Use & Care Guide

Model No.

153.592500 50 Gallon Tall

153.592600 66 Gallon Tall

153.592800 80 Gallon Tall

Kenmore® Elite

Hybrid Electric Heat Pump

Water Heater

For potable water heating only.

Not suitable for space heating.

INSTALLER: Affix these instructions to or near the water heater.

OWNER: Retain these instructions for future reference.

ADVERTENCIA

Si no puede leer o entender el inglés y necesita el manual de

instrucciones en español, puede solicitarlo al 1-800-821-2017. NO

TRATE DE INSTALAR U OPERAR ESTE CALENTADOR DE AGUA

SI NO ENTIENDE LAS INSTRUCCIONES. No hacer caso de esta

advertencia podría originar lesiones graves o mortales.

P/N 100270593 (0516)

Sears Brands Management Corporation,

Hoffman Estates, IL 60179 U.S.A.

www. kenmore.com

TABLE OF CONTENTS

Product Warranty ....................................................................................................................................... 3

Typical Installa on ......................................................................................................................................4

Important Safety Informa on ..................................................................................................................5-7

Ge ng Started ...........................................................................................................................................8

Installa on ..................................................................................................................................................9

Water Pressure/Thermal Expansion .....................................................................................................9

Leaks and Temperature Regula on .................................................................................................... 10

Proper Loca on .................................................................................................................................. 10

Removing the Old Water Heater ........................................................................................................12

Installing the New Water Heater ........................................................................................................13

Installing Condensate Drain Lines ....................................................................................................... 13

T&P Relief Valve Pipe ..........................................................................................................................14

Shutoff and Mixing Valves ..................................................................................................................15

Connec ng the Water Supply .............................................................................................................15

Verify Connec ons and Fill Tank ......................................................................................................... 16

Electrical Connec ons ........................................................................................................................17

Adjus ng the Temperature .................................................................................................................18

Kenmore® Smart Water Heater Module (sold seperately) .......................................................................20

Diagnos c Codes .................................................................................................................................24-25

Troubleshoo ng Chart ..............................................................................................................................26

Troubleshoo ng ..................................................................................................................................27-30

Maintenance .......................................................................................................................................31-35

Repair Parts Illustra on ............................................................................................................................36

TANK

MODEL

NUMBER

153.592500 50 189 22 (559) 63 (1600) 21 4500 4500 10 30

153.592600 66 250 26.5 (673) 61 (1549) 21 4500 4500 10 30

153.592800 80 303 26.5 (673) 69 (1753) 21 4500 4500 10 30

*Wiring size based on standard 60°C copper wire. If distance from fuse box to water heater is more than 90 feet, refer to your local electric code.

**Recovery rate is based on backup heating element performance.

2 • Residen al Electric Water Heater Use and Care Guide

CAPACITY

DIMENSIONS

IN INCHES (mm)

RECOVERY

RATE GALS.

PER HOUR @

90°F RISE**

BACKUP HEATING

ELEMENT WATTAGE

@ 240 VOLTS

MINIMUM WIRE

SIZE* (GAUGE)

MINIMUM FUSE

OR CIRCUIT

BREAKER SIZE

(AMPS)Gals Liters DIA. HEIGHT UPPER LOWER

PRODUCT WARRANTY

KENMORE ELITE LIMITED WARRANTY

WITH PROOF OF SALE, the following warranty coverage applies

when this water heater is correctly connected, installed, operated and

maintained according to all supplied instructions. In all cases, replacement units, tanks or parts are warranted only for the unexpired portion

of the warranty period from the original date of sale.

FOR ONE YEAR from the date of sale this water heater is warranted

against defects in material or workmanship. A defective water heater

will receive free repair or replacement at option of seller.

FOR TEN YEARS from the date of sale this water heater is warranted

against leaks in the tank. If a tank leak occurs within the first year, a

new water heater of equal capacity and quality will be supplied and

installed at no charge. If a tank leak occurs after the first year, a new

water heater of equal capacity and quality will be supplied but not

installed at no charge. You are responsible for the labor cost of water

heater installation after the first year from the date of sale.

FOR TEN YEARS from the date of sale all water heater parts are

warranted against defects in material or workmanship. If a part is

defective within the first year, a new part will be supplied and installed

at no charge. If a part is defective after the first year, a new part will

be supplied but not installed at no charge. You are responsible for the

labor cost of part installation after the first year from the date of sale.

For warranty coverage details to obtain free repair or replacement,

visit the web page: www.kenmore.com/warranty

This warranty applies for only two years on the tank and one year on

all parts if this water heater is ever used in a residence of more than

one family or in a commercial, institutional or industrial installation.

This warranty covers ONLY defects in material and workmanship, and will NOT pay for:

1. Expendable items that can wear out from normal use, including but

not limited to filters, belts, bags or screw-in base light bulbs.

2. A service technician to clean or maintain this appliance, or to

instruct the user in correct appliance installation, operation and

maintenance.

3. Service calls to correct appliance installation not performed by

Sears authorized service agents, or to repair problems with house

fuses, circuit breakers, house wiring, and plumbing or gas supply

systems resulting from such installation.

4. Damage to or failure of this appliance resulting from installation not

performed by Sears authorized service agents, including installation that was not in accord with electrical, gas or plumbing codes.

5. Damage to or failure of this appliance, including discoloration or

surface rust, if it is not correctly operated and maintained according

to all supplied instructions.

6. Damage to or failure of this appliance, including discoloration or

surface rust, resulting from accident, alteration, abuse, misuse or

use for other than its intended purpose.

7. Damage to or failure of this appliance, including discoloration or

surface rust, caused by the use of detergents, cleaners, chemicals

or utensils other than those recommended in all instructions supplied with the product.

8. Damage to or failure of parts or systems resulting from unauthorized modifications made to this appliance.

9. Service to an appliance if the model and serial plate is missing,

altered, or cannot easily be determined to have the appropriate

certification logo.

Disclaimer of implied warranties; limitation of remedies

Customer’s sole and exclusive remedy under this limited warranty

shall be product repair or replacement as provided herein. Implied

warranties, including warranties of merchantability or fitness for a

particular purpose, are limited to one year on the water heater, and

ten years on the tank and parts, or the shortest period allowed by

law. Seller shall not be liable for incidental or consequential damages.

Some states do not allow the exclusion or limitation of incidental or

consequential damages, or limitation on the duration of implied warranties of merchantability or fitness, so these exclusions or limitations

may not apply to you.

This warranty applies only while this appliance is used in the United

States.

This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

Sears Brands Management Corporation,

Hoffman Estates, IL 60179

Master Protection Agreements

Congratulations on making a smart purchase. Your new Kenmore

Elite® product is designed and manufactured for years of dependable

operation. But like all products, it may require preventive maintenance

or repair from time to time. That’s when having a Master Protection

Agreement can save you money and aggravation.

The Master Protection Agreement also helps extend the life of your

new product. Here’s what the Agreement* includes:

• Parts and labor not just for repairing defects, but to help keep

products operating properly under normal use. Our coverage

goes well beyond the product warranty. No deductibles, no

functional failure excluded from coverage— real protection.

• Expert service by experienced service technicians trusted in millions of homes every year.

• Unlimited service calls and nationwide service, as often as

you want us, whenever you want us.

• “No-lemon” guarantee – replacement of your covered product

after three separate product failures occur within twelve months

and a fourth repair is required. Includes free delivery and installation, if necessary of replacement product.

• Product replacement if your covered product can’t be fixed.

• Annual Preventive Maintenance Check at your request – no

extra charge.

• Fast help by phone – phone support from a service agent on all

products to help troubleshoot problems. Think of us as a “talking

owner’s manual””

• Power surge protection against electrical damage due to power

fluctuations.

• $300 Food Loss Protection for any food spoilage that is the

result of mechanical failure of any covered refrigerator or freezer.

• Service Promise: $50 if first attempt repair of your covered

kitchen or laundry product can’t be accomplished and product is

not usable while awaiting further repair service.

• 25% discount off the regular price of any non-covered repair

service and related installed parts.

Once you purchase the Agreement, a simple phone call is all that it

takes for you to schedule service. You can call anytime day or night.

The Master Protection Agreement is a risk free purchase. If you cancel for any reason during the product warranty period, we will provide

a full refund. Or, a prorated refund any time after the product warranty

period expires. Purchase your Master Protection Agreement today!

Some limitations and exclusions apply. For prices and additional

information in the U.S.A. call 1-800-827-6655.

* Coverage in Canada varies on some items. For full details call

Sears Canada at 1-800-361-6665.

Sears Installation Service

For Sears professional installation of home appliances, garage door

openers, water heaters, and other major home items, in the U.S.A.

call 1-844-553-6667 and in Canada call 1-844-553-6667.

