Kenmore 153.335943, 153.335863, 153.335846 User Manual

Owners

Manual

FOR POTABLEWATER

HEATING ONLY

NOT SUITABLEFOR

SPACEHEATING

NOT FOR USE IN

MOBILE HOMES

Model No.

153.335816 40 Gal.

153.335846 40 Gal. High Altitude L.R

153.335863 40 Gal. L.R

153.335916 50 Gal.

153.335943 50 Gal. High Altitude L.R

153.335963 50 Gal. L.!_

POWER MISER TM 9

POWER VENT

GAS WATER HEATER

• Safety Instructions • Care and Maintenance

• Installation • Troubleshooting

• Operation • Parts List

For Your Safety

AN ODORANT IS ADDED TO THE GAS USED BY THIS

WATER HEATER

WARNING: If the information in these instructions are not fol-

lowed exactly, a fire or explosion may result, causing property

damage, personal inlury or death.

Read and Follow

All Safety Rules and

Operating Instructions

Before First Use of

This Product.

Savethis Manual for Future Reference.

-Do not store or use gasoline or other flammable vapors and liq-

uids in the vicinity of this or any other appliance.

-WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your

building.

i Immediately call your gas supplier from a neighbor's phone.Follow the gas supplier'sinstructions.

If you can not reach your gas supplier, call the fire department.

-Installation and service must be performed by a qualified installer,

service agency or the gassupplier.

_WARNING

Improper installation, adjustment, alteration, service or maintenance

can cause DEATH, SERIOUS BODILY INJURY, OR PROPERTY DAM-

AGE. Refer to this manual for assistance or consult the local Sears

Service Center or gas utility for further information.

AWARNING

Flammable vapors may be drawn by air currents from other areas

of the structure to this appliance.

READ THE GENERAL SAF_N BEGINNING ON INSIDE

COVER AND THEN THIS ENTIRE MANUAL BEFORE INSTALLING

OR OPERATING THIS WATER HEATER.

=t WARNING 1

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Safety Precautions

J _,WARNING 1

Improper installation, adjustment, alteration, service orJ

maintenance can cause death, serious bodily injury, orJ

property damage. Refer to this manual for assistanceorJ

consult your local Sears Service Center for furtherJ

information. J

_,WARNING

WATER HEATERS EQUIPPED FOR ONE TYPE GAS

ONLY: This water heater is equipped for one type gas

only. Check the model rating plate near the gas control

valve for the correct gas. DO NOT USE THIS WATER

HEATER WITH ANY GAS OTHER THAN THE ONE

SHOWN ON THE MODEL RATING PLATE. Failure to

usethe correct gascan causeproblemswhichcanresult in

DEATH, SERIOUS BODILY INJURY, OR PROPERTY

DAMAGE. If you have any questions or doubts consult

yourgassupplieror localutility.

_,VQARNING

INSTALLATIONS IN AREAS WHERE FLAMMABLE LIQ-

UIDS (VAPORS) ARE LIKELY TO BE PRESENT OR

STORED (GARAGES, STORAGE, AND UTILITY AREAS,

ETC): Flammable liquids (such as gasoline, solvents,

propane(LP) or butane, etc.), allof whichemit flammable

vapors, may be improperly stored or used in such areas.

The gaswater heater pilot light or main burner canignite

such vapors. The resulting flashback and fire can cause

death or serious burns to anyone in the area, as well as

property damage.

If installation in such areas is your only option, then the

installation must be accomplishedin a way that the pilot

flame and main burner flame are elevated from the floor

at least 18 inches.While this may reduce the chancesof

flammable vaporsfrom a floor spillbeing ignited, gasoline

and other flammable substancesshouldnever bestored or

used in the same room or area containing a gas water

heater or other open flame or sparkproducingappliance.

NOTE: Flammable vapors may be drawn by air currents

from other areasof the structure to the appliance.

_,WARNING

If this water heater will be used in beauty shops,barber

shops,cleaning establishments, or self-service laundries

with dry cleaning equipment, it is imperative that the

water heater or water heaters be installed sothat com-

bustion and ventilation air be taken from outside these

areas. Refer to the "Locating The New Water Heater"

section of this manual and also the latest edition of the

National Fuel Gas Code, ANSI Z223.1, also referred to as

NFPA 54 for specificsprovidedconcerningair required.

_,WARNING I

A fire can start if combustible materials suchas clothing,

cleaningmaterials, or flammable liquidsare placed against

or next to the water heater.

_,WARNING

At the time of manufacture this water heater was provid-

edwith a combination temperature-pressures relief valve

certified by a nationally recognized testing laboratory

that maintains periodic inspectionof production of listed

equipment or materials, as meeting the requirements

for Relief Valves and Automatic Gas Shutoff Devices for

Hot Water Supply Systems, and the latest edition of

ANSI Z21.22 and the code requirements of ASME. If

replaced, the valve must meet the requirements of local

codes,but not lessthan a combination temperature and

_ressure relief valve certified as meeting the require-

ments for Relief Valves and Automatic Gas Shutoff

Devicesfor Hot Water Supply Systems, ANSI Z21.22 by

a nationally recognized testing laboratory that maintains

_eriodic inspection of production of listed equipment or

materials.

The valve must be marked with a maximum set pressure

not to exceed the marked hydrostatic working pressure

of the water heater (150 Ibs./sq. in.) and a discharge

capacity not less than the water heater input rate as

shown on the model rating plate. (Electric heaters -

watts dividedby 1000x 3415 equal BTU/Hr. rate.)

Your local jurisdictional authority, while mandating the

use of a temperature-pressure relief valve complying

with ANSI Z21.22 and ASME, may require a valve model

different from the one furnishedwith the water heater.

Compliance with such local requirements must be satis-

fied by the installer or end user of the water heater with

a locally prescribed temperature-pressure relief valve

installed in the designatedopeningin the water heater in

daceof the factory furnishedvalve.

For safe operation of the water heater, the relief valve

must not be removed from it's designated opening or

plugged.

The temperature-pressure relief valve must be installed

directly into the fitting of the water heater designated

for the relief valve. Positionthe valve downwardand pro-

vide tubing so that any dischargewill exit only within 6

inches above, or at any distance below the structural

floor. Be certain that no contact is made with any live

electrical part. The discharge opening must not be

blocked or reduced in size under any circumstances.

Excessivelength, over 30 feet, or use of more than four

elbows can cause restriction and reduce the discharge

capacity of the valve.

No valve or other obstruction is to be placed between

the relief valve and the tank. Do not connect tubing

directly to dischargedrain unlessa 6" air gap isprovided.

To prevent bodily injury, hazard to life, or property dam-

age, the relief valve must be allowed to dischargewater

in quantities should circumstances demand. If the dis-

charge pipe isnot connected to a drain or other suitable

means, the water flow may causeproperty damage.

The DischargePipe:

• Must not be smaller in sizethan the outlet pipe sizeof

the valve, or have any reducing couplings or other

restrictions.

• Must not be pluggedor blocked.

• Must be of material listedfor hot water distribution.

• Must be installed so as to allow complete drainage of

both the temperature-pressure relief valve, and the

dischargepipe.

• Must terminate at anadequate drain.

• Must not have any valve between the relief valve and

tank.

Safety Precautions

AWARNING

A gas water heater cannot operate properly without the

correct amount of air for combustion. Do not install in a

confined area such a closet, unless you provide air as

shown in the "Locating The New Water Heater" section.

Never obstruct the flow of ventilation air. If you have any

doubts or questions at all, call your gas company. Failure

to provide the proper amount of combustion air can result

in a fire or explosion and can cause DEATH, SERIOUS

BODILY INJURY, OR PROPERTY DAMAGE.

_,WARNING

HOTTER WATER CAN SCALD: Water heaters are

intended to produce hot water. Water heated to a tem-

perature which will satisfy clothes washing, dish washing,

and other sanitizing needs can scald and permanently

injure you upon contact. Some people are more likely to

be permanently injured by hot water than others. These

include the elderly, children, the infirm, or physicallylmen-

tally handicapped. If anyone using hot water in your home

fits into one of these groups_r if there is a local code or

state law requiring a certain temperature water at the hot

water tap, then you must take special precautions. In addi-

tion to using the lowest possible temperature setting that

satisfies your hot water needs, a means such as a mixing

valve, should be used at the hot water taps used by these

people or at the water heater. Mixing valves are available

at plumbing supply or hardware stores. Follow manufac-

turers instructions for installation of the valves. Before

changing the factory se_ing on the thermostat, read the

"Temperature Regulation" section in this manual.

_,WARNING

This water heater must not be installed directly on car-

peting. Carpeting must be protected by a metal or wood

panel beneath the appliance extending beyond the full

width and depth of the appliance by at least 3 inches

(76.2mm) in any direction, or if the appliance is installed

in an alcove or closet, the entire floor must be covered b

the panel. Failure to heed this warning may result in

fire hazard.

_WARNING

The power vent water heater requires its own (separate)

venting system. It cannot be connected to an existing vent

pipe or chimney, it must be terminated to the outdoors.

Failure to properly install the venting system can result in

asphyxiation, a fire or explosion and can cause DEATH, SE-

RIOUS BODILY INJURY, OR PROPERTY DAMAGE.

AWARNING

No vent damper installation is compatible with this power

vented water heater design. No vent damper, whether it is

operated thermally or otherwise is to be installed on this

power vented water heater. Alteration of any part of the fac-

tory-furnished vent assembly could result in improper oper-

ation due to restriction of flue gases, spillage of flue gases

and may cause carbon monoxide poisoning.

AWARNING

Soot build-up indicates a problem that requires correc-

tion before further use. Turn "off" gas to water heater

and leave "off" until repairs are made, because failure to

correct the cause of the sooting can result in a fire or

explosion causing DEATH, SERIOUS BODILY INJURY,

OR PROPERTY DAMAGE.

_,WARNING

BEFORE LIGHTING [PROPANE (L.P.) GAS WATER

HEATERS]: Propane (L.R) gas is heavier than air. Should

there be a leak in the system, the gas will settle near the

ground. Basements, crawl spaces, skirted areas under

mobile homes (even when ventilated), closets and areas

below ground level will serve as pockets for the accumula-

tion of this gas. Before attempting to light or relight the

water heater's pilot or turning on a nearby electrical light

switch, be absolutely sure there is no accumulated gas in

the area. Search for odor of gas by sniffing at ground level

in the vicinity of the appliance. If odor is detected, follow

steps indicated at "For Your Safety" on the cover page of

this manual then leave the premises.

_,WARNING

• The appliance and its individualshutoff"valvemust bedis-

connected from the gassupplypiping systemduring any

pressure testing of the gassystem at test pressuresin

excessof I/2 pound per squareinch(3.5kPa).

