Page 1

Kenmore

SEWING MACHINE MODEL 17921

OWNER’S

MANUAL

Page 2

Sears, Roebuck and Co.

Dear Homemaker;

You have just invested in a very fine zigzag sewing machine.

Before using your new Kenmore machine, please pause for a

moment and carefully read this booklet which contains instructions

on how to operate and care for your machine.

Specific instructions are given on threading, tension adjustments,

cleaning, oiling, etc. This will help you obtain the best sev/ing

results and avoid unnecessary service expense for conditions

beyond our control.

Advice on the operation and care of your machine is always

available at your nearest Sears Retail Store. Please remember, if

you have questions about your machine, always mention the model

number and serial number when you inquire.

Kenmore Sewing Machine

Record in space provided below the model number

and serial number of this appliance.

The model number and serial number are located

on the nomenclature plate, as identified on Page 3

of this booklet.

Model No.

Retain these numbers for future reference.

Serial No.

Page 3

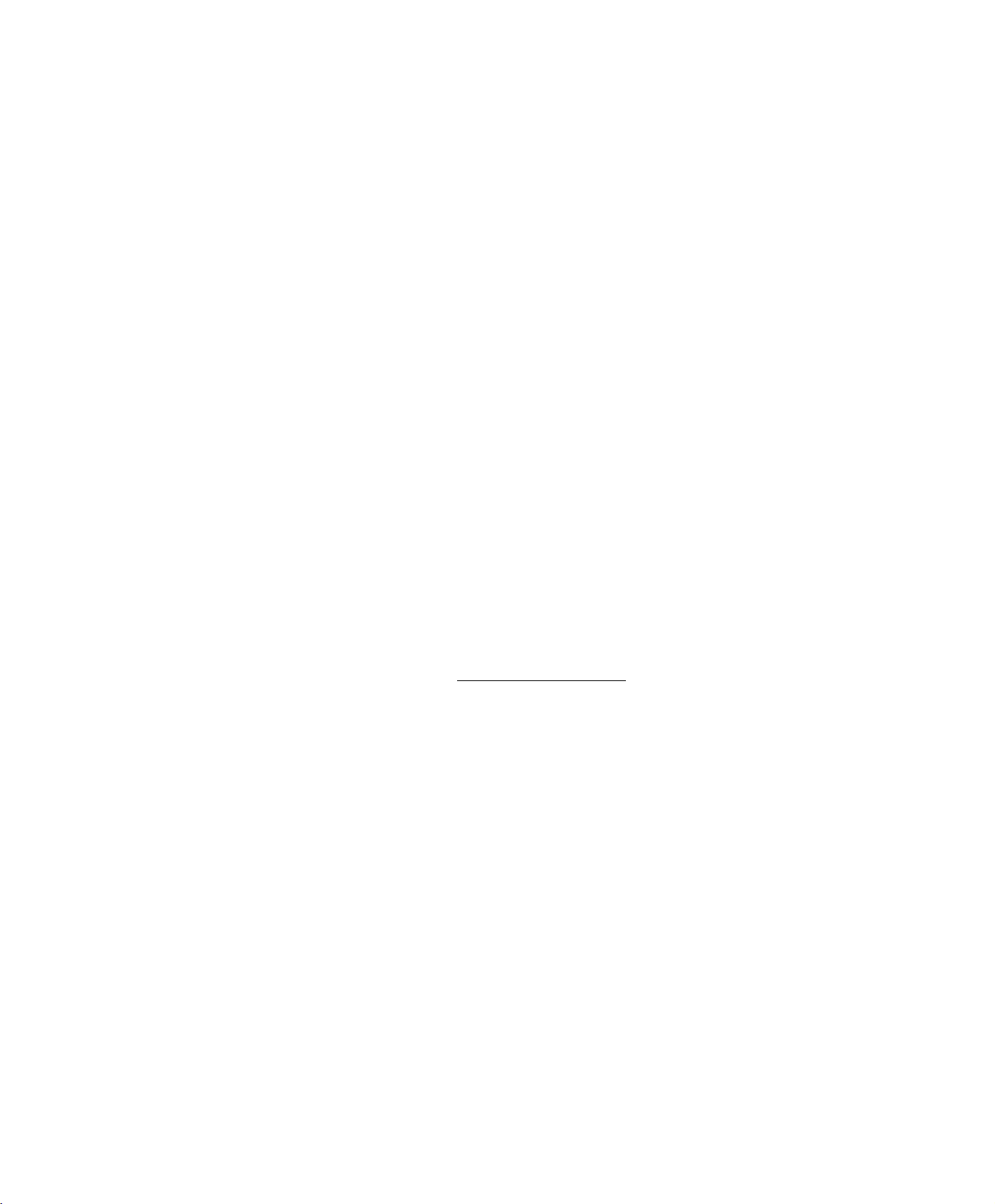

YOUR SEWING PLACE IS ALWAYS READY WITH SEARS KENMORE SEWING FURNITURE

Sewing machine cabinet is available at your

nearest Sears retail store or through our

general catalog. Whenever you're ready to

sew, so is your sewing plage. Another

option... buy a Carrying Case... then your

Kenmore goes anywhere, can be stored

anywhere.

Page 4

TABLE OF CONTENTS

1. KNOWING YOUR SEWING MACHINE

Machine identification

Setting up your machine......................................................4-5

Foot control, Light/power switch, Electronic needle

control. Maximum speed control. Accessory box

Parts list.................................................................................6-7

Spool pins and caps............................................................... 8

Converting to free-arm sewing.............................................. 8

Winding the bobbin................................................................. 9

Threading the bobbin case

Picking up bobbin thread......................................................12

Threading top thread.............................................................11

Picking up bobbin thread......................................................12

CONTROLS

Thread tension control..........................................................13

Stitch selector and indicator. Stitch width control.............14

Stitch length control. Reverse stitch lever. Stitch modifier... 15

Buttonhole control. Pressure regulator

Seam guides, Presser foot lever

ACCESSORIES

Needles, Placement of needle

Needle, thread and fabric chart, Presser feet

Even feed foot. Adjustable holder........................................20

Edgestitcher, Quilting guide

Needle plates. Feed cover plate

CARING FOR THE MACHINE

Cleaning feed dogs and shuttle

Oiling................................................................................ 24-25

Changing light bulb

CHECKING PERFORMANCE PROBLEMS

2. STARTING TO SEW................................................................28

Machine setting chart............................................................29

Straight stitching

Fastening a seam. Turning a square corner. Removing

fabric. Top-stitching, darning. Temporary sewing by

machine. Zipper application-cording. Narrow hemming.

Quilting

Zigzag stitching.................................,...............................35-38

Overcasting, Satin stitching. Bar tacking, Appliqueing,

Embroidery, Monogramming, Button sewing

Mending and overcast stitching...........................................39

Box stitch................................................................................40

Blind hemming

Scallop stitch

Stretch stitches.................................................................44-47

Adjusting stitch length. Adjusting stitch balance.

Straight stretch stitch. Rick-rack stretch. Feather stretch.

Smocking stretch. Elastic stretch. Overcast stretch,

Paris point stretch

Getting the most from fabrics that give

Hints on sewing different fabrics

Buttonhole making

Decorative Embroidery designs

WARRANTY

..................................

.........................................................................43

...................................................

..........................................................

...................................................

..............................

..........................................

..............................................

.....................

................................................

...........................................

...........................................

...............................................................

.....................

..............................................................

................................41 -42

.........................

.........................................

.........................................................

........

.............................

Inside back cover

2-3

10

16

17

18

19

21

22

23

25

26 -27

29-34

48-49

49

50 - 58

59-60

1

Page 5

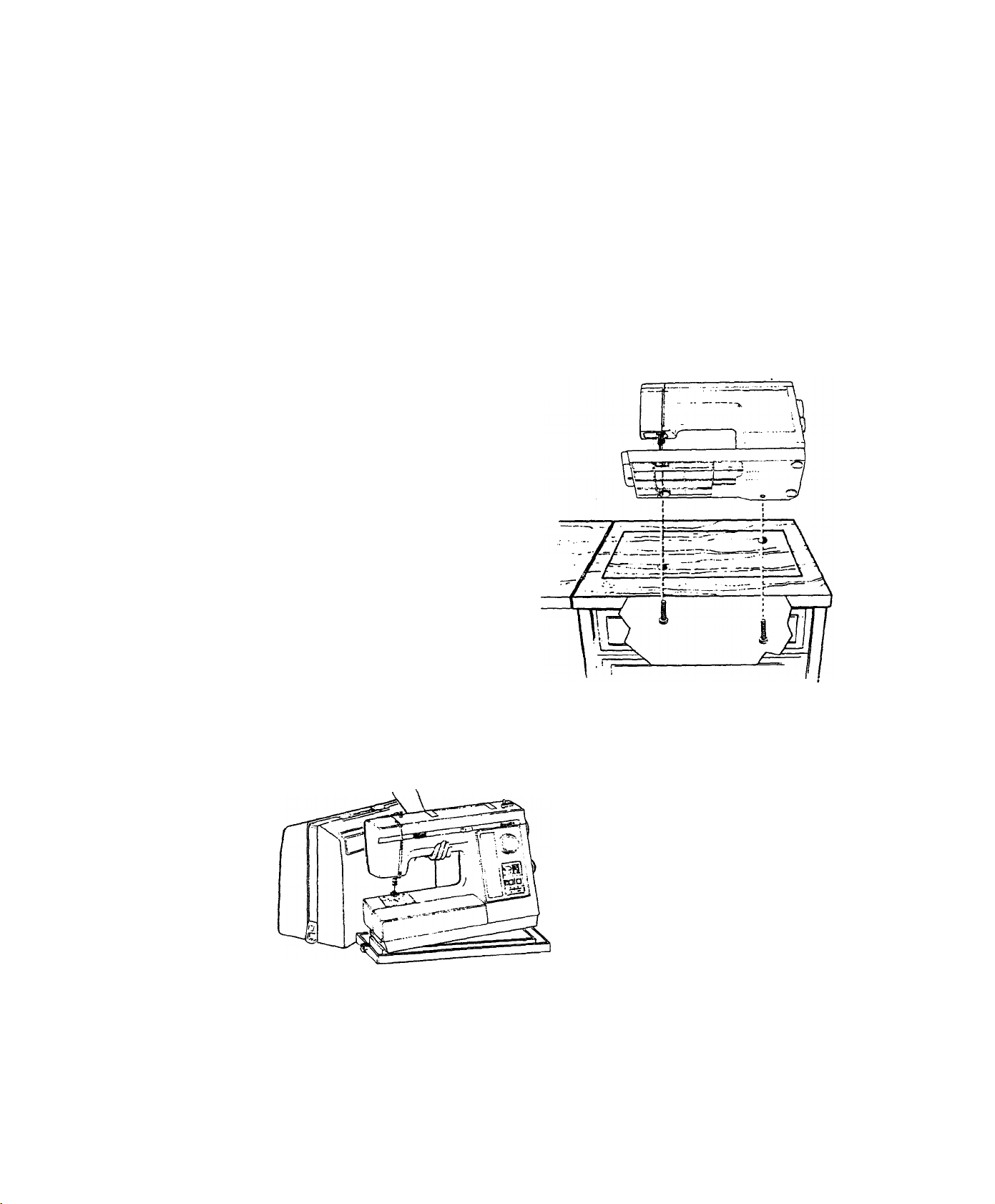

1. KNOWING YOUR SEWING MACHINE

IDENTIFICATION CHART

Top thread tension control

Bobbin winder tension disc

Slotted take-up lever

Threading channel

Face cover

Check spring

Thread guide

Needle clamp screw

Presser foot

Needle plate

Feed dogs

Foldaway carrying handle

Built-in buttonhole control

-Bobbin winder shaft

Bobbin winder latch

Stitch width dial

Stitch indicator

• Stitch selector

Reverse stitch lever

Stitch length dial

Needle up/down switch

Basting switch

Bobbin cover plate

Bobbin window

Accessory box

Maximum speed control

Page 6

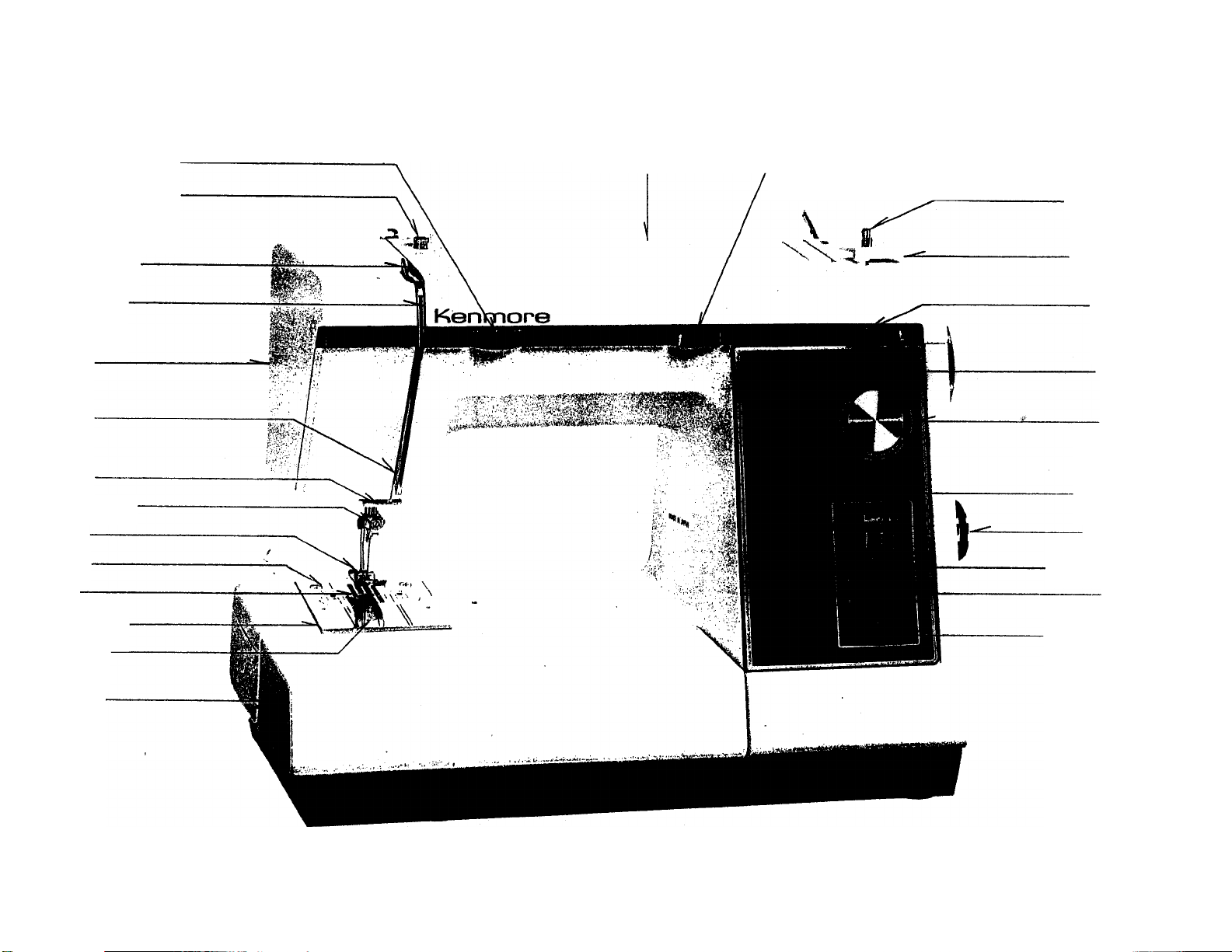

Telescoping spool pin

Rear thread guide

Swing-away spool pin

Hand wheel/,

push-pull clutch

Stitch modifier.

