Owner'sManual

CONTINUOUSPILOT

MODELNO.

229.960330

229.960340

229.960360

229.960360

229.960370

229.960380

229.960390

ELECTRONIC

INTERMITTENTIGNITION

MODELNO.

220.960230

229.960240

229.960260

229.960260

229.960270

229.960280

229.960290

Theseinstructionsmustbeaffixed

onor adjacenttotheboiler.

CAUTION

Readall instructionscarefully

beforestartingtheinstallation.

Save this manual

for future reference.

®

Gas-Fired

CastIron

STEAM

BOILER

• Installation

• Operation

• RepairParts

WARNING: Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage. Refer to this manual.

For assistance or additional information consult a qualified installer,

service agency or the gas supplier. Natural gas boilers are not to be

converted to Propane gas.

PRINTED IN U.S.A. FOAM e37-_00-02_02-6"7949

Warranty .................................................... 2

Rules for Safe Installation and Operation .................. 3

Boiler Ratings and Capacities ............................. 4

Before You Start ............................................ 5

Locating the Boiler ......................................... 5

Fresh Air for Combustion .................................. 6

Installation - System Piping ............ : ................... 7

Chimney and Vent Pipe Connection ....................... 10

Vent Damper Operation .................................... ! 1

Gas Supply Piping ......................................... 12

Electrical Wiring ............................................ !3

Controls and Accessories - What They Do ............... 19

For Your Safety - Read Before Operating ................. 20

Operating Your Boiler ...................................... 22

Checking and Adjusting ................................... 23

Cleaning Your Boiler ....................................... 24

Maintaining Your Boiler ...................................... 25

Service Hints ............................................... 26

Repair Parts ................................................ 27

E_ AIRS

KENNMORE CAST IRON BOILERS

FULLONEYEARWARRANTYON HOTWATERAND GAS STEAMCASTIRONBOILERS

For one {1) year from the date of installation,when this boiler is installed and maintained in accordance

with our instructions. Searswill repair defects in material orworkmanship inthe boiler,free of charge.

LIMITED 12 YEAR WARRANTY ON STEAM CAST IRON BOILERS

After one {1)yearand through twelve (12} yearsfrom the date of installation,Searswillfurnish a replacement

heatexchanger, ifthe heat exchanger in the boiler is defective. YOU PAY FOR LABOR.

LIMITED 20 YEAR WARRANTY ON HOT WATER CAST IRON BOILERS

After one (1)yearand through twenty (20) years from the date of installation,Searswill furnish areplacement

heat exchanger ifthe heat exchanger inthe boiler isdefective. YOU PAY FOR LABOR.

SEARS INSTALLATION WARRANTY

Inaddition to any warranty extended to you on the Sears merchandise involved, which warranty becomes

effective the date the merchandise is installed,should the workmanship of any Sears arranged installation

prove faulty within one year, Sears will, upon notice from you, cause such faults to be corrected at

no additional cost to you.

FOR WARRANTY SERVICE, SIMPLY CONTACT THE NEAREST SEARS STORE OR SERVICE

CENTER THROUGHOUT THE UNITED STATES. This warranty gives you specific legal rights, and

you mayalso haveother rights which vary from state to state.

IMPORTANT

The following are the responsibilities of the user and are

not covered by the Warranty

1. Filter cleaning or replacement.

2. Damage to unit or unsatisfactory operation due to improper

cleaning or use of unit in corrosive atmosphere.

3. Damage to unit or unsatisfactory operation due to blown

fuses or inadequate or interrupted electricaI protective

devices.

4. Damage to unit caused by the use of components or other

accessories not compatible with the unit.

5. If the unit is removed from the place it was originally

installed, this Warranty becomes void.

6. Damage tothe unit caused by accident, abuse, negligence,

misuse, riot, fire, flood, or acts of God.

SEARS ROEBUCKAND COMPANY

D/817WA

Hoffman Estates, IL 60179

®,_E 2

1. Read the Owner's Manual carefully Failure to fallow the

rules for safe operation and the instructions can cause

a malfunction of the boiler and result in death, serious

bodily injury, and/or property damage.

2. Check your local codes and utility requirements before

installation, The installation must be in accordance with

their directives,

3. Before servicing, allow boiler to cool. Always shut off any

electricity and gas to boiler when working on it. This will

prevent any electrical shocks or burns.

4. Never test for gas leaks with an open flame. Use soap

and check all connections. This will avoid any possibility

of fire or explosion.

5. Be certain your new boiler will be using the correct gas.

Overfiring will result in premature failure of the boiler

sections and cause dangerous operation.

6. Never vent this boiler into an enclosed space. Always vent

to the outside. Never vent to another room or inside a

building.

7. Be sure there is adequate air supply for complete

combustion.

8. Follow a regular service and maintenance schedule for

efficient and safe operation.

TOOLS

Pipe Wrench

Screwdrivers

Tin Snips

6 foot tape or folding rule

Hack Saw

LP Torch, if you have copper piping

Pipe cutter and threading tools

(for iron pipe systems)

MATERIALS

Pipe joint compound suitable for natural and propane gas.

Iron or copper pipe for the water lines,

Black pipe for the gas lines.

Miscellaneous fittings.

Solder and flux if you have copper piping.

The following booklets will help you in making the installation:

Electrical Wiring - Available at Sears from the Plumbing, Heating or Electrical Departments at nominal cost.

American National Standards, Installation of Gas Appliances and Gas Piping, ANSI Z223.1-1atest revision.

©btain from American Gas Association, 1515 Wilson Boulevard, Arlington (Roslyn), VA 22209

e07_3,_

VENT

DAMPER

ASME

POP

SAFETY

VALVE

, ; J i

: 2'/2" NPT _ ",

\ :

29" ; \ :

; LEFT SIDE

I

i

J I I

I iL

PRESSURE

GAUGE

SPILL '_

/ SWITCI-€

WATER

LiNE -- __ --

PROBE

ROLLOUT 36_e"

-SWITCH

_ -, _o _ _

GAS

A ...._ UNE

43/,=. 261/="

RESSURE

LIMIT

ONTROL

_$8 6 CUT'OFF

GAS

FRONT RIGHT SIDE

24"

DESIGN

CERTIFIED FOR

NATURAL GAS

GAS-FIRED STEAM BOILERS

BOILER MODEL NUMBER DgMENSlO_

INTERMrr_NT s'rANOING NO.OF (_)

IGNITION PLOT SECTIONS

FLUE "A"

Wr_l VIg_IT I_MPER WiTH vl_rr DAMPER DIAMErE_ WlEI].I

229960230

22996024O

229960250

229960260

229.960270

229.960280

229.960290

229.960330

229.960340

229.960350

229960360

229.960370

229.960380

229.960390

3

4

5

6

7

8

9

"[h_TURALG/_

NET N_ _B_

AGA HEATING _B-R RARN6

INPUT CAPAQ'rY

"MW'I *MOH RA'J_NG SO.

°MBH PJ_4ATIQ#

75 62 47 196 5 111_

112 91 68 283 6 14V_

150 122 92 383 6 !7¾

187 153 115 479 7 21

225 183 137 571 7 24%

262 214 161 67! 7 2_/_

299 245 184 767 7 303/4

* MBH = 1,000 8tuh. Btuh = British Tnermat Unit Per Hour

**Add 5Vz"to height for Vent Damper

1"For altitudes above 2,000 ft rabngs should be reduced a[ the rate of 4% fc_ each 1,000 ft above sea level

Heating Capacity is based on DOE. (Department of Energy) test prc_edure

The Ratings marked "Net I=B=R Ratings" indicate the amount

of equivalent direct cast iron radiation each boiler will take

care of under normal conditions and thermostatic control.

The Net I=B=R Steam Ratings shown are based on an

allowance of 1.333 in accordance with the factors shown

in the I=B=R Code as published by The Hydronics Institute.

Selection of boiler size should be based upon "Net I--E_R

Rating" being equal to or greater than installed radiation in

square feet. Consult manufacturer before selecting a boiler

for installations having unusual piping and pickup requirements,

Specifications and dimensions are subject to change without

notice.

These Gas-Fired Steam Boilers are low pressure, sectional

cast iron boilers Design Certified by A.G.A. (American Gas

Association} for use with Natural Gas. They are constructed

and hydrostatically tested for a maximum working pressure

of 15 psi (pounds per square inch) in accordance with A.S.M.E.

(American Society of Mechanical Engineers) Boiler and

Pressure Vessel Code Section IV Standards for cast iron

heating boilers.

BOILERS FOR USE AT HIGH ALTITUDE

This boiler is factory equipped for use at altitudes of 0-2,000

feet above sea level. For use at altitudes above 2,000 feet

above sea level, the input ratings are reduced by a change

in main burner orifice size.

For altitudes above 2,000 feet above sea level, input ratings

should be reduced at the rate of 4% for each 1,000 feet

above sea level. Consult the National Fuel Gas Code

(NFPA54/ANSl Z223.1 -latest edition}, or the manufacturer for

correct orifice sizing information. High altitude orifices are

available from the boiler manufacturer.

r_7_c 4

Checktobesureyouhavetherightsizeboilerbeforestartingtheinstallation.

Seeratingand capacitytableon previouspage.Alsobe surethe new

boiler is for the type of gas youare using.Checkthe ratingplate on

therightsideof theboiler.

Youmustsee that the boiler is suppliedwith the correcttype of gas,

fresh air for combustion,anda suitableelectricalsupplyAlso,the boiler

mustbe connectedto a suitablechimneyandanadequatepipingsystem.

Finallya thermostat,properlylocated,is neededfor controlof theheating

system.If you haveany doubtsas to the variousrequirements,check

with local authoritiesandobtain professionalhetp whereneeded.Take

the time to completeall of the stepsfor SAFEandPROPERoperation

oftheheatingsystem.

