Page 1

Electric Dryer

Secadora Eléctrica

Models/Modelos 110.8508^, 8509^, 8586^^^, 8587:^^

= color number/número de color

8576658 Sears Roebuck and Co., Hoffman Estates, IL 60179 U.S.A. www.seai^.com

Page 2

TABLE OF CONTENTS

PROTECTION AGREEMENTS

PROTECTION AGREEMENTS..................................................2

WARRANTY...............................................................................3

PEDESTAL OPTION WARRANTY............................................3

DRYER SAFETY........................................................................4

INSTALLATION INSTRUCTIONS

Tools and Parts.......................................................................5

Optional Pedestal....................................................................5

Location Requirements...........................................................6

Electrical Requirements..........................................................8

Electrical Connection..............................................................9

Venting Requirements

Plan Vent System

Install Vent System...............................................................16

Install Leveling Legs

Connect Vent........................................................................17

Level Dryer

Reverse Door Swing.............................................................17

Complete Installation

DRYER USE.............................................................................20

Starting Your Dryer

Stopping Your Dryer.............................................................21

Pausing or Restarting...........................................................21

Control Locked

Drying and Cycle Tips

Status Lights

Cycles...................................................................................22

Options..................................................................................23

Modifiers...............................................................................24

Changing Cycles, Options and Modifiers..............................24

End of Cycle Signal

TUMBLE FREE™ Heated Dryer Rack..................................24

DRYER CARE.........................................................................25

Cleaning the Dryer Location

Cleaning the Lint Screen.......................................................25

Cleaning the Dryer Interior....................................................26

Removing Accumulated Lint

Vacation and Moving Care....................................................26

Changing the Drum Light

TROUBLESHOOTING

SERVICE NUMBERS

...........................................................................

.........................................................................

..........................................................

.................................................................

.............................................................

............................................................

...............................................................

.....................................................................

..........................................................

..............................................................

.............................................................

............................................

.............................................

.................................................

.................................................

......................................................

BACK COVER

14

15

16

17

19

20

21

21

22

24

25

26

26

27

Master Protection Agreements

Congratulations on making a smart purchase. Your new

Kenmore® product is designed and manufactured for years of

dependable operation. But like all products, it may require

preventive maintenance or repair from time to time. That’s when

5

having a Master Protection Agreement can save you money and

aggravation.

PurchasQ a Master Protection Agreement now and protect

yourself from unexpected hassle and expense.

The Master Protection Agreement also helps extend the life of

your new product. Here’s what’s included in the Agreement:

✓ Expert service by our 12,000 professional repair specialists

✓ Unlimited service and no charge for parts and labor on all

covered repairs

✓ “No-lemon” guarantee - replacement of your covered

product if four or more product failures occur within twelve

months

✓ Product replacement if your covered product can’t be fixed

✓ Annual Preventive Maintenance Check at your request - no

extra charge

✓ Fast help by phone - phone support from a Sears technician

on products requiring in-home repair, plus convenient repair

scheduling

✓ Power surge protection against electrical damage due to

power fluctuations

✓ Rental reimbursement if repair of your covered product takes

longer than promised

Once you purchase the Agreement, a simple phone call is all that

it takes for you to schedule service. You can call anytime day or

night, or schedule a service appointment online.

Sears has over 12,000 professional repair specialists, who have

access to over 4.5 million quality parts and accessories. That’s

the kind of professionalism you can count on to help prolong the

life of your new purchase for years fo come. Purchase your

Master Protection Agreement today!

Some limitations and exclusions apply. For prices and

additional information, call 1-800-827-6655.

Sears Installation Service

For Sears professional installation of home appliances, garage

door openers, water heaters, and other major home items, in the

U.S.A. call 1-800-4-MY-HOME®.

Page 3

WARRANTY

PEDESTAL OPTION

FULL ONE-YEAR WARRANTY ON MECHANICAL AND ELECTRICAL PARTS

For one year from the date of purchase, when this dryer is

installed and operated according to the Instructions provided in

this Use and Care Guide, Sears will repair this dryer, free of

charge, if defective in materials or workmanship.

NOTE: Exhausting this dryer with a plastic vent will void this

warranty. See “Installation Instructions" for the complete exhaust

requirements for this dryer.

Limited Two-Year Warranty on Eiectronic Controi Board

For the second year from the date of purchase, Sears will replace

the electronic control board if defective in material or

workmanship. You will be charged for labor after the first year.

Warranty Restriction

If the dryer is subject to other than private family use, the above

warranty coverage is effective for only 90 days.

Warranty Service

Warranty service is available by contacting the nearest Sears

Service Center. This warranty applies only while the product is in

use in the United States.

This warranty gives you specific legal rights and you may also

have other rights which vary from state to state.

For Sears Warranty information or to contact a Sears Service

Center, please refer to the service numbers located on the back

page of this manual.

Sears, Roebuck and Co.

D/817WA, Hoffman Estates, IL 60179

WARRANTY

Full One-Year Warranty on Mechanical Parts

For one year from the date of purchase, supplier will repair or

replace any of its mechanical parts if defective in material or

workmanship. This Pedestal must be installed with this dryer

according to the instructions provided in the Pedestal Installation

Instructions.

Warranty Restriction

If the Pedestal is subject to other than private family use and/or

used with any other product than those listed in the installation

instructions, this warranty is null and void.

In the space following, record your complete model number,

serial number, and purchase date. You can find this information

on the model and serial number label.

Have this information available to help you quickly obtain

assistance or service when you contact Sears concerning your

appliance.

Model number 110.__________________________________________

Serial number

Purchase date

Save these instructions and your saies receipt for future

reference.

Product Record

In the space following, record your complete model number,

serial number, and purchase date. You can find this information

on the model and serial number label, located at the top inside

dryer door well.

Have this information available to help you quickly obtain

assistance or service when you contact Sears concerning your

appliance.

Model number 110.

Serial number

Purchase date

Save these instructions and your sales receipt for future

reference.

__________________________________________

Page 4

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manuai and on your appliance. Aiways read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

AWARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the dryer, follow basic precautions,

including the following:

Read all instructions before using the dryer.

Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to

a chemical reaction that could cause a load to catch fire.

Do not dry articles that have been previously cleaned in.

washed in, soaked In, or spotted with gasoline, dry

cleaning solvents, or other flammable or explosive

substances as they give off vapors that could ignite or

explode.

Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer is

used near children.

Before the dryer is removed from service or discarded,

remove the door to the drying compartment.

Do not reach into the dryer if the drum is moving.

Do not install or store the dryer where it will be exposed

to the weather.

Do not tamper with controls.

instructions.

Do not repair or replace any part of the dryer or attempt

any servicing unless specifically recommended in this

Use and Care Guide or in published user-repair

instructions that you understand and have the skills to

carry out.

Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials.

Clean lint screen before or after each load.

Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint, dust,

and dirt.

The interior of the dryer and exhaust vent should be

cleaned periodically by qualified service personnel.

See installation instructions for grounding requirements.

SAVE THESE INSTRUCTIONS

Page 5

INSTALLATION INSTRUCTIONS

Gather the required tools and parts before starting installation.

Read and follow the instruotions provided with any tools listed

here.

Flat-blade screwdriver

#2 Phillips screwdriver

Adjustable wrench that

opens to 1" (2,54 cm) or

hex-head socket wrench

(for adjusting dryer feet)

Wire stripper (for direct

wire installations)

Level

Parts supplied

Remove parts package from dryer drum. Check that all parts are

included.

4 Leveling legs

NOTE: Do not use leveling legs if installing the dryer on a

pedestal.

Vent clamps

Caulking gun and

compound (for installing

new exhaust vent)

Tin snips (new vent

installations)

Va" nut driver or socket

wrench (recommended)

Tape measure

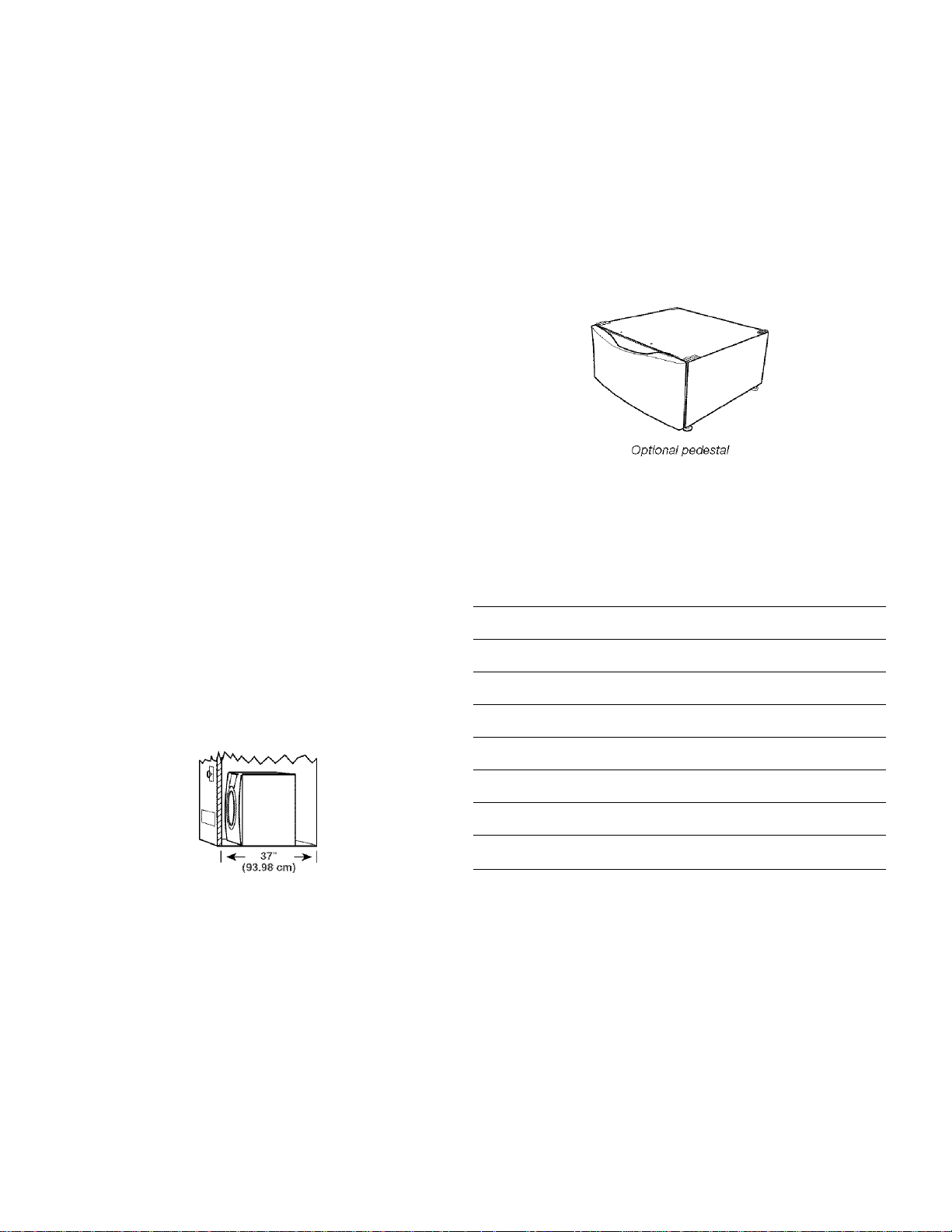

Are you placing the dryer on a pedestal? You have the option of

purchasing pedestals of different heights separately for this dryer.

