Kenmore 141.157951, 141.157941 Owner's Manual

Owner's Manual

E: L ! T

Liquid Propane Gas Grill

Model141.157941

Natural Gas Grill

Model141.157951

f

TM

IIfllll

Z_ WARNING:

ReadthisOwner'sManualcarefullyandbesure your

gas grillispropedyassembled, installedand main-

tained. Failure to follow these instructionscould

resultinsedous bodilyinjuryand/orpropertydam-

age. This gas gdll is intendedfor outdooruseonly

and isnot intendedto be installedinor on

recreationalvehiclesor boats.

Note to Installer:

Leave thisOwner's Manual withtheconsumer

afterdeliveryand/orinstallation.

O O

m

Note to Consumer:

Leave this Owner'sManual ina convenientplace

for future reference.

Manufacturer Customer Service Helpline:

If the shipping box is missing parts or you have

questions about assembly,call the Customer Ser-

vice Helpline 8am - 11pro CST, Mondaythrough

Fridayat 1-888-317-7642.

Sears, Roebuck and Co.,

Hoffman Estates, IL 60179 U.S.A.

P4775B - Rev: 04/21/00

Warranty ..................................................... 2

Safety Instructions ..................................... 2

Pre-Assembly Instructions ......................... 4

Parts Diagram and Part Lists ............... 5

Assembly Instructions ................................. 8

Lighting Instructions .................................. 14

Cooking Instructions ................................ 16

Cleaning and Maintenance Instructions .... 16

Frequently Asked Questions .................. 19

Cooking Guide and Recipes ................ 20

From the date of purchase for the designated time

periods listed below, Sears will replace the following

grillpartsfree of charge if theyare defectiveinmaterial

or workmanship.

• Lifetime of Grill: Exterior Stainless Steel Parts,

Aluminum Castings (except for paint loss)

/_ WARNING

Failure to comply with these instructions

could result in a fire or explosion which

could cause serious bodily injury, death,

or property damage.

Grill Installation Codes

This gas grill must be installed in accordance

with all local codes. In areas without local

codes, follow the latest edition of the National

Fuel Gas Code ANSI Z223.1. In Canada. installa-

tion must conform to standard CAN/CGA lb149.1

or 1-b149.2 (Installation Code for Gas Burning

Appliances and Equipment) and all local codes.

Proper Placement and Clearance of Grill

Never use your gas grill ina garage, porch,shed,

breezewayor anyotherenclosedarea. Yourgas grill

isto be used outdoors only, at least 24" from the

back and side of any combustible surface.Your

gas grillshould not be placed under any surface

that will bum. Do not obstruct theflow of ventila-

tion air around the gas gdll housing.

This outdoorgas grillis notintendedto be installedin

or on recreational vehicles and/or beats.

• 3 Years: Flame Tamers, Cooking Grids, Burners

• 5 Years: All Other Grill Parts (except ignitorbattery)

This warranty does not cover:

• Labor costs for repairs

• Grill if it is used for commercial or rental

purposes.

Replacement parts are available by contacting the

nearest Sears Service Center.

This warranty applies only when the grill is used

in the United States.

This warranty gives you specific legal rights, and

you may also have other rights which vary from

state to state.

Sears, Roebuck and Co., Dept. 817WA,

Hoffman Estates, IL 60179

Correct LPG Cylinder Use

LPG grill models are designed for use with a

standard 20 lb. Liquid Propane Gas (LPG)

cylinder, not included with grill box. Never

connect your gas grill to an LPG cylinder that

exceeds this capacity. A cylinder of approxi-

mately 12 inches in diameter by 18-1/2 inches

high should be the maximum size LPG cylinder

used. We recommend buying an "OPD" gas

cylinderwhich offers an Overfill Prevention

Device. This safety feature prevents the cylinder

from being overfilledwhich can cause malfunction

of the LPG cylinder, regulator and/or grill.

The LPG cylinder must be constructed and

marked in accordance with specificationsof the

U.S. Dept. of Transportation (DOT). In Canada,

the LPG cylinder must meet the Canadian

Transportationand Communications(CTC)

specifications. Also be sure:

1. The LPG cylinder has a shutoff valve, termi-

nating in an LPG supply cylinder valve outlet,

that is compatible with a Type 1 cylinder

connection device. The LPG cylinder must

also have a safety relief device that has a

direct communication with the vapor space of

the cylinder.

2. The cylinder supply system must be arranged

for vapor withdrawal.

3. The LPG cylinder used must have a collar

to protect the cylinder valve.

2 © Sears, Roebuck and Co.

WARNING

Failure to comply with these instructions

could result in a fire or explosion which

could cause serious bodily injury, death,

or property damage.

• Never connect an unregulated LPG cylinder

to your gas grill. The gas regulator assembly

supplied with your gas grill is adjusted to

have an outlet pressure of 11" water column

(W.C.) for connection to an LPG cylinder.

• Only use the regulator and hose assembly

supplied with your gas grill. Replacement

regulators and hose assemblies must be

those specified by Sears.

• Have your LPG cylinder filled by a reputable

propane gas dealer and visually inspected

and re-qualified at each filling.

• Never fill the gas cylinder beyond 80% full.

Have your propane gas dealer check the

release valve after every filling to ensure that

it remains free of defects.

• Always keep LPG cylinders in an upright

position.

• Do not store (or use) gasoline or other flammable

vapors and liquids in the vicinity of this gas gdll.

• An LPG cylinder that is not connected for use

must not be stored in the vicinityof this or any

other gas grill.

• Do not subject the LPG cylinder to excessive

heat.

• Never store an LPG cylinder indoors. If you

store your gas grill in the garage or other

indoor location, always disconnect the LPG

cylinder first and store it safely outside.

• LPG cylinders must be stored outdoors in a

well-ventilated area. Disconnected LPG cylin-

ders must not be stored in a building,

garage or any other enclosed area.

• When your gas grill is not in use the gas

must be turned off at the LPG cylinder.

• The regulator and hose assembly must be

inspected before each use of the grill. If

there is excessive abrasion or wear or if the

hose is cut, it must be replaced prior to the

grill being used again.

• Keep the gas regulator hose away from

hot grill surfaces and dripping grease.

Avoid unnecessary twisting of hose. Visually

inspect hose prior to each use for cuts,

cracks, excessive wear or other damage.

