Owners

Manual

FOR POTABLEWATER

HEATING ONLY

NOT SUITABLEFOR

SPACEHEATING

NOT FOR USE IN

MOBILE HOMES

Model No.

153.335803 40 Gal. High Altitude

-153.335814 40 Gal.

-153.335815 40 Gal.

153.335844 40 Gal. HighAltitude LP.

153.335861 40 Gal. L.R

153.335903 50GaL High Altitude

_153.335914 50 Gal.

--.153.335915 50 GaL

153.335941 50 Gal. HighAltitude LR

153.335961 50 Gal. L.R

KENMORE POWER MISER TM 8

POWER VENT

GAS WATER HEATER

• Safety Instructions • Care and Maintenance

• Installation • Troubleshooting

• Operation • Parts List

For Your Safety

AN ODORANT IS ADDED TO THE GAS USED BY THIS

WATER HEATER

WARNING: If the information in these instructions are not fol- I

lowed exactly, a fire or explosion may result, causing property

damage, personal injury or death. I

-Do not store or use gas.oline or other flammable vapors and liq-

uids in the vicinity of this or any other appliance.

-WHAT TO DO IF YOU SMELL GAS

: Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your

building.

Immediately call your gas suppher from a neighbor's phone.

i Follow the gas supplier'sinstructions.

If you can not reach your gas supplier, call the fire department.

-Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

Caution:

Read and Follow

All Safety Rules and

Operating Instructions

Before First Use of

This Product.

Savethis Manualfor Future Reference.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

_,WARNING 1

Improper installation, adjus_on, service or maintenance I

can cause DEATH, SERIOUS BODILY INJURY, OR PROPERTY DAM- I

AGE. Refer to this.manual for assistance or consult the local Sears I

Serv ce Center or gas utility for further information. I

AWARNING

Flammable vapors may be drawn by air currents from other areas

i of the structure to this appliance.

_,WARNING

READ THE GENERAL SAFETY SECTION BEGINNING ON INSIDE

COVER AND THEN THIS ENTIRE MANUAL BEFORE INSTALLING

OR OPERATING THIS WATER HEATER.

Safety Precautions

AW,.ARNING . .

Imp,roper installation, ad|ustment, alteratlon, service or I

maintenance can cause death, serious bodily injury, or I

property damage. Refer to this manual for assistanceor I

consult your local Sears Service Center for further

information.

AWARNING

WATER HEATERS EQUIPPED FOR ONE TYPE GAS

ONLY: This water heater is equipped for one type gas

only. Check the model rating plate near the gascontrol

valve for the correct gas. DO NOT USE THIS WATER

HEATER WITH ANY GAS OTHER THAN THE ONE

SHOWN ON THE MODEL RATING PLATE. Failure to

usethe correct gascan causeproblemswhichcanresultin

DEATH, SERIOUS BODILY INJURY, OR PROPERTY

DAMAGE. If you have any questions or doubts consult

yourgassupplieror localutility.

AWARNING

INSTALLATIONS IN AREAS WHERE FLAMMABLE LIQ-

UIDS (VAPORS) ARE LIKELY TO BE PRESENT OR

STORED (GARAGES, STORAGE, AND UTILITY AREAS,

ETC): Flammable liquids (such as gasoline, solvents,

propane(LP) or butane, etc.), all ofwhich emit flammable

vapors, may be improperly stored or used in suchareas.

The gaswater heater pilot light or main burner can ignite

such vapors. The resulting flashback and fire can cause

death or serious burns to anyone in the area, aswell as

property damage.

If installation in such areas is your only option, then the

installation must be accomplishedin a way that the pilot

flame and main burner flame are elevatedfrom the floor

at least 18 inches.While this may reduce the changesof

flammable vaporsfrom a floor spillbeing ignited, gasoline

and other flammable substancesshouldnever be stored or

used in the same room or area containing a gas water

heater or other openflame or spark producingappliance.

NOTE: Flammable vapors may be drawn by air currents

from other areasof the structure to the appliance.

_,WARNING

If this water heater will be used in beauty shops,barber

shops,cleaning establishments, or self-service laundries

with dry cleaning equipment, it is imperative that the

water heater or water heaters be installed so that com-

bustion and ventilation air be taken from outside these

areas. Refer to the "Locating The New Water Heater"

section of this manual and also the latest edition of the

i National FuelGas Code, ANSI Z223.1, also referred to as

INFPA 54 for specificsprovidedconcerningairrequired.

_,WARNING I

A E_ can start if combustiblematerials suchas clothing,I

cleaningmaterials, or flammable liquidsare placedagainst

or next to the water heater.

_,WARNING

At the time of manufacture thiswater heater wasprovid-

ed with a combination temperature-pressurosrelief vaive

certified by a nationally recognized testing laboratory

that maintains periodic inspectionof production of listed

equipment or materials, as meeting the requirements

for Relief Valvesand Automatic Gas Shutoff Devices for

Hot Water Supply Systems, and the latest edition of

ANSI Z21.22 and the code requirements of ASME. If

replaced,the valve must meet the requirements of local

codes,but not lessthan a combination temperature and

pressure relief valve certified as meeting the require-

ments for Relief Valves and Automatic Gas Shutoff

Devicesfor Hot Water SupplySystems,ANSI Z21.22 by

a nationally recognized testing laboratory that maintains

periodic inspectionof production of listed equipment or

materials.

The valve must be marked with a maximum set pressure

not to exceed the marked hydrostaticworking pressure

of the water heater (150 Ibs./sq. in.) and a discharge _

capacity not lessthan the water heater input rate as

shown on the model rating plate. (Electric heaters -

watts dividedby 1000 x 3415 equal BTU/Hr. rate.)

Your local jurisdictional authority, while mandating the

use of a temperature-pressure relief valve complying

with ANSI Z21.22 and ASME, may require a valve model

different from the one furnishedwith the water heater.

Compliance with suchlocal requirements must be satis-

fied by the installer or end user ofthe water heater with

a locally prescribed temperature-pressure relief valve

installedin the designatedopeningin the water heater in

placeof the factory furnishedvalve.

For safe operation of the water heater, the relief valve

must not be removed from it's designated opening or

plugged.

The temperature-pressure relief valve must be installed

directly into the fitting of the water heater designated

for the relief valve. Positionthe valvedownward and pro-

vide tubing so that any dischargewill exit only within 6

inches above, or at any distance below the structural

floor. Be certain that no contact is made with any live

electrical part. The discharge opening must not be

blocked or reduced in size under any circumstances.

Excessivelength, over 30 feet, or useof more than four

elbows can cause restriction and reduce the discharge

capacityofthe valve.

No valve or other obstruction is to be placed between

the relief valve and the tank. Do not connect tubing

directly to dischargedrain unlessa 6" air gap isprovided.

To prevent bodilyinjury, hazard to life, or property dam-

age, the relief valve must be allowed to discharge water

in quantities should circumstances demand. If the dis-

charge pipe is not connected to a drain or other suitable

means, the water flow may causeproperty damage.

The DischargePipe:

Must not be smaller in sizethan the outlet pipe size of

the valve, or have any reducing couplings or other

restrictions.

Must not be pluggedor blocked.

Must be of material listedfor hot water distribution.

Must be installed so as to allow complete drainage of

both the temperature-pressure relief valve, and the

dischargepipe.

Must terminate at an adequatedrain.

Must not have any valve between the relief valve and

tank.

Safety Precautions

AWARNING

A gas water heater .cannotoperate properly without the

correct amount of mr for combustion. Do not install in a

confined area such a closet, unless you provide air as

shownin the "Locating The New Water Heater" section.

Never obstruct the flow of ventilation air. If you haveany

doubtsor questionsat all, call your gascompany. Failure

to providethe proper amount of combustionair can result

in a fire or explosion and can cause death, seriousbodily

injury,or property damage.

AWARNING

HOTTER WATER CAN SCALD: Water heaters are

intended to produce hot water. Water heated to a tem-

perature which will satisfyclotheswashing,dish washing

and other sanmzing needs can scald and permanently

injure you uponcontact. Some people are more likely to

be permanently injured by hot water than others. These

includethe elderly,children, the infirm, or physically/men-

tally handicapped.Ifanyone usinghot water in your home

fits into one of these groupsor if there is a local code or

state law requiring a certain temperature water at the hot

water tap, then you must take specialprecautions.In addi-

tion to usingthe lowestpossibletemperature setting that

satisfiesyour hot water needs,a means suchas a mixing

valve, should be used at the hot water taps usedby these

people or at the water heater. Mixingvalvesare available

at plumbing supplyor hardware stores. Follow manufac-

turers instructions for installation of the valves. Before

changingthe factory setting on the thermostat, read the

"Temperature Regulation"sectioninthis manual.

_WARNING

This water heater must not be installed directly on car-

peting. Carpeting must be protected by a metal or wood

panel beneath the appliance extending beyond the full

width and depth of the appliance by at least 3 inches

(76.2mm) in any direction, or if the appliance isinstalled

in an alcoveor closet,the entire floor must becoveredby

the panel. Failure to heed this warning may result in a

fire hazard.

_,WARNING

The power vent water heater requiresits own (separate)

ventingsystem.It cannot be connectedto an existing vent

pipeor chimney.It must beterminated horizontallyto the

outdoors.Failureto properly installthe ventingsystem can

result in asphyxiation, a fire or explosion and can cause

DEATH, SERIOUS BODILY INJURY, OR PROPERTY

DAMAGE.

AWARNING

No vent damper installationis compatible with this power

vented water heater design.No vent damper, whether it is

operated thermally or otherwise is to be installed on this

power vented water heater. Alteration of any part of the

factory-furnished ventassemblycouldresultin improperop-

eration dueto restriction offlue gases,spillageoffluegases

and may causecarbon monoxide poisoning.

_,WARNING

Soot build-up indicates a problem that requires correc-

tion before further use. Turn "off" gas to water heater

and leave"off" until repairs are made, becausefailure to

correct the cause of the sooting can result in a fire or

explosioncausingdeath, seriousbodily injury,or property

damage.

AWARNING

BEFORE LIGHTING [PROPANE (L.R) GAS WATER

HEATERS]: Propane (L.R) gasis heavier than air. Should

there be a leak in the system,the gaswill settle near the

ground. Basements, crawl spaces, skirted areas under

mobile homes (even when ventilated), closets and areas

belowground levelwill serve as pocketsfor the accumula-

tion of this gas. Before attempting to light or relight the

water heater's pilot or turning on a nearbyelectrical light

switch, be absolutely sure there is no accumulated gasin

the are_ Search for odor of gasbysniffingat groundlevel

in the vicinity of the appliance.If odor is detected, follow

stepsindicated at "For Your Safety" on the cover pageof

this manual then leavethe premises.

AWARNING

•The applianceand its individualshutoffvalvemustbe dis-

connectedfrom the gassupplypipingsystemduring any

pressure testing of the gas system at test pressuresin

excessof I/2 pound per squareinch (3.5kPa).

•The appliancemust be isolatedfrom the gas supplypip-

ing system by closingits individualmanual shutoff valve

during any pressuretesting of the gassupplypipingsys-

tem at test pressuresequal or lessthan I/2 pound per

squareinch(3.5kPa).

_,WARNING

Chemical vapor corrosion of the flue and vent system

may occur ifair for combustioncontainscertain chemical

vapors.Spray canpropellants,cleaningsolvents,refHgera.

tor and air conditioner refrigerants, swimming pool

chemicals, calcium and sodium chloride, waxes, bleach,

and processchemicalsare typical compounds which are

potentially corrosive.

