K^ nm o r^

Owners

Manual

FOR POTABLE WATER

HEATING ONLY

NOT SUITABLE FOR

SPACE HEATING

NOT FOR USE IN.

MOBILE HOMES

Model No.

153.334290 40 Gal. Short

153.334390 30 Gal.

153.334490 40 Gal.

153.334590 so Gal,

Caution:

Read and Follow

All Safety Rules and

Operating Instructions

Before First Use of

This Product.

"ENERGY EFFICIENTES

GAS WATER HEATER

• Safety Instructions • Care and Maintenance

• Installation • Troubleshooting

• Operation • Parts List

For Your Safety

AN ODORANT IS ADDED TO THE GAS USED BY THIS

WATER HEATER

WARNING; If the information in these instructions are not fol

lowed exactly, a fire or explosion may result, causing property

damage, personal injury or death.

-Do not store or use easoline or other flammable vapors and liq

uids in the vicinity of mis or any other appliance.

-WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your

building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you can not reach your gas supplier, call the fire department.

-Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

Save this Manual for Future Reference.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

A WARNING

Improper installation, adjustment, alteration, service or maintenance

can cause DEATH, SERIOUS BODILY INJURY, OR PROPERTY DAM

AGE. Refer to this manual for assistance or consult the local Sears

Service Center or gas utility for further information.

A WARNING

Flammable vapors may be drawn by air currents from other areas

of the structure to this appliance.

AWARNING

READ THE GENERAL SAFETY SECTION BEGINNING ON INSIDE

COVER AND THEN THIS ENTIRE MANUAL BEFORE INSTALLING

OR OPERATING THIS WATER HEATER.

Safety Precautions

AWARNING

Improper installation, adjustment, alteration, service

or maintenance can cause DEATH, SERIOUS BODILY

INJURY OR PROPERTY DAMAGE. Refer to this manu

al for assistance or consuit your local Sears Service

Center for further information.

AWARNING

WATER HEATERS EQUiPPED FOR ONE TYPE GAS

ONLY: This water heater is equipped for one type gas

oniy. Check the modei rating plate near the gas control

valve for the correct gas. DO NOT USE THIS WATER

HEATER WITH ANY GAS OTHER THAN THE ONE

SHOWN ON THE MODEL RATING PLATE. Failure to

use the correct gas can cause problems which can resuit in

DEATH, SERIOUS BODILY INJURY, OR PROPERTY

DAMAGE. If you have any questions or doubts consult

your gas supplier or locai utility.

AWARNING

INSTALLATIONS IN AREAS WHERE FLAMMABLE LIQ

UIDS (VAPORS) ARE LIKELY TO BE PRESENT OR

STORED (GARAGES, STORAGE, AND UTILITY AREAS,

ETC): Flammable liquids (such as gasoline, solvents,

propane (LP) or butane, etc.), all of which emit flammabie

vapors, may be improperiy stored or used in such areas.

The gas vrater heater pilot light or main burner can ignite

such vapors. The resulting flashback and fire can cause

death or serious bums to anyone in the area, as weil as

property damage.

if installation in such areas is your only option, then the

installation must be accomplished in a way that the pilot

flame and main burner flame are elevated from the floor

at least 18 inches. While this may reduce the chances of

flammable vapors from a floor spill being ignited, gasoiine

and other flammabie subst»ices should never be stored or

used in the same room or area containing a gas water

heater or other open flame or spark producing appiiance.

NOTE: Flammable vapors may be drawn by air currents

from other areas of the structure to the appliance.

AWARNING

If this water heater will be used in beauty shops, barber

shops, cieaning estabiishments, or self-service laundries

with dry cleaning equipment, it is imperative that the

water heater or water heaters be installed so that com

bustion and ventiiation air be taken from outside these

areas. Refer to the “Facts to Consider About the

Location” section of this manual and also the latest edi

tion of the National Fuel Gas Code, ANSI Z223.I, also

referred to as NFPA 54 for specifics provided concerning

air required.

AWARNING

A fire can start if combustible materials such as clothing,

cieaning materials, or flammable liquids are placed against

or next to the water heater.

_______________

^

AWARNING

At the time of manufrcture this water heater was provid

ed with a combination temperature-pressures relief valve

certified by alinationaliy recognized testing iaboratory

that maintains periodic inspection of production of iisted

equipment or materiais, as meeting the requirements for

Relief Valves and Automatic Gas Shutoff Devices for Hot

Water Suppiy Systems, and the latest edition of ANSI

Z2i.22 and the code requirements of ASME. If replaced,

the valve must meet the requirements of local codes, but

not less than a combination temperature and pressure

relief valve certified as meeting the requirements for

Relief Valves and Automatic Gas Shutoff Devices for Hot

Water Supply Systems, ANSI Z2I.22 by a nationally rec

ognized testing laboratory that maintains periodic

inspection of production of listed equipment or

materials.

The valve must be marked with a maximum set pressure

not to exceed the marked hydrostatic working pressure

of the water heater (ISO lbs./sq. in.) and a discharge

capacity not less than the water heater input rate as

shown on the model rating plate. (Electric heaters watts divided by 1000 x 3415 equal BTU/Hr. rate.)

Your local jurisdictional authority, while mandating the

use of a temperature-pressure relief valve complying

with ANSI Z21.22 and ASME, may require a valve model

different from the one furnished with the water heater.

Compliance with such local requirements must be satis

fied by the installer or end user of the water heater with

a locally prescribed temperature-pressure relief valve

installed in the designated opening in the water heater in

place of the factory furnished valve.

For safe operation of the water heater, the relief valve

must not be removed from it’s designated opening or

plugged.

The temperature-pressure relief valve must be installed

directly into the fitting of the water heater designated for

the relief valve. Position the valve downward and provide

tubing so that any discharge will exit only within 6 inches

above, or at any distance below the structural floor. Be

certain that no contact is made with any live electrical

part. The discharge opening must not be blocked or

reduced in size under any circumstances. Excessive

length, over 30 feet, or use of more than four elbows can

cause restriction and reduce the discharge capacity of

the valve.

No valve or other obstruction is to be placed between

the relief valve and the tank. Do not connect tubing

directly to discharge drain unless a 6" air gap is provided.

To prevent bodily injury, hazard to life, or property dam

age, the relief valve must be allowed to discharge water

in quantities should circumstances demand. If the dis

charge pipe is not connected to a drain or other suitable

means, the water flow may cause property damage.

The Discharge Pipe:

* Must not bie smaller in size than the outlet pipe size of

the valve, or have any reducing couplings or other

restrictions.

* Must not be plugged or blocked.

* Must be of material listed for hot water distribution.

* Must be installed so as to allow complete drainage of

both the temperature-pressure relief valve, and the dis

charge pipe.

* Must terminate at an adequate drain.

* Must not have any valve between the relief valve and

tank.

Safety Precautions

AWARNING

A gas water heater cannot operate properly without the

correct amount of air for combustion. Do not install in a

confined area such a closet, unless you provide air as

shown in the “Facts to Consider About the Location” sec

tion. Never obstruct the flow of ventilation air. If you have

any doubts or questions at all, call your gas company.

Failure to provide the proper amount of combustion air

can result in a fire or explosion and can cause DEATH,

SERIOUS BODILY INJURY, OR PROPERTY DAMAGE.

AWARNING

HOTTER WATER CAN SCALD; Water heaters are

intended to produce hot water. Water heated to a tem

perature which will satisfy clothes washing, dish washing,

and other sanitizing needs can scald and permsmently

injure you upon contact. Some people are more litely to

be permanently Injured by hot water than others. Tliese

include the elderly, children, the infirm, or physically/mentafly handicapped. If anyone using hot water in your home

fits into one of these graups or If there is a local code or

state law requiring a certain temperature water at the hot

water tap, then you must tala special precautions. In addi

tion to using the lowest possible temperature setting that

satisfies your hot water needs, a means such as a mixing

valve, should be used at the hot water taps used by these

people or at the water heater. Mixing valves are available

at plumbing supply or hardware stores. Follow manufac

turers instructions for installation of the valves. Before

changing the factory setting on the thermostat, read the

"Temperature Regulation" section in this manual.

AWARNING

Soot build-up indicates a problem titat requires correc

tion before further use. Turn “OFF” gas to water heater

and leave “OFF" until repairs are made, because failure

to correct the cause of the sooting can result in a fire or

explosion causing DEATH, SERIOUS BODILY INJURY,

OR PROPERTY DAMAGE.

AWARNING

This water heater must not be installed directly on car

peting. Carpeting must be protected by a metal or wood

panel beneath the appliance extending beyond the full

width and depth of the appliance by at least 3 inches

p6.2mm) in any direction, or if the appliance is installed

in an alcove or closet, the entire floor must be covered by

the panel. F^lure to heed this warning may result in a

fire hazard.

AWARNING

VENT DAMPERS - Any vent damper, whether it is operat

ed thermally or otherwise must be removed if its use

inhibits proper drafting of the water heater.

Thermally Operated Vent Dampers; Gas-fired water

heaters having thermal efficiency in excess of 80% may

produce a relatively low flue gas temperature. Such tem

peratures may not be high enough to properly open ther

mally operated vent dampers. This would cause spillage of

flue gases and may cause carbon monoxide poisoning.

