Page 1

Owners

Manual

FOR POTABLE WATER

HEATING ONLY

NOT SUITABLE FOP,

SPACEHEATING

NOT FOR USE IN

MOBILE HOMES

Model No.

153,335816 40 Gal.

153.335845 40 Gal. HighAltitude LR

153.335862 40Gal./R

153.335916 50 Gal.

153.335942 50 Gal. High Altitude I-P.

153.335962 50 Gal. L.R

©

I

POWER MISER TM 9

POWER VENT

GAS WATER HEATER

• Safety Instructions • Care and Maintenance

• Installation • Troubleshooting

• Operation • Parts List

Caution:

Read and Follow

All Safety Rules and

Operating Instructions

Before First Use of

This Product.

For Your Safety

AN ODORANT IS ADDED TO THE GAS USED BY THIS

WATER HEATER

WARNING: If the information in these instructions are not fol-

lowed exactly, a fire or explosion may result, causing property

damage, personal ,nlury or death.

-Do not store or use _as.oline or other fl.a_n.mable vapors and liq-

rods ,n the viomty of th,s or any other appliance.

-WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrscal sw,tch; do not use any phone ,n your

buildin£.

• Immeoqately call your gas supplier from a ne,ghbor's phone.

Follow the gas supplier's]nstructions.

• If you can not reach your gas suppl,er, call the fire department.

-Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

• AWARNING 1

Improper Installation, adjustment, alteration, service or maintenance I

can cause DEATH, SERIOUS BODILY INJURY, OR PROPERTY DAM-|

AGE. Refer to this manual for assistance or consult the local Sears/

Service Center or gas utility for further information. |

AWARNING

Flammable vapors may be drawn by air currents from other areas

of the structure to this appliance.

Savethis Manual for Future Reference.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

AWARNING

READ THE GENERAL SAFETY SECTION BEGINNING ON INSIDE

COVER AND THEN THIS ENTIRE MANUAL BEFORE INSTALLING

OR OPERATING THIS WATER HEATER.

Page 2

Safety Precautions

I_n A,WARNING 1

Improper installation, adjustment, altoratJon, service or [

aintanance can cause death, serious bodily injury, or

property damage. Refer to this manual for assistance or [

onsolt your local Sears Service Center for further[

nformatlon.

AWARNING

WATER HEATERS EQUIPPED FOR ONE TYPE GAS

ONLY: This water heater is equipped for one type gas

only. Check the model rating plate near the gas control

valve for the correct gas. DO NOT USE THIS WATER

HEATER WITH ANY GAS OTHER THAN THE ONE

SHOWN ON THE MODEL RATING PLATE. Failure to

usethe correct gas cancause problems which can result in

DEATH, SERIOUS BODILY INJURY, OR PROPERTY

DAMAGE. If you have any questions or doubts consult

your gassupplier or localutility.

A,WARNING

INSTALLATIONS IN AREAS WHERE FLAMMABLE LIQ-

UIDS (VAPORS) ARE LIKELY TO BE PRESENT OR

STORED (GARAGES, STORAGE, AND UTILITY AREAS,

ETC): Flammable liquids (such as gasoline, solvents,

propane (LP) or butane, etc.), all of which emit flammable

vapors, may be improperly stored or used in suchareas.

The gas water heater pilot light or main burner can Ignite

such vapors. The resulting flashback and fire can cause

death or serious burns to anyone in the area, as well as

property damage.

If installation in such areas is your only option, than the

installation must be accomplished in a way that the pilot

flame and main burner flame are elevated from the floor

at least 18 inches. While this may reduce the chances of

flammable vapors from a floor spill being ignited, gasoline

and other flammable substancesshould never be stored or

used in the same room or area containing a gas water

heater or other open flame or spark producing appliance.

NOTE: Flammable vapors may be drawn by air currents

from other areasof the structure to the appliance.

A, WARNING

If this water heater will be used in beauty shops, barber

shops, cleaning establishments, or serf-service laundries

with dry cleaning equipment, it is imperative that the

water heater or water heaters be installed so that com-

bustion and ventilation air be taken from outside these

areas. Refer to the "Locating The New Water Heater"

section of this manual and also the latest edition of the

National Fuel Gas Code, ANSI 7.223.1, also referred to as

NFPA 54 for specificsprovided concerning air required.

I _,WARNING

A fire can start if co_Hals suchasclothing,

cleaningmaterials,or flammableliquidsam placedagainst

or nexttothe waterheater.

AWARNING

At the time of manufacture this water heater was provid-

ed with a coml_nation temperature-pressures relief valve

certified by a nationally recognized testing laboratory

that maintains periodic inspection of production of listed

equipment or materials, as meeting the requirements

for Relief Valves and Automatic Gas Shutoff Devices for

Hot Water Supply Systems, and the latest edition of

ANSI Z21.2Z and the code requirements of ASME. If

replaced, the valve must meet the requirements of local

codes, but not less than a combination temperature and

pressure relief valve certified as meeting the require-

ments for Relief Valves and Automatic Gas Shutoff

Devices for Hot Water Supply Systems, ANSI Z21.22 by

a nationally recognized testing laboratory that maintains

periodic inspection of production of listed equipment or

materials.

The valve must be marked with a m_imum set pressure

not to exceed the marked hydrostatic working pressure

of the water heater (150 Ibs./sq. in.) and a discharge

capacity not less than the water heater input rate as

shown on the model rating plate. (Electric heaters -

watts divided by 1000 x 3415 equal BTU/Hr. rate.)

Your local jurisdictional authority, while mandating the

use of a temperature-pressure relief valve complying

with ANSI Z21.22 and ASME, may require a valve model

different from the one furnished with the water heater.

Compliance with such local requirements must be satis-

fled by the installer or end user of the water heater with

a locally prescribed temperature-pressure relief valve

installed in the designated opening in the water heater in

dace of the factory furnished valve.

For safe operation of the water heater, the relief valve

must not be removed from it's designated opening or

plugged.

The temperature-pressure relief valve must be installed

[directly into the fitting of the water heater designated

for the relief valve. Position the valve downward and pr_

vide tubing so that any discharge will exit only within

inches above, or at any distance below the structural

floor. Be certain that no contact is made with any live

electrical part. The discharge opening must not be

blocked or reduced in size under any circumstances.

Excessivelength, over 30 feet, or use of more than four

elbows can cause restriction and reduce the discharge

capacity of the valve.

No valve or other obstruction is to be placed between

the re ef vave and the tank. Do not connect tub ng

directly to discharge drain unlessa 6" air gap isprovided.

To prevent bodily injury, hazard to life, or property dam-

age, the relief valve must be allowed to discharge water

in quantities should circumstances demand. If the dis-

charge pipe is not connected to a drain or other suitable

means, the water flow may cause property damage.

The Discharge Pipe:

Must not be smaller in size than the oudet pipe size of

the valve, or have any reducing couplings or other

restrictions.

Must not be plugged or blocked.

Must be of material listed for hot water distribution.

Must be installed so as to allow complete drainage of

both the temperature-pressure relief valve, and the

discharge pipe.

Must terminate at an adequate drain.

Must not have any valve between the relief valve and

tank.

2

Page 3

Safety Precautions

AWARNING

A gaswater heater cannot operate properly without the

correct amount of air for combustion. Do not install in a

confined area such a closet, unless you provide air as

shown in the "Locating The Now Water Heater" section.

Never obstruct the flow of ventilation air. If you haveany

doubts or questions at all, call your gas company. Failure

to provide the proper amount of combustion air can result

in a fire or explosion and can cause DEATH, SERIOUS

BODILY INJUR_, OR PROPERTY DAMAGE.

AWARNING

HOTTER WATER CAN SCALD: Water heaters are

intended to produce hot water. Water heated to a tem-

mraturo which will satisfyclothes washing, dish washing,

and other sanitizing needs can scald and permanently

injure you upon contact. Some people are more likely to

be permanently injured by hot water than others. These

include the elderly, children, the infirm, or physicaily/mea.

tally handicapped. If anyone using hot water in your home

fits into one of these groups or if there is a local cede or

state law requiring a certain temperature water at the hot

water tap, then you must take special precautions. In addi-

tion to usingthe lowest possible temperature setting that

satisfies your hot water needs, a means such as a mixing

valve, should be used at the hot water taps used by these

people or at the water heater. Mixing valves are available

at plumbing supply or hardware stores. Follow manufac-

turers instructions for installation of the valves. Before

changing the factory setting on the thermostat, read the

'_l'emperatoro Regulation" section in this manual.

i

This water heater must not be installed directly on car-

peting. Carpeting must be protected by a metal or wood

panel beneath the appliance extending beyond the full

width and depth of the appliance by at least 3 inches

(76.2mm) in any direction, or if the appliance is installed

in an alcove or closet, the entire floor must be covered by

the panel. Failure to heed this warning may result in a

fire hazard.

AWARNING

AWARNING

The power vent water heater requires its own (separate)

venting system. It cannot be connected to an existing vent

pipe or chimney. It must be terminated horizontally to the

outdoors. Failure to properly install the ventingsystem can

result in asphyxiation, a fire or explosion and can cause

DEATH, SERIOUS BODILY INJURY,OR PROPERTY DAM-

AGE.

AWARNING

No vent damper installation iscompatible with this power

vented water heater design.No vent damper, whether it is

operated thermally or otherwise isto he installed on this

power vented water heater. Alteration of any part of the fac-

tory-furnished vent assemblycould result inimproper oper-

ation due to restriction of flue gases, spillage of flue gases

and may causecarbon monoxide poisoning.

_,WARNING

Soot build-up indicates a problem that requires correc-

tion before further use. Turn "off" gas to water heater

and leave "off" until repairs are made, because failure to

correct the cause of the sooting can result in a fire or

explosion causing DEATH, SERIOUS BODILY INJURY,

OR PROPERTY DAMAGE.

AWARNING

BEFORE LIGHTING [PROPANE (L.P.) GAS WATER

HEATERS]: Propane (I-R) gas is heavier than air. Should

there be a leak in the system, the gas will settle near the

ground. Basements, crawl spaces, skirted areas under

mobile homes (even when ventilated), closets and areas

below ground level will serve as pockets for the accumula-

tion of this gas. Before attempting to light or relight the

water heater's pilot or turning on a nearby electrical light

switch, be absolutely sure there is no accumulated gas in

the area. Search for odor of gas by sniffingat ground level

in the vicinity of the appliance. If odor is detected, follow

steps indicated at "For Your Safety" on the cover page of

this manual then leave the premises.

AWARNING

•The appliance and its individual shutoff valve must be dis-

connected from the gassupply piping system during any

pressure testing of the gas system at test pressures in

excess of I/2 pound per square inch (3.5kPa).

•The appliance must be isolated from the gas supply pip-

ing system by closingits individual manual shutoff valve

during any pressure testing of the gas supply piping sys-

tem at test pressures equal or less than I/2 pound per

square inch (3.SkPa).

_,WARNING

Chemical vapor corrosion of the flue and vent system

may occur if air for combustion contains certain chemical

vapors.Spray can propellants, cleaning solvents,refrigera-

tor and air conditioner refrigerants, swimming pool

chemicals, calcium and sodium chloride, waxes, bleach,

and process chemicals are typical compounds which are

potentially corrosive.

Obstructedor deteriorated vent systemsmay present

serioushealthriskor asphyxiation.

3

AWARNING a

Safety Precautions continued on page 4.

