OWNER'S MANUAL

SEWING MACHINE

MODEL 1340 / 1345 / 1350 / 1355 / 1358

1561/1595

69548

.

KNOWING YOUR SEWING MACHINE

Machine identification .............................................. 2 -3

Parts list................................................................ 4- 5

Setting up your machine ................. :........................... 6

Spool pins, Foot control, Light/power switch

Installing extension table ............................................. 6

Winding bobbin ........................................................ 7

Removing bobbin case from shuttle ............................... 8

Inserting bobbin into bobbin case .................................. 9

Inserting bobbin case into shuttle .................................. 9

Threading top th read .................................................. 10

Picking up bobbin thread ............................................. 11

CONTROLS

Thread tension control ................................................ 12

Stitch selector, Stitch length control .............................. 13

Reverse stitch control, Pressure regulator ........................ 14

Seam guides, Presser foot lever, Feed dog control ............. 15

ACCESSORIES

Needles ................................................................... 16

Placement of needle ................................................... 16

Needle, thread and fabric chart ..................................... 17

Feed cover plate, Presser feet ...................................... 18

CARING FOR THE MACHINE

Cleaning feed dogs and shuttle ..................................... 19

Oiling ................................................................ 20 - 21

Changing light bulb .................................................... 21

CHECKING PERFORMANCE PROBLEMS ............. 22-23

2_

STARTING TO SEW ............................................... 24

Straight stitching ................................................. 25 - 27

Fastening a seam, Turning a square corner,

Removing fabric, Top stitching, Darning,

Temporary sewing by machine, Zipper application-Cording

Zigzag stitching ................................................... 28 - 30

Checking thread tension, Overcasting, Satin stitching,

Bar tacking, Appliqueing, Button sewing

Blind Hemming ................................................... ;..... 31

Mending and overcast stitching (three-step zigzag) ............ 32

Shell stitching ........................................................... 33

Box stitch ................................................................ 34

Stretch stitches ................................................... 35- 38

Adjusting stitch length, Straight stretch stitch,

Rick-rack stretch, Smocking stretch, Overcast stretch,

Serging {or pine leaf) stretch, Elastic stretch

Where to use which stretch stitch: A check-chart .............. 39

Buttonhole making ............................................... 40 - 47

Free-arm sewing ........................................................ 48

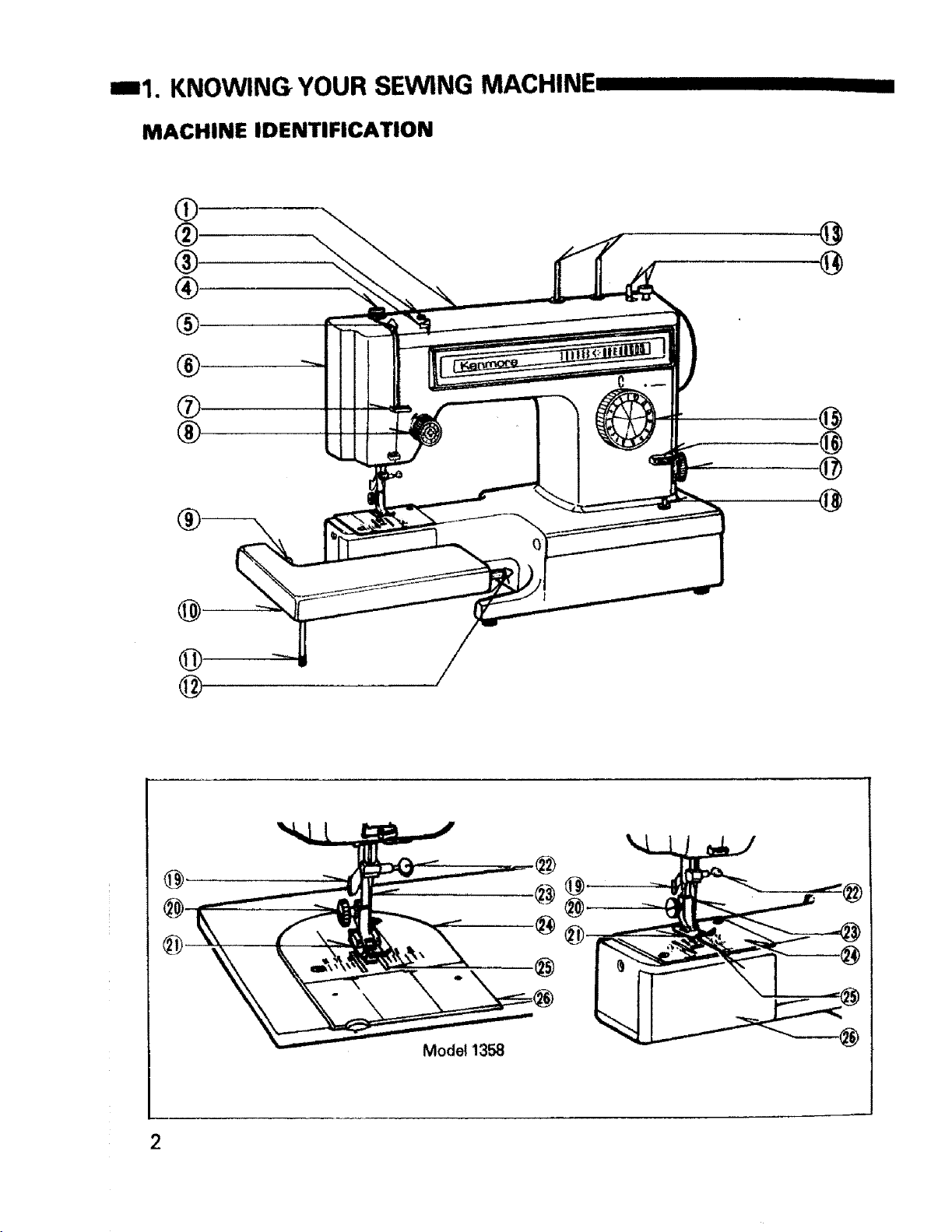

==1. KNOWING YOUR SEWING MACHINE

MACHINE IDENTIFICATION

O

®.

