Page 1

Owners

Manual

FOR POTABLEWATER

HEATING ONLY

NOT SUITABLEFOR

SPACEHEATING

NOT FOR USE IN

MOBILE HOMES

THE ECONOMIZER TM6

MODEL NUMBERS:

153.332861 40 Gal.L.R

153.332870HA 40 Gal. High Altitude L.E

153.332880 50 Gal.L.R

153.332890HA 50 Gal. High Altitude L.E

153.332960 40 Gal.

153.332970HA 40 Gal. High Altitude

153.332980 50 Gal.

153.332990HA 50 Gal. High Altitude

POWER VENT

GAS WATER HEATER

• Safety Instructions

• Installation

• Operation

For Your Safety

AN ODORANT IS ADDED TO THE GAS USED BY THIS

WATER HEATER

WARNING: If the information in these instructions are not followed exactly, a

fire or explosionmay result, causingproperty damage, personalinjury or death.

- Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or anyother appliance.

-WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the

gassuppliers instructions.

• If you cannot reach your gassupplier,call the fire department

-Installation and service must be performed by a qualified installer, service

agencyor the gassupplier.

• Care and Maintenance

• Troubleshooting

• Parts List

Caution:

Read and Follow

All Safety Rules and

Operating Instructions

Before First Use of

This Product,

Save this Manual for Future Reference.

Improper installation, adjustment, alteration, service or maintenance can I

cause DEATH, SERIOUS BODILY INJURY, OR PROPERTY DAMAGE. Refer I

to this manual for assistance or consult the local Sears Service Center or gas

ut ty for further nformat on.

AWARNING

Flammable vapors may be drawn by air currents from other areas of the

structure to this appliance.

AWARNING

READ THE GENERAL SAFETY SECTION BEGINNING ON INSIDE

COVER AND THEN THIS ENTIRE MANUAL BEFORE INSTALLING OR

OPERATING THIS WATER HEATER.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Printed in the U.S.A. 0304 www.sears.com Part No. 184820_0OO

AWARNING I

Page 2

Safety Precautions

AWARNING J

Improper installation, adjustment, alteration, service

or maintenance can cause DEATH, SERIOUS BODILY

INJURY,OR PROPERTY DAMAGE. Referto this manu- J

al for assistance or consult your local Sears Service

Center for further information.

_;LWARNING

WATER HEATERS EQUIPPED FOR ONE TYPE GAS

ONLY: This water heater is equipped for one type gas

only. Check the model rating plate near the gas control

valve for the correct gas. DO NOT USE THIS WATER

HEATER WITH ANY GAS OTHER THAN THE ONE

SHOWN ON THE MODEL RATING PLATE. Failure to

use the correct gas can cause problems which can result in

DEATH, SERIOUS BODILY INJURY, OR PROPERTY

DAMAGE. If you have any questions or doubts consult

your gassupplier or local utility.

AWARNING

INSTALLATIONS IN AREAS WHERE FLAMMABLE LIQ-

UIDS (VAPORS) ARE LIKELY TO BE PRESENT OR

STORED (GARAGES, STORAGE, AND UTILITY AREAS,

ETC): Flammable liquids (such as gasoline, solvents,

propane (LP) or butane, etc.), all of which emit flammable

vapors, may be improperly stored or used in such areas.

The gas water heater ignitor or main burner can ignite

such vapors. The resulting flashback and fire can cause

death or serious burns to anyone in the area, as well as

property damage.

If installation in such areas is your only option, then the

installation must be accomplished in a way that the ignitor

and main burner flame are elevated from the floor at least

18 inches. While this may reduce the chances of

flammable vapors from a floor spill being ignited, gasoline

and other flammable substances should never be stored or

used in the same room or area containing a gas water

heater or other open flame or spark producing appliance.

NOTE: Flammable vapors may be drawn by air currents

from other areas of the structure to the appliance.

_WARNING

If this water heater will be used in beauty shops, barber

shops, cleaning establishments, or self-service laundries

with dry cleaning equipment, it is imperative that the

water heater or water heaters be installed so that combus-

tion and ventilation air be taken from outside these areas.

Refer to the "Facts to Consider About the Location" sec-

tion of this manual and also the current edition of the

National Fuel Gas Code, ANSI Z223.1, also referred to as

NFPA 54 for specificsprovided concerning air required.

AWARNING

A fire can start if combustible materials suchas clothing,

cleaningmaterials, or flammable liquidsare placedagainst

or nextto the water heater.

AWARNING

At the time of manufacture this water heater was provided

with a combination temperature-pressure relief valve certi-

fied by a nationally recognized testing laboratory that

maintains periodic inspection of production of listed equip-

ment or materials, as meeting the requirements for Relief

Valves and Automatic Gas Shutoff Devices for Hot Water

Supply Systems, and the current edition of ANSI Z21.22,

CSA 4.4 and the code requirements of ASME. If replaced,

the valve must meet the requirements of local codes, but

not less than a combination temperature and pressure

relief valve certified as meeting the requirements for Relief

Valves and Automatic Gas Shutoff Devices for Hot Water

Supply Systems ANSI Z21.22 • CSA 4.4 by a nationally rec-

ognized testing laboratory that maintains periodic inspec-

tion of production of listed equipment or materials.

The valve must be marked with a maximum set pressure

not to exceed the marked hydrostatic working pressure of

the water heater (I 50 Ibs./sq. in.) and a discharge capacity

not lessthan the water heater input rate as shown on the

model rating plate. (Electric heaters, watts divided by

1000 x 3412 equal BTU/Hr. rate.)

Your localjurisdictional authority, while mandating the use of

a temperature-pressure relief valve complying with ANSI

Z21.22, CSA 4.4 and ASME, may require a valve model dif-

ferent from the one furnished with the water heater.

Compliance with such local requirements must be satis-

fied bythe installer or end user of the water heater with a

locally prescribed temperature-pressure relief valve

installed in the designated opening in the water heater in

place of the factory furnished valve.

For safe operation of the water heater, the relief valve must

not be removed from it's designated opening or plugged.

The temperature-pressure relief valve must be installed

directly into the fitting of the water heater designated for

the relief valve. Position the valve downward and provide

tubing so that any discharge will exit only within 6 inches

above, or at any distance below the structural floor. Be cer-

tain that no contact is made with any live electrical part.

The discharge opening must not be blocked or reduced in

size under any circumstances. Excessive length, over 30

feet, or use of more than four elbows can cause restriction

and reduce the discharge capacity of the valve.

No valve or other obstruction is to be placed between

the relief valve and the tank. Do not connect tubing

directly to discharge drain unless a 6" air gap is provided.

To prevent bodily injury, hazard to life, or property dam-

age, the relief valve must be allowed to discharge water

in quantities should circumstances demand. If the dis-

charge pipe is not connected to a drain or other suitable

means, the water flow may cause property damage.

The Discharge Pipe:

_Must not be smaller in size than the outlet pipe size of

the valve, or have any reducing couplings or other

restrictions.

_Must not be plugged or blocked.

_Must be of material listed for hot water distribution.

_Must be installed so as to allow complete drainage of

both the temperature-pressure relief valve, and the

discharge pipe.

--Must terminate at an adequate drain.

_Must not have any valve between the relief valve and

tank.

2

Page 3

Safety Precautions (cont'd)

AWARNING

A gas water heater cannot operate properly without the

correct amount of air for combustion. Do not install in a

confined area such a closet, unless you provide air as

shown in the "Facts to Consider About the Location" sec-

tion. Never obstruct the flow of ventilation air. If you have

any doubts or questions at all, call your gas company.

Failure to provide the proper amount of combustion air

can result in a fire or explosion and can cause DEATH

SERIOUS BODILY INJURY, OR PROPERTY DAMAGE.

AWARNING

HOTTER WATER CAN SCALD: Water heaters are

intended to produce hot water. Water heated to a tem-

perature which will satisfy clothes washing, dish washing,

and other sanitizing needs can scald and permanently

injure you upon contact. Some people are more likely to

be permanently injured by hot water than others. These

include the elderly, children, the infirm, or physically/men.

tally handicapped. If anyone using hot water in your home

fits into one of these groups or if there is a local code or

state law requiring a certain temperature water at the hot

water tap, then you must take special precautions. In addi-

tion to using the lowest possible temperature setting that

satisfies your hot water needs, a means such as a mixing

valve, should be used at the hot water taps used by these

people or at the water heater. Mixing valves are available

at plumbing supply or hardware stores. Follow manufac-

turers instructions for installation of the valves. Before

changing the factory setting on the thermostat, read the

"Temperature Regulation" section in this manual.

AWARNING

This water heater must not be installed directly on car-

peting. Carpeting must be protected by a metal or wood

panel beneath the appliance extending beyond the full

width and depth of the appliance by at least 3 inches

(76.2mm) in any direction, or if the appliance is installed

in an alcove or closet, the entire floor must be covered b

the panel. Failure to heed this warning may result in

fire hazard.

AWARNING

The power vent water heater requires its own (separate)

venting system. It cannot be connected to an existing vent

pipe or chimney. It must be terminated to the outdoors.

Failure to properly install the venting system can result in

asphyxiation, a fire or explosion and can cause DEATH, SE-

RIOUS BODILY INJURY, OR PROPERTY DAMAGE.

AWARNING

No vent damper installation is compatible with this power

vented water heater design. No vent damper, whether it is

operated thermally or otherwise is to be installed on this

power vented water heater. Alteration of any part of the fac-

tory-furnished vent assembly could result in improper oper-

ation due to restriction of flue gases, spillage of flue gases

and may cause carbon monoxide poisoning.

AWARNING

Soot build-up indicates a problem that requires correc-

tion before further use. Turn "off" gas to water heater

and leave "off" until repairs are made, because failure to

correct the cause of the sooting can result in a fire or

explosion causing DEATH, SERIOUS BODILY INJURY,

OR PROPERTY DAMAGE.

_,WARNING

BEFORE OPERATING [PROPANE (L.P.) GAS WATER

HEATERS]: Propane (LR) gas is heavier than air. Should

there be a leak in the system, the gas will settle near the

ground. Basements, crawl spaces, skirted areas under

mobile homes (even when ventilated), closets and areas

below ground level will serve as pockets for the accumula-

tion of this gas. Before attempting to operate the water

heater or turning on a nearby electrical light switch, be

absolutely sure there is no accumulated gas in the area.

Search for odor of gas by sniffing at ground level in the

vicinity of the appliance. If odor is detected, follow steps

indicated at "For Your Safety" on the cover page of this

manual then leave the premises.

AWARNING

•The appliance and its individual shutoff valve must be dis-

connected from the gas supply piping system during any

pressure testing of the gas system at test pressures in

excess of I/2 pound per square inch (3.5kPa).

•The appliance must be isolated from the gas supply pip-

ing system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping sys-

tem at test pressures equal or less than I/2 pound per

square inch (3.5kPa).

AWARNING

Chemical vapor corrosion of the flue and vent system

may occur if air for combustion contains certain chemical

vapors. Spray can propellants, cleaning solvents, refrigera-

tor and air conditioner refrigerants, swimming pool

chemicals, calcium and sodium chloride, waxes, bleach,

and process chemicals are typical compounds which are

potentially corrosive.

Obstructed or deteriorated vent systemsmay present

serioushealth risk or asphyxiation.

AWARNING a

Safety Precautions continued on page 4.

3

Page 4

Safety Precautions (cont'd)

&WARNING

Minimum clearances between the water heater and com-

bustible construction are 0" at the sides and rear, 5" at the

front, and 0"from the vent pipe. Clearance from the top of

the jacket is 12". Provide 24 inches front clearance for ser-

vicing and adequate clearance between the jacket top &

ceiling for servicing the flue area. (See Figure I). Refer to

the label on the water heater adjacent to the gas control

valve for all clearances.

AWARNING

Flood damage to a water heater may not be readily visible

or immediately detectible. However, over a period of time

a flooded water heater will create dangerous conditions

which can cause DEATH, SERIOUS BODILY INJURY, OR

PROPERTY DAMAGE. Call a Sears Service Technician or

contractor to replace a flooded water heater. Do not

attempt to repair the unit! It must be replaced!

_,WARNING

HYDROGEN GAS: Hydrogengascan beproducedina hot

water systemthat has not been usedfor a long period of

time (generally two weeks or more). Hydrogen gas is

extremely flammable and explosive.To preventthe possi-

bility of injury under these conditions,we recommend the

hot water faucet be opened for several minutes at the

kitchen sink before any electrical appliances which are

connected to the hot water system are used (such as a

dishwasheror washing machine). If hydrogen gasis pre-

sent, there will probablybean unusualsoundsimilar to air

escaping through the pipe as the hot water faucet is

opened. There must be no smoking or open flame near

the faucet at the time it isopen.

_,WARNING J

such termination must not be within 4 feet of any items

Vent as gas meters, gas valves or other gas regulating

equipment.