Page 4

Safety Precautions

&WARNING I

The water heater with draft hood installed must be prep- I

erly vented to a chimney which terminates outdoors. I

Never operate the water heater unless it is vented to the

outdoors and has adequate air supply to avoid risks of

improper operation, expos on or asphyxiation.

_,WARNING

Minimum clearances between the water heater and €om-

bustible construction are 0" at the sidesand rear, 5" at the

front, and 0" from the vent pipe. Clearance from the top

of the jacket is 14" on most models. Note that s lesser

dimension may be allowed on some models. Refer to the

label on the water heater adjacent to the gascontrol valve

for all clearances.

•,WARNING ]

Do not use this appliance if any part of it has been under|

water. Immediately call a Sears Service Technician to|

inspect the appliance and to replace tee gascontrol or any|

part of the bureer system wh ch hasbeen under water. |

AWARNING

HYDROGEN GAS: Hydregen gas canbe produced in a hot

water system that has not been used for a long period of

time (generally two weeks or more). Hydrogen gas is

extremely flammable and explosive. To prevent the possi-

bility of injury under these conditions, we recommend the

hot water faucet be opened for several minutes at the

kitchen sink before any electrical appliances which are

connected to the hot water system are used (such as a

dishwasher or washing machine). If hydrogen gas is pre-

sent, there will probably be an unusualsound similar to air

escapin_through the pipe as the hot water faucet is

opened. There must be no smoking or open flame near

the faucet atthe time it isopen.

I AWARNING ]

Venttermination mustnot be within 4 feet of any items|

suchas gas meters, gasvalvesor other gasregulating|

equipment. |

&,CAUTION

WATER HEATERS EVENTUALLY LEAK: Installation of

the water heater must be accomplished in such a manner

that if'the tank or any connections should leak, the flow of

water will not cause damage to the structure. When such

locations cannot be avoided, a suitable drain pan should

be installed under the water heater, Drain pansare avail-

able at your local Sears store. Such a drain pan must be

not greater than 1I/2 inches deep. have a minimum

length and width of at least 2 inches greater than the

water heater dimensions and must be piped to an ade-

quate drain. The pan must not restrict combustion air

flow. Under no circumstances is the manufacturer or

Sears to be held liable for any water damage in connec-

tion with this water heater.

AWARNING

INSULATING JACKETS: When instailin S an external

water heater insulation jacket on a gaswater heater:

• DO NOT cover the temperature-pressure relief valve.

• DO NOT put insulation over any part of the top of the

gaswater heater.

• DO NOT put insulation over the gascontrol valve or gas

control vaivefbumer cover, or any access Meas to the

burner, i

DO NOT let insulation around the gas water heater to

get within 8 inches of the floor (air must get to the

burner).

DO NOT cover or remove operating instructions, and

safety related warning labelsand materials affixed to the

water heater.

:allure to heed thiswill result in the possibilityof afire or

explosion.

4

Page 5

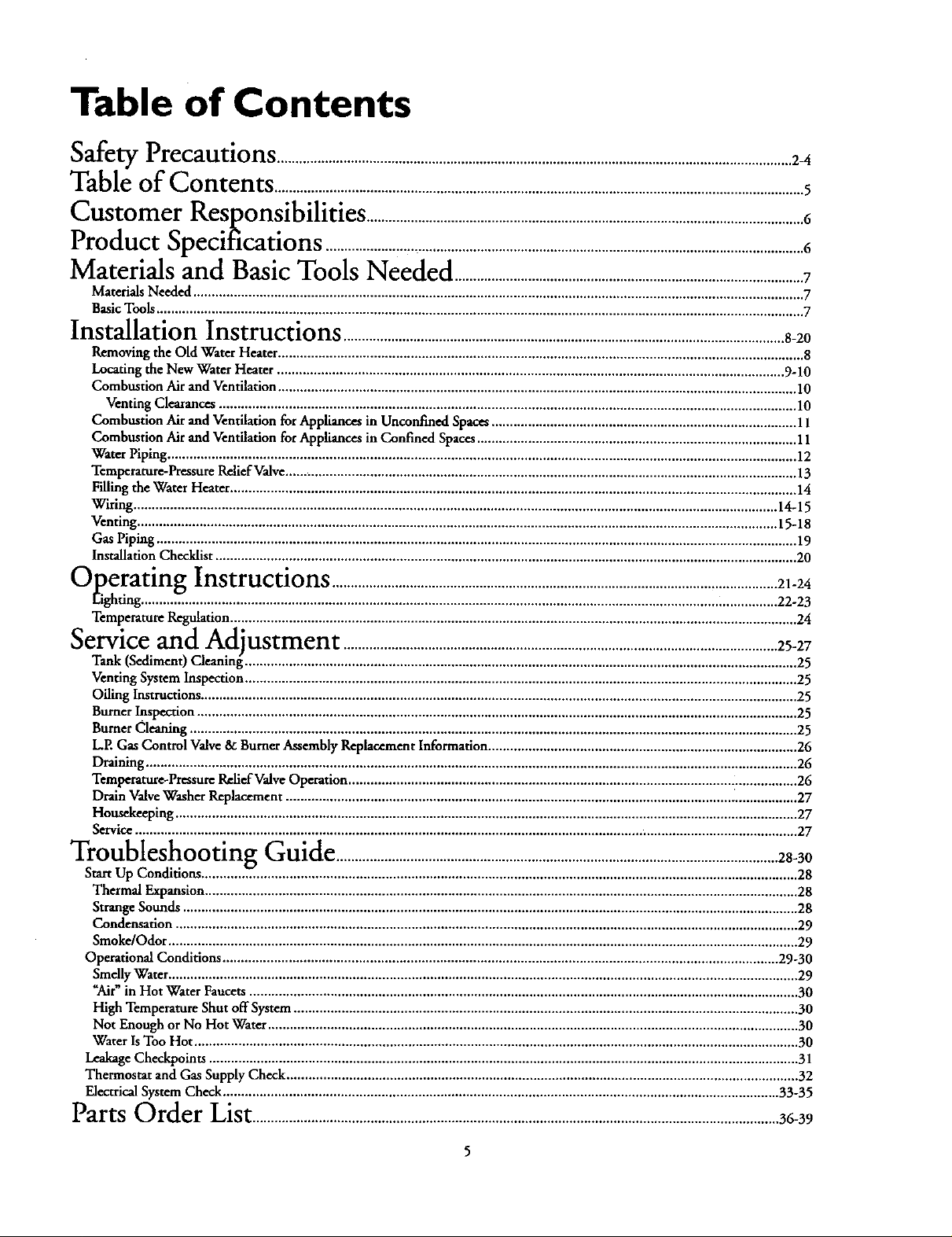

Table of Contents

Safety Precautions ............................................................................................................................................24

Table of Contents ................................................................................................................................................5

Customer

Product Specitlcations'_"..................................................................................................................................6

Materials and Basic Tools Needed ...............................................................................................7

Materials Needed ...................................................................................................................................................................... 7

Basic Tools ................................................................................................................................................................................ 7

Installation Instructions ........................................................................................................................8-20

Removing the Old Water Heater ............................................................................................................................................... 8

Locating the New Water Heater .......................................................................................................................................... 9-10

Combustion Air and Ventilation ............................................................................................................................................. 10

Venting Clearances ............................................................................................................................................................. 10

Combustion Air and Ventilation for Appliances in Unconfined Spaces ................................................................................... 11

Combustion Air and Ventilation for Appliances in Confined Spaces ....................................................................................... 11

Water Piping ........................................................................................................................................................................... 12

Temperature-Pressure Relief Valve........................................................................................................................................... 13

Filling the Water Heater .......................................................................................................................................................... 14

Wiring ............................................................................................................................................................................... 14-15

Venting .............................................................................................................................................................................. 15-18

Gas Piping .............................................................................................................................................................................. 19

Installation Checklist .............................................................................................................................................................. 20

""Overatln_ Instructions .........................................................................................................................21-24

-- 1"_Eighting ........................................................................................................................................................... i.;............... 22-23

Temperature Regulation .......................................................................................................................................................... 24

Service and Adjustment ...................................................................................................................... 25-27

Tank (Sediment) Cleaning ...................................................................................................................................................... 25

Venting System Inspection ...................................................................................................................................................... 25

Oiling Instructions .................................................................................................................................................................. 25

Burner Inspection ................................................................................................................................................................... 25

Burner Cleaning ..................................................................................................................................................................... 25

L.E Gas Control Valve & Burner Assembly Replacement Information .................................................................................... 26

Draining ................................................................................................................................................................................. 26

Temperature-Pressure Rehef Valve Operation .......................................................................................................................... 26

Drain Valve Washer Replacement ........................................................................................................................................... 27

Housekeeping ......................................................................................................................................................................... 27

Service .................................................................................................................................................................................... 27

Responsibilities- .......................................................................................................................6

Troubleshooting Guide ........................................................................................................................28-30

Start Up Conditions .................................................................................................................................................................. 28

Thermal Expansion ................................................................................................................................................................. 28

Strange Sounds ....................................................................................................................................................................... 28

Condensation ......................................................................................................................................................................... 29

Smoke/Odor ........................................................................................................................................................................... 29

Operational Conditions ....................................................................................................................................................... 29-30

Smelly Water ........................................................................................................................................................................... 29

"Air" in Hot Water Faucets ..................................................................................................................................................... 30

High Temperature Shut off System ......................................................................................................................................... 30

Not Enough or No Hot Water ................................................................................................................................................ 30

Water Is Too Hot .................................................................................................................................................................... 30

Leakage Checkpoints ................................................................................................................................................................ 31

Thermostat and Gas Supply Check ........................................................................................................................................... 32

Electrical System Check ....................................................................................................................................................... 33-35

Parts

"-'-OrderList ...............................................................................................................................................36-39

