Page 1

Embroidery/Sewing Machine

Owner’s Manual

Model 385.19010200

851-811-004

Sears, Roebuck and Co., Hoffman Estates, iL 60179 U.S.A.

Sears Canada Inc., Toronto, Ont., MSB 2B8

www.sears.com

www.sears.ca

Page 2

IMPORTANT SAFETY INSTRUCTIONS

When using an eiectricai appliance, basic safety precautions should always be followed, including the followings:

Read all instructions before using this appliance.

DANGER- To reduce the risk of electric shock:

1. An appliance should never be left unattended when plugged in. Always unplug this sewing machine from the

electric outlet immediately after using and before cleaning.

2. Always unplug before replacing a sewing machine bulb. Replace bulb with same type rated 13.2 V, 3 Watts.

WARNING ■ To reduce the risk of burns, fire, electric shock, or injury to persons:

1. Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used by or near children.

2. Use this appliance only for its intended use as described in this owner's manual.

Use only attachments recommended by the manufacturer as contained in this owner's manual.

3. Never operate this sewing machine if it has a damaged cord or plug, If it is not working properly, if it has been dropped

or damaged, or dropped Into water.

Return this sewing machine to the nearest Sears store or service center for examination, repair, eiectricai or

mechanical adjustment.

4. Never operate the appliance with any air opening blodied. Keep ventilation openings of this sewing machine and foot

controller free from accumulation of lint, dust and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

8. To disconnect, turn ail controls to the off ("O") position, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14. Switch this sewing machine off ("O") when making any adjustment in the needle area, such as threading the needle,

changing the needle, threading the bobbin or changing the presser foot, and the like.

15. Always unplug this sewing machine from the eiectricai outlet when removing covers, lubricating, or when making any

other adjustments mentioned In this owner's manual.

16. Hold plug when rewinding into cord reel. Do not allow plug to whip when rewinding.

SAVE THESE INSTRUCTIONS

Before using your sewing machine for the first time, place a waste fabric under the presser foot

and run the machine with thread for a few minutes. Wipe away any oil which may appear.

Page 3

PROTECTION AGREEMENTS

In the U.S.A.

Master Protection Agreements

Congratuiations on making a smart purchase. Your new

Kenmore® appliance is designed and manufactured for

years of dependable operation. But like all products, it may

require preventive maintenance or repair from time to time.

That’s when having a Master Protection Agreement can

save you money and aggravation.

Purchase a Master Protection Agreement now and protect

yourself from unexpected hassle and expense.

The Master Protection Agreement also helps extend the

life of your new appliance. Here’s what’s included in the

Agreement:

0 Expert service by our 12,000 professional repair

specialists

0 Unlimited service and no charge for parts and labor

on ail covered repairs

0 “No-lemon” guarantee - replacement of your covered

product if more than three product failures occur within

twelve months

0

Product replacement if your covered product can’t be

fixed

0

Annual Preventive Maintenance Check at your request

- no extra charge

0

Fast help by phone - non-technicai and instructional

assistance on products repaired in your home, plus

convenient repair scheduling

0

Power surge protection against electrical damage due

to power fluctuations

0

Rental reimbursement if repair of your covered product

takes longer than promised

In Canada

Maintenance Agreements

Your purchase has added value because you can depend

on Sears HomeCentrai® for service. With over 2400

Service Technicians and access to over 900,000 parts and

accessories, we have the tools, parts, knowledge and skills

to ensure our pledge: We Service What We Sell.

Your Kenmore® appliance is designed, manufactured and

tested to provide years of dependable operation. Yet any

major appliance may require service from time to time. The

Sears Maintenance Agreement offers you an outstanding

service program, affordably priced.

The Sears Maintenance Agreement

• Is your way to buy tomorrow’s service at today’s price.

• Eliminates repair bills resulting from normal wear and

tear.

• Provides for non-technical and instructional assistance.

• Even if you don't need repairs, provides an annual

Preventive Maintenance Check, at your request, to

ensure that your appliance is in proper running condition.

Some limitations apply. For information concerning

Sears Canada Maintenance Agreements, call

1-800-361-6665.

Once you purchase the Agreement, a simple phone call is

all that it takes for you to schedule service. You can call

anytime day or night, or schedule a service appointment

online.

Sears has over 12,000 professional repair specialists, who

have access to over 4.5 million quality parts and

accessories. That’s the kind of professionalism you can

count on to help prolong the life of your new purchase for

years to come. Purchase your Master Protection

Agreement todayl

Some limitations and exclusions apply.

For prices and additional information, call

1-800-827-6655.

Sears Installation Service

For Sears guaranteed professional installation of home

appliances and items like garage door openers and water

heaters, in the U.S.A. call 1-800-4-MY-HOME®

Page 4

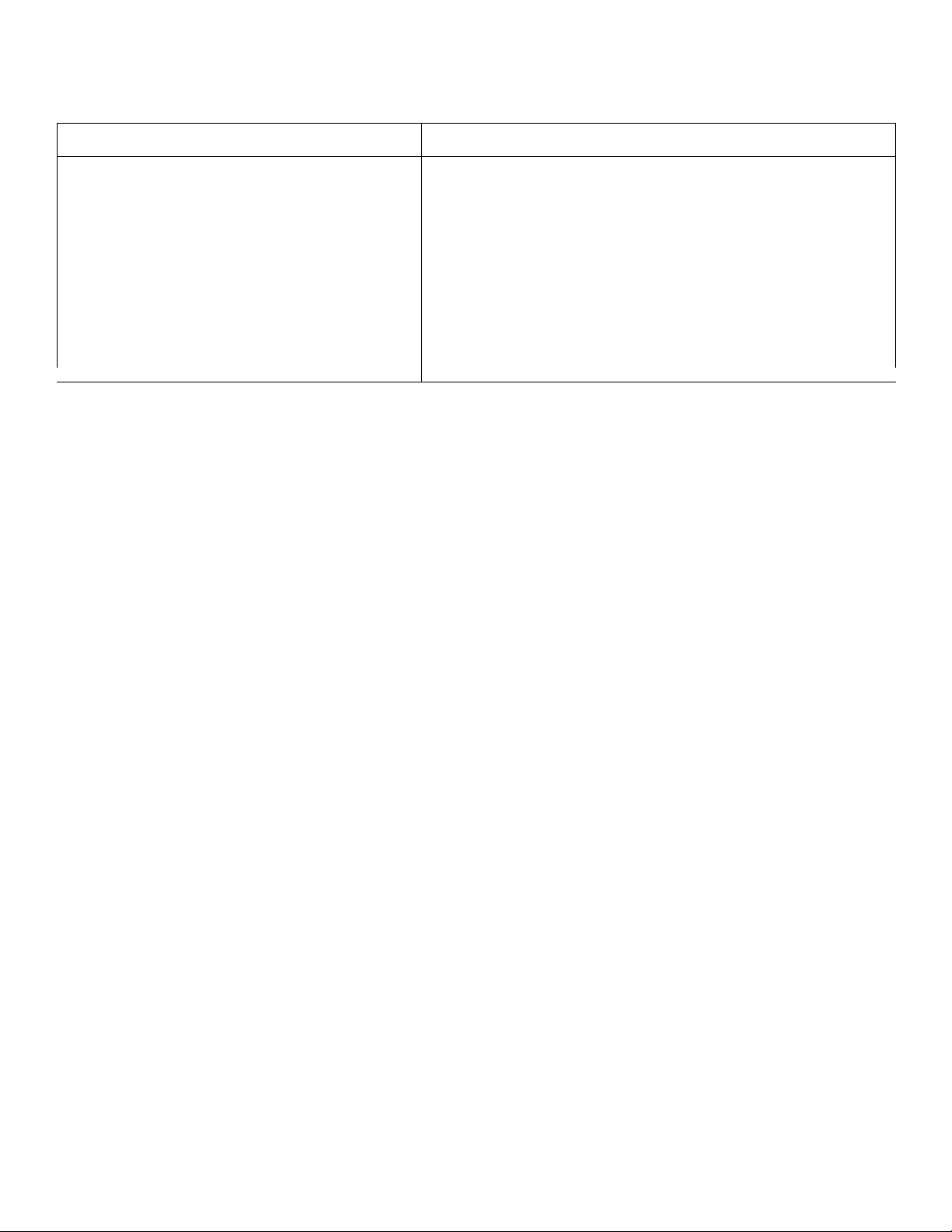

Machine Specifications

Item specification

Sewing speed (Maximum):

Stitch length: 5 mm (Maximum)

Stitch width: 7 mm (Maximum)

Stitch package (Stitch functions):

(Built-in stitches): Conventional 673 buiit-in stitches with 447 built-in embroidery

Buttonhole: 1 step built-in buttonhole

Machine dimensions:

Weight (Net): 23.9 lbs (11kg)

V

Kenmore Sewing Machine Warranty

Full 25 Year Warranty on Internal Mechanical Components

For 25 years from the date of purchase, Sears will provide free repair for the interna! mechanical components of

this sewing machine if they are defective in materia! or workmanship.

Full Two Year Warranty on Electrical Equipment

For two years from the date of purchase, Sears will provide free repair for the electrica! equipment of this sewing

machine, if any part of it, including motor, wiring, electronic circuitry, switch and speed control, is defective in

materia! or workmanship. This two-year warranty does not inciude light bulbs, which are expendable parts only

included in the 90 day warranty described below.

Full 90 Day Warranty on Ail Parts and Mechanical Adjustments

For 90 days from the date of purchase, Sears will provide free parts replacement and mechanical service

necessary for the proper operation of this sewing machine, except for normal maintenance as described in the

owner's manual.

Warranty service is available by returning this sewing machine to the nearest Sears Service Center in

the United States. If this sewing machine is used for commercial or rental purposes, warranty service is

available for only 90 days from the date of purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., D/817WA, Hoffman Estates, IL 60179

Over 820 s.p.m.

1160

design

W 18.9” (481.1 mm) x D 9.2” (234.5 mm) x H 12.8” (326.2 mm)

y

Kenmore Sewing Machine Warranty

Full 25 Year Warranty on Internal Mechanical Components

For 25 years from the date of purchase. Sears will provide free repair for the interna! mechanical components of

this sewing machine if they are defective in material or workmanship.

Full Two Year Warranty on Electrical Equipment

For two years from the date of purchase. Sears will provide free repair for the electrical equipment of this sewing

machine, if any part of it, including motor, wiring, electronic circuitry, switch and speed control, is defective in

material or workmanship. This two-year warranty does not inciude light bulbs, which are expendable parts only

included in the 90 day warranty described below.

Full 90 Day Warranty on All Parts and Mechanical Adjustments

For 90 days from the date of purchase. Sears will provide free parts replacement and mechanical service

necessary for the proper operation of this sewing machine, except for normal maintenance as described in the

owner's manual.

Warranty service is available by returning this sewing machine to the nearest Sear^ Service Center in

Canada. If this sewing machine is used for commercial or rental purposes, warranty service is available for only 90

days from the date of purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary from province to

province.

Sears Canada,Toronto, Ont., M5B 2B8

!!l

Page 5

TABLE OF CONTENTS

SECTION !. NAME OF PARTS

Names of Parts .............................................................. 2

Available Accessories and Attachments

SECTION II. GETTING READY TO SEW

Connecting Machine to Power Supply

Before Using Your Sewing Machine ............................................................................................................... 4

For Your Safety

Polarized Plug

Machine Operating Buttons

Start/stop Button..............................................................5

Reverse Button......

• Patterns 1,2, 6 and 7:

• All other patterns:........................................................5

Auto-lock Button ............................................................. 5

• Patterns 1,2, 6 and 7:.................................................5

• All the other patterns:

Up/down Needle Button ................................................ 5

Speed Control Lever

Foot Control

Operation Instructions; ................................................ 6

Pressure Dial...................................................................6

To Drop or Raise the Feed Dogs

Extension Table

• Detaching the Table

• Attaching the Table .................................................... 7

Presser Foot Lifter...........................................................7

Thread Cutter................................................................ 8

Changing Needle ........................................................... 8

Changing Presser Foot

• To remove................................................................. 8

• To attach .................................................................... 8

Correcting Distorted Stitch Patterns

Presser Foot Types

• Zigzag foot (Foot A)...................................

• Straight stitch foot (Foot H)

• Automatic buttonhole foot (Foot R)

• Zipper foot (Foot E)

• Overedge foot (Foot C)............................................. 10

• Satin stitch foot (Foot F).......................................... 10

• Blind hem stitch foot (Foot G)................................... 10

• 1/4"Seam foot (Foot O)

• Embroidery foot (Foot P)

• Walking foot.............................................................. 11

Selecting Needle and Fabric ......................................... 12

Bobbin Winding............................................................ 13

• Removing the hook cover plate

• Horizontal spool pin

• Additional spool pin

Bobbin Winding....................................................... 14-15

• Inserting the bobbin................................................. 15

Threading the Machine

• Threading the machine............................................ 16

• Built-in needle threader

• Drawing up bobbin thread ........................................ 17

SECTION III. CONVENTIONAL SEWING

Visual Touch Screen..................................................... 18

Mode Selection Keys

............................................................. 4

.................................................................

............................................

........................................................ 5

.................................................

.................................................

.......................................................

....................................................................

.................................. 6

..............................................................

.....

........................................... 7

...................................................

....................................................... 10

.....................................

.................................................

.................................... 11

........................................

.................................................. 13

.................................................

.................................

............................................

...................................................

.........................

............................

...............................

10

.........................

...........

........................................................................................................ 13

16-17

3

4

4

5

5

5

5

6

7

8

9

10

10

10

11

13

16

18

Pattern Selection...........................................................19

Utility Stitches.....

Machine Settings

Common Set Mode

Embroidery Set Mode

Flag Mode-Language Selection ....................................21

Straight Stitch...........................................................22-23

•To sew .....................................................................

• Securing seam..........................................................22

•Changing sewing direction ......................................22

• Needle plate guide line.............................................23

• To sew from the edge of thick fabric

Quilting ..........................................................................23

Quilting with Walking Foot.............................................24

• To attach the walking foot.........................................24

Manual Adjustment of Straight Stitches ................. 24-25

• Changing needle drop position.................................25

•Changing stitch length..

Adjust the Needle Thread Tension for Straight Stitch.... 26

• Correct tension

• Tension Is too tight...................................................26

• Tension is too loose

Variety of Straight Stitches

Lock-a-matic Stitch

Locking Stitch.....

Triple Stretch Stitch.......................................................27

Stretch Stitch.................................................................28

Basting Stitch .................................................

Zipper Sewing

• To snap on the zipper foot........................................28

• Fabric preparation.

• To sew

Zigzag Stitch

Manual Adjustment of Zigzag Stitch Width and Length 30

• Changing stitch width...............................................31

• Changing stitch length

Adjust the Needle Thread Tension for Zigzag Stitch ..... 32

• Correct tension

• Tension is too tight

• Tension Is too loose

Variety of Overcasting Stitches

Overedge Stitch ............................................................33

Overedge Stitch (using zigzag stitch)

Multiple Zigzag Stitch

• Seam finishing

• Mending....................................................................33

Serging..........................................................................34

Double Overedge Stitch................................................34

Blind Hem Stitch.

• To sew

Shell Tuck......................................................................35

......................................................................

......................................................................

.......................................................... 19

..........................................................20

.......................................................

...................................................21

.........................

....................................

.........................................................

.................................................

...................................... 27-28

.......................................................

...........................................................27

...............................................................

..................................................29

.................................................................30

.............................................

.........................................................

...................................................

...

..................................

.....................................

...........................

.......

..................................

..........................................................33

.........................................................35

SECTION IV. BUTTONHOLE

Various kinds of buttonholes and their uses

Square BH....

• Preparation for sewing

•To sew ..................................................

................................................................37

.............................................

.................

37-38

20

22

23

25

26

26

27

28

28

29

31

32

32

32

33

33

33

35

36

37

IV

Page 6

TABLE OF CONTENTS

• To repeat buttonhoie sewing.....................................38

• Changing buttonhole width ....................................... 39

• Changing buttonhole stitch density......

Corded Buttonhoie

•To sew

Darning .........................................................................

• To sew......................................................................41

• To sew a shorter darning

• To sew the same size darning

• To adjust the evenness of darning

Tacking..........................................................................42

• To sew a shorter tack

• To sew the same size tack.....