Theseboilersare designedfor use in closedheatingsystemswhereall

of the steam is returnedto the boileras condensateandthe amount

of make-upwaterrequiredis minimal.Theseboilers are not designed

for or intendedfor use in opensystemsor processapplicationsusing

I

100%make-upwater.Damageto theboilerresultingfromsuchuseshall

notbecoveredunderthewarranty

Whererequiredby theauthorityhavingjurisdiction,the installationmust

conformto AmericanSocietyof MechanicalEngineersSafetyCodefor

ControlsandSafetyDevicesforAutomaticallyFiredBoilers,No.CSD-1.

Theinstallationmus_conformto therequirementsof theauthorityhaving

jurisdictionor,in theabsenceof suchrequirements,to the NationalFuel

GasCode,ANSIZ223.1-1atestrevision.

Thefollowingstepsareallnecessaryforproperinstallationandsafeoperation

ol yourboiler.

1. LOCATINGTHEBOILER 5. GASSUPPLYPIPING

2. FRESHAIRFORCOMBUSTION 6. ELECTRICALWIRING

3. INSTALLATION- SYSTEMPIPING 7. CHECKING&ADJUSTING

4. CHIMNEY& VENTPIPECONNECTION

KEEP BOILER AREA CLEAN AND FREE FROM COMBUSTIBLE MATERIALS,

GASOLINE AND OTHER FLAMMABLE VAPORS AND LIQUIDS

1. Selectlevellocationas centralizedwith pipingsystem,and as near

chimney,aspossible.

2. Placecratedboilerat selectedlocation,removecrateby pullingcrate

sidesfromtop and bottom boards.Combustiblefloors:Whenboiler

is to be installedon a combustiblefloor,a SpecialBasePlatemust

beused- 146-14-031(3-6Section}or 146-14-032(7-9 Section}.

Thisboilermustnotbeinstalledoncarpeting.

3. If this boileris equippedwith cast iron burners,it is alsoequipped

with stainlesssteel wire ties to hold the backend of the cast iron

burnersin placeduringshipping.In orderto removetheburnersfor

cleaningor inspection,the wireties mustbe cut andremoved.The

wire ties are accessedthroughthe combustionair openingon the

backside of the boiler at the bottomof the rearjacketpanel,and

maybe cut with anywire cuttingpliers. I1the boileris installedat

its minimumclearancesit maybe difficultto reachthewireties after

the boileris installed,and lhe wireties shouldbe cutnow.Thewire

tiesareonlyneededduringshipping,anddo notneedtobereplaced.

Boilersequippedwithstainlesssteelburnersdonothavewire

ties andthis informationdoesnotapply.

4. Boiler is to be level.Metalshimsmaybe used underbaselegs for

finalleveling.

5. Accessibility clearances must take precedence over fire

protectionclearances.18"clearanceshouldbemaintainedat a side

wherepassageis requiredto accessto anothersidefor cleaningor

servicing,inspection,or replacementof any partsthat normallymay

requiresuchattention.18" clearanceis recommendedon thecontrol

sidefor servicing.

Figure2showsminimumclearancesto combustibleconstruction.Rooms

thatare largein comparisonwith the size of the boiler are defined

as rooms havinga volumeequal to or greaterthan16 times the

volumeof the boiler. Wherethe actualceilingheightof a room is

greaterthan8', the volumeof a roomshaftbe figuredon the basis

of a ceilingheighto18'. Determinationof roomsizeshouldbebased

on thetotal volumeof air gas fired equipmentinstalledin the room.

Consuttsection 6.3.1 of the NationalFuel Gas Code for further

information,includingapprovedmethodsfor reducingclearancesin

largerooms.

6. Equipmentshallbe installedin a locationin which the facilitiesfor

ventilationpermitsatisfactorycombustionof gas,properventing,and

maintenanceof ambienttemperatureat safe limits under normal

conditionsof use.Equipmentshall be locatedso as notto interfere

withpropercirculationofair.Whennormalinfiltrationdoesnotprovide

thenecessaryair,outsideairshallbeintroduced(SeePage6- "Fresh

Airfor Combustion").

7. Adviseownerto keepair passagesfree of obstructions.Ventilating

andcombustionairmustenterboilerroomwithoutrestrictions.

8. Theboilershallbeinstalledsuchthattheautomaticgasignitionsystem

componentsare protectedfrom water(dripping,spraying,rain,etc.)

during applianceoperationand service (condensatetrap, control

replacement,etc.).

Top

Rear

Control Side

Opposite Side

Front

Flue/Vent Connecto_

Near Boiler Piping

BoilerVolume

(Cu.Ft.)

63

8!

99

11.7

13.5

153

17.2

BoilerSize

3 sect.

4 sect.

5 sect.

6 sect.

7 sect.

8 sect.

9 sect.

Alcove,orRoomNMLarge

InComparisonWithBoiler

6'

6' 6*

7' 6*

6' 6'

18" 18'

6" 6"

1" 1"

MinimumRoomVolumeRequiredToBe

LargeRoom(Cu.Ft.)*

100.4

129.4

158.4

187.4

216,4

245.4

274,5

RoomLargeIn

ComparisonWithBoiler

6'

* FORROOMWITHSINGLEBOILERONLY

THIS UNIT MUST BE SET ON A CONCRETE OR OTHER

NON-COMBUSTIBLE MATERIAL BASE OR FLOOR.

Provision for combustion and ventilation air must be in accordancewith Section 5.3, Air for Combustionand

Ventilation, of the National Fuel Gas Code,ANSI Z223.1-1atest revision, or applicable provisionsof the local buildingcodes.

WARNING

Besure to provideenough fresh air for combustion.

Enoughair insuresproper combustionand assuresthat

nohazardwilldevelopdueto the lackofoxygen.

You must provide for enough fresh air to assure proper

combustion. The fire in the boiler uses oxygen. It must have

a continuous supply. The air in a house contains only enough

oxygen to supply the burner for a short time. Outside air

must enter the house to replace that used by the burner.

Study following examples 1 and 2 to determine your fresh

air requirements,

EXAMPLE 1: Boiler Located in Unconfined Space

If your boiler is in an open area (unpartitioned basement)

in a conventional house, the air that leaks through the cracks

around doors and windows will usually be adequate to provide

air for combustion. The doors should not fit tightly. Do not

caulk the cracks around the windows,

An unconfined space is defined as a space whose volume

is not less than 50 cubic feet per 1,000 Btu per hour of

the total input rating of all appliances installed in that space.

EXAMPLE 2: Boiler Located in Confined Space

A. All Air from Inside the Building: The confined space

shall be provided with two permanent openings

communicating directly with an additional room(s) of

sufficient volume sothat thecombined volume of all spaces

meets the criteria foran unconfined space. The total input

of all gas utilization equipment installed in the combined

space shall be considered in making this determination.

Each opening shall have a minimum free area of one

square inch per 1,000 Btu per hour of thetotal input rating

of all gas utilization equipment in the confined space, but

not less than 100 square inches. One opening shall be

within 12 inches of the top and one within 12 inches of

the bottom of the enclosure,

B, All Air from Outdoors: The confined space shall be

provided with two permanent openings, one commencing

within 12 inches of the top and one commencing within

12 inches of the bottom of the enclosure. The openings

shall communicate directly, or by ducts, with the outdoors

or spaces (crawl or attic) that freely communicate with

the outdoors.

1. When directly communicating with the outdoors, each

opening shall have a minimum free area of one square

inch per 4,000 Btu per hour of total input rating of alt

equipment in the enclosure.

NOTE

If you use a fireplace or a kitchen or bathroom exhaust

fan, you should install an outside air intake.These devices

will rob the boiler and water heater of combustion air.

2. When communicating with the outdoorsthrough vertical

ducts, each opening shall have a minimum free area

of one square inch per 4,000 Btu per hour of total

input rating of all equipment in the enclosure.

3. When communicating with the outdoors through

horizontal ducts, each opening shall have a minimum

free area of one square inch per 2,000 Btu per hour

of total input rating of all equipment inthe enclosure.

4. When ducts are used, they shall be of the same cross-

sectional area as the free area of the openings to which

they connect. The minimum dimension of rectangular

air ducts shall be not less than three inches.

Fresh Air Duct Capacities for Ducts Supplying Fresh Air to

boiler in tightly constructed houses. British Thermal Units per

hour Input (Btuh)*.

Fresh Air 1/,-Mesh Wood Metal

Duct Screen Louvers Louvers

Size Btuh Btuh Btuh

3' x 12' 144,000 36,000 108,000

8" x 8' 256,000 64,000 192,000

8' x 12" 384,000 96,000 288,000

8V2' x 16' 512,000 128,000 384,000

*Basedon opening covered by V4"meshscreen,woodIouvers,ormetallouvers.

FRESH AIR DUCT

FOR TIGHTLY

SEALED HOUSE

FRESH

AIR

DUCT

,_,* 6

The near boiler piping, that is the piping around the boiler,

must be considered as part of the boiler for proper water

level control, and to produce dry steam. Correct near boiler

piping is crucial to the proper operation of the boiler and

the heating system. Follow these recommendations carefully

1 Place boiler in selected location, as near chimney as

possible.

2. Install the pop safety valve, using the furnished 3/4"

coupling, into the 3/4' pipe nipple on the top of the boiler.

