Page 1

Model 17920

17921

17922

OWNER'S

MANUAL

Sewing Machine

TABLE OF CONTEIMTS

1. KNOWING YOUR SEWING MACHINE

Machine identification..................................................1-2

Setting your machine...................................................3-4

Foot control, Light/power switch, Electronic

needle control. Maximum speed control.

Accessory box

Parts list.......................................................................5 - 6

Spool pins and caps

Converting to free-arm sewing

Winding the bobbin

Threading the bobbin case

Threading top thread

Picking up bobbin thread

CONTROLS

Thread tension control..................................................12

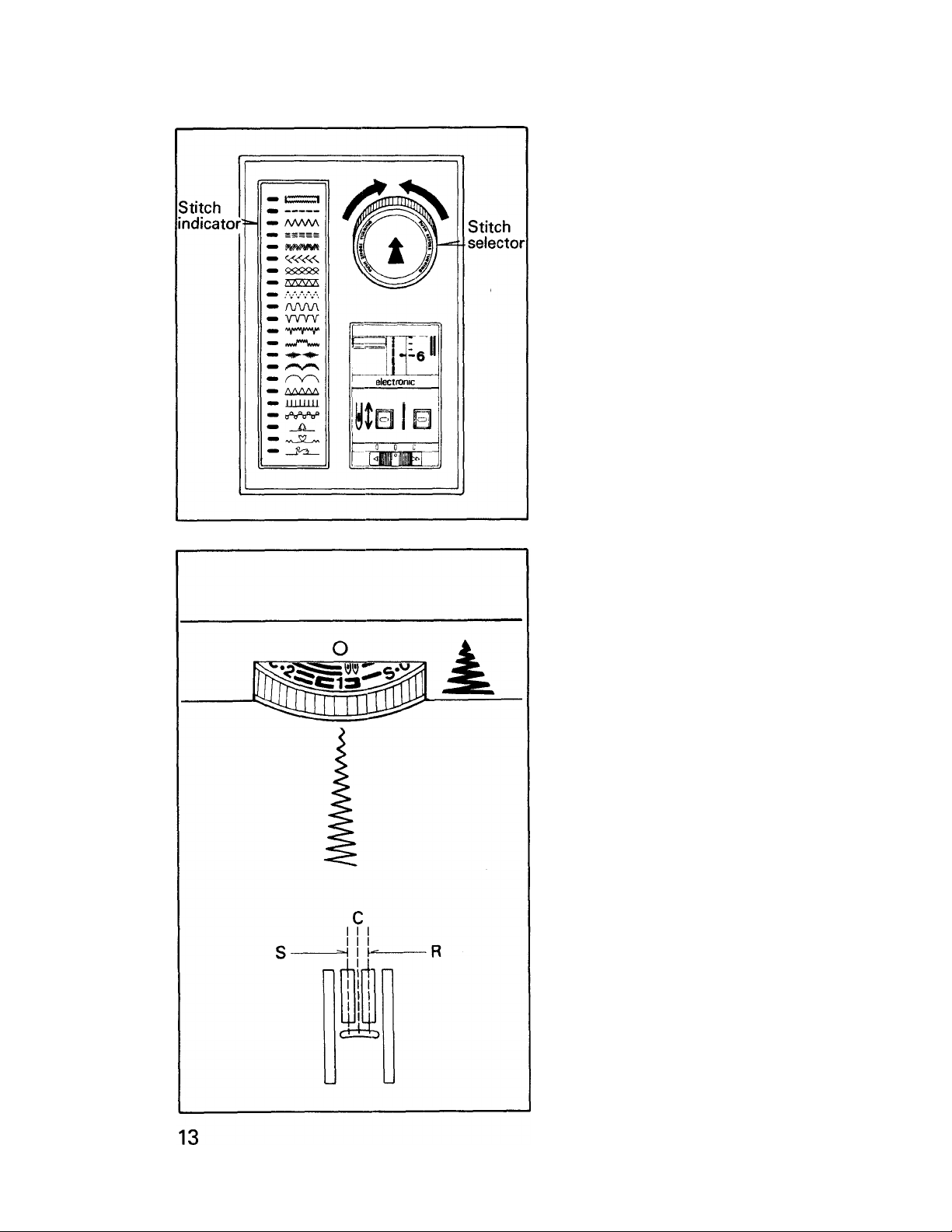

Stitch selector and indicator. Stitch width control.... 13

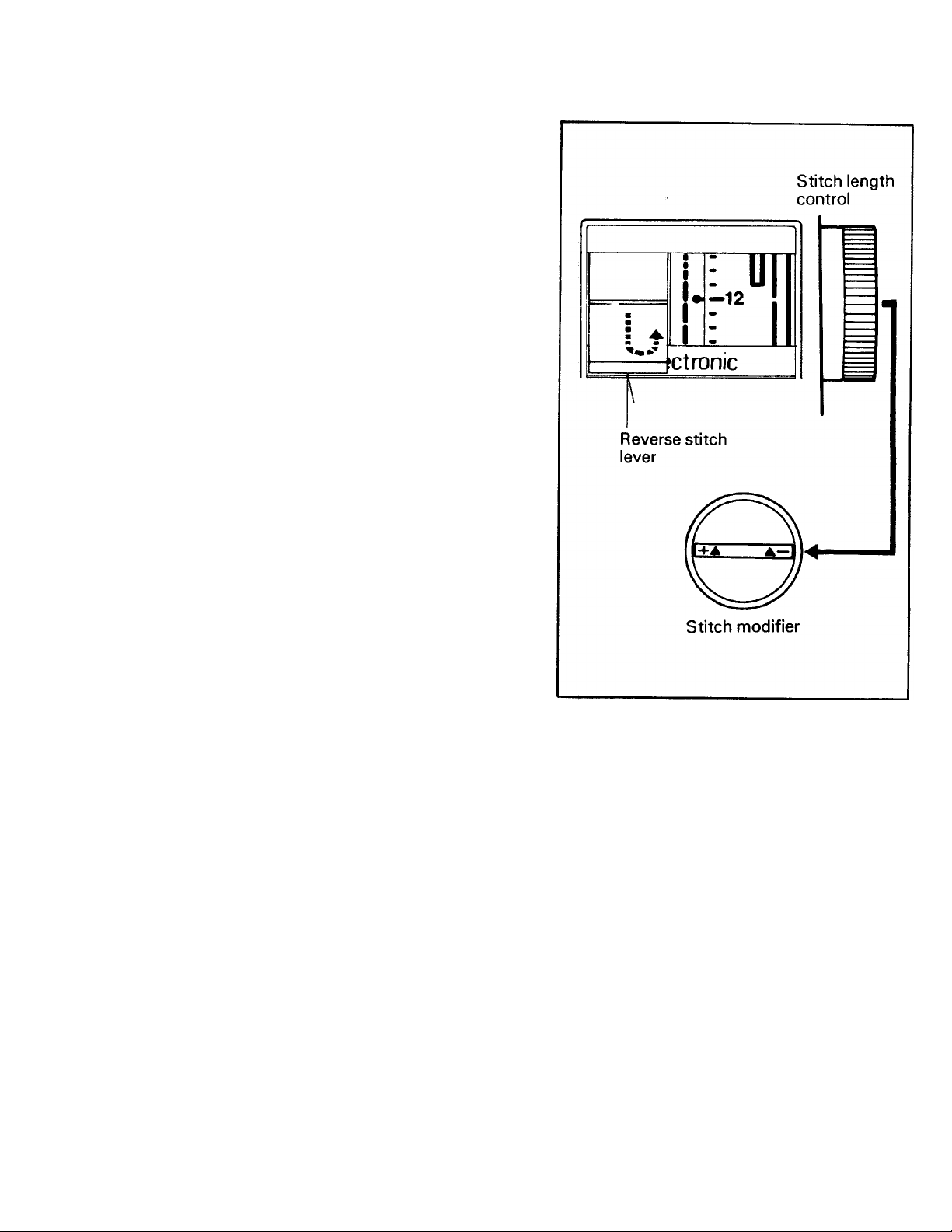

Stitch length control, Reverse stitch lever

Stitch modifier............................................................. 14

Buttonhole control. Pressure regulator.........................15

Seam guides, Presserfoot lever

ACCESSORIES

Needles, Placement of needle

Needle, thread and fabric chart, Presser feet

Even feed foot. Adjustable holder

Edgestitcher, Quilting guide..........................................19

Needle plates. Feed cover plate...................................20

CARING FOR THE MACHINE

Cleaning feed dogs and shuttle

Oiling

.......................................................................

Changing light bulb.......................................................23

CHECKING PERFORMANCE PROBLEMS.. .24 - 25

2. STARTING TO SEW ...................................................26

Machine setting chart

Straight stitching......................................................29-32

Fastening a seam. Turning asquare corner.

Removing fabric. Darning, Temporary sewing

by machine. Zipper application - cording. Narrow

hemming. Quilting

Zigzag stitching........................................................33 - 35

Overcasting, Satin stitching. Bar tacking,

Appliqueing, Embroidery, Monogramming,

Button sewing

Blind hemming..............................................................36

Stretch stitches........................................................37-39

Recommendation, Adjusting stitch balance,

Straight stretch stitch. Rick-rack stretch.

Feather stretch. Smocking stretch. Elastic

stretch. Overcast stretch, Paris point stretch

Buttonhole making

......................................................

......................................

........................................................

............................................

....................................................

.............................................

....................

...................................

.....................................

...........

................................

...................................

22-23

..............................................

..................................................

27-28

40-46

11

17

21

7

7

8

9

10

14

15

16

18

Page 2

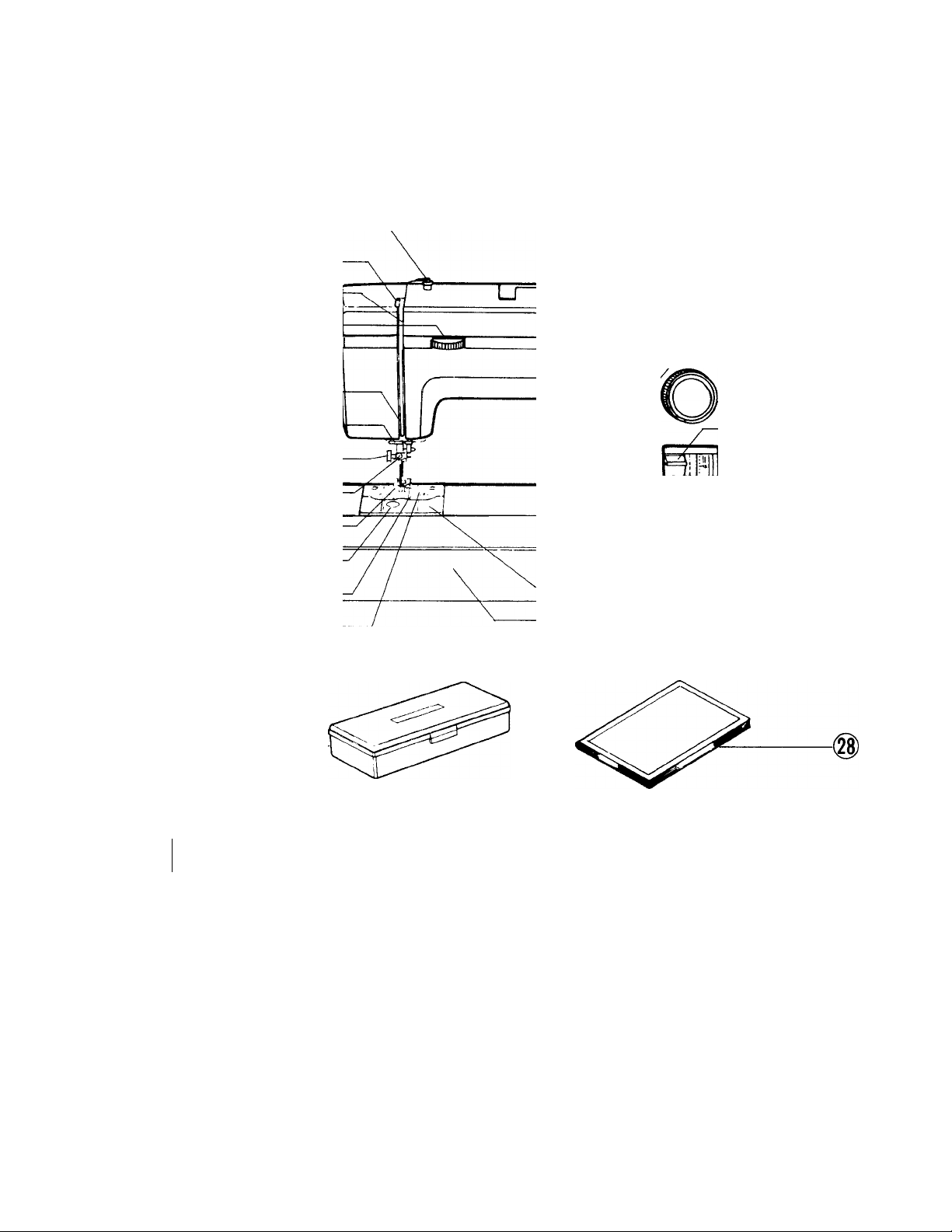

■1. KNOWING YOUR SEWING MACHINEi

IDENTIFICATION CHART

FRONT VIEW

13^

toiling *

z_

®-

®-

®-

t

®-

1.

