Page 1

TABLE OF CONTENTS

KNOWING YOUR MACHINE Page

Knowing parts and features 1 - 2

GETTING READY TO SEW

Setting up your machine 3

Electronic needle contro|, stitch selector and indicator 4

Winding the bobbin

Threading your machine

Checking for correct tension

Changing needies, needleplates

Special fabnc chart

STRAIGHT AND ZIGZAG SEWING

Using the free-arm

Straight stitching

Securing seams, top-stitching

3 ways to do basting

Zigzag sewing -- the basics

Blind hemming

Mending, darning, fagoting, bar-tacking

Interfacing

BUTTONHOLES AND FASTENERS

Using your "built-in" system

Your "attachment" system

6- 7 STRETCH AND SPECIAL STITCHES

Choosing the right buttonhole

"' Regular-worked" buttonholing

Purl-edging, bound buttonholes

installing zippers

5 Machine-sewing buttons

8 Straight stretch stitching

9 Rick-rack, stretch

10 Feather, elastIc and overcast stretch

Paris point stretch, built-in decorative stretch stitches 33

13 FINISHING AND PERSONAL TOUCHES

14 Satin stitches, machine emboridery

15 Narrow hemming

16 Edgestitchlng, even feed foot

17 Shell stitching, lettuce edging

19 Appliques and quilting

20 CARING FOR YOUR MACHINE

22 Performance check chart

Keeping your machine clean

23 Oiling your machine

24 Ordenng replacement parts

Page

25

26

27

28

29

30

3t

32

34

35

36

38

39

4O

42

44

45

Page 2

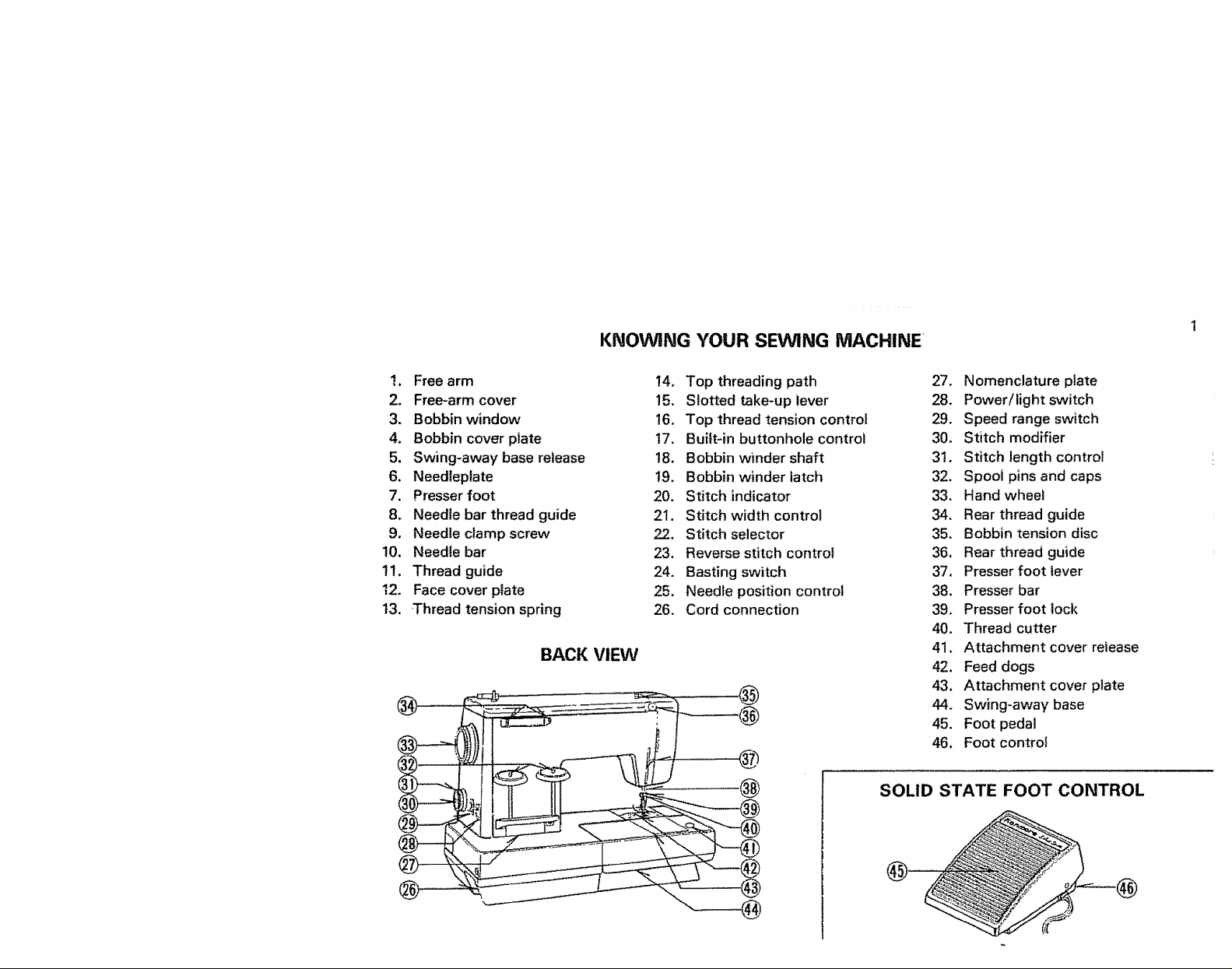

KNOWING YOUR SEWING MACHINE

!. Free arm

2. Free-arm cover

3. Bobbin window

4. Bobbin cover piate

5. Swing-away base release

6. Needleptate

7, Presser foot

8. Needle bar thread guide

9. Needle clamp screw

t0. Needle bar

11. Thread guide

12, Face cover pIate

13. -Thread tension spring

BACK VIEW

!4. Top threading path

!5. Slotted take-up lever

16. Top thread tension control

17. Built-in buttonhole control

18. Bobbin winder shaft

19. Bobbin winder latch

20. Stitch indicator

21. Stitch width control

22. Stitch selector

23. Reverse stitch control

24. Basting switch

25. Needle position control

26. Cord connection

@

@

:27. Nomenclature plate

28. Power/light switch

29. Speed range switch

30. Stitch modifier

31. Stitch length control

32. Spool pins and caps

33, Hand wheel

34. Rear thread guide

35, Bobbin tension disc

36. Rear thread guide

37. Presser foot lever

38. Presser bar

39, Presser foot lock

40. Thread cutter

41, Attachment cover release

42. Feed dogs

43, Attachment cover plate

44. Swing-away base

45. Foot pedal

46. Foot control

SOLID STATE FOOT CONTROL

Page 3

@

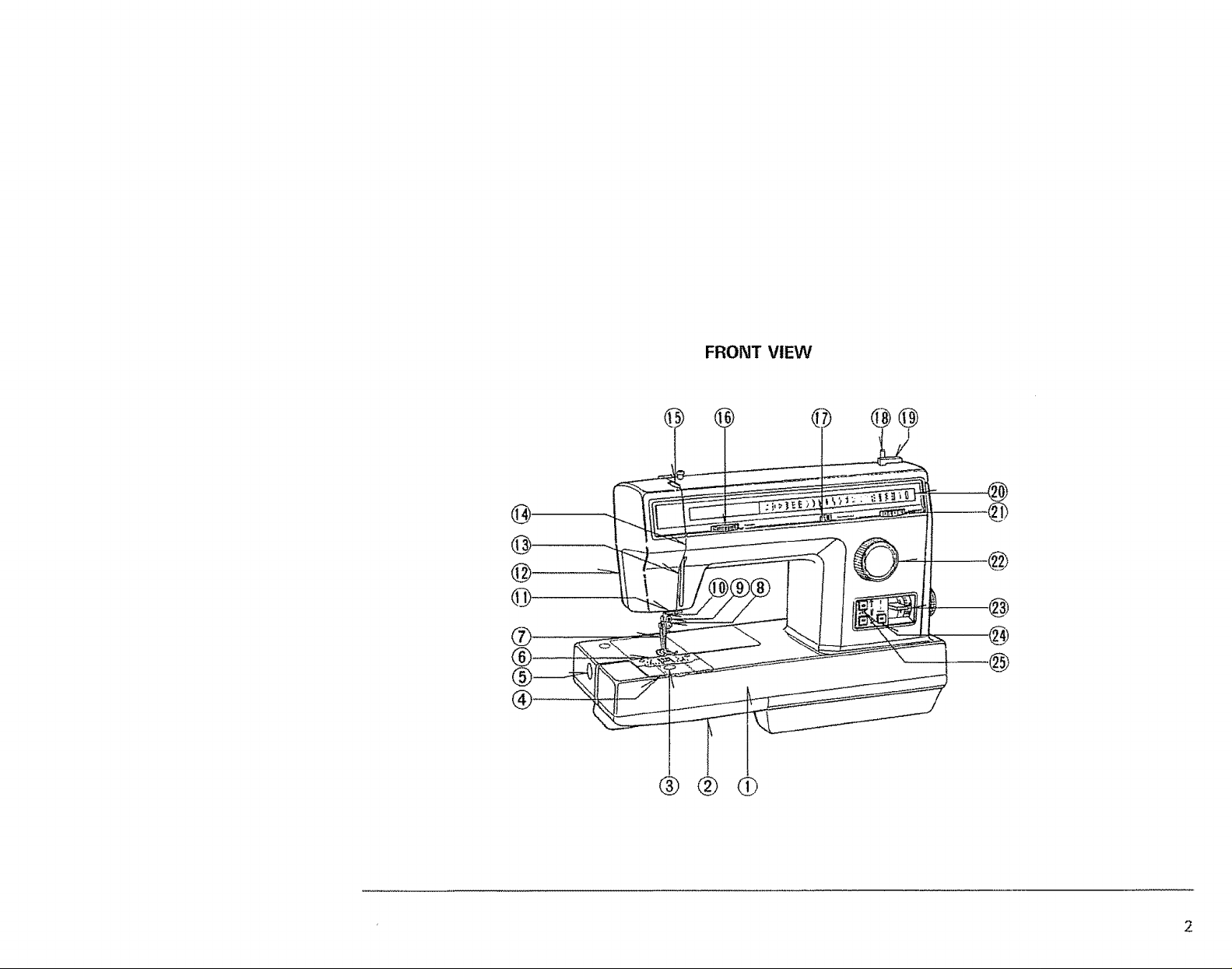

FRONT VIEW

@@

1

®®0

Page 4

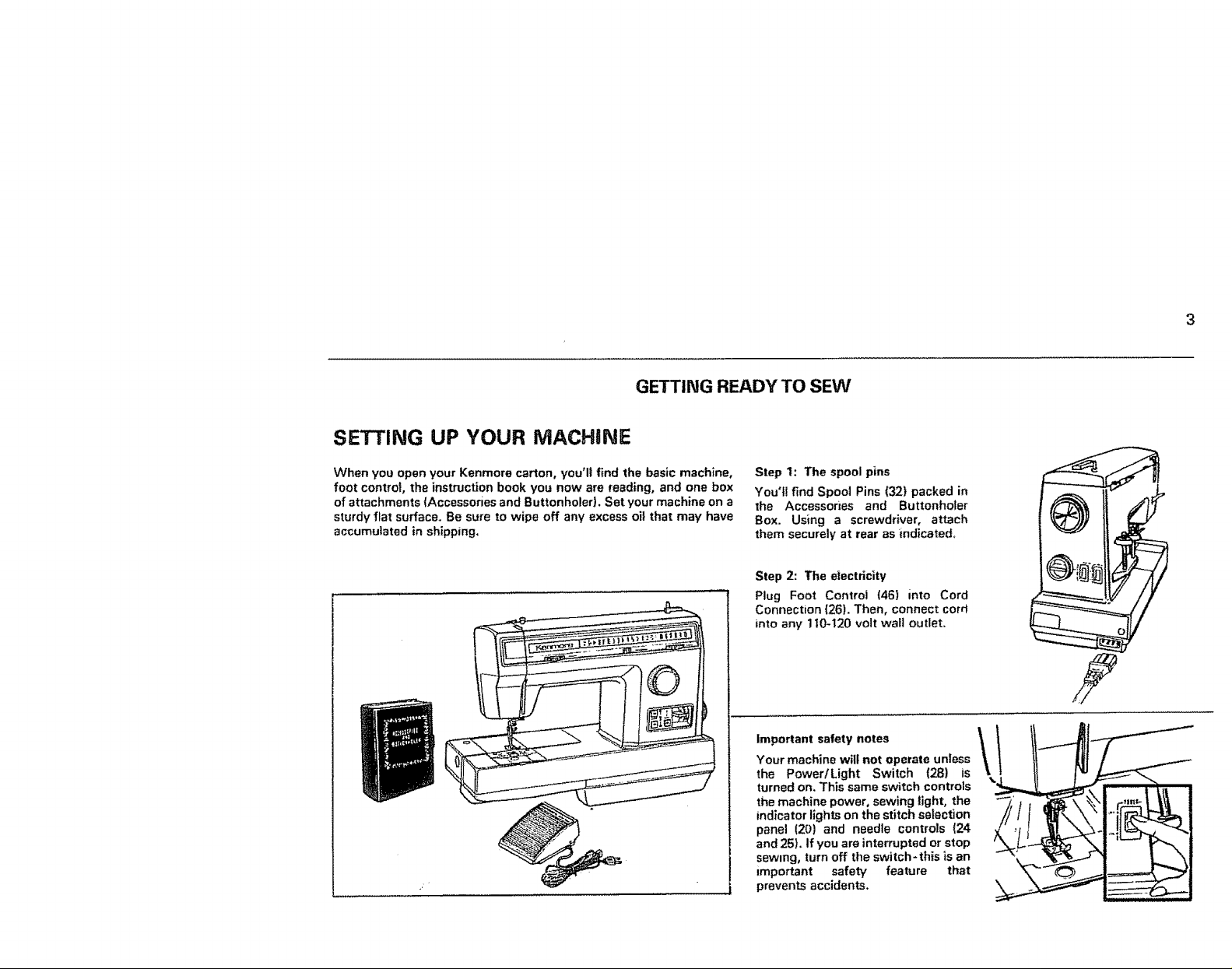

SETrlNG UP YOUR MACHINE

GETTING READY TO SEW

When you open your Kenmore carton, you'll find the basic machine,

foot control, the instruction book you now are reading, and one box

of attachments {Accessories end ButtonholerL Set your machine on a

sturdy flat surface. Be sure to wipe off any excess oil that may have

accumulated in shipping,

Step 1: The spool pins

You'tl find Spool Pins (32) packed in

the Accassones and Buttonholer

Box. Using a screwdriver, attach

them securely at rear as indicated.