Make a discharge pipe, using 3/4' pipe (not furnished}

to carry the water or steam to a nearby drain. Do not

connect the discharge pipe directly to a drain but leave

an air gap. The downstream end of the discharge pipe

must be unthreaded. No shutoff of any description shall

be placed between the pop safety valve and the boiler,

,

4.

or on discharge pipes between such safety valves and

the atmosphere. Installation of the pop safety valve shall

conform to the requirements of the ANSI/ASME Boiler and

Pressure Vessel Code, Section IMThe manufacturer is not

responsible for any water damage

This boiler is equipped with two 2V2' supply connections

and two 2V2" return connections, one each on both the

left and right sides of the boiler. Unused connections must

be plugged with the 2V2" plugs (furnished}

Recommended near boiler piping for gravity return

systems is shown in Figure 5. This configuration uses one

supply and one return tapping. This setup can be used

on any size boiler in this series. The supply and return

connections may be piped both into the same side (either

left or right} or one into each side of the boiler.

PiPEFULLSIZESAME

ASBOILERTAPPING

(2

POPSAFETYVALVE

FLUE

2 1/2" TEEWITH

PLUGFOR

24"

JFEED

STEAMMAINS

- REDUCINGELLPOINTING

DOWN

6" TO 10"

1 1/2" MIN

PIPESIZE

15" MIN.

28' MIN - DIMENSIONA

NIPPLE

)RD LOOP

WETRETURN

-GATE VALVE(NOT FURNISHED)

_" DRAINVALVE(FURNISHED)

FOR FLUSHINGSYSTEM

I 1/2" FULL PORT BALL VALVE

FOR BOTTOMBLOWDOWN

AND DRAINING BOILER

& SYSTEM(NOT FURNISHED)

MAINVENT

DRYRETURN

MAIN

7,_

5. For installers choosing to use both supply tappings, Figure

6A shows the correct way to pipe this system. Figure

6B shows the wrong way to pipe a header with two risers.

• Headers must be fitted with header offsets or swing joints,

or be equipped with expansion joints, so that thermal

expansion and contraction of the header will not damage

the boiler. Headers shall not be welded.

• System takeoffs from the header must be between the

equalizer and the riser to the header nearest the

equalizer. System takeoffs must never be between two

risers.

6. System takeoffs from the header must never be bul-

lheaded. If the steam main goes in two directions, there

must be two takeoffs from the header, one for each main.

7. All boilers in gravity return systems must be equipped

with a Hartford Loop as shown in Figures 5 and 6A.

8. When piping the vertical risers from the boiler to the

header, the bottom of the header must be a minimum

of 24 inches above the water level line on the right side

of the boiler.

9. Steam riser(s) and header shall be 2V2"pipe size.

10. Equalizer line shall be minimum iV2" pipe size.

11. The near boiler piping shall include a 21/2, tee with a

plug located on the supply line as shown for skimming

{i.e. surface blowdown).

PIPEFULLSIZESAN_E

AS BOILERTAPPING

(2 1/2"

POP SAFETY VALVE

CONNECTRISERTO BOILERWITH

2 I/2"ELBOWAND NIPPLE

(NOTSHOWN)

FLUE

COLLAR

MIN

2 1/2" TEEWITH

PLUGFOR

@ 24"

W_AfERFEED

STEAM MAINS

ELLPOINTING

DOWN

1 1/2" MIN.

PIPESIZE

NIPPLE

6" TO 10"

MAINVENT

DRY RETURN

MAIN

1S"MIN.

28" MIN DIMENSIONA

HARTFORD LOOP

RETURN

-GATEVALVE(NOTFURNISHED)

_ORAIN VALVE(FURNISHED)

FOR FLUSHINGSYSTEM

I I/2"FULLPORT BALLVALVE

FOR BOTFOMBLOW DOWN

AND DRAININGBOILER

& SYSTEM(NOTFURNISHED)

WRONG WAY

DO NOT BULLHEAD,USE

TWO TAKEOFFS

THIS PIPING CONFIGURATION

IS INCORRECTTO SHOW

COMMONMISTANES

WRONG WAY

TAKE OFFS MUST BE BETWEEN RISER & EQUALIZER

WRONG WAY

SWING JOINTS ARE MISSING

)NG WAY

MISSING TEE

FOR SKIMMING

12. The near boiler piping shall include a 1V2" ball valve

in the return piping as shown for bottom blowdown and

draining.

13. For gravity return systems, the bottom of the lowest steam

carrying pipe, be it a dry return, or the end of the steam

main, must be at least 28' above the normal water level

line on the right side of the boiler. This is known as

"Dimension A."

14. For pumped return systems, follow the condensate pump

or boiler feed pump manufacturer's instructions for proper

installation and hookup.

15. In connecting the cold water supply to the water inlet

valve, make sure that a clean water supply is available.

When the water supply is from a well or pump, a sand

strainer should be installed at the pump.

FOR USE WITH COOLING UNITS

A. This boiler, when used in connection with chilled water

systems, must be installed so that the chilled water is piped

in parallel with the heating boiler. Appropriate valves must

be used to prevent the chilled water from entering the

heating boiler (Fig. 7).

B. When this boiler is connected to heating coils located

in air handling units where they may be exposed to

refrigerated air circulation, the piping system shall be

equipped with flow control valves or other automatic means

to prevent gravity circulation of the boiler water during

the cooling cycle.

VALVES A & B

OPEN FOR HEATING;

CLOSE FOR COOLING

VALVES C & D

CLOSE FOR HEATING:

OPEN FOR COOLING

TO SYSTEM t

C

O

CHILLER

_4_o7

I For boilers for connection to gas vents or chimneys, vent installations shall be I

In accordance with Part 7, VenUng of Equipment, of the National Fuel Gas Code,

IANSI Z223.1-1atest revision and applicable provisions of the local building codes.

CHECK YOUR CHIMNEY

This is a very important part of your heating system. It must

be clean, the right size, properly constructed and in GOOD

CONDITION. No boiler can function properly with a bad chim-

ney Inspect the chimney and verify that the construction and

size of the chimney meets all applicable provisions of the

National Fuel Gas Code and local building codes. Fig. 8

gives you an idea how a boiler might be vented to a chimney.

Note that the height (HT) is measured from the vent pipe

to the top.

CHIMNEY SIZING

Chimney sizing and all other aspects of the vent installation

must be in accordance with Part 7 of the National Fuel Gas

Code, ANSI Z223.1-latest revision, and applicable provisions

of the local building codes.

CONNECTING THE VENT DAMPER

AND VENT CONNECTOR

Refer to Fig. 1 flue diagram for the size and location of the

vent (flue opening). Use a 28 gauge (minimum) galvanized

pipe to connect to the chimney

IMPORTANT - The damper blade on the furnished vent

damper has a 1/2square inch hole (approximately 3A,diame-

ter). On boilers equipped with standing pilot, the hole must

be left open. On boilers equipped with intermittent ignition,

the hole should be plugged by using the plug supplied with

the vent damper.

1. Position furnished vent damper on top of flue outlet collar,

Fasten damper securely to flue outlet collar with sheet

metal screws. Make sure damper blade has clearance

to operate inside of diverter.

As An Option

The damper may be installed in any horizontal or vertical

position, closer to the flue outlet collar preferred. Follow

the diagrams - Figures 9, 10 and 11.

2. Install the vent damper to service only the single boiler

for which it is intended. The damper position indicator

shall be in a visible location following installation. Locate

the damper so that it is accessible for servicing.

3. The damper must be inthe open position when appliance

main burners are operating.

4. The boiler is equipped with a factory wired harness that

plugs into the vent damper. The thermostat must be

connected to the black wires marked 24 volt thermostat

on the boiler.

5. Vent pipe must be same size as the flue outlet collar.

6. Slope pipe up from boiler to chimney not less than V4'

per foot.

7. Run pipe as directly as possible with as few elbows as

possible.

8. Do not connect to fireplace flue.

9. End of vent pipe must be flush with inside face of chimney

flue. Use a sealed-in thimble for the chimney connection.

10. Horizontal run should not be longer than 3Athe chimney

height (HT) (Fig. 8).

The sections of vent pipe should be fastened with sheet metal

screws to make the piping rigid. Horizontal portions of the

vent system must be supported to prevent sagging. Use

stovepipe wires every 5' to support the pipe from above.

If the vent pipe must go through a crawl space, double wall

vent pipe should be used. Where vent pipe passes through

a combustible wall or partition, use a ventilated metal thimble,

The thimble should be 4 inches larger in diameter than the

vent pipe.

MINIMUM VENT PIPE CLEARANCE

Wood and other combustible materials must not be closer

than 6' from any surface of single wall metal vent pipe. Listed

Type B vent pipe or other listed venting systems shall be

installed in accordance with their listing.

REMOVING EXISTING BOILER FROM

COMMON VENTING SYSTEM

When an existing boiler is removed from a common venting

system, the common venting system is likely to be too large

for proper venting of the appliances remaining connected

to it.

At the time of removal of an existing boiler, the following

steps shall be followed with each appliance remaining

connected tothe common venting system placed in operation,

while the other appliances remaining connected to the

common venting system are not in operation.

1,

2.

Seal any unused openings in the common venting system.

Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other deficiencies which

could cause an unsafe condition.

,

Insofar as is practical, close all building doors and windows

and all doors between the space in which the appliances

remaining connected to the common venting system are

located and other spaces of the building. Turn on clothes

dryers and any appliance not connected to the common

venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will operate at

maximum speed. Do not operate a summer exhaust fan.

Close fireplace dampers.