AE,WARNING

Obstructed or deteriorated vent systemsmay present a

serious health riskor asphyxiation.

Safety Precautions continued on page 4.

3

Safety Precautions

AWARNING I

The water heater with draft hood installedmust be prop-J

Jerly vented to a chimney which terminates outdoors. I

I Never operate the water heater unlessit is vented to the J

outdoors and has adequate air supply to avoid risks of J

Jimproper operation,explosionor asphyxiation.

AWARNING

Minimum clearancesbetween the water heater and com-

bustibleconstructionare I" at the sidesandroar, 4" at the

front, and 6" from the vent pipe. Clearance from the top

of the jacket is 18" on most models. Note that a lesser

dimension may be allowed on some models. Refer to the

labelon the water heater adjacent to the gascontrol valve

for all cleerance_

_WARNING I

Do not usethis applianceif any part of it hasbeen under J

Jwater. Immediately call a Sears Service Technician to J

inspectthe applianceandto replace the gascontrol or any

part ofthe burner systemwhich hasbeen under water. J

I AWARNING J

Vent termination must not be within 4 feet of any items J

such as gas meters, gas valves or other gas regulating J

equipment. I

ACAUTION

WATER HEATERS EVENTUALLY LEAK: Installation of

the water heater must be accomplishedin sucha manner

that ifthe tank or any connectionsshould leak,the flow of

water will not causedamageto the structure. When such

locations cannot be avoided a suitable drain pan should

be installed under the water heater. Drain pansare aval-

able at your local Sears store. Such a drain pan must be

not greater than I I/2 inches deep, have a minimum

length and width of at least 2 inches greater than the

water heater dimensionsand must be piped to an ade-

quate drain. The pan must not restrict combustion air

flow. Under no circumstances is the manufacturer or

Sears to be held liable for any water damage in connec-

ionwith this water heater.

_E,WARNING

HYDROGEN GAS: Hydrogengascan be producedin a hot

water systemthat has not been usedfor a long period of

time (generally two weeks or more). Hydrogen gas is

extremely flammable and explosive. To prevent the possi-

bility of injury under these conditions,we recommend the

hot water faucet be opened for several minutes at the

kitchen sink before any electrical appliances which are

connectedto the hot water systemare used(suchasa dis-

hwasber or washingmachine). If hydrogengasis present,

there will probably be an unusual sound similar to air

escaping through the pipe as the hot water faucet is

opened. There must be no smoking or open flame near

the faucetat the time it isopen.

AWARNING

INSULATING JACKETS: When installing an external

water heater insulationjacket ona gaswater heater:

DO NOT cover the temperaturo-prossurerolief valve.

DO NOT put insulation over any part of the top of the

gaswater heater.

DO NOT put insulationoverthe gascontrol valve or gas

control valve/burner cover, or any accessareas to the

burner.

DO NOT let insulationaround the gaswater heater to

get within 8 inches of the floor (air must get to the

burner).

• DO NOT cover or remove operating instructions, and

safety related warninglabelsand materials affixedto the

water heater.

Failureto heed thiswill result in the possibilityof a fire or

explosion.

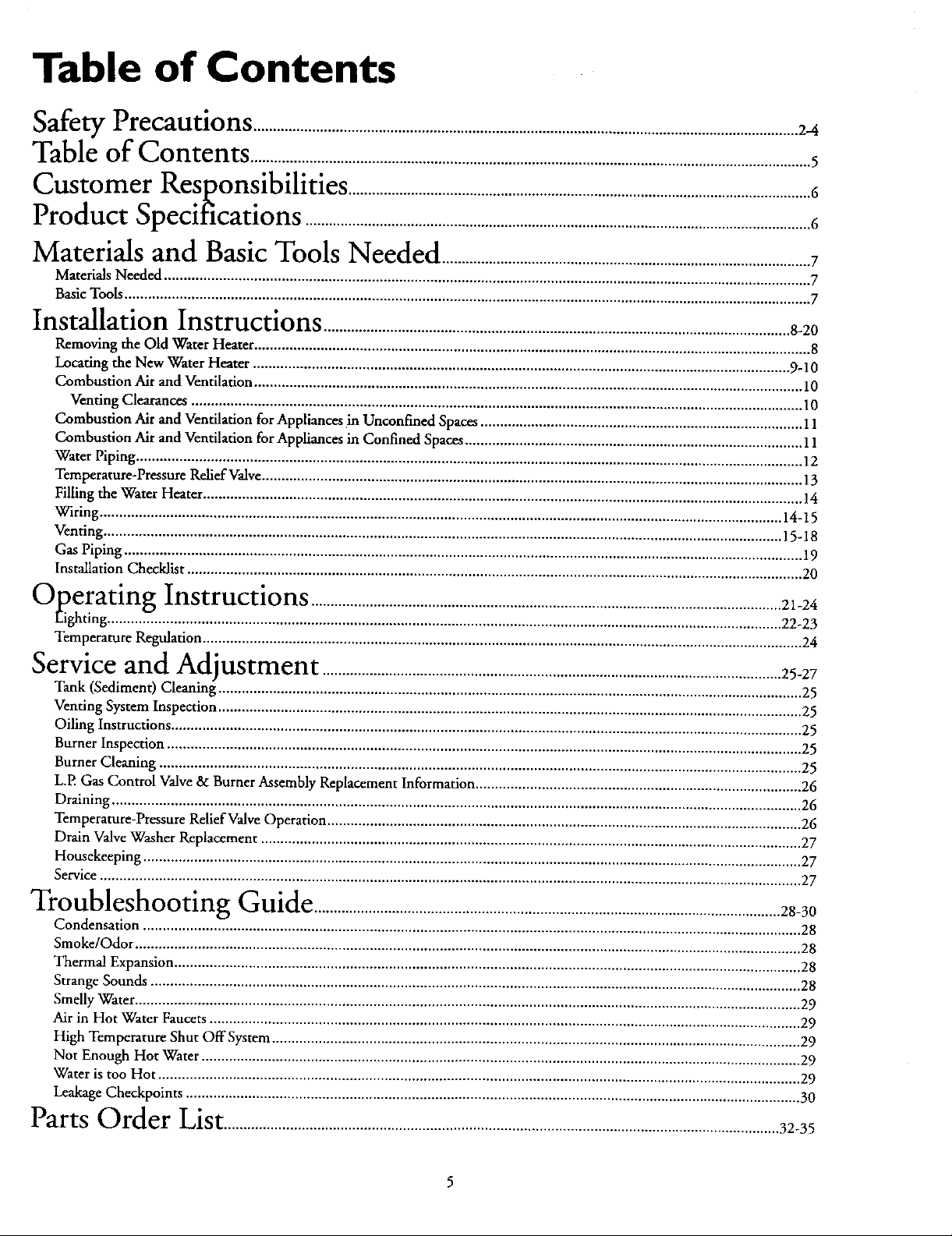

Table of Contents

Safety Precautions ............. 2-4

Table of Contents ................................................................................................................................................5

Customer

Product

l_esponslt_lllUes.......................................................................................................................6

_pecmcauons ..................................................................................................................................6

Materials and Basic Tools Needed ..........................................................................7

Materials Needed ...................................................................................................................................................................... 7

Basic Tools ................................................................................................................................................................................ 7

Installation Instructions ........................................................................................................................8-20

Removing the Old Water Heater ............................................................................................................................................... 8

Locating the New Water Heater .......................................................................................................................................... 9-10

Combustion Air and Ventilation ............................................................................................................................................. 10

Venting Clearances ............................................................................................................................................................. 10

Combustion Air and Ventilation for Appliances jn Unconfined Spaces ................................................................................... 11

Combustion Air and Ventilation for Appliances in Confined Spaces....................................................................................... 11

Water Piping ........................................................................................................................................................................... 12

Temperature-Pressure Relief Valve........................................................................................................................................... 13

Filling the Water Heater .......................................................................................................................................................... 14

Wiring ............................................................................................................................................................................... 14-15

Venting .............................................................................................................................................................................. 15-18

Gas Piping .............................................................................................................................................................................. 19

Installation Checklist .............................................................................................................................................................. 20

"-""Uperatmg Instructions .........................................................................................................................21-24

Eighting ............................................................................................................................................................................. 22-23

Temperature Remalation...

J 0 '...................................................................................................................................................... 24

Service and Adjustment ......................................................................................................................25-27

Tank (Sedimen0 Cleaning ...................................................................................................................................................... 25

Venting System Inspection ...................................................................................................................................................... 25

Oiling Instructions .................................................................................................................................................................. 25

Burner Inspection ................................................................................................................................................................... 25

Burner Cleaning ..................................................................................................................................................................... 25

L.P. Gas Control Valve & Burner Assembly Replacement Information .................................................................................... 26

Draining ................................................................................................................................................................................. 26

Temperature-Pressure Relief Valve Operation .......................................................................................................................... 26

Drain Valve Washer Replacement .................... 97

Housekeeping ......................................................................................................................................................................... 27

Service .................................................................................................................................................................................... 27

"_ 11 ""lrout)Jestiootmg Guide ........................................................................................................................28-30

Condensation ......................................................................................................................................................................... 28

Smoke/Odor ........................................................................................................................................................................... 28

Thermal Expansion ................................................................................................................................................................. 28

Strange Sounds ....................................................................................................................................................................... 28

Smelly Water ........................................................................................................................................................................... 29

Air in Hot Water Faucets ........................................................................................................................................................ 29

High Temperature Shut OffSystem ........................................................................................................................................ 29

Not Enough Hot Water .......................................................................................................................................................... 29

Water is too Hot ..................................................................................................................................................................... 29

Leakage Checkpoints .............................................................................................................................................................. 30

Parts Order List...............................................................................................................................................32-35

Customer Responsibilities

Thank Youfor purchasing a Searswater heater. Properly

installedand maintained, it should give you years of trouble free ser-

vice. If you should decide that you want the new water heater profes-

sionally installed by Sears call the local Sears Service Center or any

Searsstore. They will arrange for prompt, quality installation by Sears

authorizedcontractors.

Abbreviations Found In This Instruction Manual

A.G.A. - American Gas Association

A.N.S.I. - American National Standards Institute

AWARNING

This gas-fired water heater is design certified by the

American Gas Association Laboratories under American

National Standards for Gas Water Heaters. The installa-

tion must conformwith this manual, Local Codes andwith

the latest edition of the National Fuel Gas Code, ANSI

Z223.1.

This publicationisavailablefrom your focal government or

public library, gas company, or by writing NFPA,

Batterymarch Park,Quincy,MA 02269.

• Read the "Safety Precautions" section, pages 2 and 3 of this

manual first and then the entire manual carefully. If you dont

follow the safety rules, the water heater will not operate prop-

erly. It could cause DEATH, SERIOUS BODILY INJURY

AND/OR PROPERTY DAMAGE.

This manual contains instructions for the installation, op_a-

tion, and maintenance of the gas-fired water heater. It also

contains warnings through out t_e manual that you must read

and be aware of. All warnings and all instructions are essential

to the proper operation of the water heater and your safety.

Since we cannot put everything on the first few pages, READ

THE ENTIRE MANUAL BEFORE ATTEMPTING TO

INSTALL OR OPERATE THE WATER HEATER.

The installation must conform with the instructions in this

manual; gas company rules; and Local Codes, or in the

absence of Local Codes, with the latest edition of the National

Fuel Gas code, ANSI Z223.1, also referred to as NFPA 54.