Eyelet.............................................................................43

• To sew

•To adjust the size of an eyelet.................................. 43

SECTION V. SATIN, DECORATIVE STITCHES AND

Key Functions

One Cycle Pattern Sewing

Example: pattern 28, L.S

•To sew

Elongation Sewing

Example: pattern 28 ...................................................... 46

•To sew

Programming Pattern Combination

Example: pattern 28 and 31

•To sew

Programming Pattern Combination with Mirror Image

Example: pattern 30 ...................................................... 47

•To sew

Programming French Knot

Example: pattern 51, 39, 40

•To sew

Combination of Satin Stitch and Decorative Stitch

Example: pattern 28, 70................................................48

• To sew

To Sew from the Beginning of a Combination Pattern with

Beginning Key

Example: pattern 30......................................................49

•To sew

Twin Needle Sewing

• To sew

Individual Pattern Adjustment

Exam pie: patterns 28, 30 and 32

Editing Programmed Patterns.......................................50

• Example:

• Example:

Program Check.............................................................51

• Example:

Saving and Opening a File..

• Saving a file .............................................................. 52

.......................................................................40

......................................................................

.......................................................................46

.......................................................................46

.......................................................................47

....................................................... 47

.......................................................................48

......................................................................

.......................................................................49

......................................................................

To delete pattern 30 from the combination with patterns

28, 30 and 32....

To insert pattern 38 between pattern 28 and 30 in the .

combination of patterns 28. 30 and 32

To check the patterns when patterns 64, 70, 30. 26,

31 and 38.................................................................51

........................................................

.......................................... 41

.................................

...............................................

.................................. 42

MONOGRAMMING

..........................................................

..............................................

......

.................................... 47

.......................................... 48

.....................................................

.................................

....................................................... 50

.......................................... 52

...............

.......................... 41

39

40

41

41

42

43

44-45

46

48

49

49

50

...............

50

• Assigning a file name................................................52

Opening a Saved File................................................... 53

Deleting a Saved File ....................................................53

MONOGRAMMING.................................................54-55

Programming a Monogram

Example: Programming in Block Type ..55

Editing a Monogram

Deleting a Letter

inserting a Letter (Character)

SECTION VI. EMBROIDERY

Getting Ready to Sew Embroidery...............................56

• Embroidery Hoop F ................................................. 56

• Instruction for Template...........................................56

Stabilizer.......................................................................57

Types of Stabilizer........................................................ 57

• Tear-away Stabilizer................................................57

• Iron-on Stabilizer

• Cut-away Stabilizer.....

• Water Soluble Stabilizer

• Sticky Stabilizer

Usage:..........................................................................57

Adhesive (iron-on) Stabilizer

To Attach the Stabilizer................................................ 58

To Set the Fabric in the Embroidery Hoop

To Attach the Embroidery Hoop to the Machine .......... 59

To Attach Embroidery Foot P .......................................

Thread Holder...............................................................59

Built-in Embroidery Designs............

Pattern Selection Window .............................................60

Embroidery Mode Set..................................................61

Embroidery Screen ....................................

Starting to Sew Embroidery ..........................................64

Sewing Results.............................................................64

Monogram Embroidery ................................................65

Monogram Selection Screen...........................

2-letter Monogram .........................................................67

Example: 2-Letters with a crest....................................67

Example: 2-Letters without a crest...............................67

• Making Corrections.....

ATA PC Card................................................................68

• To insert the ATA PC card.......................................68

• To eject the ATA PC card

Selecting the Card Designs..........................................68

Reader/writer 19000

• Connecting Reader/writer 19000

Pattern Selection Screen

Edit Mode...

Pattern Selection Windows in the Edit Mode ..........

Selecting the Pattern on the Edit Screen

Moving the Selected Design

Cancel Key...................................................................71

Resizing the Selected Pattern.............................

Flipping the Selected Pattern

Rotating the Selected Pattern......................................71

Delete Key..

Changing the Fabric and Thread Colors

V

......

.................................................................72

......................................................

............................................................55

.......................................

.....................................................

.................................

..........................................

.......................................................

........................................

....................

.............................................67

...........

....................................................69

.............................................

............................................................70

........................................

......................................

.............................68

............................69

..................... 70

......................

..57

....................

..60

..62-63

...65-66

..71

55

55

57

57

57

57

58

.59

69

70

70

71

72

Page 7

TABLE OF CONTENTS

• Fabric color change

• Thread color change

.................................................

72

................................................. 73

Pattern Combination {example 1) ................................74

Sewing Results.............................................................74

Pattern Combination {example 2) ........................

.75

Sewing Results .............................................................76

SECTION VII. NORMAL MAINTENANCE

Replacing the Light Bulbs

• To replace the light bulb behind the face cover

.............................................

........

78

78

• To replace the light bulb on the underside of the

sewing arm

............................................................... 78

Cleaning the Hook Area................................................79

Assemble the Hook Race..............................................79

STITCH/DESIGN CHART ............................ 80-81

Conventional Sewing

....................................................

80

Monogram..................................................................... 80

Built-in Embroidery Designs

......................................... 81

Built-in Embroidery Monogram.....................................81

Troubleshooting

........................................

82-83

VI

Page 8

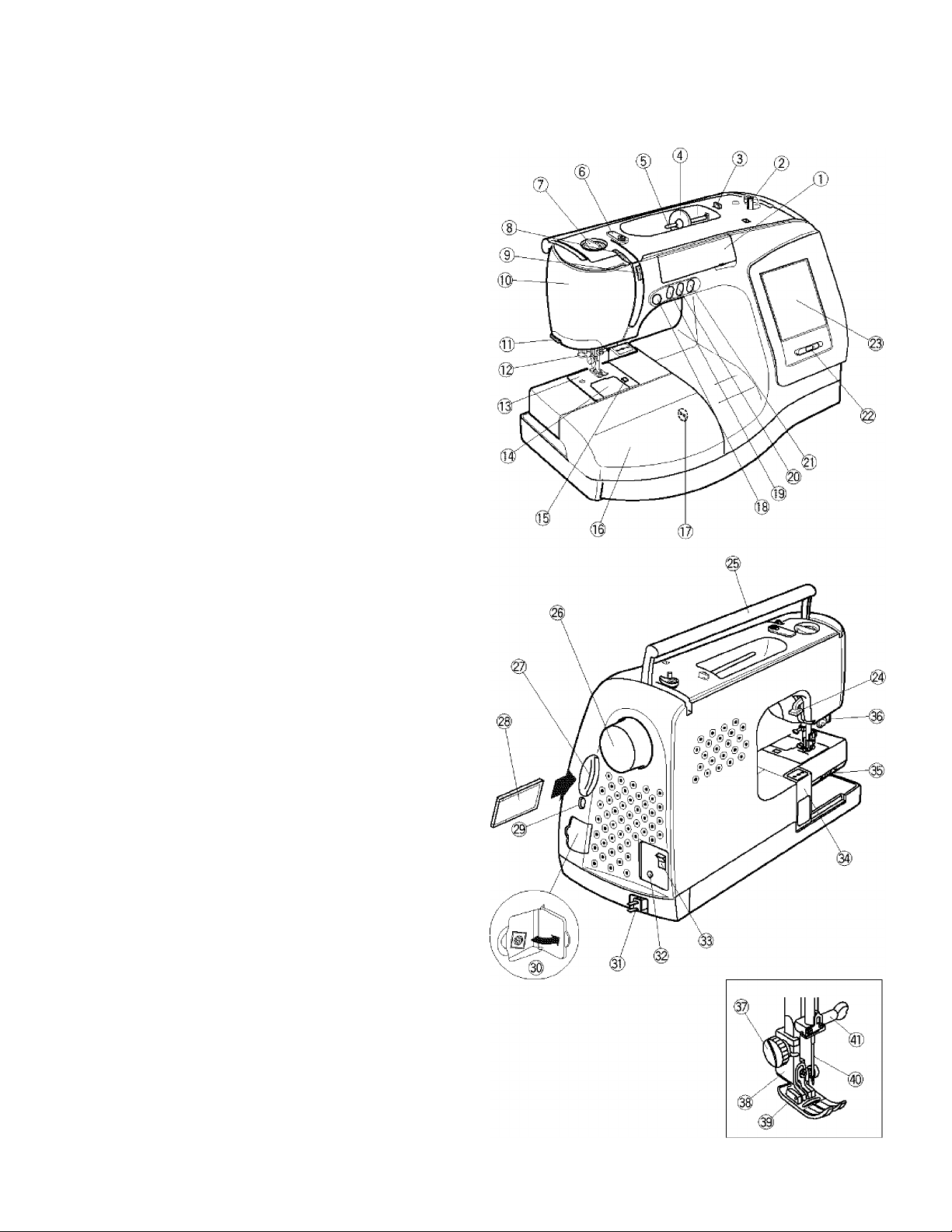

SECTION I. NAME OF PARTS

Names of Parts

® Fiip-top quick reference chart

(2) Bobbin winder spindle

CD Bobbin thread cutter

0

Spool holder (Large)

0 Spool pin

® Upper thread guide

0 Pressure dial

0 Thread take-up lever

0

Thread tension dial

® Face cover

0 Thread cutter/holder

® Built-in needle threader

0 Needle plate

0 Hook cover plate

® Hook cover plate release button

® Extension table

® Feed balancing dial

® Start/stop button

® Reverse button

® Auto-lock button

Up/down needle button

@

@ Speed control lever

® Visual touch screen

0 Presser foot lifter

® Carrying handle

® Hand wheel

@ PC card slot

® ATA PC Card (optional)

® Card eject button

® RS-232C port

(|f) Power supply plug (cord reel)

0 Machine sodiet

® Power switch

0 Carriage (for embroidery)

® Drop feed dog lever

0 Buttonhole lever

0 Thumb screw

® Foot holder

® Presser foot

® Needle

@ Needle clamp screw

Page 9

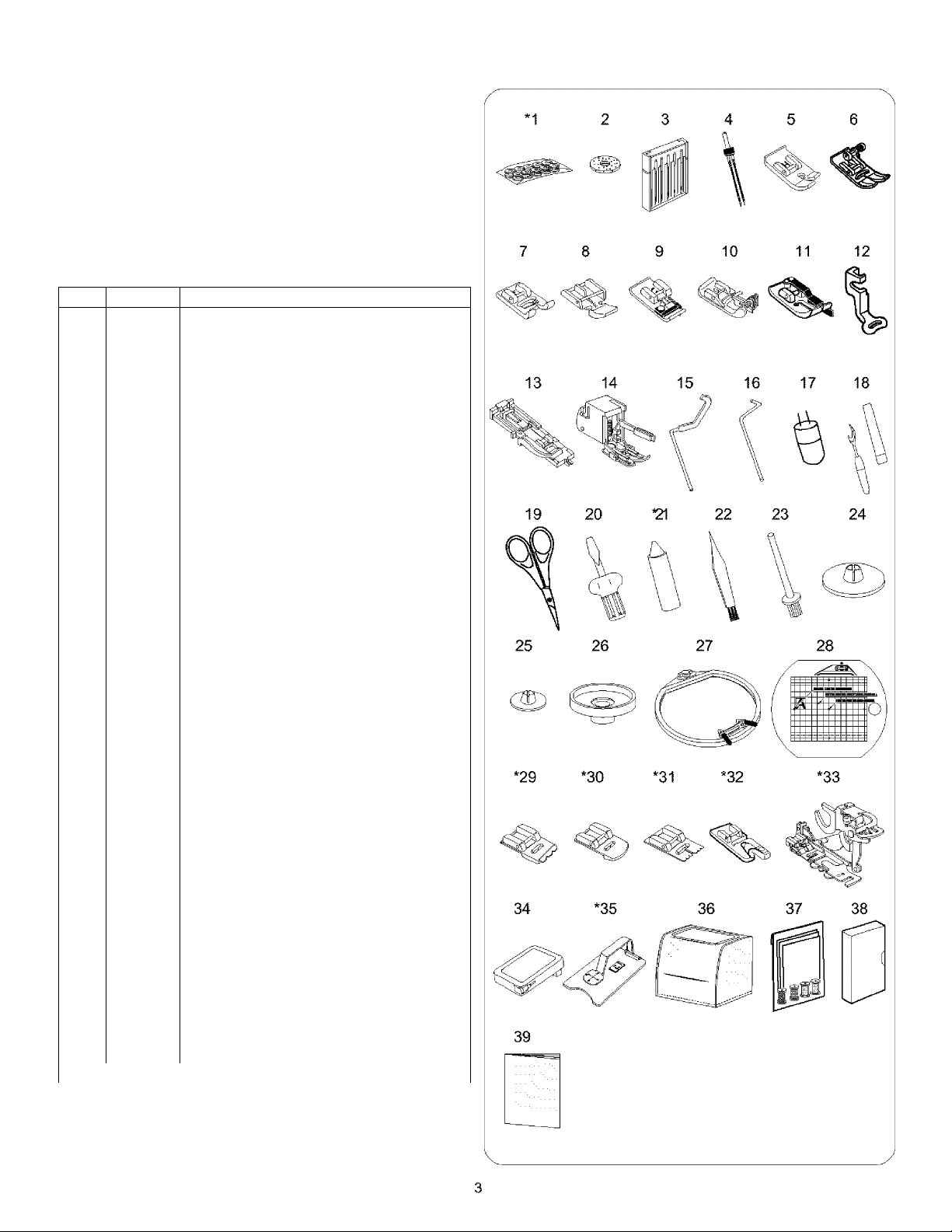

Available Accessories and Attachments

To order parts and accessories listed below, call:

1-800-366-PART (1-800-366-7278)

6 am - 11 pm, CST, 7 days a week

When ordering parts and accessories, provide the following

information:

1. Part Number

2. Part Name

3. Model Number of Machine

Ref. No.

Part No. Description

*102869107 10 X Bobbin

1

2

102403109

3 650807101

*993010900

*993001100

*993011100 5 X No. 11 needle (ORANGE)

*993011400 5 X No. 14 needle (RED)

*993011600

*993011800

4

826815000 Twin needle

5

823801015 H;Straight stitch foot

6 832523007 A: Zigzag foot

7

822804118

8 829801002

9 822801001 C: Overedge foot

10 820817015

11 200008004 0:1/4” seam foot

12 830810031

13

830823118

214508002 Walking foot

14

15 214015007 Quilter bar (for walking foot)

802422002 Quilter

16

17 000009907

560406104

18

822814007

19

20 820832005

21 *741814003 Oil

22 802424004 Lint brush

625031500 Additional spooi pin

23

24 822020514

25 822019509

829803004

26

27 851801104 F:Embroidery hoop

851801403 Template

28

29

*200002008

30 *200003009

31 *200005001

32 *200013105

33

*941620000

34

043271155 Foot control

35 *851401007 Clothsetter

36 851813006

37 851821007 Starter kit

38 851816009 Video

39 851820006

Spooi pin felt

Assorted needle set

5 X No. 9 needle (BROWN)

5 X No. 11 stretch fabric needle (BLUE)

5 X No. 16 needle (PURPLE)

5 xNo.18 needle (GREEN)

F; Satin stitch foot

E: Zipper foot

G;Blind hem foot

P:Embroidery foot

R: Automatic buttonhole foot

Light bulb

Seam ripper/Buttonhole opener

Scissors

Large screwdriver

Large spool holder

Small spooi holder

Spooi stand

Piping foot

Gathering foot

Pin-tuck foot

Hemmer foot (2mm)

Ruffler

Dust cover

Template sheet

These ítems are not furnished with the machine, but may be

ordered per instructions above.