Residen al Electric Water Heater Use and Care Guide • 3

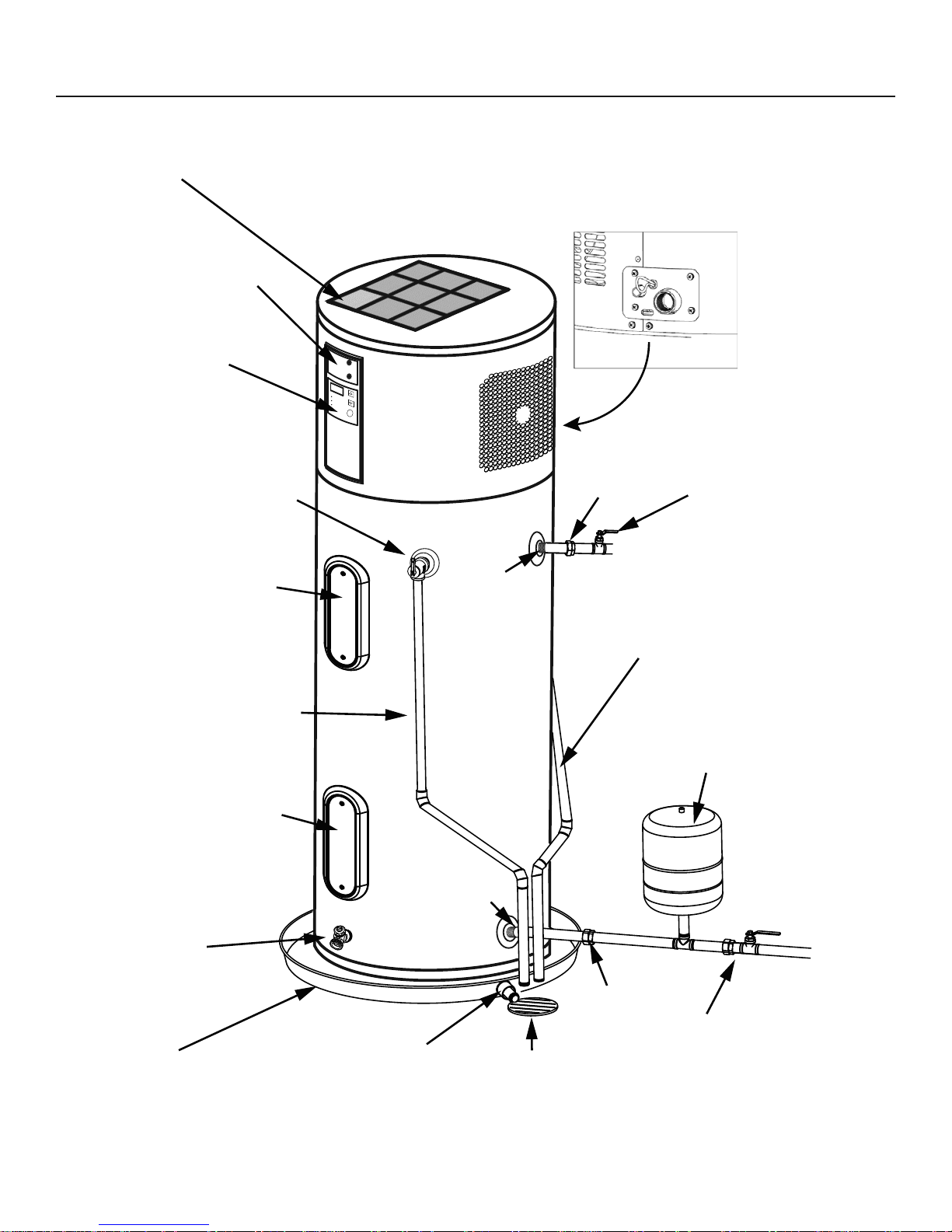

COMPLETED INSTALLATION TYPICAL

TYPICAL INSTALLATION FOR 208V/240V

Air Filter

Connectivity Port

User Interface

Module (UIM)

Temperature and

Pressure Relief Valve

Upper Element

and ECO

Condensate Drain

Access Cover

xxxxx

xxxxx

xxxxx

xxxxx

Union*

Shut-off Valve

(Hot)

Hot

(Outlet)

Discharge Pipe

(Do Not Cap or Plug)

Lower Element

Drain Valve

Primary Condensate

Drain (3/4” PVC)

Thermal Expansion Tank

Cold

(Inlet)

Union*

Shut-off Valve

Drain LineDrain Pan

Drain

(Cold)

*NOTE: If copper piping is used, unions must be dielectric at inlet and outlets.

4 • Residen al Electric Water Heater Use and Care Guide

IMPORTANT SAFETY INFORMATION

Read and follow all safety messages and instruc ons in

this manual.

This is the safety alert symbol. It is used to alert you to

poten al physical injury hazards. Obey all safety messages

that follow this symbol to avoid possible property damage,

serious injury or death. Do not remove any permanent

instruc ons, labels, or the data plate from either the outside of the water

heater or on the inside of the access panels. Keep this manual near the

water heater.

DANGER indicates hazardous

DANGER

WARNING

situa on that, if not avoided, will

result in death or serious injury.

WARNING indicates a hazardous

situa on that, if not avoided, could

result in death or serious injury.

Important informa on to keep

Fill out this sec on and keep this

manual in the pocket of the water

heater for reference.

Date Purchased:

Model number:

Serial number:

Maintenance performed:* Date:

SAFETY

CAUTION

NOTICE

CAUTION indicates a hazardous

situa on that, if not avoided, could

result in minor or moderate injury.

NOTICE indicates prac ces not

related to physical injury.

*Drain and fl ush tank, clean air fi lter,

clean condensate pan, and remove and

inspect anode rod a er fi rst six months

of opera on and at least annually

therea er. Operate the Temperature

and Pressure Relief Valve (T&P) annually and inspect T&P valve every 2-4

years (see the label on the T&P valve for

maintenance schedule). See the Maintenance sec on for more informa on

about maintaining this water heater.

Residen al Hybrid Electric Heat Pump Water Heater Use and Care Guide • 5

IMPORTANT SAFETY INFORMATION

o reduce the risk of property

damage, serious injury or death,

T

read and follow the precau ons below,

all labels on the water heater, and

SAFETY

the safety messages and instruc ons

throughout this manual.

RISKS DURING INSTALLATION

AND MAINTENANCE

Electric Shock Risk

Contact with the electrical

parts in the junction box,

behind the access doors

and inside the top shroud can result in

severe injury or death from electrical

shock:

• Disconnect power by opening the

circuit breaker or removing the

disconnects before installing or

servicing.

• Use a non-contact circuit tester to

confirm that power is off before

working on or near any electrical

parts.

• Replace the junction box cover and

access doors after servicing.

Lifting Risk

The water heater is

heavy. Follow these

precau ons to

reduce the risk of property damage,

injuries from li ing or impact injuries

from dropping the water heater.

• Use at least two people to lift the

water heater.

• Be sure you both have a good grip

before lifting.

• Unit is top heavy, u se an appli-

ance dolly (with strap) to move the

water heater.

RISKS DURING OPERATION

Scalding Risk

This water heater

can make water hot

enough to cause

severe burns instantly, resulting in

severe injury or death.

• Feel water before bathing or s how-

ering

• To reduce the risk of scalding,

install a Thermostatic Mixing Valve

(temperature limiting valves) at

each point of use. These valves

automatically mix hot and cold

water to limit the temperature at

the tap. Mixing valves are available

at local plumbing supply stores . Follow manufacturer’s instructions for

installation and adjustment of the

valves.

• The User Interface Module (UIM)

on this water heater have been factory set to approximately 120°F to

reduce the risk of scalding. Higher

temperatures increase the risk of

scalding, but even at 120°F, hot

water can scald. If you choose a

higher temperature, installing a

Thermostatic Mixing Valve located

at each point of use are particularly

important to help avoid scalding.

Temperature Time to Produce a

Serious Burn

120°F (49°C) More than 5 minutes

125°F (52°C) 1½ to 2 minutes

130°F (54°C) About 30 seconds

135°F (57°C) About 10 seconds

140°F (60°C) Less than 5 seconds

145°F (63°C) Less than 3 seconds

150°F (66°C) About 1½ seconds

155°F (68°C) About 1 second

For informa on about changing the

factory thermostat se ng(s), refer to

the “Adjus ng Temperature” sec on in

this manual (“Step 12” on page 8).

Even if you set the water heater

thermostat(s) to a low se ng, higher

temperatures may occur in certain

circumstances:

• In some cases, repeated small

draws of water can cause the

hot and cold water in the tank to

“stack” in layers. If this happens,

the water can be as much as thirty

degrees hotter than the thermostat setting. This temperature variation is the result of your usage pattern and is not a malfunction.

• Water temperature will be hotter if someone adjusted the

thermostat(s) to a higher setting.

• Problems with the thermostat(s),

or other malfunctions may result in

higher than expected water temperatures.

• If the water heater is in a hot environment, the water in the tank can

become as hot as the surrounding

air, regardless of the thermostat

setting.

• If the water supplied to the water

heater is pre-heated (for example,

by a solar system) the temperature

in the tank may be higher than the

water heater’s thermostat setting.

To reduce the risk of unusually hot

water reaching the fi xtures in the

house, install Thermosta c Mixing

Valves at each point of use.

If anyone in your home is at par cular

risk of scalding (for example, the elderly, children, or people with disabili es) or if there is a local code or state

law requiring a certain water temperature at the hot water tap, then these

precau ons are par cularly important.

6 • Residen al Hybrid Electric Heat Pump Water Heater Use and Care Guide

IMPORTANT SAFETY INFORMATION

According to a na onal standard

American Society of Sanitary Engineering (ASSE 1070) and most local plumbing

codes, the water heater’s thermostat

should not be used as the sole means to

regulate water temperature and avoid

scalds.

Properly adjusted Thermosta c Mixing

Valves, installed at each point of use,

allow you to set the tank temperature

to a higher se ng without increasing

risk of scalds. A higher temperature

se ng allows the tank to provide much

more hot water and can help provide

proper water temperatures for appliances such as dishwashers and washing

machines. Higher tank temperatures

(140°F) also kill bacteria that cause a

condi on known as “smelly water” and

can reduce the levels of bacteria that

cause water-borne diseases.

Water Contamination Risk

Do not use chemicals that could contaminate the potable water supply. Do

not use piping that has been treated

with chromates, boiler seal, or other

chemicals.

Fire Risk

To reduce the risk of a

fire that could destroy

your home and serious-

ly injure or kill people:

• D o not store things that can burn

easily such as paper or clothes next

to the water heater.

• Be sure the junction box cover and

the access door covers are in place.

These covers keep debris from

entering and potentially being ignited, and help keep any internal fires

from spreading.

• Keep the water heater from becoming wet. Immediately shut the water

heater off and have it inspected by a

qualified person if you find that the

wiring, thermostat(s) or surrounding insulation have been exposed to

water in any way (e.g., leaks from

plumbing, leaks from the water

heater itself can damage property

and could cause a fire risk). If the

water heater is subjected to flood

conditions or the thermostat(s) have

been submerged in water, the entire

water heater must be replaced.

• Make electrical connections properly, according to the instructions

on page 17. Use 10 gauge solid

copper wire. Use a UL listed or CSA

approved strain relief. Connect

ground wire to green ground screw.

Explosion Risk

High temperatures and

pressures in the water

heater tank can cause an

explosion resulting in property

damage, serious injury or death. A

new Temperature and Pressure (T&P)

Relief Valve is included with your water

heater to reduce risk of explosion by

discharging hot water. Additional

temperature and pressure protective

equipment may be required by local

codes.

A nationally recognized testing laboratory maintains periodic inspection of

the valve production process and certifies that it meets the requirements

for Relief Valves for Hot Water Supply

Systems, ANSI Z21.22. The T&P Relief

Valve’s relief pressure must not exceed

the working pressure rating of the water heater as stated on the rating plate.

Maintain the T&P Relief Valve properly.

Follow the maintenance instructions

provided by the manufacturer of the

T&P Relief Valve (label attached to T&P

Relief Valve) and the procedure on

page 32.

