158.120

158.12000

158.12020

15g.121

158.12250

158.12260

158.220

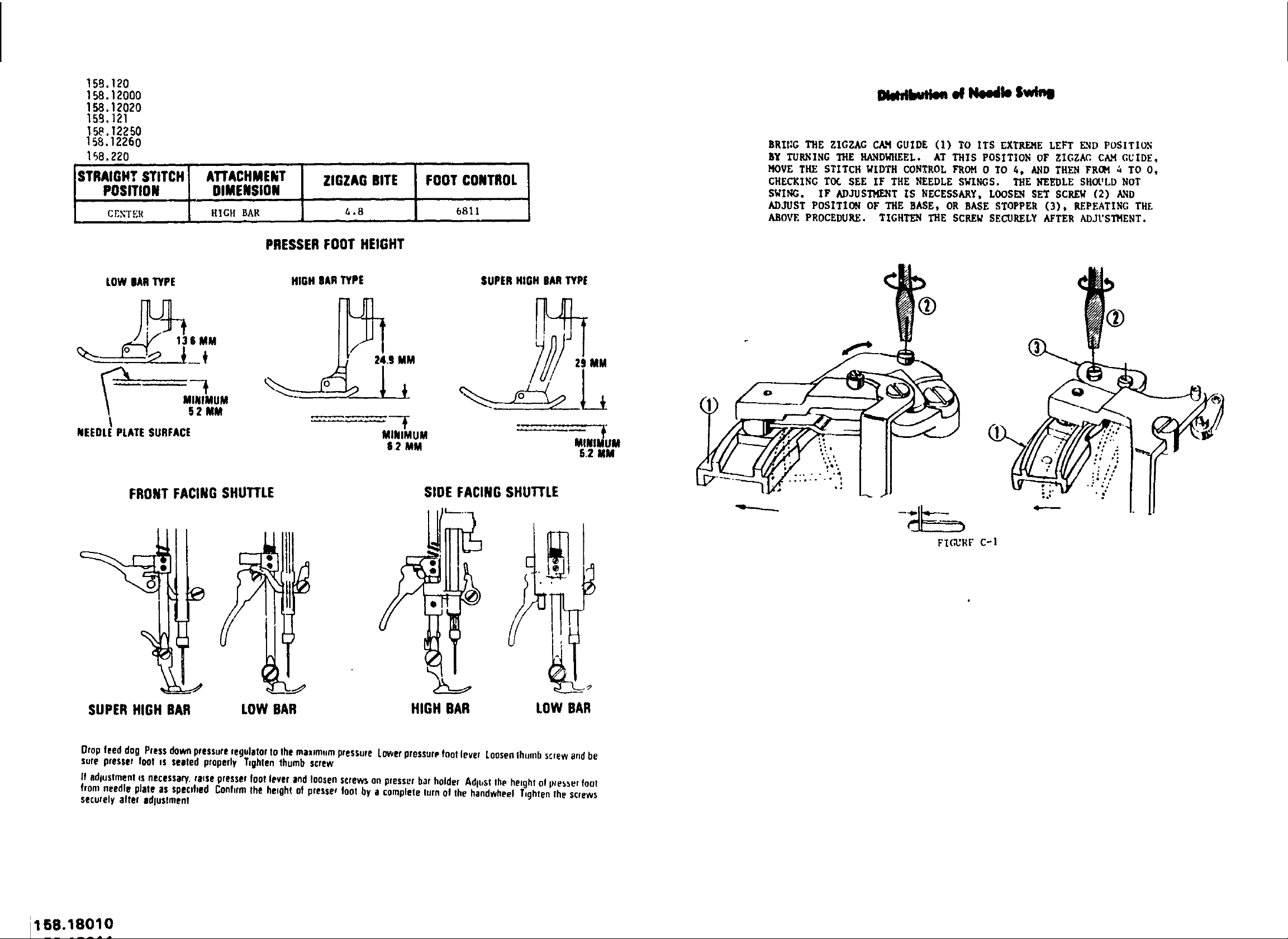

STRAIGHTSTITCH ATTACHMENT ZIGZAG BITE FOOTCONTROL

POSITION DIMENSION

CF._TER HIGH BAR 6.8 6811

PRESSERFOOTHEIGHT

d Sw l

BKIf:G THE ZIGZAG CAN GUIDE (l) TO ITS r,XTRE/tE LEFT L_D POSITION

bY TURNING THE HAND'EEL* AT THIS POSITION OF ZIGZAC C_M GUIDE,

MOVE THE STITCH WIDTH CON._ROL FROH O TO 4, AND THEN FROH _ TO O,

CHECKING TO(. SEE IF THE NEEDLE SW][NGS. THE NEEDLE SHOULD NOT

SWING. IF ADJUSTHENT IS NECESSARY, LOOSEN SET SCREW (2) AND

ADJUST POSITION OF THE BASE, OR BASE STOPPER (3), REPEATING THE

ABOVE PROCEDURE. TIGHTEN THE SCREW SECUItELY AFTER ADJ_STHENT.

LOW|ARTYPE

..__._13 6 MM

MINIMUM

52 MM

NEEDLE PLATE SURFACE MINIMUM

HIGH BARTYPE

62 MM

FRONTFACINGSHUTTLE

SUPER HIGH lIAR TYPE (

MINIMUM

5.2 MM

SlOE FACINGSHU'i'rLE

FI €,_RF C-I

SUPERHIGH BAR LOW BAR HIGH BAR LOW BAR

Drop feed dog Pressdownpressureregulatortothe max;mum pressureLowerpressorPfootlever LoosenIhumb soew andbe

sure presser foot os seated properly Taghtenthumb screw

If adluslmenl asnecessary,raise presserloot lever and loosenscrewson pressor bar holder Adlustthe hefght of p_es_effoot

from needle plate as specdled Conformthe height of presser toot by a complete turn of the handwheel T_ghtenthe sc|ews