Page 10

SECTION II. GETTING READY TO SEW

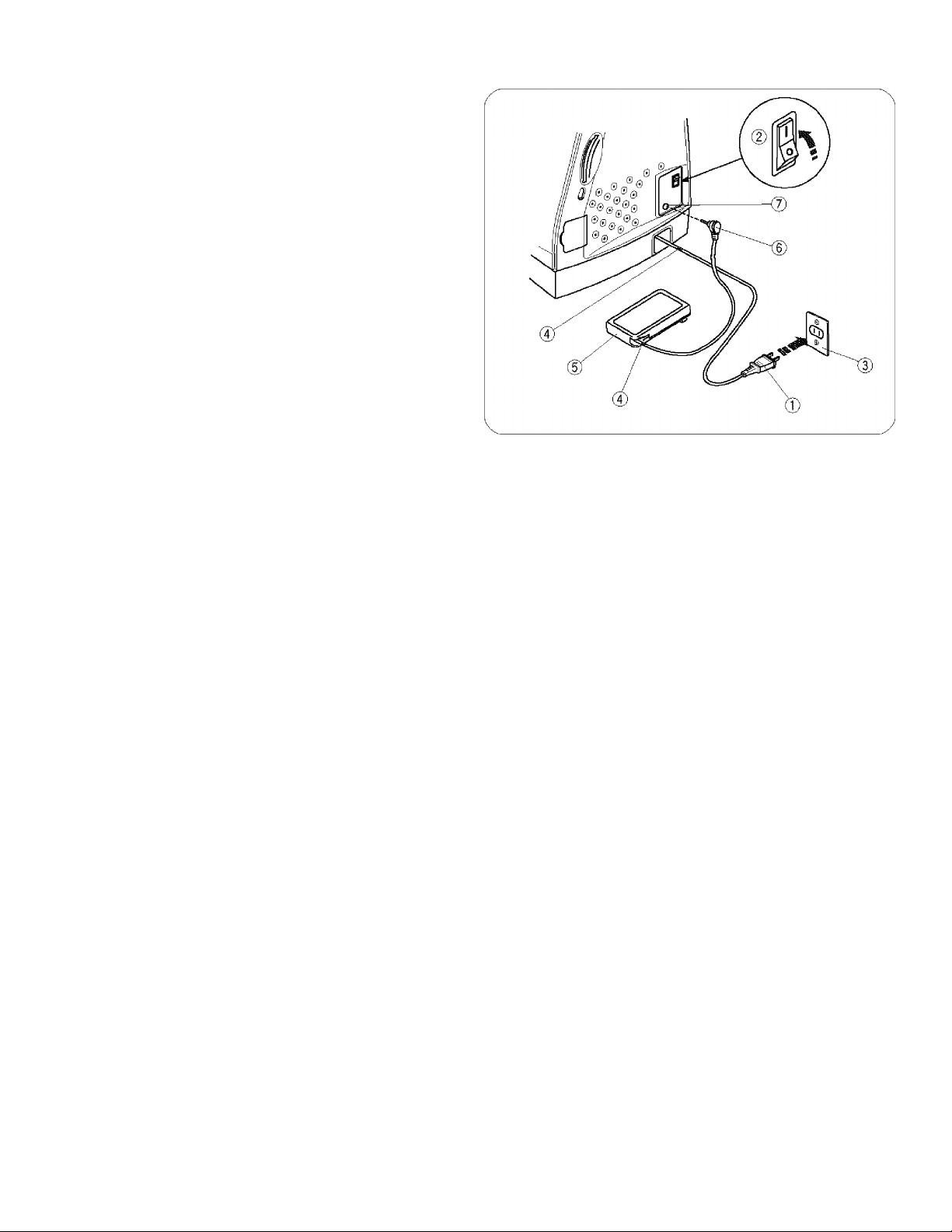

Connecting Machine to Power Supply

(T) Power supply plug

(2) Power switch

(D Outlet

® Red marker

(f) Foot control

® Foot control plug

® Machine socket

1. Turn off the power switch (2). Insert the foot control plug

® into the machine socket

2. Insert the power supply plug ® into the outlet ®.

3. Turn the power switch (2) to turn on the power and

sewing lights.

Notes:

• Do not pul! the cords beyond the red marker ® on the

cords.

• If you turn off the power switch, wait 5 seconds before

turing it on again.

• Hold plug when rewinding into cord reel. Do not allow

plug to whip when rewinding.

Before Using Your Sewing Machine

Before using your sewing machine for the first time, place a

waste fabric under the presser foot and run the machine

with thread for a few minutes. Wipe away any oil which may

appear.

For Your Safety

* While in operation, always keep your eyes on the sewing

area. Do not touch any moving parts such as the thread

take-up lever, handwheel or needle.

* Always turn off the power switch and unplug from the

power supply:

• When leaving the machine unattended.

• When attaching or removing any parts.

• When cleaning the machine.

* Do not place anything on the foot control, when not

sewing.

Polarized Plug

This appliance has a polarized plug (one blade wider than

the other). To reduce the risk of electric shock, this plug is

intended to fit in a polarized outlet only one way. If the plug

does not fit In the outlet, reverse the plug. If it still does not

fit, contact a qualified electrician to install the proper outlet.

Do not modify the plug in any way.

Page 11

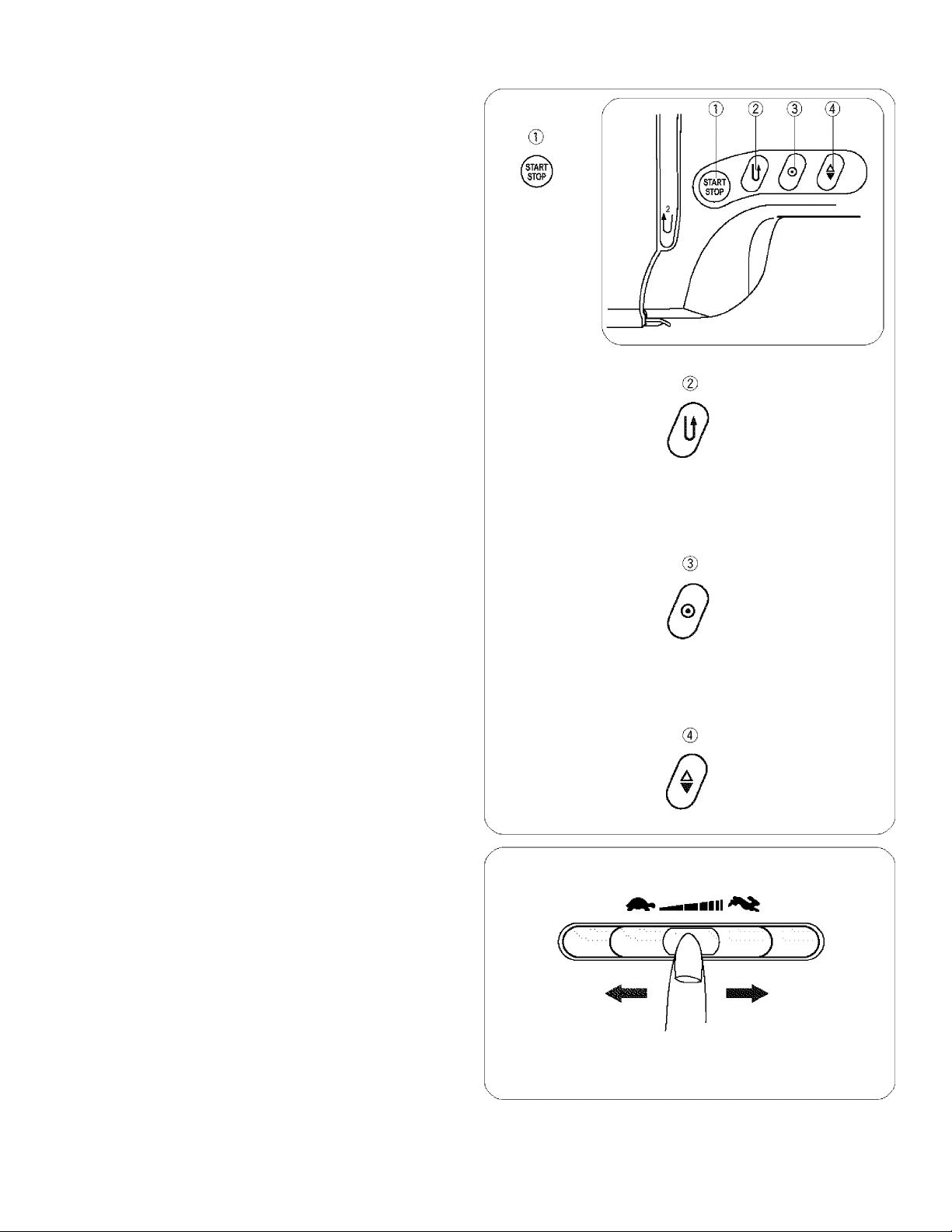

Machine Operating Buttons Start/stop Button

(T) Start/stop button

Press the button to start or stop the machine. This button

can be used either in conventionai sewing mode or Embroi

dery mode. In conventional sewing mode, the machine

starts running slowly for the first few stitches; it then runs at

the speed set by the speed control lever.

Note:

The Start/stop button cannot be used when the foot

control is connected to the machine.

Reverse Button

(2) Reverse button

• Patterns 1,2,6 and 7:1 -i- - ' .

The machine will sew in reverse while the reverse button

is pressed.

• All other patterns:

When the reverse button is pressed, the machine will sew

locking stitches immediately and automatically stop.

Auto-lock Button

(

1

) Auto-lock button

• Patterns 1, 2,6 and 7:

When the auto-lock button is pressed, the machine will

immediately sew locking stitches and automatically stop .

• All other patterns:

When the auto-lock button is pressed, the machine will

sew locking stitches at the end of the current pattern and

automatically stop.

Up/down Needle Button

0 Up/down needle button

Press this button to bring the needle up or down.

Speed Control Lever

Sewing speed can be varied by the speed control lever

according to your sewing needs.

To increase sewing speed, slide the lever to the right.

To decrease sewing speed, slide the lever to the left.

Page 12

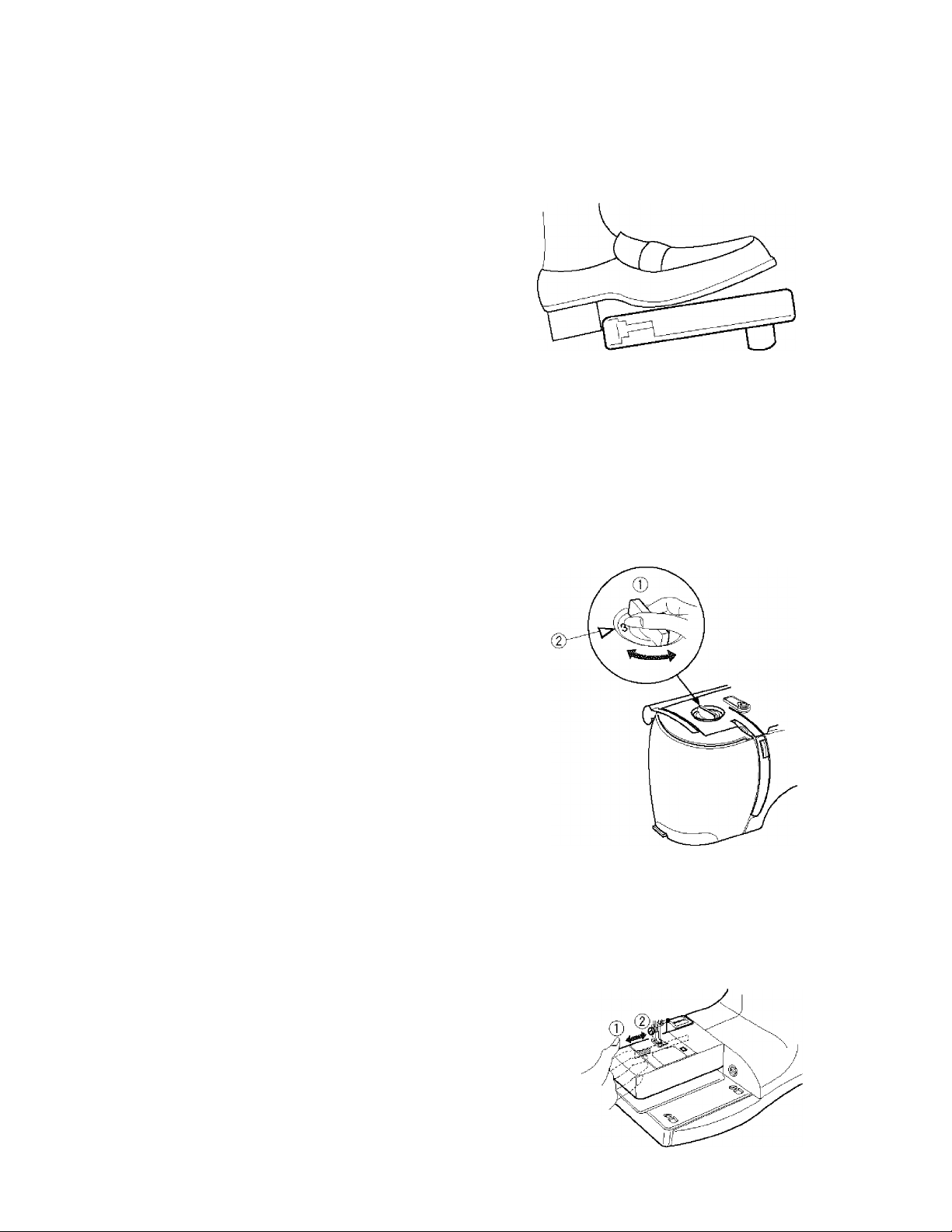

Foot Control

Sewing speed can be varied by the foot control.

The harder you press on the foot control, the faster the

machine runs.

Note;

The machine runs at the maximum speed set by the

speed control lever when the foot control Is being fully

depressed.

Operation Instructions;

Foot Controller Model 21371 is used with Sewing Machine

Model 385.19010XXX (XXX represents numbers 000

through 999).

Note;

The Kenmore Elite sewing machine model 19010 is

equipped with an automatic shutdown safety feature to

prevent overheating. Follow safety instructions that appear

on the visual touch screen.

Pressure Dial

The pressure dial should be set at “3” for regular sewing.

г

Reduce the pressure to “2” for applique, cut work, drawn

work, basting and embroidery.

Set the pressure to “1” when sewing chiffon, lace, organdy

and other fine fabrics.

Velour and knits with a lot of stretch may also require a “1"

setting.

Turn the pressure dial ® and set the desired number at the

setting (2).

® Pressure dial

(2) Setting mark

To Drop or Raise the Feed Dogs

The drop feed dogs lever is located underneath the free

arm bed on the back side of the machine.

® To drop the feed dogs, push the lever in the direction

of the arrow, as illustrated.

(|) To raise the feed dogs, push the lever in the direction

of the arrow, as illustrated, and turn the handwheel

toward you. Feed dogs must be up for normal sewing.

7

®

Page 13

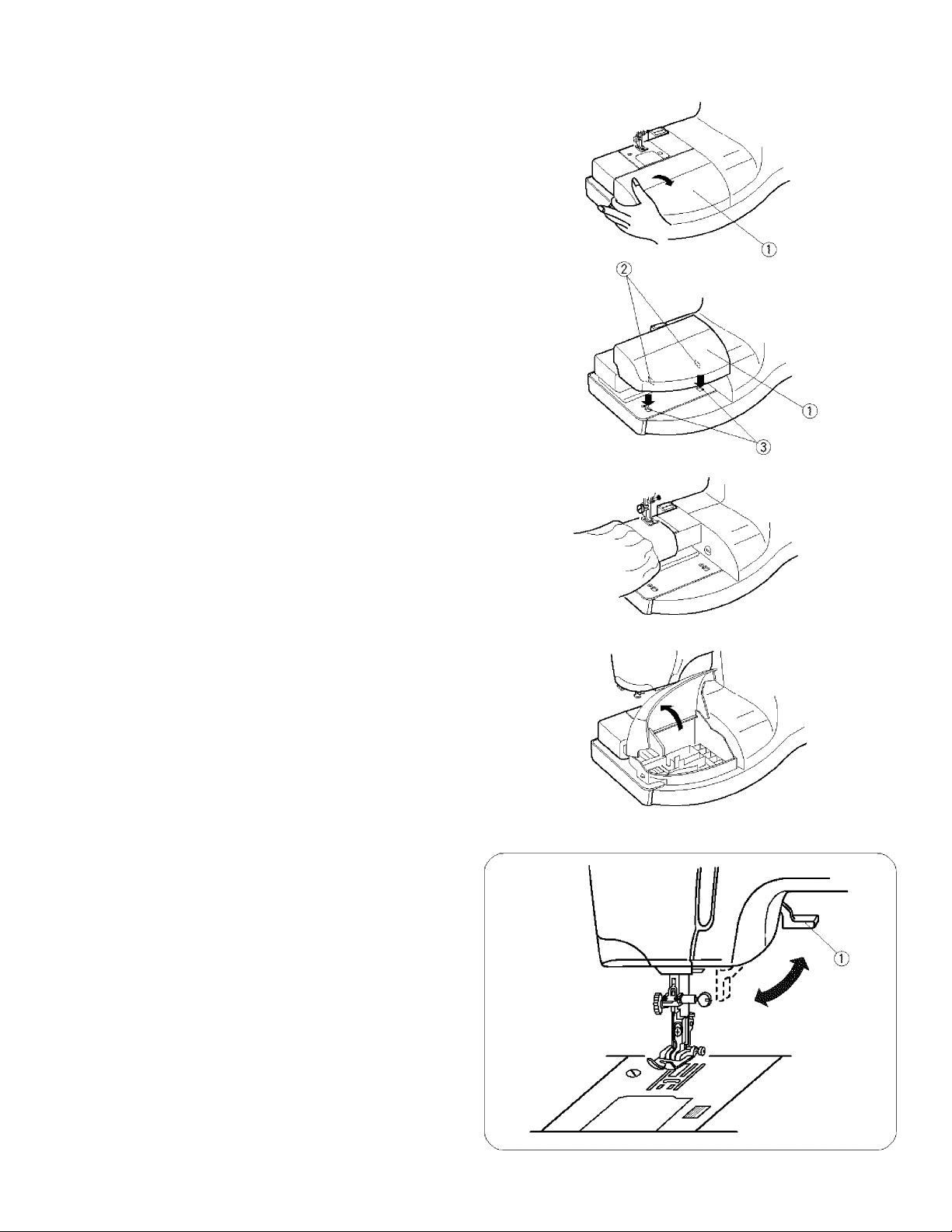

Extension Table

• Detaching the table

Close the accessory box, and lift out the extension

table (T) toward you, as illustrated, for “free-arnn” sewing.