Vent dampers must bear evidence of certification as com

plying with the latest edition of American National

Standard ANSI Z2I.68 (ANSI Z2I.66 & 67. respectively,

cover electrically and mechanically actuated vent

dampers). Before instaJIation of any vent damper, consult

your loc^ Sears Service Center or the gas utility for fur

ther information.

AWARNING

• The appliance and its individual shutoff valve must be dis

connected from tile gas supply piping system during any

pressure testing of the gas system at test pressures in

excess of 'A pound per square inch (3.5kPa).

> The appliance must be isolated from the gas supply pip

ing system by closing its individual manud shutoff valve

during any pressure testing of the gas supply piping sys

tem at test pressures equal or less than 'A pound per

square inch (3.5kPa).

AWARNING

BEFORE LIGHTING [PROPANE (L.P.) GAS WATER

HEATERS]; Propane (L.P.) gas is heavier than air. Should

there be a leak in the system, the gas will settle near the

ground. Basements, crawl spaces, skirted areas under

mobile homes (even when ventilated), closets and areas

below ground level will serve as pockets for the accumula

tion of this gas. Before attempting to light or relight the

water heater^ pilot or turning on a nea^ electri^ light

switch, be absolutely sure there is no accumulated gas in

the area. Search for odor of gas by sniffing at ground level

in the vicinity of the appliance. If odor is detected, follow

steps indicated at “For Your Safety” on the cover page of

this manual then leave the premises.

AWARNING

Chemical vapor corrosion of the flue and vent system

may occur if air for combustion contains certain chemical

vapors. Spray can propellants, cleaning solvents, refrigera

tor and air conditioner refrigerants, swimming pool

chemicals, calcium and sodium chloride, waxes, bleach,

and process chemicals are typical compounds which are

potentially corrosive.

_______________AWARNING

Obstructed or deteriorated vent systems may present a

serious hedth risk or asphyxiation.

Safety Precautions continued on page 4

________________

Safety

AWARNING

The mter heater with draft hood installed must be prop

erly vented to a chimney which terminates outdoors.

Never operate the water heater unless it is vented to the

outdoors and has adequate air supply to avoid risks of

improper operation, explosion or asphyxiation.

AWARNING

Minimum clearances between the water heater and com

bustible or non-combustible construction are I" at the

sides and rear, 4" at the front, and 6" from the vent pipe.

Clearance from the top of the jacket is 18" on most mod

els. Note that a lesser dimension may be allowed on some

models. Refer to the label on the water heater adjacent to

the gas control valve for all clearances.________

AWARNING

Do not use this appliance if any part of it has been under

water. Immediately call a Sears Service Technician to

inspect the appliance and to replace the gas control or any

part of the burner system which has been under water.

AWARNING

HYDROGEN GAS: Hydrogen gas can be produced in a hot

water system that has not been used for a long period of

time (generally two weeks or more). Hydrogen gas Is

ex^mely flammable and explosive. To prevent the possi

bility of injury under these conditions, we recommend the

hot water faucet be opened for several minutes at the

kitchen sink before any electrical appliances which are

connected to the hot water system are used (such as a dis

hwasher or vnishing machine). If hydrogen gas is present,

there will probably be an unusual sound similar to air

escaping through the pipe as the hot water faucet is

opened. There must be no smoking or open flame near

the foucet at the time it is open.

ACAUTION

WATER HEATERS EVENTUALLY LEAK: Installation of

the mter heater must be accomplished in such a manner

that if the tank or any connections should leak, the flow of

vrater will not cause damage to the structure. When such

locations cannot be avoided, a suitable drain pan should

be installed under the water heater. Drain pans are avail

able at your local Sears store. Such a drain pan must be

not greater than I 'A inches deep, have a minimum length

and width of at least 1 inches greater than the water

heater dimensions and must be piped to an adequate

drain. The pan must not restrict combustion air flow.

Under no circumstances is the manufacturer or Sears to

be held liable for any water damage in connection with

this water heater.

AWARNING

INSULATING JACKETS: When installing an external

water heater insulation jacket on a gas water heater:

• DO NOT cover the temperature-pressure relief valve.

• DO NOT put insulation over any part of the top of the

gas water heater.

• DO NOT put insulation over the gas control valve or gas

control valve/bumer cover, or any access areas to the

burner.

• DO NOT let insulation around the gas water heater to

get within 8 inches of the floor (air must get to the

burner).

• DO NOT cover or remove operating instructions, and

safety related warning labels and materials affixed to the

water heater.

Failure to heed this will result in the possibility of a fire or

explosion.

Table of Contents

Safety Precautions........................................................................................................................................................................................2-4

Table of Contents..............................................................................................................................................................................................5

Customer Responsibilities................................................................................................................................................................................6

Product Specifications......................................................................................................................................................................................6

Materials and Basic Tools Needed...................................................................................................................................................................7

Materials Needed.......................................................................................................................................................................................7

Basic Tools................................................................................................................................................................................................7

Installation Instructions................................................................................................................................................................................sa6

Removing the Old Water Heater...............................................................................................................................................................8

Facts to Consider About the Location.......................................................................................................................................................9

Combustion Air and Ventilation for Appliances in Ünconhncd Spaces.................................................................................................10

Combustion Air and Ventilation for Appliances in Confined Spaces.................................................................................................. 10

Water Piping............................................................................................................................................................................................11

Temperature-Pressure Relief Valve........................................................................................................................................................ 12

Filling the Water Heater......................................................................................................................................................................... 13

Venting................................................................................................................................................................................................13-14

Gas Piping...........................................................................................................................................................................................14-15

Installation Checklist................................................................................................................................................................................16

Operating Instructions.............................................................................................................................................................................17-19

Lighting...............................................................................................................................................................................................17-18

Temperature Regulation...........................................................................................................................................................................19

Service and Adjustment.......................................................................................................................................................................... 20-21

Tank (Sediment) Cleaning....................................................................................................................................................................... 20

Venting System Inspeaion........................................................................................................................................................................20

Burner Inspection.....................................................................................................................................................................................20

Burner Cleaning.......................................................................................................................................................................................20

Draining...................................................................................................................................................................................................21

Temperature-Pressure RcliefValve Operation.........................................................................................................................................21

Drain Valve Washer Replacement.......................................................................................................................................................... 21

Housekeeping...........................................................................................................................................................................................21

Service......................................................................................................................................................................................................21

Troubleshooting Guide............................................................................................................................................................................22-25

Start Up Conditions............................................................................................................................................................................22-23

Condensation..........................................................................................................................................................................................22

Smoke/Odor............................................................................................................................................................................................22

Thermal Expansion...........................................................................................................................................................................22-23

Strange Sounds.......................................................................................................................................................................................23

Operational Conditions.......................................................................................................................................................................23-24

Smelly Water..........................................................................................................................................................................................23

Air in Hot Water Faucets....................................................................................................................................................................... 23

High Temperature Shut Off System...................................................................................................................................................... 24

Not Enough Hot Water..........................................................................................................................................................................24

Water is Too Hot....................................................................................................................................................................................24

Leakage Checkpoints...............................................................................................................................................................................25

Parts Order List........................................................................................................................................................................................26-27

Customer Responsibilities

Thank You for purchasing a Sears water heater.

Properly installed and maintained, it mould give you years of

trouble free service. If you should decide that you want the new

water heater professionally installed by Sears call the local Sears

Service Center or any Sears store. They will arrange for prompt,

quality installation by Sears authorized contractors.

Abbiwiations Found In This Instruction Manual

IA.S. - International Approval Services, A Division of CSA

A.N.S.I. - American National Standards Institute

AWARNING

This gas-fired water heater is design certified by the

Intenutionai Approval Services, A Division of CSA under

American National Standard/CSA Standard for Gas Water

Heaters ANS Z2I.I0.I • CSA 4.1 (latest edition). The

installation must conform with this manual, Local Codes

and with die latest edition of the National Fuel Gas Code,

ANSIZ223.I.

This publication is available from your local government or

public library, gas company, or by writing NFPA,

Batterymarch Parit, Quincy, MA 02269.

Read the “Safety Precautions” section, pages 2 throi^ 4 of

this manual first and then the entire manual carefully. If you

don’t follow the safety rules, the water heater will not operate

properly. It could cause DEATH, SERIOUS BODILY

INJURY AND/OR PROPERTY DAMAGE.

This manual contains instructions for the installation, opera

tion, and maintenance of the as-fired water heater. It also

contains warnings through out me manual that you must read

and be aware ofTAll warnings and all instruaions are essential

to the proper operation of the water heater and your safety.

Since wc cannot put everything on the first few pages, READ

THE ENTIRE MANUAL BEFORE ATTEM^ING TO

INS'mX OR OPERATE THE WTER HEATER.

The installation must conform with the instructions in this

manual; gas company rules; and Local Codes, or in the

absence or Local Codes, with the latest edition of the National

Fuel Gas code, ANSI Z223.1, also referred to as NFPA 54.

This publication is available from your local government or

public library or gas company or by writing NFPA,

Batterymarch Park, Quincy, MA 02269.

If after reading this manual you have any questions or do not

understand any portion of the instructions, call the Sears

Service Center.