,,_ 10

4 Placeinoperationtheappliancebeinginspected.Follow

thelightinginstructions.Adjustthermostatsoappliance

willoperatecontinuousl_z

5.Testforspillageatthedrafthoodreliefopeningafter5

minutesofmainburneroperation.Usetheflameofamatch

orcandle,orsmokefromacigarette,cigarorpipe

6.Afterithasbeendeterminedthateachapplianceremain-

ingconnectedto thecommonventingsystemproperly

ventswhentestedas outlinedabove,returndoors,

windows,exhaustfans,fireplacedampersandanyother

gas-burningappliancetotheirpreviousconditionsofuse

7 Any_mproperoperationof thecommonventingsystem

shouldbecorrectedsotheinstallationconformswiththe

NationalFuelGasCode,ANSIZ223.1-latestrevision.When

resizinganyportionof thecommonventingsystem,the

commonventingsystemshouldbe resizedtoapproach

them_n_mumsizeasdeterminedusingtheappropriate

tablesin Part11 in the NationalFuelGasCode,ANSI

Z223.1-latestrewsion.

For boilers for connection to gas vents or chimneys,

vent installations shall be in accordance with Part 7,

Venting of Equipment, of the National Fuel Gas Code,

ANSI Z223.1-1atest revision and applicable provisions

of the local building codes,

Vent connectors serving appliances vented by natural

draft shall not be connected into any portion of mech-

anical draft systems operating under positive pressure.

ROOF

RIDGE

3/4 HT MAXIMUM

HT

MUST SLOPE UP

AT LEAST 1/4 INCH

PER FOOT OF

HORIZONTAL RUN

HORIZONTAL INSTALLATION

TO FURNACE VENT TO CHIMNEY

OR BOILER DAMPER INSTALL VENT DAMPER WITH

ACTUATOR TO SIDES OF

VENT ONLY, DO NOT MOUNT

ABOVE OR BELOW VENT.

VERTICAL INSTALLATION

TO CHIMNEY [_

FLOW VENT

DAMPER

ACTUATOR MAY BE

TO FURNACE N INSTALLED IN ANY POSITION

OR BOILER

U

TYPICAL INSTALLATION FOR VENT DAMPER

NOTE CAUTION AND FOOTNOTES

1. Install the vent damper to service only the single appliance for

which it is intended,ff improperlyinstalled,a hazardous condition,

such as an explosion or carbon monoxide poisoning, could result.

2. Do not install the vent damper on vent pipe curve.

3. DO not run wiras near high temperature surfaces. Use stand-off

brackets itnecessary

For safe, efficient operation, the vent damper and all flue

product carrying areas of the appliance must be checked

annually by you, with particular attention given to deterioration

from corrosion or other sources. Ifyou see corrosion or other

deterioration, contact your heating contractor for repairs.

Check vent damper operation as follows:

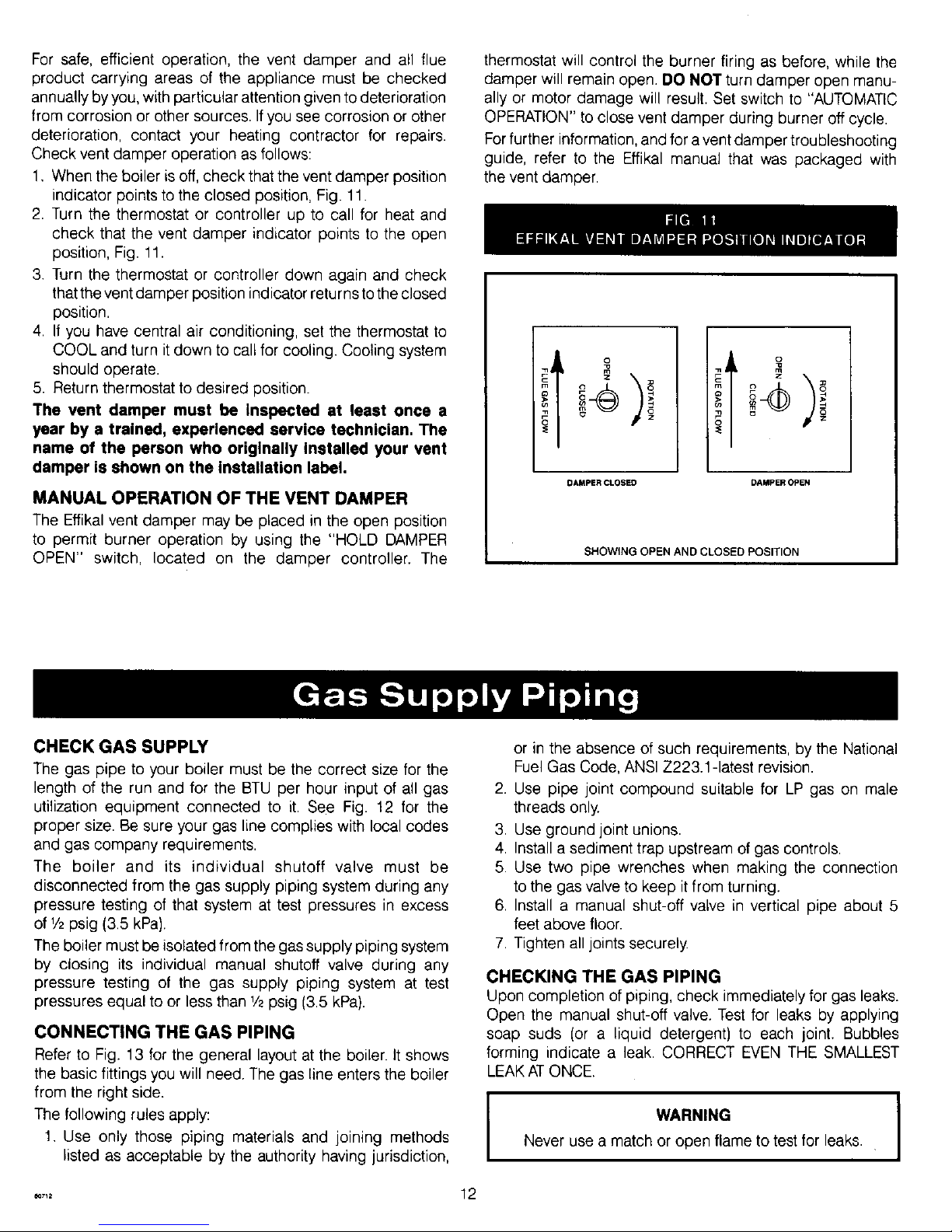

1. When the boiler is off, check that the vent damper position

indicator points to the closed position, Fig. 11.

2. Turn the thermostat or controller up to call for heat and

check that the vent damper indicator points to the open

position, Fig. 11.

3. Turn the thermostat or controller down again and check

that the vent damper position indicator returns to the closed

position.

4. If you have central air conditioning, set the thermostat to

COOL and turn it down to call for cooling. Cooling system

should operate.

5. Return thermostat to desired position.

The vent damper must be Inspected st least once a

year by a trained, experienced service technician, The

name of the person who originally installed your vent

damper is shown on the installation label.

MANUAL OPERATION OF THE VENT DAMPER

The Effikal vent damper may be placed in the open position

to permit burner operation by using the "HOLD DAMPER

OPEN" switch, located on the damper controller. The

thermostat will control the burner firing as before, while the

damper will remain open. DO NOT turn damper open manu-

ally or motor damage will result. Set switch to "AUTOMATIC

OPERATION" to close vent damper during burner off cycle.

For further information, and for a vent damper troubleshooting

guide, refer to the Effikal manual that was packaged with

the vent damper.

iI

DAMPER CLOSED DAMPER OPEN

SHOWING OPEN AND CLOSED POSITION

CHECK GAS SUPPLY

The gas pipe to your boiler must be the correct size for the

length of the run and for the BTU per hour input of all gas

utilization equipment connected to it. See Fig. 12 for the

proper size. Be sure your gas line complies with local codes

and gas company requirements.

The boiler and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess

of V2psig (3.5 kPa).

The boiler must be isolated from the gas supply piping system

by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than V2psig (3.5 kPa).

CONNECTING THE GAS PIPING

Refer to Fig. 13 for the general layout at the boiler. It shows

the basic fittings you will need. The gas line enters the boiler

from the right side.

The following rules apply:

1. Use only those piping materials and joining methods

listed as acceptable by the authority having jurisdiction,

or in the absence of such requirements, by the National

Fuel Gas Code, ANSI Z223.1-latest revision.

2. Use pipe joint compound suitable for LP gas on male

threads only.

3. Use ground joint unions.

4. Install a sediment trap upstream of gas controls.

5. Use two pipe wrenches when making the connection

to the gas valve to keep it from turning.

6. Install a manual shut-off valve in vertical pipe about 5

feet above floor.

7. Tighten all joints securely

CHECKING THE GAS PIPING

Upon completion of piping, check immediately for gas leaks.

Open the manual shut-off valve. Test for leaks by applying

soap suds (or a liquid detergent) to each joint. Bubbles

forming indicate a leak. CORRECT EVEN THE SMALLEST

LEAK AT ONCE.

WARNING 1Never use a match or open flame to test for leaks.

.... 12

NATURAL GAS

Pipe Capactty- BTUPer Hourlnput

Length of Includes Fittings

Pipe - Ft.

½" ¾" 1" 1%"

20 92,000 190,000 350,000 625,000

40 63,000 130,000 245,000 445,000

60 50,000 ! 05,000 195,000 365,000

MANUAL

SHUT-OFF

VALVE

AUTOMATIC

VALVE

GROUND

JOINT

MANIFOLD UNION

S OI.ENTTRAP p l

FLOOR

LINE _u

ELECTRIC POWER SUPPLY

All electrical work must conform to local codes, as well as

the National Electrical Code, ANSI/NFPA-70, latest revision.

Run a separate 120 volt circuit from a separate overcurrent

protective device in your electrical service entrance panel.

This should be a 15 ampere circuit. Locate a shut-off switch

at the boiler. It must be turned off during any maintenance.

Connect 120 volt electrical supply to the primary leads on

the 24 volt transformer. Solder and tape or securely fasten

these connections with wire nuts.