(T) Extension table

Attaching the table

Push the extension table (T) until it snaps into the

machine.

(T) Extension table

(DTabs

(3) Holes

Free-arm sewing can be used for:

• Stitching sleeves, waistbands, pant legs or any tubular

garment area.

• Darning socks or mending knees, elbow or children’s

wear.

In Conventional sewing set mode, you can adjust the free

arm length. To adjust the free-arm length, please refer to

page 20.

Open the lid of the extension table and you can

conveniently store feet and accessories in the handy

compartments.

Presser Foot Lifter

(T) Presser foot lifter

The presser foot lifter raises and lowers the presser foot.

You can raise it higher than the normal up position for easy

removal of the presser foot or to help you place heavy fabric

under the foot.

Page 14

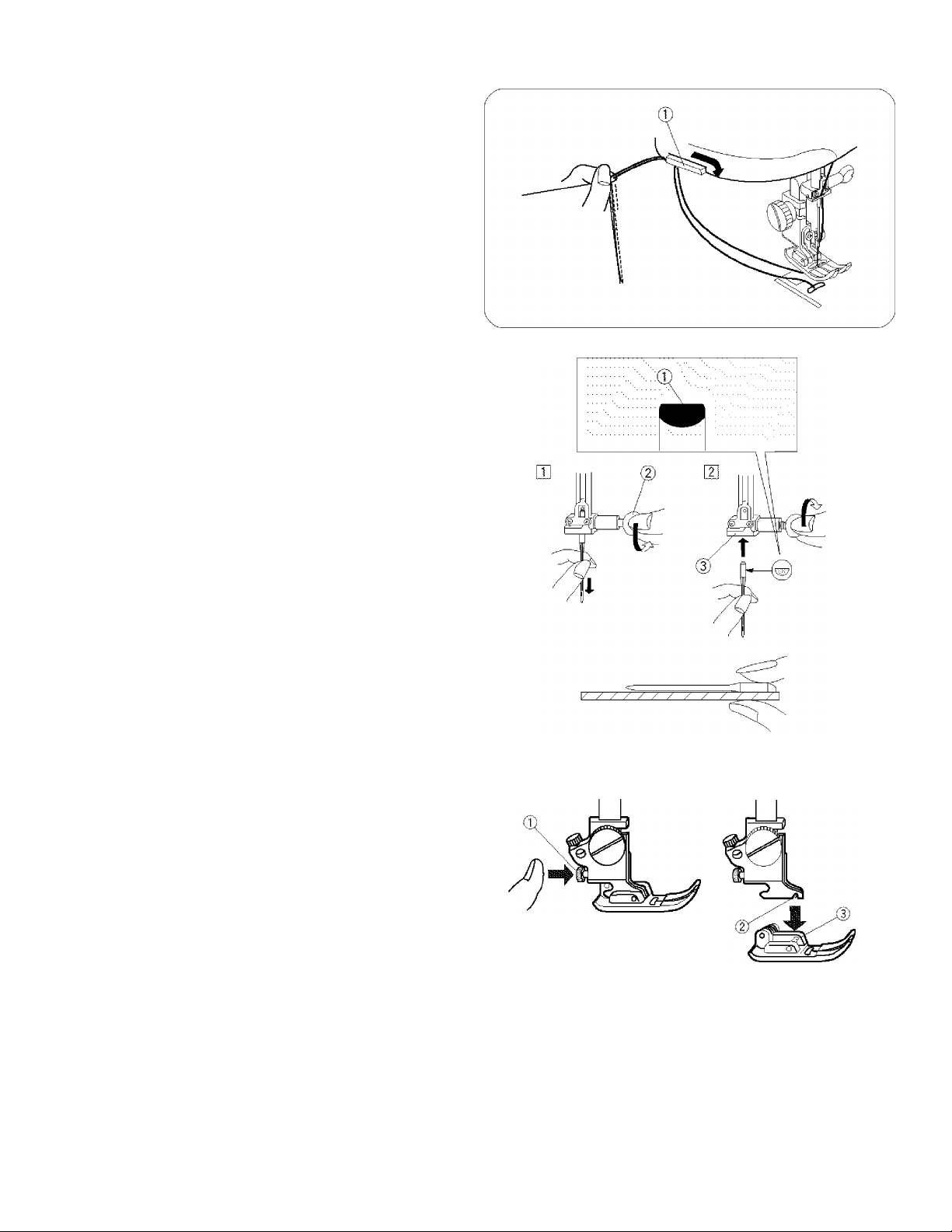

Thread Cutter

(T) Thread cutter

You do not need a pair of scissors to cut threads after

sewing. Just use the built-in thread cutter (T).

Changing Needle

(T) Fiat side

(D Needle damp screw

(3) Needle damp

[T] Turn off the power switch.

Raise the needle to its highest position by turning the

handwheei counterclockwise, toward you, and lowering

the presser foot. Loosen the needle clamp screw (2) by

turning it counterclockwise. Remove the needle from the

needle clamp (3).

[2] Insert a new needle Into the needle damp (3) with the

flat side ® to the rear. When inserting the needle into

the needle clamp (3), push it up as far as it goes. Tighten

the needle clamp screw (2) firmly by turning it clockwise.

[U To check for a good needle, place the flat side of the

needle onto something fiat (needle plate, glass, etc.).

The gap between the needle and the fiat surface should

be consistent. Never use a bent or blunt needle.

A damaged needle can cause permanent snags or runs

in knits, fine silks and silk-like fabrics.

Changing Presser Foot

(T) Snap-on button (red button)

(D Groove

CD Pin

• To remove

Raise the needle to its highest position by turning the

handwheel counterclockwise. Raise the presser foot, and

press the red button ® on the back of the foot holder.

• To attach

Place a selected presser foot so the pin (3) on the foot lies

Just under the groove (D on the foot holder. Lower the

presser bar to lock the foot in place.

Page 15

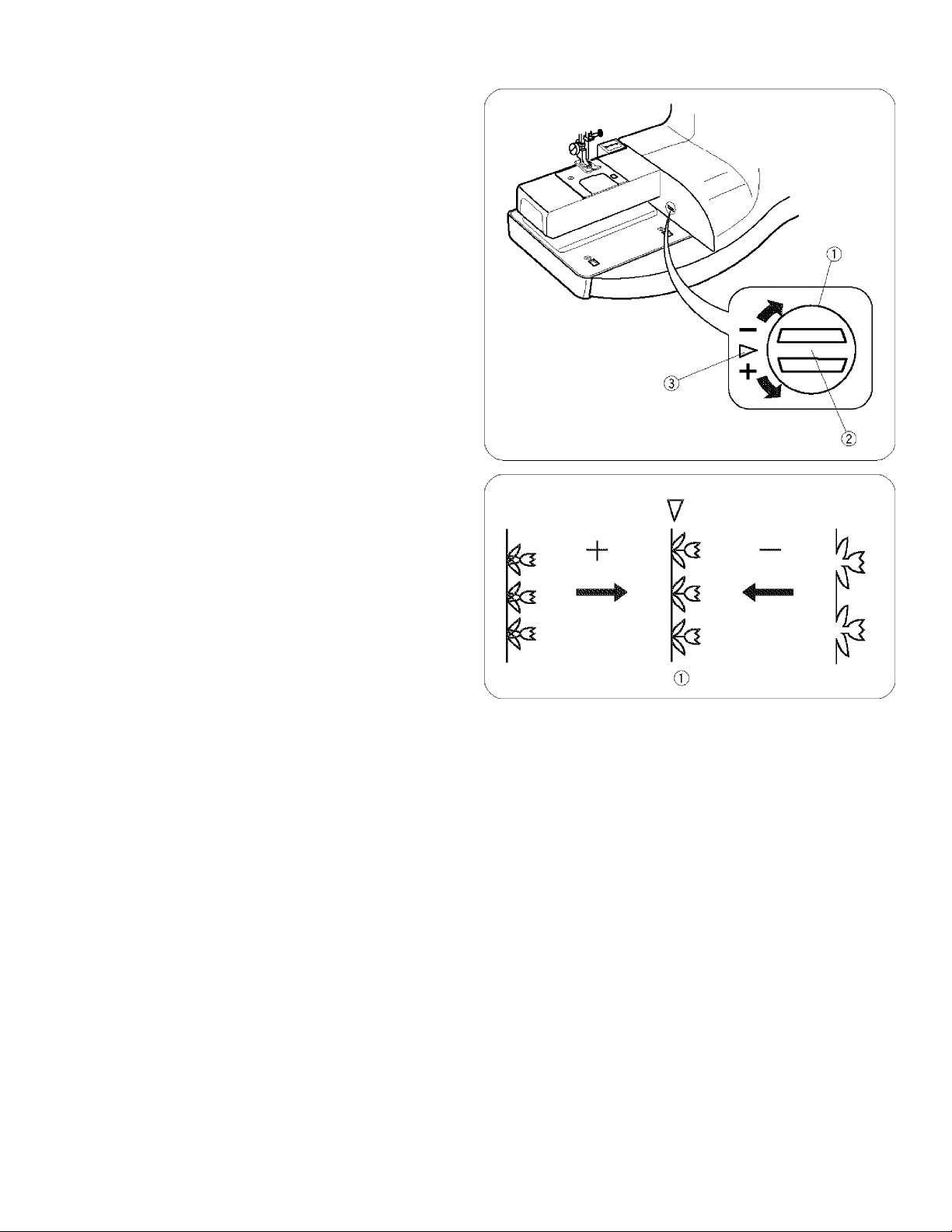

Correcting Distorted Stitch Patterns

The sewing results of the stretch stitch patterns may vary

depending upon the sewing conditions, such as sewing

speed, type of the fabric, number of layers etc.

Always make test sewing on a scrap piece of the fabric that

you wish to use.

if decorative stitch patterns, letters, or numbers are

distorted, correct it with the feed baiancing dial.

Notes:

• In normal sewing, set the feed baiancing dial CD to the

neutrai position, i.e., the groove on the dial ® is

centered with the standard setting mark (3).

• Turn the feed balancing dial CD with a coin.

(T) Feed baiancing dial

(D Groove on the dial

(3) Standard setting mark

• If the pattern is compressed, turn the dial in the direction

of

• If the pattern is drawn out, turn the dial in the direction

of

(T) Correct shape

Note:

Return the feed baiancing dial ® to its neutral position

when the sewing is finished.

