Kenmore 117.552, 117.812, 117.813, 117.560 Instructions Manual

%j4.4Z

OWNt

1

0-4

Cet’tijficate

the

guarantee

We

ing

head

family

workmanship

and

date

from

prove

parts

manship,

machine

the

or

Simpsons-Sears

returning

securely.

parts

or

from

cluded

further

We

be

date

When

ing

model

We

to

any

sewing

in.

the

For

machine

free

of

us

do

make

liability

Any

foregoing

ready

Model

Cabinet

from

referring

number.

not

this

of

to

use

purchase.

of

to

they

toamail

(Needles,

which

the

guarantee

defects

purchase.

about

authorize

any

other

in

machine

agreements

reference

this

on

No.

Model

ond

to

machine

be

free

for

defective

be

will

be

is

returned

retail

order

belts,

wear

out

guarantee.)

for

this

to

your

machine,

any

guarantee

connection

other

shallbevoid

page.

No.

SEARS,

SIMPSONS-SEARS

cjf

original

when

from

a

period

the

In

replaced

to

or

store,

bobbins,

from

all

electrical

period

a

guarantee

person

with

those

than

outside

and

record

ROEBUCK

iatan

purchaser

used

defects

of

twenty

event

material

free

the

order

be

natural

of

always

or

to

or

the

contained

or

contradictory

of

number

Read

Date

that

nearest

sure

shuttles,

equipment

one

or

representative

assume

no

in

mail

the

tee

the

for

normal

in

material

working

or

of

charge

store.

and

are

use

year

when

mention

for

sale

of

effect.

of

Serial

Delivered

AND

LIMITED

sew

years

work

Sears

pack

bulbs,

ex

from

writ

the

this

here

your

No.

CO.

We

in

service.

carefully

yourself

over

of

tighten

cord

Unwind

into

drive

Book

directions

are

machine

this

even

other

cabinet

round

cut-out

head

near

as

cord

back

the

any

operation.

for

merely

pulley

connections.

TO

11

extremely

Therefore

and

with

though

make.

Head

and

shanks

in

hinge

into

into

extension

base

IMPOR

AND

top

to

slot

12.

for

thor

the

you

slide

the

hole

plug

place

as

re

of

of

set

at

of

This

Object

The

sewing

this

your

to

order

this

head

lug

head

2)

possible

plate

(see

the

the

around

is

you

in

read

sewing

holes

attached

securely.

up

cabinet,

machine

is

no

provide

In

is

—

operating

anxious

turns

you

oughly

if

In

to

us

to

a

operation

tony

head

the

cabinet.

screws

motor

edge

in

cord

outlet,

leather

course

GIVE

TANT

that

the

urged

are

iii

be

accustomed

To

Install

the

luee

hinge

hinges

two

Tip

(Fig.

bushing

Pull

as

bed

of

plate

bed

inside

and

machine

If

belt

there

PARTICULAR

INFORMATION

e

utmost

of

of

with

machine.

investment

satisfactory

this

familiarize

to

to

machine,

using

Sewing

On

Cabinet

top

on

(Fig.

to

and

back

motor

on

and

slip

push

and

Fig.

9).

is

treadle

hand

or

motor

IMPORTANT

ATTENTION

ON

complete

book

some

Machine

of

open

2)

back

motor

bushing

plug

ready

operated,

wheel

electrical

PAGES

A

needs

sary

wear

Oil

which

Depending

mines

the

occasional

trations

sewing

oiling

holes

cannot

oiling

drop

shown.

machine,

to

insure

of

the

are

provided

be

on

requirements.