Page 6

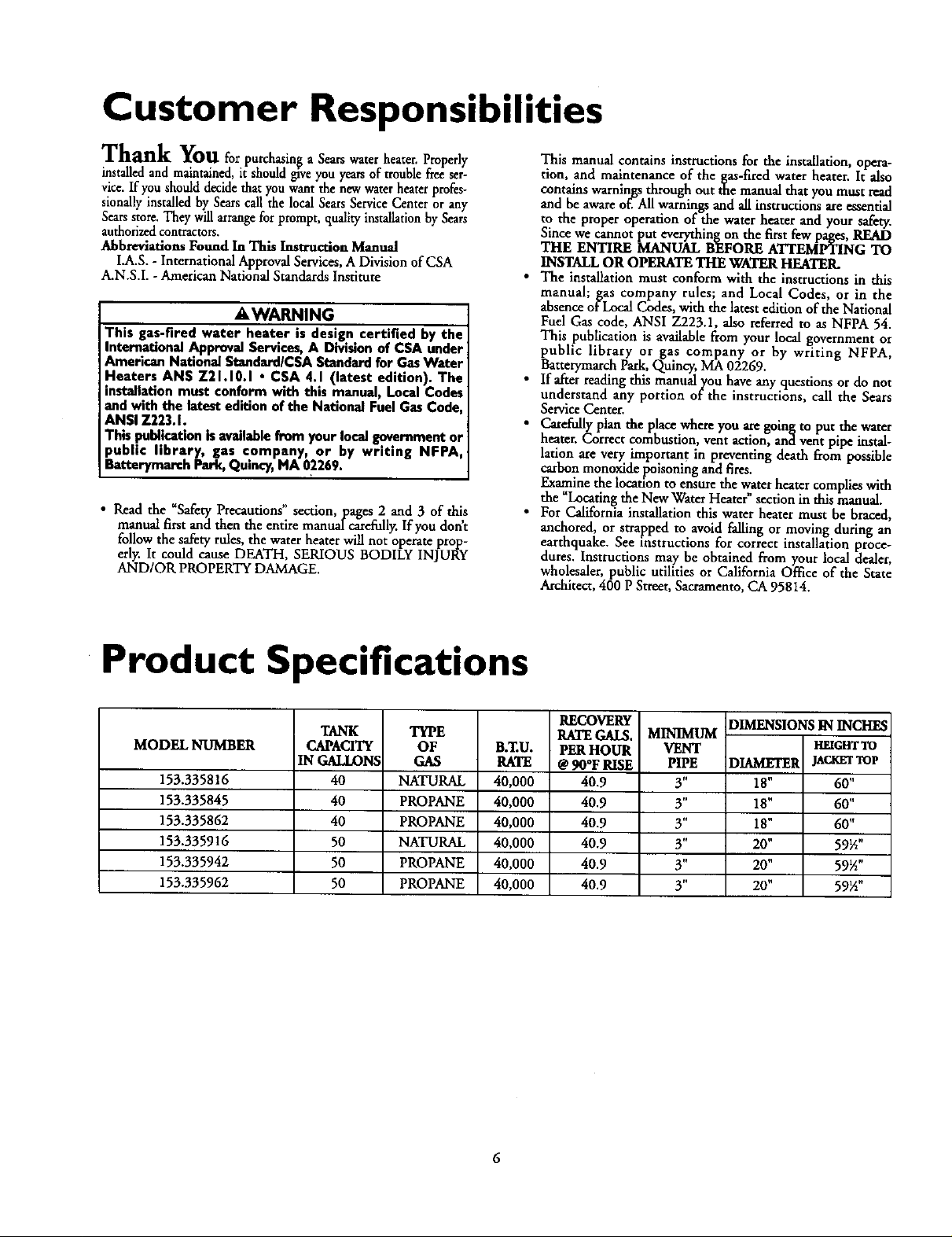

Customer Responsibilities

Thank You p°rch in aSo rsw terheater.Properly

installedand maintained,it shouldgweyouyearsof troublefreeser-

vice.If youshoulddecidethatyouwant the newwaterheaterprofes-

sionallyinstalledbySearscall the localSearsServiceCenter orany

Scarsstore.Theywillarrangeforprompt, qualityinstallationbySears

authorizedcontractors.

AbbreviationsFound In This Instruction Manual

I.A.S.- InternationalApprovalServices,A Division of CSA

A.N.S.I. - AmericanNational Standards Institute

AWARNING

This gas-fired water heater is design certified by the

International Approval Services, A Division of CSA under

American National Standard/CSA Standard for GasWater

Heaters ANS Z21.10.1 • CSA 4.1 (latest edition). The

installation must conform with this manual, Local Codes

and with the latest edition of the National Fuel Gas Code

ANSI Z223.1.

This publication is available from your localgovernment or

public library, gas company, or by writing NFPA,

Batterymarch Park, Quincy, MA 02269.

• Readthe "SafetyPrecautions"section, pages 2 and 3 of this

manual first and then the entire manualc,_efully.If you don t

followthe safety rules, the water heater will not operateprop-

erly. It could cause DEATH, SERIOUS BODILY INJURY

AND/OR PROPERTY DAMAGE.

This manual contains instructions for the installation, opera-

tion, and maintenance of the gas-frred water heater. It also

contains warnings through out the manual that you must read

and be aware of. All warnings and all instructions are essential

to the proper operation of the water heater and your safety.

Since we cannot put everything on the first few pages, READ

THE ENTIRE MANUAL BEFORE ATTEMPTING TO

INSTALL OR OPERATE THE WATER HEATER.

• The installation must conform with the instructions in this

manual; gas company rules; and Local Codes, or in the

absence of Local Codes, with the latest edition of the National

Fuel Gas code, ANSI Z223.1, also referredto as NFPA 54.

This publication is available from your local government or

public library or gas company or by writing NFPA,

Battetymarch Park,Quincy, MA 02269.

• If after reading this manualyou have any questions or do not

understand any portion of the instructions, call the Sears

Service Center.

heater. Correct combustion, vent action, and vent pipe instal-

lation are very important in preventing death from possible

cathon monoxide poisoning and fires.

i arefully plan the place where you are going to put the water

Examine the location to ensure the water heater complies with

the "Locating the New Water Heater" section in this manual.

For California installation this water heater must be braced,

anchored, or strapped to avoid falling or moving during an

earthquake. See instructions for correct installation proce-

dures. Instructions may be obtained from your local dealer,

wholesaler, public utilities or California Office of the State

Architect, 400 P Street, Sacramento, CA 95814.

Product Specifications

MODEL NUMBER

153.335816

153.335845

153.335862

153.335916

153.335942

153.335962

TANK

CAPACITY

IN GALLON,'

40

40

40

50

50

50

TYPE

OF

GAS

NATURAL

PROPANE

PROPANE

NATURAL

PROPANE

PROPANE

B.ZU.

RATE

40,000

40,000

40,000

40,000

40,000

40,000

RECOVERY

RATE GM$.

PER HOUR

@ 900F RISE

40.9

40.9

40.9

40.9

40.9

40.9

MINIMUM

VENT

PIPE

3"

3"

3"

3"

3"

3"

DIMENSIONS IN INCHES

HEIGHTTO

DIAMETER JAC_'r TOp

18" 60"

18" 60"

18" 60"

20" 59½"

20" 59½"

20" 59½"

6

Page 7

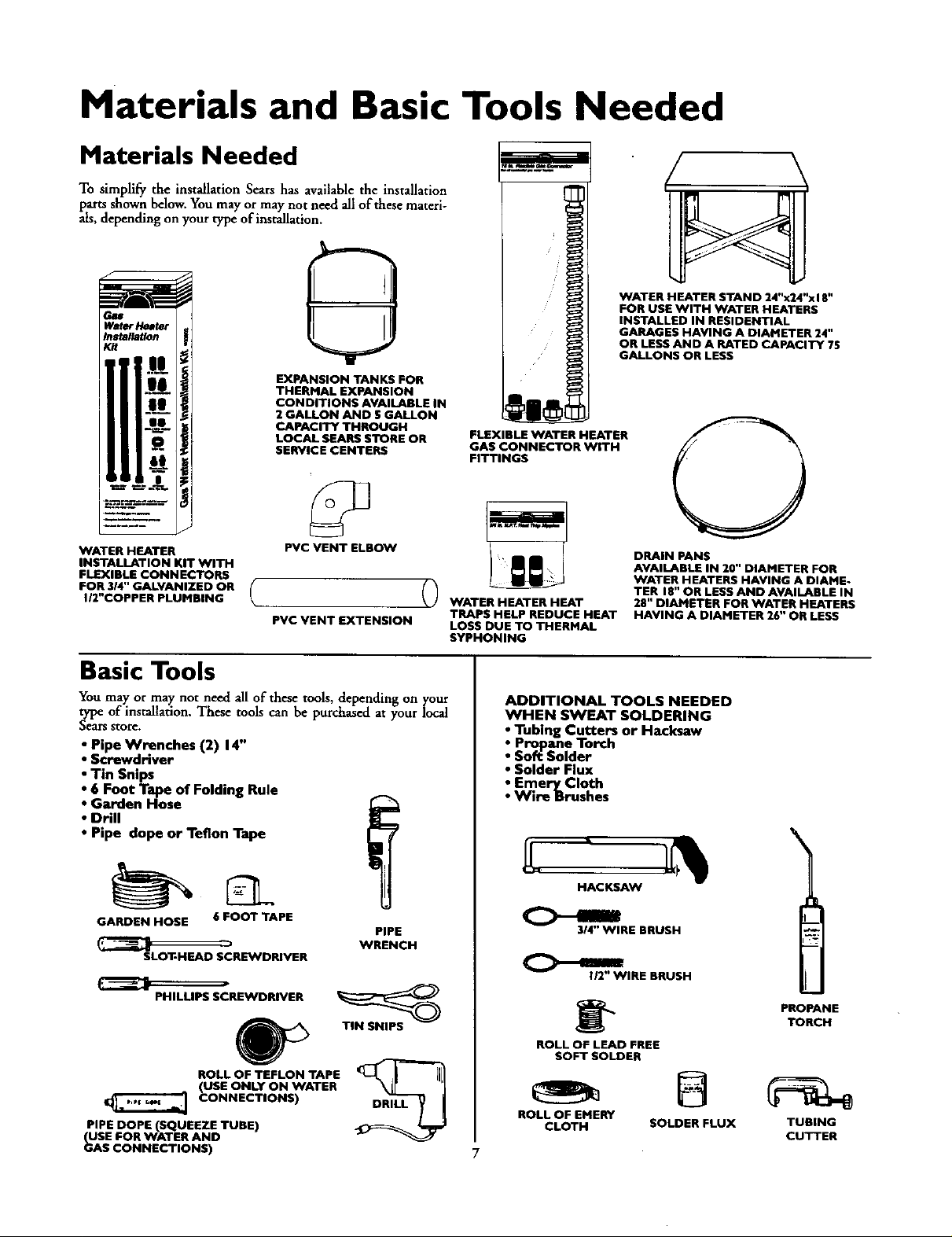

Materials and Basic Tools Needed

Materials Needed

To simplify the installation Sears has availablethe installation

parts shownbelow.You may or may not need allof these materi-

als, dependingonyour type of installation.

WATER H EATER STAND 24"x24"xl 8"

FOR USE WITH WATER HEATERS

W#hDr I¢_ttu"

I_stallatlon

II

ii

EXPANSION TANKS FOR

THERMAL EXPANSION

CONDITIONS AVAILABLE IN

2 GALLON AND 5 GALLON

CAPACITY THROUGH

LOCAL SEARS STORE OR

SERVICE CENTERS

FLEXIBLE WATER HEATER

GAS CONNECTOR WITH

FITTINGS

INSTALLED IN RESIDENTIAL

GARAGES HAVING A DIAMETER 24"

OR LESS AND A RATED CAPACITY 75

GALLONS OR LESS

WATER HEATER

INSTALLATION KIT WITH

FLEXIBLE CONNECTORS

FOR 3/4" GALVANIZED OR

I/2"COPPER PLUMBING

PVC VENT ELBOW

PVC VENT EXTENSION

Basic Tools

Youmay or may not need all of these tools, dependingon your

type of installation. These tools can be purchased at your local

Searsstore.