Page 16

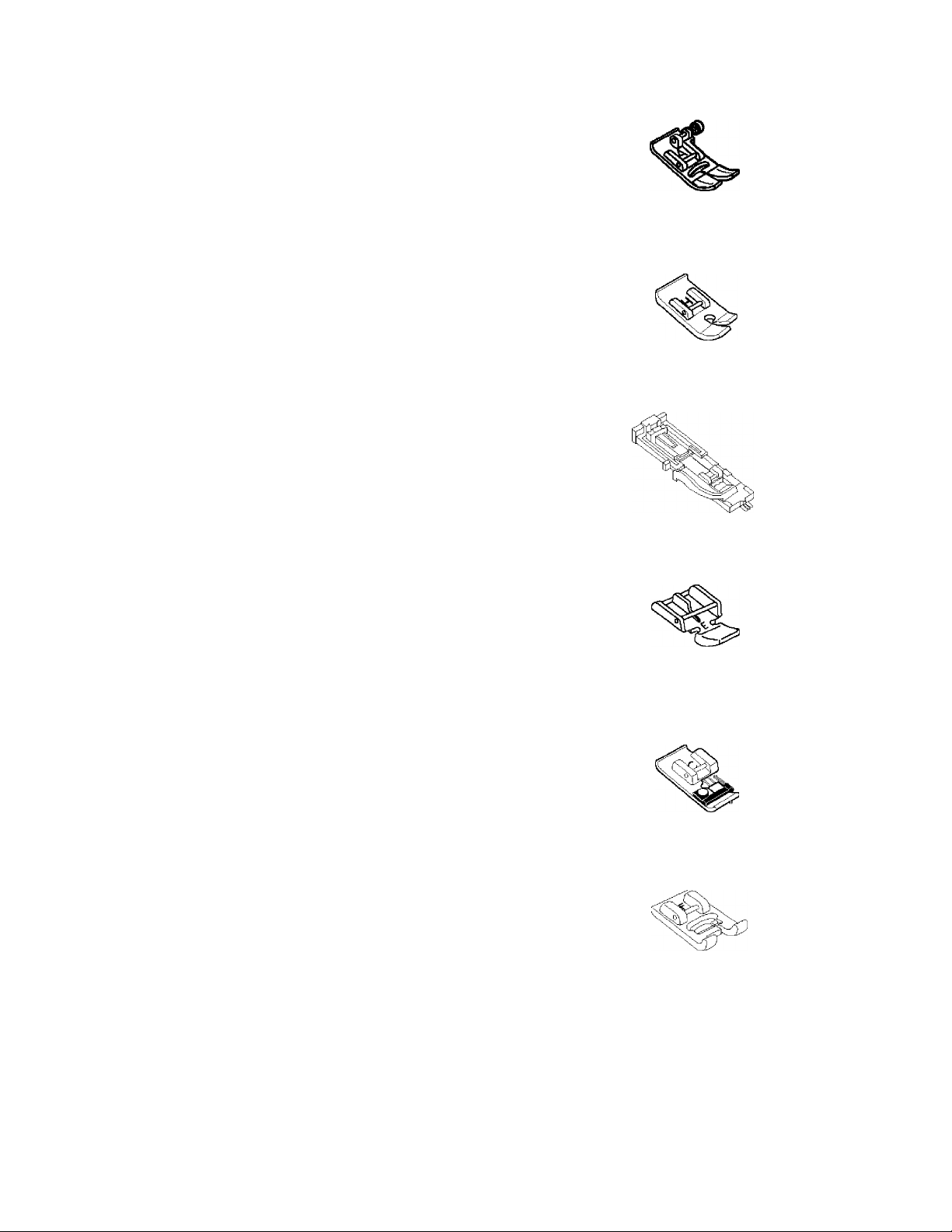

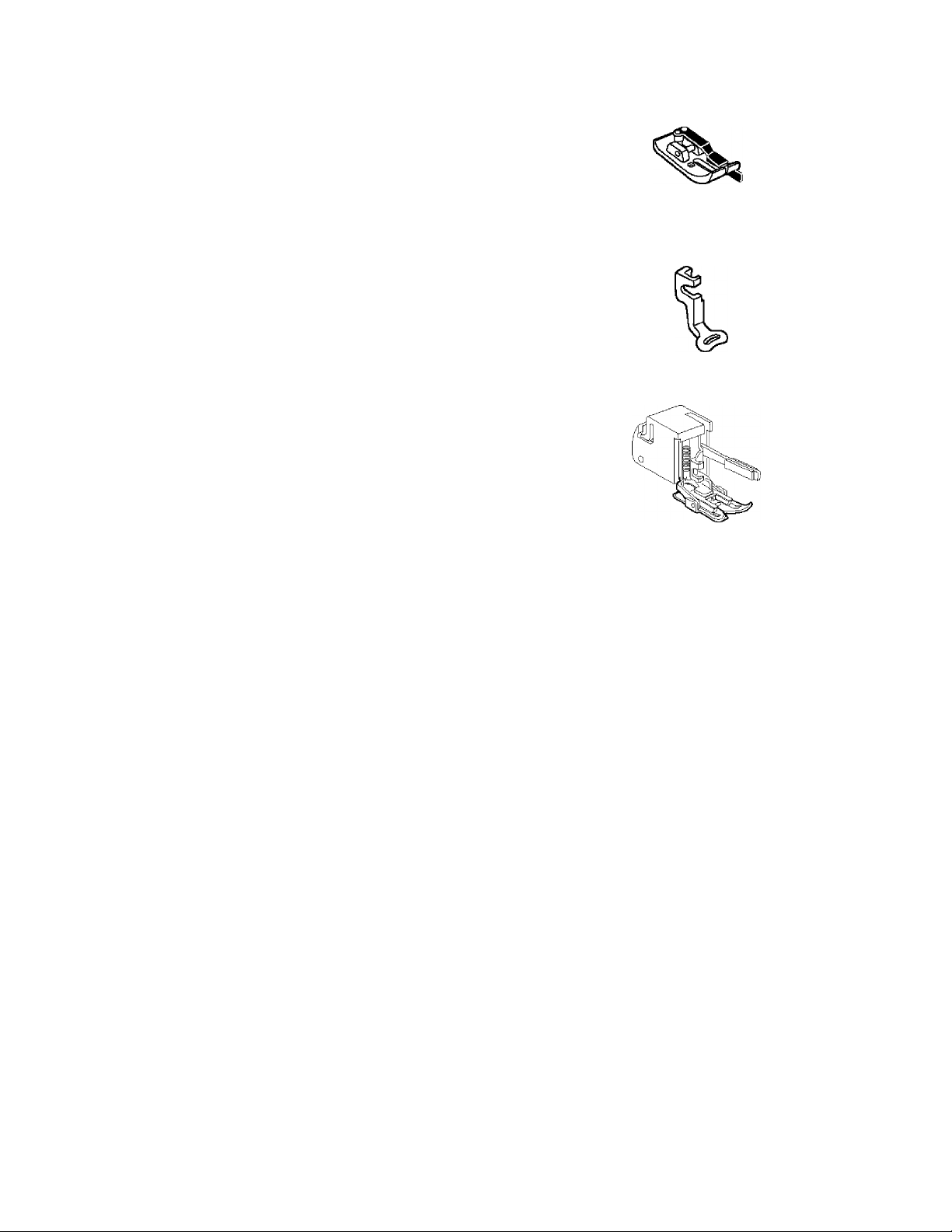

Presser Foot Types

• Zigzag foot (Foot A)

Use this foot for both straight and zigzag stitching.

Straight stitch foot (Foot H)

Use this foot for exclusively for straight stitching with

center needle position.

Automatic buttonhole foot (Foot R)

Use this foot for one step automatic buttonhole sewing.

Simply set a button on the guide of this foot and depress

the foot control. You can sew exactly the same length of

buttonhole as the button.

' Zipper foot (Foot E)

This foot can be set to sew on each side of the zipper.

The edge of the foot guides the zipper and keeps the

seam straight.

Overedge foot (Foot C)

This foot is specially constructed for stitching and/or

overcasting seams. The small brush and wire guides help

control the fabric, hold the raw edge in place and keep it

from puckering, especially when sewing on knit fabrics.

Satin stitch foot (Foot F)

Use this foot for satin stitch and outlining applique.

Blind hem stitch foot (Foot G)

Use this foot for perfect blind hemming and topstitching.

The foot has ridges on the bottom to keep the fabric from

slipping and a screw on top to guide the folded edge of

your hem.

10

Page 17

1/4"Seam foot {Foot O)

This foot is useful for patchwork quilt. The guide on the

foot maintains an exact 1/4" {0.7 cm) seam ailowance.

Embroidety foot {Foot P)

This foot is a speciai attachment for professionahstyie

embroidery.

•Walking foot

This is special attachment for hard-to-feed materials. This

foot effectively prevents fabrics from shifting and

puckering. It is great for quilting and matching plaids.

11

Page 18

Selecting Needle and Fabric

For genera! sewing, use needie sizes 11 or 14. A fine thread and needie should be

used for sewing lightweight fabrics, so the fabric will not be marred. Heavy fabrics

require a needle large enough to pierce the fabric without fraying the needle thread.

In the needie set, there is one each of sizes 11,14,16, and 18, and a blue needle.

Use the blue needie to eliminate skipped stitches when sewing knits and synthetic

fabrics.

Special needles should be used on certain fabrics. A denim needle with a sharp tip

effectively pierces dense fabrics such as denim and canvas. For topstitching, a

special topstitching needie with a larger eye, accommodates heavier weight thread.

Leather needles punch small holes in leather and suede, allowing the thread to

follow through the hole.

Check your needles frequently for rough or blunt tips. Snags and runs in knits, fine

silks and silk-like fabrics are permanent, and are often caused by damaged

needles.

Always purchase a good quality thread. It should be strong, smooth and consistent

in thickness.

WEIGHT FABRIC

Very Light

Chiffon, Georgette, Fine Lace. Organdy, Organdy

Net, Tulle

Batiste. Voile. Lawn, Pure Silk, Crepe de Chine,

Sheer Crepe, Chambray, Handkerchief Linen,

Gingham, Challis, Percale, Wool Crepe, Peau de Soie,

Taffeta. Satin, Silk Surah, Satin-backed Crepe,

Light

Qiana

Single Knits, Jersey, Swimwear, Tricot

Leather, Suede

Flannel, Velour, Velvet, Muslin, Velveteen, Poplin,

Corduroy, Broadcloth, Linen, Chintz, Gabardine, Felt,

Terry, Burlap, Quilted Fabrics

Medium

Double Knits, (synthetic and natural) Stretch

Velour,

Stretch Terry

Sweater Knits

Leather, Vinyl, Suede

TYPE OF NEEDLE NEEDLE SIZE

Universal

Ball Point

Orange

Blue

9(65)

9(65)

11 (75)

11 (75)

12(80)

Blue

Ball Point

Wedge Point Leather

Red

Ball Point

Wedge Point Leather

11 (75)

11 (75)

11 (75)

14(90)

14(90)

14(90)

V

Heavy

All

Denim, Sailcloth, Ticking Denim

Double Faced Wool. Heavy Coating, Fake Fur,

Purple

Drapery Fabrics

Leather, Suede

Canvas, Duck, Upholstery Fabrics

Topstitching for Special Finish

12

Wedge Point Leather

Green

Topstitching

16 (100)

16(100)

16(100)

18(110)

11 (75)

14(90)

J

Page 19

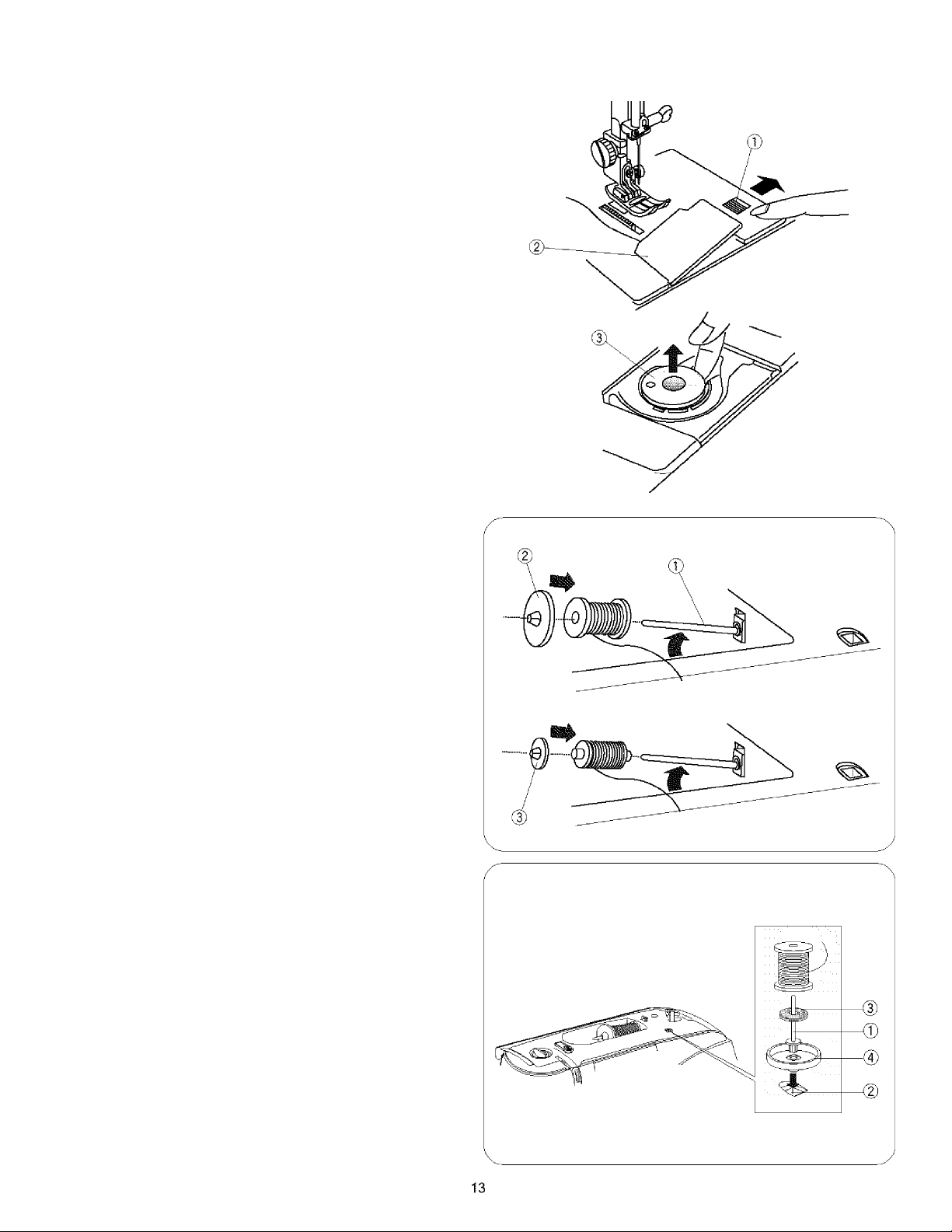

Bobbin Winding

• Removing the hook cover plate

(T) Hook cover plate release button

(D Hook cover plate

(3) Bobbin

Slide the hook cover plate release button ® to the right,

and remove the cover plate (2).

Lift out the bobbin (I) from the bobbin holder.

' Horizontal spool pin

(T) Spool pin

(D Large spool holder

(3) Small spool holder

Lift up the spool pin (T). Place a spool of thread on the

spool pin with the thread coming off the spool as shown.

Attach the iarge spool holder (2), and press it firmly

against the spool of thread.

The small spool holder (3) is used with narrow or small

spools of thread.

' Additional spool pin

(T) Additional spool pin

(D spool pin hole

(D Spool pin felt

(4) Spool stand

The additional spool pin (T) is for bobbin winding, without

unthreading the machine, and for twin needle sewing.

Insert the additional spool pin ® into spool stand 0 and

the hole 0.

Place the felt 0 and a spool on the pin as illustrated.

Page 20

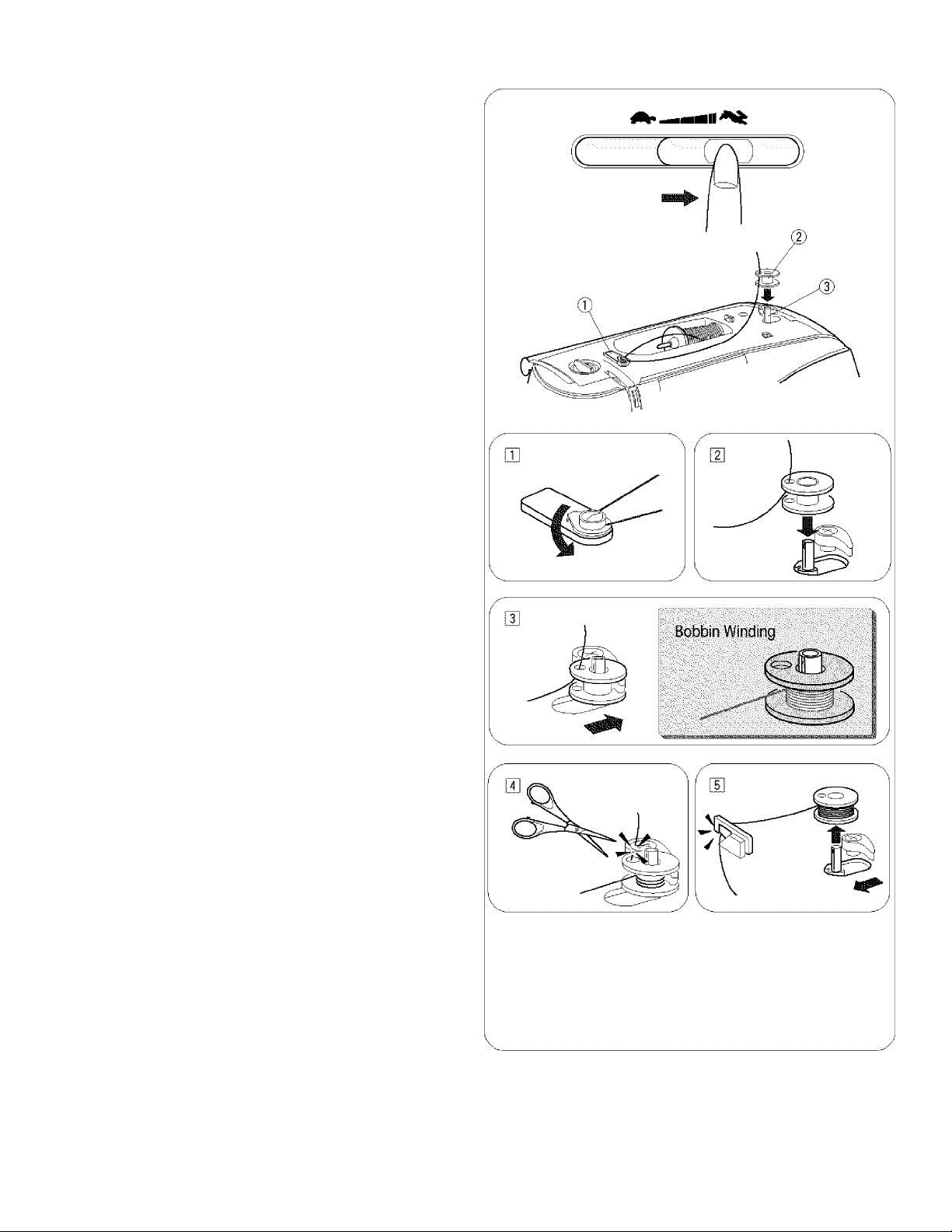

Bobbin Winding

Note:

Set the speed control lever at its fastest position for

bobbin winding.

CD Upper thread guide

(2) Bobbin

(D Bobbin winder spindle

Q] Guide the thread around the upper thread guide (T).

[2] Insert the thread through the hole on the bobbin (2),

threading from the inside to the outside. Put the

bobbin on the bobbin winder spindie (|).

[U Push the bobbin winder spindie (D to the right. The

visual touch screen shows “Bobbin Winding”.

E] With the free end of the thread held in your hand,

depress the foot control. Stop the machine when

the bobbin has made a few turns, and cut the

thread close to the hole on the bobbin.

[5] Depress the foot control again. When the bobbin is

fully wound, it will stop automatically. Return the

bobbin to its original position by moving the spindle

to the left, and cut the thread as shown.