• The appliance must be isolatedfrom the gassupplypip-

ing system by closingits individualmanual shutoff valve

during any pressuretesting of the gas supplypiping sys-

tem at test pressuresequal or lessthan 1,2 pound per

squareinch (3.5kPa).

_,WARNING

Chemical vapor corrosion of the flue and vent system

may occur if air for combustion contains certain chemical

vapors. Spray can propellants, cleaning solvents, refrigera-

tor and air conditioner refrigerants, swimming pool

chemicals, calcium and sodium chloride, waxes, bleach,

and process chemicals are typical compounds which are

potentially corrosive.

AWARNING

Obstructed or deteriorated vent systems may present a

serious health risk or asphyxiation.

Safety Precautions continued on page 4.

3

Safety Precautions

AWARNING

The water heater wi_talled must be prop- I

erly vented to a chimney which terminates outdoors. I

Never operate the water heater unlessit is vented to the I

outdoors and has adequate air supply to avoid risks of I

improper operation,explosionor asphyxiation. J

AWARNING

Minimum clearances between the water heater and com-

bustible construction are 0" at the sides and rear, 5" at the

front, and fl" from the vent pipe. Clearance from the top

of the jacket is 14" on most models. Note that a lesser

dimension may be allowed on some models. Refer to the

labelon the water heater adjacent to the gascontrol valve

for all clearances.

I AWARN,NG I

Do not usethis appl_of it hasbeen under I

water. Immediately calka Sears Service Technician to I

inspectthe applianceandto replace the gascontrol or any I

part ofthe burner systemwhich hasbeen under water. I

AWARNING J

Vent termination must not be within 4 feet of any items J

such as gas meters, gasvalves or other gas regulating

equipment.

A CAUTION

WATER HEATERS EVENTUALLY LEAK: Installation of

the water heater must be accomplishedin sucha manner

that if the tank or any connectionsshould leak, the flow of

water will not cause damage to the structure. For this

reason, it is not advisableto install the water heater inan

attic or upper floor.When suchlocationscannot beavoid-

ed, a suitable drain pan should be installed under the

water heater. Drain pansare availableat your localSears

store. Sucha drain pan must be not greater than 1½inch-

es deep, have a minimum length and width of at least 2

inches greater than the water heater dimensions and

must be piped to an adequate drain. The pan must not

restrict combustion air flow. Under no circumstances is

the manufacturer or Searsto be held liable for anywater

damage in connectionwith thiswater heater.

AWARNING

HYDROGEN GAS: Hydrogengascan be producedin a hot

water system that hasnot been usedfor a long period of

time (generally two weeks or more). Hydrogen gas is

extremely flammable and explosive.To prevent the possi-

bility of injury under these conditions,we recommend the

hot water faucet be opened for several minutes at the

kitchen sink before any electrical appliances which are

connected to the hot water system are used (such as a

dishwasheror washing machine). If hydrogen gas is pre-

sent,there will probablybe an unusualsoundsimilar to air

escaping through the pipe as the hot water faucet is

opened. There must be no smoking or open flame near

the faucet at the time it isopen.

AWARNING

INSULATING JACKETS: When installing an external

water heater insulationjacket on a gaswater heater:

DO NOT cover the temperature-pressure relief valve.

DO NOT put insulation over any part of the top of the

gaswater heater.

DO NOT put insulation over the gascontrol valve or gas

control valve/burner cover,or any accessareas to the

burner.

DO NOT let insulationaround the gaswater heater to

get within 8 inches of the floor (air must get to the

burner).

DO NOT cover or remove operating instructions, and

safetyrelated warning labelsand materials affixed to the

water heater.

:allure to heed this will result in the possibilityof a fire or

explosion.

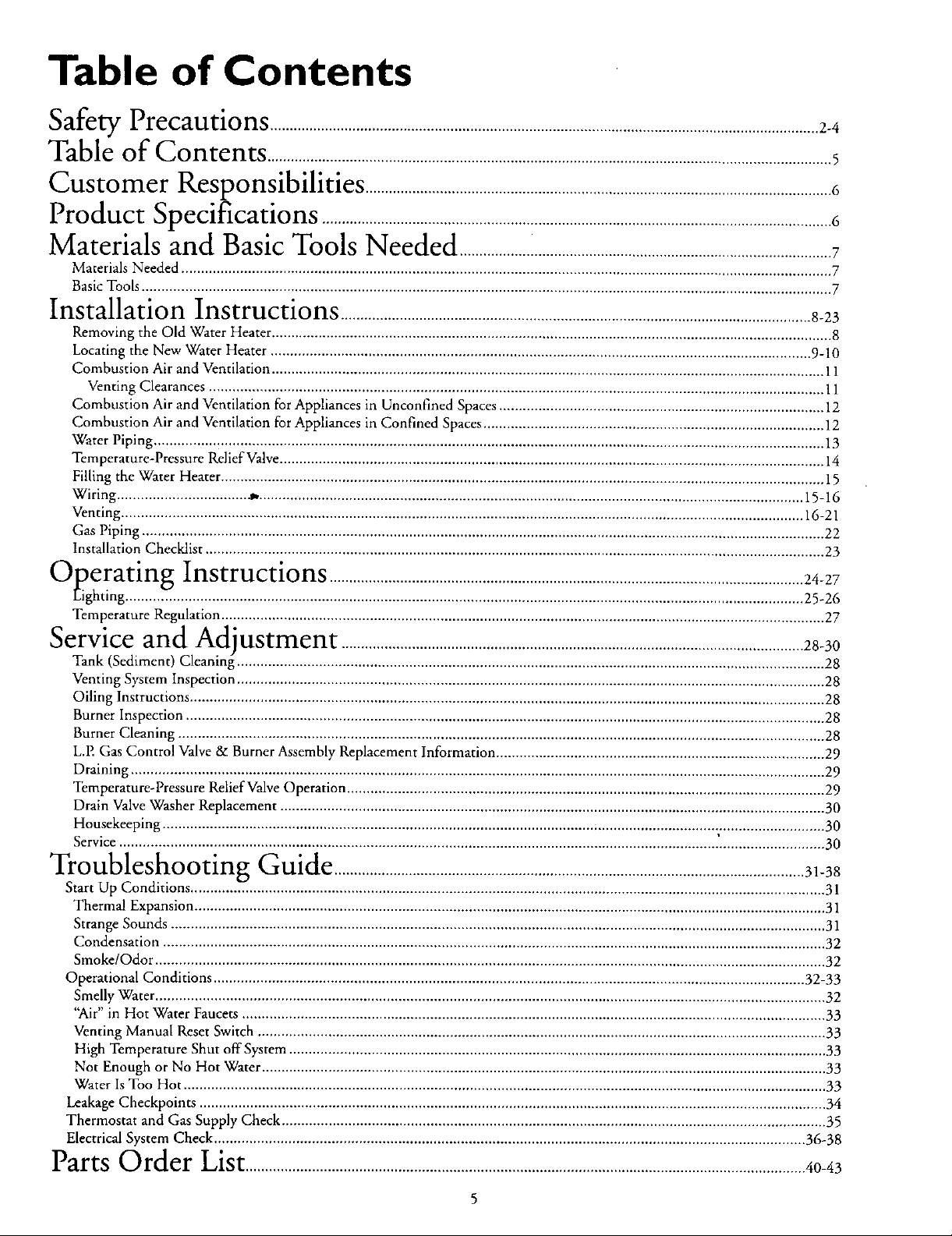

Table of Contents

_¢...._,a,,.tyPrecautions ............................................................................................................................................2-4

Table of Contents ................................................................................................................................................5

Customer

l_esponsibilities .......................................................................................................................6

Product Specifications ..................................................................................................................................6

Materials and Basic Tools Needed ...............................................................................................7

Materials Needed ...................................................................................................................................................................... 7

Basic Tools ................................................................................................................................................................................ 7

T ,,-installation Instructions ........................................................................................................................8-23

Removing the Old Water Heater ............................................................................................................................................... 8

Locating the New Water Heater .......................................................................................................................................... 9-10

Combustion Air and Ventilation ............................................................................................................................................. 11

Venting Clearances ............................................................................................................................................................. 11

Combustion Air and Ventilation for Appliances in Unconfined Spaces ................................................................................... 12

Combustion Air and Ventilation for Appliances in Confined Spaces ....................................................................................... 12

Water Piping ........................................................................................................................................................................... 13

Temperature-Pressure Rdief Valve ........................................................................................................................................... 14

Filling the Water Heater .......................................................................................................................................................... 15

Wiring .................................. I,,........................................................................................................................................... 15-16

Venting .............................................................................................................................................................................. 16-21

Gas Piping .............................................................................................................................................................................. 22

Installation Checklist .............................................................................................................................................................. 23

O eratin Instructions 2427

_ighting ............................................................................................................................................................................. 25-26

Temperature Regulation .......................................................................................................................................................... 27

g ......................................................................................................................... _

Service and Adjustment ......................................................................................................................2s-30

Tank (Sediment) Cleaning ...................................................................................................................................................... 28

Venting System Inspection ...................................................................................................................................................... 28

Oiling Instructions .................................................................................................................................................................. 28

Burner Inspection ................................................................................................................................................................... 28

Burner Cleaning ..................................................................................................................................................................... 28

L.R Gas Control Valve & Burner Assembly Replacement Information .................................................................................... 29

Draining ................................................................................................................................................................................. 29

Temperature-Pressure Rdief Valve Operation .......................................................................................................................... 29

Drain Valve Washer Replacement ........................................................................................................................................... 30

Housekeeping ......................................................................................................................................................................... 30

Service ........................................................................................................................................................ :........................... 30

Troubleshooting Guide ........................................................................................................................31-38

Start Up Conditions .................................................................................................................................................................. 31

Thermal Expansion ................................................................................................................................................................. 31

Strange Sounds ....................................................................................................................................................................... 31

Condensation ......................................................................................................................................................................... 32

Smoke/Odor ........................................................................................................................................................................... 32

Operational Conditions ....................................................................................................................................................... 32-33

Smelly Water ........................................................................................................................................................................... 32

"Air" in Hot Water Faucets ..................................................................................................................................................... 33

Venting Manual Reset Switch ................................................................................................................................................. 33

High Temperature Shut off System ......................................................................................................................................... 33

Not Enough or No Hot Water ................................................................................................................................................ 33

Water Is Too Hot .................................................................................................................................................................... 33

Leakage Checkpoints ................................................................................................................................................................ 34

Thermostat and Gas Supply Check ........................................................................................................................................... 35

Electrical System Check ....................................................................................................................................................... 36-38

Parts "-'-!OrderList...............................................................................................................................................40-43