• Pipe Wrenches (2) 14"

Screwdriver

Tin Snips

6 Foot Tape of Folding Rule

Garden Hose

Drill

Pipe dope or Teflon Tape

GARDEN HOSE 6 FOOT TAPE

SLOT-HEAD SCREWDRIVER

PHILLIPS SCREWDRIVER

ROLL OF TEFLON TAPE

(USE ONLY ON WATER

CONNECTIONS)

PIPE DOPE (SQUEEZE TUBE)

USE FOR WATER AND

_AS CONNECTIONS)

PIPE

WRENCH

TIN SNIPS

WATER HEATER HEAT

TRAPS HELP REDUCE HEAT

LOSS DUE TO THERMAL

SYPHONING

ADDITIONAL TOOLS NEEDED

WHEN SWEAT SOLDERING

• Tubing Cutters or Hacksaw

• Propane Torch

• Soft Solder

• Solder Flux

• Emery Cloth

• Wire Brushes

HACKSAW

3/4" WIRE BRUSH

112" WIRE BRUSH

ROLL OF LEAD FREE

SOFT SOLDER

ROLL OF EMERY

CLOTH SOLDER FLUX TUBING

DRAIN PANS

AVAILABLE IN 20" DIAMETER FOR

WATER HEATERS HAVING A DIAME-

TER 18" OR LESS AND AVAILABLE IN

28" DIAMETER FOR WATER HEATERS

HAVING A DIAMETER 26" OR LESS

\

PROPANETORCH

CUTTER

Page 8

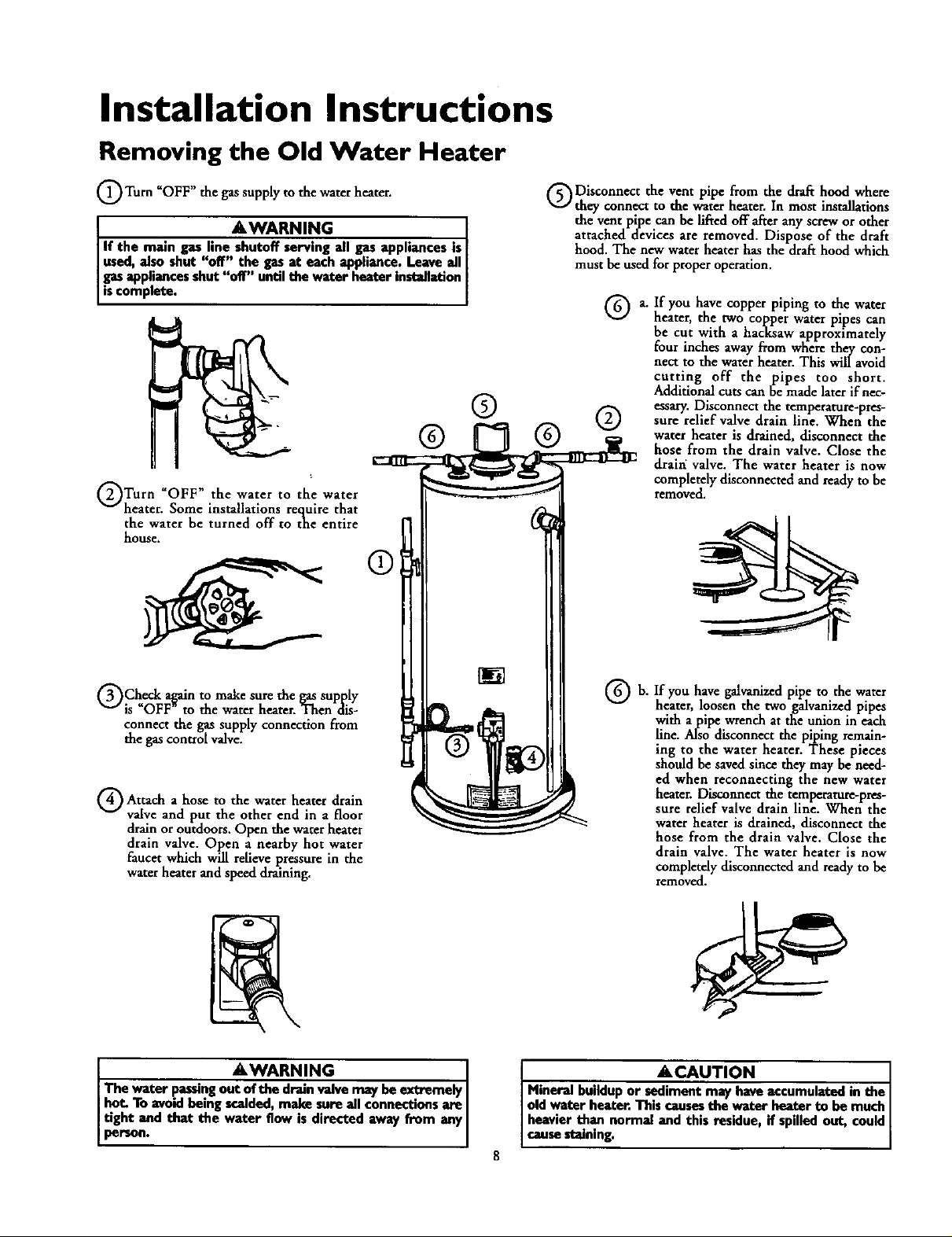

Installation Instructions

Removing the Old Water Heater

_OFF" the the heater.

Turn gassupply to water

AWARNING

If the maingas line shutoffservingall gas appliances is[

used,alsoshut "off" the gasat each appliance.Leaveall I

gasappliancesshut "off" untilthewater heaterinstallation

scompere.

® ®

_OFF" the the

Turn water to water

heater. Some installations require that

the water he turned off to the entire

house.

®

Disconnect the vent pipe from the draft hood where

they connect to the water heater. In most installations

the vent pipe can belifted off after anyscrew or other

attached devices are removed. Dispose of the draft

hood. The new water heater has the drafthood which

must be used for proper operation.

Q a.

If you have copper piping to the water

heater, the two copper water pipes can

be cut with a hacksaw approximately

four inches away from where they con-

nect to the water heater. This will avoid

cutting off the pipes too short.

Additional cuts can be made later if nec-

essary. Disconnect the temperature-pres-

sure relief valve drain line. When the

water heater is drained, disconnect the

hose from the drain valve. Close the

drain valve. The water heater is now

completely disconnected and ready to be

removed.

GCheck a_ain to makesure the gassupply

is OFF to the water heater. Then dis-

connect the gas supply connection from

the gascontrol valve.

a to

Attach hose the heater drain

valve and put the other end in a floor

drain or outdoors. Open the water heater

drain valve. Open a nearby hot water

faucet which will relieve pressure in the

water heater and speed draining.

water

AWARNING I

The water passingout of the drain valve may be extremely I

bet. To avoid being scalded, make sum all connections are I

tight and that the water Bow is directed away from any

persoo.

®h

If you have galvanized pipe to the water

heater, loosen the two galvanized pipes

with a pipe wrench at the union in each

line. Also disconnect the piping remain-

ing to the water heater. These pieces

should be saved since they may be need-

ed when reconnecting the new water

heater. Disconnectthe temperature-pres-

sure relief valve drain line. When the

water heater is drained, disconnect the

hose from the drain valve. Close the

drain valve. The water heater is now

completely disconnected and ready to be

removed.

ACAUTION I

Mineral buildup or sediment may have accumulated in the J

old water heater. This causes the water heater to be much J

heavier than normal and this residue_ if spilled out, could

cause staining. I

8

Page 9

Installation Instructions

Locating the New Water

Heater

You should carefully choose an indoor location for the new water

heater, because the placement is a very important consideration

for the safety of the occupants in the building and for the most

economical use of the appliance. TI_ water heater is not for

me in mobile homes or outdoor installation.

Whether replacing an old water heater or putting the water

heater in a new location, the following critical points must be

observed.

1. The location selected should be indoors as close as practical

to the vent termination point, and as centralized with the

water piping system as possible, The water heater, as all water

heaters, willeventually leak. Do not install without adequate

drainage provisions where water flow will cause damage.

2, The vent piping cannot exceed a total of 35 feet including

vertical and horizontal runs and have no more than 3 elbows.

It cannot slope downward and horizontal runs require ¼" per

foot rise. All horizontal runs require adequate support at 3½

feet intervals.

3. The water heater requires its own (separate) venting system.

It mot be connected to an existing ventpipe or chimney.

It must terminate horizontally to the outdoors. Whenever

possible terminate the vent on the leaward side of the build-

ing. NOTE: Condensation may be created, at times, as the

combustion gases _it the vent cap and discoloration of

surfaces in proximity to the vent cap may occur.

&WARNING

The powerventwater heater requiresitsown(separate)veatin_

system.It cannotbe connectedto anexistingventpipeorchim-

ne_ It rnust betormieatod horizontellyto theontdoor& Failureto

properiyinstalltheventingsystemon result inasphlndati_ alira

or explosionand can causeDEATH, SERIOUS BODILY INJUI_,

OR PROPERTYDAMAGF.

4. The water heater comes equipped with a 5 foot power cord

which can be used to connect to a 110/120 volt power

source if(l) local codes allow, and (2) there is a three prong

receptacle available.

5. The location selection must provide adequate dearances for

servicing and proper operation of the water heater.

a_WARNING

INSTALLATIONS IN AREASWHERE FLAMMABLELIQUIDS

VAPORS) ARE LIKELY TO BE PRESENT OR STORED

GARAGES, STORAGE, AND UTILITY AREAS, ETC):

:lammableliquids(suchasgasoline,solvents,propane(LP) or

butane, etc.), all of which emit flammable vapors, may be

improperlystoredor usedin suchareas.The gaswater heater

pilotlight or main burner can ignitesuchvapor_The reselting

flashbackand Ere cancausedeath or seriousburnsto anyonein

the arna,aswellas prapertydamage.

If installationin suchareasisyour onlyoption,then the iest;dla-

tion must be accomplished in a way that the pilot tlame and

nminbumerflame aure_ frem thefloor at lexst 18inche_

Wh_ this may reduce the cbences of flammable vapers from a

Ilonrspillbeing ignited,gasolineandotherflammablesubstances

shouldneverbe storedor usedin the same room or area con-

teining a gaswater heater or other openflameor sparkproduc-

ingappiiance.

NOTE: Flammable vaporsmay be drawn by air cmxentsfrom

other areasofthe structureto the appliance.

AWARNING

Propellantsof aerosol spraysand volatile compounds,(dean-

or_ chlorinebasedchemicals,refrigerants,etc.) inadditionto

being highlyflammable in many cases,will alsochangeto cor-

rosive hydrochloric acid when exposed to the combustion

products of the water heater. The resultscan be hazardon_

and alsocauseproductfailure.

AWARNING

This water heater must not be installeddirectlyon carpeting.

Carpeting must be protected by a metal or wood panel

beneath the appliance extending beyond the full width and

depth of the applianceby at least 3 inches(76.2mm) in an)

diredion, or if the applianceis iestalledin an alcoveor dosot

the emtre floormust be coverndby the penel. Failureto hne_

this waroingmayresultin afire hazard,

AWARNING ]

Do not usean exteesi_not a suitablerecapta.I

de and/or localcodesprohibituseof a power cord,field wiring

must beprovided,

A, CAUTION

WATER HEATERS EVENTUALLY LEAK: Installation of the

water heater must he accomplished in sucha manner that if

the tank or any connections should leak, the flow of water

will not causedamage to the structure. When suchlocations

cannot be avoided, a suitable drain pan should be installed

under the water heater. Drain pans are available at your

local Searsstore. Sucha drainpan must he not greater than

I% inchesdeep, havea minimum length and width of at least

2 Inchesgreater than the water heater dimensionsand must

be piped to an adequate drain. The pan must not restrict

combustion air flow. Under no circumstancesis the manu-

facturer or Sears to be held liable for any water damage In

connectionwith this water heater.

A,WARNING

Minimum clearances between the water heater and com-

bustible construction am 0" at the sidesand rear,5" at the

frnnt,and 0" from the vent pipe. CI_ frnm the top of the

jacketis 14"on mostmodels.Note that alesserdimensionmay

be allowed on some models.Refer to the label on the water

heater adjacentto the gascontrolvalvefor all clearances.