Step 2: The electrlclty

Plug Foot Controt {46) into Cord

Connection {26). Then, connect cord

into any 110-120 volt wall outlet.

Important safety notes

Your machine will not operate unless

the Power/Light Switch (28) is

turned on. This same switch controls

the machine power, sewing light, the

indicator lights on the stitch selection

panel (20) and needle controls (24

and 25). If you are interrupted or stop

sewing, turn off the switch-this is an

important safety feature that

prevents accidents.

!llt_ i

Page 5

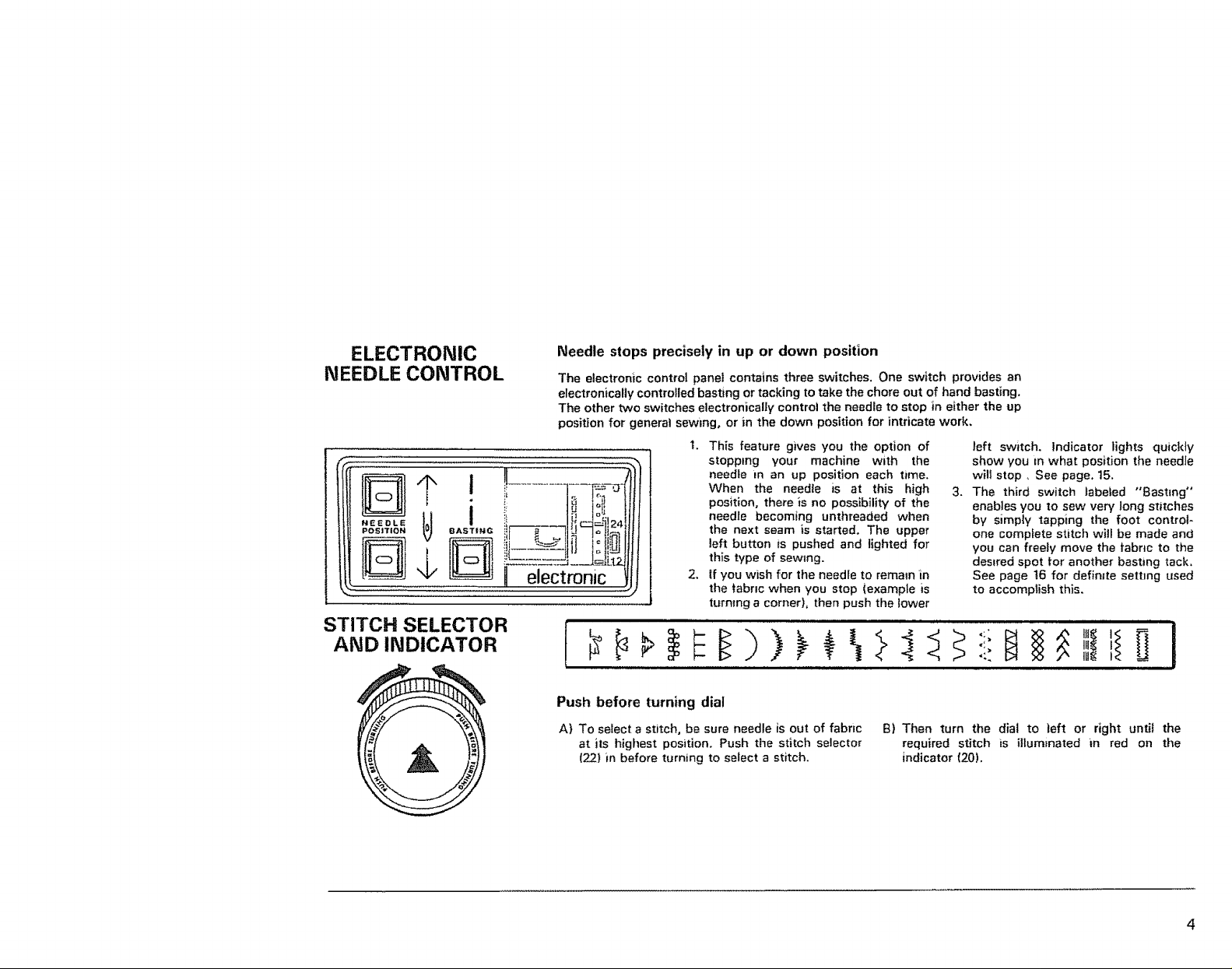

ELECTRONIC

NEEDLE CONTROL

STITCH SELECTOR

Needle stops precisely in up or down position

The electronic control panel contains three switches. One switch provides an

electronically controlled basting or tacking to take the chore out of hand basting.

The other two switches electronically control the needle to stop in either the up

position for general sewing, or in the down position for intricate work.

1. This feature gives you the option of

stopping your machine with the

needle m an up position each time.

When the needle is at this high

position, there is no possibility of the

needle becoming unthreaded when

the next seam is started. The upper

left button is pushed and lighted for

this type of sewing.

2. If you wish for the needle to remain in

the tabnc when you stop (exampte is

turning a corner), then push the lower

Push before turning dial

A) To select a stitch, be sure needle is out of fabric

at its highest position. Push the stitch selector

(22) in before turning to select a stitch.

B) Then turn the dia! to left or right until the

required stitch is illuminated in red on the

indicator (20),

left switch. Indicator lights quickly

show you m what position the needle

will stop, See page. 15.

3.

The third switch labeled "'Basting"

enables you to sew very long stitches

by simply tapping the foot control-

one complete stitch will be made and

you can freely move the fabric to the

desired spot for another basting tack,

See page 16 for defin=te setting used

to accomplish this.

i iii i i i iii i i I

I

Page 6

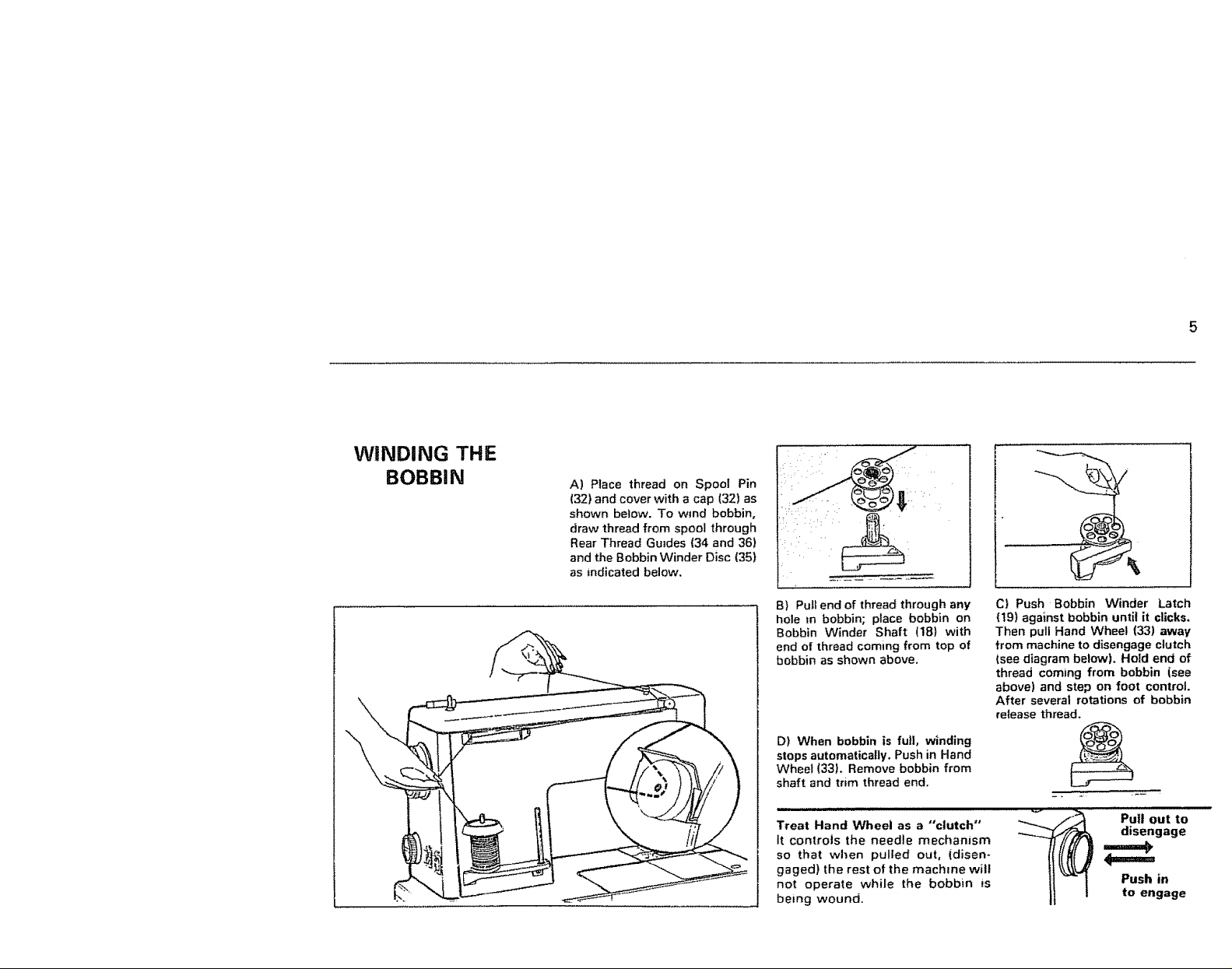

WINDING THE

BOBBIN

A) Place thread on Spool Pin

(32) and cover with a cap (32) as

shown below. To wind bobbin,

draw thread from spool through

Rear Thread Guides (34 and 36)

and the Bobbin Winder Disc (35)

as indicated below.

B) Pull end of thread through any

hole m bobbin; place bobbin on

Bobbin Winder Shaft (18) with

end of thread coming from top of

bobbin as shown above.

\

D) When bobbin is full, winding

stops automatically. Push in Hand

Wheel (33L Remove bobbin from

shaft and trim thread end.

Treat Hand Wheel as a "clutch"

It controls the needle mechanism

so that when pulled out, (disen-

gaged) the rest of the machine will

not operate while the bobbin fs

being wound,

C) Push Bobbin Winder Latch

(19) against bobbin until it clicks.

Then pull Hand Wheel (33) away

from machine to disengage clutch

(see diagram below), Hold end of

thread coming from bobbin (see

above) and step on foot control.

After several rotations of bobbin

re_ease thread.

Putt out to

disengage

Push in

to engage

Page 7

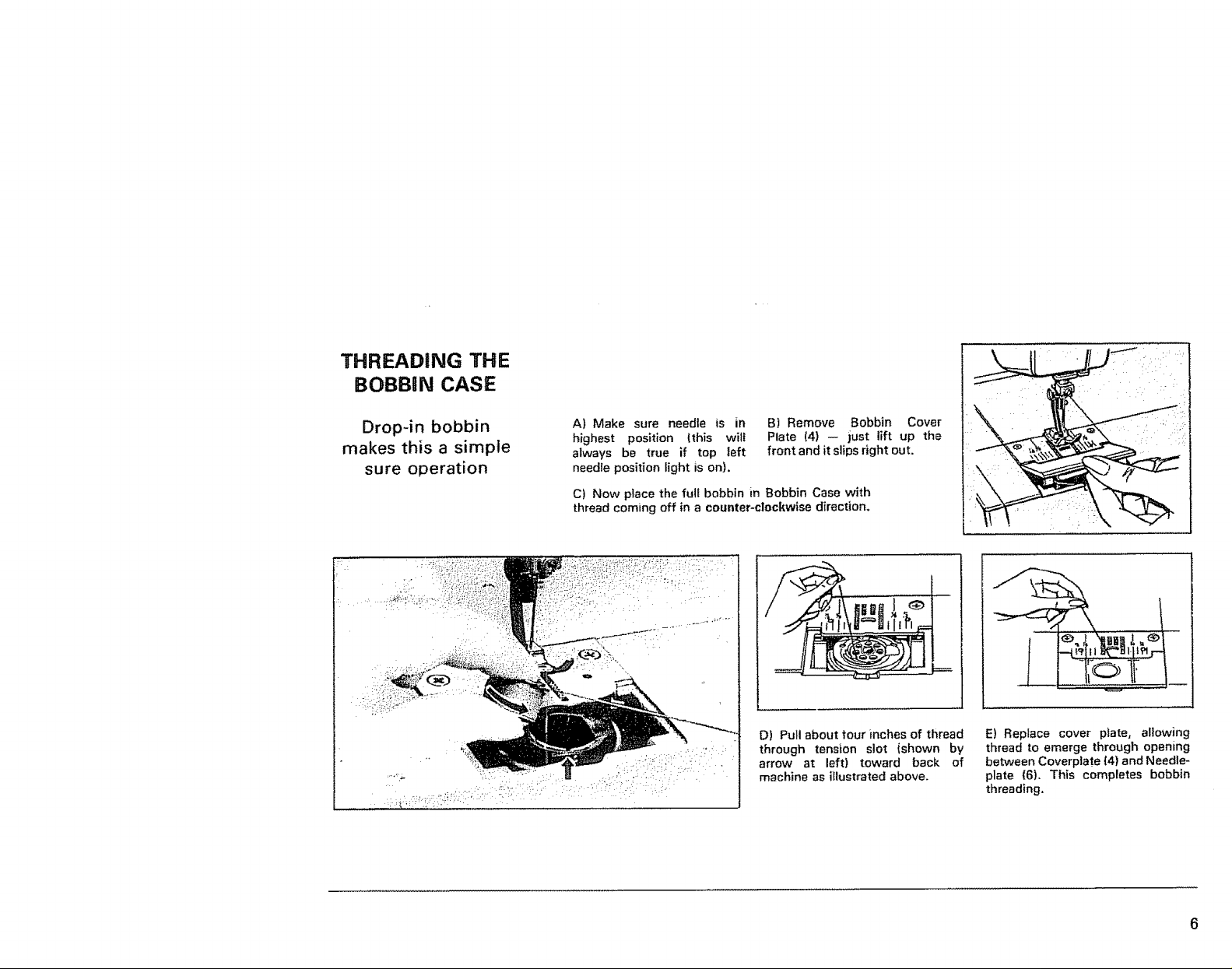

THREADING THE

BOBBIN CASE

Drop-in bobbin

makes this a simple

sure operation

i i_ i ,_ i !i _i _i i! _

A) Make sure needle is in

highest position (this will

always be true if top left

needle position light is on).