®

®

IIII IIIIII IIIII

@

@

®

@

@

@

Model 1358

2

Model 1595

I IIIIIIIII IIIII II I IIIII IIII III

®

1. Top cover

2. Bobbin winder tension disc

3. Thread guide

4, Pressure regulator

5. Take-up lever

6. Face cover

7, Face cover thread guide

8, Top thread tension control

9. Guide pin

10, Extension table

11. Support leg

12, Guide pin

13. Spool pins

14. Bobbin winder

15. Stitch selector

16. Reverse stitch lever

17. Stitch length dial

.@

18. Light/power switch

19. Thread cutter

20. Presser foot thumb screw

21. Presser foot

_. Needle clamp screw

23. Needle

24, Needle plate

25. Feed dogs

26. Shuttle cover

27. Hand wheel

28. Clutch knob

29. Nomenclature plate

30, Electric cord receptacle

31. Presser foot lever

32. Foot control

33. Accessory box

34. Owner's manual

I

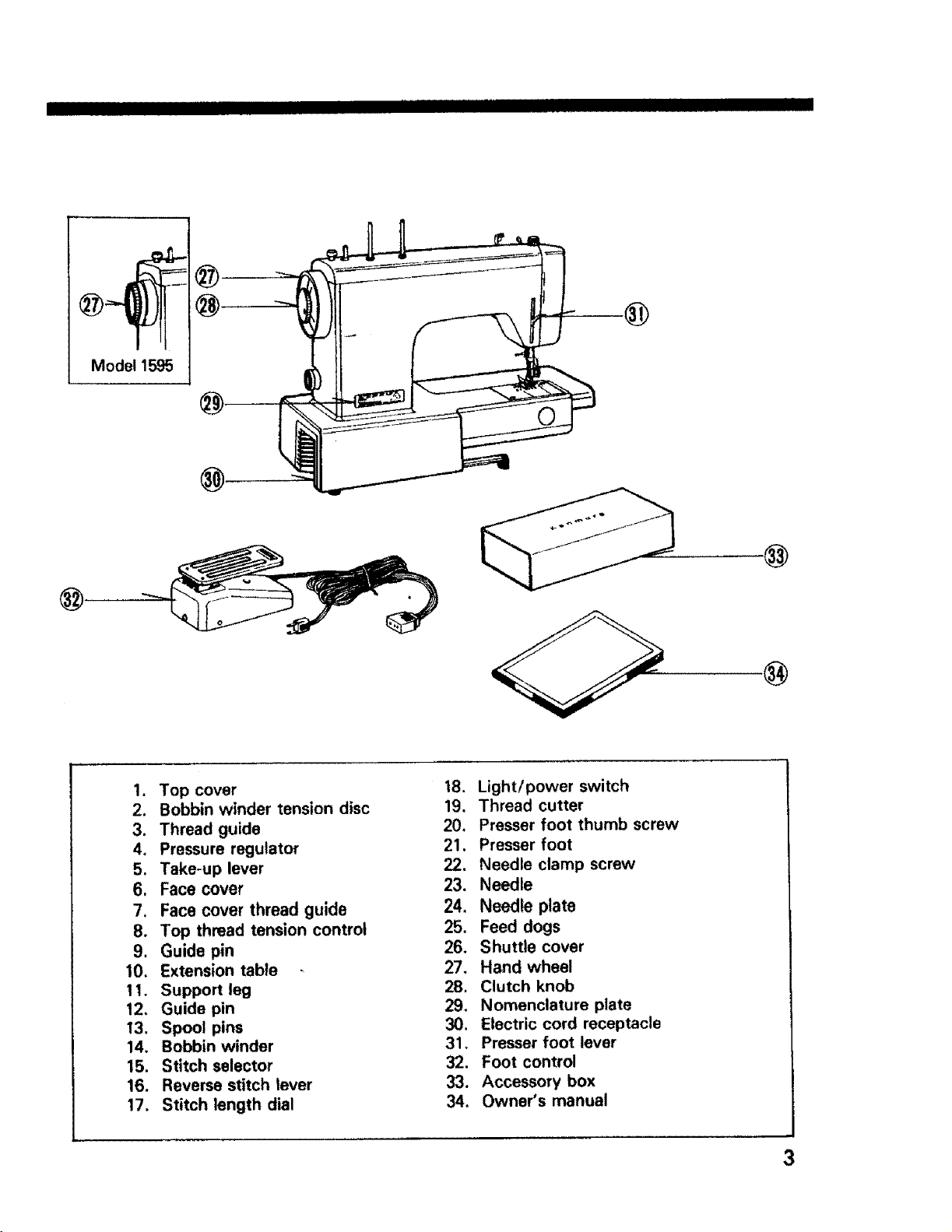

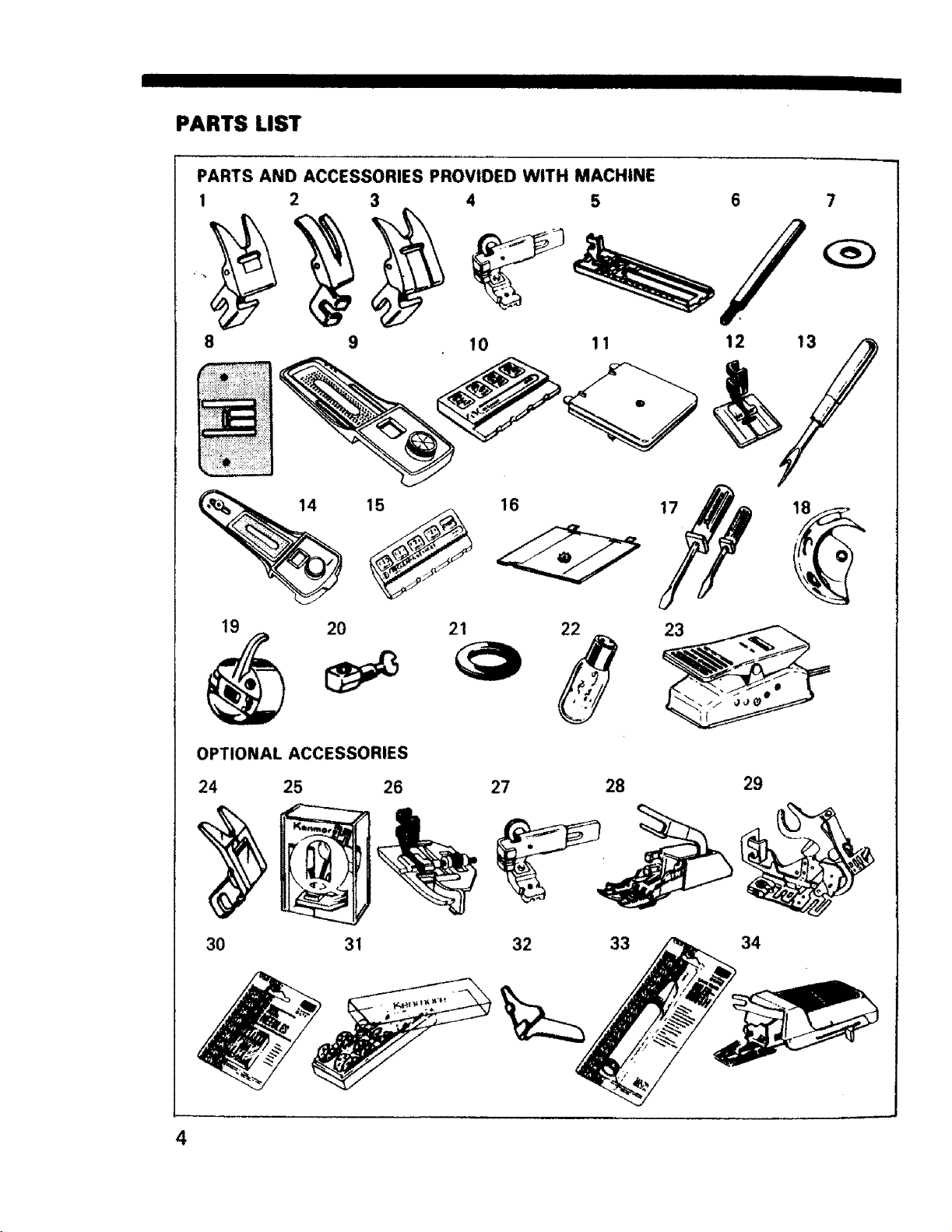

PARTS LIST

PARTS AND ACCESSORIES PROVIDED WITH MACHINE

1

2 4

IIIIIII

6

8

15

19

OPTIONAL ACCESSORIES

24 25 26

20 21

10

16

27 28

11

12 13

23

29

30 31

4

32 33

34

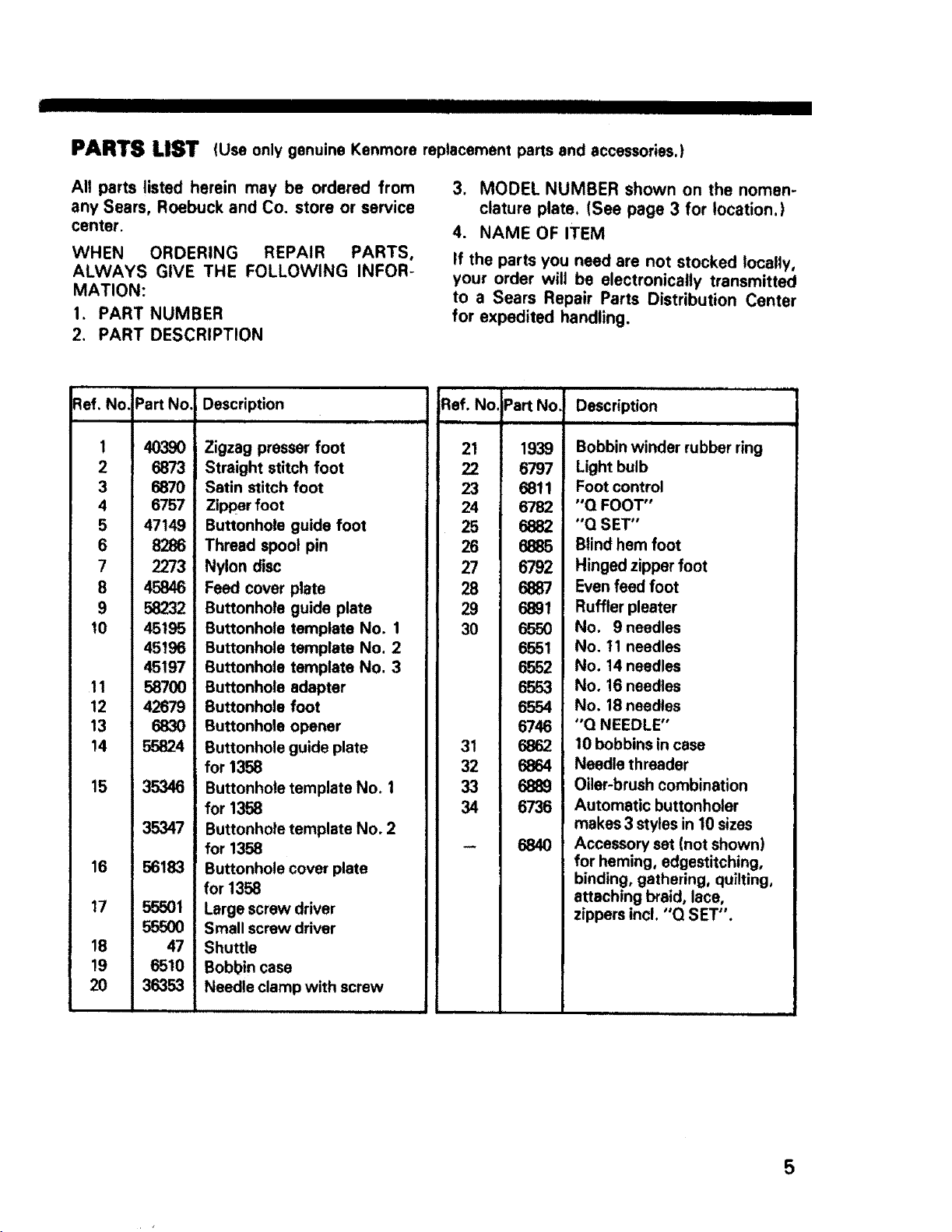

PARTS LIST (Useonly genuine Kenmore replacement parts and accessories,)

All parts listed herein may be ordered from

any Sears, Roebuck and Co. store or service

center.

WHEN ORDERING REPAIR PARTS,

ALWAYS GIVE THE FOLLOWING INFOR-

MATION:

1. PART NUMBER

2. PART DESCRIPTION

_lef. NO,

11

10

12

13

14

15

16

17

18

19

2O

2

3

4

5

6

7

8

9

1

Part No.

40390

6873

6870

6757

47149

8286

2273

45846

58232

45195

45196

45197

58700

42679

6830

55824

35346

35347

68183

55501

47

6510

36353

Description

Zigzag presser foot