5

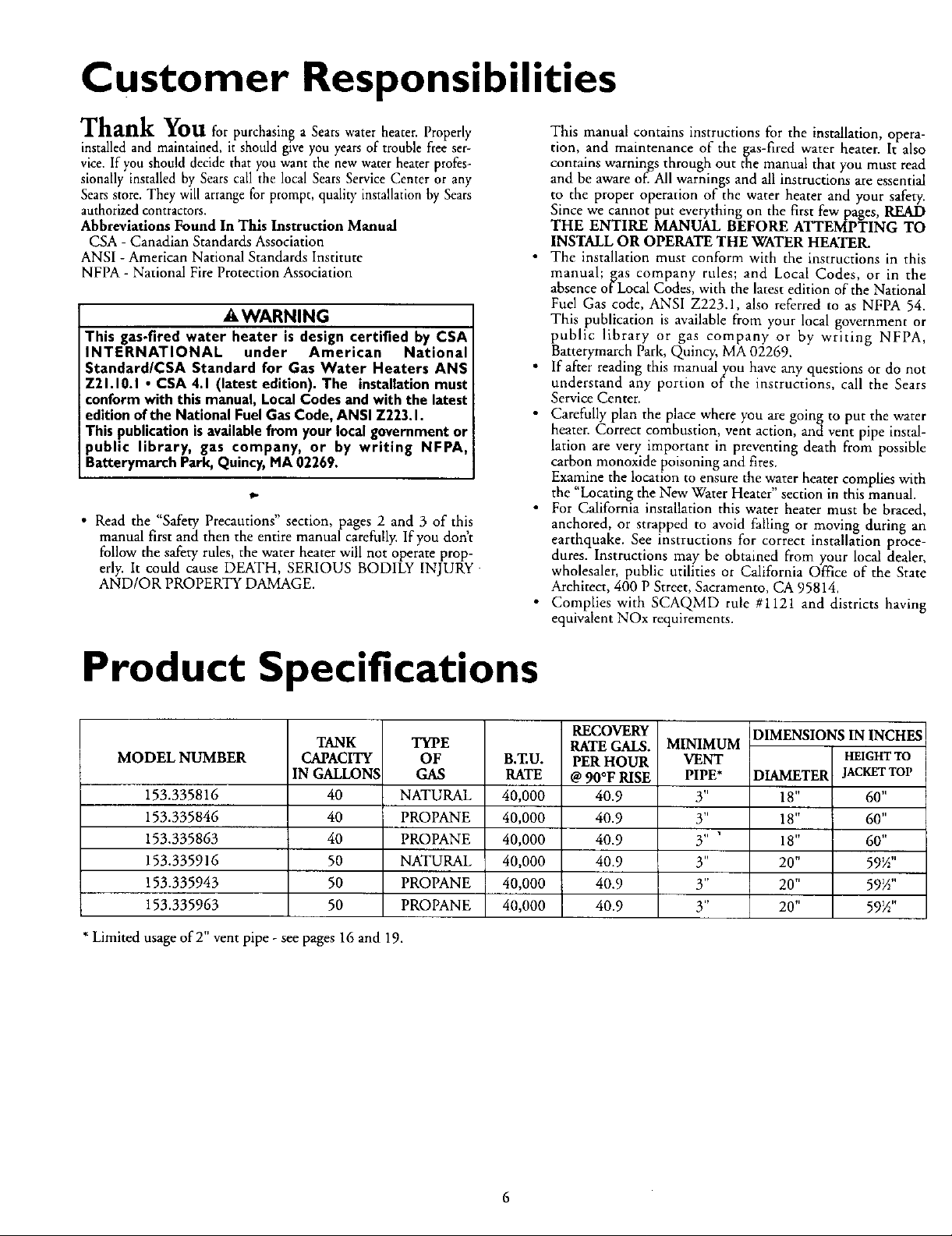

Customer Responsibilities

_""inanK Youfor purchasing a Sears water heater. Properly

installedand maintained, it should give you years of trouble free ser-

vice. If you should decidethat you wantthe new waterheater profes-

sionally installed by Sears call the local Seats ServiceCenter or any

Searsstore.They will arrangefor prompt, quality,installation by Sears

authorized contractors.

Abbreviations Found In This Instruction Manual

CSA - Canadian Standards Association

ANSI - American National Standards Institute

NFPA - National FireProtection Association

AWARNING

This gas-fired water heater is design certified by CSA

INTERNATIONAL under American National

Standard/CSA Standard for Gas Water Heaters ANS

Z21.10.1 • CSA 4.1 (latest edition). The installation must

conform with this manual, LocalCodesand with the latest

edition ofthe National Fuel Gas Code, ANSI Z223.1.

This publicationisavailablefrom your local government or

lublic library, gas company, or by writing NFPA,

Batterymarch Park, Quincy,MA 02269.

• Read the "Safety Precautions" section, pages 2 and 3 of this

manual first and then the entire manual carefully. If you don't

follow the safety rules, the water heater will not operate prop-

erly. It could cause DEATH, SERIOUS BODILY INJURY

AND/OR PROPERTY DAMAGE.

This manual contains instructions for the installation, opera-

tion, and maintenance of the gas-fired water heater. It also

contains warnings through out the manual that you must read

and be aware of. All warnings and all instructions are essential

to the proper operation of the water heater and your safety.

Since we cannot put everything on the first few pages, READ

THE ENTIRE MANUAL BEFORE ATTEMPTING TO

INSTALL OR OPERATE THE WATER HEATER.

• The installation must conform with the instructions in this

manual; sas company rules; and Local Codes, or in the

absence of Local Codes, with the latestedition of the National

Fuel Gas code, ANSI Z223.1, also referred to as NFPA 54.

This publication is available from your local government or

public library or gas company or by writing NFPA,

Battetymarch Park, Quincy, MA 02269.

• If after reading this manualyou have any questions or do not

understand any portion of the instructions, call the Sears

Service Center.

• Carefully plan the place where you are going to put the water

heater. Correct combustion, vent action, and vent pipe instal-

lation are very important in preventing death from possible

carbon monoxide poisoning and fires.

Examine the location to ensure the water heater complies with

the "Locating the New Water Heater" section in this manual.

• For California installation this water heater must be braced,

anchored, or strapped to avoid falling or moving during an

earthquake. See instructions for correct installation proce-

dures. Instructions may be obtained from your local dealer,

wholesaler, public utilities or California Office of the State

Architect, 400 P Street, Sacramento, CA 95814.

• Complies with SCAQMD rule #1121 and districts having

equivalent NOx requirements.

Product Specifications

TANK

MODEL NUMBER

CAPACITY

IN GALLONS

153.335816

153.335846

153.335863

153.335916

153.335943

153.335963

* Limited usage ofT' vent pipe - see pages 16 and 19.

40

40

40

50

50

50

TYPE

OF

GAS

NATURAL

PROPANE

PROPANE

NATURAL

PROPANE

PROPANE

B.ZU.

RATE

40,000

40,000

40,000

40,000

40,000

40,000

RECOVERY

RATE GALS.

PER HOUR

@ 90°F RISE

40.9

40.9

40.9

40.9

40.9

40.9

MINIMUM

VENT

PIPE*

3"

3"

3" '

y'

3"

3"

DIMENSIONS IN INCHES

HEIGHTTO

DIAMETER

18"

18"

18"

20"

20"

20"

JACKETTOP

60"

60"

60"

59_"

59_"

59V2"

6

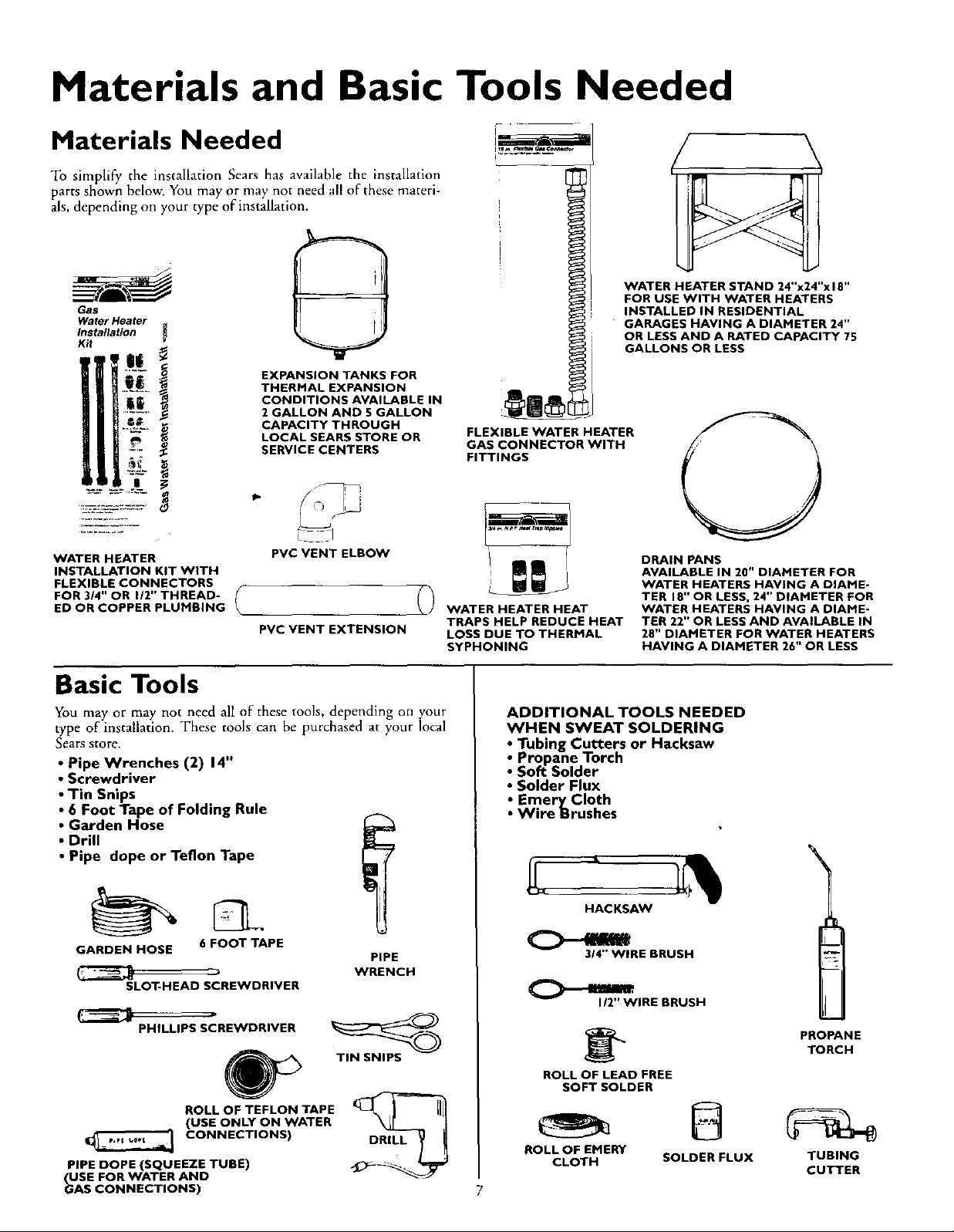

Materials and Basic Tools Needed

Materials Needed

To simplify the installation Sears has available the installation

parts shown below. You may or may not need all of these materi-

als, depending on your type of installation.