Needle plate

Feed dogs

2.

Bobbin window

3.

Presser foot

4.

5. Needle clamp screw

Presser foot thumb screw

6.

7. Thread guide

Check spring

8.

Face cover

9.

Top thread tension control

10.

Threading channel

11.

Slotted take-up lever

12.

Bobbin winder tension disc

13.

14.1Built-in buttonhole control

liBIB

Bobbin winder shaft

15.

Bobbin winder latch

16.

17. Stitch width dial

Stitch indicator

18.

Stitch selector

19.

Reverse stitch lever

20.

Stitch length dial

21.

Needle up/down switch

22.

Basting switch

23.

24. Maximum speed control

Bobbin cover plate

25.

Accessory box

26.

Buttonholer/accessory box

27.

Owner's manual

28.

Page 3

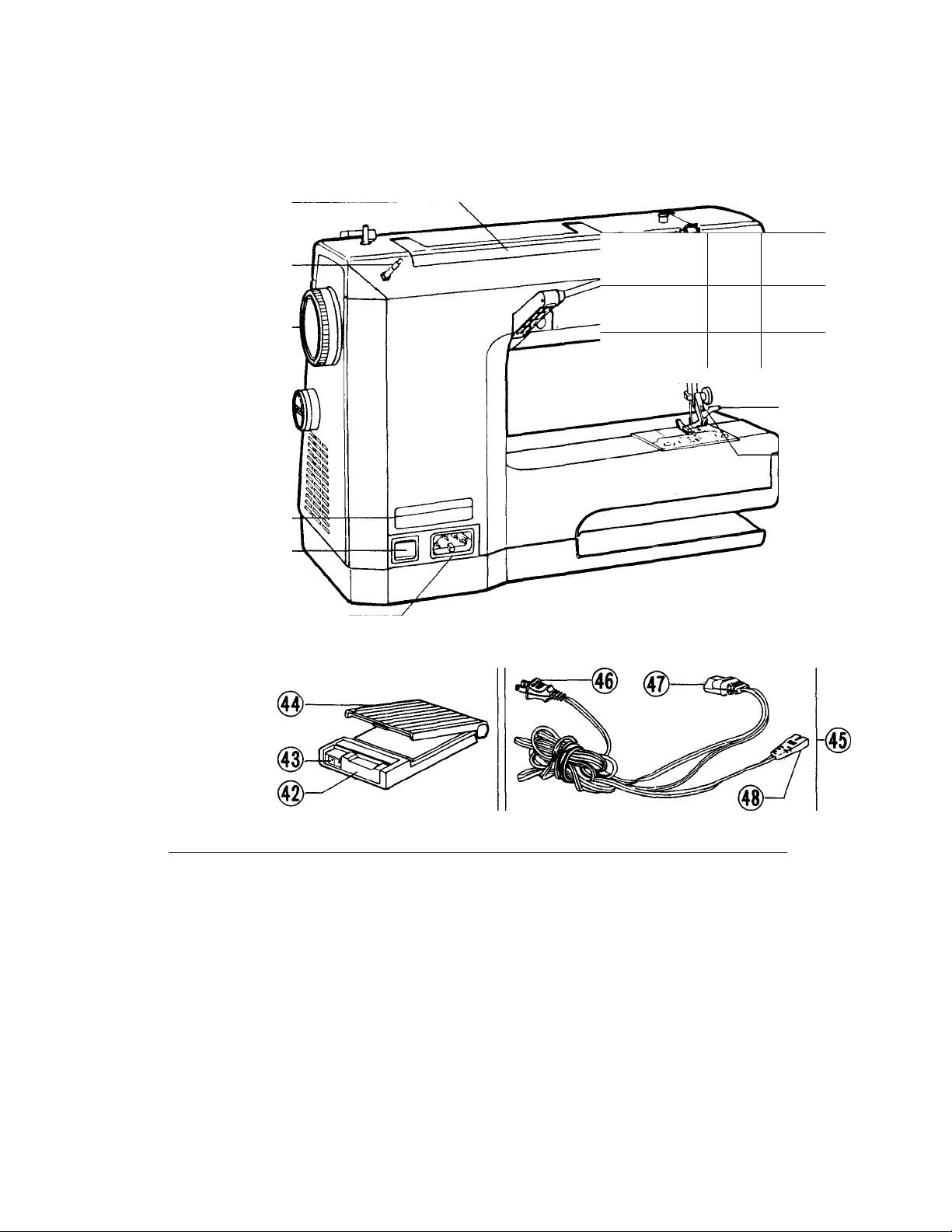

BACK VIEW

\ ihi

(

J

J

J

V

(

Electric cord receptacle 39.

29.

Light/power switch

30.

Nomenclature plate

31.

Stitch modifier

32.

Hand wheel/push-pull clutch 43.

33.

34. Telescoping spool pin

Foldaway carrying handle

35.

40.

41.

42.

44. Foot pedal

45.

36. Rear thread guide 46.

37.

Swing-away spool pin

Presser foot lever

38.

47.

48.

Presser foot release lever

Thread cutter

Foot control

Pedal lock knob

Cord receptacle

Foot control cord

Machine plug

Power-line plug

Foot control plug

Page 4

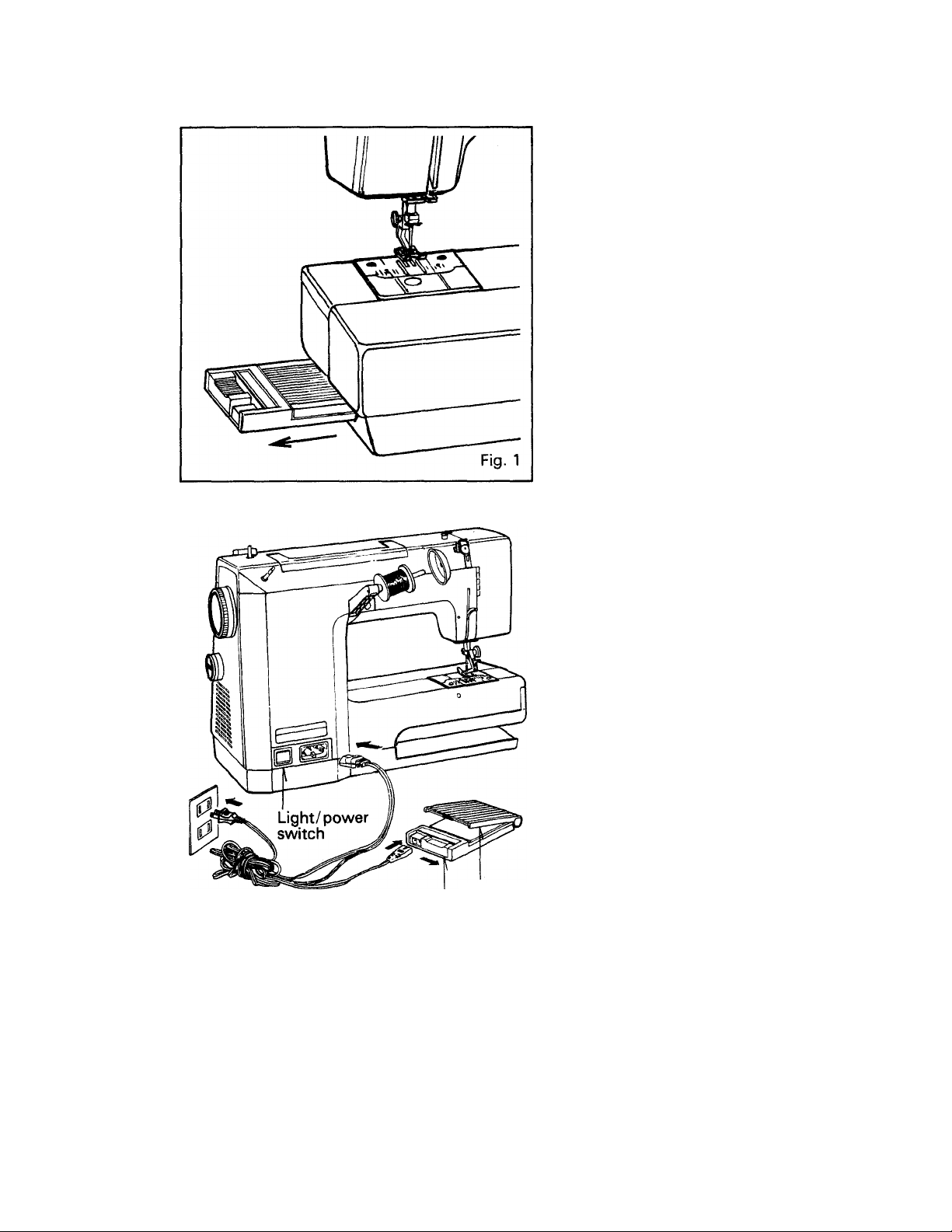

SETTING UP YOUR MACHINE

1. Install your Kenmore sewing machine in a

Kenmore cabinet, case or set the machine

on a sturdy flat surface.

2. Your Kenmore sewing machine has been

thoroughly oiled at the factory. Be sure to

wipe off the needle plate area and bed

plate carefully before sewing a garment.

It is wise to practice on a scrap of fabric

so any surplus oil is absorbed.

3. FOOT CONTROL

Your machine is supplied with an

electronic foot control which enables you

to sew very slowly. Even at low speed you

have extra power for the needle to

penetrate through several thicknesses of

fabric. Faster speeds are also easily

controlled.

1. Pull out the foot control from its

storage position under the free arm.

(Fig. 1)

2. Slide pedal lock knob to the right and

the foot pedal will pop up to its

operating position. Push foot control

plug into the cord receptacle on the

foot control. (Fig. 2)

Pedal lock knob

Foot

Fig. 2

3. Push machine plug into the cord

receptacle at the rear side of the

machine. Then connect power-line

plug into any 110-120 volt A.C. wall

outlet. (Fig. 2)

4. LIGHT/POWER SWITCH

Your machine will not operate unless the

light/power switch is turned on. This

same switch controls the machine power,

sewing light and indicator lights on the

stitch indicator panel and electronic

needle control. If you are interrupted or

stop sewing, turn off the switch.

Page 5

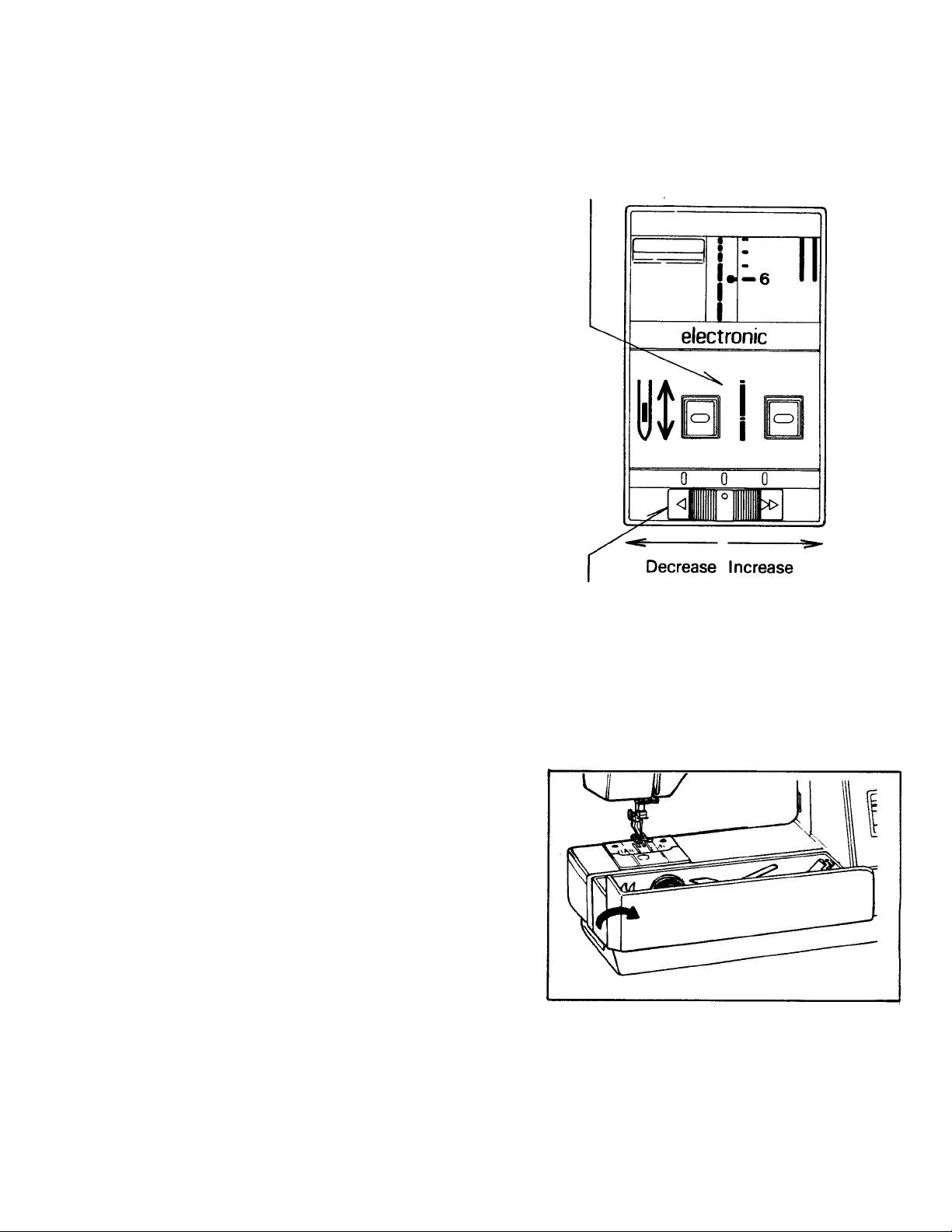

ELECTRONIC NEEDLE CONTROL

Your machine is electronically controlled

to stop with the needle in the up position

every time you remove pressure from foot

control.

