CIRCULATING PUMP

Every forced hot-water system requires a circulating pump.

A separate pump or zone valve is required for each zone,

if you have a two or more zone system. This pump must

have the capacity to provide the circulation required by your

system. The pump is connected into the return main just

ahead of the boiler. It is also wired to the electrical system.

VENT DAMPER

This product is an automatic, motorized stack damper that

has been developed to increase the efficiency of heating

systems by reducing standby losses from the heating

apparatus and the conditioned air space. The damper closes

the chimney vent when the burner is off and fully opens

it when combustion is required.

ROLLOUT SWITCH

(FLAME ROLLOUT SAFETY SHUTOFF)

The rollout switch is a temperature-sensitive fuse link device.

It is located on the boiler base just outside the fire box. In

the event of heat exchanger flueway blockage causing flame

to roll out of the fire box, the fuse will blow, shutting down

the f!ow of gas to the main burners. The fuse does not change

in appearance when blown.

If the rollout sw!tch blows, it must be replaced with an exact

replacement. Check heat exchanger flueways for blockage

when restoring system to operating condition. Do not operate

system without a rollout switch.

SPILL SWITCH

(BLOCKED VENT SAFETY SHUTOFF)

The spill switch is a manual reset disc thermostat with a fixed

setpoint (340°F), and normally closed contacts. It is located

at the relief opening of the integral draft diverter. In the event

of chimney or venting system blockage causing products

of combustion to spill out of the relief opening, the spill switch

disc heats up and the spill switch contacts will open, shutting

down the flow of gas to the main burners by removing power

to the gas valve.

In the event that the spill switch contacts open, the reset

button on the back of the switch wilt pop up The spill switch

must be reset manually, after the switch has cooled off, by

pushing the reset button down. Check the venting system

and chimney for blockage when restoring the system to

operating condition. DO NOT operate the boiler without a

spill switch.

HOW A HOT-WATER SYSTEM OPERATES

Your entire heating system (boiler, piping and radiation units}

is filled with water. As the water in the boiler is heated, it

is pumped from the top of the boiler through the supply

main to the radiation units. The cooler water in them flows

back through the return main to the boiler. This provides

positive and rapid response to the thermostat.

FILLING SYSTEM WITH WATER

Close the air vents on all radiation units. Open the valves

to these units. Make sure the boiler and expansion tank drain

cocks are closed. The air bleed screw on the tank drain

fitting should be closed. Open the valve in the line from the

boiler to the expansion tank (see page 17 for additional

information}. Open the water inlet to your boiler and leave

it open. Start with the lowest radiation unit. Open the air

vent on this unit. When all the air has escaped and water

starts to flow from the vent, close it. Go to the next radiation

unit, and repeat this process. Repeat until you have covered

every radiation unit in the system (ending up at the highest

unit in the system}. If your units have automatic vents, this

manual venting is unnecessary but itwill speed up the proper

filling of your system.

If your system is a closed expansion tank system, you may

have an Automatic Fill Valve. You may leave it open to refill

the system automatically as needed. Check the temperature-

pressure gauge. Not the position of the hand indicating

pressure. This should be between t 0 and t5 Ibs. Any lowering

of this movable hand below 10 Ibs. will indicate loss of water

due to leakage. The automatic fill valve should compensate

for this. Instructions are packaged with the valve.

I WARNING - Never run water into a hot empty boiler. I

5 7oal,

WARNING: If you do not follow these instructions exactly, a fire or explosion I

may result causing property damage, personal injury or loss of life,

I

I

A. Some boilers are equipped with an intermittent ignition

device which automatically lights the pilot. Do not try to

light the pilot by hand.

Some boilers are equipped with a continuous pilot and

must be manually lighted. (See lighting instructions on

page 15.) A match holder is included in the parts bag.

B. BEFORE OPERATING smell all around the appliance area

for gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone

in your building.

1. STOP! Read the safety information on page 14.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition

automatically lights the pilot. Do not try to

by hand.

device which

light the pilot

•AsINLET

GAS CONTROL KNOB

SHOWN IN "ON" POSITION

5. Remove lower front panel.

6. Rotate the gas control knob clockwise _I to "OFE"

*Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

elf you cannot reach your gas supplier, call the fire

department.

C,

Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or turn

by hand, don't try to repair it, call a qualified service

technician. Force or attempted repair may result in a fire

or explosion.