You may select a 13" (33 cm) ora 15.5" (39.4 cm) pedestal. These

pedestals will add to the total height of the unit for a total height

of approximately 51" (129.5 cm) or 53" (134.6 cm).

For a garage installation, you will need to place the 13" (33 cm)

pedestal at least 6" (15.2 cm) above the floor. You will need to

place the 15.5" (39.4 cm) pedestal at least 3" (7.6 cm) above the

floor.

The pedestal (with storage drawer) is available in several colors.

To order, call your local Sears store. For further information,

please call 1-800-4-MY-HOME® (1-800-469-4663).

Pedestal

Height

13" (33 cm) White 42842

Color Part

Number

Parts needed

Check local codes. Check existing electrical supply and venting.

See “Electrical Requirements” and “Venting Requirements”

before purchasing parts.

■ For close-clearance installations between 31.5" (80.01 cm)

and 37" (93.98 cm), see “Plan Vent System” section for

venting requirements.

Mobile home installations require metal exhaust system hardware

available for purchase from your local Sears store or Sears

Service Center. For further information, please call

1-800-4-MY-HOME® (1-800-469-4663).

13" (33 cm) Bisque 42844

13" (33 cm) Graphite 42846

15.5" (39.4 cm) White 55842

15.5" (39.4 cm) Bisque 55844

15.5" (39.4 cm) Graphite 55846

15.5" (39.4 cm) Pacific Blue 55847

15.5" (39.4 cm) Champagne 55848

15.5" (39.4 cm) Sedona 55849

Page 6

AWARNING

J

U/

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches (46 cm) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

You wiii need

■ A location that allows for proper exhaust installation. See

“Venting Requirements."

■ A separate 30-amp circuit.

■ If using a power supply cord, a grounded electrical outlet

located within 2 ft (61 cm) of either side of the dryer. See

“Electrical Requirements.”

■ A sturdy floor to support the total dryer weight of 200 lbs

(90.7 kg). The combined weight of a companion appliance

should also be considered.

■ A level floor with a maximum slope of 1" (2.5 cm) under entire

dryer. (If slope is greater than 1" [2.5 cm], install Extended

Dryer Feet Kit, Part Number 279810.) Clothes may not tumble

properly and automatic sensor cycles may not operate

correctly if dryer is not level.

■ For a garage installation, you will need to place the dryer at

least 18" (46 cm) above the floor. If using a 13" (33 cm)

pedestal, you will need to place the pedestal at least

6" (15.2 cm) above the floor. If using a 15.5" (39.4 cm)

pedestal, you will need to place the pedestal at least

3" (7.6 cm) above the floor.

Do not operate your dryer at temperatures below 45“F (7°C). At

lower temperatures, the dryer might not shut off at the end of an

automatic cycle. Drying times can be extended.

The dryer must not be installed or stored in an area where it will

be exposed to water and/or weather.

Check code requirements. Some codes limit, or do not permit,

installation of the dryer in garages, closets, mobile homes, or

sleeping quarters. Contact your local building inspector.

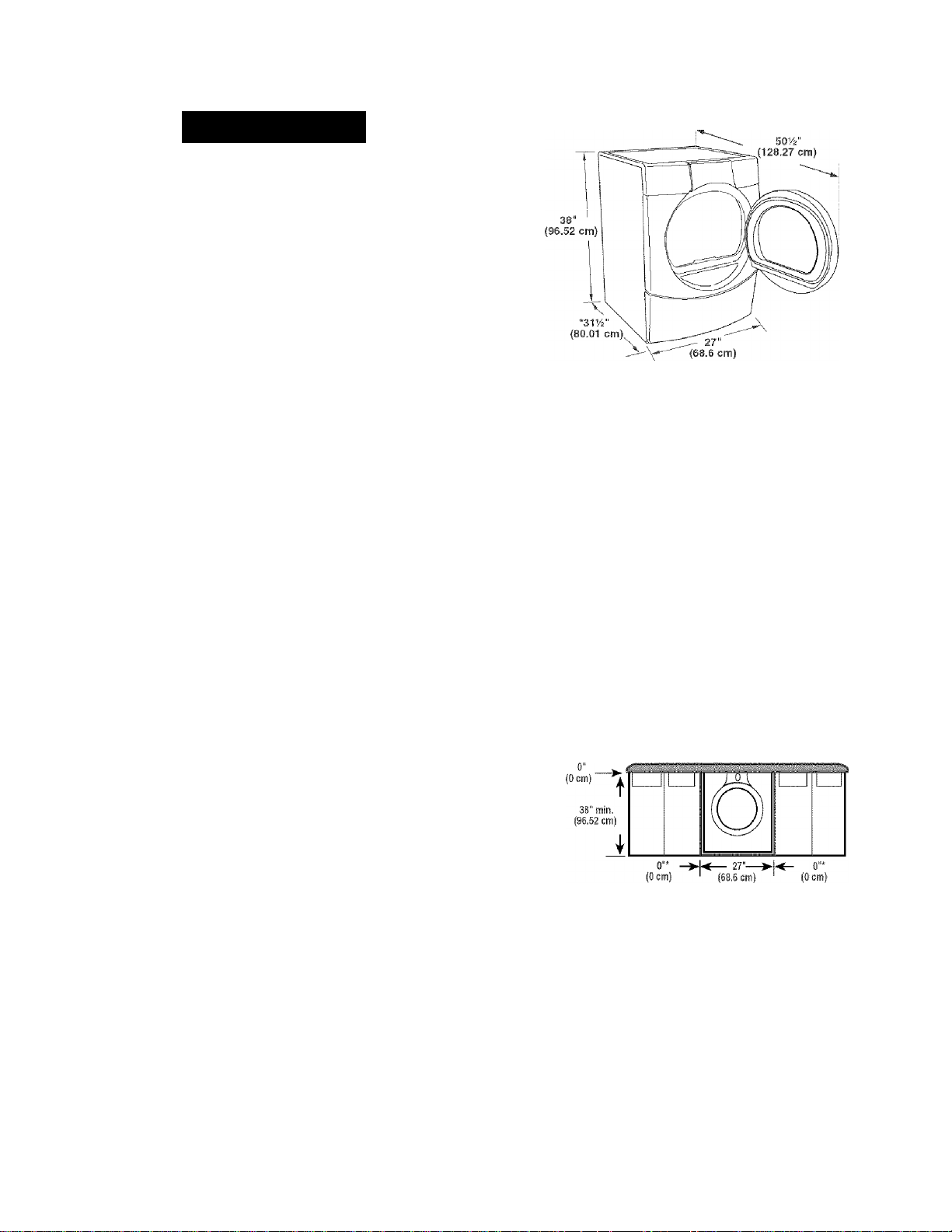

Dryer Dimensions

*Most installations require a minimum 5y2" (14 cm) clearance

behind the dryer for the exhaust vent with elbow. See “Venting

Requirements.”

Minimum installation spacing for recessed area, custom

undercounter or closet installation

The following dimensions shown are for the minimum spacing

allowed.

■ Additional spacing should be considered for ease of

installation and servicing.

■ Additional clearances might be required for wall, door and

floor moldings.

■ Additional spacing of 1" (2.5 cm) on all sides of the dryer is

recommended to reduce noise transfer.

■ For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

■ Companion appliance spacing should also be considered.

Custom undercounter installation - Dryer only

‘Additional spacing recommended

Installation clearances

The location must be large enough to allow the dryer door to

open fully.