NEEDLE UP/DOWN SWITCH

When you want to lower the needle, push

the left switch and the needle will move to

the down position with red light turned

on. Push it again or activate the foot

control and the light will disappear to

indicate the cancellation of needle down

position and the needle will move back to

the up position.

BASTING SWITCH

Tap the foot control with the right switch

pushed and lighted and the machine will

take one stitch only and stop with needle

in the up position. This feature provides

an electronically controlled basting or

tacking to take the chore out of hand

basting.

MAXIMUM SPEED CONTROL

You may want to vary the speed of the

machine, sewing slowly in special tight

places or if you are a new seamstress.

This control can be moved to the left to

slow the sewing of the machine. To

increase to the maximum speed, slide the

control to the right.

Electronic needle

control

Maximum speed

control

7. ACCESSORY BOX

Accessory box is opened by lifting the lid

up and swinging it toward you as shown.

Inside you will find many of the acces

sories that you use each time you sew.

The box may be fully removed from the

machine to convert it for free arm

stitching. See page 8.

Page 6

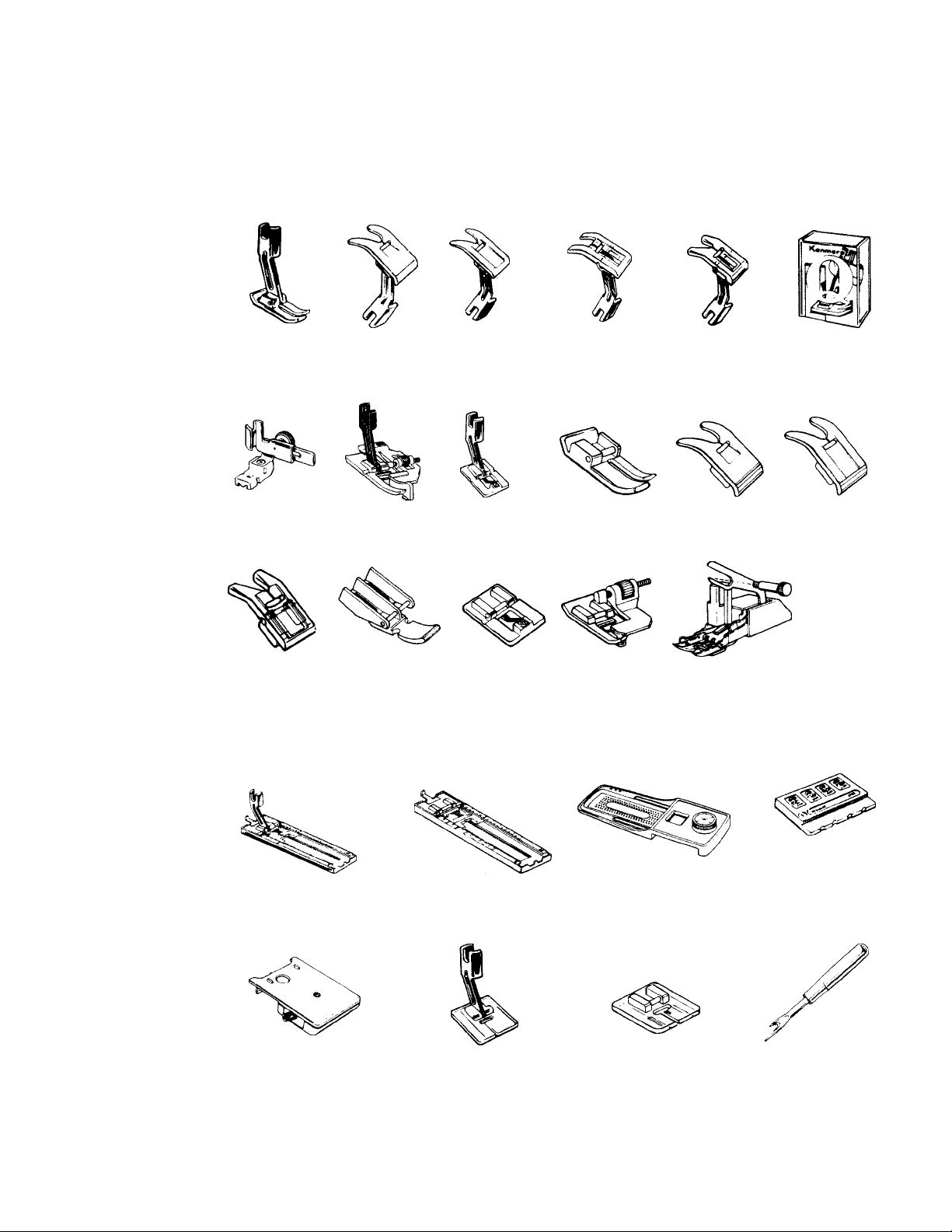

PARTS LIST (Use only genuine Kenmore replacement parts and accessories.)

PRESSER FEET

Straight Stitch Standard Zigzag Satin Stitch

(No. 45171) (No. 44985) (No. 44988)

Zipper Foot

(No. 6759)

Plastic Satin Stitch

(No. 57978)

Blind Hem Foot

(No. 6886)

Zipper Foot

(No. 59090)

BUTTONHOLE ACCESSORIES

Overcasting

(No. 35094)

Overcasting

(No. 57983)

Plastic Satin

Stitch (No. 43776)

Straight Stitch

(No 57976)

Blind Hem Foot * Even Feed Foot

(No. 57986) (No. 6888)

“Q FOOT”

(No. 6843)

Standard Zigzag

(No. 57975)

* Included in the buttonholer box

■■QSKT"..

(No. 6858)

Satin Stitch

(No. 57977)

Built-in Buttonhole Guide

Foot (No. 43840)

Buttonhole Cover

Plate (No. 60753)

Built-in Buttonhole Guide

Foot (No. 57984)

Buttonhole Foot

(No. 41040)

Buttonhole Guideplate

(No. 58232)

Buttonhole Foot

(No. 57979)

Buttohole Templates

No. 1 Part 45195

No. 2 Part 45196

No. 3 Part 45197

No. 4 Part 45198

No. 5 Part 45199

Buttonhole Opener

(No. 6830)

Page 7

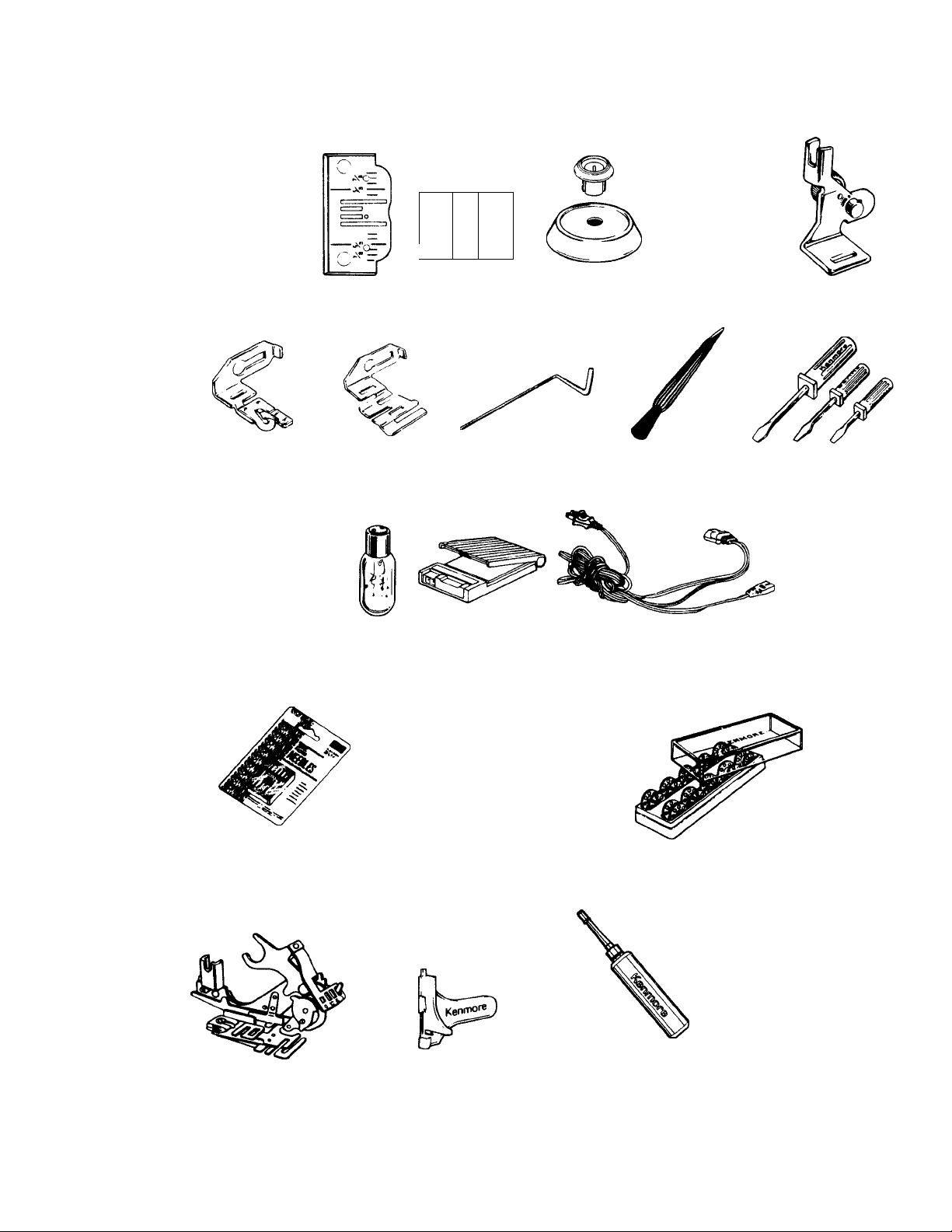

OTHER VITAL ITEMS

Zigzag

Needleplate

(No. 57860)

Narrow Hemmer

(No. 29396)

Bobbin Winder

Rubber Ring

(No. 1913)

Bobbin Winder Light Bulb

Tension Disc (No. 6797)

(No. 39619)

Straight Stitch

Needleplate

(No. 57861)

Edge Stitcher

(No. 29306)

1

'liii

Feed Cover

(No. 43166)

IS/

Li

Plate

Quilting Guide

(No. 28861)

Foot Control

(No. 57544)

.

2 Spool Pin Caps

Large — No. 55503

Small - No. 53871

Foot Control Cord

(No. 57543)

C3)

Nylon Disc

(No. 2273)

Lint Brush

(No. 35848)

Adjustable

Holder

(No. 29308)

Large Screw Driver

(No. 55501)

Small Screw Driver

(No. 55500)

Magnetized

Mini Screw Driver

(No. 55499)

OPTIONAL ACCESSORIES

Packet of needles

with your machine

includes a variety of sizes.

Replacement needles

come in packages

of one size only.

Ruffler/Pleater

(No. 6895)

Needle Size

No. 9

No. 11

No. 14

No. 16

No. 18

"Q NEEDLE"

Double Needle

Needle Threader

(No. 43780)

Part No.