securelyafter adjustment

i158.18010

158.120

158.12000

158.12020

158.121

1 58.12250

158.12260

1 58.220

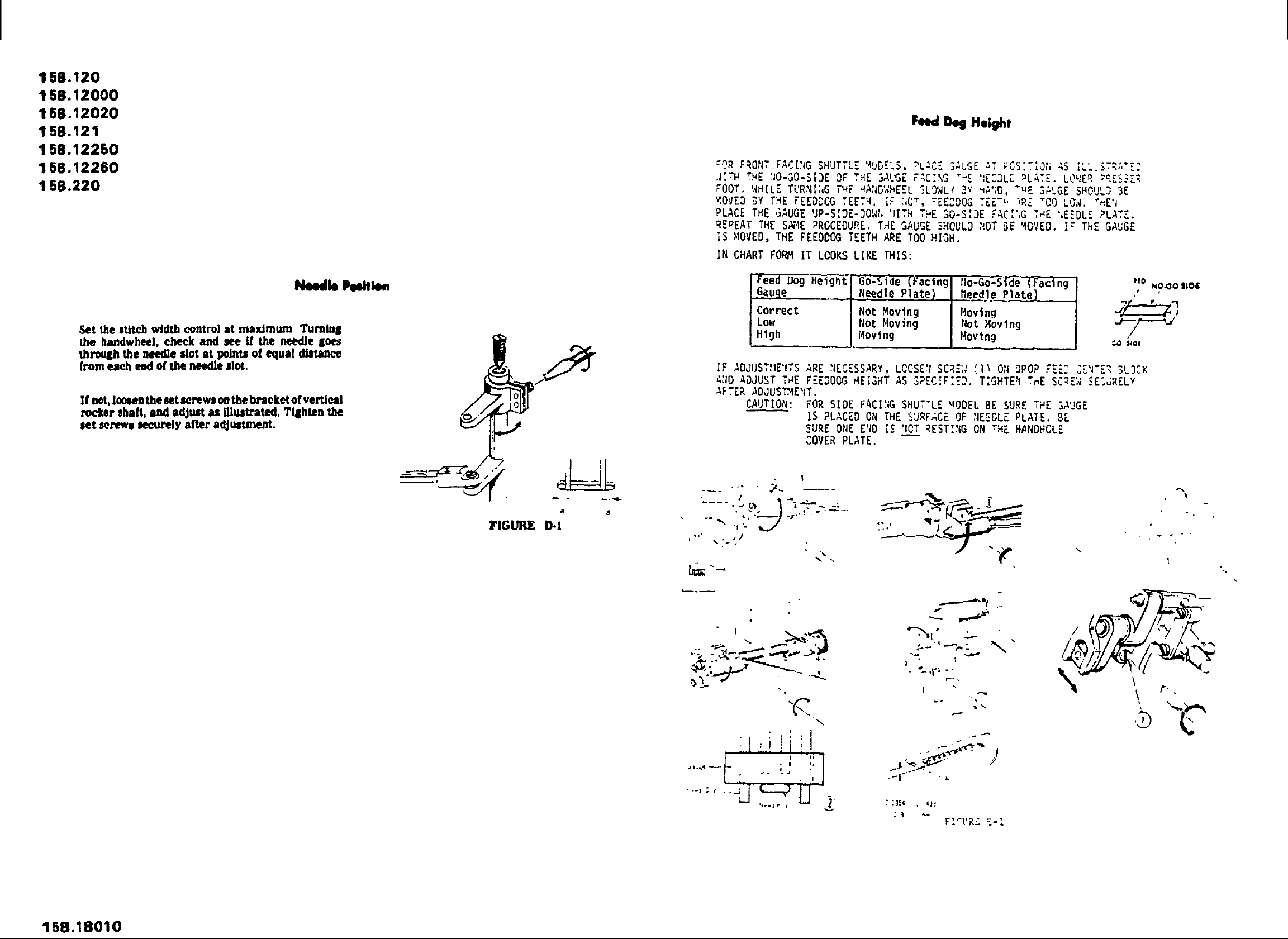

Feed 0cO Height

:OR FRO_ITFA,_,I:_GSHUTTLE '_g&ELS,-_LzC_;_US[ _T ;OS:TIOI__,S;LL.STR'.'ZC

._ITHTHE _IO-GO-SI_EOF THE SALSE F':,C:_S"_E ':Z=SL__L_TE. LO'.IER_R[_.._ZR

FOOT. WHILE TL'RNI:,GT_F 4A:|G'._HEELSLOWL¢ 3v _';D, ÷uE SALGE GHOUL] SE

'4OVE3BY THE FEEDCOG TEETH. ;F :40T, :EE_DOG TF.F'T_._RE "00 LO._._HE'_

PLACE THE GAUGE UP-SIDE-DOW_J'rITHT._ESO-SIDE FACI',GT#[ ',EEDLEPLATE.

REPEAT THE SM'IEPROCEDURE. THE GAUGE SHOULD ;.'OTBE '_OVED. I_ THE GAUGE

IS ,_IOVED,THE FEEDDOG TEETH ARE TOO HIGH.

IN CHART FORM IT LOOKS LIKE THIS:

NeedlePmdtle.

Set thestitch width control at maximum Turnlni

the handwheel,cheek and see If the nero goes

throuEh the needle slot at points of equal diltanee

from each end of the needle slot.

If not, loosen the set screws on the bracket of vertical

rocker shaft, and adjust as illustrated. T_hten the

set screws securely after adjustment.

FIGURE D-I

Feed Dog Height Go-Side (FacingI r|o-Go-Si_ (Facing l ,,oNo_ossos

COrrect Hot Moving I Moving _._-------_/

Low Hot Moving lHot Moving

Gauge Needle Plate} I Needle P_ate) i '"

High _ovlng J Moving

IF ADJUST)IE'ITSARE :IEOESSARY,LODGE';SCRE:(',ll0_IDROP ,€':'-.=-_'I'[_"_LD_Kr'

&:(DADJUST T#E FEEDDOG HEIGHT AS SPECIFIED. TIGHTE_ T_[ SCI[',.;S[;.JREL'_

AFTER ADJUS,_,<E'4T.

CAUTION: FOR SIDE FACI2;GSHUT'L[ _ODEL BE SURE T_E )AUGE

IS _LACED ON THE SJRFACE OF :|EEDLEPLATE. B_.

