0291319

SE_A/RS o:

Gas Water Heater

Owners Manual

FOR POTABLE WATER HEATING ONLY

NOT SUITABLE FOR SPACE HEATING

NOT FOR USE IN

MOBILE HOMES

MODEL NUMBERS:

153.335200 40 Gal. High Altitude

153.335250 40 Gal.

153.335251 40 Gal.

153.335302 30 Gal. High Altitude

153.335350 30 Gal.

153.335351 30 Gal.

153.335400 40 Gal. High Altitude

153.335450 40 Gal.

153.335451 40 Gal.

153.335502 50 Gal. High Altitude

153.335550 50 Gal.

153.335551 50 Gal.

153.335600 65 Gal. High Altitude

153.335650 65 Gal.

153.335651 65 Gal.

153.335750 50 Gal.

153.335751 50 Gal.

153.335850 65 Gal.

153.335851 65 Gal.

153.335951 40 Gal. L.P.

k2

• Installation • Operation • Repair Parts

For Your Safety ANODORANT,SADDEDTOTHECAS

WARNING: If the information in these

instructions are not followed exactly, a

fire or explosion may result, causing prop-

erty damage, personal injury or dea]l_.

-Do not store or use gasoline or other

flammable vapors affd liquids in the

vicinity of this or any other appliance.

-WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not to°uch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neigh_bor's phone. Follo'w the

gas supplierV's instrui:tions.

• if you can not reach your gas supplier,

call the fire department.

-Installation and service must be per-

formed by a qualified installer, service

agency or the gas supplier.

Save this Manual for Future Reference.

USED BY THIS WATER HEATER

WARNING

Improper installation, adjustment, alter-

ation, service or maintenance can cause

DEATH, SERIOUS BODILY INJURY, OR

PROPERTY DAMAGE. Refer to this manu-

al for assistance or consult the local Sears

Service Center or gas utility for further

information.

WARNING

Flammable vapors may be drawn by air

currents from other areas of the struc-

ture to this appliance.

WARNING

READ THE GENERAL SAFETY SECTION

BEGINNING ON INSIDE COVER AND

THEN THIS ENTIRE MANUAL BEFORE

INSTALLING OR OPERATING THIS

WATER HEATER.

0

Z

WARNING

Improper installation, adjustment, alteration, service or mainte-

nance can causeDEATH, SERIOUS BODILY INJURY OR PROP-

ERTY DAMAGE. Refer to this manual for assistanceor consult

your local Sears ServiceCenter for further information.

WARNING

At the time of manufacture thiswater heater was providedwith a

combination temperature-pressures relief valve certified by a

nationally recognized testing laboratory that maintains periodic

inspedion of produdion of listed equipment or materials,asmeet-

ing the requirementsfor Relief Valvesand Automatic Gas Shutoff

Devices for Hot Water Supply Systems,and the latest edition of

ANSI Z21.22 and the code requirementsof ASME.If replaced,the

valvemust meet the requirementsof local codes,butnot lessthan

a combination temperature and pressure relief valve certified as

meeting the requirements for Relief Valves and Automatic Gas

ShutoffDevicesfor Hot Water SupplySystems,ANSI Z21.22 by a

nationally recognized testing laboratory that maintains periodic

inspectionofprodudion of listedequipment or materials. _

The valve must be marked with amaximum set pressurenot to

exceed the marked hydrostatic working pressure of the water

heater (150 Ibs:q./sin.) anda dischargecapacity not less.than the

water heater input rate as shown on the model rating plate.

(Electric heaters- watts divided by 1000 x 3415 equal BTU/Hr.

rate.)

Your local jurisdictional authority, while mandating the use of a

temperature-pressurerelief valve complyingwith ANSI Z21.22 and

ASME,may require a valvemodel different from the one furnished

with the waterheater.

Compliance with such local requirementsmustbe satisfiedby-the

installeror end userof the water heater with a locally prescribed

temperature-pressurerelief valve installedin the designatedopen-

ingin thewater heater in placeof the factory furnishedvalve.

For safeoperation of the water heater,the relief valve mustnot be

removedfrom it's designatedopeningor plugged.

The temperature-pressure reh'ef valve must be installeddirectly

into the fitting of the water heater designatedfor the relief valve.

Positionthe valve downward and provide tubing so that any dis-

charge will exit only within 6 in(_hesabove, or at any distance

below the structural"floor.Becertain that no contact ismade with

any live electricalpart. The dischargeopeningmustnot be blocked

or reducedin sizeunder anycircumstances.Excessivelength, over

15 feet, or useof more than two elbows can causerestridion and

reduce the dischargecapacityofthe valve.

No valve or other"obst'ructionis to be placed between the relief

valve and the tank. Do not connect tubing directly to discharge

drain unlessa 6" air gap is provided. To prevent bodily injury,haz-

r ' ....

a d to life, or property-damage,the relief valve mustbe allowed to

dischargewater in quantitiesshould circumstancesdemand.If the

discharge pipe is not connected to a drain or other suitable

means,the water flow may causeproperty damage.

The Discharge Pipe:

--Must not Me smaller in size than the outlet pipe size of the

valve, or haveany reducing couplingsor other restridions.

--Must not be plugged or blocked.

--Must be of material listed for hot water distribution.

--Must be installed so as to allow complete drainage of both

the temperature-pressure relief valve, and the discl_argepipe.

--Must terminate at an adequate drain.

--Must not have any valve between the relief valve and tank.

WARNING

A fire can start if combustiblematerialssuchasclothing, cleaning

materials, or flammable liquidsare placed againstor next to the

water heater.

WARNING

WATER HEATERSEQUIPPED FOR ONE TYPEGAS ONLY: This

water heater is quipped for one type gas only.Checkthe model

ratingplate nearthe gascontrolvalvefor thecorred Eas.DO NOT

USE"IHIS WATERHEATERWITH ANY GAS OTHEI_ THAN THE

ONE SHOWN ON THE MODEL RATING PLATE.Failureto usethe

corred gascancauseproblemswhich can resultin DEATH,SERI-

OUS BODILYINJURY,OR PROPERTYDAMAGE. If you have any

questionsor doubtsconsultyourgassupplieror localutility.

WARNING

INSTALLATIONS IN AREAS WHERE FLAMMABLE LIQUIDS

(VAPORS)ARELIKELYTO BEPRESENTOR STORED(GARAGES,

STORAGE,AND UTILITYAREAS,ETC):Flammableliquids(suchas

gasoline,solvents,propane(LP)or butane,etc.), all of whichemit

flammable vapors, may be improperly stored or used in such

areas.The gas water heater pilot light or main burner can ignite

suchvapors.The resultingflashbackand fire can causedeath or

seriousburnsto anyonein the area,aswell aspro_rty damage.

If installationin suchareasis your only option,then the installa-

tion mustbe accomplishedin a way that the pilot flame and main

burner flame are elevatedfrom the floor at least 18 inches.While

thismayreducethe changesof flammable vaporsfrom a floor spill

being ignited, gasoline and other flammable substancesshould

never I_ storedor usedinthe sameroom or area containinga gas

water heateror otheropen flameor sparkproducingappliance.

NOTE: Flammable vapors may be drawn by air (_urrentsfrom

other areasof thestructureto the appliance.

WARNING

HOTTER WATERCAN SCALD:Water heatersare intendedto pro-

duce hot water. Water heated to a temperaturewhich will satisfy

clothes washing, dish washing, and other sanitizing needs can

scaldand permanentlyinjure you upon contact.Somepeople are

more likely to be permanently injured by hot water than others.

Theseincludethe elderly,children, the infirm, or physically/men-

tally handicapped.If anyoneusinghot water in your home fits into

one of thesegroupsor if there is a local code or statelaw requir-

ing a certain temperature water at the hot water tap, then you

must takespecialprecautions.In additionto usingthe lowestpos-

sibletemperaturesettingthat satisfiesyour hot water needs,some

type of temperingdevice,suchas a mixing valve, shouldhe used

at the hot water taps usedby thesepeopleor at the water heater.

Mixing valvesare availableat plumbing supplyor hardwarestores.

Follow manufacturersinstructionsfor installation of the valves.

Before changing the factory setting on the thermostat, read the

"Temperature Regulation"sectionin this manual.

WARNING

BEFORELIGHTING [PROPANE (L.P.) GAS WATER HEATERS]:

Propane(LP.) gasis heavierthan air. Shouldthere be a leak in the

system, the gaswill settle near the ground. Basements,crawl

spaces,skirtedareasundermobile homes(evenwhenventilated),

closetsandareasbelow ground level will serveaspocketsfor the

accumulationof this as Beforeattemptingto light or relightthe

g , • -- --_ . •

water heater'spilot or turning on a nearbyelectrical lightswitch,

be absolutelysurethere isno accumulatedgasin the area. Search

for odor of gas by sniffingat _round level in the vicinity of the

appliance. If odor isdetected,_'ollow stepsindicatedat "For Your

Safety"on the coverpageof thismanualthenleavethepremises.

WARNING

Do not usethis appliance if any part of it hasbeen underwater.

Immediately call a SearsServiceTechnicianto inspectthe appli.

ance and to replacethe gas control or any part of the burner sys-

tem which hasbeenunderwater.

WARNING

;This water heater must not be installed directly on carpeting.

Carpetin.gmustbe protected by a metal or woodpanel beneath

the appliance extending b.eyondthe full width and depth of the

applianceby at least 3 inches (76.2mm) in any direction, or if the

appliance !s installedinan a!coveor closet,the entire floor must

be covered by the panel. Failure to heed this warning may result

in afire hazard.

WARNING

A gaswater heater cannot operate properly without the correct

amount of air for combustion.Do notinstall in a confined area

such a closet, unlessyou provide air as shown in the "Locating

The New Water Heater" section. Never obstructthe flow of ven-

tilation air. If you have any doubtsor questionsat all, call your

gas company. Failure toprovide the proper amount of combus-

tion air can result in a fire or explosion and can cause DEATH,

. SERIOUS BODILY INJURY, OR PROPERTYDAMAGE.

WARNING

If this water heater will be usedin beauty shops,barber shops,

cleaningestablishments,or self-servicelaundrieswith dry clean-

"ing equlpment, it is imperative that the water heater or water

heaters be installed so that combustion and ventilation air be

taken from outside these areas. Refer to the "Locating The New

Water Heater" sectionof thismanual andalsothe latestedition of

the National Fuel Gas Code, ANSI Z223.1, also referred to as

NFPA54 for specificsprovided concerningair required.