Page 7

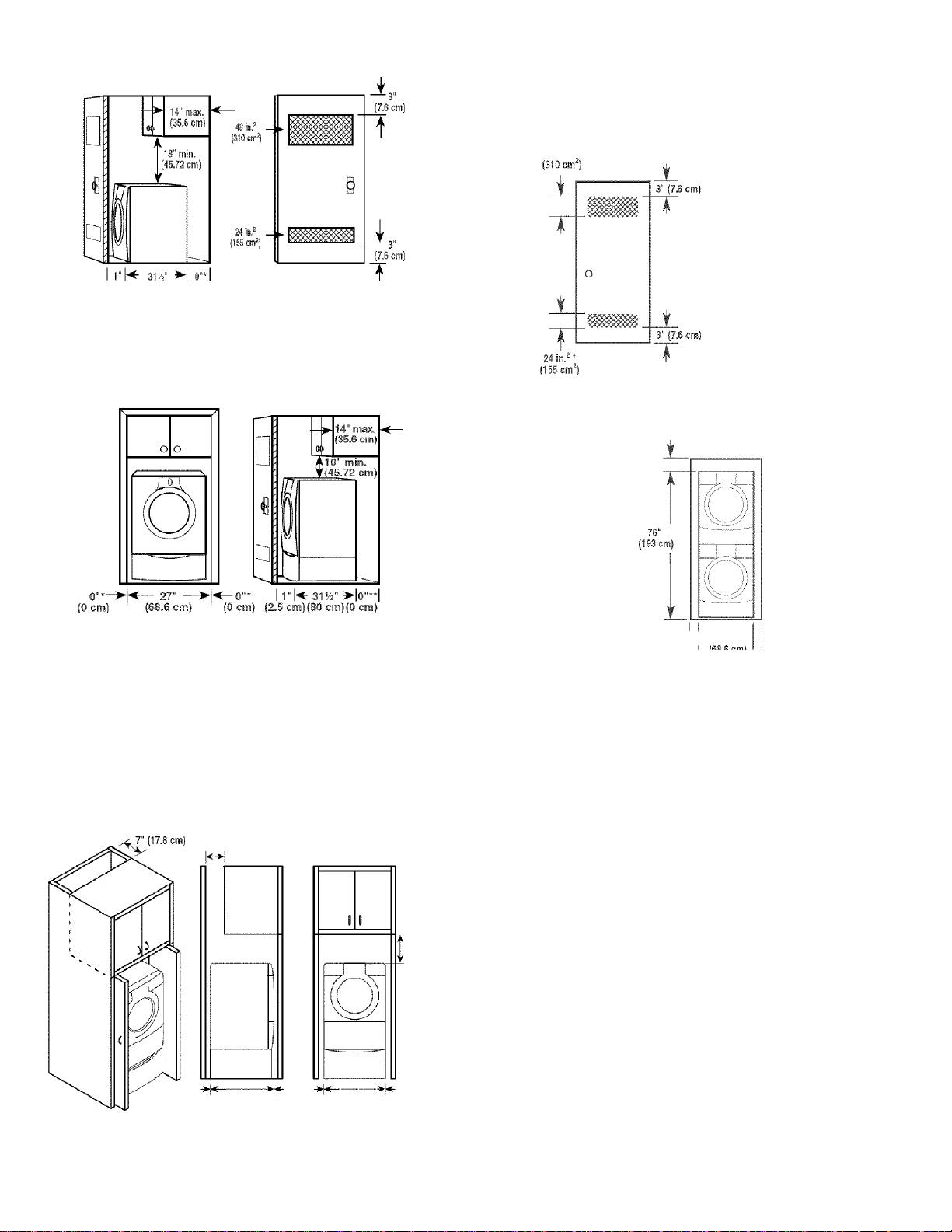

Closet installation - Dryer only

Recommended installation spacing for recessed or closet installation, with stacked washer and dryer

The dimensions shown are for the recommended spacing.

48 in.^

(2.5 cm) (80 cm)

(0 cm)

A

A. Side view - closet or confined area

B. Closet door with vents

‘Side or bottom venting - additional spacing recommended

Recessed or closet installation - Dryer on pedestal

A. Recessed area

B. Side view - closet or confined area

‘Additional spacing recommended

‘Side or bottom venting - additional spacing recommended

Minimum installation spacing for cabinet installation

The dimensions shown are for the minimum spacing allowed.

For cabinet installation, with a door, minimum ventilation

openings in the top of the cabinet are required.

7" (17.8 cm)

1" (2.5 cm)

*Min. top and bottom air openings for closet door

6“ (15.2 cm)

5K""

(14 cm) (2.5 cm)

^ 27" ^

(68.6 cm)

- r**f

(2.5 cm)

External exhaust elbow requires additional space.

**^\Nail, door and floor molding may require additional spacing.

Mobile home - additional installation requirements

This dryer is suitable for mobile home installations.

The installation must conform fo the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280).

Mobile home installations require:

■ Metal exhaust system hardware, which is available for

purchase from your local Sears store or Sears Service Center.

■ Special provisions must be made in mobile homes to

introduce outside air into the dryer. The opening (such as a

nearby window) should be at least twice as large as the dryer

exhaust opening.

0"* 31'/2" 1" 0"** 27" 0"”

(0 cm) (80.0 cm) (2.5 cm) (0 cm) (68.6 cm) (0 cm)

‘Additional spacing recommended

‘Side or bottom venting - additional spacing recommended

Page 8

It is your responsibility

■ To contact a qualified electrical installer.

■ To be sure that the electrical connection is adequate and in

conformance with the Nationai Electricai Code, ANSI/NFPA

70-latest edition and ali local codes and ordinances.

The National Electric Code requires a 4-wire supply

connection for homes built after 1996, dryer circuits involved

in remodeling after 1996, and all mobile home installations.

A copy of the above code standards can be obtained from:

National Eire Protection Association, One Batterymarch Park,

Quincy, MA 02269.

■ To supply the required 3 or 4 wire, single phase, 120/240 volt,

60 Hz., AC only electrical supply (or 3 or 4 wire, 120/208 volt

electrical supply, if specified on the serial/rating plate) on a

separate 30-amp circuit, fused on both sides of the line. A

time-delay fuse or circuit breaker is recommended. Connect

to an individual branch circuit. Do not have a fuse in the

neutral or grounding circuit.

■ Do not use an extension cord.

■ If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

Electrical Connection

To properly install your dryer, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

■ This dryer is manufactured ready to install with a 3-wire

electrical supply connection. The neutral ground wire is

permanently connected to the neutral conductor (white wire)

within the dryer. If the dryer Is installed with a 4-wire electrical

supply connection, the neutral ground wire must be removed

from the external ground conductor screw (green screw), and

secured under the neutral terminal (center or white wire) of

the terminal block. When the neutral ground wire is secured

under the neutral terminal (center or white wire) of the

terminal block, the dryer cabinet is isolated from the neutral

conductor.

■ If local codes do not permit the connection of a neutral

ground wire to the neutral wire, see “Optional 3-wlre

connection” section.

■ A 4-wlre power supply connection must be used when the

appliance is installed in a location where grounding through

the neutral conductor is prohibited. Grounding through the

neutral is prohibited for (1) new branch-circuit installations, (2)

mobile homes, (3) recreational vehicles, and (4) areas where

local codes prohibit grounding through the neutral

conductors.

If using a power supply cord:

Use a UL listed power supply cord kit marked for use with

clothes dryers. The kit should contain:

■ A UL listed 30-amp power supply cord, rated

120/240 volt minimum. The cord should be type SRD or

SRDT and be at least 4 ft (1.22 m) long. The wires that

connect to the dryer must end in ring terminals or spade

terminals with upturned ends.

■ A UL listed strain relief.

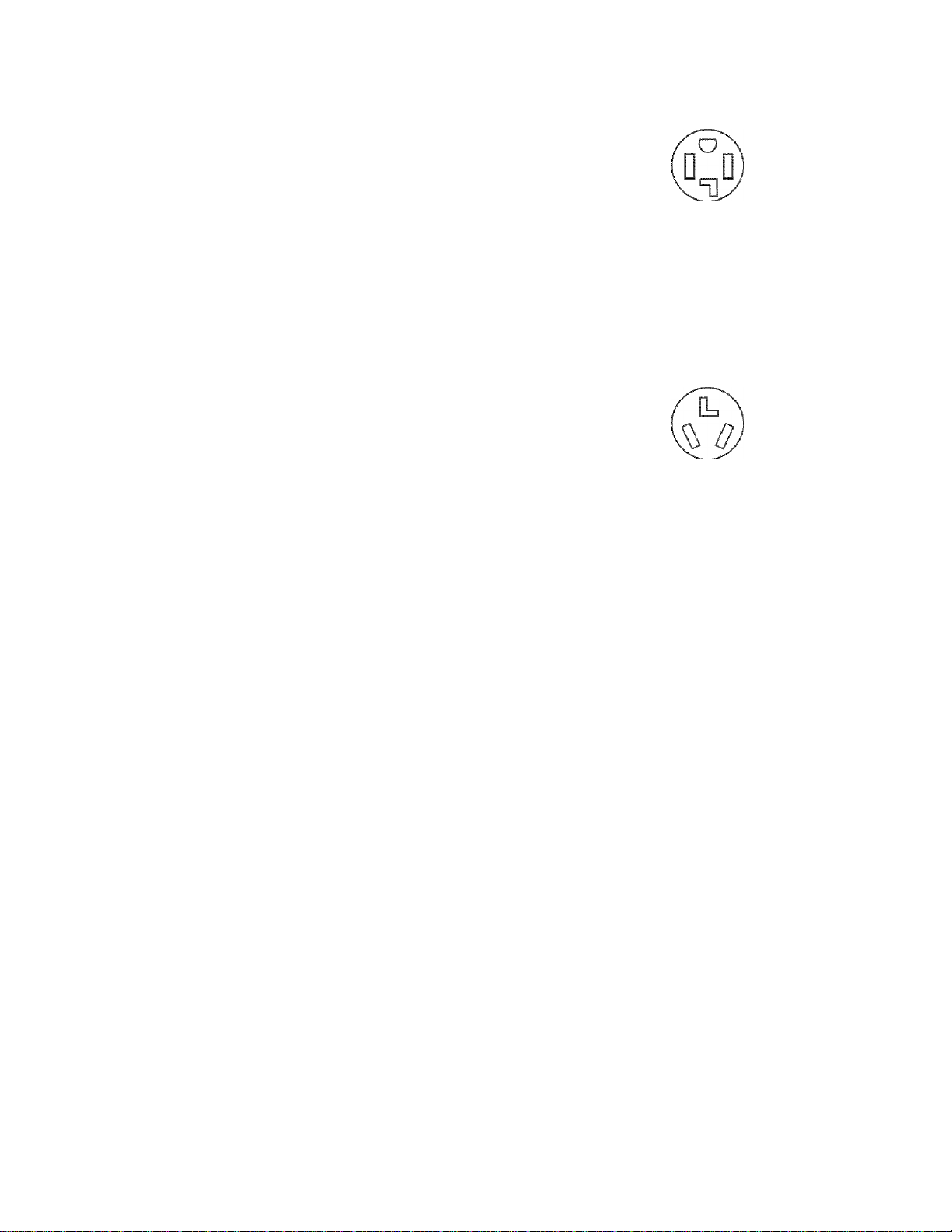

If your outlet looks like this:

4-wire recGptacIe (14-30R)

Then choose a 4-wire power supply cord with ring or spade

terminals and UL listed strain relief. The 4-wire power supply

cord, at least 4 ft (1.22 m) long, must have four 10-gauge copper

wires and match a 4-wire receptacle of NEMAType

14-30R. The ground wire (ground conductor) may be either green

or bare. The neutral conductor must be identified by a white

cover.