Carefully plan the place where you are going to put the water

heater. Correct combustion, vent action, and vent pipe instal

lation are very important in preventing death from possible

carbon monoxide poisoning and fires.

Examine the location to ensure the water heater complies with

the “Facts to Consider About the Location” section in this

manual.

For California installation this water heater must be braced,

anchored, or strapped to avoid falling or moving during an

earthquake. Sec instructions for correct installation proce

dures. Instructions may be obtained from your local dealer,

wholesaler, public utilities or California Office of the State

Architca, 400 P Street, Sacramento, CA 95814.

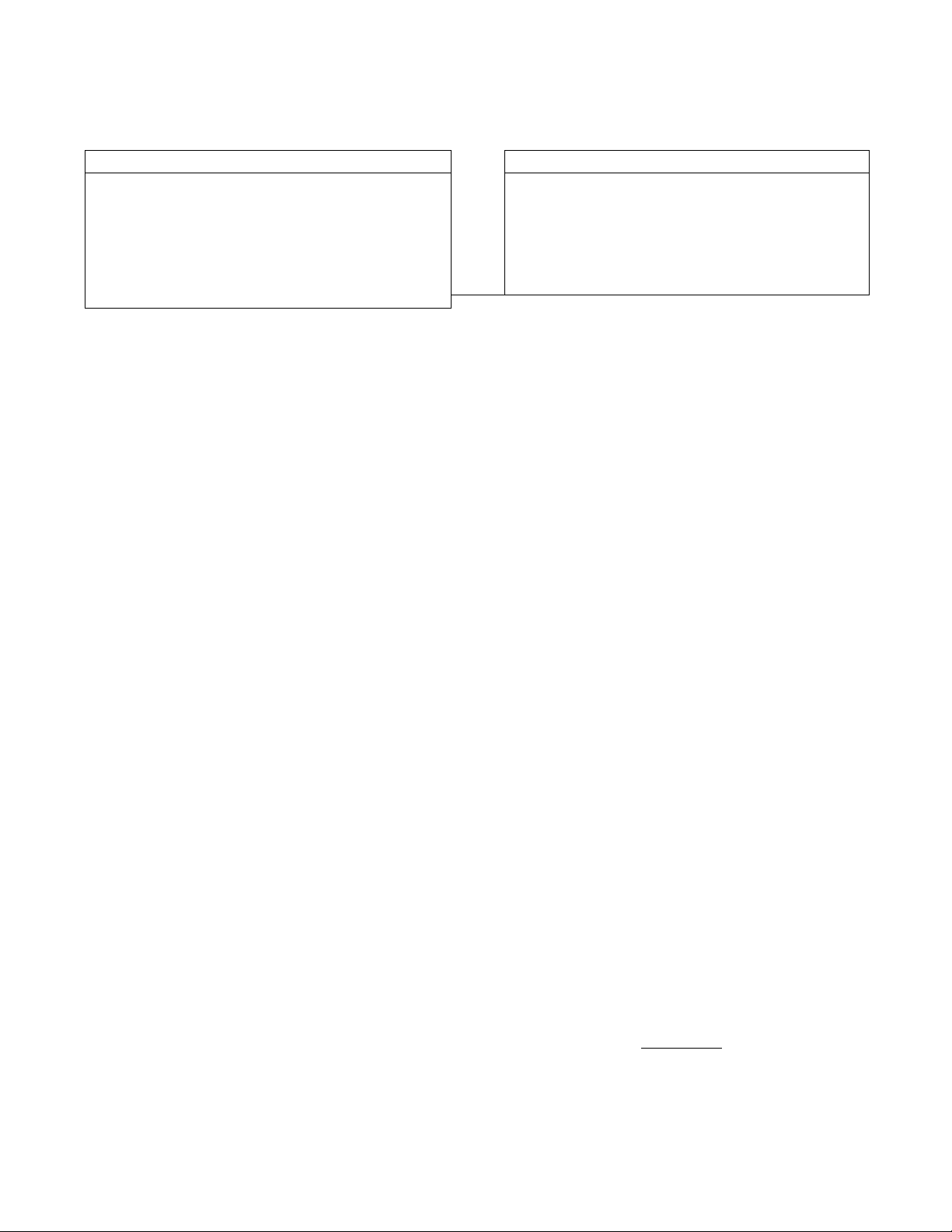

Product Specifications

MODEL

NUMBER

153.334290

153.334390 30

153.334490

153.334590 50

TANK

CAPACITY

IN GALLONS

40

40

TYPE

OF

GAS

NATURAL

NATURAL

NATURAL

NATURAL

B.T.U.

RATE

35.000

28,000

30,000

30,000

RECOVERY RATE

GALS. PER HOUR

@ 90-F RISE

35.8

28.7

31.0

31.0

MINIMUM

VENT

PIPE

3" - 4”