D,

Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the control

system and any gas control which has been under water.

7. Wait five (5) minutes to clear out any gas. Then smell

for gas, including near the floor. If you smell gas, STOP!

Follow "B" in the safety information on page 14. If you

don't smell gas, go to next step.

8. Rotatethe gascontrol knobcounterclockwise If to "ON."

9. Replace lower front panel.

10. Turn on all electric power to the appliance.

11. Set thermostat to desired setting.

12. If the appliance will not operate, follow the instructions

"To Turn Off Gas To Appliance" and call your service

technician or gas supplier.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if service is

to be performed.

3. Push in gas control knob slightly and turn clockwise

to "OFF' Do not force.

.... 16

1. STOP! Read the safety information on page 14.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. Remove lower front panel.

5. Rotate gas control knob slightly and turn clockwise

to "OFE"

GAS

INLET

RESET BUTTON

_ GAS CONTROL KNOB

SHOWN IN "ON" POSITION

......i

I Ol

6)1"i

6. Wait five (5) minutes to clear out any gas. Then smell

for gas, including near the floor. If you smell gas, STOP!

Follow "B" in the safety information on page 14. If you

don't smell gas, go to next step.

7. Find pilot - follow metal tube from gas control. The pilot

is between two burner tubes as shown in Fig. 14.

8. Turn knob on gas control counterclockwise It to

"PILOT"

9. Rotate the gas control knob counterclockwise It to

"PILOT" Push down and hold the red reset button while

you light pilot burner with a match.

After about one minute, release reset button. Pilot should

remain lit. If it goes out, turn gas control knob clockwise

to OFE To relight, repeat steps 5-9.

• If button does not pop up when released, stop and

immediately call your service technician or.gas supplier.

• If the pilot will not stay lit after several tries, turn the

gas control knob to "OFF" and call your service

technician or gas supplier.

10. After pilot remains lit when red reset button is released,

turn gas control knob counterclockwise ic to "ON."

11. Replace lower front panel.

12. Turn on all electric power to the appliance.

13. Set thermostat to desired setting.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if service is

to be performed.

3. Push in gas control knob slightly and turn clockwise

_I to "OFE" Do not force.

AUTOMATIC GAS VALVE

The Automatic Gas Valve opens or closes according to the

heat requirements of the thermostat and temperature limit

control. It closes if the pilot goes out. Each individual control

must be operating correctly before any gas can pass to the

burners. Any one control can hold the gas supply from burner

regardless of the demand of any other control.

SAFETY PILOT

Safety Pilot prevents the flow of gas to burner if the pilot

goes out, or will not ignite.

GAS VALVE SAFETY SHUTDOWN TEST

1. For boilers equipped with continuous pilot, with main

burners firing, disconnect the thermocouple from the gas

valve. The gas valve should immediately shut off the main

burners and the pilot.

2. For boilers equipped with intermittent ignition, with main

burners firing, disconnect the ignition cable from the

intermittent pilot control box. The gas valve should shut

off the main burners. TURN OFF ELECTRIC POWER to

boiler before reconnecting ignition cable, to prevent

electric shock.

RELIGHT

Theelectricand gasshallbeofffor 5 minutesbeforerelighting.

THERMOSTAT

Keep it set at a desired room temperature. If windows are

to be opened or heat is not needed, move thermostat pointer

to a lower setting.

NOTE

In the event of failure of any component, the system

will not operate or will go into safety lockout. The system

iscompletely self-checking On every call for heat, each

component must be functioning properly to permit

operation. On safety lockout the system has to be reset

by turning the thermostat to the lowest setting for one

minute, then back to the normal setting.

Safe lighting and other performance criteria were met with

the gas manifold and control assembly provided on the boiler

when the boiler underwent tests specified in ANSI Z21.13

- latest revision.

7 _8

pRESSURERI_GUI._TO/I

AOJUSTMKNT

(UNC)I[ R CA/' SCRI[W

PRI_SURI_ TA

WIRING

TAr

a T| RMIF_AI._II)

IN,

€ _LOT OUTUtT

oo._

(UNr_ER CAP SCREW)

MANTEL

SHARPINNERCONES

ADJUST PILOT BURNER

Pilot flame should surround 3/8" to 1/2" of the pilot sensor.