An explosion could occur if the T&P

Relief Valve or discharge pipe is

blocked. Do not cap or plug the T&P

Relief Valve or discharge pipe.

Fire and Explosion Risk if Hot Water is

Not Used for Two Weeks or More

CAUTION! Hydrogen gas builds up in

a hot water system when it is not used

for a long period (two weeks or more).

Hydrogen gas is extremely fl ammable.

If the hot water system has not been

used for two weeks or more, open a

hot water faucet for several minutes at

the kitchen sink before using any electrical appliances connected to the hot

water system. Do not smoke or have

an open fl ame or other igni on source

near the faucet while it is open.

SAFETY

Residen al Hybrid Electric Heat Pump Water Heater Use and Care Guide • 7

GETTING STARTED

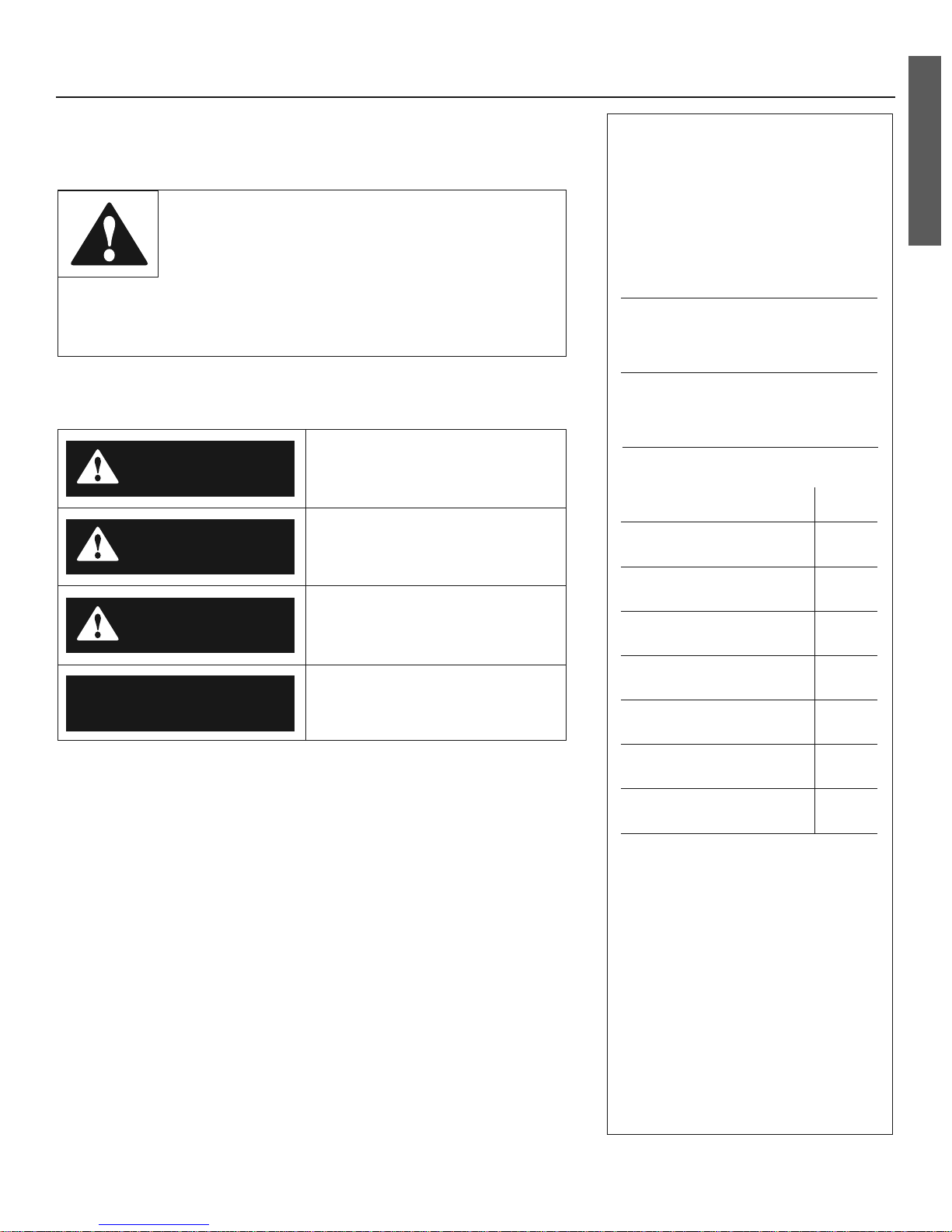

Figure 1 - Flexible connectors use compres-

sion fittings and do not require soldering.

Figure 2 - Use a non-contact circuit tester to

insure that the power is off before you work

on a circuit.

GETTING STARTED

Figure 3 - Install a Pressure Reducing Valve

set to 50 to 60 PSI.

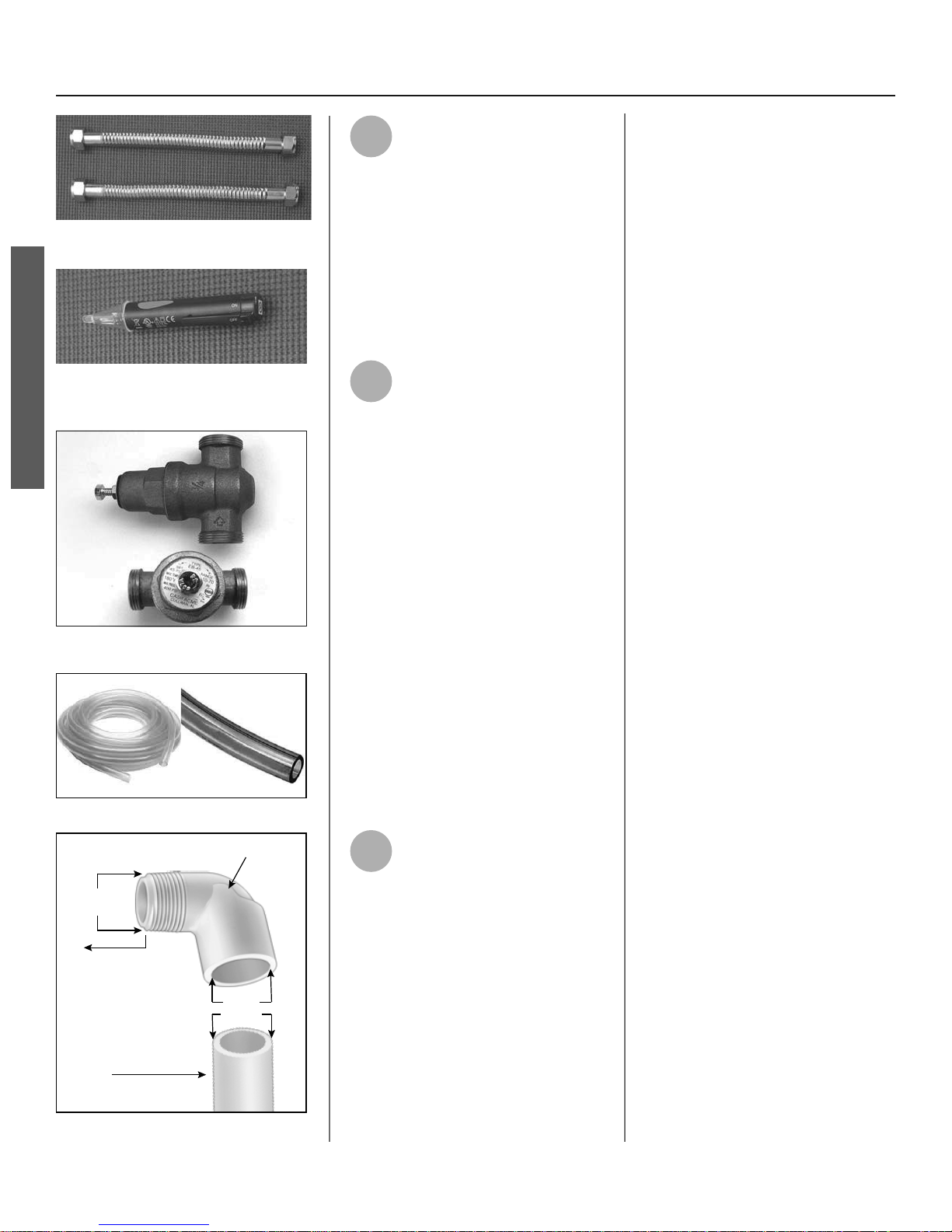

Figure 4 - Condensate overflow flexible tub-

ing.

Elbow

3/4” OD

To Main

Drain Connection

3/4” ID

3/4” OD

Pipe

Figure 5 - Main Drain Connection piping.

Review all of the instruc ons

1

before you begin work.

If you aren’t sure that you can

safely and properly do this work

yourself, contact a qualifi ed person of

your choice, such as a licensed

plumber or electrician to have the

work done. Improper installa on can

damage the water heater, your home

and other property, and can present

risks of serious injury or death.

Check with your local and

2

state authori es for any local

or state codes that apply to

your area. In the absence of local and

state codes, follow Na onal Fire

Protec on Associa on (NFPA-70) and

the current edi ons of the Na onal

Electric Code (NEC) and the Interna onal Plumbing Code (IPC). The

instruc ons in this manual comply with

na onal codes, but the installer is

responsible for complying with local

codes.

Massachuse s code requires this wa-

ter heater to be installed in accordance

with Massachuse s 248-CMR 2.00 and

248-CMR 5.00: State Plumbing Code.

Other local and state authori es may

have similar requirements or other

codes applicable to the installa on of

this water heater.

Before you start, be sure you

3

have, and know how to use, the

following tools and supplies:

• Plumbing tools and supplies appro-

priate for the type of water pipes in

your home

• Threaded connectors (Figure 1) for

the cold and hot water pipes

• For homes plumbed with plastic

pipe, use threaded connectors suitable for the specific type of plastic

pipe used: CPVC and PEX (crosslinked polyethylene). Do not use

PVC pipe.

• For homes with copper pipes, you

may purchase connector kits with

compression fittings that don’t

require soldering (Figure 1). Compression fittings are easier to install

than soldering copper pipes.