of

parts

directly

how

oil

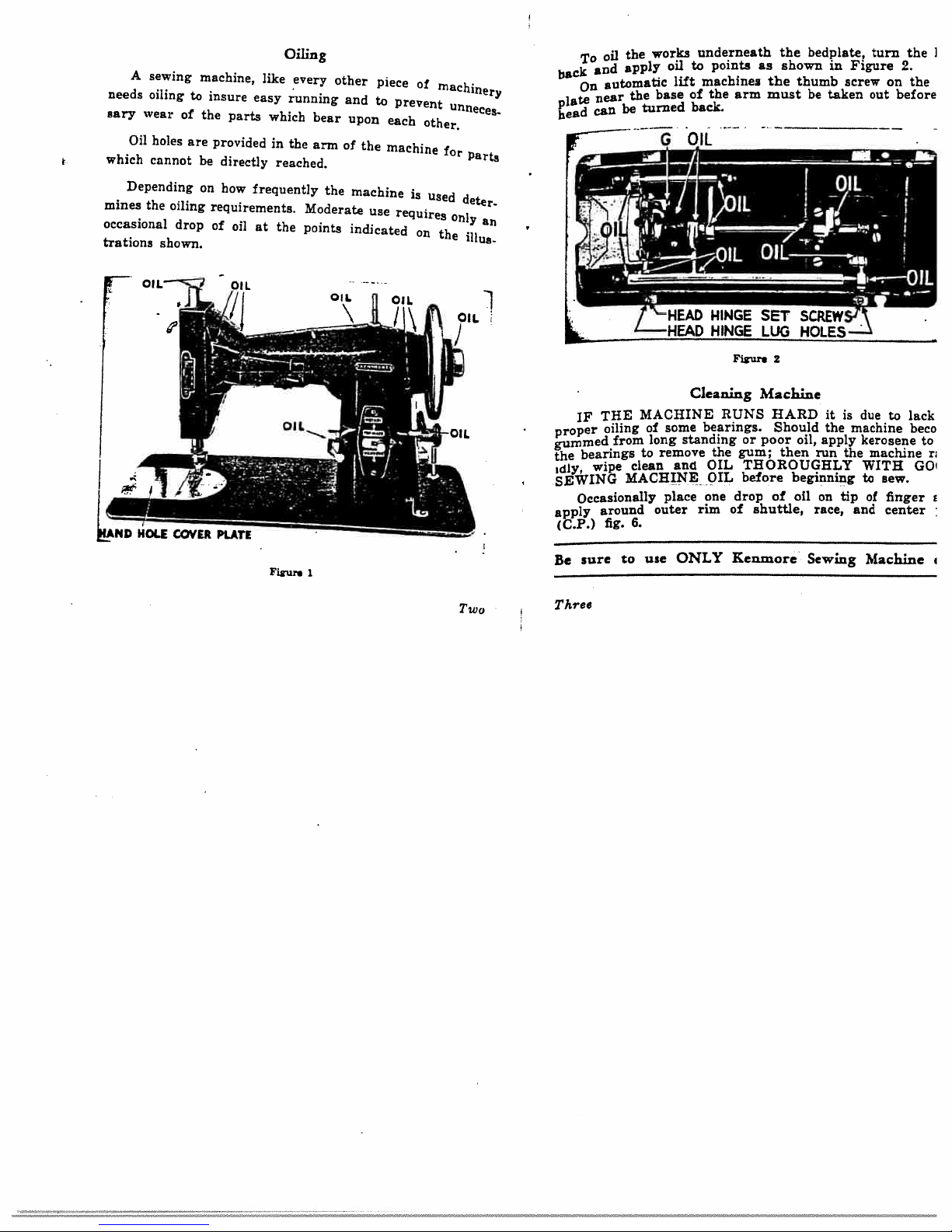

Oiling

like

every

easy

running

which

in

the

reached.

frequently

at

the

other

bear

arm

of

the

Moderate

points

piece

and

to

upon

the

machine

use

indicated

of

prevent

each

machine

is

require

5

on

machinery

unneee

other.

for

used

only

the

Parts

deter.

ilins.

back

plate

bead

‘

On

oil

and

automatiC

near

c&fl

the

apply

the

be

works

base

turned

oil

li-ft

underneath

points

to

machines

the

of

back.