Nomenclature plate

Light/power switch

Electric cord receptacle

Presser foot lever

Presser foot lock

Thread cutter

Foot control

Page 7

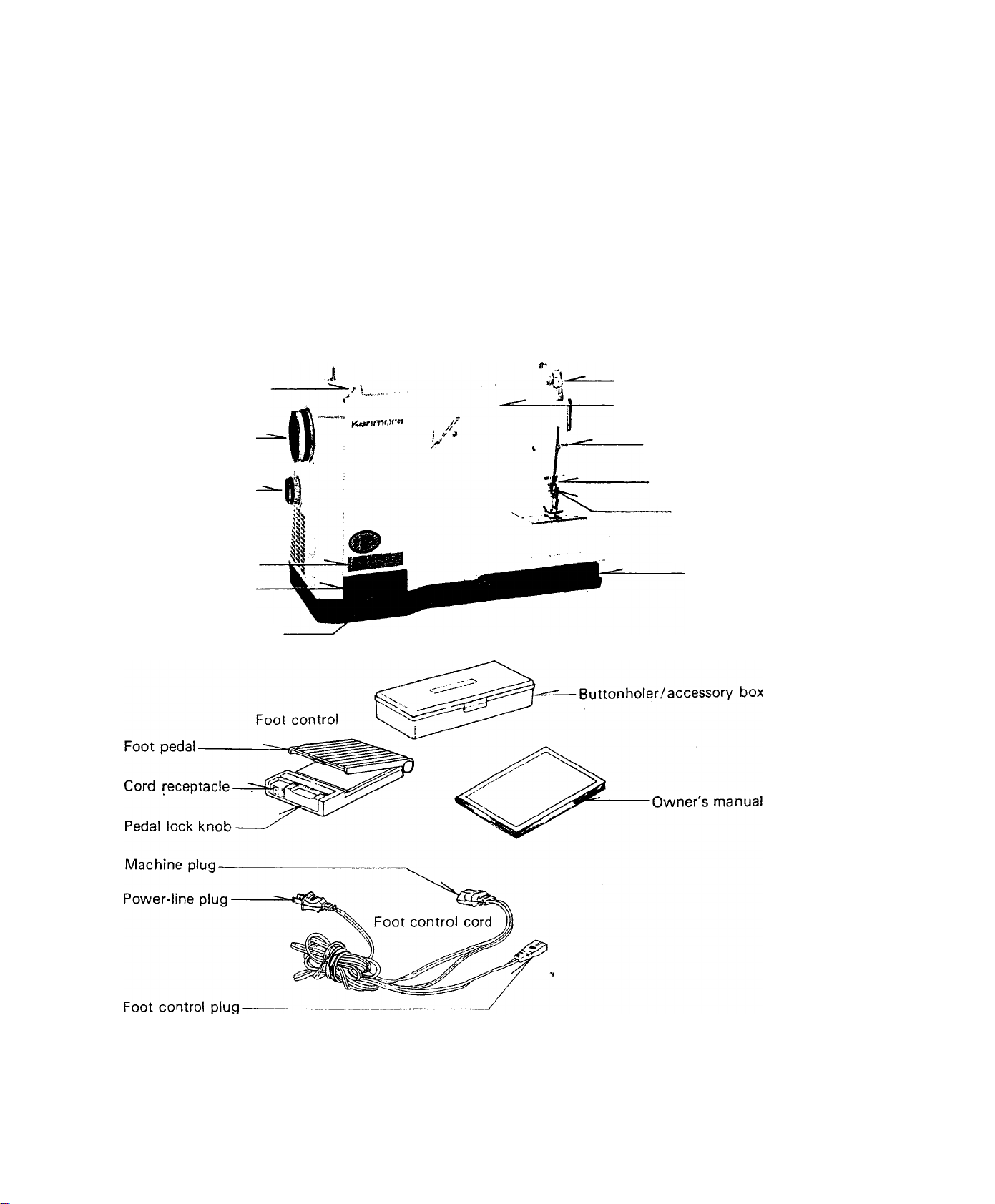

SETTING UP YOUR MACHINE

1. Install your Kenrnore sewing machine in a

Kenmore cabinet, case or set the machine

on. a sturdy flat surface.

2. Your Kenmore sewing machine has been

thoroughly oiled at the factory. Be sure to

wipe off the needle plate area and bed

plate carefully before sewing a garment.

It is wise to practice on a scrap of fabric

so any surplus oil is absorbed.

3. FOOT CONTROL

Your machine is supplied with an

electronic foot control which enables you

to sew very slowly. Even at low speed you

have extra power for the needle to

penetrate through several thicknesses of

fabric. Faster speeds are also easily

controlled.

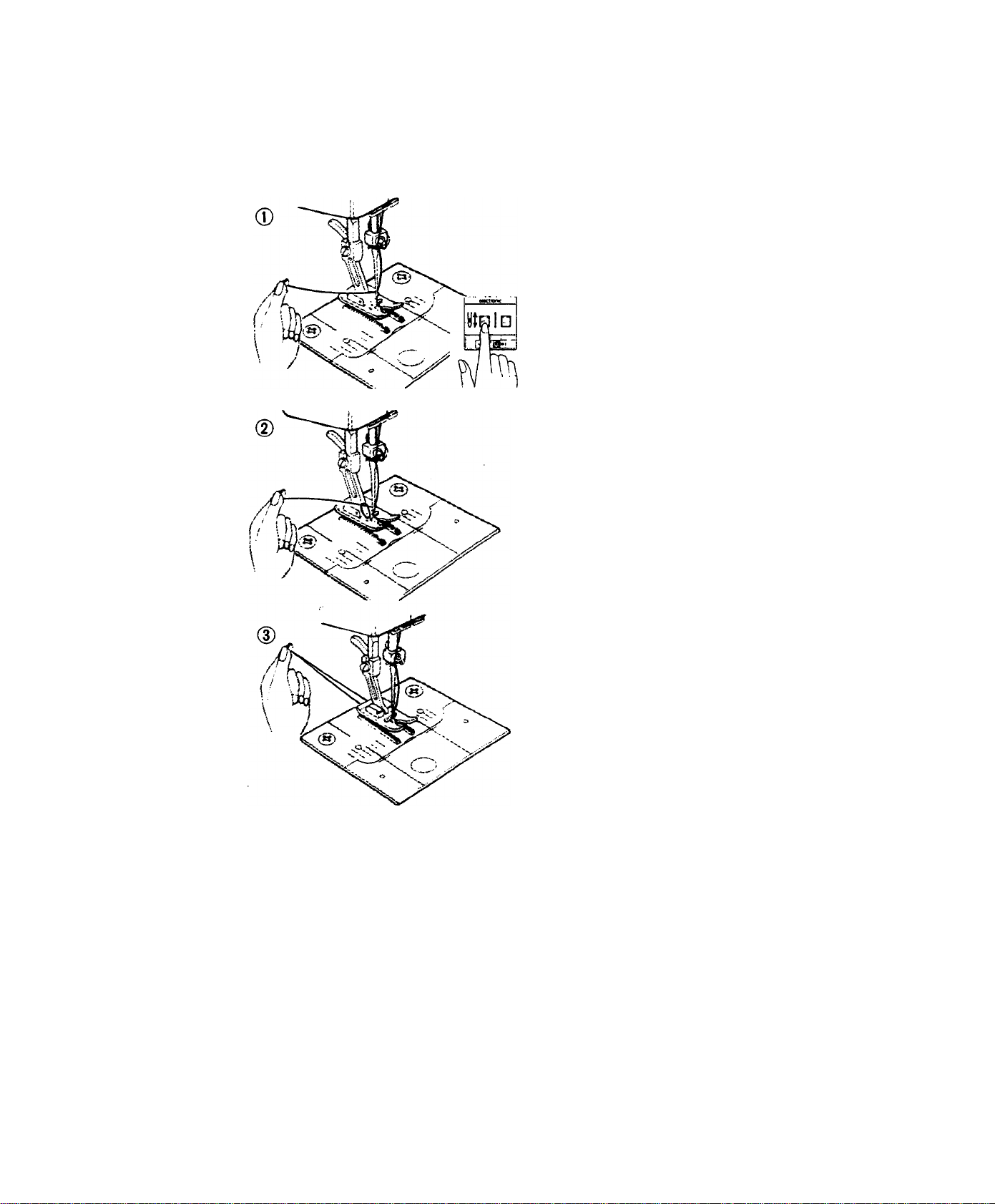

1. Pull out the foot control from its

storage position under the free arm.

(Fig. 1)

2. Slide pedal lock knob to the right and

the foot pedal will pop up to its

operating position. Push foot control

plug into the cord receptacle on the

foot control. (Fig. 2)

3. Push machine plug into the cord

receptacle at the rear side of the

machine. Then connect power-line

plug into any 110-120 volt A.C. wall

outlet. (Fig. 2)

4. LIGHT/POWER SWITCH

Your machine will not operate unless the

light/power switch is turned on. This

same switch controls the machine power,

sewing light and indicator lights on the

stitch indicator panel and electronic

needle control. If you are interrupted or

stop sewing, turn off the switch.

Page 8

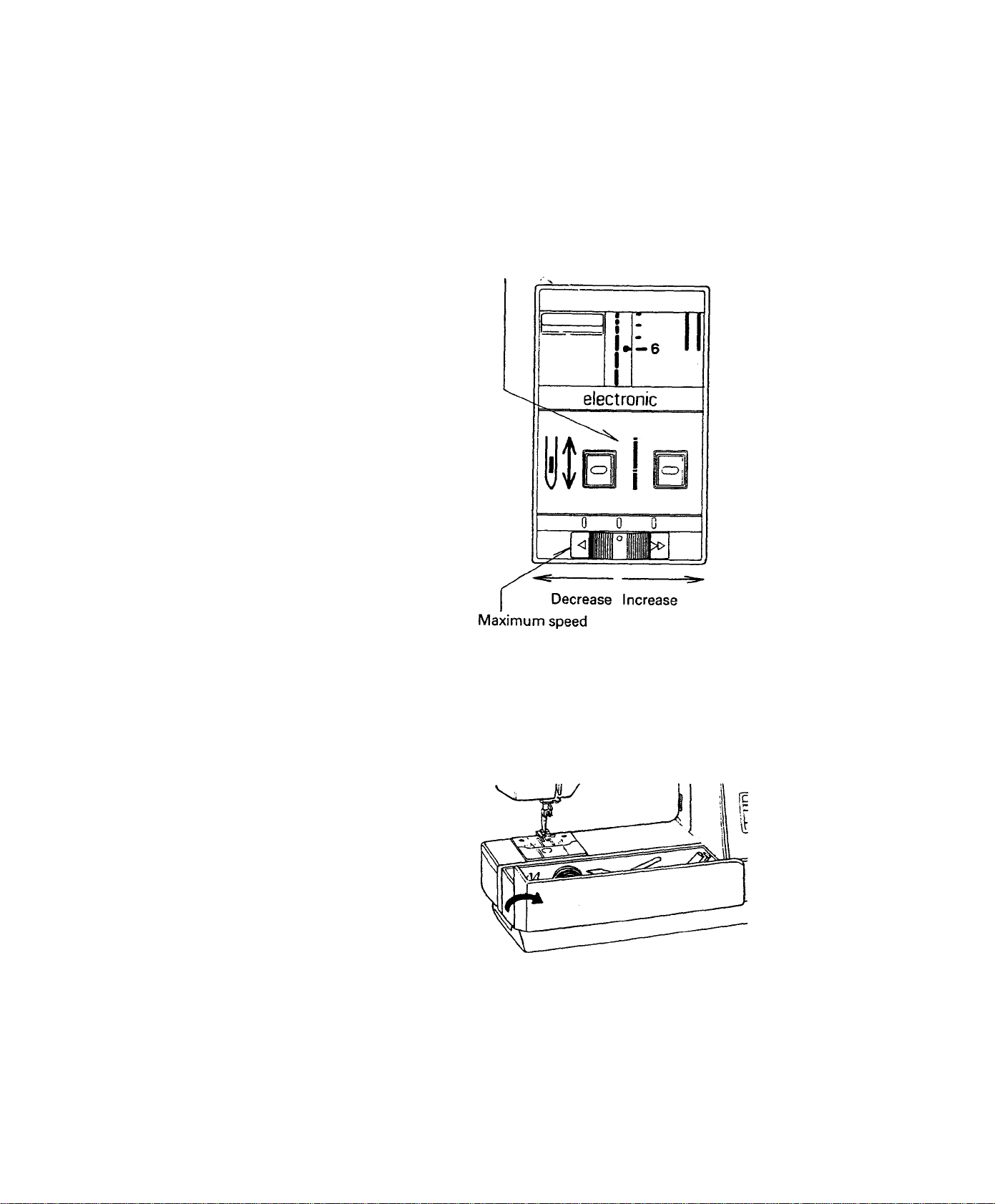

5. ELECTRONIC NEEDLE CONTROL

Your machine is electronically controlled

to stop with the needle in the up position

every time you remove pressure from foot

control.

NEEDLE UP/DOWN SWITCH

If you wish the machine to stop with the

needle in the down position (as in turning

a corner), push the left switch. A red light

will appear showing you that the machine

is so set. To return to the Needle Up

position push the left switch again and

when the light disappears, machine is

again set to stop with the needle in an up

position each time.

BASTING SWITCH

Tap the foot control with the right switch

pushed and lighted and the machine will

take one stitch only and stop with needle

in the up position. This feature provides

an electronically controlled basting or

tacking to take the chore out of hand

basting.