CAUTION

WATER HEATERS EVENTUALLY LEAK: Installation of

the water heater must be accomplished in such a manner

that if the tank or any connections should leak, the flow of

water will not cause damage to the structure. For this

reason, it is not advisable to install the water heater in an

attic or upper floor. When such locations cannot be avoid-

ed, a suitable drain pan should be installed under the

water heater. Such a drain pan must be not greater than

1½ inches deep, have a minimum length and width of at

least 2 inches greater than the water heater dimensions

and must be piped to an adequate drain. The pan must

not restrict combustion air flow.

_,WARNING

INSULATING JACKETS: When installinganexternalwater

heater insulationjacketona gaswater heater:

• DO NOT coverthetemperature-pressurerelief valve.

• DO NOT put insulationoveranypartofthe top ofthe gas

water heater.

• DO NOT put insulationoverthe gascontrol valveor gas

control valve/burner cover,or any accessareas to the

burner.

• DO NOT let insulationaroundthe gaswater heater to get

within 8 inchesofthefloor (air must getto the burner).

• DO NOT remove operating instructions,andsafetyrelat-

ed warning labels and materials affixed to the water

heater.

• DO obtain new warning andinstructionlabelsfrom Sears

for placement on the jacket directly over the existing

labels.

Failureto heed this will result in the possibilityof a fire or

explosion.

4

Page 5

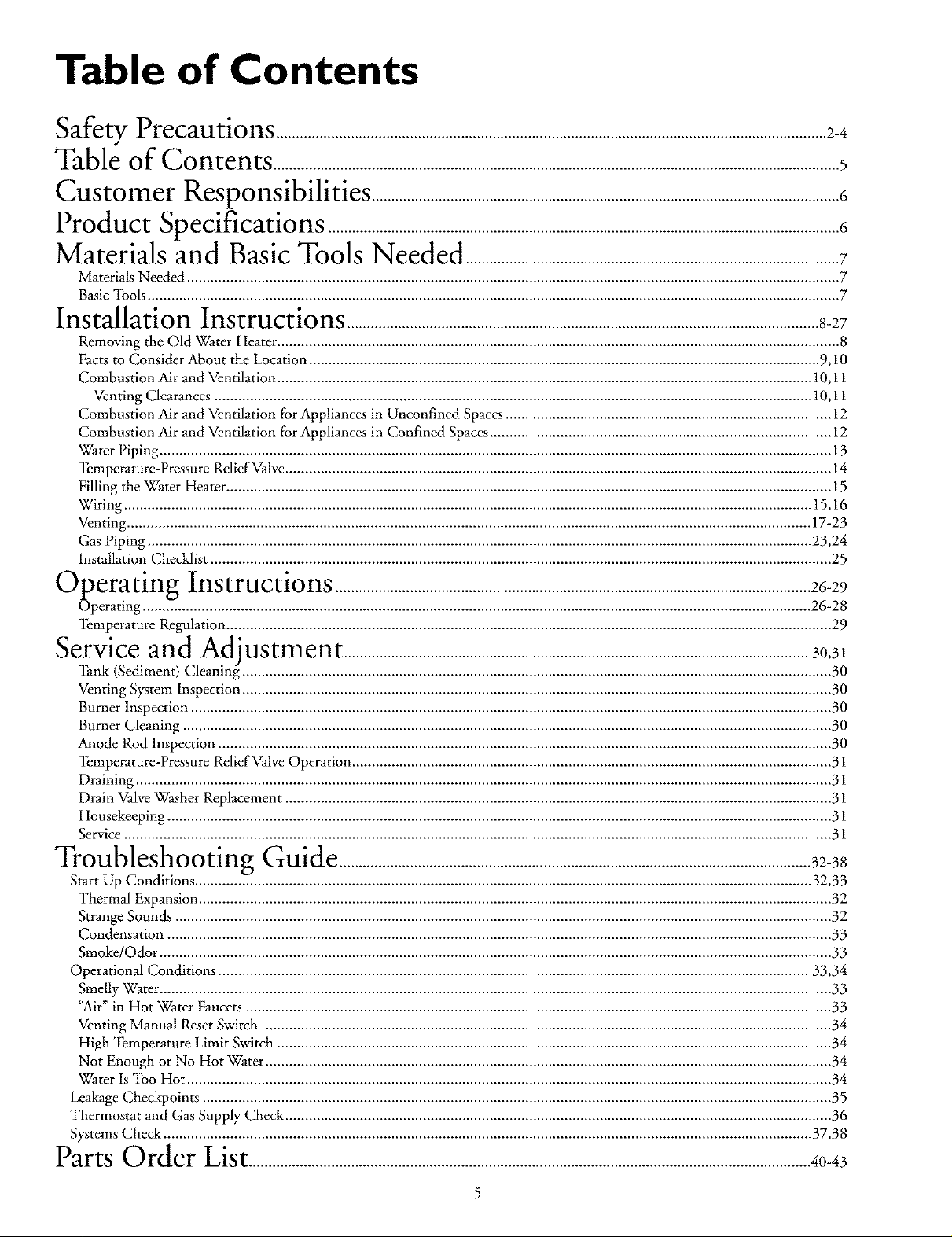

Table of Contents

ec_L__oa,cty Precautions ............................................................................................................................................2-4

Table of Contents ................................................................................................................................................5

Customer

Responsibilities .......................................................................................................................6

>d:cmgPn%atic°}aoe :::::::::::::::::::::::::::::::::::::::

Materials Needed ..................................................................................................................................................................... 27

Basic 2bols............................................................................................................................................................................... 27

Installation Instructions ........................................................................................................................8-27

Removing the Old Water Heater. ............................................................................................................................................ .8

Facts m Consider About the Location .................................................................................................................................. 9,10

Combustion Air and Ventilation ........................................................................................................................................ 10,11

Venting Clearances ........................................................................................................................................................ 10,11

Combustion Air and Ventilation for Appliances in Unconfined Spaces ................................................................................... 12

Combustion Air and Ventilation for Appliances in Confined Spaces....................................................................................... 12

Water Piping ........................................................................................................................................................................... 13

"l_mpemture-Pressure Relief Valve........................................................................................................................................... 14

Filling the Water Hearer .......................................................................................................................................................... 15

Wiring ............................................................................................................................................................................... 15,16

Venring. ............................................................................................................................................................................. 17-23

Gas Piping ......................................................................................................................................................................... 2324

Installation Checklist .............................................................................................................................................................. 25

_gpertat!n.g....!ns.t.ruc.t!_n.s..:Z_:ZZ:::::ZZ_::::::::ZZ::::::::_ZZ::::::::Z::::::::::::::::::::::::::::::Z::_:x:

_I_mpemture Regulation ......................................................................................................................................................... 229

Ser_vi_ceiand.lAd ) =============================:::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::..:!!:33a

Venting SystemInspection......................................................................................................................................................30

Burner Inspection...................................................................................................................................................................30

Burner Cleaning .....................................................................................................................................................................30

Aim& Rod Inspection............................................................................................................................................................30

"lhnperature-Pressure Relief Valve Operation ......................................................................................................................... .31

Draining ................................................................................................................................................................................ .31

Drain Valve Washer Replacement .......................................................................................................................................... .31

Housekeeping ........................................................................................................................................................................ .31

Service ................................................................................................................................................................................... .31

Troubleshooting Guide ........................................................................................................................32-38

Start Up Conditions ............................................................................................................................................................ 32,33

Thermal Expansion ................................................................................................................................................................ .32

Strange Stun& ...................................................................................................................................................................... .32

Condensation ....................................................................................................................................................................... .33

Smoke/Odor .......................................................................................................................................................................... .33

Operational Conditions ....................................................................................................................................................... 33,34

Smelly Water .......................................................................................................................................................................... .33

"Air" in Hot Water Faucets ................................................................................................................................................... .33

Venting Manual Reset Switch ............................................................................................................................................... .34

High "Ihnperature Limit Switch ........................................................................................................................................... .34

Not Enough or No Hot Water .............................................................................................................................................. .34

Water Is _Ibo Hot ................................................................................................................................................................... .34

Leakage Checkpoints ............................................................................................................................................................... .35

Thermostat and Gas Supply Check .......................................................................................................................................... .36

Systems Check ..................................................................................................................................................................... 37,38

Parts Order Lisa.............................................................................................................................................40-43

Page 6

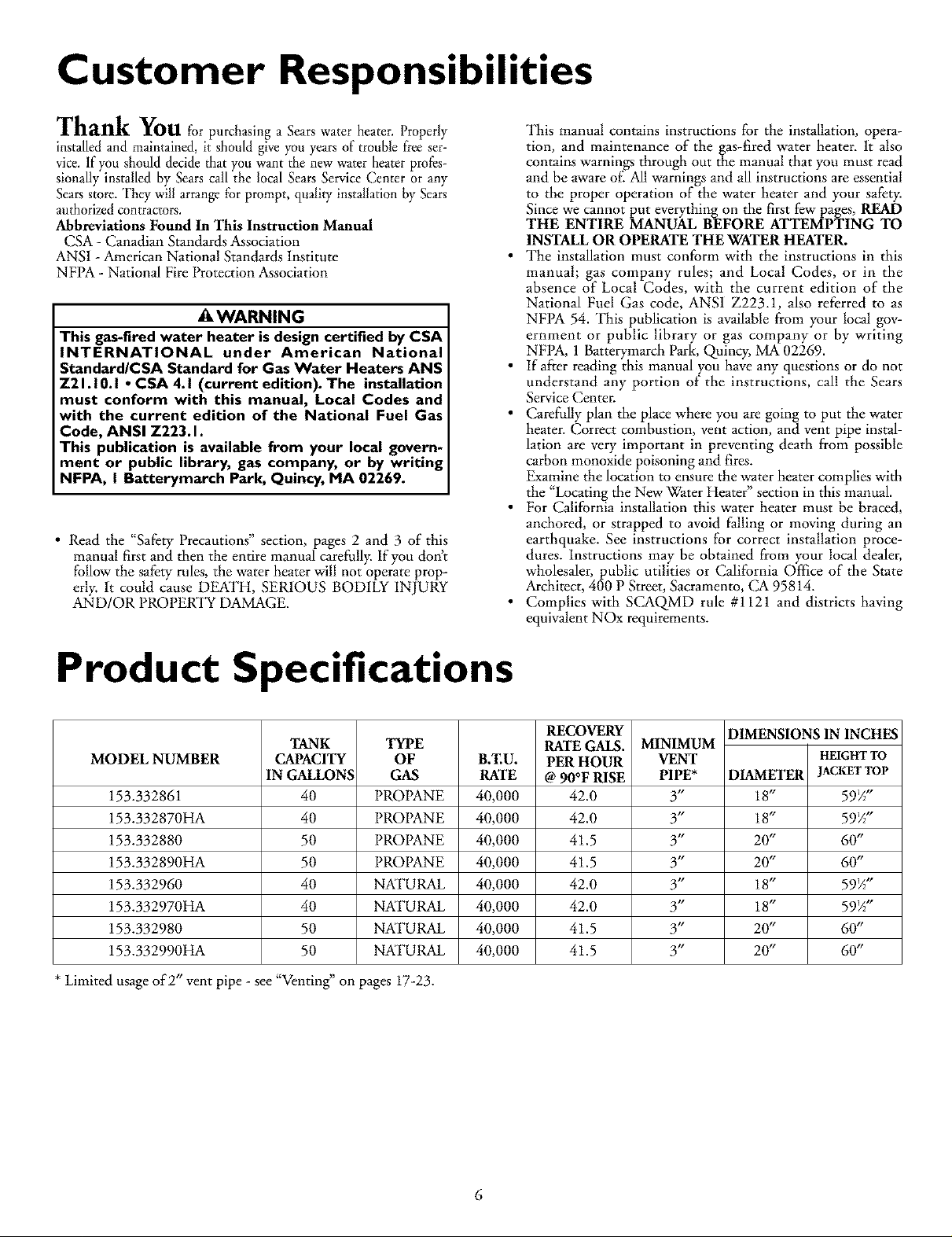

Customer Responsibilities

•-rl l

_r

lnanK xou for purchasing a Searswater heater. Properly

installedand maintained, it should giveyouyears of trouble freeser-

vice. If you should decidethat you want the new water heater profes-

sionally installed by Searscall the local SearsServiceCenter or any

Searsstore.They will arrangefor prompt, quality installationby Sears

authorizedcontractors.

Abbreviations Found In This Instruction Manual

CSA - Canadian Standards Association

ANSI - American National Standards Institute

NFPA - National Fire Protection Association

AWARNING

This gas-fired water heater is design certified by CSA

INTERNATIONAL under American National

Standard/CSA Standard for Gas Water Heaters ANS

Z21.10.1 ° CSA 4.1 (current edition). The installation

must conform with this manual, Local Codes and

with the current edition of the National Fuel Gas

Code, ANSI Z223.1.