14

Page 21

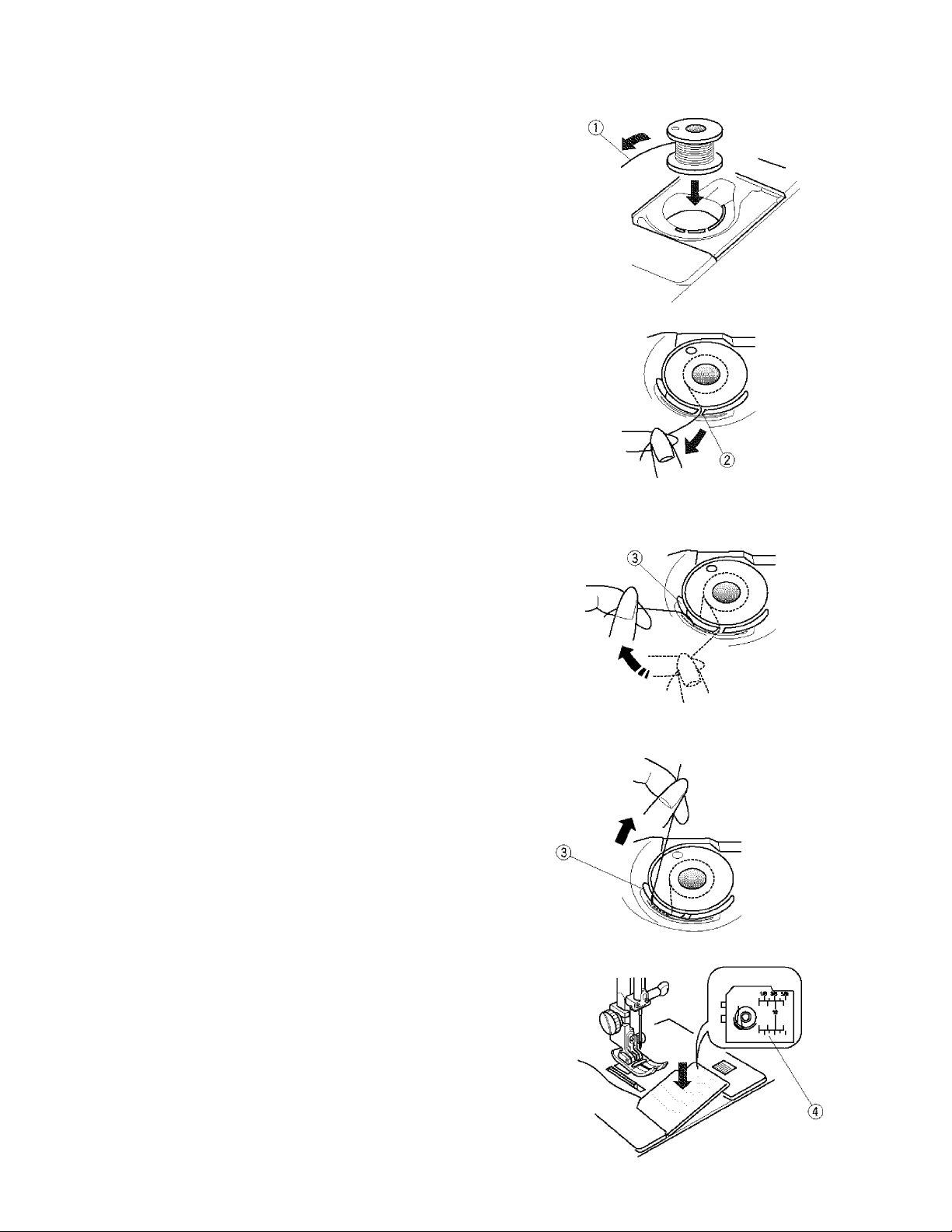

Inserting the bobbin

(T) End of thread

(D Notch

(3) Notch

(4) Threading diagram

D Piace a bobbin in the bobbin holder with the thread

running off counterclockwise.

I Guide the thread into the notch (2) on the front side of

the bobbin holder.

Draw the thread to the left, sliding it between the tension

spring biades.

S] Continue to draw the thread lightly until the thread slips

into notch (3). Pull out about 6" (15.0 cm) of thread.

I Attach the hook cover plate. Check the threading by

referring to the diagram (¡) shown on the hook cover plate.

15

Page 22

Threading the Machine

• Threading the machine

* Raise the thread take-up lever to its highest position by

turning the handwheel counterclockwise.

* Raise the presser foot lifter.

* Piace a spool on the spool pin, with the thread coming

off from the bottom toward the front of the sewing

machine.

Q] Draw the end of the thread around the upper thread guide.

[U While holding the thread near the spool, draw the end of

the thread down around the check spring holder.

[U Firmly draw the thread up to the take-up lever, and down

into the take-up lever eye.

d] Pass the thread behind the lower thread guide on the left.

[U Slip the thread in the needle bar thread guide on the left.

Thread the needle from front to back, or use the built-in

needle threader.

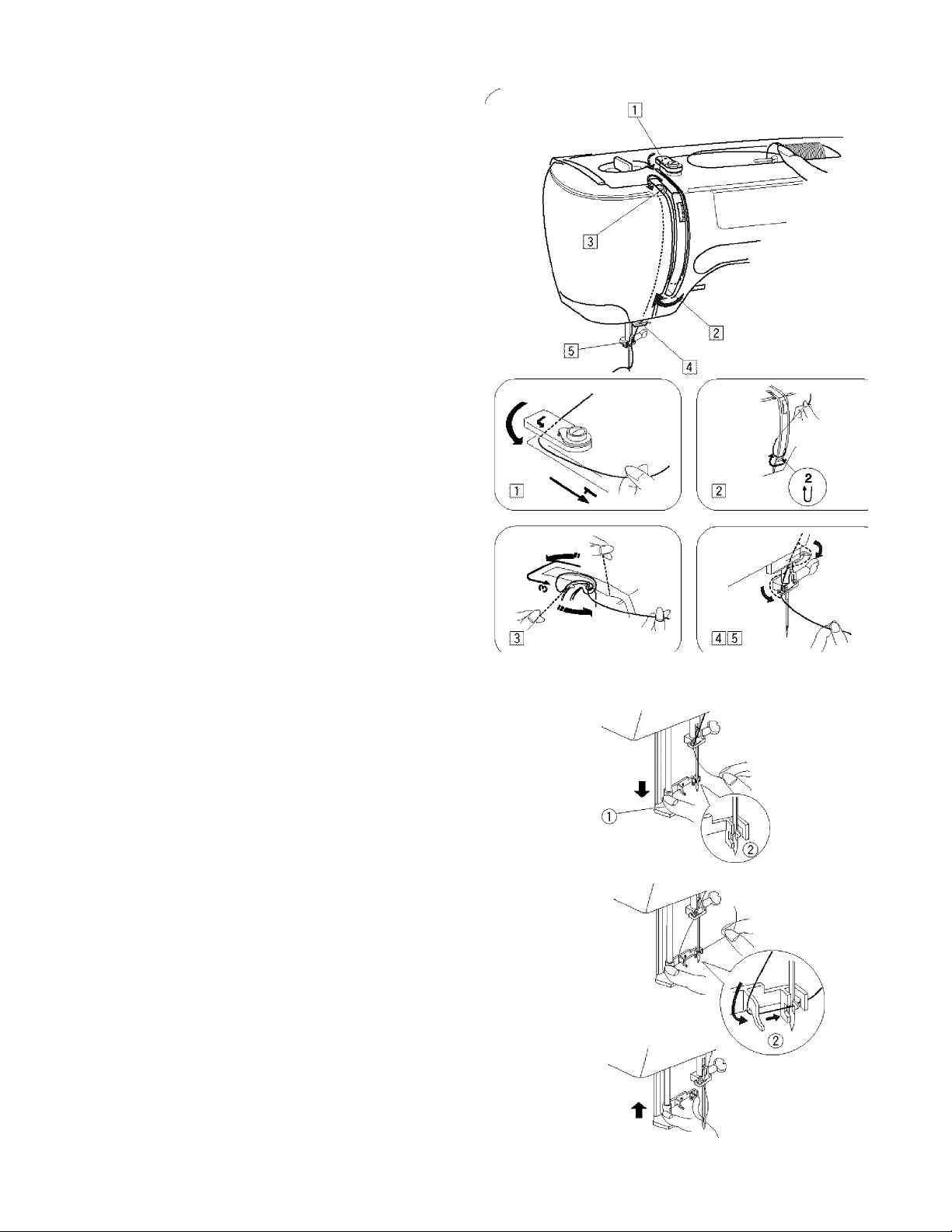

Built-in needle threader

(T) Knob

(2) Hook

Q Raise the needle to its highest position. Push down the

needle threader knob (T) as far as it will go.

The hook comes out through the needle eye from

behind.

[] Paying close attention to the needle point, draw the

thread around the guide and under the hook (2).

3] Release the knob slowly while holding the thread end

with your hand. A loop of the thread is pulled up through

the needle eye.

Note;

The needle threader can be used with a #11 to #16

needle, or a #11 Blue needle.

Thread size 50 to 100 is recommended.

16

Page 23

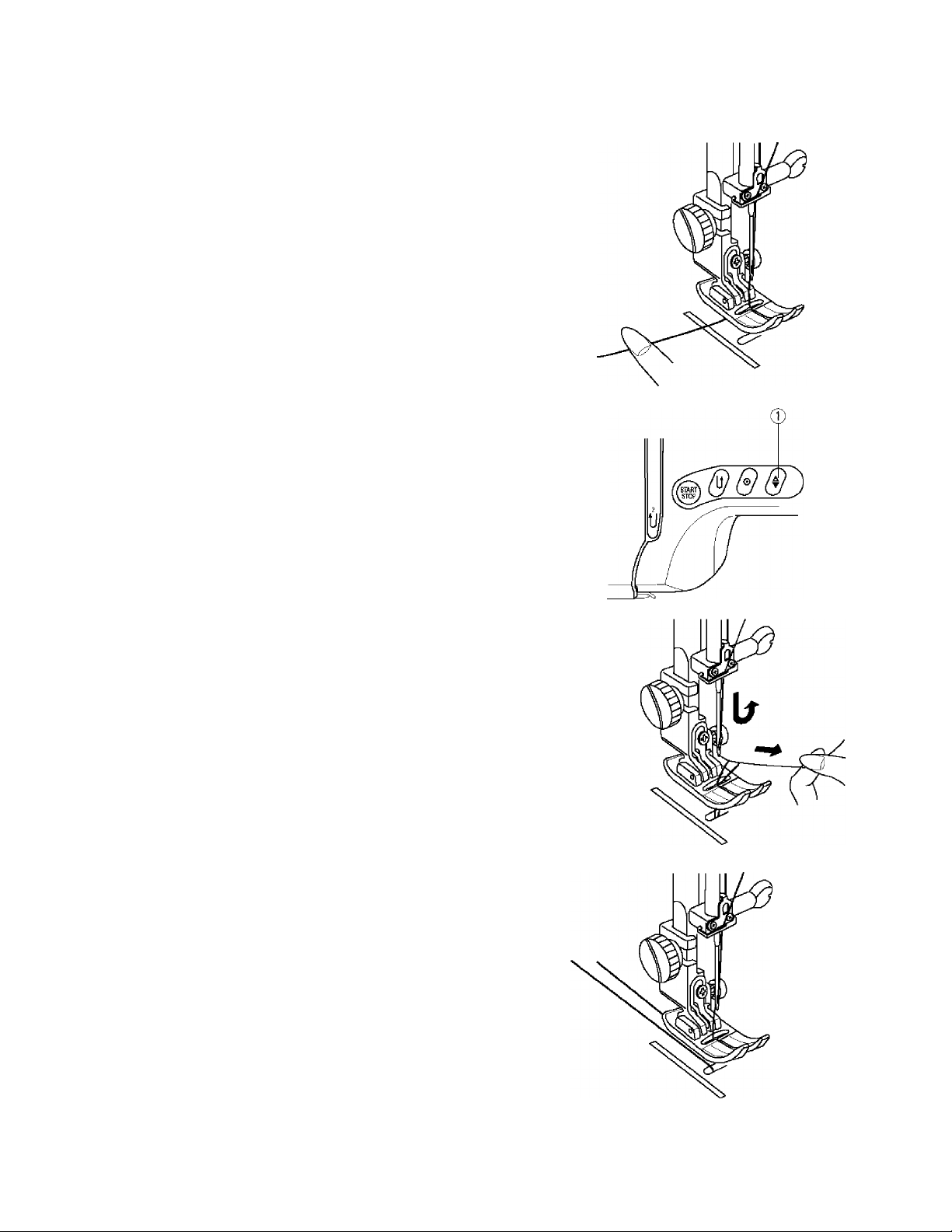

Drawing up bobbin thread

(T) Up/down needle button

D Raise the presser foot. Hold the needle thread lightly

with your left hand.

I Press the up/down needle button (T) twice to bring the

bobbin thread up. Draw up the needle thread to bring up

a loop of the bobbin thread.

Pull both threads 4" to 6" {10.0 to 15.0 cm) under and

behind the presser foot.

17

Page 24

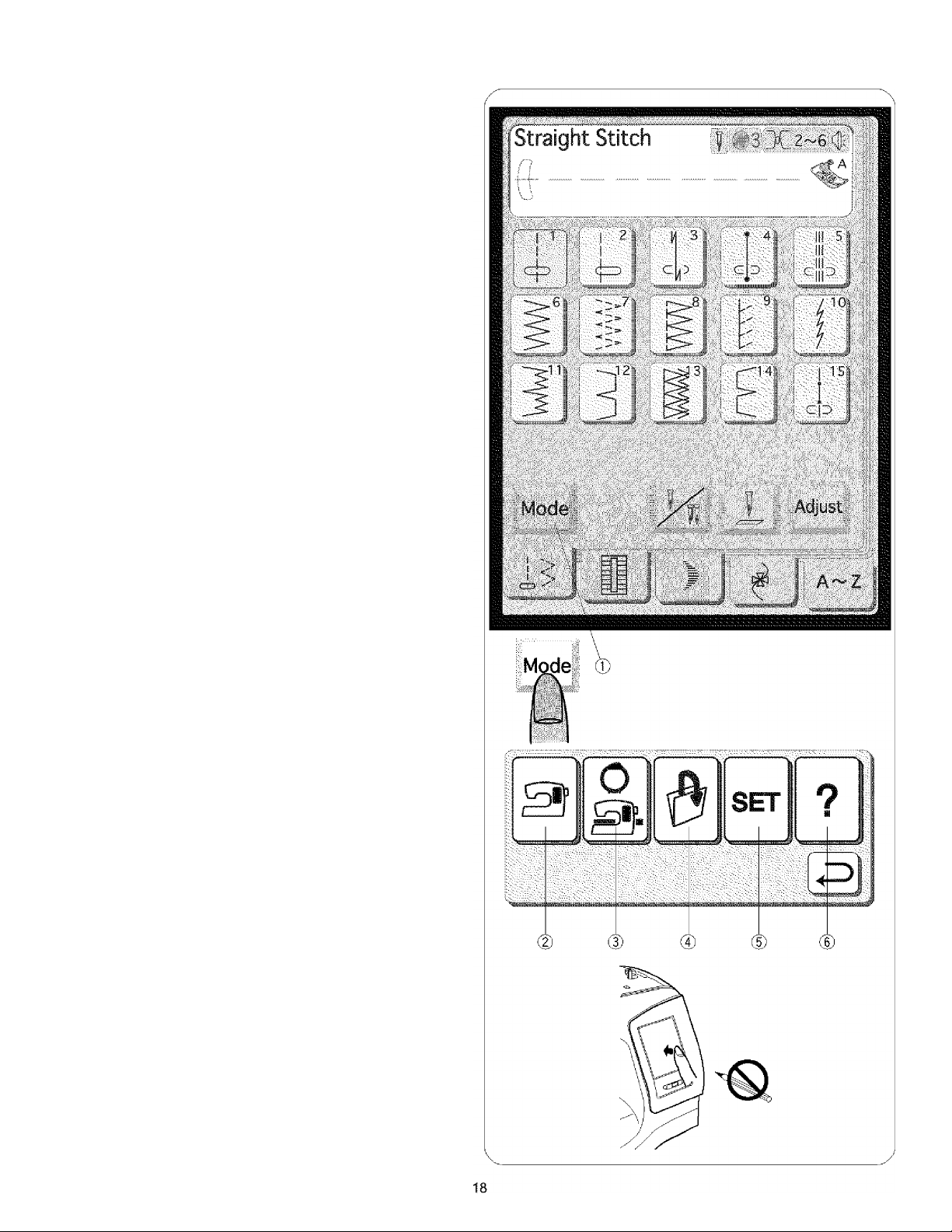

SECTION III. CONVENTIONAL SEWING

Visual Touch Screen

The “Kenmore Eiite” display appears on the visual touch

screen for a few seconds when turning the machine on,

then it shows the initial screen as illustrated.