6550

6551

6552

6553

6554

6746

6749

Bobbin Box with

10 Metal Bobbins

(No. 6862)

Plastic Bobbins

(No. 6868)

Oiler

(No. 6890)

Page 8

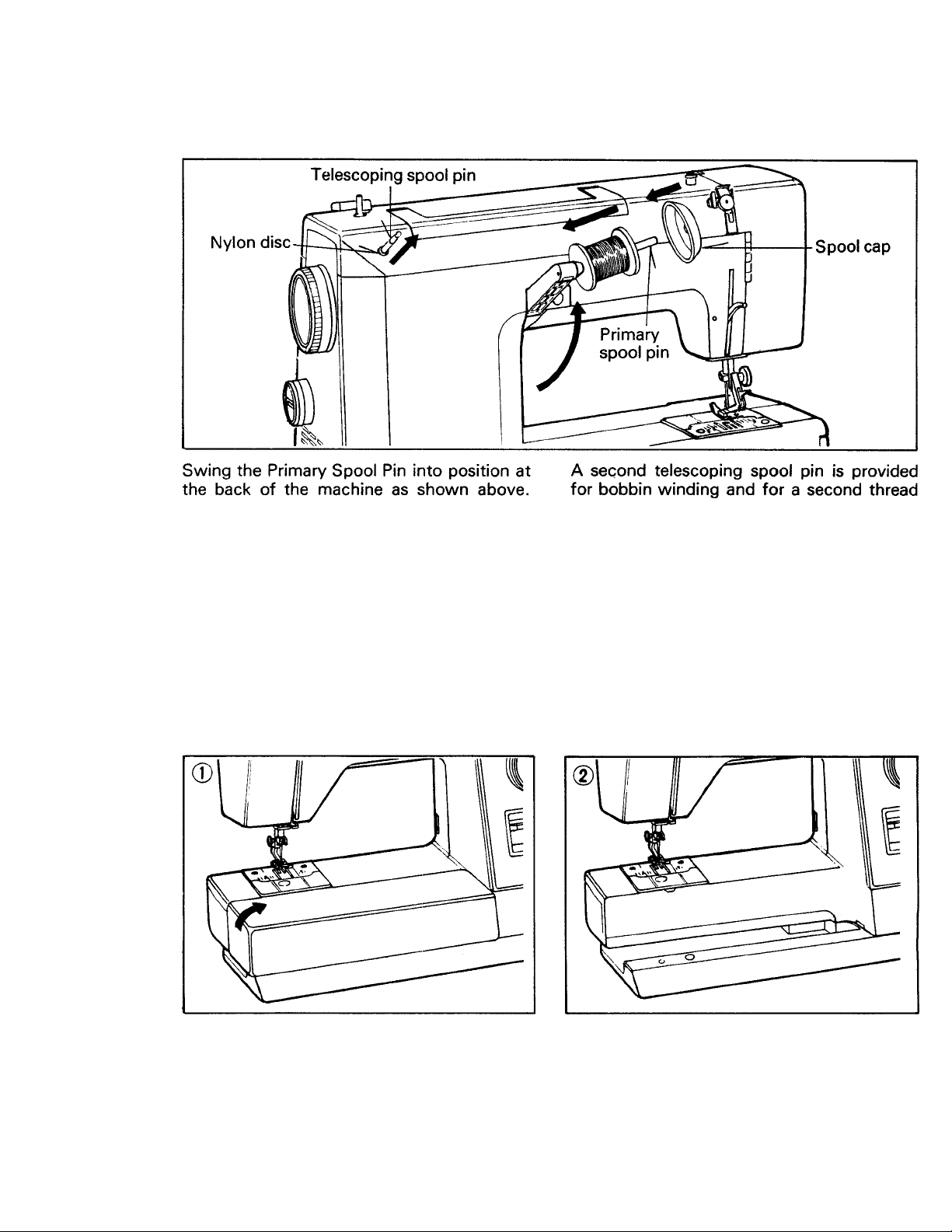

SPOOL PINS AND CAPS

Place a spool of thread on the pin and place

the appropriate size spool cap over the

thread.

CONVERTING TO FREE-ARM SEWING

This machine can be used either as a flatbed

or as a freearm model. With the accessory

box in place, the machine is a flatbed model

with a large working surface, which slopes

gently towards you to help the smooth flow

of fabric.

when sewing with a double needle. Pull it out

and place a nylon disc over it when using.

By removing the accessory box, the machine

converts into a slim freearm model for sewing

children's clothes, cuffs, trouser legs,

armholes and other awkward places.

1. To remove the accessory box, take it

firmly with your left hand and lift it up

until it clicks. Your machine is then ready

for free arm sewing.

2. To replace, slide the accessory box back

into place until it clicks.

Page 9

WINDING THE BOBBIN

1. Place thread on Telescoping Spool Pin.

Draw thread through Rear Thread Guide

and Bobbin Winder Tension Disc as

indicated.

2. Pull end of thread through any hole in

bobbin; place bobbin on Bobbin Winder

Shaft with end of thread coming from top

of bobbin as shown above.

Push Bobbin Winder Latch against bobbin

until it clicks. Then pull Hand Wheel away

from machine to disengage clutch (see

diagram below). Hold end of thread

coming from bobbin (see above) and step

on foot control. After several rotations of

bobbin release thread.

When bobbin is full, winding stops

automatically. Push in Hand Wheel.

Remove bobbin from shaft and trim

thread end.

Treat Hand Wheel as a "clutch"

It controls the needle mechanism so that

when pulled out (disengaged), the rest of

the machine will not operate while the

bobbin is being wound.

For best stitching results use clear plastic

lightweight bobbins when stitching at high

speed with widest and longest stitch

setting.

8

Page 10

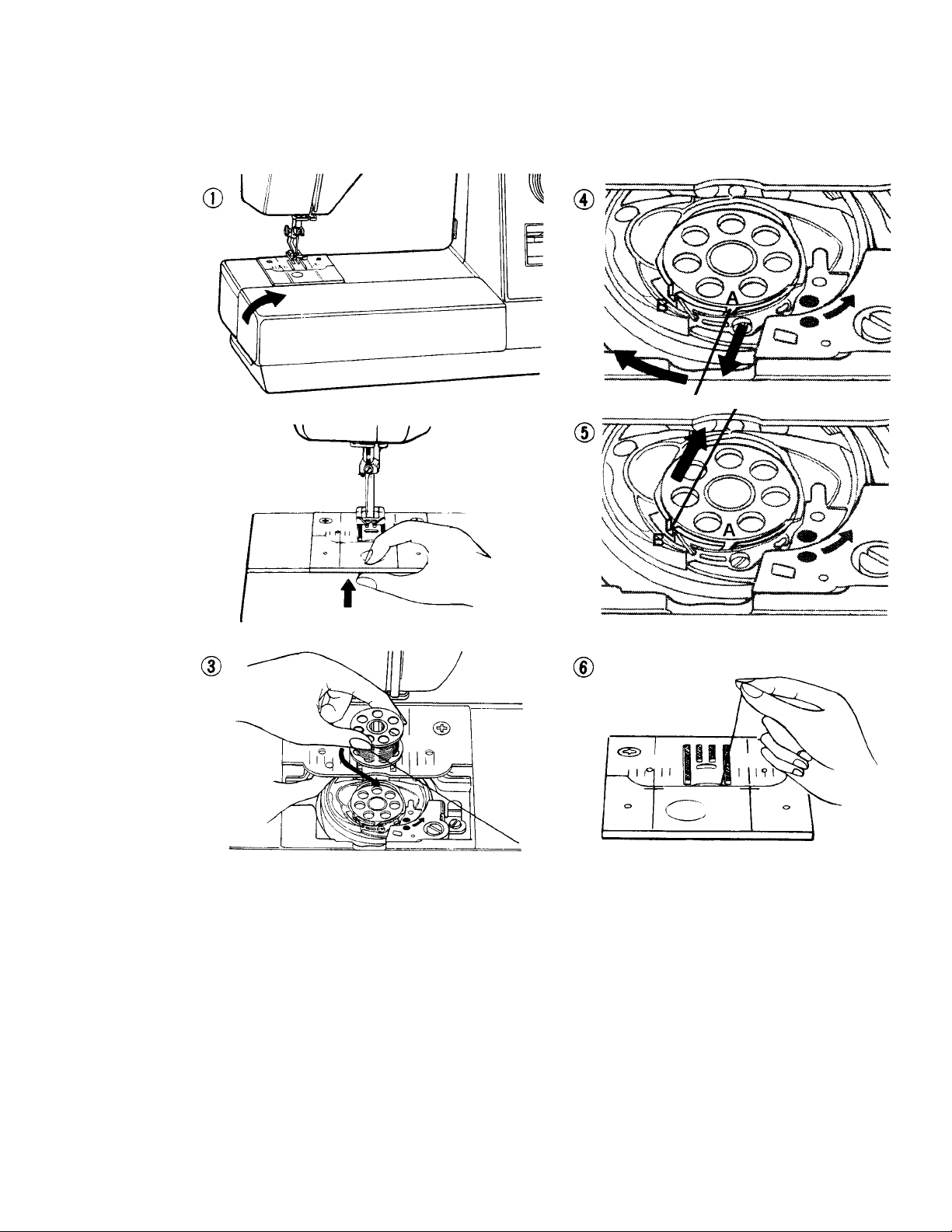

THREADING THE BOBBIN CASE

(D

1. Remove accessory box.

2. Remove bobbin cover plate by lifting up

the front.

3. Insert bobbin into bobbin case making

sure bobbin rotates counter clockwise.

4. Pull thread through slot (A) and then to

the left.

5. Pull thread through slot (B) and leave

about 4 inches of thread.

6. Replace bobbin cover plate allowing

thread to emerge through slot in needle

plate.

Page 11

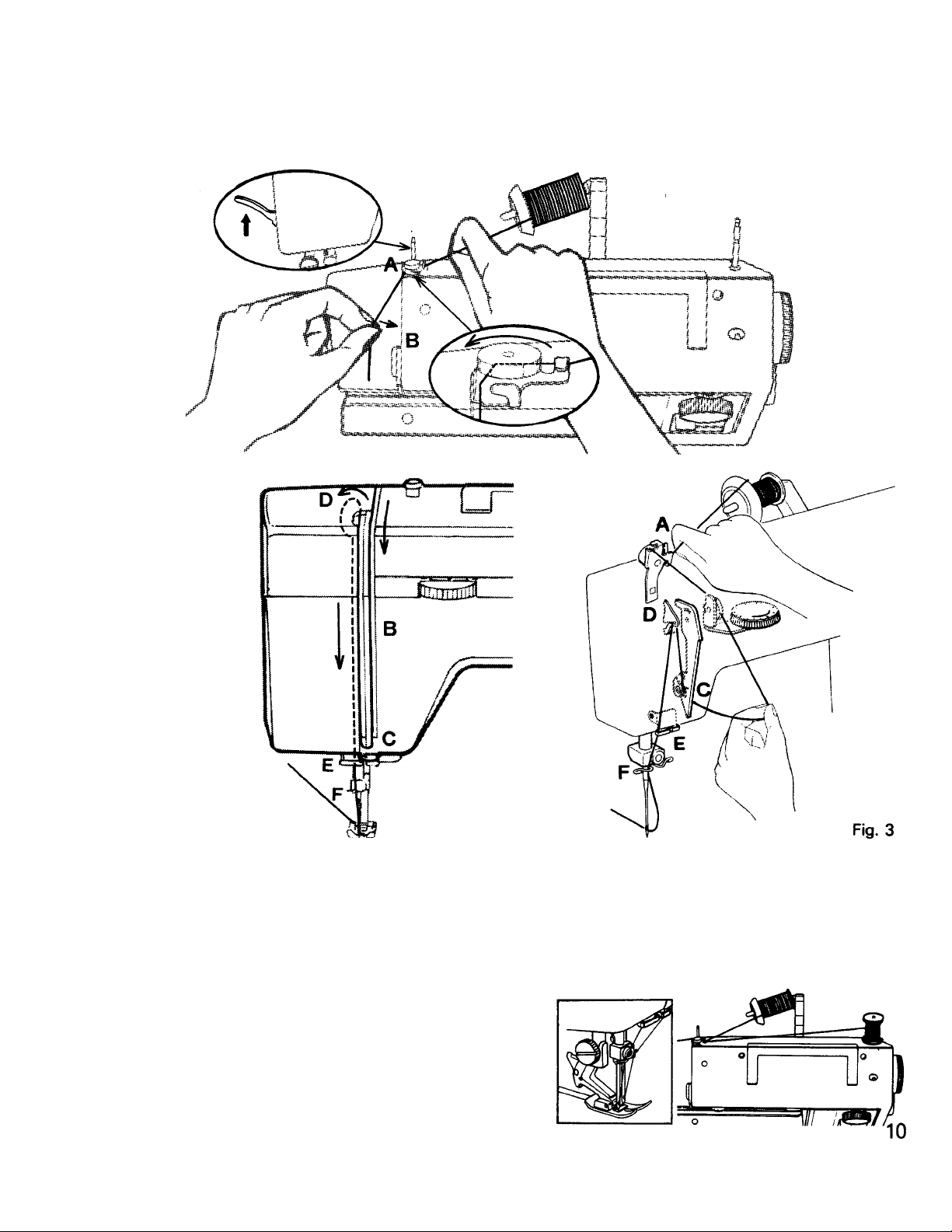

THREADING TOP THREAD

Fig. 1

Fig. 2

1. Raise slotted take-up lever to its highest

position.

Place thread spool onto spool pin. Place

appropriate spool cap over the spool of

thread.

Draw thread through rear thread guide

(A) and into threading channel (B) toward

you. (Fig. 1)

2. Draw thread down and around check

spring (C) and up through slotted take-up

lever (D). (Fig. 2)

3. Draw thread down into thread guides (E)

and (F). Thread needle from front to back

as shown in Fig. 3.

THREADING DOUBLE NEEDLE

Place second spool of thread on second

spool pin, and thread machine as you would

for a single needle except double thread

guides are provided. Draw one thread

through each of these and through each side

of needle from front to back.