C) Now place the full bobbin in Bobbin Case with

thread coming off in a counter-clockwise direction.

B) Remove Bobbin Cover

Plate (4) -- just lift up the

front and it slips right out.

D) Pull about tour inches of thread

through tension slot (shown by

arrow at left) toward back of

machine as illustrated above.

E) Replace cover plate, allowing

thread to emerge through opening

between Coverplate (4) and Needle-

plate (6). This completes bobbin

threading.

Page 8

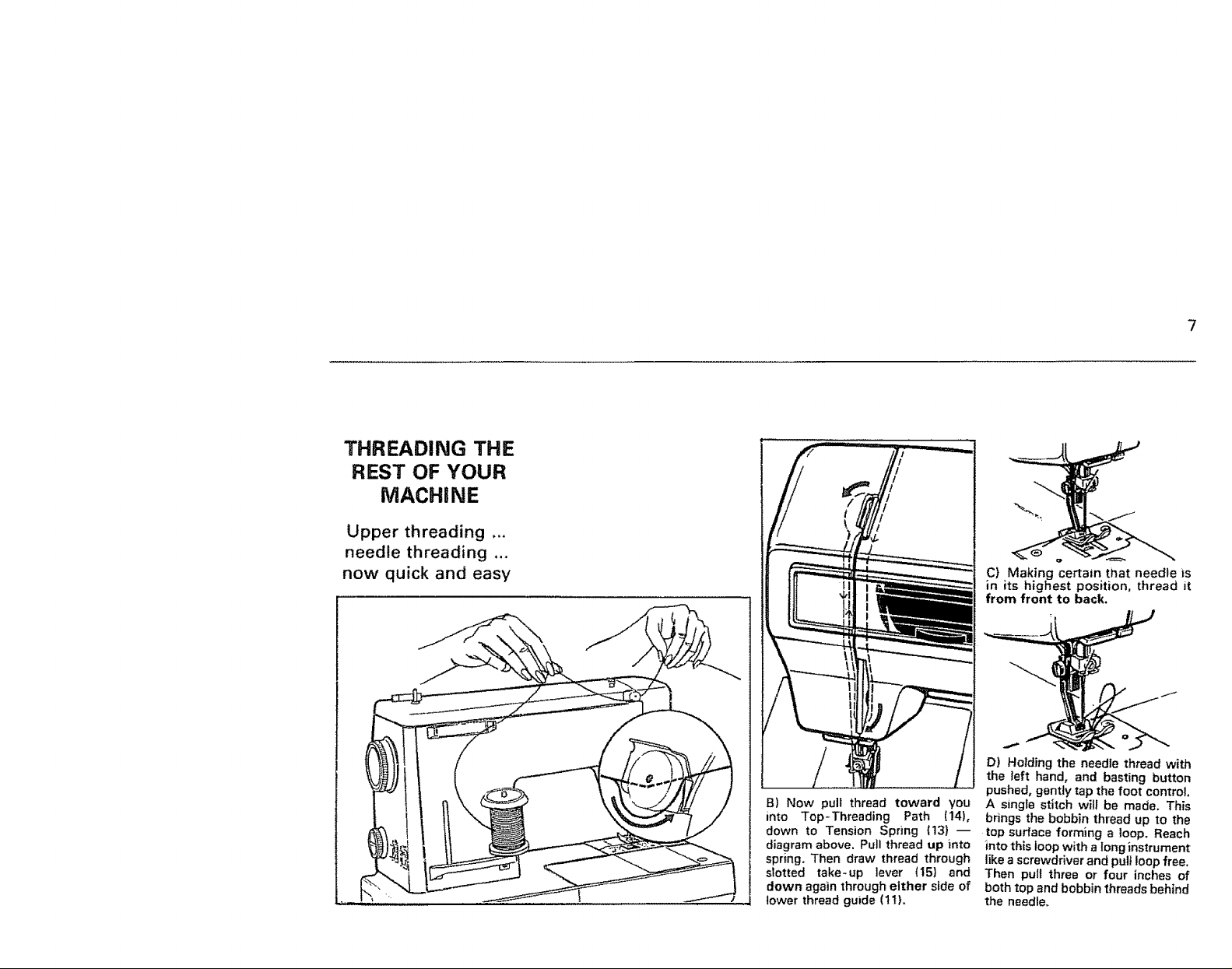

THREADING THE

REST OF YOUR

MACHINE

Upper threading ...

needle threading ...

now quick and easy

B) Now pull thread toward you

into Top-Threading Path (14),

down to Tension Spring (13) --

diagram above, Pull thread up into

spring. Then draw thread through

stotted take-up ]ever (t5} and

down again through either side of

lower thread guide (1t).

C) Making certain that needle is

in its highest position, thread it

from front to back.

D) Holding the needle thread with

the left hand, and basting button

pushed, gently tap the foot control.

A single stitch will be made. This

brings the bobbin thread up to the

top surface forming a loop. Reach

into this loop with a long instrument

like a screwdriver and pug loop free,

Then pull three or four inches of

both top and bobbin threads behind

the needle.

7

Page 9

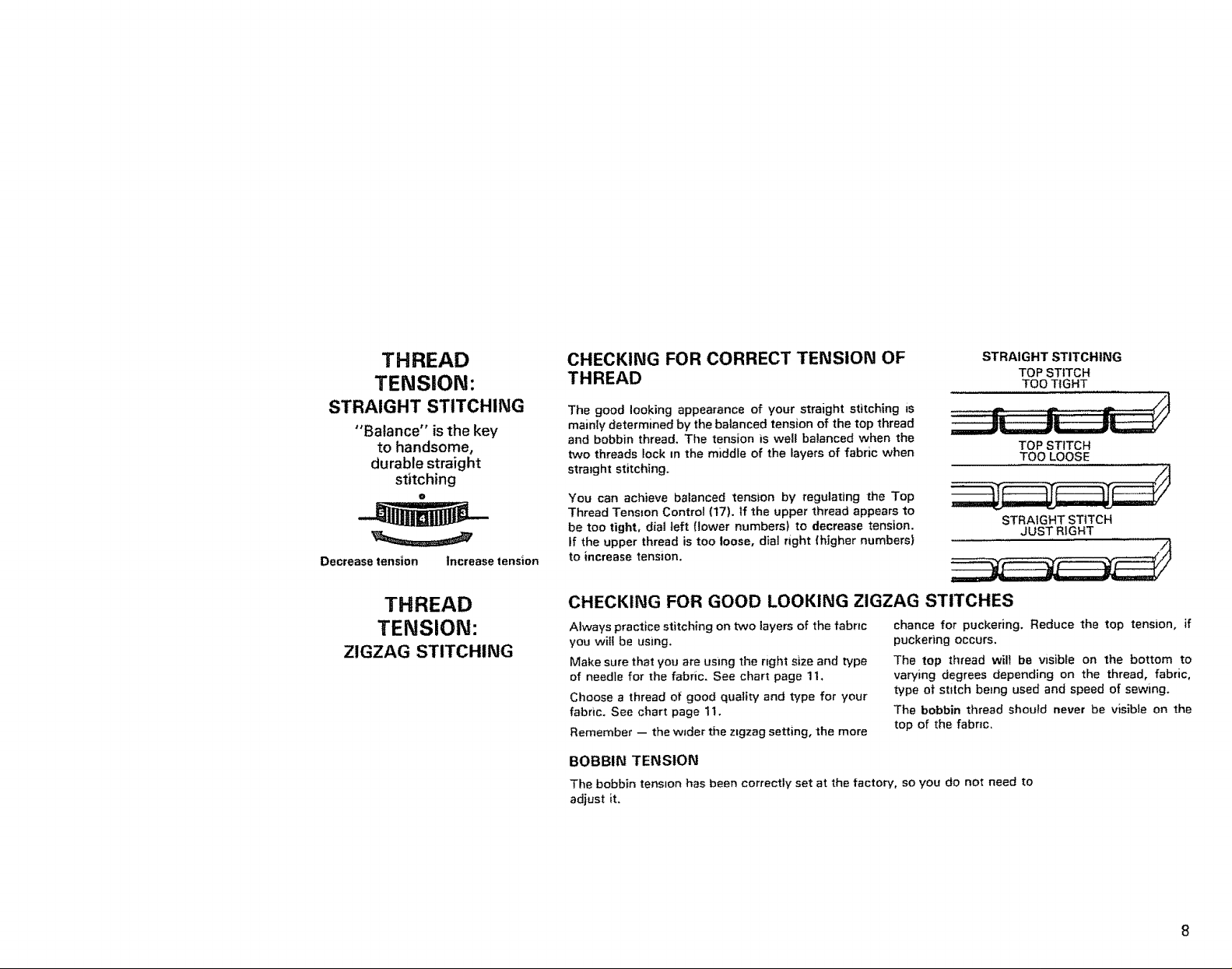

THREAD

TENSION:

STRAIGHT STITCHING

"Balance" is the key

to handsome,

durable straight

stitching

o

Decrease tension Increase tension

CHECKING FOR CORRECT TENSION OF

THREAD

The good looking appearance of your straight stitching is

mainly determined by the balanced tension of the top thread

and bobbin thread. The tension is well balanced when the

two threads lock m the middfe of the layers of fabric when

straight stitching.

You can achieve balanced tension by regulating the Top

Thread Tension Control (17). if the upper thread appears to

be too tight, dial left (lower numbers) to decrease tension.

If the upper thread is too loose, dial right (higher numbers}

to increase tension.

STRAIGHT STITCHING

TOP STITCH

TOO TIGHT

TOP STITCH

TOO LOOSE

STRAIGHT STITCH

JUST RIGHT

THREAD

TENSION:

ZIGZAG STITCHING

CHECKING FOR GOOD LOOKING ZIGZAG STITCHES

Always practice stitching on two layers of the fabr=c

you will be using.

Make sure that you are using the right size and type

of needle for the fabric. See chart page 11,

Choose a thread of good quality and type for your

fabric. See chart page 11.

Remember -- the wider the zigzag setting, the more

BOBBIN TENSION

The bobbin tension has been correctly set at the factory, so you do not need to

adjust it.

chance for puckering. Reduce the top tension, if

puckering occurs,

The top thread will be visible on the bottom to

varying degrees depending on the thread, fabric,

type of stitch being used and speed of sewing.

The bobbin thread should never be visible on the

top of the fabric,

Page 10

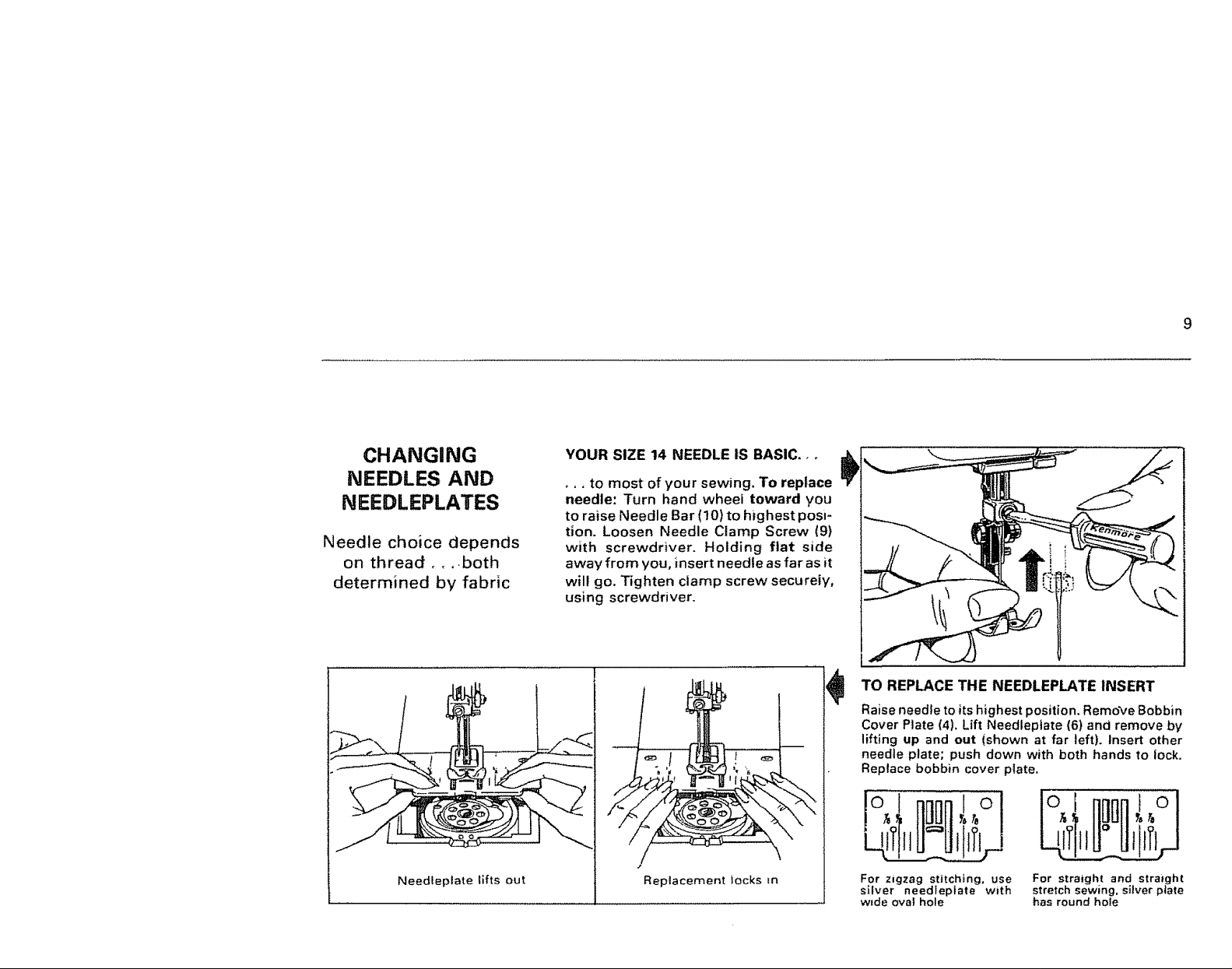

CHANGING

NEEDLES AND

NEEDLEPLATES

Needle choice depends

on thread _,.,both

determined by fabric

YOUR SIZE 14 NEEDLE IS BASIC., o

o,. to most of your sewing, To replace

needle: Turn hand wheel toward you

to raise Needle Bar (10) to highest posi-

tion. Loosen Needle Clamp Screw (9)

with screwdriver. Holding flat side

away from you, insert needle as far as it

will go. Tighten clamp screw securely,

using screwdriver.