WARNING

_VENTDAMPERS- Any vent damper,whether it isoperated ther-

mally or otherwise must be removed if its use inhibits proper

drafting of the water heater.

Thermally Operated Vent Dampers:Gas-firedwater heaters hav-

ingthermal efficiency in excessof 80% may producea relatively

low flue gas temperature. Suchtemperatures may not be high

enough to properly open thermally operated vent dampers.This

would causespillageof fluegasesandmay causecarbon monox-

'ide poisoning.

Vent dampers must bear evidence of certification as complying

with the latest edition of American National Standard ANSI

Z21.68 (ANSI Z21.66 & 67, respectively, cover electrically and

mechanically actuated vent dampers). Before installationof any

vent damper, consult your local SearsService Center or the gas

utility for further information.

WARNING

1. The appliance and its individual shutoff valve mustbe discon-

nectedfrom the gassupply piping systemduringany pressure

testingof thegas systemat test pressuresin excessof '/2pound

per square inch (3.5kPa).

2. The appliancemust be isolatedfrom the gassupplypiping sys-

tem by closin.gits individual manual..shutoffvarve during any

pressuretesting of the gassupply piping systemat test pres-

suresequal or lessthan _2pound per squareinch (3.5kPa).

WARNING

_!Sootbuild-upindicatesa problem that requirescorrectionbefore

further use. Turn "OFF" gasto water heater and leave "OFF"

until repairsare made, becausefailure to correct the causeofthe

Sootingcan result in a fire or explosion causing DEATH, SERI-

OUS BODILY INJURY,OR PROPERTYDAMAGE.

WARNING

The water heater with draft hood installed must be properly

vented to a chimney which terminates outdoors.Never operate

the water heater unlessit isvented to the outdoors and has ade-

quate air supplyto avoid risksof improper operation, explosion

or asphyxiateon.

WARNING

Obstructed or deteriorated vent systems may presenta serious

health riskor asphyxiation.

WARNING

Chemicalvapor corrosionof the flue and vent systemmay occur

if air for combustioncontainscertain chemical val_rs. Spraycan

propellants, cleaning solvents, refrigerator and air conditioner

refrigerants, swimming pool chem|cals, calcium and sodium

chloride, waxes, bleach, and processchemicalsare typical com-

poundswhich are potentiallycorrosive.

WARNING

Minimum clearancesbetweenthe water heater and combustible

constructionare 1" at the sidesand rear, 4" at the front, and 6"

from the vent pipe. Clearance from the top of the jacket is 18"

on most models. Note that a lesser dimensionmay be a!lowed

on somemodels.Referto the label on the water heater adjacent

to the gascontrolvalvefor all clearances.

WARNING

HYDROGEN GAS: Hydrogengascan be producedin a hot water

systemthat hasnot been usedfor a long period of time (general-

ly two weeks or more). Hydrogen gas ts_ extremely flammable

and explosive.To prevent the poss_ility of injury under these

conditions,we recommendthe hot water faucetbe opened for

several minutes at the kitchen sink before any electrfcal appli-

ances which are connected to the hot water systemare used

(such as a dishwasheror washing machine). If hydrogengas is

present,there will probably be an unusualsoundsim]lar to a!r

escaping through the pipe as the hot water faucet is opened.

There mustbe no smokingor open flame near the faucet at the

time it isopen.

WARNING

INSULATING JACKETS:When installingan external water heater

insulationjacketon a gaswater heater:

a. DO NOT cover the temperature-pressurerelief valve.

b. DO NOT put insulationover any part of the top of the gas

water heater.

c. DO NOT put insulationover the gas control valve or gas con-

trol valve/burner cover,or any accessareastothe burner.

d. DO NOT let insulation around the gaswater heater to get

within 8 inchesof the floor (air must get to the burner).

e. DO NOT cover or remove operating instructions,and safety

related warning labels and materials affixed to the water

heater.

Failure to heed this will result in the possibility of a fire or

explosion.

WARNING

Do not usethis appliance if any part of it hasbeenunder water.

Immediately call a SearsServiceTechmclan to inspectthe appli-

ance andto replace the gascontrolor anypart of the burner sys-

tem which hasbeen underwater.

CAUTION

WATER HEATERSEVENTUALLYLEAK: Installation of the water

heater mustbeaccomplishedin such a manner that if the tank or

any connectionsshould leak, the flow of water will not cause

damageto the structure.When suchlocationscannot be avoid.

ed, a suitable drain pan should be installed under the water

heater. Drain pansare available at yourlocal Searsstore, Sucha

drain pan mustbe not greater than 11/_inches deepthave a mini-

mum lengthandwidth of at least 2 inchesgreaterthan the water

heater dimensionsand must be .pipedto an adequate drain. The

pan must not restrict combust,on air flow. Under no circum-

stancesis the manufacturer or Searsto be held liable for any

water damageinconnectionwith this water heater.

General Safety................................................................................................................................._-_

Table of Contents ...........................................................................................................................4

Introduction ..........................................................................................................................................5

SPepeCifications.......................................................................................................................................5

aring for the New Installation ...................................................._.................s

Materiafs and Basic Tools Needed ............._............._...................................,........6

Materials Needed .................................................................................................................................................. 6

Basic Tools ............................................................................................................................................................ 6

Removing the Old Water Heater. ............................................................................7

Locating the New Water Heater ...........................................................................8-9

Facts to Consider About Location .......................................................................................................................... 8

Combustion Air and Ventilation for Appliances Located in Unconfined Spaces ..................................................... 9

Combustion Air and Ventilation for Appliances Located in Confined Spaces ......................................................... 9

Installing the New Water Heater .............,.......................................................lo-14

Water Piping .......................................................................................................... .............................................. 10

Temperature-Pressure Relief Valve ....................................................................................................................... 11

Filling the Water Heater..: .................................................................................................................................... 12

Venting ................................................................................................................................................................ 12

Gas Piping ................................................................................................................................................... •........ 13

Installation Checklist ........................................................................................................................................... 14

Lighting ..................................................................................................................................................._s-_6

Temperature Regulation .....................................................................................................lz

For Your Information ........................................................................................................;_a-19

Start Up Conditions ... .......................................................................................................................................... I 8

Condensation .................................................................................................................................... "................ 18

Smoke/Odor ...................................................................................................................................................... 18

Thermal Expansion ............................................................................................................................................. 18

Strange Sounds .................................................................................................................................................. 18

Operational Conditions ......................... . .................... .................................................................................... 18-19

Smelly Water ..................................... _.......................................................................................................... 18-19

"Air" In Hot Water Faucets ................................................................................................................................ 19

High Temperature Shut Off System .................................................................................................................... 19

Not Enough or No Hot Water ............................................................................................................................ 19

Water Is Too Hot ........................... i.................................................................... ................................................ 19

Periodic Maintenance .......................................................................................................2o-2_

Venting System Inspection ................................................................................................................................... 20

Burner Inspection ................................................................................................................................................ 20

Burner Cleaning .................................................................................................................................................. 20

Propane (L.P.) Gas Control Valve & Burner Assembly Replacement Information .................................................. 20

Housekeeping ........................................................................................................... .......................................... 20

Temperature-Pressure Relief Valve Operation ...................................................................................................... 21

Tank Sediment Cleaning ................. •..................................................................................................................... 21

Draining .............................................................................................................................................................. 21

Drain Valve Washer Replacement .............................................................................. _......................................... 21

Service ................................................................................................................................................................ 21

Leakage Checkpoints ...............................................................................................................22

Repair Parts..................................................................................................................................... 24-31

IAI ._L..

vvarramv ...................................................................................................................................................

About Your"!warranty .............. ................................. ,........................................................................................... 32

Sears Installation Policy ....................................................................................................................................... 32

Sears Installation Warranty ................................................................... .'.............................................................. 32

F

32

-""/hanK You for purchasing a Sears water heater.

_roDerly installed and maintained, it should give you years of

rouble free service. If you should decide that you want the new

rater heater professionally installed by Searscall the local Sears

;erviceCenter or any Sears store. They will arrange for prompt,

luality installation by Searsauthorized contractors.

_bbreviations Found In This Instruction Manual

A.G.A. - American Gas Association

,.N.S.I. - American National Standards Institute

J.F.P.A.- National Fire Prevention Association

WARNING

This gas-fired water heater is design certified by the

American Gas Association Laboratories under

American National Standards for Gas Water Heaters.

The installation must conform with this manual, Local

Codes and with the latest edition of the National Fuel

Gas Code, ANSI Z223.1.

This publication is available from your local govern-

ment or public library, gas company, or by writing

NFPA, Batterymarch Park, Quincy, MA 02269.

RECOVERY DIMENSIONS IN INCHES

MODEL NUMBER CAPACITY OF B.T.U. PERHOUR VENT HEIGHT TO

153.335200 40 NATURAL 35,000 35.8 3" or 4 'I 20" ..... 47'/2"

153.335250 40 NATURAL 35 O00 35.8 3" or 4" 20" 47'/2"

153.335251 40 NATURAL 35,000 35.8 3" or 4" 20" 471/2''

153.335302 30 NATURAL 40,000 40.9 3" or 4" -16" 57'/2"

153.335350 30 NATURAL 40,000 40.9 3" or 4" 16" 57'/2"

153.335351 30 NATURAL 40.000 40.9 3" or 4" 16" 57'/,."

153.335400 40 NATURAL 40,000 40.9 3" or 4" 18" 58'/4"

153.335450 40 NATURAL 40,000 40.9 3" or 4" 18" 581/4''

153.335451 40 NATURAL 40,000 40.9 3" or 4" 18" 58'/4"

153.335502 50 NATURAL 40,000 40.9 3" or 4" 20'I 58"

153.335550 50 NATURAL 40,000 40.9 3" or 4" 20" 58"

153.335551 50 NATURAL 40,000 40.9 3" or 4" 20" 58"

153.335600 65 NATURAL 40,000 40.9 3" or 4" 22" 59'/2"

153.335650 65 NATURAL 40,000 40.9 3" or 4" 22" 59'/2"

153.335651 65 NATURAL 40,000 40.9 3I' or 4" "22" 591/2''

153.335750 50 NATURAL 52,500 53.7 4" 20" 583/4''

153.335751 50 NATURAL 52,500 53.7 4" 20" 58¥4"

153.335850 65 NATURAL 50,000 51.2 4" 22" 591/2'i

153.335851 65 NATURAL 50,000 51.2 4" 22" "' 591/2"

153.335951 40 PROPANE 40,000 40.9 3" or 4" 18" ",58'/4"

TANK TYPE I I _._l_- tJAL_. MINIMUM

IN GALLONS GAS RATE @90°F RISE PIPE DIAMETER JACKET TOP

, ,, . , ....