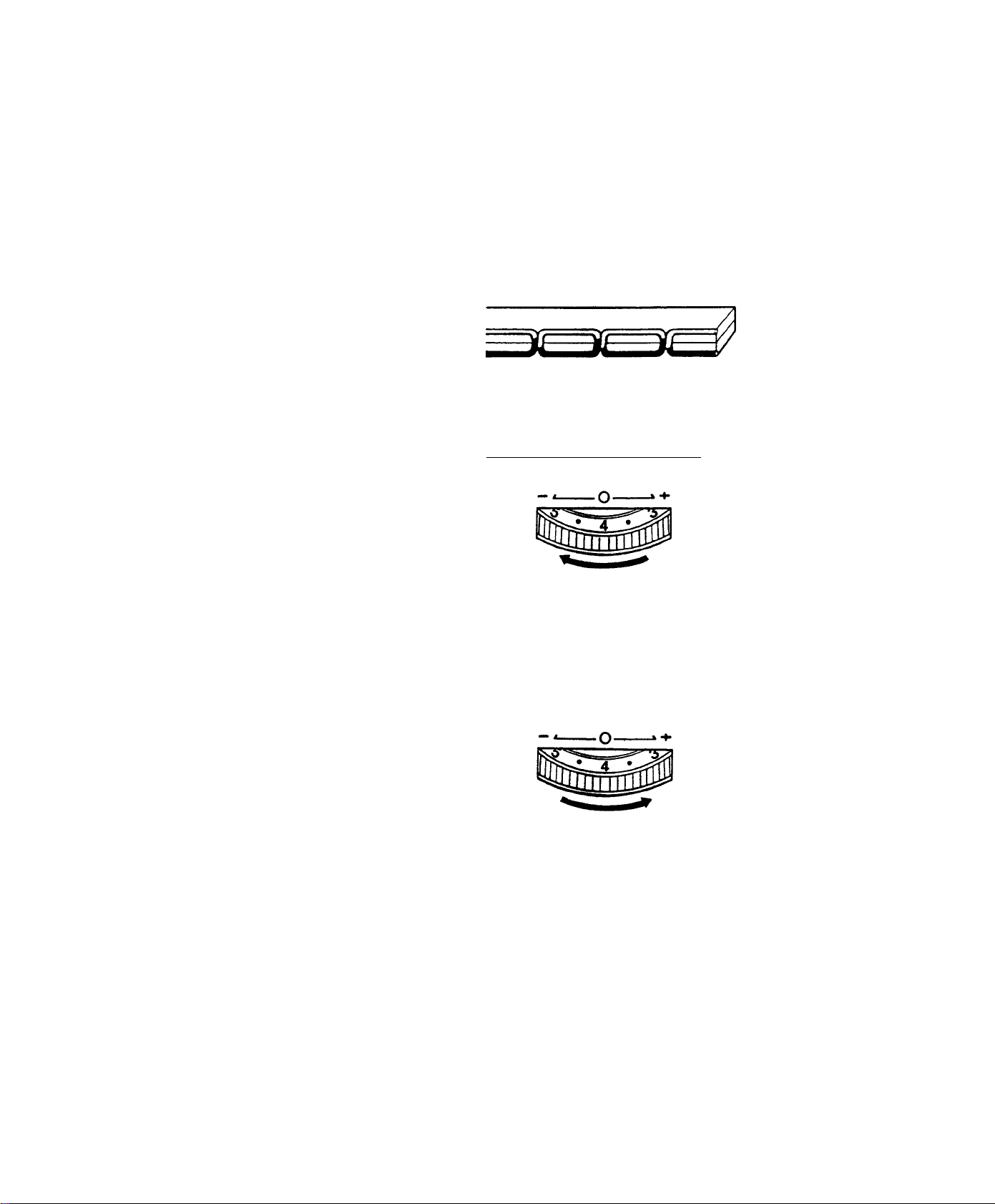

6. MAXIMUM SPEED CONTROL

You may want to vary the speed of the

machine, sewing slowly in special tight

places or if you are a new seamstress.

This control can be moved to the left to

slow the sewing of the machine. To

increase to the maximum speed, slide the

control to the right.

Electronic needle

control

control

7. ACCESSORY BOX

Accessory box is opened by lifting the lid

up and swinging it toward you as shown.

Inside you will find many of the acces

sories that you use each time you sew.

The box may be fully removed from the

machine to convert it for free arm

stitching. See page 8.

Page 9

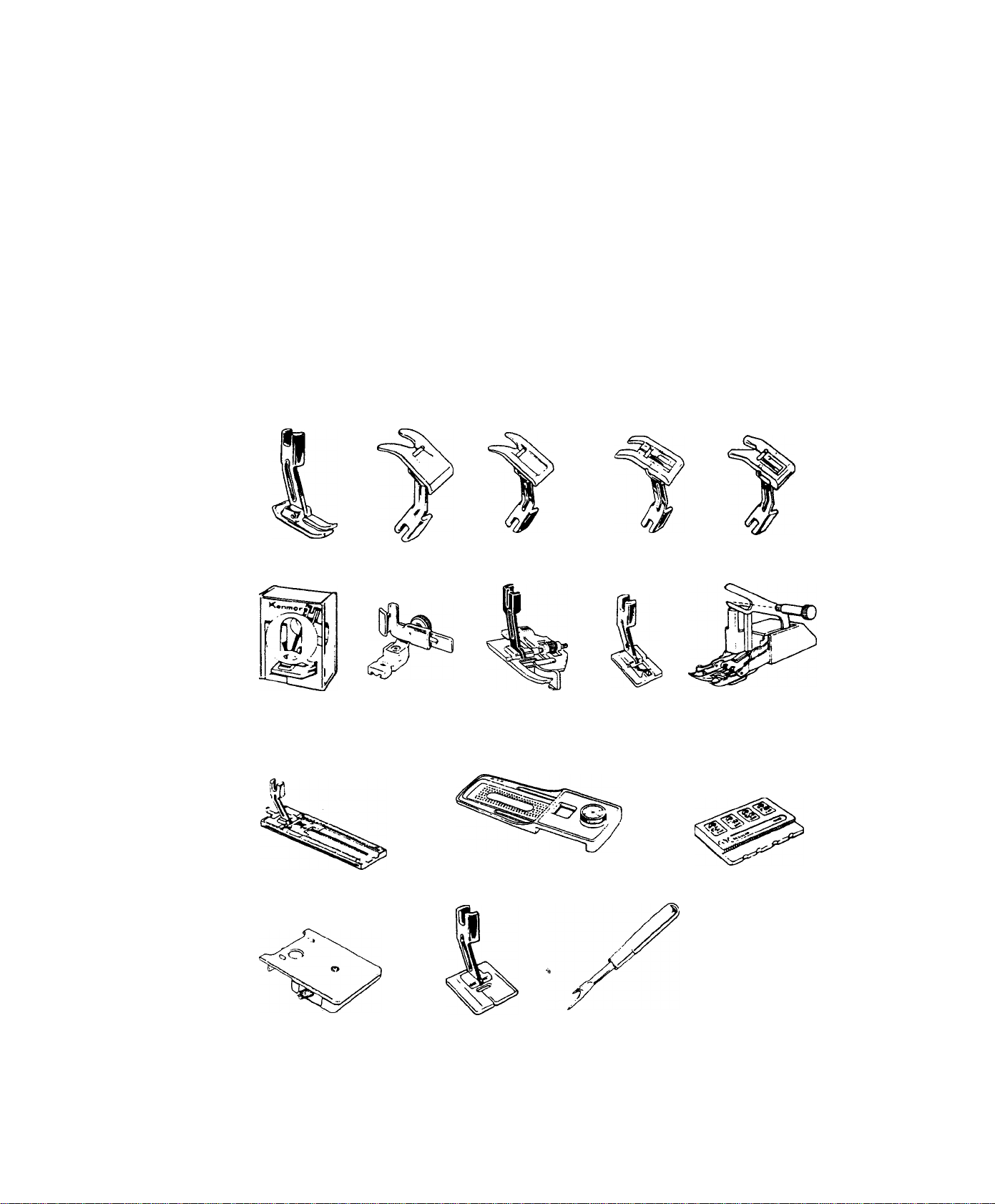

PARTS LIST (Use only genuine Kenmore replacement parts and accessories.)

All parts listed herein may be ordered from

any Sears, Roebuck and Co. store or service

center.

WHEN ORDERING REPAIR PARTS,

ALWAYS GIVE THE FOLLOWING INFOR

MATION;

1. PART NUMBER

2. PART DESCRIPTION

PRESSER FEET

Straight Stitch Standard Zigzag Satin Stitch Plastic Satin "Q FOOT"

(No. 45171) (No. 44985) (No. 44988) Stitch (No. 43776) (No. 6843)

3. MODEL NUMBER shown on the nomen

clature plate. (See page 3 for location.)

4. NAME OF ITEM

If the parts you need are not stocked locally,

your order will be electronically transmitted

to a Sears Repair Parts Distribution Center

for expedited handling.

"QSET"

(No. 6858)

BUTTONHOLE ACCESSORIES

Built-in Buttonhole Guide

Foot (No. 43840)

Buttonhole Cover

Plate (No. 58210)

Zipper Foot

(No. 6759)

Buttonhole Foot

Blind Hem Foot Overcasting

(No. 6886) (No. 35094)

Buttonhole Guideplate

(No. 58232)

(No. 41040)

Even Feed Foot

(No. 6888)

Included in the buttonholer box

Buttohole Templates

No. 1 Part 45195

No. 2 Part 45196

N0.3 Part 45197

No. 4 Part 45198

No. 5 Part 45199

Buttonhole Opener

(No. 6830)

Page 10

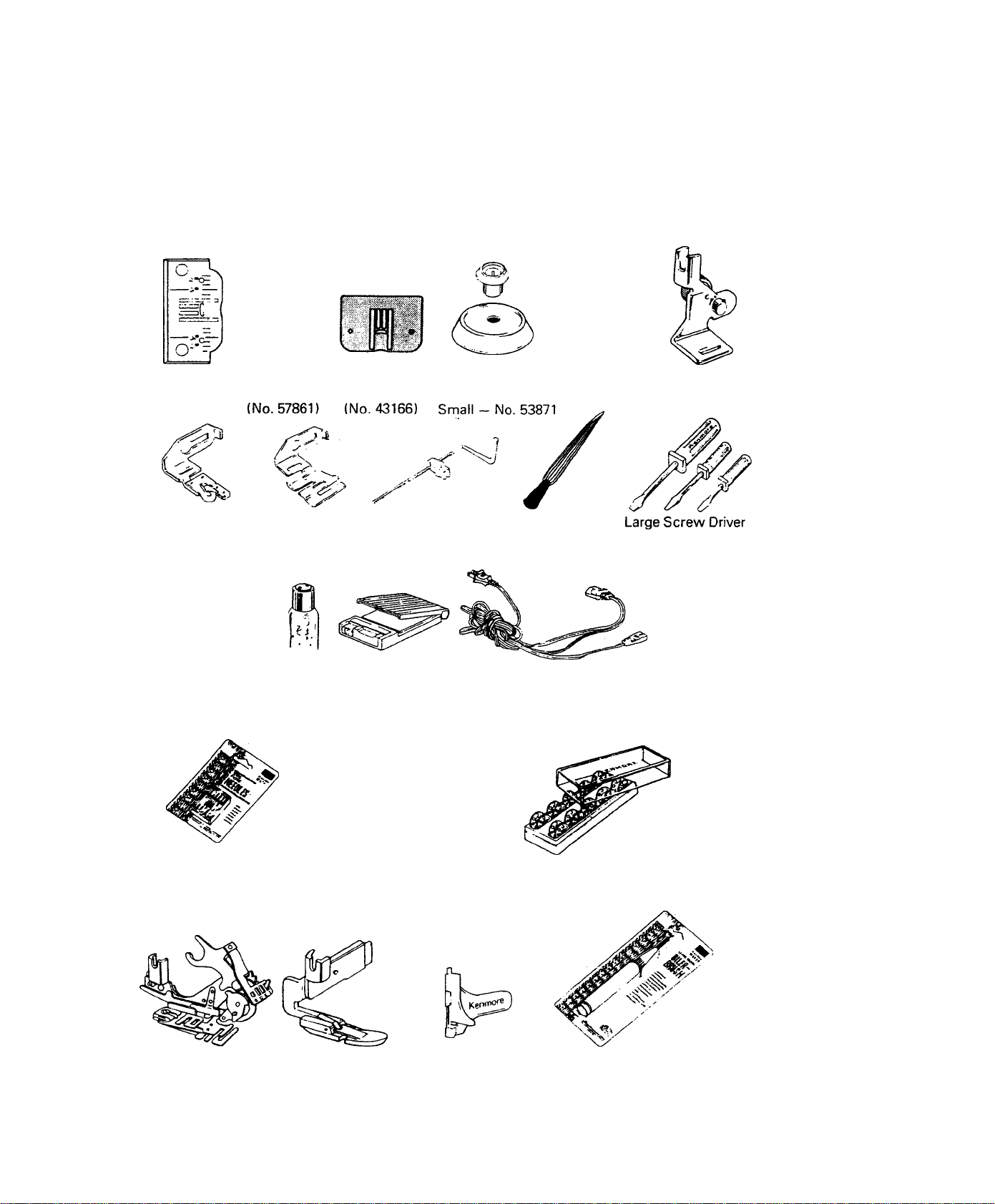

OTHER VITAL ITEMS

CS)

Zigzag

Needleplate

(No. 57860)

Narrow Hemmer

(No. 29396)

Bobbin Winder

Rubber Ring

(No. 1913)

Bobbin Winder

Tension Disc

(No. 39619)

OPTIONAL ACCESSORIES

Packet of needles

with your machine

includes a variety of sizes.

Replacement needles

come in packages

of one size only.

Straight Stitch

Needleplate

Edge Stitcher

(No. 29306)

Light Bulb

(No. 6797)

Feed Cover

Plate

Quilting Guide

(No. 35105)

Foot Control

(No. 57544)

Needle Size

No. 9

No. 11

No. 14

No. 16

No. 18

"Q NEEDLE"

Double Needle

2 Spool Pin Caps

Large — No. 55503

Lint Brush

(No. 35848)

Foot Control Cord

(No. 57543)

Part No.