Refer to Fig. 18. If flame needs adjusting, do it as follows:

1. Remove screw cover over pilot adjusting screw.

2. Insert small screwdriver and adjust flame as needed.

Turn screw counterclockwise to increase flame, clock-

wise to decrease.

3. Replace screw cover over pilot adjusting screw.

MAIN BURNER(S)

The main burners do not require primary air adjustment and

are not equipped with primary air shutters. Main burner

flames should form sharp blue inner cones in a softer blue

outer mantel, with no yellow. Puffs of air from blowing on the

flame or stamping on the floor will cause the flames to turn

orange momentarily. This is not unusual. Remain still when

observing the main burner flames. If the flame appearance is

not correct, check main burner orifices and the burner throat

and flame ports for dust and lint obstruction. It may be nec-

essary to remove the rollout shield to observe the main burn-

er flames. Replace rollout shield after observation. Refer to

Figure 17.

ADJUST LIMIT CONTROLS

Instructions for each control are included with the controls.

These settings can be changed after you have had some

idea how the system works. Example: If your system does not

give quite enough heat in very cold weather, you can raise

the limit setting to 220° R Use the boiler gauge to check your

settings. Make the adjustments according to its readings.

Check thermostat operation. When set above temperature

indicated on the thermometer, boiler should ignite. Make cer-

tain the thermostat turns off the boiler when room tempera-

ture reaches the selected setting and starts the boiler oper-

ating when room temperature falls a few degi-ees.

After setting limit control to limit setting, check to see if it shuts

off the gas supply to the burners. Turn your thermostat up to

call for heat and let your boiler run until the temperature of the

water reaches the limit setting. The gas valve should shut off

and the circulator keep running until the thermostat is satis-

fied, or the water cools enough to restart the burners through

the limit control.

Finally, set the thermostat for the desired temperature.

Special conditions in your home and the location of the ther-

mostat will govern this setting.

3/8" to 1/2"

Type of Heating Unit Limit Control Setting

Standing Radiators .................... 180° F.

J RECOMMENDED BOILER WATER TEMPERATURES

Baseboard and Convector Radiators ...... 200 ° F.

BURNERS

A visual check of the pilot and main burner flames should

be made at least once each year, preferably at the beginning

of the heating season. See page 18.

RELIEF VALVE

This valve should open automatically if the system pressure

exceeds the pressure rating (usually 30 psi) of the relief valve.

Should it ever fail to open under this condition, shut down

your system. Drain the system until system pressure is

reduced below the relief valve pressure rating. If valve

discharge occurs, or if valve fails to open as described above,

contact an authorized contractor or qualified service

technician to replace the relief valve and inspect the heating

system to determine the cause, as this may indicate an

equipment malfunction.

This valve should be tested every month during periods of

boiler operation, and at the beginning and end of any

extended non-service period. Prior to testing, make certain

discharge pipe is properly connected to valve outlet and

arranged so as to contain and safely dispose of boiler

discharge. Test at normal system operating pressure. Hold

the trip lever fully open for at least five seconds in order

to flush free any sediment that may lodge on the valve seat.

Then permit the valve to snap shut.

EXPANSION TANK

As previously noted, this tank may become waterlogged, or

may receive an excess of air. Frequent automatic opening

of the relief valve indicates water logging. A high boiler

temperature accompanied by unusually low radiation unit

temperature (and "knocking") indicates excess air in tank.

To correct either condition, close the valve between the boiler

and the tank. Drain the tank until it is empty Check all the

tank plugs and fittings. Tighten as necessary Open the valve

between the boiler and tank. Water will rise to the normal

height in the tank ifyou have an automatic fill valve (otherwise,

manually refill the system).

BOILER FLUE PASSAGES

Under normal operating conditions, with the burners properly

adjusted, it should not be necessary to clean the boiler flue

gas passages. However, to assure trouble-free operation, we

recommend that you have the flue passages, burner

adjustment, and operation of the controls checked once each

year by a competent Service Technician.

Before the start of each season (or whenever system has

been shut down for some time) recheck the whole system

for leaks.., and recheck the boiler and vent pipe for leaks.

Replace or patch any boiler seals that are faulty

VENT PIPE

The venting of this unit is very important and the piping

should be checked at least once a season. If the vent

piping shows any sign of leaking, replace it immediately.