WATER HEATER STAND 24"x24"xlS"

Gas

Water Heater

Installation

K_t

EXPANSION TANKS FOR

THERMAL EXPANSION

CONDITIONS AVAILABLE IN

2 GALLON AND 5 GALLON

CAPACITY THROUGH

LOCAL SEARS STORE OR

SERVICE CENTERS

FLEXIBLE WATER HEATER

GAS CONNECTOR WITH

FITTINGS

FOR USE WITH WATER HEATERS

INSTALLED IN RESIDENTIAL

GARAGES HAVING A DIAMETER 24"

OR LESS AND A RATED CAPACITY 75

GALLONS OR LESS

O

WATER HEATER

INSTALLATION KIT WITH

FLEXIBLE CONNECTORS

FOR 3/4" OR I/2" THREAD-

ED OR COPPER PLUMBING

PVC VENT ELBOW

{ D

PVC VENT EXTENSION

Basic Tools

You may or may not need all of these tools, depending on your

type of installation. These tools can be purchased at your local

Searsstore.

• Pipe Wrenches (2) 14"

• Screwdriver

• Tin Snips

• 6 Foot Tape of Folding Rule

• Garden Hose

• Drill

• Pipe dope or Teflon Tape

GARDEN HOSE 6 FOOT TAPE

SLOT-HEAD SCREWDRIVER

PHILLIPS SCREWDRIVER

PIPE

WRENCH

TIN SNIPS

4P

ROLL OF TEFLON TAPE

(USE ONLY ON WATER

CONNECTIONS)

PIPE DOPE (SQUEEZE TUBE)

USE FOR WATER AND

_AS CONNECTIONS)

DRILL

WATER HEATER HEAT

TRAPS HELP REDUCE HEAT

LOSS DUE TO THERMAL

SYPHONING

ADDITIONAL TOOLS NEEDED

WHEN SWEAT SOLDERING

• Tubing Cutters or Hacksaw

• Propane Torch

• Soft Solder

• Solder Flux

• Emery Cloth

• Wire Brushes

HACKSAW

314" WIRE BRUSH

I/2" WIRE BRUSH

ROLL OF LEAD FREE

SOFT SOLDER

ROLL OF EMERY

CLOTH

DRAIN PANS

AVAILABLE IN 20" DIAMETER FOR

WATER HEATERS HAVING A DIAME-

TER 18" OR LESS, 24" DIAMETER FOR

WATER HEATERS HAVING A DIAME-

TER 22" OR LESS AND AVAILABLE IN

28" DIAMETER FOR WATER HEATERS

HAVING A DIAMETER 26" OR LESS

PROPANE

TORCH

@

SOLDER FLUX

TUBING

CUTTER

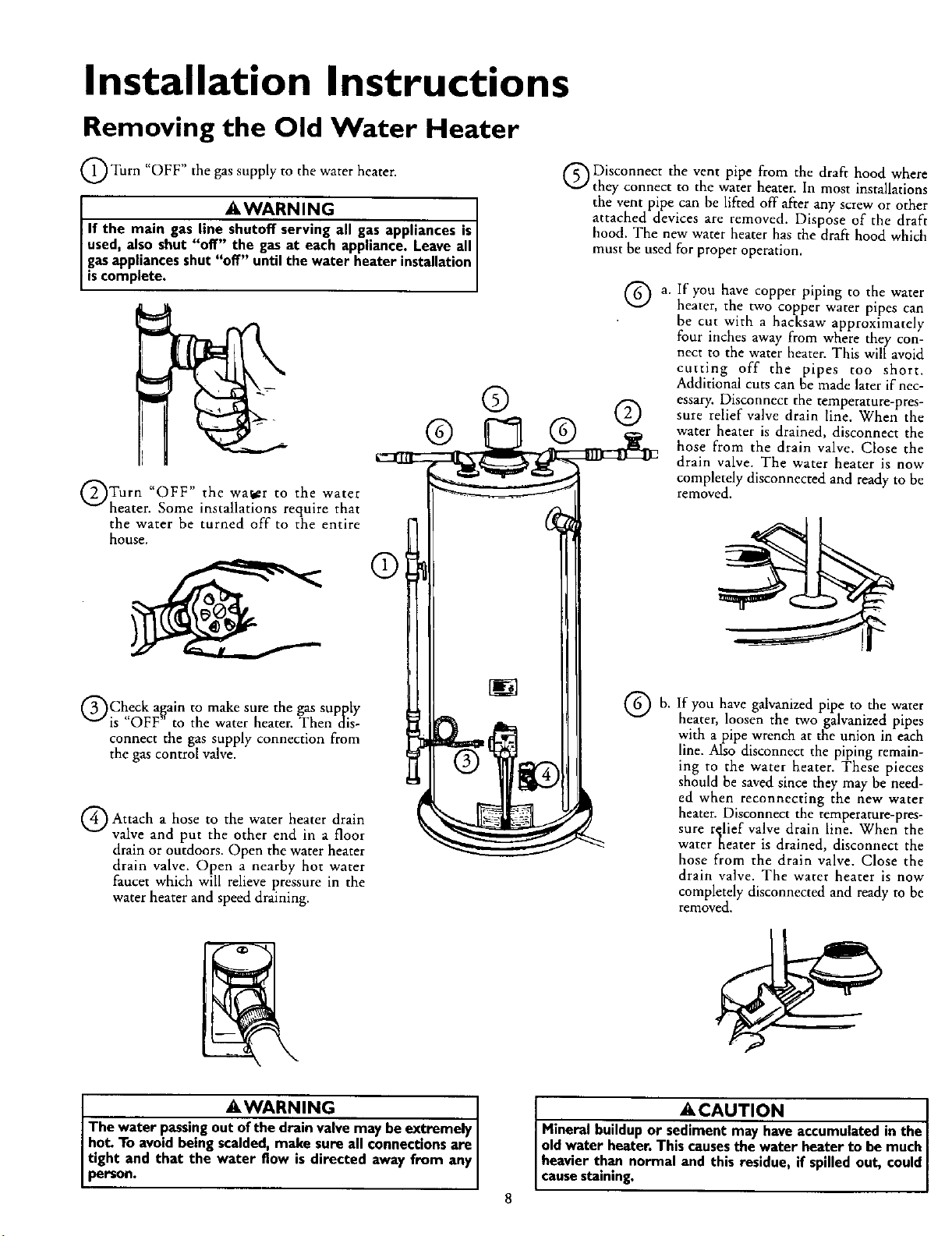

Installation Instructions

Removing the Old Water Heater

Q Turn gas supply to water

"OFF" the the heater.

_WARNING

If the main gas line shutoff serving all gas appliances is

used,also shut "off" the gasat each appliance.Leaveall

gasappliancesshut "off" until the water heater installation

iscomp ete.

QTurn water to water

"OFF" the the

heater. Some installations require that

the water be turned off to the entire

house.

®

Q Disconnect the vent pipe from the draft hood where

they connect to the water heater. In most installations

the vent pipe can be lifted off after any screw or other

attached devices are removed. Dispose of the draft

hood. The new water heater has the draft hood which

must be used for proper operation,

Q a. If you have copper piping to the water

® ®

heater, the two copper water pipes can

be cut with a hacksaw approximately

four inches away from where they con-

nect to the water heater. This will avoid

cutting off the pipes too short.

Additional cuts can he made later if nec-

essary. Disconnect the temperature-pres-

sure relief valve drain line. When the

water heater is drained, disconnect the

hose from the drain valve. Close the

drain valve. The water heater is now

completely disconnected and ready to be

removed.

QCheck again to make sure the gas supply

is "OFF" to the water heater. Then dis-

connect the gas supply connection from

the gas control valve.

Q Attach hose the heater drain

a to water

valve and put the other end in a floor

drain or outdoors. Open the water heater

drain valve. Open a nearby hot water

faucet which will relieve pressure in the

water heater and speed draining.

I AWARNING

The water passingou_ve may be extremely

hot. To avoidbeing scalded,make sure all connectionsare

tight and that the water flow is directed away from any

person.

If

G b. you galvanized pipe to water

have the

heater, loosen the two galvanized pipes

with a pipe wrench at the union in each

line. Also disconnect the piping remain-

ing to the water heater. These pieces

should be saved since they may be need-

ed when reconnecting the new water

heater. Disconnect the temperature-pres-

sure r_lief valve drain line. When the

water nearer is drained, disconnect the

hose from the drain valve. Close the

drain valve. The water heater is now

completely disconnected and ready to be

removed.

ACAUTION [

Mineral buildupor sediment may haveaccumulatedin the [

oldwater heater. This causesthe water heater to be much [

[ heavier than normal and this residue, if spilledout, could I

[ causestaining. ]

Installation Instructions

Locating the New Water

Heater

You should carefully choose an indoor location for the new water

heater, because the placement is a very important consideration

for the safety of the occupants in the building and for the most

economical use of the appliance. This water heater is not for

use in mobile homes or outdoor installation.

Whether replacing an old water heater or putting the water

heater in a new location, the following critical points must be

observed.

1. The location selected should be indoors as close as practical

to the vent termination point, and as centralized with the

water piping system as possible. The water heater, as all water

heaters, will eventually leak. Do not install without adequate

drainage provisions where water flow will cause damage.

2. If vented through an outside wall or through the roof the

vent piping cannot exceed a total of 35 feet including vertical

and horizontal runs and have no more than 3 elbows. It can-

not slope downward and horizontal runs require ¼" per foot

rise. All horizontal runs require adequate support at 3_ feet

intervals.

3. The water heater requires i_s own (separate) venting system.

It cannot be connected to an existing vent pipe or chimney.

It must terminate to the outdoors. Whenever possible termi-

nate the vent on the leaward side of the building if vented

through an outside wall. NOTE: Condensation may be cre-

ated, at times, as the combustion gases exit the vent cap

and discoloration of surfaces in proximity to the vent cap

may occur.

AWARNING

The powerventwater heaterrequires itsown(separate)venting

system.Itcannotbeconnectedto anexistingventpipeor chim-

ney.It mustbeterminatedto theoutdoors,Failureto pmperlyin-

stalltheventingsystemcanresultinasphyxiation,afireorexplo-

sionand can causeDEATH, SERIOUS BODILY INJURY,OR

PROPERTYDAMAGE.

