Kenmore 11081932510, 11091932510, 11091932511 Installation Guide

installation instructions

instructions d'installation

Instrucciones de instalaci6n

English / Espa_ol / Fran£:ais

Table of Contents / Jndice / Table des mati_res ...... 2

l<e more

Commercial T)ry_r

co__rc:al

co___rcial_

P/N W10589674A

Sears Brands Management Corporation

Hoffman Estates, IL 60179 U.S.A.

www. ken more.corn

www.sears.com

Sears Canada Inc.

Toronto, Ontario, Canada M5B 2B8

www.sears.ca

Table of Contents

DRYER SAFETY ................................ 2

TOOLS & PARTS............................. 5

DIMENSIONS/CLEARANCES ....... 6

GAS DRYER INSTALLATION

REQUIREMENTS ............................. 7

ELECTRIC DRYER INSTALLATION

REQUIREMENTS ........................... 10

DRYER VENTING

REQUIREMENTS ............................ 13

GAS SUPPLY CONNECTION ......15

INSTALLING LEVELING LEGS.... 17

ELECTRIC DRYER ELECTRICAL

CONNECTIONS ............................ 18

LEVELING ...................................... 23

COMPLETE iNSTALLATiON ........ 23

REVERSING DRYER

DOOR SWING ............................. 24

MAINTENANCE

iNSTRUCTiONS ............................ 26

ELECTRONIC CONTROL SETUP

iNSTRUCTiONS ............................ 27

WARRANTY ................................... 32

ASSISTANCE

OR SERVICE .............. BACK COVER

Indice

SEGURIDAD DE

LA SECADORA .............................. 33

HERRAMiENTAS Y PIEZAS .......... 36

DiMENSIONES Y

ESPACIOS LiBRES......................... 37

REQUiSITOS DE INSTALACION

DE LA SECADORA A GAS .......... 38

REQUiSITOS DE INSTALACION

DE LA SECADORA ELECTRICA .. 41

REQUiSITOS DE VENTiLACION

DE LA SECADORA ....................... 43

CONEXION DEL SUMiNISTRO

DE GAS .......................................... 45

INSTALACION DE LAS PATAS... 47

CONEXIONES ELECTRiCAS

DE LA SECADORA ELECTRiCA..48

NIVELACION ................................ 54

COMPLETE LA INSTALACION .... 55

COMO INVERTIR EL CiERRE DE

LA PUERTA DE LA SECADORA

(OPCIONAL) ................................. 56

INSTRUCCIONES DE

MANTENIMIENTO ....................... 58

INSTRUCCIONES DE

PROGRAMACION DEL

CONTROL ELECTRONICO .........59

GARANTJA .................................... 64

AYUDA O SERVICIO

TECNICO ......... CONTRAPORTADA

Table des mafi_res

SECURiTE DE LA SECHEUSE ....... 65

OUTILS ET Pif:CES ........................ 68

DIMENSIONS/DiSTANCES

DE DEGAGEMENT ....................... 69

EXIGENCES D'INSTALLATION

POUR LA SECHEUSE A GAZ ..... 70

EXIGENCES D'INSTALLATION

POUR LA SF_CHEUSE

ELECTRiQUE .................................. 73

EXiGENCES CONCERNANT

L'F:VACUATION DE LA

SECHEUSE ..................................... 75

RACCORDEMENT ik LA

CANALISATION DE GAZ ........... 77

INSTALLATION DES PIEDS DE

NIVELLEMENT ............................... 79

NIVELLEMENT ............................... 80

ACHEVER L'INSTALLATION .........81

INVERSION DU SENS

D'OUVERTURE DE LA PORTE DE

LA SF_CHEUSE(FACULTATIF) ....... 82

iNSTRUCTiONS D'ENTRETIEN ...84

iNSTRUCTiONS DE RF_GLAGE

[_U TABLEAU DE COMMANDE

ELECTRONIQUE ........................... 85

GARANTI E...................................... 91

ASSISTANCE OU

SERVICE ....COUVERTURE ARRIF:RE

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided manyimportant safety messages inthis manual and onyour appliance.Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructionsare not followed.

2

DRYERSAFETY

WARN|NG - ofFir°..

- Clothes dryer installation must be performed by a qualified installer.

- Install the clothes dryer according to the manufacturer's instructions and local codes.

- Do not install a clothes dryer with fle×ible plastic venting materials or fle×ible metal

(foil type) duct. if fle×ible metal duct is installed, it must be of a specific type identified

by the appliance manufacturer as suitable for use with clothes dryers. Fle×ible venting

materials are known to collapse, be easily crushed, and trap lint. These conditions will

obstruct clothes dryer airflow and increase the risk of fire.

- To reduce the risk of severe injury or death, follow all installation instructions.

- Save these instructions.

[] It is recommended that the owner post, in a prominent location, instructions for the customer's use in the event the customer smells

gas. This information should be obtained from your gas supplier.

[] Post the following warning in a prominent location.

i FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

WARNING: For your safety, the information in this manual must be followed to minimize

the risk of fire or explosion, or to prevent property damage, personal injury, or death.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

WHAT TO DO iF YOU SMELL GAS:

[] Do not try to light any appliance.

® Do not touch any electrical switch; do not use any phone in your building.

• Clear the room, building, or area of all occupants.

[] Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

® if you cannot reach your gas supplier, call the fire department.

installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

i

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the "What to do if you smell gas" instructions.

DRYER SAFETY

In the State of Massachusetts, the following installation instructions apply:

[] Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

[] If using a ball valve, it shall be a T-handle type.

[] A flexible gas connector, when used, must not exceed 3 feet.

IMPORTANT: The gas installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSi Z223.1/NFPA 54 or the Canadian Natural Gas and Propane Installation Code, CSA B149.1.

The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70 or Canadian Electrical Code, CSA C22.1.

IMPORTANT SAFETY INSTRUCTIONS

When discarding or storing your old clothes dryer, remove the door.

SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the dryer, follow basic precautions,

including the following:

[] Read all instructions before using the dryer.

[] This dryer is intended only for drying clothes and textiles

that have been washed in water. Do not use for any other

purpose.

[] WARNING: If you smell gas, do not use the dryer or any

electrical equipment nearby. Warn other people to clear

the area. Contact the dryer owner immediately.

[] Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to

a chemical reaction that could cause a load to catch fire.

[] Do not dry articles that have been previously cleaned

in, washed in, soaked in, or spotted with gasoline,

dry-cleaning solvents, other flammable, or explosive

substances as they give off vapors that could ignite

or explode.

[] Do not dry unwashed items in the dryer.

[] Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer

is used near children.

[] Before the dryer is removed from service or discarded,

remove the doors to the dryer compartment.

[] Do not reach into the dryer if the drum is moving.

[] Do not open door while dryer is in operation. It will stop.

[] Do not install or store the dryer where it will be exposed

to water and/or the weather.

[] Do not tamper with controls.

[] Clean dryer lint screen before or after each load.

[] Do not use this dryer without the lint screen in place.

[] Do not repair or replace any part of the dryer or attempt

any servicing unless specifically recommended in this

Installation Instructions or in published user-repair

instructions that you understand and have the skills

to carry out.

[] Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

[] Do not use heat to dry articles containing foam rubber

or similarly textured rubber-like materials.

[] The final part of a tumble dryer cycle occurs without

heat (cool-down cycle) to ensure that the articles are left

at a temperature that ensures that the items will not be

damaged.

[] WARNING: Never stop a tumble dryer before the end

of the drying cycle unless all items are quickly removed

and spread out so that the heat is dissipated. (Avoids risk

of spontaneous combustion).

[] Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint,

dust, and dirt.

[] The interior of the dryer and dryer exhaust vent should

be cleaned periodically by qualified service personnel.

[] See "Electrical Requirements" section for grounding

instructions.

SAVE THESE INSTRUCTIONS

State of California Proposition 65 Warnings:

WARNING: This product contains one or more chemicals known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals known to the State of California to cause birth defects or other

reproductive harm.

4

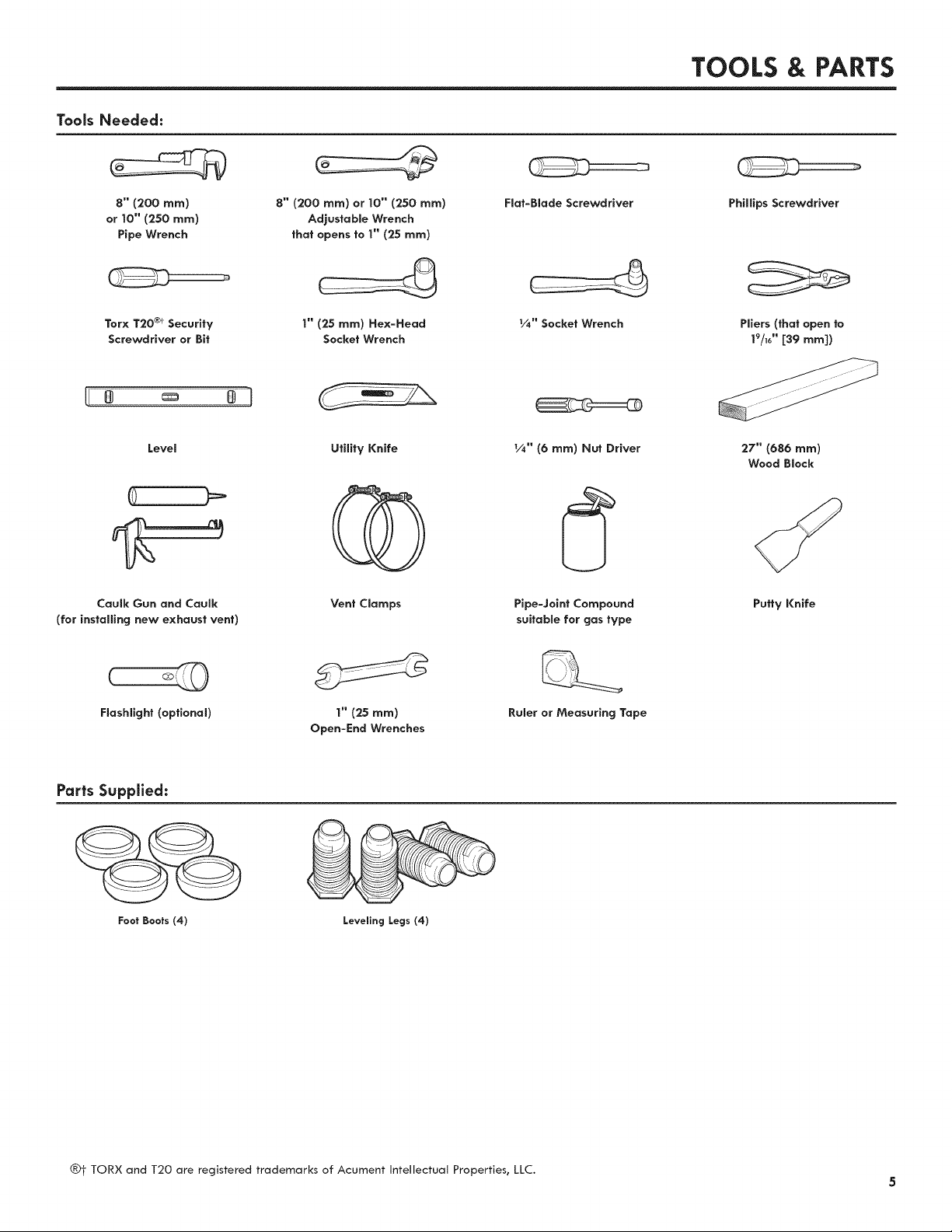

Tools Needed:

TOOLS & PARTS

8" (200 ram)

or 10" (250 ram)

Pipe Wrench

Torx T20 ®t Security

Screwdriver or Bit

Level

Caulk Gun and Caulk

(for installing new exhaust vent)

8" (200 ram) or 10" (250 ram)

Adjustable Wrench

that opens to 1" (25 ram)

|" (25 ram) Hex=Head

Socket Wrench

Utility Knife 1/4" (6 ram) Nut Driver 27" (686 ram)

Vent Clamps Pipe-Joint Compound Putty Knife

Flat=Blade Screwdriver

V4" Socket Wrench

suitable for gas type

Phillips Screwdriver

PEers (that open to

19/16" [39 ram])

Wood Block

Parts Supplled:

Foot Boots (4) Leveling Legs (4)

1" (25ram)

Open-EndWrenches

Ruler or Measuring Tape

®t TORX and T20 are registered trademarks of Acument intellectual Properties_ LLC.

5

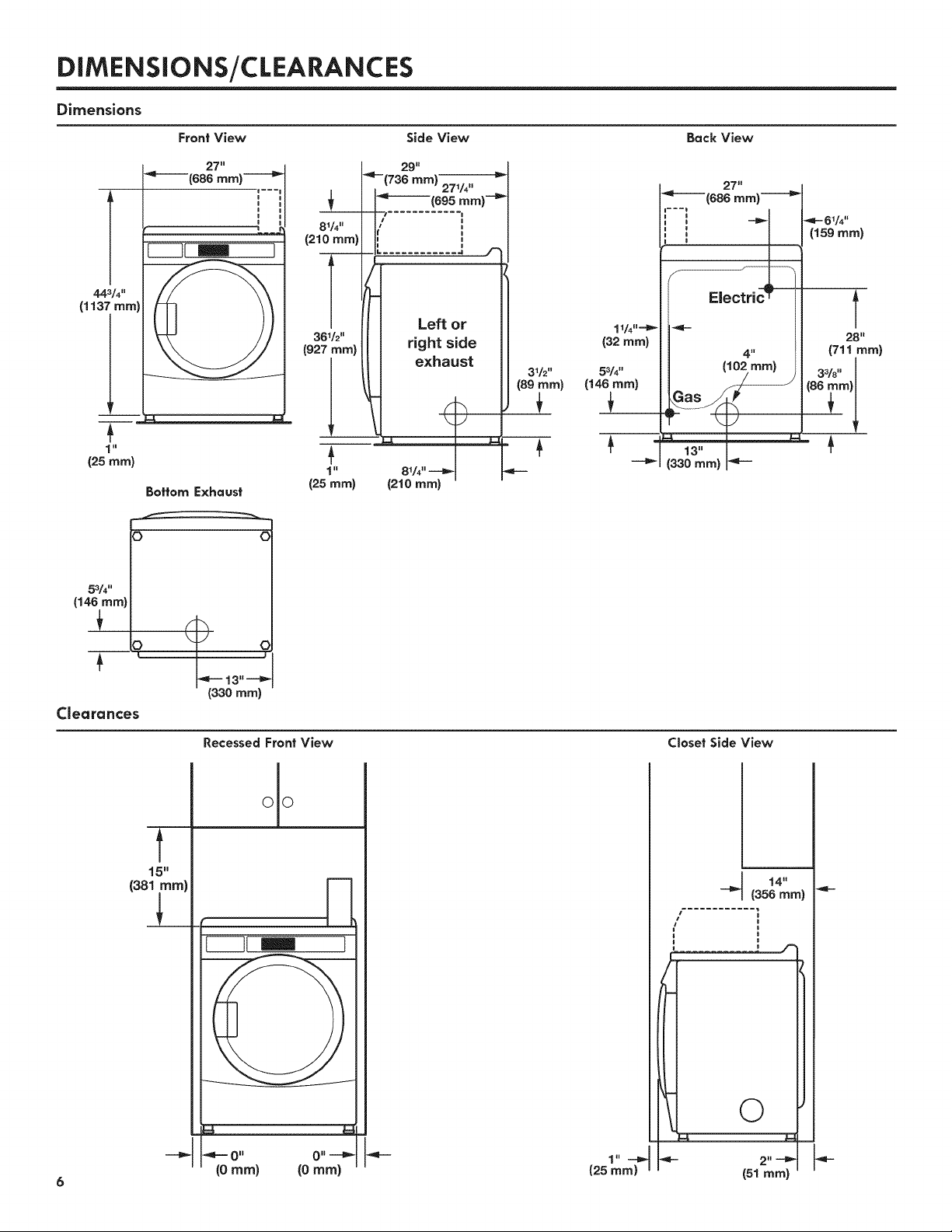

DiMENSiONS/CLEARANCES

Dimensions

Front View Side View Back View

443/4 tj

(1137 mr")

1 "

(25 mr")

53/4"

(146 mr.)

_'_-----(686 ram) _

27 _l

Bottom Exhaust

_ c

I===l

I

m

I

I

1

81/4''

(210 ram)

361h"

(927 ram)

!