Page 12

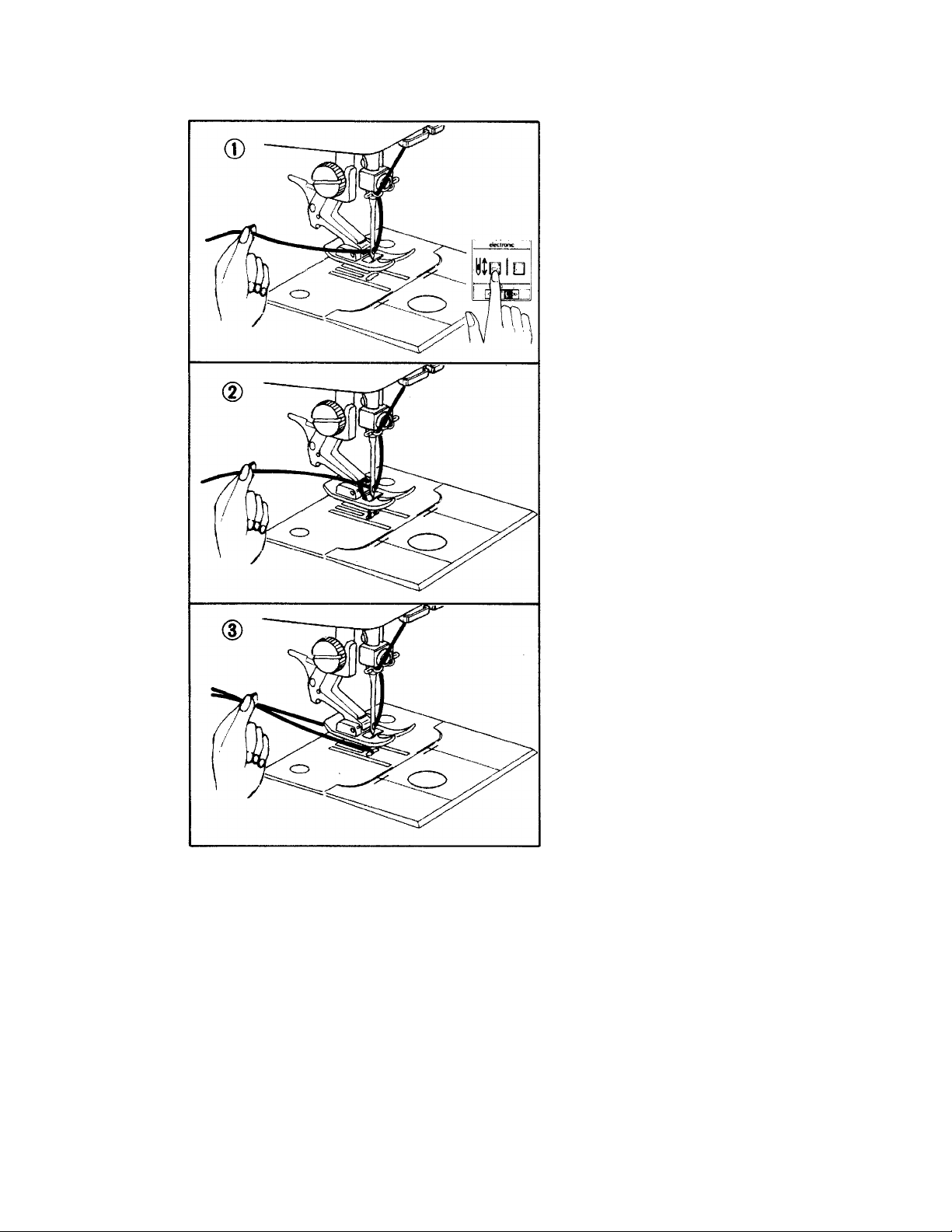

PICKING UP BOBBIN THREAD

1. Raise presser foot lever.

Hold needle thread loosely in left hand

and push needle up/down switch two

times or rotate hand wheel toward you

one complete turn.

2. Bring bobbin thread up by pulling upper

thread.

3. Pull both threads under and to the back

of the presser foot, leaving 3 to 4 inches

of thread clear.

If you can not pick up bottom thread by

following above steps, then check:

1. Is needle threaded ?

2. Is thread tangled around needle ?

3. Is bobbin case threaded correctly with

thread going through slots A and B as

shown on page 9, Fig. 4 and 5 ?

4. Is there 4 inches of thread coming from

bobbin case and through slot of needle

plate as shown on page 9, Fig. 6 ?

5. Is thread from bobbin case tangled ?

11

Page 13

iCONTROLSi

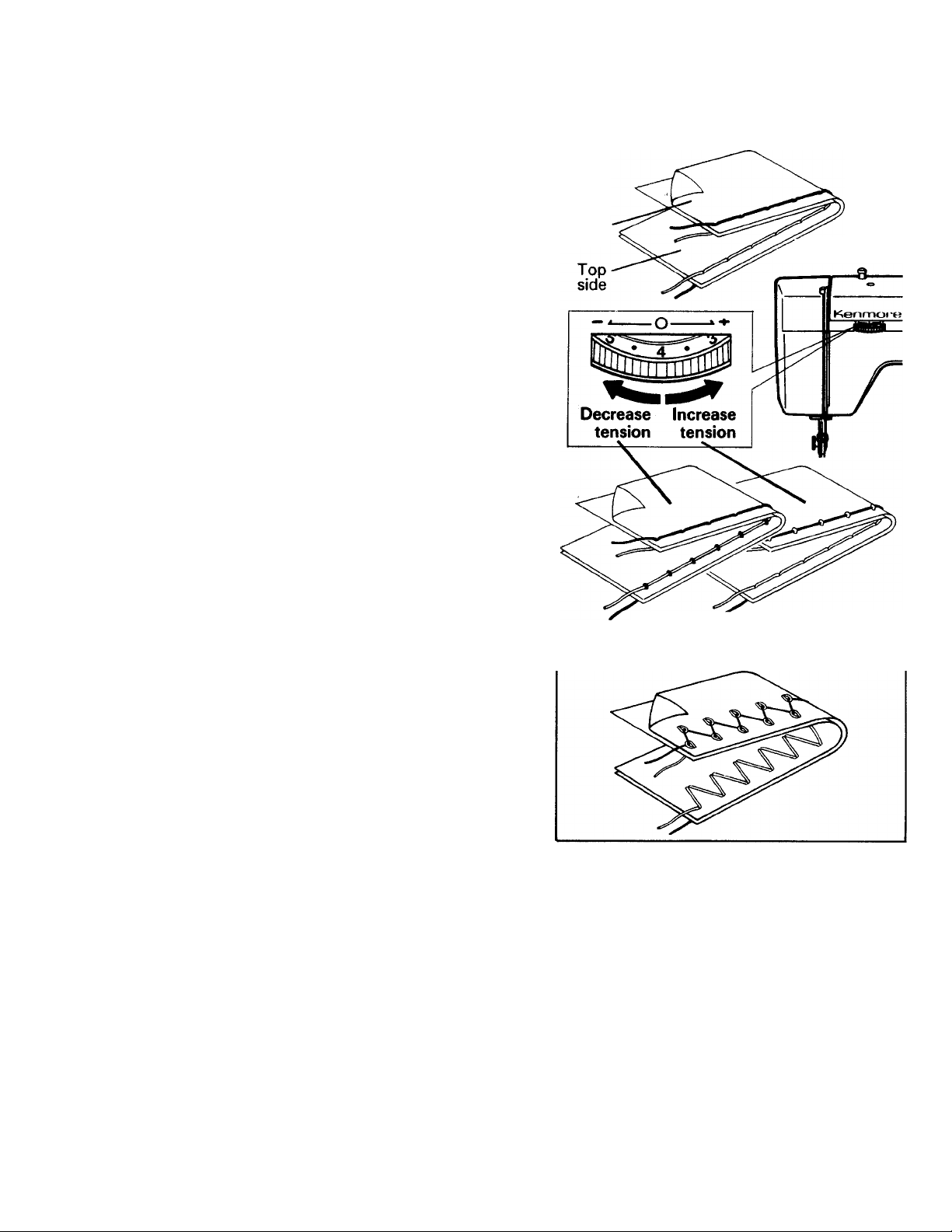

THREAD TENSION CONTROL

STRAIGHT STITCHING

The good looking appearance of your stitching

is largely determined by the balanced tension of

both top and bobbin threads. The tension is well

balanced when these two threads 'lock' in the

middle of layers of fabric you are sewing.

For most fabrics the top thread tension control

should be set in the white zone between 3 and 5.

If, when you start to sew, you find that the

stitching is irregular, you will need to adjust the

tension control.

Make any adjustments with presser foot 'down'.

1. If the threads are locking on the top surface

with the top thread lying flat, the top stitch is

too tight. Tension can be decreased by

turning the tension control to the left (lower

numbers).

2. If the reverse is happening with the threads

on the underside of the fabric, the tension is

too loose. This can be corrected by turning

the tension control to the right (higher

numbers).

Under

side

STRAIGHT STITCHING

Well balanced

ZIGZAG STITCHING

The top thread may appear on the bottom

depending on the thread, fabric, type of stitch

and sewing speed, but the bobbin thread must

never appear on the top of the fabric.

In the case of zigzag stitching, the wider the

zigzag setting, the more chance there is of

puckering. If this occurs decrease the top

tension slightly and/or reduce the zigzag width.

BOBBIN THREAD TENSION

The bobbin thread tension has been correctly

set at the factory, so you do not need to adjust

it.

MORE TIPS ON THREAD TENSION BALANCE

A perfect stitch is obtained when the tension

is well balanced, but the tension balance may

vary according to the type and size of needle,

thread and fabric. The fabric determines size of

thread and needle. The presser foot pressure

and the thread tension control should also be

adjusted properly.

FABRICS:

Heavy fabrics, stiff - Increase top thread

tension. Use larger size needle, heavier thread

and longer stitch length.

Heavy fabrics, soft - Decrease top thread

tension. Use longer stitch length.

Light, sheer fabrics - Decrease top thread

tension and presser foot pressure. Use shorter

stitch length. Sew slowly.

THREADS:

Polyester and silk - Decrease top thread tension.

Nylon - Increase top thread tension.

Top stitch ^ Top stitch

too tight too loose

ZIGZAG STITCHING

12

Page 14

STITCH SELECTOR AND INDICATOR

1. To select a stitch, be sure needle is out of

fabric at its highest position. Push the

stitch selector in and out to release the

mechanism.

2. Then turn the selector to left or right until

the required stitch is indicated by the red

light on the indicator panel.

STITCH WIDTH/NEEDLE

POSITION CONTROL

STITCH WIDTH CONTROL

The width of all the stitches produced on this

machine, with the obvious exception of

straight stitch, can be made narrower or

wider by adjusting the stitch width control.

To decrease or increase the width of a stitch,

turn the stitch width control dial from 0-4.

The higher the number the wider the stitch.

Recommended setting ranges are indicated

and color-coded with patterns on the stitch

indicator panel.

When sewing with a double needle, do not

use a setting above 2, as indicated on the

dial.

NEEDLE POSITION CONTROL

(Model 17922 only)

This dial is used to change needle position

when straight stitching. Three different

needle positions can be selected: S - standard

position for general sewing, C - center and

R - right.

Page 15

STITCH LENGTH CONTROL

The stitch length control regulates the length

of the stitch you select. THE HIGHER THE

NUMBER-THE SHORTER THE STITCH.

Turn only the outer rim of this control to set

the stitch length.

The number on stitch length control indicates

the approximate number of stitches per inch.

The stitch setting you use will be determined

by the thickness of the fabric you are sewing.

A longer stitch setting should be used for

thicker fabric or more layers of fabric. The

middle range of the control is the 12 stitch per

inch range which is the most commonly

used.

Recommended stitch length settings are

indicated in three colors. The colors are

color-coded with the stitches on the indicator

panel.

The red marking between 0 and 24 is

the setting used for the shortest stitches such

as in satin stitching.

REVERSE STITCH LEVER

It is best to begin and end seams with a few

stitches taken in reverse. This is called back

tacking. Back tacking fastens the ends of the

seams firmly and prevents raveling.

When reverse stitching is needed, push

down the lever and hold there during sewing.

The fabric will immediately start feeding

backwards and seam will be fastened.

STITCH MODIFIER

When using stretch stitches and making

buttonholes, you may need to make use of

the stitch modifier. This regulates the

movement of the fabric backwards and

forwards to produce perfect stitches on fine

or thick fabrics.

The .stitch modifier should be in neutral

notched position for most materials.

14

Page 16

SEAM GUIDES

Seam guides are printed on needle plate, at

both sides of needle, to help you line up the

fabric and keep it straight. The standard

seam width is 5/8". So these lines are

emphasized, easy to follow.

Also the cross lines are "cornering guides" to

help when turning a square corner 5/8" from

the fabric edge. (For details on cornering, see

page 29.)

PRESSER FOOT LEVER

Presser foot lever has a two position lift.

In order to place heavy fabric under the

presser foot or to change the presser foot

raise the presser foot lever to its maximum

upward position as shown.

BUTTONHOLE CONTROL

This control is used in making bar tacked

buttonholes with two control settings.

Detailed instructions are given on page 51.

PRESSURE REGULATOR

Presser foot pressure is vital for straight

seams, uniform stitch length, even handling

of both layers of fabric. To adjust pressure;

use Pressure Regulator which is situated

inside the face cover. Then to increase

pressure, turn the dial clockwise (or vice

versa). Just remember... for lightweight

fabric, more pressure; for heavy fabric, less

pressure.

Page 17

I ACCESSORIES!