3" 16

3" 18

3" 20

DIMENSIONS IN INCHES

HEIGHT TO

DIAMETER

20

JACKET TOP

47/j

56

56‘A

56A

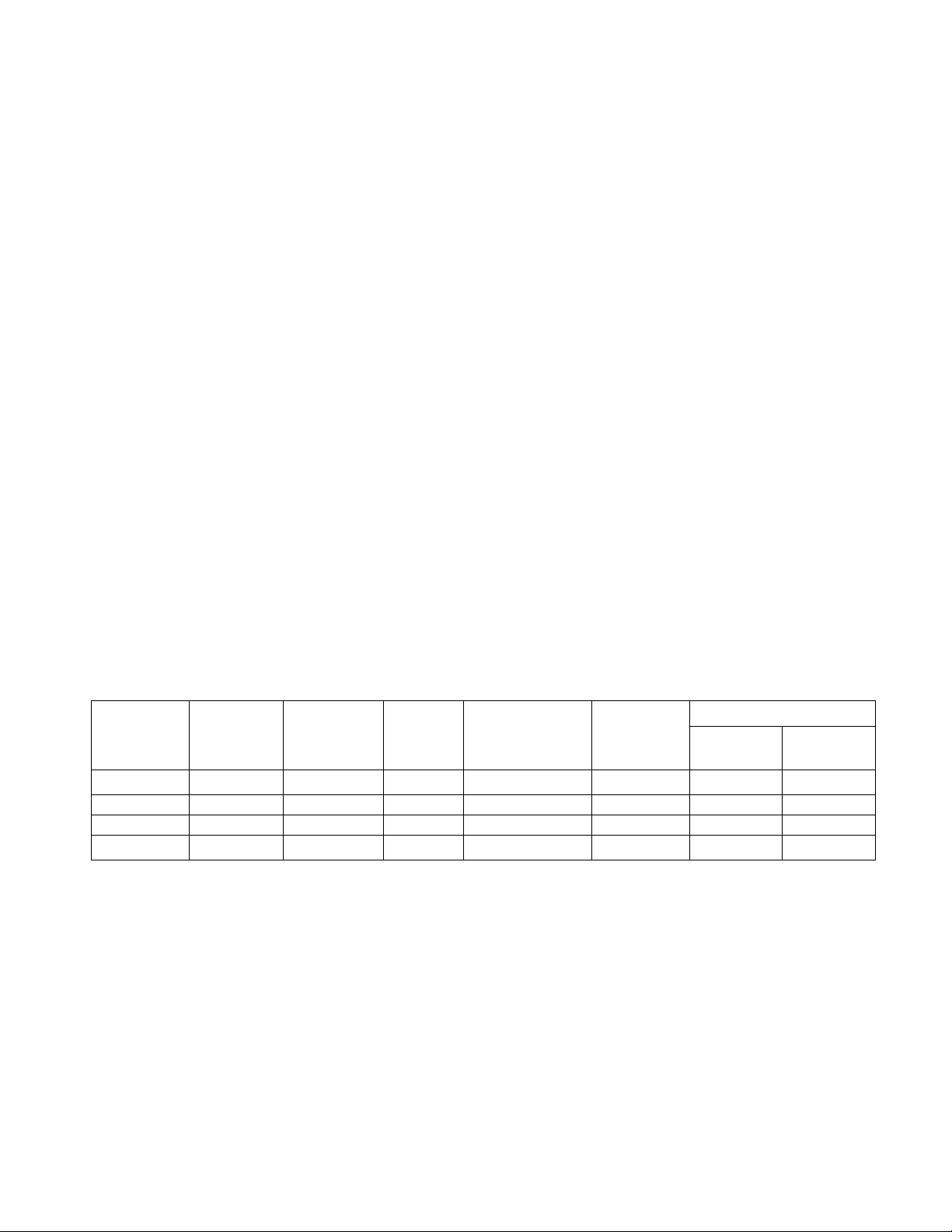

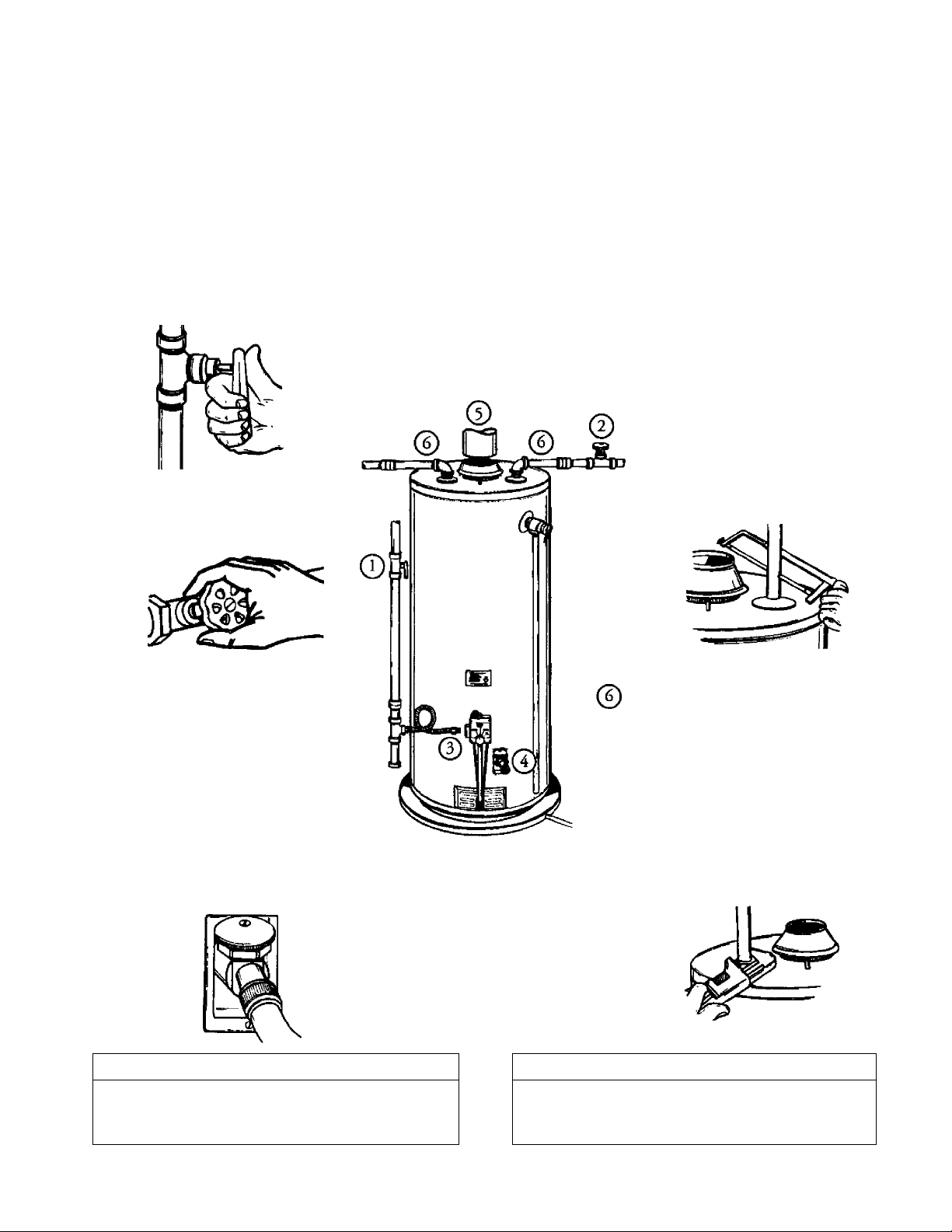

Materials and Basic Tools Needed

Materials Needed

To simplify the installation Sears has available the installation

parts shown below. You may or may not need all of these materb

als, depending on your type of installation.

WATER HEATER STAND 24"xl4"xl8"

FOR USE WITH WATER HEATERS

INSTALLED IN RESIDENTIAL

GARAGES HAVING A DIAMETER 24"

OR LESS AND A RATED CAPACITY

75 GALLONS OR LESS

VENT ELBOW

EXPANSION TANKS

FOR THERMAL

EXPANSION CONDI

TIONS AVAILABLE IN

2 GALLON AND 5

GALLON CAPACITY

THROUGH LOCAL

SEARS STORE OR

SERVICE CENTERS

WATER HEATER INSTAL

LATION KIT WITH FLEXI

BLE CONNECTORS FOR

3/4" OR 1/1" THREADED

OR COPPER PLUMBING

c

VENT PIPE

Basic Tools

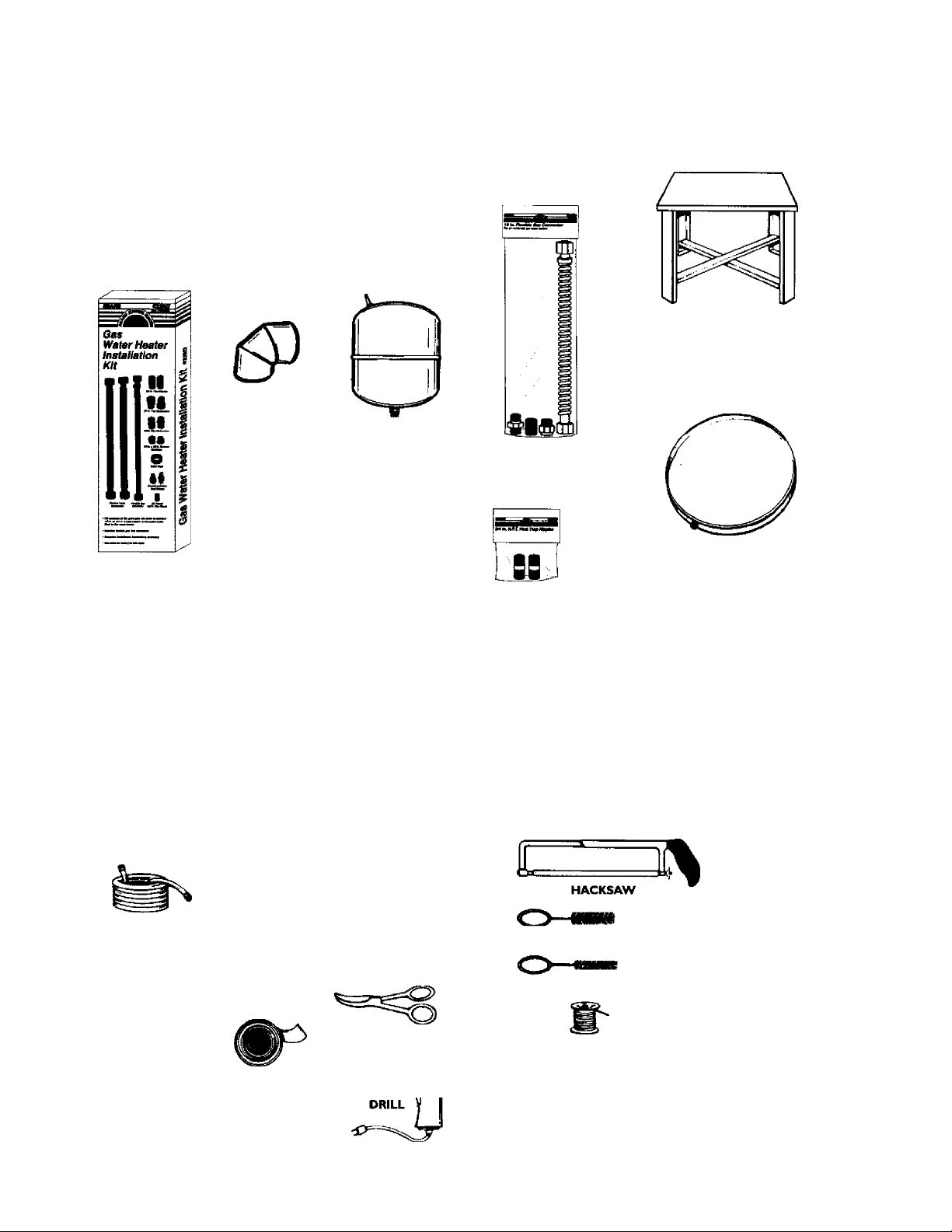

You may or may not need ail of these tools, depending on your

type of installation. These tools can be purchased at your local

Sears store.

• Pipe Wrenches (2) 14"

• Screwdriver

• Tin Snips

• 6 Foot Tape of Folding Rule

• Garden Hose

•Drill

• Pipe dope or Teflon Tape

FLEXIBLE WATER

HEATER GAS CON

NECTOR WITH

FITTINGS

DRAIN PANS AVAILABLE IN 20" DIAME

WATER HEATER HEAT

TRAPS HELP REDUCE HEAT

LOSS DUE TO THERMAL

SYPHONING

TER FOR WATER HEATERS HAVING A

DIAMETER 18" OR LESS AND AVAIL

ABLE IN 28" DIAMETER FOR WATER

HEATERS HAVING A DIAMETER 26" OR

LESS

ADDITIONAL TOOLS NEEDED

WhlEN SWEAT SOLDERING

• Tubing Cutters or Hacksaw

• Propane Torch

• Soft Solder

• Solder Flux

• Emery Cloth

• Wire Brushes

CARDEN HOSE

SLOT-HEAD SCREWDRIVER

PHILLIPS SCREWDRIVER

PIPE DOPE (SQUEEZE TUBE)

(USE FOR WATER AND

GAS CONNECTIONS)

6 FOOT TAPE

ROLL OF TEFLON TAPE

(USE ONLY ON WATER

CONNECTIONS)

PIPE

WRENCH

TIN SNIPS

3/4" WIRE BRUSH

1/2" WIRE BRUSH

ROLL OF LEAD FREE

SOFT SOLDER

ROLL OF EMERY

CLOTH

SOLDER FLUX

PROPANE

TORCH

TUBING

CUTTER

Installation Instructions

Removing the Old Water Heater

Turn “OFF” the gas supply to the water heater.