• Teflon® tape or pipe joint compound approved for potable water

• Tools to make the electrical connections (for example, screwdrivers,

wire strippers)

• Non-Contact circuit tester to check

for power (Figure 2)

• Water Pressure Gauge (Figure 6 on

page 7)

Recommended Accessories:

• Suitable drain pan (Figure 8 on page

10)

• Pressure Reducing Valve (Figure 3

on page 8)

• Thermal Expansion Tank (Figure 7

on page 9)

• Point of use Thermostatic Mixing

Valve (Figure 9 on page 10)

• 1/2” Flexible tubing for Condensate

Overflow (Figure 4 on page 8)

• 90° Elbow with 3/4” Female

Unthreaded Socket End X 3/4”

Male NPT Threaded End (Figure 5

on page 8)

• 3/4” OD Plastic Pipe for Condensate

Drain (Figure 5 on page 8)

8 • Residen al Hybrid Electric Heat Pump Water Heater Use and Care Guide

INSTALLATION

Follow these steps for proper

installa on:

Step 1:

Verify that your

✓

home is equipped

and up-to-date for

proper opera on

Installing a new water heater is the

perfect me to examine your home’s

plumbing system and make sure the

system is up to current code standards.

There have likely been plumbing code

changes since the old water heater was

installed. We recommend installing the

following accessories and any other

needed changes to bring your home up

to the latest code requirements.

Use this checklist and inspect your

home. Install any devices you need to

comply with codes and assure that your

new water heater performs at its best.

Check with your local plumbing offi cial

for more informa on.

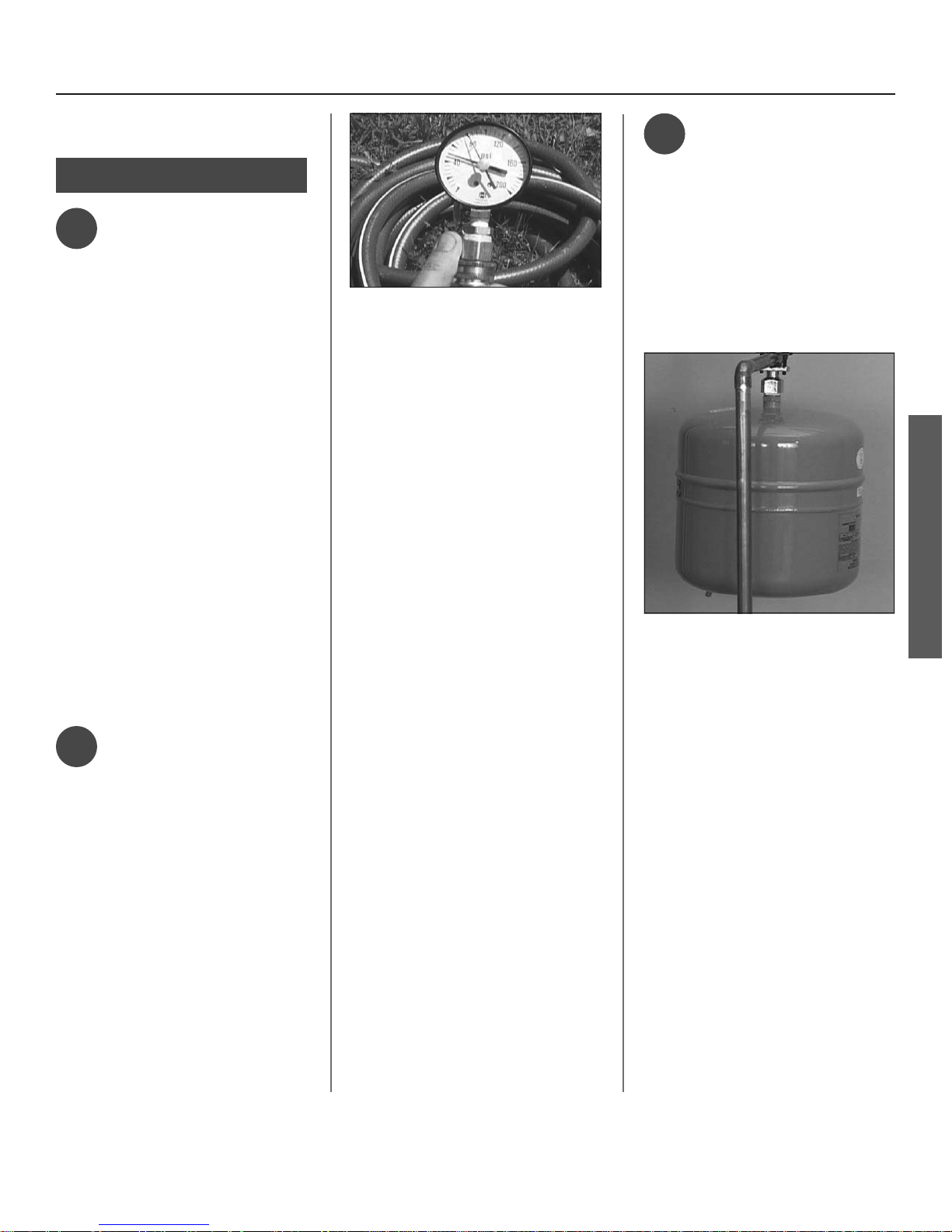

Water pressure

✓

We recommend checking your

home’s water pressure with a pressure

gauge (Figure 6). Most codes allow a

maximum incoming water pressure of

80 psi. We recommend a working pressure no higher than 50-60 psi.

HOW: Purchase an inexpensive water

pressure gauge available at your local

plumbing supply stores. Connect the

Water Pressure Gauge to an outside

faucet and measure the maximum water pressure experienced throughout

the day (highest water pressures o en

occur at night).

Figure 6 - Use a Water Pressure Gauge to

make sure your home’s water pressure is

not too high.

To limit your home’s water pressure:

Locate your home’s Pressure Reducing Valve (PRV) on the main incoming

(cold) water supply line and adjust the

water pressure control to between 50

and 60 psig. If your home does not

have a Pressure Reducing Valve, install

a PRV on the home’s main water supply line and set it to between 50 and

60 psig. Pressure Reducing Valves are

available at your local plumbing supply

stores .

BACKGROUND: Over the years, many

u li es have increased water sup-

ply pressures so they can serve more

homes. In some homes today, pressures exceed 100 psig. High water

pressures can damage water heaters,

causing premature leaks. If you have

replaced toilet valves, had a water

heater leak, or had to repair appliances connected to the plumbing system,

pay par cular a en on to your home’s

water pressure. When purchasing a

PRV, make sure the PRV has a built-in

bypass.

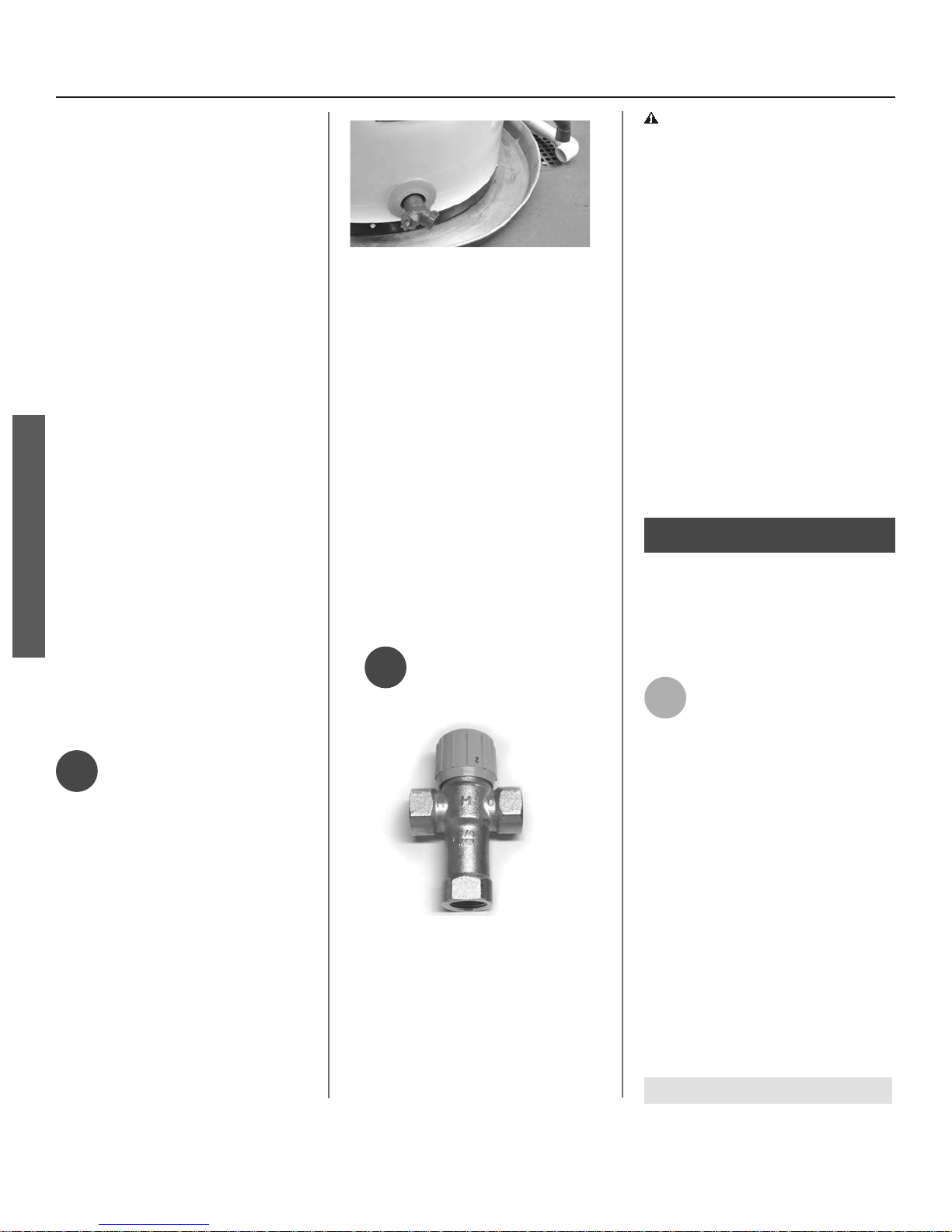

✓

Water Pressure/

Thermal Expansion

Verify that you have a properly sized

Thermal Expansion Tank (Figure 7). We

recommend installing an expansion

tank if your home does not have one.

Codes require a properly pressurized,

properly sized Thermal Expansion Tank

in almost all homes. (See illustra on

on inside front cover.)

Figure 7 - A Thermal Expansion Tank helps

protect the home’s plumbing system from

pressure spikes.