WATER SYSTEM

If system is to remain out of service during freezing weather,

always drain It completely (water left in to freeze will crack

the pipes and/or boiler).

CLEANING YOUR BOILER AND BURNERS

Flue passages between sections should be examined yearly

and cleaned if necessary. To clean, remove burners, pilot,

and vent pipe. Remove top and front jacket panels. Remove

the two screws attaching the intermediate front panel to the

left and right side jacket panels. Remove the draft diverter

and intermediate front panel as a unit. Carefully remove the

cerafelt gasket strips. Clean passageways between sections

with a flexible handle wire brush. Remove dirt from bottom

of boiler and from between sections by vacuuming. Make

sure all flame ports in burners are open and clear. Shake

out or blow out all loose dirt in burners. Reseal seams between

adjacent sections as necessary with 400 F RTV silicone

sealant. Reassemble all parts. Be sure to check tightness

of pilot connections and condition of burner flames after

reassembly (see Figures 17 and 18). Be sure vent pipe

connections to chimney are secure and no obstructions are

present.

CIRCULATOR PUMP ISOLATION VALVES

The isolation valves in the circulator pump flanges should

be operated manually once or twice per year to prevent

the valves from becoming stuck in the open position.

Rotate the valves from the open position to the closed

position and back to the open position.

You may avoid inconvenience and service calls by checking these points before you call for service.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS

1. Do Not try to light any appliance.

2. Do not touch any electric switch, do not use the phone.

3. Leave the building immediately, then call your gas supplier.

4. If you cannot reach the gas supplier, call the fire department.

Poseibie Cause

Thermostat is not set correctly

Burner is not operating properly

No electric power to boiler

Controls out of adjustment

Radiators not heating

Circulating pump not running

Poor electrical contact

Rollout switch blown

Spill switch blown

Vent damper not operating

What to do

Reset thermostat above room temperature.

Check flame. If it is yellow, the burner is not getting enough air. Or, if flame

is blue and noisy and seems to lift off the burner, the burner is getting too

much air. Contact your service technician.

Check overcurrent protection. Check to be sure electric power supply circuit

is "ON."

Reset according to instructions.

Open radiator vents to vent excess air. Check flow control valve (if used). It

may be in closed position.

Check overcurrent protection. Check relay operation.

Check all control terminals and wire joints.

Have your service technician check heat exchanger for blockage. Replace rollout

switch with exact replacement.

Have your service technician check venting system and chimney for blockage,

or down draft condition. Reset spill switch.

Consult troubleshooting guide in Effikal manual, packaged with vent damper.

Possible Cause

Gas input amount is incorrect

What to do

Contact your service technician.

HAVE YOUR SERVICE TECHNICIAN CHECK ANY PROBLEM YOU ARE UNABLE TO CORRECT.

GAS-FIRED HOT WATER BOILERS

-- IMPORTANT --

READ THESE INSTRUCTIONS BEFORE ORDERING

All parts listed in the following Parts List may be ordered

through your nearest supplier.

When ordering parts, first obtain the Model Number from

the data plate on your boiler, then determine the Part No.

{not the Key No.) and the Description of each part from the

following illustrations and list. Be sure to give us all this

information:

The Part No. - The Part Description - The Boiler Model No.

JACKET - SECTION AND BASE PARTS

THIS IS A REPAIR PARTS LIST - NOT A PACKING LIST

KEY

NO. DESCRIPTION

1 Jacket,RightSidePanel

2 _flO× 1/2"SheetMetalScrew

3 RatingPlate

4 BaseInsulation BaseSides(2)

- BaseFront

- BaseRear

5 BaseBaffle

6 Base

7 JacketTieBar

8 PushNipple

9 Jacket,LeftSidePanel

10 Knob,ServiceDoor(pair)

11 JacketServiceDoor

12 JacketintermediatePanel

13 JacketFrontPanel

14 1/4"Tie RodandNut

15 BoilerSection,Left End

16 BoilerSection,Middle

t 7 JacketTopPanel

t 8 DraftOiverter

19 BoilerSection,RightEnd

20 JacketBackPanel

JacketComplete

BlockAssembly(19,16, 15,14,8)

CembustibleFloorPlale

CerafeltGasket

21 VentDamper

BaseAssembly(4, 5, 6)

:Not Illustrated

2 SECTION

PartNo.