The boiler, when installed, must be electrically grounded in

accordance with the requirements of the authority having

jurisdiction or, in the absence of such requirements, with the

National Electrical Code, ANSI/NFPA No. 70-latest revision.

Run a 14 gauge or heavier copper wire from the boiler to

a grounded connection in the service panel or a properly

driven and electrically grounded ground rod.

]

WARNING

Turn off electric power at fuse box before making any

line voltage connections. Follow local electrical codes.

I

INSTALL YOUR THERMOSTAT

The thermostat location has an important effect on the

operation of your boiler system. BE SURE TO FOLLOW THE

INSTRUCTIONS INCLUDED WITH YOUR THERMOSTAT.

Locate the thermostat about five feet above the floor on an

inside wall. It may be mounted directly on the wall or on

a vertically mounted outlet box. Itshould be sensing average

room temperature, so avoid the following:

DEAD SPOTS:

Behind doors

Corners and alcoves

HOT SPOTS:

Concealed pipes

Fireplace

TV sets

Radios

Lamps

Direct sunlight

Kitchens

COLD SPOTS:

Concealed pipes or ducts

Stairwells - drafts

Doors - drafts

Unheated rooms on other side of wall

Set heat anticipator at 0.4 amps for boilers equipped with

standing pilot, and at 0.6 amps for boilers equipped with

intermittent ignition. The 24 volt thermostat leads shall be

connected to the two wires tagged "24 volt thermostat" on

the boiler. For boilers with 67D-1 float type low water cut-

off, the two wires are black. One wire is located on the

secondary of the 24 volt transformer, the second wire is

located on the pressure limit control. For boilers with PS-

802 probe type low water cut-off, one wire is green and

is located on terminal B of the PS-802, the second wire is

black and located on the pressure limit control.

ELECTRONIC THERMOSTATS

Certain types ofelectronic therrnostats may lose their memory

or shut down. With 67D-! float type low water cut offs,

this may occur each time the thermostat calls for heat,

due to the internal circuit in the vent damper. With PS-802

probetypelowwatercutotis,thismayoccureachtimethe

lowwatercutoffdetectsa lowwaterconditionIfthisisthe

case,anisolationrelayisrequiredforthethermostatcircuit

A24voltsinglepolesinglethrow(SPST)normallyopen(N.O.)

relay _srequired,such as the HoneywellR8222Aor

equivalent.WireasshowninFig.14AorFig.14B.

VENT DAMPER

The boiler is equipped with a factory wired harness with 4

pin molex plug, that plugs into the 4 pin molex receptacle

inside the vent damper operator.

The vent damper must be connected for the boiler to operate.

Wiring diagrams follow for the various different models.

CAUTION

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation, Verify proper

operation after servicing.

24 VOLT

TRANSFORMER

VENT DAMPER

4 PLN

MOLEX PLUG

TO LWCO AND

IGNITION SYSTEM

-ISOLATION RELAY 24V.

SPST N+O. HONEYWELL

Y I R8222A OR EQUIVALENT

' !O

,_-----t----IBK

]_,_? i PRESSURE LIMIT

L........ p.J

.... .+tJ

%\

ELECTRONIC

THERMOSTAT

.... FIELD WLRING

VENT DAMPER

4 PIN

MOLEX PLUG

BK

24 VOLT r_

TRANSFORMER L_

7

TO LWCO AND

IGNITION SYSTEM

_y _-ISpOs[TATI?o ' REoLNAYyW22E VL

R8222A OR EQUIVALENT

°

+ ++ __±,,",PRES_ LIMIT

L -," TERMINAL++

-o"o--- G OF LWCO

_- ELECTRONIC

THERMOSTAT

--- FIELD WLRING

..... 14

_ -- WIRE NUT

COLOR CODE

8K-BIJ_CK

BR-BROWN

0 -ORA_C£

y -_AA_OW

R -RED

BT-BIJ_CN WITH TRACER

W -11_41rE

G -GRE[]_

8 -BLUE

EFFIKAL RVGP VENT OA,_PER

MOLEX PLUG

I15V/BOHZ/I f L_

pOWER B_X

SUPPLY

r-l_ \/

j\®/.....

L_ _____.j'--"

OP_ONAL WF-2U-2_.

WATi_

_"l{EOER

NOTE:

T_¼1N_. N0 ] APpFJ_R$ ONLy

ON WATER FEEC_R MODELS WITH

tJXNL_I. _£0 PUSH 8U_'ON.

INTERMITTENT IGNITION

) _

iiii

_LWC 0 pRoBEWt_RMRTF'NT pIL'OT CONTRCt

R TO PrLOT

SAP_ SHUTOFF

AI_V[

VR8204A / VR8304M

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THIS APPLIANCE MUST BE REPLACED,

IT MUST BE REPLACED WITH TYPE 105° C THERMOPLASTIC WIRE OR ITS EQUIVALENT.

15 7411_

_--WIRE NUT

HeVI_OHZllm i (

pOW_ 8K

SUpPLy

.T

_SO3NNECT _

A

',IQ-÷ .......

I_@-4

L_X=/___J- .....

COLOR CODE

8X-B_

BR-E_ROWN

0 -ORANGE OPI1ONAL _-2U--:14

y -YELLOW W_TER

R -RED REED_

BT-B_ VCh'H TRACER NOTE:

W -WHITE

G -GREEN TERMIteS. NO, 3 APpF_S C_NLY

8 -BLUE ON WATER F_ER MOC_'LS

MANUAL BEF.,D PUSH t_,rrTON

STANDING PILOT

EFFIKAL RVGP V_NT DAMPER

MOLEX PLUG

)@(

Y

r......

J

PRESSURE UMIT

I

I

I

RVGP-KS-BKF VENT OA._PER

OOUBL_ POLE, DOUBLE THROW RELAy

II 4 POLE CONNECrOR

/-;

NC

C

N.C.

I I

12_._?I

i 7J-_6 I

15_15 I

.... _2 J

A.C. TO D.C POWER

). CONVERSION CIRCUIT

,3-

MOTOR

_2 4 VAC

50/60 HZ

N'O

N.C,

N,C, C

®..o.__-___J

PI_osTAT

LIMI T LWCO

1_ 24 V.

_1-0411yll

FLA_E ROLLOUT

SHUTOFF

_ N[UT_ L

BLOCKED _NT HOT

S_E_ O_RCURRENT

SHUTOFF PROTECT[D

GAS DISCONNECT

VAL_

i1_V/BOHZ/I_

NOTE:

SlA AND SlB ARE THE AUTOk_T_C Op[RATJON / HOLD BAMPER OPEN SWITCH

SWITCH SHOWN tN AUTOMATICPOSLTION.

$2, $3. AND S4 ARE CAXt ACTUATEDSNAP SV_TCHES

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THIS APPLIANCE MUST BE REPLACED,

IT MUST BE REPLACED WITH TYPE 105° C THERMOPLASTIC WIRE OR ITS EQUIVALENT.

I_-- WIRE NUT

INTERMITTENT IGNITION

24 VOLT

TRANSFORMER

115V/BOHZ/I_ %

POWER SUPPLY

.oT-_Jo-._

0V£RCURRENT PROTECTED

DISCONNECT

W

NEUT

\ )

\(_ .....

OPTIONAL WF-2U-24

WAFER FEEDER

NOTE:

TERMINAL NO. 3

APPEARS ONLY ON

WATER FEEDER MODELS

WITH MANUAL FEED PUSH BUTTON

EFFIKAL RVGP VENT DAMPER

MOLEX PLUG

pR_SSURC LIMIT

FLAME ROLLOUI T

GAS VALVE

RVCp-KS-BKF V,ENT O_IpzR

" i _ ZNr DAtaPER C_.81E

I 7 I I r

_ _6 I --

is i ...... 'p._L"o,1 r.ER'_OS,^T

Kt r r _ Ll_Ir

°," ,'

-- i Y BK _

o D ,°'-°",1I

S2j'a-_

( _°,fv°_ _--i L# I ;2_;, I.

50/60 HZ. 8K N_UIRAL

LWC0 _ _HO T 115'V/60HZ/ II_

NC N0 Nj

.-% .o1o

kOTD

SlA A_O SIB _g THE AUT0_TIC

OPg_TrON / HIN_ _I_R OPEN NTCH

S,N_TCH SHNH IN _OMATIC POSmI_.

_FFPr

5NUIOFF

BLOCKED _T

SV_"ET_

SHUTOFF

cAs

VRB204A / VR8304M

OV£RCURRENI PROT[CTED

DISCORNECT

S8600(F,M) INI[RUlTT[N_ PILOI CONTROL

>>>Z _" N _.

1234 S 6 g

T TO pILOt BURN£R

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THIS APPLIANCE MUST BE REPLACED,

IT MUST BE REPLACED WITH TYPE 105° C THERMOPLASTIC WIRE OR ITS EQUIVALENT.

1 7 741_3

EFFIKAL RVGP VENT DAMPER STANDING PILOT

MOLEX PLUG

NOTE:

I_ -- WIRE NUT

24 VOLT

TRANSFORMER

IIBV/6OHZ/I¢

POWER SUPPLY

HOT ._----_--_

OVERCURRENT PROTECTED

DISCONNECT

W

NEUT

OPTIONAL WF-2U-24

WATER FEEDER

TERMINAL NO. 3 APPEARS ONLY

ON WATER FEEDER MODELS WITH

MANUAL FEED PUSH BUTTON.