• If the hose appears damaged do not use gas

grill. Call Sears at 1-800--4-MY-HOME for

a Sears authorized replacement hose.

• Never light your gas grill with the lid closed

or before checking to insure the burner tubes

are fully seated over the gas valve orifices.

• Never allow children to operate your grill. Do

not allow children to play near your grill.

WARNING

IF YOU SMELL GAS:

• Shut off gas supply to the grill.

• Extinguish any open flame.

• Open grill lid.

• If odor continues, immediately call your

gas company or local fire department.

Failure to comply with these instructions

could result in a fire or explosion which

could cause serious bodily injury, death, or

property damage.

WARNING

A strong gas smell, or the hissing sound of

gas indicates a serious problem with your

gas grill or the LPG cylinder. Failure to

immediately follow the steps listed below

could result in a fire or explosion which

could cause serious bodily injury, death, or

propertydamage.

• Get away from the LPG cylinder.

• Do not try to fix the problem yourself.

• Call your fire department. (Do not call

near the LPG cylinder because your

telephone is an electrical device.)

CAUTION: Spiders and small insects occa-

sionally spin webs or make nests in the

grill burner tubes dudng transit and

warehousing. These webs can lead to a gas

flow obstruction which could result in a fire

in and around the burner tubes. This type of

fire is known as a "FLASH-BACK" and can

cause serious damage to your grill and

create an unsafe operating condition for the

user.

Although an obstructed burner tube is not

the only cause of "FLASH-BACK", it is the

most common cause.

To reduce the chance of "FLASH-BACK",

you must clean the burner tubes before

assembling your grill, and at least once a

month in late summer or early fall when

spiders are most active. Also perform this

burner tube cleaning procedure if your gdll

has not been used for an extended period

of time.

3

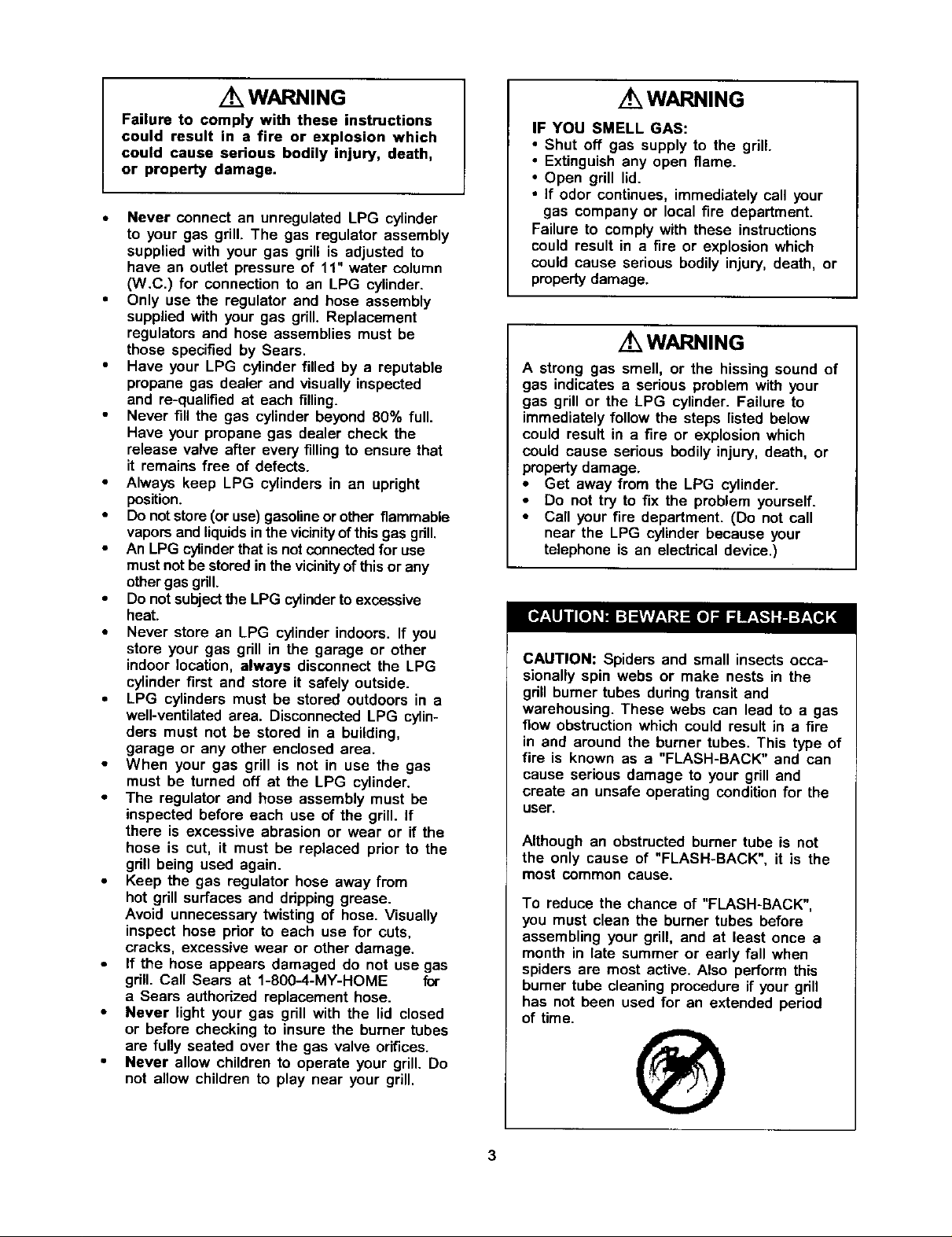

/h WARNING

Toreduce the chance of "FLASH-BACK" (see

caution on page 3) clean the burner tubes and

burners before fully assembling your grill• Remove

the cotter pin from the rear underside of each

burner using a pair of long nose pliers. Carefully

lift each burner up and away from the gas valve

orifice, then refer to Figure 1 and perform one of

these three cleaning methods:

1. Bend a stiff wire, (a lightweight coat hanger

works well) into a small hook as shown

below• Run the hook through the burner tube

and inside the burner several times to remove

any debris•

( ;- '1)

2. Use a bottle brush with a flexible handle• Run

the brush through the burner tube and inside

the burner several times, removing any debris.