This publication is available from your local government or

public library or gas company or by writing NFPA,

Batterymarch Park, Quincy, MA 02269.

If afterreading this manualyou have any questions or do not

understand any portion of the instructions, call the Sears

Service Center.

Carefully plan the place where you are going to put the water

heater. Correct combustion, vent action, ana vent pipe instal-

lation are very important in preventing death from possible

carbon monoxide poisoning and fires.

Examine the location to ensure the water heater complies with

the "Locating the New Water Heater" section in this manual.

For California installation this water heater must be braced,

anchored, or strapped to avoid falling or moving during an

earthquake. See instructions for correct installation proce-

dures. Instructions may be obtained from your local dealer,

wholesaler, public utilities or California Office of the State

Architect, 400 P Street, Sacramento, CA 95814.

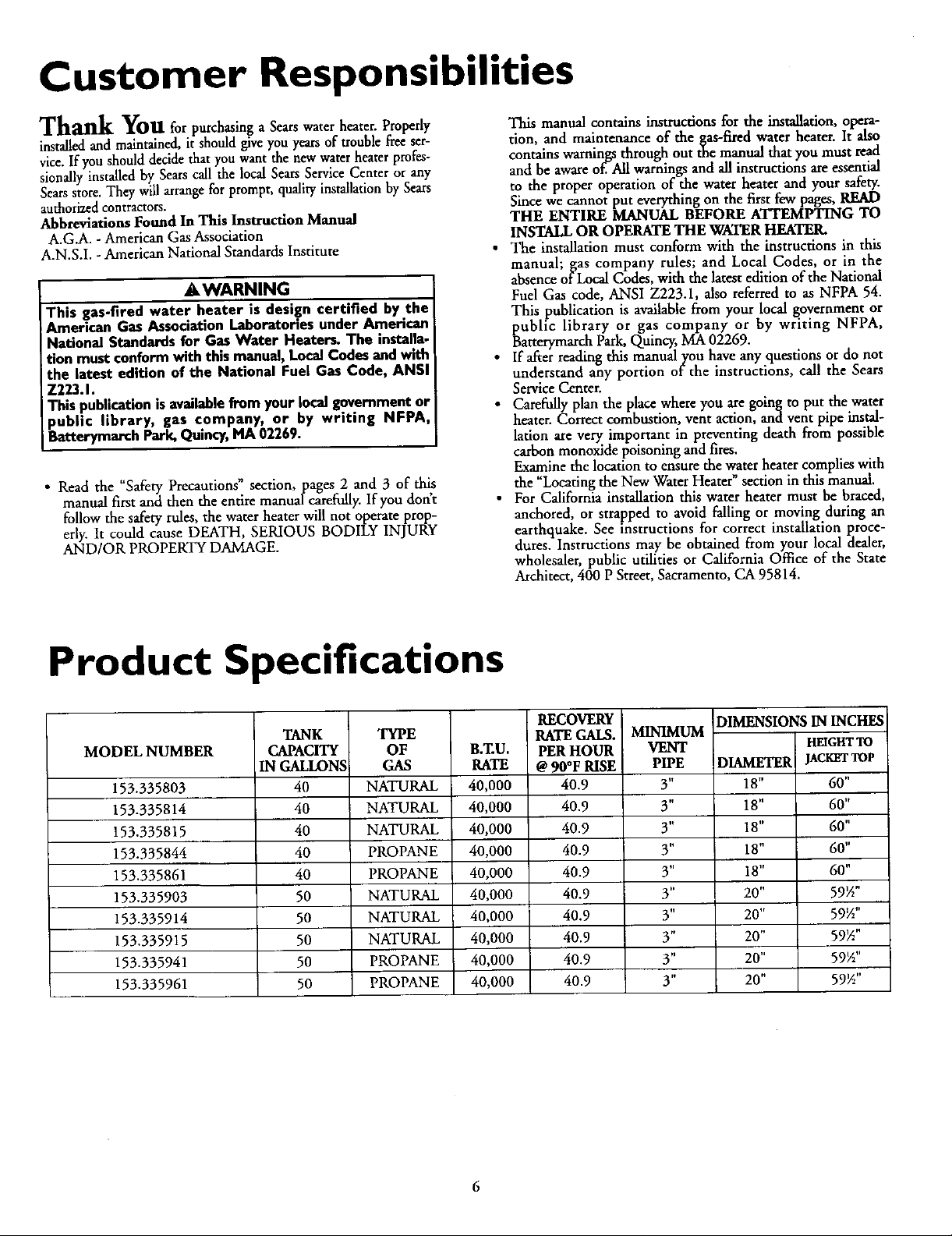

Product Specifications

TYPE

OF

GAS

NATURAL

NATURAL

NATURAL

PROPANE

PROPANE

NATURAL

NATURAL

NATURAL

PROPANE

PROPANE

MODEL NUMBER

153.335803

153.335814

153.335815

153.335844

153.335861

153.335903

153.335914

153.335915

153.335941

153.335961

TANK

CAPACITY

IN GALLONS

40

40

40

40

40

50

50

50

50

50

B.ZU.

RATE

40,000

40,000

40,000

40,000

40,000

40,000

40,000

40,000

40,000

40,000

RECOVERY

RATE GALS.

PER HOUR

@ 90°F RISE

40.9

40.9

40.9

40.9

40.9

40.9

4O.9

40.9

40.9

40.9

MINIMUM

VENT

PIPE

3"

3"

3"

3"

3"

3"

3"

3"

3"

3"

DIMENSIONS IN INCHES

HEIGHT TO

DIAMETER

18"

18"

18"

18"

18"

20"

20"

20"

20"

20"

JACKET TOP

60"

60"

60"

60"

60"

59½"

59½"

59½"

59½"

59½"

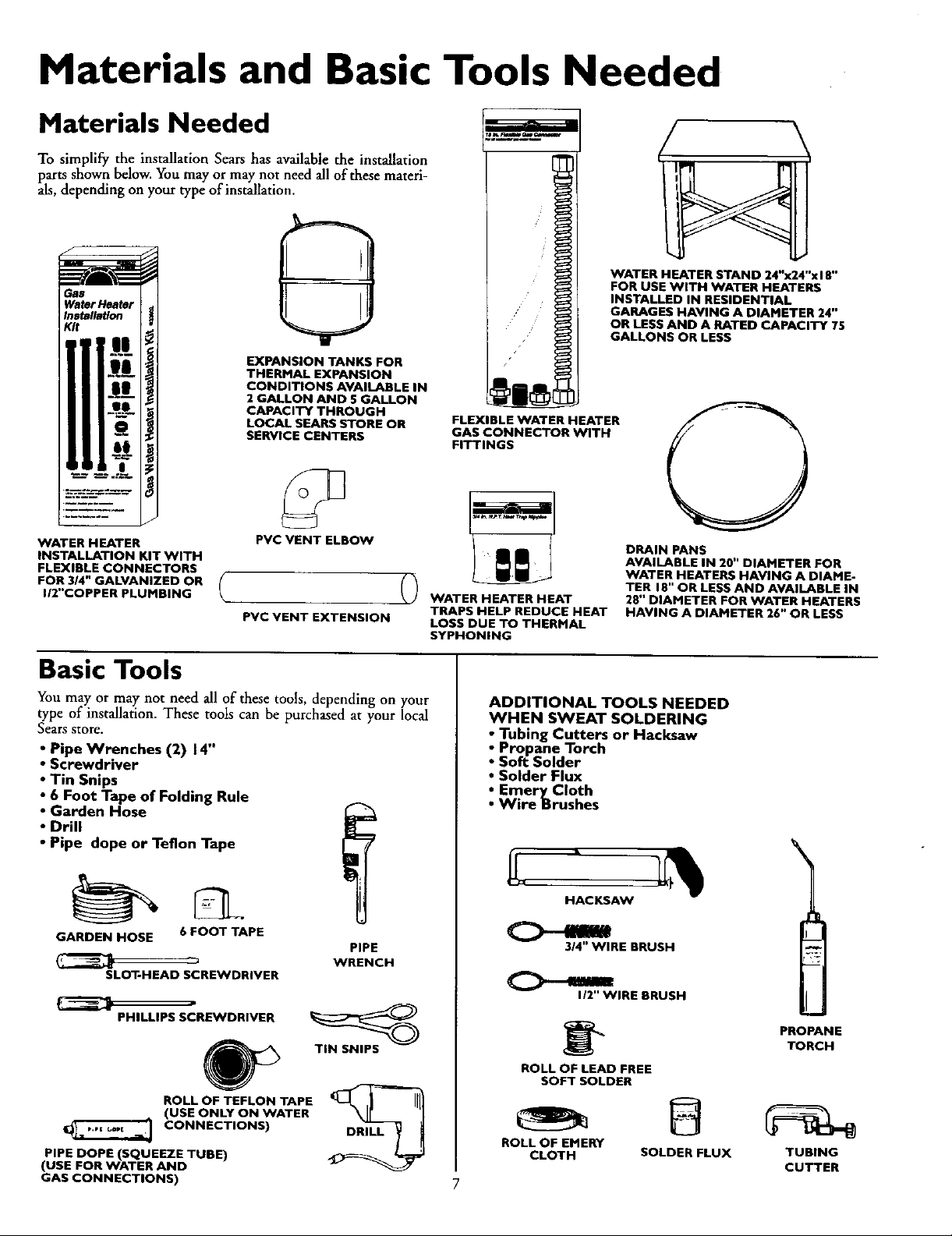

Materials and Basic Tools Needed

Materials Needed

To simplify the installation Sears has available the installation

_larts shown below. You may or may not need all of these materi-

s, depending on your type of installation.

f

WATER HEATER STAND 24"x24"x18"

Gas

Water Heater

Installation

Kit

EXPANSION TANKS FOR

THERMAL EXPANSION

CONDITIONS AVAILABLE IN

2 GALLON AND 5 GALLON

CAPACITY THROUGH

LOCAL SEARS STORE OR

SERVICE CENTERS

/

FLEXIBLE WATER HEATER

GAS CONNECTOR WITH

FITTINGS

FOR USE WITH WATER HEATERS

INSTALLED IN RESIDENTIAL

GARAGES HAVING A DIAMETER 24"

OR LESS AND A RATED CAPACITY 75

GALLONS OR LESS

WATER HEATER

INSTALLATION KIT WITH

FLEXIBLE CONNECTORS

FOR 3/4" GALVANIZED OR

I/2"COPPER PLUMBING

PVC VENT ELBOW

( ()

PVC VENT EXTENSION

Basic Tools

You may or may not need all of these tools, depending on your

type of installation. These tools can be purchased at your local

Sears store.