6550

6551

6552

6553

6554

6746

6749

Nylon Disc

(No. 2273)

Small Screw Driver

Mini Screw Driver

Bobbin Box with

10 Metal Bobbins

Plastic Bobbins

Adjustable

Holder

(No. 29308)

(No. 55501)

(No. 55500)

Magnetized

(No. 55499)

(No. 6862)

(No. 6868)

Ruffler/Pleater

(No. 6895)

Hinged Zipper

Foot (No. 6794)

Needle Threader

(No. 43780)

Oiler-brush Combination

(No. 6889)

Page 11

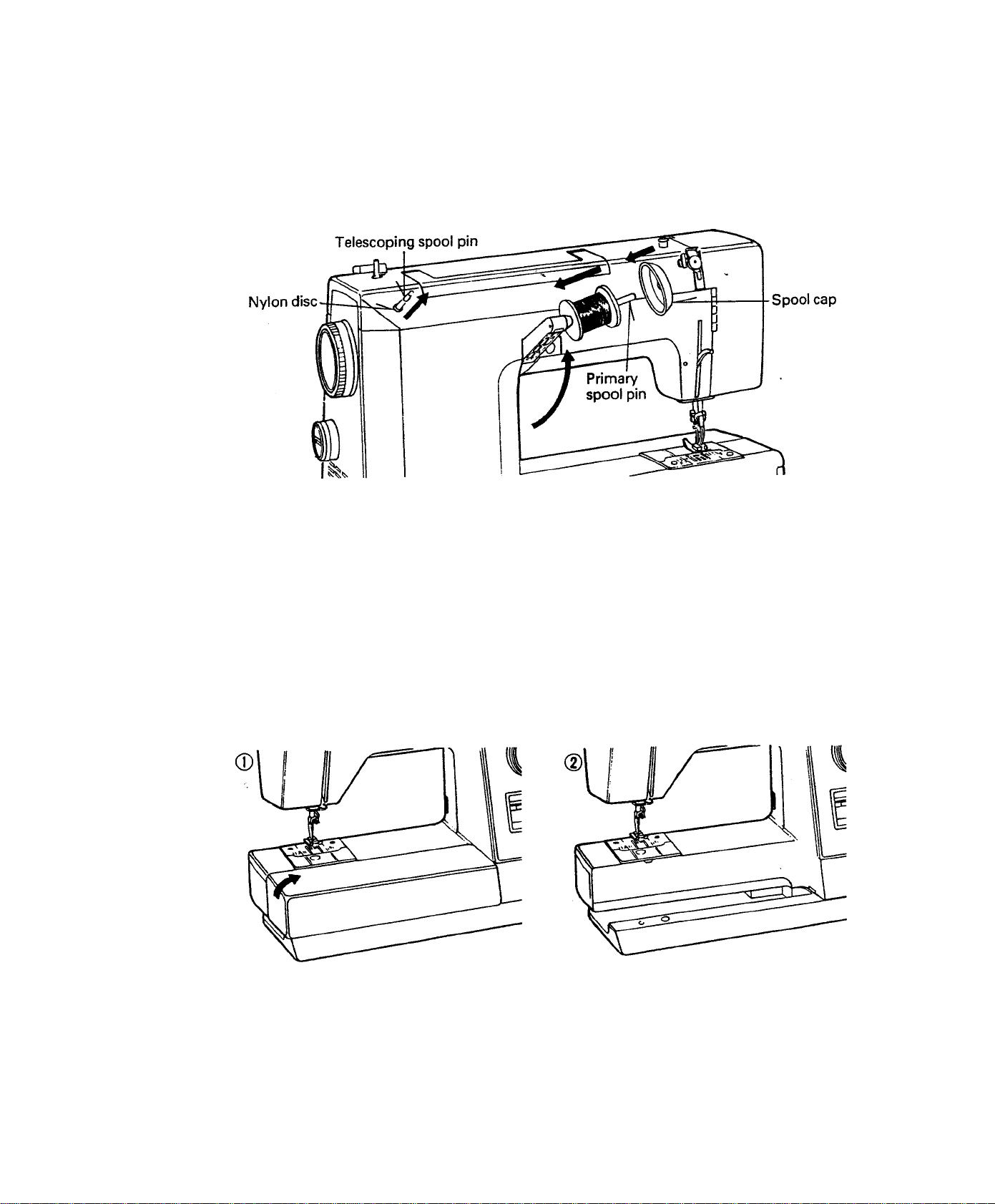

SPOOL PINS AND CAPS

Swing the Primary Spool Pin into position at

the back of the machine as shown above.

Place a spool of thread on the pin and place

the appropriate size spool cap over the

thread.

CONVERTING TO FREE-ARM SEWING

This machine can be used either as a flatbed

or as a freearm model. With the accessory

box in place, the machine is a flatbed model

with a large working surface, which slopes

gently towards you to help the smooth flow

of fabric.

A second telescoping spool pin is provided

for bobbin winding and for a second thread

when sewing with a double needle. Pull it out

and place a nylon disc over it when using.

By removing the accessory box, the machine

converts into a slim freearm model for sewing

children's clothes, cuffs, trouser legs,

armholes and other awkward places.

1. To remove the accessory box, take it

firmly with your left hand and lift it up

until it clicks. Your machine is then ready

for free arm sewing.

8

2. To replace, slide the accessory box back

into place until it clicks.

Page 12

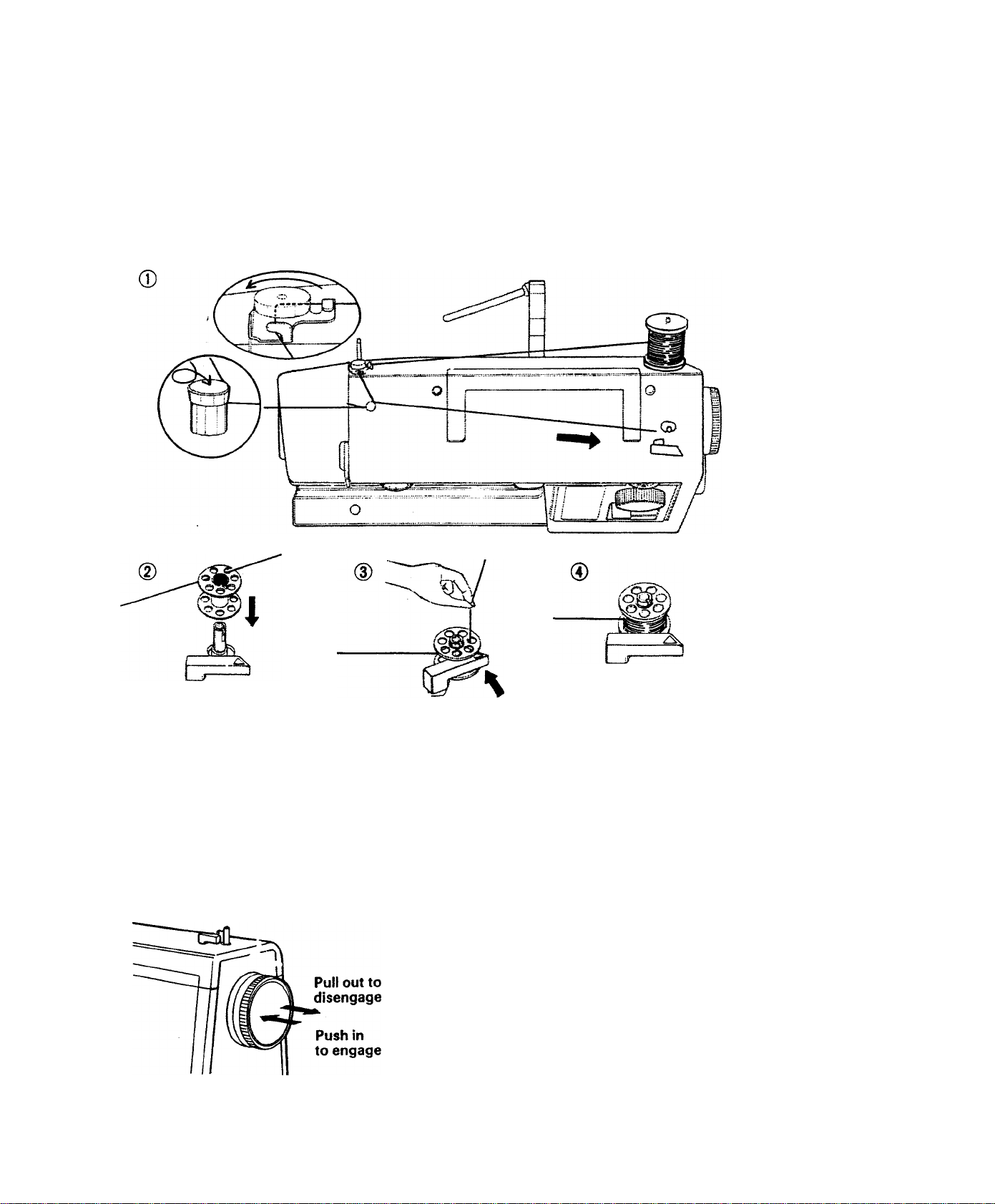

WINDING THE BOBBIN

1.

Place thread on Telescoping Spool Pin.

Draw thread through Rear Thread Guide

and Bobbin Winder Tension Disc as

indicated.

2.

Pull end of thread through any hole in

bobbin; place bobbin on Bobbin Winder

Shaft with end of thread coming from top

of bobbin as shown above.

3. Push Bobbin Winder Latch against bobbin

until it clicks. Then pull Hand Wheel away

from machine to disengage clutch (see

diagram below). Hold end of thread

coming from bobbin (see above) and step

on foot control. After several rotations of

bobbin release thread.

4. When bobbin is full, winding stops

automatically. Push in Hand Wheel.

Remove bobbin from shaft and trim

thread end.

* Treat Hand Wheel as a "clutch"

It controls the needle mechanism so that

when pulled out (disengaged), the rest of

the machine will not operate while the

bobbin is being wound.

For best stitching results use clear plastic

lightweight bobbins when stitching at high

speed with widest and longest stitch

setting.

Page 13

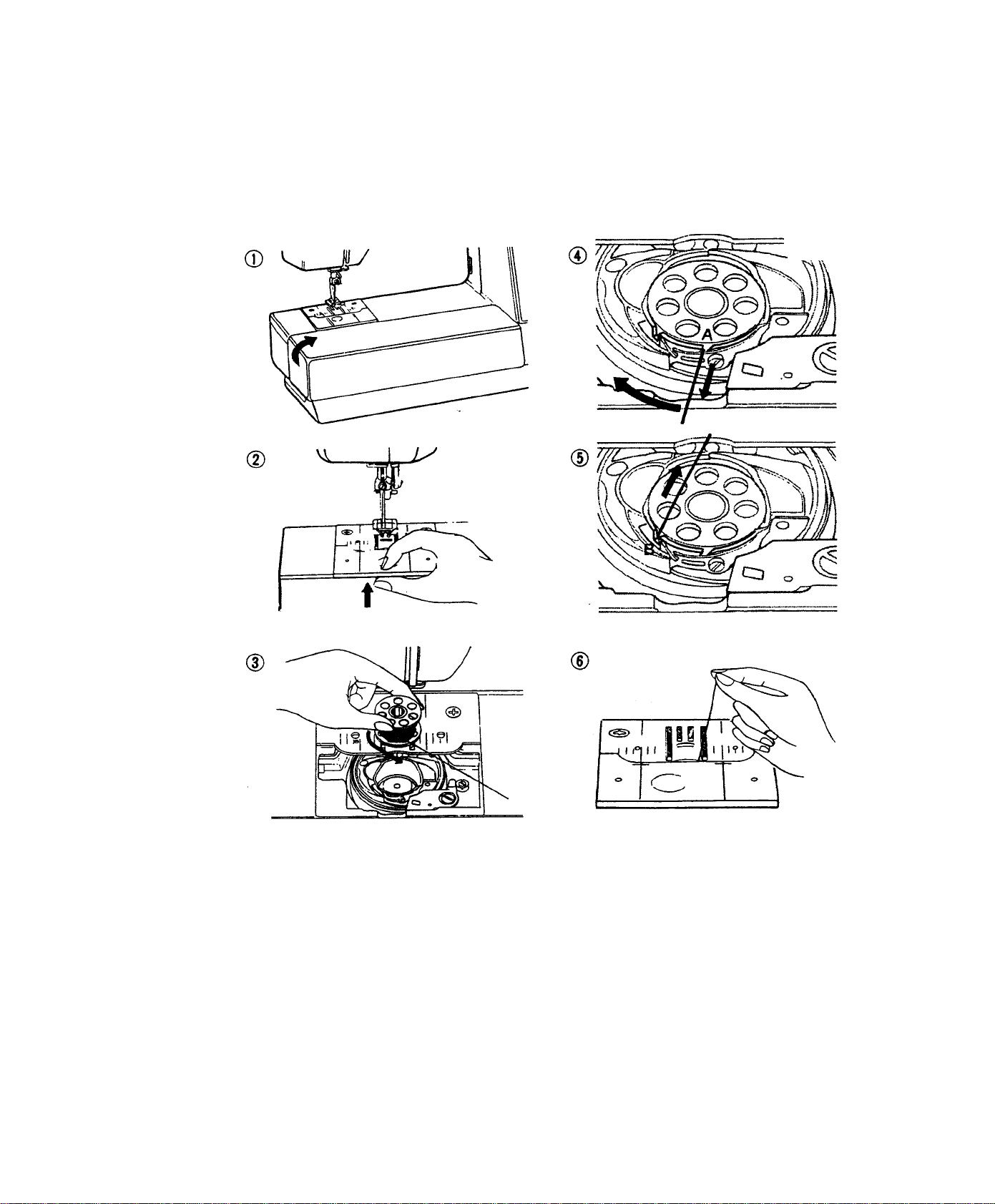

THREADING THE BOBBIN CASE

1. Remove accessory box.

2. Remove bobbin cover plate by lifting up

the front.

3. Insert bobbin into bobbin case making

sure bobbin rotates counter clockwise.

4. Pull thread through slot (A) and then to

the left.

10

5. Pull thread through slot (B) and leave

about 4 inches of thread.

6. Replace bobbin cover plate allowing

thread to emerge through slot in needle

plate.

Page 14

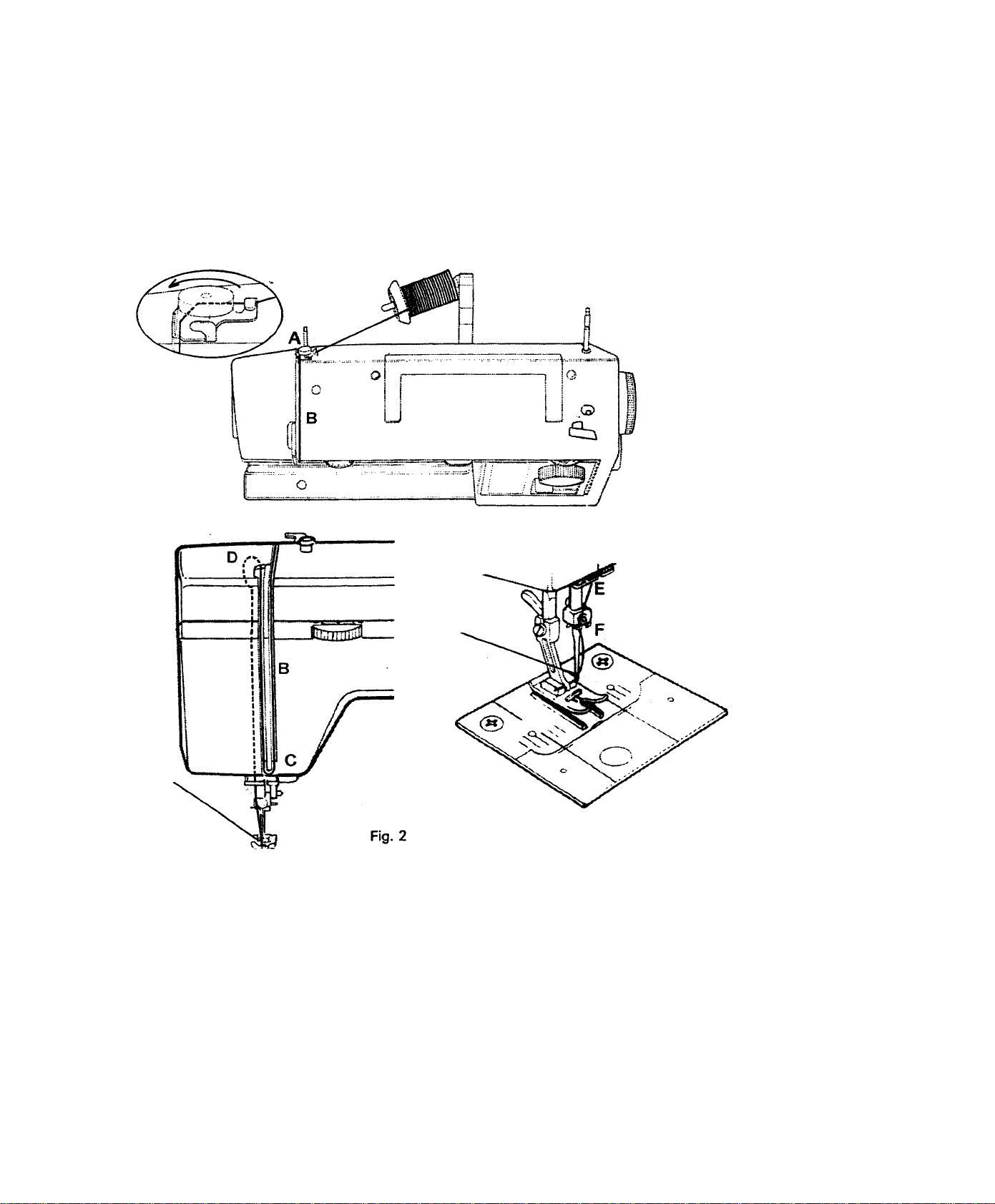

THREADING TOP THREAD

Fig. 1

Raise slotted take-up lever to its highest

position.