TO REPLACE THE NEEDLEPLATE INSERT

Raise needle to its highest position. Remove Bobbin

Cover Plate (4), Lift Needleptate (6) and remove by

lifting up and out (shown at far left). Insert other

needle plate; push down with both hands to lock.

Replace bobbin cover plate.

Needteplate Ufts out Replacement Jocks =n

_1 1o

I,, ,,. I

For zigzag stitching, use

silver needleptate with

wtde oval hole

ol to

!,, I

For straight and strmght

stretch sewing, silver plate

has round ho_e

Page 11

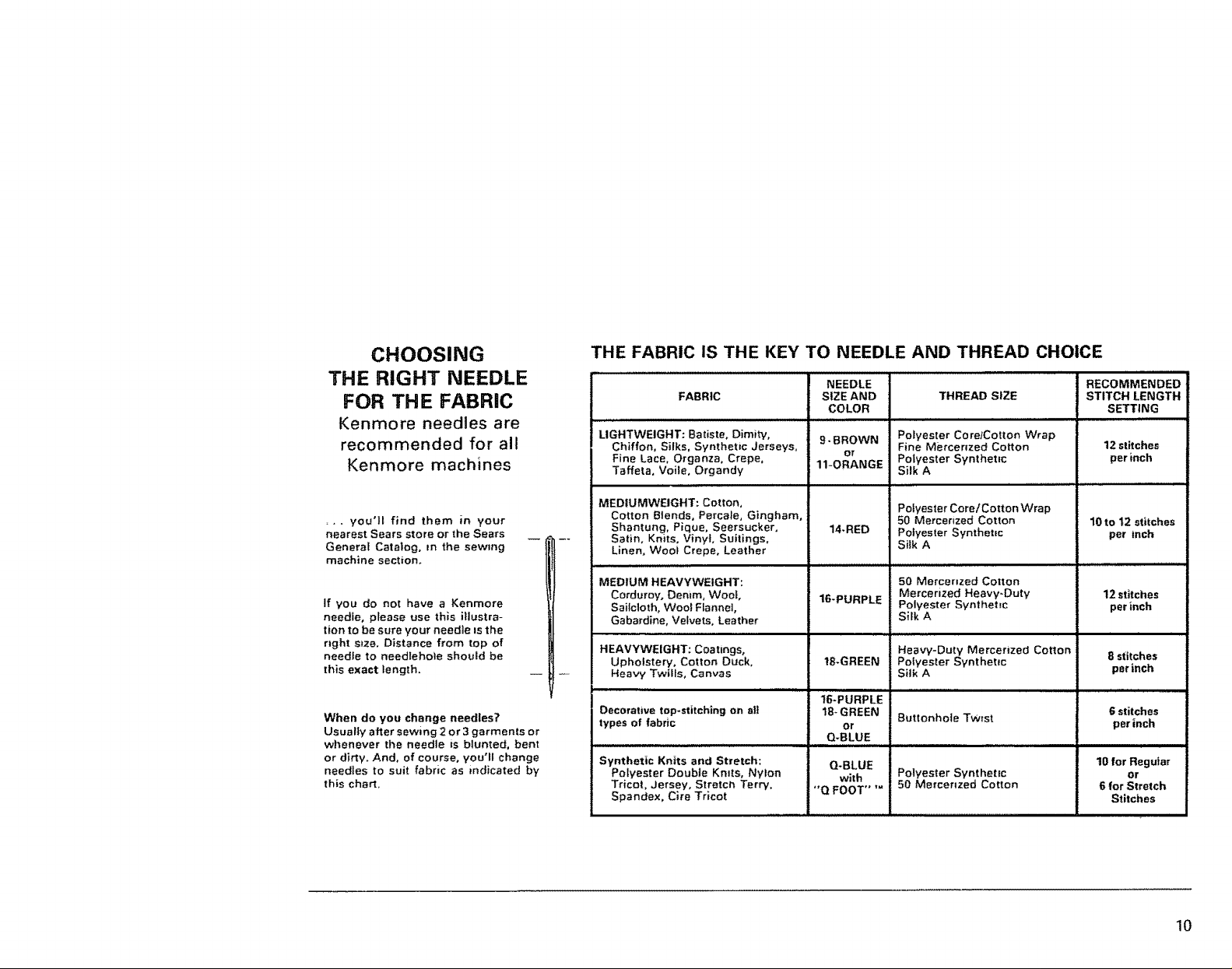

CHOOSING

THE RIGHT NEEDLE

FOR THE FABRIC

Kenmore needles are

recommended for all

Kenmore machines

,,. you'll find them in your

nearest Sears store or the Sears

General Catalog. m the sewing

machine section.

If you do not have a Kenmore

needle, prease use th_s illustra-

tion to be sure your needle as the

right size. Distance from top of

needle to needlehote should be

this exact length,

When do you change needles?

Usually after sewing 2 or 3 garments or

whenever the needle is blunted, bent

or dirty. And, of course, you'lt change

need{es to suit fabric as indicated by

this chart,

THE FABRIC IS THE KEY TO NEEDLE AND THREAD CHOICE

FABRIC

LIGHTWEIGHT: Batiste, Dimity,

Chiffon, Silks, Synthetic Jerseys,

Fine Lace, Organza. Crepe,

Taffeta, Voile, Organdy

i i i.i.

MEDIUMWEtGHT: Cotton.

Cotton Blends, Percale, Gingham,

Shantung, Pique, Seersucker,

Satin, Knits, Vinyl, Suitings,

Linen, Wool Crepe, Leather

, ,, ,, ,,,,,,,,,,,,,,,,,,,,,,,,m,,,,,

MEDIUM HEAVYWEIGHT:

Corduroy, Denim. Wool,

Sailcloth, Woo! Flannel,

Gabardine, Velvets, Leather

HEAVYWEIGHT; Coatings,

Upholstery, Cotton Duck,

Heavy Twills, Canvas

Decorative top-stitching on ell

types of fabric

Synthetic Knits and Stretch:

Polyester Doubie Kmts, Nylon

Tricot, Jersey, Stretch Terry,

Spandex, Cire Tricot

, N,,, • J ,J.J

NEEDLE

SIZE AND

COLOR

9- BROWN

or

11-ORANGE

14-RED

1B-PURPLE Polyester Synthetm

1B-GREEN

16-PURPLE

18÷ GREEN

or

Q-BLUE

Q-BLUE

with

"Q FOOT ....

THREAD SIZE

Polyester Core/Cotton Wrap

Fine Mercerized Cotton

Polyester Synthetm

Silk A

Polyester Core! Cotton Wrap

50 Mercerized Cotton

Polyester Synthetm

Siik A

50 Mercerized Cotton

Mercerized Heavy-Duty

Sirk A

Heavy-Duty Mercerized Cotton

Po{yester Synthetic

Silk A

Buttonhole Twist

Polyester Synthetic

50 Mercenzed Cotton

• , ,.i,, ,

RECOMMENDED

STITCH LENGTH

SETTING

12 stitches

per inch

10 to 12 stitches

per inch

12 stitches

per inch

8 stitches

per inch

6 stitches

per inch

10 for Reguiar

or

6 for Stretch

Stitches

10

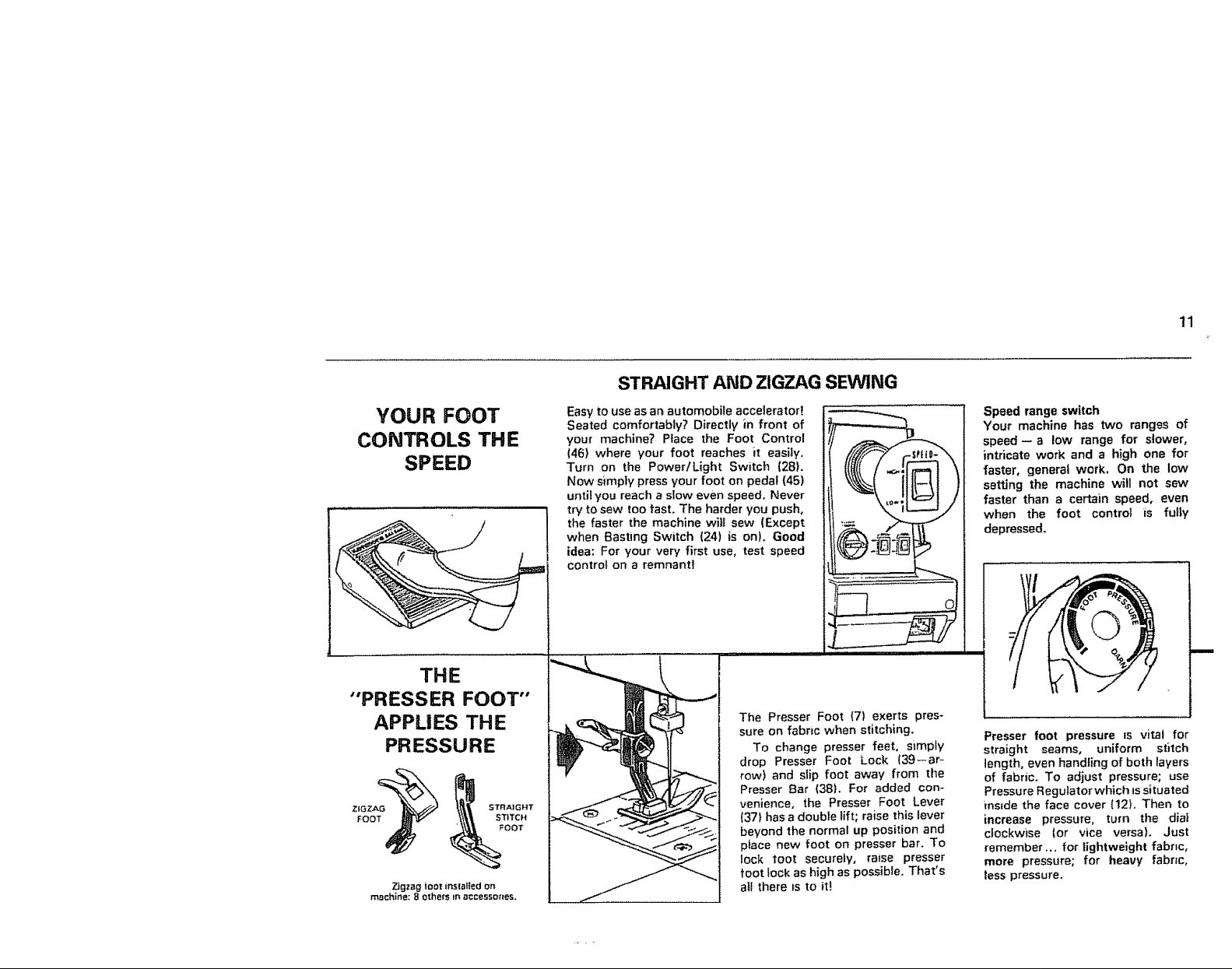

Page 12

STRAIGHT AND ZIGZAG SEV_NG

11

YOUR FOOT

CONTROLS THE

SPEED

THE

"PRESSER FOOT"

APPLIES THE

PRESSURE

ZIGZAG_ _ STRAIGHT

FOOT _ _F_IOTOC_

Z3gzag |ool mstatled on

machine: 8 others In _:cesso_ea,

Easy to use as an automobile accelerator{

Seated comfortably? Directly in front of

your machine? Place the Foot Control

(46) where your foot reaches it easily,

Turn on the PowerlLight Switch (28).

Now simply press your foot on pedal (45)

until you reach a slow even speed. Never

try to sew too fast. The harder you push,

the faster the machine will sew (Except

when Basting Switch (24) is on}, Good

idea: For your very first use, test speed

control on a remnant!

The Presser Foot (7) exerts pres-

sure on fabnc when stitching.

To change presser feet, simply

drop Presser Foot Lock (39--ar-

row) and slip foot away from the

Presser Bar (38). For added con-

venience, the Presser Foot Lever

(371 has a double lift; raise this lever

beyond the normal up position and

ptace new foot on presser bar. To

lock toot securely, raise presser

toot lock as high as possible. That's

a!I there ts to it!

Speed range switch

Your machine has two ranges of

speed- a low range for slower,

intricate work and a high one for

faster, general work. On the low

setting the machine will not sew

faster than a certain speed, even

when the foot control is fully

depressed.

i _ O i

Presser foot pressure is vitat for

straight seams, uniform stitch

length, even handling of both layers

of fabric. To adjust pressure; use

Pressure Regulator which is situated

reside the face cover (12). Then to

increase pressure, turn the dial

clockwise (or vice versa). Just

remember.., for lightweight fabnc,

more pressure; for heavy fabr=c,

tess pressure.