Pipe Wrenches (2) 14"

Screwdriver

Tin Snips

6 Foot Tape of Folding Rule

Garden Hose

Drill

• Pipe dope or Teflon Tape

GARDEN HOSE 6 FOOT TAPE

SLOT-HEAD SCREWDRIVER

PHILLIPS SCREWDRIVER

ROLL OF TEFLON TAPE

(USE ONLY ON WATER

CONNECTIONS)

PIPE DOPE (SQUEEZE TUBE)

(USE FOR WATER AND

GAS CONNECTIONS)

PIPE

WRENCH

TIN SNIPS

DRILL

WATER HEATER HEAT

TRAPS HELP REDUCE HEAT

LOSS DUE TO THERMAL

SYPHONING

ADDITIONAL TOOLS NEEDED

WHEN SWEAT SOLDERING

Propane Torch

i Tubing Cutters or Hacksaw

Soft Solder

• Solder Flux

_ EmeryCIoth

Wire Brushes

HACKSAW

314" WIRE BRUSH

I/2" WIRE BRUSH

ROLL OF LEAD FREE

SOFT SOLDER

ROLL OF EMERY

CLOTH

7

DRAIN PANS

AVAILABLE IN 20" DIAMETER FOR

WATER HEATERS HAVING A DIAME-

TER 18" OR LESS AND AVAILABLE IN

28" DIAMETER FOR WATER HEATERS

HAVING A DIAMETER 26" OR LESS

PROPANE

TORCH

SOLDER FLUX

TUBING

CUTTER

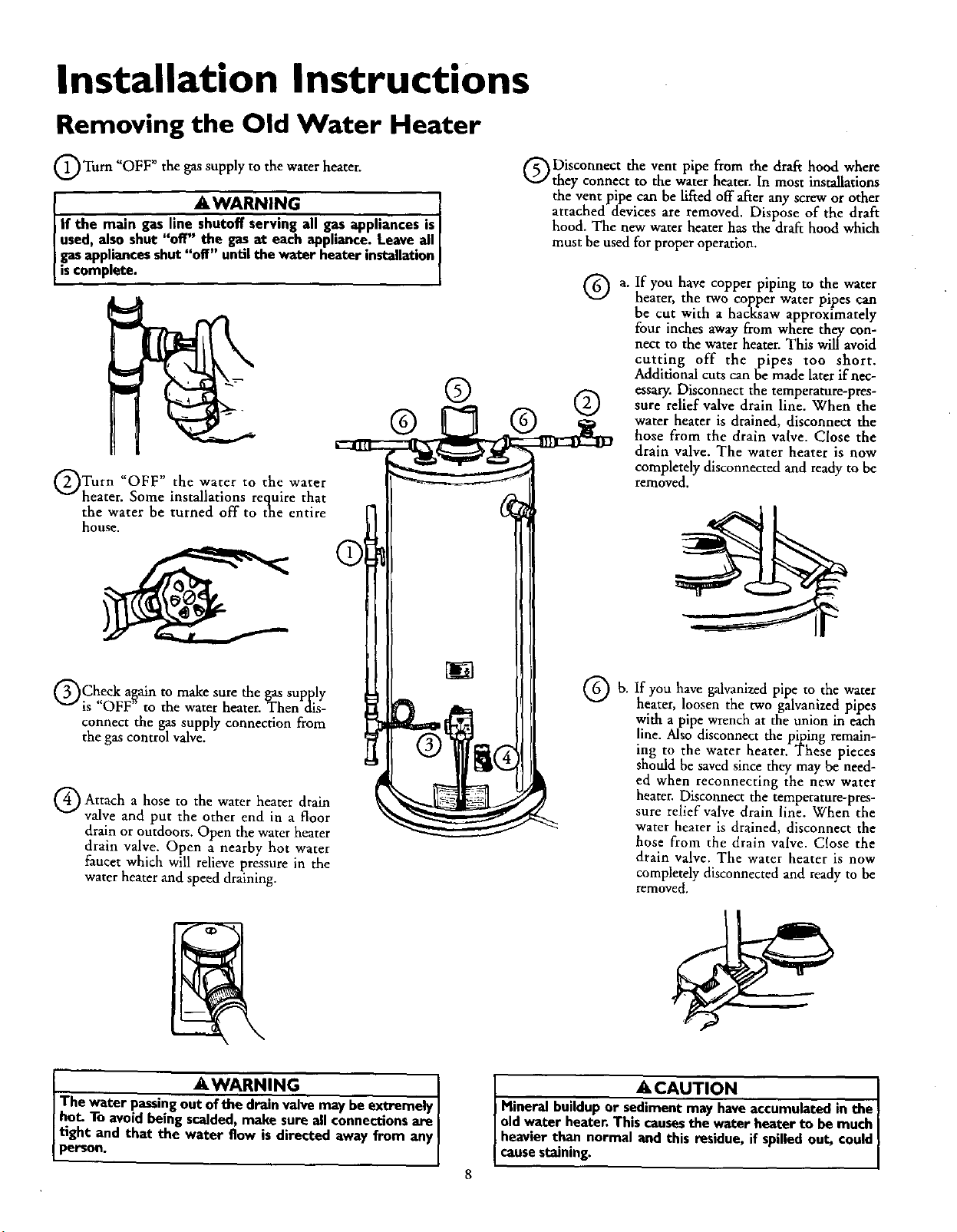

Installation Instructions

Removing the Old Water Heater

Q Turn "OFF" the gas supply to the water heater.

AWARN,. 1

If the main gas line--all gas appliances isl

used, also shut "off" the gas at each appliance. Leave all [

gas appliances shut "off" until the water heater installation I

iscomplete, l

OTurn water to water

_OWP _9 the the

heater. Some installations requite that

the water be turned off to the entire

house,

Q Disconnect the vent pipe from the draft hood where

they connect to the water heater. In most installations

the vent pipe can be lifted off after any screw or other

attached devices are removed. Dispose of the draft

hood. The new water heater has the draft hood which

must be used for proper operation.

G a. If you have copper piping to the water

® ®

heater, the two copper water pipes can

be cut with a hacksaw approximately

four inches away from where they con-

nect to the water heater. This will avoid

cutting off the pipes too short.

Additional cuts can be made later if nec-

essary. Disconnect the temperature-pres-

sure relief valve drain line. When the

water heater is drained, disconnect the

hose from the drain valve. Close the

drain valve. The water heater is now

completely disconnected and ready to be

removed.

QCheck again to make sure the gas supply

is "OFF" to the water heater. Then dis-

connect the gas supply connection from

the gas control valve.

Q Attach a to water heater drain

hose the

valve and put the other end in a floor

drain or outdoors. Open the water heater

drain valve. Open a nearby hot water

faucet which will relieve pressure in the

water heater and speed draining.

...... AWARNING I

The water passingout of the drainvalve may be extremely I

hot. To avoidbeingscalded,make sureall connectionsare [

[ tight and that the water flow is directed away from anyI

I pers°n" I

If you have galvanized pipe to the water

heater, loosen the two galvanized pipes

with a pipe wrench at the union in each

line. Also disconnect the piping remain-

ing to the water heater. These pieces

should be saved since they may be need-

ed when reconnecting the new water

heater. Disconnect the temperature-pres-

sure relief valve drain line. When the

water heater is drained, disconnect the

hose from the drain valve. Close the

drain valve. The water heater is now

completely disconnected and ready to be

removed.

ACAUTION I

Mineral buildupor sedimentmay haveaccumulatedin the }

oldwater heater.Thiscausesthe water heater to be much I

heavier than normal and this residue, if spilledout, could

causestaining.

Installation Instructions

Locating the New Water

Heater

You should carefully choose an indoor location for the new water

heater, because the placement is a very important consideration

for the safety of the occupants in the building and for the most

economical use of the appliance. This water heater is not for

use in mobile homes or outdoor installation.

Whether replacing an old water heater or putting the water

heater in a new location, the following critical points must be

observed.

1. The location selected should be indoors as dose as practical

to the vent termination point, and as centralized with the

water piping system as possible. The water heater, as all water

heaters, will eventually leak. Do not install without adequate

drainage provisions where water flow will cause damage.

2. The vent piping cannot exceed a total of 35 feet including

vertical and horizontal runs and have no more than 3 elbows.

It cannot slope downward and horizontal runs require ¼" per

foot rise. All horizontal runs require adequate support at 3½

feet intervals.

3. The water heater requires its own (separate) venting system.

It cannot be connected to an existing ventpipe or chimney.

It must terminate horizontally to the outdoors. Whenever

possible terminate the vent on the leaward side of the build-

ing. NOTE: Condensation may be created, at times, as the

combustion gases exit the vent cap and discoloration of

surfaces in proximity to the vent cap may occur.

AWARNING

Thepowerventwater heaterrequiresitsown(separate)venting

system.It cannotbe connectedto an existingventpipeor chim-

ney.It mustbeterminatedhorizontallyto theoutdoors.Failureto

properlyinstallt_ ventingsystemcanresultinasphyxiation,aEre

orexplosionandcancauseDEATH,SERIOUSBODILYINJURY,

ORPROPERTYDAMAGE.

4. The water laeater comes equipped with a 5 foot power cord

which can be used to connect to a 110/120 volt power

source if (1) local codes allow, and (2) there is a three prong

receptacle available.

5. The location selection must provide adequate clearances for

servicing and proper operation of the water heater.

AWARNING

INSTALLATIONSIN AREASWHERE FLAMMABLELIQUIDS

(VAPORS) ARE LIKELY TO BE PRESENT OR STORED

GARAGES, STORAGE, AND UTILITY AREAS, ETC):

Flammableliquids(suchasgasoline,solvents,propane(LP) or

butane, etc.), all of which emit flammable vapors,may be

improperlystoredor usedin sucharea_The gaswaterheater

)notlightor mainburnercanignitesuchvapor_The resulting

8ashbeckandfirecancausedeathor seriousburnste anyonein

thearea,aswellaspropertydamage.

If installationinsuchareasisyouronlyoption,thenthe instana-

tion must be accomplished in a waythat the pilotflame and

mainburnerflameareelevatedfromtheBoorat least18inches.

While this mayreducethe changesofflammable vaporsfroma

floor spillbeingignited,gasolineandother8ammablesubstances

shouldneverbe storedor usedinthe sameroom or areacon-

taininga gaswater heaterorotheropen8ameor sparkpnxluc-

ingappliance.

NOTE: Flammablevaporsmaybe drawnbyair currentsfrom

otherareasof thestngtoreto the appliance.

AWARNING

Propellantsof aerosol spraysand volatilecompounds,(ci_m-

ers,chlorinebasedchemicals,refrigerants,etc.) in additionto

being highlyflammableinmanycases,will also changeto cor-

rusive hydrochloricacid when exposedto the combustion

productsofthe water heater.The resultscanbe hazardous

and alsocauseproductfailure.

AWARNING

This water heater must not be installeddirectlyon carpeting.

Carpeting must be protected by a metal or wood panel

beneaththe appliance extending beyondthe full width and

depthof the appliance byat least3 inches(76.2mm) in an)

direction,or if the applianceis installedin an alcoveor closet

the entirefloor mustbe coveredbythe panel.Failureto bee<

this warningmayresult inaErehazard.

AWARNING ]

Do not usean extensioncord.Iftbereisnot a suitablerecepta-

cleand/or localcodesprohibituseofa powercord,fieldwiringI

mustbeprovided. I

ACAUTION

WATER HEATERSEVENTUALLY LEAK:Installationof the

water heater must be accomplished in such a manner that if

the tank or any connectionsshouldleak,the flow of water

will not causedamageto thestructure. When suchlocations

cannotbe avoided,a suitabledrain pan should be installed

under the water heater. Drain pans are available at your

localSearsstore.Sucha drainpan musthe not greater than

1½inchesdeep,havea minimumlengthand widthofat least

2 inchesgreaterthan the water heater dimensionsandmust

be piped to an adequate drain. The pan must not restrict

combustionair flow.Under no circumstancesisthe manu-

facturer or Searsto be held liablefor any water damage in

connectionwith thiswater heater.