Place thread spool onto spool pin. Place

appropriate spool cap over the spool of

thread.

Draw thread through rear thread guide

(A) and into threading channel (B) toward

you. (Fig. 1)

Fig. 3

2. Draw thread down and around check

spring (C) and up through slotted take-up

lever (D). (Fig. 2)

3. Draw thread down into thread guides (E)

and (F). Thread needle from front to back

as shown in Fig. 3.

11

Page 15

PICKING UP BOBBIN THREAD

1. Raise presser foot lever.

Hold needle thread loosely in left hand

and push. peedle up/down switch two

times or rotate hand wheel toward you

one complete turn.

2. Bring bobbin thread up by pulling upper

thread.

3. Pull both threads under and to the back

of the presser foot, leaving 3 to 4 inches

of thread clear.

If ycwj can not pick up bottom thread by

following above steps, then check:

1. Is needle threaded ?

2. Is thread tangled around needle ?

3. Is bobbin case threaded correctly with

thread going through slots A and B as

shown on page 10, Fig. 4 and 5 ?

4. Is there 4 inches of thread coming from

bobbin case and through slot of needle

plate as shown on page 10, Fig. 6 ?

5. Is thread from bobbin case tangled ?

12

Page 16

CONTROLS

THREAD TENSION CONTROL

STRAIGHT STITCHING

The good looking appearance of your straight

stitching is, mainly determined by the

balanced tension of the top thread and

bobbin thread. The tension is well balanced

when the two threads lock in the middle of

the layers of fabric when straight stitching.

You can achieve balanced tension by

regulating the Top Thread Tension Control.

If the upper thread appears to be too tight,

dial left (lower numbers) to decrease tension.

If the upper thread is too loose, dial right

(higher numbers) to increase tension.

For most fabrics the tension control shuld be

set in the white zone between 3 and 5.

ZIGZAG STITCHING

Always practice stitching on two layers of the

fabric you will be using.

Make sure that you are using the right size

and type of needle for the fabric. See chart

page 19.

Choose a thread of good quality and type for

your fabric. See chart page 19.

Remember — the wider the zigzag setting,

the more chance for puckering. Reduce the

top tension, if puckering occurs.

The top thread will be visible on the bottom

to varying degrees depending on the thread,

fabric, type of stitch being used and speed of

sewing.

The bobbin thread should never be visible on

the top of the fabric.

STRAIGHT STITCH

JUST RIGHT

TOP STITCH

TOO TIGHT

-JLJL-Jci

Decrease tension

TOP STITCH

TOO LOOSE

Increase tension

BOBBIN TENSION

The bobbin tension has been correctly set at

the factory, so you do not need to adjust it.

13

Page 17

Stitch

selector

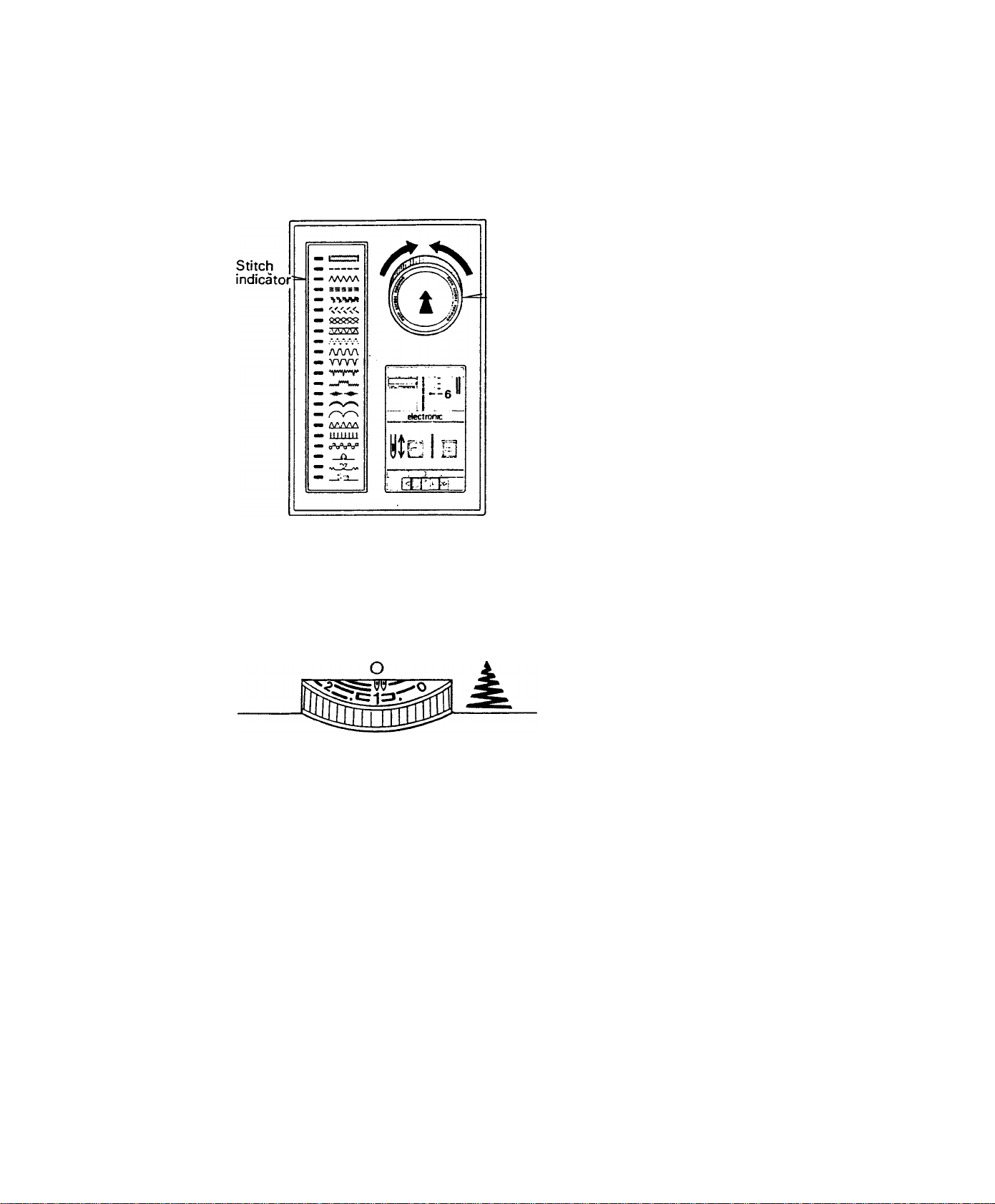

STITCH SELECTOR AIMD INDICATOR

1. To select a stitch, be sure needle is out of

fabric at its highest position. Push the

stitch selector in and out to release the

mechanism.

2. Then turn the selector to left or right until

the required stitch is indicated by the red

light on the indicator panel.

STITCH WIDTH CONTROL

The width of all the stitches produced on this

machine, with the obvious exception of

straight stitch, can be made narrower or

wider by adjusting the stitch width control.

14

To decrease or increase the width of a stitch,

turn the stitch width control dial from 0 - 4.

The higher the number the wider the stitch.

Recommended setting ranges are indicated

and color-coded with patterns on the stitch

indicator panel.

When sewing with a double needle, do not

use a setting above 2, as indicated on the

dial.

Page 18

STITCH LENGTH CONTROL

The stitch length control regulates the length

of the stitch'you select. THE HIGHER'THE

NUMBER-THE SHORTER THE STITCH.

Turn only the« outer rim of this control to set

the stitch length.

The number on stitch length control indicates

the approximate number of stitches per inch.

The stitch setting you use will be determined

by the thickness of the fabric you are sewing.

A longer stitch setting should be used for

thicker fabric or more layers of fabric. The

middle range of the control is the 12 stitch per

inch range which is the most commonly

used.

Recommended stitch length settings are

indicated in three colors. The colors are

color-coded with the stitches on the indicator

panel.

The red marking between 0 and 1 Is the

setting used for the shortest stitches such as

in satin stitching.

REVERSE STITCH LEVER

Stitch length

control

m

-12

ctronic

Reverse stitch

lever

Stitch modifier

It is best to begin and end seams with a few

stitches taken in reverse. This is called back

tacking. Back tacking fastens the ends of the

seams firmly and prevents raveling.

When reverse stitching is needed, push

down the lever and hold there during sewing.

The fabric will immediately start feeding

backwards and seam will be fastened.

STITCH MODIFIER

When using stretch stitches and making

buttonholes, you may need to make use of

the stitch modifier. This regulates the

movement of the fabric backwards and

forwards to produce perfect stitches on fine

or thick fabrics.

The stitch modifier should be in neutral

notched position for most materials.

15

Page 19

BUTTONHOLE CONTROL

This control is used in making bar tacked

buttonholes with two control settings.

Detailed instructions are given on page 51.

PRESSURE REGULATOR

Presser foot pressure is vital for straight

seams, uniform stitch length, even handling

of both layers of fabric. To adjust pressure;

use Pressure Regulator which is situated

inside the face cover. Then to increase

pressure, turn the dial clockwise (or vice

versa). Just remember... for lightweight

fabric, more pressure; for heavy fabric, less

pressure. -

16

Page 20

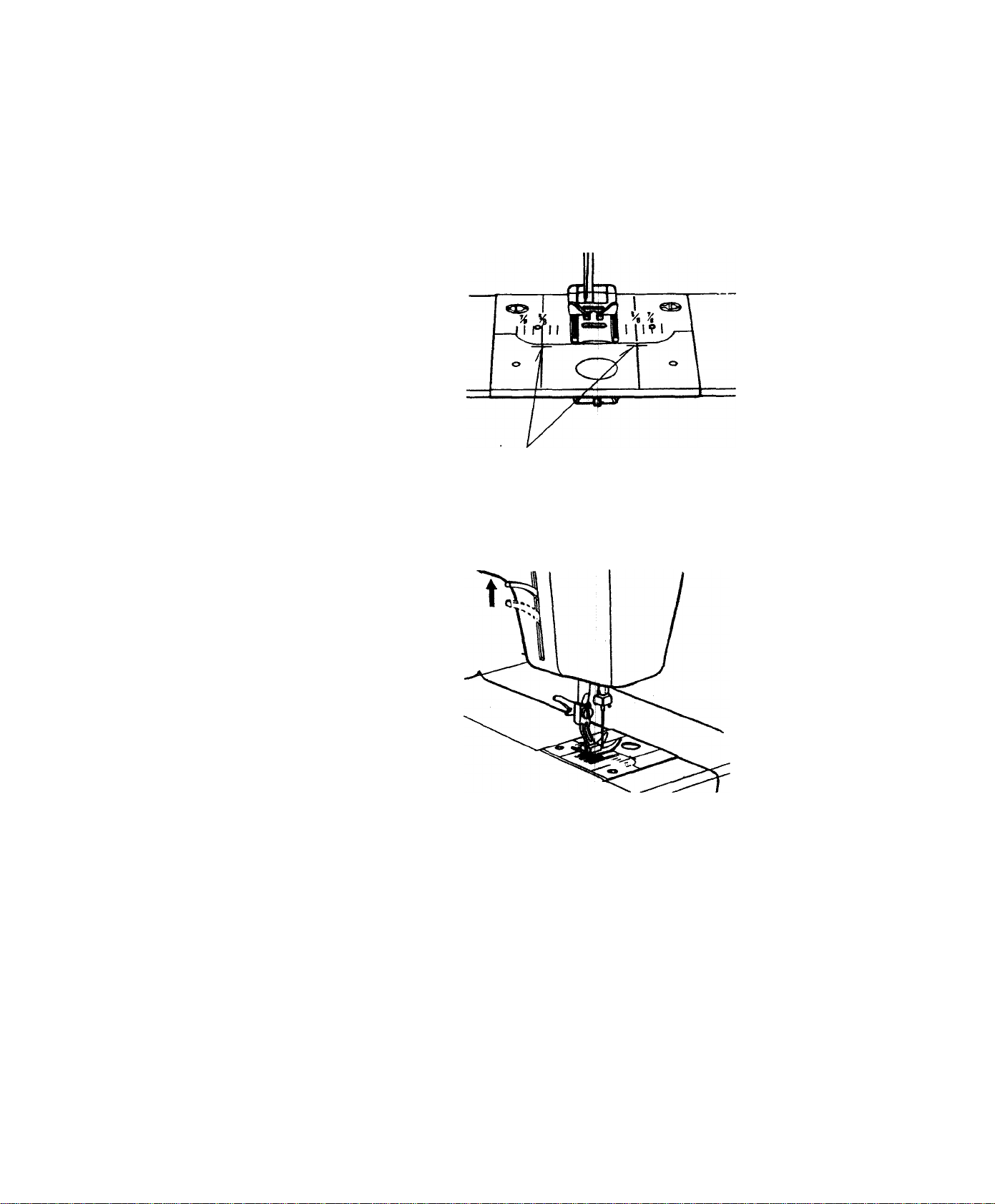

SEAM GUIDES

Seam guides are printed on needle plate, at

both sides of needle, to help you line up the

fabric and keep it straight. The standard

seam width is 5/8”. So these lines are

emphasized, easy to follow.

Also the cross lines are "cornering guides” to

help when turning a square corner 5/8” from

the fabric edge. (For details on cornering, see

page 30.)

PRESSER FOOT LEVER

Presser foot lever has a two position lift.

In order to place heavy fabric under the

presser foot or to change the presser foot

raise the presser foot lever to its maximum

upward position as shown.

Cornering Guide

17

Page 21

ACCESSORIES

NEEDLES

I I I

TPI

Use KENMORE needles. The size of the

needle should conform with the size of the

thread and both should be suitable to the

fabric. Kenmore needles are color-coded by

size for your convenience (See chart on

next page).

Never use a bent needle or one with a dull

point.

The exact length of your needle is shown at

left. Be sure you never use one in your

machine that is not this exact length.

You will find among your accessories a

•Q NKKDLK' -with blue shank. This special

needle is to be used when sewing knits and

certain difficult synthetic fabrics. If you

experience skipped stitches in any of your

sewing, use -Q nkkdlK"-and "Q FOOT"..