Page 13

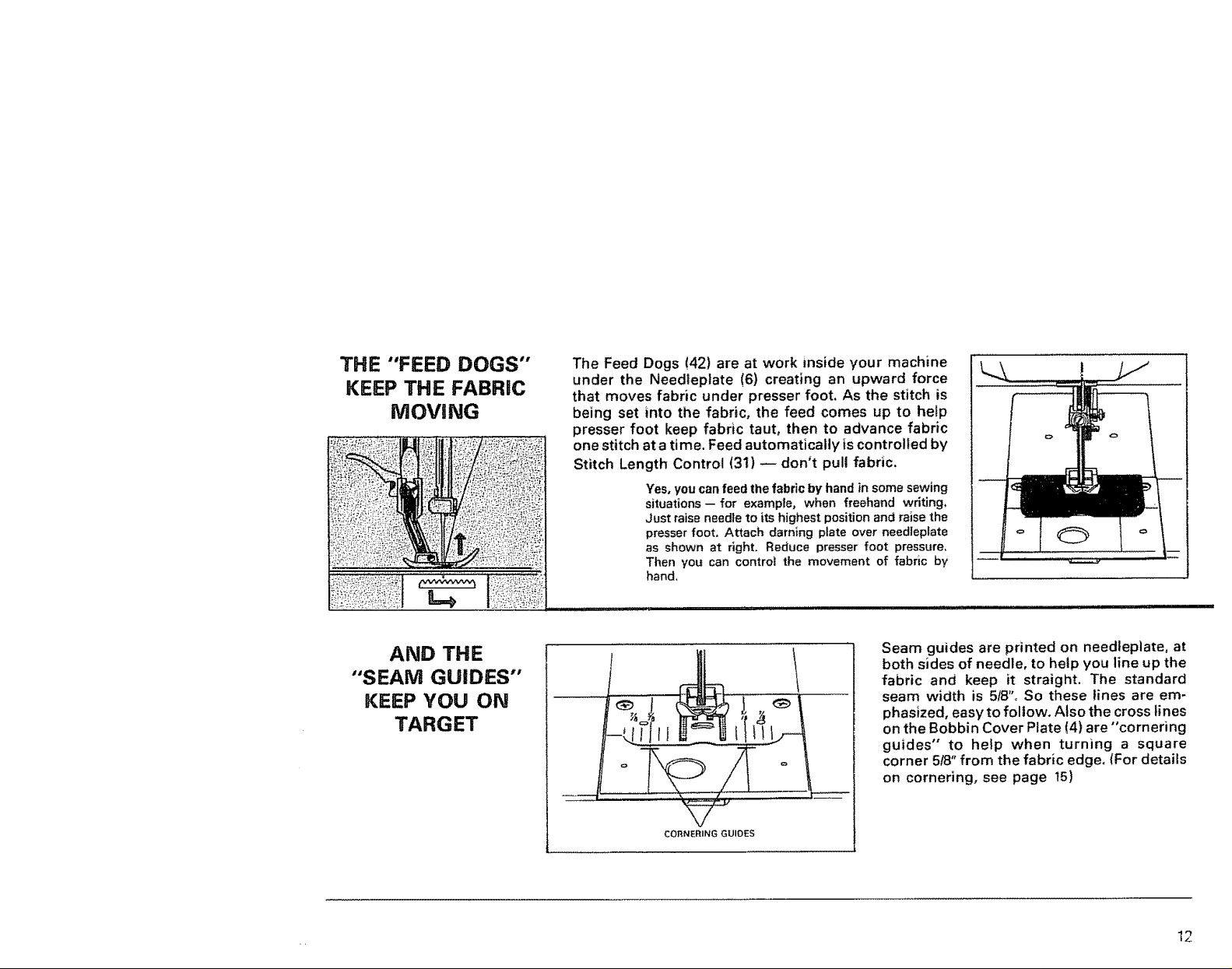

THE "FEED DOGS'"

KEEP THE FABRIC

MOVING

The Feed Dogs (42) are at work reside your machine

under the Needleplate (6) creating an upward force

that moves fabric under presser foot. As the stitch is

being set into the fabric, the feed comes up to help

presser foot keep fabric taut, then to advance fabric

one stitch at a time. Feed automatically is controlled by

Stitch Length Control (31) m don't pull fabric,

Yes, you can feed the fabric by hand in some sewing

situations- for example, when freehand writing,

Just raise needle to its highest position and raise the

presser foot, Attach darning plate over needleplate

as shown at right. Reduce presser foot pressure.

Then you can control the movement of fabric by

hand,

AND THE

"SEAM GUIDES"

KEEP YOU ON

TARGET

Seam guides are printed on needleplate, at

both sides of needle, to help you line up the

fabric and keep it straight. The standard

seam width is 5/8 °', So these lines are em-

phasized, easy to follow. Also the cross lines

on the Bobbin Cover Plate (4) are "cornering

guides" to help when turning a square

corner 5/8" from the fabric edge. (For details

on cornering, see page t5)

CORNERING GUIOES

12

Page 14

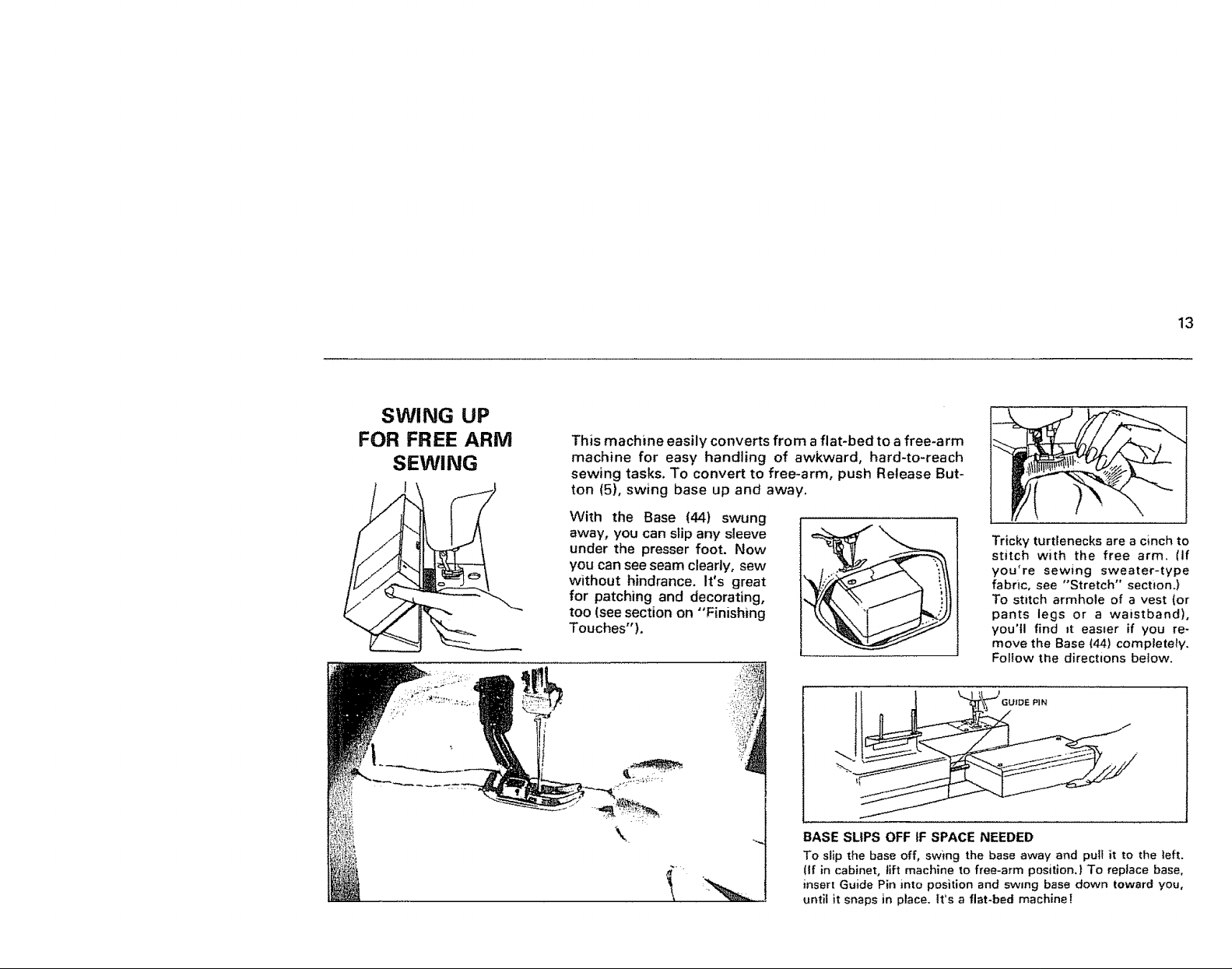

SWING UP

FOR FREE ARM

SEWING

i

This machine easily converts from a flat-bed to a free-arm

machine for easy handling of awkward, hard-to-reach

sewing tasks. To convert to free-arm, push Release But-

ton (5), swing base up and away.

With the Base (44) swung

away, you can ship any sleeve

under the presser foot. Now

you can see seam clearly, sew

without hindrance, It's great

for patching and decorating,

too (see section on "Finishing

Touches").

13

Tricky turtlenecks are a cinch to

stitch with the free arm. (If

you're sewing sweater-type

fabric, see "Stretch" section.)

To stitch armhole of a vest (or

pants legs or a waistband),

you'll find Jt easIer if you re-

move the Base (44) completely,

Fofiow the directions be!ow.

BASE SLIPS OFF tF SPACE NEEDED

To slip the base off, swing the base away and puil it to the left.

(if in cabinet, lift machine to free-arm position,| To replace base,

insert Guide Pin into position and swing base down toward you,

until it snaps in place, it's a flat-bed machlne!

Page 15

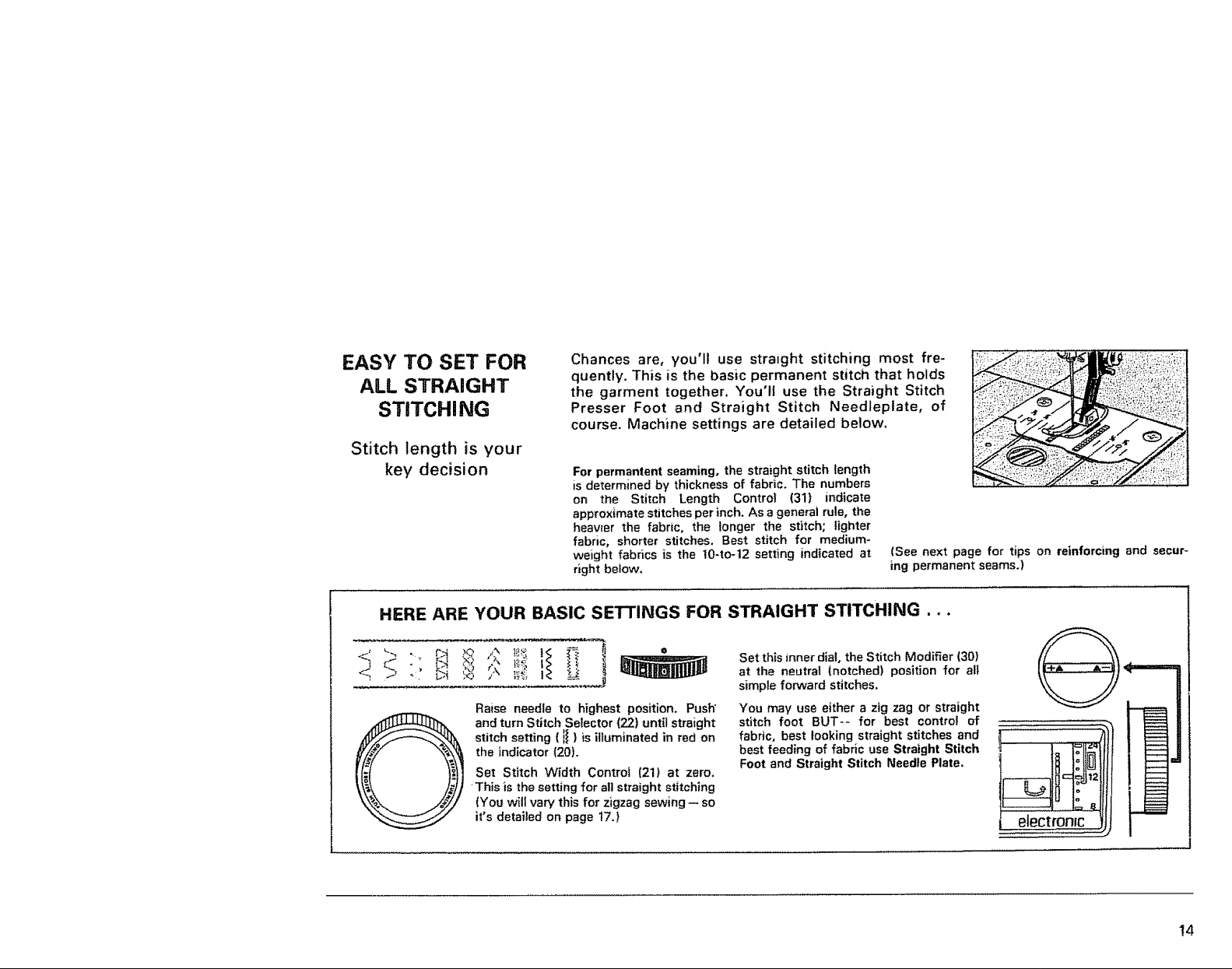

EASY TO SET FOR

ALL STRAIGHT

STITCH I NG

Stitch length is your

key decision

HERE ARE YOUR BASIC SE_INGS FOR STRAIGHT STITCHING .°.

Raise needle to highest position. Push"

and turn Stitch Selector (22) until straight

stitch setting (iI) is illuminated in red on

the indicator (20),

Set Stitch Width Control (21) at zero,

This is the setting for all straight stitching

.

(You will vary this for zigzag sewing -- so

it's detailed on page 17.)

Chances are, you'll use straight stitching most fre-

quently. This is the basic permanent stitch that holds

the garment together. You'll use the Straight Stitch

Presser Foot and Straight Stitch Needteplate, of

course. Machine settings are detailed below.

For permantent seaming, the straight stitch length

is determined by thickness of fabric. The numbers

on the Stitch Length Contro! (31) indicate

approximate stitches per inch. As a general rule, the

heawer the fabric, the longer the stitch; lighter

fabric, shorter stitches, Best stitch for medium-

weight fabrics is the t0-to-t2 setting indicated at

right below,

Set this inner dial, the Stitch Modifier (30)

at the neutral (notched) position for all

simple forward stitches.

You may use either a zig zag or straight

stitch foot BUT-- for best control of

fabric, best looking straight stitches and

best feeding of fabric use Straight Stitch

Foot and Straight Stitch Needle Plate.

(See next page for tips on reinforcing and secur-

ing permanent seams.)

@

electronic

14

Page 16

15

MAKING

PERMANENT

SEAMS TRULY

PERMANENT

Backtacking..,

crossing seams o_o

turning square corners

HANDSOME

TOP-STITCHING

It's a good idea to begin and end each seam by

stitching in reverse, pressing down Reverse

Stitch Control (23). Be sure both threads are

drawn back under presser foot. Stitch backwards

about _", This iscalled backtacking; it reinforces

, electronic ,,jjj

When you have two seams crossing, sew slowly and carefully so

seam will be strong, if sewing thick fabrics, you may need to

lengthen stitch and reduce pressure on presser foot.

This is a seam you may want to show of!! tt's on the front side of

the garment, possibly at the top of a "kick pleat" or on a lapel, both

functional and decorative. Usually, it's a simple, forward stitch m

with an extra-long stitch tength, or with special thread, matching or

contrasting. {For decorative sewing, try fancy threads, double nee-

die, other ideas you will read about in later sections|)

seams, prevents unraveling.