AWARNING

If the main gas line shutoff serving all gas appliances Is

used, al» shut “OFF" the gas at each appliance. Leave ^1

gas appliances shut “OFF" until the water heater installa

tion is complete.

Turn “OFF” the water to the water

©

heater. Some installations require that

the water be turned off to the entire

house.

/^Disconnect the vent pipe from the draft hood where

' they connect to the water heater. In most installations

the vent pipe can be lifted off after any screw or other

attached devices are removed. Dispose of the draft

hood. The new water heater has the draft hood which

must be used for proper operation.

. If you have copper piping to the water

©

heater, the two copper water pipes can be

cut with a hacksaw approximately 4"

away from where they connect to the

water heater. This will avoid cutting off

the pipes too short. Additional cuts can

be made later if necessary. Disconnect

the temperature-pressure relief valve

drain line. When the water heater is

drained, disconnect the hose from the

drain valve. Close the drain valve. The

water heater is now completely discon

nected and ready to be removed.

Check again to make sure the e« supply

(?)

is “OFF to the water heater. Then dis

connect the gas supply connection from

the gas control valve.

Attach a hose to the water heater drain

©

valve and put the other end in a floor

drain or outdoors. Open the water heater

drain valve. Open a nearby hot water

faucet which will relieve pressure in the

water heater and speed draining.

AWARNING

The water passing out of the drain valve may be extremely

trot To avoid being scalded, make sure all connections are

tight and that the water flow is directed away from any

person.

b. If you have galvanized pipe to the water

heater, loosen the two galvanized pipes

with a pipe wrench at the union in each

line. ATso disconnect the pming remain

ing to the water heater. These pieces

should be saved since they may be need

ed when reconnecting the new water

heater. Disconnea the temperature-pres

sure relief valve drain line. When the

water heater is drained, disconnect the

hose from the drain valve. Close the

drain valve. The water heater is now

completely disconnected and ready to be

removed.

ACAUTION

Mineral buildup or sediment may have accumulated in the

old water heater. This causes the water heater to be much

heavier than normal and this residue, if spilled out, could

cause staining.

8

Installation Instructions (cont’d)

Facts to Consider About the Location

You should carefully choose an indoor location for the new

water heater, because the placement is a very important consid

eration for the safety of me occupants in the building and for

the most economical use of the appliance. This water heater is

not for use in mobile homes or outdoor installation.

Whether replacing an old water heater or putting the water

heater in a new location, the following critical points must be

observed,

• The location selected should be indoors as close as practical

to the gas vent or chimney to which the water heater vent is

going to be connected, and as centralized with the water pip

ing system as possible. The water heater, as all water heaters,

will eventually leak. Do not install without adequate

drainage provisions where water flow will cause damage.

▲CAUTION

WATER HEATERS EVENTUALLY LEAK: Installation of the

vrater heater must be accomplished in such a manner that if

the tank or any connections stwuld leak, the flow of water wilt

not cause damage to the structure. When such locations can

not be avoided, a suitable drain pan should be installed under

the vrater heater. Drain pans are available at your local Sears

store. Such a drain pan must be not greater than I /> inches

deep, have a minimum length and width of at least 2 inches

greater than the water heater dimensions and must be piped

to an adequate drain. The pan must not restrict combustion air

flow. Under no circumstances is the manufacturer or Sears to

be held liable for any water dam^ in connection with this

water heater.

▲WARNING

INSTALLATIONS IN AREAS WHERE FLAMMABLE UQUIDS

(VAPORS) ARE LIKELY TO BE PRESENT OR STORED

(GARAGES, STORAGE, AND UTILITY AREAS, ETC);

Flammable liquids (such as gasoline, solvents, propane (LP) or

butane, etc.), all of which emit flammable vapors, may be

improperly stored or used in such areas. The gas water heftter

pilot light or main burt№r can ignite sudi vapors. The resulting

flashback and fire can cause death or serious bums to anyone in

the area, as well as property dam;^.

If kistailation in su^ areas is your only option, then the installa

tion must be accomplished in a way that the pilot flame and

main burner fiame are elevated from the floor at least 18 inches.

While this imqr reduce the chances of flammable vapors from a

floor spill being ignited, gasoline and other flammable substances

should never stored or used in the same room or area contaning a gas water heater or other open flame or spark produc

ing appliance.

NOTE; Flamm^le vapors may be drawn by air currents from

other ueas of the structure to the appliance.

▲WARNING

Propellants of aerosol sprays and volatile compounds, (clean

ers, chlorine based chemicals, refrigerants, etc.) in addition to

being hi^ly flammable in many cases, will also change to cor

rosive l^drochloric acid when exposed to the combustion

products of the vrater heater. The results can be hazardous,

and also cause product failure.

The location selection must provide adequate clearances for ser

vicing and proper operation of the water heater.

▲WARNING

This water heater must not be installed directly on carpeting.

Carpeting must be protected by a metal or wood panel

beneath the appliance extending beyond the full width and

depth of the appliance by at least 3 inches (76.2mm) in any

direction, or if tiie appliance is installed in an alcove or closet,

the entire floor must be covered by the panel. Failure to heed

this warning may result in a fire hazard.

▲WARNING

Minimum clearances between the water heater and com

bustiMe or non-combustible construction are I" at tiie sides

and rear, 4" at the front, and 6" from tiie vent pipe. Clearance

from the top of the jacket b 18" on most models. Note that a

lesser dimension may be allowed on some models. Refer to die

label on the water heater adjacent to the gas control valve for

ail clearances.

12'MAX,

T

VENTJ^TON

r MIN.

OPENINGS

Il0p^m.|

I mwwnilim I

12" MAX.

Figure I

AIR DUCT

▲WARNING

A gas water heater cannot operate properiy without the cor

rect amount of air for combu^on. Do not install in a confined

area such a doset, unless you provide air as shown in the “Facts

to Consider About the Location” section. Never obstruct the

flow of ventilation air. If you have any doubts or questions at all,

call your gas company. Failure to provide the proper amount of

combustion air can result in a fire or explosion and can cause

DEATH, SERIOUS BODILY INJURIT, OR PROPERTY DAMAGE

▲WARNING

If thb water heater will be used in beauty shops, barber shops,

cleaning establishments, or self-service laundries with dry

cleaning equipment, it b imperative that the water heater or

water heaters be installed so that combustion and ventilation

air be taken from outside these areas. Refer to the “Facts to

Consider About the Location” section of thb manual and also

the latest edition of the National Fuel Gas Code, ANSI Z223.I,

also referred to as NFPA 54 for specifics provided concerning

air required.

Installation Instructions (cont’d)

Combustion Air and Ventilation

for Appliances Located in

Unconfined Spaces

Unconfined Space is a space whose volume is not less than 50

cubic feet per 1,000 Btu per hour of the ^gregate input rating

of all appliances installed in that space. Rooms communicating

directly with the space in which the appliances are installed,

through openings not furnished with doors, are considered a

part of the unconfined space.

In unconfined spaces in buildings, infiltration may be adequate

to provide air for combustion, ventilation and dilution of flue

gases. However, in buildings of tight construction (for example,

weather stripping, heavily insulated, caulked, vapor barrier, etc.),

additional air may need to be provided using the methods

described in Combustion Air and Ventilation for Appliances

Located in Confined Spaces, b.

Combustion Air and Ventilation

for ^pliances Located in

Confined Spaces ,

Confined Space is a space whose volume is less than 50 cubic

feet per 1,000 Btu per hour of the aggregate input rating of all

appliances installed in that space,

a. ALL AIR FROM INSIDE BUILDINGS:

(See Page 9 Figure 1, and Figure 2 below)

The confined space shall be provided with two permanent

openiMs communicating directly with an additional room(s)

of sufficient volume so that the combined volume of all

spaces meets the criteria for an unconfined space. The total

input of all gas utilization equipment installed in the com

bined space snail be considered in making this determination.

Each opening shall have a minimum free area of one square

inch per 1,000 BTU per hour of the total input rating of all

gas utilization equipment in the confined space, but not less

than 100 square inches. One opening shall commence within

12" of the top and one commencing within 12" of the bot

tom of the enclosure.

« tiMHfY 0Ц QM VEHT

1. When directly communicating with the outdoors, each open

ing shall have a minimum free area of 1 square inch per 4,000

BTU per hour of total input rating of all equipment in the

enclosure. (See Figure 3.)

2. When communicating with the outdoors through vertical

ducts, each opening shall have a minimum free area of 1

square inch per 4,000 BTU per hour of total input rating of

all equipment in the enclosure. (See Figure 4.)

Figure 4

3. When communicating with the outdoors throu^ horizontal

ducts, each opening shall have a minimum free area of 1

square inch per 2,000 BTU per hour of total input rating of

all equipment in the enclosure. (See Figure 5.)

Figure 5

-CHWNev OH <i*S VENT

OOTLET AIR CUCI

MLETMRDUCl

Figure 2

m

ALL AIR FROM OUTDOORS: (see Figures 3-5)

The confined space shall be provided with two permanent

openings, one commencing within 12" of the top and one

commencing within 12" from the bottom of the enclosure.