4. The water hearer comes equipped with a 5 foot power cord

which can be used to connect to a 110/120 volt power

source if (1) local codes allow, and (2) there is a three prong

receptacle available.

A WARNING

Donot usean extensioncord.If there isnot a suitablerecepta-

cleand/or localcodesprohibituseof a powercord,fieldwiring

mustbeprovided.

ACAUTION

WATER HEATERS EVENTUALLY LEAK: Installation of the

water heater must be accomplished in such a manner that if

the tank or any connections should leak, the flow of water

will not cause damage to the structure. For this reason, it is

not advisable to install the water heater in at attic or upper

floor. When such locations cannot be avoided, a suitable

drain pan should be installed under the water heater. Drain

pans are available at your local Sears store. Such a drain pan

must be not greater than I% inches deep, have a minimum

length and width of at least 2 inches greater than the water

heater dimensions and must be piped to an adequate drain.

The pan must not restrict combustion air flow. Under no cir-

cumstances is the manufacturer or Sears to be held liable

for any water damage in connection with this water heater.

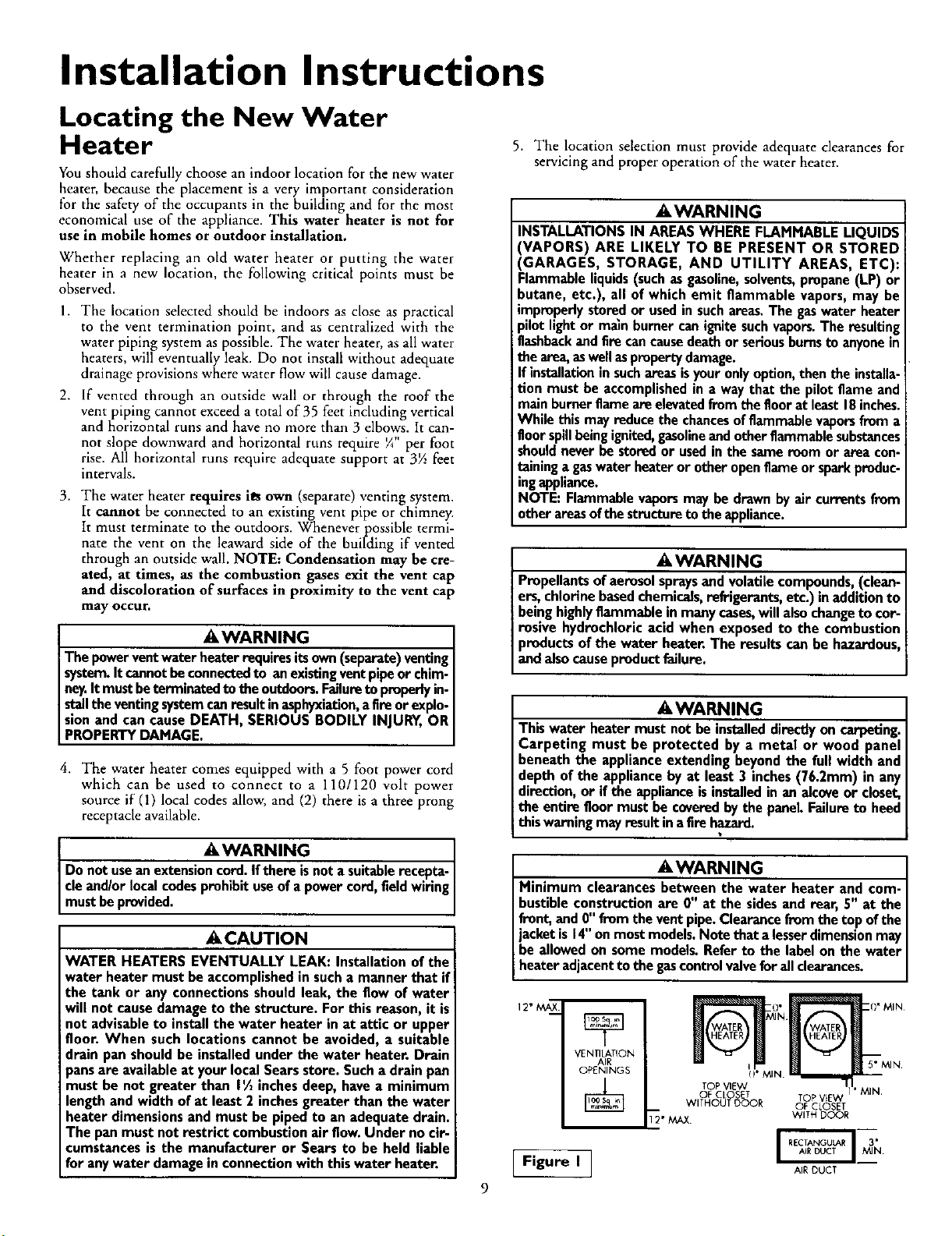

5. The location selection must provide adequate clearances for

servicing and proper operation of the water heater.

AWARNING

INSTALLATIONSIN AREASWHERE FLAMMABLELIQUIDS

(VAPORS) ARE LIKELY TO BE PRESENT OR STORED

(GARAGES, STORAGE, AND UTILITY AREAS, ETC):

Flammableliquids(suchas gasoline,solvents,propane(LP) or

butane, etc.), all of which emit flammable vapors,may be

improperlystoredor usedin suchareas.The gaswater heater

pilot lightor ma_nbumercanignitesuchvapors.The resulting

flashbackandfire cancausedeathor seriousburnsto anyonein

the area,aswellaspropertydamage.

Ifinstallationinsuchareasisyouronlyoption,thenthe installa-

tion must be accomplishedin a waythat the pilot flame and

mainburnerflameareelevatedfromthefloorat least18inches.

While this mayreducethechancesofflammablevaporsfroma

floorspillbeingignited,gasolineandotherflammablesubstances

shouldneverbestoredor usedin the sameroom or areacon-

tainingagaswater heateror otheropenflameor sparkproduc-

ingappliance.

NOTE: Flammablevaporsmaybe drawnby air currentsfrom

otherareasofthe structure to theappliance.

AWARNING

Propellantsofaerosolspraysand volatilecompounds,(clean-

ers,chlorinebasedchemicals,refrigerants, etc.)inadditionto

beinghighlyflammable in manycases,willalsochangeto cor-

rosive hydrochloricacid when exposedto the combustion

productsof the water heater.The results canbe hazardous,

andalsocauseproductfailure.

A WARNING

Thiswater heater mustnot be installeddirectlyon carpeting.

Carpeting must be protected by a metal or wood panel

beneath the applianceextendingbeyondthe full width and

depth of the appliance byat least3 inches(76.2mm) in any

direction,or if the applianceis installedin an alcoveorcloset,

the entire floor mustbe coveredby the panel.Failureto heed

this warningmayresultina firehazard.

AWARNING

Minimum clearances between the water heater and com-

bustibleconstructionare 0" at the sidesand rear, 5" at the

front,and 0"fromthe vent pipe.Clearancefromthe top ofthe

jacketis 14"onmostmodels.Notethat a lesserdimensionmay

beallowedon somemodels.Referto the labelon the water

heateradjacentto the gascontrolvalveforallclearances.

12" MAX

Figure I ]

VENTILATION

AIR

OPENINGS

TOP VIEW 1 I

OF CLOSET TOP VIEW 1' MIN

WITHOUT OOOR OF CLOSET

'_2" MAX. WITH DOOR

_'_N [1' MIN

MIN'(!_MIN.

AlE DUCT

Installation Instructions (cont'd)

AWARNING

A gaswater heater cannot operate properly without the cor-

rect amount of air for combustion. Do not install in a con-

fined area such a closet, unless you provide air as shown in

the "Locating The New Water Heater" section. Never

obstruct the flow of ventilation air If you have any doubts or

questions at all, call your gascompany. Failure to provide the

proper amount of combustion air can result in a fire or explo-

sion and can cause DEATH, SERIOUS BODILY INJURY, OR

PROPERTY DAMAGE.

_iWARNING

If this water heater will be used in beauty shops, barber shops,

cleaning establishments, or self-service laundries with dry

cleaning equipment, it is imperative that the water heater or

water heaters be installed so that combustion and ventilation

air be taken from outside these areas. Refer to the "Locating

The New Water Heater" section of this manual and also the

latest edition of the National Fuel Gas Cede, ANSI Z223.1, also

referred to as NFPA 54 for specifics provided concerning air

required.

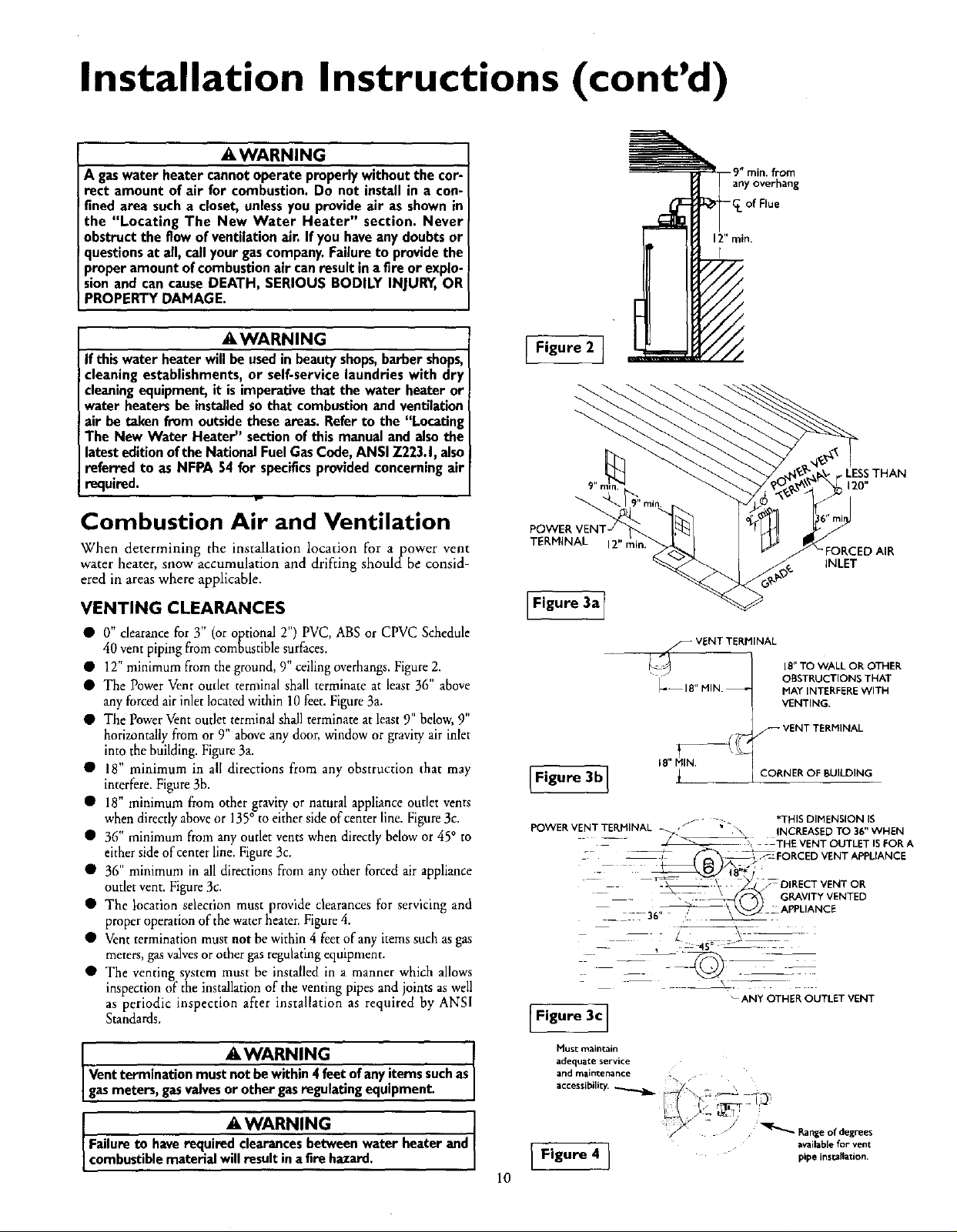

Combustion Air and Ventilation

When determining the installation location for apower vent

water heater, snow accumulation and drifting shouldbe consid-

ered in areas where applicable.