3. Use an air hose to force air through each

burner tube. The forced air should pass debds

or obstructions through the burner and out the

ports.

The location of the burner tube with respect

to the orifice is vital for safe operation.

Check to ensure the orifice is inside of the

burner tube before using your gas grill. See

Fig. 2. If the burner tube does not fit over

the valve orifice, lighting the burner may

cause explosion and/or fire.

Figure 2

GAS VALVE ASSEMBLY

ORIFICE BURNER TUBE

Figure 1

TO CLEAN BURNER TUBE,

INSERT HOOK HERE

• Size 2 phillipsscrewdriver

• Size 4 phillips screwdriver

• Adjustable wrench

• Long nose pliers

• Open-end wrench, 11116" size

• Protective work gloves

• Eye protection

SPARK ELECTRODE AS-

SEMBLY "_ _ BURNER BURNER PORT

/

BURNER TUBE COTTER PIN

GAS COLLECTOR BOX

_J

I i

FOOT _

4

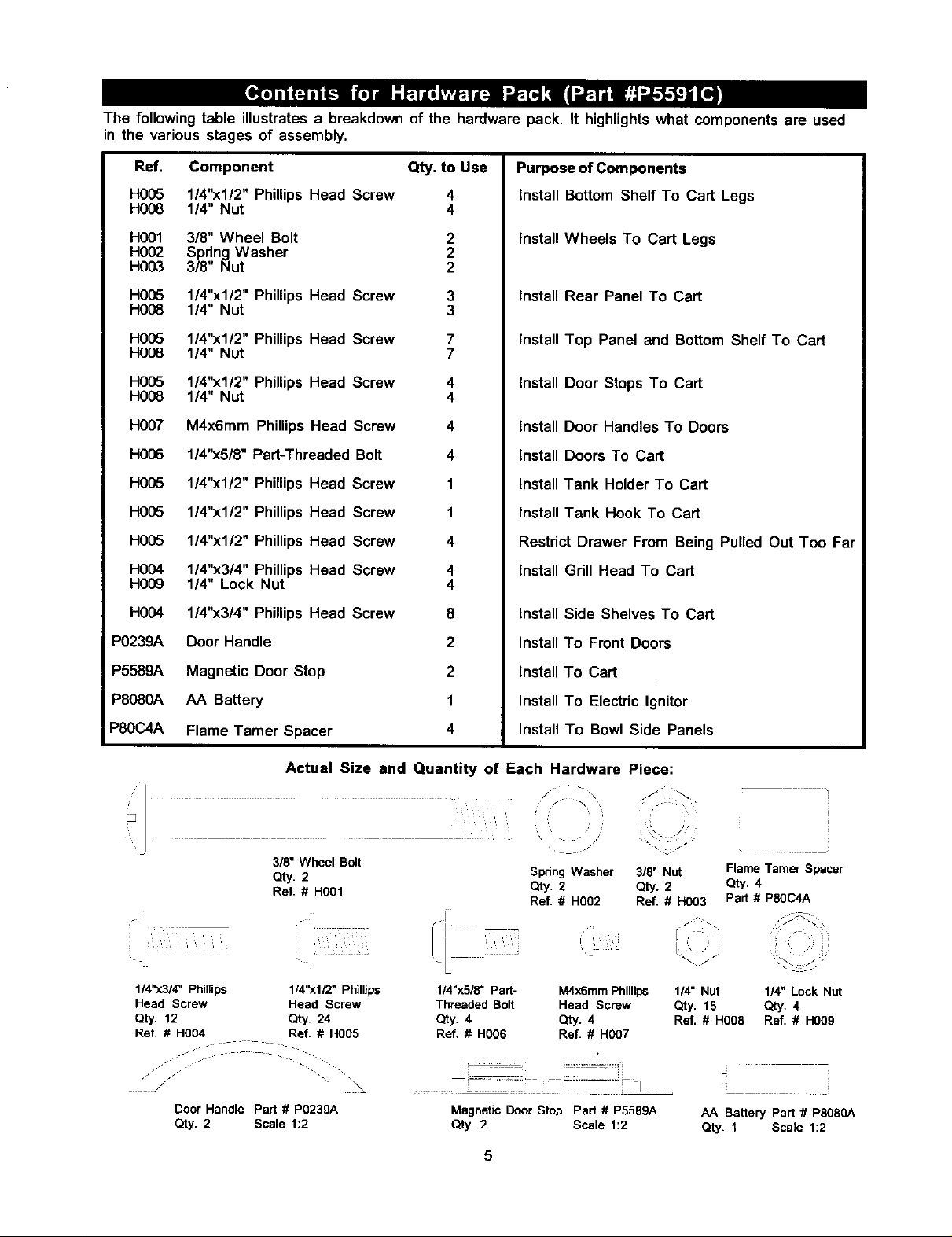

The following table illustrates a breakdown of the hardware pack. It highlights what components are used

in the various stages of assembly.

Ref,

H005

H008

H001

H002

H003

H005

H008

H005

H008

H005

Hog8

HO07

H006

H005

H005

H005

H004

H009

HO04

P0239A

Component Qty. to Use

1/4"xl/2" Phillips Head Screw 4

1/4" Nut 4

3/8" Wheel Bolt 2

Spring Washer 2

3/8" Nut 2

1/4"xl/2" Phillips Head Screw 3

1/4" Nut 3

1/4"xl/2" Phillips Head Screw 7

1/4" Nut 7

1/4"xl/2" Phillips Head Screw 4

1/4" Nut 4

M4x6mm Phillips Head Screw 4

1/4"x5/8" Part-Threaded Bolt 4

1/4"xl/2" Phillips Head Screw 1

1/4"xl/2" Phillips Head Screw 1

1/4"xl/2" Phillips Head Screw 4

1/4"x3/4" Phillips Head Screw 4

1/4" Lock Nut 4

1/4"x3/4" Phillips Head Screw 8

Door Handle 2

Purpose of Components

Install Bottom Shelf To Cart Legs

Install Wheels To Cart Legs

Install Rear Panel To Cart

Install Top Panel and Bottom Shelf To Cart

Install Door Stops To Cart

Install Door Handles To Doors

Install Doors To Cart

Install Tank Holder To Cart

Install Tank Hook To Cart

Restdct Drawer From Being Pulled Out Too Far

Install Grill Head To Cart

Install Side Shelves To Cart

Install To Front Doors

P5589A

P8080A

P80C4A

114"x3/4"Phillips 114"xl/2" Phillips

Head Screw Head Screw

Qty. 12 Qty. 24

Ref. # H004 Ref. # H005

Magnetic Door Stop 2

AA Battery 1

Flame Tamer Spacer 4

Actual Size and Quantity of Each Hardware Piece:

3/8" Wheel Bolt

Qty. 2

Ref. # H001

\

J J ". \\

/ •

Door Handle Part # P0239A

Qty. 2 Scale 1:2

Install To Cart

Install To Electric Ignitor

Install To Bowl Side Panels

Spring Washer 318" Nut Flame Tamer Spacer

Qty. 2 Qty. 2 Qty. 4

r

Ref. # H002 Ref. # H003 Part # PSOC4A

, , ,, ,

1/4"x518" Part- M4x6mm Phillips

Threaded Bolt Head Screw

Qty. 4 Qty. 4

Ref, # H006 Ref. # H007

Magnetic Door Stop Part # P5589A

Qty. 2 Scale 1:2

5

i

1/4" Nut 1/4" Lock Nut

Qty. 18 Qty. 4

Ref. # H0O8 Ref. # H009

AA Battery Part # PS08OA

Qty. 1 Scale 1:2

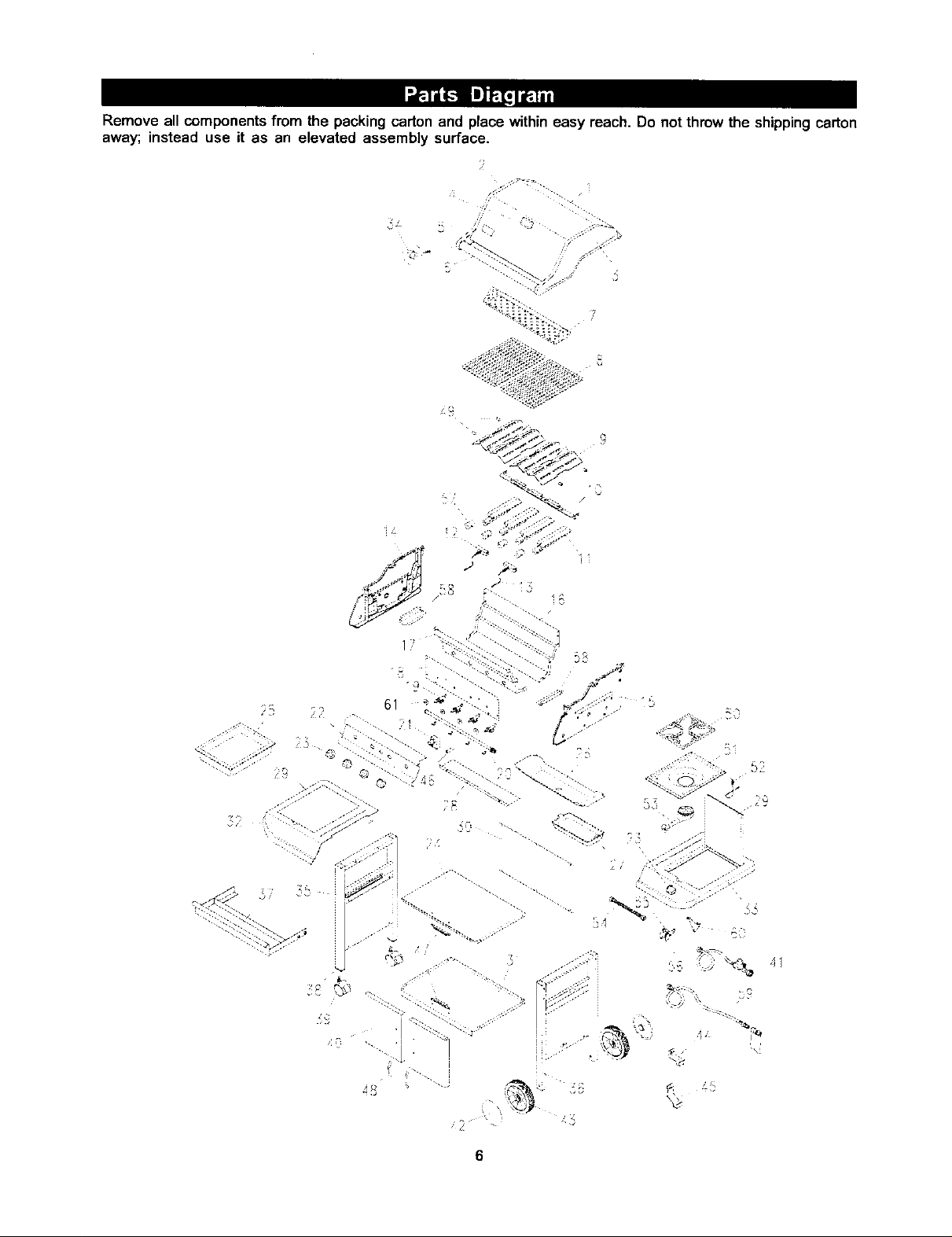

Removeallcomponentsfrom the packing carton and place within easy reach. Do not throw the shipping carton

away; instead use it as an elevated assembly surface.

_ . 7f

= .