1"

(25 ram)

29"

"_--(736 mm) 271/4,' _"

__(695 mm) "-'_

_K

........... , /-

Left or

right side

exhaust

,_L I J-J

81/4"

(210 ram)

31/2"

(89 ram)

53/4"

(146 ram)

+ -

"<-----(686 ram} "-'-'-'-_

27"

, _ 61/4"

i (ls9 ram)

<- Electri l

28"

4" (711 mr")

(lo2 mr.) 3_/_" I

_ _----------:------->(a6r"r")l

(330 mr")

CJearances

7-

15"

(381rnm)

1_._13,,___

(330 mr")

Recessed Front View Closet Side View

°i°

--_ {356 mr")

(

7 ...........

I

©

14"

6

(0 ram) (0 ram) (25 mm)

2" --_

(51 mr")

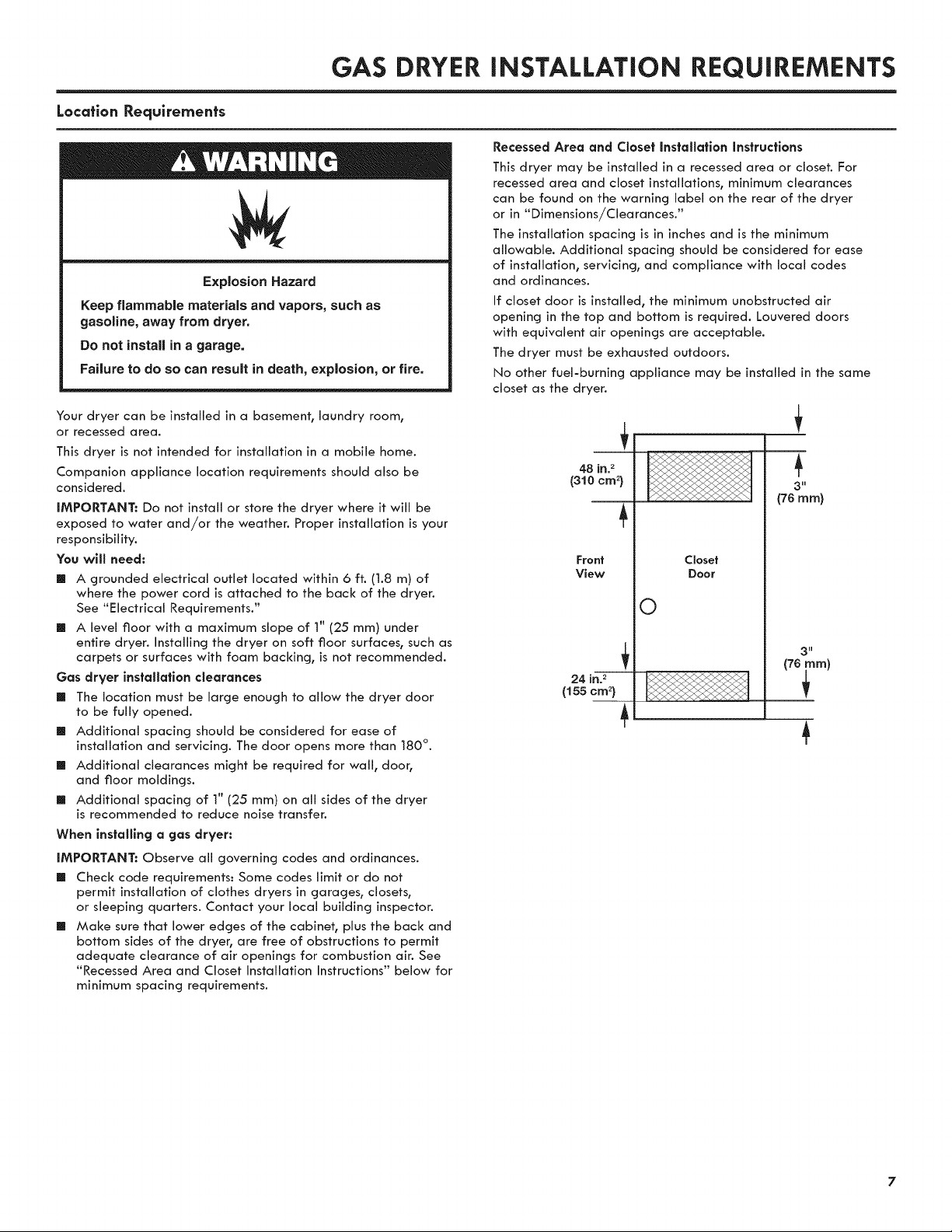

GAS DRYER iNSTALLATiON REQUIREMENTS

Location Requirements

Explosion Hazard

Keep flarnnrnablematerials and vapors, such as

gasoline, away from dryer.

Do not install in a garage.

Failure to do so can result in death, explosion, or fire.

Recessed Area and Closet installation instructions

This dryer may be installed in a recessed area or closet. For

recessed area and closet installations, minimum clearances

can be found on the warning label on the rear of the dryer

or in "Dimensions/Clearances."

The installation spacing is in inches and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes

and ordinances.

If closet door is installed, the minimum unobstructed air

opening in the top and bottom is required. Louvered doors

with equivalent air openings are acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

closet as the dryer.

Your dryer can be installed in a basement, laundry room,

or recessed area.

This dryer is not intended for installation in a mobile home.

Companion appliance location requirements should also be

considered.

iMPORTANT: Do not install or store the dryer where it will be

exposed to water and/or the weather. Proper installation is your

responsibility.

You will need:

[] A grounded electrical outlet located within 6 ft. (1.8 m) of

where the power cord is attached to the back of the dryer.

See "Electrical Requirements."

[] A level floor with a maximum slope of 1" (25 mm) under

entire dryer. Installing the dryer on soft floor surfaces, such as

carpets or surfaces with foam backing, is not recommended.

Gas dryer installation clearances

[] The location must be large enough to allow the dryer door

to be fully opened.

[] Additional spacing should be considered for ease of

installation and servicing. The door opens more than 180 °.

[] Additional clearances might be required for wall, door,

and floor moldings.

[] Additional spacing of 1" (25 ram) on all sides of the dryer

is recommended to reduce noise transfer.

When installing a gas dryer:

iMPORTANT: Observe all governing codes and ordinances.

[] Check code requirements: Some codes limit or do not

permit installation of clothes dryers in garages, closets,

or sleeping quarters. Contact your local building inspector.

[] Make sure that lower edges of the cabinet, plus the back and

bottom sides of the dryer, are free of obstructions to permit

adequate clearance of air openings for combustion air. See

"Recessed Area and Closet Installation Instructions" below for

minimum spacing requirements.

48 in.2

(310 cm 2)

Front

View

24 in. 2

(I 55 cm 2)

+

+

+

+

+

+

3 mm

(76 ram)

Closet

Door

0

3 mm

(76_-nm)

+

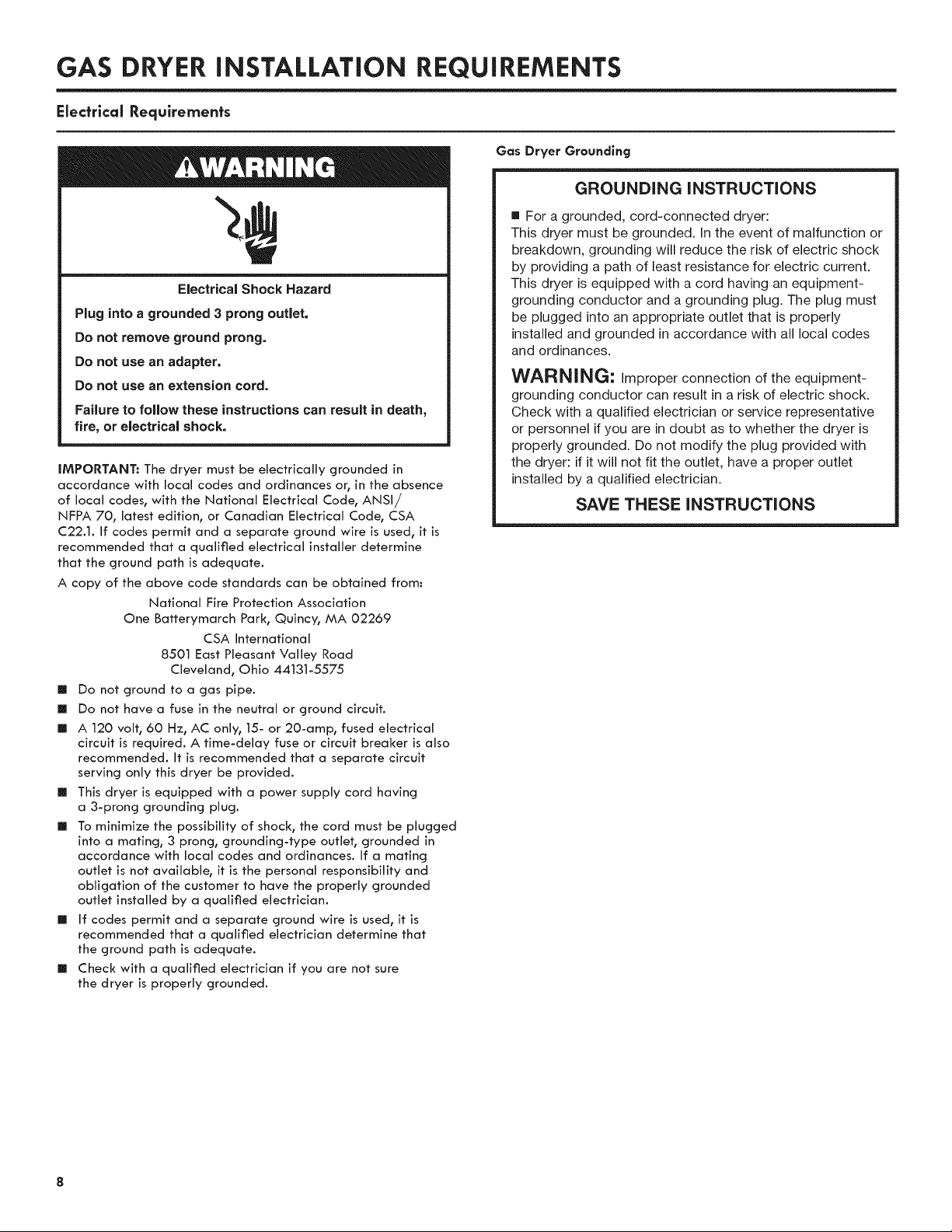

GAS DRYER iNSTALLATiON REQUIREMENTS

Elecfrlcal Requirements

Gas Dryer Grounding

GROUNDING iNSTRUCTiONS

m For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

iMPORTANT: The dryer must be electrically grounded in

accordance with iocai codes and ordinances or, in the absence

of local codes, with the Nationai Electrical Code, ANSI/

NFPA 70, latest edition, or Canadian Electrical Code, CSA

C22.1. If codes permit and a separate ground wire is used, it is

recommended that a qualified eiectricai instaiier determine

that the ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

[] Do not ground to a gas pipe.

[] Do not have a fuse in the neutral or ground circuit.

[] A 120 volt, 60 Hz, AC only, 15- or 20-amp, fused electricai

circuit is required. A tJme-deiay fuse or circuit breaker is also

recommended. It is recommended that a separate circuit

serving only this dryer be provided.

[] This dryer is equipped with a power supply cord having

a 3-prong grounding plug.

[] To minimize the possibility of shock, the cord must be plugged

into a mating, 3 prong, grounding-type outlet, grounded in

accordance with local codes and ordinances. If a mating

outlet is not available, it is the personal responsibility and

obligation of the customer to have the properly grounded

outlet installed by a qualified electrician.

[] If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that

the ground path is adequate.

[] Check with a qualified electrician if you are not sure

the dryer is properly grounded.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

GAS DRYER iNSTALLATiON REQUIREMENTS

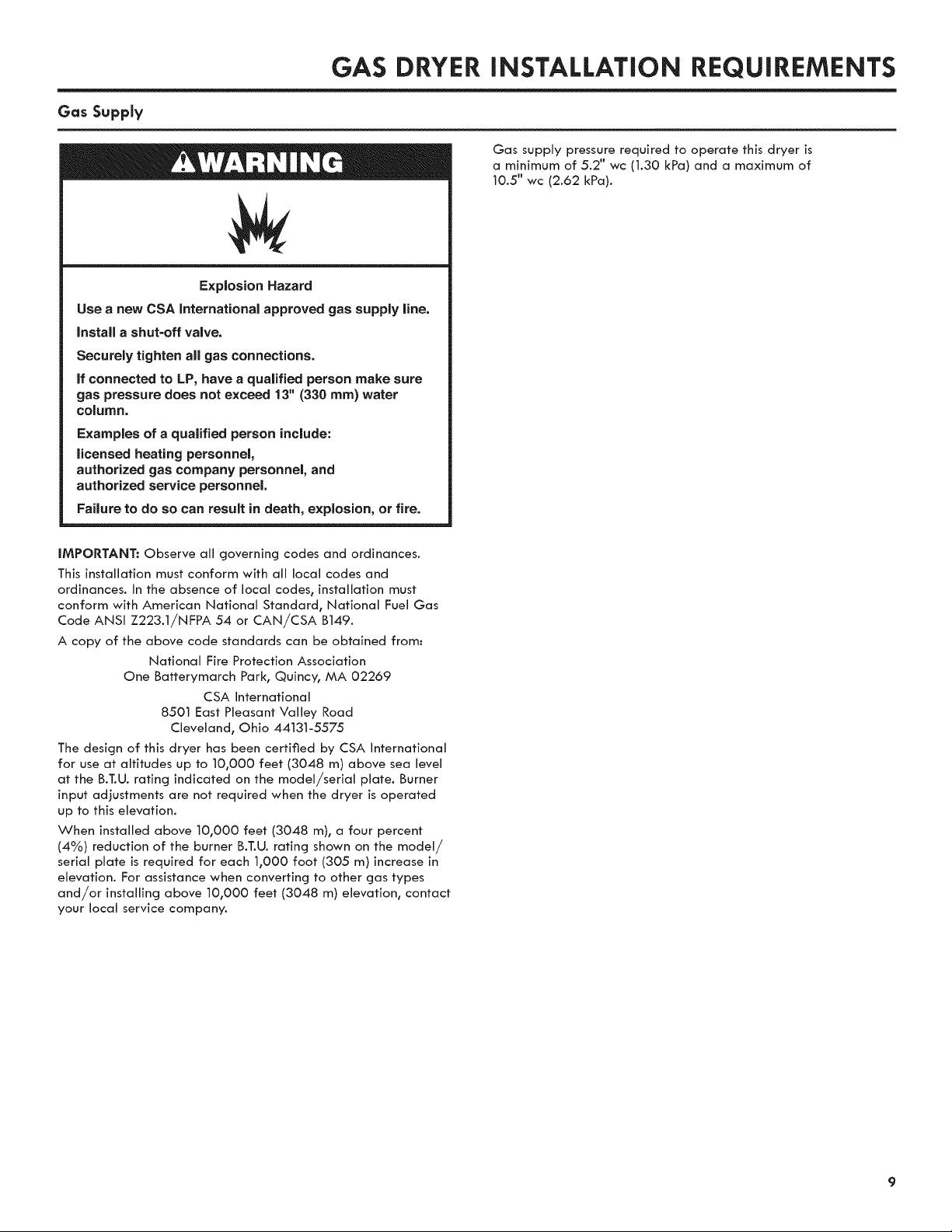

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut=off valve.

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 13" (330 ram) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Gas supply pressure required to operate this dryer is

a minimum of 5.2" wc (1.30 kPa) and a maximum of

10.5" wc (2.62 kPa).

iMPORTANT." Observe all governing codes and ordinances.

This installation must conform with all local codes and

ordinances. In the absence of local codes, installation must

conform with American National Standard, National Fuel Gas

Code ANSI Z223.]/NFPA 54 or CAN/CSA B149.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131=5575

The design of this dryer has been certified by CSA International

for use at altitudes up to 10,000 feet (3048 m) above sea level

at the B.T.U. rating indicated on the model/serial plate. Burner

input adjustments are not required when the dryer is operated

up to this elevation.

When installed above 10,000 feet (3048 m), a four percent

(4%) reduction of the burner B.T.U. rating shown on the model/

serial plate is required for each 1,000 foot (305 m) increase in

elevation. For assistance when converting to other gas types

and/or installing above 10,000 feet (3048 m) elevation, contact

your local service company.