Turning square corners? Your machine has a convenient guide (diagram, far left)

for turning corners 5/8" from fabrics edge. Stop stitching with needle tn the

fabric. This is done automatica!ly by making sure left lower needle position

button is pushed. Raise the presser foot. Turn fabric. New stitching line should

align with 5/8" seam guide on side of bobbin plate(near left diagram), Lower the

presser foot and begin stitching in new direction. (When turning square corners

or sewing pointed areas of collars, you may want to shorten the stitch length to

strengthen the corner.)

Finished the seam? The

Presser Foot Lock (39) has a

Thread Cutter (40) built in,

Hold threads on either side

of cutter and pull thread

toward you to cut.

Page 17

"TEMPORARY'"

SEWING

BY MACHINE

New free

basting method for

very long stitches

Free Basting For Very Long Stitches

Stitch Se ector -- II

Stitch Width Controf-- 0

Stitch Length Control -- Any number

Stitch Modifier -- Neutral

Basting Switch -- On

Straight Stitch Foot, Darning Plate

Straight Stitch Needleplate

No pressure on Presser Foot

!%!o longer do you need to baste by hand!

Regular basting (above right) by machine is

easy -- simply use straight stitching with

longest available length setting (6 stitches per

inch). And your Kenmore has a free basting

method for yew long stitches (lower right) that

sometimes,can be used for "marking". Just set

your machine and sew as indicated below. _.

Using settings at left (be sure atl pressure is removed from presser toot) press

basting switch, Lower presser foot and tap down on foot control, (You will want

to hold ends of thread with left hand). Machine wi!l take one stitch and stop with

needle up. Move fabric freely with both hands to achieve desired stitch length.

Regular Besting

Free Method

PIN BASTING,

STAY-STITCHING

NOW SIMPLE

Yes, you can sew over pins easily (if done correctly)

because your presser feet are hinged. Pins must be in-

serted at right angles to seam line, Tip of pin should just

touch seam line. Sew over tip of pins. Pins must not

come In contact with feed dogs: Never pin on the under-

side of the fabric. Sew slowly. If in doubt about sewing

over pins, remove each p=n as you approach it.

"Stay-stitching" is a form of

temporary seaming that prevents

stretching of curved edges of gar-

ments. Usually this is on a single

layer of fabric, so reduce top thread

tension slightly to prevent pucker-

ing. Baste about '/C away from in-

tended seamline.

t6

Page 18

ZIGZAG

STITCHING

m AND HOW IT

EXPANDS

YOUR SKILLS

Many plain and

fancy uses

Simple zigzag stttching enables you to

do many exciting things with your Ken-

more sewing machine. Beyond basics,

you'll use zigzag stitching to applique,

embroider and monogram. Unlike

straight stitches, zigzag stitches have a

side-to-side width as well as a stitch

length. You'll find "recipes" for many

zigzag operations on following pages.

You can create an exciting variety of zig-

zag stitches by adjusting stitch width

and length controls (see chart below).

17

Simple settings

for easy zigzag

sewing

Stitch Selector - Jl

Stitch Width Control -- Various

Stitch Length Control -- 8-t2-24

Stitch Modifier -- Neutral

Zigzag Presser Foot or Satin Stitch Foot

Zigzag Needle Plate

Page 19

CHANGE

STITCH LENGTH

AND WIDTH

FOR STRENGTH

...FOR VARIETY

YOUR KEY CONTROL is the

Stitch Width Control (21),

When adjusting settings,

remember: the higher the

number the wider the zigzag

stitch, Your choice of zigzag

stitch width and length wilt

depend on the fabric and

job. The stitch length-rule is

usually the lighter the fabric,

the shorter the stitch.

Extra wide zigzag for heavy fab-

rics or those that fray- set

width at 4

Wide zigzag for double layers,

like hemming -- set at 3

Medium zigzag for most con-

struction seems -- set at 2

Narrow zigzag for light febrJcs,

barely shows -- set at 1

o

Q

_i_ Vwv,_W,_,_vVVWv_NVvv_

A most important use for basic zigzag

Fabrics that fray? Here's the

solution o,, Use zigzag

overcasting for seams that

tend to ravel, This is gener-

ally done after the garment

is finished. Also, raw or

worn edges of older gar-

ments can be overcast to

prevent further raveling.

Special Edge Stitch Settings

Stitch Selector -- il

Stitch Width -- usually at 3

Stitch Length -- usually at !0

Stitch Modifier -- Neutral

Overcast Foot

Zigzag Needleplate

18

Page 20

19

BLIND HEMMING--

A BASIC STITCH

THAT ADDS A

FINISHING TOUCH

Built-in Blindstitch is a

reai time-saver

RIGHT SIDE OF

FINISHED HEM

Blind hemming is a good technique to use on garments, and

especially on curtains and drapery hems so that stitches need not

show on the front of the fabnc. Because your Kenmore has two

types of blindstitches built in, blind hemming is easier than you'd

expect. It's just a matter of folding.., give it a try!

-- Regular blind stitch for normal fabrics

._ -- Elastic blind stitch for soft, stretchable fabncs

INSIDE

DRESS

FtNISHED

EDGE

Finish raw edge of fabrtc ap-

propriately. You may want to

use seam tape on woven fab-

rics. With knits use a lace seam

tape or just use decorative

stretch stitch.

Now the right side of your garment will show

only the blind stitches! Be sure to press both

sides of the finished hem!

Working on wrong side of fab-

ric, fold hem up. Press and pin

in place. Then fold hem allow-

ance under.., leaving _" of

hem edge extending. (Blind

hemming can be simplified by

also using the special Kenmore

Edgestitcher-ptease refer to

p. 37 for details.)

EDGE

Here's how to set your machine:

Stitch Se,ector- _ or

Stitch Width Control -- I_ to 2

Stitch Length Control -- 12 to 10

Stitch Modifier -- Neutral

Blind Stitch Foot

Zigzag Needleplate

SCREW

GUIDE

Place garment under blind stitch

foot with the fold of the garment

against guide and slide it by

turning screw so that the zigzag

just catches the fold,

Page 21

MENDING AND

DARNING--

BY MACHINE!

So much easier!

Takes little practice!

HOW TO REPAIR STRAIGHT OR 3-CORNERED T_-_AR

Setting your machine

Stitch Selector --ii;_

Stitch Width Control -- 4

Stitch Length Control -- Red zone

Stitch Modifier -- Neutral

Zigzag Foot

Zigzag Needleplate

Fit torn edges together closely

as possible under the needle,

starting from rear of damaged

area. Sew slowly, making sure

that stitching catches both

sides of the tear. When turn-

ing, lift needle to highest posi-

tion, back up one or two

stitches to secure corner, then

repeat above operation.

USE A HOOP FOR EASY DARNING

Setting your machine

Stitch Selector -- if

Stitch Width Control - 0

Stitch Length Control -- Various

Stitch Modifier - Neutral

Darning Plate

No Presser Foot

An embroJdeP/hoop will help you hold dam-

aged area securely. Remove presser foot.

Stretch fabric between embroidery hoops, cen-

tering hole to be darned. Draw bobbin thread up

through fabric by holding top thread and taking

one stitch at spot where you want to start darn-

ing. Lower the presser bar, then sew at slow

speed. Move fabric by hand, back and forth with

a steady rhythm, to cover darning area. Next,

turn the fabric and sew another layer of stitch-

mg across the first layer.

2O

Page 22

OTHER USEFUL UTiLiTY AND BASIC ZIGZAG STITCHES

21

FAGOTING

BAR-TACKING

RBNFORCING SEAMS

REINFORCING CORNERS

ARROWHEAD TACKING

A decorative stitch that also is good for mending knits.

This is a popular decorative stitch {used in sleeves or

fronts of blouses and dresses). To attach two sepa-

t

rate pieces of fabric together, leave a little space

inbetweem To prepare the fabric:

!

!

t

I

Fold under the seam allowances on the cut edges,

and press. Baste folded edges to tissue paper with

about _,_'° space between. Stitch over the _" afiow-

ance, just catching the fabric fold on both sides with

needle. Remove bastings and paper; press.

Setting your machine

Stitch Selector --

Stitch Width Control -- 4

Stitch Length Control -- Various

(Depending on fabric)

Stitch Modifier -- Neutrai

Zigzag Foot

Zigzag Needleplate

To reinforce points of strain on any garment

A valuable stitch to strengthen corners of pockets or

straps of lingerie. Simply stitch ... turn fabric in

reverse direction ... stitch again ... four to six

times. Use a wide z_gzag stitch at the satin-stitch

length (red line) for strap reinforcements. Use a

medium-width zigzag set at a fine stitch length for

securing corners -- great for pockets!

Try "arrowhead" tacking for reinforcing small (but

visible) areas of strain. Start, from the top, with your

zigzag width setting at 4, slowly change width to 3

.., and so on.,. to reach the "point of the arrow" at

width setting 0.

Setting your machine

Stitch Selector -- i_

Stitch Width Contro{ - t to 4

Stitch Length Control -- Red

zone

Stitch Modifier -- Neutral

Zigzag Presser Foot

Zigzag Needtep_ate

Page 23

iNTERFACING

To support and shape edges and details

I

You will use this for stiffening collars, cuffs, flaps

m many garment areas -- fronts, hems, iapels.

The interfacing may be any special fabric applied

to the inside of a garment to give it shape, body

and/or support. "'tnterfacings" come m light,

medium and heavy weaghts w also in "fusible"

fabrics, with adhesives applied, Generally, you

will use the machine settings shown at right, for

seams or darts in interfacing.

YOU'LL USE STRAIGHT AND ZIGZAG STITCHES FOR SUPER-SEWING, TOO!

%> <'

® ® ® ® ® ®

The following stitches are built into your machine to give you the

optimum in ease of use in sewing basic stitches. Below are some of the

uses for each stitch:

t. Straight----Basting, seaming, and top stitching. (See pages 15

and 16).

2. Zigzag----Satin stitching, AppIiclue (Page 39), Overcasting and

Bar Tacking.

3. Mending---- Repair garments end sew interfacings, (Page 20).

Setting your machine

Stitch Selector -- il

Stitch Width Controt-- 2 to 4

Stitch Length Control -- 12

Stitch Modifier -- Neutral

Zigzag Presser Foot

Zigzag Needleplate

1. Straight

2, Zigzag

3. Mending

4. Box

5. Blind Hem

6. Elastic Blind

7. Fagoting

4. Box ---- Can be used for Overcasting also, or a decorative stitch

around a collar etc.

5. Blind Hem ---- Hemming of all types of fabrics, Especially helpful

when sewing large pieces of fabric such as draperies.

6, Elastic Blind Hem ---- provides a stretchy, durable hem finish to

soft, stretchable materials.

7. Fagoting ----A decorative stitch that can be used for repair of

tears that requae a backing for stability.

|_

22

Page 24

BUTTONHOLES AND FASTNERS

23

USING YOUR

BUILT-IN

BUTTONHOLE

SYSTEM

It's great for

making single and

extra-long buttonholes

_p

Your Kenmore built-in system is the only one that can be

used on free-arm. It is an excellent way to make button-

holes on cuffs, waist bands, other tight places. An

important aid is the Buttonhole Guide Foot (in your

buttonhole attachment box). It has graduated markings

IYB" apart) to help you make buttonholes to exact size.

Mark buttonhole length on your garment.

Pull the guide foot (A) all the way forward so that the notch

(B) is aligned with the graduation (C), with thread to rear.

Place fabric with marked buttonholes under the foot.

The buttonhole control lever (t7) shows you the direction you w_l{ be

stitching, The control set to the left starts your buttonhole. Position

marked buttonhote so your needle pierces the beginning of the

buttonhole.

1. Switch the control to left, (if it has been already at left, set it at

right, sew several stitches and switch to left again.) Step on foot

control to form first bartack and left side of buttonhole,

2. When you reach end of left side, slide the control to the right and

complete the buttonhole.

ADJUSTING STITCH BALANCE

Stitch length differences in forward and reverse stitches of the

buttonhole are equalized with the stitch modifier.

If the reverse stitches are too far apart, turn the modifier slightly

clockwise; if they ere too close together, turn counter-clockwise.

Setting your machine

Stitch Selector - L_

Stitch Width Control _ 1 to 1_

Stitch Length Control _ 24 to 12

(Green zone)

Stitch Modifier -- Neutral

{See below)

Buttonhole Guide Foot

Zfgzag NeedEe Plate

@

Page 25

USING YOUR

SPECIAL

BUTTONHOLE

ATTACHMENT

It wilt become

your "best friend"

BUTTONHOLE

GU{DEPLATE

TEMPLATES

Another important buttonhole accessory.,

Your Buttonhole Guideplate is a Kenmore

"special" that guides the fabric for you, elimi-

nates the need to turn fabric by hand, enables

you to make a variety of bas}c and spec_a!

buttonholes.

Get acquainted with what's in your

"buttonhole box"

BUTTONHOLE

FOOT

Here you see your five templates which

give you a choice of buttonhole styles

and lengths -- illustrated on opposite

page. When you turn the template ad-

vance knob to the desired size, the

length is indicated in window on guide-

plate. Don't forget to use interfacing

when sewing buttonholes. If working

with knits, use Q NEEDLE'"°

Your Buttonhole Guideplate ,s easily in-

stalled, just behind the needieplate.

You have a square clear plastic foot to

use with your attachment.

You can dia! the style of buttonhole you

want simply by turning the Template

Advance Knob.

ADVANCE

KNOB

24

Page 26

25

IT CAN BE FUN

TO TRY OUT

(and show off)

YOUR NEW

BUTTONHOLE

SKILLS

Start with the ones

you like in the

chart below

ROUND END

STRAIGHT

BUTTONHOLE

Template

Sizes

Template

Sizes

43141

_/_,'. _sll d'

43142

1¼".1½"

Choosing buttonhole style and size _

Each buttonholing situation will be differ-

ent so you will want to experiment with

your garment, considering fabric and

placement of button, Here are some basic

applications:

Built-in buttonholes (described previously)

are ideal for one or two buttons used on waist-

band or cuff, or for "belt slots."

Straight buttonholes (lower left) are most

popular for everyday sewing -- for series of

buttons on dress, blouse, vest, jacket or coat.

BUTTONHOLE AND

i

KEYHOLE _ PURL-EDGE

43143 43144 43145

"-! _f_6" - '_'hd'-I 't_ " - W_d'- I thd'-

1¼ "-t _" Eyelet _=/_"-%"

EYELET

Keyhole buttonholes are a variation of the

above, with an enlarged opening at one end to

allow more room for button shank. These are

normally used in tailored vests, jackets, coats.