AWARNING

Minimum clearancesbetween the water heater and c_m-

bustibleconstructionare I" at the sidesand rear,4" at the

front,and6" fromthe ventpipe.Clearancefromthe topof the

jacketis18"on mostmodelgNote that alesserdimensionmay

be allowedon some models Referto the labelon the water

heateradjacentto the gascontrolvalveforall clearance_

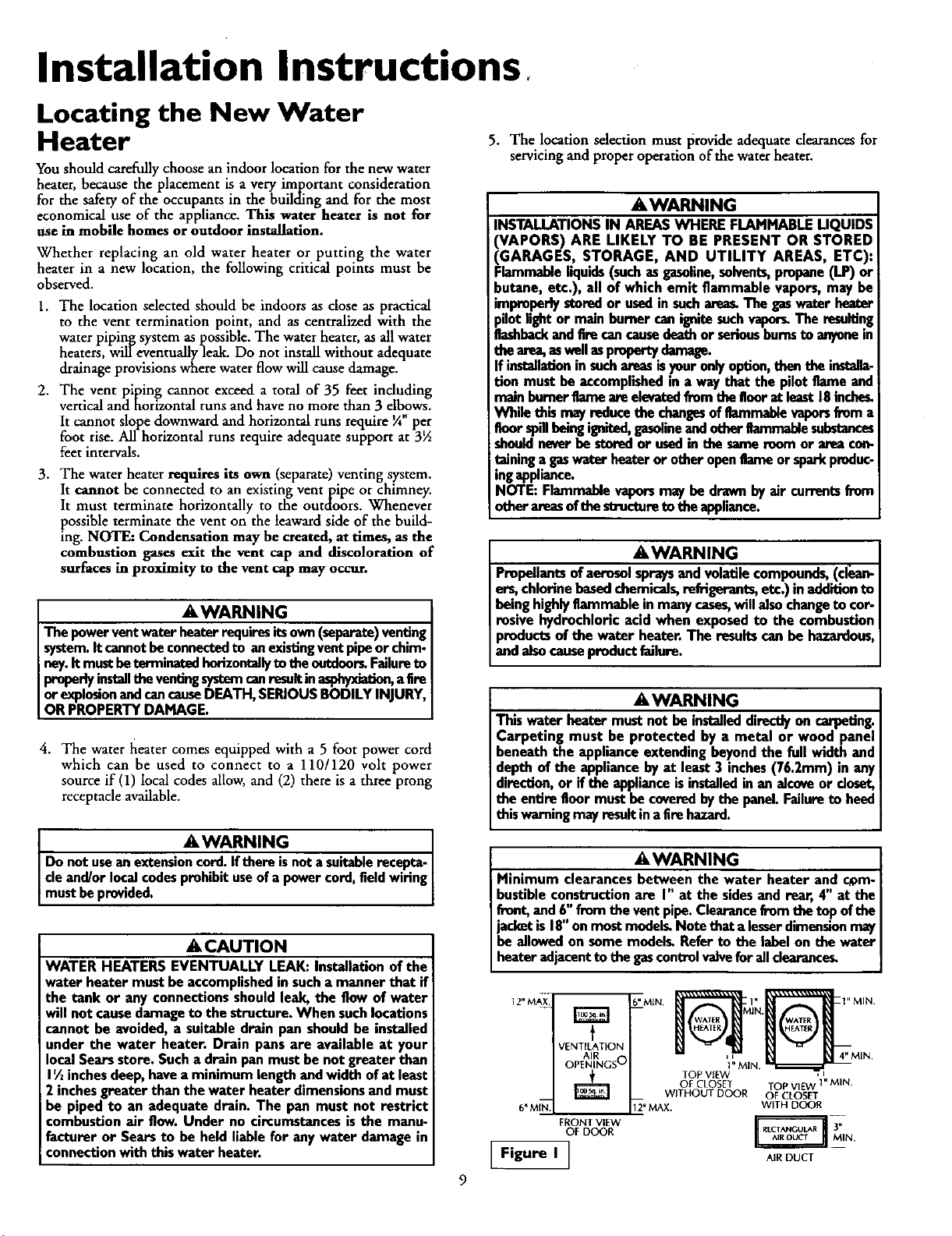

VENTILATION

AIR O

OPENINGS

[# MIN.

FRONT VIEW

OF DOOR

[F,g°.I]

6" MIN. _l}t IjIN" 1" MIN

TOP VIEW ,

OF CLOSET TOP VIE_CV1" MIN.

WITHOUT DOOR OF CLOSET

i_" MAX. WITH DOOR

_l 41"MIN.

AIR DuCT

Installation Instructions (cont'd)

_,WARNING

A gaswnt_ heater cannotoperateproperlywithoutthe cor-

rectamountof air for combustion.Do not im_dl in a confined

area sucha closet, unlessyou provide air as shown in the

"Locating The New Water Heater" section.Never obstruct

theflowofventgationair.Ifyouhaveanydoubtsor questionsat

all, call your gascompany. Failure to provide the proper

amountof combustionair can resultin a fire or explosionand

cancausedeath,seriousbodilyinjury,or propertydamage.

AWARNING

If this water heater will be used in beauty shops,barber shops,

cleaning establishments, or self-service laundries with dry

deaning equipment, it is imperative that the water heater or

water heaters be installed so that combustion and vent_latlou

air be taken from outside these area_ Refer to the "Locating

The New Water Heater" section of this manual and also the

latest edition ofthe National Fuel Gas Code, ANSI Z223.1, also

referred to as NFPA 54 for specifics provided €oncerning air

required,

Combustion Air and Ventilation

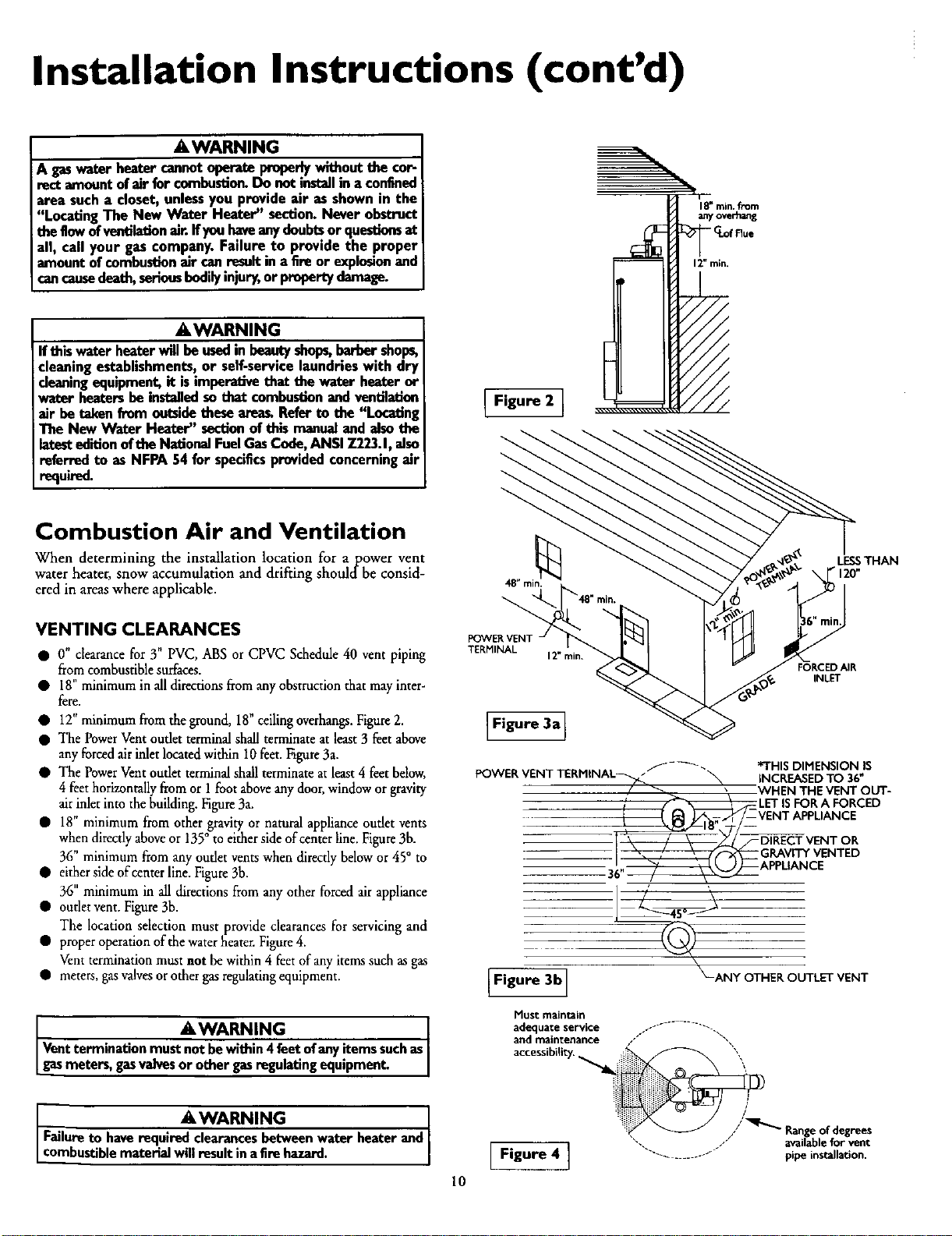

Figure 2 I

When determining the installation location for apower vent

water heater, snow accumulation and drifting shouldbe consid-

ered in areas where applicable.

VENTING CLEARANCES

• O" clearance for 3" PVC, ABS or CPVC Schedule 40 vent piping

from combustible surfaces.

• 18" minimumin alldirections from any obstruction that mayinter-

fere.

• 12" minimum from the ground, 18" ceiling overhangs.Figure 2.

• The Power Vent oudet terminal shall terminate at least 3 feet above

any forced airinlet located within 10 feet. Figure 3a.

• The Power Vent outlet terminal shall terminate at least 4 feet below,

4 feet hofizontaUy from or I foot above any door, window or gravity

air inlet into the building. Figure 3a.

• 18" minimum from other gravity or natural appliance oudet vents

• either side of center line. Figure 3b.

• outlet vent. Figure 3b.

• proper operationofthewaterheater. Figure4.

• meters, gasvalves or other gas regulating equipment•

Vent termination must not be within 4feet of any items such as

gasmeters, gasvalves or other gasregulating equipment.

• o. , , , ,

when direcdy above or 135 to either side of center hne. Figure 3b.

36" minimum from any outlet vents when directly below or 45° to

36" minimum in all directions from any other forced air appliance

The location selection must provide clearances for servicing and

Vent termination must not be within 4 feet of any items such as gas

a_ WARNING

LESSTHAN

• 120"

POWER VENT

TERMINAL

12" rain.

FORCED AIR

INLET

Figure 3a]

POWERVENTTERMINAL_ _ INCREASEDTO 36"

7_[ \\ / \ _/_VENTOR

f-_ *THISDIMENSIONIS

/ _ _ WHEN THEVENTOUT-

,' [_ LETISFORA FORCED

_/-- VENTAPPLIANCE

GRAVITYVENTED

; i APPL,ANCE

I Figure 3b I

Must main_Jn

adequate service --- ......... ".

arid maiRtenance ///" "',

_-ANY OTHER OUTLET VENT

AWARNING

I Failure to have required clearances between water beater and

Lcombustible material will result in a fire hazard.

// Rangeofdegrees

".. /" availableforvent

[ Figure 4 ] .................. pipeinstallation.