This publication is available from your local govern-

ment or public library, gas company, or by writing

NFPA, I Batterymarch Park, Quincy, MA 02269.

• Read the "Safety Precautions" section, pages 2 and 3 of this

manual first and then the entire manual carefully. If you don't

follow the sai?ty rules, the water heater will not operate prop-

erly. It could cause DEATH, SERIOUS BODILY INJURY

AND/OR PROPERTY DAMAGE.

This manual contains instructions for the installation, opera-

tion, and maintenance of the gas-fired water heater. It also

contains warnings through out the manual that you must read

and be aware o£ All warnings and all instructions are essential

to the proper operation of the water heater and your safety.

Since we cannot put everythingon the first few pages, READ

THE ENTIRE MANUAL BEFORE ATTEMPTING TO

INSTALL OR OPERATE THE WATER HEATER.

• The installation must confbrm with the instructions in this

manual; gas company rules; and Local Codes, or in the

absence of Local Codes, with the current edition of the

National Fuel Gas code, ANSI Z223.1, also referred to as

NFPA 54. This publication is available from your local gov-

ernment or public library or gas company or by writing

NFPA, 1 Batterymarch Park, Quincy, MA 02269.

• If after reading this manual you have any questions or do not

understand any portion of the instructions, call the Sears

Service Center.

• Carefully plan the place where you are going to put the water

heater. Correct combustion, vent action, and vent pipe instal-

lation are very important in preventing death from possible

carbon monoxide poisoning and fires.

Examine the location to ensure the water heater complies with

the "Locating the New Water Heater" section in this manual.

• For California installation this water heater must be braced,

anchored, or strapped to avoid falling or moving during an

earthquake. See instructions for correct installation proce-

dures. Instructions may be obtained from your local dealer,

wholesaler, public utilities or California Office of the State

Architect, 400 P Street, Sacramento, CA 95814.

• Complies with SCAQMD rule #1121 and districts having

equivalent NOx requirements.

Product Specifications

TANK

MODEL NUMBER

153.332861

153.332870HA

153.332880

153.332890HA

153.332960

153.332970HA

153.332980

153.332990HA

CAPACITY

IN GAIA.ONS

40

40

50

50

40

40

50

50

* Limited usageof 2" vent pipe - see "Venting" on pages 17-23.

TYPE

OF

GAS

PROPANE

PROPANE

PROPANE

PROPANE

NKFURAL

NKFURAL

NKFURAL

NKFURAL

B.ZU.

RATE

40,000

40,000

40,000

40,000

40,000

40,000

40,000

40,000

RECOVERY

RATE GALS.

PER HOUR

@ 90°F RISE

42.0

42.0

41.5

41.5

42.0

42.0

41.5

41.5

MINIMUM

VENT

PIPE*

3"

3"

3"

3"

3"

3"

3"

3"

DIMENSIONS IN INCHES

HEIGHT TO

DIAMETER

18"

18"

20"

20"

18"

18"

20"

20"

JACKET TOP

59/"

59/"

60"

60"

59/"

59/"

60"

60"

6

Page 7

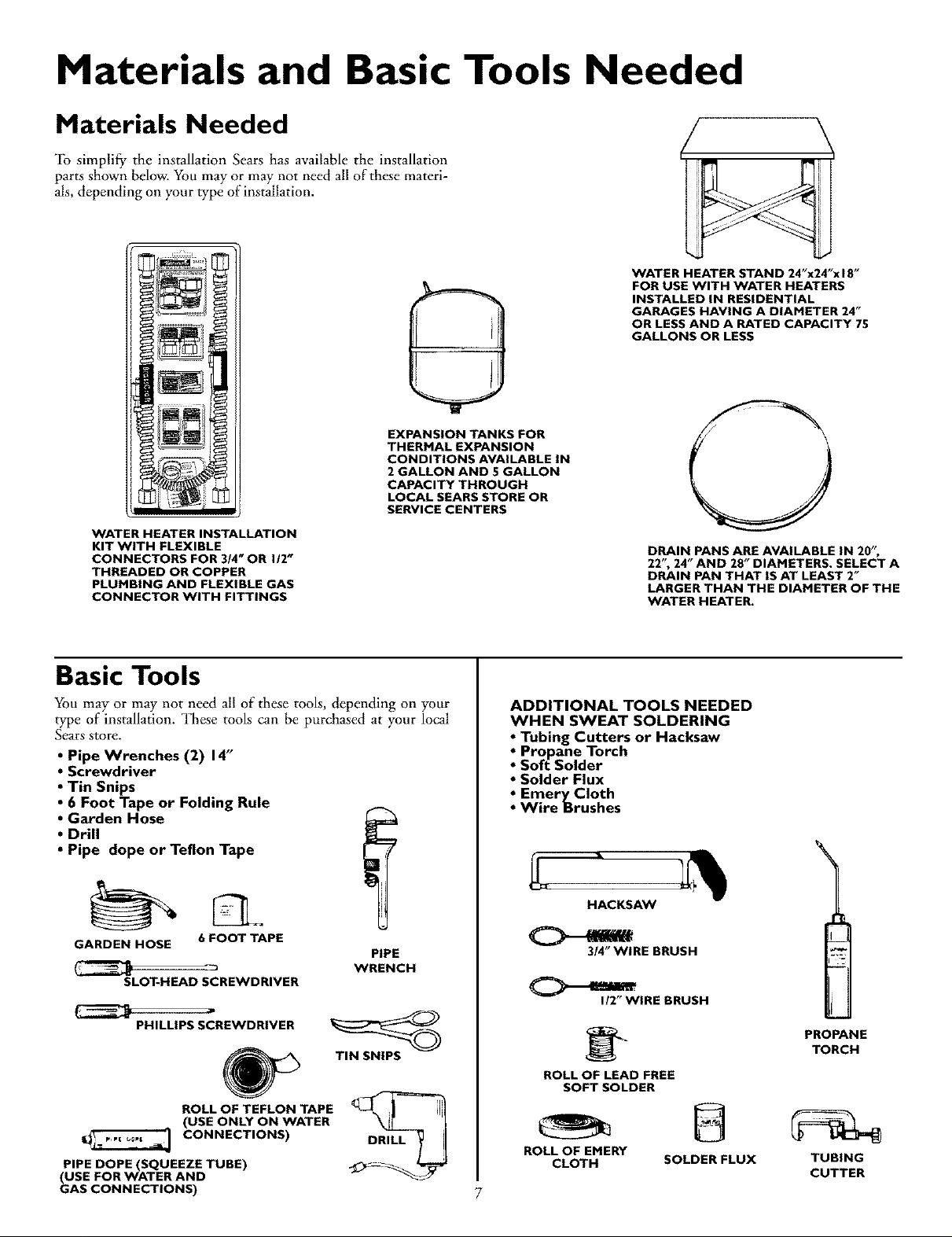

Materials and Basic Tools Needed

Materials Needed

"Ib simplify the installation Sears has available the installation

parts shown below. You may or may not need all of these materi-

als, depending on your type of installation.

WATER HEATER STAND 24"x24"x I 8"

FOR USE WITH WATER HEATERS

INSTALLED IN RESIDENTIAL

GARAGES HAVING A DIAMETER 24"

OR LESS AND A RATED CAPACITY 75

GALLONS OR LESS

EXPANSION TANKS FOR

THERMAL EXPANSION

CONDITIONS AVAILABLE IN

2 GALLON AND 5 GALLON

CAPACITY THROUGH

LOCAL SEARS STORE OR

SERVICE CENTERS

WATER HEATER INSTALLATION

KIT WITH FLEXIBLE

CONNECTORS FOR 3/4" OR I/2"

THREADED OR COPPER

PLUMBING AND FLEXIBLE GAS

CONNECTOR WITH FITTINGS

DRAIN PANS ARE AVAILABLE IN 20",

22", 24" AND 28" DIAMETERS. SELECT A

DRAIN PAN THAT IS AT LEAST 2"

LARGER THAN THE DIAMETER OF THE

WATER HEATER.

Basic Tools

You may or may not need all of these tools, depending on your

type of installation. These tools can be purchased at your local

Sears store.

• Pipe Wrenches (2) 14"

• Screwdriver

• Tin Snips

• 6 Foot Tape or Folding Rule

• Garden Hose

• Drill

• Pipe dope or Teflon Tape

GARDEN HOSE 6 FOOT TAPE

SLOT-HEAD SCREWDRIVER

PHILLIPS SCREWDRIVER

PIPE

WRENCH

TIN SNIPS

tP

ROLL OF TEFLON TAPE

(USE ONLY ON WATER

CONNECTIONS)

PIPE DOPE (SQUEEZE TUBE)

(USE FOR WATER AND

GAS CONNECTIONS)

DRILL

ADDITIONAL TOOLS NEEDED

WHEN SWEAT SOLDERING

• Tubing Cutters or Hacksaw

• Propane Torch

• Soft_ Solder

• Solder Flux

• EmeryCIoth

• Wire Brushes

HACKSAW

3/4" WIRE BRUSH

1/2" WIRE BRUSH

ROLL OF LEAD FREE

SOFT SOLDER

ROLL OF EMERY

CLOTH SOLDER FLUX TUBING

7

PROPANE

TORCH

CUTTER

Page 8

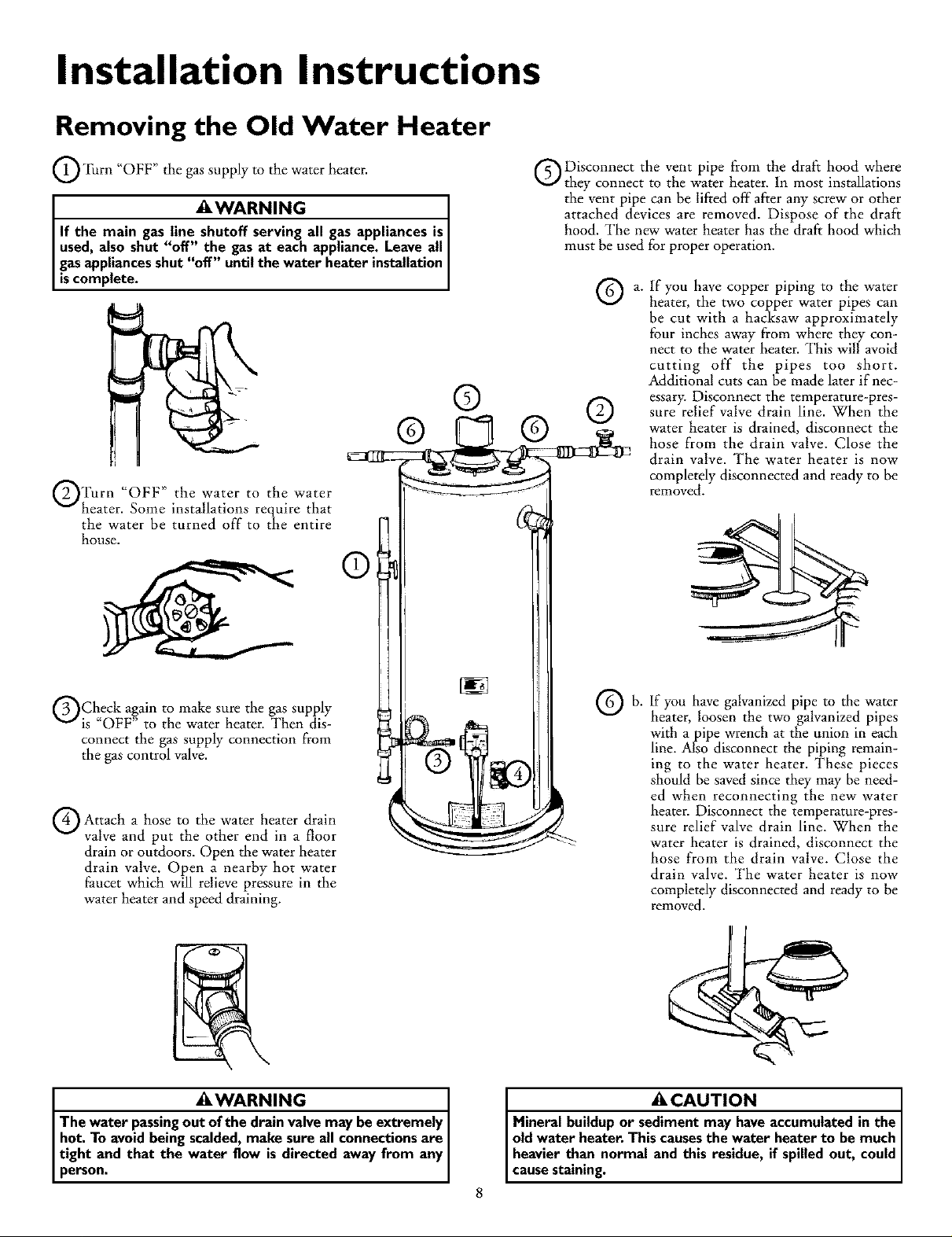

Installation Instructions

Removing the Old Water Heater

Q_Iilrn gas supply to water

If the main gas line shutoff serving all gasappliances is I

used,alsoshut "off" the gas at each appliance.Leave all

gasappliancesshut "off" untilthe water heater installation

iscomplete.