PLACEMENT OF NEEDLE

you

Raise needle bar to its highest position by

turning the hand wheel toward you. Loosen

the needle clamp screw. Holding the needle

with the flat side away from you, slip the

needle into the needle bar. When it is in as far

as it will go, tighten the needle clamp screw

with small screwdriver provided in the

accessory box.

18

Page 22

NEEDLE, THREAD AND FABRIC CHART

FABRIC

i

LIGHTWEIGHT; Batiste. Dimity,

Chiffon. Silks. Synthetic Jerseys.

Fine Lace. Organza. Crepe,

Taffeta, Voile, Organdy

MEDIUMWEIGHT: Cotton,

■ Cotton Blends, Percale, Gingham.

, Shantung, Pique, Seersucker,

Satin. Knits, Vinyl. Suitings.

Linen, Wool Crepe. Leather

MEDIUM HEAVYWEIGHT:

Corduroy, Denim. Wool,

Sailcloth, Wool Flannel,

Gabardine, Velvets, Leather

HEAVYWEIGHT: Coatings,

Upholstery. Cotton Duck,

Heavy Twills, Canvas

Decorative top-stitching on all

types of fabric

Synthetic Knits and Stretch;

Polyester Double Knits, Nylon

Tricot, Jersey, Stretcn Terry,

Spandex, Ciré Tricot

NEEDLE

SIZE AND

COLOR

9-BROWN

or

11 ORANGE

14-RED

14-RED

or

16 PURPLE

18-GREEN

16-PURPLE

18 GREEN

or

Q-BLUE

Q-BLUE

with.

•QFOOT"

THREAD SIZE

Polyester Core/Cotton Wrap

Fine Mercerized Cotton

Silk A

Polyester Core/Cotton Wrap

50 Mercerized Cotton

Silk A

Polyester Core/Cotton Wrap

50 Mercerized Cotton

Mercerized Heavy-Duty

Silk A

Polyester Core/Cotton Wrap

Heavy-Duty Mercerized Cotton

Polyester Synthetic

Silk A

Buttonhole Twist

Polyester Core/ Cotton Wrap

50 Mercerized Cotton

RECOMMENDED

STITCH LENGTH

SETTING

12 stitches

per inch

10 to 12 stitches

per inch

8 to 10 stitches

per inch

8 stitches

per inch

6 stitches

per inch

10 for Regular

or ,

6 for Stretch

Stitches

PRESSER FEET

To change presser feet, simply drop Presser

Foot Lock and slip foot away from the

Presser Bar. Raise Presser Foot Lever beyond

the normal up position and place new foot on

presser bar. To lock foot securely, raise

presser foot lock as high as possible.

19

Page 23

EVEN FEED FOOT

The even feed foot moves top and bottom

material together evenly and enables you to

sew hard-to-sew fabrics without sliding nor

slipping and with perfect matching. Use it for

sewing leather, ultra suede™, shiny fabrics

(vinyls, patents and satins), bonded fabrics,

pile fabrics and matching stripes, plaids and

patterns. It is not recommended for use when

stretch stitching.

To attach the even feed foot;

1. Raise needle to its highest position.

2. Raise presser bar to its highest position

and guide the even feed foot into position

from rear of machine.

3. Attach presser bar clamp to presser bar

and lift presser foot lock as high as it will

go to hold the foot securely.

4. Attach screw (A) provided with the foot

to needle clamp through fork arm and

tighten it.

Note: Attach the foot in exact order of steps

as written.

Thumb

screw

Narrow

hemmer

IMPORTANT:

To prevent friction and wear, put a drop of oil

at each point indicated by arrows in Fig. 2

and set pressure regulator at 2 or 3 before

using this foot.

Oil after 4 or 5 times usage. Be sure to remove

excess oil by wiping foot thoroughly and sewing

on a scrap of fabric.

ADJUSTALBLE HOLDER

Replace the regular presser foot with the

adjustable holder when using narrow hemmer

and edge stitcher attachment.

Loosen thumb screw and press it forward.

Insert the opposite end into the large hole of

the attachment. Slide the attachment to the

left as far as possible. Adjust as necessary to

the correct position for stitching. Tighten the

thumb screw securely.

20

Page 24

EDGESTITCHER

This one attachment helps you join fabric

edges ...insert lace ...do seam piping ...

simplifies blind hemming as well as "French”

seams. Slots numbered 1 to 5 serve as

sewing guides:

Slot 1 will giiide fabric to be joined to lace.

All you have to do is place the lace in slot 2.

Slot 4 will guide piping being joined to fabric

edges. Place the fabric in slots 2 or 3.

Slot 5 may be used as a guide when sewing

French seams which are stitched twice, once

on right side and once on other side. This is

the classic seam for sheers.

Use slots 1 and 3 to guide

during blind hemming.

fabric with ease

QUILTING GUIDE

This attachment comes in handy whenever

you want several rows of stitches an equal

distance apart —for garment trim as well as

quilts. It consists of a curved prong attached

to a long bar on a holder. The prong is shifted

back and forth on the holder to establish the

distance between rows of stitches.

21

Page 25

Fig. 1

NEEDLE PLATES

You are provided with two needle plates:

A. Needle plate with wide oval hole for all

zigzag stitching.

B. Needle plate with round hole for regular

straight stitching and straight stretch

sewing.

CHANGING NEEDLE PLATE

1. Raise needle to its highest position and

raise presser foot. .

2. Remove accessory box and bobbin cover

plate.

3. Remove needle plate by placing thumb

under edge of plate and lifting up and out.

(See Fig. 2)

4. Place other needle plate making sure

bobbin case is in proper position as

shown in Fig. 3 by turning it counter

clockwise until it hits bobbin case

stopper. Push down the needle plate with

both hands to lock.

5. Replace bobbin cover plate.

22

IMPORTANT:

Don't turn hand wheel while needle plate is

removed, or needle may hit bobbin case and

cause needle damage.

Don't touch screws on the bobbin case

stopper.

FEED COVER PLATE

There are a few times when you want to

control the feeding of the fabric yourself.

Raise needle to its highest position and raise

presser foot. Place feed cover plate over

needle plate aligning two pins of feed cover

plate with holes of needle plate. You may

then determine the movement of the fabric

yourself.

Page 26

CARING FOR THE MACHINE

CLEANING THE FEED DOGS

WITH A BRUSH

To insure the best possible operation of your

machine, it is necessary to keep the essential

parts clean at all times.

Remove bobbin cover plate and needle plate.

Using a small brush, remove the lint that

accumulates in and around the feed dogs and

shuttle area.

CLEANING AND OILING SHUTTLE AREA

On rare occasions, you may want to clean the

shuttle area. Just follow these simple steps.

1. Remove bobbin case by lifting it out from

left side.

2. Clean the shuttle with small brush and put

a drop of oil to the points indicated by

arrows. Don't over-oil. (Reminder: don't

use household oil...use sewing machine

oil.)

REPLACING BOBBIN CASE

1.

Insert bobbin case into shuttle from left

side and turn it counter-clockwise until it

hits bobbin case stopper.

2.

Replace needle plate in position.

NOTE: Don't touch screws on the bobbin

case stopper.

Oil and lint brush No. 6889 is available

at most Sears retail stores and

catalog.

Page 27

24

Page 28

OILING IN FACE COVER PLATE

Swing face cover plate open and oil points

indicated by arrows in illustration.

OILING IN END COVER PLATE

A drop of oil should be placed through the

hole indicated in the end cover plate.

CHANGING LIGHT BULB

The sewing light is located inside the face

cover plate as shown. To replace the bulb,

push switch to off, unplug machine and

swing the face cover plate open. Push up on

the bulb slightly and turn bulb to the left.

Withdraw bulb from socket. Push in new

bulb and turn to the right.

Page 29

CHECKING

SUSPECTED PROBLEM

IRREGULAR

STITCHES

BREAKING

NEEDLE

BUNCHING OF

THREAD

PUCKERING

SKIPPING

STITCHES

BREAKING UPPER

THREAD

BREAKING BOBBIN

THREAD

PROBABLE CAUSE

Incorrect size needle.

Improper threading.

■'Loose upper thread tension.

Pulling fabric.

Light pressure on presser foot.

Loose presser foot.

Unevenly wound bobbin.

Nicks or burrs at needleplate opening.

Pulling fabric. ■

Incorrect size needle.

Incorrect setting of needle.

Loose presser foot.

Upper and lower threads not drawn back under presser

foot before starting seam.

Incorrect thread tension(s).

Light pressure on presser foot.

Using two different sizes or kinds of thread.

Bent or blunt needle.

Loose presser foot.

Fabric too sheer or too soft.

Incorrect size needle.

Certain knits and synthetics.

Bent or blunt needle.

Incorrect setting of needle.

Tight upper thread tension.

Light pressure on presser foot.

Starting to stitch too fast.

Improper threading.

Tight upper thread tension.

Incorrect size needle.

Sharp eye in needle.

Nicks or burrs at needleplate opening.

Improper bobbin case threading.

Lint in bobbin case or shuttle.

FABRIC NOT

MOVING

MACHINE JAMMING,

KNOCKING NOISE

MACHINE DOES

NOT SEW

26

Feed cover plate attached.

Light pressure on presser foot.

Thread knotted under fabric.

Thread caught in shuttle.

Damaged needle.

Bent needle plate.

Hand wheel not returned to stitching position.

Power cord not connected.

Power/light switch off.

Page 30

POSSIBLY EASY CORRECTION

Choose correct size needle for thread and fabric.

Rethread machine; check tension spring threading.

Tighten upper thread tension.

Do not pull fabric; guide it gently.

Increase pressure on presser foot.

Reset presser foot.

Rewind bobbin.

Replace needleplate, or polish off burrs completely.

Do not pull fabric; guide it gently.

Choose correct size needle for thread and fabric.

Reset needle.

Reset presser foot.

When starting a seam be sure to draw both threads under and back of presser foot

about 4” and hold until a few stitches are formed.

Reset thread tension(s).

Increase pressure on presser foot.

Upper thread and bobbin thread should be same size and kind.

Insert new needle.

Reset presser foot.

Use underlay of tissue paper.

Choose correct size needle for thread and fabric.

Use "Q NEEDLE"’” and "Q FOOT"’".

Insert new needle.

Reset needle.

Loosen upper thread tension.

Increase pressure on presser foot.

Start to stitch at a medium speed.

Rethread machine.

Loosen upper thread tension.

Choose correct size needle for thread and fabric.

Insert new needle.

Replace needleplate, or polish off burrs completely.

Check bobbin case threading.

Clean bobbin case and shuttle.

Remove feed cover plate.

Increase pressure on presser foot.

Place both threads back under presser foot before beginning to stitch.

Disassemble and clean shuttle.

Replace needle.

Replace needle plate.

Push in clutch.

Check plug.

Push to on position.

27

Page 31

2. STARTING TO SEW

Now that you are familiar with the controls

on your machine and with the accessories

provided for the machine, you are ready to

start to sew with your sewing machine.

Below are some good habits to follow each

time you sit down to sew:

1. Check the needle-it should be straight,

properly set and sharp on the point.

It should be the correct size for the fabric

and thread being used. Do not be afraid

to change your needle frequently. Many

of the new fabrics made of synthetic

blends tend to dull the needles more

easily than fabrics made of natural fibers.

2. Before placing the material on the

machine, see that the ends of the threads

have been drawn about 3 - 4 inches to the

rear of the machine. Hold on to threads

during the sewing of the first 3 or 4

stitches of the seam.

3. Test the machine stitch on a scrap of

fabric you plan to use. The fabric should

be double thickness. Adjust the machine

for the length of stitch and tension

suitable to your fabric.

4. Fabric should be placed under the presser

foot with the bulk of the material to the

left of the needle and the right edge of the

material placed on the 5/8” seam marking

on the needle plate when making a simple

seam.

28

5. Run the machine at a slow even speed.

The more pressure you put on the foot

control, the faster the machine will sew.

6. Fasten each seam by back tacking at the

beginning and end of the seam.

7. Always finish sewing each seam with the

needle at its highest point.

8. Guide the fabric gently with your hand in

front of the needle. Never pull or hold the

fabric in such a way that the normal

feeding is altered.

9. When turning the hand wheel manually,

always turn it toward you.

Page 32

MACHINE SETTING CHART

Buttonhole

control

OI

"vi

Needle plate

; ÜÜ

: CZ3

%!y

Presser foot

Stitch width dial

Stitch modifier

Lt

Stitch length dial

Machine settings are graphically shown in

this section for your quick reference. Simply

Buttonhole

Straight stitch

Zigzag

Straight stretch

Rick-rack stretch

N -X 'S,

^ '■ X^

/ ^./ \/ \/ \,/ \

Feather stretch

Smocking stretch

Elastic stretch

Mending

Box

Blind

following illustrated charts, select and sew a

variety of stitches shown below...

Elastic blind stitch

Domino

Diamond

Crescent

Scallop

Overcast stretch

Paris point stretch

Arabesque

Tree

Tulip

Swan

29

Page 33

STRAIGHT STITCHING

O ;

L

'Straight stitch

needle plate

O

Not necessary to

adjust

Any setting but "0"

*You may use zigzag, straight stitch foot or Q foot,

but for best control of fabric, best looking straight

stitches and best feeding of fabric use Straight

Stitch Foot and Needle Plate.

30

FASTENING A SEAM

Be sure both threads are drawn back under

the presser foot. Lower needle into fabric

about 1/2 inch from beginning of seam.

Depress the reverse stitch lever and stitch in

reverse until needle reaches beginning of

seam. Release control and complete seam.

When you reach the end, depress the reverse

stitch lever and sew back (backtack) over 1/2

inch of completed seam.

TURNING A SQUARE CORNER

1. To turn a square corner 5/8" from the

fabric edge, stop stitching when reaching

the cornering guide and push needle up/

down switch to lower the needle into the

fabric.

*2. Raise the presser foot and turn fabric.

New stitching line will align with 5/8"

seam guide on side of needle plate. Lower

the presser foot and begin stitching in

new direction.

Page 34

REMOVING FABRIC

First turn the handwheel toward you until the

needle is at its highest position, then raise the

presser foot, draw materials to the rear and

cut off excess thread with the thread cutter

located on the presser bar as shown.

TOP-STITCHING

This is a seam you may want to show off! It's

on the front side of the garment, possibly at

the top of a "kick pleat" or on a lapel, both

functional and decorative. Usually, it's a

simple, forward stitch —with an extra-long

stitch length, or with special thread, match

ing or contrasting.

DARNING

SETTINGS

Stitch Length - 8 to 10

Pressure Regulator - 0 (DARN)

Zigzag foot or square automatic buttonhole

foot

Stretch fabric between embroidery hoops

with hole centered. Lower presser bar and

sew at a slow speed moving fabric back and

forth with a steady rhythm to cover darning

area. When it is covered, turn fabric 1/4 a

turn and sew layer of stitching across first

layer.

If fabric is thin or badly damaged in hole area,

you may want to put a separate piece under

the hole for reinforcement.