?: ! > -N

'I

¢ 7 "_ ,I,

AR

41

6

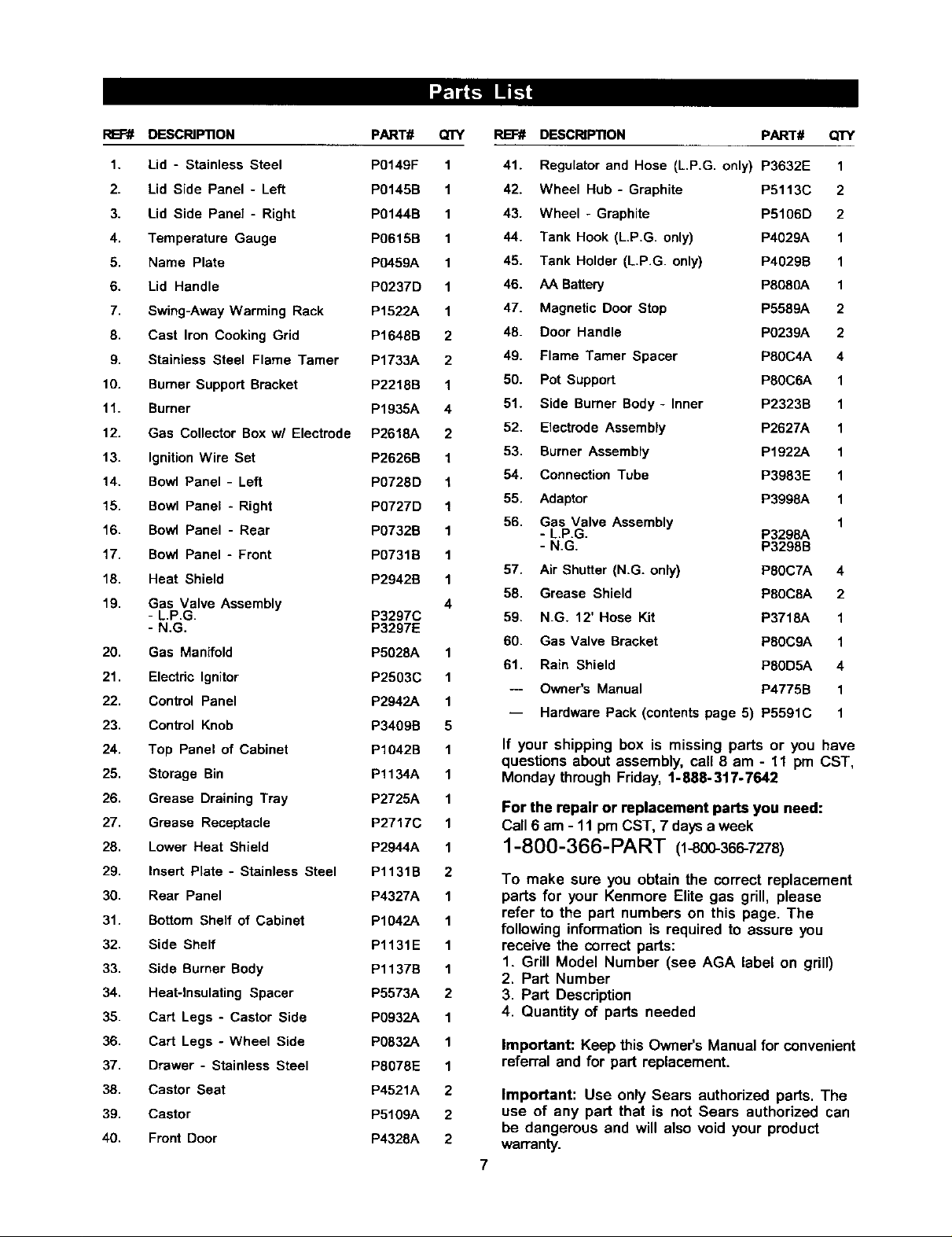

DESCRIPllON PART# QI"Y RE_# DESCRIPTION

PART# QTY

1. Lid - Stainless Steel P0149F 1

2. Lid Side Panel - Left PO145B 1

3. Lid Side Panel - Right PO144B 1

4. Temperature Gauge P0615B 1

5. Name Plate P0459A 1

6. Lid Handle P0237D 1

7. Swing-Away Warming Rack P1522A 1

8. Cast Iron Cooking Grid P1648B 2

9. Stainless Steel Flame Tamer P1733A 2

10. Burner Support Bracket P2218B 1

11. Burner P1935A 4

12. Gas Collector Box w/ Electrode P2618A 2

13. Ignition Wire Set P2626B 1

14. Bowl Panel - Left P0728D 1

15. Bowl Panel - Right P0727D 1

16. Bowl Panel - Rear P0732B 1

17. Bowl Panel - Front P0731B 1

18. Heat Shield P2942B 1

19. Gas Valve Assembly 4

- L.P.G. P3297C

- N.G. P3297F

20. Gas Manifold P5028A 1

21. Electric Ignitor P2503C 1

22. Control Panel P2942A 1

23. Control Knob P3409B 5

24. Top Panel of Cabinet P1042B 1

25. Storage Bin P1134A 1

26. Grease Draining Tray P2725A 1

27. Grease Receptacle P2717C 1

28. Lower Heat Shield P2944A 1

29. Insert Plate - Stainless Steel P1131B 2

30. Rear Panel P4327A 1

31. Bottom Shelf of Cabinet P1042A 1

32. Side Shelf P1131E 1

33. Side Burner Body P1137B 1

34. Heat-Insulating Spacer P5573A 2

35. Cart Legs - Castor Side P0932A 1

36. Cart Legs - Wheel Side P0832A 1

37. Drawer - Stainless Steel PS078E 1

38. Castor Seat P4521A 2

39. Castor P5109A 2

40. Front Door P4328A 2

41. Regulator and Hose (L.P.G. only) P3632E 1

42. Wheel Hub - Graphite P5113C 2

43. Wheel - Graphite P5106D 2

44. Tank Hook (L.P.G. only) P4029A 1

45. Tank Holder (L.P.G. only) P4029B 1

46. AA Battery P8080A 1

47. Magnetic Door Stop P5589A 2

48. Door Handle P0239A 2

49. Flame Tamer Spacer PSOC4A 4

50. Pot Support P80C6A 1

51. Side Burner Body - Inner P2323B 1

52. Electrode Assembly P2627A 1

53. Burner Assembly P1922A 1

54. Connection Tube P3983E 1

55. Adaptor P3998A 1

56. Gas Valve Assembly 1

- L.P.G. P3298A

- N.G. P3298B

57. Air Shutter (N.G. only) P80C7A 4

58. Grease Shield P80CSA 2

59. N.G. 12' Hose Kit P3718A 1

60. Gas Valve Bracket P80C9A 1

61. Rain Shield P80D5A 4

-- Owner's Manual P4775B 1

-- Hardware Pack (contents page 5) P5591C 1

If your shipping box is missing parts or you have

questions about assembly, call 8 am - 11 pm CST,

Monday through Friday, 1-888-317-7642

For the repair or replacement parts you need:

Call 6 am - 11 pm CST, 7 days a week

1-800-366-PART (1-800-366-7278)

To make sure you obtain the correct replacement

parts for your Kenmore Elite gas grill, please

refer to the part numbers on this page. The

following information is required to assure you

receive the correct parts:

1. Grill Model Number (see AGA label on grill)

2. Part Number

3. Part Description

4. Quantity of parts needed

Important: Keep this Owner's Manual for convenient

referral and for part replacement.