Mode Selection Keys

(T) Mode key

Press mode key ® to enter the Mode selection.

(2) Conventional sewing mode key

Press this key to enter the conventionai sewing mode.

The following five categories are available in this mode:

• Utility stitches

• Buttonhole stitches

• Satin stitches

• Decorative stitches

• Monogramming

(3) Embroidery mode key

Press this key to enter the Embroidery mode. The

following five categories are available in this mode;

• Built-in embroidery designs

• Monogramming

• PC card embroidery designs {PC card sold separately.)

• Design import via ReaderAA/riter 19000

(ReaderAA/riter 19000 sold separately.)

• Editing

® Open file key

Press this key to open files such as programmed stitch

patterns or embroidery designs you have saved.

(5) My setting key

Press this key to enter My setting mode. In this mode,

you can change the machine settings to your preference.

The machine settings for Conventional sewing,

Embroidery, Language selection and Common settings

are available in this mode.

(6) Quick help mode key

Press this key for helpful tips and general information on

the machine function.

CAUTION:

Do not press the surface of the Visual Touch Screen with

a hard or sharp object like pencil, screwdriver or the like.

Note;

When you select a pattern or function on the screen, it is

not necessary to press hard; just touch keys with your

lit %l[j.

fingertip.

Use a dry soft cloth to wipe off the screen.

Page 25

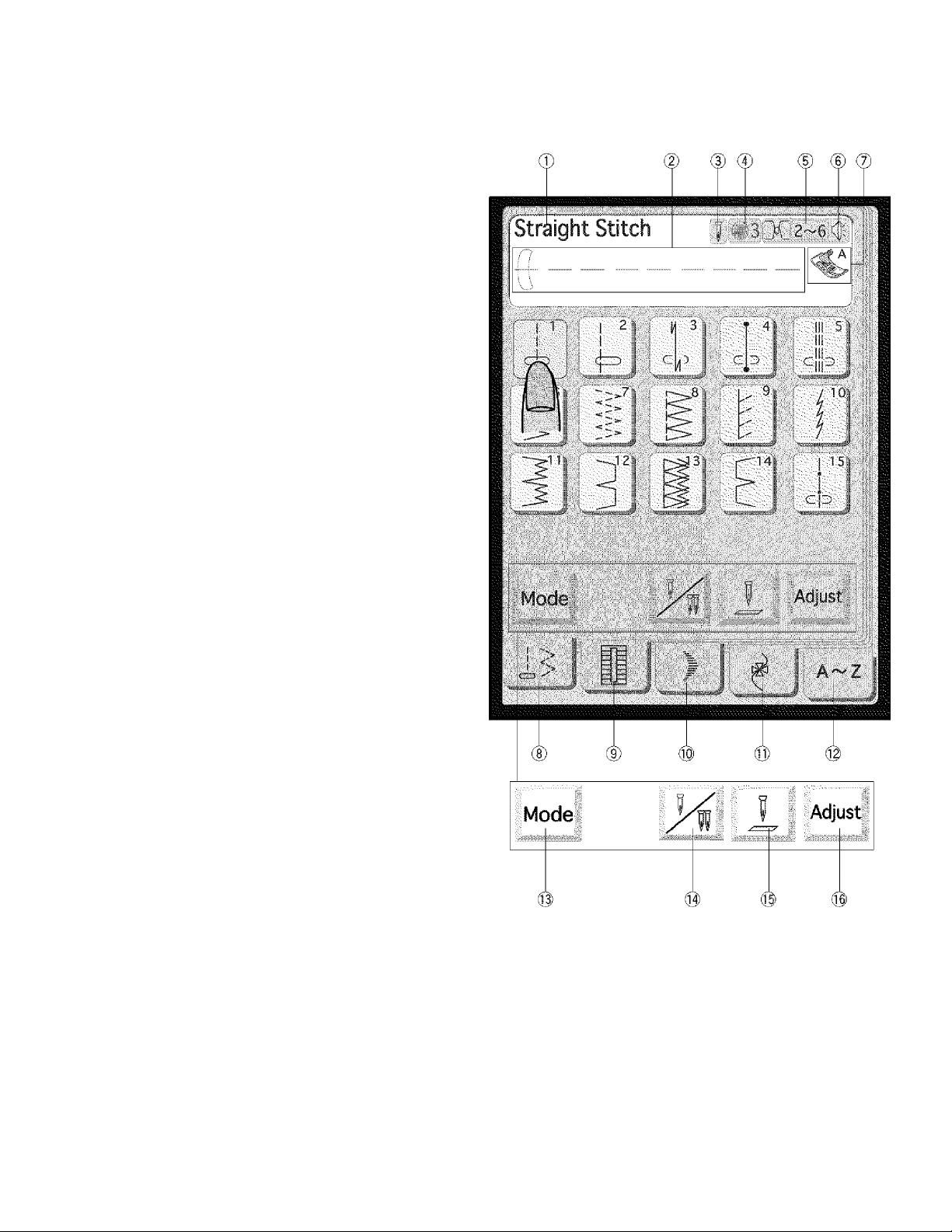

Pattern Selection

Press the stitch pattern indication key to select the desired

stitch pattern.

(T) Name of stitch

(2) Stitch image

(3) Selected needle type {single or twin)

® Suitable pressure dial number

(f) Suitable thread tension number

(D Sound mark (the mark will disappear when the sound

volume set to 0)

(7) Suitable presser foot

Utility Stitches

When you press Conventional sewing mode key, the utility

stitch window opens.

In the Conventional sewing mode, there are 6 categories of

sewing to choose from.

(8) Utility stitches

You can select 15 types of utility stitches.

(D Buttonhole stitches

You can select 7 buttonhole variations, darning, tacking

and eyelet.

@ Satin stitches

You can select the desired satin stitches, elongation

patterns and also program assorted stitch combinations.

Cl) Decorative stitches

You can select decorative stitches and also program

assorted stitch combinations.

Monogramming

You can make monograms and combinations of letters,

symbols and patterns.

C|) Mode Key

Press the ¡Mode) key to enter the Mode selection.

Twin needle key

Press twin needle key to enter the twin needle sewing

mode.

@ Needle up/down key

You can set the needle position with this key, up or down

when the machine stops.

® Adjust key

When you press this key, the stitch adjusting window will

open. You can change setting to stitch length and width

by pressing the : + or — key

19

Page 26

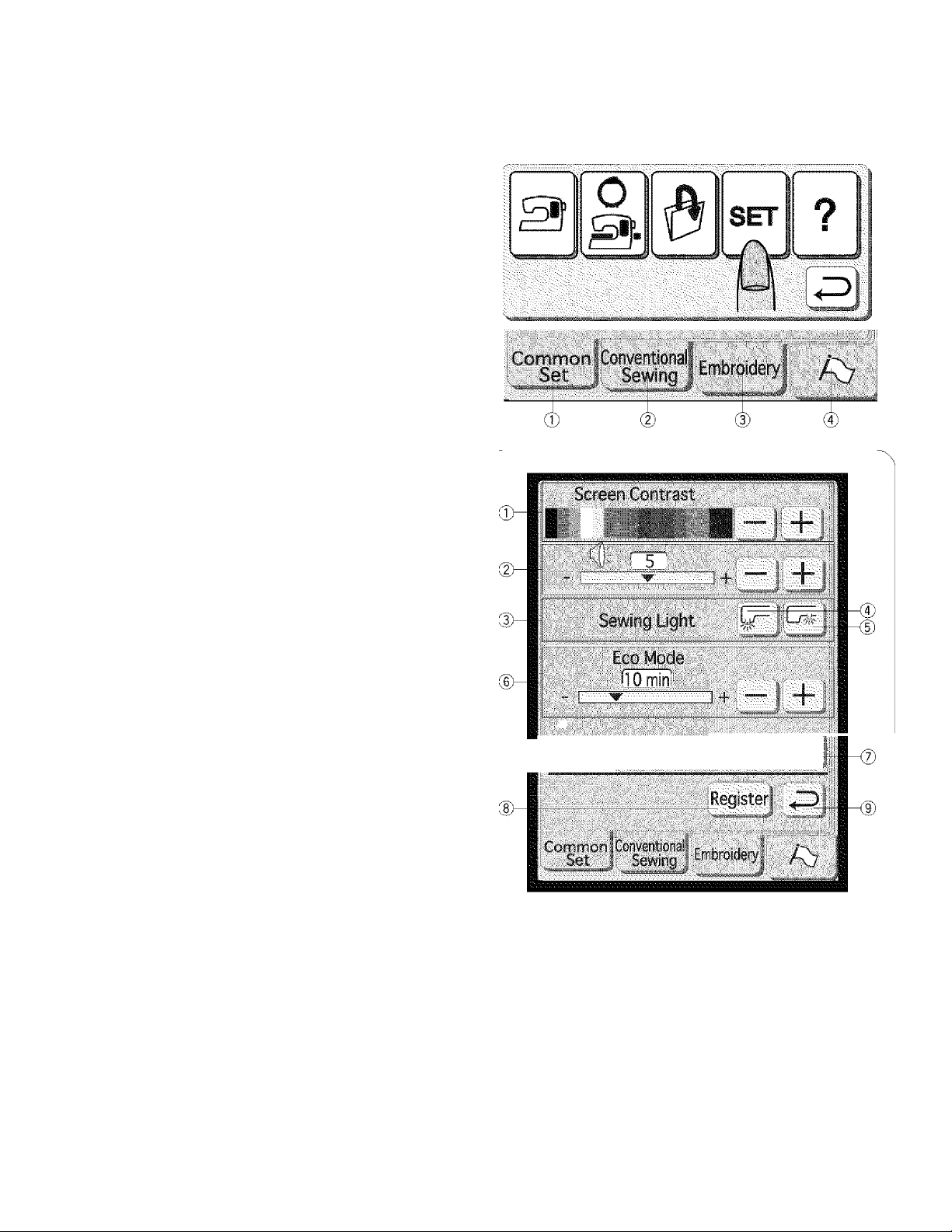

Machine Settings

When you press the SET key, the following four mode keys

will be displayed and you can customize settings within

each mode. You can select your desired mode by pressing

the corresponding key.

® Common set mode

In this mode, machine operation and function (screen

contrast, beep sound, etc.) can be adjusted and set for

both embroidery and conventional sewing.

(2) Conventional sewing set mode

In this mode, free-arm length can be adjusted and set.

(I) Embroidery set mode

In this mode, sewing function for embroidery can be

adjusted and set.

® Flag mode-language selection

In this mode, you can select one of 3 languages for the

visual touch screen.

Common Set Mode

In this mode you can set the following machine functions,

which are applicable to both embroidery and conventional

sewing.

Mode

Ф Screen contrast

The visual screen contrast can be adjusted. Press the i +

key, to sharpen the screen color contrast.

Press the “ key, to fade the screen color contrast.

® Sound control

The buzzer volume can be adjusted. The volume level

can be set from 0 to 10. The default setting is 5.

Ф Sewing light

The dual sewing lights can be individually set “On” or

"Off” depending upon your sewing needs.

Press ^ key ф to light up the needle plate area.

Press key (5) to light up the free arm area.

When both lamps are “On” it provides a well-lit sewing

area.

(6) Eco mode

After turning on the power switch, if you have not used

the machine for a set period of time, the machine will

enter Eco mode. The visual touch screen will go dark

and the sewing lights will turn off.

Whenever you touch the screen while the machine is in

Eco mode, the screen and sewing lights will turn on

again.

® Page key

You can turn the pages by pressing the page key.

Press __z. key to view the next page.

Press T key to view the previous page.

® Register key

Press ifiegisten key to register the new setting and to exit the

common set mode.

(9) Return key

Press Ф: key to exit the common set mode without

registering the new setting.

.

..

..

.

20

Page 27

® Inch/miliimeter

You can set your machine’s measuring unit to either

“inch” or ‘'millimeter” depending upon your preference.

The default measuring unit setting is “inch”.

Press iineh|(ff)or mm ® key to Select the Unit you

prefer.

® Key position adjustment

If you think the touch panel keys are out of alignment,

you can correct it in the key position adjustment window.

When you press the ^esj key, window {A) will be shown.

With your finger, press the black + sign as it appears in

order. When you press the last black + sign, the window

(B) will be shown.

The window will close and go back to the original screen

with the new setting being registered.

® Reset ail to defaults

By pressing key you can reset ail the settings to their

original setting {the same settings as when you

purchased the machine).

Embroidery Set Mode

For detailed instructions on embroidery sewing please refer

to page 61.

iRGh/mtB,, .. . I

C

s.

■ . iRegisieri)

Key Position Adjustment Key Position Adjustment

^

-----

A®

_ j|..;

END

J

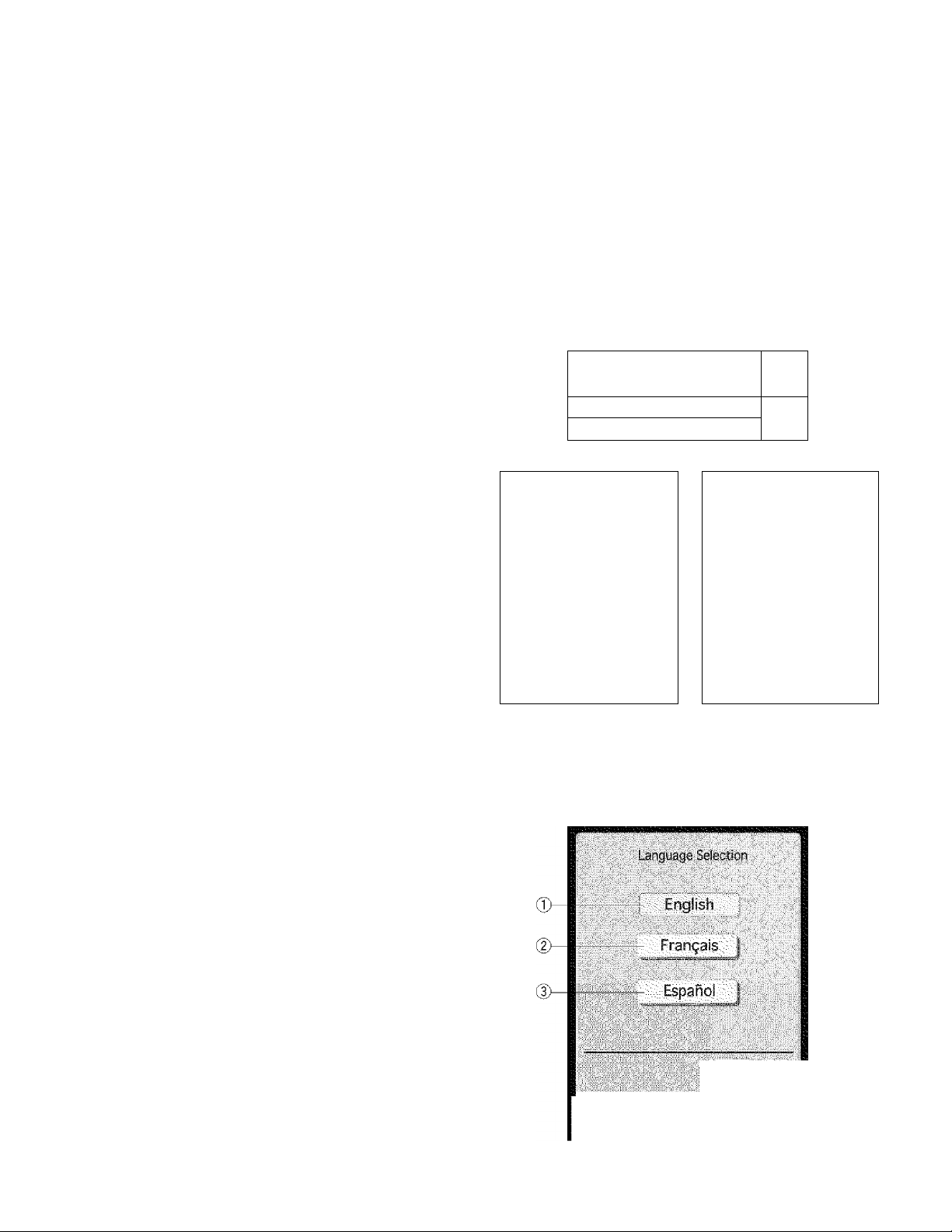

Flag Mode-Language Selection

You can select one of the following 3 languages by pressing

the desired language key.