If your outlet looks like this:

3-wire receptacle (10-30R)

Then choose a 3-wire power supply cord with ring or spade

terminais and UL listed strain relief. The 3-wire power supply

cord, at least 4 ft (1.22 m) long, must have three 10-gauge copper

wires and match a 3-wire receptacle of NEMAType 10-30R.

If connecting by direct wire:

Power supply cable musf match power supply (4-wire or 3-wire)

and be:

■ Flexible armored cable or nonmetallic sheathed copper cable

(with ground wire), protected with flexible metallic conduit. All

current-carrying wires must be insulated.

■ 10-gauge solid copper wire (do not use aluminum).

■ At least 5 ft (1.52 m) long.

GROUNDING INSTRUCTIONS

■ For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer uses a cord having an equipment-grounding

conductor and a grounding piug. The plug must be plugged

into art appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

■ For a permanently connected dryer:

This dryer must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the dryer.

WARNING: Improper connection of the equipment

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug on the power

supply cord: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

Page 9

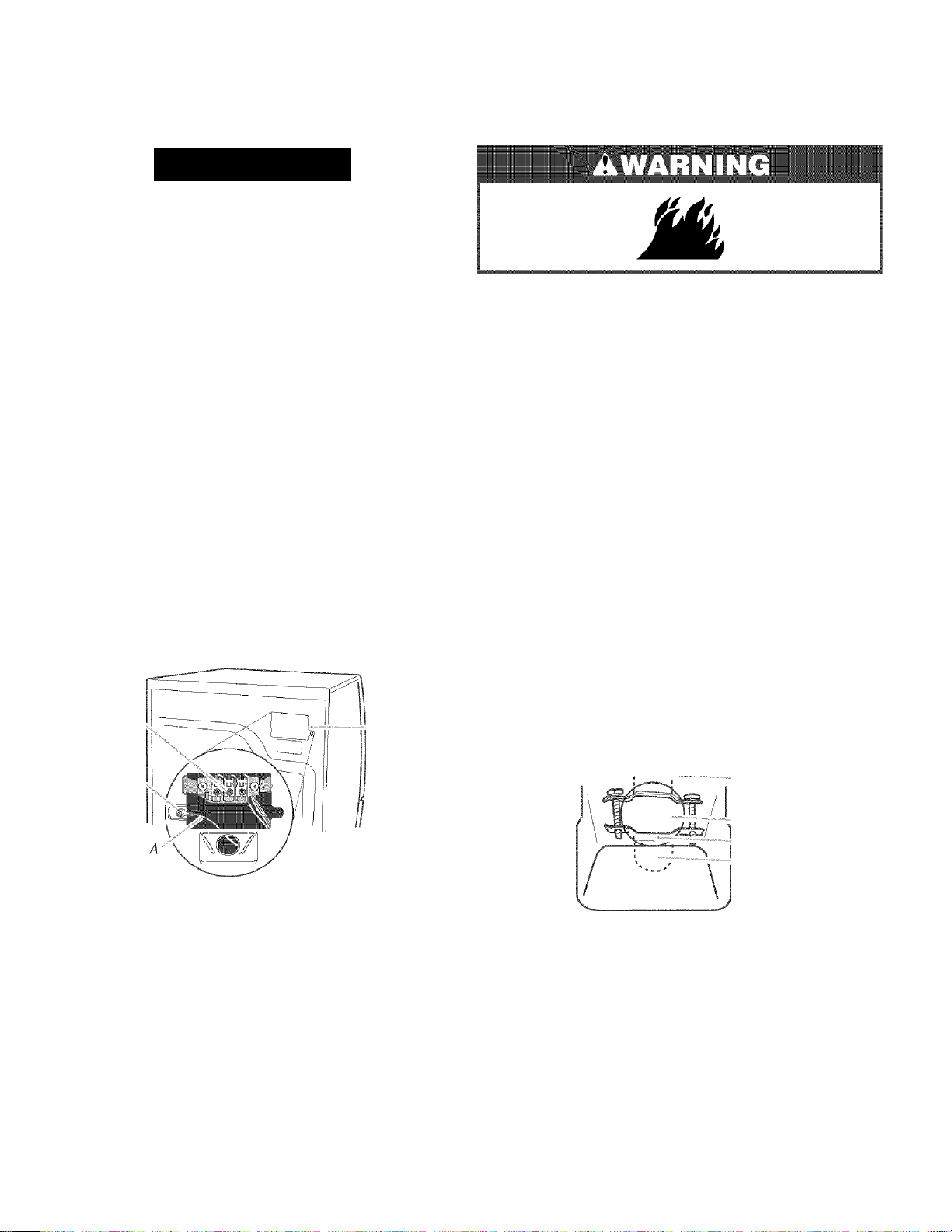

Power Supply Cord Direct Wire

▲WARNING

M

Fire Hazard

Use a new UL listed 30 amp power supply cord.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire {white or center wire) to center

terminal (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

1. Disconnect power.

2. Remove the hold-down screw and terminal block cover.

C..

Fire Hazard

Use 10 gauge solid copper wire.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire {white or center wire) to center

terminal (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten alt electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

3. Install strain relief.

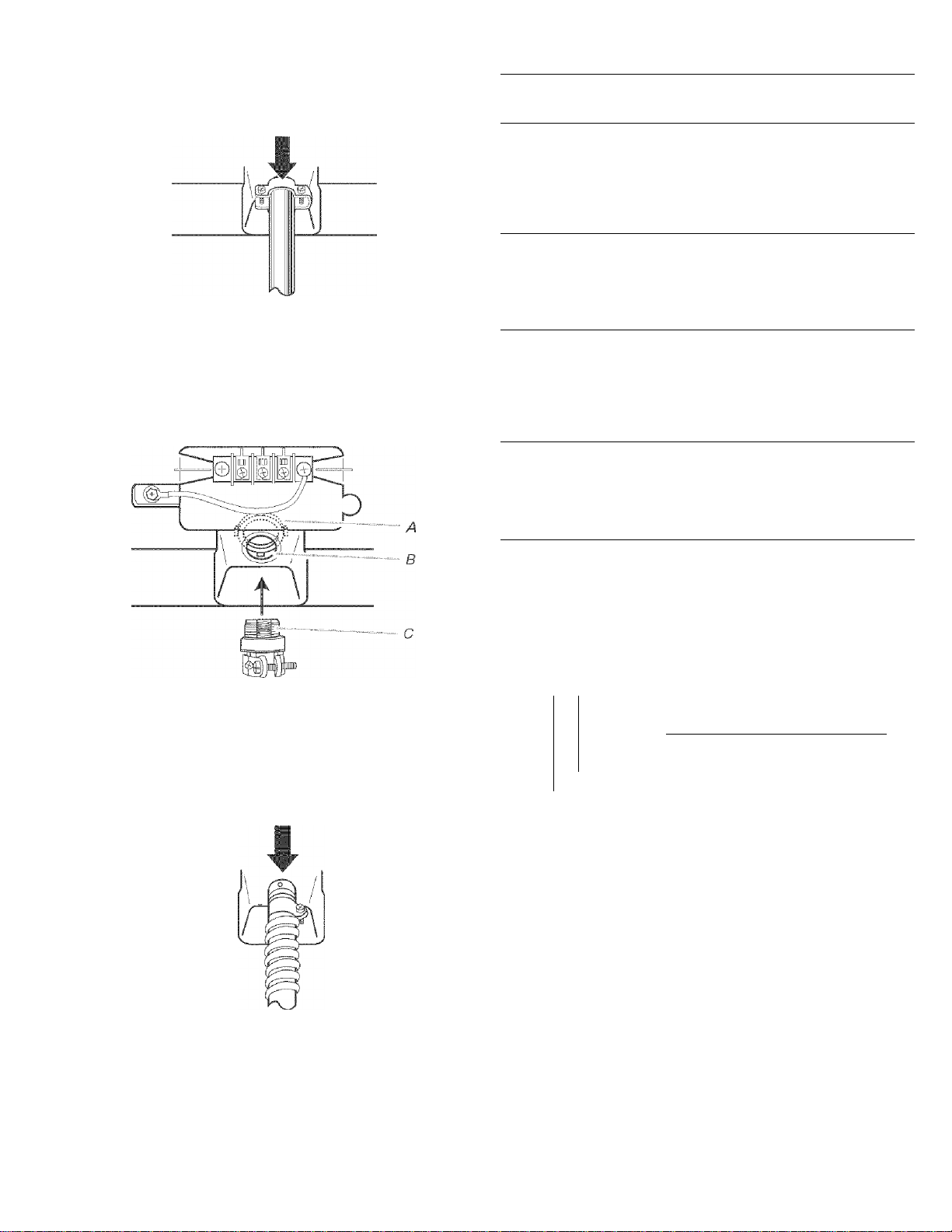

Style 1: Power supply cord strain relief

■ Remove the screws from a %" (1.9 cm) UL listed strain

relief (UL marking on strain relief). Put the tabs of the two

clamp sections into the hole below the terminal block

opening so that one tab is pointing up and the other is

pointing down, and hold in place. Tighten strain relief

screws just enough to hold the two clamp sections

together.

A. Neutral ground wire

B. External ground conductor screw

C. Center, silver-colored terminal block screw

D. Terminal block cover and hold-down screw

C

D

A. Strain relief tab pointing up

B, Hole below terminal block opening

C, Clamp section

D. Strain relief tab pointing down

Page 10

Put power supply cord through the strain relief. Be sure

that the wire insulation on the power supply cord is inside

the strain relief. The strain relief should have a tight fit with

the dryer cabinet and be in a horizontal position. Do not

further tighten strain relief screws at this point.