.... [

Readthe"GeneralSafety"section,pages2and3of this manual

firstandthentheentiremanualcarefully.If you don'tfollow the

safetyrules,thewater heaterwill notoperateproperly.Itcould

causeDEATH,SERIOUSBODILYINJURYAND/OR PROPERTY

DAMAGE.

Thismanualcontainsinstructionsfor the installation,operation,

and maintenanceof the gas-firedwater heater.It alsocontains

warningsthrough out the manualthat ou must read and be

a - Y

wareof. All warningsand all instructionsareessentialto the

properoperationof the water heaterandyour safety.Sincewe

cannotput everythingon the firstfew pages,READTHEENTIRE

MANUALBEFOREATTEMPTINGTO INSTALLOR OPERATE

THEWATERHEATER.

Theinstallationmustconformwith theinstructionsin thismanual;

gascompanyrules;and LocalCodes,or in the absenceof Local

Codes,withthelatestedition oftheNationalFuelGascode,ANSI

Z223.1,alsoreferredto asNFPA54.Thispublicationisavailable

from yourlocalgovernmentor public library or gascompanyor

bywriting NFPA,BatterymarchPark,Quincy,MA02269.

3. If after readingthis manual you haveany questionsor do not

understandanyportionof the instructions,call the SearsService

Center.

4. Carefully plan theplacewhere you aregoing to put the water

heater.Correctcombustion,ventaction,andventpipeinstallation

are very important in preventing death from possiblecarbon

monoxidepoisoningandfires.

Examinethelocationtoensurethewaterheatercomplieswith the

"LocatingtheNewWaterHeater'sectionin thismanual.

5. For California installation this water heater mustbe braced,

anchored,or strappedtoavoidfalling or movingduringan earth-

quake. See instructions for correct installation procedures.

Instructionsmaybeobtainedfrom yourlocaldealer, wholesaler,

publicutilities orCaliforniaOffice of theStateArchitect,400 P

Street,Sacramento,CA 95814.

Materials Needed

To simplify the installation Sears has available the installa-

tion parts shown below. You may or may not need all of

these materials, depending on your type of installation.

WM_

: i i

COMPRESSION COUPLINGS

FOR CONNECTING TO

COPPER PLUMBING WITH-

OUT SWEAT SOLDERING

EXPANSION TANKS FOR

THERMAL EXPANSION

CONDITIONS AVAILABLE

IN 2 GALLON AND 5

GALLON CAPACITY

THROUGH LOCAL SEARS

SERVICE CENTERES

i

WATER HEATER

INSTALLATION KIT WITH

FLEXIBLE CONNECTORS FOR

3/4" GALVANIZED OR

1/2"COPPER PLUMBING

VENT ELBOW

VENT EXTENSION

Basic Tools

You may or may not need all of these tools, depending on

your type of installation. These tools can be purchased at

your local Searsstore.

Pipe Wrenches (2) 14"

Screwdriver

Tin Snips

6 Foot Tape of Folding Rule

Garden Hose

Drill

Pipe dope or Teflon Tape

FLEXIBLE WATER

HEATER GAS CON-

NECTOR WITH

FITTINGS

Wi_ P,4attr

Heat Tr_$

WATER HEATER HEAT TRAPS

HELP REDUCE HEAT LOSS DUE

TO THERMAL SYPHONING

ADDITIONAL TOOLS NEEDED

WHEN SWEAT SOLDERING

Tubing Cutters or Hacksaw

Propane Torch

SoffSolder

Solder Flux

Emery_Cloth

Wire Brushes

WATER HEATER STAND 24"x24"x18"

FOR USE WITH WATER HEATERS INSTALLED

IN RESIDENTIAL GARAGES HAVING A DIAM-

ETER 24" OR LESS AND A RATED CAPACITY

WATER HEATERS HAVING A DIAMETER 18"

OR LESS AND AVAILABLE IN 28" DIAMETER

FOR WATER HEATERS HAVING A DIAMETER

75 GALLONS OR LESS

DRAIN PANS

AVAILABLE IN 20" DIAMETER FOR

26" OR LESS

\

GARDEN HOSE 6 FOOT TAPE

_REWDRIVER

PHILLIPS SCREWDRIVER.s..._

f(__ TIN SNIPS

ROLL OF TEFLON TAPE

(USE ONLY ON WATER

CONNECTIONS)

PIPE DOPE (SQUEEZE TUBE)

(USE FOR WATER AND GAS CONNECTIONS)

PIPE

WRENCH

HACKSAW

3/4" WIRE BRUSH

_BRUSH

ROLL OF LEAD FREE

SOFT SOLDER

ROLL OF EMERY

CLOTH

SOLDER FLUX

1

PROPANE TORCH

TUBING C(JTI'ER

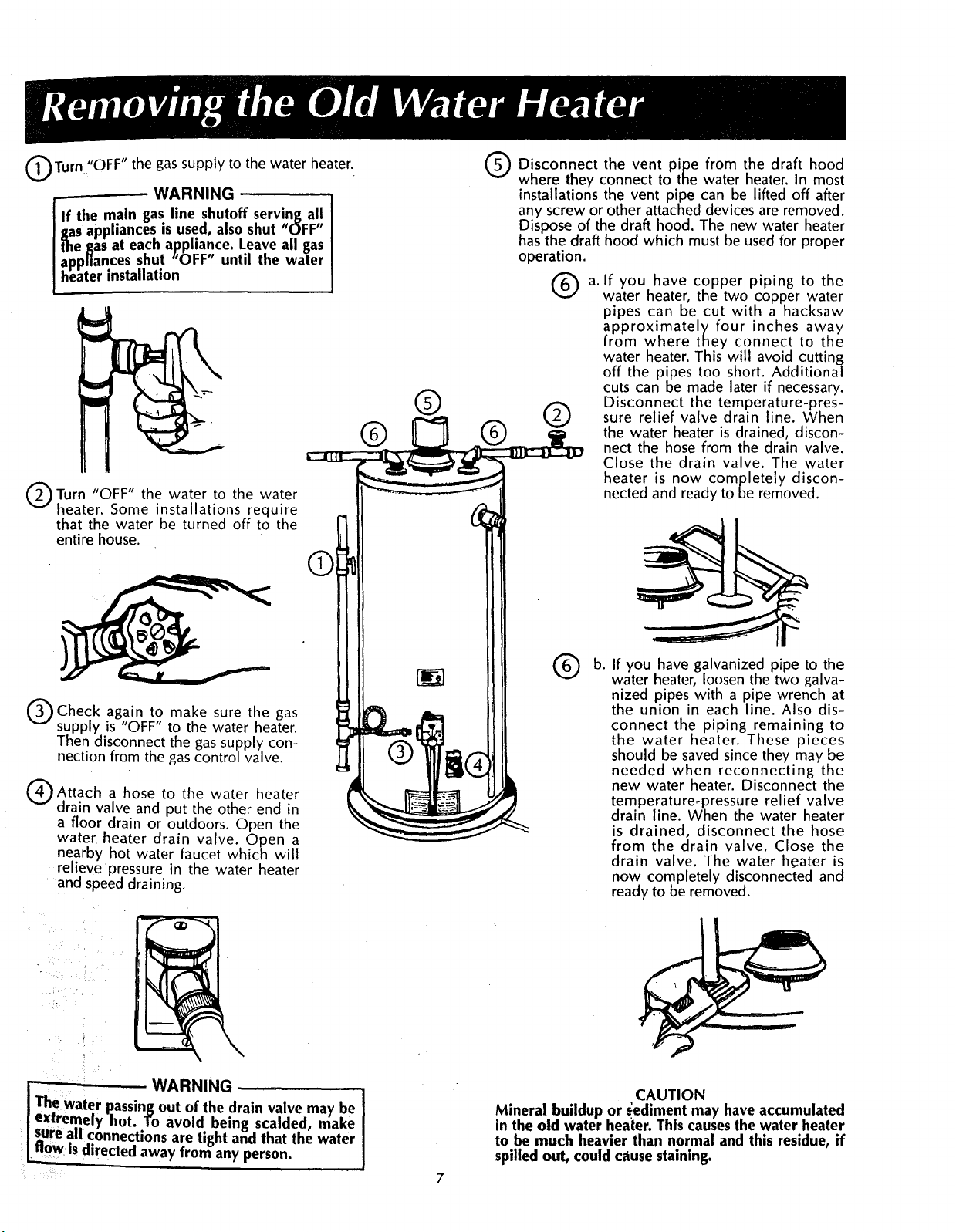

Turn"OFF" the gassupply to the water heater.

WARNING

gasappliancesis used, also shut "6FF"

{he _[asat each appliance. Leave all gas

appliances shut _'OFF" until the water

If the main gas line shutoff serving all

heater installation

Q Turn "OFF" the water to the water

heater. Some installations require

that the water be turned off to the

entire house.

®

®

®

Q Disconnect the vent from the draft hood

where they connect to the water heater. In most

installations the vent pipe can be lifted off after

any screw or other attached devices are removed.

Dispose of the draft hood. The new water heater

has the draft hood which must be used for proper

operation.

G a. lf you have copper piping to the

O sure relief valve drain line. When

water heater, the two copper water

pipes can be cut with a hacksaw

approximately four inches away

from where they connect to the

water heater. This will avoid cutting

off the pipes too short. Additional

cuts can be made later if necessary.

Disconnect the temperature-pres-

the water heater is drained, discon-

nect the hose from the drain valve.

Close the drain valve. The water

heater is now completely discon-

nected and ready to be removed.

pipe

Check again to make sure the gas

®

supply is "OFF" to the water heater.

Then disconnect the gas supply con-

nection from the gas control valve.

Q Attach a hose to the water heater

drain valve and put the other end in

a floor drain or outdoors. Open the

water heater drain valve. Open a

nearby hot water faucet which will

relievepressure in the water heater

and speed draining.

iTh WARNING

e water passin£ out of the drain valve may be

extremely hot 1_oavoid being scalded, make

sure all connec'tionsare tight and that the water

ow is directed away from any person.