Important: Use only Sears authorized parts. The

use of any part that is not Sears authorized can

be dangerous and will also void your product

warranty.

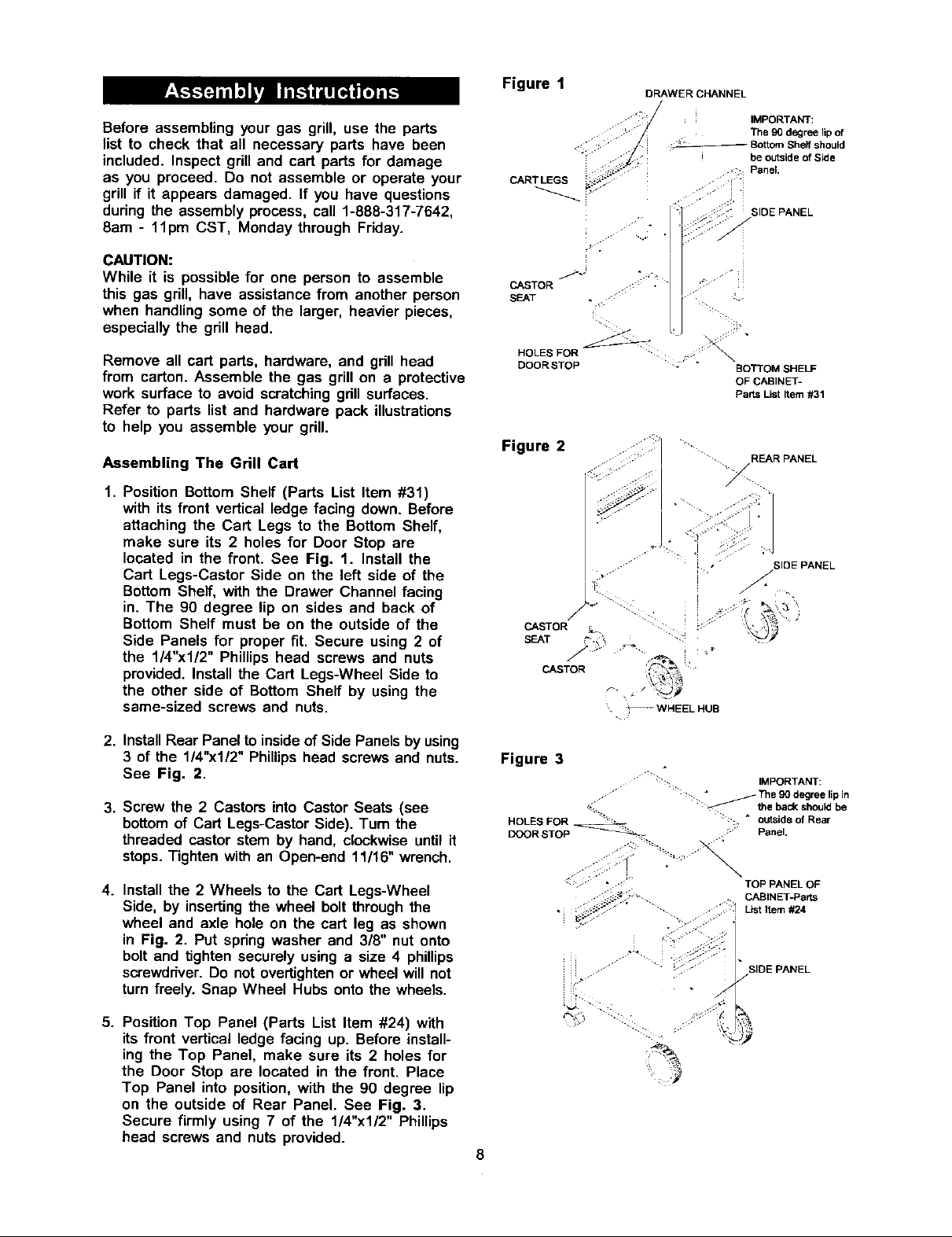

Figure 1

DRAWER CHANNEL

Beforeassemblingyourgas grill, use the parts

list to check that all necessary parts have been

included• Inspect grill and cart parts for damage

as you proceed• Do not assemble or operate your

grill if it appears damaged• If you have questions

during the assembly process, call 1-888-317-7642,

8am - 11pm CST, Monday through Friday•

CAUTION:

While it is possible for one person to assemble

this gas grill, have assistance from another person

when handling some of the larger, heavier pieces,

especially the grill head.

Remove all cart parts, hardware, and grill head

from carton. Assemble the gas grill on a protective

work surface to avoid scratching grill surfaces.

Refer to parts list and hardware pack illustrations

to help you assemble your grill•

Assembling The Grill Cart

1. Position Bottom Shelf (Parts List Item #31)

with its front vertical ledge facing down. Before

attaching the Cart Legs to the Bottom Shelf,

make sure its 2 holes for Door Stop are

located in the front. See Fig. 1. Install the

Cart Legs-Castor Side on the left side of the

Bottom Shelf, with the Drawer Channel facing

in. The 90 degree lip on sides and back of

Bottom Shelf must be on the outside of the

Side Panels for proper fit. Secure using 2 of

the 1/4"x1/2" Phillips head screws and nuts

provided. Install the Cart Legs-Wheel Side to

the other side of Bottom Shelf by using the

same-sized screws and nuts.

- _.:_/ IMPORTANT:

._- The 90 degree lip of

• ./ _ Bottom Sheff should

- _/. i be outside of Side

CART LEGS _:_: i •

CASTOR ::: ,

SEAT • ,: ::

HOLES FOR

DOORSTOP J " BOTTOM SHELF

Figure 2

CASTOR _.. ..: •

SEAT ;-.'

;J; ' Panel.

SIDE PANEL

OF CABINET-

Parts List Item #31

REAR PANEL

' SIDE PANEL

CASTOR

• _WHEELHUB

2. InstallRear Panel to insideof Side Panels by using

3 of the 1/4"x1/2" Phillipshead screws and nuts.