Electrical Connection Options

If your home has: And you will be

connecting to:

4-wire receptacle

(NEMA Type 14-30R)

(d d)

A UL listed,

120/240-volt

minimum,

30-amp, dryer

power supply

cord*

Go to Section

4-wire connection: Power supply cord

Style 2: Direct wire strain relief

■ Unscrew the removable conduit connector and any

screws from a ¥4" {1.9 cm) UL listed strain relief (UL

marking on strain relief). Put the threaded section of the

strain relief through the hole below the terminal block

opening. Reaching inside the terminal block opening,

screw the removable conduit connector onto the strain

relief threads.

A. Removable conduit connector

B. Hole below terminal block opening

C. Strain relief threads

Put direct wire cable through the strain relief. The strain

relief shouid have a tight fit with the dryer cabinet and be

in a horizontal position. Tighten strain relief screw against

the direct wire cable.

4-wire direct A fused

3-wire receptacle

(NEMA type 10-30R)

3-wire direct

{8.9 cm)

* If local codes do not permit the connection of a frame

grounding conductor to the neutral wire, go to “Optional 3-wire

connection” section.

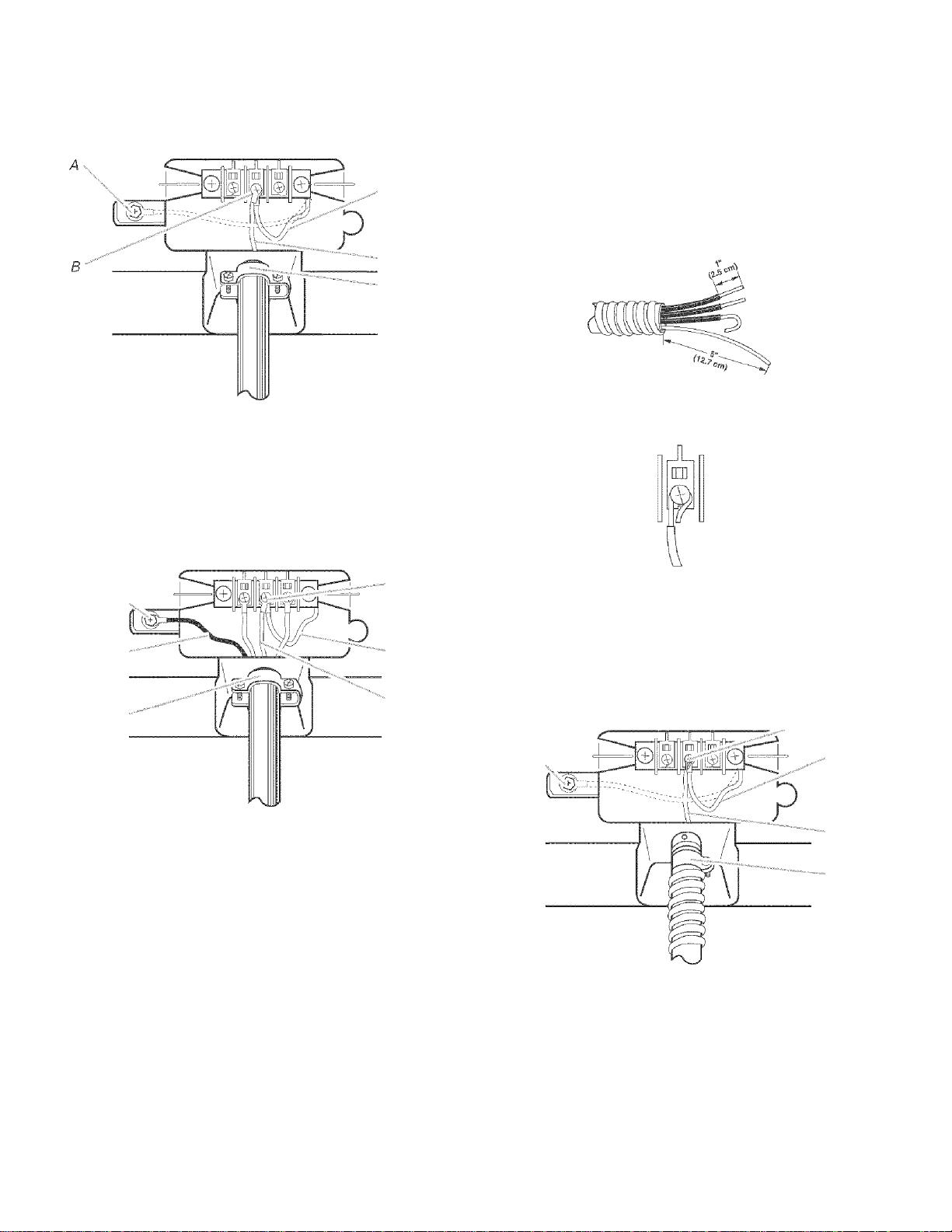

4-wire connection: Power supply cord

IMPORTANT: A 4-wire connection is required for mobile homes

and where local codes do not permit the use of 3-wire

connecfions.

A.

Tr*

u

B

@nn

^ C D

A. 4-wire receptacle (NEMA type 14-30R)

B. 4-prong plug

C. Ground prong

D. Neutral prong

E. Spade terminals with upturned ends

F. ¥4" (1.9 cm) UL listed strain relief

G. Ring terminals

disconnect or

circuit breaker

box*

A UL listed,

120/240-volt

minimum,

30-amp, dryer

power supply

cord*

A fused

disconnect or

circuit breaker

box*

£

4-wire connection:

Direct Wire

3-wire connection:

Power supply cord

3-wire oonnection:

Direct Wire

F

G

4. Now complete installation following instructions for your type

of electrical connection:

4-wire (recommended)

3-wire (if 4-wire is not available)

10

Page 11

1.

Remove center silver-colored terminal block screw.

2.

Remove neutral ground wire from external ground conductor

screw. Connect neutral ground wire and the neutral wire

(white or center wire) of power supply cord under center,

silver-colored terminal block screw. Tighten screw.

A. External ground conductor screw - Dotted line shows

position of NEUTRAL ground wire before being moved to

center siiver-colored terminal block screw

B. Center silver-colored terminal block screw

C. Neutral ground wire

D. Neutral wire (white or center wire)

E. %" (1.9 cm) UL listed strain relief

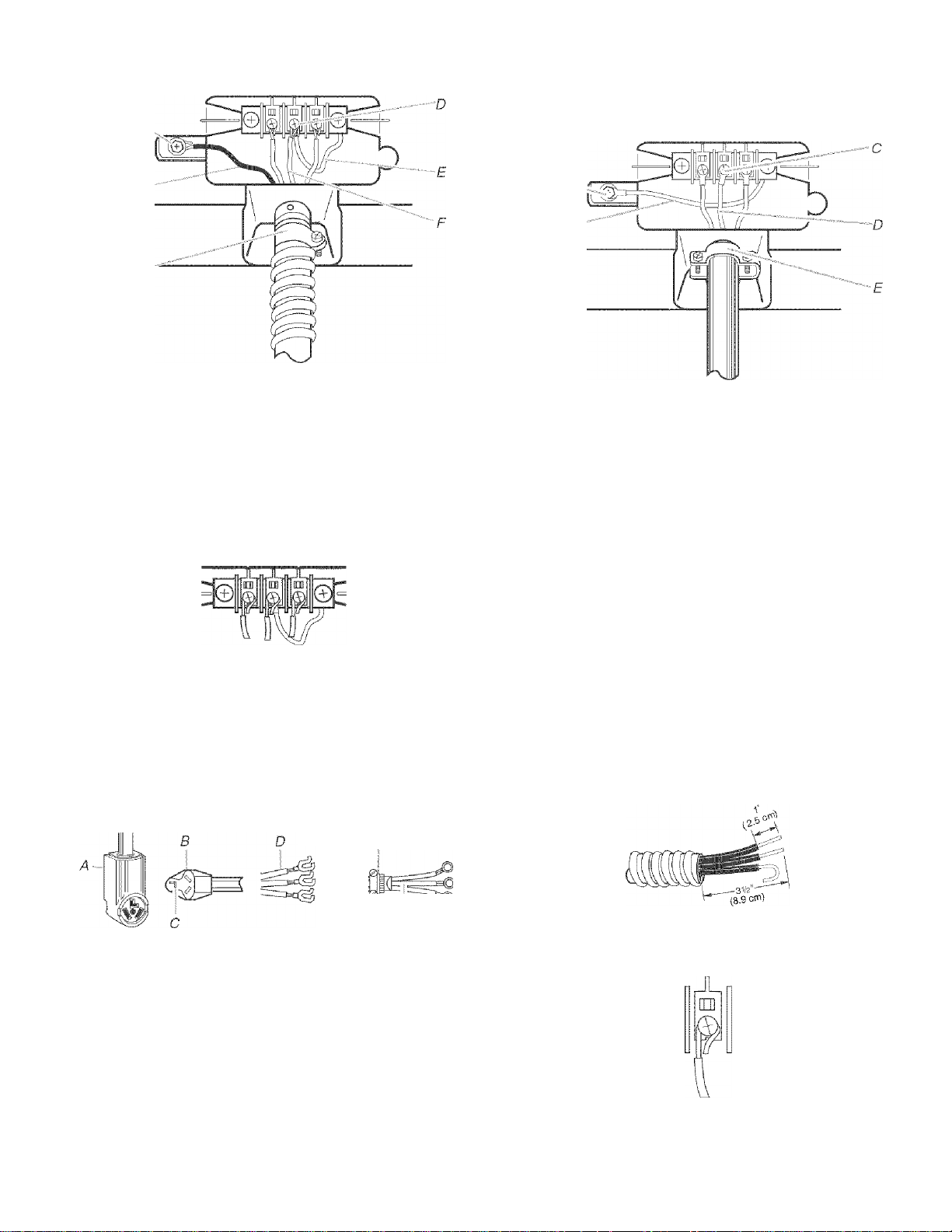

4-wire connection: Direct wire

IMPORTANT: A 4-wire connection is required for mobile homes

and where local codes do not permit the use of 3-wire

connections.