Figure 2 ]

TERMINAL 12" rain.

9"min. from

any overhang

-_. of Flue

12" min.

r

LESSTHAN

120"

FORCED AIR

INLET

VENTING CLEARANCES

• 0" clearance for Y (or optional 2") PVC, ABS or CPVC Schedule

40 vent piping from combustible surfaces,

• 12" minimum from the ground, 9" ceiling overhangs. Figure 2.

• The Power Vent outlet terminal shall terminate at least 36" above

any forced air inlet located within 10 feet. Figure 3a.

• The Power Vent outlet terminal shall terminate at least 9" below, 9"

horizontally from or 9" above any door, window or gravity air inlet

into the building. Figure 3a.

• 18" minimum in all directions from any obstruction that may

interfere. Figure 3b.

• 18" minimum from other gravity or natural appliance outlet vents

when directly above or 135° to either side of center line. Figure 3c.

• 36" minimum from any outlet vents when directly below or 45° to

either side of center line. Figure3c.

• 36" minimum in all directions from any other forced air appliance

outlet vent. Figure 3c.

• The location selection must provide clearances for servicing and

proper operation of the water heater. Figure 4.

• Vent termination must not be within 4 feet of any items such as gas

meters, gas valves or other gas regulating equipment.

• The venting system must be installed in a manner which allows

inspection of the installation of the venting pipes and joints as well

as periodic inspection after installation as required by ANSI

Standards.

li WARNING

Ventterminationmustnotbewithin4 feetofanyitemssuchas

gasmeters,gasvalvesor other gasregulating equipment,

li WARNING

Failureto haverequired clearancesbetweenwater heaterand

combustiblematerialwillresult ina firehazard.

IFigure 3a 1

f VENT TERMINAL

IE" TO WALL OR OTHER

_18" MIN. _

Figure 3b]

POWER VENT TERMINAL _ • "_ INCREASED TO 36" WHEN

-- - _ --, THE VENT OUTLET IS FOR A

-- _ ,RCED VENT APPLIANCE

.__ ---36" " _!

i

jf _ *THIS DIMENSION I$

-ANY OTHER OUTLET VENT

OBSTRUCTIONS THAT

MAY INTERFERE WITH

VENTING,

VENT TERMINAL

:ORNER OF BUILDING

- DIRECT VENT OR

GRAVITY VENTED

APPLIANCE

[F,gur c]

Must maintain

adequate service

and maintenance L

_cces$i_ili_

i Figure 4 I availableforvent

10

_i_i'_i__ ,,,

F_,_ .,-_ -_-_,

I L _ ril_'r '

pipe ins=llation.

Installation Instructions (cont'd)

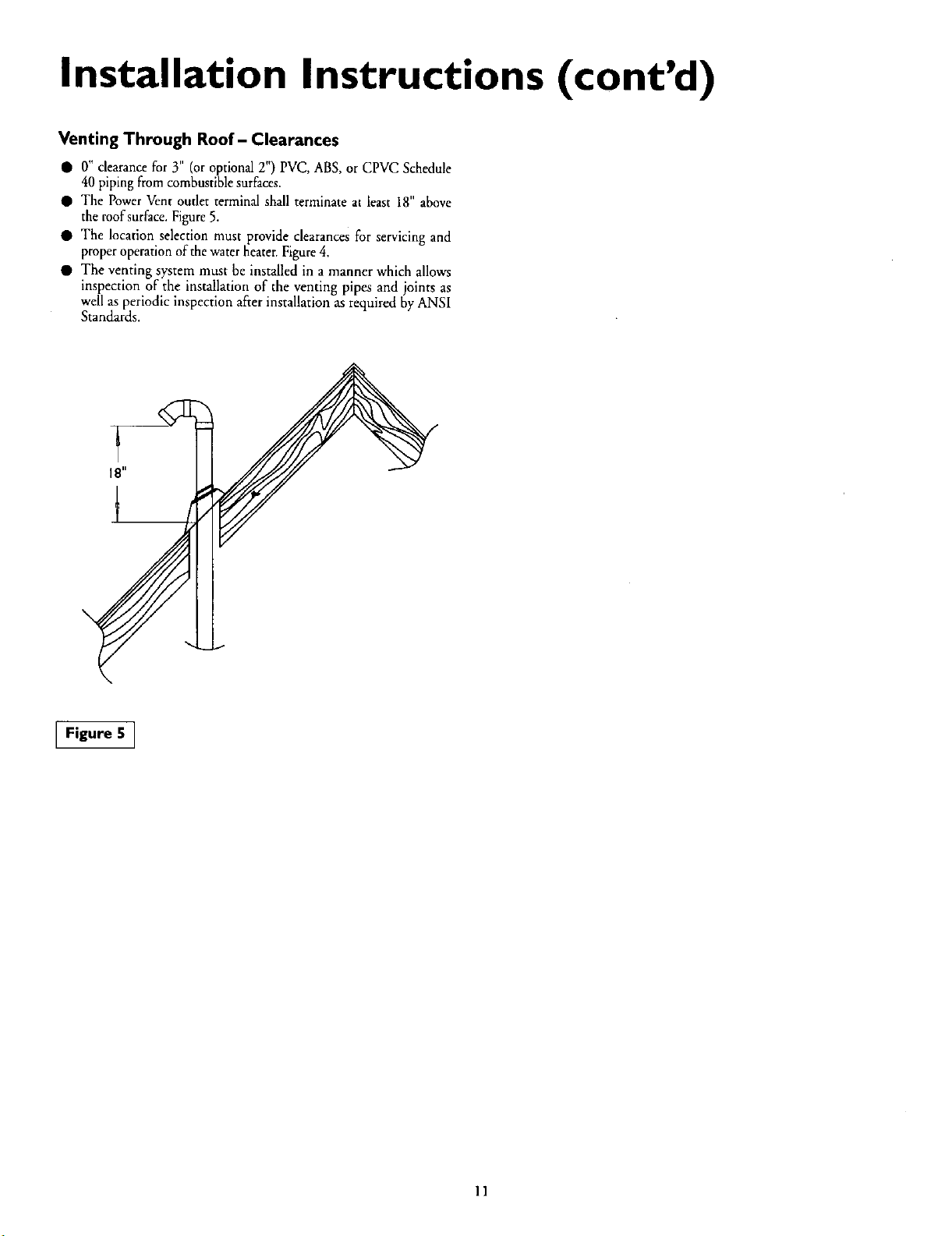

Venting Through Roof- Clearances

• 0" clearance for 3" (or optional 2") PVC, ABS, or CPVC Schedule

40 piping from combustible surfaces.

• The Power Vent outlet terminal shall terminate at least 18" above

the roof surface. Figure 5.

• The location selection must provide clearances for servicing and

properoperationof thewaterheater. Figure4,

• The venting system must be installed in a manner which allows

inspection of the installation of the venting pipes and joints as

well as periodic inspection after installation asrequired by ANSI

Standards.

18"

Figure 5_

11

Installation Instructions (cont'd)