"OFF" the the heater.

_WARNING

"OFF" the the

Turn water to water

heater. Some installations require that

the water be turned off to the entire

house.

©

Disconnect the vent pipe from the draft hood where

they connect to the water heater. In most installations

the vent pipe can be lifted off"after any screw or other

attached devices are removed. Dispose of the draft

hood. The new water heater has the draft hood which

must be used for proper operation.

Q a.

® ©

If you have copper piping to the water

heater, the two copper water pipes can

be cut with a hacksaw approximately

four inches away from where they con-

nect to the water heater. This willavoid

cutting off the pipes too short.

Additional cuts can be made later if nec-

essary. Disconnect the temperature-pres-

sure relief valve drain line. When the

water heater is drained, disconnect the

hose from the drain valve. Close the

drain valve. The water heater is now

completely disconnected and ready to be

removed.

Check again to make sure the gas supply

is "OFF" to the water heater. Then dis-

connect the gas supply connection from

the gas control valve.

a to water

Attach hose the heater drain

valve and put the other end in a floor

drain or outdoors. Open the water heater

drain valve. Open a nearby hot water

faucet which will relieve pressure in the

water heater and speed draining.

AWARNING I

The water passingout ofthe drainvalvemay be extremely I

hot. To avoid beingscalded,make sure all connectionsare

tight and that the water flow is directed away from any

person.

Qb.

If you have galvanized pipe to the water

heater, loosen the two galvanized pipes

with a pipe wrench at the union in each

line. Also disconnect the piping remain-

ing to the water heater. These pieces

should be saved since they may be need-

ed when reconnecting the new water

heater. Disconnect the temperature-pres-

sure relief valve drain llne. When the

water heater is drained, disconnect the

hose from the drain valve. Close the

drain valve. The water heater is now

completely disconnected and ready to be

removed.

_, CAUTION J

Mineral buildupor sediment may haveaccumulatedin the

old water heater.Thiscausesthe water heater to be much J

heavierthan normal and this residue,if spilledout, could

causestaining.

Page 9

Installation Instructions (cont'd)

Facts to Consider About the

Location

You should carefully choose an indoor location for the new water

heater, because the placement is a very important consideration

for the safety of the occupants in the building and for the most

economical use of the appliance. This water heater is not for

use in mobile homes or outdoor installation.

Whether replacing an old water heater or putting the water

heater in a new location, the following critical points must be

observed.

1. The location selected should be indoors as close as practical

to the vent termination point, and as centralized with the

water piping system aspossible. The water heater, as all water

heaters, will eventually leak. Do not install without adequate

drainage provisions where water flow will cause damage.

2. ALL MODELS - If vented through an outside wall or

through the roof, the 3" vent piping cannot exceed a total of

115 feet (50 feet if optional 2" vent piping is used), including

vertical and horizontal runs with one 90° elbow. If more

elbows are required, the venting distance must be reduced 5

feet for every 90° elbow. See pages 19, 20 and 23 for vent

charts.

3. Vent piping cannot slope downward and horizontal runs

require a minimum V_"rise per five feet. All horizontal runs

require adequate support at 3½ foot intervals and vertical

runs supported at 5 foot intervals.

4. The water heater requires its own (separate) venting system.

It cannot be connected to an existing vent pipe or chimney.

It must terminate to the outdoors. Whenever possible termi-

nate the vent on the leaward side of the building if vented

through an outside wall. NOTE: Condensation may be cre-

ated, at times, as the combustion gases exit the vent cap

and discoloration of surfaces in proximity to the vent cap

may occur.

_,WARNING

The power vent water heater requires its own (separate) vent-

ingsystem. It cannot beconnected to an existing vent pipe or

chimney. It must be terminated to the outdoors. Failure to

properly install the venting system can result in asphyxiation,

a fire or explosion and can cause DEATH, SERIOUS BODILY

INJURY, OR PROPERTY DAMAGE.

5. The water heater comes equipped with a 7 foot power cord

which can be used to connect to a 110/120 volt power

source if (1) local codes allow, and (2) there is a three prong

receptacle available.

CAUTION

WATER HEATERS EVENTUALLY LEAK: Installation of the

water heater must be accomplished in such a manner that if

the tank or any connections should leak, the flow of water will

not cause damage to the structure. For this reason, it is not

advisableto install the water heater in an attic or upper floor.

When such locations cannot be avoided, a suitable drain pan

should be installed under the water heater. Such a drain pan

must be not greater than 1'/2 inches deep, have a minimum

length and width of at least 2 inches greater than the water

heater dimensions and must be piped to an adequate drain.

The pan must not restrict combustion air flow.

6. The location selection must provide adequate clearances for

servicing and proper operation of the water heater.

_WARNING

INSTALLATIONS IN AREAS WHERE FLAMMABLE LIQ-

UIDS (VAPORS) ARE LIKELY TO BE PRESENT OR STORED

(GARAGES, STORAGE, AND UTILITY AREAS, ETC):

Flammable liquids(such as gasoline, solvents, propane (LP) or

butane, etc.), all of which emit flammable vapors, may be

improperly stored or used in such areas. The gaswater heater

ignitor or main burner can ignite such vapors. The resulting

flashback and fire can cause death or serious burns to anyone

in the area, aswell as property damage.

If installation in such areas is your only option, then the instal-

lation must be accomplished in a way that the ignitor and main

burner flame are elevated from the floor at least 18 inches.

While this may reduce the chancesof flammable vapors from

a floor spill being ignited, gasoline and other flammable sub-

stances should never be stored or used in the same room or

area containing a gas water heater or other open flame or

spark producing appliance.

Also, the water heater must be located andlor protected so it

isnot subject to physicaldamage by a moving vehicle.

NOTE: Flammable vapors may be drawn by air currents from

other areas of the structure to the appliance.

&WARNING

Propellants of aerosol sprays and volatile compounds,

(cleaners, chlorine based chemicals, refrigerants, etc.) in

addition to being highly flammable in many cases, will also

change to corrosive hydrochloric acid when exposed to the

combustion products of the water heater. The results can

be hazardous, and also cause product failure.

&WARNING I

Do not use an extension cord. If there is not a suitable recep-

tacle and/or local codes prohibit use of a power cord, field

w r ng must be prov ded.

9

Page 10

Installation Instructions (cont'd)

Facts to Consider About the

Location (cont'd)

AWARNING

Thiswater heatermust not be installeddirectlyoncarpeting.

Carpeting must be protected by a metal or wood panel

beneaththe applianceextendingbeyondthe full width and

depth of the appliancebyat least3 inches(76.2mm) in an)

direction,or if the applianceisinstalledinan alcoveorcloset

the entire floormust becoveredbythepanel.Failureto hee¢

thiswarningmay resultina fire hazard.

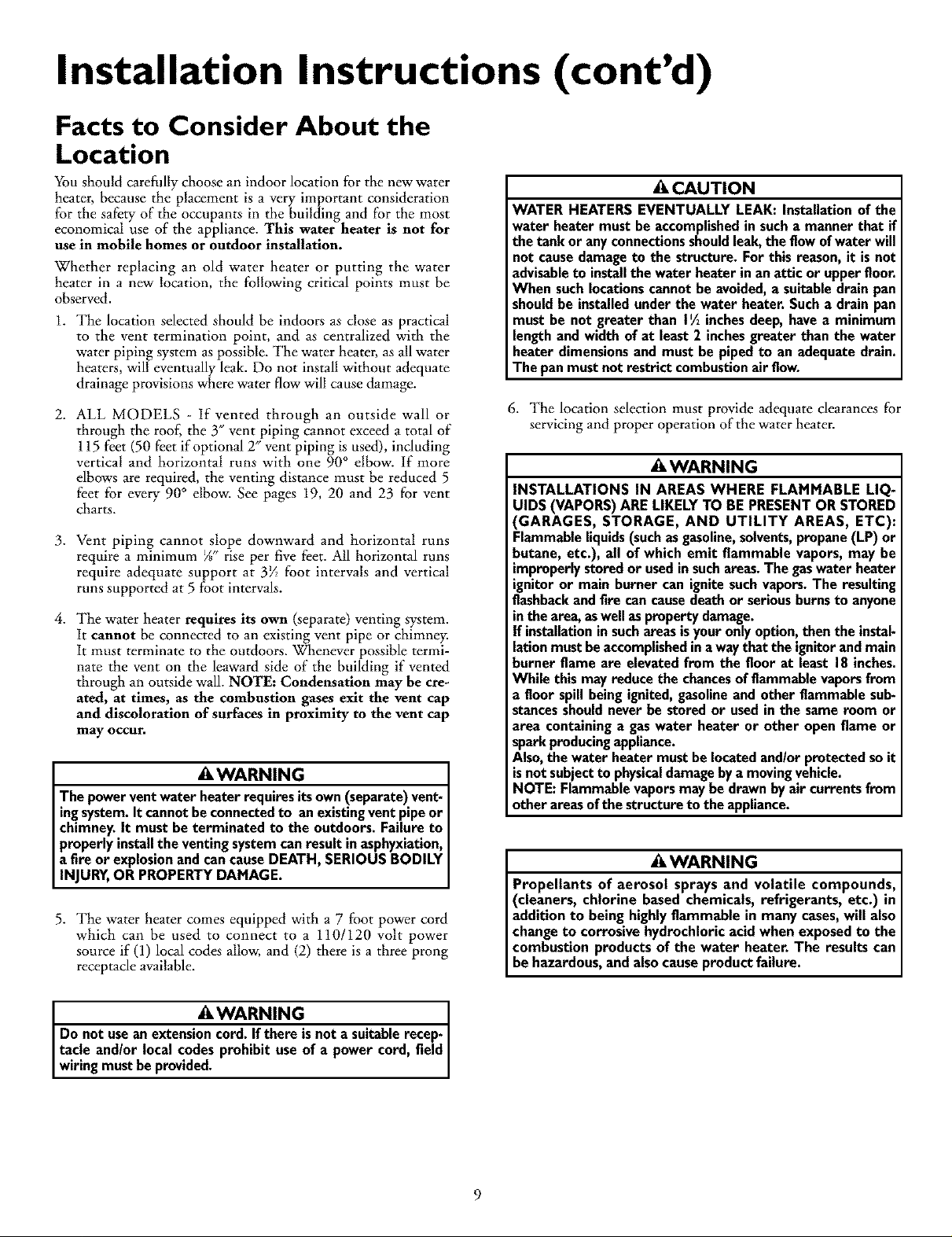

&WARNING

Minimum clearances between the water heater and com-

bustible construction are 0" at the sides and rear, 5" at the

front, and 0" from the vent pipe. Clearance from the top of

the jacket is 12". Provide 24 inches front clearance for servic-

ing and adequate clearance between the jacket top & ceiling

for servicing the flue area. (See Figure I). Refer to the label

on the water heater adjacent to the gas control valve for all

clearances.

12" MAX

Combustion Air and Ventilation

When determining the installation location for a power vent

water heater, snow accumulation and drifting should be consid-

ered in areas where applicable.