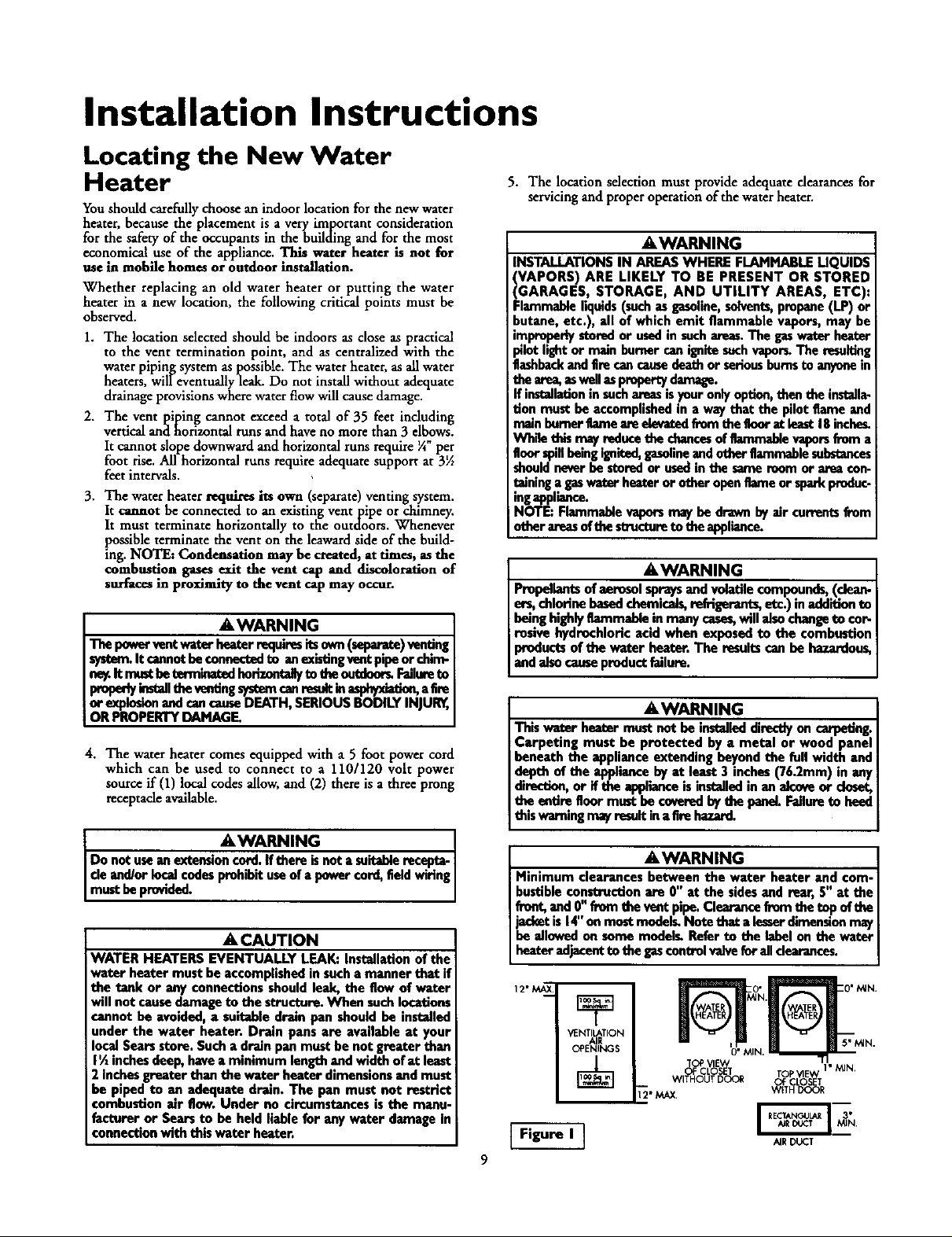

12"M_

VENI_TION

OPENINGS

WITHOUTDOOR Of CLO_V_T

[2" MAX. WITH DOOR

Figure I ]

O"t_N. _ "

TCP VIE

OF CLOSV_/T TOP VlE 1" MIN.

II

AIRDUCT

Page 10

Installation Instructions (cont'd)

AWARNING

A gaswater heater cannotoperate properly without the cor-

rect amount of air for combustion,Do not installin a con-

fined area such a closet, unlessyou provide air as shown in

the "Locating The New Water Heater" section. Never

obstruct the flow of ventilationair, If you have any doubtsor

questionsat all, call your gascompany.Failure to providethe

proper amount ofcombustionair canresult in a fire or explo-

sionand can causeDEATH, SERIOUS BODILY INJUR_,OR

PROPERTY DAMAGE.

AWARNING

If thiswater heater will be usedin beautyshops,barber shops,

cleaning establishments, or self-service laundries with dry

deaningequipment, it is imperative that the water heateror

water heaters be installedsethat _ andvanttlation

air be taken from outsidedmseareal Rofer to the "LoattMg

Tbe New Way_erHeater" sectionof this manuai and aise the

latesteditionoftbe NationalFuel GasCede,ANSI 7.223.1,also

referred to as NFPA 54 for specific_providedconcerningair

required.

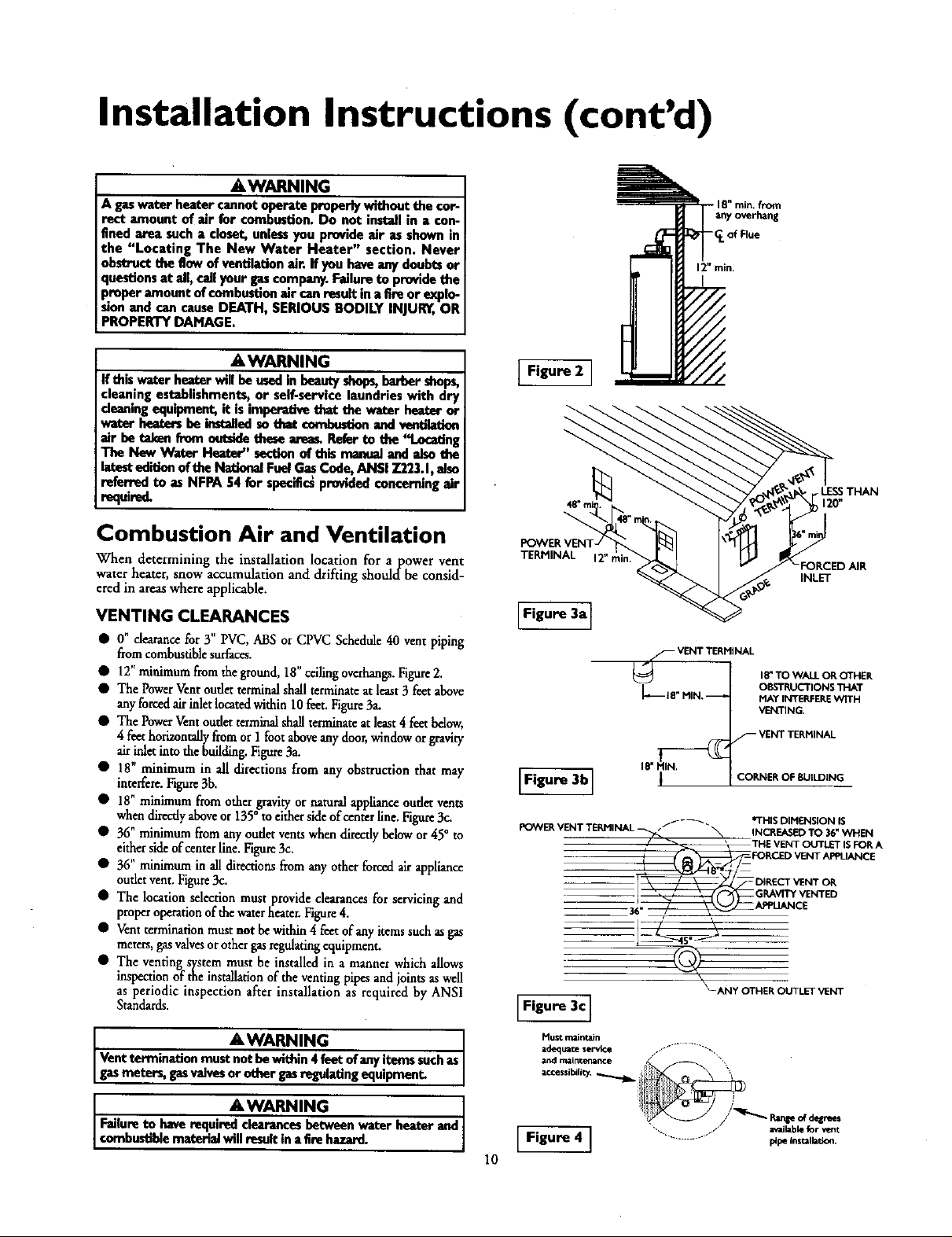

Figure 2 ]

18" min. from

any overhang

- C-p.of Flue

12" rain.

._THAN

120"

Combustion Air and Ventilation

When determining the installation location for apower vent

water heater, snow accumulation and driftingshouldbe consid-

eredin areaswhere applicable.

VENTING CLEARANCES

• O" dearance for 3" PVC, ABS or CPVC Schedule 40 vent piping

from combustible surfaces.

• 12" miuimum fromtheground, 18"ceding overhangs. Figure2.

• The PowerVent outlet terminal shall terminate at least3 feet above

anyforced air inletlocatedwithin 10feet. Figure 3a.

• The PowerVent outlet terminal shall terminate at least4 f_et below,

4 feet horizontally from or 1 foot aboveany door,window or gravity

air inlet into the building.Figure3a.

• 18" minimum in all directions from any obstruction that may

interfere.Figure 3b.

• 18" minimum from other gravity or natural appliance oudet vents

W " o ....

hen directly above or 135 m either sideof center line. Ftgu_ 3c.

• 36"minimumfrom anyoudetventswhendirectlybelowor 45° to

eithersideofcenterline.Figure3c.

• 36"minimumin alldirectionsfromanyotherforcedairappliance

outletvent.Figure3c.

• The locationselectionmustprovideclearancesfor servicingand

properoperationofthewaterheater.Figure4.

• Ventterminationmustnot bewithin4 feetof anyitemssuchasgas

meters,gasvalvesorothergasregulatingequipment.

• The venting system must be installed in a manner which allows

inspection of the installation of the venting pipes and joints as well

as periodic inspection after installation as required by ANSI

Standards.

AWARNING

Ventterminationmustnotbewithin4feetofanyitemssuchas

gasmeters,ps valvesorothergasregulatingequipment.

AWARNING

Failureto haverequiredclearancesbetweenwaterbeaterand

combustiblemateHaiwillresultin afire hazard.

POWER V

TERMINAL

Figure 3a]

f VENT TERMINAL

18" TO WALL OR OTHER

OBSTRUCTIONS 'I]'IAT

MAY INTERFERE 'WITH

VENTING.

F VENT TERMINAL

IF,gure3 ,

F_3NVER VENT TERMINAL _ _ INCREASED TO 36 _WHEN

._- -_. *TH S DIMENSION IS

/ _ ' THE VENT oLrrLET ISFOR A

_!_ DIRECTVENT OR

CORNER OF BUILDING

FOR_ VENT APPLIANCE

GL_.WP¢ VENTED

\

_-ANY OTHER OUTLET VENT

Figure 3c]

Mustmaintain

adeq_te $erv_e ............ "'--,,,

andmainterklnce / "_,,

accessibility. _ [

available for vent

[ Figure 4 ] ..................... p_peinsulbdon.