31

Page 35

Regular Basting

Free Method

TEMPORARY SEWING BY MACHINE

Regular basting by machine is easy —simply

use straight stitching with longest available

length setting. And your machine has a free

basting method for very long stitches that

sometimes can be used for "marking”.

FREE BASTING METHOD

SETTINGS

Basting switch - turn on

Pressure regulator - 0 (DARN) or 1

Use feed cover plate.

Tap the foot control and the machine will

take one stitch and stop automatically with

the needle in the up position. Holding the

fabric in both hands, pull it back to the

required stitch length.

Repeat this process, tapping down on the

foot control and guiding the fabric with your

hands.

32

PIN BASTING

You can sew over pins easily (if done

correctly) because your presser feet are

hinged. Pins must be inserted at right angles

to seam line. Tip of pin should just touch

seam line. Sew over tip of pins. Pins must not

come in contact with feed dogs: Never pin on

the under-side of the fabric. Sew slowly. If in

doubt about sewing over pins, remove each

pin as you approach it.

STAY-STITCHING

"Stay-stitching” is a form of temporary

seaming that prevents stretching of curved

edges of garments. Usually this is on a single

layer of fabric, so reduce top thread tension

slightly to prevent puckering. Baste about

Vi" away from intended seamline.

Page 36

ZIPPER APPLICATION - CORDING

Home-sewn zippers can look as nice as those

on expensive ready-mades. We recomrriend

you follow directions ^ given on zipper

package. There are two basic types: conven

tional, and invisible. Your Zipper Foot will

assist you with any of these installations.

Use these simple settings:

For conventional zippers... Your zipper foot

is adjustable for use on right or left side of

needle. Adjust foot so needle clears side

notch on foot. Then proceed according to

zipper manufacturer's instructions.

Invisible zippers are applied to an open seam,

to seam allowances only; there is no stitch

ing visible , on outside of garment. Adjust

zipper foot so needle is sewing through

center hole of foot and one groove of foot is

riding on teeth of zipper. After zipper

insertion, finish by shifting foot to side

position and sewing through side notch.

Your zipper foot also makes it easy to add

"cording" to garments as well as slip covers,

toss pillows, bedspreads, decorative pieces.

Cut fabric on bias and wrap around cord.

Pin fabric in place so seam edges are even.

With zipper foot to left of needle, stitch close

to cord.

33

Page 37

' - .S' . c

NARROW HEMMING

Attach the Narrow Hemmer to the adjustable

holder. Make sure that edge of the fabric is

cut straight. Turn a tiny double hem (% inch)

along edge for about two inches. Place end

of this hem under Narrow Hemmer. Hold

thread taut while stitching along inside' edge

of hem. Feed fabric gradually into "scroll" in

hemmer, guiding edge of fabric as shown.

QUILTING

Attach the quilting guide to presser foot as

shown. After completing the first row of

stitching, place the guiding prong on this

Stitched line. The second row then can be

placed at the desired distance from first row.

Continue working in this way for as many

rows as you want.

34

Page 38

ZIGZAG STITCHING

Simple zigzag stitching enables you to do

many exciting things with your Kenmore

sewing machine. Beyond basics, you'll use

zigzag stitching to applique, embroider and

monogram. Unlike straight stitches, zigzag

stitches have a side-to-side width as well as a

o

vyvwwvwwvvv

o

vwwwwwww

o

vwwvwwwvw

o

wwwwwvww

stitch length. You'll find "recipes" for many

zigzag operations on following pages. You

can create an exciting variety of zigzag

stitches by adjusting stitch width and length

controls (see chart below).

Narrow zigzag for light fabrics, barely

shows — set at 1.

Medium zigzag for most construction

seams — set at 2

Wide zigzag for double layers, like hemm

ing — set at 3.

Extra wide zigzag for heavy fabrics or those

that fray — set width at 4

35

Page 39

OVERCASTING

Stitch Selector - AAAAA

Stitch Length - 12-8

Stitch Width - 3-4

Use Overcast Foot.

This is one of the .nnore frequently used

zigzag stitches on garment construction.

You may want to overcast along the raw

edge of each seam allowance or fold the raw

edge toward the garment and stitch.

Stitch so the needle pierces the fabric just

short of the outside edge. Raw or worn edges

of older garments can be overcast to prevent

further raveling.

SATIN STITCHING

Stitch Selector - AAAAA

Stitch Length Dial - Between 0 and 24 (•)

Use metal or plastic Satin stitch foot which is

grooved to permit dense stitching to pass

under it easily.

Satin stitch

foot

Closely spaced zigzag stitches are called satin

stitches. This is an attractive stitch used for

appliqueing, bar tacking.

Whenever you are using this stitch, it is well

to remember to loosen the tension of the top

thread slightly. The wider the stitch you

make, the looser the tension should be.

If you are stitching on a very soft fabric, use a

backing of tissue paper or interfacing for a

well formed stitch. Puckering of the material

will be eliminated and the bobbin thread will

not be visible on the right side of the fabric.

As with all special stitches, it is best to make

a sample design on your fabric before starting

the design on the garment.

BAR TACKING

Settings same as Satin Stitching

This stitch is similar to a very short satin

stitch and is used to reinforce points of strain

such as corners of pockets and straps on

lingerie.

Sew 4 to 6 zigzag stitches.

36

Page 40

APPLIQUEING

Settings same as Satin Stitching

Select an applique design to be applied to

your garment and baste it in place. Satin

stitch around the raw edge of the applique

completely cóvering the edge. You may want

to do this with a contrasting color of thread.

EMBROIDERY

Settings same as Satin Stitching

Satin stitch can be used to produce many

different designs and patterns. To sew the

flowers illustrated, back the fabric with

interfacing or paper and draw on the design

with tailor's chalk. Turn the stitch width

control from 0-4-0 to from each petal and

leaf. Join the flowers and leaves with straight

stretch stitch. If using paper, carefully

remove it when you have finished sewing.

MONOGRAMMING

Settings same as Satin Stitching

To sew initials, first back the fabric with

interfacing or paper. Draw the initials on to

the fabric with tailor's chalk. Satin stitch,

adjusting the width from 0-4 as you begin

and end the stroke of a letter. Or the same

stitch width can be used throughout. If using

paper, carefully remove it when you have

finished sewing.

37

Page 41

BUTTON SEWING

Stitch Selector - AAAAA

Stitch Width - Adjust to Button Size

Use Feed Cover Plate and Clear Plastic

Satin Stitch Foot.

1. Position the button on fabric with clear

tape.

2. Center the left hole of button between

straight seamline and the left edge of

needle slot of foot and lower foot to hold

the button securely.

3. Turn hand wheel manually until needle

point is just above button.

4. Adjust stitch width control so needle will

enter right hole of the button.

5. Turn hand wheel again by hand so needle

enters second hole. Readjust stitch width

if necessary. Stitch a number of times.

6. Finish sewing with an extra two inches of

thread remaining. Draw these threads to

reverse side of garment and tie.

When sewing a flat button, place needle or

pin between holes of button as shown to

provide flexibility for buttoning.

38

Page 42

MENDING AND OVERCAST STITCHING (THREE STEP ZIGZAG)

YYY^^

MENDING A TEAR

Stitch Length - 0-24

Stitch Width- 3-4

To repair a straight or three-cornered tear,

position the tear under the needle in such a

way that the stitching catches both sides of

the tear. When mending a three-cornered

tear, stitch from each end to the center. It is

well to use a piece of fabric under the tear for

reinforcement.

OVERCASTING with mending stitch

Stitch Length - 24-12

Stitch Width - 3-4

Three-step zig-zag is a strong stitch because,

as its name implies, it takes three short

stitches where normal zig-zag takes one.

For this reason it is highly recommended for

overcasting, i. e. finishing a raw edge, on all

types of fabric.

ii:

( > I »

: I i: » i c i:« i>i; ft t It

1

1

1

c

c

< >

>

>

<

1

t

1

i

1

1

!

t

<

<

1

<

=t=

»:il.f

?

>

39

Page 43

BOX STITCH

mmm

Stitch Length - 24-12

Stitch Width - 2-4

OVERLAPPED SEAM

Box stitch is ideal for producing fiat

overlapped seams on almost any type of

fabric and a bolder effect will result from

sewing with a contrasting thread.

Overlap the raw edges of two pieces of fabric

2” and pin or tack. Place the fabric right side

up with the middle of the overlap under the

center of the presser foot, so that the stitch

sews just over the top and bottom raw edges.

DECORATIVE EDGING

Turn the raw edge under 2” and press. Place

the fabric right side up with the middle of the

turnover under the center of the presser foot,

so that the stitch sews on to the fold and just

over the raw edge underneath.

40

Page 44

BUND HEMMING

IkvvWyVVVAW S j

j

A/^AAA ’

mjv\

Blind hemming is a good technique to use on

garments, and especially on curtains and

drapery hems so that stitches need not show

on the front of the fabric. Because your

Kenmore has two types of blindstitches built

in, blind hemming is easier than you'd

expect. It's just a matter of folding... give it

a try!

YYYY

■Regular blind

normal fabrics

- Elastic blind stitch for soft,

stretchable fabrics

stitch for

PROCEDURE

Stitch Length Stitch Width -

Finish raw edge of fabric appropriately. You

may want to use seam tape on woven fabrics.

With knits use a lace seam tape or just use

decorative stretch stitch.

12

VA -2

41

Page 45

GUIDE

Working on wrong side of fabric, fold hem

up. Press and pin in place. Then fold hem

allowance under... leaving %" of hem edge

extending.

Place garment under blind stitch foot with

the fold of the garment against guide and

slide it by turning screw so that the zigzag

just catches the fold. (Blind hemming can be

simplified by also using the special Kenmore

Edgestitcher-please refer to p. 21 for details.)

Now the right side of your garment will show

only the blind stitches ! Be sure to press both

sides of the finished hem !

42

SHELL STITCHING with blind hem pattern

Stitch Length - 12

Stitch Width - 2-4

This shell-stitched edge is a popular finish for

lingerie and nightgowns. To achieve this

multiple scalloped effect, allow needle to

clear just the left edge of the fabric when it

zigzags.

Page 46

SCALLOP STITCH

PROCEDURE

1. With right sides of fabric together, sew

near the folded edge with scallop stitch.

2. Trim allowance to 1/8". or less. Notch

curves if necessary. Cut down into points.

3. Turn to right side and push scallops out

evenly. If they do not seem even, be sure

curves are notched similarly. Fig. 2.

4. Press flat.

Page 47

STRETCH STITCHES

ol --

c=>

See next page.

■ o

/

® @ (D © ® ® @

Zigzag needle plate

Zigzag or Q foot

Stretch stitches, as their names imply, are

mainly for use on stretch and knit fabrics

such as stretch nylon, stretch towelling,

jersey and cotton jersey; and for sewing

together knitted garments. Stretch stitches

are also often used on non-stretch fabrics.

1. Straight stretch

2. Rick-rack stretch

3. Feather stretch

4. Smocking stretch

5. Elastic stretch

6. Overcast stretch

7. Paris point stretch

ADJUSTING STITCH LENGTH

Depending upon your preference in stitch

patterns, you may make stretch stitches

closer together without changing the balance

of stitches by turning stitch length control to

lower numbers within yellow zone.

Within yellow zone

44

Page 48

ADJUSTING STRETCH STITCH BALANCE

Stitch modifier should be in neutral (notched)

position for most materials. Depending upon

the type of fabric used, you may need to

adjust this control to match forward stitches

of stretch sewing with reverse motion

stitches. If the stitches are too open, turn the

control slightly clockwise; if the stitches

overlap, turn the control counter-clockwise.

RECOMMENDATION

1. It is recommended you use the Q set for

sewing knit and woven synthetic fabrics.

2. It may be necessary to use an interfacing

or backing when sewing very soft and

thin knits or woven synthetic fabrics.

STRAIGHT STRETCH STITCH

SETTINGS

Stitch Selector - =====

Stitch Length - Yellow Zone

Stitch Width - Any number (not necessary

to adjust)

You may use either a zig zag or straight stitch

foot BUT-- for best control of fabric, best

looking straight stitches and best feeding of

fabric use Straight Stitch Foot and Straight

Stitch Needle Plate.

Use this stretch stitch with knit or synthetic

fabric. Sew as you do with regular straight

stitch.

This is also a good stitch to use on curved

seams regardless of the type of fabric. Any

seam that will receive a great deal of strain

when worn should be sewn with the stretch

stitch. Use in children's shorts and slacks as

well as adult sports clothes.

< ♦-

Rick - Rack Stretch Smocking Stretch

45

Page 49

RICKI-RACK STRETCH STITCH

Selector-

stiteb

Stilish

Length- Yellow Zone

Width- Yellow Zone

SeWion stretch fabrics in any area that you

rrtibht use a zig zag stitch. This stitch can be

usfll gs a decorative top stitch as well.

It M

whtete

anothii

ieful also on lapped or abutted seams

you lap one edge of a seam over

ir with seamlines meeting in the center.

HER STRETCH STITCH

Selector Length - Yellow Zone

Stiteh

Width - 2-4

Stitph

This

lingeri

tapei.

a good stitch to use with laces, on

IS

e, bra and girdles; and to apply bias

It's great when quilting.

46

SMOCKING STRETCH STITCH

Selector - 95^5^5^

Stitph

Stitch

Stitch

Length - Yellow Zone

Width - 2-4

T Make a straight line of gathers across the

fabric that you wish to smock.

ith a narrow strip of fabric directly

W

hder the line of gathering, stitch over the

u

athers. The design will be a series of

S

mail diamonds.

s

Notei When smocking a garment, the stitch

ing should be done before the piece is

sewn into the garment.

Page 50

ELASTIC STRETCH STITCH

Stitch Selector - AAA<V\

Stitch Length - Yellow Zone

Stitch Width - 2-4

Use this versatile stitch to insert elastic in

garments. Simply stitch elastic into place,

making sure it is evenly spaced. To do this,

mark the correct length piece into quarters,

then match these markings with center front

and side seams.

OVERCAST STRETCH STITCH

Stitch Selector - AAAAA

Stitch Length - Yellow Zone

Stitch Width - 4

This is the same type stitch used by the

garment industry in making sportswear-it

forms and finishes the seam in one operation

(for seams of Vi" to %")• It's very effective

for use in repairing raw or worn edges of

older garments.

PARIS POINT STRETCH STITCH

Stitch Selector

Stitch Length Stitch Width -

Excellent for hemstitching table and bed

covers with a elegant touch. Picot-like stitch

can also be made on sheer materials. Sew

along the raw edge of fabric and trim close to

the outside of the stitching.

null

12

2-3

47

Page 51

GETTING THE MOST FROM FABRICS THAT GIVE

Some stretchy suggestions...

Be sure to use the Q SET'“ with knits and any

synthetic woven fabric — and zigzag or satin

foot as required.

Loosely constructed knits sometimes catch

over toes of presser foot. To remedy this,

wrap short strip of transparent tape around

the foot encasing both toes.

To avoid tangled threads when working with

knits, start seams carefully. Position fabric

WHERE TO USE WHICH STRETCH STITCH: A CHECK-CHART

Specially for Stretch

Use on stretch and knit fabrics and to repair ready made

garments at stress points. Basic stitch for all garment

seams requiring "give” (i.e. armholes, crotch area, etc.).