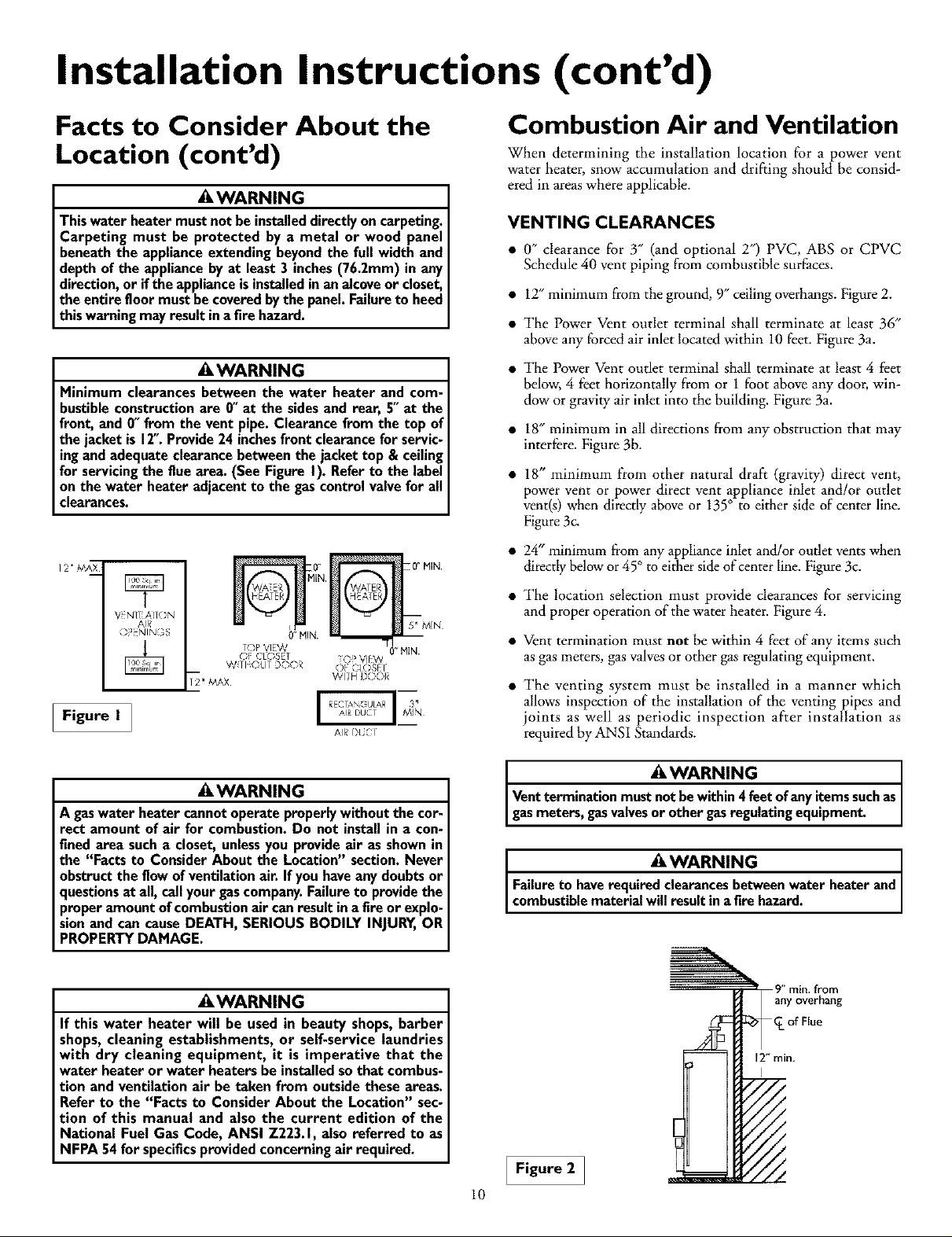

VENTING CLEARANCES

• 0" clearance for 3" (and optional 2") PVC, ABS or CPVC

Schedule 40 vent piping from combustible surfaces.

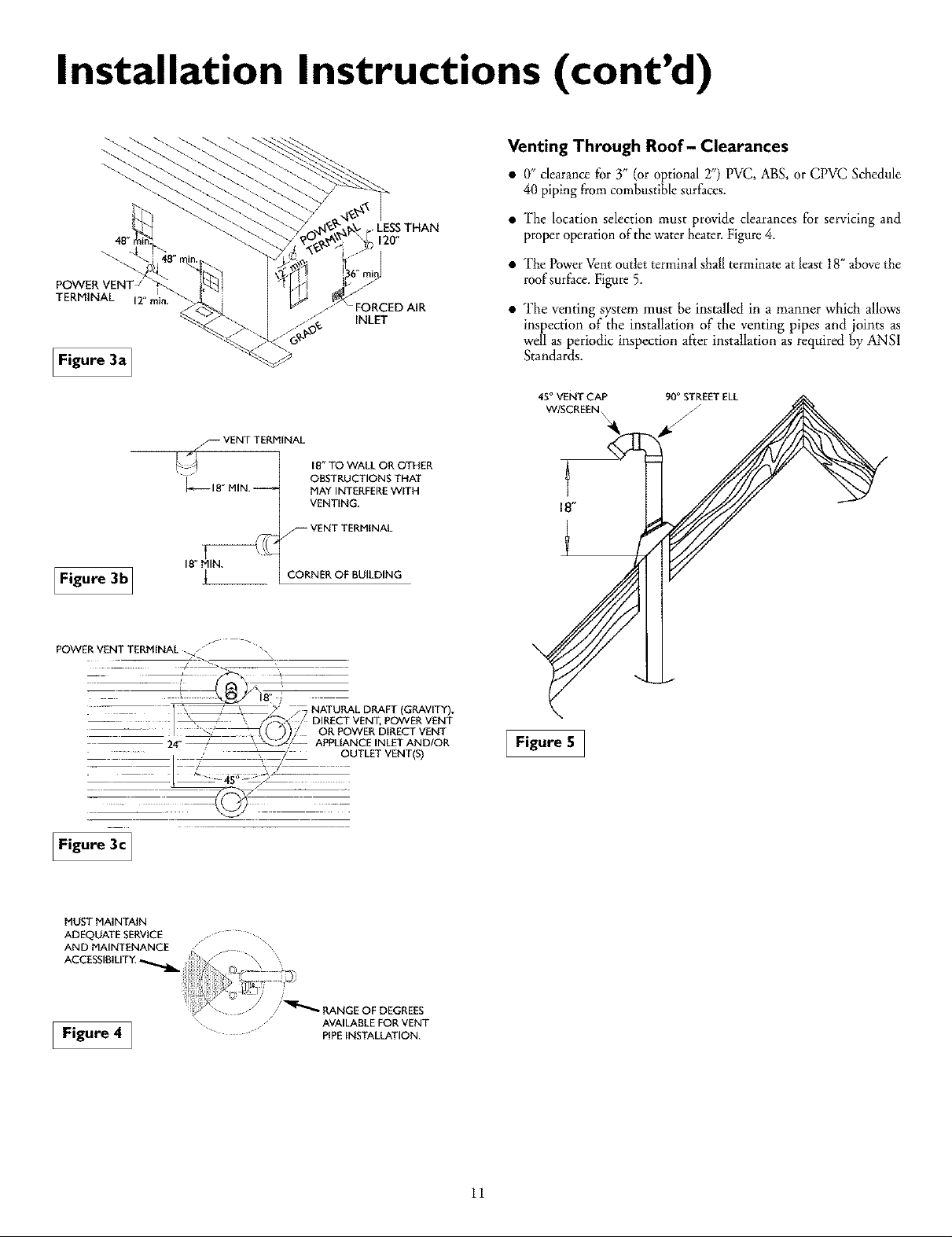

• 12"minimum from the ground, 9" ceilingoverhangs. Figure 2.

• The Power Vent outlet terminal shall terminate at least 36"

above any forced air inlet located within 10 feet. Figure 3a.

• The Power Vent outlet terminal shall terminate at least 4 feet

below, 4 feet horizontally from or 1 foot above any door, win-

dow or gravity air inlet into the building. Figure 3a.

• 18" minimum in all directions from any obstruction that may

interf?re. Figure 3b.

• 18" minimum from other natural draft (gravity) direct vent,

power vent or power direct vent appliance inlet and/or outlet

vent(s) when directly aboveor 135° to either side of center line.

Figure3c

a 24" minimum from any appliance inlet and/or outlet vents when

directlybelowor 45° to either side of center line. Figure 3c.

V N[(A[((}N

AIR

)_ NIN 3_

TOPVIEW -[_" MIN.

OF CL{}SET .')_ ViEW

WTI OUT DOOR OF (lOSE[

_2" MAX. WI]H D{){>}i

Figure I ]

AIR [>LCI

_, WARNING

A gaswater heater cannot operate properly without the cor-

rect amount of air for combustion. Do not install in a con-

fined area such a closet, unless you provide air as shown in

the "Facts to Consider About the Location" section. Never

obstruct the flow of ventilation air. If you have any doubts or

questions at all, call your gascompany. Failure to provide the

proper amount of combustion air can result in a fire or explo-

sion and can cause DEATH, SERIOUS BODILY INJURY, OR

PROPERTY DAMAGE.

_,WARNING

If this water heater will be used in beauty shops, barber

shops, cleaning establishments, or self-service laundries

with dry cleaning equipment, it is imperative that the

water heater or water heaters be installed so that combus-

tion and ventilation air be taken from outside these areas.

Refer to the "Facts to Consider About the Location" sec-

tion of this manual and also the current edition of the

National Fuel Gas Code, ANSI Z223.1, also referred to as

NFPA 54 for specificsprovided concerning air required.

• The location selection must provide clearances for servicing

and proper operation of the water heater. Figure 4.

• Vent termination must not be within 4 feet of any items such

asgas meters, gas valvesor other gas regulating equipment.

• The venting system must be installed in a manner which

allows inspection of the installation of the venting pipes and

joints as well as periodic inspection after installation as

required by ANSI Standards.

&WARNING J

Vent termination must not be within 4 feet of any items such as

gas meters, gas valves or other gas regulating equipment.

Failureto haverequired clearancesbetweenwater

combustiblematerialwillresultin afire hazard.

Figure 2 1

& WARNING heaterand

10

Page 11

Installation Instructions (cont'd)

Venting Through Roof- Clearances

• 0' clearancefor Y' (or opt'onal 2") PVC, ABS,or CPVC Schedule

40 piping fromcombustiblesurfaces.

POWER VENT J

TERMINAL 12"rain.

Figure 3a I

VENT TERMINAL

f

J_lS" MIN. _ OBSTRUCTIONS THAT

Figure 3b I

POWER VENTTERMINAL _js -- ".

•LESSTHAN

120"

FORCED AIR

INLET

18"TO WALL OR OTHER

MAY INTERFEREWFTH

VENTING.

VENT TERMINAL

CORNER OF BUILDING

• "The location selection must provide clearances for servicing and

proper operation of the water heater• Figure 4.

• "The Power Vent outlet terminal shall terminate at least 18" above the

roof surface. Figure 5.

• The venting system must be installed in a manner which allows

inspection of the installation of the venting pipes and joints as

well as periodic inspection aiier installation as required by ANSI

Standards.

45° VENT CAP 90°STREETELL

N

-- _ , / DIRECT VENT, POWER VENT

_ _/ OR POWER D,RECT VENT

24" _J_!-- APPDANCEINLETAND/OR

Figure 3c]

MUST MAINTAIN

ADEQUATE SERVICE

AVAILABLE FOR VENT

Figure 4 ]

.... " PIPEINSTALLATION.

Figure 5 ]

11

Page 12

Installation Instructions (cont'd)

Combustion Air and Ventilation

for Appliances Located in

Unconfined Spaces

Unconfined Space is a spacewhose volume is not less than 50 cubic

feet per 1,000 Btu per hour of the aggregateinput rating of all appli-

ances installedin that space. Rooms communicating directly witll the

space in which tile appliancesare installed, through openings not fur-

nishedwith doors, are considereda part ofthe unconfined space.

In unconfined spaces in buildings, infiltration may be adequate to

provide air for combustion, ventilation and dilution of flue gases.

However, in buildings of tight construction (for example, weather

stripping, heavilyinsulated, caulked,vaporbarrier,etc.), additional air

may need to be provided using the methods describedin Combustion

Air and Ventilation forAppliancesLocated in Confined Spaces.

Combustion Air and Ventilation

for Appliances Located in

Confined Spaces

Confined Space is a space whose volume is less than 50 cubic feet per

1,000 Btu per hour of the aggregate input rating of all appliances

installed in that space.