as

arm

the

shown

the

must

bedplate,

thumb

be

in

screw

taken

turn

Figure

out

on

before

I

the

2.

the

a

r

hAND

OILL

HOLE

COVER

OIL

PLATE

Figure

OIL

1

Figure

2

Cleaning

MACHINE

THE

IF

proper

gummed

bearings

the

wipe

idly

SE*ING

Occasionally

apply

(C.P.)

sure

1

Two

Be

Three

oiling

from

clean

MACHINE

around

fig.

to

of

long

to

outer

6.

use

some

standing

remove

and

place

ONLY

bearings.

the

OIL

OIL

one

rim

Machine

RUNS

HARD

Should

or

poor

gum;

then

THOROUGHLY

before

drop

of

shuttle,

of

Kenmore

it

the

oil,

apply

run

beginning

oil

on

race,

Sewing

is

due

machine

kerosene

the

WITH

to

tip

and

to

machine

sew.

of

finger

center

Machine

lack

beco

to

GO

ri

i

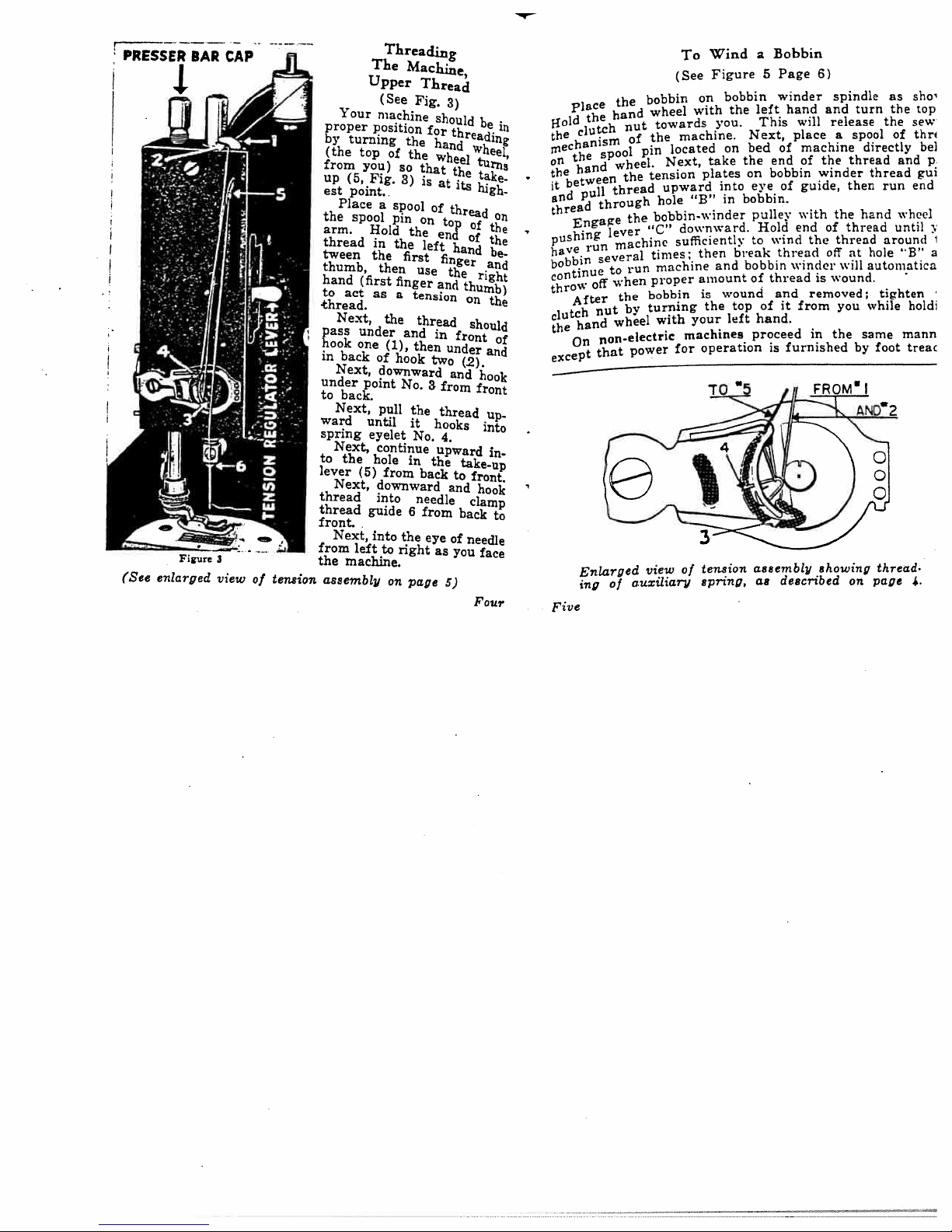

(See

Fgiire

enlarged

3

view

of

tension

Your

proper

by

turning

(the

from

up

(5,

est

point.

Place

the

spool

arm.

thread

tween

thumb,

hand

to

act

thread,

Next,

pass

oak

in

back

Next,

under

to

back.

Next,

ward

spring

Next,

to

the

lever

Next,

thread

thread

front.

Next,

from

the

machine.

assembly

The

Upper

machine

POS1tjOfl

top

you)

Fig.

Hold

in

the

then

(first

as

under

one

of

downward

point

pull

until

eyelet

Continue

hole

(5)

downward

into

guide

into

left

Threading

Machine,

(See

Fig.

the

Of

the

so

that

3)

a

spool

pin

on

the

the

first

use

finger

a

tension

the

thread

and

(1),

then

hook

No.

the

it

No.

in

from

back

needle

6

the

to

right

on

page

Thread

3)

ShoUld

for

hand

wheel

is

at

of

top

ena