HOW: Connect the Thermal Expansion

Tank (available at your local plumbing

supply stores ) to the cold water supply

line near the water heater. The expansion tank contains a bladder and an air

charge. To work properly, the Thermal

Expansion Tank must be sized according to the water heater’s tank capacity

and pressurized to match the home’s

incoming water pressure. Refer to the

installa on instruc ons provided with

the Thermal Expansion Tank for installa on details.

INSTALLATION

Residen al Hybrid Electric Heat Pump Water Heater Use and Care Guide • 9

NOTICE! Water heater must be level!

INSTALLATION

BACKGROUND: Water expands when

heated, and the increased volume

of water must have a place to go, or

thermal expansion will cause large

increases in water pressure (despite

the use of a Pressure Reducing Valve

on the home’s main water supply

line). The Safe Drinking Water Act of

1974 requires the use of backfl ow

preventers and check valves to restrict

water from your home reentering

the public water system. Backfl ow

preventers are o en installed in water

meters and may not be readily visible.

As a result, most all plumbing systems

today are now “closed,” and almost all

homes now need a Thermal Expansion Tank.

A Thermal Expansion Tank is a

prac cal and inexpensive way to help

avoid damage to the water heater,

washing machine, dishwasher, ice

INSTALLATION

maker and even toilet valves. If your

toilet occasionally runs for no apparent reason (usually briefl y at night),

that may be due to thermal expansion

increasing the water pressure temporarily.

Water pipe and

✓

tank leaks

Leaks from plumbing pipes or from

the water heater itself can damage

property and could cause a fi re risk.

Figure 8 - A suitable drain pan piped to an

adequate drain can help protect flooring

from leaks and drips.

• Install a suitable drain pan (available at your local plumbing supply

stores ) under the water heater (Figure 8) to catch condensation or

leaks in the piping connections or

tank. Most codes require and we

recommend installing the water

heater in a drain pan that is piped

to an adequate drain. The drain pan

must be at least two inches wider

than the diameter of the water

heater. Install the drain pan so the

water level would be limited to a

maximum depth of 1-3/4”.

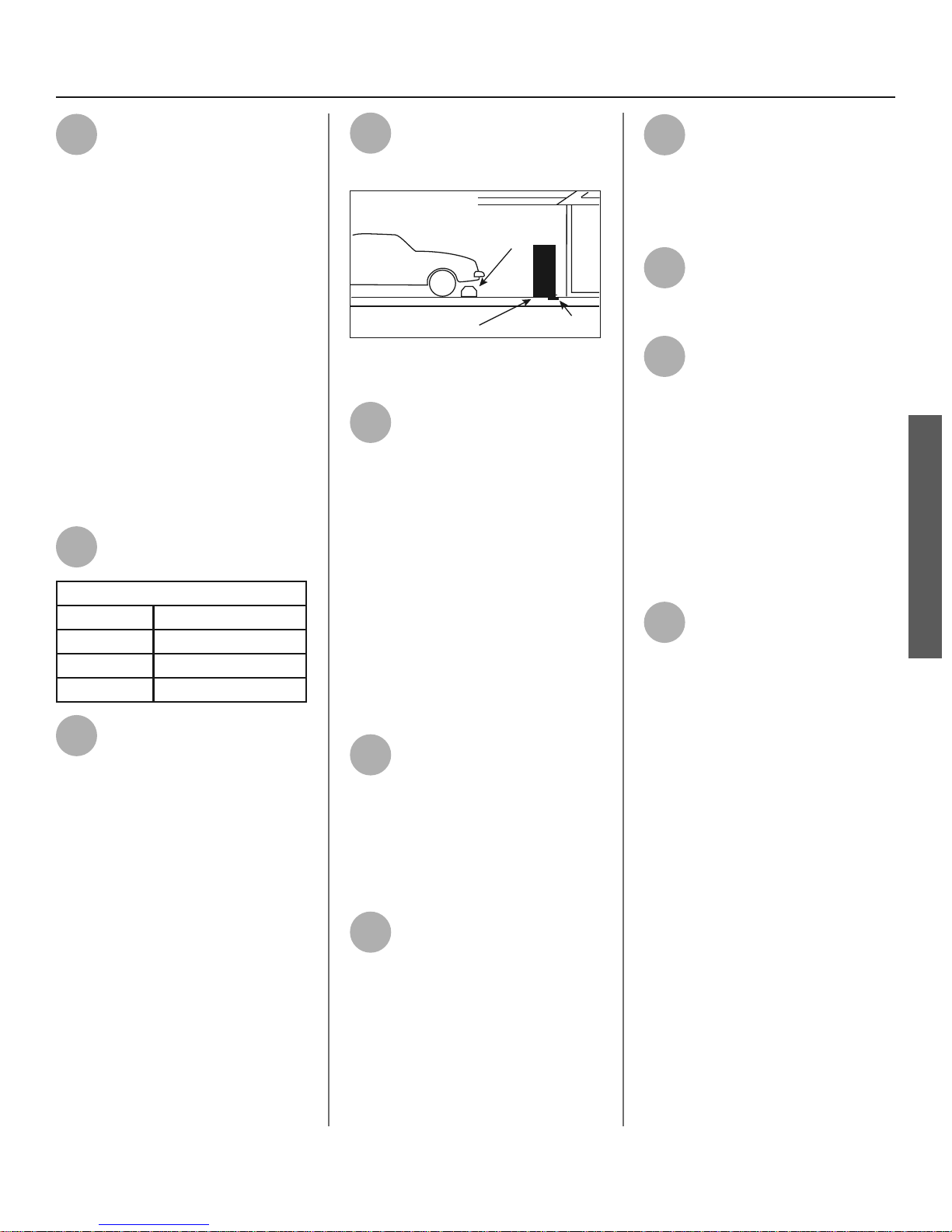

Water tempera-

✓

ture regula on

WARNING! Even if the water heater

thermostat is set to a rela vely low

temperature, hot water can scald.

Install a Thermosta c Mixing Valves at

each point of use to reduce the risk of

scalding (page 6).

BACKGROUND: A Thermosta c Mix-

ing Valve, installed at each pointof-use, mixes hot water from the

water heater with cold water to more

precisely regulate the temperature of

hot water supplied to fi xtures. If you

aren’t sure if your plumbing system

is equipped with properly installed

and adjusted Thermosta c Mixing

Valves at each point where hot water

is used, contact a qualifi ed person for

more informa on.

Step 2:

Verify that the loca on

is appropriate

Before installing your water heater,

ensure that:

The water heater will be:

1

• Installed indoors close to

the center of the plumbing

system.

• In a suitable drain pan piped to an

adequate floor drain or external to

the building (Figure 8).

• In an area that will not freeze

10 • Residen al Hybrid Electric Heat Pump Water Heater Use and Care Guide

Figure 9 - Thermostatic Mixing Valves installed at each point -of-use can help pre-

vent scalds.

Install Thermosta c Mixing Valves

(Figure 9) to regulate the temperature

of the water supplied to each pointof-use (for example, kitchen sink,

bathroom sink, bath, shower). Consult the valve manufacturer’s instruc ons or a qualifi ed person.

• In an area that is suitable for installing the water heater vertically and

on a level surface.

• Install where a typical home appliance sound would not cause a disturbance

• Should not be used for space heating.

NOTICE! Water heater must be level!

INSTALLATION

The loca on has adequate

2

space (clearances) for periodic

servicing. For op mal water

heater effi ciency, the unit must have

unrestricted airfl ow and requires a

minimum installa on space of 700

cubic feet. As an example, a room that

has an 8 foot tall ceiling and is 10 feet

long by 8-3/4 feet wide would contain

700 cubic feet.

NOTICE: This Heat Pump Water Heater

may be located within a required minimum of 6” clearance from a wall on

the outlet side, however for future

service considera ons, a minimum of

3 feet from any obstruc on on the

back, le and right side is recommend-

ed.

The fl oor can support the

3

weight of a full water heater.

Table 1

Capacity Filled Weight (lbs)

50 Gallon 573

66 Gallon 796

80 Gallon 921

Your area is not prone to

4

earthquakes. If it is, use

special straps as required by

local building codes.

NOTICE! The state of California requires bracing, anchoring, or strapping

the water heater to avoid its moving

during an earthquake. Contact local

u li es for code requirements in your

area, visit h p://www.dsa.dgs.ca.gov,

or call 1-916-445-8100 and request

instruc ons. Other loca ons may have

similar requirements. Check with your

local and state authori es.

The loca on is not prone to

5

physical damage by vehicles,

fl ooding, or other risks.

Vehicle

Stop

Drain

Pan

Figure 10 - In a garage, install a vehicle stop

to avoid water heater damage.

Avoid loca ons such as a cs,

6

upper fl oors, or where a leak

might damage the structure

or furnishings. Due to the normal

corrosive ac on of water, the tank will

eventually leak. To minimize property

damage from leaks, inspect and

maintain your water heater in accordance with this manual’s instruc ons.

Inspect the drain pan, pipes, and

surrounding area regularly and fi x any

leaks found. Drain pans are available at

your local plumbing supply store. Leaks

are frequently in the plumbing system

itself and not the water heater.

The unit cannot be placed into

7

any type of closet or small

enclosure, unless adequate

provisions are made for air exchange

(vented or louvered doors, etc.).

Contact Sears Parts & Repair Service

Center at 1-800-488-1222 for confi ned

space duc ng kit.

To ensure op mal perfor-

8

mance and servicability, a

minimum clearance of 6

inches must be maintained from all

sides and 6 inches from the top for

access to the air fi lter.

Drain

Water heaters located in

9

uncondi oned spaces (i.e.,

garages, basements etc.) may

require the water piping, condensate

piping, and drain piping to be insulated

to guard from freezing.

The air fi lter, condensa on

10

on and service.

11

such as sulfer, fl uorine, sodium and

chlorine. These elements are found in

aerosol sprays, detergents, bleaches,

air fresheners, paint and varnish

removers, refrigerants and many other

household products. In addi on,

excessive dust and lint may eff ect the

opera on of the unit, see the Air Filter

Maintenence sec on in this manual.

12

Mode the air temperature needs to be

above 45°F/7.2°C and below

120°F/48.8°C for heat pump opera on.