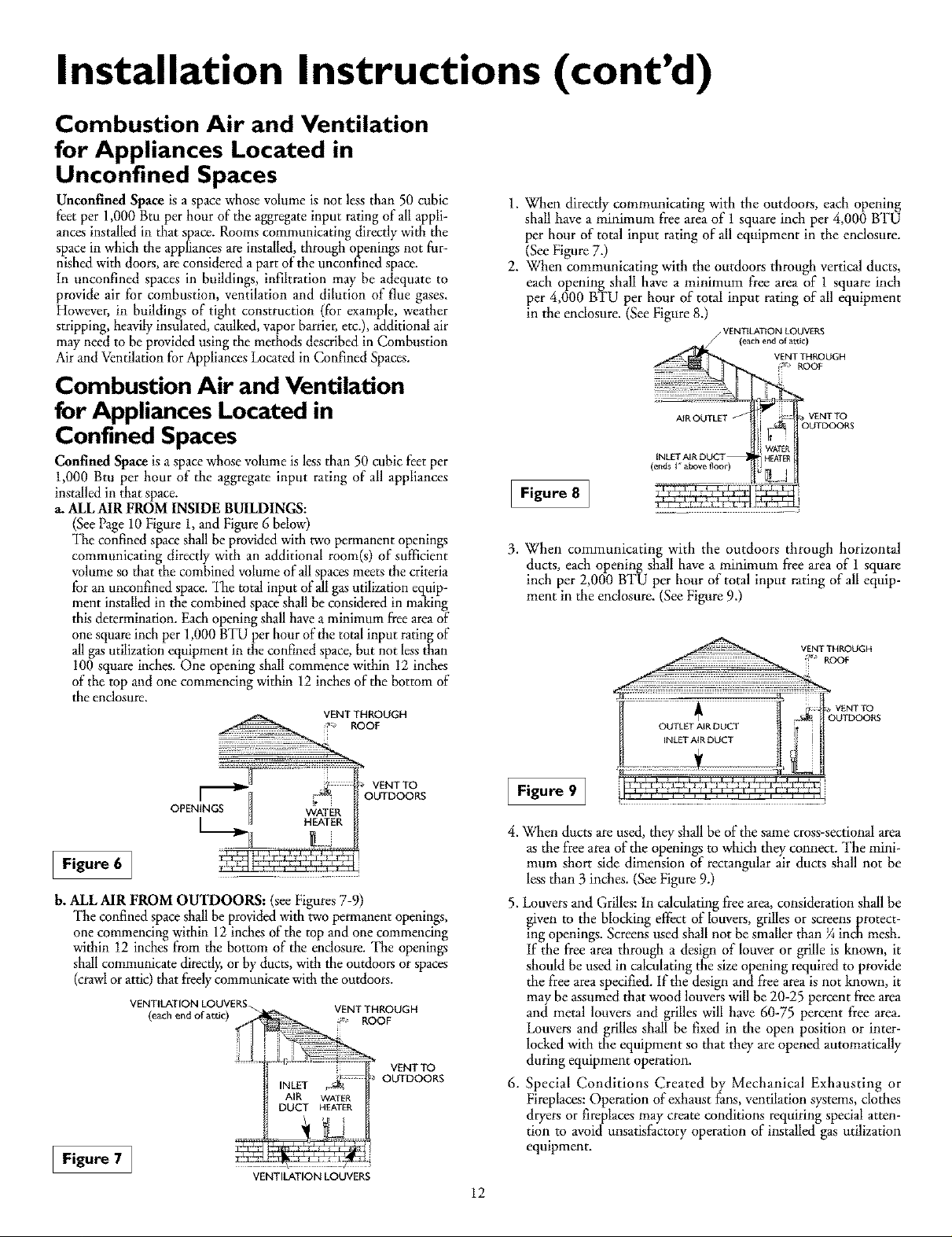

a. ALL AIR FROM INSIDE BUILDINGS:

(See Page 10 Figure 1, and Figure 6 below)

"Ille confined space shall be provided with two permanent openings

communicating directly with an additional room(s) of sufficient

volume so that the combined volume of all spaces meets the criteria

lbr an unconfined space. "Ille total input of all gas utilization equip-

ment installed in the combined space shall be considered in making

this determination. Each opening shall have a mininmm flee area of

one square inch per 1,000 BTU per hour of the total input rating of

all gas utilization equipment in the confined space, but not less than

100 square inches. One opening shall commence within 12 inches

of the top and one commencing within 12 inches of the bottom of

the endosurc.

VENT THROUGH

1. When directly communicating with the outdoors, each opening

shall have a minimum free area of 1 square inch per 4,000 BTU

per hour of total input rating of all equipment in the enclosure.

(See Figm'e 7.)

2. When communicating with the outdoors through vertical ducts,

each opening shall have a minimum free area of 1 square inch

per 4,000 BTU per hour of total input rating of all equipment

in the enclosure. (See Figure 8.)

I Figure 8 ]

3. When communicating with the outdoors through horizontal

ducts, each openingshall have a minimum free area of 1 square

inch per 2,000 BTU per hour of total input rating of all equip-

ment in the enclosure. (SeeFigure 9.)

Figure 6 ]

b. ALL AIR FROM OUTDOORS: (see Figures 7-9)

The confined space shall be provided with two permanent openings,

one commencing within 12 inches of the top and one commencing

within 12 inches from tile bottom of the enclosure. The openings

shall communicate directly, or by ducts, with the outdoors or spaces

(crawl or attic) that freely communicate with the outdoors.

VENTILATION LOUVERS_

(each end of attic)

Figure 7 ]

VENTILATION LOUVERS

VENT THROUGH

2 ROOF

VENT TO

OUTDOORS

Figure 9]

4. When ducts are used, they shall be of the same cross-sectional area

as the flee area of the openings to which they connect. The mini-

mum short side dimension of rectangular air ducts shall not be

less than 3 inches. (See Figure 9.)

5. Louvers and Grilles: In calculating flee area, consideration shall be

given to the blocking effect of louvers, grilles or screens protect-

ing openings. Screens used shall not be smaller than ¼ inch mesh.

If the flee area through a design of louver or grille is known, it

should be used in calculating the size opening required to provide

the free area specified. If the design and flee area is not known, it

may be assumed that wood louvers will be 20-25 percent flee area

and metal louvers and grilles will have 60-75 percent free area.

Louvers and grilles shall be fixed in the open position or inter-

locked with the equipment so that they are opened automatically

during equipment operation.

6. Special Conditions Created by Mechanical Exhausting or

Fireplaces: Operation of exhaust fans, ventilation systems, clothes

dryers or fireplaces may create conditions requiring special atten-

tion to avoid unsatisfactory operation of installed gas utilization

equipment.

12

Page 13

Installation Instructions (cont'd)

Water Piping

*A WARNING

HOTTER WATER CAN SCALD: Water heaters are intended to

_roduce hot water. Water heated to a temperature which will

satisfyclothes washing,dishwashing,andother sanitizingneeds

can scaldand permanently injure you upon contact. Some pet-

fie are more likelyto be permanently injured by hot water than

others. These include the elderly, children, the infirm, or physb

cally/mentally handicapped. If anyone using hot water in your

home fits into one of these groupsor if there isa local codeor

state lawrequiring a certain temperature water at the hot water

tap, then you must take specialprecautions.Inaddition to using

the lowest possibletemperature setting that satisfiesyour hot

water needs, a means suchasa mixing valve, shouldbe used at

the hot water taps usedby these people or at the water heater.

Mixing valves are available at plumbing supply or hardware

stores. Follow manufacturers instructions for installation of the

valves. Before changingthe factory setting on the thermostat

read the "Temperature Regulation"section inthis manual.

HOT WATER

OUTLET

TEMPERED

WATER

OUTL ET t

*MIXING WATER

VALVE OUTLET

This water heater shall not be connected to any heating sys-

tems or component(s) now or previously used with a non=

potable water heating appliance.

FROM HOT

ON WATER

HEATER

AWARNING

COLD WATER

TO COLDWATER

'INLET ON WATER

HEATER

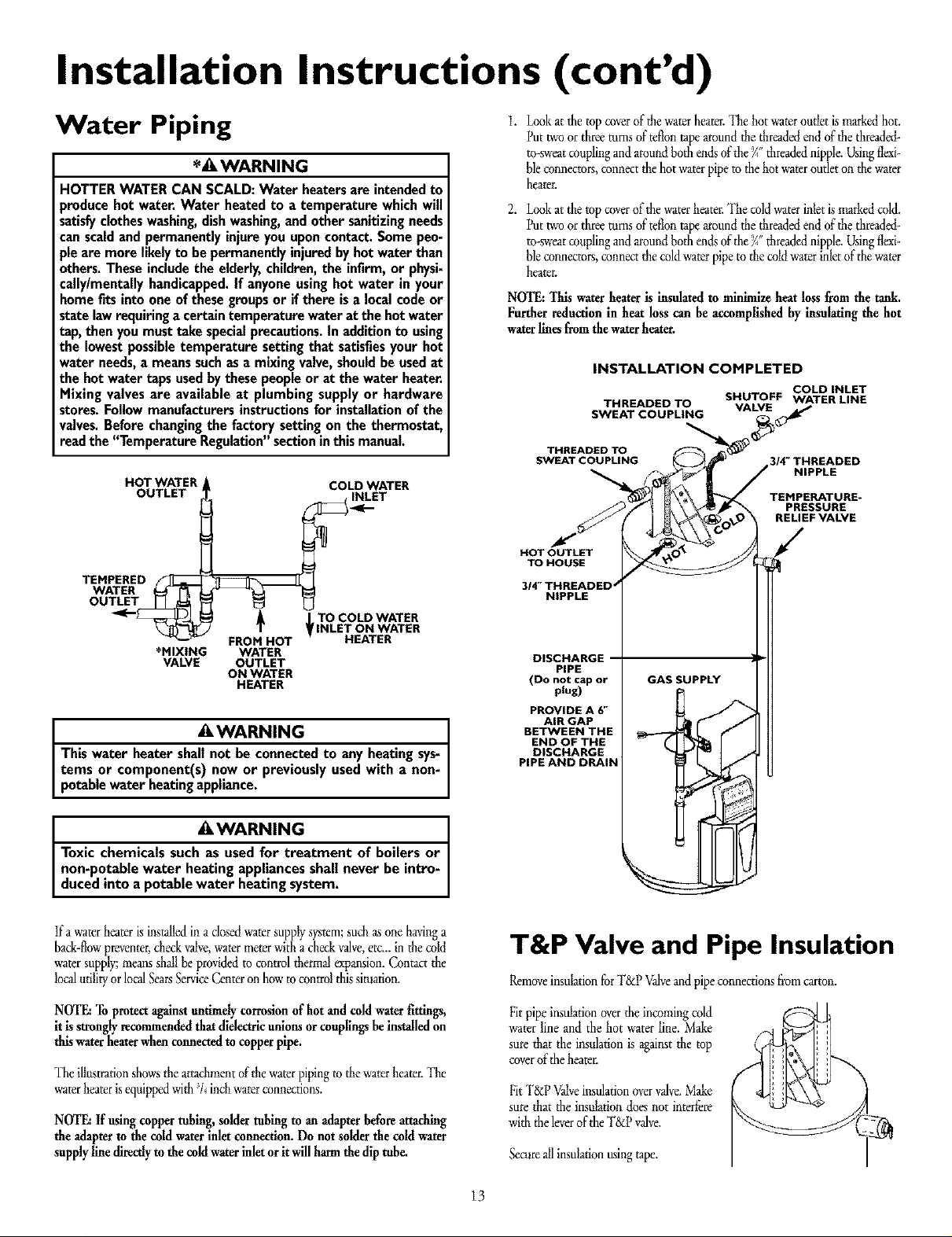

Lookatthetopcoverofrhewaterhearer.Thehotwateroutletismarkedhot.

Puttwoorthreeturnsofteflonrapearoundrilethreadedendofthethreaded-

to-sweatcouplingandaroundbothendsofthe_" threadednipple.Usingtlexi-

hieconnectors,connectthehotwaterpipetothehotwateroudetollthewater

heater.

Lookat thetopcoverofthewaterheater.Thecoldwaterinletismarkedcold.

Puttwoorthreeturnsofteflonrapearoundthethreadedendofrilethreaded-

to-sweatcouplingandaroundbothendsofthe_" threadednipple.Usingflexi-

bleconnectors,connectthecoldwaterpipetothecoldwaterinletoftbewater

hearer.

NOTE:Thiswaterheaterisinsulatedtominimizeheat lossfromthe tank.

Furtherreductionin heat losscan beaccomplishedby insulatingthe hot

waterlinesfromthewaterheater.

INSTALLATION COMPLETED

COLD INLET

NIPPLE

TEMPERATURE-

PRESSURE

RELIEF VALVE

SWEAT COUPLING

THREADED TO

SWEAT COUPLING

HOT OUTLET

TO HOUSE

3/4"THREADED j

NIPPLE

PIPE

(Do not cap or

plug)

PROVIDE A 6"

AIR GAP

BETWEEN THE

END OF THE

DISCHARGE

PIPE AND DRAIN

THREADED TO VALVE ._"

SHUTOFF WATER LINE

AWARNING

Toxicchemicalssuchas usedfor treatment of boilersor

non-potablewater heatingappliancesshall never be intro-

ducedinto a potablewater heatingsystem.

lfa waterheaterisinstalledin aclosedwatersupplysystem;suchasonehavinga

bach-flowpreventer,checkvalve,watermeterwithacheckvalve,etc..,in thecold

watersupply;meansshallheprovidedtocontrolthermalexpansion.Contactthe

localutilityorlocalSearsServiceCenteron howtocontrolthissitoarion.

NOTE:Toprotectagainstuntimelycorrosionofhot andcoldwaterfittings,

it isstronglyrecommendedthatdielectricunionsorcouplingsbeinstalledon

thiswaterheaterwhenconnectedtocopperpipe.

Theillustrationshowstheattachmentofthewaterpipingtothewaterheater.The

waterheaterisequ'ppedw'th/_ 'nchwaterconnect'ons.

NOTE:Ifusingcoppertubing,soldertubingto an adapterbeforeattaching

the adapterto thecoldwaterinletconnection.Donot solderthecoldwater

supplylinedirectlyto thecoldwaterinletorit willharmthediptube.

T&P Valve and Pipe Insulation

Removeinsulationfor T&P Valveand pipeconnectionsfromcarton.

Fitpipeinsulationover the incomingcold

water line and the hot water line. Make

sure that the insulationis against the top

coverof the heater.