left

finger

the

and

in

under

two

3

from

thread

hooks

4.

upward

the

and

from

eye

as

5)

be

threading

wh

tu

the

take

its

thre

of

the

of

the

hand

be..

and

right

thumb)

on

the

should

front

and

(2).

and

hook

front

up

into

i

takeup

to

front.

hook

clamp

back

of

needle

you

face

Four

Bobbin

Figure

bobbin

the

YOU.

on

into

in

break

and

wound

top

left

a

5

left

This

Next,

bed

the

bobbin

on

eye

bobbin.

pulley

Hold

to

bobbin

thread

of

of

hand.

proceed

Page

winder

hand

of

end

of

wind

thread

and

it

will

place

machine

of

guide,

with

end

the

winder

is

removed;

from

in

6)

spindle

and

release

a

the

winder

the

of

thread

off

viIl

wound.

you

the

turn

spool

directly

thread

thread

then

hand

thread

hole

at

automatica

while

same

by

as

the

the

of

run

until

around

tighten

foot

sha

top

sew

thr

and

gui

end

wheel

“B’

-

holdi

mann

trea

be]

,

I

a

Wind

To

(See

place

the

1{0

i

of

1d

clutch

the

inecmsm

the

fl

hand

the

between

it

null

and

thread

Engage

shin

rn

have

bobbin

contin

throw

After

clutch

hand

the

On

except

spool

through

several

off

nut

non.electriC

that

hand

nut

of

wheel.

the

thread

the

lever

machine

run

to

when

the

by

wheel

power

wheel

the

pin

tension

“C”

times;

proper

bobbin

turning

bobbin

the

on

with

towards

machine.

located

take

Next,

plates

upward

“B

hole

bobbin-winder

downward.

sufficiently

then

machine

amount

is

the

your

with

machines

operationisfurnished

for

to

on

thread.

page

4.