425-00-901

146-95-674

146-94-018

146-14-020

146-14-112

146-14-122

425-00-642

425-00-662

425-00-652

433-00-976

425-00-900

137-02-153

425-00-912

425-00-812

425-00-810

146-05-008

410-00-020

410-00-022

425-00-842

425-00-672

410-00-021

425-00-902

425-60-922

410-00-213

146-14-031

146-14-0181

146-28-011

433-00-662

3SECTION

PartNo.

425-00-901

146-95-074

146-94-016

146-14-130

146-14-113

146-14-123

425-00-643

425-00-663

425-00-653

433-00-976

425-00-900

137-02-153

425-00-913

425-00-813

425-00-811

146-05-001

410-00-020

419-00-022

425-00-843

425-00-673

410-00-021

425-00-903

425-60-929

410-00-313

146-14-031

148-14-018

146-28-001

433-00-663

4SECTION

PartNo.

425-00-901

146-95-074

146-94-016

146-t4-130

146-14-114

146-14-124

425-00-644

425-00-664

425-00-654

433-00-976

425-OO-9OO

137-02-153

425-00-914

425-00-814

425-00-804

146-05-002

410-00-020

410-00-022

425-00-844

425-00-674

410-00-021

425-00-904

425-60-924

410-00-413

146-14-031

146-14-018

146-28-002

433-00-664

\10

NATURALGAS

5SECTION 6 SECTION

PartNo. PartNo.

425-00-901 425-00-901

146-95-074 146-95-974

146-94-016 146-94-916

146-14-130 146-14-130

146-14-115 146-14-116

146-t4-125 146-14-126

425-00-645

425-00-665

425-00-655

433-00-976

425-00-900

137-02-153

425-00-915

425-00-8!5

425-00-805

146-05-051

410-00-020

410-00-022

425-00-845

425-00-675

410-00-021

425-00-905

425-6O-925

410-00-513

146-14-031

146-14-018

146-28-002

433-00-665

425-00-646

425-00-666

425-00-656

433-00-976

425-00-900

137-02-153

425-90-916

!425-00-816

425-00-806

146-05-053

410-00-020

410-00-022

425-00-846

425-00-676

410-00-021

425-90-966

425-60-926

410-00-613

146-14-031

146-14-018

146-28-003

433-00-666

4 7

7SECTION

PartNo.

425-00-991

146-95-074

146-94-016

146-14-130

146-14-117

146-14-127

425-00-647

425-06-667

425-00-657

433-OO-976

425-00-900

137-02-153

425-00-917

425-00-817

425-00-807

146-05-005

410-00-020

410-00-022

425-09-647

425-00-677

410-09-021

425-OO-9O7

425-60-927

410-00-713

146-14-032

146-14-018

146-28-003

433-00-667

8SECTION

PartNo.

425-00-901

146-95-074

146-94-016

146-t4-1_0

146-14-H6

146-14-128

425-00-648

425-00-668

425-00-658

433-00-976

425-00-900

137-02-153

425-00-918

425-00-818

425-00-808

146-05-007

410-00-020

410-00-022

425-00-848

425-09-678

410-00-021

425-00-908

425-60-928

410-00-813

146-14-032

146-14-018

146-28-003

433-00-668

18

0

1

9SECTION

PartNo.

425-00-901

146-95-074

146-94-016

146-14-130

146-14-119

146-14-129

425-00-649

425-00-669

425-00-659

433-00-976

425-00-900

137-02-t53

425-00-919

425-00-819

425-00-809

146-05-009

410-00-020

410-00-022

425-00-849

425-00-679

410-00-021

425-00-909

425-60-929

410-00-913

146-14-032

146-14-018

146-28-003

433-00-669

21 _1

FOR USE WITH NATURAL GAS ONLY

4 5

NOTE: Actual gas valve may look

different than gas valve shown

NATURAL GAS BURNERS AND MANIFOLD PARTS

THIS IS A REPAIR PARTS LIST - NOT A PACKING LIST

KEY

NO.

1

2

3

4

5

6

6A

7

1

3

DESCRIPTION

24VoltGasValve,Elect.Int.Ign

PilotTube

10-321/2 HexHeadScrew

GasManifold

MainBurnerOrifice*

MainBurner**

MainBurnerwithPilotBracket

PilotBurner

RolloutShield

24VoltGasValve,ContinuousPilet 146-62-051 146-62-051 146-62-051

10-321/2HexHeadScrew 146-95-307 146-95-307 146-95-307

2 SECTION

Pad NO.