Direct wire cable must have 5 ft (1.52 m) of extra length so dryer

can be moved if needed.

Strip 5" (12.7 cm) of outer covering from end of cable, leaving

bare ground wire at 5" (12.7 cm). Cut 1V2" (3.8 cm) from

3 remaining wires. Strip insulation back 1" (2.5 cm). Shape ends

of wires into a hook shape.

D

When connecting to the terminal block, place the hooked end of

the wire under the screw of the terminal block (hook facing right),

squeeze hooked end together and tighten screw, as shown.

3. Connect ground wire (green or bare) of power supply cord to

external ground conductor screw. Tighten screw.

D

C

A. External ground conductor screw

B. Ground wire (green or bare) of power supply cord

C. (1.9 cm) UL listed strain relief

D. Center silver-colored terminal block screw

E. Neutral ground wire

F. Neutral wire (white or center wire)

Connect the other wires to outer terminal block screws.

Tighten screws.

Tighten strain relief screws.

Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

You have completed your electrioal connection. Now go to

“Venting Requirements.”

Remove center silver-colored terminal block screw.

Remove neutral ground wire from external ground conductor

screw. Connect neutral ground wire and place the hooked

end (hook facing right) of the neutral wire (white or center

wire) of direct wire cable under the center screw of the

terminal block. Squeeze hooked ends together. Tighten

screw.

A ■

C

D

A. External ground conductor screw - Dotted line shows

position of NEUTRAL ground wire before being moved to

center silver-colored terminal block screw

B. Center silver-colored terminal block screw

C. Neutral ground wire

D. Neutral wire (white or center wire)

E. W (1.9 cm) UL listed strain relief

11

Page 12

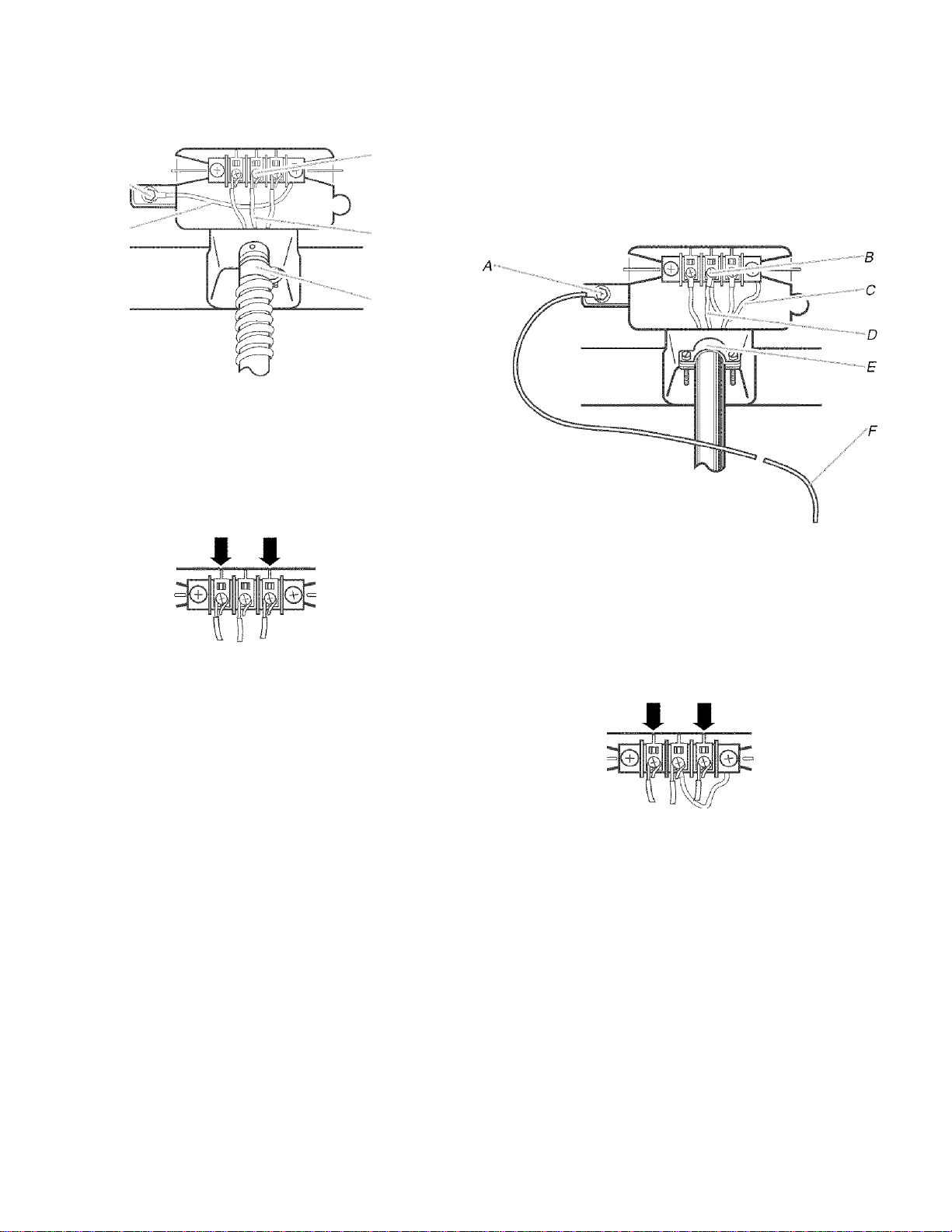

3. Connect ground wire (green or bare) of direct wire cable to

external ground oonductor screw. Tighten screw.

A

A. External ground conductor screw

B. Ground wire (green or bare) of power supply cord

C. ¥4" (1.9 cm) UL listed strain relief

D. Center silver-colored terminal block screw

E. Neutral ground wire

F. Neutral wire (white or center wire)

4. Place the hooked ends of the other direct wire cable wires

under the outer terminal block screws (hooks facing right).

Squeeze hooked ends together. Tighten screws.

1. Loosen or remove center silver-colored terminal block screw.

2. Connect neutral wire (white or center wire) of power supply

cord to the center, silver-colored terminal screw of the

terminal block. Tighten screw.

e-

A. External ground conductor screw

B. Neutral ground wire

C. Center silver-colored terminal block screw

D. Neutral wire (white or center wire)

E. W (1.9 cm) UL listed strain relief

3.

Connect the other wires to outer terminal block screws.

Tighten screws.

4.

Tighten strain relief screws.

5.

Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

. You have completed your electrical connection. Now go to

“Venting Requirements.”

5. Tighten strain relief screw.

6. Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

7. You have completed your electrical connection. Now go to

“Venting Requirements.”

3-wire connection: Power suppiy cord

Use where local codes permit connecting cabinet-ground

conductor to neutral wire.

G

A. 3-wire receptacle (NEMA type 10-30R)

B. 3-wire plug

C. Neutral prong

D. Spade terminals with up turned ends

E. ¥4' (1.9 cm) UL listed strain relief

F. Ring terminals

G. Neutral (white or center wire)

3-wire connection: Direct wire

Use where local codes permit connecting cabinet-ground

conductor to neutral wire.

Direct wire cable must have 5 ft (1.52 m) of extra length so dryer

can be moved if needed.

Strip 3V2" (8.9 cm) of outer covering from end of cable. Strip

insulation back 1" (2.5 cm). If using 3-wire cable with ground

wire, cut bare wire even with outer covering. Shape ends of wires

into a hook shape.

When connecting to the terminal block, place the hooked end of

the wire under the screw of the terminal block (hook facing right),

squeeze hooked end together and tighten screw, as shown.

12

Page 13

1. Loosen or remove center silver-colored terminal block screw.

2. Place the hooked end of the neutral wire (white or center wire)

of direct wire cable under the center screw of terminal block

(hook facing right). Squeeze hooked end together. Tighten

screw.

D

A. External ground conductor screw

B. Neutral ground wire

C. Center silver-colored terminal block screw

D. Neutral wire (white or center wire)

E. W (1.9 cm) UL listed strain relief

3. Place the hooked ends of the other direct wire cable wires

under the outer terminal block screws (hooks facing right).

Squeeze hooked ends together. Tighten screws.

Optional 3-wire connection

Use for direct wire or power suppiy cord where iocai codes

do not permit connecting cabinet-ground conductor to

neutrai wire.

Remove center silver-colored terminal block screw.

Remove neutral ground wire from external ground conductor

screw. Connect neutral ground wire and the neutral wire

(white or center wire) of power supply cord/cable under

center, silver-colored terminal block screw. Tighten screw.

4. Tighten strain relief screw.

5. Insert tab of terminal block cover Into slot of dryer rear panel.

Secure cover with hold-down screw.

6. You have completed your electrical connection. Now go to

“Venting Requirements.”

A. External ground conductor screw

B. Center silver-colored terminal block screw

C. Neutral ground wire

D. Neutral wire (white or center wire)

E. V/ (1.9 cm) UL listed strain relief

F. Grounding path determined by a qualified electrician

3. Connect the other wires to outer terminal block screws.

Tighten screws.

Tighten strain relief screws.

Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

Connect a separate copper ground wire from the external

ground conductor screw to an adequate ground.

13

Page 14

AWARNING

Ml

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

The dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, or a concealed space of a building.

It using an existing vent system

Clean lint from the entire length of the system and make sure

exhaust hood is not plugged with lint.

Replace any plastic or metal foil vent with rigid or flexible

heavy metal vent.

Review Vent system chart. Modify existing vent system if

necessary to achieve the best drying performance.

It this is a new vent system

Vent material

■ Use a heavy metal vent. Do not use plastic or metal foil vent.

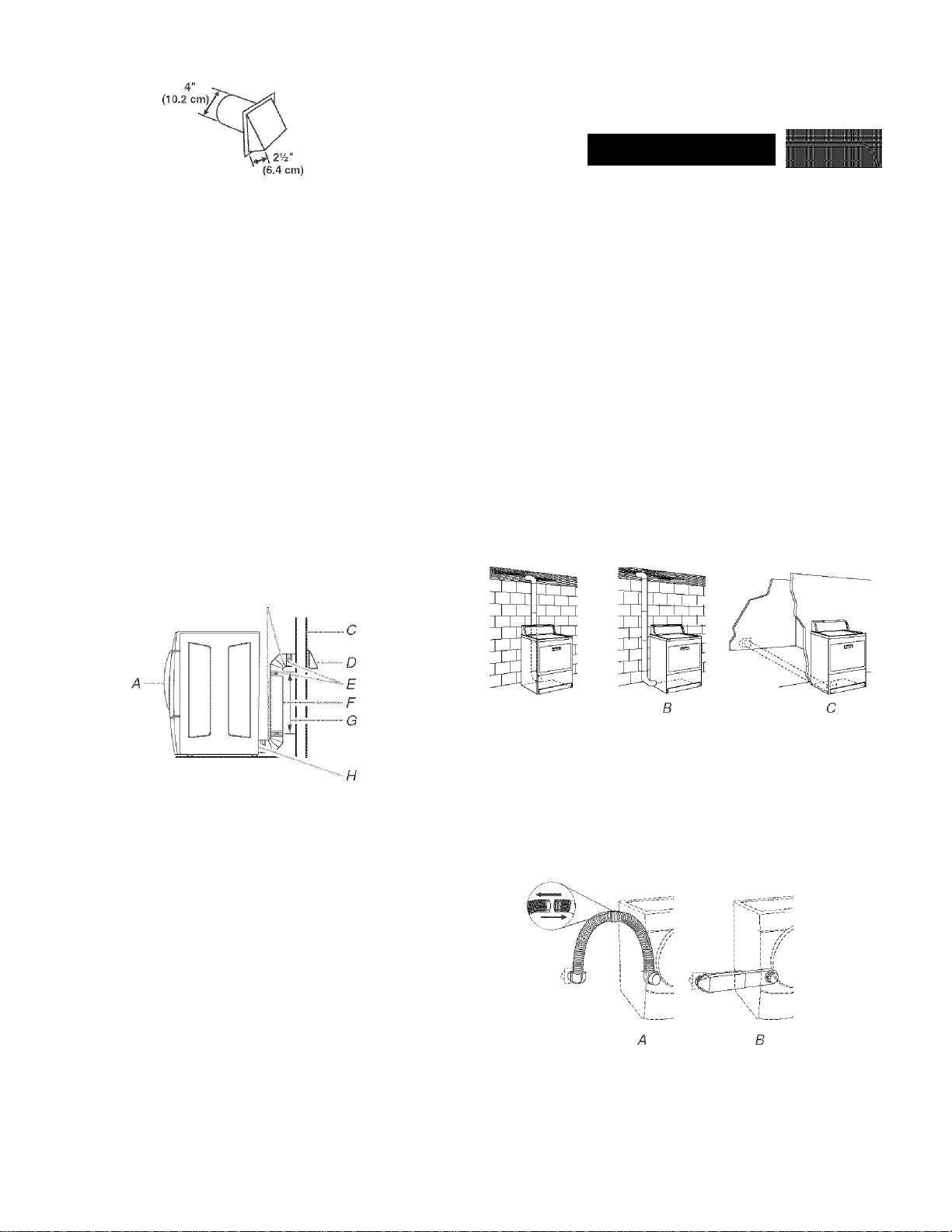

■ 4" (10.2 cm) heavy metal exhaust vent and clamps must be

used. DURASAFE^“ venting products are recommended.

Rigid metal vent

■ For best drying performance, rigid metal vents are

recommended.

■ Rigid metal vent is recommended to avoid crushing and

kinking.

Flexible metal vent

■ Flexible metal vents are acceptable only if accessible for

cleaning.

■ Flexible metal vent must be fully extended and supported

when the dryer is in its final position.

■ Remove excess flexible metal vent to avoid sagging and

kinking that may result in reduced airflow and poor

performance.

■ Do not install flexible metal vent in enclosed walls, ceilings or

floors.

Elbows

45° elbows provide better airflow than 90° elbows.

Good Better

Clamps

■ Use clamps to seal all joints.

■ Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into the interior of the

duct. Do not use duct tape.

4“ {10.2 cm) heavy metal exhaust vent

DURASAFE'^'^ vent products can be purchased from your

dealer. For further information, please call

1-800-4-MY-HOME® (1 -800-469-4663) or visit our website at

www.sears.com.

14

Clamp

Exhaust

Recommended hood styles are shown here.

A. Louvered hood style

B. Box hood style

Page 15

The angled hood style (shown here) is acceptable.

An exhaust hood should cap the vent to keep rodents and

insects from entering the home.

Exhaust hood must be at least 12" (30.5 cm) from the ground

or any object that may be in the path of the exhaust (such as

flowers, rocks or bushes, snow line, etc.).

Do not use an exhaust hood with a magnetic latch.

Improper venting can cause moisture and lint to collect

indoors, which may result in:

■ Moisture damage to woodwork, furniture, paint,

wallpaper, carpets, etc.

■ Housecleaning problems and health problems.

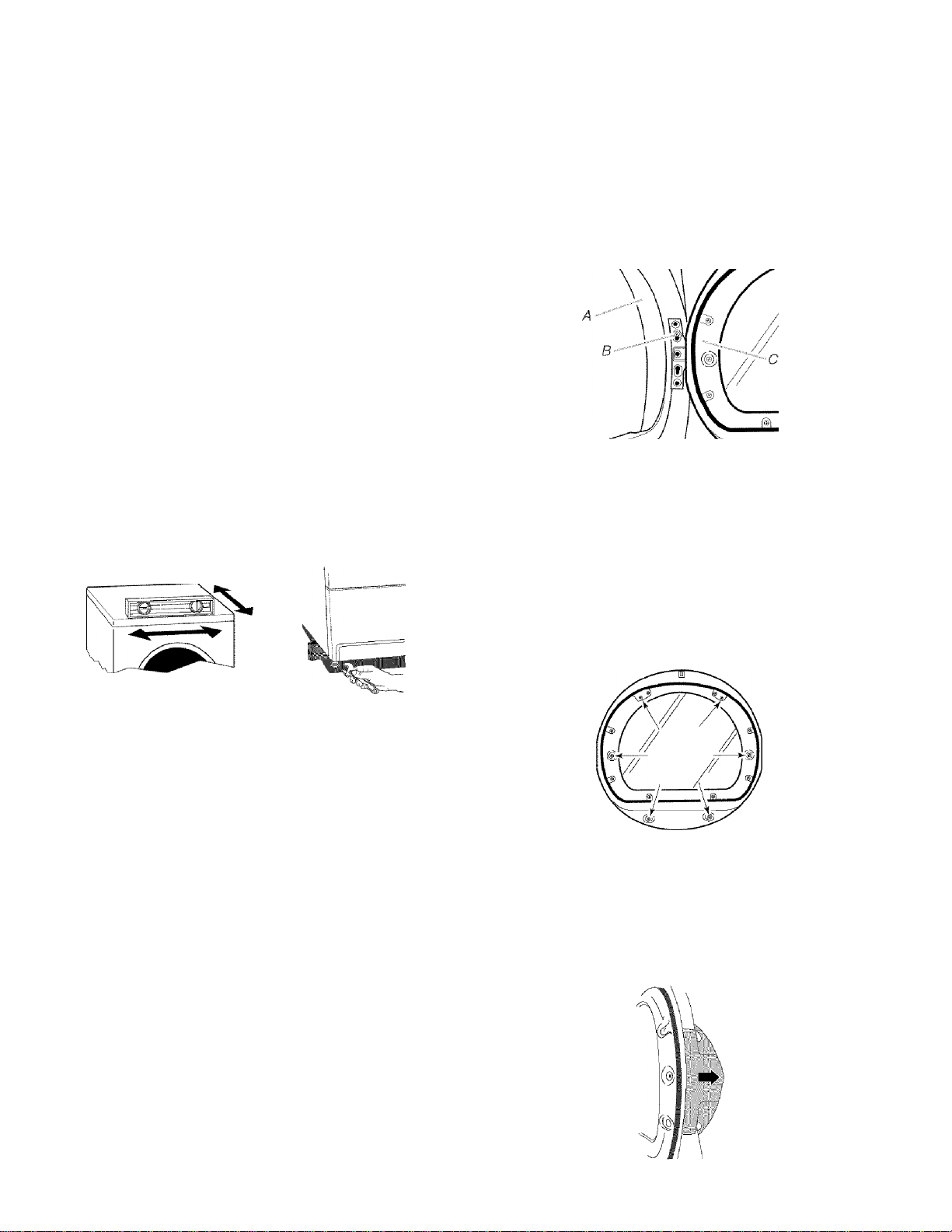

Choose your exhaust installation type

Recommended exhaust installations

Typical installations vent the dryer from the rear of the dryer.

Other installations are possible.

B

Optional exhaust installations

This dryer can be converted to exhaust out the right side, left

side, or through the bottom. Contact your local dealer to have the

dryer converted.

AWARNING

M

Fire Hazard

Cover unused exhaust holes with one of the

following kits:

279818 (white)

279915 (graphite)

279925 (biscuit)

280102 (pacific blue)

280103 (champagne)

280104(sedona)

Contact your local dealer.

Failure to follow these instructions can result in death,

fire, electrical shock, or serious injury.

A. Dryer

B. Elbow

C. Wall

D. Exhaust hood

E. Clamps

F. Rigid metal or flexible metal vent

G. Vent length necessary to connect elbows

H. Exhaust outlet

A, Standard rear offset exhaust installation

B, Left or right side exhaust installation

C, Bottom exhaust installation (not an option

with pedestal installations)

Alternate installations for close clearances

Venting systems come in many varieties. Select the type best for

your installation. Two close-clearance installations are shown.

Refer to the manufacturer’s instructions.

A. Over-the-top installation (also available with one offset elbow)

B, Periscope installation

NOTE: The following kits for close clearance alternate

installations are available for purchase. For further information,

please call 1-800-4-MY-HOME® (1-800-469-4663).