If you have galvanized pipe to the

water heater, loosen the two galva-

nized pipes with a pipe wrench at

the union in each line. Also dis-

connect the piping remaining to

the water heater. These pieces

should be saved since they may be

needed when reconnecting the

new water heater. Disconnect the

temperature-pressure relief valve

drain line. When the water heater

is drained, disconnect the hose

from the drain valve. Close the

drain valve. The water heater is

now completely disconnected and

ready to be removed.

CAUTION

Mineral buildup or ._edlmentmay haye accumulated

in the old water heater. This causes the water heater

to be much heavier than normal and this residue, if

spilled out, could cause stalnlng.

Facts to Consider About the

Location

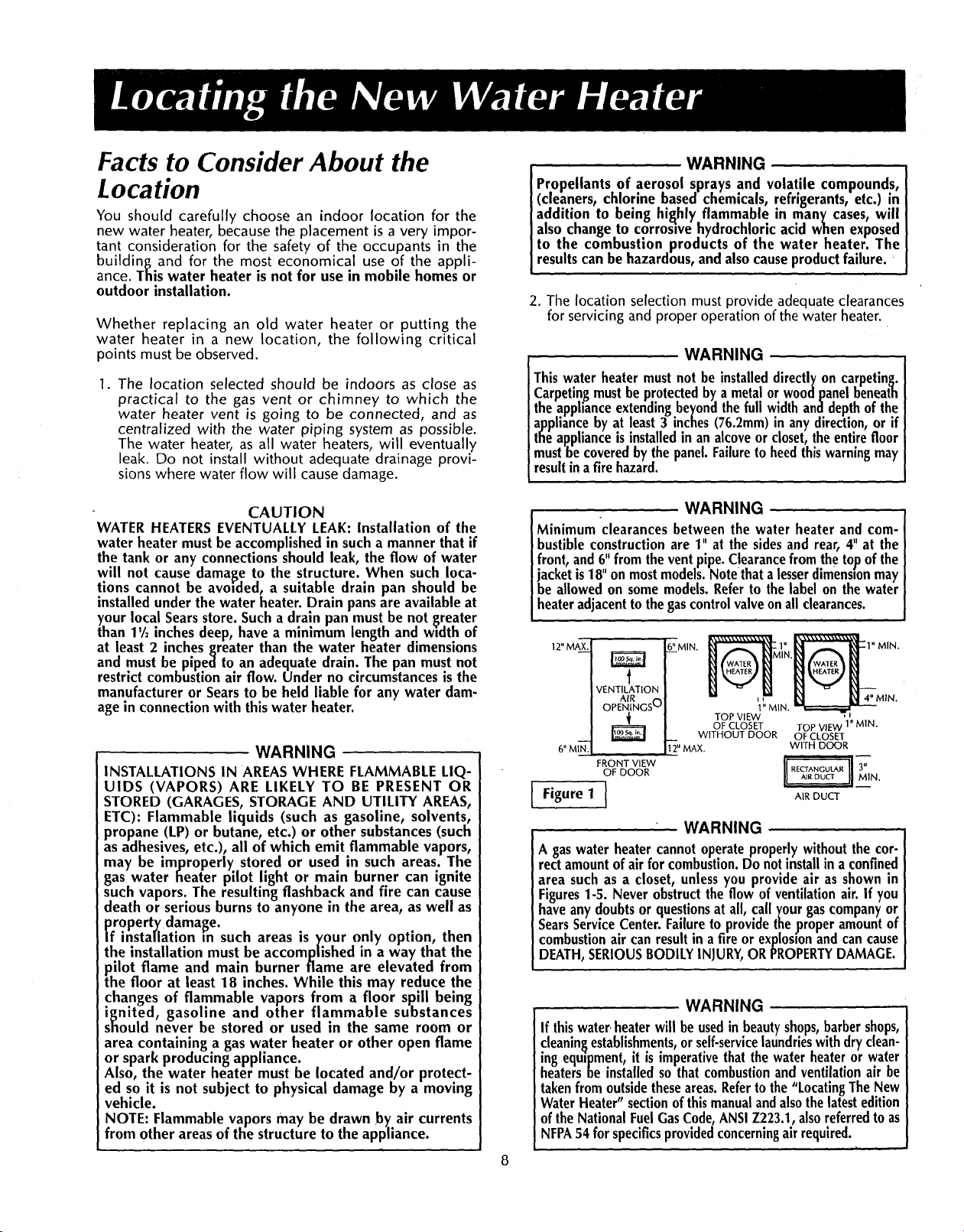

You should carefully choose an indoor location for the

new water heater, because the placement is a very impor-

tant consideration for the safety of the occupants in the

building and for the most economical use of the appli-

ance. Thiswater heater is not for use in mobile homes or

outdoor installation.

Whether replacing an old water heater or putting the

water heater in a new location, the following critical

points must be observed.

I. The location selected should be indoors as close as

practical to the gas vent or chimney to which the

water heater vent is going to be connected, and as

centralized with the water piping system as possible.

The water heater, as all water heaters, will eventually

leak. Do not install without adequate drainage provi-

sions where water flow will cause damage.

WARNING

Propellants of aerosol sprays and volatile compounds,

(cleaners, chlorine based chemicals, refrigerants, etc.) in

addition to being highly flammable in many cases, will

also change to corroslve hydrochloric acid when exposed

to the combustion products ot the water heater. The

results can be hazardous, and also cause product failure.

2. The location selection must provide adequate clearances

for servicing and proper operation of the water heater.

WARNING

This water heater must not be installed directly on carpeting.

Zarpeting must be protected by a metal or wood panel beneath

he applianceextending beyond the full width and depth of the

ippliance by at least 3 inches(76.2mm) in any direction, or if

he applianceis installedin an alcoveor closet, the entire floor

nust be covered bythe panel. Failureto heed this warningmay

'esultin a fire hazard.

WATER HEATERS EVENTUALLY LEAK: Installation of the

CAUTION

water heater must be accomplished in such a manner that if

the tank or any connections should leak, the flow of water

will not cause damage to the structure. When such loca-

tions cannot be avoided, a suitable drain pan should be

installed under the water heater. Drain pans are available at

your local Sears store. Such a drain pan must be not greater

than 1'/2 inches deep, have a minimum length and width of

at least 2 inches greater than the water heater dimensions

and must be piped to an adequate drain. The pan must not

restrict combustion air flow. Under no circumstances is the

manufacturer or Sears to be held liable for any water dam-

age in connection with this water heater.

WARNING

INSTALLATIONS IN AREAS WHERE FLAMMABLE LIQ-

UIDS (VAPORS) ARE LIKELY TO BE PRESENT OR

STORED (GARAGES, STORAGE AND UTILITY AREAS,

ETC): Flammable liquids (such as gasoline, solvents,

propane (LP) or butane, etc.) or other substances (such

as adhesives, etc.), all of which emit flammable vapors,

may be imiprroperly, stored, or used. in such areas: The.

gas water heater pdot hght or mare burner can ign,te

such vapors. The resulting flashback and fire can cause

death or serious burns to anyone in the area, as well as

ropertv damalze.

installation I_nsuch areas is your only option, then

the installation must be accomplished in a way that the

pilot flame and main burner flame are elevated from

the floor at least 18 inches. While this may reduce the

changes of flammable vapors from a floor spill being

ignited, gasoline and other flammable substances

should never be stored or used in the same room or

area containing a gas water heater or other open flame

or spark produi:ingappliance.

Also, the water heater; must be located and/or protect-

ed so it is not subject to physical damage by a moving

vehicle.

NOTE: Flammable vapors may be drawn by air currents

from other areas of the structure to the appliance.

WARNING

Minimum clearances between the water heater and com-

bustible construction are 1" at the sides and rear, 4" at the

front, and 6" from the vent pipe. Clearance from the top of the

jacket is18" on most models. Notethat a lesserdimensionmay

be allowed on some models. Refer to the label on the water

heater adjacent to the gascontrol valveon all clearances.

12" MAX.

-

f

VENTILATION

AIR O

OPENINGS

6" MI"N.

FRONT VIEW

OF DOOR

WffHOUT DOOR OF CLOSET

_" MAX. WITH DOOR

WARNING

gas operate

A water heater cannot properly without the cor-

rect amount of air for combustion.Do notinstall in a confined

Figures1-5. Never obstruct the flow of ventilation air. If you

have any doubtsor questionsat all, call your gascompany or

SearsService Center. Failure to provide the proper amount of

l area such as a closet, unless you provide air as shown in

combustion air can result in a fire or explosion and can cause

DEATH, SERIOUS BODILY INJURY,OR PROPERTYDAMAGE.

WARNING

If this water heater will be used in beauty shops,barber shops,

cleanin_establishments,or self-servicelaundries with dry clean-

ing equipment, it is imperative that the water heater or water

heatersbe installed so that combustionand ventilation air be

taken from outsidetheseareas.Refer to the "LocatingThe New

Water Heater" sectionof thismanual andalsothe latest edition

of the National FuelGasCode, ANSI Z223.1, alsoreferredto as

NFPA54 for specificsprovidedconcerningair required.

I_ MIN. 4" MIN.

TOP VIEW

OF CLOSET TOP VIEW I" MIN.

I Ii3'--;-

I ^lRoucr IIMJN.