NEEDLES

Use KENMORE needles. The size of the

needle should conform with the size of the

thread and both should be suitable to the

fabric. Kenmore needles are color-coded by

size for your convenience (See chart on

facing page).

Never use a bent needle or one with a dull

point.

NEEDLE, THREAD AND FABRIC CHART

If you do not have a Kenmore needle, please

use this illustration to be sure your needle is

the right size. Distance from top of needle to

needlehole should be this exact length.

You will find among your accessories a

• Q NEEDLE".- with blue shank. This special

needle is to be used when sewing knits and

certain difficult synthetic fabrics. If you

experience skipped stitches in any of your

sewing, use q needle"-and "Q FOOT"..

FABRIC

LIGHTWEIGHT: Batiste, Dimitv,

Chiffon, Silks, Synthetic Jerseys,

Fine Lace, Organza, Crepe,

Taffeta, Voile, Organdy

MEDIUMWEIGHT: Cotton,

Cotton Blends, Percale, Gingham,

Shantung, Pique, Seersucker,

Satin, Knits, Vinyl, Suitings,

Linen, Wool Crepe, Leather

MEDIUM HEAVYWEIGHT:

Corduroy, Denim, Wool,

Sailcloth, Wool Flannel,

Gabardine, Velvets, Leather

HEAVYWEIGHT: Coatings,

Upholstery, Cotton Duck,

Heavy Twills, Canvas

Decorative top-stitching on all

types of fabric

NEEDLE

SIZE AND

COLOR

9 BROWN

or

11 ORANGE

14 RED

14 RED

or

16 PURPLE

18 GREEN

16 PURPLE

18 GREEN

or

Q-BLUE

THREAD SIZE

Polyester Core/Cotton Wrap

Fine Mercerized Cotton

Silk A

Polyester Core/Cotton Wrap

50 Mercerized Cotton

Silk A

Polyester Core/Cotton Wrap

50 Mercerized Cotton

Mercerized Heavy-Duty

Silk A

Polyester Core/Cotton Wrap

Heavy-Duty Mercerized Cotton

Polyester Synthetic

Silk A

Buttonhole Twist

RECOMMENDED

STITCH LENGTH

SETTING

12 stitches

per inch

10 to 12 stitches

per inch

8 to 10 stitches

per inch

8 stitches

per inch

6 stitches

per inch

Synthetic Knits and Stretch:

Polyester Double Knits, Nylon

Tricot, Jersey, Stretch Terry,

Spandex, Ciré Tricot

Q BLUE

with

"QFOOT"

Polyester Core/Cotton Wrap

50 Mercerized Cotton

10 for Regular

or

6 for Stretch

Stitches

16

Page 18

CHANGING NEEDLE

Raise needle bar to its highest position by

turning the hand wheel toward you. Loosen

the needle clamp screw. Holding the needle

with the flat side away from you, slip the

needle into the needle bar. When it is in as far

as it will go, tighten the needle clamp screw

with small screwdriver provided in the

accessory box.

PRESSER FEET

This machine is supplied fitted with a zigzag

presser foot for general sewing purposes.

In the accessory box are the following

additional presser feet:

Straight stitch foot

1.

Metal and plastic satin stitch feet

2.

Buttonhole foot

3.

4.

Built-in buttonhole guide foot

Zipper foot

5.

Blind hem foot

6.

Overcasting foot

7.

•■Q FOOT".»

8.

Even feed foot

9.

Narrow hemmer

10.

Edge stitcher

11.

CHANGING PRESSER FEET

Be sure needle is in the up position. Raise

presser foot lever.

Snap-on presser feet

1. Raise foot release lever to remove the

foot. (Fig. 1 )

2. Place the desired foot on the needle plate

aligning needle holes. (Fig. 1)

3. Lower the presser foot lever so that the

foot holder snaps on the foot. (Fig. 2)

One-piece presser feet

1. Loosen presser foot thumb screw and

remove the foot holder.

2. Insert desired foot from the front. Lower

the presser foot lever and tighten the

screw using the large screw driver to

make certain the foot is secure.

Page 19

EVEN FEED FOOT

The even feed foot moves top and bottom

material together evenly and enables you to

sew hard-to-sew fabrics without sliding nor

slipping and with perfect matching. Use it for

sewing leather, ultra suede™, shiny fabrics

(vinyls, patents and satirii?), bonded fabrics,

pile fabrics and matching stripes, plaids and

patterns. It is not recommended for use when

stretch stitching.

To attach the even feed foot;

1. Raise needle to its highest position.

2. Raise presser bar to its highest position

and guide the even feed foot into position

from rear of machine.

3. Attach presser bar clamp to presser bar

and tighten presser foot thumb screw.

4. Attach screw (A) provided with the foot

to needle clamp through fork arm and

tighten it.

Note: Attach the foot in exact order of steps

as written.

IMPORTANT:

To prevent friction and wear, put a drop of oil

at each point indicated by arrows in Fig. 2

and set pressure regulator at 2 or 3 before

using this foot.

Oil after 4 or 5 times usage. Be sure to remove

excess oil by wiping foot thoroughly and sewing

on a scrap of fabric.

ADJUSTABLE HOLDER

Replace the regular presser foot holder with

the adjustable holder when using narrow

hemmer and edge stitcher attachment.

Loosen thumb screw and press it forward.

Insert the opposite end into the large hole of

the attachment. Slide the attachment to the

left as far as possible. Adjust as necessary to

the correct position for stitching. Tighten the

thumb screw securely.

Narrow

hemmer

Thumb'

screw

18

Page 20

EDGESTITCHER

This one attachment helps you join fabric

edges ...insert lace ...do seam piping ...

simplifies blind hemming as well as "French"

seams. Slots numbered 1 to 5 serve as

sewing guides:

Slot 1 will guide fabric to be joined to lace.

All you have to do is place the lace in slot 2

(A)

Slot 4 will guide piping being joined to fabric

edges. Place the fabric in slots 2 or 3.(B)

Slot 5 may be used as a guide when sewing

French seams which are stitched twice, once

on right side and once on other side. This is

the classic seam for sheers. (C)

Use slots 1 and 3 to guide fabric with ease

during blind hemming.(D)

QUILTING GUIDE

This attachment comes in handy whenever

you want several rows of stitches an equal

distance apart-for garment trim as well as

quilts. The curved prong is shifted back and

forth to establish the distance between rows

of stitches.

To attach the guide, raise foot release lever

and insert it into the hole on the presser foot

holder as shown.

Page 21

NEEDLE PLATES

You are provided with two needle plates:

A. Needle plate with wide oval hole for all

zigzag stitches and striaght stitch with

needle at "C" (center) or "R" (right)

position.

B. Needle plate with round hole for straight

stitch with needle at "S" (standard)

position.

CHANGING NEEDLE PLATE

1.

Raise needle to its highest position and

raise presser foot.

2.

Remove bobbin cover plate.

3.

Remove needle plate by placing thumb

under edge of plate and lifting up and out.

(See Fig. 2)

4.

Make sure bobbin case is in the proper

position by turning in the counter

clockwise direction as indicated by red

arrow on the bobbin case stopper until it

stops. (Fig. 3)

Snap desired needle plate into place.

(Fig. 4)

6.

Replace bobbin cover plate.

NOTE:

Fig. 2

5

1 o 1 1

1 1 o t

PP

J

___

L

Fig.3

Don't turn hand wheel while needle plate is

removed, or needle may hit bobbin case and

cause needle damage.

Don't touch screws on the bobbin case

stopper.

If bobbin case is not installed as indicated

above, it will be damaged when the needle

plate is put into position.

FEED COVER PLATE

There are a few times when you want to

control the feeding of the fabric yourself.

Raise needle to its highest position and raise

presser foot. Place feed cover plate over

needle plate aligning two pins of feed cover

plate with holes of needle plate. You may

then determine the movement of the fabric

yourself.

Bobbin case Bobbin case ^'9- 4

stopper

Page 22

CARING FOR THE MACHINEi

Feed

dogs

GLEANING THE FEED DOGS WITH A BRUSH

To insure the best possible operation of your

machine, it is necessary to keep the essential

parts clean at all times.

Remove bobbin cover plate and needle plate.

Using a small brush, remove the lint that

accumulates in and around the feed dogs and

shuttle area.

GLEANING AND OILING SHUTTLE AREA

On rare occasions, you may want to clean the

shuttle area. Just follow these simple steps.

1. Raise needle to its highest position by

turning handwheel toward you. Remove

bobbin case by lifting it out from left side.

2. Clean the shuttle with small brush and put

a drop of oil to the points indicated by

arrows. Don't over-oil. (Reminder: don't

use household oil...use sewing machine

oil.)

21

Fig. 1

Fig. 2

V.

_________

L

Bobbin case Bobbin case stopper

REPLACING BOBBIN CASE

1. Insert bobbin case into shuttle from left

side, aligning red dot on the bobbin case

with red dot on the bobbin case stopper.

(Fig. 1)

2. Turn the bobbin case in the direction of

red arrow on the stopper until it stops.

(Fig. 2)

3. Replace needle plate to its original

position. (Fig. 2)

4. Replace bobbin cover plate.

NOTE: If bobbin case is not properly installed,

it will be damaged when the needle

plate is put into position.

Don't touch screws on the bobbin

case stopper.

Oil and lint brush No. 6890 is available

at most Sears retail stores and

catalog.

Page 23

i

i " aM

W----

t-

1

, -------------------------------------------------

j

................

___________

-------------------------S____________________________________

2

i , "1

! B ra

: ; ! !i

\' i

,

OILING UNDER TOP COVER PLATE

Remove top cover plate by loosening two top

screws (A and B) as shown at left. Then

q

r

place one or two drops of Kenmore sewing

machine oil at each point.

Page 24

OILING IN FACE COVER PLATE

Swing face cover plate open and oil points

indicated by arrows in illustration.

OILING IN END COVER PLATE

A drop of oil should be placed through the

hole indicated in the end cover plate.

CHANGING LIGHT BULB

The sewing light is located inside the face

cover plate as shown. To replace the bulb,

push switch to off, unplug machine and

swing the face cover plate open. Push up on

the bulb slightly and turn bulb to the left.

Withdraw bulb from socket. Push in new

bulb and turn to the right.

Page 25

■CHECKING PERFORMANCE PROBLiEMS'

Your Kenmore sewing machine is a precision

instrument, designed to give you many years

of troublefree sewing - with minimum mainte

Stitches are irregular

1. Needle size is not correct for thread and

fabric. - See page 16.

2. Machine is not threaded correctly. - See

page 10.

3. Top thread tension is too loose. - See

page 12.

4. Fabric is being pulled or pushed against

machine feeding action. - Guide it gently.

5. Presser foot pressure is too light. - See

page 15.

6. Bobbin has not been wound evenly. -

Rewind bobbin.

7. There are nicks or burrs at needleplate

opening. - Replace needleplate or polish off

burrs completely.

Needle breaks

1. Fabric is being pulled or pushed against

machine feeding action. - Guide it gently.

2. Needle size is not correct for thread and

fabric. - See page 16.

3. Needle is not all the way up into needle

clamp. - See page 17.

4. Presser foot holder is not fastened securely.

- See page 17.

Bunching of thread

1. Top and bobbin threads are not drawn back

under presser foot before starting seam.

- Draw both threads back under presser foot

about 4" and hold until a few stitches are

formed.

nance. If you have any performance problem,

check the list below and you'll be able to

solve the problem yourself.

Fabric puckers

1. Top thread tension is too tight. - Decrease

top thread tension.

2.

Presser foot pressure is too light. - See

page 15.,

Two different sizes or types of thread are

used. - Use same size and type of thread on

top and in the bobbin.

4.

Needle is bent or blunt. - Replace needle.

5.

Presser foot holder is not fastened securely.

-See page 17.

6.

Fabric is too sheer or too soft. - Use underlay

of tissue paper.

Page 26

Machine skips stitches

1. Needle size is not correct for thread and

fabric. - See page 16.

2. Fabric is certain knit or synthetic. - Use

"Q NEEDLE"-„and -Q FOOT”,».

3. Needle is bent or blunt. - Replace needle.

4. Needle is not all the way up into needle

clamp. - See page 17.

5. Top thread tension is too tight. - Decrease

top thread tension.

6. Presser foot pressure is too light. - See

page 15.

Needle thread breaks

1. Machine is started too fast. - Start to stitch

at a medium speed.

2. Machine is not threaded correctly. - See

page 10.

3. Top thread tension is too tight. - See

page 12.

4. Needle size is not correct for thread and

fabric. - See page 16.

5. Eye of needle has sharp edges. - Replace

needle.

6. There are nicks or burrs at needleplate

opening. - Replace needleplate or polish off

burrs completely.

Bobbin thread breaks

1. Bobbin case is not threaded correctly. - See

pages.

2. Lint accumulates in bobbin case or shuttle.

- See page 21.

25

Machine does not feed fabric

1. Presser foot pressure is too light. - See

page 15.

2. Thread is knotted under fabric.

3. Feed cover plate is attached on needle plate.

- Remove feed cover plate.

Machine jams

1. Thread is caught in shuttle. Remove bobbin

case and clean shuttle (see page 21).