10

Installation Instructions (cont'd)

Combustion Air and Ventilation

for Appliances Located in

Unconfined Spaces

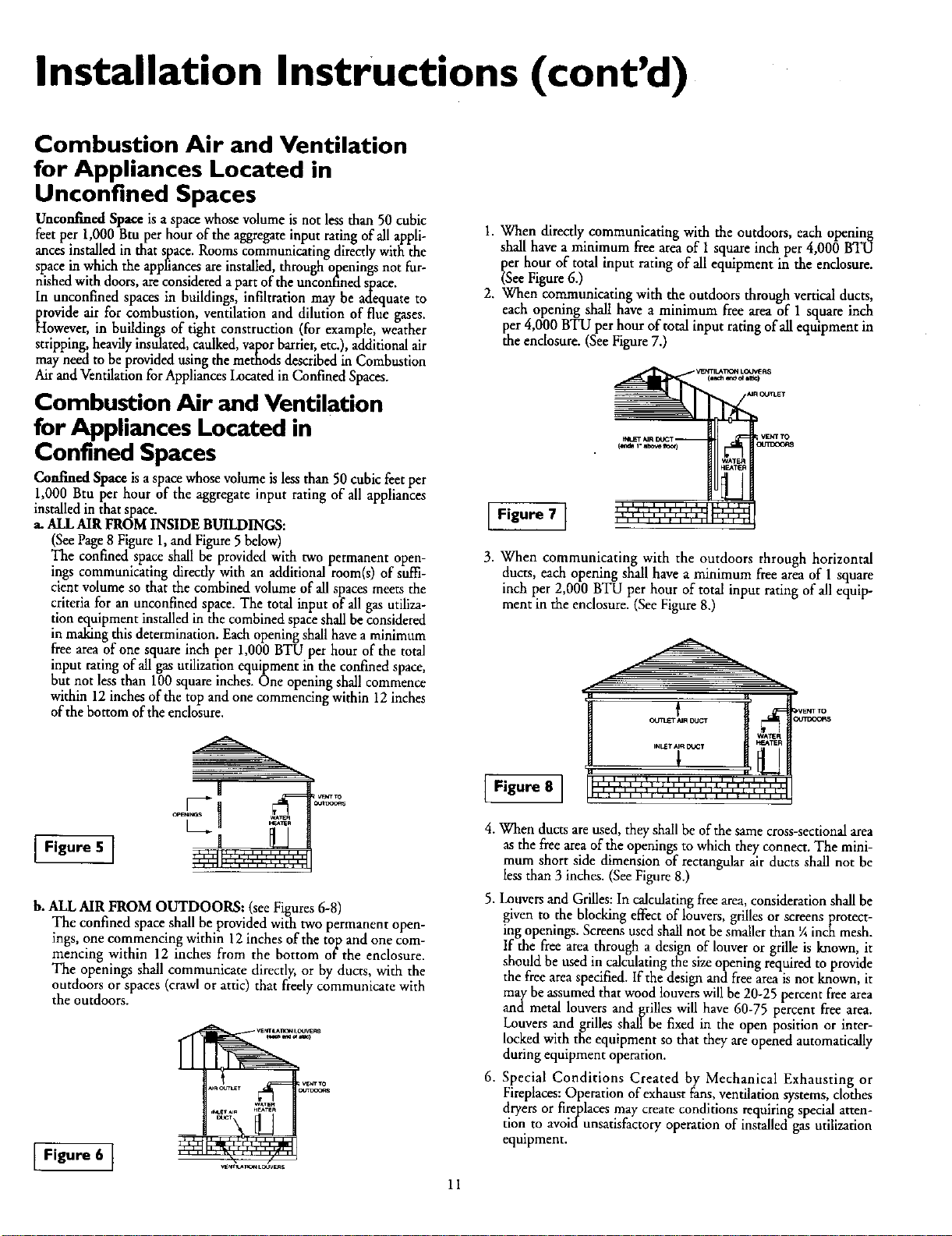

Unconfined Space is a spacewhose volume is not lessthan 50 cubic

feet per 1,000 Btu per hour of the aggregateinput rating of allappli-

ances installed in that space. Rooms communicating directly with the

space in which the appliancesareinstalled, through openingsnot fur-

nishedwith doors, areconsidereda part of the unconfined space.

In unconfined spaces in buildings, infiltration may be adequate to

provide air for combustion, ventilation and dilution of flue gases.

However, in buildings of tight construction (for example, weather

stripping, heavilyinsulated, caulked, vapor barrier, etc.), additionalair

may need to be provided using the methods describedin Combustion

Air and Ventilation for Appliances Locatedin Confined Spaces.

Combustion Air and Ventilation

1. When directly communicating with the outdoors, each opening

shall have a minimum free area of 1square inch per 4,000 BTU

per hour of total input rating of all equipment in the enclosure.

(SeeFigure6.)

2. When communicating with the outdoorsthrough vertical ducts,

each opening shall have a minimum free areaof I square inch

per 4,000 BTU per hour of total input rating of allequipment in

the enclosure. (SeeFigure7.)

VENTILAT_ LO_I:_

for Appliances Located in

Confined Spaces

Confined Space is a space whose volume is less than 50 cubic feet per

1,000 Btu per hour of the aggregate input rating of all appliances

installed in that space.

a. ALL AIR FROM INSIDE BUILDINGS:

(See Page 8 Figure 1, and Figure 5 below)

The confined space shall be provided with two permanent open-

ings communicating directly with an additional room(s) of suffi-

cient volume so that the combined volume of all spaces meets the

criteria for an unconfined space. The total input of all gas utiliza-

tion equipment installed in the combined space shall be considered

in making this determination. Each opening shall have a minimum

free area of one square inch per 1,000 BTU per hour of the total

input rating of all gas utilization equipment in the confined space,

but not less than 100 square inches. One opening shall commence

within 12 inches of the top and one commencing within 12 inches

of the bottom of the enclosure.

I Figure 5 [

b. ALL AIR FROM OUTDOORS: (see Figures 6-8)

The confined space shall be provided with two permanent open-

ings, one commencing within 12 inches of the top and one com-

mencing within 12 inches from the bottom orthe enclosure.

The openings shall communicate directly, or by ducts, with the

outdoors or spaces (crawl or attic) that freely communicate with

the outdoors.

Figure 6 1

VENT TO

]O_O0_SIr_=T AIR DOfff

I Figure 7 ]

,,,,,,,,,,,,,,,,A,,,I

3. When communicating with the outdoors through horizontal

ducts, each openingshall have a minimum free area of 1 square

inch per 2,000 BTU per hour of total input rating of all equip-

ment in the enclosure. (SeeFigure8.)

Figure 8 1

4. When ducts are used, they shall be of the same cross-sectional area

as the free area of the openings to which they connect. The mini-

mum short side dimension of rectangular air ducts shall nor be

less than 3 inches. (See Figure 8.)

5. Louvers and Grilles: In calculating free area, consideration shall be

given to the blocking effect of louvers, grilles or screens protect-

ing openings. Screens used shall not be smaller than ¼ inch mesh.

If the free area through a design of louver or grille is known, it

should be used in calculating the size opening required to provide

the free area specified. If the design and free area is not known, it

may be assumed that wood louvers will be 20-25 percent free area

and metal louvers and _rilles will have 60-75 percent free area.

Louvers and .grilles shall be fixed in the open position or inter-

locked with the equipment so that they are opened automatically

during equipment operation.

6. Special Conditions Created b7 Mechanical Exhausting or

Fireplaces: Operation of exhaust fans, ventilation systems, clothes

dryers or firefplaces may create conditions requiring special atten-

tion to avoica unsarisfactory operation of installed gas utilization

eqmpment.

11

CEt4T TO

_LrrlxX;_$

Installation Instructions (cont'd)

Water Piping

AWARNING

HOTTER WATER CAN SCAL_. Water heaters are intended to

produce hot water. Water heated to a temperatu_ which will

satisfyclothes washing, dish washing,and other sanitizing needs

can scaldand pen_anently injure you upon contact, Some peo-

de a_e more like/y to be permanently injured by hot water (_w1n

other_ These indude the elder_, children, the infirm, or physicak

ly/mentally handicapped.If anyone usinghot water in your home

Etsinto one ofthese groupsor if thore isa local code or state law

_ ac_ain _ra_rau_ wat_- at the hot wa_erta_ th_

_u must take spechl preca_on_ In addition to using the

possibletemperatu_ settingthat satisfiesyour hot water needs,

l ameans such asa mixing valve, shouldbe used at the hot water

taps usedby these people or at the water heote_.Mbdng valves

are availableat plumbing supplyor hardware store_ Follow man-

ufacturers instructions for installation of the valves. Before

changing the factory setting on the thermostat, read the

'_remperatore Regulation" sectionin this manual

This water heater shall not be connected to any heating systems

or component(s) used with a non-potable water heating appli-

ance.

If a water heater is installed in a closed water supply system;

such as one having a back-flow preventer, check valve, water

meter with a check valve, etc.., in the cold water supply; means

shall be provided to control thermal expansion. Contact the

local utility or local Sears Service Center on how to control this

situation.

NOTE: To protect against untimely corrosion of hot and

cold water fittings, it is strongly recommended that didec-

tric unions or couplings be installed on this water heater

when connected to copper pope.

2. Look at the top cover of the water heater. The cold water

inlet is markedcold. Put two or three turns of teflon tape

around the threaded end of _e threaded-to-swear coupling

and around both ends of the ¾ threaded nipple. Using flexi-

ble connectors, connect the cold water pipe to the coldwater

inlet of the water heater.

NOTE: This water heater is insulated to minimize heat

loss from the tank. Further reduction in heat loss can be

accomplished by insulating the hot water lines from the

water heater.

INSTALLATION COMPLETED USING

SEARS INSTALLATION KIT

COLD INLET

WATER LINE

3/4"THREADED

NIPPLE

TEMPERATURE-

PRESSURERELIEF

VALVE

THREADED TO

SVVEATCOUPLING

HOT OUTLET

TO HOUSE

NIPPLE

THREADED TO SHUTOFF

SVVEATCOUPUNG VALVE

The illustration shows the attachment of the water piping to the

water heater. The water heater is equipped with 3/4inch water

connections.

NOTE: If using copper tubing, solder tubing to an adapter

before attaching the adapter to the cold water inlet connec-

tion. Do not solder the cold water supply line directly to the

cold water inlet or it will harm the dip tube.

1. Look at the top cover of the water heater. The hot water outlet is

marked hot. Put two or three turns of teflon tape around the

threaded end of the threaded-to-sweat coupling and around both

ends of the ¾" threaded nipple. Using flexible connectors, con-

nect the hot water pipe to the hot water outlet on the water

heater.

DISCHARGE PIPE

(Do not capor plug)

PROVIDE A 6" AIR

GAP BETWEEN THE

END OF THE

DISCHARGE PIPE

AND DRAIN

12

Installation Instructions (cont'd)

Temperature-Pressure Relief Valve

AWARNING

At the time of manufacturethiswater heaterwas provided

witha combinationtemperature-pressuresreliefvalvecertified

bya nationallyrecognized testinglaboratory that maintains

periodicinspec_onof productionof listedequipmentormate-

rials, as meeting the requirements for Relief Valves and

AutomaticGasShutoffDevicesfurHot Water SupplySystems,

and the latesteditionof ANSI Z21.22and the coderequire-

mentsofASME.If replaced,the valvemust meet the _luire-

mentsoflocalcedes,butnotlessthan acombinationtempera-

ture and pressurerelief valvecertifiedasmeetingthe require-

meritsfur ReliefValvesandAutomaticGasShutoffDevicesfor

Hot Water SupplySystems,ANSI 7.21.22bya nationallyrecog-

nizedtestinglaboratorythat maintainsperiodicinspectionof

productionoflistedequipment or materials

The valvemustbe markedwith a maximumsetpressurenot

to exceedthe marked hydrostaticworking pressureof the

water heater(150IbsJsq.in.) anda dischargecapacitynot less

than the water heaterinputrate asshownonthe modelrating

plate.(Electricheaters- watts dividedby 1000x 3415 equal

BTU/Hr.rate.)