146-62-052

146-15-005

146-95-307

146-16-032

146-15-031

146-15-531

146-62-095

425-00-932

(2 req'd)

7

PilotBurner 146-62-097 146-62-053 146-62-053

Thermocouple 146-62-037146-62-037 146-62-039

Quantity is 1 unless otherwise noted.

• Requires1lessthanthenumber ofsections.

** Requires2 less thanthe number of sections.

NotIllustrated.

_=o2oF 22

3 SECTION

PadNo.

146-62-052

146-15-005

146-95-307'

146-16-033

146-15-031

146-15-532

146-15-531

146-62-992

425-00-933

4 SECTION

Pad No.

146-62-052

146-15-005

146-95-307

146-16-034

146-15-031

146-15-532

146-15-531

146-62-092

425-00-934

5 SECTION

Part NO.

146-62-052

146-15-005 146-15-005

146-95-307 146-95-307

146-16-035 146-16-013

146-15-031 146-15-035

146-15-532 146-15-532

146-15-531 146-15-531

146-62-092 146-62-092

425-00-935 425-00-936

146-62-051 146-62-060

146-95-307 146-95-307

146-62-053 146-62-053

146-62-039 146-62-039

7 SECTION

Pad No.

146-62-058

146-15-005

146-95-307

146-16-014

146-15-035

146-15-532

146-15-531

146-62-092

425-00-937

146-62-069

146-95-307

146-62-053

146-52-039

8 SECTION

Pad No.

146-62-058!

146-15-006

146-95-307

146-16-015

146-15-035

146-15-532

146-15-531

146-62-092

425-00-938

146-62-060

146-95-307

146-62-053

146-62-036

9SECTION

Pa_No.

146-B2-058

146-15-006

146-95-307

146-16-016

146-15-035

146-15-532

146-15-531

146-62-092

425-00-939

146-62-060

146-95-307

146-62-053

146-62-036

BOILER CONTROLS AND PIPING

KEY DESCRIPTION PART

NO. NO.

1

1

3

6 7

%" ASME Relief Valve

2

%" x 71/2"Nipple

3

Temperature Pressure Gauge - 5" Stem

6

1Y4"x %" x 1W' Tee

7

Aquastat Relay

8

Isolation Bail Valve

Grundfos UP15-42F Circulator

1:

9

"race 007 Circulator

10

1W' x 2W' Nipple

11

11/4"Ell

12

1Y4"x 3V2" Nipple

Intermittent Pilot Control - Natural Gas

13

- Propane Gas

Spill Switch (36TX16-6281) 340" F

Rollout Switch

4" Vent Damper (with 3" Adapter)

5" Vent Damper

6" Vent Damper

7" Vent Damper

Vent .Damper Operator (Motor)

400° F Black Silicone Rubber Adhesive

Sealant (10.3 oz. Cartridge)

146-22-011

146-07-041

146-23-009

146-93-049

433-00-523

146-26-043

146-26-045

146-62-047

146-07-044

146-93-042

146-07-008

146-62-303

146-62-071

146-60-001

146-29-002

146-28-011

146-28-001

146-28-002

146-28-003

146-28-006

146-06-020

41,-,2

Not Illustrated

11

23 r,_,_3

Gas-Fired

CastIron

HOTWATER

BOILER

Now that you have purchased your Boiler, should a need

ever exist for repair parts or service, simply contact any

Sears Service Center. Be sure to provide all pertinent facts

when you call or visit.

The model number of your Boiler will be found on the model

plate on the side of the Boiler.

I

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION:

• PART NUMBER

eMODEL NUMBER

All parts listed may be ordered from any Sears Service

Center.

If the parts you need are not stocked locally, your order

will be electronically transmitted to a Sears Repair Parts

Distribution Center for handling.

When Sears arranges the installation, you can be sure the

job is done right. We will arrange for professional

workmanship.., and we'll take care of the entire project.

What's more, during installation you get insured protection

• . . against property damage and also against accidents

to workmen. All you have to do is talk to your nearest Sears

store today for detailed information.

• PART DESCRIPTION

eNAME OF ITEM

Loading...

Loading...