10

FORCED AIR

INLET

Page 11

Installation Instructions (cont'd)

Combustion Air and Ventilation

for Appliances Located in

Unconfined Spaces

Uncom°med Space is a space whose volume is not less than 50 cubic

feet per 1,000 Btu per hour of the aggregateinput rating of allappli-

ances installed in that space. Rooms communicating directly withthe

space in which the%.pphancesareinstalled, through openingsnot fur-

nished with doors, areconsidered a part of the unconfined space.

In unconfined spaces in buildings, infiltration may be adequate to

provide air for combustion, ventilation and dilution of flue gases.

However, in buildings of tight construction (for example, weather

stripping, heavily insulated, caulked, vapor barrier, etc.), additional air

may need to be provided using the methods described in Combustion

Air and Ventilation forAppliances Located in Confined Spaces.

Combustion Air and Ventilation

for Appliances Located in

Confined Spaces

Confined Space isa space whose volume is less than 50 cubic feet per

1,000 Btu per hour of the aggregate input rating of all appliances

installed in that space.

a. ALL AIR FROM INSIDE BUILDINGS:

(See Page8 Figure 1,and Figure 5 below)

The confined space shall be provided with two permanent open-

ings communicating directly with an additional room(s) of suffi-

cient volume so that the combined volume of all spaces meets the

criteria for an unconfined space. The total input of all gas utiliza-

tion equipment installed in the combined space shall be considered

in making this determination. Each opening shall have a minimum

free areaof one square inch per 1,000 BTU per hour of the total

input rating of all gas utilization equipment in the confined space,

but not less than 100 square inches. One openingshall commence

within 12 inches of the top and one commencing within 12 inches

of the bottom of the enclosure.

1. When directly communicating with the outdoors, each opening

shall have a minimum free areaof I square inch per 4,000 BTU

_serhour of total input rating of allequipment in the endosure.

ee Figure 6.)

2. When communicating with the outdoors through vertical ducts,

each opening shall have a minimum free area of 1 square inch

per 4,000 BTU per hour of total input rating of all equipment in

the enclosure. (See Figure7.)

.... , , , , ,

Figure 7 1

3. When communicating with the outdoors through horizontal

ducts, each openingshall have a minimum freeareaof 1 square

inch per 2,000 BTU per hour of total input rating of all equip-

ment in the enclosure.(SeeFigure8.)

VENTIULTK_d LOU_

WA_R

J

Figure 5 ]

b. ALL AIR FROM OUTDOORS: (seeFigures6-8)

The confined space shall be provided with two permanent open-

ings, one commencing within 12 inches of the top and one com-

mencing within 12 inches from the bottom of the enclosure.

The openings shaft communicate directly, or by ducts, with the

outdoors or spaces (crawl or attic) that freely communicate with

the outdoors.

Figure 6 ]

Figure 8 ]

4. When ductsare used, they shallbe of the same cross-sectional area

as the freearea of the openings to which they connect. The mini-

mum short side dimension of rectangularair ducts shall not be

less than 3 inches. (SeeFigure 8.)

5. Louvers and Grilles: In calculating freearea,consideration shall be

given to the blocking effect of louvers, grilles or screens protect-

ing openings. Screens used shall not be smaller than ¼ inch mesh.

If the free area through a design of louver or grille is known, it

should be used in calculating the size opening requiredto provide

the free areaspecified. If the design and free areais not known, it

may be assumed that wood louvers will be 20-25 percent freearea

and metal louvers and grilles will have 60-75 percent free area.

Louvers andgrilles shall be fixed in the open position or inter-

locked with the equipment so that they areopened automatically

during equipment operation.

6. Special Conditions Created by Mechanical Exhausting or

Fireplaces:Operation of exhaust fans, ventilation systems, clothes

dryers or fireplaces may create conditions requiringspecial atten-

tion to avoidunsatisfactory operation of installed gas utilization

equipment.

11

Page 12

Installation Instructions (cont'd)

Water Piping

A WARNING

HOTTERWATERCANSCALD:.Waterheatersareintendedto

producehotwater.Water heatedto a temp_atum whichwill

satisfyclotheswashing,dishwashing,andothersanitizingneeds

cansc_l andpermanontlyinjureyouuponcontact.Somepeo.

piearumorehle.qyto bepermonentlyinjuredbyhotwaterthan

others.Theseincludetheelderly,children,thehdirm,orphy_ical-

ly/ment_lyhandicapped.Ifanyoneusinghotwaterinyourhome

Etsintooneofthesegruupsorifthoreisalocalcodeorstatelaw

requiringacertaintemperaturewateratthe hotwatertap,then

youmusttakespecialprecautions.Inadditionto usingthelowest

possible temperature se_ng that satisfiesyour hot water needs,

a meansinchasamixingvalve,shouldbeusedatthe hotwator

tapsusedbythesepeopleor atthewaterheater.Mixingvalves

areavailableatplumbingsupplyor hardwarestere_Followman-

ufacturersinstructionsfor installationofthe valves,Before

changingthe factory settingonthe thermostat,read the

"Tempor_umRegulation"sectioninthismanual.

This waterheater shall not be connected to any heating systems

or component(s) used with a non-potable water heating appli-

ance.

If a water heater is installed in a closed water supply system;

such as one having a back-flow preventer, check valve,water

meter with a check valve,etc.., in the cold watersupply; means

shall be provided to control thermal expansion. Contact the

local utility orlocal.SearsServiceCenter on how to control this

situation.

NOTE: To protect against untimely corrosion of hot and

cold water fittings, it b strongly recommended that dielec-

tric unions or couplings be installed on this water heater

when connected to copper pipe.

2. Look at the top cover of the water heater. The cold water

inlet is marked-cold. Put two or three turns of teflon tape

around the threaded end of the threaded-tu-sweat coupling

and around bothends of the _Athreaded nipple. Usingflexi-

ble connectors, connect the coldwaterpipe to the coldwater

inlet of the water heater.

NOTE: This water heater is insulated to minimize heat

loss from the tank. Further reduction in heat loss can be

accomplished by insulating the hot water lines from the

water heater.

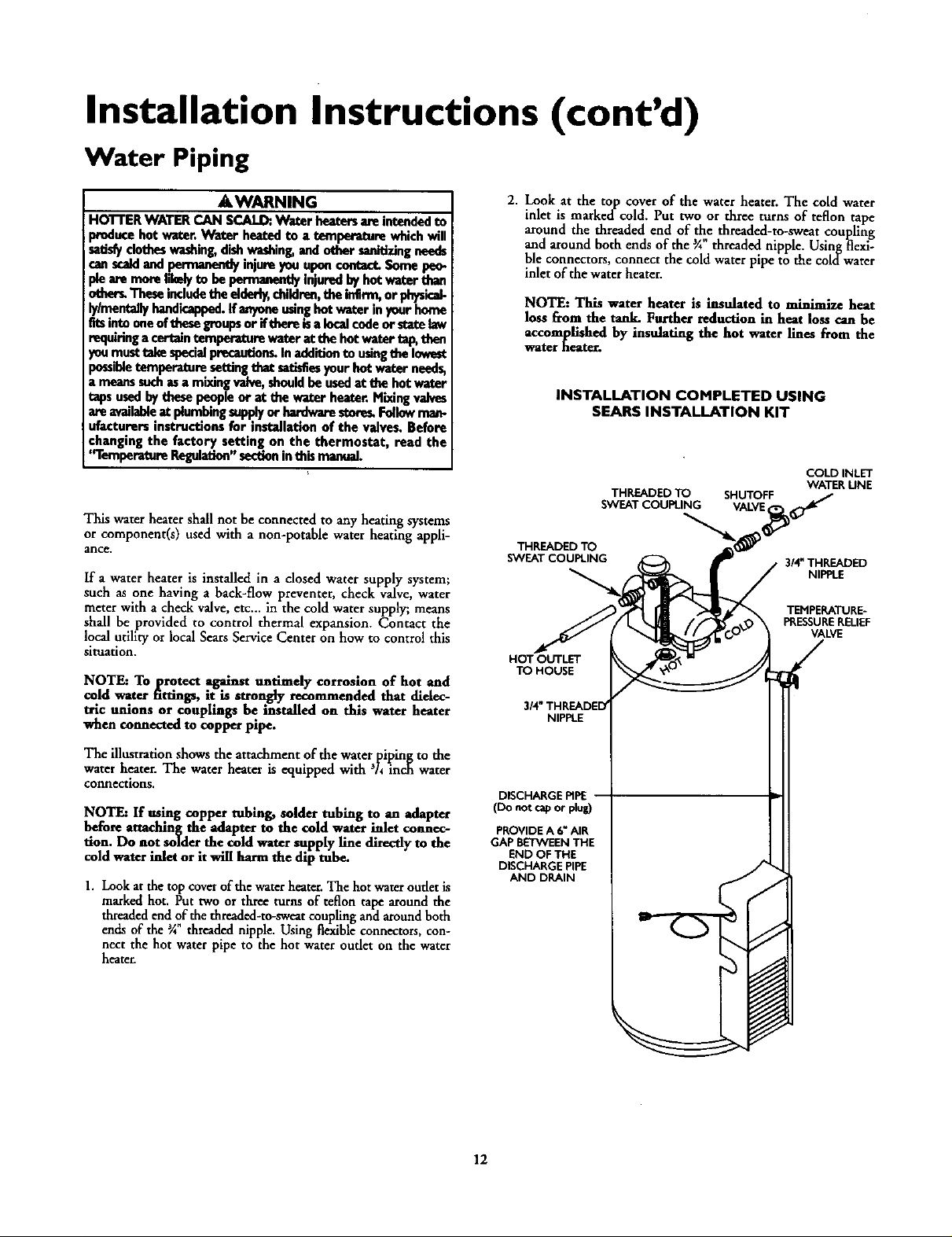

INSTALLATION COMPLETED USING

SEARS INSTALLATION KIT

COLD INLET

WATER UNE

3/4"THREADED

NIPPLE

TEMPERATURE-

PRESSURERELIEF

VALVE

THREADED TO

SWEAT COUPLING

HOT OUTLET

TO HOUSE

NIPPLE

THREADED TO SHUTOFF

SWEAT COUPLING VALVE

The illustrationshows the attachmentof the waterpipingto the

water heater.The waterbeater is equipped with 'h inch water

connections,

NOTE: If using copper tubing, solder tubing to an adapter

before etmching the adapter to the cold waterinlet connec-

tion. Do not solder the cold watersupply line directly to the

cold water inlet or it will harm the dip tube.

1. Look at the top cover of the water heater. The hot water oudet is

marked hot. Put two or three turns of teflon tape around the

threaded end of the threaded-to-sweat coupling and around both

ends of the _A threaded nipple. Using flexible connectors, con-

nect the hot water pipe to the hot water outlet on the water

heater.