AIR DUCT

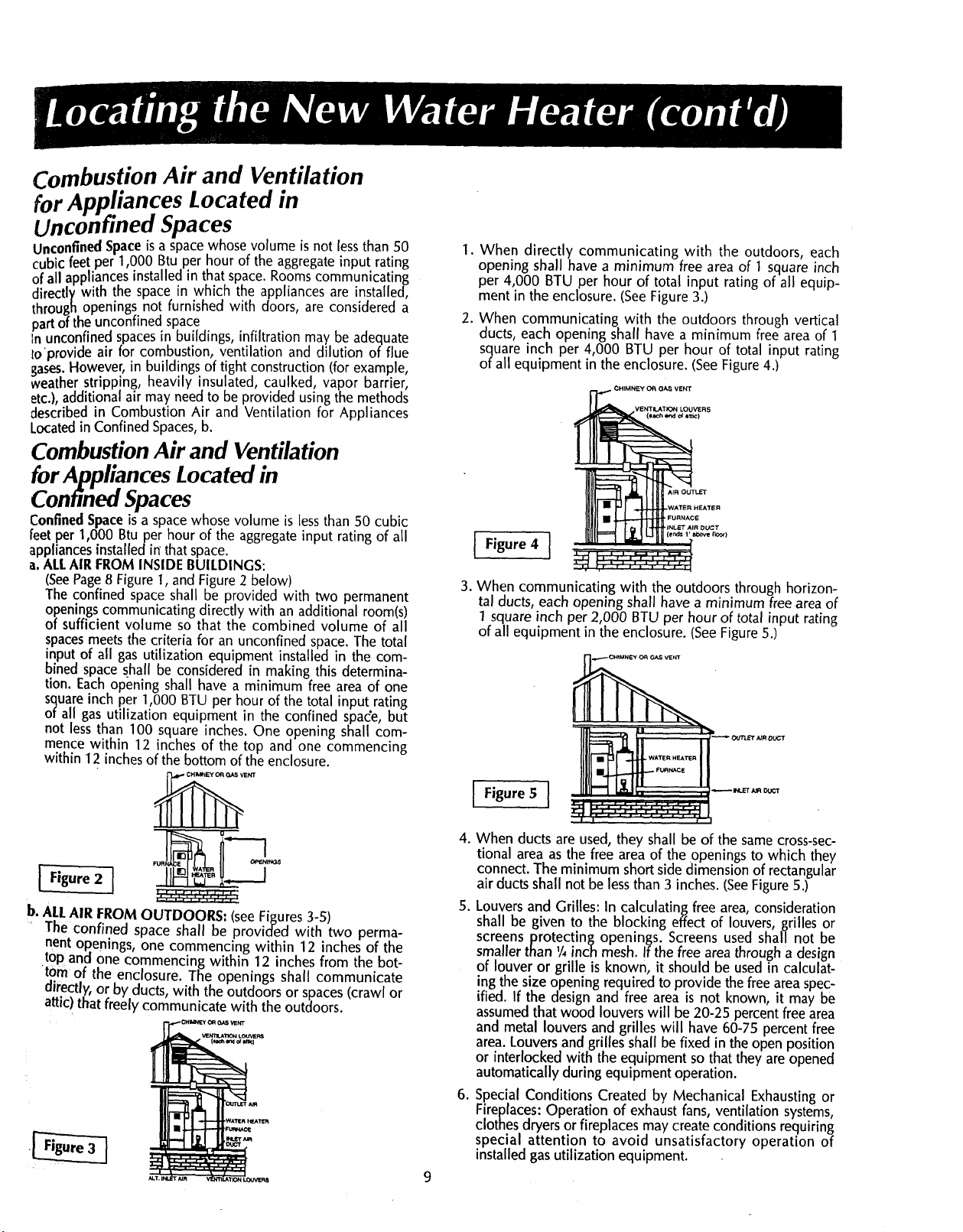

Combustion Air and Ventilation

for Appliances Located in

UnconfinedSpaces

UnconfinedSpaceisa spacewhose volume isnot lessthan 50

cubicfeet.per 1,000 .B.tu.perhourof theaggregate inputrating

ofall appliancesinstalledinthat space.Roomscommunicating

directlywith the space in which the appliances are installed,

through openingsnot furnished with doors, are considereda

partof the unconfinedspace

Inunconfinedspacesin buildings, infiltrationmaybe adequate

toprovide air for combustion,ventilation and dilution of flue

gases.However, in buildings of tight construction(forexample,

weatherstripping,heavily insulated,caulked, vapor barrier,

etc.),additional air may needto be provided usingthe methods

described in Combustion Air and Ventilation for Appliances

LocatedinConfined Spaces,b.

Combustion Air and Ventilation

1. When directly communicating with the outdoors, each

opening shall have a minimum free area of 1 square inch

per 4,000 BTU per hour of total input rating of all equip-

ment in the enclosure. (SeeFigure3.)

2. When communicating with the outdoors through vertical

ducts, each opening shall have a minimum free area of 1

square inch per 4,000 BTU per hour of total input rating

of all equipment in the enclosure. (SeeFigure 4.)

CHIMNEY OR GAS VENT

VENTUL.TION LOUVERS

for Appliances Located in

Confined Spaces

Confined Spaceis a spacewhose volume is lessthan 50 cubic

feet per 1,000 Btu per hour of the aggregateinput rating of all

appliancesinstalled in that space.

a.ALLAIRFROMINSIDE BUILDINGS:

(SeePage8 Figure1,and Figure2 below)

The confined space shall be provided with two permanent

openingscommunicating directly with an additional room(s)

of sufficient volume so that the combined volume of all

spacesmeetsthe criteria for anunconfined space. Thetotal

input of all gasutilization equipment installed in the com-

bined space s.hallbe considered in making th s determina-

tion. Eachopening shall have a minimum free area of one

squareinch per 1,000 BTU per hour of the total input rating

of all gas utilization equipment in the confined spade, but

not less than 100 square inches. One opening shall com-

mence within 12 inches of the top and one commencing

within 12 inchesof the bottom of the enclosure.

,-_i..:,::. i..

b. ALL,AIRFROM OUTDOORS: (seeFigures3-5)

The confined space shall be provided with two perma-

nent openings, one commencing within 12 inches of the

top and Onecommencing within 12 inches from the bot-

tom of the enclosure. The openings shall communicate

directly, or by ducts, with the outdoors or spaces(crawl or

attic)that freely communicate with the outdoors.

_qrulloH LOUW_

AIR OUTLET

WATER HEATER

FURNACE

INLET AIR DUCT

I l (e_ 1' abo_ _c_)

Figure4

3. When communicating with the outdoors through horizon-

tal ducts, each opening shall have a minimum free area of

1 square inch per 2,000 BTU per hour of total input rating

of all equipment in the enclosure. (SeeFigure 5.)

=_

_-.: R

I Figure 5 [

4.

When ducts are used, they shall be of the samecross-sec-

tional area as the free area of the openings to which they

connect. The minimum short side dimension of rectangular

air ducts shall not be lessthan 3 inches. (SeeFigure 5.)

,

Louversand Grilles:In calculating free area,consideration

shall be given to the blocking effect of louvers, grilles or

screens protecting openings. Screens used shal| not be

smaller than 1/4inclhmesh. If the free area through a design

of louver or grille is known, it should be usedin calculat-

ing the size opening required to provide the freearea spec-

ified. If the design and free area is not known, it may be

assumedthat wood louvers will be 20-25 percent free area

and metal louvers and grilles will have 60-75 percentfree

area.Louversand grilles shall be fixed in the open position

or interlocked with the equipment sothat they are opened

automatically during equipment operation.

,

Special Conditions Created by Mechanical Exhaustingor

Fireplaces:Operation of exhaust fans, ventilation systems,

clothes dryers or fireplaces may create conditions requiring

special attention to avoid unsatisfactory operation of

installed gasutilization equipment.

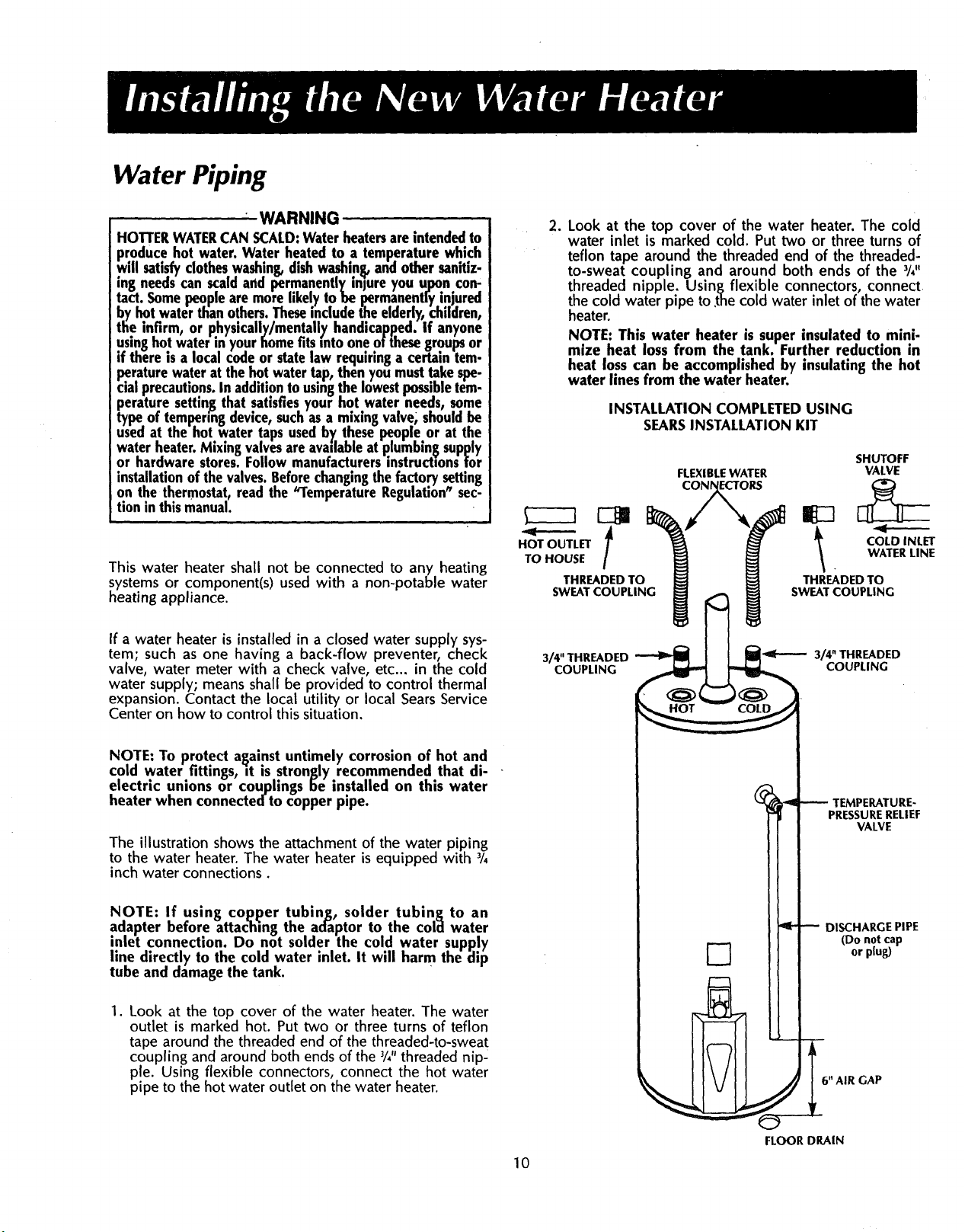

Wate Piping,

WARNING

HoI"rER WATERCAN SCALD:Water heatersareintendedto

producehot water. Water heatedto a teml_rature which

will satisfyclothes washing,dish washing,andother sanitiz-

ing needscan scaldand permanentlyinjure you upon con-

tact.Somel_.ple are morelikelyto be permanentlyinjured

by hotwater thano!hers.Theseincludethe elderly,_ildren,

the infirm, or physically/mentallyhandicapped.If anyone

usinghot water in yourhomefits Into oneofthesegroupsor

if there is a localcodeor statelaw requiringa certain tern-

perature water at thehot water tap, then you musttakespe-

cial precautions,in additionto usingthe lowestpossibletem-

perature settin_ that satisfiesyour hot water needs, some

type.of tempenngdevice,suchasa mixingvalve;shouldbe

usedat the hot water tapsusedby.thesep_.pie or at the

water heater.Mixingvalvesare avadableat plumbing supply

or hardware stores.Follow manufacturers instructionsfor

installationofthe valves.Beforechangingthe factorysetting

on the thermostat,read the "Temperature Regulation"sec-

tionin thismanual.