Straight stitch foot

Satin stitch foot

Zipper foot

Buttonhole guide foot

Thread spool pin

Nylon disc

Feed cover plate

Buttonhole guide plate

Buttonhole template No. 1

Buttonhole template No. 2

Buttonhole template No. 3

Buttonhole adapter

Buttonhole foot

Buttonhole opener

Buttonhole guide plate

for 1358

Buttonhole template No. 1

for 1358

Buttonhole template No. 2

for 1368

Buttonhole cover plate

for 1358

Large screw driver

Small screw driver

Shuttle

Bobbin case

Needle clamp with screw

3. MODEL NUMBER shown on the nomen-

clature plate. (See page 3 for location.)

4. NAME OF ITEM

If the parts you need are not stocked locally,

your order will be electronically transmitted

to a Sears Repair Parts Distribution Center

for expedited handling.

RefoNo.

Part No. Description

21

23

24

25

26

27

28

29

30

31

32

33

34

1939 Bobbin winder rubber ring

6797 Light bulb

6811 Foot control

6782 "Q FOOT"

6882 "Q SET"

6885 Blind hem foot

6792 Hinged zipper foot

6887 Even feed foot

6891 Ruffler pleater

6550 No. 9 needles

6551 No. 11 needles

6552 No. 14 needles

6553 No. 16 needles

6554 No. 18 needles

6746 "Q NEEDLE"

6862 10 bobbins in case

6864 Needle threader

6889 Oiler-brush combination

6736 Automatic buttonholer

6840 Accessory set (not shown)

iiiiii i ii i i

makes 3 styles in 10 sizes

for heming, edgestitching,

binding, gathering, quilting,

attaching braid, lace,

zippers incl. "Q SET".

5

• I IIIIIIIIIIIIIIIIIIIII J

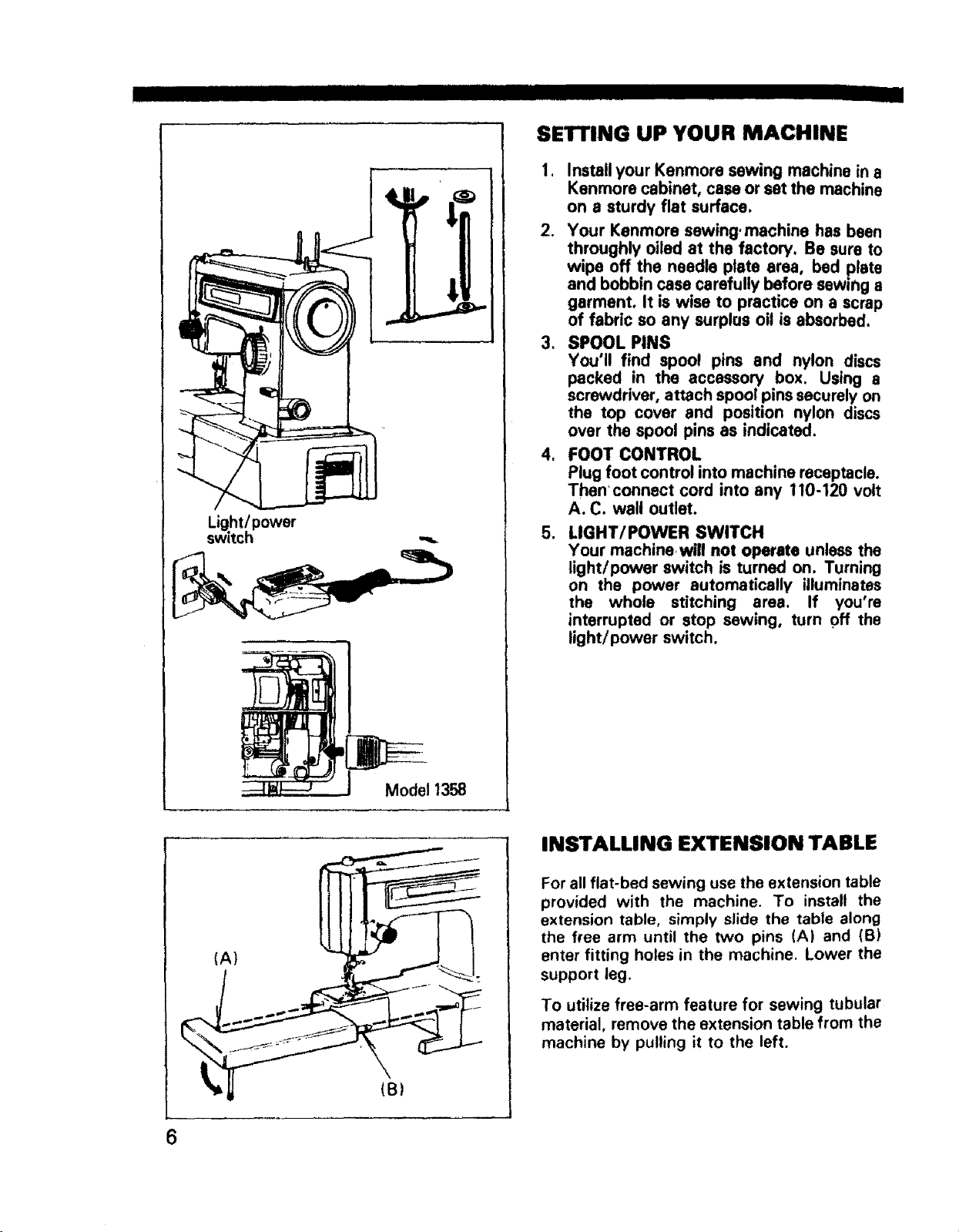

SETTING UP YOUR MACHINE

1. Install your Kenmore sewing machine in a

Kenmore cabinet, case or set the machine

on a sturdy flat surface.