PRESSURE LIMIT

BT I

I

J y

BK

FLAME ROLLOUT

SAFETY SHUTOFF

LOW WATER

CUT OFF

_ VALVE

TR T_ TH

B K

BLOCKED VENT

SAFETY SHUTOFF

RVCp-KS-BKF V_NT OA._pER

TO OC. POWER

CONVERSION CIRCUIT

NC

C

IP1-03

NOTE:

S1A AND SIB ARE THEAUTO,TIC OPERATION / HOL0 DAMPER OPEN SWITCH¸

SWITCH SHOWN IN AUrO_:ATICPOSITION¸

$2. $3. Nq0 $4 ARE CAM ACTUATEDSN_o SWITCHES.

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THIS APPLIANCE MUST BE REPLACED,

IT MUST BE REPLACED WITH TYPE 105 ° C THERMOPLASTIC WIRE OR ITS EQUIVALENT.

..... 18

POP SAFETY VALVE

The pop safety valve should open automatically if the boiler

steam pressure exceeds the pressure rating of the valve (15

psig). Should it ever fail to open under this condition, shut

down your boiler. If valve discharge occurs, or valve fails

to open as described above, contact an authorized contractor

or qualified service technician to replace the pop safety valve

and inspect the heating system to determine the cause, as

this may indicate an equipment malfunction.

Run a p_pe from the safety valve outlet (pipe must be same

size as outlet and open end must not be threaded) to an

open drain, tub or sink, or other suitable drainage point not

subject to freezing. Failure to do so may cause Water damage

or injury should relief valve release Do not cap off the drain

line from this valve!

STEAM PRESSURE GAUGE

Every system should have a pressure gauge installed in the

boiler. This gauge enables you to monitor the pressure in

the system. If the safety devices fail to shut off your boiler

at the proper settings, notify your serviceman immediately

WATER LEVEL GAUGE

The water level in the boiler can be seen through the glass

tube in the water level gauge at side of boiler. Correct cold

boiler water revel is stamped on side jacket panel. The water

level should be checked regularly for the proper level.

On the right side jacket panel of the boiler, there are three

holes for the glass water level gauge. The top hole is common

for both types of low water cut off, and is used for the upper

gauge glass fitting. The middle hole, 9" down from the top

hole, is used for the bottom gauge glass fitting for the Model

67D-1 and 47-2 float type low water cut off. The lowest hole,

12V4"down from the top hole, is used for the bottom gauge

glass fitting for the Model PS-802 probe type low water cut

off. The hole that is not being used is covered with a sheet

metal knockout.

STEAM PRESSURE CONTROL

The steam pressure limit control {pressuretrol) shuts off the

gas to the main burners when the steam pressure in the

boiler reaches the cut-off setpoint (i.e. the sum of the cut-

in and the differential setpoints). Burners retire when the steam

pressure drops to the cut-in setpoint. System pressure

requirements are based on the size and condition of the

pipes, and the load.

LOW WATER CUT-OFF

1 Model 67D-1

This is a float operated switch which shuts down the gas

burner if water falls below the visible bottom of the gauge

glass.

2. Model PS-802

This is an electronic probe type LWCO. The probe is

located inside the boiler. The LWCO will shut down the

burners if the water loses contact with the probe for a

period of 10 seconds.

Refer to manufacturer's instructions {enclosed) for more

information.

WATER FEEDER (Optional)

The Model WF-2U-24 water feeder may be used with either

of the available low water cut-offs. The water feeder's job

is to maintain a safe minimum water level It's used to

keep the boiler running by compensating for minor

evaporative steam leaks, and to prevent freeze-ups if the

homeowners are away and a return line should spring

a leak.

McDonnell and Miller Model 101 water feeders may be

used, however the water feed rates are too high and need

to be regulated or throttled, and wiring will have to be

revised. Consult the boiler manufacturer before using these

or any other non-standard types of controls.

The automatic water feeder is a safety device, not a

convenience item. It is not designed to maintain a "normal"

water line. The water feeder does not take the place of

a responsible person monitoring and maintaining the

normal water line. Steam boilers require personal attention.

VENT DAMPER

This is an automatic, motorized stack damper that has

been developed to increase the efficiency of heating

systems by reducing standby losses from the boiler end

the conditioned air space. The damper closes the chimney

vent when the burner is off and fully opens it when

combustion is required.

ROLLOUT SWITCH

(FLAME ROLLOUT SAFETY SHUTOFF)

The rollout switch is a temperature-sensitive fuse link

device. It is located on the boiler base just outside the

fire box. In the event of heat exchanger flueway blockage

causing flame to roll out of the fire box, the fuse will blow,

shutting down the flow of gas to the main burners. The

fuse does not change in appearance when blown.

If the rollout switch blows, it must be replaced with an

exact replacement. Check heat exchanger flueways for

blockage when restoring system to operating condition.

Do not operate system without a rollout switch.

SPILL SWITCH

(BLOCKED VENT SAFETY SHUTOFF)

The spill switch is a manual reset disc thermostat with

a fixed setpoint (280 ° F), and normally closed contacts.

It is located at the relief opening of the draft diverter. In

the event of chimney or venting system blockage causing

products of combustion to spill out of the relief opemng,

the spill switch disc heats up and the spill switch contacts

will open, shutting down the flow of gas to the main burners

by removing power to the gas valve.

In the event that the spill switch contacts open, the reset

button on the back of the switch will pop up. The spill

switch must be reset manually, after the switch has cooled

off, by pushing the reset button down. Check the venting

system and chimney for blockage when restoring the

system to operating condition. DO NOT operate the boiler

without a spill switch.

1 9 7_ISH

WARNING: If you do not follow these instructions exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

A. Some boilers are equipped with an intermittent ignition

device which automatically lights the pilot. Do not try to

light the pilot by hand.

Some boilers are equipped with a continuous pilot and

must be manually lighted. (See lighting instructions on page

17.)A match holder is included in the parts bag.

B. BEFORE OPERATING smell all around the appliance area

for gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone

in your building.

C.

E_

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire

department.

Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or turn

by hand, don't try to repair it, call a qualified service

technician. Force or attempted repair may result in a fire

or explosion.

Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the control

system and any gas control which has been under water.

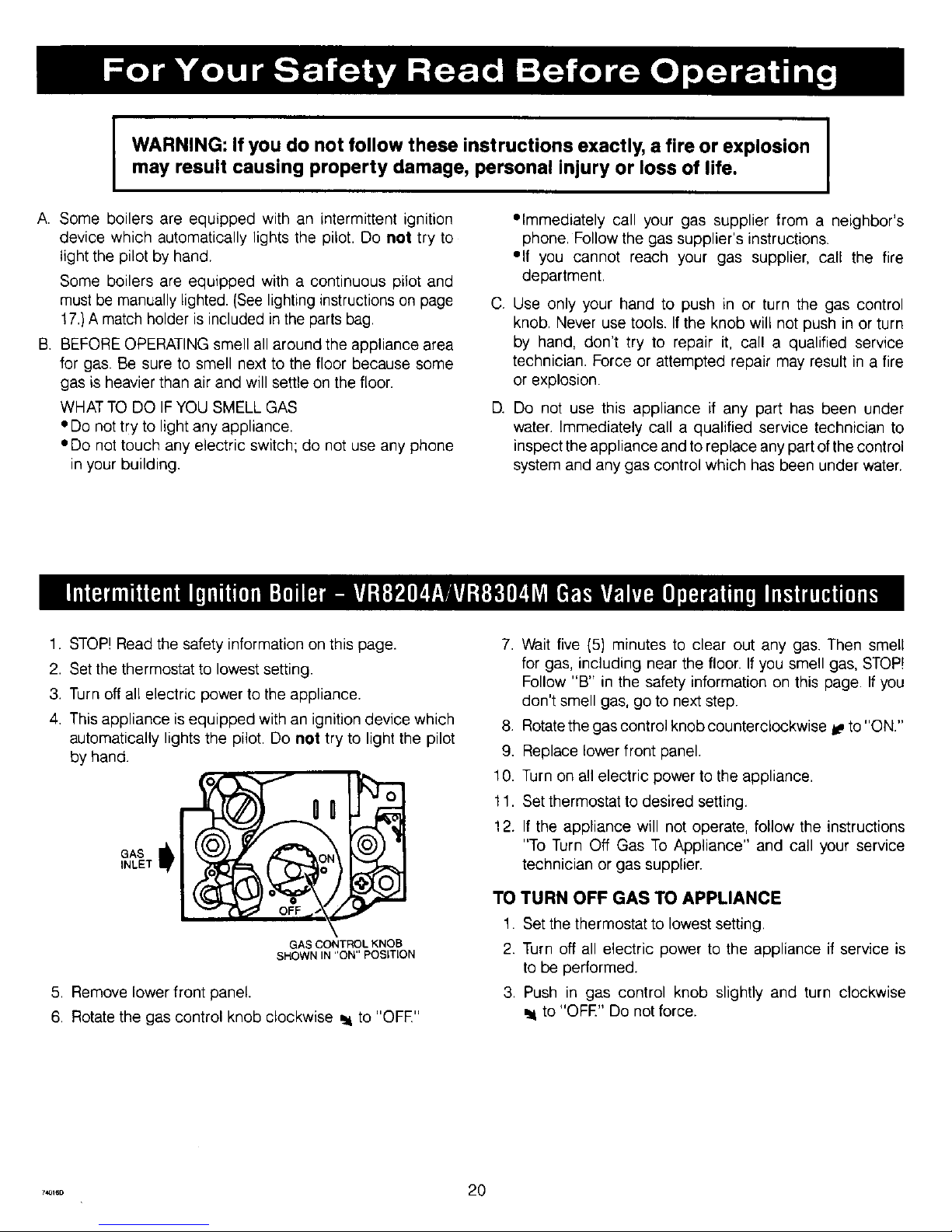

1. STOP! Read the safety information on this page.

2. Set the thermostat to lowest setting.

3. Turn off al! electric power to the appliance.

4. This appliance is equipped with an ignition device which

automatically lights the pilot. Do not try to light the pilot

by hand.