ELECTRIC DRYER iNSTALLATiON REQUIREMENTS

Location Requirements

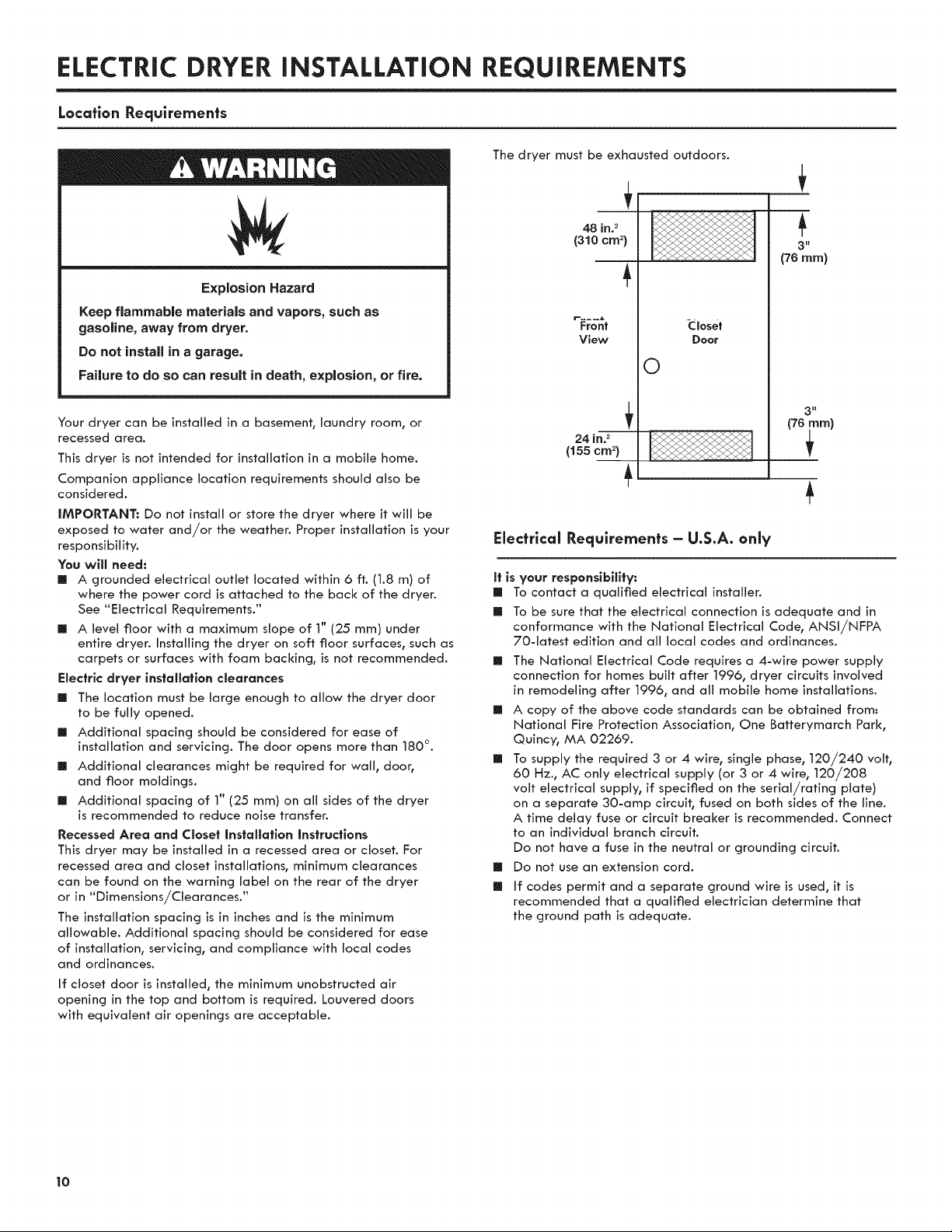

The dryer must be exhausted outdoors.

+

48 in.2

(310 cm 2)

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Do not install in a garage.

Failure to do so can result in death, explosion, or fire.

+

Front

View

0

+

+

3 mm

(76 mr

Closet

Door

Your dryer can be installed in a basement, laundry room, or

recessed area.

This dryer is not intended for installation in a mobile home.

Companion appliance location requirements should also be

considered.

iMPORTANT: Do not install or store the dryer where it will be

exposed to water and/or the weather. Proper installation is your

responsibility.

You will need:

[] A grounded electrical outlet located within 6 ft. (1.8 m) of

where the power cord is attached to the back of the dryer.

See "Electrical Requirements."

[] A level floor with a maximum slope of 1" (25 mm) under

entire dryer. Installing the dryer on soft floor surfaces, such as

carpets or surfaces with foam backing, is not recommended.

Electric dryer installation clearances

[] The location must be large enough to allow the dryer door

to be fully opened.

[] Additional spacing should be considered for ease of

installation and servicing. The door opens more than 180 °.

[] Additional clearances might be required for wall, door,

and floor moldings.

[] Additional spacing of 1" (25 mm) on all sides of the dryer

is recommended to reduce noise transfer.

Recessed Area and Closet Installation Instructions

This dryer may be installed in a recessed area or closet. For

recessed area and closet insta(lations, minimum clearances

can be found on the warning label on the rear of the dryer

or in "Dimensions/Clearances."

The installation spacing is in inches and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes

and ordinances.

If closet door is installed, the minimum unobstructed air

opening in the top and bottom is required. Louvered doors

with equivalent air openings are acceptable.

+

24 in?

(155 cm 2)

3 ml

(76i-nm}

+

+

Elecfrlcal Requirements = U.S.A. only

It is your responsibility:

[] To contact a qualified electrical installer.

[] To be sure that the electrical connection is adequate and in

conformance with the Nat(ona( Electrical Code, ANSI/NFPA

70-latest edition and all local codes and ordinances.

[] The National Electrical Code requires a 4-wire power supply

connection for homes built after 1996, dryer circuits involved

in remodeling after 1996, and all mobile home installations.

[] A copy of the above code standards can be obtained from:

National Fire Protection Association, One Batterymarch Park,

Quincy, MA 02269.

[] To supply the required 3 or 4 wire, single phase, 120/240 volt,

60 Hz., AC only electrical supp(y (or 3 or 4 wire, 120/208

volt electrical supply, if specified on the serial/rating plate)

on a separate 30-amp circuit, fused on both sides of the line.

A time delay fuse or circuit breaker is recommended. Connect

to an individual branch circuit.

Do not have a fuse in the neutral or grounding circuit.

[] Do not use an extension cord.

[] If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that

the ground path is adequate.

10

ELECTRIC DRYER iNSTALLATiON REQUIREMENTS

Electrlcal Requirements - U.S.A. only (cont.)

Electrical Connection

To properly install your dryer, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

[] This dryer is manufactured ready to install with a 3-wire

electrical supply connection. The neutral ground conductor

is permanently connected to the neutral conductor (white

wire) wivthin the dryer. If the dryer is installed with a 4-wire

electrical supply connection, the neutral ground conductor

must be removed from the external ground connector

(green screw) and secured under the neutral terminal (center

or white wire) of the terminal block. When the neutral ground

conductor is secured under the neutral terminal (center or

white wire) of the terminal block, the dryer cabinet is isolated

from the neutral conductor.

[] If local codes do not permit the connection of a neutral

ground wire to the neutral wire, see "Optional 3-wire

connection" section.

[] A 4-wire power supply connection must be used when the

appliance is installed in a location where grounding through

the neutral conductor is prohibited. Grounding through the

neutral is prohibited for (1) new branch-circuit installations

and (2) areas where local codes prohibit grounding through

the neutral conductor.

Electric Dryer Grounding

GROUNDING iNSTRUCTiONS

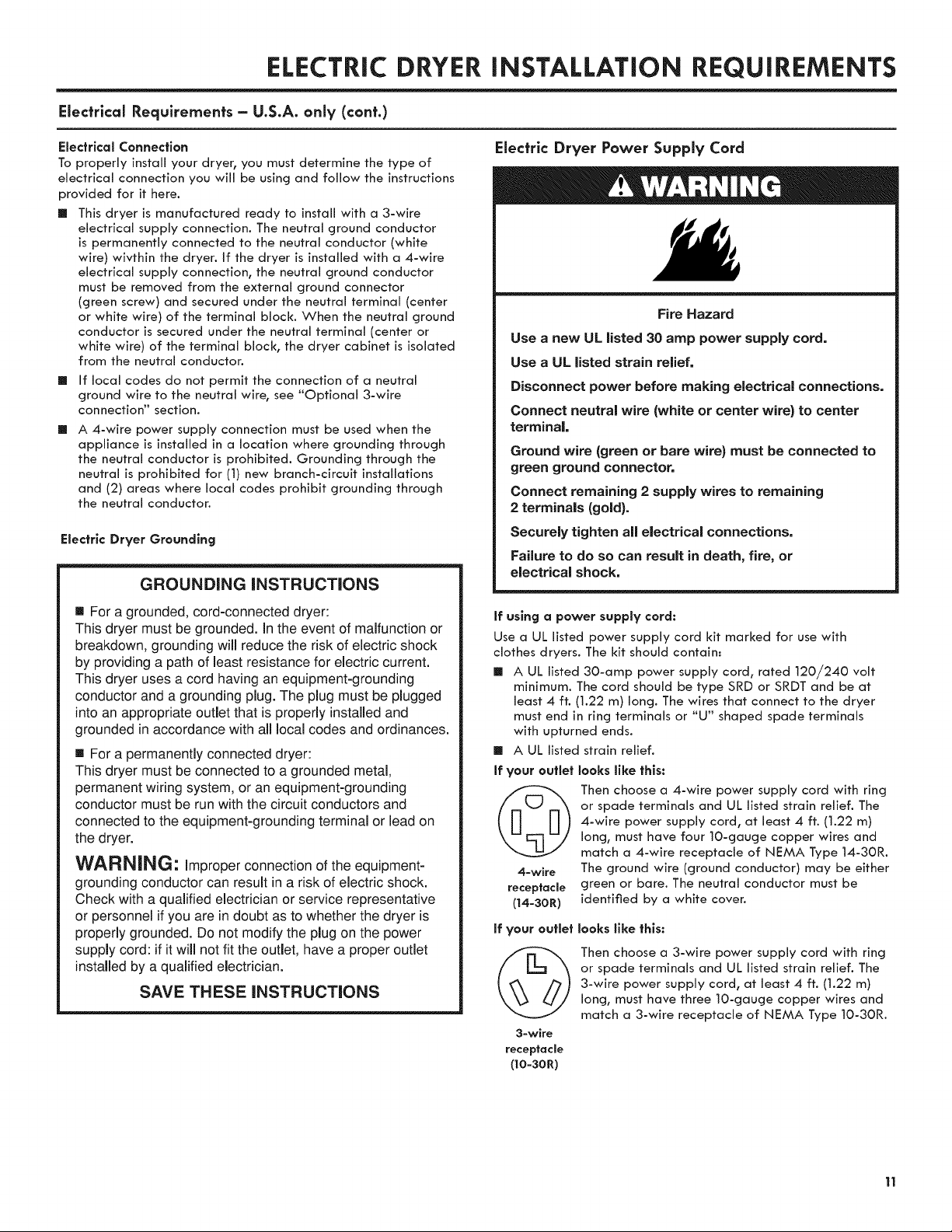

Elecfrlc Dryer Power Supply Cord

Fire Hazard

Use a new UL listed 30 amp power supply cord.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal.

Ground wire (green or bare wire) must be connected to

green ground connector,

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

[] For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer uses a cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

[] For a permanently connected dryer:

This dryer must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the dryer.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug on the power

supply cord: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

If using a power supply cord:

Use a UL listed power supply cord kit marked for use with

clothes dryers. The kit should contain:

[] A UL listed 30-amp power supply cord, rated 120/240 volt

minimum. The cord should be type SRD or SRDT and be at

least 4 ft. (1.22 m) long. The wires that connect to the dryer

must end in ring terminals or "U" shaped spade terminals

with upturned ends.

[]

A UL listed strain relief.

If your outlet

4-wire

receptacle

(|4-30R)

looks like this:

Then choose a 4-wire power supply cord with ring

or spade terminals and UL listed strain relief. The

4-wire power supply cord, at least 4 ft. (1.22 m)

long, must have four 10-gauge copper wires and

match a 4-wire receptacle of NEMA Type 14-30R.

The ground wire (ground conductor) may be either

green or bare. The neutral conductor must be

identified by a white cover.

If your outlet looks like this:

Then choose a 3-wire power supply cord with ring

or spade terminals and UL listed strain relief. The

3-wire power supply cord, at least 4 ft. (1.22 m)

long, must have three 10-gauge copper wires and

match a 3-wire receptacle of NEMA Type 10-30R.

3-wire

receptacle

(|O-30R)

11

ELECTRIC DRYER iNSTALLATiON REQUIREMENTS

Direct Wire

if connecting by direct wire:

Power supply cable must match power supply (4-wire or 3-wire)

and be:

[] Flexible armored cable or nonmetallic sheathed copper cable

(with ground wire), covered with flexible metallic conduit. All

current-carrying wires must be insulated.

[] 10-gauge solid copper wire (do not use aluminum).

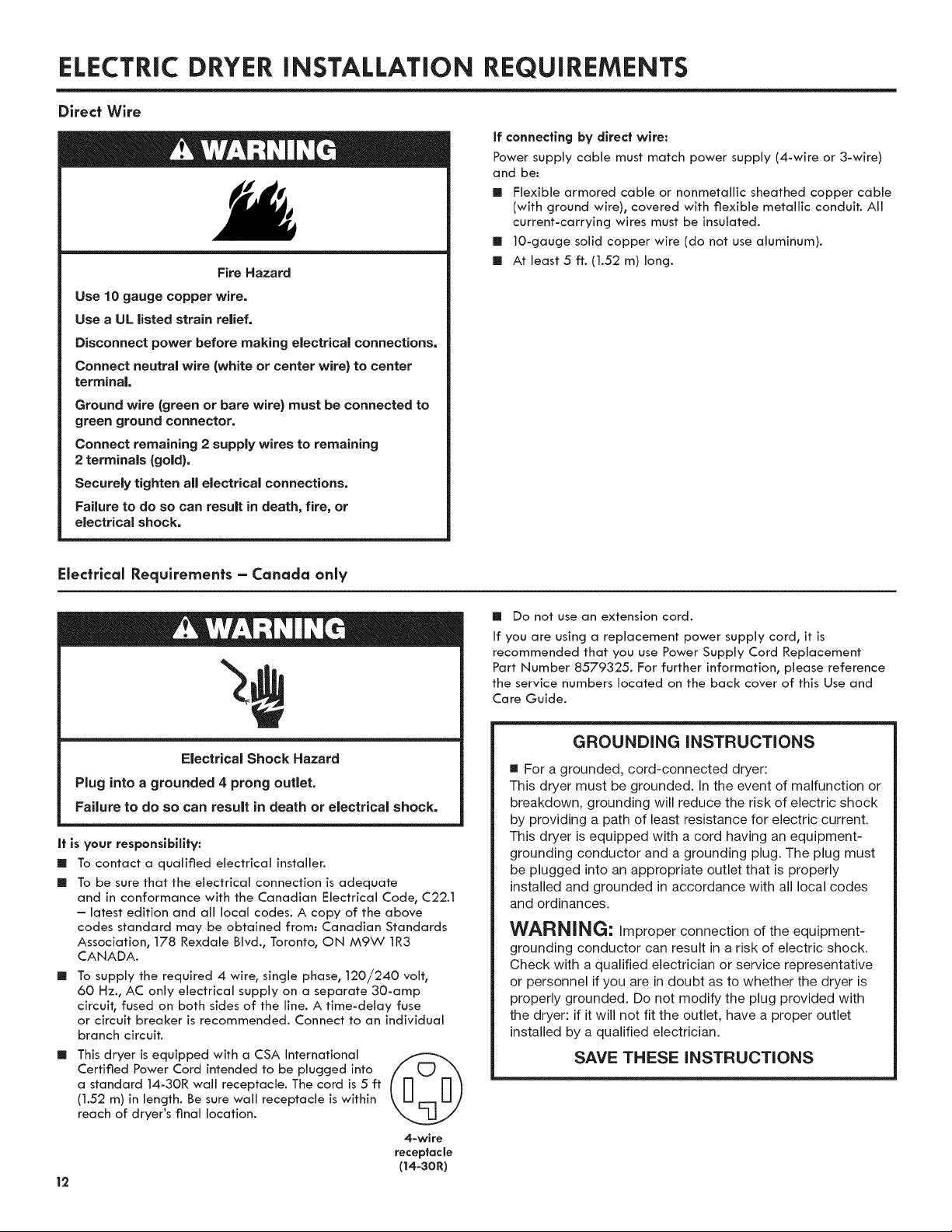

Fire Hazard

Use 10 gauge copper wire.

Use a UL listed strain re|ief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (go|d),

Securely tighten all electrical connections.

Failure to do so can resu|t in death, fire, or

electrical shock.

[] At least 5 ft. (1.52 m) long.

Electrlcal Requirements - Canada only

Electrical Shock Hazard

Plug into a grounded 4 prong outlet.

Failure to do so can result in death or electrical shock.

it is your responsibility:

[] To contact a qualified electrical installer.