2. Your Kenmore sewing, machine has been

throughly oiled at the factory. Be sure to

wipe off the needle plate area, bed plate

and bobbin case carefully before sewing a

garment, It is wise to practice on a scrap

of fabric so any surplus oil is absorbed,

3. SPOOL PINS

You'll find spool pins and nylon discs

packed in the accessory box. Using a

screwdriver, attach spool pins securely on

the top cover and position nylon discs

over the spool pins as indicated.

4. FOOT CONTROL

Plug foot control into machine receptacle.

Then connect cord into any 110-120 volt

A. C. wall outlet,

Light(power

switch

5. LIGHT/POWER SWITCH

Your machine will not operate unless the

light/power switch is turned on. Turning

on the power automatically illuminates

the whole stitching area. If you're

interrupted or stop sewing, turn off the

light/power switch.

(A)

Model 1358

INSTALLING EXTENSION TABLE

For all fiat-bed sewing use the extension table

provided with the machine. To install the

extension table, simply slide the table along

the free arm until the two pins (A) and (B)

enter fitting holes in the machine, Lower the

support leg.

To utilize free-arm feature for sewing tubular

material, remove the extension table from the

machine by pulling it to the left.

II IH II H IIIIII I I IIIIIIIIIIIIIIIIIIIIIIIIHIIIIIHII

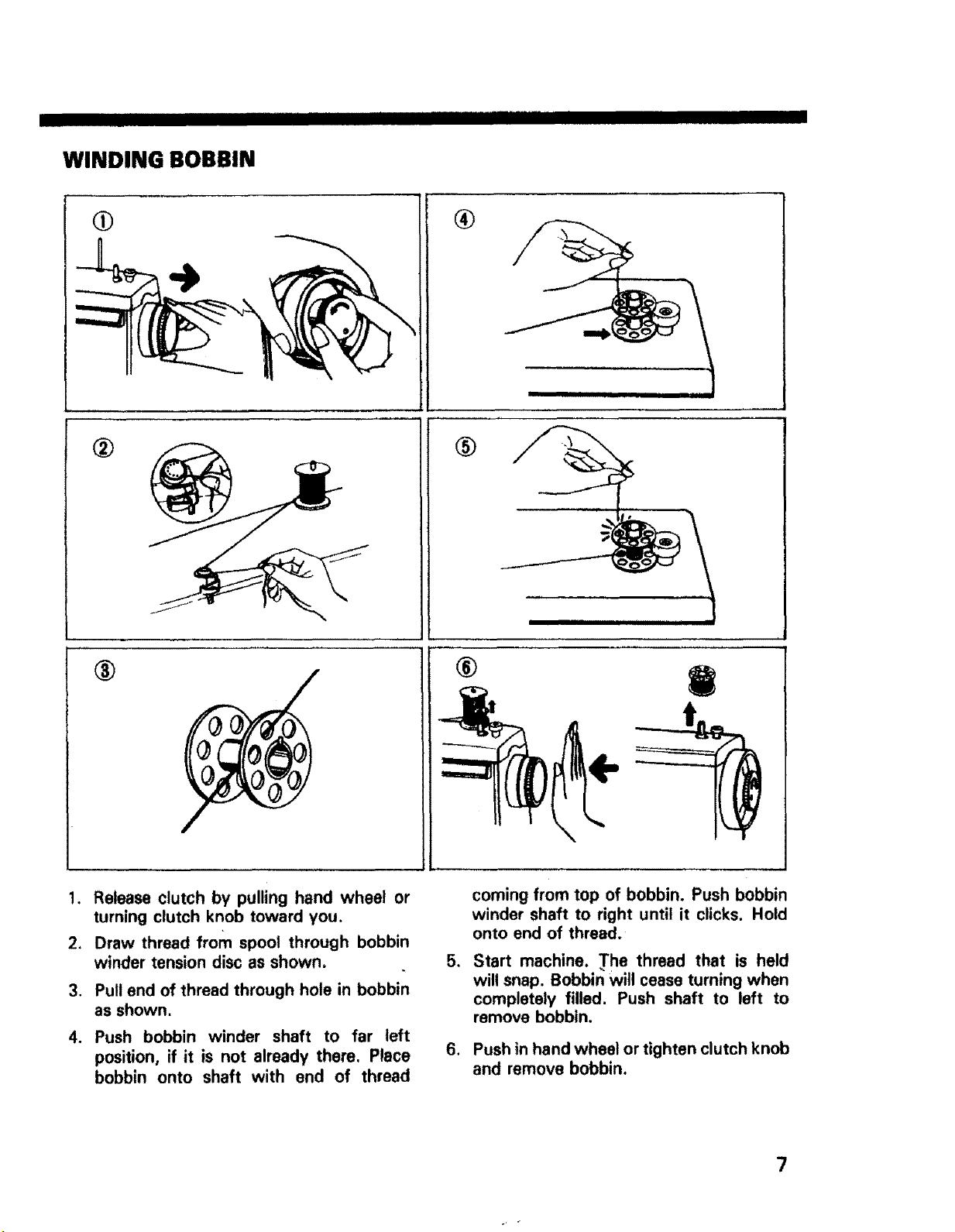

WINDING BOBBIN

O

®

®

®

i I i t

®

!. Release clutch by pulling hand wheel or

turning clutch knob toward you.

2. Draw thread from spool through bobbin

winder tension disc as shown.

3. Pull end of thread through hole in bobbin

as shown.

4. Push bobbin winder shaft to far left

position, if it is not already them. Place

bobbin onto shaft with end of thread

coming from top of bobbin. Push bobbin

winder shaft to right until it clicks. Hold

onto end of thread.

5.

Start machine. The thread that is held

will snap. Bobbin will cease turning when

completely filled. Push shaft to left to

remove bobbin.

,

Push in hand wheel or tighten clutch knob

and remove bobbin.