GAS

INLET |

GAS CONTROL KNOB

SHOWN IN "ON" POSITION

5. Remove lower front panel.

6. Rotate the gas control knob clockwise _ to "OFE"

7. Wait five (5) minutes to clear out any gas. Then smell

for gas, including near the floor. If you smell gas, STOP!

Follow "B" in the safety information on this page. If you

don't smell gas, go to next step.

8. Rotate the gas control knob counterclockwise I# to "ON."

9. Replace lower front panel.

10. Turn on all electric power to the appliance.

11. Set thermostat to desired setting.

12. If the appliance will not operate, follow the instructions

"To Turn Off Gas To Appliance" and call your service

technician or gas supplier.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if service is

to be performed.

3. Push in gas control knob slightly and turn clockwise

to "OFE" Do not force.

..... 20

1.STOP!Readthesafetyinformationonpage16.

2. Setthethermostattolowestsetting.

3.Turnoffallelectricpowertotheappliance.

4. Removelowerfrontpanel.

5. Rotategas controlknobslightlyandturn clockwise

to

GAS CONTROL KNOB

[-SHOWN IN "ON" POSITION

/

GAS

INLET

• O

RESET BUTTON

6. Wait five (5) minutes to clear out any gas. Then smell

for gas, including near the floor. Ifyou smell gas, STOP!

Follow "B" in the safety information on page 16. If you

don't smell gas, go to next step.

7. Find pilot - follow metal tube from gas control. The pilot

is between two burner tubes as shown in Fig. 15.

8. Turn knob on gas control counterclockwise _ to

"PILOT"

9 Rotate the gas control knob counterclockwise _, to

"PILOT" Push down and hold the red reset button while

you light pilot burner with a match.

After about one minute, re[ease reset button. Pilot should

remain lit If it goes out, turn gas control knob clockwise

to OFE To relight, repeat steps 5-9.

• If button does not pop up when released, stop and

immediately call your service technician or gas supplier.

• If the pilot will not stay lit after several tries, turn the

gas control knob to "OFF" and call your service

technician or gas supplier.

10. After pilot remains lit when red reset button is released,

turn gas control knob counterclockwise _ to "ON."

1!. Replace lower front panel.

12. Turn on all electric power to the appliance.

13 Set thermostat to desired setting.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if service is

to be performed.

3. Push in gas control knob slightly and turn clockwise

_i to "OFE" Do not force.

MATCH HOLDER

P_ESSUR( R£GULATOR CONVENIENCE WIRING

ADJUSTMENT TERMINAl{2} TERMINAL3 (2)

{UNDERpRESSUREINLETCAPTApSCREW)_I_i_(OPTION_L} OAUpTLET PRESSURE

;,:LoToU*L'T

THERMOCOUP OT ADJUSTt'_E NT

CONNECTION . 'RREEN \GA S (UNDER CAP SCREW)

BUTTON CONTROL/VALVE

11,523A KNOll

PRESSUR_R{GULATOR

A_JUSTMENT

(UNDER CAP SCREW)

PRESSURETA_

INLET

WIRING

TERMINALS(3)

OUTLETPRESSUR£

TAP

GROUNO

TERMCNAL$(2)

.: , ;:LOTOUTL'T

OTADJ_STM_NT

{UNOERCAPSCREW)

_GA$

CONTROL

KNOE

21 7_0t 7H

HOW A STEAM SYSTEM OPERATES

The water in the boiler is heated until it reaches the boiling

point. As the water boils it turns into steam. The steam rises

from the top of the water through the supply main to the

radiation units. As it passes through the radiators it releases

its heat and condenses into water. The water returns to the

boiler through the return main. Most residential systems

operate at less than 1 pound steam pressure.

FILLING SYSTEM WITH WATER

©n steam heating systems the boiler is partially filled with

water. It is very important to the proper operation of the entire

system thatyour boiler befilled to the proper level. The correct

water level is about halfway up the glass water level gauge

as marked on the boiler jacket. To fill:

1. Close the boiler drain valve.

2. Open the valves at the top and bottom of the glass water

level gauge. Also open the drain valve at the bottom of

the gauge.

3. Open the fill valve and allow water to run into the boiler.

J WARNING - Never run water into a hot empty boiler, J

4. Allow boiler to fill until water runs out the gauge drain

valve. Then close the gauge drain valve.

5. Continue to fill boiler until water reaches the indicated water

line. This is about halfway up the glass tube.

THERMOSTAT

Keep it set at a desired room temperature. If windows are

to be opened or heat is not needed, move thermostat pointer

to a lower setting.

NOTE

In the event of failure of any component, the system

will not operate or will go into safety lockout. The system

iscompletely self-checking On every call for heat, each

component must be functioning properly to permit

operation. On safety lockout the system has to be reset

by turning the thermostat to the lowest setting for one

minute, then back to the normal setting.

Safe lighting and other performance criteria were met with

the gas manifold and control assembly provided on the boiler

when the boiler underwent tests specified in ANSI Z21.13

- latest revision.

WATER LEVEL

The normal water level is shown on the right side of the

boiler and is 24' above the floor. The normal water level

is determined when the boiler is off and cold, i.e. when all

of the water in the system is inside the boiler and the return

piping below the water line, and everything above the water

line is air, no steam. When the boiler is making steam, the

water level win drop two to three inches below the normal

water line.

AUTOMATIC GAS VALVE

The Automatic Gas Valve opens or closes according to the

heat requirements of the thermostat and temperature limit

control. It closes if the pilot goes out. Each individual control

must be operating correctly before any gas can pass to the

burners. Any one control can hold the gas supply from burner

regardless of the demand of any other control.

..... 22

ADJUST PILOT BURNER

Pilot flame should surround 3/8' to 1/2" of the pilot sensor.

Refer to Fig. 19. If flame needs adjusting, do it as follows:

1. Remove screw cover over pilot adjusting screw.

2. Insert small screwdriver and adjust flame as needed. Turn

screw counterclockwise to increase flame, clockwise to

decrease.

3. Replace screw cover over pilot adjusting screw.

MAIN BURNER AIR ADJUSTMENT

The primary air shutters on the cast iron main burners should

be adjusted so the flame forms a sharp blue cone with no

yellow. Refer to Fig. 18.

li_[_ll i1I:]

0000@@0@0000 °°'''°°''

I_ARKIER BLUE

INNER CONE

t ) .Lo.

GAS VALVE SAFETY SHUTDOWN TEST

1. For boilers equipped with continuous pilot, with main

burners firing, disconnect the thermocouple from the gas

valve. The gas valve should immediately shut off the main

burners and the pilot.

2. For boilers equipped with intermittent ignition, with main

burners firing, disconnect the ignition cable from the

intermittent pilot control box. The gas valve should shut

off the main burners. TURN OFF ELECTRIC POWER to

boiler before reconnecting ignition cable, to prevent

electric shock.

ADJUST STEAM PRESSURE CONTROL

The steam pressure limit control (pressuretrol) shuts off the

gas to the main burners when the steam pressure in the

boiler reaches the cut-off setpoint (i.e. the sum of the cut-

in and the differential setpoints). Burners retire when the steam

pressure drops to the cut-in setpoint. System pressure

requirements are based on the size and condition of the

pipes, and the load.

For 'good system operation, the cut-in setting of the

pressuretrol should never be less than twice the system

pressure drop. In a typical single family residence with a

clean one pipe heating system and cast iron radiation, this

means that the cut-in will usually be set atthe minimum setting,

i.e. 1/2psi.

Steam radiation is usually sized based on square feet of

equivalent direct radiation (EDR). This is based on a steam

pressure in the radiator of just less than 1 psi. Therefore,

in our example system from above, we would set the

differential adjustment at 1 psi, i.e. the steam pressure

required in the radiators. This will give us a cut-off setpoint

of 11/2psi.

The above is an example of a typical one pipe system. For

larger systems or other types of systems such as two pipe

systems, or systems with convectors or fan coil units, the

pressuretrol settings will need to be determined on a system-

by-system basis.

The cut-in setpoint is determined by the system pressure

drop tothe furthest radiator or terminal unit. Double the system

pressure drop as a safety factor, resulting in the rule that

the cut-in setting should never be less than twice the system

pressure drop.

The differential setpoint is the steam pressure required at

the terminal heating units.

Now your boiler will operate in the correct pressure range.

It will maintain enough steam pressure to send the steam

out to the furthest radiator, and not go over the optimum

steam pressure that is required at the radiators.

CHECKING CONTROLS

To check the Low Water Cut-Off, turn off power to the boiler

or turn the thermostat down to the lowest setting. Drain water

to below the visible bottom of the water gauge glass. Turn

power on and turn the thermostat to call for heat. When the

boiler is equipped with the float type LWCO, the gas valve

should not open on a call for heat when the water is low.

When the boiler is equipped with a probe type LWCO, the

gas control should be powered for approximately 10 seconds

(the time delay on the probe type LWCO), then the gas valve

will close and the red indicator will illuminate on the LWCQ

If your boiler is equipped with the optional WF-2U-24 water

feeder, continue to keep the thermostat calling for heat after

the low water cut off recognizes the low water condition. After

a one minute time delay, the water feeder should start feeding

water to the boiler, The feeder should feed for one minute,

and then go into another one minute waiting period. This

cycle of alternately waiting and feeding should repeat until:

1. For Model 67D-1 float type low water cut offs - as the

water leve! raises the float above the burner cut off switch

level, the burners should ignite. The water feeder remains

powered until the water level raises the float to the water

feeder switch level, satisfying the water feeder,

2. For Model PS-802 probe type tow water cut offs - the

water level wil! rise until water in the boiler makes contact

with the probe, satisfying the water feeder, and igniting

the burners

In either case, there should be between one and two inches

of water visible in the gauge glass when both the water feeder

is satisfied, and the burners are allowed to ignite.