2. Needle is damaged. - Replace needle.

3. Needle plate is bent. - Replace needle plate.

Machine will not sew

1. Hand wheel is not returned to stitching

position. - Push in clutch.

2. Power cord is not connected. - Check plug.

3. Power/light switch is turned off. - Turn on

the switch.

Page 27

i2. STARTING TO SEWi

Now that you are familiar with the controls

on your machine and with the accessories

provided for the machine, you are ready to

Check the needle-it should be straight,

1.

properly set and sharp on the point.

It should be the correct size for the fabric

and thread being used. Do not be afraid

to change your needle frequently. Many

of the new fabrics made of synthetic

blends tend to dull the needles more

easily than fabrics made of natural fibers.

Before placing the material on the

2.

machine, see that the ends of the threads

have been drawn about 3 - 4 inches to the

rear of the machine. Hold on to threads

during the sewing of the first 3 or 4

stitches of the seam.

stall to sew with your sewing machine.

Below are some good habits to follow each

time you sit down to sew:

5.

Run.the machine at a slow even speed.

The more pressure you put on the foot

control, the faster the machine will sew.

Fasten each seam by back tacking at the

beginning and end of the seam.

Test the machine stitch on a scrap of

3.

fabric you plan to use. The fabric should

be double thickness. Adjust the machine

for the length of stitch and tension

suitable to your fabric.

Fabric should be placed under the presser

4.

foot with the bulk of the material to the

left of the needle and the right edge of the

material placed on the 5/8" seam marking

on the needle plate when making a simple

seam.

7.

Always finish sewing each seam with the

needle at its highest point.

Guide the fabric gently with your hand in

8.

front of the needle. Never pull or hold the

fabric in such a way that the normal

feeding is altered.

When turning the hand wheel manually,

9.

always turn it toward you.

)

26

Page 28

NJ

f RTtTrH

STRAIGHT STITCH

ZIGZAG STITCH

MENDING STITCH

BOX STITCH

BLIND STITCH

ELASTIC BLIND STITCH

STRAIGHT STRETCH STITCH

RICK-RACK STRETCH STITCH

FEATHER STRETCH STITCH

SMOCKING STRETCH STITCH

OVERCAST STRETCH STITCH

PARIS POINT STRETCH STITCH

DECORATIVE DESIGNS

BUILT-IN BUTTONHOLE

(Use Buttonholer 7 .)

DARNING Mi

SATIN STITCH :iM~a

1 iMnir'ATnpl 2- LENGTH

I. 1DIAL

AAAAA

A A A A A

/V/\/\/\/\

f V V V V ^

AAAA

YYYY

/yyyVAYA/VyVN

su «s

mwwm

<<<<<<^

AAAAA

1 1 1 1 1 1 1 1

oVW“

H/VWVWWVVVV\I|

HwWSMA/VWwl

AAAAA

RED ZONE

GREEN ZONE

GREEN ZONE

12

12

YELLOW ZONE

YELLOW ZONE

YELLOW ZONE

YELLOW ZONE

YELLOW ZONE

12

GREEN ZONE

YELLOW ZONE

BUTTONHOLE

ZONE

8-10

BETWEEN 0 AND 241

3. STITCH

MODIF1ER

NEUTRAL

NEUTRAL

NEUTRAL

NEUTRAL

NEUTRAL

NEUTRAL

'NEUTRAL

'NEUTRAL

'NEUTRAL

•NEUTRAL '

♦NEUTRAL

'NEUTRAL

NEUTRAL

'NEUTRAL

'NEUTRAL

NEUTRAL

NEUTRAL

4. WiDTH/NFFDl F

POSITION DIAL

"S"

"C" or "R"

RED ZONE B

3-4

2-4

1^-2

VA-2

"S"

"C" or "R"

YELLOW ZONE

YELLOW ZONE

YELLOW ZONE

YELLOW ZONE

2-3

GREEN ZONE

YELLOW ZONE

BUTTONHOLE

ZONE

"C"

RED ZONE

p; pRtrgdfn

FOdT“ "

A

B

B

B

E

E

A

8 or D

B or D

B or D

B or D

B or D

B or D

B or C

B or C

F

B

C

R KICprSi c'N

PLATE

G

H

H

H

H

H

H

G

H

H

H

H

H

H

H

H

H

H

H

May need to adjust depending upon type of fabric.

Page 29

PRACTICAL STITCH CHART (Model 17920,17921)

ol

w

G. Straight stitch H. Zigzag needle

needle plate plate

A. Straight B. Zigzag C. Satin D. Q foot E. Blind hem F. Buttonhole

foot foot foot foot guide foot

STITCH

STRAIGHT STITCH

ZIGZAG STITCH

MENDING STITCH

BOX STITCH

BLIND STITCH

ELASTICH BLIND STITCH

STRAIGHT STRETCH STITCH NOT APPLICABLE

RICK-RACK STRETCH STITCH

FEATHER STRETCH STITCH

SMOCKING STRETCH STITCH YELLOW ZONE YELLOW ZONE

OVERCAST STRETCH STITCH

PARIS POINT STRETCH STITCH

1. INDICATOR

AAAAA

AAAAA

/\/\/\/\/\

f V V V V \

AAAA

YYYY

<<<<<<<^

AAAAA

lili

2. WIDTH

DlAi

NOT APPLICABLE RED ZONE NEUTRAL

RED ZONE

Mi-2

VA NEUTRAL

YELLOW ZONE YELLOW ZONE

YELLOW ZONE

YELLOW ZONE

2-3

3. LENGTH

DfAL

RED ZONE

GREEN ZONE

GREEN ZONE

YELLOW ZONE

YELLOW ZONE

YELLOW ZONE

4. STITCH

MODIFIER

NEUTRAL

NEUTRAL

NEUTRAL

NEUTRAL

* NEUTRAL

‘NEUTRAL

»NEUTRAL

‘NEUTRAL B or D

‘NEUTRAL

‘NEUTRAL

5. PRESSER

FOOT

B or D

B or D

B or D

B or D

I. Darning

plate

6. NEEDLE

PLATE

N5

00

DECORATIVE DESIGNS

BUILT-IN BUTTONHOLE

(Use Buttonholer (f ■)

DARNIG

oVW

||/WVW\AAM/V\Ai|

Ivwwwwwvwll

AAAAA

YELLOW ZONE

BUTTONHOLE

ZONE

NOT APPLICABLE

RED ZONE

GREEN ZONE

YELLOW ZONE

BUTTgNHOLE

NOT APPLICABLE

BETWEEN 0 AND 1

NEUTRAL

NEUTRAL

»NEUTRAL H

NOT APPLICABLE

NEUTRAL

May need to adjust depending upon type of fabric.

B or C

B or C

NONE

H and I

H

Page 30

yti

lo_J

m

Cornering

Guide

STRAIGHT STITCHING

You may use zigzag, straight stitch foot or Q foot,

but for best control of fabric, best looking straight

stitches and best feeding of fabric use Straight

Stitch Foot and Needle Plate.

ASTENING ASEAIVI

8e sure both threads are drawn back under

the presser foot. Lower needle into fabric

about 1/2 inch from beginning of seam.

Depress the reverse stitch lever and stitch in

rf^verse until needle reaches beginning of

seam. Release control and complete seam.

When you reach the end, depress the reverse

stitch lever and sew back (backtack) over 1/2

irjch of completed seam.

Turning a square corner

1 To turn a square corner 5/8” from the

fabric edge, stop stitching when reaching

the cornering guide and push needle up/

down switch to lower the needle into the

fabric.

2 Raise the presser foot and turn fabric.

New stitching line will align with 5/8"

seam guide on side of needle plate. Lower

the presser foot and begin stitching in

new direction.

REMOVING FABRIC

First turn the handwheel toward you until the

needle is at its highest position, then raise the

presser foot, draw materials to the rear and

ait off excess thread with the thread cutter

lofcated on the presser bar as shown.

29

Page 31

DARNING

SETTINGS

Stitch Length - 8 to 10

Pressure Regulator - 0 (DARN)

Zigzag foot or square automatic buttonhole

foot

Stretch fabric between embroidery hoops

with hole centered. Lower presser bar and

sew at a slow speed moying fabric back and

forth with a steady rhythm to cover darning

area. When it is covered, turn fabric 1/4 a

turn and sew layer of stitching across first

layer.

If fabric is thin or badly damaged in hole area,

you may want to put a separate piece under

the hole for reinforcement.

TEMPORARY SEWING BY

MACHINE

Regular basting by machine is easy —simply

use straight stitching with longest available

length setting. And your machine has a free

basting method for very long stitches that

sometimes can be used for "marking”.

Regular Basting

Free Method

FREE BASTING METHOD

SETTINGS

Basting switch - turn on

Pressure regulator - 0 (DARN) or 1

Use feed cover plate.

Tap the foot control and the machine will

take one stitch and stop automatically with

the needle in the up position. Holding the

fabric in both hands, pull it back to the

required stitch length.

Repeat this process, tapping down on the

foot control and guiding the fabric with your

hands.

30

Page 32

RIPPER APPLICATION - CORDING

Home-sewn zippers can look as nice as those

qn expensive ready-mades. We recommend

you follow directions given on zipper

package. Your Zipper Foot will assist you

with any of these installations. Use these

simple settings:

Your zipper foot is adjustable for use on right

or left side of needle. Adjust foot so needle

Clears side notch on foot. Then proceed

according to zipper manufacturer's

itistructions.

our zipper foot also makes it easy to add

cording" to garments as well as slip covers,

ss pillows, bedspreads, decorative pieces,

tq!

ut fabric on bias and wrap around cord,

C

Pi

n fabric in place so seam edges are even.

VVith zipper foot to left of needle, stitch close

to cord.

Page 33

NARROW HEMMING

Attach the Narrow Hemmer to the adjustable

holder. Make sure that ©dge of the fabric is

cut straight. Turn a tiny double hem (Vs inch)

along edge for about twb inches. Place end

of this hem under Narrow Hemmer. Hold

thread taut while stitchiiig along inside edge

of hem. Feed fabric gradually into "scroll" in

hemmer, guiding edge of fabric as shown.

QUILTING

Attach the quilting guide to presser foot as

shown. After completin

stitching, place the guiding prong on this

stitched line. The secón

placed at the desired dist

Continue working in this way for as many

rows as you want.

g the first row of

d row then can be

ance from first row.

32

Page 34

ZIGZAG STITCHING

OVERCASTING

Stitch Selector - AAAAA

Stitch Length - 12-8

Stitch Width - 3-4

Use Overcast Foot.

This is one of the more frequently used

zigzag stitches on garment construction.

You may want to overcast along the raw

edge of each seam allowance or fold the raw

edge toward the garment and stitch.

Stitch so the needle pierces the fabric jusi

short of the outside edge Raw or worn edges

of older garments can be overcast to prevent

further raveling.

SATIN STITCHING

Stitch Selector - AAAAA

Stitch Length Dial - Between 0 and 24 (*•)

Use metal or plastic Satin stitch foot which is

grooved to permit dense stitching to pass

under it easily.

Closely spaced zigzag stitches are called satin

stitches. This is an attractive stitch used for

appliqueing, bar tacking.

Whenever you are using this stitch, it is well

to remember to loosen the tension of the top

thread slightly. The wider the stitch you

make, the looser the tension should be.

If you are stitching on a very soft fabric, use a

backing of tissue paper or interfacing for a

well formed stitch. Puckering of the material

will be eliminated and the bobbin thread will

not be visible on the right side of the fabric.

As with all special stitches, it is best to make

a sample design on your fabric before starting

the design on the garment.

33

BAR TACKING

Settings same as Satin Stitching

This stitch is similar to a very short satin

stitch and is used to reinforce points of strain

such as corners of pockets and straps on

lingerie.

Sew 4 to 6 zigzag stitches.

Page 35

APPLIQUEING

Settings same as Satin Stitching

Select an applique design to be applied to

your garment and bast^ it in place. Satin

stitch around the raw edge of the applique

completely covering the ^dge. You may want

to do this with a contrasting color of thread.

EMBROIDERY

Settings same as Satin Stitching

Satin stitch can be used to produce many

different designs and patterns. To sew the

flowers illustrated, back the fabric with

interfacing or paper and draw on the design

with tailor's chalk. Turn the stitch width

control from 0-4-0 to from each petal and

leaf. Join the flowers and leaves with straight

stretch stitch. If usir^g paper, carefully

remove it when you haYe finished sewing.

MONOGRAMMING

Settings same as Satin Stitching

To sew initials, first back the fabric with

interfacing or paper. Drjaw the initials on to

the fabric with tailor's chalk. Satin stitch,

adjusting the width frotfn 0-4 as you begin

and end the stroke of a letter. Or the same

stitch width can be used throughout. If using

paper, carefully remove it when you have

finished sewing.

Page 36

BUTTON SEWING

3iitch Selector - AAAAA

flitch Width - Adjust to Button Size

Use Feed Cover Plate and Clear Plastic

Satin Stitch Foot.

1i Position the button on fabric with clear

tape.

2, Center the left hole of button between

straight seamline and the left edge of

needle slot of foot and lower foot to hold

the button securely.

LEFT HOLE

OF

BUTTON

= +î

PRESSER

FOOT

STRAIGHT

SEAMLINE

BUTTON

3| Turn hand wheel manually until needle

point is just above button.