Yourlocaljurisdictionalauthority,whilemandatingthe useofa

temperature-pressurereliefvaivecomplyingwithANSI Z21.22

andASME,may require a valvemodel differentfromthe one

furnishedwiththe water heater.

Compliancewith suchlocalrequirementsmustbe satisfiedby

the installeror end userofthe waterheaterwith a locallypre-

scribedtemperature-pressurerelief valveinstalledin the desig-

nated openinginthe water heater in placeofthe factory fur-

nishedvalve.

Forsafeoperationofthe water heater,the reliefvalvemustnot

beremovedfromit'sdesignatedopeningor plugged.

Thetemperature-pressurerelief valvemustbe installeddirectly

intothe fittingofthewaterheaterdesignatedforthe reliefvalve.

Positionthe valvedownwardandprovidetubingsothat anydis-

chargewill exit onlywithin6 inchesabove,or at any distance

belowthe structuralfloor.Be certainthat no contactismade

withanyliveelectricalpart.The dischargeopeningmustnotbe

blockedor reduced in sizeunderany circumstancesExcessive

length,over30feet,or useofmorethan fourelbowscancause

restrictionandreducethedischargecapacityofthevalve.

No valveor otherobstructionisto be placedbetweenthe relief

valveandthe tank.Do not connecttubing directlyto discharge

drainunlessa 6"air gapisprovided.Topreventbodilyinjury,haz-

ardto life,or propertydamage,the relief valvemustbeallowed

todischargewaterinquantitiesshouldcircumstancesdemand.If

the dischargepipeisnot connectedto a drainor othersuitable

means,thewaterflowmaycausepropertydamage.

The DischargePipe:

• Mustnot be smaiierin sizethan the outletpipesizeof the

valve,or haveanyreducingcouplingsor otherrestrictions.

• Mustnot bepluggedor blocked.

• Mustbeof materiallistedforhotwaterdistribution.

• Mustbe installedsoas to allowcompletedrainageof both

the temperature-pressurerelief valve, andthe discharge

pipe.

• Mustterminateat anadequatedrain.

• Mustnothaveanyvalvebetweenthe relief valveandtank.

AWARNING

The temperature-pressure relief valve must be manually

operated at least once a _ Cautionshouldbe taken to

ensurethat (I) no one isin frontof or aroundthe outiot of

the temperature-pressure relief valvedischargeI'me,and (2)

the water manually dischargedwill not causeany bodily

mjury or property damage because the water may be

ex_mely hot.

If after manuallyoper_Jng the valve, it fails to completely

resetand continuesto releasewater,immediatelyclosethe

cold water inlet to the water heater, follow the draining

instructions,and replace the temperatore-preasure relief

valvewitha new one.

TEMPERATURE-PRESSURE

RFJJEF VALVE

HOT

(Do not cap or plug)

PROVIDE A 6" AIR

GAP BETWEEN

THE END OF THE

DISCHARGE PIPE

AND DRAIN

RELIEFVALVEOPENING

At the time of manufacture, this water heater wasprovided with a cornbinadontern-

perature-pressurerelief valve listedas complyingwith the standardfor relief valvesand

automatic gas shut-off devices for hot water supplysystems, ANSI Z21.22. For safe

operation of the water heater,the relief valvemust not be removed from its designated

point of installationor plugged.

Your local jurisdictional authority,while mandating the use of a temperature-pressure

relief valve complyingwith ANSI Z21.22 and ASME, mayrequire a valvemodel different

from the one furnishedwith the water heart.

Compliancewith such local requirementsmust be satisfied by the installeror end user

of the water heater with a locally prescribedtemperature-pressure relief valveinstalled

inthe designated openingin the water heater.

See manual heading-"Temperature-Pressure Relief Vahres"for installationand mainte-

nanceof relief valve, dischargeline,and other safetyprecautions.

13

Installation Instructions (cont'd)

Filling the Water Heater

You must provide all wiring of the proper size outside of the

ACAUTION

Never usethiswater heater unlessit iscompletelyElledwith

water,To preventdamageto the tank, thetankmustbeElled

with water. Water must flow from the hot water faucet

beforeturning"ON" gasto the water heater,

water heater. You must obey local codes and electric company

requirements when you install this wiring.

Ifyou are not familiar with electric codes and practices, or ifyou

have any doubt, even the slightest doubt, in your ability to con-

nect the wiring to this water heater, obtain the service of a com-

petent electrician or contact your local electric utility.

To fill the water heater with water:

Close the water heater drain valve by turning the handle to

the right (clockwise). The drain valve is on the lower front of

the water heater.

• Open the cold water supply valve to the water heater.

NOTE: The cold water supply valve must be left open

when the water heater is in use.

• To insure complete filling of the tank, allow air to exit by

opening the nearest hot water faucet. Allow water to run

until a constant flow is obtained. This will let air out of the

water heater and the piping.

• Check allnew water piping for leaks. Repair as needed.

Wiring

USE WITH POWER CORD

The water heater comes equipped with a 5 foot power cord

which can be used to connect to a 110/120 volt power source if,

(1) local codes allow, and (2) there is a three prong receptacle

available.

\

\

\

\

\

\

\

\

\

\

\

5' MAXIMUM

CORD LENGTH

(Factorysupplied)

AWARNING

WATER HEATERSEQUIPPED FOR ONE TYPE VOLTAGE

ONLY:Thiswaterheaterisequippedfor 1101120voltsonly.DO

NOT USE THIS WATER HEATERWITH ANY VOLTAGE

OTHERTHAN THE ONE SHOWN ABOVE.Failuretousethe

correctvoltagecancauseproblemswhichcanresultinDEATH,

SERIOUSBODILY INJURYOR PROPERTYDAMAGE.If you

havenayquestionsor doubtsconsultyour electriccompany.

A CAUTION

If wiring from the fusebox or circuitbreaker box was alu-

minumfor the oldwater heater,replace it with copperwire.

If you wishto reuse the existing aluminum wire, havethe

connectionat the water heater made by a competent elec-

trician.Contacta localelectrical contractorand/orthe local

electricutility.

USE WITHOUT POWER CORD

If power cord cannot be used, then follow these wiring instruc-

tions.

1. Provide a way to easily shut off the electric power when work-

ing on the water heater. This could be with a circuit breaker

or fuse block in the entrance box or a separate disconnect

switch.

2. Install and connect a circuit directly from the main fuse or

circuit breaker box. This circuit must be the right size and

have its own fuse or circuit breaker.

\

\

\

You must provide all wiring, (1) to a receptacle or, (2) between

the water heater and junction box when the power cord is nor

used.

_,WARNING ]

Do notuseanextensioncord.Ifthereisnota suitablerecepta-J

tie and/or localcodesprohibituseofa powercord,fieldwiringI

must beprovided, J

14

GREEN

GROUND SCREW

Installation Instructions (cont'd)

USE WITHOUT POWER CORD (cont'd)

3. A standard ½" conduit opening has been made in the water

heater junction box for the conduit connection.

4. Use wire nuts and connect the power supply wiring to the

wires "ns'de the water heaters junction box.

5. The water heater must be electrically _grounded" by the

installer. A green ground screw has been provided on the

WIRING DIAGRAM

SgflT_4

S_T_H

water heater's junction box. Connect ground wire to this

location. For complete grounding details and all allowable

exceptions, refer to the latest edition of the National

Electrical Code.

6. Replace the wiring junction cover using the screw

provided.

Venting

_WARNING I

Toinsureproperventingofthisgas-Eredwater heater,the cot- I

rect vent pipe diameter must be utilized.Any additionsof I

other gas applianceson vent with this water heater will

adverselyaffectthe operationofthe water heater.

The combustion and ventilation air flow must not be obstructed.

a_WARNING I

The water heater with draft hood installed must be properly I

vented to a chimney which terminates outdoors. Never oper-

_e the water heater unlessit isvented to the outdoors and has

adequate air supply to avoid risksof improper operation explo-

sion or asphyxiation.

&WARNING I

Obstructed or deteriorated vent systems may present a serious

health risk or asphyxiation.

The vent pipe from the water heater must be 3 diameter I

•,WARNING ,, I

PVC schedule 40 pipe and must slope upward I/4 inch per

near foot.

All vent gases must be completely vented to the outdoors of the

structure (dwelling).

Min. rise I/4"

perfoot

A,WARNING

Failureto haverequiredclearancesbetweenwater heaterand

combustiblematerialwillresultinafire hazard.

15

Installation Instructions (cont'd)

Venting (cont'd)

AWARNING

Be sure vent pipe is p,_porly connected to prevent escape of

dangerousflue gaseswhich couldcausedeadly asphyxiation,

AWARNING

Chemical vapor corrosion of the Rue and vent system may

occur if air for combustion contains certain chemical vapors,

Spray can propellants, cleaning solvents, refrigerator and air

conditioner refrigerants, swimming pool chemicals, calcium

and sodium chloride, waxes, bleach, and processchemicals are

typical compoundswhich are potentially corrosive.

3" PVC SCHEDULE 40 VENT PIPING

Supplied in the carton with the water heater are:

1. A 3" PVC Schedule 40-45 ° vent cap with wire screen.

2. A 3" PVC Schedule 40-90 ° street ell; used to connect the

vent pipe to the water heater when the vent pipe is to be

turned horizontally directly off the blower.

3. A 5' section of 3" PVC Schedule 40 pipe (more may be

required and must be supplied locally).

3"opvcSchedule40

90 Elbow

VENTING SYSTEM EXAMPLE INSTALLATIONS

FOR ALL MODELS

The vent piping cannot under any circumstances be run down-

hill.

The vent piping can be installed as follows:

1.No more than 3 elbows can be used.

Max. 3

MIN. RISE ¼"

PER FOOT

Vent Cap with

Screen

1

1. The water heater requires its own (separate) venting

system.

2. 3" PVC, ABS or CPVC Schedule 40 piping and fittings are

acceptable materials for the vent system on all 40 gallon

models and 50 gallon 40,000 BTU/HR models.

3. It cannot be connected to existing vent piping or

chimney.

4. It must terminate horizontally to the outdoors.

MAX. 20'

MAX_3

MIN. RISE ¼"

PER FOOT

TOTAL VERTICAL AND

HORIZONTAL RUNS

CANNOT EXCEED 35'

MIN. RISE ¼"

PER FOOT

TOTAL VERTICAL AND

HORIZONTAL RUNS

CANNOT EXCEED 35'

16

Installation Instructions (cont'd)

VENTING SYSTEM EXAMPLE INSTALLATIONS

FOR ALL MODELS (cont'd)

2. Horizontal runs require a minimum ¼" rise per foot.

35' Max.

16"MIN.

13" MIN. Min. rise ¼"

I1" MIN. per foot

3. A vertical run can be no more than 20'.

4. The total vertical and horizontal run cannot exceed 35'.

Min. rise ¼"

OneElbow perfoot

Ma_ 20'

CEMENTING PVC, ABS OR CPVC PIPE AND FITHNGS

Read and observe all safety information printed on primer,

cleaner, and cement containers.