SURE ONE E'¢OIS 'lOTRESTING ON .'HEHANDHGLE

COVER PLATE.

I

• _ • o ,

158.18010

/

. _,_;-

I

\

NEEDLE TIMING TO SHUTTLE

NEEDLE BAR HEIGHT

THE RADIAL TIMING GAUGESAND TEST PINS, AS

ILLUSTIL_TED BELOW,ARE AVAILABLE FROMDIVISION

92, SOURCE192. THE KIT IS IDENTIFIED AS

#69659° EACHGAUGEAND TEST PIN CAN ALSO BE

ORDEREDINDIVIDUALLY.

THIS KIT IS USEDFOR SOURCE148 AND 15B

VERTICAL BOBBIN sEWING MACHINES.

Nudb Ck_mm m Shrine

The clelrmce *'1.'* *'b." "c." and the In_e "'d" are v_ry

¢¢ltlCal _omts *n (llaticm to _e n4Ndke tlm*r_ 1o shuttle.

HOW_. the_ 9_ntt a_e wsu&lly _t_moned _ usual tl_

Rado_W_mlng _lU!leS.

NOTE:

No _tme_t _ d4omd fo_ "_meemo_ _" for me

feat.lint mut_e md_s. Fo_Niultment foqJNk_le

modM$._eme rsforto Filwaee(_3.

RADIAL

TIMING GAUGE

#69894

RADIAL

TIMI[;GGAUGE

#69892

RADIAL

TIMING GAUGE

'69893

_"_ z. TEST PIN

w /7

FIGURE G-I eb9895

A #69313

RADIAL

TIMING GAUGE

(O2S - O..lSmm)

FIGURE G-2

168.18010

NEEDLETIMINGTOSHUTTLE

Nmldll¢ktm l ll mkl

The t0tl0Wml] Klfustmanl _s_dl_wd or,Iv for the SKJe.tKIhe

shuttle models

Ifltett nlqldlO and tighten the handle clamp s_r(_w tKuroly

8ring the n_ldtt t0 ,tS i0*lit potltt0fl by turnl_l the hind

v_41el ChKk Io _ ,f tl_O¢ttMM_Ca betw_ln IP,4n_KIIo and

the Ihuttle iS wdhm the koeclf_ld Itm,I If nOt. Io_en screw

12) On the muttll gu,dM _#kel tad adl_st the pCht,Oa of

shuttle by st,dOg zt etth_ toward the lift 0€ rill'el untd the

wol_r €lewance _s oDtolned, T_ten the zcrew 14cutely

after IdNstment,

CAUTION: 114_ th41 _ el4mady dote n_l rltlN

DIMENSIONB

FIGUREO.3

Figure G 3 gives e general zdee of the use of the radral

!truing gauge Fallacythe mstzucPOns _t the lell which

pertain to thts modelis}

_o I,N4-I.INt._

(t.! - I.l _)

PlOdR| G4

168.120

168.12000

158.12020

168.121

168.12250

158,12260

168.220

Zigzag Synchrenixati_n

Set stitch width control at maximum Turntn| the

handwl_eJ, checx and see if the needle side motion

on the standard plone (0.0,194'_ch above the upper

surface of the ntedJe pJase)at both needle posJUonl

,|

i" q

' 12

e OO_3e 030_'_'i

FIGUItE H-_ -

come within the enlOneerln| limit of 0.0131 inch. If

not. Ioo_n set so_w 42) on the worm gear either

dire_on. TIl_ten the screw ,2) securely after

ad.hlsunent.

.#

tj ;. I

\

Set ititcll lfld_ control lit O, Andhun UseJlald-

wheel tow_rda;you. ;t the need;e i,alnp ,t taJa

settln4, lo_en |¢r_ (1) I_d adjust thaipmPition

o( z_z_ stopper Ine/the: cUrecUontoms/nta/n

pet/eet strsqlht IutehJnlr. T_bten the |crew

securely after adJu4tment.

$_, S*,chinS

FIGURE 1.1

Loading...

Loading...