Five

Enlarged

of

ing

view

auxiliary

of

tension

spring,

assembly

as

described

showing

BOBBIN

CASE

OGLE

BOBBIN

If

STOP

SCREW

u

CoNL

WINDER

PULLEy

Sz

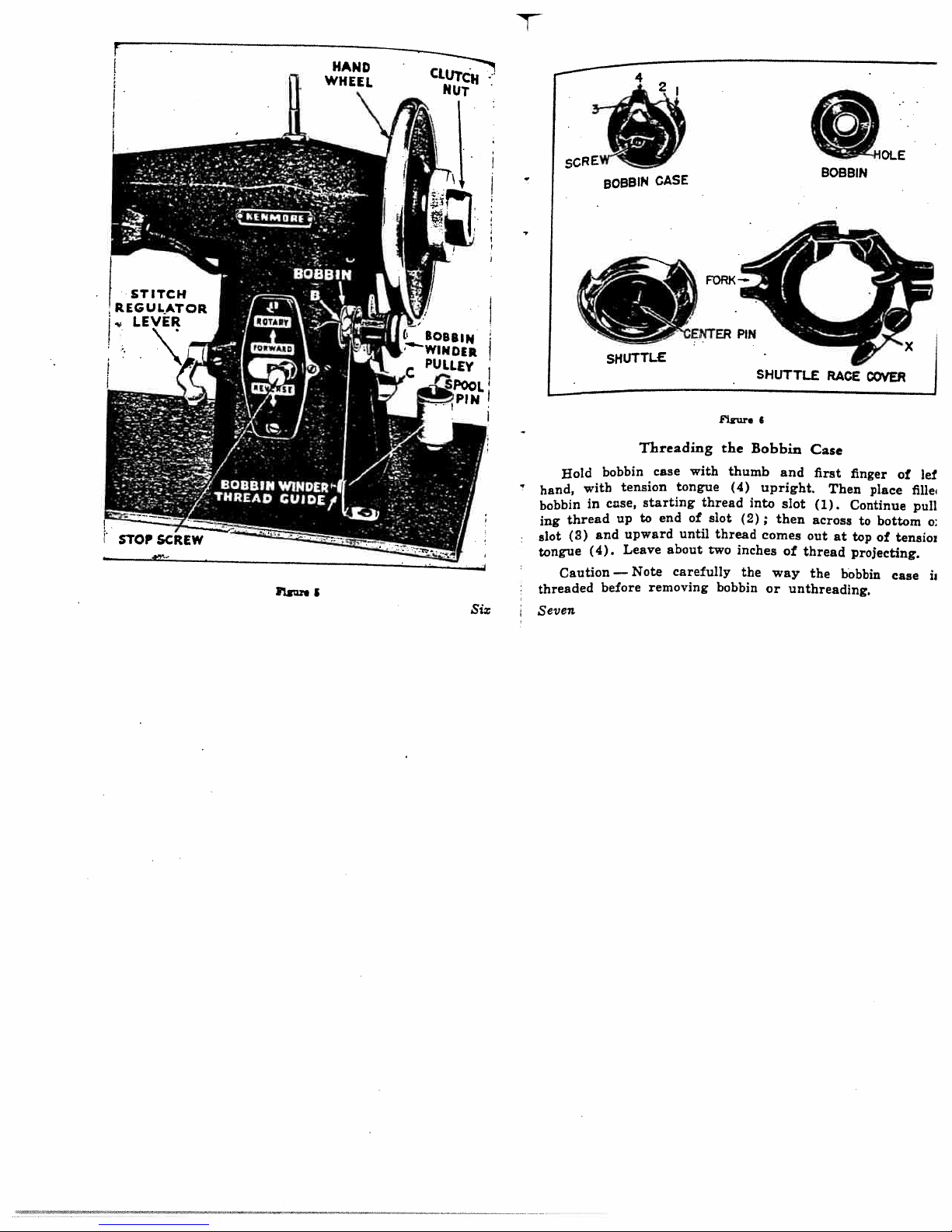

Hold

hand,

bobbin

thread

ing

(3)

slot

tongue

Caution

threaded

Seven

SHUTTLE

bobbin

with

cnse,

in

and

(4).

before

tension

U

upward

Leave

—

Note

Threading

case

tongue

starting

end

to

until

about

carefully

removing

with

thread

of

xu

the

slot

thread

two

bobbin

Bobbin

thumb

(4)

into

(2);

inches

the

7x

and

upright.

slot

then

conies

of

way

or

unthreading.