The openings shall communicate directly, or bj ducts, with

the outdoors or spaces (crawl or attic) that freely communi

cate with the outdoors.

Figure 3

4. When ducts are used, thev shall be of the same cross-sectional

area as the free area of the openings to which they connect.

The minimum short side dimension of rectangular air ducts

shall not be less chan 3". (See Figure 5-)

5. Louvers and Grilles: In calculatiim free area, consideration

shall be given to the blocking effect of louvers, grilles or

screens protecting openings. Screens used shall not be smaller

than V* mesh. If the free area through a design of louver or

grille is known, it should be used in ^dilating the size open

ing required to provide the free area specified. If the design

and free area is not known, it may be assumed that wood lou

vers will be 20-25 percent free area and metal louvers and

grilles will have 60-75 percent free area. Louvers and grilles

shall be fixed in the open position or interlocked with the

equipment so that they are opened automatically during

equipment operation.

6. Special Conditions Created by Mechanical Exhausting or

Fireplaces: Operation of exhaust fans, ventilation systems,

clothes dryers or fireplaces may create conditions requiring

special attention to avoid unsatisfactory operation of installed

gas utilization equipment.

10

Installation Instructions (cont’d)

Water Piping

AWARNING

HOTTER WATER CAN SCALD: Witer heaters are intended to

produce hot water. Water heated to a temperature which wiii

satisfy dothes washing, dish washing, and otter sanitizing needs

can scaid and permanently injure you upon contact Socne peo

ple are more likely to be permanently injured by hot water than

others. These include the etdeiiy, children, the Mrm, or physically/mentally handicapped. If anyone using hot water in your home

fits into one of these groups or if there is a local code or state law

requiring a certain temperature water at the hot water tap, then

you must tate special precautions. In addition to using the lowest

possible temperature setting that satisfies your hot water needs,

a means such as a mixing valve, should be used at the hot water

taps used by these people or at the water heater. Mixing valves

are available at plumbing supply or hardvrare stores. Follow man

ufacturers instructions for installation of the valves. Before

changing the factory setting on the thermostat, read the

‘Temperature Regulatíon" section in this manual.

AWARNING

This water heater shall not be connected to any

heating systems or component(s) used with a non

potable water heating appliance.

AWARNING

Toxic chemicals such as used for treatment of boilers

or non-potable water heating appliances shall never

be introduced into a potable water heating system.

Look at the top cover of the water heater. The cold water

inlet is marked cold. Put two or three turns of teflon tape

around the threaded end of the threaded-to-sweat coupling

and around both ends of the threaded nipple. Using flexi

ble connectors, connect the cold water pipe to the cold water

inlet of the water heater,

NOTE: This water heater is super insulated to minimize

heat loss from the tank. Further reduction in heat loss

can be accomplished by insulating the hot water lines

from the water heater.

INSTALLATION COMPLETED USING

SEARS INSTALLATION KIT

SHUTOFF

If a water heater is installed in a closed water supply system;

such as one having a back-flow preventer, check t^ve, wafer

meter with a check valve, etc... in the cold water supply; means

shall be provided to control thermal expansion. Contact the

local utility or local Scars Service Center on how to control this

NOTE: To protect against untimely corrosion of hot and

cold water fittings, it is strongly recommended that di-elec

tric unions or couplings be installed on this water heater

when connected to copper pipe.

The illustration shows the attachment of the water piping to the

water heater. The water heater is equipped with Vt water

connections.

NOTE: If using copper tubing, solder tubing to an adapter

before attaching the adapter to the cold water inlet connec

tion. Do not solder the cold water supply line diiecdy to the

cold water inlet. It will harm the dip tube and damage the

tank.

• Look at the top cover of the water heater. The water oudet is

marked hot. Put two or three turns of teflon tape around the

threaded end of the threaded-to-sweat coupling and around

both ends of the M" threaded nipple. Using flexible connec

tors, connect the hot water pipe to the hot water outlet on

the water heater.

11

Installation Instructions (cont’d)

Temperature-Pressure Relief Valve

AWARNING

At the time of manufacture this water heater was provided

with a combination temperature-pressures reiief valve certified

by a nationally recognized testing laboratory that maintains

periodic inspection of production of listed equipment or mate

rials, as meeting the requirements for Relief Valves and

Automate Gas Shutoff Devices for Hot Water Supply Systems,

and the latest edition of ANSI 221.22 and the code require

ments of ASME. If replaced, the valve must meet the require

ments of local codes, but not less than a combination tempera

ture and pressure relief valve certified as meeting the require

ments for Relief Valves and Automatic Gas Shutoff Devices for

Hot Water Supply Systems, ANSI Z2I.22 by a nationally recog

nized testing laboratory that maintains periodic infection of

production of listed equipment or materials.

The valve must be mariœd with a maximum set pressure not

to exceed the marked hydrostatic working pressure of the

vrater heater (ISO IbsJsq. in.) and a discharge capacity not less

than the water heater input rate as shown on the model rating

plate. (Electric heaters - watts dividecl by 1000 x 3415 equal

BTU/Hr. rate.)

Your local jurisdictional authority, while mandating the use of a

temperature-pressure relief valve complying with ANSI Z2I.22

and ASME, may require a valve model different from the one

furnished with die water heater.

Compliance with such local requirements must be satisfied by

the installer or end user of the water heater with a locally pre

scribed temperature-pressure relief valve installed in the desig

nated opening in the water heater in place of the fiictory fur

nished valve.

For safe operation of the water heater, the relief valve must not

be removed from № designated opening or plugged.

The temperature-pressure relief ràlve must be installed directly

into the fitting of the water heater designated for the relief valve.

Position the v^ downward and provide tubing so that any dis

charge will exit only within 6 inches above, or at any distance

below the structural floor. Be certain that no contact is made

with any live electrical part The discharge opening must not be

blocked or reduced in size under any circumstances. Excessive

length, over 30 feet, or use of more than four elbows can cause

restriction and reduce the discharge capacity of the valve.

No valve or other obstruction is to be placed between the relief

valve and the tank. Do not connect tubing directly to discharge

drain unless a 6" air gap is provided. To prevent bodily Injury, haz

ard to life, or property damage, the relief valve must be allowed

to discharge vrater in quantities should circumstances demand. If

the discharge pipe is not connected to a drain or other suitable

means, the water flow may cause property damage.

The Discharge Pipe:

* Must not be smaller in size than the outlet pipe size of the

valve, or have any reducing couplings or other restrictions.

* Must not be plumed or blocked.

* Must be of material listed for hot water distribution.

* Must be installed so as to allow complete drainage of both

the temperature-pressure relief valve, and the discharge

pipe.

* Must terminate at an adequate drain.

* Must not have any valve between the relief valve and tank.

AWARNING

The temperature-pressure relief valve must be manually

operated at least once a year. Caution should be taken to

ensure that (I) no one is in front of or around the outlet of

the temperature-pressure relief valve discharge line, and (2)

the water manually discharged will not cause any bodily

injury or property damage because the water may be

extremely hot

If after manually operating the valve, it foils to completely

reset and continues to release water, immediately dose the

cold water inlet to the water heater, follow the draining

instructions, and replace the temperature-pressure relief

valve with a new one.

SHUTOFF COLD

VALVE

TEMPERATURE-

PRESSURE

RELIEF VALVE

DISCHARGE PIPE

(Do not cap or piug)

6” AIR GAP

RELIEF VALVE OPENING

At the time of nunuficture, this water heater was providetl with a combinatìon tem

perature-pressure relief valve listed as complying with the standard for relief valves and

automatic gas shut-off devices for hot water suppiy systems, ANSI Z2I.22. For safe

operation of the water heater, the relief vaive must not be removed from its designated

point of installadon or plugged.

Tour local jurisdictional authority, while mandating the use of a temperature-pressure

relief valve compijnng with ANSI Z21.22 and ASME, msy require a valve model different

from the one furnished with the water heater.

Compliance with such local requirements must be sadslied by the installer or end user

of the water heater with a locally prescribed temperature-pressure relief valve installed

in the designated opening In the water heater.

See manual heading -‘Temperature-Pressure Relief Valves" for installation and mainte

nance of relief valve, discharge line, and other safety precautions.

12

Installation Instructions (cont’d)

Filling the Water Heater

A CAUTION

Never use this water heater unless it is completeiy filied with

water. 1b prevent damage to the tank, the tank must be liiled

with vrater. Water must flow from the hot water faucet

before turning "ON” gas to the water heater.

To fill the water heater with water:

• Close the water heater drain valve by turning the handle to

the right (clockwise). The drain valve is on the lower firont of

the water heater,

• Open the cold water supply valve to the water heater.

NOTE: The cold water supply valve must be left open

when ¿e water heater is in use.

• To insure complete filling of the tank, allow air to exit by

opening the nearest hot water faucet. Allow water to run

until a constant fiow is obtained. This will let air out of the

water heater and the piping.

• Check all new water piping for leaks. Repair as needed.

Venting

AWARNING

VENT DAMPERS - Any vent damper, whether it is operated

thermally or otherwise must be remov^ if its use inhibits prop

er drafting of the water heater.