7

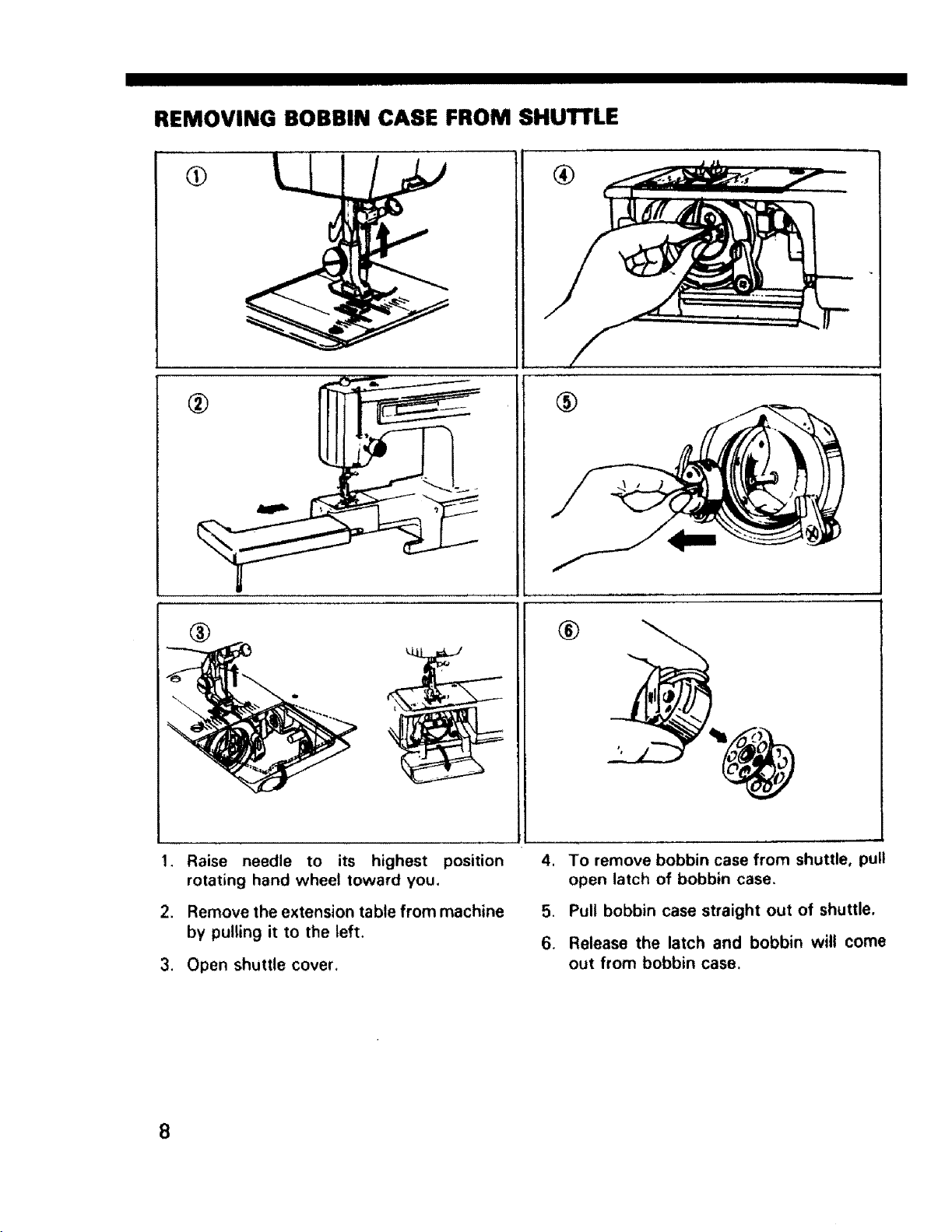

REMOVING BOBBIN CASE FROM SHUTTLE

®

®

1, Raise needle to its highest position 4.

rotating hand wheel toward you.

2. Remove the extension table from machine 5.

by pulling it to the left.

3. Open shuttle cover.

®

To remove bobbin case from shuttle, pull

open latch of bobbin case.

Pull bobbin case straight out of shuttle.

6.

Release the latch and bobbin wilt come

out from bobbin case.

8

I IIII IMH

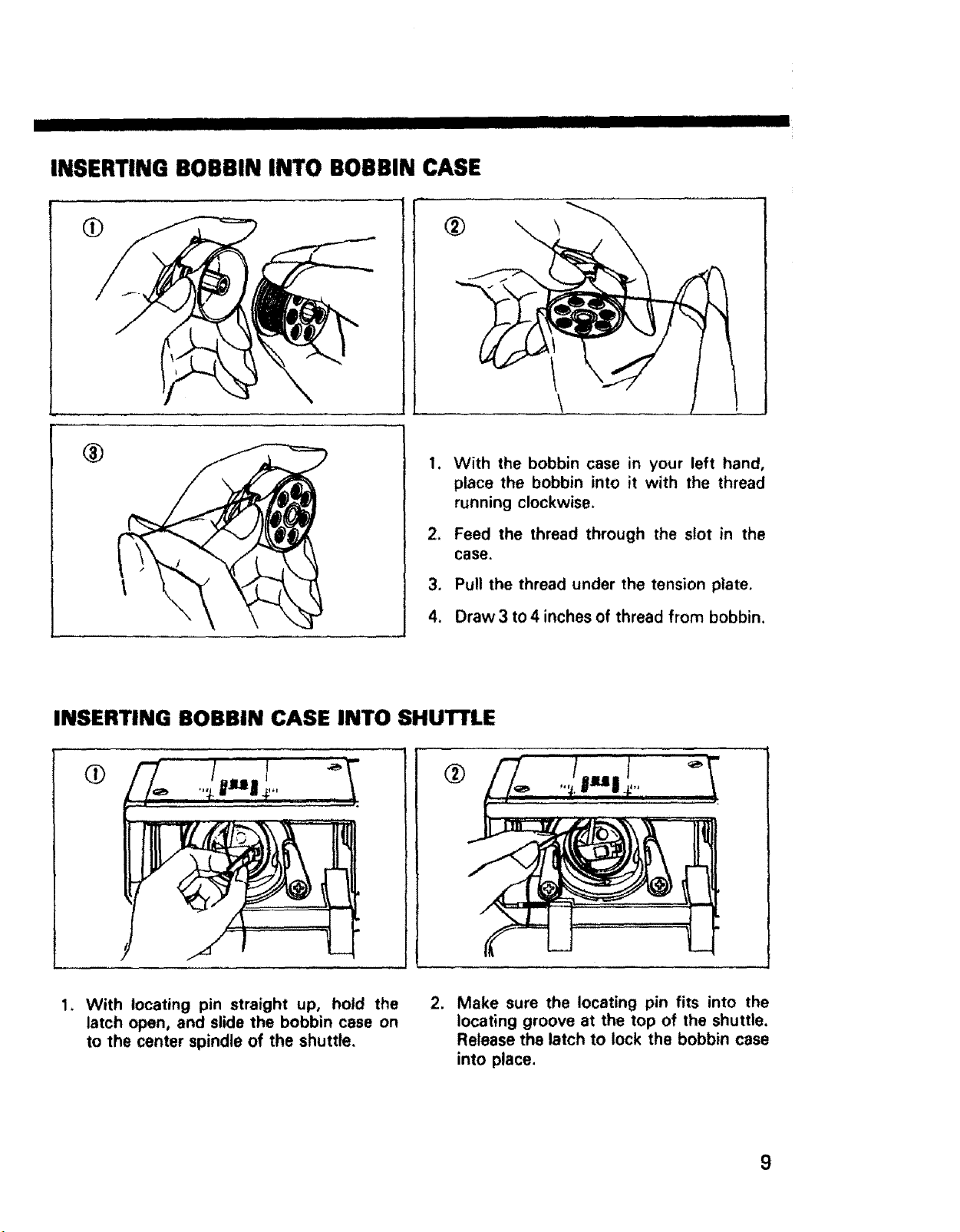

INSERTING BOBBIN INTO BOBBIN CASE

I HI I II

®

,

With the bobbin case in your left hand,

place the bobbin into it with the thread

running clockwise.

*

Feed the thread through the slot in the

case.

3.

Pull the thread under the tension plate.

4.

Draw 3 to 4 inches of thread from bobbin,

INSERTING BOBBIN CASE INTO SHUTTLE

i

With locating pin straight up, hold the

latch open, and slide the bobbin case on

to the center spindle of the shuttle.

.

Make sure the locating pin fits into the

locating groove at the top of the shuttle.

Release the latch to lock the bobbin case

into place.