The time delays in the feed cycles are designed to prevent

the boiler from flooding due to slow return lines.

To check the pressure limit, run the boiler until the pressure

reaches system demand. Then turn the pressure screw and

3 _21A

drop the pressure setting until the boiler shuts down. This

will show that the pressure limit is operating properly

Refer to control manufacturer's instructions (enclosed} for

more information.

Check thermostat operation. When set above temperature

indicated on the thermometer, boiler should ignite. Make

certain the thermostat turns off the boiler when room

temperature reaches the selected setting and starts the boiler

operating when room temperature falls a few degrees.

Finally, set the thermostat for the desired temperature. Special

conditions in your home and the location of the thermostat

will govern this setting.

It is very important to clean a new steam boiler after it has

3/8" to 1/2"

been installed and put into continuous operation. This must

be done to remove any accumulation of oil, grease, sludge,

etc., that may have been present in the system. These

substances may cause the boiler water to foam and surge,

thus producing a very unsteady water line, throwing water

into the steam header, and possibly preventing steam

generation. Follow these steps in order to remove these

contaminants.

SKIMMING AND BLOWDOWN

New boilers must be skimmed at the time of installation to

remove threading oil and other impurities that float on the

surface of the water.

1. Remove the plug from the skimmer tapping and pipe to

a floor drain or bucket.

2. Raise the water level to the skimmer tapping.

3. Fire the boiler to maintain a water temperature of 180-

200 degrees.

4. Feed water to the boiler to maintain the water level. Adjust

the water feed rate to keep water continuously flowing

out of the skimmer tapping without the water level going

above or falling below the tapping. Cycle the burners to

prevent boiling.

5. Continue skimming until the water runs clear. This may

take several hours.

6. Float type low water cut offs must be blown down after

skimming. The float chamber of the low water cut off must

be flushed clean and maintained clear of sediment to allow

free movement of the float: This must be done frequently

during initial operation of the boiler, and at least once

a week thereafter. Follow the instructions on the tag

attached to the control.

Probe type low water cut offs require no maintenance

at this time.

7. After blowing down the low water cut off and before

blowing down the boiler, fill the boiler to the water line.

Fire the burners and allow normal steam pressure to build

up. Run a connection from the boiler blowdown valve to

a nearby sewer or floor drain or to a safe discharge point

outside. Shut off the gas burners, open the blowdown

valve, and allow all of the water in the boiler to drain out.

Close the b!owdown valve. Allow the boiler to cool

thoroughly and then slowly refill the boiler to the water

line. Repeat this step as many times as necessary until

the blowdown water is clear.

.

Following the final blow down, allow the boiler to thoroughly

cool, and then add fresh water slowly up to the normal

water line. Start the burners and maintain at least 180

degrees for 15 minutes to remove dissolved gasses from

the fresh water. Shut off burners.

Now, let the boiler steam for a few days, to give the majority

of the system dirt a chance to work its way back to the boiler.

Then check the water in the gauge glass. The gauge glass

should be dry above the water line. The water line should

not bounce more than one inch when the boiler is steaming.

If you see water droplets carrying over from the top of the

gauge glass, or excessive bouncing of the water line, the

boiler needs further cleaning. Take a water sample and boil

it on the stove, to see if it foams. If it does, this also indicates

the boiler needs to be cleaned.

If cleaning is necessary, repeat the skimming and blow down

procedure from above. Usually a long skim will be all you

need to clean the boiler.

In more troublesome cases it may be desirable to flush the

system as well. This is accomplished by closing the gate

valve in the Hartford Loop, and opening the drain(s) at the

end of the wet return(s). Run a hose from the drain valve

on the wet return to a nearby floor drain or bucket. Run

the boiler at two pounds of steam pressure. Feed just enough

water to compensate for the waste condensate going down

the drain, and to keep the boiler from going off on low water

cut off. Run the boiler until all waste condensate runs clear.

NOTE

Boiler cleaners and chemical cleaning additives are not

recommended. If used and not rinsed properly, they

will do more harm than good. The cleaning procedures

laid out above will clean out the typical oilsand impurities

found in new boilers and in residential heating systems.

The best thing for your boiler and heating system is

clean water with no additives.

In very extreme cases it may be necessary to chemically

clean and flush the heating system. Consult the boiler manu-

facturer before introducing any chemicals into the boiler.

,,+_ 24

Checkthewaterleveleverydayortwo.Verifythewaterlineshownby

operatingthedrainvalveonthegauge.BESURETOPANDBOTTOM

VALVESONGAUGEAREALWAYSOPENSOTHATACTUALWATERLEVEL

WILLBESHOWNATALLTIMES,

Thegaugeglassshouldbedryabovethewaterline.Thewaterlineshould

notbouncemorethanaboutoneinchwhentheboilerissteaming.If

youseewaterdropletscarryingoverthroughthetopofthegaugeglass,

orexcessivebouncingofthewaterline,theboilerneedsto becleaned.

Followtheinstructionsunder"CleaningYourBoiler."

POP SAFETY VALVE

This valveshouldopenautomaticallywhenthe steampressureexceeds

the safe limit (per instructionspackagedwith valve).Shouldit ever fail

to openundertheseconditions,shutdownyour system.Havethe valve

replacedimmediately

LOW WATER CUT-OFF

TheLowWaterCut-Offwill interruptthe electricalcurrentto theburner

whenthewaterlineintheboilerdropsto a lowlevel.

On float type low watercut-offs,it is very importantto keep the float

chamberfree from sediment,a conditionessenlialto dependabilityTo

keepanyaccumulationfrominterferingwithfloatactionisto"BLOWDOWN"

or flush out thecontrol regularly.This mustbe donetwo to threetimes

duringthe first weekafter installationand oncea weekthereafterduring

theheatingseason.Do it whiletheboileris inoperation.Firstnotewater

level in gaugeglass.Open blow-offvalve at bottomof control;water

will pour out, flushingawaysediment.Drain untilwater is clear,about

a pailful,then close valve, g waterlevel in gaugeglass hasdropped,

addwatertoboilerto restorelevel.Consultlowwatercut-offmanufacturer's

instructionsincludedwithboiler.

NOTE: Openingblow-off valvechecks cut-off operationtoo. As float

dropswithfallingwaterlevel,burnerswill shutoff. Aftervalveis closed

andnormaloperatingconditionsarerestored,burnerswillresumefiring.

Forprobetype LowWaterCut-Offs,checkactionof the LowWaterCut-

Offmonthlytomakesureitisprovidingtheproperprotection.See"Checking

and Adjusting"on page23. Low WaterCut-0ff remoteprobesmustbe

removedfor periodicinspectionandcleaning,preferablyatthe beginning

ofeachheatingseason.Morefrequentcleaningmaybe requiredonboilers

requiringconstantorveryfrequentadditionsof makeupwater.

BURNERS

A visualcheckof the pilot and mainburnerflamesshouldbe madeat

leastonceeachyear,preferablyat thebeginningof the heatingseason.

Seepage23.

BOILER FLUE PASSAGES

Undernorma]operatingconditions,with the burnersproperlyadjusted,

it shouldnotbe necessaryto cleantheboilerfluegaspassages.However,

to assuretrouble-freeoperation,we recommendthat you havethe flue

passages,burneradjustment,andoperationof the controlscheckedonce

eachyearbya competentServiceTechnician.

Beforethestartof eachseason(or wheneversystemhasbeenshutdown

for sometime)recheckthe wholesystemfor leaks... andrecheckthe

boilerandventpipefor leaks.

VENT PIPE

Theventingof thisunitis veryimportantandthepipingshouldbechecked

at leastonce a season.If the vent piping showsany sign of leaking,

replaceit immediately

CLEANING YOUR BOILER FLUE PASSAGES

AND BURNERS

FluePassagesbetweensectionsshouldbe examinedyearlyandcleaned,

if necessaryToclean,removeburners,pilot,andvenl pipe,Removetop

andfrontjacketpanels.Removethetwoscrewsattachingtheintermediate

front pand 1o lhe left andrighl side jacketpanels.Removethe draft

diverlerandintermediatefrontpanelasa unit.Carefullyremovethecerafeg

gasketstrips.Cleanpassagewaysbetweensectionswitha flexiblehandle

wirebrush.Removedirt from botlomof boilerandfrombetweenseclions

by vacuuming,Makesureall flameports in burnersare openand clear.

Shakeout or blow out all loosedirt in burners.Resealseamsbetween

adjacentsectionsasnecessarywith400FRTVsiliconesealant.Reassemble

all parts.Be sureto checktightnessof pilot connectionsand condftion

of burnerflamesafterreassemNy(seeFigures18 and19).Besurevent

pipeconnectionstochimneyaresecureandnoobslructionsarepresent.

FOAMING, PRIMING OR SURGING

Theseterms areusedto describea fluctuatingwaterline- whenwater

leavestheboilerwiththesteam.

It iscausedbyanycombinationofthefollowing:

1. Threadingoil andorganicmatterin the boiler water,(Mineraloil, or

coresanddoesnotcausesurging.)Followinstructionsunder"Cleaning

YourBoiler."

2. Faultyquick ventsthat do not releaseair unlil a sizeablepressure

is builtup - if old style, reptace it dirty cleanso you caneasily

blowthroughvalve.

3. Improperheaderdesign- whensteamflowsin oppositedirection

of equalizerlineon "HartfordLoop."Generallya 15" horizontalrun

betweenriser andmaintakeoffwill allowentrainedwaterto fall out