This water heater shall not be connected to any heating

systems or component(s) used with a non-potable water

heating appliance.

If a water heater is installed in a closed water supply sys-

tem; such as one having a back-flow preventer, check

valve, water meter with a check valve, etc.., in the cold

water supply; means shall be provided to control thermal

expansion. Contact the local utility or local Sears Service

Center on how to control this situation.

2. Look at the top cover of the water heater. The cold

water inlet is marked cold. Put two or three turns of

teflon tape around the threaded end of the threaded-

to-sweat coupling and around both ends of the 3/4"

threaded nipple. Using flexible connectors, connect

the cold water pipe to .thecold water inlet of the water

heater.

NOTE: This water heater is super insulated to mini-

mize heat loss from the tank. Further reduction in

heat loss can be accomplished by insulatingthe hot

water lines from the water heater.

INSTALLATION COMPLETED USING

SEARS INSTALLATION KIT

FLEXIBLEWATER

ECTORS

HOT OUTLET

TO HOUSE

THREADED TO

SWEAT COUPLING

3/4" THREADED

COUPLING

THREADED TO

COUPLING

SHUTOFF

VALVE

COLD INLET

WATER LINE

NOTE: To protect against untimely corrosion of hot and

cold wate_fittings, it is strongly recommended that di-

electric unions or couplings I_e installed on this water

heater when connectedto copper pipe.

The illustration shows the attachment of the water piping

to the water heater. The water heater is equipped with 3/4

inch water connections.

NOTE: If using copper tubing, solder tubing to an

adapter before attac]_ingthe adaptor to the cola water

inlet connection. Do not solder the cold water supply

line directly to the cold water inlet. It will harm the iJip

tube and damage the tank.

1. Look at the top cover of the water heater. The water

outlet is marked hot. Put two or three turns of teflon

tape around the threaded end of the threaded-to-sweat

coupling and around both ends of the 3/4"threaded nip-

ple. Using flexible connectors, connect the hot water

pipe to the hot water outlet on the water heater.

10

t_l _ TEMPERATURE-

i PRESSURERELIEF

_ DISCHARGE PIPE

:LOOR DRAIN

VALVE

(Do not cap

or plug)

Temperature-PressureRelief Valve

WARNING

At the time of manufacture this water heater was provided

with a combination temperature-pressures relief valve certi-

fied by a nationally recognized testing laboratory that main-

tains periodic inspection of production of listed equipment

or materials, as meeting the requirements for Relief Valves

and Automatic Gas Shutoff Devices for Hot Water Supply

Systems,and the latest eoidon of ANSI Z21.22 and the code

requtrements of ASME. If replaced, the valve must meet the

requirementsof local codes, but not lessthan a combination

temperature and pressure relief valve certified as meeting

the requirements for Relief Valves and Automatic Gas

Shutoff Devices for Hot Water Supply Systems,ANSI Z21.22

by a nationally recognized testing laborato_ that maintains

periodic inspection of production of listed equipment or

materials.

The valve must be marked with a maximum set pressurenot

to exceed the marked hydrostatic working pressure of the

water heater (150 Ibs./sq. in.) and a discharge cai_city not

lessthan the water heater input rate as shown on the model

rating plate. (Electric heaters - watts divided by 1000 x 3415

equa| BTU/Hr. rate.)

Your local jurisdictional authority, while mandating the use

of a temperature-pressure relief valve complyingwith ANSI

Z21.22 and ASME, may require a valve moc'leld_erent from

the one furnishedwith the water heater.

Compliance with such local requirements must be satisfied

by the installer or end user of the water heater with a locally

prescribed temperature-pressure relief valve installed in the

€leslgnated opening in the water heater in place of the facto-

ry furnished valve.

For safe operation of the water heater, the relief valve must

notbe removed from it's designated opening or plugged.

The temperature-pressure relief valve must be installed

directly into the fittin_of the water heater designated for the

relief valve. Position t_e valve downward and provide tubing

sothat any discharge will exit only within 6 inchesabove, or

at any distance below the structural floor. Be certain that no

contact is made with any live electrical part. The discharge

opening must not be blocked or reduced in size under any

circumstances. Excessivelength, over 15 feet_or useof more

than two elbows can cause restriction and reduce the

dischargecapacity of the valve.

No valve or other obstruction is to be placed between the

relief valve and the tank. Do not connect tubing directly to

discharge drain unless a 6" air gap is provided. To prevent

bodily injury, hazard to life, or oroperty damage, the relief

valve must be allowed to discharge water in quantities

should circumstances demand. If the discharge pnpe is not

connected to a drain or other suitable means, t-hewater flow

may causeproperty damage.

The Discharlze Pipe: . _

'--Must not Ee smaller in size than the outlet pipe size of the

valve, or have any reducing couplingsor other restriction.

---Must not be plumedor blocked.

_ust be of mate_]'al listedfor hot water distribution.

_ust be installed so asto allow complete drainage of both

the temperature-pressure relief valve, and the discharge

". . ..

._-_!! tner_nl_;va_eaatyana_vd;bqe_edr_e relief valve and tank.

WARNING

The temperature-pressure relief valve must be manual-

ly operated at least once a year. Caution should be

taken to ensure that (1) no one is in front of or around

the outlet of the temperature-pressure relief valve dis-

charge line, and (2) the water manually dischargedwill

not cause any bodily injury or property damage

becausethe water may beextremely hot.

If after manually operating the valve, it fails to com-

pletely reset and continues to release water, immedi-

ately closethe coldwater inlet to the water heater, fol-

low the draining instructions, and replace the tempera-

ture-pressurerelief valve with a new one.

..,_q

HOT

SHUTOFF COLD

VALVE

RELIEFVALVE

(Do not cap or plug)

[]

6" AIR GAP

FLOOR DRAIN

RELIEFVALVEOPENING

ATTHETIMEOFMANUFACTURE,THISWATERHEATERWASPROVIDED

WITHACOMBINATIONTEMPERATURE-PRESSURERELIEFVALVELISTED

ASCOMPLYINGWITHTHESTANDARDFORRELIEFVALVESANDAUTO-

MATICGASSHUTOFFDEVICESFORHOTWATERSUPPLYSYSTEMS,

ANSIZ21.22.FOR SAFEOPERATIONOFTHE WATERHEATER,THE

RELIEFVALVEMUSTNOTBEREMOVEDFROMITSDESIGNATEDPOINT

OFINSTALLATIONORPLUGGED.

YOURLOCALJURISDICTIONALAUTHORITY,WHILEMANDATINGTHEUSE

OFATEMPERATURE-PRESSURERELIEFVALVECOMPLYINGWITHANSI

Z21.22ANDASME,MAYREQUIREA VALVEMODELDIFFERENTFROM

THEONEFURNISHEDWITHTHEWATERHEATER.

COMPLIANCEWITHSUCHLOCALREQUIREMENTSMUSTBESATISFIED

BYTHEINSTALLERORENDUSEROFTHEWATERHEATERWITHA

LOCALLYPRESCRIBEDTEMPERATURE-PRESSURERELIEFVALVE

INSTALLEDINTHEDESIGNATEDOPENINGINTHEWATERHEATER.

SEEMANUALHEADING--"TEMPERATURE-PRESSURERELIEFVALVES"

FORINSTALLATIONANDMAINTENANCEOFRELIEFVALVE,DISCHARGE

LINEANDOTHERSAFETYPRECAUTIONS.

11

JRE-PRESSURE

Filling the Water Heater

CAUTION

Never usethis water heater unlessit is completely filled

with water. To prevent damageto the tank, the tank must

be filled with water. Water must flow from the hot water

faucet before turning "ON" gasto the water heater.

Tofill the water heaterwith water:

1. Close the water heater drain valve by turning the han-

dle to the right (clockwise). The drain valve is on the

lower front of the water heater.

2. Open the cold water supply valve to thewater heater.

NOTE: The cold water supply valve must be left open

when the water heater is|rl use.

3. To insure complete fillin_ of the tank, allow air to exit

by opening the nearesthot water faucet. Allow water

to run unti/a constantflow is obtained. Thiswill let air

out of the water heaterand the piping.

4. Check all new waterpipingfor leaks. Repairasneeded.

Venting

WARNING

VENT DAMPERS- Any ventdamper,whetherit isoperated

thermally or otherwisemust he removedif its useinhlbits

properdrafting of the waterheater.

Thermally OperatedVentDampers:Gas-firedwater heaters

havingthermalefficiencyin excessof 80% may producea

relativelylow flue gastemperature.SuchtemperaturesmaX

nut be high enoughto properlyopen thermally operated

v_nt dampers.Thlswould causespillageof flue gasesand

may causecarbon monoxidepoisoning.

Vent dampersmustbear evidenceof-certificati0nas com-

plying with the latest edition of the American National

Standard ANSI Z21.68 (ANSI Z21.66 & 67, respectively,

coverelectricallyandmechanically actuatedvent dampers).

Beforeinstallationof any vent damper, consultthe local

SearsServiceCenteror gasutility for further information.