9

IIIIIIII IIIII IIIII I IIII IIIIIIIIIIIIIIIII

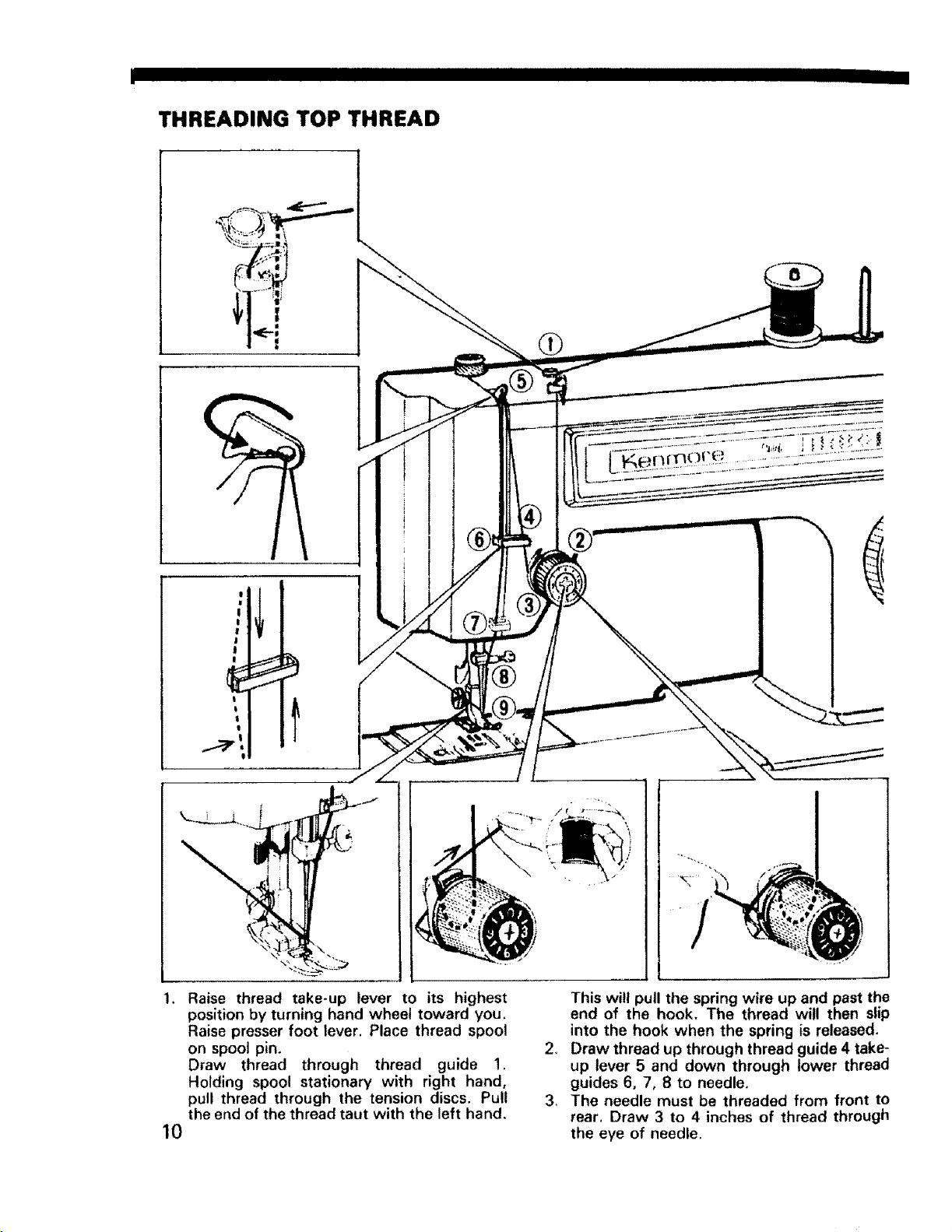

THREADING TOP THREAD

...........

Raise thread take-up lever to its highest

position by turning hand wheel toward you.

Raise presser foot lever. Place thread spool

on spool pin,

Draw thread through thread guide 1.

Holding spool stationary with right hand,

pull thread through the tension discs. Pull

the end of the thread taut with the left hand.

10

This will pull the spring wire up and past the

end of the hook. The thread will then slip

into the hook when the spring is released.

2_

Draw thread up through thread guide 4 take-

up lever 5 and down through lower thread

guides 6, 7, 8 to needle.

3_

The needle must be threaded from front to

rear, Draw 3 to 4 inches of thread through

the eye of needle.

.... IIIIIIIIIIIIII I IIIIIIIIIHIIIIIIIIIIIIIIIIIIIIIII I II I

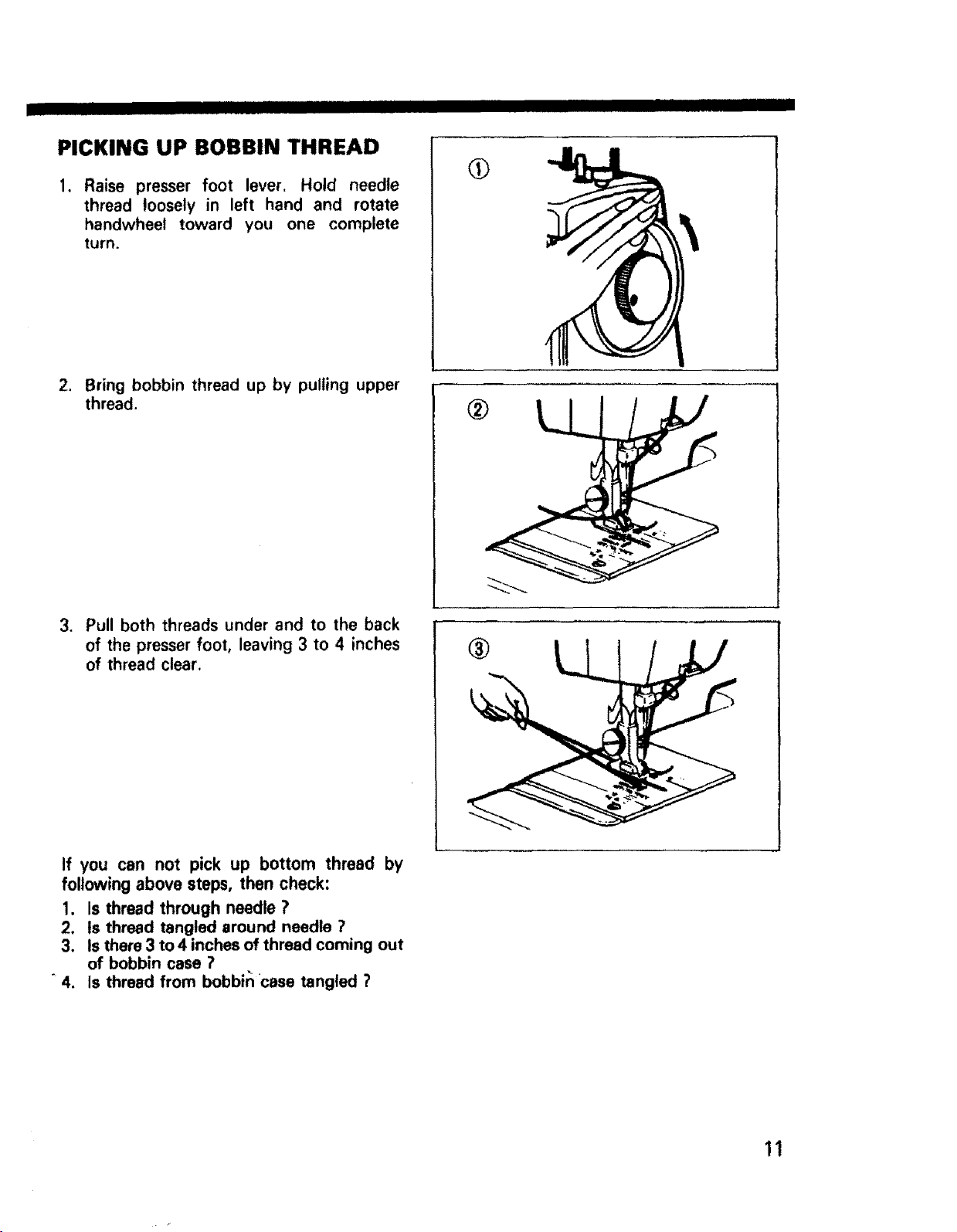

PICKING UP BOBBIN THREAD

1. Raise presser foot lever. Hold needle

thread loosely in left hand and rotate

handwheel toward you one complete

turn.