FitT&PValveinsulationovervalve.Make

suredlartheinsulationdoesnotinterfbre

withtheleverof'theT&I valve.

Secureallinsulationusingtape.

13

)

Page 14

Installation Instructions (cont'd)

Temperature-Pressure Relief Valve

AWARNING

At the time of manufacture thiswater heater wasprovided

with a combinationtemperature-pressuresrelief valvecerti-

fied bya nationallyrecognized testinglaboratorythat main-

tains periodicinspectionof productionof listedequipment

or materials, as meeting the requirements for ReliefValves

and Automatic Gas ShutoffDevicesfor Hot Water Supply

Systems,andthe current edition of ANSI Z21.22, CSA 4.4

Standardsandthe code requirements of ASME. If replaced,

the valve must meet the requirements of localcodes,but

not lessthan a combinationtemperature and pressurerelief

valvecertifiedasmeeting the requirements forReliefValves

and Automatic Gas ShutoffDevicesfor Hot Water Supply

Systems,ANSI Z21.22 • CSA 4.4 Standardsbya nationally

recognized testing laboratory that maintains periodic

inspectionof productionoflistedequipmentormaterials.

The valve must be marked with a maximum set pressure

not to exceed the marked hydrostaticworking pressureof

the water heater (150 Ibs./sq.in.) and a dischargecapacity

not lessthan the water heater input rate as shownon the

model rating plate. (Electric heaters- watts dividedby 1000

x 3412equalBTU/Hr. rate.)

Your localjurisdictionalauthority, while mandatingthe use

of a temperature-pressurerelief valvecomplyingwith ANSI

Z21.22 •CSA 4.4 StandardsandASME, may require a valve

model different from the one furnished with the water

heater.

Compliancewith suchlocalrequirements must be satisfied

bythe installeror end user of the water heater with a locally

_rescribedtemperature-pressurerelief valveinstalledinthe

designatedopeninginthe water heater in placeof the facto-

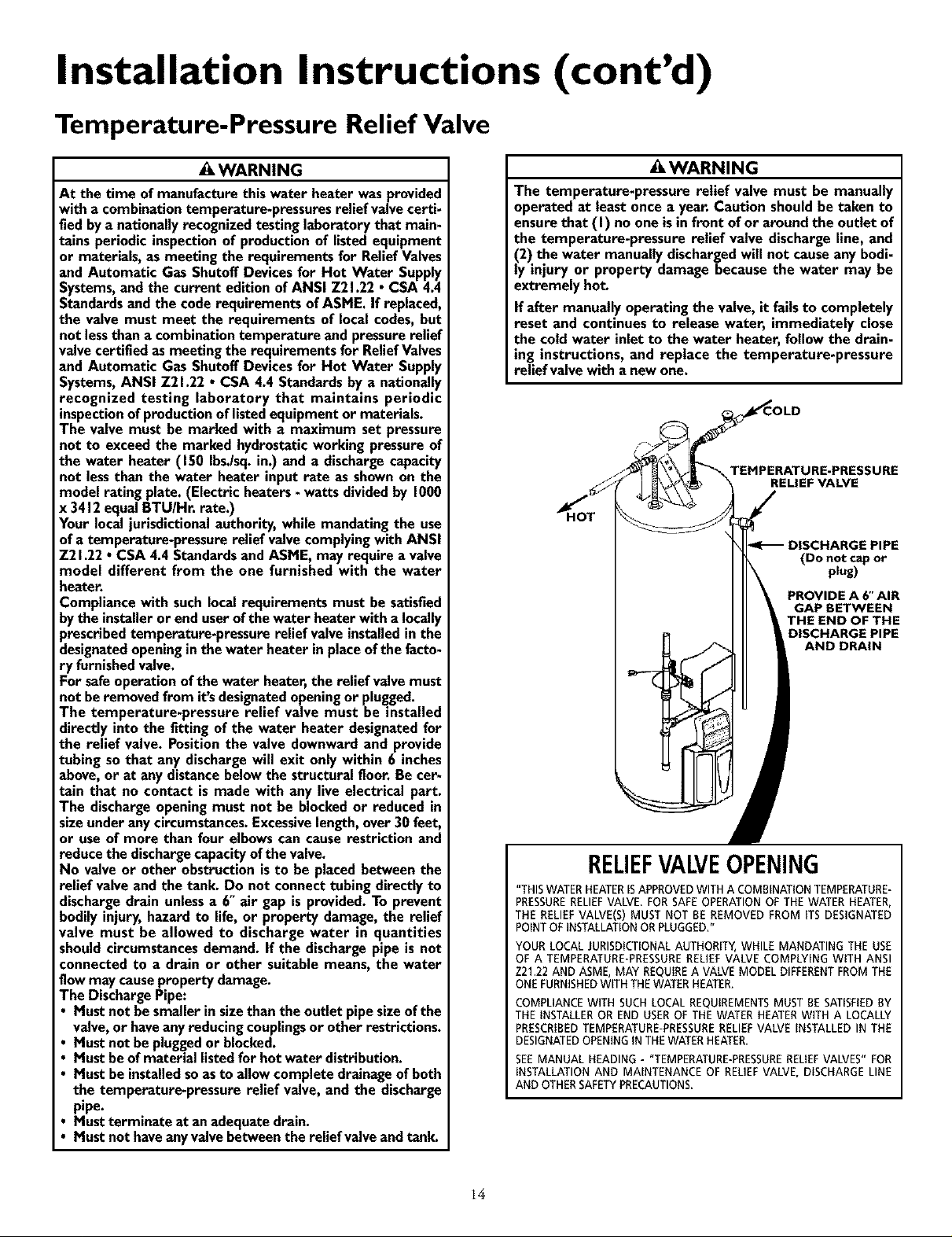

ry furnishedvalve.

For safeoperationofthe water heater,the relief valvemust

not beremoved from it'sdesignatedopeningor plugged.

The temperature-pressure relief valve must be installed

directly into the fitting of the water heater designatedfor

the relief valve. Positionthe valve downward and provide

tubing so that any dischargewill exit only within 6 inches

above,or at any distancebelowthe structuralfloor. Becer-

tain that no contact is made with any live electrical part.

The dischargeopeningmust not be blockedor reduced in

sizeunderanycircumstances.Excessivelength,over30 feet,

or useof more than four elbowscan causerestriction and

reduce the dischargecapacityof the valve.

No valveor other obstructionisto be placedbetween the

relief valveandthe tank. Do not connecttubing directlyto

dischargedrain unlessa 6"air gap is provided.Toprevent

bodilyinjury,hazard to life, or property damage, the relief

valve must be allowed to dischargewater in quantities

shouldcircumstancesdemand.If the dischargepipe is not

connected to a drain or other suitablemeans, the water

flowmaycausepropertydamage.

The DischargePipe:

• Must not be smallerinsizethan the outlet pipesizeof the

valve,or haveanyreducing couplingsor other restrictions.

• Must notbe pluggedor blocked.

• Must be ofmateriallistedforhot water distribution.

• Must be installedsoasto allowcomplete drainageof both

the temperature-pressurerelief valve, and the discharge

pipe.

• Mustterminate at anadequatedrain.

• Must nothaveanyvalvebetweenthe relief valveandtank.

_'LWARNING

The temperature-pressure relief valve must be manually

operated at least oncea year.Caution shouldbe taken to

ensurethat (I) no one isinfront of or aroundthe outlet of

the temperature-pressure relief valve dischargeline, and

(2) the water manuallydischargedwill not causeany bodi-

ly injury or property damage becausethe water may be

extremely hot.

If after manually operating the valve, it failsto completely

reset and continuesto release water, immediately close

the cold water inlet to the water heater,followthe drain-

ing instructions, and replace the temperature-prossuro

relief valvewith a new one.

TEMPERATURE-PRESSURE

R_LIEF VALVE

DISCHARGE PIPE

I I_ (Do not cap or

I1\

II \ PROVIDEA6"AIR

I I \ GAPBETWEEN

I I t THE END OF THE

I I • DISCHARGE PIPE

__ AND DRAIN

RELIEFVALVEOPENING

"THISWATERHEATERISAPPROVEDWITHA COMBINATIONTEMPERATURE-

PRESSURERELIEFVALVE. FORSAFEOPERATIONOF THEWATERHEATER,

THE RELIEFVALVE(S) MUST NOT BE REMOVED FROM ITS DESIGNATED

POINTOF INSTALLATIONORPLUGGED."

YOUR LOCALJURISDICTIONALAUTHORITY,WHILEMANDATINGTHE USE

OF A TEMPERATURE-PRESSURERELIEFVALVE COMPLYING WITH ANSI

Z21.22 AND ASME,MAY REQUIREA VALVEMODEL DIFFERENTFROM THE

ONEFURNISHEDWITHTHEWATERHEATER.

COMPLIANCEWITH SUCH LOCALREQUIREMENTSMUST BE SATISFIEDBY

THE INSTALLEROR END USEROFTHEWATERHEATERWITH A LOCALLY

PRESCRIBEDTEMPERATURE-PRESSURERELIEFVALVEINSTALLEDIN THE

DESIGNATEDOPENINGIN THEWATERHEATER.

SEEMANUAL HEADING- "TEMPERATURE-PRESSURERELIEFVALVES" FOR

INSTALLATIONAND MAINTENANCEOF RELIEFVALVE, DISCHARGELINE

AND OTHERSAFETYPRECAUTIONS.

14

Page 15

Installation Instructions (cont'd)

Filling the Water Heater

A CAUTION J

Never usethiswater heater unlessit iscompletelyfiredwith J

water.Topreventdamageto thetank,the tank must befilled

with water. Water must flow from the hot water faucet

beforeturn ng ON gasto thewater heater.

"Ib fill the water heater with water:

• Close the water heater drain valve by turning the handle to

the right (clockwise). The drain valve is on the lower front of

the water heater.

• Open the cold water supply valveto the water heater.

NOTE: The cold water supply valve must be left open

when the water heater is in use.

• "Ib insure complete filling of the tank, allow air to exit by

opening the nearest hot water faucet. Allow water to run until

a constant flow is obtained. This will let air out of the water

heater and the piping.

• Check all new water piping fbrleaks.Repair asneeded.

Wiring

USE WITH POWER CORD

You must provide all wiring of the proper size outside of the

water heater. You must obey local codes and electric company

requirements when you install this wiring.

If you are not familiar with electric codes and practices, or if you

have any doubt in your ability to connect the wiring to this

water heater, obtain the service of a competent electrician or

contact your local electric utility.

AWARNING

WATER HEATERS EQUIPPED FOR ONE TYPE VOLTAGE

ONLY:Thiswaterheater isequippedfor 110/120voltsonly.DO

NOT USE THIS WATER HEATER WITH ANY VOLTAGE

OTHERTHAN THE ONE SHOWN ABOVE.Failureto usethe

correctvoltagecancauseproblemswhichcanresult inDEATH,

SERIOUSBODILY INJURYOR PROPERTYDAMAGE. If you

haveanyquestionsor doubtsconsultyourelectriccompany.

CAUTION

If wiring from the fuse box or circuit breaker box wasalu-

minumfor the old water heater,replace it with copperwire.

If you wish to reuse the existingaluminum wire, havethe

connectionat the water heater made bya competent elec-

trician.Contact a localelectricalcontractor and/or the local

electricutility.

The water heater comes equipped with a 7 foot power cord

which can be used to connect to a 110/120 volt power source if,

(1) local codes allow, and (2) there is a three prong receptacle

available. This unit must have a grounded outlet to operate.

7" MAXIMUM

CORD LENGTH

i

/

/

You must provide all wiring, (1) to a receptacle or, (2) between

the water heater and junction box when the power cord is not

used.

USE WITHOUT POWER CORD

If power cord cannot be used, then follow these wiring instruc-

tions.

1. Provide a way to ea_silyshut off'the electric power when work-

ing on the water heater. This could be with a circuit breaker

or fuse block in the entrance box or a separate disconnect

switch.

2. Install and connect a circuit directly from the main fuse or

circuit breaker box. This circuit must be the right size and

have its own fuse or circuit breaker.

WIRENUTS

AWARNING I

Do not useanextensioncord.If thereisnotasuitablerecepta-

cleand/orlocalcodesprohibituseof a powercord,fieldwiring

mustbe provided.

GROUND SCREW

15

Page 16

Installation Instructions (cont'd)

Wiring (cont'd)

USE WITHOUT POWER CORD (cont'd)

3. A standard 7_"conduit opening has been made in the water

heater junction box for the conduit connection.

4. Use wire nuts and connect the power supply wiring to the

wires inside the water heater's junction box.

5. The water heater must be electrically "grounded" by the

installer. The unit will not operate unless it is properly

WIRING DIAGRAM

ECO LI

_H [ ON/OFF m

THERMOSTAT

[] SWITCH

sw._._

L2 GND

"<'-1

BLOWER

VACUUM

SWITCH

[] I EXHAIIST

BLOCKAGE)

grounded. A green ground screw has been provided on the

water heater's junction box. Connect ground wire to this

location. For complete grounding details and all allowable

exceptions, refer to the current edition of the National

Electrical Code ANSI/NFPA 70.