[] To be sure that the electrical connection is adequate

and in conformance with the Canadian Electrical Code, C22.1

- latest edition and all local codes. A copy of the above

codes standard may be obtained from". Canadian Standards

Association, 178 Rexdale Blvd., Toronto, ON M9W 1R3

CANADA.

[] To supply the required 4 wire, single phase, 120/240 volt,

60 Hz., AC only electrical supply on a separate 30-amp

circuit, fused on both sides of the line. A time-delay fuse

or circuit breaker is recommended. Connect to an individual

branch circuit.

[]

This dryer is equipped with a CSA International

Certified Power Cord intended to be plugged into

a standard 14-30R wall receptacle. The cord is 5 ft

(1.52 m) in length. Be sure wall receptacle is within

reach of dryer's final location.

4-wlre

receptacle

(14=30R)

12

[] Do not use an extension cord.

If you are using a replacement power supply cord, it is

recommended that you use Power Supply Cord Replacement

Part Number 8579325. For further information, please reference

the service numbers located on the back cover of this Use and

Care Guide.

GROUNDING INSTRUCTIONS

[] For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

DRYERVENTING REQUIREMENTS

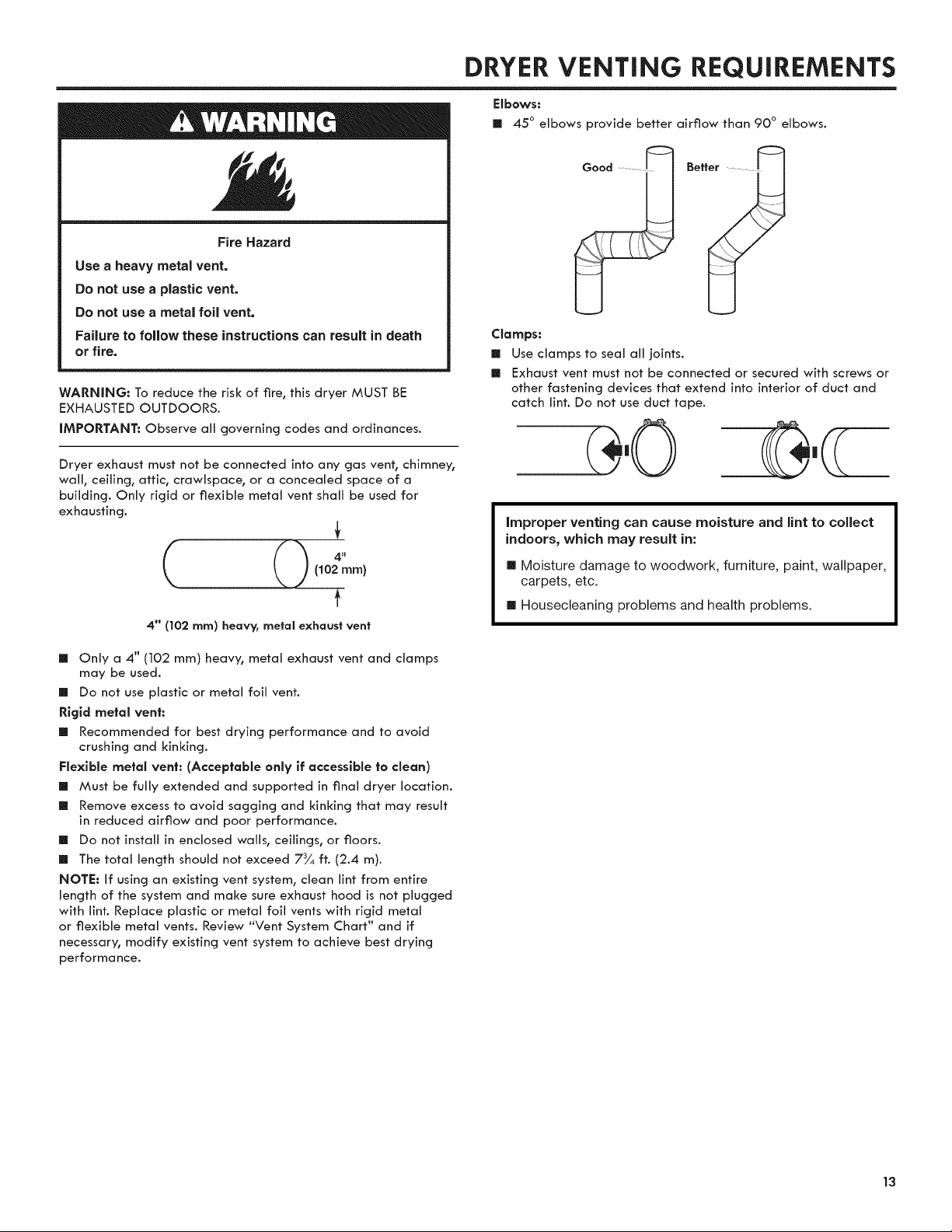

Elbows:

[] 45 ° e(bows provide better airflow than 90 ° e(bows.

Good ...........

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

Dryer exhaust must not be connected into any gas vent, chimney,

wa((, ceiling, attic, crawlspace, or a concealed space of a

building. Only rigid or flexible metal vent shall be used for

exhausting.

(102 mm)

--r

4" (102 ram) heavy, meta( exhaust vent

[] Only a 4" (102 mm) heavy, metal exhaust vent and clamps

may be used.

[] Do not use plastic or metal foil vent.

Rigid metal vent:

[] Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to clean)

[] Must be fully extended and supported in final dryer location.

[] Remove excess to avoid sagging and kinking that may result

in reduced airflow and poor performance.

[] Do not install in enclosed walls, ceilings, or floors.

[] The total length should not exceed 7_4 ft. (2.4 m).

NOTE: If using an existing vent system, clean lint from entire

length of the system and make sure exhaust hood is not plugged

with lint. Replace plastic or metal foil vents with rigid metal

or flexible metal vents. Review °'Vent System Chart" and if

necessary, modify existing vent system to achieve best drying

performance.

Bert

Clamps:

[]

Use clamps to seal all joints.

Exhaust vent must not be connected or secured with screws or

[]

other fastening devices that extend into interior of duct and

catch lint. Do not use duct tape.

Gc_

Improper venting can cause moisture and lint to collect

indoors, which may result in:

[] Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

[] Housecleaning problems and health problems.

13

DRYERVENTING REQUIREMENTS

Vent Hoods

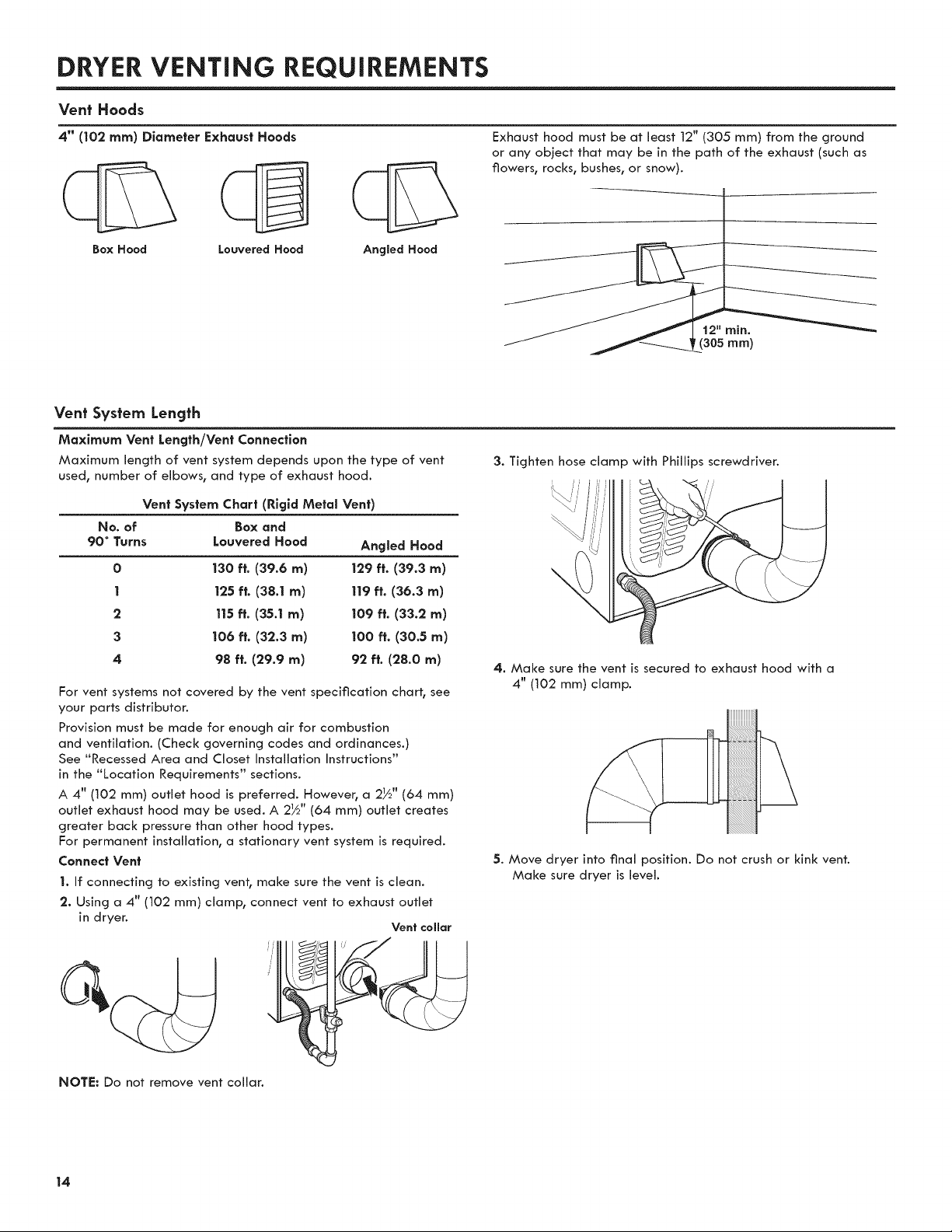

4" (102 ram) Diameter Exhaust Hoods

Box Hood Louvered Hood Angled Hood

Vent System Length

Maximum Vent Length/Vent Connection

Maximum length of vent system depends upon the type of vent

used, number of elbows, and type of exhaust hood.

Vent System Chart (Rigid Metal Vent)

No. of Box and

90 ° Turns Louvered Hood Angled Hood

0 130 ft. (39.6 m) 129 ft. (39.3 m)

1 125 ft. (38.1 m) 119 ft. (36.3 m)

2 115 ft. (35.1 m) 109 ft. (33.2 m)

3 106 ft. (32.3 m) 100 ft. (30.5 m)

4 98 ft. (29.9 m) 92 ft. (28.0 m)

For vent systems not covered by the vent specification chart, see

your parts distributor.

Provision must be made for enough air for combustion

and ventilation. (Check governing codes and ordinances.)

See "Recessed Area and Closet Installation Instructions"

in the "Location Requirements" sections.

A 4" (102 mm) outlet hood is preferred. However, a 2_" (64 mm)

outlet exhaust hood may be used. A 2_6" (64 ram) outlet creates

greater back pressure than other hood types.

For permanent installation, a stationary vent system is required.

Connect Vent

1. If connecting to existing vent, make sure the vent is clean.

2. Using a 4" (102 ram) clamp, connect vent to exhaust outlet

in dryer.

Vent collar

Exhaust hood must be at least 12" (305 ram) from the ground

or any object that may be in the path of the exhaust (such as

flowers, rocks, bushes, or snow).

3. Tighten hose clamp with Phillips screwdriver.

\

4. Make sure the vent is secured to exhaust hood with a

4" (102 mm) clamp.

1

5. Move dryer into final position. Do not crush or kink vent.

Make sure dryer is level.

NOTE: Do not remove vent collar.

14

DRYERVENTING REQUIREMENTS

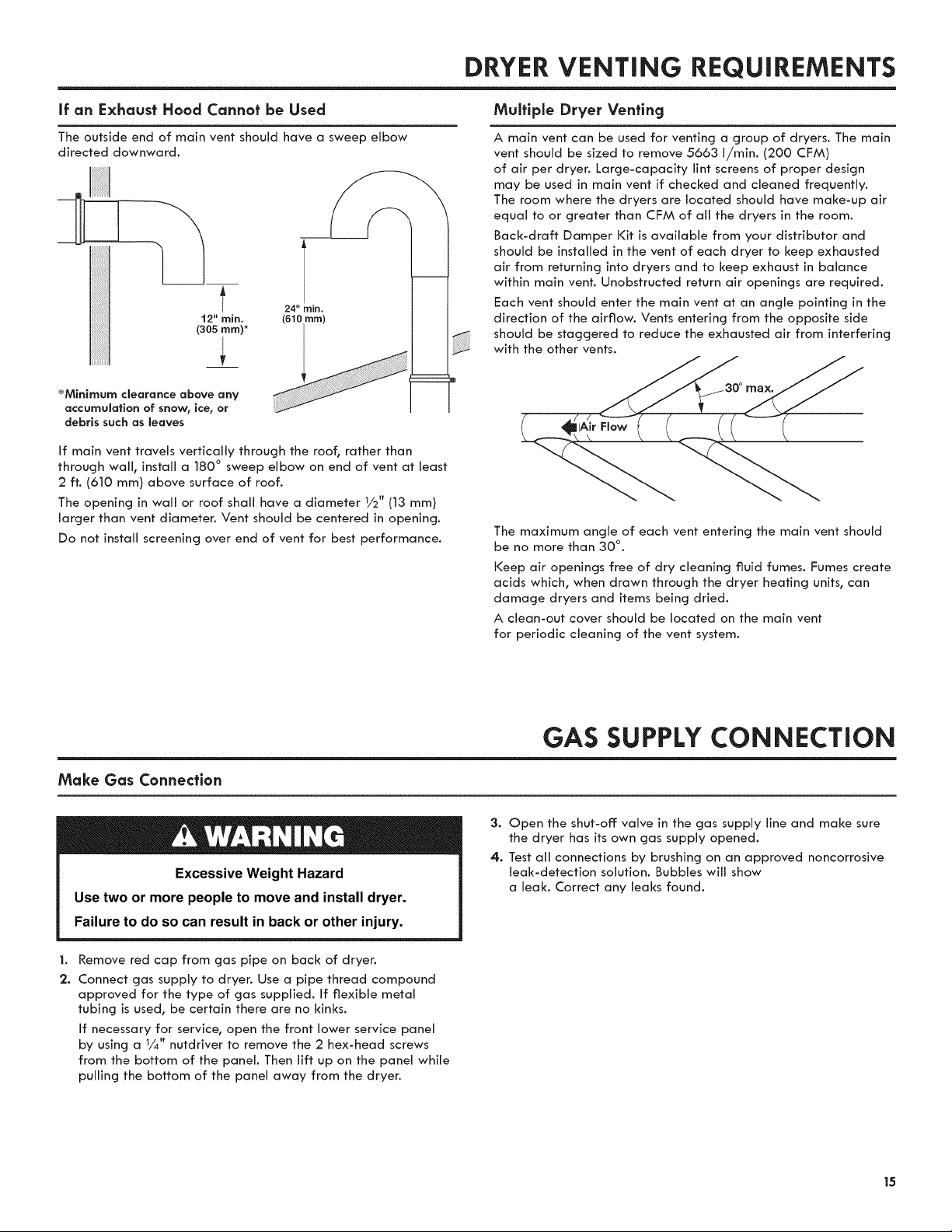

if an Exhaust Hood Cannot be Used

The outside end of main vent should have a sweep elbow

directed downward.

24" rain.

(610 rnm)

_Minimum clearance above any

accumulation of snow, ice, or

debris such as leaves

If main vent travels vertically through the roof_ rather than

through wall, install a 180 ° sweep elbow on end of vent at least

2 ft. (610 ram) above surface of roof.

The opening in wall or roof shall have a diameter 1/2" (13 ram)

larger than vent dJameten Vent should be centered in opening.

Do not install screening over end of vent for best performance.

i

Multiple Dryer Venting

A main vent can be used for venting a group of dryers. The main

vent should be sized to remove 5663 I/min. (200 CFM)

of air per dryer. Large-capacity lint screens of proper design

may be used in main vent if checked and cleaned frequently.

The room where the dryers are located should have make=up air

equal to or greater than CFM of all the dryers in the room.

Back-draft Damper Kit is available from your distributor and

should be installed in the vent of each dryer to keep exhausted

air from returning into dryers and to keep exhaust in balance

within main vent. Unobstructed return air openings are required.

Each vent should enter the main vent at an angle pointing in the

direction of the airflow. Vents entering from the opposite side

should be staggered to reduce the exhausted air from interfering

with the other vents.

The maximum angle of each vent entering the main vent should

be no more than 30 °.