DANGER

Primer, cleaner, and cements are extremely flammable.

They are harmful or fatal if swallowed. The vapors are

harmful. They may irritate eyes and skin and can be

absorbed through the skin.

PRECAUTIONS

Always store primers, cleaner, and cements in cool, dry,

well ventilated places. Do not store them near heat,

sparks, or flames. Keep containers closed. Use them in

well ventilated areas. Wear impervious clothing while

handling. Do not smoke, eat, or drink while handling.

Wash thoroughly after handling and before eating. Wear

eye protection when handling. If swallowed, drink water,

do not induce vomiting, and call a physician or poison

control center immediately. If inhaled, get fresh air and

seek medical attention if ill feelings persist. In case of

eye and skin contact, immediately flush with plenty of

water for 15 minutes and seek medical attention if irri-

tation persists. KEEP OUT OR REACH OF CHILDREN.

All primers, cleaners, and cements must meet all local codes and

applicable standards of the American Society For Testing

Materials Standards.

Before using primers, cleaners, and cements, stir or shake, mak-

in sure contents are liquid. Do not use if found to be lumpy or

jei_;-like.

I I

T

Max.20'

I

Min. rise ¼"

per foot

TOTAL VERTICAL AND

HORIZONTAL RUNS

CANNOT EXCEED 35'

Min. rise ¼"

per foot

TOTAL VERTICAL AND

HORIZONTAL RUNS

CANNOT EXCEED 35'

1. Cut pipe ends squarely removing all burrs and dirt.

2. Dry fit pipe and fittings to be connected for proper fit.

3. Clean pipe and fitting with a primer/cleaner.

4. Apply a thin coat of cement to fitting, avoiding puddling

inside.

5. Apply a liberal coat of cement to pipe leaving no voids.

6. QUICKLY assemble parts while cement is fluid! If you wait

too long, re-coar pipes.

7. Push pipe completely into socket of fitting, turning as it goes

until it bottoms.

8. Hold pipe and fitting together for 30 seconds. Then carefully

clean off excess with a cloth. Allow connections a sufficient

time to cure before disturbing.

9. Remember that vent pipes must be adequately and securely

supported.

APPROXIMATE SETTING TIME FOR 2½" TO 4" PIPE

OINTS

MOVEMENT COMPLETE

OF JOINT SET

90°F to 150°F 3Ahr. 8 hrs.

50°F to 90°F 1 hr. 15 hrs.

0°F to 50°F 1_ hr. 18 hrs.

17

Installation Instructions (cont'd)

Venting (cont'd)

CUTTING OPENING THROUGH AN OUTSIDE

WALL AND COLLAR INSTALLATION

After readingthe manual and you have determined the location

of the opening in the wall, (using the drawing below), cut a 3½"

hole through an exterior wall.

NOTE: When determining location of the opening in the

outside wall allow for the ¼" rise per foot that has taken

place in the horizontal run.

CL of Flue--_....... _ "_[_t

?-

40 gal.-60"

50Gal.-59½"

CONNECTING PVC, ABS OR CPVC PIPE VENT TO

BLOWER

1. The manufacturer has supphed a 3 PVC or ABS Schedule

street elbow for connection to the water heater when turning

immediately horizontally off the blower• Place the elbow in

the required direction on the blower and usinl_ 3 sheet metal

screws, attach the elbow. If using a galvanized elbow attach-

ment is the same.

• " 40

I I

2. If there is to be a vertical run of vent from the blower, the 3"

PVC, ABS or galvanized pipe must be attached to the blower

using 3 sheet metal screws. If using galvanized piping attach-

ment is the same. Additionally, you must seal all joints using a

suitable silicone sealer such as GE RTV-103 or equivalent.

_r

The Y' PVC Schedule 40 vent pipe can be run from the water

heater through the wall or from the wall to the water heater,

whichever is most convenient. The vent pipe must extend a

minimum of 1½" through the exterior wall. Extending the vent

cap as far as possible from the surface of the exterior wall will

help minimize discoloration of the wall in this area which may

be caused by the flue gases. Note that the inside collar must be

slipped over the vent piping before locating the pipe through the

wall. Before securin_ the inside and outside collars to the wall,

use a silicone sealer between pipe and opening to insure a water

and air tight seal.

INSTALLATION SHOWING USE OF PVC, ABS OR

CPVC PIPE

SEALER

SILICONE_

__ 1 +h" MIN.EXTENSION

THROUGH

EXTERIOR WALL

SCREW

SEALER

VENT CAP MUST BE

_ POSITIONED

DOWNWARD

SCREEN

18

Installation Instructions (cont'd)

Gas Piping

I AWARNING ]

Make sure the gassure type listed on the I

modelrating plate. The inlet gaspressuremust not exceed

14incheswater column 'Apoundper squareinch(3.5kPa)].I

The minimum inlet gaspressurelistedon the model rating I

plateisforthe purposeof inputadjustment.

AWARNING , J

Ifthe gascontrolvalveissubjectedto pressuresexceeding'A

poundper square inch(3.5kPa),the damageto the gascon-

trolvalvecouldresult ina fireor expiosionfrom leakingga_ J

AWARNING

If the main gasline shutoffservingall gasappliancesisused,

alsotorn "off" the gasat eachappliance.Leaveall gasappli-

ancesshutoff untildm water heaterinstallationiscomplete.

A gas line of sufficient size must be run to the water heater.

Consult the latest edition of National Fuel Gas Code ANSI

Z223.1, also referred to as NFPA54 and the gas company con-

cerning pipe size.

There must be:

•A readily accessible manual shut off valve in the gas supply line

serving the water heater, and

•A drip leg (sediment trap) aheadof the gas control valve to help

prevent dirt and foreign materials from entering the gas control

ValVe.

•A flexible gas connector or a ground joint union between the

shutoffvalve and control valve to permit servicing of the unit.

f AWARNING J

Use pipe joint €omp_tape marked as beingI

resistantto the actionofpetroleum [Propane(LR)] gese_ 1

SEDIMENT TRAP

A sediment trap shall be installed as close to the inlet of the

water heater as practical at the time of water heater installation.

The sediment trap shall be either a tee fitting with a capped nip-

ple in the bottom outlet or other device recognized as an effec-

tive sediment trap. If a tee fitting is used, it shall be installed in

conformance with one of the methods of installation shown

below.

Connecting the gas piping to the gas control valve of the water

heater can be accomplished by either of the two methods shown.

GAS PIPING WITH

FLEXIBLE CONNECTOR

MANUAL _('AS SUPPLY PIPING

SHUTOFF

VALVE

FLEXIBLE G_S CONNECTOR

LABELED AS COMPLYING

WITH ANSI STANDARDS

GROUND

UNION (Optional)

DRIP LEG

(Sediment trap)

CAP

GAS

CONTROL

VALVE

Be sure to check all the gas piping for leaks before li_hting the

water heater. Use a soapy water solution, not a match or open

flame. Rinse offsoapy solution and wipe dry.

Standard Models are for installation up to 3,300 feet above sea

level.

High Altitude Models are for installation from 3,300 to 5,500

feet above sea level.

Ifa standard model is installed above 3,300 feet or a high altitude

model is installed above 5,500 feet, the input rating must be

reduced at the rate of 4 percent for each 1,000 feet above sea level.

Contact your local Sears Service Center or gas utility for further

information.

The appliance and its gas connectionmust

beforeplacingthe appliancein operation.

AWARNING be leak tested

AWARNING

•The applianceand its individualshutoffvalvemust be discon-

nectedfromthe gassupplypipingsystemduringanypressure

testingofthe gassystemat test pressuresin excessof I/2

poundpersquareinch(3.5kPa).

•The appliancemust beisolatedfromthe gassupplypipingsys-

tem byclosingits individualmanualshutoffvalveduringany

pressuretestingof the gassupplypipingsystemat test pres-

suresequalorlessthan I/2 poundper squareinch(3.5kPa).

GAS PIPING WITH ALL BLACK IRON

PIPE TO GAS CONTROL

SHUTOFF

VALVE

MANUAL_;ASSUPPLY PIING

GROUND lOIN1

UNION

T

6"

BLACK PIPE

DRIP LEG

(Sediment t_ap)

CAP

GAS

CONTROL

VALVE

&WARNING

Contaminants in thegaslinesmaycauseimproperoperation

of the gascontrolvalvethat may resultin fire or explosion.

Beforeattachingthe gasline be surethat all gaspipeisclean

on the inside.Totrap any dirt or foreign material in the gas

supplyline, a drip leg (sometimes calleda sediment trap)

must be incorporated in the piping.The drip leg must be

readily accessible.Installinaccordancewiththe "Gas Piping"

section.Referto the latestedition of the National Fuel Gas

Code,ANSI Z223.1,alsoreferred to as NFPA 54.

19

Installation Instructions (cont'd)

Installation Checklist

BEFORE LIGHTING THE PILOT:

• Check the gas lines for leaks.

a. Use a soapy water solution. DO NOT test for gas leaks

usinga match or open flame.

b. Brush the soapy water solution on all gas pipes, joints and

fittings.

c. Check for bubbling soap. This means you have a leak.

Turn OFF gas andmake the necessary repairs.

d. Recheck for leaks.

e. Rinse off soapy solution and wipe dry.

Is the new temperature-pressure relief valve properly installed

and piped to an adequate drain? See "Temperature-Pressure

Relief Valve" section.

Are the cold and hot water lines connected to the water

heater correctly? See "Water Piping" instructions in the

"Installing the New Water Heater" section.

• Is the water heater completely filled with water? See "Filling"

instructions in the "Installing the New Water Heater" sec-

tion.

• Will a water leak damage anything? See the "Locating the

New Water Heater sectmn.

VENT PIPETO

OUTDOORS

COLD

SHUTOFF

VALVE

TEt4PERATURE-

PRESSURERELIEF

VALVE

DISCHARGE PIPE

Is there proper clearance between the water heater and any-

thing that might catch fire? See the "Locating the New water

Heater section.

Do you have adequate ventilation so that the water heater

will operate properly? See ' Combust'on A'r and Vent'lation"

in the 'Locating the New Water Heater" sect'on.

Is the draft hood vent piping properly secured? See "Venting"

instructions in the "Installing the New Water Heater" sec-

tion.

Is there proper clearance between the vent pipe and anything

that might catch on fire? See 'Venting instructions in the

"Installing the New Water Heater" section.

Is the vent pipe properly sloped and does the vent terminate

outdoors? See "Venting" instructions in the "Installing the

New Water Heater" section.

(Sediment trap)

PIPECAP

Do you need to call your gas company to check the gas pipe

and its hookup?

CHECK FOR LEAKS

Be sure to check all your gas pipes for leaks before lighting your

water heater. Use a soapy water solution, not a match or open

flame. Check the factory gas,,fittings after pilot is lit and gas con-

trol knob is still in PILOT position. Then, check the fittings

when the main burner is turned "ON". Use a soapy water solu-

tion for this, too. MODEL RATING PLATE

20

Operating Instructions -

This water heater is equipped with an electrically operated vent-

ing system and a standing pilot. For the burner to come on, the

water heater thermostat must call for heat. Then the system will

begin sequencing, each section proving itself before gas is

allowed to flow to the burner.

BEFORE THE WATER HEATER WILL OPERATE: