Kenmore 158.17560, 158.17571, 158.17570, 158.17572, 158.17740 User Manual

...

158.17572

158.17560 158.17740

158.17570 158.17741

1S8.17S71

STRAIGHTSTITCH ATTACHMENT ZIGZAG BITE FOOTCONTROL

POSITION DIMENSION

ml

(;ENTER LO1€ BAR _,8 6816

ii

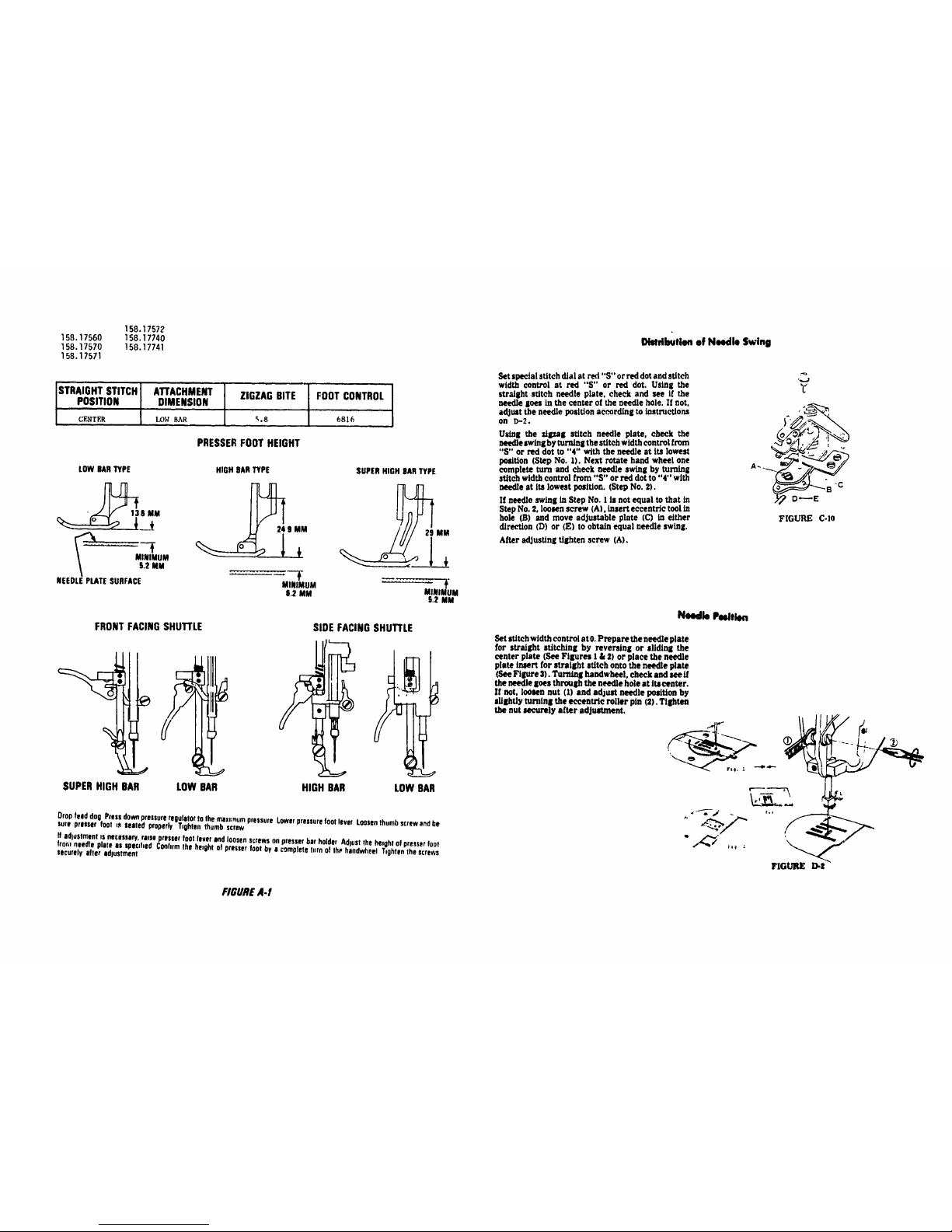

PRESSERFOOT HEIGHT

LOW BARTYPE

•_136 MM

MINIMUM

5.2 MM

NEEDLEPLATESURFACE

HIGHBARTYPE

24 S MM

MINIMUM

8.2 MM

SUPERHIGH OARTYPE

...... . NllOM

5.2 MM

FRONTFACINGSHUTrLE

SIDE FACINGSHUTrLE

SUPERHIGH BAR

LOW BAR HIGH BAR LOW BAR

Drop feed dog Pressdo_ pressureregulatorto the max,mumpressure Lowerpressurefoot lever Loosenthumbscrewend be

sure presser foot t,* seated properly Tighten thumbscrew

If adjustmentIs necessaw, raise presser foot leverandloosenscrews onpresserbar holder AdluSt the heightof presserfoot

fror,r needle plate as _oecd,ad Coohrmthe he,oht of presserfoot by a completeturn of the handwheel T,ghtenthe screws

securely after edlustment

Disldbuticm of Needle Swing

Set spe_al stitch dial at red "S" or ted dot and sUtch

width control at red "S" or red dot. Using the

straight stitch needle plate, check and see if the

needle Sees in the center of the needle hole. If not,

adjust the needle poslUon according to inst_eUons

on I)-2.

Us_g the _d_g stitch needle plate, check the

needle swing by turning the stitch width control from

"S" or red dot to "4" with the needle at Its lowest

pooit/on (Step No. l). Next rotate hand wheel one

complete turn =nd check needle swing by turning

stitch width control from "S" or red dot to "4"' with

needle st its lowest position. (Step No. Z).

If needle swins in Step No. I is not equal to that in

Step No. 2, loosen screw (A), insert eccentric tool in

hole (B) and move adjustable plate (C) in either

d/reetton (D) or (E) to obta/n equal needle swing.

After adjusting tighten screw (A).

,_..J

"8.c

FIGURE C-le

Needle Pedtlen

Set stitch width control at 0. Prepare the needle plate

for straight stitching by revers/ng or sliding the

center plate (See Figures l & 21 or place the needle

plate Insert for straight stitch onto the needle plate

(See Figure 3). Tur'n_g handwheel, check and see if

the needle goes through the needle hole at lteeenter.

If not, loosen nut (1) and adjust needle posit/on by

sUShtly turnlnl the eccentric roller pin (3). TlShten

the nut securely after adjustnlant.

FIGUREA-f

158.17560 I_IWwwIIIN I

158.17570

158.17571

158.17572

158.17740

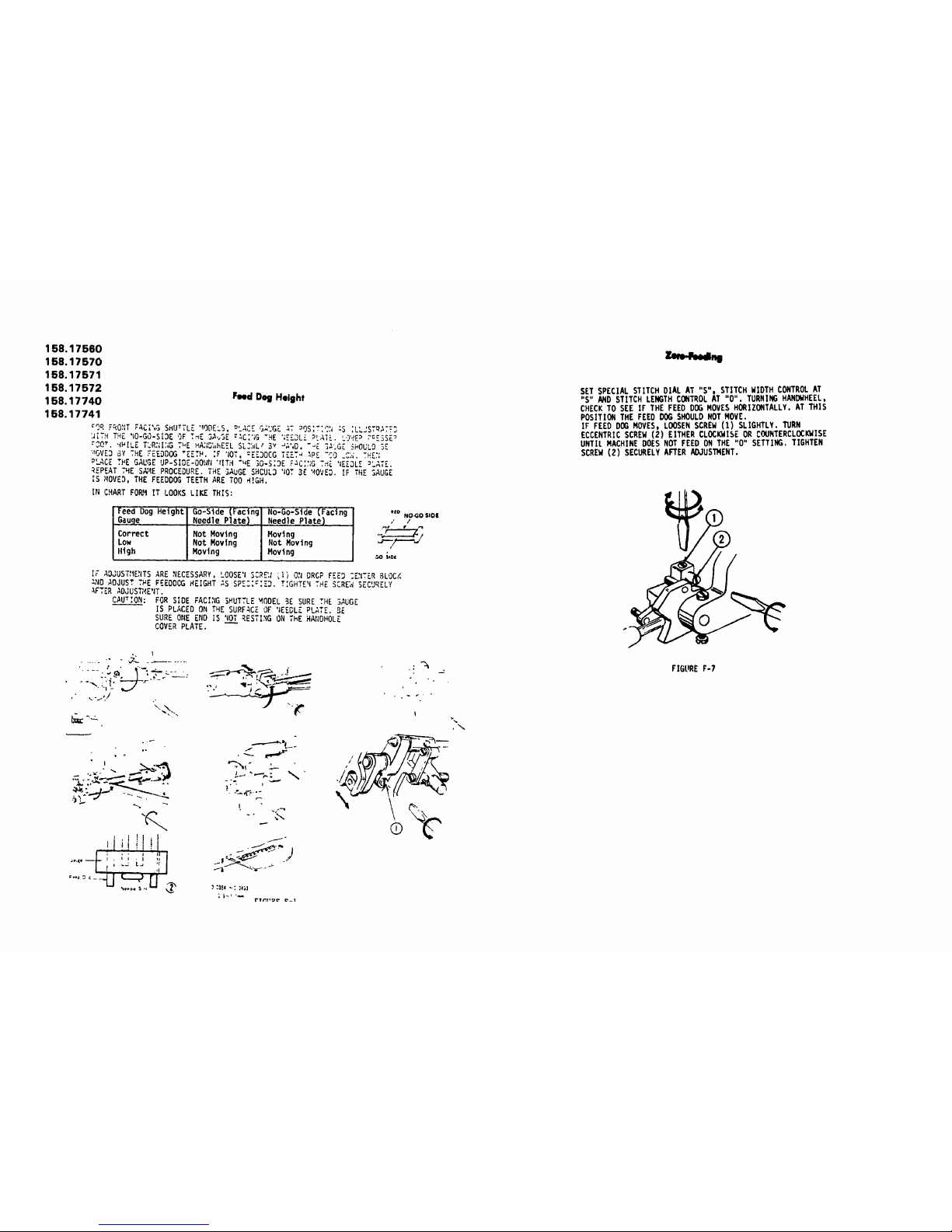

Feed Dog Height

158.17741

€OR F_O_IT PACT',&SHUTTLE '_ODE=S, _LACZ GAUGE _T _9S:T:_:I=S ;LLJSTRATT3

:JITHT_E 'IO-GO-SiOEOF T_E 3_._SE :4C;';G"_E ';€_DL_PLATE. LO'.!E_ PcE3SE_

_00". '_HILET_R_;I:;GThE HA:;_hE_L SL_LI 3v _;',D."_E ];'.GZ_OULO SE

'._OVE3BY THE ?EEDDOG "EZTH. IF 'lOT,:EE3DCG TEET_ _PE "CO _C_. THE_:

PLACE THE GAUGE UP-SIDE-DOWrl'IITH÷"E IO-S;3E F_C:_;GTHE 'EE_L[ _LATE.

REP{AT THE S_4E PROCEDURE. THE SAuGE SHCUL3 'lOT3E '40VED. IF THE SAUGE

IS MOVED, THE FEEDDOG TEETH ARE TOO _!GH.

IN CHART FORM IT LOOKS LIKE THIS:

Feed Dog Height Go-Side (Facing No-Go-Slde (Facing ,,oNO:OS,OI

Gauge Needle Plate) Needle Plate) ,' /

Correct Not Moving Moving .-_/

Low Not Moving Not Roving

High Moving Moving

I

_0 SiOi

I; ADJU T_I'S E.ITSARE NECESSARY, LOOSE'ISCRE:_ i) ON DRCP FEED :ENTER BLOCK

AND ADJUST THE PEEDDOG HEIGHT _S r"_':_

SP....... TIGHTE_ THE SCREW SECURELY

AFTER ADJUSW4E'IT.

T_

CAU ,ON: FOR SIDE FACI_IGSHUTTLE MODEL BE SURE THE SAUGE

IS PLACED ON THE SURFACE OF 'EEGLE PLATE. 5E

SURE ONE END IS 'lOTRESTING ON THE HAIIDHOLE

COVER PLATE.

., I

-.'_ _-.,--__.

-%

,i t!t!t

i * , I il

lll,(ll -- I = I I • I II

•..,,__.U<__,,ri'

"ltl+_i _ ,I i.i_

f

i:; ._' ""

r,..

I

+ ,w¢*_

/"

i'? ¢Zlll_ _--1

.\

SET SPECIAL STITCH DIAL AT "S". STITCH WIDTH CONTROLAT

"S" AND STITCH LENGTH CONTROLAT "0". TURNING HANDWHEEL,

CHECKTO SEE IF THE FEED DOG ROVESHORIZONTALLY. AT THIS

POSITION THE FEEO DOG SHOULDNOTROVE.

IF FEED DOGMOVES, LOOSENSCREW(1) SLIGHTLY. TURN

ECCENTRICSCREW(2) EITHER CLOCKWISEOR COUNTERCLOCKWISE

UNTIL MACHINE DOES NOT FEED ON THE "0" SETTING. TIGHTEN

SCREW(2) SECURELYAFTER ADJUS'ff4ENT.

FIGURE F-7

Loading...

Loading...