Case

first

(1).

across

out

thread

the

finger

Then

Continue

at

top

projecting.

bobbin

to

place

bottom

of

of

flI1e

pull

tensioz

case

let

o:

N

While

thread

inches),

with

cornea

and

thread

the

hole.

foot,

extending

turn

right

the

Lead

keeping

To

To

holding

the

hand,

back

you

the

the

Remove

gu

Draw

up.

are

ends

loosely

through

of

top

until

The

holding

of

upper

the

Up

in

hand

the

lower

both

thread

Bobbin

Lower

the

eye

needle

and

threads

left

of

wheel

thread

come

in

Case

Turn

wise)

3)

Then

cover

reach

Clasp

the

your

Fig.

finger

and

readily

Follow

in

in

spindle

fits

shuttle,

Thread

hand,

needle

from

goes

will

up

back

presser

from

hand

until

at

is

remove

plate

down

thumb

left

7.

Then

lift

the

replacing

shuttle.

The

over

the

(three

:,OU

all

the

fonn

through

under

foot

take-up

its

permitting

to

the

bobbin

and

hand

with

up

bobbin

removed.

the

same

the

hole

inside

the

center

as

shown

end

way

a

loop

the

the

slot.

Shuttle

wheel

highest

the

hand

bobbin.

first

as

the

on

case

bobbIn

in

the

the

bottom

of

or

OClcwiae)

do

°‘er

nee.fle

(clock.

(5,

Fig.

point

hole

YOU

case

with

finger

shown

second

latch

“s”

can

procedure

center

of

pin

in

Fig.

Eigkt

to

of

j

be

case

case

the

6.

First

on

bACk

iained.

point

press

shuttle

the

from

shuttle

OUT

Turn

entering

finger

(CP,

opposite

exactly

lined

over

5

huttle

FORCED

place

under

which

Nine

Remove

remove

its

Next,

the

of

end

rear

under

iCP,

FORCE.

the

the

the

of

Fig.

each

in

the

U,

tail

the

be

shuttle

pin

will

hinges.

turn

nele

of

cover

race

Pin

Fig.

hand

needle

left

so

8)

other

with

line

SHARP

of

properly

position.

into

race

(H)

snap

Shuttle

the

Next,

is

latch

H.

8)

To

wheel

band,

the

the

and

back

hand

the

just

G,

(Fig.

Next,

and

Replace

plate

centers

in

the

point

arrow

placed

cover

push

to

from

Pigur.

hole

remove

hand

entering

shown

6)take

it

until

hole.

hold

the

driving

of

in

When

by

right

its

8

wheel

in

so

be

can

the

the

the

of

outer

pins

shuttle

(S).

the

the

slipping

holding

the

cover

bobbin

needle

Fig.

may

it

hold

readily

Shuttle

point

With

shuttle

the

edge

It

race,

shuttle

side

position.

Shuttle

plate

case

(clockwise)

plate

This

8.

be

readily

the

of

removed

the

of

thumb

the

by

slotted

the

of

(DP).

be

will

imperative

is

it

and

is

fork

the

back

and

as

center

needle

the

holes,

When

almost

must

in

over

Race

tip

already

until

hole.

will

removed

and

center

shuttle,

properly

that

never

position

left

at

latch

head

ex

the

Then

release

pin

WITH

just

is

first

pin

directly

are

directly

the

side

(G)

in

be

re

Loading...

Loading...