Keep air openings free of dry cleaning fluid fumes. Fumes create

acids which, when drawn through the dryer heating units, can

damage dryers and items being dried.

A clean-out cover should be located on the main vent

for periodic cleaning of the vent system.

Make Gas Connection

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

1. Remove red cap from gas pipe on back of dryer.

2. Connect gas supply to dryer. Use a pipe thread compound

approved for the type of gas supplied. If flexible metal

tubing is used, be certain there are no kinks.

If necessary for service, open the front lower service panel

by using a t/4" nutdriver to remove the 2 hex-head screws

from the bottom of the panel. Then lift up on the panel while

pulling the bottom of the panel away from the dryer.

GAS SUPPLY CONNECTION

3. Open the shut=off valve in the gas supply line and make sure

the dryer has its own gas supply opened.

4. Test all connections by brushing on an approved noncorrosive

leak=detection solution. Bubbles will show

a leak. Correct any leaks found.

15

GAS SUPPLY CONNECTION

Type of Gas

This dryer is equipped for use with natural gas. It is design-

certified by CSA International for LP (propane and butane)

gases with appropriate conversion. No attempt shall be made to

convert dryer from gas specified on serial/rating plate for use

with a different gas without consulting the serving gas supplier.

Conversion must be done by a qualified service technician.

Gas conversion kit part numbers are listed on gas valve

burner base.

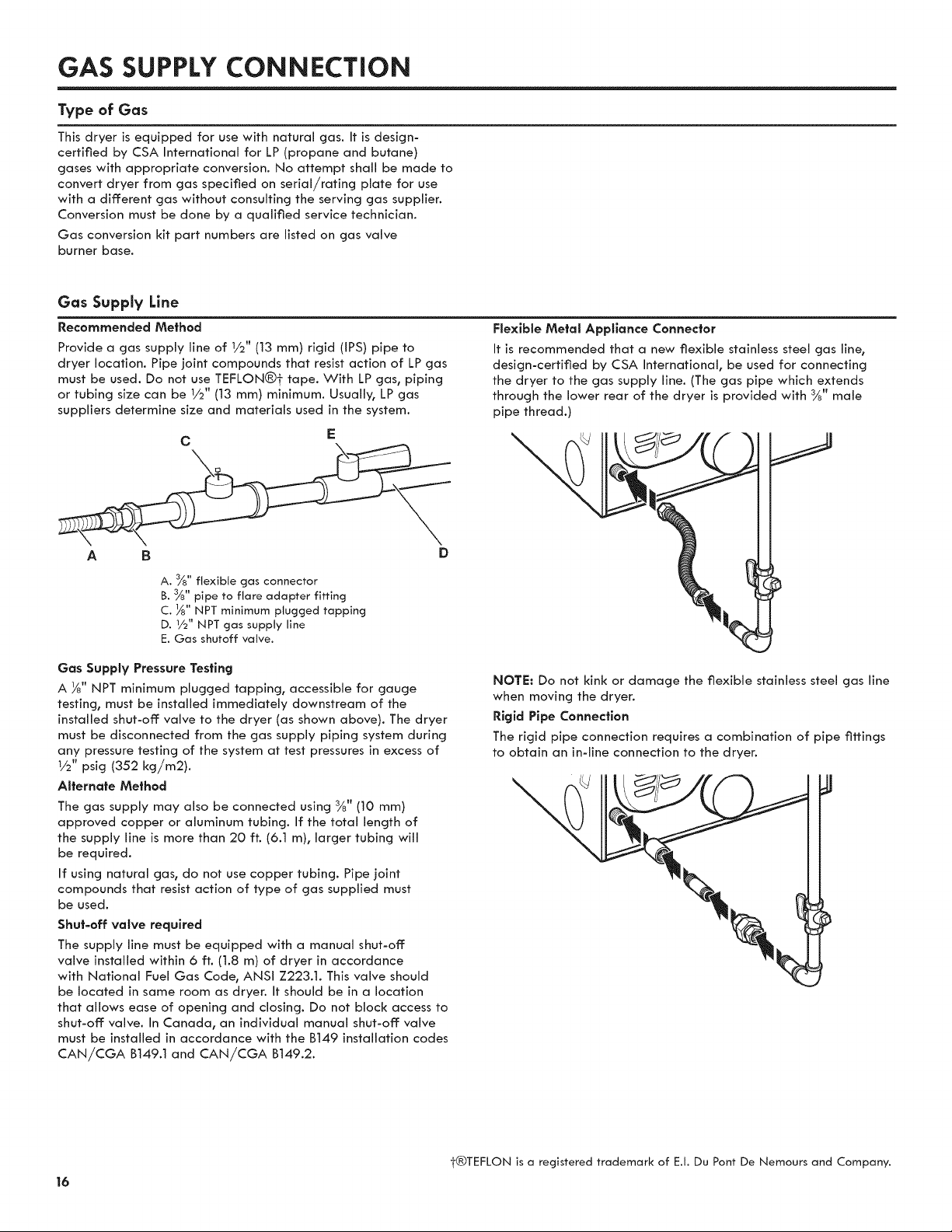

Gas Supply Line

Recommended Method

Provide a gas supply line of 1/2" (13 ram) rigid tiPS) pipe to

dryer location. Pipe joint compounds that resist action of LP gas

must be used. Do not use TEFLON®t tape. With LP gas, piping

or tubing size can be 1/2" (13 mm) minimum. Usually, LP gas

suppliers determine size and materials used in the system.

C

E

Flexible Metal Appliance Connector

It is recommended that a new flexible stainless steel gas line,

design-certified by CSA International, be used for connecting

the dryer to the gas supply line. (The gas pipe which extends

through the lower rear of the dryer is provided with %" male

pipe thread.)

A B D

A. _" flexible gas connector

B. _/8" pipe to flare adapter fitting

C. _" NPT minimum plugged tapping

D. 1/2" NPT gas supply line

E. Gas shutoff valve.

Gas Supply Pressure Testing

A _" NPT minimum plugged tapping, accessible for gauge

testing, must be installed immediately downstream of the

installed shut-off valve to the dryer (as shown above). The dryer

must be disconnected from the gas supply piping system during

any pressure testing of the system at test pressures in excess of

1/2" psig (352 kg/m2).

Alternate Method

The gas supply may also be connected using %" (10 ram)

approved copper or aluminum tubing. If the total length of

the supply line is more than 20 ft. (6.1 m), larger tubing will

be required.

If using natural gas, do not use copper tubing. Pipe joint

compounds that resist action of type of gas supplied must

be used.

Shut=off valve required

The supply line must be equipped with a manual shut=off

valve installed within 6 ft. (1.8 m) of dryer in accordance

with National Fuel Gas Code, ANSI Z223.1. This valve should

be located in same room as dryer. It should be in a location

that allows ease of opening and closing. Do not block access to

shut-off valve. In Canada, an individual manual shut-off valve

must be installed in accordance with the B149 installation codes

CAN/CGA B149.1 and CAN/CGA B149.2.

NOTE: Do not kink or damage the flexible stainless steel gas line

when moving the dryer.

Rigid Pipe Connection

The rigid pipe connection requires a combination of pipe fittings

to obtain an in-line connection to the dryer.

16

t®TEFLON is a registered trademark of E.i. Du Pont De Nemours and Company.

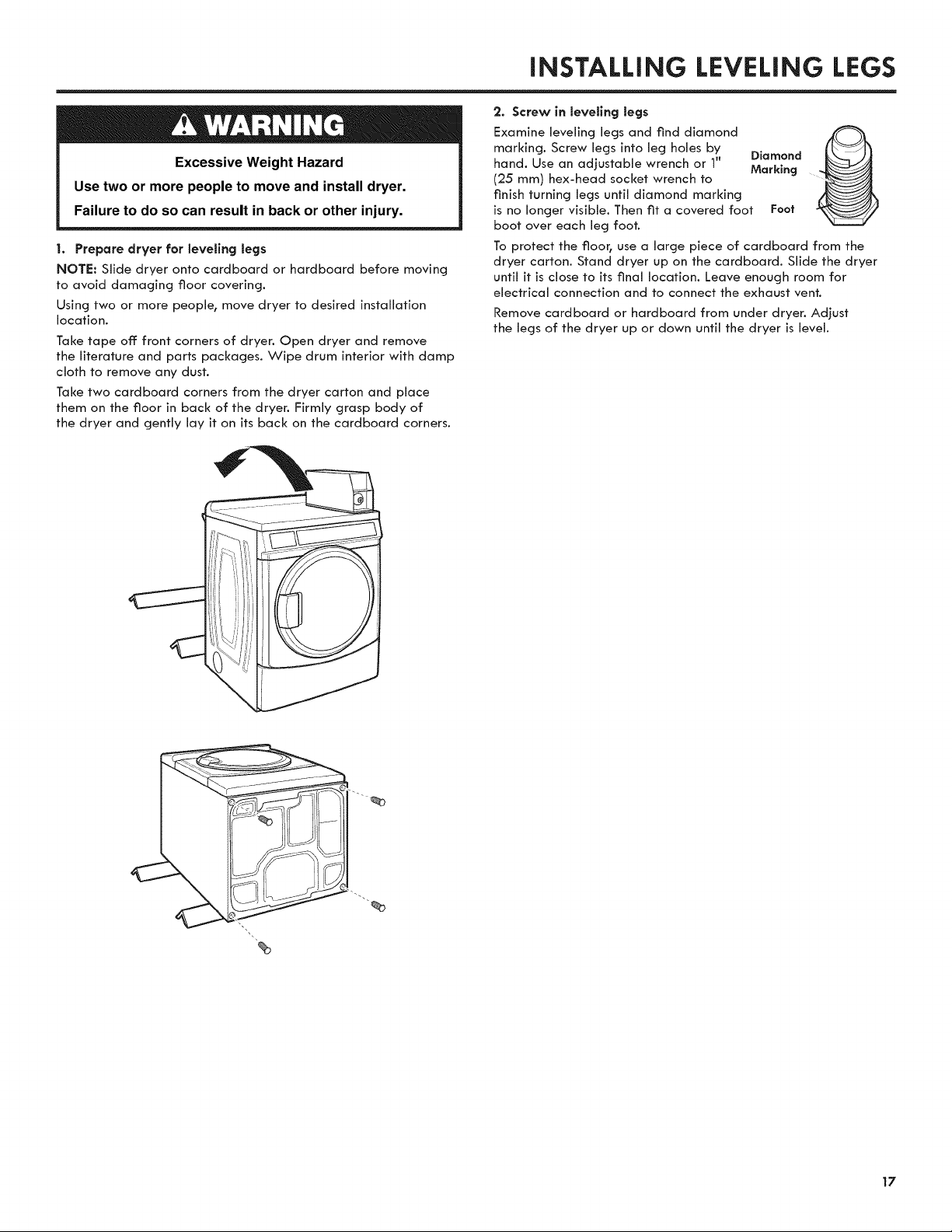

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

1. Prepare dryer for leveling legs

NOTE: Slide dryer onto cardboard or hardboard before moving

to avoid damaging floor covering.

Using two or more people, move dryer to desired installation

location.

Take tape off front corners of dryer. Open dryer and remove

the literature and parts packages. Wipe drum interior with damp

cloth to remove any dust.

Take two cardboard corners from the dryer carton and place

them on the floor in back of the dryer. Firmly grasp body of

the dryer and gently lay it on its back on the cardboard corners.

iNSTALLiNG LEVELING LEGS

2. Screw in leveling legs

Examine leveling legs and find diamond

marking. Screw legs into leg holes by Diamond

hand. Use an adjustable wrench or 1" Markin

(25 mm) hex-head socket wrench to g

finish turning legs until diamond marking

is no longer visible. Then fit a covered foot Foot

boot over each leg foot.

To protect the floor r use a large piece of cardboard from the

dryer carton. Stand dryer up on the cardboard. Slide the dryer

until it is close to its final location. Leave enough room for

electrical connection and to connect the exhaust vent.

Remove cardboard or hardboard from under dryer. Adjust

the legs of the dryer up or down until the dryer is level.

%

17

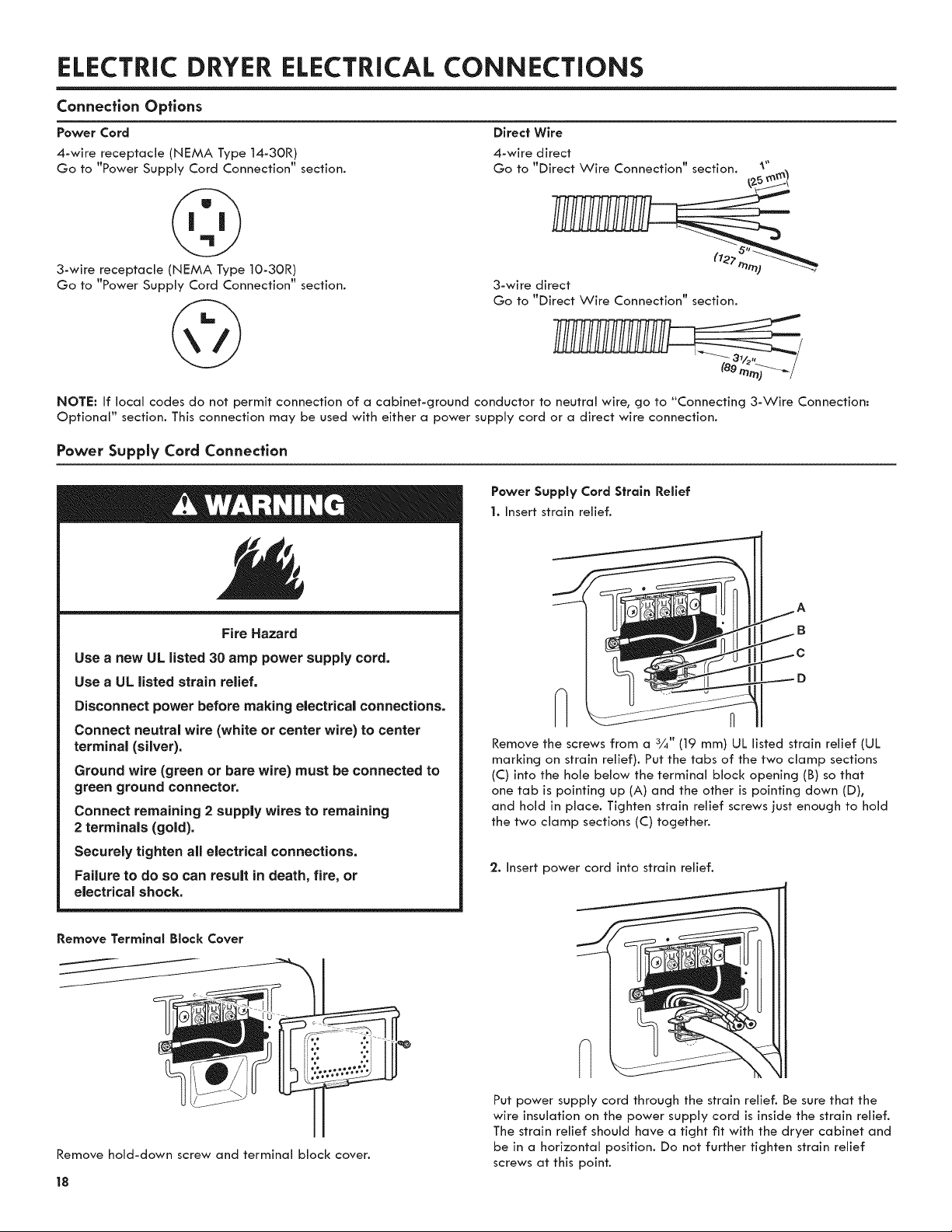

ELECTRIC DRYER ELECTRICAL CONNECTIONS

Connection Options

Power Cord

4-wire receptacle (NEMA Type 14-30R)

Go to "Power Supply Cord Connection" section.

Direct Wire

4-wire direct

Go to "Direct Wire Connection" section.

3-wire receptacle (NEMA Type 10-30R)

Go to "Power Supply Cord Connection" section.

NOTE: If local codes do not permit connection of a cabinet-ground conductor to neutral wire, go to "Connecting 3-Wire Connection:

Optional" section. This connection may be used with either a power supply cord or a direct wire connection.

3-wire direct

Go to "Direct Wire Connection" section.

(127

Power Supply Cord Connection

Power Supply Cord Strain Relief

1. Insert strain relief.

Fire Hazard

Use a new UL listed 30 amp power supply cord.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections,

Failure to do so can result in death, fire, or

electrical shock.

N n

Remove the screws from a 3¼" (19 mm) UL listed strain relief (UL

marking on strain relief). Put the tabs of the two clamp sections

(C) into the hole below the terminal block opening (B) so that

one tab is pointing up (A) and the other is pointing down (D),

and hold in place. Tighten strain relief screws just enough to hold

the two clamp sections (C) together.