If the air temperature falls outside

these upper and lower limits, the

electrical elements will ac vate to meet

the hot water demand and the heat

pump does not operate in either

Effi ciency or Hybrid Mode.

drain and controls must be

easily accessable for opera-

The site loca on must be

free from any corrosive

elements in the atmosphere

The ambient air temperature

must also be considered when

installing this unit. In Effi ciency

INSTALLATION

Residen al Hybrid Electric Heat Pump Water Heater Use and Care Guide • 11

INSTALLATION

Step 3:

Removing the old water

heater

Read each installa on step

1

and decide if you have the

necessary skills to install the

water heater. Only proceed if you can

safely perform the work. If you are

not comfortable, have a qualifi ed

person perform the installa on.

Locate the water heater’s

2

circuit breaker and turn it OFF

(or remove the circuit’s

disconnects).

On the old water heater,

3

remove the electrical

junction box access panel.

Using a non-contact circuit tester,

check the wiring to make certain the

power is OFF.

INSTALLATION

WARNING! Working on an ener-

gized circuit can result in severe injury

or death from electrical shock.

Disconnect the electrical

4

wires.

Open a hot water faucet and

5

let the hot water run un l it

is cool (This may take 10

minutes or longer).

WARNING! Be sure the water runs

cool before draining the tank to reduce the risk of scalding.

Connect a garden hose to

6

the drain valve and place the

other end of the hose in a

drain, outside, or a bucket. (Note

that sediment in the bo om of the

tank may clog the valve and prevent

it from draining. If you can’t get the

tank to drain, contact a qualifi ed

person.)

Turn the cold water supply

7

valve OFF.

Open the drain valve on the

8

water heater.

Figure 12 - Draining the old water heater.

Also open a hot water faucet

9

to help the water in the tank

drain faster.

When the tank is empty,

10

discharge pipe. You may be able to

reuse the discharge pipe, but do not

reuse the old T&P Relief Valve. A new

T&P Relief Valve comes installed on

your water heater (or on some models,

is in the carton with the water heater).

Figure 13 - Removing the T&P Relief Valve

11

union which can be disconnected with

wrenches. If you must cut the water

pipes, cut the pipes close to the water

heater’s inlet and outlet connec ons,

leaving the water pipes as long as

possible. If necessary, you can make

them shorter later when you install

the new water heater.

12

disconnect the Temperature &

Pressure (T&P) Relief Valve

discharge

Disconnect the water pipes.

Many water pipes are

connected by a threaded

Remove the old water heater.

pipe.

Figure 11 - Let the hot water run until it is

cool.

12 • Residen al Hybrid Electric Heat Pump Water Heater Use and Care Guide

WARNING! Use two or more people

to remove or install water heater.

Failure to do so can result in back or

other injury.

INSTALLATION

Step 4:

Installing the new

water heater

Completely read all instruc-

1

ons before beginning. If you

are not sure you can complete

the installa on, DO NOT RETURN THIS

UNIT TO THE STORE. Schedule an

appointment with a qualifi ed person

to install your water heater.

Install a suitable drain pan

2

that is piped to an adequate

drain.

Set the water heater in place

3

taking care not to damage the

drain pan.

NOTICE! Most codes require se ng

the water heater in a suitable drain

pan piped to an adequate drain. The

drain pan helps avoid property damage

which may occur from condensa on

or leaks in the piping connec ons or

tank. The drain pan must be at least

two inches wider than the diameter

of the water heater. Install the drain

pan so the water level is limited to a

maximum depth of 1-3/4”.

Verify that the water heater is

4

set in place properly. Check

that:

• The T&P Relief Valve will not be in

contact with any electrical parts.

• There is adequate space to install

the T&P Relief Valve discharge pipe

and that it can be piped to a separate drain (and not into the drain

pan).

• There is adequate space to install

proper condensate drain piping.

• There is adequate access and space

around the water heater for future

maintenance. A minimum clearance

of 6 inches must be maintained

from all sides and 6 inches from the

top for access to the air filter.

• Unit is level to allow proper condensate drainage. An unlevel unit

may lead to condensate draining

improperly and resulting in property

damage.

DO NOT CONNECT ELECTRICAL

WIRING UNTIL YOU ARE

INSTRUCTED TO DO SO.

NOTICE! Connec ng electrical power

to the tank before it is completely

full of water (water must run FULL

STREAM from a hot water tap for a full

three minutes) will cause the upper

hea ng element to burn out.

Step 5:

Connec ng the Conden-

sate Pump When Required

NOTE: If no fl oor drain is available or

the drain is above the level of the

condensate line, a condensate pump

must be installed.

Follow condensate drain

1

pump manufacturers instruc ons for installa on.

Connec ng the Conden-

sate Pump Op onal

Overfl ow Shut Off

Switch

Locate the wire loop inside

1

the condensate drain access

compartment by removing

the 4 screws a aching the condensate

drain access cover to the unit. Cut the

loop and strip insula on off the 2 ends

(Figures 14 & 15 on page 13 & 14).

Measure the distance from

2

the condensate drain access

cover to the condensate

pump, and cut two 22 AWG wires to

correct length and strip the insula on

at both ends. Thread both ends

through the grommet on the drain pan

cover.

Connect these 2 wires to the

3

2 wires on the water heater

using wire nuts or other connectors. Reinstall the condensate drain

access cover and keep the connec on

joints inside of the cover.

Connect the free ends of the

4

2 wires to the shut off switch

on the condensate pump in

accordance with the condensate pump

manufacturers recommenda ons.

Condensate Pump Wiring Loop

(Loop Located Close to the Drain Connections)

Wires From

Water Heater

Figure 14 - Wiring Loop for connec on of

Condensate Pump.

Wires to Condensate

Pump Overflow

Shut Off Switch

INSTALLATION

Residen al Hybrid Electric Heat Pump Water Heater Use and Care Guide • 13

INSTALLATION

Condensate Drain

Access Cover

Primary Drain

Connection

Secondary Drain

Connection

Overflow Slot

Condensate Pump Wiring Loop

(Loop Located Close to the Drain Connections)

Figure 15 - Condensate Pump Wiring

Step 6:

Install Condensate

Drain Lines:

NOTE: When making condensa on

connec ons to the primary connec-

on DO NOT over ghten! These con-

nec ons should be HAND TIGHTENED

ONLY. Over ghtening could crack or

damage the condensate drain pan.

• Plas c pipe or tubing must be

used to connect the condensate

INSTALLATION

drain to a suitable drain or condensate pump.

• Condensate drain lines should

be installed in condi oned areas

only. Install approved insula on

on the condensate drain lines to

prevent condensa on from form-

ing on the outside of the drain

lines. Condensa on drain lines

installed in areas that are subject

to freezing temperatures should

be wrapped with a na onally

recognized heat tape. Install per

manufacturer’s instruc ons.

• Do not connect condensate

drain lines with other drain or

discharge lines into a single (common) pipe or line. Each line (condensate drain line, temperature

and relief valve discharge pipe,

etc.) should be independently

run to an adequate drain.

• Slope the condensate drain lines

toward the inside fl oor drain or

condensate pump.

• The condensate drain lines and

connec ons to the drain piping

must comply with all local codes.

• Use appropriate fi ngs and

primer to cement the condensate

drains to the heat pump drain

pan.

• If a condensate pump is installed,

it should be wired to shut off the

heat pump in the event the condensate pump fails or the fl oat

switch in the pump ac vates (see

step 5 on page 13).

Using 3/4” PVC piping, a 90°

1

elbow that is 3/4” slip & 3/4”

NPT and an approved sealant

(none supplied with unit), a ach the

elbow to the primary drain connec on and insert the PVC pipe into the

female end allowing enough length to

access an adequate drain.

Using 1/2” ID rubber or fl exi-

2

ble plas c tubing, slip one

end over the secondary drain

connec on allowing enough length to

access an adequate drain.

Step 7:

Connect the Temperature and Pressure (T&P)

Relief Valve/Pipe

Most T&P Relief Valves are preinstalled at the factory. In some cases,

they are shipped in the carton and

must be installed in the opening

marked and provided for this purpose

and according to local codes. .

WARNING! To avoid serious injury

or death from explosion, install a T&P

Relief Valve according to the following

instruc ons:

If your water heater does not have

a factory installed T&P Relief Valve,

install the new T&P Relief Valve that

came with your water heater. Do not

reuse an old T&P Relief Valve. Install

a T&P Relief Valve discharge pipe according to local codes and the following guidelines:

The discharge pipe should be

1

at least 3/4” inside diameter

and sloped for proper

drainage. Install it to allow complete

drainage of both the T&P Relief Valve

and the discharge pipe.

The discharge pipe must

2

withstand 250°F (121°C) with-

out distor on. Use only

copper or CPVC pipe. Most homes

use copper water pipes, but some use

CPVC or cross-linked polyethylene

(PEX). Use fi ngs appropriate for the

type of pipe in your home. Do not use

any other type of pipe, such as PVC,

iron, fl exible plas c pipe, or any type

of hose.

Figure 16 - The T&P Relief Valve discharge

pipe must be installed properly and piped to

an adequate drain.

14 • Residen al Hybrid Electric Heat Pump Water Heater Use and Care Guide

INSTALLATION

Terminate the discharge pipe

3

a maximum of six inches

above a fl oor drain or outside

the building. Do not drain the discharge pipe into the drain pan; instead

pipe it separately to an adequate

drain. In cold climates, terminate the

discharge pipe inside the building to an

adequate drain. Outside drains could

freeze and obstruct the drain line.

Protect the drain from freezing.

DISCHARGE

PIPE

DRAIN

PIPE

Figure 17 - The end of the T&P Relief Valve

discharge pipe must stop no more than

six inches above a floor drain or outside.

Do not place any valve or

4

other restric on between the

tank and T&P Relief Valve. Do

not cap, block, plug, or insert any valve

between the T&P Relief Valve and the

end of the discharge pipe. Do not

insert or install any reducer in the

discharge pipe.

Step 8:

Install shutoff and

mixing valves

If one is not already installed,

1

install a manual shutoff valve

in the cold water line that supplies the water heater. Install the

shutoff valve near the water heater so

that it is readily accessible. Only use

valves that are compa ble with

potable water. Use only full-fl ow ball

or gate valves. Other types of valves

may cause excessive restric on to the

water fl ow.

Install a Thermosta c Mixing

2

Valve at each point of use (for

example, kitchen sink, bathroom sink, bath,shower). Consult the

valve manufacturer’s instruc ons or a

qualifi ed person.

Figure 18 - Install Thermostatic Mixing

Valves at each point where hot water

will be used.

WARNING! Even if the water

heater’s UIM is set to a rela vely low

temperature, hot water can scald.