Eyelet buttonholes (another variation of

"straight") most often are used for studs on

skirts or holes for tongues of belt buckles.

Purl-edge buttonholes are made by stitching a

larger straight buttonhole on top of a narrow

one -- for a unique look.

Bound buttonholes -- made with extra fabric

"hemming" the hole -- provide "professional

look" to dresses, lackets, coats and for con-

trasting, decorative buttonholes.

BOUND

BUTTONHOLE

I

f

I

I

t

I

t

Page 27

"'REGULAR-

WORKED"

BUTTONHOLING

An art by our

. grandmothers..,

now easy to do

by machine

Settings for round-end, keyhole, eyelet ..,

Stitch Selector - il

Stitch Width Control'-- i! to 1_

Stitch Length Control -- 0

Stitch Modifier - Neutral

Buttonhole Foot

Zigzag Needieplate

Darntng Plate

First, place darning plate over zigzag needleplate; then,

select correct template for type buttonhole you want. Insert

template into slot of guldepIate.. Turn template knob to

desired size ... ust dial!

Now press Retease Button (4t} to remove

Attachment Coverplate (43). This will

expose the pinion gear tn base, as

indicated at upper right. (When button-

holing is completed, be sure to replace

attachment coverplate!)

Slip guideplate onto machine so it fits in

place over pm_on gear. Be sure guide pin

ts inserted in slot.

Pul! guide piate all the way forward so

that guide pin rs at "'S" and pimon gear is

in the center of arc hole of template.

Draw bobbin thread up through guide-

plate by turning hand wheel, Place fabric

between presser toot and guideplate.

Align marked buttonhole with cut-out of

toot. Line up edge of fabric w_th markings

on guideplate. If you wish all buttonholes

to be 3/4" from edge of garment, for

example, llne up fabric with 3/4" marking

each time you start a buttonhole.

Now you're ready to stitch the shape you've selected

straight, keyhole or eyelet. Your template will guide you,

RELEASE

BUTTON

PINION GEAR

TEMPLATE

HOLDER

TEMPLATE

ADVANCE KNOB

GUIDE

GUIDE SLOT

26

Page 28

27

PURL-EDGING

FOR THAT

PROFESSIONAL

TOUCH

TIPS ON MAKING

BOUND

BUTTONHOLES

} ................. !

You can make a purl-edge buttonhole by sewing

a wide buttonhole over a narrow stitched but-

tonhole. Machine settings are the same as for a

round-end buttonhole. Simply choose the cor-

rect size purl-edge template for your button. But

be sure to adjust stitch width control to 1.

Sew around the buttonhole once, Then remove

guJdeplate and turn template to the wider size

purl-edge. Adjust stitch width to 1½ and sew

around buttonhole again.

Yes, these are tricky -- but worth it for fine gar-

ments._ There are a number of ways, most re-

quiring sewing exact-size rectangles. There are

several-size templates included with your Ken-

more attachments. Use them as for other but-

't

I

i

1

i

tonholes but set machine as indicated at right.

For nearest, easiest bound buttonholes, use an

iron-on interfacing on underside of fabric. This

is essential with stretch fabrics or those that

tend to fray easily,

Bound buttonhole settings:

Stitch Selector -- il

Stitch Width Control -- Zero

Stitch Length Control -- 0

Stitch Modifier --Neutrai

Buttonhole Foot

Zigzag Needleplate

Darning Plate

Page 29

ZIPPERS THAT ARE

SMOOTH-WORKING,

GOOD LOOKING

Home-sewn zippers can look as nice as those on ex-

pensive ready-mades. We recommend you follow di-

rections given on zipper package. There are two basic

types: conventional, and invisible. Your Zipper Foot

will assist you with any of these installations. Use

these simple settings:

For conventional zippers ... Your zipper

foot is adjustable for use on right or left side

i

i

I

i

i

I

of needle. Adjust foot so needle clears side

notch on foot. Then proceed according to

zipper manufacturer's instructions.

Invisible zippers are applied to an open

seam, to seam allowances only; there is no

stitching visible on outside of garment. Ad-

just zipper foot so needle is sewrng through

center hole of foot and one groove of foot is

riding on teeth of zipper, After zipper inser-

tion, finish by shifting foot to side position

and sewing through side notch.

REGULAR

ZIPPER

!

CORDING IS SIMPLE WITH SAME "ZIPPER" SETTINGS

Your zipper foot also makes it easy to add

"cording" to garments as well as slip cov-

ers, toss pillows, bedspreads, decorative

pieces. Cut fabric on bias and wrap around

cord. Pin fabric in place so seam edges are ""_'_-

even. With zipper foot to left of needle,

stitch close to cord.

28

Page 30

29

MACHINE-SEWED

BUTTONS? YES--

WiTH THiS

KENMORE!

Clear plastic foot

makes job easy!

Your settings: Stitch Selector ii

Set Length Control at any number

Width Contro! -- adjust to button size

Use Zigzag Needleptate and Darning Plate

Use Clear Plastic Satin Stitch Foot

Scotchtape button on fabric to hold

in place while needle stitches-from

side to side. Stitch width must equal

space between holes in button, You

will need to experiment with each

style button, For the same series of

buttons, settings remain the same,

Center left hole of button between straight seamline and left edge of

presser foot slot. Lower foot to hold button securely,

Turn hand wheel until needle point is just above button. Adiust stitch

width control so needle will enter right hole of button. Turn hand wheel

again so needle enters second hole. Readjust stitch width if necessary.

Stitch 6-8 times,

Finish sewing with an extra two inches of thread remaining. Draw these

threads to reverse side of garment and tie.

PUT. A SHANK ON YOUR BUTTONS.,.

Recommended for heavy, bulky tabrics,

buttons sewn w_th a shank add extra

strength. Set machine as indicated above.

Tape a pin to button so it fits in groove

in presser foot. Sew over the pro, adding a

few more stitches than usual Remove

from machine, wrap excess thread

around shank, and tie.

LEFT OF HOLE

BU_ON

PRESSER

t/ FOOT

STRAIGHT

BUTTON

Page 31

STRAIGHT STRETCH

STITCHING

For seams

that need to stretch

with the fabric

STRETCH AND SPECIAL STITCHES

You'll use this basic stitch often- for garment construction

or anywhere else you would use a straight stitch for seaming --

p|ain, pressed-open or double-stitched, tf you want a good

looking top stitch on knits, use straight stretch ... particularly for

strength when making sportswear. And when you do curved

seams on children's shorts or slacks, for example, the straight

stretch stitch really adds life!

SETTING YOUR MACHINE FOR STRAIGHT STRETCH STITCHING

F-_

, IRI o

\

STITCH WIDTH

CONTROL - 0

DIAL YOUR STITCH

FOR SETTING ON

INDICATOR (20)

USE STRAIGHT STITCH PRESSER FOOT

AND STRAIGHT STITCH NEEDLEPLATE

electronic

STITCH LENGTH

CONTROL -- 6 TO 24

STITCH MODIFIER

--NEUTRAL

(NOTCHED)

POSITION

(SEE NEXT PAGE)

3O

Page 32

31

THE STRETCH

STITCHES YOU USE

MOST ARE BUiLT-IN

Rick-Rack Stretch Smocking Stretch

RI_CK-RACK STR ETCH

Used most often for

top-stitching

So many ways to sew today's knits! You have a Your basic settings are illustrated immediately

wide variety of zigzag stitches_ simpiy set Stitch below. The only changes you need consider are

Selector (22) as indicated in each "recipe"_ All variations in stitch width w as you become ex-

other machine settings are the same for each of pert, you may wish stitches to show, either short-

the stitches. With all these, use the zigzag presser er or longer. Don't forget, the Stitch Modifier |30),

foot or Q FOOT TM and appropriate needleplate, lower right, is inside Stitch Length Control (3t).

ADJUSTING STRETCH STITCH

BALANCE

Stitch modifier should be in neutral

(notched) position for most materials.

Depending upon the type of fabric

used, you may need to adjust this

control to match forward stitches of

stretch sewing with reverse motion

stitches. If the stitches are too open,

turn the control slightly clockwise; if

the stitches overlap, turn the control

counter-clockwise.

WIDTH -- USUALLY AT 4

0

DIAL YOUR STITCH

FOR SE]-FING ON

INDICATOR (20)

LENGTH

SETAT24-6

Stitch Selector _{

Rick-rack stretch stitches are useful also on lapped or

abutted seams where you lap one edge of a seam over

another with seamlines meeting in the center.

MODIFIER -- SET AT

NEUTRAL INOTCHED)

POSITION (SEE AT LEFT)

ii

Page 33

FEATHER

STRETCH

F

Stitch Selector --

This is a good stitch to use with laces, on lingerie, bra

and girdles; and to apply bias tape. It's great when

quilting.

ELASTIC

STRETCH

You'll love this

for skirt-bands

and lingerie

OVERCAST

STRETCH

A "must" for

making stretch

sportswear

Stitch Selector _

Use this versatile stitch to insert elastic in gar-

ments. Simply stitch elastic into place, making sure

it is evenly spaced. To do this, mark the correct

length piece into quarters, then match these mark-

ings with center front and side seams.

Stitch Selector-

This is the same type stitch used by the garment

industry in making sportswear -- it forms and

finishes the seam in one operation (for seams of

¼" to %'). It's very effective for use in relSairing raw

or worn edges of older garments.

32

Page 34

33

PARIS POINT

STRETCH

SOME FAVORITE

STITCHES

CAN BE

DECORATIVE

Smocking stitch effect:

strictly for charm

Stitch Selector - G

Stitch Width Control -- 2 to 3

Stitch Length Control -- 24 to 12

Excellent for hemstitching table and bed covers with a

•eiegant touch. Picot-like stitch can also be made on sheer

materials, Sew along the raw edge of fabric and trim close to

the outside of the stitching.

Of course, you can "create" with basics ..,

Rick-Rack,-Feather, and Elastic Stretch stitches

previously described can be used to decorate

garments as well as to construct them. Try them

all -- just dial your choice and use your imagina-

tion!

Here's another beautiful, built-in

stretch stitch -- the Smocking

Stretch creates a design that is a

series of small diamonds.

HOW TO GET THE HAND-SMOCKED EFFECT BY MACHINE

Setting your machine:

Stitch Selector --

Stitch Width Control -- 3 to 4

Stitch Length Control -- 6

Stitch Modifier - Neutral

(See page 3t )

Q FOOT and Q NEEDLE"

Zigzag Needleplata

Be sure to use a clear plastic foot, so

you can see stitches as you sew.

First, the smocked area: The stitching

is done before the piece is sewn into

the garment. Make a straight line of

gathers across the fabric being

smocked, Directly under the line of

gathering, stitch over the gathers. Con-

tinue rows of stitches ¼" apart with

gathers inbetween.

Page 35

SATIN STITCHES

AS THE

PROFESSIONALS

USE THEM

FINISHING AND PERSONAL TOUCHES

Closely-spaced zigzag stitches are called

satin stitches. They add a lovely

finishing touch to garments and {inens--

whether in simple sewing or super

decorations with any of your patterns or

embroidery designing. Use a Zigzag

Needleptate and the special Satin Stitch

Foot. This foot is "grooved" to permit

dense stitching to pass under it easily,

Here are your basic settings:

O

e

Important tips on satin stitching: It's a good idea to

loosen the tension of the top thread slightly. The

wider the stitch, the looser the tension needed,

MACHINE

EMBROIDERY?

CUSTOM DESIGNS

BY MACHINE?

DOMINO DIAMOND

DIAL YOUR STITCH

FOR SE'T[tNG ON

INDICATOR (20)

You may get the look and feel of hand

embroidery infinitely faster and easier by

machine thanks to your Kenmore.

Just choose which of the designs shown

below you want to sew alone or in

combination with each other.

PYRAMID CRESCENT

SCALLOP ARABESQUE"

STITCH

STITCH LENGTH CONTROL (inner dial) --

{outer dial) -- Red zone Neutral

*When sewing these decorative designs,

you may need to make slight adjustments

to the stitch modifier (30) to produce

perfect designs,

To lengthen the reverse motion stitches of

these pattens turn modifier slightly clock-

wise.., to shorten, turn counter-clock-

wise,

MODIFIER

l

TREE" TULIP* SWAN"

34

Page 36

HERE ARE SOME

"'SINGLE-NEEDLE"

DESIGNS YOU'LL

LIKE TO USE

Now we demonstrate variations and applications

35

you'll want to master as you become more expert.

For examp(e ...

Only your "fancy"

is needed for

this fanciwork

We've added an embroidered touch to a bias tape at

right and perked-up the coller below with a crescent

stitch, But you'll find the right place in.much of your

sewing for these nice "extras",

Remember these single-needle settings

DIAL YOUR STITCH

FOR SETTING ON

INDICATOR (20} STITCH LENGTH

CONTROL -- RED ZONE

FOR SIMPLE (FORWARD)

DESIGNS OR

6 FOR SUPER (REVERSE)

DESIGNS

i_ Ill

YOUR WIDTH

CONTROL SHOULD

BEAT t TO4

STITCH MODIFIER --

NEUTRAL (NOTCHED)

POSITION

(SEE PAGE 34)

_1 USE SATIN STITCH FOOT AND

ZIGZAG NEEDLEPLATE (SHOWN AT LEFT)

Page 37

iMPROVE YOUR

SKILLS WiTH

THESE KENMORE

SPECIAL AIDS

Thumb screw

able

Want to do "narrow-hemming"? Your Kenmore special at-

tachments (found in your Accessories & Buttonhoier box) will

help you develop these talents. You'll want to meet m and try

all these aids. But first, we suggest, you get acquainted with

your "adjustable holder" (at left).

USING YOUR ADJUSTABLE HOLDER

Your regular presser foot is replaced

Adjustable holdar

fitted on needIebar

with the adjustable holder for the fol-

lowing operations. You'll need to ad-

just the attachment for correct stitching

position.

SUGGESTIONS FOR USING THESE

ATTACHMENTS

When replacing the regular presser foot with one of these new sewing

aids, be sure that the presser bar is up and the needle is at its highest

position. After you have threaded the machine correctly, turn the hand

wheel to bring up the bobbin thread. Draw both threads under the

sewing aid and to the back of the machine to avoid tangles, It's a good

idea to test stitching first on a scrap of fabric being used.

NOW NARROW

HEMMING

IS EASY

SCROLL

FORM AND STITCH IN ONE OPERATION

Attach the Narrow Hemmer to the adjustable holder. Set

your machine for any stitch you want to use.