WARNING

To insureproperventingof this gas-firedwater heater,the

correctvent p}_oediametermustbeutilized.Anyadditionsor

deletionsof otEergasapplianceson a commonventwiththis

waterheatermayadverselyaffectthe operationofthe water

heater.ConsultthelocalSearsService(_enteror gasutilityif

anysuchchangesareplanned.

For proper venting in certain installations, a larger diameter

vent pipe may be necessary. Due to great variances in

installations, unforeseeable by the manufacturer of the

water heater, you must consult your gas company to aid

you in determining the proper venting for your water heater

from the vent tables in the latestedition of the National Fuel

GasCode ANSI Z223.1, also referred to asNFPA 54.

Check the venting systemfor signsof obstruction or deterio-

ration and replace if needed.

The combustion and ventilation air flow must not be

obstructed.

WARNING

Obstructed or deteriorated vent systemsmay present[

serioushealth risk or asphyxiation.

/

J

1. Place the draft hood legs in the receiving holes on the

top of the water heater. The legs will snap in the holes

to give a tight fit.

2. Place the vent pipe over the draft hood. With the vent

pipe in position, drill a small hole through both the

vent pipe and draft hood. Secure them together with a

sheet metal screw.

DRAFT HOOD _r VENE.w=,_ _rDRA

! !

HO.<"_ I if-OR CHIMNEY

DRAFT _

Thewater heaterwith draft hoodinstalledmustbeconnect-

ed to a chimneywhich terminatesto the outdoors.Never

operatethe water heaterunlessit isventedto the outdoors

andhasadequateair supplyto avoidrisksofimproperopera-

tion,explosionor asphyxiation.

diameterofthedrafthoodoutletonthewaterheater,andmust

ITheventpipefromthewaterheatermustbeno lessthanthe

slopeupwardto thechimneyatleast'/4inchperlinearfoot.

All vent gases mustbe completely vented to the outdoors

of the structure (dwelling). installonly the draft hood pro-

vided with the new water heater and no other draft hood.

Vent pipes must be secured at each jointwith sheet metal

screws.

L_ VENT TO OUTDOORS

WARNING

WARNING

FT HOOD

,,.,NC. ,sE

LINEAR FOOT I

!

VENTPIPEINSTALLATION

Theremust bea minimum of 6 clearancebetweensinglewa I

vent pipe and any combustiblematerial.Fill andsealanyclear-

ance between single wall vent pipe and combustible material

with mortar mix, cement, or other noncombustiblesubstance.

Forother thansinglewall, follow vent pipe manufacturer'sclear-

ancespecifications.To insurea tightfit of theventpipe in abrick

chimney,sealaroundtheventpipe with mortarmix cement.

WARNING

and combustiblematerial will resultin afire hazard.

Failureto have required clearancesbetweenvent piping

I Besurevent pipeisproperlyconnectedto preventescapeofdangerousfluegaseswhichcouldcausedeadlyasphyxiation.

Chemicalvaporcorrosionof theflue and vent systemmay

occurif air for combustioncontainscertainchemicalvapors.

Spraycanpropellants,cleaningsolvents,refrigeratorandair

conditionerrefrigerants,swimmingpool chen_icals,calcium

and sodiumchloride,waxes,bleachandprocesschemicals

aretypicalcompoundswhicharepotential|ycorrosive.

12

WARNING '1

WARNING

Gas Piping

WARNING

Make sure the gassuppl!ed is the same type listed on the

model rating plate./ne Jme[gas pressure must not exceed 14

inches water column [I/2 pound per square inch (3.5kPa)].

The minimum inlet gas pressure listed on the model rating

plate is for the purpose of input adjustment.

WARNING

If the gas control valve is subjected to pressuresexceeding '/2

i pound-per square inch (3.5kPa), the damage to the gas con-

|rol valve could result in afire or explosion from leak|ng gas.

WARNING

If the main gas line shutoff servingall gas appliances is used,

alsoturn "OFF" the gas at each appliance. Leave all gasappli-

ancesshutoH until the water heater installation is complete.

L

WARNING

I se pipe joint compound or teflon tape marked as being|

resistant to the action of petroleum [Propane (L.P.)] gases.

SEDIMENT TRAP

A sediment trap shall be installed as close to the inlet of

the water heater as practical at the time of water heater

installation. The sediment trap shall be either a tee fitting

with a capped nipple in the bottom outlet or other device

recognized as an effective sediment trap. If a tee fitting is

used, it shall be installed in conformance with one of the

methods of installation shown below.

Connectingthe gaspiping to the gascontrol valve of the water

heatercanbeaccomplishedby eitherofthe two methodsshown.

GAS PIPING WITH FLEXIBLE CONNECTOR

!

A gas line of sufficient size must be run to the water

heater. Consult the latest edition of National Fuel Gas

Code ANSI Z223.1, also referred to as NFPA54 and the

gas company concerning pipe size.

There must be:

-A readily accessible manual shut off valve in the gas sup-

ply line serving the water heater, and

"A drip leg (sediment trap) ahead of the gas control valve

to help prevent dirt and foreign materials from entering

the gas control valve.

"A flexible gas connector or a ground joint union between

the shutoff val_,e and control valve to permit servicing of

the unit.

Be sureto check all the gas piping for leaks before lighting

the water heater. Use a soapy water solution, not a match

or open flame. Rinse off soapy solution and wipe dry.

Standard Models are for installation up to 3,300 feet

above sea level.

High Altitude Models are for installation from 3,300 to

5,500 feet above sea level.

Ifa standard model is installed above 3,300 feet or a high

altitude model is installed above 5,500 feet, the input rat-

ing must be reduced at the rate of 4 percent for each

1,000 feet above sea level. Contact your local Sears

SeWice Center or gas ut I ty for further information.

..... WARNING

i,The appliance and its gas connection must be leak test- I

Led before placing the appliance in operation,

, WAR NIN G

appliance and its individual shutoff valve must be discon-

|ned_ from the gassupply piping systemduring any pressure

llesting of that systemat test pressures in excess of' I/2pound

_square . .

ll_ appliance must be isolated from the gassupplypiping sys-

Jte_n_by closing its individual manual shutoff valve during any

Ipressure testing of the gassupply piping system at test pres-

inch

(3.5kPa).

qual to or lessthan 1/2pound per square inch (3.5kPa).

_[_GAS SUPPLY PIPING

MANUAL IlK I

SHUTOFF ] I[_

VALVE _J__

GROUND JOINT

UNION (Optional)

T

6. DRIP LEG

FLEXIBLE GAS CONNECTOR

LABELED AS COMPLYING

WITH ANSI STANDARDS

(Sediment trap)

CAP

GAS

CONTROL

VALVE

GAS PIPING WITH ALL BLACK IRON PIPE

TO GAS CONTROL

GAS SUPPLY PIPING

MANUAL]_- I

SHUTOFFll_Ll

VALVE _

GROUND JOINT [t:::_ I

UNION.._ _ GAS

I

"-_ BLACK PIPE

6" I J DRIP LEG

H (Sediment trap)

CAP

CONTROL

VALVE

WARNING

Contaminants in the gas lines may cause improper operation

of the gas control valve that may result in fire or explosion.

Before attaching the gasline be sure that all gas pipe is clean

on the inside. "totrap any dirt or foreign material in the gas

supplyline, a drip leg (sometimes caged a sediment trap)

mustbe incorporated-in the piping. The drip leg must De

readily accessible. Install in accordance with the "Gas

Piping_ section. Refer to the latest edition of the National

FuelGas Code, ANSI Z223.1, also referred to as NFPA54.

13

Installation Checklist

BEFORELIGHTING THE PILOT:

1. Check the gas lines for leaks.

a. Use a soapy water solution. DO NOT test for gas

leaks using a match or open flame.

b. Brush the soapy water solution on all gas pipes,

joints and fittings.

c. Check for bubbling soap, This means you have a

leak. Turn "OFF" gas and make the necessary

repairs.

d. Recheck for leaks.

e. Rinse off soapy solution and wipe dry.

2. Is the new temperature-pressure relief valve properly

installed and piped to an adequate drain? See

"Temperature-Pressure Relief Valve" section.

3. Are the cold and hot water lines connected to the

water heater correctly? See "Water Piping" instructions

in the "Installing the New Water Heater" section.

4. Is the water heater completely filled with water? See

"Filling" instructions in the "Installing the New Water

Heater" section.

5. Will a water leak damage anything? See the "Locating

the New Water Heater" section,

VENT PIPETO

OUTDOORS

OR CHIMNEY

UNION

6. Is there proper clearance between the water heater

and anything that might catch fire? See the

"Locating the New water Heater" section.

7. Do you have adequate ventilation so that the

water heater will operate properly? See

"Combustion Air and Ventilation" in the "Locating

the New Water Heater" section.

8. Is the draft hood vent piping properly secured? See

"Venting" instructions in the "Installing the New

Water Heater" section.

9. Is there proper clearance between the vent pipe

and anything that might catch on fire? See

"Venting" instructions in the "Installing the New

Water Heater" section.

10. Is the vent pipe properly sloped and does the vent

terminate outdoors? See "Venting" instructions in

the "Installing the New Water Heater" section.

11. Do you need to call your gas company to check

the gas pipe and its hookup?

SHUTOFF VALVE

SHUTOFF VALVE

TEE

DRIP LEG

(Sediment trap)

DRAIN VALVE

HOT

GAS SUPPLY

PIPECAP

COLD

DRAFT HOOD

TEMPERATURE-PRESSURE

RELIEF VALVE

DISCHARGE PIPE

(Do not cap or plug)

6 INCH AIR GAP

FLOOR DRAIN

14

WARNING

IEFORE LIGHTING [PROPANE (L.P.) GAS WATER

_EATERS]: Propane (L.P..) gas is heavier than air.

ihould,there be a leak in the system,the gaswill settle

_ear the_rouna., uasements, crawl spaces, skirted

areas unaer mooue nomes (even when ventilated),

closets and areas below ground level will serve as

pockets for the accumuFation of this gas. Before

attempting to light or reli_ht the water heater's pilot or

turning on a nearby electr,cal light switch, be absolute-

ly sure there is no accumulated gas in the area. Search

for odor of gas by sniffing at ground level in the vicini-

ty of the appliance. If odor is detected, follow the steps

indicated at "For Your Safety" on the cover page of

thismanual, then leave the premises.