See Fig. 2.

3. Screw the 2 Castors into Castor Seats (see

bottomof Cart Legs-Castor Side). Turn the

threaded castor stem by hand, clockwise until it

stops•Tighten with an Open-end 11/16" wrench.

4. Install the 2 Wheels to the Cart Legs-Wheel

Side, by inserting the wheel bolt through the

wheel and axle hole on the cart leg as shown

in Fig. 2. Put spring washer and 3/8" nut onto

bolt and tighten securely using a size 4 phillips

screwddver. Do not overtightan or wheel will not

turn freely. Snap Wheel Hubs onto the wheels•

5. Position Top Panel (Parts List Item #24) with

its front vertical ledge facing up. Before install-

ing the Top Panel, make sure its 2 holes for

the Door Stop are located in the front• Place

Top Panel into position, with the 90 degree lip

on the outside of Rear Panel. See Fig. 3.

Secure firmly using 7 of the 1/4"x1/2" Phillips

head screws and nuts provided•

Figure 3

IMPORTANT:

... " :" :-:. _ The 90 degree lip in

HOLES FOR < _..... :': " o_uesiLde(_ofheOUa_be

DOOR STOP _ ;'" Panel.

TOP PANEL OF

: ;:-" . . . CABINET-Parts

_;_-. . , List Item #24

-" SIDE PANEL

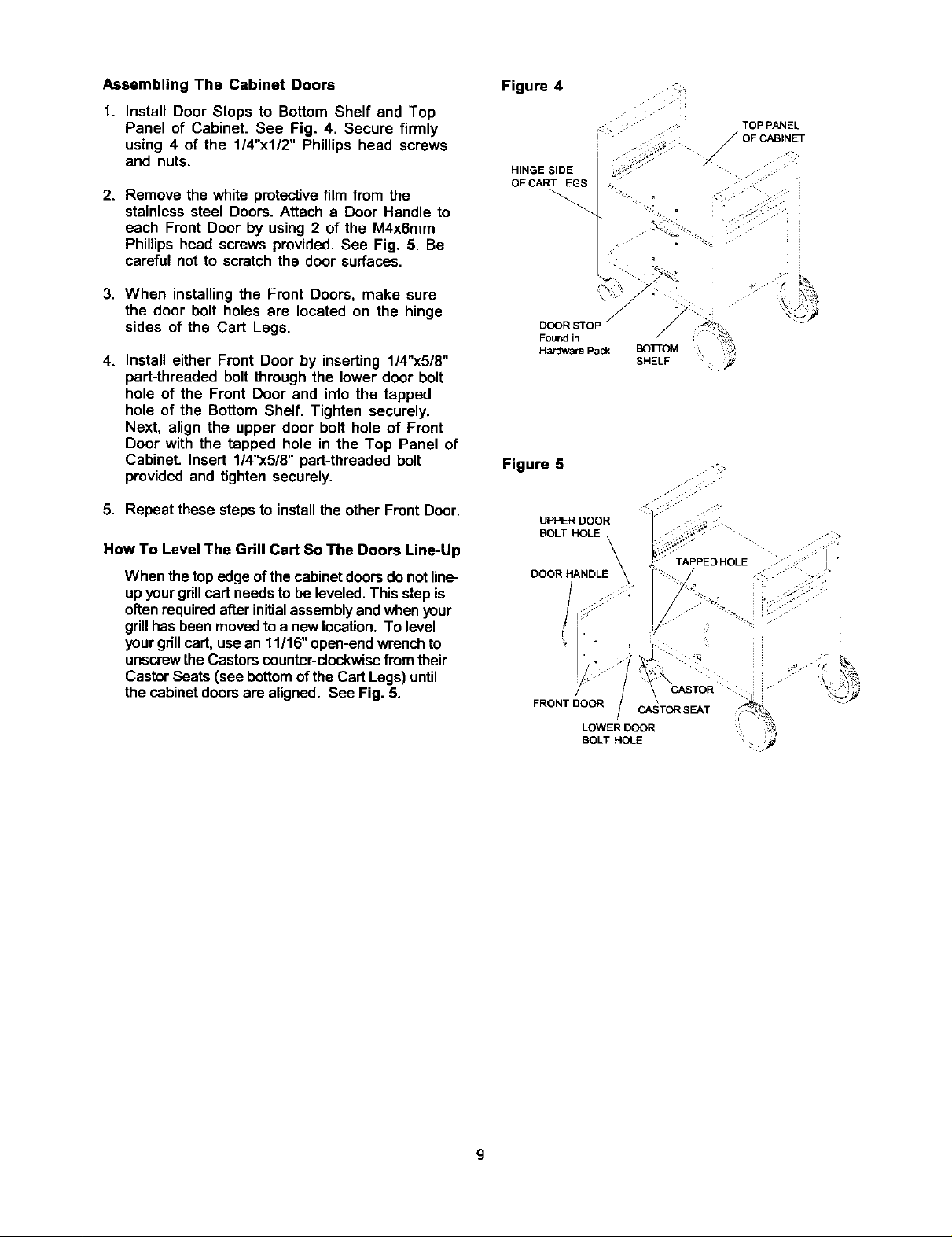

Assembling The Cabinet Doors

1. Install Door Stops to Bottom Shelf and Top

Panel of Cabinet. See Fig. 4. Secure firmly

using 4 of the 1/4"x1/2" Phillips head screws

and nuts.

2. Remove the white protective film from the

stainless steel Doors. Attach a Door Handle to

each Front Door by using 2 of the M4x6mm

Phillips head screws provided. See Fig. 5. Be

careful not to scratch the door surfaces.

3. When installingthe Front Doors, make sure

the door bolt holes are located on the hinge

sides of the Cart Legs.

4. Install either Front Door by inserting 1/4"x5/8"

part-threaded bolt through the lower door bolt

hole of the Front Door and into the tapped

hole of the Bottom Shelf. Tighten securely.

Next, align the upper door bolt hole of Front

Door with the tapped hole in the Top Panel of

Cabinet. Insert 1/4"x5/8" part-threaded bolt

provided and tighten securely.