.

Bring bobbin thread up by pulling upper

thread.

®

3. Pull both threads under and to the back

of the presser foot, leaving 3 to 4 inches

of thread clear.

If you can not pick up bottom thread by

following above steps, then check:

1. Is thread through needle ?

2. Is thread tangled around needle ?

3. Is there 3 to 4 inches of thread coming out

of bobbin case ?

4. Is thread from bobbin case tangled ?

®

11

j IIIIII UlIHHHIIIIIII IIIIII

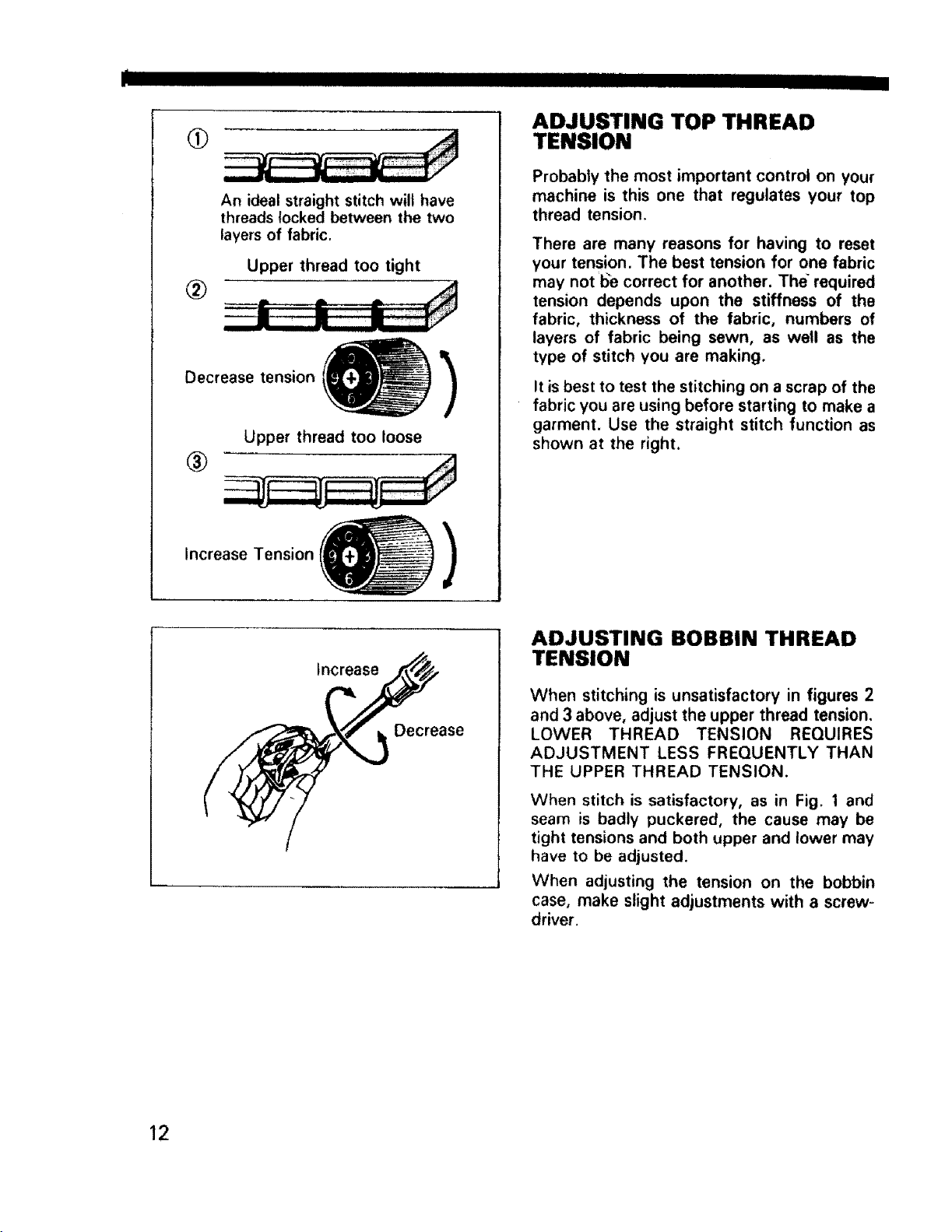

ADJUSTING TOP THREAD

q>

An ideal straight stitch will have

threads locked between the two

layers of fabric.

Upper thread too tight

®

Decrease tension

Upper thread too loose

TENSION

Probably the most important control on your

machine is this one that regulates your top

thread tension.

There are many reasons for having to reset

your tension. The best tension for one fabric

may not I_e correct for another. The required

tension depends upon the stiffness of the

fabric, thickness of the fabric, numbers of

layers of fabric being sewn, as well as the

type of stitch you are making.

It is best to test the stitching on a scrap of the

fabric you are using before starting to make a

garment. Use the straight stitch function as

shown at the right.

®

Increase Tension

Increase

)

Decrease

ADJUSTING BOBBIN THREAD

TENSION

When stitching is unsatisfactory in figures 2

and 3 above, adjust the upper thread tension.

LOWER THREAD TENSION REQUIRES

ADJUSTMENT LESS FREQUENTLY THAN

THE UPPER THREAD TENSION.

When stitch is satisfactory, as in Fig. 1 and

seam is badly puckered, the cause may be

tight tensions and both upper and lower may

have to be adjusted.

When adjusting the tension on the bobbin

case, make slight adjustments with a screw-

driver.