2. Insert power cord into strain relief.

D

Remove Terminal Block Cover

Remove hold-down screw and terminal block cover.

18

Put power supply cord through the strain relief. Be sure that the

wire insulation on the power supply cord is inside the strain relief.

The strain relief should have a tight fit with the dryer cabinet and

be in a horizontal position. Do not further tighten strain relief

screws at this point.

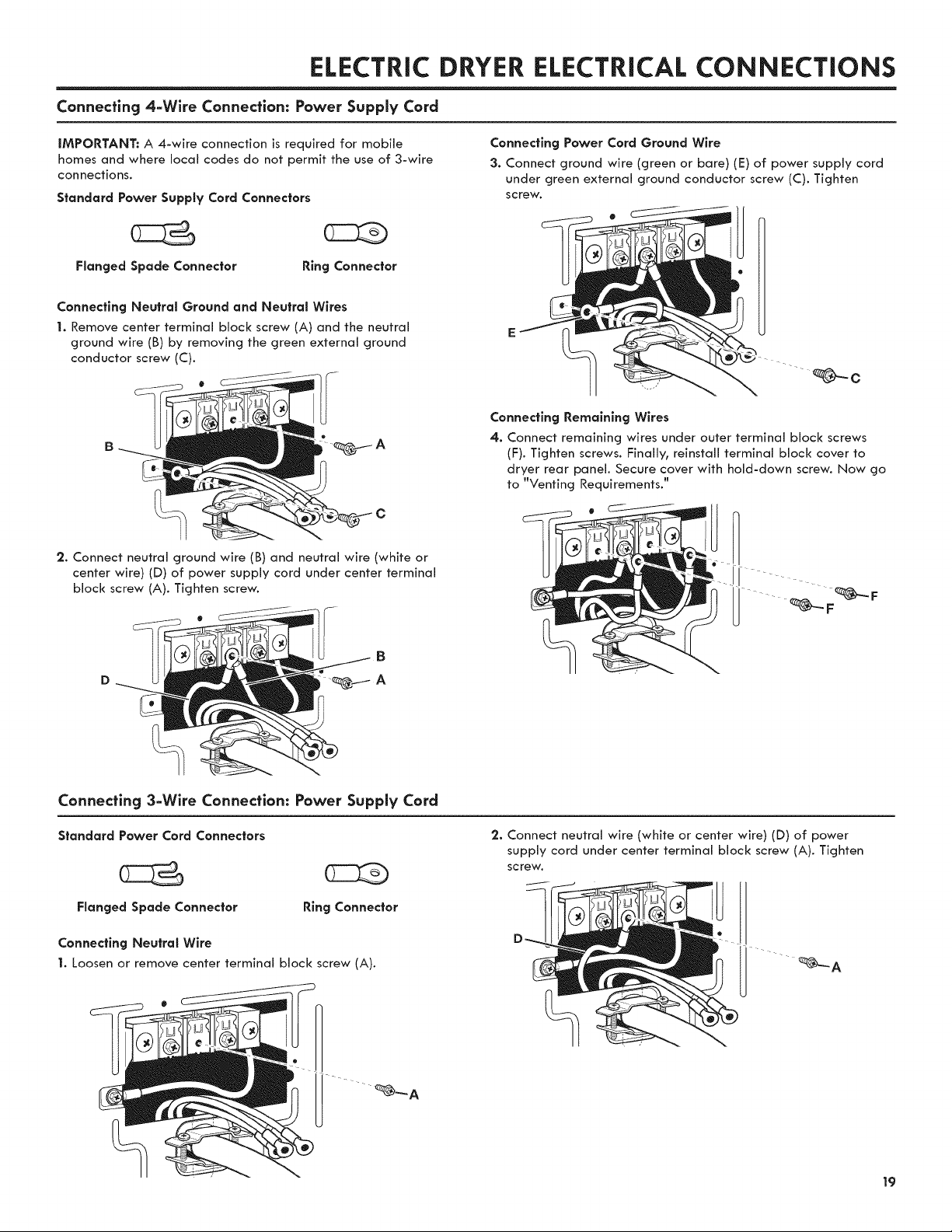

ELECTRIC DRYER ELECTRICAL CONNECTIONS

Connecting 4-Wire Connection: Power Supply Cord

iMPORTANT: A 4-wire connection is required for mobile

homes and where local codes do not permit the use of 3-wire

connections.

Standard Power Supply Cord Connectors

Flanged Spade Connector

Connecting Neutral Ground and Neutral Wires

1. Remove center terminal block screw (A) and the neutral

ground wire (B) by removing the green external ground

conductor screw (C).

@

B

2. Connect neutral ground wire (B) and neutral wire (white or

center wire) (D) of power supply cord under center terminal

block screw (A). Tighten screw.

Connecting Power Cord Ground Wire

3. Connect ground wire (green or bare) (E) of power supply cord

under green external ground conductor screw (C). Tighten

screw.

Connecting Remaining Wires

4. Connect remaining wires under outer terminal block screws

(F). Tighten screws. Finally, reinstall terminal block cover to

dryer rear panel. Secure cover with hold-down screw. Now go

to "Venting Requirements."

D

Connecting 3=Wire Connection: Power Supply Cord

Standard Power Cord Connectors

Flanged Spade Connector

Connecting Neutral Wire

1. Loosen or remove center terminal block screw (A).

2. Connect neutral wire (white or center wire) (D) of power

supply cord under center terminal block screw (A). Tighten

screw.

19

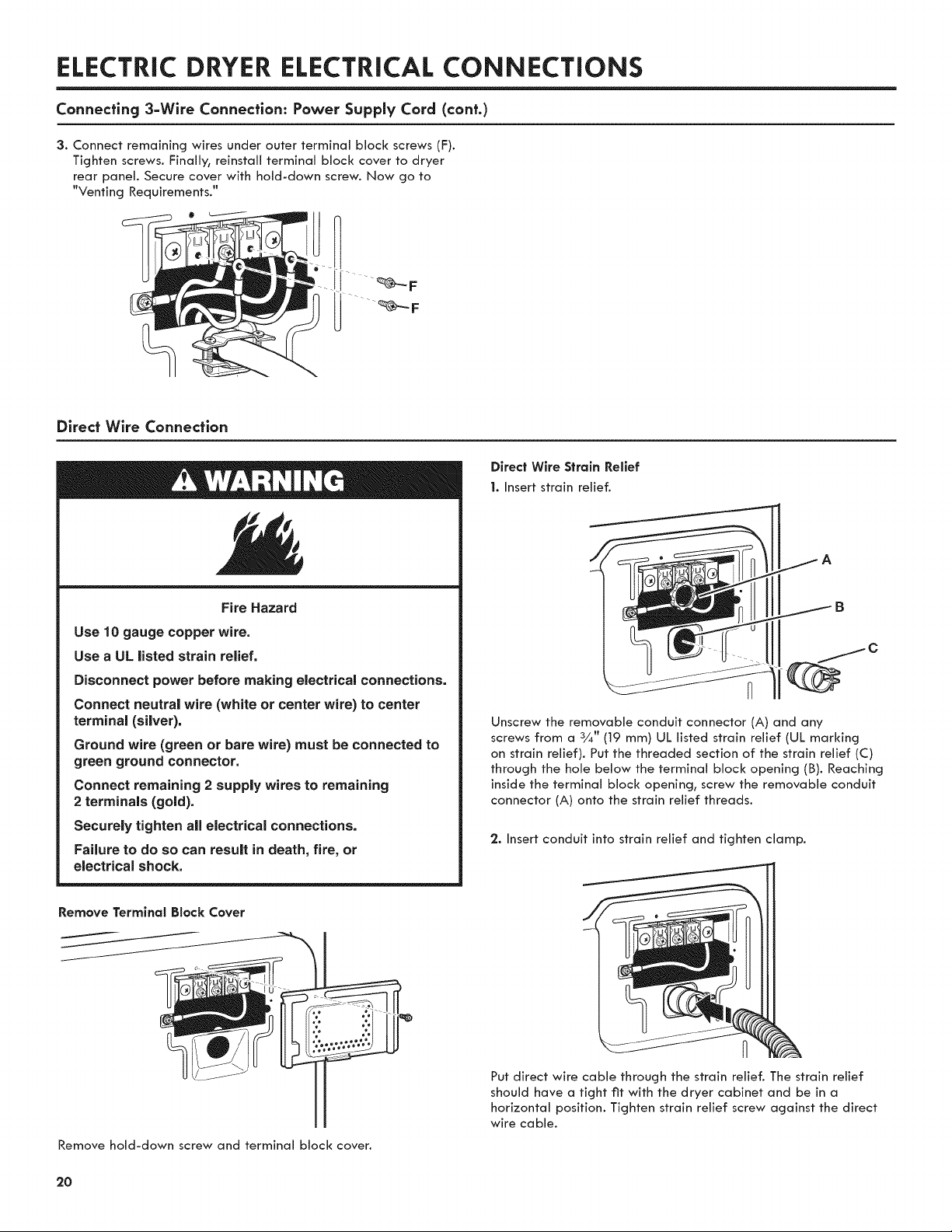

ELECTRIC DRYER ELECTRICAL CONNECTIONS

Connecting 3=Wire Connection: Power Supply Cord (cont.)

3. Connect remaining wires under outer terminal block screws (F).

Tighten screws. Finally, reinstall terminal block cover to dryer

rear panel. Secure cover with hold-down screw. Now go to

"Venting Requirements."

Direct Wire Connection

Direct Wire Strain Relief

1. Insert strain relief.

Fire Hazard

Use 10 gauge copper wire.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire_ or

electrical shock.

Remove Terminal Block Cover

A

Unscrew the removable conduit connector (A) and any

screws from a 3¼" (19 mm) UL listed strain relief (UL marking

on strain relief). Put the threaded section of the strain relief (C)

through the hole below the terminal block opening (B). Reaching

inside the terminal block opening, screw the removable conduit

connector (A) onto the strain relief threads.

2. Insert conduit into strain relief and tighten clamp.

Remove hold-down screw and terminal block cover.

20

Put direct wire cable through the strain relief. The strain relief

should have a tight fit with the dryer cabinet and be in a

horizontal position. Tighten strain relief screw against the direct

wire cable.

ELECTRIC DRYER ELECTRICAL CONNECTIONS

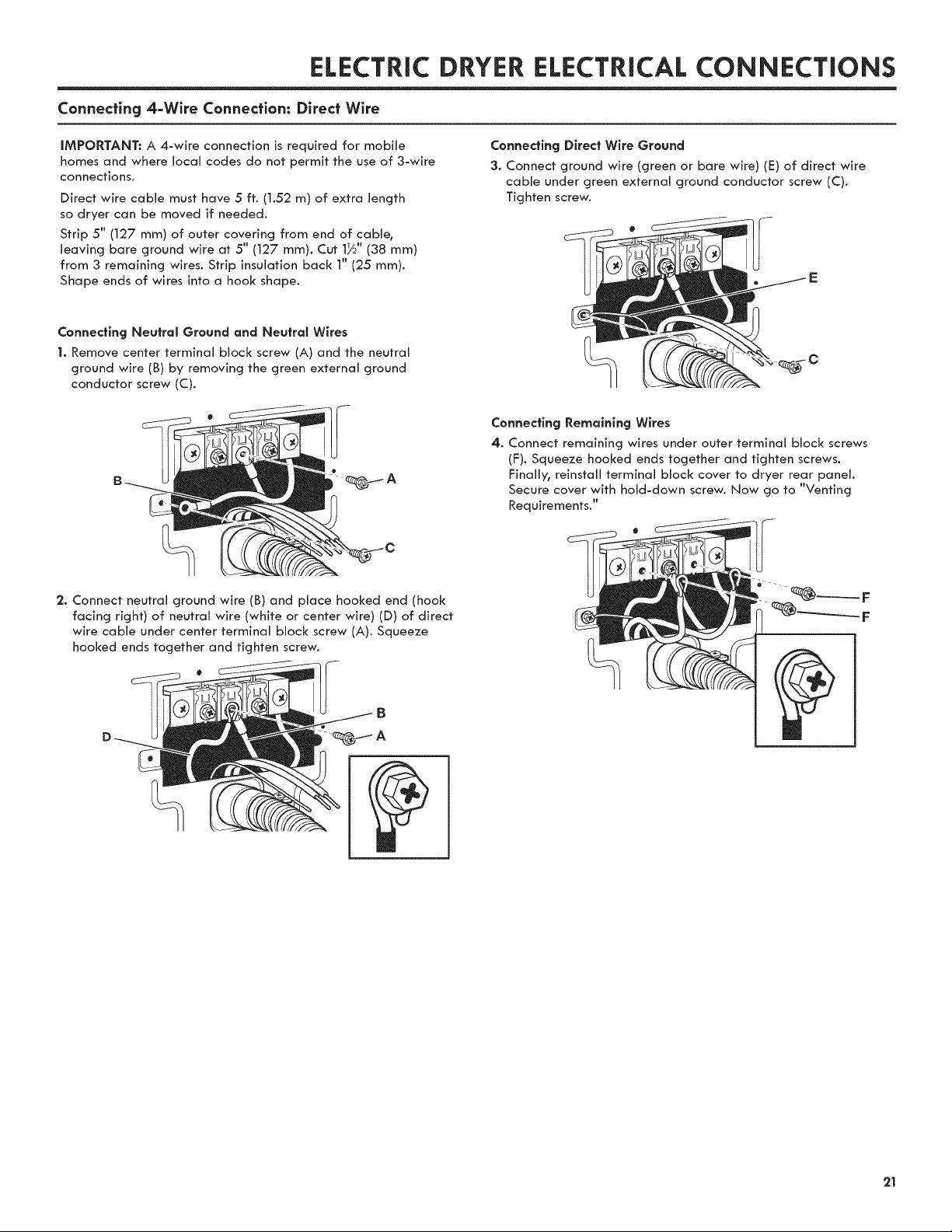

Connecting 4-Wire Connection: Direct Wire

iMPORTANT: A 4-wire connection is required for mobile

homes and where local codes do not permit the use of 3-wire

connections.

Direct wire cable must have 5 ft. (1.52 m) of extra length

so dryer can be moved if needed.

Strip 5" (127 mm) of outer covering from end of cable,

leaving bare ground wire at 5" (127 mm). Cut 1½" (38 mm)

from 3 remaining wires. Strip insulation back 1" (25 mm).

Shape ends of wires into a hook shape.

Connecting Neutral Ground and Neutral Wires

1. Remove center terminal block screw (A) and the neutral

ground wire (B) by removing the green externai ground

conductor screw (C).

Connecting Direct Wire Ground

3. Connect ground wire (green or bare wire) (E) of direct wire

cable under green external ground conductor screw (C).

Tighten screw.

Connecting Remaining Wires

4. Connect remaining wires under outer terminal block screws

(F). Squeeze hooked ends together and tighten screws.

Finally, reinstall terminal block cover to dryer rear panel.

Secure cover with hold-down screw. Now go to "Venting

Requirements."

2. Connect neutral ground wire (B) and place hooked end (hook

facing right) of neutral wire (white or center wire) (D) of direct

wire cable under center terminal block screw (A). Squeeze

hooked ends together and tighten screw.