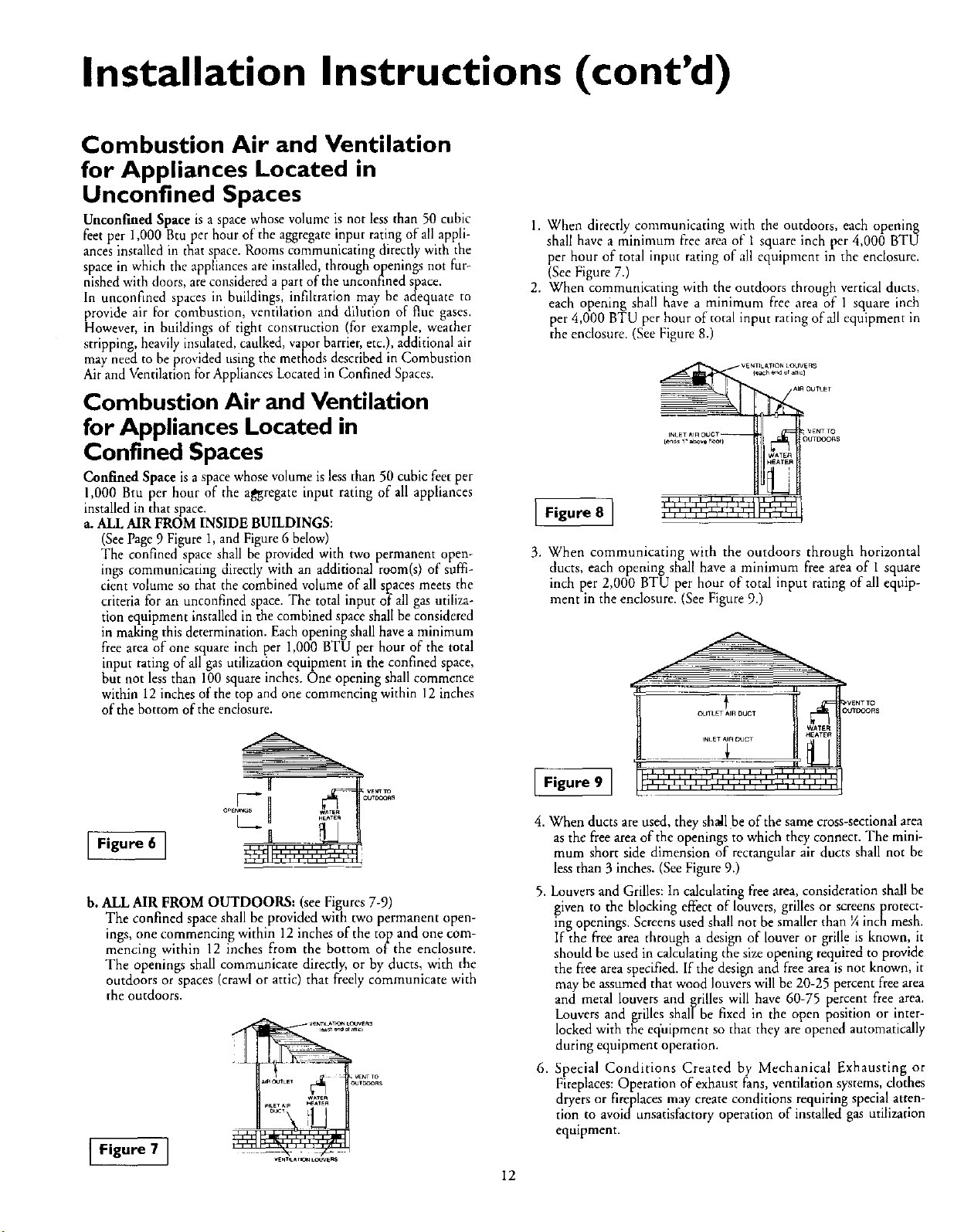

Combustion Air and Ventilation

for Appliances Located in

Unconfined Spaces

Unconfined Space is a space whose volume is not less than 50 cubic

feet per 1,000 Btu per hour of the aggregate input rating of all appli-

ances installed in that space. Rooms communicating directly with the

space in which the appliances are installed, through openings not fur-

nished with doors, are considered a part of the unconfined space.

In unconfined spaces in buildings, infiltration may be adequate to

provide air for combustion, ventilation and dilution of flue gases.

However, in buildings of tight construction (for example, weather

stripping, heavily insuhted, caulked, vapor barrier, etc.), additional air

may need to be provided using the methods described in Combustion

Air and Ventilation for Appliances Located in Confined Spaces.

Combustion Air and Ventilation

1. When directly communicating with the outdoors, each opening

shall have a minimum free area of 1 square inch per 4,000 BTU

per hour of total input rating of all equipment in the enclosure.

(See Figure 7.)

2. When communicating with the outdoors through vertical ducts,

each opening shall have a minimum flee area of 1 square inch

per 4,000 BTU per hour of total input rating of all equipment in

the endosure. (See Figure 8.)

vEr_TKAhON LOUVERS

4each er_ or amc]

AIR OUTLET

for Appliances Located in

Confined Spaces

Confined Space is a space whose volume is less than 50 cubic feet per

1,000 Btu per hour of the a_regate input rating of all appliances

installed in that space.

a. ALL AIR FROM INSIDE BUILDINGS:

(See Page 9 Figure 1, and Figure 6 below)

The confined space shall be provided with two permanent open-

ings communicating directly with an additional room(s) of suffi-

cient volume so that the combined volume of all spaces meets the

criteria for an unconfined space. The total input of all gas utiliza-

tion equipment installed in the combined space shall be considered

in making this determination. Each opening shall have a minimum

free area of one square inch per 1,000 BTU per hour of the total

input rating of all gas utilization equipment in the confined space,

but not less than 100 square inches. One opening shall commence

within 12 inches of the top and one commencing within 12 inches

of the bottom of the enclosure.

_ VEr_Tm

,o.....

J Figure 6 J

b. ALL AIR FROM OUTDOORS: (see Figures 7-9)

The confined space shall be provided with two permanent open-

ings, one commencing within 12 inches of the top and one com-

mencing within 12 inches from the bottom of the enclosure.

The openings shall communicate directly, or by ducts, with the

outdoors or spaces (crawl or attic) that freely communicate with

the outdoors.

Figure 7 ]

Figure 8 ]

{ends 1, a_e _le,00

i i i i i i i i i I I

I I I I I llliJik I I_1_

WATE¢_

H_ATER

3. When communicating with the outdoors through horizontal

ducts, each opening shall have a minimum flee area of 1 square

inch per 2,000 BTU per hour of total input rating of all equip-

ment in the enclosure. (SeeFigure 9.)

OUTLET AIR DUCT Ol/TP'_OFI$

tNLE

Figure 9 ]

4. When ducts are used, they shatl be of the same cross-sectional area

as the free area of the openings to which they connect. The mini-

mum short side dimension of rectangular air ducts shall not be

less than 3 inches. (See Figure 9.)

5. Louvers and Grilles: In calculating free area, consideration shall be

given to the blocking effect of louvers, grilles or screens protect-

ing openings. Screens used shall not be smaller than ¼ inch mesh.

If the free area through a design of louver or grille is known, it

should be used in calculating the size opening required to provide

the free area specified. If the design and free area is not known, it

may be assumed that wood louvers will be 20-25 percent free area

and metal louvers and grilles will have 60-75 percent free area.

Louvers and grilles shall be fixed in the open position or inter-

locked with the equipment so that they are opened automatically

during equipment operation.

6. Special Conditions Created by Mechanical Exhausting or

Fireplaces: Operation of exhaust Fans, ventilation systems, clothes

dryers or fireplaces may create conditions requiring special atten-

tion to avokl unsatisfactory operation of installed gas utilization

equipment.

I2

illllllllllll'l'l'l ' _'_l_l_II

WATER

Installation Instructions (cont'd)

Water Piping

AWARNING

HOTTERWATERCAN SCALD:Water heatersareintendedto

)reducehot water.Water heatedto a temperaturewhichwill

satisfyclotheswashing,dishwashing,andothersanitizingneeds

canscaldandpermanently iniureyou uponcontact.Somepeo-

)leare more likelyto bepermanentlyinjuredby hotwaterthan

others.Theseincludethe elderly,children,theinfirm,orphysical-

ly/mentallyhandicapped.Ifanyoneusinghotwaterinyour home

fits into oneofthesegroupsor if there is alocalcode or state law

requiringa certaintemperature waterat the hot water tap, then

_)umusttakespecialprecautions.Inadditionto usingthelowest

_ossibletemperaturesettingthatsatisfiesyourhotwaterneeds,

a meanssuchasa mixingvalve,shouldbe usedat thehotwater

tapsusedbythesepeopleor at the water heater.Mixingvalves

areavailableat plumbingsupplyor hardwarestores.Followman-

ufacturersinstructions for installation of the valves. Before

changing the factory setting on the thermostat, read the

"TemperatureRegulation"sectioninthismanual.

This water heater shall nor be connected to any heating systems

or component(s) used with a non-potable water hearing appli-

2d_ce.

If a water heater is installed in a closed water supply system;

such as one having a back-flow preventer, check valve, water

meter with a check valve, etc.., in the cold water supply; means

shall be provided to control thermal expansion. Contact the

local utility or local Sears Service Center on how to control this

situation.

NOTE: To rotect against untimely corrosion of hot and

cold water _ it is strongly recommended that dielec-

tric unions or couplings be installed on this water heater

when connected to copper pipe.

tings,

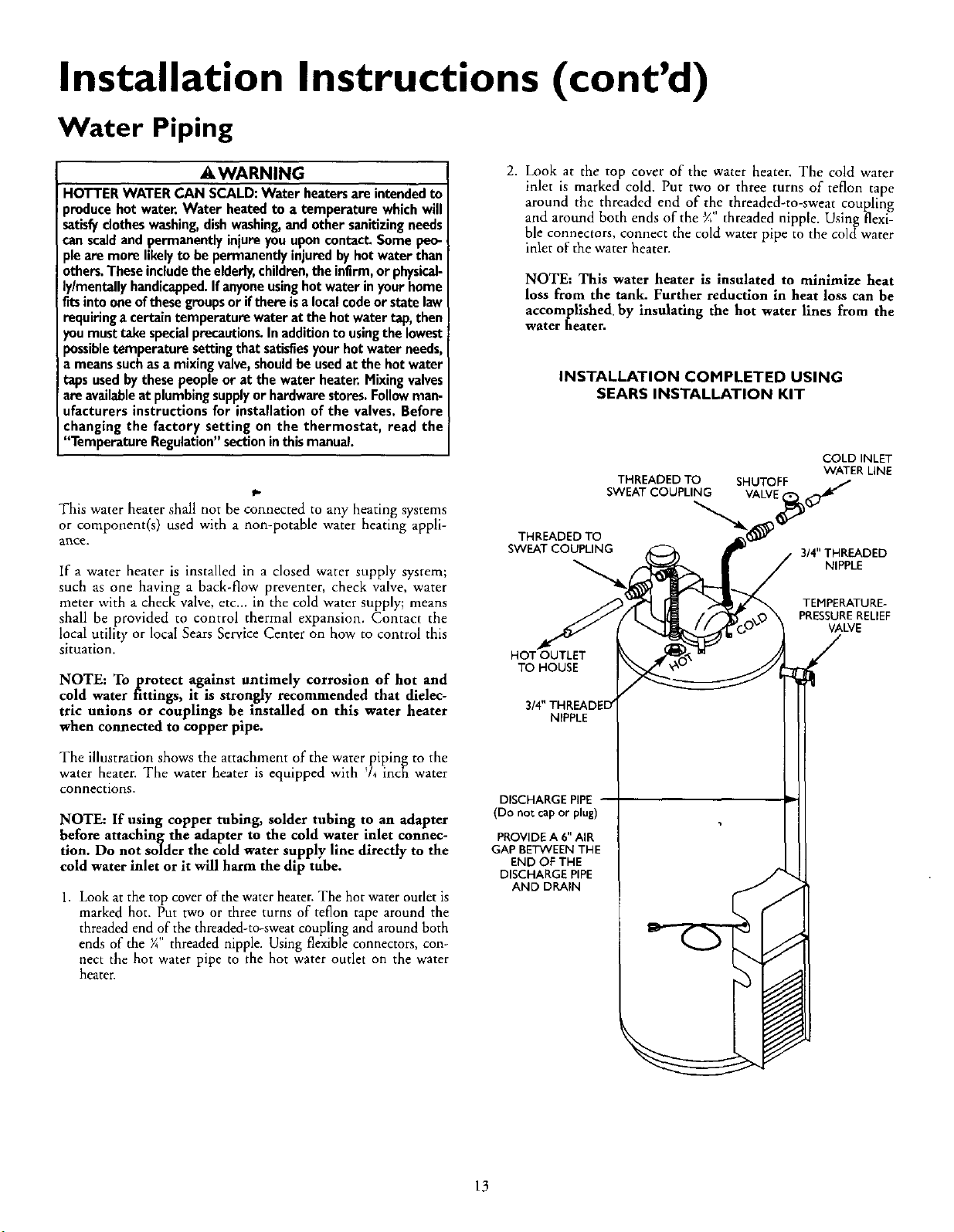

2. Look at the top cover of the water heater. The cold water

inlet is marked cold. Put two or three turns of teflon tape

around the threaded end of the threaded-to-sweat coupling

and around both ends of the _" threaded nipple. Using flexi-

ble connectors, connect the cold water pipe to the coldwater

inlet of the water heater.