(T) English

(2) French

(3) Spanish

+

(A) (B)

21

RegistetJ

Page 28

straight Stitch

(T) Stitch pattern:

(2) Needie thread tension

(

1

) Presser foot A:

® Presser foot H:

(D Pressure dial

Note:

When using the straight stitch foot, make sure to adjust

the needie position to 3.5. Otherwise the needle may hit

the sewing foot and possibly break.

To sew

Raise the presser foot and position the fabric next to a

seam guideline on the needle plate. Lower the needle to

the point where you want to start.

Pull the threads towards the back and lower the presser

foot. Press the start/stop button or foot control, and gently

guide the fabric aiong the seam guideline letting the fabric

feed naturally.

1 or 2

2 to 6

Zigzag foot

Straight stitch foot

0

0 0

I 1

1

Straight Stitch

0

m

m

Securing seam

0 Reverse button

Jj For fastening the ends of seams, press the reverse

button 0 and sew several reverse stitches.

The machine sews reverse stitches as long as you press

and hold the reverse button

When sewing with the lock*a-matic stitch and locking

stitch, press the reverse button once, the machine will

sew several reverse or locking stitches and stop

automatically.

2] Raise the presser foot. Remove the fabric, draw it to the

back.

3] Cut the thread by using the thread cutter.

Now the threads are cut the proper length for starting the

next seam.

Changing sewing direction

0

Up/down needie button

Stop the machine and bring the needie down into the

fabric by pressing the up/down needle button

the presser foot. Pivot the fabric around the needie to

change the sewing direction as directed. Lower the

presser foot and sew in a new direction.

0

.

0

. Raise

Page 29

Needle plate guide line

The seam guides on the needle plate and hook cover

plate help you to measure seam allowance.

The number marks on the needle plate indicate the

distance between the center needle position and the

edge of the fabric. There are marks for 15 mm, 20 mm,

4/8 in., 5/8 in. and 6/8 in.

• To sew from the edge of thick fabric

(T) Black button

(D Thick fabrics

The black button (T) on the zigzag foot locks the foot in the

horizontal position.

This is helpful when starting sewing from the far edge of

thick fabrics (D or sewing across a hem.

Lower the needle into the fabric at the point where you

wish to start sewing.

Lower the foot while pushing the black button ® in. The

foot is locked in the horizontal position to avoid slipping.

The lock releases when the hem is passed.

Quiiting

® Stitch pattern:

(2) Needle thread tension

(D Presser foot A:

0 Presser foot H:

0 Quilter

® Pressure dial

Note:

When using the straight stitch foot, make sure to adjust

the needle position to 3.5. Otherwise the needle may hit

the sewing foot and possibly break.

Use the seam guide lines on the needle plate, or free-arm,

to help determine the spacing between quilting stitches. The

quilter will help keep the stitching line straight.

[T] Loosen the quilter holding screw.

Slide the quilter @ in the hole 0 to the desired width

and tighten the screw ©.

[2] Sew, guiding the quilter over the previous row of

stitching.

© Quilter holding screw

(D Quilter

© Hole

0 Spacing

1

2 to 6

Zigzag foot

Straight stitch foot

©

I 1

I

4^

Page 30

Quilting with Walking Foot

The walking foot is effective in preventing the fabric (iight

materials, knits, reai and imitation feather etc.) from slipping

or puckering, because it sandwiches the materia! between

the upper and the lower feed dog on the machine.

The quilting bar can also be attached on the walking foot to

make it easier to sew evenly spaced parallel rows of

stitches.

• To attach the walking foot

(T) Walking foot

(D Lever

(D Needle clamp screw

(4) Quilting bar {for walking foot)

D] Loosen the thumbscrew and remove the foot holder.

[U Attach Walking foot ® to the presser bar with the

lever (2) over the needle clamp screw (3).

Tighten the thumbscrew (3) firmly with the large screw

driver.

[U Use quilting bar for walking foot when quilting. The

walking foot helps you to feed bulky layers of fabric

smoothly.

H Push the quilting bar (J) down into the slot on the plastic

cover of the walking foot.

[5] Shift the quilting bar (¡) to the right or left to acquire the

desired position.

Manual Adjustment of Straight Stitches

Press the key.

The adjusting window displays the H- and — keys for

needle drop position, stitch length and thread tension

adjustment.

Press the + or — ’ key to change settings, then press the

key to register the settings.

(T) Needle drop position adjusting keys

(2) Stitch length adjusting keys

CD Defauit key: When you press If!!“ key, ail settings in

the adjusting window will return to their default settings

{the same settings as when you purchased the

machine).

® Cancel key: When you press ^key, the adjust

window will close and the setting remains unchanged.

CD Ok key: When you press the i ok key, your settings are

registered.

Page 31

Changing needle drop position

® + key

(D-key

(3) 0.0 (left position)

d) 3.5 (center position)

(5) 7.0 (right position)

Needie drop position is adjusted with the +; and

— keys.

When you press the I + key, the needle moves to the

right.

When you press the — key the needle moves to the left.

Changing stitch length

® + key

(2)-key

@1.0

® 5.0

Stitch length is adjusted with the +) and i — J keys.

The larger the number, the greater the stitch length.

Press the + key to increase the stitch length.

Press the — key to decrease the stitch length.

25

Page 32

Adjust the Needle Thread Tension for Straight Stitch

• Correct tension

(T) Needle thread (Top thread)

(2) Bobbin thread (Bottom thread)

(D To loosen

(J) To tighten

The ideal straight stitch has threads locked between two

layers of fabric, as illustrated (magnified to show detail).

If you look at the top and bottom of a seam, notice that

the stitches are evenly balanced.

When adjusting the needle thread tension, the higher the

number, the tighter the top thread tension.

Results depend on:

• stiffness and thidiness of the fabric

• number of fabric layers

• type of stitch

■Tension is too tight

(T) Needle thread (Top thread)

(2) Bobbin thread (Bottom thread)

(D To ioosen tension

(4) Right side (Top side) of fabric

(5) Wrong side (Bottom side) of fabric

The bobbin thread shows through on the right side of the

fabric, and the stitch feels bumpy. Turn the dial to a lower

tension setting number to loosen the needle thread

tension.

■Tension is too loose

(T) Needle thread (Top thread)

(D Bobbin thread (Bottom thread)

(D To tighten tension

d) Right side (Top side) of fabric

(5) Wrong side (Bottom side) of fabric

The needle thread shows through on the wrong side

of the fabric, and the stitch feels bumpy. Turn the dial to a

higher tension setting number to tighten the needle thread

tension.

26

Page 33

Variety of Straight Stitches Lock-a-matic Stitch

(T) Stitch pattern;

(D Needle thread tension

(D Presser foot A:

d) Presser foot H:

(5) Pressure dial

Use this stitch to secure the beginning and the end of a

seam with backstitching.

Press pattern 3 on the visual touch screen.

When you reach the end of the seam, press the reverse

button once.

Note:

When using the straight stitch foot, make sure to adjust

the needle position to 3.5. Otherwise the needle may hit

the sewing foot and possibly break.

3

2 to 6

Zigzag foot

Straight stitch foot

3

Locking Stitch

® Stitch pattern:

(2) Needle thread tension

(1) Presser foot A:

® Presser foot H:

(D Pressure dial

This unique stitch is used where an invisible locking stitch is

needed. Press pattern 4 on the visual touch screen.

Lower the needle ciose to the front edge of the fabric.

The machine will sew several locking stitches in place and

continue sewing forward.

When you press the reverse button at the end of the seam,

the machine will sew several locking stitches in place, then

stop sewing automatically.

Note:

When using the straight stitch foot, make sure to adjust

the needle position to 3.5. Otherwise the needle may hit

the sewing foot and possibly break.

4

2 to 6

Zigzag foot

Straight stitch foot

3

Triple Stretch Stitch

0 Stitch pattern:

(2) Needle thread tension

CD Presser foot A;

0 Presser foot H:

CD Pressure dial

This strong, durable stitch is recommended for areas where

both elasticity and strength are needed to ensure comfort

and durability.

Use it to reinforce areas such as crotch and armhole

seams.

Also use it when constructing items such as backpacks for

extra strength.

Press pattern 5 on the visual touch screen.

Note:

When using the straight stitch foot, make sure to adjust

the needle position to 3.5. Otherwise the needle may hit

the sewing foot and possibly break.

5

2 to 6

Zigzag foot

Straight stitch foot

3

r 0 0

‘ 4

c

3

^ 0

: 15

: l!l -

: c|d

ffl!

0

LsJ

a

1]

0

0

27

Page 34

stretch Stitch

(D Stitch pattern: 10

(D Needle thread tension 3 to 6

(D Presser foot A: Zigzag foot

(4) Pressure dial 3

This is a narrow stretch stitch designed to eliminate

puckering on knit fabrics and bias seams, while permitting

the seam to be pressed completely open flat.

Basting Stitch

(T) Stitch pattern: 15

(D Needle thread tension 1 to 4

(D Presser foot A: Zigzag foot

0 Pressure dial 1

The basting stitch is used to hold fabric layers together

during fitting. Use a fine needle so as not leave permanent

needle marks on fabrics.

Press pattern 15 on the visual touch screen. Drop the feed

dogs (see page 6).

Depress the foot control. The machine will take one stitch

and stop automaticaiiy.

Hold the fabric taut and slide it to where you want the next

stitch, then depress the foot control again.

Continue in this manner sliding the fabric sideways or

forward.

Zipper Sewing

0 Stitch pattern: 1

0 Needle thread tension 2 to 6

0 Presser foot E: Zipper foot

0

Pressure dial 3

0

1 5

Cp

To snap on the zipper foot

0

Groove

0

Pin

0

To sew left side

0

To sew right side

Fit the pin on the zipper foot into the groove on the foot

holder.

* To sew the left side of the zipper, attach zipper foot with

the right-hand side of pin.

* To sew the right side of zipper, attach the zipper foot with

the left-hand side of pin.

Page 35

Fabric preparation

® Right {top) side of fabric

(2) Wrong (bottom) side of fabric

(3) Bottom seam

0 Zipper bottom stop position

0 Basting stitch

Place the right (top) sides of the fabric 0 together. Sew a

bottom seam 0 5/8" (2.2 cm) from the right edge to the

estimated zipper bottom stop position

0

. Sew in reverse

a few stitches to iock.

increase the stitch length to 5, set needle thread tension

to 0, and sew basting stitch 0 the entire length of the

zipper tape.

To sew

0

1/8" (0.4cm) fabric margin

0

Zipper teeth

0

Zipper tape

Jj Attach zipper foot on right-side of pin.

Fold back the upper layer seam allowance. Fold back

the lower layer seam allowance to leave a 1/8" (0.4 cm)

margin of fabric

0

.

Place zipper teeth next to margin edge and pin margin to

zipper tape.

Align zipper foot with margin edge. Return thread tension

and stitch length to original settings. Sew a seam the

entire length of zipper tape, removing pins as you go.

Before reaching pull-tab, stop the machine with needle in

the fabric and raise the foot, then unzip a few inches to

clear a path for the stitch.

Remove fabric and close zipper.

I Raise and release foot, and re-attach it on left-hand side

of pin.

Take the upper fabric layer and lay it flat over the zipper.

Starting just below zipper bottom stop, sew across fabric

to about 3/8” to 1/2" distance from the basting stitch line.

Turn fabric 90° and sew a seam the entire length of

zipper tape. Before reaching pull-tab, stop the machine

with needle in fabric and raise the foot. Use seam ripper

to open a few inches of basting stitch, then unzip a few

inches to dear a path for the stitch. At the end of the

zipper tape, sew in reverse a few stitches to iock.

Once both sides of zipper are sewn, use seam ripper to

open the basting stitch.

Page 36

Zigzag Stitch

® Stitch pattern: 6

(2) Needle thread tension 3 to 7

CD Presser foot A: Zigzag foot

0 Pressure dial 3

The zigzag stitch is one of the most common and versatile

stitches. It can be a utility stitch for button sewing,

buttonhole making, hemming, overcasting, mending and

darning.

It can also be used to decorate with trims, appliques and

cut work or as a decorative stitch.

Manual Adjustment of Zigzag Stitch Width and Length

Press the key.

keys for stitchThe adjusting window display the : + and

width and stitch length.

Press the \± or — j key to change settings, then press the

« key to register the settings.

0 Stitch width adjusting keys

0 Stitch length adjusting keys

0 Default key: When you press ?=Mkey, all settings in the

adjusting window will return to their default settings (the

same settings as when you purchased the machine).

0 Cancel key: When you press key, the adjust

window will close and the setting remains unchanged.

0 OK key; When you press the i ok key your settings are

registered.

[ 0

i '^6

$

'

..........

i

m

Adjust

30

Page 37

Changing stitch width

® + key

(D-key

(3) Stitch width

Stitch width is adjusted with the '+] and keys.

The larger the number, the wider the stitch width.

Press the + key to increase the stitch width.

Press the —' key to decrease the stitch width.

Changing stitch length

(T) + key

(2) -key

(3) Stitch iength

Stitch iength is adjusted with the : + and — keys.

The larger the number, the longer the stitch iength.

Press the + key to increase the stitch iength.

Press the — key to decrease the stitch iength.

31

Page 38

Adjust the Needle Thread Tension for Zigzag

Stitch

For an ideal zigzag stitch, the bobbin thread does not show

on the right side (Top side) of the fabric, and the needle

thread shows siightly on the wrong side (Bottom side) of the

fabric.

See the illustrations for the correct appearance.

To match this appearance, adjust the needle tension.

• Correct tension

(T) Right side (Top side) of fabric

(D Wrong side (Bottom side) of fabric

Minimize the amount of needle thread visible on the

wrong side (Bottom side) of the fabric without causing

excessive puckering, or causing the bobbin thread to

show on the right side (Top side) of the fabric.

Results vary with fabric, thread and sewing conditions.

•Tension is too tight

(T) Right side (Top side) of fabric

(D Wrong side (Bottom side) of fabric

The corner of each zigzag pulls together on the right side

of the fabric.

•Tension is too loose

(T) Right side (Top side) of fabric

(D Wrong side (Bottom side) of fabric

The corner of each zigzag pulls together on the wrong

side of the fabric.

32

Page 39

Variety of Overcasting Stitches

Overedge Stitch

(T) Stitch pattern: 8

(2) Needle thread tension 3 to 7

(3) Presser foot C: Overedge foot

(4) Brush holder seam guide

(D Presser foot A: Zigzag foot

(6) Pressure dial 3

This stitch is often used as a seam finish to prevent fraying.

If using a zigzag foot, start overedging with the leftmost

needle position about 1/8" (0.3 cm) from the raw edge of a

fabric. The right tip of the stitch should just clear the raw

fabric. For lightweight fabrics, use the overedge foot. To

sew, line the fabric edge up with the inner side of the brush

holder seam guide

Note:

When using an overedge foot, make sure to set the stitch

width at 5 to 7.0, otherwise the needle may hit the

overedge foot.

0

.

Overedge Stitch (using zigzag stitch)

0 Stitch pattern: 6

(2) Needle thread tension 3 to 7

(

1

) Presser foot C: Overedge foot

0

Brush holder seam guide

0 Presser foot A; Zigzag foot

® Pressure dial 3

To prevent raw edge of fabric from raveling, overcast the

edge with zigzag stitch. It is the fastest way to finish the raw

edge of most woven fabrics.

Note:

When using an overedge foot, make sure to set the stitch

width at 5 to 7.0. otherwise the needle may hit the

overedge foot.

Muitipie Zigzag Stitch

0

Stitch pattern: 7

0

Needle thread tension 3 to 6

0

Presser foot A; Zigzag foot

0

Pressure dial 3

(4)

HB

1

m

0

m

Seam finishing

This stitch is used to finish the seam allowance on

synthetics and other fabrics that tend to pucker. The stitch

is also excellent for darning and mending tears.

Place your fabric to allow a 5/8" (1.5 cm) seam. Trim

excess close to stitching. Be careful not to cut the stitches.

Mending

Position the tear under the needle so that the stitch

catches both sides.

33

Page 40

Serging

(T) Stitch pattern: 9

(2) Needie thread tension 3 to 7

(3) Presser foot A: Zigzag foot

® Pressure dial 3