Install Thermosta c Mixing Valves at

each point of use to reduce the risk of

scalding.

For water heaters that are fed

3

by a solar water hea ng

system (or any other pre-heating system), always install a Thermosta c Mixing Valve or other tempera-

ture limi ng device in the inlet water

supply line to limit water supply inlet

temperature to 120°F (49°C). Solar

water hea ng systems can supply water

with temperatures exceeding 170°F

(76.7°C) and may result in water heater

malfunc on.

WARNING! Hot water provided by

solar hea ng systems can cause severe

burns instantly resul ng in severe

injury or death (page 6).

Step 9:

Connect the water

supply

Determine the type of water

1

pipes in your home. Most

homes use copper water pipes,

but some use CPVC or cross-linked

polyethylene (PEX). Use fi ngs

appropriate for the type of pipe in your

home. Do not use iron or PVC pipe –

they are not suitable for potable water.

Connect the cold water supply

2

using 3/4 inch Na onal Pipe

Thread “NPT” to the blue cold

water connec on near the bo om of

the heater.

For ease of removing the water heater

for service or replacement, connect

the water pipes with a coupling called

a union. Dielectric type unions are

recommended (available at your

local plumbing supply store ). Dielectric unions can help prevent corrosion caused by tiny electric currents

common in copper water pipes and

can help extend the life of the water

heater.

Recircula ng Loop

In order to optimize efficiency of this

unit, it is not recommended for use

with a recirculation loop. Using this in

a recirculation loop may cause the unit

to run excessively.

INSTALLATION

Residen al Hybrid Electric Heat Pump Water Heater Use and Care Guide • 15

INSTALLATION

IF YOU HAVE COPPER PIPES:

If your home has copper water pipes,

you can solder the water pipe connec ons or use compression fi ngs which

don’t require soldering. Compression

fi ngs are easier to install than solder-

ing pipe. Check with local plumbing offi cials to determine what types of pipe

materials are suitable for your loca on.

Do not use lead-based solder.

NOTICE! Do not solder pipes while

they are a ached to the water heater.

The water heater’s inlet and outlet

INSTALLATION

connec ons contain non-metallic parts

which could be damaged. The proper

way to connect the water heater to

copper water pipes is as follows:

• Solder a short length of pipe (about

a foot or so) to a threaded adapter

using only 95/5 n-an mony or

equivalent solder. A ach the thread-

ed adapters to the water heater’s

connec ons (using Tefl on® tape or

pipe joint compound). Connect the

home’s water pipes by soldering,

keeping the connec ons at the water

heater cool with wet rags.

NOTICE: This water heater model contains an outlet connec on (J-tube) that

has an orienta on mark that must line

up with arrow (in a 12 o’clock posi on).

Connect the hot water supply

3

using 3/4 inch NPT to the hot

water outlet. Follow the same

connec on guidelines as for the cold

water supply.

Install insula on (or heat tape)

4

on the water pipes especially

if the indoor installa on area

is subject to freezing temperatures.

Insula ng the hot water pipes can

increase energy effi ciency.

Double check to make sure

5

the hot and cold water pipes

are connected to the correct

hot and cold water fi ngs on the

water heater.

If needed, install (or adjust)

6

the home’s Pressure Reducing

Valve to 50-60 psig and install

a Thermal Expansion Tank.

Figure 19 - A Pressure Reducing Valve is

required if your home’s water pressure is

above 80 psi.

Figure 20 - The Thermal Expansion Tank

should be pressurized with air, to match the

home’s incoming water pressure, before

water pressure is applied to the tank.

Step 10:

Verify connec ons and

completely fi ll tank

To remove air from the tank and allow

the tank to fi ll completely with water,

follow these steps:

Remove the aerator at the

1

nearest hot water faucet. This

allows any debris in the tank

or plumbing system to be washed out.

Turn the cold water supply

2

back on.

Full-fl ow ball valve

NOTE: Do not over apply joint com-

pound.

16 • Residen al Hybrid Electric Heat Pump Water Heater Use and Care Guide

Figure 21 - Fully open the cold water supply

valve.

INSTALLATION

Open a hot water faucet and

3

allow the water to run un l it

fl ows with a full stream.

Let the water run full stream

4

for three full minutes.

Close the hot water faucet and

5

replace the aerator.

Check inlet and outlet connec-

6

ons and water pipes for leaks.

Dry all pipes so that any drips

or leaks will be apparent. Repair any

leaks. Almost all leaks occur at connec ons and are not a tank leak.

Step 11:

Make electrical

connec ons

WARNING! Working on an energized circuit can result in severe injury

or death from electrical shock.

NOTICE! Do not turn electrical power

on unless you are sure all of the air is

out of the tank and the tank is completely full of water. Although this water

heater is equipped with “Dry Fire” protec on, be certain all air is purged from

the tank before making any electrical

connec ons.

Be sure the electrical power to

1

the water heater is turned OFF

at the circuit breaker panel (or

remove the circuit’s disconnects).

Using a non-contact circuit

2

tester, check the wiring to make

certain the power is OFF.

This water heater requires a

3

240/208 VAC single phase 30

amp power supply, at 60Hz.

Check the water heater’s data plate (see

Figure 23 on page 17) and ensure that

the home’s voltage, wiring size (ampacity) and circuit breaker ra ng and type

are correct for this water heater. Refer to

the wiring diagram located on the water

heater for the correct electrical connec ons. Ensure that wire sizes, type, and

connec ons comply with all applicable

local codes. In the absence of local

codes, follow NFPA-70 and the current

edi on of the Na onal Electric Code

(NEC).

Power Supply

Connector

1/2” Conduit

Opening

Green Ground

Screw

Green

Ground

Wire

Red Wire

Black Wire

Figure 22 - Connecting the electrical wires.

If metal conduit is used for the grounding

conductor:

• The grounding electrode conductor

shall be of copper, aluminum, or

copperclad aluminum. The material

shall be of one con nuous length

without a splice or joint.

• Rigid metal conduit, intermediate

metal conduit, or electrical metallic

tubing may be used for the grounding means if conduit or tubing is

terminated in fi ngs approved for

grounding.

• Flexible metal conduit or fl exible

metallic tubing shall be permi ed

for grounding if all the following

condi ons are met:

A. The length in any ground return path

does not exceed 6 feet.

B. The circuit conductors contained

therein are protected by overcurrent

devices rated at 30 amperes.

C. The conduit or tubing is terminated

in fi ngs approved for grounding.

For complete grounding details and

all allowable excep ons, refer to the

current edi on of the Na onal Electric

Code NFPA 70.

Figure 23 - The water heater’s electrical requirements can be determined from the data

Remove the cover on the

4

electrical junc on box on the

side of the water heater.

Install wiring in an approved

5

conduit (if required by local

codes). Use a UL listed or CSA

approved strain relief to secure the

electrical wiring to the water heater.

Connect the ground wire to the

6

green ground screw. Connect

the home’s two power wires to

the water heater’s two power wires. Use

suitable wire nuts or other approved

means to make the power connec ons.

Replace the junc on box cover

7

and secure with the screw

provided.

WARNING! Be sure cover is secured

to reduce the risk of fi re and electric

shock.

plate.

INSTALLATION

Residen al Hybrid Electric Heat Pump Water Heater Use and Care Guide • 17

INSTALLATION

Operation

The water heater is now ready for

normal operation. To keep your water

heater working safely and efficiently

and extend its life, perform maintenance as described in maintenance

section beginning on page 29.

Start-up and Opera on

NOTE: The default opera ng mode is

Hybrid, to select a diff erent mode see

Opera ng Modes sec on on page 19.

PRIOR TO BEGINNING OPERATION:

Air fi lter is factory installed with tabs

oriented down for shipping. Please see

maintenance sec on for instruc ons on

removal, cleaning and replacing.

Turn on electrical power to the

1

water heater.

NOTICE: The water heater will conduct

a system diagnos c (approximately 8

minutes) each me power is applied

from an off state. Normal opera on will

INSTALLATION

begin a er the system diagnos c has

been completed..

Once the diagnos c sequence

2

has fi nished, the fan should

turn on. This typically takes 8

minutes, (the User Interface Module will

display “-”, “--”, “---” repe vely during

this period).

NOTICE: The heat pump’s fan will not

turn on if the incoming water tempera-

ture is less than 59°F/15°C and/or the

ambient air temperature is above

120°F/15°C, or below 45°F/7.2°C.

Should the internal diagnos cs detect a

problem with the heat pump, an error

code will be displayed.

Step 12:

Adjus ng the

Temperature

With the installa on steps completed,

you may adjust the water heater’s temperature se ng if desired.

The water heater’s tempera-

1

ture se ng has been factory

set to approximately 120°F to

reduce the risk of scald injury. You may

wish to set a higher temperature to

provide hot water for automa c

dishwashers or laundry machines, to

provide more hot water capacity, and to

reduce bacterial growth. Higher tank

temperatures (140° F) kill bacteria that

cause a condi on known as “smelly

water” and can reduce the levels of

bacteria that cause water-borne

diseases.

WARNING! Higher temperatures in-

crease the risk of scalding, but even at

120°F, hot water can scald (page 6).

If you increase the water heater’s temperature se ng, install Thermosta c

Mixing Valve(s) at each point of use to

reduce the risk of scalding.

Down buttons

(User Interface Module). Using the

up or down buttons, cycle through

the available temperature set points

until the desired temperature is displayed. The temperature setting will

blink on the display; press the Mode/

Enter button to confirm the selection

(see figure 26, page 21).

• The available temperature set points

can be cycled through quickly by

pressing and holding the Up button.

Please allow adequate me for

2

the heater to provide hot

water.

WARNING! If you have increased the

temperature se ng and the Thermo-

sta c Mixing Valves are not set prop-

erly (or not installed) you could scald

yourself while checking the temperature.

Check water temperature at

3

several points of use in your

home (for example, bathtub

faucet, shower, or lavatory sink) and

adjust the Thermosta c Mixing Valves as

needed. If you aren’t sure how to adjust

the Thermosta c Mixing Valve se ngs,

or aren’t sure if you have Thermosta c

Mixing Valves, contact a qualifi ed

person.

on the UIM

Set the desired opera onal

3

mode. For typical installa ons,

the factory default mode,

Hybrid Mode off ers the best combina-

on of effi ciency and hot water delivery.

For detailed descrip ons of all opera-

onal modes see “Opera ng Mode

Descrip ons” page 19.