NOTE: This water heater is insulated to minimize heat

loss from the tank. Further reduction in heat loss can be

accomplished by insulating the hot water lines from the

water heater.

INSTALLATION COMPLETED USING

SEARS INSTALLATION KIT

COLD INLET

WATER LINE

3/4" THREADED

NIPPLE

TEMPERATURE-

PRESSURERELIEF

VALVE

THREADED TO

SWEAT COUPLING

HOT OUTLET

TO HOUSE

3/4" THREADED'

NIPPLE

THREADED TO SHUTOFF

SWEAT COUPLING

The illustration shows the attachment of the water piping to the

water heater. The water heater is equipped with 74 inch water

connections.

NOTE: If using copper tubing, solder tubing to an adapter

before attaching the adapter to the cold water inlet connec-

tion. Do not solder the cold water supply line directly to the

cold water inlet or it will harm the dip tube.

1. Look at the top cover of the water heater. The hot water outlet is

marked hot. Put two or three turns of teflon tape around the

threaded end of the threaded-to-sweat coupling and around both

ends of the ¼" threaded nipple. Using flexible connectors, con-

nect the hot water pipe to the hot water outlet on the water

heater.

DISCHARGE PIPE

(Do not cap or plug)

PROVIDE A 6" AIR

GAP BETWEEN THE

END OF THE

DISCHARGE PIPE

AND DRAIN

13

Installation Instructions (cont'd)

Temperature-Pressure Relief Valve

_,WARNING

_-- AWARNING

At the time of manufacturethiswater heater wasprovided

with a combinationtemperature-pressuresrelief valvecertified

bya nationallyrecognizedtestinglaboratory that maintains

periodicinspectionofproductionoflistedequi.p,ment or mate-

rials, as meeting the requirements for Rehef Valves and

AutomaticGasShutoffDevicesforHot Water SupplySystems,

andthe latest editionof ANSI Z21.22and the code require.

ments ofASME. If replaced,the valvemustmeet the require.

ments oflocalcodes,butnot lessthana combinationtempera-

ture and pressure reliefvalvecertifiedasmeetingthe require-

mentsfor ReliefValvesandAutomaticGasShutoffDevicesfor

Hot Water SupplySystems,ANSI Z21.22bya nationally recog-

nized testinglaboratorythat maintains periodicinspectionof

productionoflistedequipmentor materials.

hevalvemust be markedwith a maximumset pressurenot

to exceed the marked hydrostaticworking pressureof the

water heater(150 Ibs./sq.in,)anda dischargecapacitynot less

thanthe water heaterinputrate asshownon the modelrating

plate. (Electric heaters- watts dividedby 1000x 3415 equal

BTU/Hr.rate.) _.

Yourlocaljurisdictionalauthority,whilemandatingthe useofa

temperature-pressurerelief valvecomplyingwithANSI Z21.22

and ASME, may require a valvemodeldifferentfrom the one

furnishedwiththe water heater.

Compliancewith suchlocalrequirements mustbe satisfiedby

the installeror enduserofthewater heaterwith a locallypre-

scribedtemperature-pressurereliefvalveinstalledinthe desig-

nated openingin the water heaterin placeof the factoryfur-

nishedvalve.

Forsafeoperationofthewaterheater,the relief valvemustnot

beremovedfrom it'sdesignatedopeningor plugged,

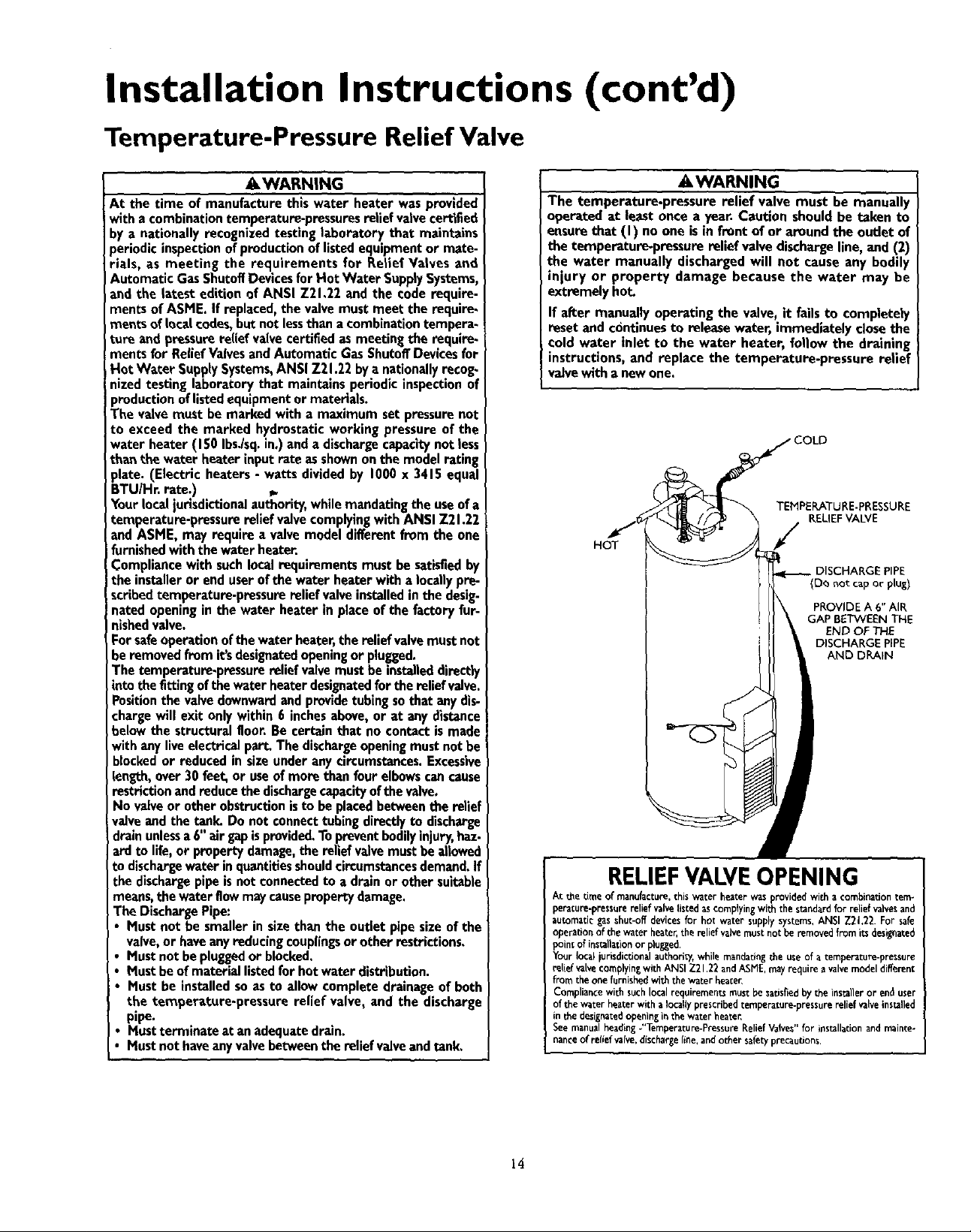

The temperature-pressurereliefvalvemust be installeddirectly

intothe fittingofthe water heaterdesignatedforthe relief valve.

Positionthe valvedownwardandprovidetubingsothatanydis-

chargewill exit onlywithin6 inchesabove,or at any distance

belowthe structuralfloor.Be certainthat no contactismade

withany liveelectricalpart.The dischargeopeningmustnot be

blockedor reduced in sizeunderanycircumstances.Excessive

length, over 30 feet,or useof more thanfour elbowscancause

restriction andreducethe dischargecapacityofthe valve.

No valveor other obstructionisto beplacedbetweentherelief

valveandthe tank.Do not connecttubingdirectlyto discharge

drainunlessa6" airgapisprovided.Topreventbodilyinjury,haz-

ardto life,or propertydamage,the relief valvemustbeallowed

to dischargewaterinquantitiesshouldcircumstancesdemand.If

thedischargepipe isnot connectedto a drainor othersuitable

means,thewaterflowmaycausepropertydamage.

The DischargePipe:

Mustnot be smallerin sizethanthe outletpipesizeof the

I" valve,or haveanyreducingcouplingsor other restrictions.

Mustnot be pluggedorblocked.

Mustbeofmateriallistedforhotwater distribution.

Mustbe installedsoasto allowcomplete drainageof both

the temperature-pressurerelief valve, and the discharge

pipe.

Mustterminateat anadequatedrain.

Mustnothaveanyvalvebetweenthe relief valveandtank,

The temperature.pressure relief valve must be manually

operated at leastonce a year.Caution shouldbe taken to

ensurethat (I) no one isin frontof or aroundthe outlet of

the temperature-pressurerelief valvedischargeline,and (2)

the water manually dischargedwill not causeany bodily

injury or property damage because the water may be

extremelyhot.

If after manually operatingthe valve,it failsto completely

reset and continuesto releasewater, immediatelyclosethe

coldwater inlet to the water heater, follow the draining

instructions,and replace the temperature-pressure relief

valvewitha newone.

HOT

RELIEFVALVEOPENING

At the tir_e of manufacture, this water heater was provided with a combination tem-

perature-pressurerelief valve listedas complying with the standard for relief valvesand

automatic gas shut-off devices for hot water supply systems, ANSI Z21.22. For safe

operationofthe waterheater,the reliefvalvemustnot beremovedfromitsdesignated

point of installationor plugged.

Your local jurisdictionalauthority,while mandating the use of a temperature-pressure

relle_valve complyinZwith ANSI 721.22 and ASME,may require avalve model different

fromthe onefurnishedwiththewaterheater,

Compliancewithsuchlocalrequirementsmustbesatisfiedbytheinstalleror enduser

of the water heater with a locallyprescribedtemperature-pressure relief valveinstalled

in the designatedopeningin the water beater

See manual headingJ'Temperature-PressureRelief Valves" for installationand mainte-

nance of relief valve,dischargeline, and other safety precautions.

TEMPERATURE-PRESSURE

RELIEFVALVE

/

• DISCHARGE PIPE

{D_ r_otcap or plus)

PROVIDE A 6" AIR

GAP BETWEEN THE

END OF THE

DISCHARGE PiPE

AND DRAIN

14

Loading...

Loading...