Use also to sew center seam of men's neck ties and seams

STRAIGHT STRETCH

cut on the bias.

A basic multi-purpose stretch stitch with same usage as

zigzag stitch, especially for lightweight stretch fabrics.

and lower needle before lowering presser

foot.

It is always a good idea to test thread tension

and stitches on a scrap of the fabric being

used.

Knits contain more yarn than woven fabrics,

so you will need to take greater care to keep

your machine clean specially in feed dog and

bobbin case area.

RICK-RACK STRETCH

Use with laces, on lingerie, bra and girdles; and to apply

<<<<<<<<<<<

FEATHER STRETCH

SMOCKING STRETCH

vwww

ELASTIC STRETCH

AAAAAAA

OVERCAST STRETCH

1 1 1 1 1 1

PARIS POINT STRETCH

bias tape. It's great when quilting.

A decorative stitch for use on children's clothing, lingerie,

yokes of blouses, dress bodice.

Use to apply elastic to top of lingerie or to repair ready

made lingerie and replace or restitch elastic.

Use on sportswear where 14” seams are required. Makes

and finishes seams at same time.

Use for hemstitching and seam finishes. Also for applique

and other decorative elastic blind hem, hem on knits.

%

48

Page 52

A/VVWW\

PLAIN ZIGZAG

"Everyday" Stitches with Stretch Applications

Use for all-purpose stretch sewing, seam finishing, edge

finishing, or attaching stretch laces.

YYW

A good shell stitch for nylon tricot lingerie.

BLIND HEM

Can be use for attaching girdle panels and applying stretch

laces.

CRESCENT STITCH

HINTS ON SEWING DIFFERENT FABRICS

The chart below provides many details but

you'll also want to remember...

•Soft fabrics may need backing — especially

where stitches are close together.

•In sewing knits, if you can't match fabric

and thread exactly, use the strongest fine

thread available and use a Q NEEDLE.

FABRICS USEFUL STITCHES TO USE

Overcast Stretch Feather Stitch

NYLON TRICOT

TERRY CLOTH

REGULAR

CORDUROY

TERRY CLOTH

STRETCH

LEATHER Straight or simple Zigzag

STRETCH KNITS

FOR SWIMWEAR

AND SKIWEAR

OR GIRDLES

Elastic Stretch Blind Hem

Mending Stitch

Crescent Stitch

Paris Point Stretch

Elastic Blind Hem

Simple Zigzag

Mending Stitch

Paris Point Stretch

Simple Zigzag

Mending Stitch

Overcast Stretch

Overcast Stretch Crescent Stitch

Elastic Stretch

Mending Stitch

Feather Stitch

Scallop Stitch

Elastic Blind Hem

•When working on tweed — or other multi

colored bulky fabrics — use one color thread

on bobbin, another on top. (Great for

repairs — the "patch" practically dis

appears!)

SPECIAL NOTIONS TO USE

QNEEDLE™

Polyester, nylon or

dacron core thread

QFOOT™

Mercerized Thread

Size 14 needle

Mercerized Thread

Polyester, nylon or

dacron core thread

QNEEDLE™

□ FOOT™

Mercerized or silk thread

Size 14 needle

Vi pressure on presser foot

Even feed foot

Polyester, nylon or

dacron core thread

Q NEEDLE™

QFOOT™

Lace seam tape

Pre-shrunk zippers

49

Page 53

BUTTONHOLE MAKING

Your Kenmore brings you two buttonhole

systems along with several special acces

sories that enable you to solve all your

clothes "closing" problems. '

Your built-in system enables you to sew

buttonholes with finished ends (bar-tacked)

by simply turning the stitch selector. Only

two control settings are required. An

important aid is the buttonhole guide foot.

Your buttonhole attachment is a Kenmore

"special" that guides the fabric for you,

eliminates the need to turn fabric by hand.

You will find following parts in your

accessory box:

1. Buttonhole guide plate.

2. Five templates which give you a choice

of buttonhole styles and lengths.

50

3. Cover plate with pinion gear.

4. Buttonhole foot.

TIPS ON BUTTONHOLING

Always make a practice buttonhole on a

scrap of fabric you plan to use. Try the

buttonhole with the button you will use.

Always use an interfacing in area of

garment where buttonholes are placed.

Tissue paper or regular interfacing can

be used. Tear paper away after stitch

ing, if it is used.

For heavier weight fabrics, loosen your

top thread tension slightly.

Buttonhole attachment

Page 54

BUTTONHOLE MAKING - BUILT-IN SYSTEM

PREPARATION

Carefully mark the buttonhole length on your

garment. Place the fabric with the buttonhole

marked under the buttonhole foot. Puli the

guide foot (A) all the way forward so that the

index mark (B) is aligned with the graduation

(C), with thread to rear. (Reproduction of the

identical size buttonholes is facilitated with

the aid of the graduations on the both sides

of the buttonhole guide foot. These garduations are 1/8" (left side) or 2.5 mm (right side)

apart. Graduations act as reference mark.)

PROCEDURE

1. Switch the control to left. (If it has been

already at left, set it at right, sew several

stitches and switch to left again.) Step on

foot control to form first bartack and left

side of buttonhole.

2. When you reach end of left side, switch

the control to the right and complete the

buttonhole.

©

@

51

Page 55

ADJUSTING STITCH DENSITY

Less density

i

•

.1

I

1»

—24

1

1

More density

Depending upon the fabrics on which you are

sewing, or your own preference in button

holes, you may alter buttonhole stitch density

by varying the original stitch length setting

within the green buttonhole zone.

1. For more density, turn the dial toward

A

"0".

2. For less density, turn the dial toward

"12”.

ADJUSTING STITCH BALANCE

Stitch length differences in forward and

reverse stitches of the buttonhole are

equalized with the stitch modifier.

If the reverse stitches are too far apart, turn

the modifier slightly clockwise; if they are too

close together, turn counter-clockwise.

52

CORDED BUTTONHOLES

Hook filler cord (crotchet thread or button

hole twist) to the spur (A), pull both ends of

cord forward under foot and tie to the spur

(B). Sew buttonhole in such a way that

zigzag stitches cover the cord.

When stitching is completed, release cord

from foot, pull ends of cord and snip off extra

length.

Page 56

BUTTONHOLE MAKING - USING BUTTONHOLE ATTACHMENT

1 - VA

eHHHHI

YYTY

/vywvyvwyv'

REGULAR WORKED BUTTONHOLE

(STRAIGHT, KEYHOLE AND EYE

LET)

Zigzag needle plate

and feed cover plate

Buttonhole foot

Any setting

PROCEDURE

Stitch Selector - AAAAA

Stitch Width - ^ -VA

Zigzag Needle Plate

Feed Cover Plate

Buttonhole Foot

Raise needle to its highest position and

1.

raise presser foot. Remove accessory box

and bobbin cover plate.

Insert buttonhole cover plate at 45 degree

angle and snap it down into place

pressing it against the needle plate.

Select correct template for type button

2.

hole you want. Insert template into slot of

guide plate. Turn template advance knob

until desired size appears in window on

the top side of guide plate.

53

Page 57

3. Slip guide plate onto machine so it fits in

place with pinion gear in the center of arc

hole of template. Be sure guide block is

inserted in guide slot.

54

Pick up bobbin thread through guide plate

by turning hand wheel. Place fabric

between presser foot and guideplate.

Align marked buttonhole with cut-out of

foot. Line up edge of fabric with markings

on guideplate. If you wish all buttonholes

to be 3/4" from edge of garment, for

example, line up fabric with 3/4" marking

each time you start a buttonhole.

Now you're ready to stitch the shape

you've selected-straight, keyhole or

eyelet. Your template will guide you.

Page 58

PURL-EDGE BUTTONHOLE

To add a professional touch to your sewing

you will want to make purledged button

holes. These are obtained by sewing a wide

buttonhole over a narrow stitched button

hole. '

Choose the correct size for your button,

insert the template into the guide plate

turning to the narrower of the sizes. Use the

same settings as for regular buttonhole and

adjust stitch width control to 1.

Drop the guide plate over the pinion gear and

sew around the buttonhole once. (STEP 1)

To sew wider outer buttonhole, lift the guide

plate from the pinion gear and turn the

template to wider size. Adjust stitch width

setting to 1.5. and sew around buttonhole

again. (STEP 2)

STEP1

ADJUSTING STITCH DENSITY

Depending upon the fabrics on which you are

sewing, or your own preference in button

holes, you may alter buttonhole stitch density

by turning stitch density control knob.

1. For more density, turn the knob,toward

you.

2. For less density, turn the knob away from

you.

STEP 2

(D

55

Page 59

iai5) fcO fdQ ic+3l

0C5

BOUND BUTTONHOLE

A template had been provided so that you

may sew perfectly sized rectangles each time

you make a bound buttonhole. Just follow

the directions given below.

SETTING

Stitch Width - 0 or Stitch Selector

Pressure Regulator - 1 or 2

Other settings same as regular worked

buttonhole ,

1. Space buttonholes on garment-mark

length on right side of fabric with pins.

Place patch of fabric over each button

hole and mark ends of buttonhole with

chalk or pencil. Baste patch into place.

Using template similar in size to button

hole, stitch rectangle on patch and

garment. Do not sew over pins. (Fig. 1)

2. Slash through patch and garment to

within 1/4” of ends of rectangle. Carefully

cut diagonally into corners as shown.

(Fig. 2)

-------------------

56

Fig. 2

3. Turn patch to wrong side through slash.

Press as shown. (Fig. 3, 4)

Fig. 3

Fig. 4

Page 60

4. Fold patch forming lips of buttonhole.

Press and baste lips together. (Fig. 5)

5. Stitch across pleats formed by lips of

patch. (Fig. 6)

Fig. 5

Fig. 6

6. After buttonhole has been pressed, baste

facing of garment around buttonhole and

slash opening in facing same length as

buttonhole. (Mark ends of buttonhole

with pins for guides). Turn under facing

edges and hem to buttonhole carefully.

(Fig. 1, 8)

7. Remove all bastings and press. (Fig. 9)

FACING SIDE

I fl

I 6 4

Slash Opening in Facing

FACING SIDE

.........

Hem to Buttonhole

RIGHT SIDE

Fig. 7

—'■>

Fig. 8

Complete Bound Buttonhole ^^'9- 9

57

Page 61

CHOOSING BUTTONHOLE STYLE AND SIZE

Each buttonholing situation will be different

so you will want to experiment with your

garment, considering fabric and placement of

button. Here are some basic applications:

Built-in buttonholes (described previously)

are ideal for one or two buttons used on

waistband or cuff, or for "belt slots.”

Straight buttonholes are most popular for

everyday sewing — for series of buttons on

dress, blouse, vest, jacket or coat.

Keyhole buttonholes are a variation of the

above, with an enlarged opening at one end

to allow more room for button shank. These

are normally used in tailored vests, jackets,

coats.

Template

Straight

buttonhole

Keyhole

buttonhole

Eyelet buttonholes (another variation of

"straight”) most often are used for studs on

skirts or holes for tongues of belt buckles.

Purl-edge buttonholes are made by stitching

a larger straight buttonhole on top of a

narrow one — for a unique look.

Bound buttonholes — made with extra fabric

"hemming” the hole — provide "professional

look" to dresses, jackets, coats and for

contrasting, decorative buttonholes.

Purl-edge

and eyelet

buttonhole

Bound

buttonhole

O

45195

45196

45197

45198

45199

1'/4--1’/2"

%"-r/i6" -

V/4"-V/e"

A WORD ABOUT BUTTONHOLE WIDTH

The width indicated for each operation in this

section is an approximate setting. You may

need to adjust width to suit your fabric...

experiment!

58

Eyelet

Page 62

DECORATIVE EMBROIDERY DESIGNS

4- 1

See next page.

-A

____

T ree

O I - ! C

. '<J u

c=> ,

^1 J /-

Zigzag needle plate

Donnino

Diamond

Crescent

Arabesque

Tulip

*1-6

u

Green Yellow

patterns patterns

You may get the look and feel of hand

embroidery infinitely faster and easier by your

machine.

Just choose which of the designs you want

to sew alone or in combination with each

other.

TIPS ON DESIGN STITCHING

1. Always make a practice design on a scrap

of the fabric you plan to use.

2. Start with a full bobbin and plenty of

thread on the spool to avoid running out

of thread in the middle of your design.

3. Reduce the top therad tension slightly.

4. On a very soft fabric you may want to use

a tissue paper backing or organdy that

can be cutaway.

iy^ iy^ Swan

59

Page 63

APPLICATIONS

ADJUSTING STITCH BALANCE OF YELLOW PATTERNS

When sewing yellow patterns, you may need

to make slight adjustment to the stitch

modifier to produce perfect designs.

If the stitches are too far apart, turn the

control slightly clockwise; if they are closer

together, turn counter-clockwise.

Create the loveliest of custom designs-your

own personal touch. There is much you can

do by adjusting stitch width or length. Below

Crescent pattern on collar Diamond on narrow hem

Tulip on pocket

Arabesque on pillow case

you see some applications and variations.

You'll find many more design ideas as you

become more expert.

Domino on bias tape

Crescent and diamond in

combination

60

Variation of width of

diamond pattern

Variation of both width and

length of swan pattern

Page 64

WARRANTY

FULL 30-YEAR WARRANTY ON SEWING MACHINE HEAD

For 30 years from the date of purchase, Sears will, free of charge,

repair defects in material or workmanship which appear in the sewing

machine head.

FULL TWO YEAR WARRANTY ON ELECTRICAL EQUIPMENT OF

SEWING MACHINE

For two years from the date of purchase. Sears will, free of charge,

repair defects in material or workmanship which appear in the

electrical equipment of the sewing machine, including motor, wiring,

switch and speed control.

FULL 90-DAY WARRANTY ON ALL PARTS AND MECHANICAL

ADJUSTMENTS

For 90 days from the date of purchase. Sears will, free of charge,

replace any parts and provide mechanical service necessary for proper

operation of the sewing machine, except for normal maintenance.

To obtain warranty service described above, SIMPLY CONTACT THE

NEAREST SEARS STORE OR SERVICE CENTER IN THE UNITED

STATES. This warranty applies only while this product is in use in the

United States.

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

SEARS, ROEBUCK AND CO., Dept. 698/731A, Sears Tower, Chicago, IL 60684

Page 65

Now that you have purchased your Kenmore Sewing Machine,

should a need ever exist for repair parts or service, simply contact

any Sears Service Center and most Sears, Roebuck and Co.

Stores. Be sure to provide all pertinent facts when you call or

visit.

The model number of your Sewing Machine will be shown on

your nomenclature plate on the back of your Sewing Machine.

See page 3 for location.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION:

*MODEL NUMBER *NAME OF ITEM »PART DESCRIPTION

If the parts you need are not stocked locally, your order will be

electronically transmitted to a Sears Repair Parts Distribution

Center for handling.

SEARS, ROEBUCK AND CO., Chicago, IL 60684 U.S.A.

S - 158

Printed in Japan

Part No.55079 dD

Loading...

Loading...