Figure 4

DOOR STO D

Found in

Figure 5

.,.J..

f

TOP PANEL

• OF CABINET

/

/

SHELF

5. Repeat these stepsto installthe other Front Door.

How To Level The Grill Cart So The Doors Line-Up

When the top edge of the cabinetdoorsdo not line-

up yourgdllcart needsto be leveled. Thisstep is

oftenrequiredafterinitialassemblyandwhenyour

grillhas been movedtoa newlocation. To level

yourgrillcart,usean 11/16"open-endwrenchto

unscrewthe Castorscounter-clockwisefrom their

CastorSeats (see bottomofthe Cart Legs) until

the cabinet doorsare aligned. See Fig. 5.

UPPER DOOR

ZL\

TAPPED HOLE

,- j,

.':_ >

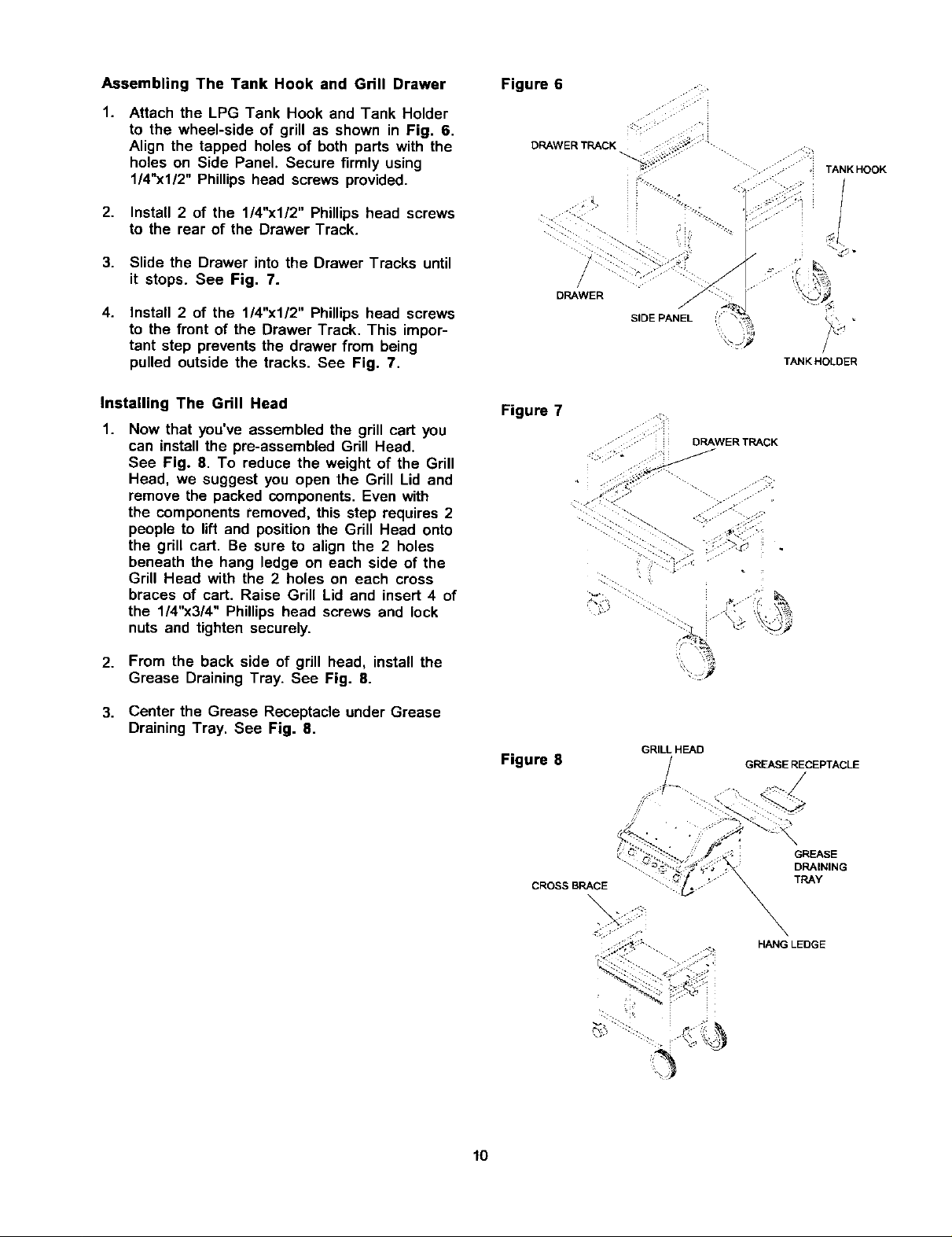

Assembling The Tank Hook and Grill Drawer

1.

Attach the LPG Tank Hook and Tank Holder

to the wheel-side of grill as shown in Fig. 6.

Align the tapped holes of both parts with the

holes on Side Panel. Secure firmly using

1/4"xl/2" Phillips head screws provided.

2. Install 2 of the 1/4"x1/2" Phillips head screws

to the rear of the Drawer Track.

3. Slide the Drawer into the Drawer Tracks until

it stops. See Fig. 7.

4.

Install 2 of the 1/4"x1/2" Phillips head screws

to the front of the Drawer Track. This impor-

tant step prevents the drawer from being

pulled outside the tracks. See Fig. 7.

Figure 6

DRAWER TRACK

TANK HOOK

DRAWER

SIDE PANEL

TANK HOLDER

Installing The Grill Head

1.

Now that you've assembled the grill cart you

can install the pre-assembled Grill Head.

See Fig. 8. To reduce the weight of the Grill

Head, we suggest you open the Grill Lid and

remove the packed components. Even with

the components removed, this step requires 2

people to lift and position the Grill Head onto

the grill cart. Be sure to align the 2 holes

beneath the hang ledge on each side of the

Grill Head with the 2 holes on each cross

braces of cart. Raise Grill Lid and insert 4 of

the 1/4"x3/4" Phillips head screws and lock

nuts and tighten securely.

2. From the back side of grill head, install the

Grease Draining Tray. See Fig. 8.

3. Center the Grease Receptacle under Grease

Draining Tray. See Fig. 8.

Figure 7

Figure 8

CROSS BRACE

DRAWER TRACK

.... •••,

GRILL HEAD

GREASE RECEPTACLE

GREASE

DRAINING

TRAY

10

HANG LEDGE

Loading...

Loading...