Make sure that edge of the fabric is cut straight. Turn a tiny double

hem (% tnch) along edge for about two inches. Place end of this

hem under Narrow Hemmer. Hold thread taut while stitching

along inside edge of hem. Feed fabric gradually into "scroll" m

hemmer, guiding edge of fabric as shown.

36

Page 38

YOUR KENMORE

EDGESTITCHER

MAKES MANY

TRIMS POSSIBLE

A MOST USEFUL, VERSATILE ACCESSORY

37

This one attachment helps you join fabric edges.., insert lace,..

do seam piping simplifies blind hemming as well as "French"

1

2

seams. Slots numbered 1 to 5 serve as sewing guides,

EVEN FEED

FOOT

moves top and

bottom material

together evenly

Presserfoot

screw

Presserbar

clamp

3

Presser foot

Set your machine for the stitch you want to use, Then follow these slot

5

numbers for the task at hand:

Slot I will guide fabric to be joined to lace. All you have to do is place

the lace in s|0t 2.

Slot 4 will guide piping being joined to fabric edges. Place the fabric in

slots 2 or 3.

Slot 5 may be used as a guide when sewing French seams which are

stitched twice, once on right side and once on other side, This is the

classic seam for sheers.

Use slots I and 3 to guide fabric with ease during blind hemming. (For

details on this technique, see p. 19.)

The even feed foot enables you to sew hard-to-sew fabrics without

sliding nor slipping and with perfect matching, Use it for sewing

leather, ultra suede TM , shiny fabrics {vinyls, patents and satins), bonded

fabrics, pile fabrics and matching stripes, plaids and patterns, It is not

recommended for use when stretch stitching,

To attach the even feed foot;

1. Rinse needle to its highest position.

2. Raise presser bar to its highest position and guide the even feed foot

into position from rear of machine.

3. Attach presser bar clamp to presser bar and lift presser foot lock as

high as it will go to hold the foot securely.

4. Attach screw (A) provided with the foot to needle clamp through

fork arm and tighten it.

Note: Attach the foot in exact order of steps as written.

Page 39

PROBLEM FABRICS? TOO SOFT TO FINISH? HERE ARE HAPPY ENDINGS ...

The extreme stretchiness of some soft fa brics (like jerseys

and lingerie tricot) can make hemming troublesome, Here

are two good answers with your Kenmore.

HANDSOME

SHELL

STITCHING

LOVELY

LETTUCE

EDGING

This shell-stitched edge is a popular finish for lingerie

and n_ghtgowns. To achieve this multiple scalloped

effect, set your machine as shown below. When sewing,

allow needle to clear }ust the left edge of the fabnc when

it z_gzags.

Stitch Setector --

Stitch Width Control -- 4

Stitch Length Control -- 12

Stitch Modifier -- Neutral

Q FOOT" Q NEEDLE"

Zigzag Needfeplate

Lettuce edges take advantage of the fabric's stretchi-

hess. To get the frilly effect, you stretch the fabric

while stitching the garment edge. The more the fabric

is stretched, the smaller and more numerous the r_p-

pies, in this process, some fabrics tend to develop

runs, so test a swatch first. Machine settings are the

same as above except:

Stitch Selector-- it

Stitch Width -- 2 ....

Stitch Lengtl_ _-- ! 2

The exclusive Kenmore Q FOOT TM and.Q NEEDLE TM are

invaluable he|pers for stitching these stretch fabrics.

38

Page 40

APPLIQUES,

OTHER ADD-ONS m

EASIER WITH

YOUR KENMORE

Neat ways to

personalize

your sewing

39

Appliques, small pieces of fabric applied as

decorative trim- now are more popular than

ever in adding interest to children's wear,

sportswear, even dressy clothing. Select an

applique to compliment the main fabric and baste

it in-place, Using the satin stitch or paris point

stretch stitch isee page 33), sew around raw edge

of applique completely covering edge.

Try these ideas: Use a contrasting color

thread or a decorative pattern for visible

stitching. Use a delicate edge stitch, same

color thread, for appliques that look

practically "woven in",

A GUIDE FOR

QUILTING

THE KENMORE

WAY

Great for

orderly rows,

uniformly spaced

QUILTING

GUIDE

This attachment comes in handy whenever you

want several rows of stitches an equal distance

apart--for garment trim as well as quilts, it consists

of a curved prong attached to a long bar on a holder,

The prong Js shifted back and forth on the holder to

establish the distance between rows of stitches.

Attach the quilting guide to presser foot as shown. Select

the desired stitch --straight or an embroidery type -- and

set the machine accordingly. After completing the first

row of stitching, place the guiding prong on this stitched

llne. The second row then can be placed at the desired

distance from first row, Continue working in this way for

as many rows as you want.

Page 41

CARING FOR YOUR MACHINE

PERFORMANCE PROBLEMS? THIS CHART MAY SOLVE THEM

Your Kenmore sewing machine =s a precision instrument, designed to give you

many years of troublefree sewing -- with minimum maintenance. But it is a

complex machine, And you may sometimes have difficulty in mastering a given

stitch, . adjusting for an unusual fabric., , learning when to replace a needle or

use a different thread. So if trouble occurs, don't panic. •

First, check to see if machine is plugged into the electrical outlet, (Remember, for

safety's sake, you always should unplug your machine when not in use!)

Second, check the list below. Often you'll be able to solve the problem yourself

without a service call.

Then if you still need help, it's available.., call your nearest Sears Serv,ce Center.

SUSPECTED PROBLEM PROBABLE CAUSE POSSIBLY EASY CORRECTION

IRREGULAR

STITCHES

BREAKING

"NEEDLE

i i

BUNCHING OF

THREAD

incorrect size needle,

Improper threading,

Loose upper thread tension.

Pulling fabric,

Light pressure on presser foot,

Loose presser foot.

Unevenly wound bobbin.

Nicks or burrs at needleplate opening.

Pulling fabric.

Incorrect size needle.

Incorrect setting of needle.

Loose presser foot.

Upper and lower threads not drawn

back under presser foot before

starting seam.

Choose correct size needle for thread and fabric.

Rethread machine; check tension spring threading.

Tighten upper thread tension.

Do not pull fabric; guide it gently,

Increase pressure on presser foot.

Reset presser foot.

Rewind bobbin,

Replace needleplate, or polish off burrs completely,

Do not pull fabric; guide it gently.

Choose correct size needle for thread and fabric.

Reset needle.

Reset presser foot.

When starting a seam be sure to draw both threads

under and back of presser foot about 4" and hold

until a few stitches are formed. 40

Page 42

SUSPECTED PROBLEM

PROBABLE CAUSE

POSSIBLY EASY CORRECTION

41

Incorrect thread tension{s),

Light pressure on presser foot.

Using two different sizes or kinds

PUCKERING

SKIPPING

STITCHES

BREAKING UPPER

THREAD

BREAKING BOBBIN

THREAD

FABRIC NOT

MOVING

of thread.

Sent or blunt needle.

Loose presser foot_.

Fabric too sheer or too soft.

Incorrect size needle.

Certain knits and synthetics.

Bent or blunt, needle.

incorrect setting of needle,

Tight upper thread tension,

Light pressure on presser foot.

Starting to stitch too fast.

Improper threading.

Tight upper thread tension.

Incorrect size needle.

Sharp eye m needle.

Nicks or burrs at need|epiate opening,

Improper bobbin case threading.

Lint in bobbin case or shuttle.

!

J

Darning plate attached.

Light pressure on presser foot.

Thread knotted under fabric,

t

MACHINE JAMMING, Thread caught in shuttle. Disassemble and ctean shuttle,

KNOCKING NOISE Bent needle plate. Replace needle plate,

i

Damaged needle. Replace needle.

Reset thread tension(s),

Increase pressure on presser foot.

Upper thread and bobbin thread should be same

size and kind.

Insert new needle.

Reset presser foot.

Use underlay of tissue paper.

Choose correct size needle for thread and fabric.

Use "Q NEEDLE .... and "Q FOOT "T"

insert new needle.

Reset needle.

Loosen upper thread tension.

Increase pressure on presser foot.

Start to stitch at a medium speed.

Rethread machine.

Loosen upper thread tension.

Choose correct size needle for thread and fabric,

Insert new needle.

Replace needleplate, or polish off burrs completely.

Check bobbin case threading.

Clean bobbin case and shuttle.

Remove darning ptate.

Increase pressure on presser foot.

Place both threads back under presser foot before

beginning to stitch.

MACHINE DOES

NOT SEW

Hand wheel not returned to

stitching position,

Power cord not connected,

Power!light switch off.

Push m clutch,

Check plug.

Push to on position.

Page 43

CLEANING YOUR

MACHgNE AND

KEEPING IT CLEAN

A clean machine

sews better...

runs smoother...

lasts longer

It takes a little time -- and very little effort -- to keep the

essential parts of your sewing machine in finest working order.

For the easy maintenance described on these pages, you may

want to buy the special sewing machine oil and brush available

in the sewing machine department of your nearest Sears

storeo

The small brush can be used to clean in and around the feed

dogs and shuttle area to remove accumulated dust and lint.

This is specially important when you're working with knits and

fabrics with nap that tend to shed more than woven fabrics.

Cleaning shuttle area. On rare occasions, you may want to clean the shuttle area.

Just follow these s_mp_e steps ,..

FEED DOGS

Lift out bobbin case from front,

SCREW FREE-ARM COVER

Turn hand wheel toward you until

needle bar (8} is at its highest position

and pointed hook at 12 o'clock (under

feed dogs). Pull out two locking wings

in direction of arrows.

NOTICE: Two black screws should not

be removed.

Step 3

Tilt machine head back and remove

free-arm cover by loosenIng screw, 42

Page 44

43

HOLE

A LIGHT JOB

TO KEEP YOUR

SEWING BRIGHT

Then clean shuttle area with small brush

and discharge lint from hole on the left

wal!, Put a drop of oi! to the points

indicated by arrows, Don't over-oif.!

(Reminder: don't use household oil,,,

use sewing machine oil,)

SHUTTLE

Step 4

When replacing a burned out bulb, only use a new

sewin9 machine light bulb (see part #6797 on

page 46), The light is located inside the Face Cover

Plate (12) of your machine. Turn the light switch off

and swing open the cover plate, Push up the bulb

slightly and turn clockwise. Insert new bulb, push

up and turn counterclockwise.

LOCKING WINGS Step 5

Replacing bobbin case and free*arm

cover. Make sure needle bar and

pointed hook are at the same pisition as

step t, insert bobbin case into shuttle

and push two tocking wings outward

untit they snap into place, Replace

free-arm cover in position and secure it

w=th screw, See step 3,

REMOVING MACHINE

When you need to remove your'mach|ne from its

cabinet or case for repa=r, loosen the screws hold-

ing your machine tn cabinet or case. Then lift

machine ouL

Page 45

OILING YOUR

MACHINE

KEEPS IT

SMOOTH

RUNNING

Be sure to

use special

sewing machine oil

i

To prevent friction and wear, oil your machine regularly. If you use

the machine all day every day, oil it weekly. If it is used moderate!y,

oil it every two months. If the machine is not used for some time, oil

it the day before you start to sew to be sure you don't soil fabrics.

Always remove dust and lint before oiling. Just a drop or two of oil

at each point is sufficient. Remove any excess oil from thread-

handling parts with a lintless fabric, like cheesec!oth.

OILING UNDER

TOP COVER PLATE

Lift Top Cover Plate by loosening two top

screws, as shown at left, Then oil points

indicated by arrows in top of machine

head.

OILING

UNDERSIDE

%rT e i_

o _lt_i o

Oiling in face cover plate. Swing hinged

Face Cover Plate !12) open and oil points

indicated by arrows in illustration at left.

It's a good idea to polish the take-up lever,

thread guides and area around the needle

and presser foot, on a regular bas_s.

If machine is in cabinet, remove bottom t-

screws first. Tilt machine head back and

remove bottom cover by removing screws

A, B, C and D shown in illustration at left.

Then just oil points indicated on underside

of unit as shown.

L

44

Page 46

REPLACING (OR ADDING)

iMPORTANT A3-[ACHNIENTS

All the attachments and accessories

shown on these two pages may be ob-

tained from any Sears, Roebuck and

Co. or Simpson-Sears Limited store or

service center,

NEEDLES- additional needles:

Size Needle Part No,

Packet of needles _ "No. 9 6550

with your machine _No._11 655t

includes a variety of sizes, No, 14 6552

Replacement needles No, t6 6553

come in packages No, 18 6554

of one size only. "Q NEEDLE ''T= 6746

PRESSER FEET %-:.., .&_..-,.

__ You may want to order these

Double Needle 6749

45

When ordering parts, please refer to

this illust]'ated list and give the fol*

lowing information to Sears:

1. MACHINE MODEL NUMBER

2. PART NUMBER

3. ITEM NAME

4. ITEM DESCRIPTION

(Part No. 44985) Stitch (#43776) (#6858)

ACCESSORIES

BUTTONHOLE

ButtonhoIe Guideptate

(Part 55511)

Buttonhole Templates

No. 1 Par[ 45195

No. 2 Part 45196

No, 3 Part 45197

No. 4 Part 45198

No. 5 Part 45199

Blind Stitch Foot

(#6886)

Buttonhole Opener

Overcasting

|#35094|

Buttonho|e Foot

(# 4t040)

(#6830)

Even Feed

Foot(#6888)

Page 47

OTHER VITAL

iTEMS

Adjustable Holder

art 29308) _bbin Box with

Plastic Bobbins

I# 6868)

10 Metal(# 6862)Bobbins

mo, ..r.....°o,

__ I# 55501)

Small Screw Driver

I # 55500)

*Oil & Lint Brush Magnetized

|#6889) Extra Small Screw Narrow Hemmer

"Not furnished with machine Drwer {# 55499) 4#29396)

Zigzag Needleplate

!# 45747)

Spool Pin

Cap 1# 55503)

Edge Stitcher

(#29306)

Straight Stitch

Needleplate t# 45748)

Bobbin Winder

Rubber Ring 1#1939)

Bobbin Winder Tension

Disc (#39619)

Quilting Guide

1#35105)

Darning Plate

(#43166)

Motor Belt

450231

Needle Threader

(#43780)

46

Page 48

o_

ul

o_

c_

_' _z

r . !.

i

..:..

.... .. ...... ..

• -.,°.

Loading...

Loading...