12

I I ! III I

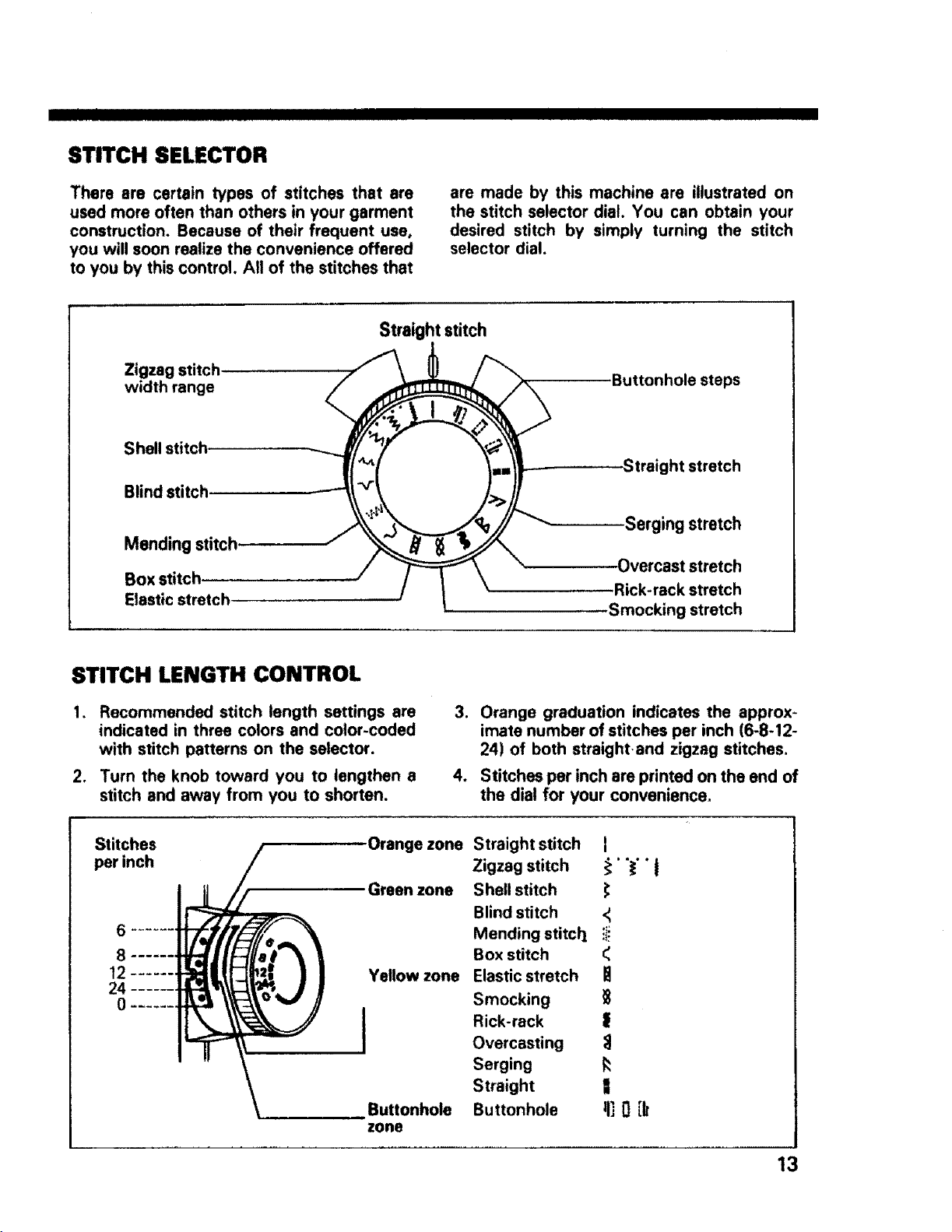

STITCH SELECTOR

There are certain types of stitches that are

used more often than others in your garment

construction. Because of their frequent use,

you will soon realize the convenience offered

to you by this control. All of the stitches that

Straight stitch

Zigzag stitch.

width range

Shell stitch

Blind 1

Mending stitch

Elastic stretch

are made by this machine are illustrated on

the stitch selector dial. You can obtain your

desired stitch by simply turning the stitch

selector dial.

Buttonhole steps

Straight stretch

Serging stretch

stretch

Rick-rack stretch

Smocking stretch

STITCH LENGTH CONTROL

.

Recommended stitch length settings are

indicated in three colors and color-coded

with stitch patterns on the selector.

,

Turn the knob toward you to lengthen a

stitch and away from you to shorten.

Stitches Orange zone

per inch

Green zone

6

8

t2 Yellow zone

24

° I

Buttonhole

zone

3. Orange graduation indicates the approx-

imate number of stitches per inch (6-8-12-

24) of both straight.and zigzag stitches.

4. Stitches per inch are printed on the end of

the dial for your convenience,

Straight stitch [

Zigzag stitch i' '_'" J

Shell stitch

Blind stitch <_

Mending stitcll iii

Box stitch

Elastic stretch

Smocking

Rick-rack |

Overcasting :_

Serging _:

Straight |

Buttonhole II] 0 [k

13

I I ]11[11!11111111IIII

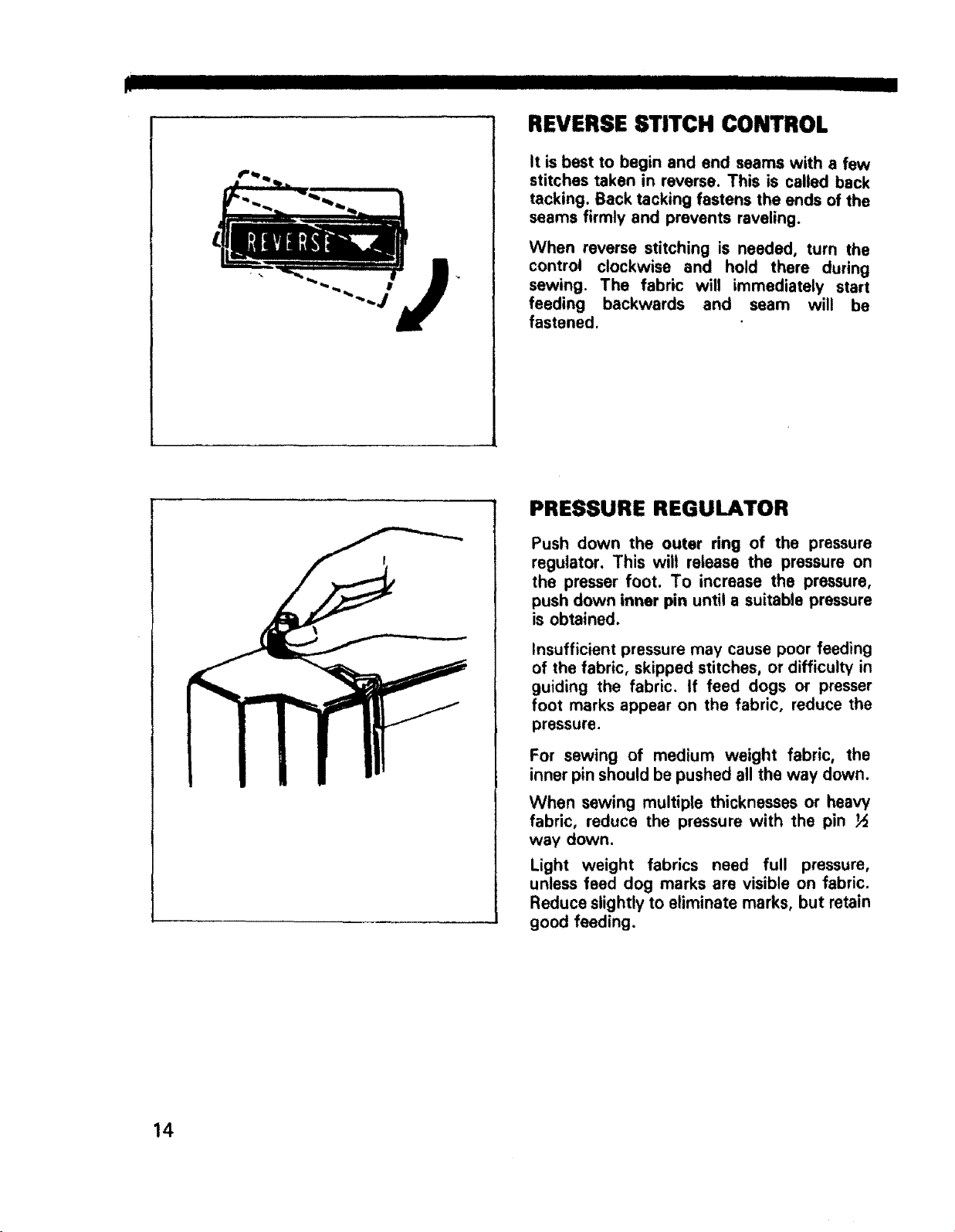

REVERSE STITCH CONTROL

It is best to begin and end seams with a few

stitches taken in reverse. This is called back

tacking. Back tacking fastens the ends of the

seams firmly and prevents raveling.

When reverse stitching is needed, turn the

control clockwise and hold there during

sewing. The fabric will immediately start

J

feeding backwards and seam will be

fastened.

PRESSURE REGULATOR

Push down the outer ring of the pressure

regulator. This will release the pressure on

the presser foot. To increase the pressure,

push down inner pin until a suitable pressure

is obtained.

insufficient pressure may cause poor feeding

of the fabric, skipped stitches, or difficulty in

guiding the fabric. If feed dogs or presser

foot marks appear on the fabric, reduce the

pressure.

For sewing of medium weight fabric, the

inner pin should be pushed all the way down.

When sewing multiple thicknesses or heavy

fabric, reduce the pressure with the pin ½

way down.

Light weight fabrics need full pressure,

unless feed dog marks are visible on fabric.

Reduce slightly to eliminate marks, but retain

good feeding.

14

Loading...

Loading...