Thermally Operated Vbnt Dampers: Gas-fired water heaters

hawing thermal efficiency in excess of 80% may produce a rela

tively kw flue gas temperature. Such temperatures may not be

high enough to properly open thermally operated vent

dampers. This would cause spillage of flue gases and may cause

carbon monoxide poisoning.

>fent dampers must bear evidence of certification as complying

with the latest edition of American National Standard ANSI

Z2I.68 (ANSI Z2I.66 & 67, respective, cover electrically and

mechanically actuated vent danripers). ElA>re installation of any

vent damper, consult your local Sevs Serdce Center or the gas

utility for further infomation.

AWARNING

To insure proper venting of this gas-fired water heater, the

correct vent pipe diameter must be utilized. Any additions or

deletions of other gas appliances on a common vent with this

water heater may advenety affect the operation of the water

heater. Consult the local Sears Service Center or gas utility if

any such changes are planned.

For proper venting in certain installations, a larger diameter vent

pipe may be necessary. Due to great variances in installations,

unforeseeable by the manufiicturer of the water heater, you must

consult your gas company to aid you in determining the proper

venting for your water heater from the vent tables m the latest

edition of the National Fuel Gas Code ANSI Z223.1, also

referred to as NFPA 54.

Check the venting system for signs of obstruction or deteriora

tion and replace if needed.

The combustion and ventilation air flow must not be obstructed.

AWARNING

Obstructed or deteriorated vent systems may present a serious

health risk or asphyxiation.

Place the draft hood legs in the receiving holes on the top of

the water heater. The legs wiU snap in the holes to give a tight

fit.

Place the vent pipe over the draft hood. With the vent pipe in

position, drill a small hole through both the vent pipe and

draft hood. Secure them together with a sheet metal screw.

DRAFT HOOD ^ VENT,

DRAFT

'si I 4'

SCRE

VENT TO OUTDOORS OR

CHJMNEY

AWARNING

The water heater with draft hood installed must be properly

vented to a chimney which terminates outdoors. Never opei^

ate the water heater unless it is vented to the outdoors and has

adeqw^ air supply to avoid risks of improper operation, explo

sion or asphyxiation.

AWARNING

The vent pipe from the water heater must be no less than the

diameter of the draft hibod outlet on the water heater, and

must slope upward to the chimney at least inch per linear

foot

DRAFT HOOD

13

Installation Instructions (cont’d)

Venting (cont’d)

All vent gases must be completely vented to the outdoors of the

structure (dwelling). Install only the draft hood provided with

the new water heater and no other draft hood.

Vent pipes must be secured at each joint with sheet metal screws.

VENT PIPE INSTALLATION

There must be a minimum of 6" clearance between single wall

vent pipe and any combustible material. Fill and seal any clear

ance oetween single wall vent pipe and combustible material

with mortar mix, cement, or other noncombustible substance.

For other than single wall, follow vent pipe manufteturer’s clear

ance speciGcations. To insure a tight fit of the vent pipe in a

brick chimney, seal around the vent pipe with mortar mix

cement.

AWARNING

Failure to have required clearances between vent piping and

combustible material will result In afire hazard.

AWARNING

Be sure vent pipe Is properly connected to prevent escape of

dangerous flue gases which could cause deadly asphyxiation.

Gas Piping

AWARNING

Make sure the gas supplied is the same type listed on the

mod^ rating plate. The inlet gas pressure must not exceed

10.5 in. voter column (2.6kPa) for natural gas or 13 in. water

column (3.2kPa) for propane (LP.) gas. The minimum inlet

gas pre^re listed on the moM rating plate is for the pur

pose of input adjustment.

__________

H the gas control valve is subjected to pressures exceeding 'A

pound per square inch (3.5k^), the dam^ to the gas con

trol vaho could result in a fire or explosion ^m leaking gas.

K the main gas line shutoff serving all gas apfriiances is used,

also turn “OFP’ ^ gas at each a^iance. Lem all gas appli

ances shut off until the water heater installation is complete.

A gas line of sufficient size must be run to the water heater.

Consult the latest edition of National Fuel Gas Code ANSI

Z223.1, also referred to as NFPA54 and the gas company concern

ing pipe size.

There must be:

• A readily accessible manual shut off valve in the gas supply line

serving the water heater, and

• A drip leg (sediment tr^) ahead of the gas control valve to help

prevent dirt and fere^ materials from entering the gas control

valve.

• A flexible gas connector or a ground joint union between the

shutoff valve and control valve to permit servicing of the unit.

Be sure to check all the ^ piping for leaks before lighting the

water heater. Use a soapy water solution, not a match or open

flame. Rinse off soapy solution and wipe dty.

AWARNING

AWARNING

_________________

_________________

^

^

AWARNING

Chemical vapor corrosion of the flue and vent system may

occur if air for combustion contains certain chemical vapors.

Spray can propellants, cleaning solvents, refrigerator and air

conditioner refrigerants, swimming pool chemicals, calcium

and sodium chioride, waxes, bleadi, and process chemicals are

typical compounds which are potentially corrosive.

Standanl Modds are for installadon up to 3,300 feet above sea

level.

Altitude Models are for installation from 3,300 to 5,500

feet above sea level.

If a standard model is installed above 3,300 feet or a high altitude

model is installed above 5,500 feet, the input rating must be

reduced at the rate of 4 percent for each 1,000 feet above sea level.

Contact your local Sears Service Center or gas utility for further

information.

AWARNING

The appliance and its gas connection must be leak tested

before placing the appliance in operation.

14

Installation Instructions (cont’d)

______________

• The appliance and its individual shutoff valve must be discon^

nected from die gas supply piping system durii^ any pressure

testing of the gas system at test pressures in excess of '/i

pound per square indi (3.5kPa).

• The appliance must be isolated from the gas supply piping sys

tem by doting its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test pres

sures equal or less than Yt pound per square inch (3.5kPa).

Use pipe joint compound or teflon tape marked as being

resistant to the action of petroleum [Propane (LR)] gases.

SEDIMENT TRAP

A sediment trap shall be installed as cldse to the inlet of the

water heater as practical at the time of water heater installation.

The sediment trap shall be either a tee fitting with a capped nip

ple in the bottom outlet or other device recognized as an effec

tive sediment trap. If a tee fitting is used, it shall be installed in

conformance with one of the methods of installation shown

below.

Connecting the gas piping to the gas control valve of the water

heater can be accomplished by either of the two methods shown.

Contaminants in the gas lines may cause improper operation

of the gas control valve that may result in fire or ei^osion.

Before attaching the gas line be sure that all gas pipe is dean

on the inside, lb trap any dirt or foreign material in the gas

supply line, a drip leg (sometimes called a sediment tr^)

must be incorporated in the piping. The drip leg must be

readily accessible. Install In accordance with the *'&s Piping”

section. Refer to the latest edition of the National Fuel Gas

Code, ANSI Z223.I, also referred to as NFRA 54.

A WARNING

AWARNING

AWARNING

________________

_________

GAS PIPING WITH

FLEXIBLE CONNECTOR

FLEXIBLE GAS CONNECTOR

I CONTROL

GAS PIPING WITH ALL BLACK IRON

PIPE TO GAS CONTROL

GAS

¡CONTROL

VALVE

GAS

VALVE

15

Installation Instructions (cont’d)

Installation Checklist

BEFORE LIGHTING THE PILOT:

• Check the gas lines for leaks.

a. Use a soapy water solution. DO NOT test for gas leaks

using a match or open ñame.

b. Brum the soapy water solution on all gas pipes, joints and

ñttings.

c ChecK for bubbling soap. This means you have a leak.

Turn “OFF” gas ana make the necessary repairs.

d. Recheck for leaks.

e. Rinse off soapy solution and wipe dry.

• Is the new temperature-pressure relief valve properly installed

and piped to an adequate drain? See “Temperature-Pressure

Relief Valve” section.

• Are the cold and hot water lines connected to the water

heater correctly? See “Water Piping” instructions in the

“Installation Instructions” section.

• Is the water heater completely filled with water? Sec “Filling”

instructions in the “installation Instructions” section.

• Will a water leak damage anything? See the “Facts to

Consider About the Location” section.

Is there proper clearance between the water heater and any

" ' that might catch ^ ~ ‘ ' ''

thing that might catch fire? See the “Facts to Consider About

Dcation” section.

the Loc ' " '

Do you have adequate ventilation so that the water heater

will operate properly? See “Combustion Air and Ventilation”

in the “Facts to Consider About the Location” section.

VENT PIPE TO

OUTDOORS

OR CHIMNEY SHUTOFF VALVE

Is the draft hood vent piping properly secured? See “Venting”

. . . „ piping. . .

instructions in the “Installation Instructions” section.

• Is there proper clearance between the vent pipe and anything

that mi^t catch on fire? See “Venting” instructions in the

“Installation Instructions” section.

• Is the vent pipe properly sloped and does the vent terminate

outdoors? See “Venting” instructions in the “Installation

Instructions” section.

• Do you need to call your gas company to check the gas pipe

and its hookup?

•

16

Operating Instructions

Lighting

AWARNING

BEFORE LIGHTING [PROPANE (LP.) GAS WATER

HEATERS]: Propane (LR) gas is heavier than air. Should there

be a leak in the system, the gas will settle near the ground.