4j Adjust stitch width control so needle will

enter right hole of the button.

5. Turn hand wheel again by hand so needle

I

enters second hole. Readjust stitch width

if necessary. Stitch a number of times.

6^ Finish sewing with an extra two inches of

thread remaining. Draw these threads to

reverse side of garment and tie.

When sewing a flat button, place needle or

pin between holes of button as shown to

Orovide flexibility for buttoning.

35

Page 37

BLIND HEMMING

YYW —Regular blind

normal fabrics

— Elastic blinpl stitch for soft,

stretchabib fabrics

Blind hemming is a good technique to use on

garments, and especially on curtains and

drapery hems so that stifches need not show

on the front of the fabric. Because your

Kenmore has two types of blindstitches built

in, blind hemming is easier than you'd

expect. It's just a matter of folding... give it

a try!

stitch for

PROCEDURE

Stitch Length - 12

Stitch Width- VA -2

1. Finish raw edge of fabric appropriately.

You may want to use seam tape on

woven fabrics. With knits use a lace seam

tape or just use decorative stretch stitch.

2. Working on wrong side of fabric, fold

hem up. Press and pih in place. Then fold

hem allowance undOr... leaving 1/8" of

hem edge extending.

3. Place garment und$r blind stitch foot

with the fold of the garment against guide

and slide it by turnirig screw so that the

zigzag just catches the fold. (Blind

hemming can be sirpplified by also using

the special Kenmore Edgestitcher-please

refer to 19 for details.)

4. Now the right side Of your garment will

show only the blind stitches! Be sure to

press both sides of the finished hem!

Page 38

Stretch stitches

$tretch stitches, as their names imply, are

rainly for use on stretch and knit fabrics

rri

lich as stretch nylon, stretch towelling,

sey and cotton jersey; and for sewing

t|

together knitted garments. Stretch stitches

e also often used on non-stretch fabrics.

aifi

ADJUSTING STRETCH STITCH BALANCE

$titch modifier should be in neutral (notched)

position for most materials. Depending upon

tfie type of fabric used, you may need to

aiJjust this control to match forward stitches

pf stretch sewing with reverse motion

stitches. If the stitches are too open, turn the

control slightly clockwise; if the stitches

oyerlap, turn the control counter-clockwise.

Straight stretch stitch

recommendation

1. It is recommended you use the Q set for

sewing knit and woven synthetic fabrics.

2. It may be necessary to use an interfacing

or backing when jewing very soft and

thin knits or woven synthetic fabrics.

Settings

Stitch Selector - =====

Stitch Length - Yellow Zone

Stitch Width - Any number (not necessary

to adjust)

bu may use either a zig zag or straight stitch

fbot BUT-- for best control of fabric, best

looking straight stitches and best feeding of

fabric use Straight Stitch Foot and Straight

Stitch Needle Plate.

Ijlse this stretch stitch with knit or synthetic

fabric. Sew as you do with regular straight

stitch.

This is also a good stitch to use on curved

seams regardless of the type of fabric. Any

seam that will receive a great deal of strain

when worn should be sewn with the stretch

Stitch. Use in children's shorts and slacks as

Wpll as adult sports clothes.

37

Page 39

RICK-RACK STRETCH STITCH

Stitch Selector Stitch Length - Yellow Zone

Stitch Width - Yellow ZOne

Sew on stretch fabrics in any area that you

might use a zig zag stitch. This stitch can be

used as a decorative top stitch as well.

It is useful also on lapped or abutted seams

where you lap one edgó of a seam over

another with seamlines meeting in the center.

FEATHER STRETCH STITCH

Stitch Selector

Stitch Length Stitch Width -

This is a good stitch to pse with laces, on

lingerie, bra and girdles; and to apply bias

tape. It's great when quill|ing.

<<<<<^

Yellow |:one

2-4

SMOCKING STRETCH STITCH

Stitch Selector

Stitch Length Stitch Width -

1. Make a straight line of gathers across the

fabric that you wish to smock.

2. With a narrow strip of fabric directly

under the line of gathering, stitch over the

gathers. The design will be a series of

small diamonds.

Yellow Zone

2-4

Note: When smocking a garment, the stitch

ing should be done before the piece is

sewn into the garment.

Page 40

ELASTIC STRETCH STITCH

titch Selector - /VVVXA

titch Length - Yellow Zone

Stitch Width - 2-4

se this versatile stitch to insert elastic in

iSrrnents. Simply stitch elastic into place,

$

irlh-

laking sure it is evenly spaced. To do this,

1^1

lark the correct length piece into quarters,

th

len match these markings with center front

hd side seams.

Cf)VERCAST STRETCH STITCH

Stitch Selector - AAAAA

Stitch Length - Yellow Zone

Stitch Width- 4

This is the same type stitch used by the

arment industry in making sportswear-it

rms and finishes the seam in one operation

I

Dr seams of to ^"). It's very effective

(f

r use in repairing raw or worn edges of

fb

^l^er garments.

39

^RIS POINT STRETCH STITCH

titch Selector - 11111111

itch Length - 12

itch Width - 2-3

EiJcellent for hemstitching table and bed

covers with a elegant touch. Picot-like stitch

C0

n also be made on sheer materials. Sew

ai

png the raw edge of fabric and trim close to

th

outside of the stitching.

Page 41

BUTTONHOLE MAKING - BUILT-IN SYSTEM

PREPARATION

Carefully mark the buttonhole length on your

garment. Place the fabric vjvith the buttonhole

marked under the buttonhole foot. Pull the

guide foot (A) all the way forward so that the

index mark (B) is aligned vyith the graduation

(C), with thread to rear. (F^eproduction of the

identical size buttonholes is facilitated with

the aid of the graduation^ on the both sjdes

of the buttonhole guide fQot. These garduationsare 1/8” (left side) or 2.5mm (right side)

apart. Graduations act as reference mark.)

PROCEDURE

1. Switch the control to left. (If it has been

already at left, set it ai right, sew several

stitches and switch to left again.) Step on

foot control to form fitst bartack and left

side of buttonhole.

2. When you reach end pf left side, switch

the control to the right and complete the

buttonhole.

ADJUSTING STITCH BALANCE

Stitch length difference^ in forward and

reverse stitches of thp buttonhole are

equalized with the stitch modifier.

If the reverse stitches are too far apart, turn

the,modifier slightly clockyvise; if they are too

close together, turn counter-clockwise.

CORDED BUTTONHOLES

Hook filler cord (crotchet thread or button

hole twist) to the spur (A), pull both ends of

cord forward under foot and tie to the spur

(B). Sew buttonhole in such a way that

zigzag stitches cover the cord.

When stitching is competed, release cord

from foot, pull ends of corjd and snip off extra

length.

A «

II

40

Page 42

BUTTONHOLE MAKING - USING BUfTONHOLE ATTACHMENT

||/WWWWWVVA| f

Ikvwvwwwwl :=r—?/

--------

AAAAA

W

<<<<<<<<<.

ZVVWN

AAAAA

/\/\/\/\/\

' V V V V \

AAAA

Y~V~VY

/vywvywv^

— —

(

Zigzag needle plate

V^and feed cover plate J

~T^

--------------

)

«

J

Buttonhole foot

Any setting

FiEGULAR WORKED BUTTONHOLE

(STRAIGHT, KEYHOLE AND EYE-

j.ET)

Template advance

knob

41

Guide plate

PROCEDURE

titch Selector - AAAAA

titch Width - 1-114

igzag Needle Plate

eed Cover Plate

uttonhole Foot

Raise needle to its highest position and

raise presser foot. Remove accessory box

and bobbin cover plate.

Insert buttonhole cover plate at 45 degree

angle and snap it down into place

pressing it against the needle plate.

Select correct template for type button

hole you want. Insert template into slot of

guide plate. Turn template advance knob

until desired size appears in window on

the top side of guide plate.

Page 43

Slip guide plate onto machine so it fits in

3.

place with pinion gear in the center of arc

hole of template. Be sure guide block is

inserted in guide slot.

Pick up bobbin thread through guide plate

4.

by turning hand Wheel. Place fabric

between presser fojat and guideplate.

Align marked buttonhole with cut-out of

foot. Line up edge of fabric with markings

on guideplate. If you wish ail buttonholes

to be 3/4" from ed^e of garment, for

example, line up fabrib with 3/4" marking

each time you start el buttonhole.

Now you're ready fo stitch the shape

you've selected-straight, keyhole or

eyelet. Your template will guide you.

Page 44

PURL-EDGE BUTTONHOLE

to add a professional touch to your sewing

ou will want to make purledged button-

oles. These are obtained by sewing a wide

uttonhole over a narrow stitched buttonole.

hoose the correct size for your button,

risert the template into the guide plate

lurning to the narrower of the sizes. Use the

iiame settings as for regular buttonhole and

just stitch width control to 1.

Drop the guide plate over the pinion gear and

sew around the buttonhole once. (STEP 1)

0 sew wider outer buttonhole, lift the guide

ate from the pinion gear and turn the

Wmplate to wider size. Adjust stitch width

etting to 1.5. and sew around buttonhole

ijjain. (STEP 2)

ADJUSTING STITCH DENSITY

Depending upon the fabrics on which you are

|i!Wing, or your own preference in button-

oles, you may alter buttonhole stitch density

I

turning stitch density control knob.

It

For more density, turn the knob toward

you.

For less density, turn the knob away from

you.

43

Page 45

BOUND BUTTONHOLE

A template has been provided so that you

may sew perfectly sized rfectangles each time

you make a bound buttbnhole. Just follow

the directions given below.

SETTING

Stitch Width - 0 or Stitch Selector

Pressure Regulator - 1 or 2

Other settings same as regular worked

buttonhole

1. Space buttonholes on garment-mark

length on right side of fabric with pins.

Place patch of fabric over each button

hole and mark ends of buttonhole with

chalk or pencil. Bastp patch into place.

Using template similar in size to button

hole, stitch rectangle on patch and

garment. Do not sew over pins. (Fig. 1)

2. Slash through patch and garment to

within 1 /4" of ends of rectangle. Carefully

cut diagonally into corners as shown.

(Fig. 2)

---------------------

oia| fc)i3| (cO iof5|

. I 2>wmJ I I

®(5

Fig. 1

3. Turn patch to wrong side through slash.

Press as shown. (Fig. 3, 4)

Fig. 2

Fig. 3

Fig. 4

44

Page 46

Fold patch forming lips of buttonhole.

Press and baste lips together. (Fig. 5)

V.i

FACING SIDE

I i

I R

¥ f i

Fig, 5

fl. Stitch across pleats formed by lips of

patch. (Fig. 6)

Fig. 6

After buttonhole has been pressed, baste

facing of garment around buttonhole and

slash opening in facing same length as

buttonhole. (Mark ends of buttonhole

with pins for guides). Turn under facing

edges and hem to buttonhole carefully.

a

(Fig. 7, 8)

Slash Opening in Facing

FACING SIDE

Hem to Buttonhole

RIGHTSIDE

Complete Bound Buttonhole Fig. 9

45

Fig. 7

•-T

Fig. 8

t. Remove all bastings and press. (Fig. 9)

Page 47

DECORATIVE EMBROIDERY DESIGNS

You may get the look and feel of hand

embroidery infinitely faster and easier by your

machine.

Just choose which of the designs you want

to sew alone or in combination with each

other.

TIPS ON DESIGN STITCHING

1. Always make a practice design on a scrap

of the fabric you plan to use.

Z- Start with a full bobbin and plenty of

thread on the spool to avoid running out

of thread in the middle of your design.

3. Reduce the top thread tension slightly.

4. On a very soft fabric you may want to use

a tissue paper backing or organdy that

can be cut away.

5. Decorative designs are very attractive

sewn with a double needle and two colors

or shades of a color of thread.

nvwvTWrW

Domino

Diamond

Crescent

Arabesque

Ù Ù Ù Tree

Tulip

Swan

ADJUSTING STITCH BALANCE OF YELLOW PATTERNS

When sewing yellow patterns, you may need

to make slight adjustment to the stitch

modifier to produce perfect designs.

If the stitches are too far apart, turn the

control slightly clockwise; if they are closer

together, turn counter-clockwise.

----

--------- ■ ■ ■ ..................................................

46

Page 48

SEWING MACHINE

Now that you have purchased your ¡Sewing Machine, should a

need ever exist for repair parts or fMîrvice, simply contact any

Sears Service Center and most Sjîars, Roebuck and Co. or

Simpsons-Sears Limited Stores. Be sure to provide all pertinent

facts when you call or visit.

The model number of your Sewing

your nomenclature plate on the fro

Sewing Machine. See Section 1, Pi

WHEN ORDERING REPAIR PARr$, ALWAYS GIVE THE

FOLLOWING INFORMATION:

*MODEL NUMBER *NAME OF IT|iyi *PART DESCRIPTION

If the parts you need are not stocke|l locally, your order will be

electronically transmitted to a Seals Repair Parts Distribution

Center for handling.

(Machine will be shown on

ht side of bedplate of your

ge 2 for location.

SEARS, ROEBUCK AND CO., Îfhicago, IL60684 U S A.

S-158

Printed in Japan

Part No. 69562 9/91

Loading...

Loading...