6. Replace the wiring junction cover using the screw provided.

""x

)WEF

_LE_:EMALE

SPADE

TERMINAI,_

J

I

I

IWIRE NUT WIRE NUT

[]

FLAME SENSE ROD

NORMAL OPERATION SEQUENCE

INDICATED BY BOXED NUMERALS

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and I

dangerous operation. Verify proper operation after

servicing.

!'I-j o

,-,.

A CAUTION I

16

Page 17

Installation Instructions (cont'd)

Venting

_WARNING

To insure proper venting of this gas-fired water

heater, the correct vent pipe diameter must be uti-

lized. Any additions of other gas appliances on vent

with this water heater will adversely affect the oper-

ation of the water heater.

The combustion alld ventilation air flow must not be obstructed.

AWARNING

The power vent water heater requires its own (sepa-

rate) venting system. It cannot be connected to an ex-

isting vent pipe or chimney. It must be terminated to

the outdoors. Failure to properly install the venting sys-

tem can result in asphyxiation, a fire or explosion and

can cause DEATH, SERIOUS BODILY INJURY, OR

PROPERTY DAMAGE.

Chemical vapor corrosion of the flue and vent sys-

tem may occur if air for combustion contains certain

chemical vapors. Spray can propellants, cleaning sol-

vents, refrigerator and air conditioner refrigerants,

swimming pool chemicals, calcium and sodium chlo-

ride, waxes, bleach, and process chemicals are typi-

cal compounds which are potentially corrosive.

&WARNING

\

STRAPPING

Obstructed or deteriorated vent systems may

sent a serious health risk or asphyxiation.

The vent pipe from the water heater must

upward % inch per five linear feet.

MI vent gases must be completely vented to the outdoors of the

structure (dwelling).

Failure to have required clearances between water I

heater and combustible material will result in a fire

hazard.

WARN ING pre-

_, WARN ING slope

MIN. RISE½'

PERFIVEFEET

AWARNING I

Horizontal runs must be securely supported at 3V2foot intervals

and vertical runs supported at 5 foot intervals.

VENTING THROUGH AN OUTSIDE WALL

ALL MODELS

3" PVC, ABS or CPVC Schedule 40 vent piping:

1. A Y"PVC Schedule 40-45 ° vent cap with wire screen is sup-

plied with the water heater.

2. A 3 I VC, ABS or CPVC Schedule 40-90 ° street ell; used to

connect the vent pipe to the water heater when the vent pipe

is to be turned horizontally directly off" the blower (supplied

locally).

3. 3 _tVC, ABS or CPVC Schedule 40 pipe (must be supplied

locally).

3" PVC,ABSORCPVC

SCHEDULE

4ogOOELOOW t

• The water heater requires its own (separate) venting system.

3" PVC,ABSOR CPVC

SCHEDULE40 PiPE VENTCAP

SCREEN

WITH

&WARNING I

Be sure vent pipe is properly connected to prevent I

escape of dangerous flue gases which could cause

dead y asphyx at on.

• 3 I VC, ABS or CPVC Schedule 40 piping and fittings are

acceptable materials for the vent system on all models.

• It cannot be connected to existing vent piping or chimney.

• It must terminate horizontally to the outdoors.

17

Page 18

Installation Instructions (cont'd)

Venting (cont'd)

ALL MODELS _ OPTIONAL 2"VENT PIPING

2" PVC, ABS or CPVC Schedule 40 vent piping:

1. A wire screen to fit a 2" PVC, ABS or CPVC Schedule 40-

45° vent cap is supplied with the water heater.

2. A 2" PVC, ABS or CPVC Schedule 40-45 ° vent cap (elbow)

(must be supplied locally).

3. A Y" PVC, ABS or CPVC Schedule 40 pipe, minimum

length of Y" (must be supplied locally), to make vent connec-

tion at the blower outlet.

4. A Y"to 2" PVC, ABS or CPVC Schedule 40 reducer (must

be supplied locally).

5. A 2" PVC, ABS or CPVC Schedule 40-90 ° street ell; used to

connect the vent pipe to the reducer when the vent pipe is to

be turned horizontally off"the blower (supplied locally).

6. 2" PVC, ABS or CPVC Schedule 40 pipe (must be supplied

locally).

VENTING SYSTEM EXAMPLE INSTALLATIONS

FOR ALL MODELS

The vent piping cannot under any circumstances be run down-

hill.

The vent piping may be installed as follows:

2" PVC, ABS OR CPVC

SCHEDULE 40...---_1

90° ELBOW _]_

i_ 3" TO 2" PVC, ABS ORCPVC REDUCER

2" PVC, ABS OR CPVC

SCHEDULE 40 PIPE

3" PVC, ABS OR CPVC

SCHEDULE 40 PIPE

(MINIMUM LENGTH 3")

VENT CAP

WITH SCREEN

• The water heater requires its own (separate) venting system.

• 2" and 3" PVC, ABS or CPVC Schedule 40 piping and fittings

are acceptable materials for the vent system on all models.

• It cannot be connected to existing vent piping or chimney.

• It must terminate horizontally to the outdoors.

NOTE: See pages 22 and 23 for vertical venting through a roof.

Horizontal runs require a minimum %"rise per five feet.

3

ELBOW

EXAMPLE

MIN, RISE¼"

PERFIVE FEET

3

ELBOW

EXAMPLE

MIN, RISE¼"

PERFIVE FEET

18

MIN. RISE¼"

PER FIVEFEET

Page 19

Installation Instructions (cont'd)

ALL MODELS- VENTING THROUGH WALL

3

ELBOW

EXAMPLE

MIN. RISEY;"

PER FIVEFEET

MIN. RISEY¢'

PER FIVEFEET

OPTIONAL 2°"VENT PIPING

2" DIA.VENT

MAX. LENGTH (FT.)

5O

45

4O

35

3O

25

* NOTE: Two 45 ° elbows are equivalent to one 90 ° elbow.

One 90 ° elbow equals 5 feet of equivalent vent length.

NUMBER OF 90° DEG.

ELBOWS*

I

2

3

4

5

6

ALL MODELS (3" VENT)

See tables for max. length.

157;'MIN. 14"MIN. MIN, RISE¼"

1. The total vertical and horizontal vent run cannot exceed the

maximum length with the number of 90 ° elbows as specified

in the following tables. If more elbows are required, the vent-

ing distance must be reduced 5 feet for every 90 ° elbow:

ALL MODELS- VENTING THROUGH WALL

3" DIA.VENT

MAX. LENGTH (FT.)

115

II0

105

100

95

9O

4' MiN.

PERFIVEFEET

NUMBER OF 90° DEG.

ELBOWS*

I

2

3

4

5

6

_S'MAX.

MIN. RISEY;"

20'

(EXAMPLE)

2. Minimum vent length Gr all models is 4 feet.

ONE ELBOW

EXAMPLE

_l_ 3"VENT PIPE

PERFIVE FEET

EXAMPLE USING ONE ELBOW

WITH 3" VENT PIPE

19

Page 20

Installation Instructions (cont'd)

Venting (cont'd)

VENTING THROUGH AN OUTSIDE WALL WITH

LOW GROUND CLEARANCE

CEMENTING PVC, ABS OR CPVC PIPE AND

FITTINGS

1. When the vent piping cannot pass through an outside wall at

a height greater than or equal to 12" above the ground (or

above snow accumulation level), then the installation can be

modified as shown below.

/,%

[//_,

/%

7[ MIN. ABOVE

>:_ I I GROUNDORSNOW

_ ACCiNULATION LEVEL

2. Refer to the tables below for maximum vent lengths for low

ground clearance installations. All installations assume the use

of two additional 90° elbows and the standard 45° vent cap

with screen outside of the exterior wall.

Read and observe all safety information printed on primer,

cleaner, and cement containers.

_. DANGER I

Primer, cleaner, and cements are extremely I

flammable. They are harmful or fatal if swallowed. The I

vapors are harmful. They may irritate eyes and skin

and can be absorbed through the skn.

_. PRECAUTIONS

Always store primers, cleaner, and cements in cool,

dry, well ventilated places. Do not store them near

heat, sparks, or flames. Keep containers closed. Use

them in well ventilated areas. Wear impervious cloth-

ing while handling. Do not smoke, eat, or drink while

handling. Wash thoroughly after handling and before

eating. Wear eye protection when handling. If swal-

lowed, drink water, do not induce vomiting, and call a

physician or poison control center immediately. If

inhaled, get fresh air and seek medical attention if ill

feelings persist. In case of eye and skin contact, imme-

diately flush with plenty of water for 15 minutes and

seek medical attention if irritation persists. KEEP

OUT OR REACH OF CHILDREN.

All primers, cleaners, and cements must meet all local codes and

applicable standards of the American Society For Testing

Materials Standards.

ALL MODELS -- LOW GROUND CLEARANCE

3"DIA.VENT

MAX. LENGTH (FT.)

105

100

95

90

85

8O

ALL MODELS -- LOW GROUND CLEARANCE

OPTIONAL 2" VENT PIPING

2" DIA.VENT

MAX. LENGTH (FT.)

4O

35

3O

25

2O

15

* o o

NOTE: Two 45 elbows are equivalent to one 90 elbow.

NUMBER OF 90° DEG.

ELBOWS* (inside bldg)

I

2

3

4

5

6

NUMBER OF 90° DEG.

ELBOWS* (inside bldg)

I

2

3

4

5

6

One 90° elbow equals 5 feet of equivalent vent length.

Before using primers, cleaners, and cements, stir or shake, mak-

ing sure contents are liquid. Do not use if found to be lumpy or

jelly-like.

1. Cut pipe ends squarely removing all burrs and dirt.

2. Dry fit pipe and fittings to be connected for proper fit.

3. Clean pipe and fitting with a primer/cleaner.

4. Apply a thin coat of cement to fitting, avoiding puddling

inside.

5. Apply a liberal coat of cement to pipe leaving no voids.

6. QUICKLY assemble parts while cement is flui!! If you wait

too long, re-coat pipes.

7. Push pipe completely into socket of fitting, turning as it goes

until it bottoms.

8. Hold pipe and fitting together for 30 seconds. Then carefully

clean off"excess with a cloth. Allow connections a sufficient

time to cure before disturbing.

9. Remember that vent pipes must be adequately and securely

supported.

2O

Page 21

Installation Instructions (cont'd)

APPROXIMATE SETTING TIME FOR 2" TO 3" PIPE

JOINTS

MOVEMENT COMPLETE

OF JOINT SET

90°F to 150°F % hr. 8 hrs.

50°F to 90°F I hr. 15 hrs.

0°F to 50°F 1% hr. 18 hrs.

CUTTING OPENING THROUGH AN OUTSIDE

WALL AND COLLAR INSTALLATION

After reading the manual and you have determined the location

of the op,eningin the wall, (using the draw!ng below), cut a 2_"

hole for 2 vent piping or a 3_' hole for 3 vent piping through

an exterior wall.

NOTE: When determining location of the opening in the

outside wall allow for the ¼° rise per five feet that has taken

place in the horizontal run.

" '" "" I N PER FIVE FEET

L

INSTALLATION SHOWING USE OF PVC, ABS OR

CPVC PIPE

_. EXTERIOR

SEALER

SILICONE

SEALER _ BE POSITIONIED

CONNECTING PVC, ABS OR CPVC PIPE VENT TO

BLOWER

_// _"_ WALL

HIN EXTENSION

...... THROUG H

J_ _ EXTERIOR WALL

_/ _ SCREW

VENT CAP MUST

/

DOWNWARD

1. If making an immediate horizontal run of vent off'the blower,

a Y' PVC, ABS or CPVC Schedule 40 (supplied locally) elbow

is required. Place the elbow in the required direction on the

blower and using 3 sheet metal screws, attach the elbow.

40 GAL.- 59½"

50 GAL.- 6(7'

N

The 3" (or optional 2") PVC, ABS, or CPVC Schedule 40 vent

pipe can be run from the water heater through the wall or from

the wall to the water heater, whichever is most convenient. The

vent pipe must extend a minimum of 1_" through the exterior

wall. Extending the vent cap as far as possible from the surface

of the exterior wall will help minimize discoloration of the wall

in this area which may be caused by the flue gases. Note that the

inside collar must be slipped over the vent piping before locat-

ing the pipe through the wall. Before securing the inside and

outside collars to the wall, use a silicone sealer between pipe and

opening to insure a water and air tight seal.

SEALWITH _ _ _" _"

I

2. If there is to be a vertical run of vent from the blower, the Y'

PVC, ABS or CPVC pipe must be attached to the blower using

3 sheet metal screws.

SEALWITH

RTVSEALANT _ _"