DISCHARGE PIPE

(Do not cap or plug)

PROVIDE A 6" AIR

GAP BETWEEN THE

END OF THE

DISCHARGE PIPE

AND DRAIN

12

Page 13

Installation Instructions (cont'd)

Temperature-Pressure Relief Valve

A WARNING

At the time of manufacture this water heater wasprovided

with a combination temperature-pressuresrelief valvecertified

by a nationally recognized testing laboratory that maintains

periodic inspectionof productionof listedequipment or mute-

rials, as meeting the requirements for Relief Valves and

Automatic GasShutoffDevicesfor Hot Water SupplySystems,

and the latest edition of ANSI Z21.22 and the code require-

ments of ASME. If replaced, the valvemust meet the require-

mentsof localcedes,but net lessthana combinationtempera-

ture and pressure reliefvalvecertified asmeeting the require-

meritsfor ReliefValvesand Automatic GasShutoffDevicesfor

Hot Water SupplySystems,ANSI Z21.22 by a nationally recog.

nizedtesting laboratory that maintains periodic inspectionof

productionuf list_l equipment or material_

The _lve must be mark_ wi_ a meximum set pressuronot

to exceed the marked hydrostatic working pressureof the

water heater (150 IbsJsq.in.) and a dischargecapacitynet less

than the water heater input rate as shownonthe modelrating

plate. (Electric heaters • watts divided by 1000x 3415 equal

BTU/Hr. rate.)

Your localjurisdictionalauthority,whilemandatingthe useofa

temperature-pressurerelief valvecomplyingwith ANSI 7.21.22

and ASME, may require a valve model differentfrom the one

furnishedwiththe water heater.

Compliancewith suchIoc_ requirements must be satisfiedby

the installeror end userof the water heater with a locallypre-

scribedtemperaturo-prossuro reliefwdve instadl_din the desig-

nutedopeningin the water heater in place of the factoryfur-

nishedvalve.

For safeoperationof the water heater,the relief valvemustno_

be removedfrom it'sdesignatedopeningor plugged.

The temperature-pressure reliefvalvemustbe installeddirectly

intothe fittingef thewater hexterdesignatedfer the reliefvalve.

Positionthe valvedownwardand providetubingsothat anydis-

chargewill exit only within 6 inchesabove,or at anydistance

below the structuralfloor.Be certain that no contact ismade

with anyliveelectricalpart. The dischargeopeningmust not be

blockedor reducedin sizeunder anycircumstances.Excessive

length,over30 feet, or useof more than four elbowscancause

restrictionand reducethe dischargecapacityoftbe valve.

No wive or other obstructionisto be placedbetween the relief

valveandthe tank. Do net connecttubingdirectlyto discharge

drainunlessa 6" air gapisprovided.To preventbodilyinjury,haz-

ardto life, or property damage,the reliefvalvemust beallowed

to dischargewater inquantitiesshouldcircumstancesdemand.If

the dischargepipeisnot connectedto a drain or other suitable

means,the water flowmay causepropertydamage.

The DischargePipe:

Must net be smaller in sizethan the outlet pipe size of the

valve,or haveanyreducingcouplingsor other restrictions.

Mustnot be pluggedorblocked.

Mustbeof materiallistedfor hot water distribution.

Must be installedso as to allow complete drainageof both

the temperature-pressure relief valve, and the discharge

pipe.

Mustterminate at an adequatedrain.

Mustnet haveany valvebetweenthe relief valveand tank.

AWARNING

The temperature-pressure relief valve must be manually

operotod at least once a ye_ Caution shouldbe taken to

ensurethat (I) no one is in frant of or around the oudet of

the temperature-pressure reliefvalve dischargeline, and (2)

the water manually discharged will not cause any bodily

injury or property damage because the water may be

extremely hot.

If after manually operating the valve, it failsto completely

reset and continuesto release water, immediately dose the

cold water inlet to the water heater, follow the draining

instructions, and replace the temperature-pressure relief

valvewlth a new one.

TEMPERATURE-PRESSURE

RELIEF VALVE

HOT

/

DISCHARGEPiPE

PROVIDE A 6" AIR

GAP BETWEEN THE

END OF THE

DISCHARGE PIPE

AND DRAIN

plug)

RELIEFVALVEOPENING

Atthetimeofmanufacture,thiswaterheaterv_sprovidedwithacombinationter_

peratum-pressurereliefvabelistedascomplyingwiththestandardforreliefvalvesand

automaticipsthut-offdevtce_for hotwater supply systems.ANSI;[21.22.Forsafe

operationof_ewaterheater,therelief_ mustnotberemovedfromitsdesignated

pointofinstadationor plul_ed,

Yourlocaliuri_ctional authority,while mandating theuseofatemperature-pressure

relief_ahecomplyingwithANSI7.21.22andASME.mayrequireavalvem_eldilferem

fromtheonefurnishedwiththewaterheart

Compliancewithsuchlocalrequirementsmustbesati_ndbytheinstallerorenduser

ofthewaterbeaterwithaIc_al;yprescribedtemperature-pressurereliefvalveinstalled

intheda_ignatedopeninginthewaterheater

Seemanualheading-'_Temporamre-Pressure ReliefValves"forinstallationandmainte-

nanceofreliefvalve,dischargeline,andothersafetyprecautions.

13

Page 14

Installation Instructions (cont'd)

Filling the Water Heater

You must provide all wiring of the proper size outside of the

A CAUTION

Never usethis water heater unlessit iscompletely filed with

wator.To prevent damage te the tank, the tonk must be filled

with water. Water must flow from the hot water faucet

beforeturn ng"ON ' gasto thewater _

To fill the water heater with water:

Close the water heater drain valve by turning the handle to

the right (clockwise). The drain valve is on the lower front of

the water heater.

Open the cold water supply valve to the water heater.

NOTE: The cold water supply valve must be left open

when the water heater is in use.

To insure complete filling of the tank, allow air to exit by

opening the nearest hot water faucet. Allow water to run

until a constant flow is obtained. This will let air out of the

water heater and the piping.

Check all new water piping for leaks. Repair as needed.

Wiring

USE WITH POWER CORD

water heater. You must obey local codes and electric company

requirements when you install this wiring.

If you are not familiar with electric codes and practices, or if you

have any doubt, even the slightest doubt, in your ability to con-

nect the wiring to this water heater, obtain the service of acom-

petent electrician or contact your local electric utility.

A WARNING

WATER HEATERS EQUIPPED FOR ONE TYPE VOLTAGE

ONLY:Thiswater heateris equippedfor 110/120voltsonly.DO

NOT USE THIS WATER HEATER WITH ANY VOLTAGE

OTHER THAN THE ONE SHOWN ABOVE. Failureto usethe

correctvoltagecancauseproblemswhichcanresultinDEATH,

SERIOUS BODILY INJURY OR PROPERTY DAMAGE. If you

haveanyquestionsor doubtsconsultyourelectriccompany.

A CAUTION

If wiring from the fuse box or circuit breaker box was alu-

minum for the old water heater, replace it with copper wire.

If you wish to reuse the existing aluminum wire, have the

connectionat the water heater made by a competent elec-

trician. Contact a localelectrical contractor and/or the local

electric utility.

The water heater comes equipped with a 5 foot power cord

which can be used to connect to a 110/120 volt power source if,

(1) local codes allow, and (2) there is a three prong receptacle

available.

N\

\\

\\

\\

\\

x\

\\

\\

\\

\\

\\

\\

\\

\\

\\

You must provide all wiring, (1) to a receptacle or, (2) between

the water heater and junction box when the power cord is not

used.

5' MAXIMUM

A WARNING

Donotuseanextensioncord.Ifthereisnotasuitablerecepta-

cleand/orlocalcodesprohibituseofapowercord,fieldwiring

mustbeprovided.

USE WITHOUT POWER CORD

If power cord cannot be used, then follow these wiring instruc-

tions.

1. Provide a way to easily shut off the electric power when work-

ing on the water heater. This could be with a circuit breaker

or fuse block in the entrance box or a separate disconnect

switch.

2. Install and connect a circuit directly from the main fuseor

circuit breaker box. This circuit must be the right size and

have its own fuse or circuit breaker.

GROUND SCREW

14

Page 15

Installation Instructions (cont'd)

USE WITHOUT POWER CORD (cont'd)

3. A standard ½" conduit opening has been made in the water

heater junction box for the conduit connection.

4. Use wire nuts and connect the power supply wiring to the

w res inside the water heater's junction box.

5. The water heater must be electrically _grounded" by the

installer. A green ground screw has been provided on the

WIRING DIAGRAM

SW_A4,

_aj_ NO '

I_TO_ _ I_V

O

SWTT_

_Lrmm.

ater heaters _unctlon box. Connect ground wire to th s

location. For complete grounding details and all allowable

exceptions, refer to local codes or in the absence of local

codes, with the latest edition of the National Electrical Code,

ANSI/NFPA 70.

6. Replace the wiring junction cover using the screw

provided.

LtmT_

I

[_

[

p_ss_qE

[

Venting

AWARNING ]

Toinsureproper ventingofthis gas-firedwater heater,the €or- ]

rect vent pipe diameter must be utilized. Any additions of]

other gas appliances on vent with this water heater will

adverselyaffectthe operation ofthe water heater.

The combu.stion and ventilat on a r flow must not be obstructed.

A WARNING [

Thewaterheaterwithdrafthoodinstalledmustbeproperly[

ventedto a chimneywhichterminatesoutdoor_Neveroper-I

atethe_ heat_"unle_itisventedtotheoutdonrsandhasI

adequateairsupplyto avoidrisksof improperoperation,explo-

sionorasphyxiation. I

_i'WARNING I

Ob_ructedordeterioratedve_systemsmaypr--_entaserousI

healthrisk or asphyx_on. I

AWARNING 3" diameter

PVC schedule 40 pipe and must slope upward

The vent pipe from the water heater must be I/4 nch per

near foot.

All vent gases must be completely vented to the outdoors of the

structure (dwelling).

AWARNING I

Failuretohaverequi_l clearancesbetweenwaterheaterand

combustiblemateHaiwillresultn atimhazard.

15

Page 16

Installation Instructions (cont'd)

Venting (cont'd)

VENTING SYSTEM EXAMPLE INSTALLATIONS

Be surevent pipeis properly connectedto p_vent escapeof

dangerousfluegaseswh ch couldcausedeadlyasphyxiation.

•,WARNING r

_kWARNING

Chemical vapor corrosion of the flue and vent system may

occur if air for combustioncontainscertain chemicalvapors.

Spray canpropellants, cleaningsolvents,refrigerator and air

conditioner refrigerants, swimming pool chemicals, calcium

and sodiumchloride, waxes,bleach,and processchemicalsare

typicalcompoundswhichare pote_ally corrosive.

3" PVC SCHEDULE 40 VENT PIPING

Supplied in the carton with the water heater are:

1. A 3" PVC Schedule 40-45 ° vent cap with wire screen.

2. A 3" PVC Schedule 40-90 ° street ell; used to connect the

vent pipe to the water heater when the vent pipe is to be

turned horizontally directly off the blower.

3. A 5' section of 3" PVC Schedule 40 pipe (more may be

required and must be supplied locally).

3" PVC SCHEDULE 40

90* ELBOW

FOR ALL MODELS

The vent piping cannot under any circumstances be run down-

hill.

The _nt piping c_mbe installed as follows:

1. No more than 3 elbows can be used.

ELBO'_¢S

VENT CAP

WITH SCREEN

1. The water heater requires its own (separate) venting

system.

2. 3" PVC, ABS or CPVC Schedule 40 piping and fittings are

acceptable materials for the vent system on all 40 gallon

models and 50 gallon 40,000 BTU/HR models.

3, It cannot be connected to existing vent piping or

chimney.