21

ELECTRIC DRYER ELECTRICAL CONNECTIONS

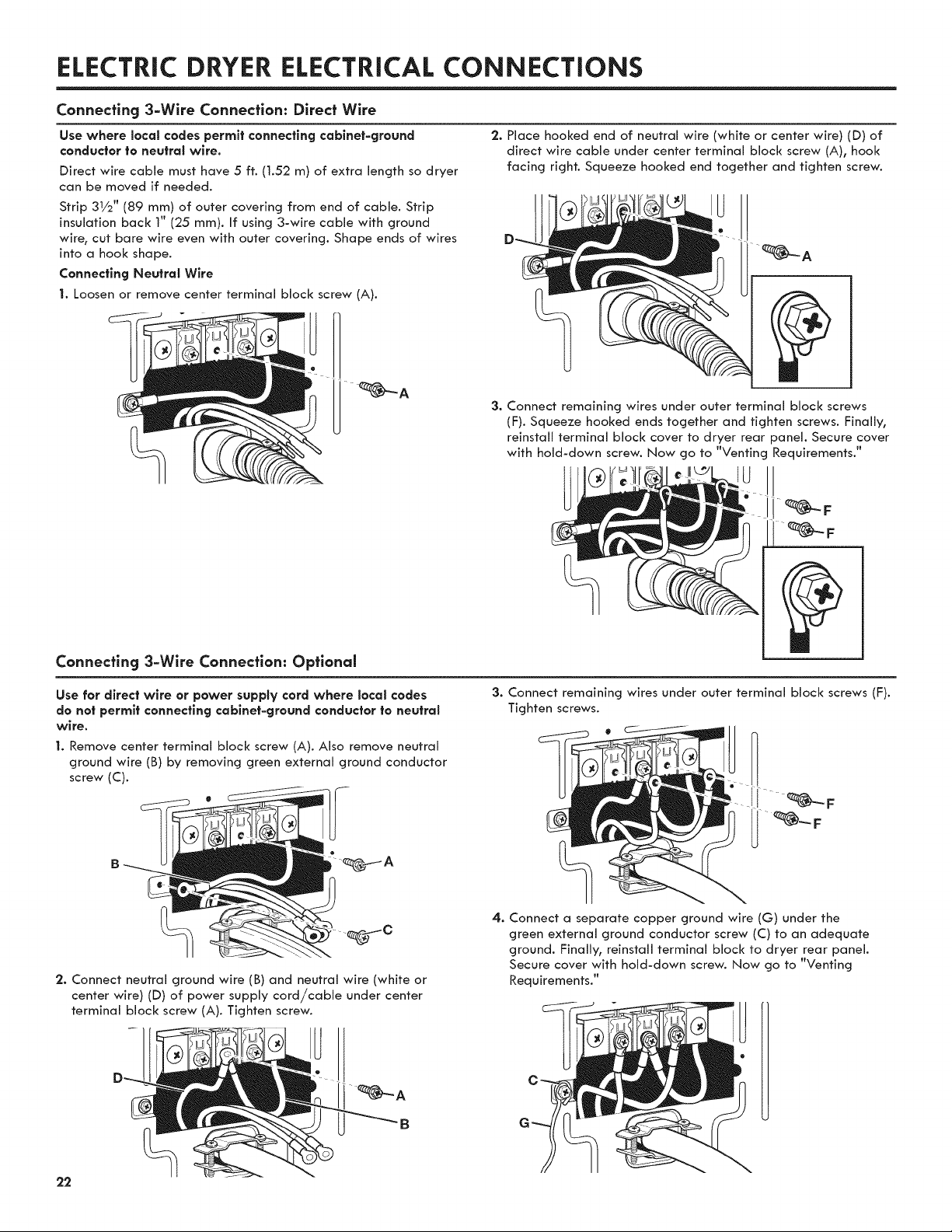

Connecting 3-Wire Connection: Direct Wire

Use where local codes permit connecting cabinet-ground

conductor to neutral wire.

Direct wire cable must have 5 ft. (1.52 m) of extra length so dryer

can be moved if needed.

Strip 31/2'' (89 ram) of outer covering from end of cable. Strip

insulation back 1" (25 mm). If using 3-wire cable with ground

wire, cut bare wire even with outer covering. Shape ends of wires

into a hook shape.

Connecting Neutral Wire

1. Loosen or remove center terminal block screw (A).

2. Place hooked end of neutral wire (white or center wire) (D) of

direct wire cable under center terminal block screw (A), hook

facing right. Squeeze hooked end together and tighten screw.

3. Connect remaining wires under outer terminal block screws

(F). Squeeze hooked ends together and tighten screws. Finally,

reinstall terminal block cover to dryer rear panel. Secure cover

with hold-down screw. Now go to "Venting Requirements."

Connecting 3-Wire Connection: ONional

Use for direct wire or power supply cord where local codes

do not permit connecting cabinet-ground conductor to neutral

wire.

1. Remove center terminal block screw (A). Also remove neutral

ground wire (B) by removing green external ground conductor

screw (C).

O

B

2. Connect neutral ground wire (B) and neutral wire (white or

center wire) (D) of power supply cord/cable under center

terminal block screw (A). Tighten screw.

3. Connect remaining wires under outer terminal block screws (F).

Tighten screws.

4. Connect a separate copper ground wire (G) under the

green external ground conductor screw (C) to an adequate

ground. Finally, reinstall terminal block to dryer rear panel.

Secure cover with hold-down screw. Now go to "Venting

Requirements."

22

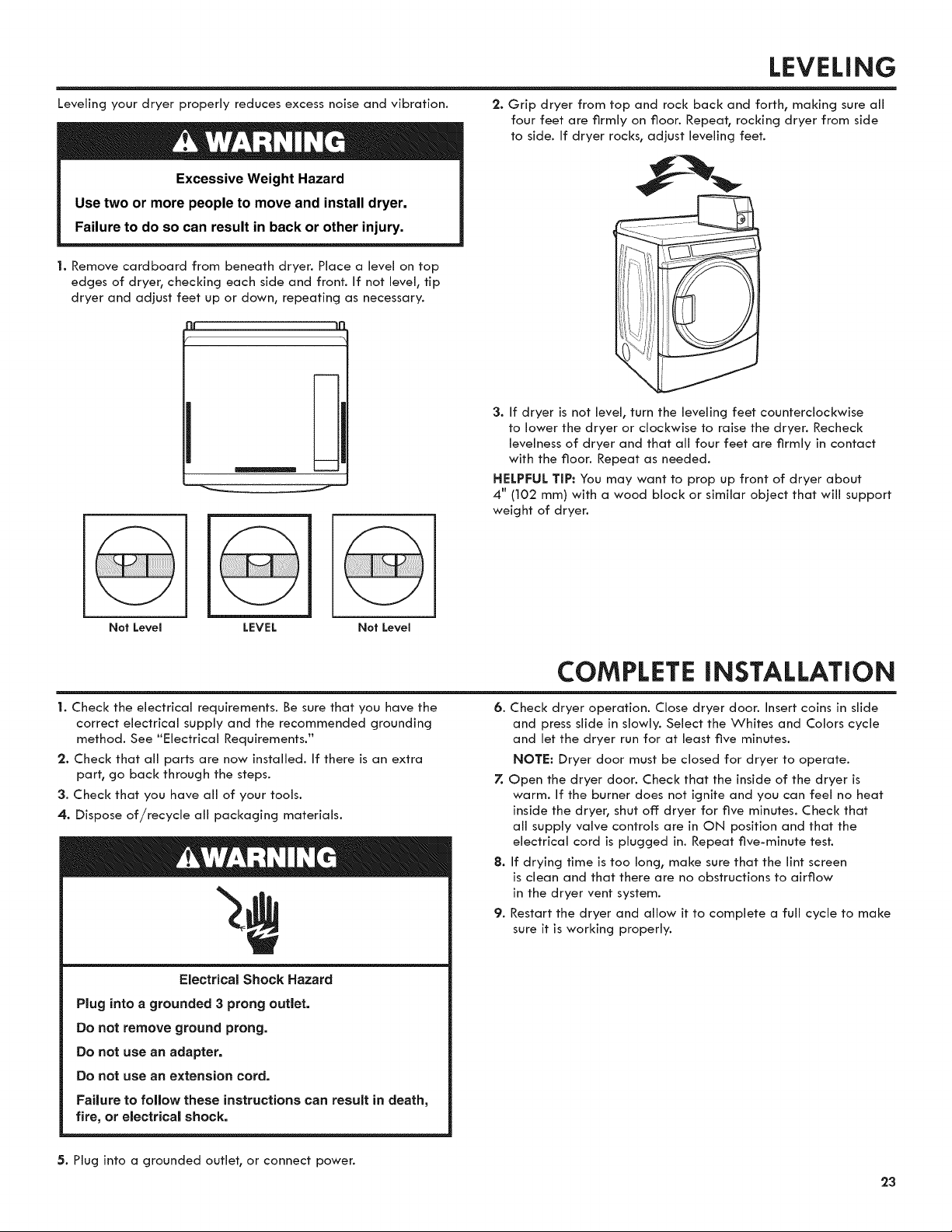

LEVELING

Leveling your dryer properly reduces excess noise and vibration.

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

1. Remove cardboard from beneath dryer. Place a level on top

edges of dryer, checking each side and front. If not level, tip

dryer and adjust feet up or down, repeating as necessary.

8[ )8

2. Grip dryer from top and rock back and forth, making sure all

four feet are firmly on floor. Repeat, rocking dryer from side

to side. If dryer rocks, adjust leveling feet.

3. If dryer is not level, turn the leveling feet counterclockwise

to lower the dryer or clockwise to raise the dryer. Recheck

levelness of dryer and that all four feet are firmly in contact

with the floor. Repeat as needed.

HELPFUL TiP: You may want to prop up front of dryer about

4" (102 ram) with a wood block or similar object that will support

weight of dryer.

Not Level LEVEL Not Level

1. Check the electrical requirements. Be sure that you have the

correct electrical supply and the recommended grounding

method. See °'Electrical Requirements."

2. Check that all parts are now installed. If there is an extra

part, go back through the steps.

3. Check that you have all of your tools.

4. Dispose of/recycle all packaging materials.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

COMPLETE iNSTALLATiON

6. Check dryer operation. Close dryer door. Insert coins in slide

and press slide in slowly. Select the Whites and Colors cycle

and let the dryer run for at least five minutes.

NOTE: Dryer door must be closed for dryer to operate.

7. Open the dryer door. Check that the inside of the dryer is

warm. If the burner does not ignite and you can feel no heat

inside the dryer, shut off dryer for five minutes. Check that

all supply valve controls are in ON position and that the

electrical cord is plugged in. Repeat five-minute test.

8. If drying time is too long, make sure that the lint screen

is clean and that there are no obstructions to airflow

in the dryer vent system.

9. Restart the dryer and allow it to complete a full cycle to make

sure it is working properly.

5. Hug into a grounded outlet, or connect power.

23

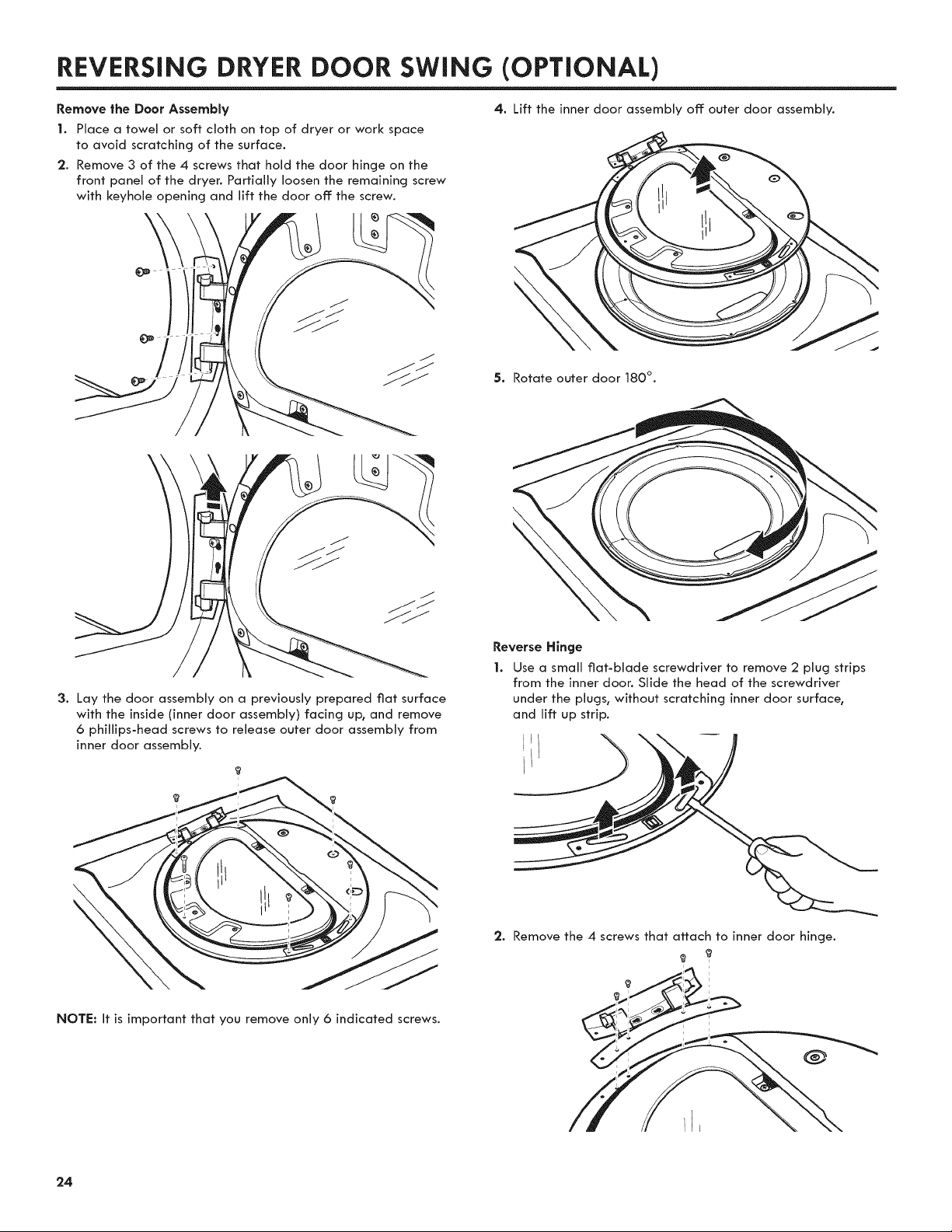

REVERSING DRYER DOOR SWING (OPTIONAL)

Remove the Door Assembly

1. Place a towel or soft cloth on top of dryer or work space

to avoid scratching of the surface.

2. Remove 3 of the 4 screws that hold the door hinge on the

front panel of the dryer. Partially loosen the remaining screw

with keyhole opening and lift the door off the screw.

\

4. Lift the inner door assembly off outer door assembly.

5. Rotate outer door 180 °.

3. Lay the door assembly on a previously prepared fiat surface

with the inside (inner door assembly) facing up, and remove

6 phillips=head screws to release outer door assembly from

inner door assembly.

NOTE: It is important that you remove only 6 indicated screws.

Reverse Hinge

1. Use a small fiat=blade screwdriver to remove 2 plug strips

from the inner door. Slide the head of the screwdriver

under the plugs, without scratching inner door surface,

and lift up strip.

2. Remove the 4 screws that attach to inner door hinge.

24

REVERSING DRYER DOOR SWING (OPTIONAL)

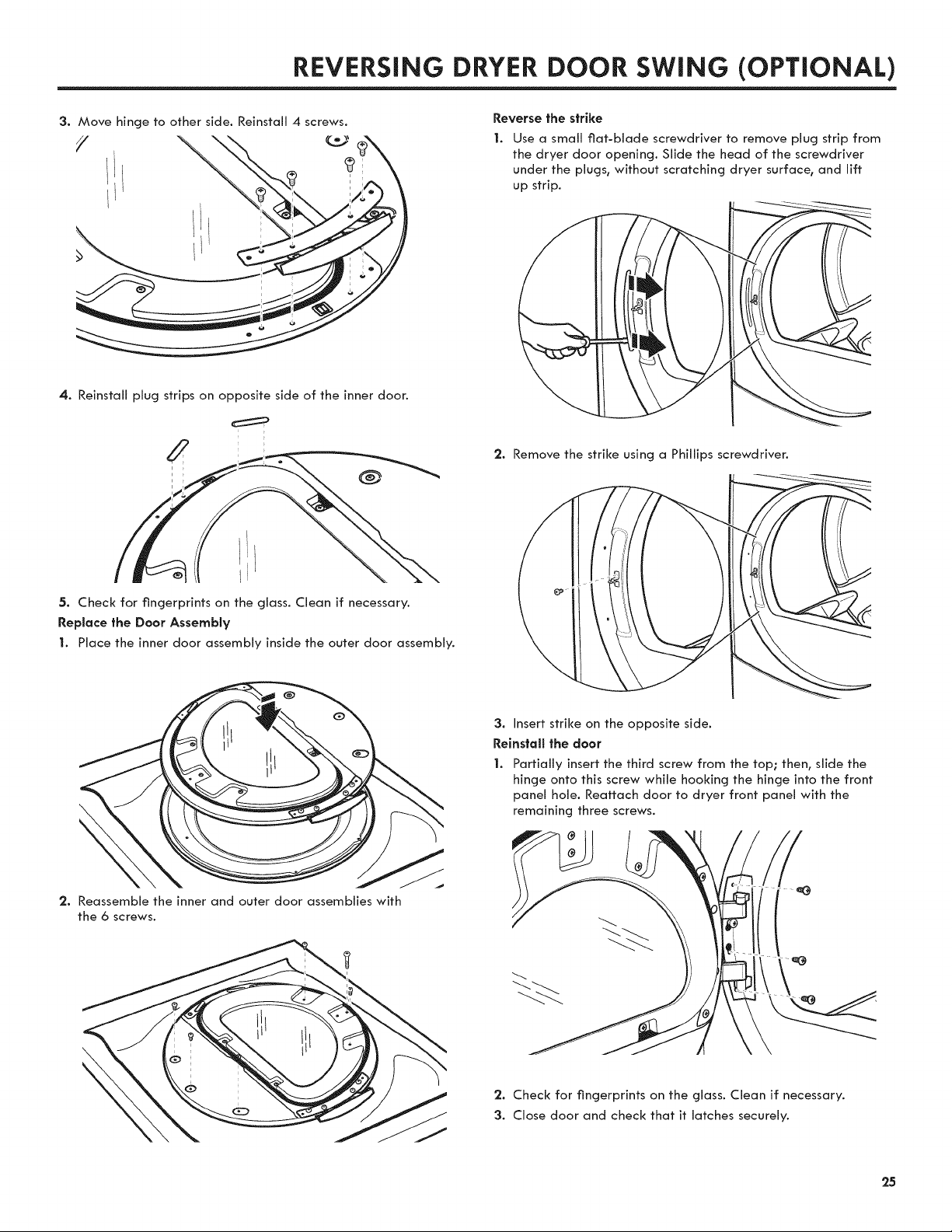

3. Move hinge to other side. Reinstall 4 screws.

7

4. Reinstall plug strips on opposite side of the inner door.

Reverse the strike

1. Use a small fiat-blade screwdriver to remove plug strip from

the dryer door opening. Slide the head of the screwdriver

under the plugs, without scratching dryer surface, and lift

up strip.