18 • Residen al Hybrid Electric Heat Pump Water Heater Use and Care Guide

Figure 24 - Adjust Thermostat Mixing

Valves at each point of use to 120°F or

lower.

To adjust the water heater’s temperature se ng:

• The water temperature setting can

be adjusted by using the Up and

INSTALLATION

Post Installa on Review

Understand how to use the

1

User Interface Module to set

the various modes and

func ons.

Hybrid Mode is the recom-

2

mended Opera ng Mode.

Understand the various

Opera ng Modes and which mode may

be best, based on ambient temperature

and hot water demands.

Understand the importance of

3

rou ne inspec on/ mainte-

nance of the condensate drain

pan and lines. This is to prevent any

possible drain line blockage resul ng in

the condensate drain pan overfl owing.

NOTE: If water is coming from the

overfl ow slot of the condensate drain

access cover, this indicated that both

condensate drain lines may be blocked

and immediate ac on is required.

Drain Access Cover

Secondary Drain

Primary Drain

Overflow Slot

Figure 25 - Condensate Drain Access

Cover

To maintain op mal opera on,

4

check, remove and clean the

air fi lter as needed.

The Installa on Instruc ons

5

and Use and Care Guide should

be kept with the water heater

for reference.

Water Temperature Adjustment

The water temperature can be

adjusted from 95°F / 35°C to 150°F /

65.5°C. Use the Up and Down Bu ons

on the front panel to

set the desired temperature (fi gure 26,

page 21). The se ng temperature will

blink on the display, press Mode/Enter

bu on to confi rm.

The water temperature can be adjusted

quickly by pressing the “Temperature

Up” bu on and holding for three

seconds.

NOTE: Before a emp ng to adjust

the thermostat, read the “Water

Temperature Regula on” sec on. If

the instruc ons are not clear, contact a

qualifi ed person.

NOTE: For increased water demand,

switching (temporarily) to Hybrid

Mode or Electric Mode will decrease

the recovery/re-heat me. Be sure to

switch back to the desired opera onal

mode when fi nished.

Opera ng Mode De-

scrip ons

The opera ng modes can be changed

sequen ally by pressing the Mode/

Enter bu on (Figure 26, page 21). The

Opera on Mode Indica on Light will

turn on when the relevant mode is

selected.

This unit is equipped with technology

that senses the hot water demand

from the unit. While in Effi ciency or

Hybrid mode, during normal usage,

the unit will operate the heat pump

for maximum effi ciency. In the Hybrid

mode during periods when the water

usage is above normal, this unit

has the ability to use one element

(upper or lower) and the heat pump

simultaneously to help improve

recovery. This transi on is seamless

and will go unno ced.

Efficiency Mode -

Provides the highest efficiency and

lowest cost operation by using only

the heat pump for heating. Recovery

time and efficiency will vary with

ambient temperature and relative

humidity. Efficiency will be greatest,

and recovery quickest, when both

are high. At lower temperatures and

relative humidity levels, efficiency

will be lower and recovery will take

longer. Heat pump operation is allowed

between 45°F / 7.2°C to 120°F / 48.8°C

ambient temperature. At ambient

temperatures lower than 45°F / 7.2°C

and greater than 120°F / 48.8°C, the

heat pump will not operate. Similarly,

if the water temperature in the tank is

less than 59°F / 15°C, the heat pump

will not operate. The unit will operate

in electric mode until ambient air and

water temperatures return to the safe

operating range of the heat pump.

Hybrid Mode -

This is the default, recommended

setting, combining high energy

efficiency with reduced recovery time.

This mode uses the heat pump as the

primary heating source. One of the

heating elements (upper or lower)

will provide supplementary heating if

demand exceeds a predetermined level

so that the set point temperature can

be recovered more quickly.

Electric Mode -

The water heater functions as a

conventional electric unit, relying on

only the elements for heat. This mode

may be useful in periods of increased

hot water demands. Electric Mode will

remain for 48 hours before reverting

back to default mode setting.

INSTALLATION

Residen al Hybrid Electric Heat Pump Water Heater Use and Care Guide • 19

INSTALLATION

Vacation Mode -

The controller will maintain a 60°F

tank temperature while in Vacation

setting. This mode is recommended

when the water heater is not in use

for a long period of time, to minimize

energy consumption and prevent the

water heater from freezing during cold

conditions.

To enter Vacation Mode Press and hold the up ↑ button. If

selected, the unit will default to 7

days, but you will be able to adjust the

number of days by pressing the up ↑

and down ↓ arrows; press the Mode/

Enter button to confirm the number of

days. When set time for Vacation Mode

has completed, UIM will automatically

return to last mode selected.

C AUTION! Hydrogen gas builds up in

a hot water system when it is not used

for a long period (two weeks or more).

Hydrogen gas is extremely fl ammable.

If the hot water system has not been

INSTALLATION

used for two weeks or more, open a

hot water faucet for several minutes at

the kitchen sink before using any electrical appliances connected to the hot

water system. Do not smoke or have

an open fl ame or other igni on source

near the faucet while it is open.

NOTE: When Vacation Mode is

selected, the vacation timer will be displayed. Press the Up and Down button

to modify the timer to desired number

of vacation days (setting range: 1 to

99 days). The vacation timer will blink

on the display; press the Mode/Enter

button to confirm the vacation timer.

To deactivate Vacation Mode, press the

Mode/Enter button to switch to the

desired mode.

NOTE: Do not shut off power to the

unit for extended periods of time.

If power must be turned off for an

extended period of time, drain the tank

completely.

Other Controls

°F/°C Switch - Press “Temperature

Down” button and hold for 3 seconds

to switch temperature unit between

Farenheit and Celsius

Remote Access Enable/Disable -

• Press “Mode/Enter” button and

hold for 3 seconds. The power

saver feature will be activated and

the display will show “rA”, and

the setting temperature alternatively. This feature allows the unit

to be monitored and controlled

using the Connectivity Port and

a seperate control module. See

the Kenmore Smart Water Heater

Module section.

• To deactivate Remote Access,

press “Mode/Enter” button and

hold for 3 seconds.

Heat pump defrosting indication -

• There will be frost accumulating on the evaporator when the

heat pump is operated under low

ambient temperatures. The controller will order the unit to enter

into defrosting cycle to optimize

the heat pump operation performance. During the defrosting period, the user interface module will

display “ICE” as an indication.

Out of heat pump operation range -

• The user interface module will

display “HPO” as an indication

that the ambient air and/or water

temperature is out of the heat

pump operation range. See the

“Operating Mode Description”

section for heat pump ambient air

and water temperature operating

range.

NOTE: The display will go into “Sleep

Mode” for energy saving if there is no

operation on any button for 15 minutes. All the display and lights will be

turned off except for the “Operational

Mode Indication Light”, which will

remain illuminated while the unit is

powered on. The unit can be awakened

by pressing any button.

Your Heat Pump Water Heater is Smart

Grid capable. Contact your local electric

utilities company for participation and

plug in module availability and to learn

more about potential energy savings

opportunities.

Kenmore® Smart Water

Heater Module

This water heater is a connected-ready

appliance, allowing you to remotely

monitor and control it from your

smartphone via the Kenmore Smart

Water Heater Module, which is sold

seperately.

To get started you will need the

following:

• Kenmore Smart Water Heater

Module.

• WI-FI home router connected to

the internet.

• Smartphone.

• Kenmore smart app.

For more information about the

Kenmore Smart Water Heater Module,

visit: www.Kenmore.com/smart

20 • Residen al Hybrid Electric Heat Pump Water Heater Use and Care Guide

INSTALLATION

Display Segment

Temperature Unit

Indication Light

°F

°C

DAYS

Temperature Up

(Increase) Button

Temperature Down

(Decrease) Button

Operational Mode

Indication Light

Temperature and

Pressure Relief Valve

1/2” Flexible

Secondary

Condensate

Tubing

Discharge Pipe

(Do Not Cap or Plug)

Metal Drain Pan 2 1/2”

Depth Maximum and

2 Inches wider than

the water heater.

Mode/Enter

Button

Vacation Time Indication

Figure 26: User Interface Module (UIM)

Massachusetts: Install a vacuum relief in

cold water line per section 19 MGL 142.

Optional Heat Trap Piping

xxxxx

xxxxx

xxxxx

xxxxx

Cold

(Inlet)

*Union

Hot

(Outlet)

*Union

Union

Shut-off Valve (Hot)

Untempered Water Outlet

**Optional Mixing Valve - Follow the

Mixing Valve’s Manufacturer’s Installation

Instructions. (Set to 120°F / 48.8°C)

Tempered Water to Fixtures

***Primary Condensate Drain (3/4” PVC)

Union

Vacuum Relief Valve

(when required by local code)

Cold Water

Inlet Valve

Cold Water

Inlet

Pressure Reducing Valve (PRV)

should be installed where the water

supply enters the residence.

When installed PRVs create a

closed water system, a thermal

expansion tank must be installed.

In a closed system, use a

thermal expansion tank.

See “Water Pressure/

Thermal Expansion”

section.

INSTALLATION

Drain Line 3/4”

ID Minimum

*If copper piping is used, unions must be dielectric at inlet and outlets.

**Use a heat trap when installing a mixing valve near the water heater.

*** If an adequate drain is not available for the condensate drain lines then a condensate pump must be used. DO NOT discharge the condensate drain

lines into the metal drain pan.

Drain

6” Maximum

Air Gap

Shut-off Valve

(Cold)

Figure 27: Completed Water System Piping

Residen al Hybrid Electric Heat Pump Water Heater Use and Care Guide • 21

DIAGNOSTIC CODES

WARNING! Electric Shock Hazard; Disconnect power before servicing. Do not remove the plac c guard from over wiring. Do not

touch electrical wiring. Failure to do so can result in death or electrical shock.

DISPLAY SHOWS INDICATES CORRECTIVE ACTION

*

*

*

*

TROUBLESHOOTING

*

*

- -- --- (series of dashes) Unit is doing a system

ICE Heat pump is in defrosting

HPO Ambient temperature <45°F

EUC Upper element is not

ELC Lower element is not

SF The air filter is dirty. Refer to “Air Filter Maintenance” page 33.

ECF The heat pump compressor is

E20 or E21 Upper Temperature Sensor is

E30 or E31 Lower Temperature Sensor is not

E50 or E51 Heat Pump Suction Temperature

E10 or E11 Heat Pump Coil Temperature

E40 or E41 Heat Pump Discharge

E60 Upper and Lower Temperature