Lightingand operating instructions are located on front of

the water heater, above or to one side of the gas control

valve.

WARNING

• AN ODORANT IS ADDED TO THE GAS USED

BY THIS WATER HEATER.

FOR YOUR SAFETY

IF YOU SMELL GAS:

1. Do not try to light any appliance.

2. Do not touch any. electrical switch; do not use any

phone in your building.

3. Immediately call your gas supplier from a neighbor's

, p.hone. Follow the gas s-upplie"r"s instructions.

4. It you cannot reach your gas supplier, call the fire

department.

Figure6 [

I Figure 7 [

WARNING

i DO NOT force the gas control knob. Use only your

I ,lland to push it down to light the pilot, or to turn it to

I _ON", _OFF" or "PILOT". Never use a tool such as a

I lever, wrench or pliers. Do not hit or damage the knob.

I A da_n-aged knol} may result in an explosion aid seri-

i .ousinju_-y_lf you have problem turning the knob, call

th_thegas s_plsupplierimmediately

_! HECK FOR LEAKS

_Be_re to check all your gas pipes for leaks before light-

i!ng your water heater. Use a soapy water solution, not a

!thatch or open flame Check the factory gas fittings after

Pilot is lit and gas con'trol knob is still in "PILOT" position.

iT,h_en,check the fittings when the main burner is turned

ON". Use a soapy water solution for this, too.

[Figure8 ]

INNER

DOOR

OUTER

DOOR

Figure9 ]

15

FOR YOUR SAFETY READ BEFORE LIGHTING

If you do not follow these instructions exactly, a fire or explosion

I WARNING I

may result causing property damage, personal injury or loss of life.

A,

Thisappliancehas a pilot whichmust be lightedby

hand.Whenlightingthepilot,followtheseinstructions

exactly.

B.

BEFORELIGHTINGsmellallaroundtheappliancearea

for gas. Besure to smellnext to the floor because

somegasisheavierthanairandwillsettleonthefloor.

WHATTODOIFYOUSMELLGAS

Do not touchany electric switch;do not useany

i o nottryto lightanyappliance,

phoneinyourbuilding.

Immediatelycallyourgassupplierfrom a neighbor's

phone.Followthegassuppliersinstructions.

LIGHTING INSTRUCTIONS

• If youcannotreachyour gassupplier,cell thefire

department, r

C.

Useonlyyourhandto pushinorturnthegascontrol

knob.Neverusetools,ff theknobwillnotpushin or

turnbyhand,don'ttrytorepair it,cell a qualifiedser-

vicetechnician.Forceorattemptedrepair mayresult

Inafireorexplosion,

D,

Do notusethis applianceff any part has beenunder

water.Immediatelycell a qualifiedservicetechnician

to inspectthe applianceand to replaceanypartofthe

controlsystemandanygas controlwhichhasbeen

underwater.

1.STOP!Readthesafetyinformationaboveonthislabel.

2.Removeouterdoor.

3. Set the thermostatto lowest settingby turning the

watertemperaturedialclockwise,(( _,)to itslowest

temperaturesetting (witharrowondial)asshown.DO

NOT FORCE.

4.Turngascontrolknobclockw--ise _, _to ",OFF"posi-

tion. Knobcannotbe turnedfrom 'PILOT to "OFF"

unlessknobisdepressedslightly.DO NOT FORCE.

(Figure6,page15)

5. Waitfive (5) minutestoclearoutanygas. If youthen

smellgas,STOP!Follow B inthe safety information

aboveon this label.If youdon'tsmell gas,go to the

nextstep.

6. Remove(or open)innerdoorlocatedbelowthe gas

controlunit.(Figure9, page15)

7.Findpilot-followmetaltubefromgas control.Thepilot

islocatedontherighthandsideof theburner.

PILOT BURNER _THERMOCOUPLE

8.If youdon'tsmellgas,turnknobongascontrolcounter

clockwise__(_ to"PILOT"position.(Figure7,page15)

9. Push in control knob all the way and hold down.

Immediatelylightthe pilotwithamatch.Continueto

holdcontrolknobin for aboutone(1) minuteafter

thepilotis lit. Releaseknobandit willpopbackup.

Pilotshouldremainlit. If it goesout,repeatsteps3

through8.

• Ifknobdoesnotpopupwhenreleased,stopandl

immediatelycall your servicetechnicianor gasl

supplier.

• If the pilot will not stay lit after severaltries,

depress__ andturn,thegascontrolknobclockwise

V to' OFF andcellyourservicetechnician

orgassupplier.(Figure6, page15)

10.Replace(orclose)innerdoor.Replaceouterdoorif

doordoesnotcovergas controlon/offknobor tem-

peratureadjustmentknob.(Figure9,page15)

11. At armslengthaway,turngascontrolknobcounter-

clockwise _ to the full "ON" position.

WARNING Do not use gas control knob to reg.

ulate gas flow, (Figure8,page15)

12. At armslengthaway,setthe thermostatto desired

setting.Themark(• ) HOTindicativeofapproximate

120°F is preferredstartingpoint.Somelocallaws

may requirea lowerstartingpoint.If hotterwateris

desired,seeinstructionmanualand"warning" below.

13.Replacetheouterdoorifnotreplacedinstep10.

l WARNING j

Hotterwaterincreasestheriskof scaldinjury.Beforechangingtemperaturesettingseeinstructionmanual.

TO TURN OFF GAS TO APPLIANCE

1.Setthethermostatto lowestsetting byturningthe

watertemperaturedialclockwise(F_) to its lowest

temperaturesetting(witharrowondial)asshown.DO

NOT FORCE,

2,Turngascontrolknobclockwise_') to "OFF"posi-

tion,Knobcannotbe turnedfrom "PILOT"to "OFF"

unlessknobisdepressedslightly.DO NOT FORCE.

(Figure6,page15)

3.Replaceouterdoor(ifremoved),

16

Duetothe natureof thetypicalgaswaterheater,the

watertemperaturein certainsituationsmayvaryupto

30°Fhigherorloweratthepointofusesuchas,bathtubs,

showers,sink,etc.

Thismeansthatwhenthetemperatureadjustmentdialis

setatthemarkapproximating120° F,theactualwater

temperatureatanyhotwatertapcouldbeashighas

150°Foraslowas90°F.

Anywaterheater'sintendedpurposeistoheatwater.Hot

waterisneededforcleaning(bodies,dishes,clothing).

Hotwaterwill presenta scaldhazard.Dependingonthe

timeelement,andthepeopleinvolved(normaladults,

Children,toddlers,elderly,infirm,etc.)scaldingmay

occuratdifferenttemperatures.

WARNING

HOTTER WATER CAN SCALD: Water heaters are

ntended to produce hot water. Water heated to a tem-

perature which will satisfy clotheswashing, dishwash-

ng_and other sanitizing needs can scald-and perma-

lently injure you upon contact. Somepeople are more

ikelyto be permanently injured by hot water than oth-

._rs.These include the elderly, children, the infirm, or

physically/mentally handicapped. If anyone using hot

water in your home fits into one of these groupsor if

there is a local code or state law requiring a certain

temperature water at the hot water tap, then you must

take special precautions. In addition to usingthe low-

estpossibletemperature setting that satisfiesyour hot

Waterneeds,sometype of tempering device, suchas a

mixing valve, shouldbe usedatthe hot water tapsused

bythesepeopleor at the water heater.

WA RN ING ,

_e_er allow smallchildren to usea hot water tap, or to

d_w their own bath water. Never leave a child or hand-

|_p ed ers0n unattended

p

in a bathtub or shower.

Turnthewatertemperaturedialclockwise(/"-_) to

decreasethetemperature,orcounterclockwise(_",_)

toincreasethetemperature.

Y HOT-Is a thermostat setting of approximately

120°F, which will supply hot water at the

most economical temperatures. The temper-

ature adjustment knob can be turned lower

than "HOT" if desired.

A-Is a thermostat setting of approximately

130°F.

B-Is a thermostat setting of approximately

140°E This is the lowest setting for supply of

hot water to dishwashers.

C-Is a thermostat setting of approximately

150°F.

VERY HOT-Is a thermostat setting of 160°F. It is recom-

mended that the dial be set lower whenever

possible.

of this water heater has been factory set at

position, to reduce the risk of scald injury. It is

and must be reset to the desired temperature

The mark (V) HOT indicative of approximately

the preferred starting point. Some states have a

for a lower setting. If you need hotter water,

_'directions for temperature adjustment, but beware

nings in this section.

WARNING

Should overheating occur or the gas supply fail to

shut off, turn "OFF" the manual gas control valve to

the appliance.

17

Start Up Conditions

CONDENSATION

Whenever the water heater is filled with cold water, a cer-

tain amount of condensation will form while the burner is

on. A water heater may appear to be leaking when in fact

the water is condensation. This usually happens when:

a. When a new water heater is filled with cold water

for the first time.

b. When gas burns and water vapor is produced in

water heaters, particularly high efficiency models

where flue temperatures are lower.

c. When you use large amounts of hot water in a short

time and the refill water isvery cold.

Moisture from the products of combustion condense on

the cooler tank surfaces and form drops of water which

may fall onto the burner or other hot surfaces to produce

a "sizzling" or "frying" noise.

Excessive condensation can cause pilot outage due to

water running down the flue tube onto the main burner

and putting out the pilot.

Because of the suddenness and amount of water, conden-

sation water may be diagnosed as a "tank leak". After the

water in the tank warms up (about 1-2 hours), the condi-

tion should disappear.

Do not assume the water heater is leaking until there has

been enough time for the water in the tank to warm up.

An undersized water heater will cause more condensa-

tion. The water heater must be sized properly to meet the

family's demands for hot water including dishwashers,

washing machines and shower heads.

Excessive condensation may be noticed during the winter

and early spring months when incoming water tempera-

tures are at their lowest.

Good venting is essential for a gas fired water heater to

operate properly as well as to carry away products of

combustion and water vapor.

SMOKE/ODOR

It is not uncommon to experience a small amount of

smoke and odor during the initial start-up. This is due to

burning off of oil from metal parts, and will disappear in a

short while.

THERMAL EXPANSION

Water supply systems may, because of high line pressure,

frequent cut-offs, the effects of water hammer and others,

have installed devices such as pressure reducing valves,

check valves, back flow preventers, etc...to control these

types of problems. When these devices are not equipped