2. Remove the strike using a Phillips screwdriver.

5. Check for fingerprints on the glass. Clean if necessary.

Replace the Door Assembly

1. Place the inner door assembly inside the outer door assembly.

2. Reassemble the inner and outer door assemblies with

the 6 screws.

3. Insert strike on the opposite side.

Reinstall the door

1. Partially insert the third screw from the top; then, slide the

hinge onto this screw while hooking the hinge into the front

panel hole. Reattach door to dryer front panel with the

remaining three screws.

2, Check for fingerprints on the glass. Clean if necessary.

3. Close door and check that it latches securely.

25

MAINTENANCE (NSTRUCT(ONS

[] Clean lint screen before and after each cycle.

[] Removing accumulated lint..

From inside the dryer cabinet..

Lint shou(d be removed every 2 years or more often,

depending on dryer usage. Cleaning should be done

by a qualified person.

From the exhaust vent..

Lint should be removed every 2 years, or more often,

depending on dryer usage.

[] Keep area around dryer clear and free from combustible

materials, gasoline, and other flammable vapors and liquids.

[] Keep dryer area clear and free from items that would

obstruct the flow of combustion and ventilation air.

if dryer does not operate, check the following:

[] Electrical supply is connected.

[] Circuit breaker is not tripped or house fuse is not blown.

[] Door is c(osed. Listen c(oseiy to hear the door switch activate.

[] Contro( is set up properly and display shows cycle time.

[] Cycle se(ection button has been pushed firmly.

[] For gas dryers, check that gas supply shut-off valves are set

in open position.

26

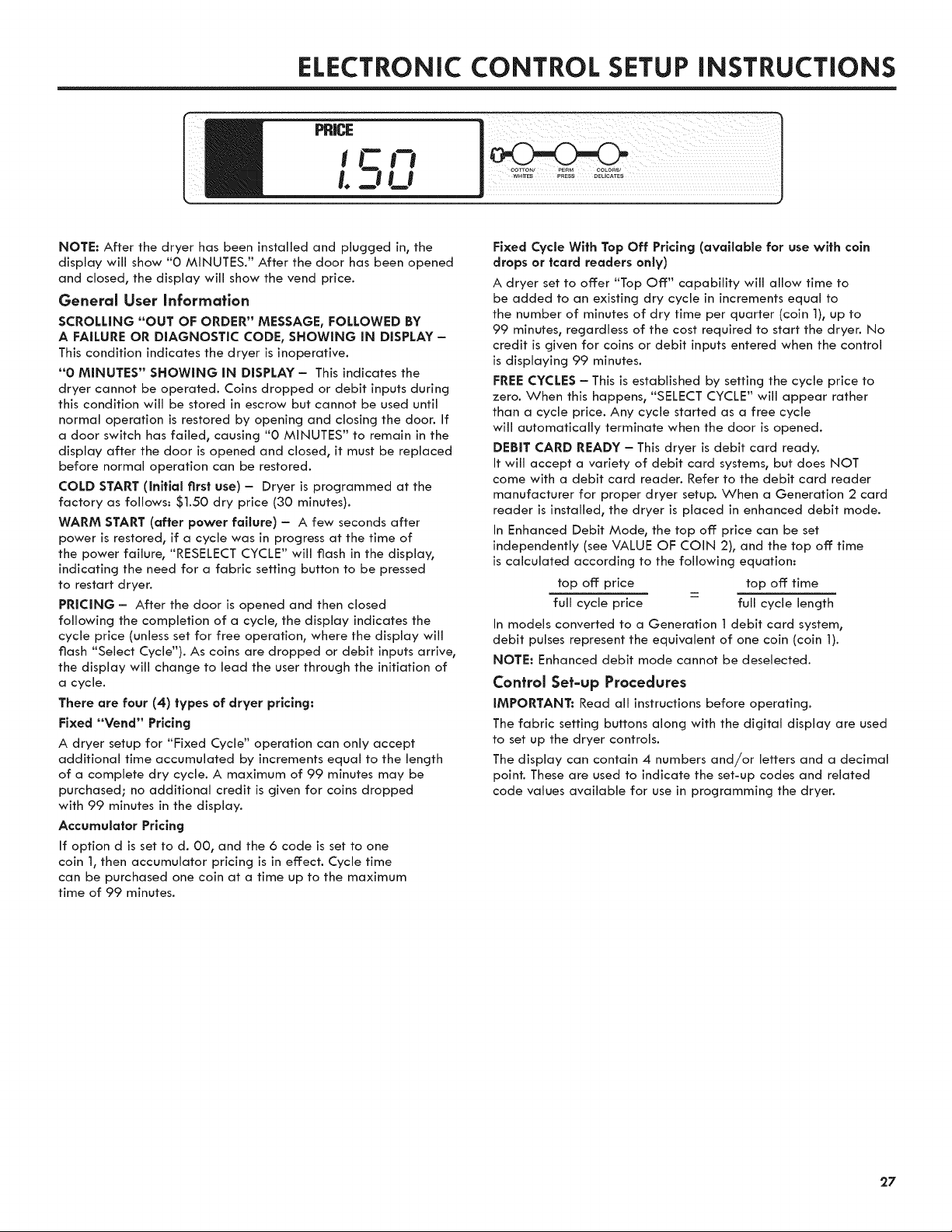

ELECTRONIC CONTROL SETUP iNSTRUCTiONS

NOTE: After the dryer has been installed and plugged in, the

display will show "0 MINUTES." After the door has been opened

and closed, the display will show the vend price.

General User information

SCROLLING "OUT OF ORDER" MESSAGE, FOLLOWED BY

A FAILURE OR DiAGNOSTiC CODE, SHOWING iN DISPLAY -

This condition indicates the dryer is inoperative.

"0 MINUTES" SHOWING IN DISPLAY - This indicates the

dryer cannot be operated. Coins dropped or debit inputs during

this condition will be stored in escrow but cannot be used until

normal operation is restored by opening and closing the door. If

a door switch has failed, causing "0 MINUTES" to remain in the

display after the door is opened and closed, it must be replaced

before normal operation can be restored.

COLD START (Initial first use) - Dryer is programmed at the

factory as follows: $1.50 dry price (30 minutes).

WARM START (after power failure) - A few seconds after

power is restored, if a cycle was in progress at the time of

the power failure, "RESELECT CYCLE" will flash in the dispiay,

indicating the need for a fabric setting button to be pressed

to restart dryer.

PRiCiNG - After the door is opened and then closed

following the completion of a cycle, the display indicates the

cycle price (unless set for free operation, where the display will

flash "Select Cycle"). As coins are dropped or debit inputs arrive,

the display will change to lead the user through the initiation of

a cycle.

There are four (4) types of dryer pricing:

Fixed "Vend" Pricing

A dryer setup for "Fixed Cycle" operation can only accept

additional time accumulated by increments equal to the length

of a complete dry cycle. A maximum of 99 minutes may be

purchased; no additional credit is given for coins dropped

with 99 minutes in the display.

Accumulator Pricing

If option d is set to d. 00, and the 6 code is set to one

coin 1, then accumulator pricing is in effect. Cycle time

can be purchased one coin at a time up to the maximum

time of 99 minutes.

Fixed Cycle With Top Off Pricing (available for use with coin

drops or tcard readers only)

A dryer set to offer "Top Off" capability will allow time to

be added to an existing dry cycle in increments equal to

the number of minutes of dry time per quarter (coin 1), up to

99 minutes, regardless of the cost required to start the dryer. No

credit is given for coins or debit inputs entered when the control

is displaying 99 minutes.

FREE CYCLES - This is established by setting the cycle price to

zero. When this happens, "SELECT CYCLE" will appear rather

than a cycle price. Any cycle started as a free cycle

will automatically terminate when the door is opened.

DEBIT CARD READY - This dryer is debit card ready.

It will accept a variety of debit card systems, but does NOT

come with a debit card reader. Refer to the debit card reader

manufacturer for proper dryer setup. When a Generation 2 card

reader is installed, the dryer is placed in enhanced debit mode.

In Enhanced Debit Mode, the top off price can be set

independently (see VALUE OF COIN 2), and the top off time

is calculated according to the following equation:

top off price top off time

full cycle price full cycle length

In models converted to a Generation I debit card system,

debit pulses represent the equivalent of one coin (coin 1).

NOTE: Enhanced debit mode cannot be deselected.

j_

Control Set=up Procedures

iMPORTANT: Read all instructions before operating.

The fabric setting buttons along with the digital display are used

to set up the dryer controls.

The display can contain 4 numbers and/or letters and a decimal

point. These are used to indicate the set-up codes and related

code values available for use in programming the dryer.

27

ELECTRONIC CONTROL SETUP iNSTRUCTiONS

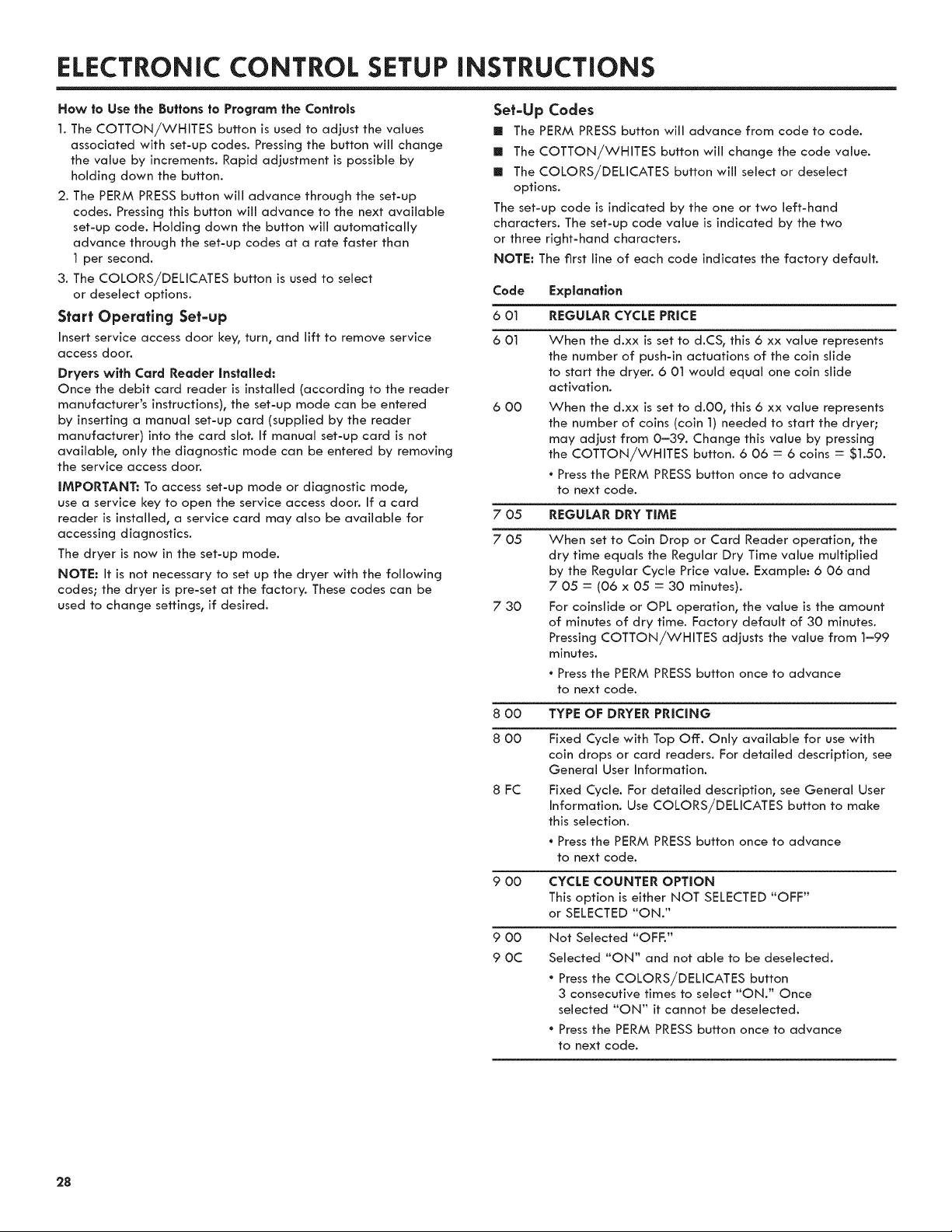

How to Use the Buttons to Program the Controls

1. The COTTON/WHITES button is used to adjust the values

associated with set-up codes. Pressing the button will change

the value by increments. Rapid adjustment is possible by

holding down the button.

2. The PERM PRESS button will advance through the set-up

codes. Pressing this button will advance to the next available

set-up code. Holding down the button will automatically

advance through the set-up codes at a rate faster than

1 per second.

3. The COLORS/DELICATES button is used to select

or deselect options. Code

Start Operating Set=up 6 01

Insert service access door key, turn, and lift to remove service 6 01

access door.

Dryers with Cord Reader Installed:

Once the debit card reader is installed (according to the reader

manufacturer's instructions), the set-up mode can be entered 6 O0

by inserting a manual set-up card (supplied by the reader

manufacturer) into the card slot. If manual set-up card is not

available, only the diagnostic mode can be entered by removing

the service access door.

iMPORTANT: To access set-up mode or diagnostic mode,

use a service key to open the service access door. If a card

reader is installed, a service card may also be available for

accessing diagnostics.

The dryer is now in the set-up mode.

NOTE: it is not necessary to set up the dryer with the following

codes; the dryer is pre-set at the factory. These codes can be

used to change settings, if desired. 7 30

Set=Up Codes

[] The PERM PRESS button will advance from code to code.

[] The COTTON/WHITES button will change the code value.

[] The COLORS/DELICATES button will select or deselect

The set-up code is indicated by the one or two left-hand

characters. The set-up code value is indicated by the two

or three right-hand characters.

NOTE: The first line of each code indicates the factory default.

7 05 REGULAR DRY TiME

7 05

8 O0 TYPE OF DRYER PRiCiNG

8 O0

8 FC

9 O0

9 O0

90C

options.

Explanation

REGULAR CYCLEPRICE

When the d.xx is set to d.CS, this 6 xx value represents

the number of push-in actuations of the coin slide

to start the dryer. 6 01 would equal one coin slide

activation.

When the d.xx is set to d.O0, this 6 xx value represents

the number of coins (coin 1) needed to start the dryer;

may adjust from 0-39. Change this value by pressing

the COTTON/WHITES button. 6 06 = 6 coins = $1.50.

* Press the PERM PRESS button once to advance

to next code.

When set to Coin Drop or Card Reader operation, the

dry time equals the Regular Dry Time value multiplied

by the Regular Cycle Price value. Example: 6 06 and

7 05 = (06 x 05 = 30 minutes).

For coinslide or OPL operation, the value is the amount

of minutes of dry time. Factory default of 30 minutes.

Pressing COTTON/WHITES adjusts the value from 1-99

minutes.

* Press the PERM PRESS button once to advance

to next code.

Fixed Cycle with Top Off. Only available for use with

coin drops or card readers. For detailed description, see

General User Information.

Fixed Cycle. For detailed description, see General User

Information. Use COLORS/DELICATES button to make

this selection.

* Press the PERM PRESS button once to advance

to next code.

CYCLECOUNTER OPTION

This option is either NOT SELECTED"OFF"

or SELECTED"ON."

Not Selected "OFF."

Selected "ON" and not able to be deselected.

* Press the COLORS/DELICATES button

3 consecutive times to select "ON." Once

selected "ON" it cannot be deselected.

* Press the PERM PRESS button once to advance

to next code.

28

Loading...

Loading...