Basements, crawl spaces, skirted areas under mobile homes

(even when ventilated), closets and areas bekw ground level will

serve as pockets for the accumulation of this gas. Before

attNTipting to light or relight the water heaterb pilot or turning

on a nearby eiedrical light switch, be absolutely sure there is no

accumulated gas in the area. Sear^ for odor of gas by sniffing at

ground level in the vicinity of the appliance. If odor is detected,

follow steps indicated at “For Your Safety” on the cover page of

this manual then leave the premises.

Lighting and operating instructions are located on front of the

water heater, above or to one side of the gas control valve.

AWARNING

AN ODORANT IS ADDED TO THE GAS USED

BY THIS WATER HEATER.

FOR YOUR SAFETY

IF YOU SMELL GAS:

Do not try to light any appliance.

Do not tMJch any electrical switch; do not use any phone in

your buiiding.

• Immediateiy call your gas supplier from a neighbor^ phone.

Follow the gas suppliei^ instructions.

If you cannot reach your gas supplier, call the fire depart

ment.

Figure 6

Figure 7

AWARNING

DO NOT force the gas contnri knob. Use only your hand to

push it down to light the pilot, or to turn it to “ON”, “OFF”

or “PILOT’. Never use a tool such as a lever, wrench or pli

ers. Do not hit or damage the knob. A damaged knob may

result in an explosion and serious injury. If you have problem

turning the loiob, call the gas supplier immediately.

CHECK FOR LEAKS

Be sure to check all your gas pipes for leaks before lighting your

water heater. Use a soapy water solution, not a match or open

flame. Check the factory gas fittings after pilot is lit and gas con

trol knob is still in “PILOT” position. Then, check the fittings

when the main burner is turned “ON”. Use a soapy water solu

tion for this, too.

Figure 8

17

Operating Instructions (cont’d)

Lighting label on the water heater as it appears above the thermostat

FOR YOUR SAFETY READ BEFORE LIGHTING

If you do not follow these instructions exactiy, a fire or explosion

may result causing property damage, personai injury or ioss of ilfe.

A. This appiiance has a piiot which must be iighted by

hand. When iighting the pilot, follow these instructions

exactly.

B. BEFORE LIGHTING smell all around the appliance area

for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

* Do not try to light any appliance.

* Do not touch any electric switch; do not use any

phone in your building.

* Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

LIGHTING INSTRUCTIONS

WARNING

1. STOP! Read the safety information above on this label.

2. Remove outer door.

3. Set the thermostat to lowest settli^by turning the

water temperature dial clockwise, ('''> ) to Its lowest

temperature setting (with arrow on dial] as shown. DO

NOT FORCE.

4. Turn gas control knob clodcwise * to “OFF” posi

tion. Knob cannot be turned from “PILOT” to “OFF”

unless knob is depressed slightly. DO NOT FORCE.

(Figure 6, page 17)

5. Wait five (5) minutes to clear out any gas. If you then

smell gas, STOP! Follow “B” in the safety information

above on this label. If you don’t smell gas, go to the

next step.

6. Remove (or open) inner door located below the gas

control unit

7. Find pilot-foilow metal tube from gas control. The pilot

is located in front of the burner.

PILOT BURNER

THERMOCOUPLE

£l

8. If you don’t smell gas, turn knob on gas control counter

clockwise^ to “PILOT” position. (Figure 7, page 17)

* If you cannot reach your gas supplier, call the fire

department.

C. Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or

turn by hand, don’t try to repair it, call a qualified ser

vice technician. Force or attempted repair may result

In a fire or explosion.

D. Do not use this appliance if any part has been under

water. Immediately call a qualirM service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has bwn

under water.

9. Push in control knob all the way and hold down.

Immediately light the pilot virlth a match. Continue to

hold control knob in for about one (1) minute after

the pilot is lit Release knob and it will pop back up.

Pilot should remain lit ff it goes out, repeat steps 3

through 8.

* If knob does not pop up when released, stop and

immediately call your service technician or gas

supplier.

* If the pilot will not stay tit after several tries,

depress and turn the gas control knob clockwise

) to “OFF” and call your service technician

or gas supplier. (Figure 6, page 17)

10. Replace (or dose) inner door. Replace outer door if

door does not cover gas control on/off knob or tem

perature adjustment knob. (Figure 9, page 17)

11. At arms lengfri away, turn gas control knob counter-

dockwise to the full “ON” position. Warning

do not use gas control knob to regulate gas

flow. (Figure 8, page 17)

12. At arms length away, set the thermostat to desired

setting. The mark (A) HOT indicative of approximate

120°F is preferred starting point. Some local laws

may require a tower starting point, if hotter water is

desired, see Instruction manual and “warning” below.

13. Replace the outer door if not replaced in step 10.

WARNING

Hotter water increases the risk of scald Injury. Before changing temperature setting see Instruction manual.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting by turning the

water temperature dial dockwise (/^) to Its lowest

temperature setting (with arrow on dial) as shown. DO

NOT FORCE.

2. Turn gas control knob dockunse J to “OFF’ posi

tion. Knob cannot be turned from “PILOT” to “OFF”

unless knob is depressed slightly. DO NOT FORCE.

3. Replace outer door (if removed).

18

Operating Instructions (cont*d)

Temperature Regulation

Due to the nature of the typical gas water heater, the water tem

perature in certain situations may vary up to 30°F higher or

lower at the point of use such as, bathtubs, showers, sink, etc.

This means that when the temperature adjustment dial is set at

the mark approximating 120°F, the actual water temperature at

any hot water tap could be as high as 150°F or as low as 90“F.

Any water heater’s intended purpose is to heat water. Hot water

is needed for cleaning {bodies, dishes, clothing). Hot water will

present a scald hazard. Depending on the time element, and the

people involved (normal adults, children, toddlers, elderly,

infirm, etc.) scalding may occur at different temperatures.

AWARNING

HOTTER WATER CAN SCALD: Wtter heaters are intended to

produce hot water. Water heated to a temperature which will

satisfy clothes washing, dish washing, and other sanitizing needs

can scald and permanently injure you upon contact. Sotne peo

ple are more lilceiy to be permanentiy injured by hot water than

others. These include the elderly, children, the infirm, or physical-

ly/mentally handicapped. K anyone using hot water in your home

fits into one of these groups or if there is a local code or state law

requiring a certain temperature ¥rater at the hot voter tap, then

you must take spedal precautions. In addition to using the lowest

possible temperature setting that satisfies your hot water needs,

a meaiu such as a mbdng valve, should be used at the hot water

taps used by these peo|^ or at the water heater. Mbdng valves

are available at plumbing supply or hardware stores. Follow man

ufacturers instructions for installation of the valves. Before

changing the factory setting on the thermostat, read the

**Temperature Regulation” section in this manual.

Turn the water temperature dial clockwise ^) to decrease

the temperature, or counterclockwise to increase the

temperature.

PILOT LIGHTING-Sct here before attempting to light pilot.

A HOT-Is a thermostat setting of approximately

120°F, which will supply hot water at the

most economical temperatures. The

temperature adjustment knob can be

turned lower than “HOT” if desired.

A-Is a thermostat setting of approximately

130°F.

B—Is a thermostat setting of approximately

140“F.

AWARNING

Newer allow small children to use a hot water tap, or to draw

their own bath water. Never leave a child or handicapped per

son unattended in a bathtub or shower.

The thermostat of this water heater has been fectory set at its

lowest position, to reduce the risk of scald injury. It is adjustable

and must be reset to the desired temperature setting. The mark

(▲) HOT indicative of approximately 120°F is the preferred

starring point. Some states nave a requirement for a lower set

starring point. Some states have a requirement for a lower setting. If you need hotter water, follow directions for temperature

adjustment, but beware of the warnings in this section.

- . . . . ' ‘

C-Is a thermostat setting of approximately

ISO'E

VERY HOT-Is a thermostat setting of 160“F. It is

recommended that the dial be set lower

whenever possible.

NOTE: Water temperature range of 120°—140°F recom

mended by most dishvrashcr manufficturets.

AWARNING

Should overheating occur or the gas supply fail to shut off,

turn “OFF’ the manud gas control valve to the appliance.

19

Service and Adjustment

Tank (Sediment) Cleaning

Sediment build-up on the tank bottom may create varying

amounts of noise, and if left in the tank will cause premature

tank failure. In some water areas, you may not be able to drain

all sediment deposits by simply draining the tank. In these cases

Mag

Erad (part no. 23600) can be used to help remove the sedi

ment deposits. This may be ordered from the Sears Service

Center. For ordering, refer to the “Parts Order List” section.

Venting System Inspection

At least once a year a visual inspection should be made of the

venting system. You should look for:

* Obstructions which could cause improper venting. The com

bustion and ventilation air flow must not be obstructed.

* Damage or deterioration which could cause improper vent

ing or leaks^e of combustion products.

* Rusted flakes around top of water heater.

▲WARNING

Chemical vapor corrosion of the flue and vent system may

occur if air for combustion contains certain chemical vapors.

Spray can propellants, cleaning solvents, refrigerator and air

conditioner refri^rants, swmming pool chemicals, calcium

and sodium chloride, waxes, bleach, and process chemicals are