4. It must terminate horizontally to the outdoors.

MAX. 20'

TOTAL VERTICAL AND

rIE;aTt CANNOT EXCEED 35'

I

HA_3

ELBOWS

HIN. RISE V4"

PER FOOT

MIN. RISE I/4"

PER FOOT

TOTAL VERTICAL AND

HORIZONTAL RUNS

CANNOT EXCEED 35'

16

Page 17

Installation Instructions (cont'd)

VENTING SYSTEM EXAMPLE INSTALLATIONS

FOR ALL MODELS (cont'd)

2. Horizontal runs requzrea m n mum ¼ rise per foot.

13"MIN. I 1" MIN. MIN. RISE¼"

3. A vertical run can be no more than 20'.

4. The total vertical and horizontal run cannot exceed 35'.

MAX. 20'

• , , i i .

35' MAX.

16"HIN.

PEP.FOOT

HIN. RISE ¼"

ONE ELBOW PER FOOT

CEMENTING PVC, ABS OR CPVC PIPE AND FITTINGS

Read and observe all safety information printed on primer,

cleaner, and cement containers.

DANGER

PHmer, cleaner, and cements are extremely flammable.

They are harmful or fatal if swallowed. The vapors are

harmful. They may irritate eyes and skin and can he

absorbed through the skin.

PRECAUTIONS

Always store primers, cleaner, and cements in cool, dry,

well ventilated places. Do not store them near heat,

sparks, or flames. Keep containers closed. Use them in

well ventilated areas. Wear impervious clothing while

handling. Do not smoke, eat, or drink while handling.

Wash thoroughly after handling and before eating. Wear

eye protection when handling. If swallowed, drink water,

do not induce vomiting, and call a physician or poison

control center immediately. If inhaled, get fresh air and

seek medical attention if ill feelings persist. In case of

eye and skin contact, immediately flush with plenty of

water for 15 minutes and seek medical attention if irri-

tation persists. KEEP OUT OR REACH OF CHILDREN.

All primers, cleaners, and cements must meet all local codes and

applicable standards of the American Society For Testing

Materials Standards.

Before using primers, cleaners, and cements, stir or shake, mak-

ing sure contents are liquid. Do not use if found to be lumpy or

jelly-like. --

T

I I

TOTAL VEffFICAL AND

HORIZONTAL RUNS

CANNOT EXCEED 35'

MIN. RISE ¼"

PER FOOT

TOTAL VERTICAL AND

HORIZONTAL RUNS

CANNOT EXCEED 351

1. Cut pipe ends squarely removing all burrs and dirt.

2. Dry fit pipe and fittings to be connected for proper fit.

3. Clean pipe and fitting with a primer/deaner.

4. Apply a thin coat of cement to fitting, avoiding puddling

inside.

5. Apply a liberal coat of cement to pipe leaving no voids.

6. QUICKLY assemble parts while cement is flui!! If you wait

too long, re-coat pipes.

7. Push pipe completely into socket of fitting, turning as it goes

until it bottoms.

8. Hold p_e and fitting together for 30 seconds. Then carefully

clean orr excess with a cloth. Allow connections a sufficient

time to cure before disturbing.

9. Remember that vent pipes must be adequately and securely

supported.

APPROXIMATE SETTING TIME FOR 2½" TO 4" PIPE

OINTS

MOVEMENT COMPLETE

90°F to 150°F _Ahr. 8 hrs.

50°F to 90°F 1 hr. 15 hrs.

O°Fto 50°F 1¼ hr. 18 hrs.

OF JOINT SET

17

Page 18

Installation Instructions (cont'd)

Venting (cont'd)

CUTTING OPENING THROUGH AN OUTSIDE

WALL AND COLLAR INSTALLATION

After reading themanual and you have determined the location

of the opening in the wall, (using the drawingbelow), cut a 3½

hole through a_ exteriorwall.

NOTE: When determining location of the opening in the

outside wall allow for the ¼" rise per foot that has taken

place in the horizontal run.

C LofFlue .-_.........

40 GAL- 00"

SO GAL- S9'A"

]._

CONNECTING PVC, ABS OR CPVC PIPE VENT TO

BLOWER

1. The manufacturerhas supplied a 3" PVC Schedule 40 street

elbowfor connection to the water heaterwhen t " "

:urmngimme-

diately horizontally off the blower. Place the elbow in the

required direction on the blower and using 3 sheet metal

screws,attach the elbow.

2. If there is to be a vertical runof vent from the blower,the 3"

PVCor ABSpipe must be attached to the blowerusing 3 sheet

metal screws.Additionally,you must sealalljoints using a suit-

ablesiliconesealersuch as GE RTV-103or equivalent.

/

The 3" FVC,ABS or CPVC Schedule40 vent pipe can be run

from the water heater through the wall or from the wall to the

water heater, whichever ismost convenient. The vent pipe must

extenda minimum of 1½ through the exterior wall. Extending

the vent cap as far as possible from the surface of the exterior

wall will help minimize discoloration of the wall in this area

which may be caused by the flue gases.Note that the inside col-

lar must be slipped over the vent piping before locating the pipe

through the wall. Before securing the inside and outside collars

to the wall, use a silicone sealer between pipe and opening to

insure a water and airtight seal.

INSTALLATION SHOWING USEOF PVC, ABS OR

CPVC PIPE

EXTERIOR WALL

_EALEIt

1_ _N,EX_IENSION

THROUGH

EXI'EI_IOR WALL

SCREW

I I

18

Page 19

Installation Instructions (cont'd)

Gas Piping

AWARNING

Make sure the gas supplied is the same type listed on the

model rating plato, The inlet gas pressuremust not exceed

10.5in.water column(2.6kPa) for natural gasor 13in, water

column (3.2kPa) for propane (L.R) gas. The minimum inlet

gaspressurelisted on the model rating plate isfor the pur-

poseof input adjustment.

AWARNING , I

Ifthe gascontrolvalveissubjectedto pressuresexceeding½

I poundpersquareinch(3.SkPa),the damageto the gascon-I

[trel valvecouldresultinafireor explosionfromleakingga_ J

AWARNING ]

If themaingaslinesh_gas appliancesisused_|

elsotorn "off" thegasat each_ianco. Leave_ irasapp,-|

ancesshutoffuntilthewaterheaterinstellationiscomplete./

A gas line of sufficient size must be run to the water heater.

Consult the latest edition of National Fuel Gas Code ANSI

Z223.1,also referredto as NFPA54 and the gascompany concern-

ingpipe size.

Ther_ i_l._t be;

• A readily accessible manual shut off valve in the gas supply line

serving the water heater, and

• A drip leg (sediment trap) ahead of the gas control valve to help

prevent dirt and foreign materials from entering the gas control

Valve.

• A flexible gas connector or a ground joint union between the

shutoff valve and control valve to permit servicing of the unit.

t AWARNING 1

Usepipe joint compoundorteflon tape markedasbeingI

resistantto the actionofpetroleum[Propane(L.R)]gase_

SEDIMENT TRAP

A sediment trap shall be installed as close to the inlet of the

water heater as practical at the time of water heater installation.

The sediment trap shall be either a tee fitting with a capped nip-

ple in the bottom outlet or other device recognized as an effec-

tive sediment trap. Ifa tee fitting is used, it shall be installed in

conformance with one of the methods of installation shown

below.

Connecting the gas piping to the gas control valve of the water

heater can be accomplished by either of the two methods shown.

GAS PIPING WITH

FLEXIBLE CONNECTOR

F1ANI2AL_HU'r OFFVAI_VE _ ;'_ SUPPI-YFIFqNG

GROUND

UNION

FLEX)B_EGAS CONNECTOR

I.ABIEIA_ AS COMPLYING

VVI_ ANSIffTAN[R_DS

LOOp

GAS

CONTROL

VALVE

Be sure to check all the gas piping for leaksbefore lighting the

water heater. Use a soapy watersolution, not a match or open

flame.Rinseoffsoapysolutionand wipe

Standard Modds are for instanadoa up to 3,300 feet above sea

level.

High Altitude Modds are for installation from 3,300 to 5,500

leer above sea level.

Ifa standard model is installed above 3,300 feet or a high altitude

model is installed above 5,500 feet, the input rating must be

reducedat the rate of 4 percent for each 1,000 feet above sea level.

Contact your local Sears Service Center or gas utility for further

informatiorL

AWARNING

The appliance and Its gas connection must be leak tested

beforeplacng the appliance n operation.

AWARNING

• The applianceand its individualshutoffvalvemust be discon-

nectedfrom the gassupplypiping s/stem duringany pressure

testing of the gassystem at test pressuresin excessof I/2

•poundper square inch(3.5kPa).

The appliancemustbe isolatedfrom the gassupplypipingsys-

tem by €_ng its iedhddu_ manual shuto_ valve during any

pressuretestingof the gassupply pipingsystemat test pres-

suresequalor lessthan I/2 poundper square inch(3.SkPa).

GAS PIPING WITH ALL BLACK IRON

PIPE TO GAS CONTROL

GROUND_NT

UNION

3_ FtlN"

Contaminants in the gaslinesmay causeimpmpor operation

of the gascontrol valve that may result in fire or explosion.

Before at_'mchingthe gaslinebe sure that allgas pipe isclean

on the inside.To trap any dirt or foreignmaterial in the gas

supply line, a drip leg (sometimes called a sediment trap)

must be incorporated in the piping. The drip leg must be

readilyaccessible. Installin accordancewith the "Gas Piping_'

section. Referto the latest edition of the National Fuel Gas

Code, ANSI Z223.1,alsoreferred to asNFPA 54.

BLACK F1PE

C_

AWARNING

19

Page 20

Installation Instructions (cont'd)

Installation Checklist

BEFORE LIGHTING THE PILOT:

• Check the gas lines for leaks.

a. Use a soapy water solution. DO NOT test for gas leaks

usinga match or open flame.

b. Brush the soapy water solution on all gas pipes, joints and

fittings.

c. Check for bubbling soap. This means you have a leak,

Turn"OFF gas and make the necessary repairs.

d. Recheck for leaks,

e. PJ.nse off soapy solution atld wipe dry.

• Is the new temperature-pressure relief ,,v_lveproperly installed

and piped to an adequate drain? See Temperature-Pressure

Relief Valve" section,

• Are the cold and hot water lines connected to the water

heater correctly? See _Water Piping _ instructions in the

°Installing the New WaterHeater"section.

• ISthe water heater comp|etely filled with water? See "Filling"

instructions in the "Installing the New Water Heater" sec-

tion.

• Will a water leak damage anything? See the "Locating the

New Water Heater" section.

• Is there proper clearance between _e water heater and any-

thing that might catch fire? See the Locating the New water

Heater" section.

i

VENT PIPE TO

OUTDOORS

SHUTOFF ,_

VALVE

COLD

TEMPERATURE-

PRESSUREREUEF

VALVE

(Do not cap or plug}

• Do you have adequate ventilation so that the water heater

will operate properly? See "Combustion Air and Ventilation"

in the "Locating the New Water Heater" section.

• Is the draft hood vent piping properly secured? See "Venting"

instructions in the "Installing the New Water Heater" sec-

tion,

• Is there proper clearance between the vent pipe and anything

that might catch on fire? See "Venting_ instructions in the

"Installing the New Water Heater" section.

• Is the ventpipe properly sloped and does the vent terminate

outdoors? See "Venting" instructions in the "Installing the

New Water Heater" section.

• Do you need to call your gas company to check the gas pipe

and its hookup?

(Sedimenttrap)