15

Page 16

■ Over-the-Top Installation:

Part Number 26-49900

■ Periscope Installation (For use with dryer vent to wall vent

mismatch):

Part Number 26-49901 - Less than 5" (12.7 cm) mismatch

Part Number 26-49908 - 5" (12.7 cm) to 18" (45.72 cm)

mismatch

Part Number 26-49904 - 18" (45.72 cm) to 29" (73.66 cm)

mismatch

Part Number 26-49905 - 29" (73.66 cm) to 50" (127 cm)

mismatch

Vent system chart

NOTE: Side and bottom exhaust Installations have a 90° turn

inside the dryer. To determine maximum exhaust length, add one

90° turn to the chart.

Number of

90° turns

or elbows

0 Rigid metal

1 Rigid metal 54 ft (16.5 m) 48 ft (14.6 m)

Type of

vent

Flexible metal

Flexible metal 31 ft (9.4 m) 23 ft (7 m)

Box or

Louvered

hoods

64 ft (20 m)

36 ft (11 m)

Angled

hoods

58 ft (17.7 m)

28 ft (8.5 m)

Special provisions for mobile home installations

The exhaust vent must be securely fastened to a noncombustible

portion ot the mobile home structure and must not terminate

beneath the mobile home. Terminate the exhaust vent outside.

Determine vent path

Select the route that will provide the straightest and most

direct path outdoors.

Plan the installation to use the fewest number of elbows and

turns.

When using elbows or making turns, allow as much room as

possible.

Bend vent gradually to avoid kinking.

Use the fewest 90° turns possible.

Determine vent length and elbows needed for best

drying performance

■ Use the Vent system chart below to determine type of vent

material and hood combinations acceptable to use.

■ NOTE: Do not use vent runs longer than those specified in

the Vent system chart. Exhaust systems longer than those

specified will:

■ Shorten the life of the dryer.

■ Reduce performance, resulting in longer drying times and

increased energy usage.

The Vent system chart provides venting requirements that will

help to achieve the best drying performance.

2 Rigid metal 44 ft (13.4 m) 38 ft (11.6 m)

Flexible metal 27 ft (8.2 m) 19 ft (5.8 m)

3 Rigid metal 35 ft (10.7 m) 29 ft (8.8 m)

Flexible metal 25 ft (7.6 m) 17 ft (5.2 m)

4 Rigid metal 27 ft (8.2 m) 21 ft (6.4 m)

1. Install exhaust hood. Use caulking compound to seal exterior

wall opening around exhaust hood.

2. Connect vent to exhaust hood. Vent must fit inside exhaust

hood. Secure vent to exhaust hood with 4" (10.2 cm) clamp.

3. Run vent to dryer location. Use the straightest path possible.

See “Determine vent path” in “Plan Vent System.” Avoid 90°

turns. Use clamps to seal all joints. Do not use duct tape,

screws or other fastening devices that extend into the interior

of fhe vent to secure vent.

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

To protect the floor, use a large flat piece of cardboard from

the dryer carton. Place cardboard under the entire back edge

of the dryer.

2.

Firmly grasp the body of the dryer (not the console panel).

Gently lay the dryer on the cardboard. See illustration.

Flexible metal 23 ft (7 m) 15 ft (4.6 m)

Excessive Weight Hazard

16

Page 17

3. Examine the leveling legs. Find the diamond marking.

You can change your door swing from a right-side opening to a

left-side opening, if desired.

4. Screw the legs into the leg holes by hand. Use a wrench to

finish turning the legs until the diamond marking is no longer

visible.

5. Place a carton corner post from dryer packaging under each

of the 2 dryer back corners. Stand the dryer up. Slide the

dryer on the corner posts until it is close to its final location.

Leave enough room to connect the exhaust vent.

1. Using a 4" {10.2 cm) clamp, connect vent to exhaust outlet in

dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must fit over the dryer exhaust outlet

and inside the exhaust hood. Make sure the vent is secured

to exhaust hood with a 4" (10.2 cm) clamp.

2. Move dryer into its final position. Do not crush or kink vent.

3. (On gas models) Check to be sure there are no kinks in the

flexible gas line.

4. Once the exhaust vent connection is made, remove the

corner posts and cardboard.

Check the levelness of the dryer. Cheok levelness first

side to side, then front to back.

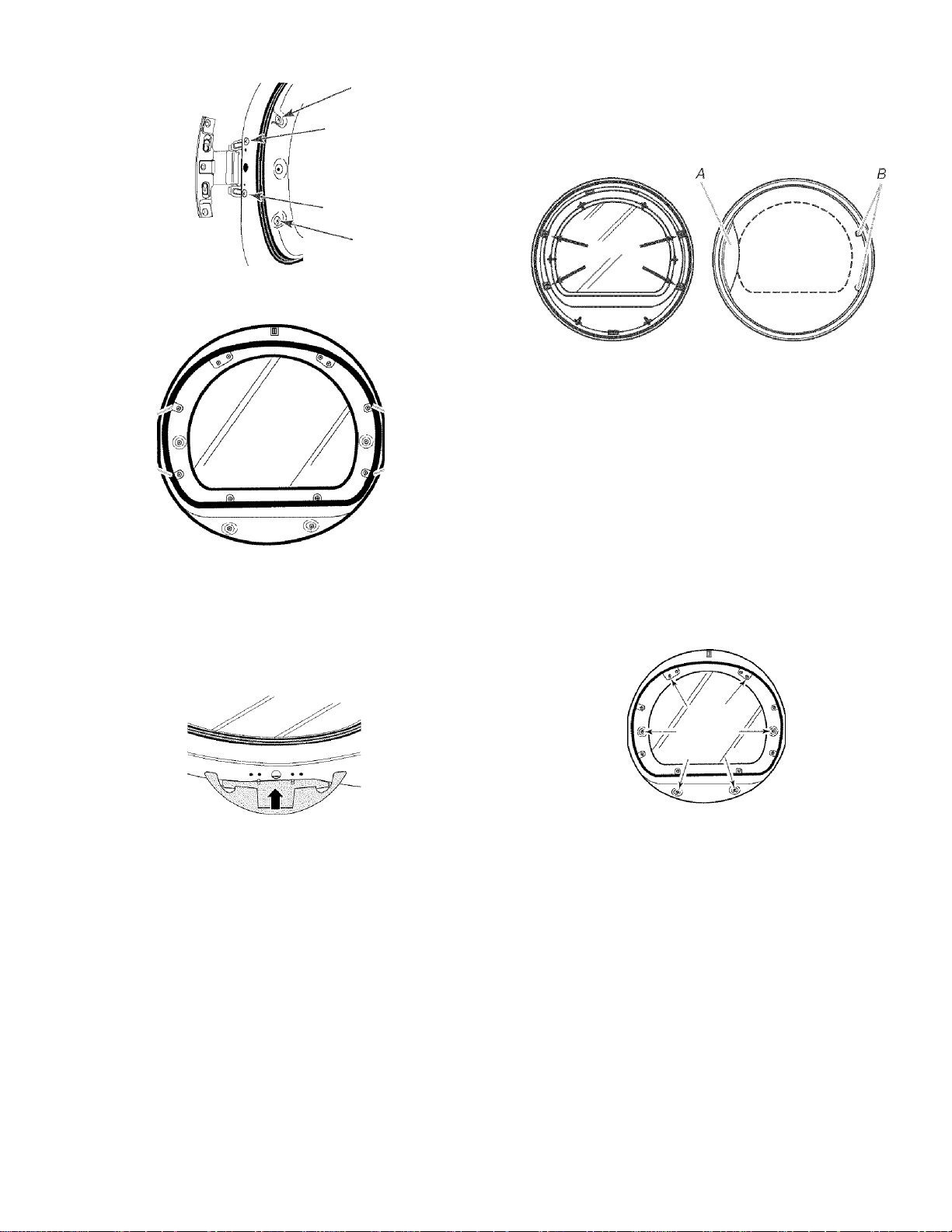

Remove the door

1. Place a towel or soft cloth on top of the dryer or work space

to protect the surface.

Open the dryer door. Remove the 4 screws that hold the door

hinge on the front panel of the dryer. Loosen, but do not

remove, the screw with the top keyhole opening last (2nd

from the top).

A. Dryer

B. Do not remove

C. Dryer door

3. Lift and pull forward on the door so that the keyhole clears

the screw head. Remove the door.

4. Lay the dryer door on a flat, protected surface with the inside

door assembly facing up. Remove the last screw from Step 2.

Remove the 6 screws to release the outer door assembly

from the inner door assembly, as indicated below. See

illustration. It is important that you remove only the

6 indicated screws.

If the dryer is not level, prop up the dryer using a wood block.

Use a wrench to adjust the legs up or down and check again for

levelness.

5. Lift the inner door assembly off of the outer door assembly.

Set the outer door assembly aside.

Reverse the hinge and hinge cover

1. Place the inner door, screw head side up, on the work space.

2. Gently pull the plastic cover out and down. This unsnaps the

plastic hinge cover from the inside door assembly.

17

Page 18

3. Remove the 4 screws that hold the hinge to the door.

4. Move the 2 large hole screw plugs to the opposite side and

insert in the original screw holes.

A.

A. Hinge screws

B. Hole screw plugs

5. Move hinge to the other side and reattach with the 4 screws

removed in Step 3.

6. Reverse the plastic cover. Slide it up over the inner door

assembly edge and gently snap into place.

Reverse the door handle

1.2.Place the outer door assembly face down on work space.

Remove the 2 screws that hold the door handle and the

2 screws holding the hole plugs. If hole plugs do not easily fall

out after screws are removed, insert a small screwdriver into

the holes and gently push the plugs out.

A. Door handle

B. Hole plugs

3. Move the door handle to the other side and reattach with the

2 screws removed from the door handle in Step 2.

4. Move the hole plugs to the new hinge side and attach with

the 2 screws removed from the hole plugs in Step 2.

Reinstalling the door

1. Check for fingerprints on the glass. Clean the glass if

necessary.

2. Place the inner door assembly into the outer door assembly.

Align the hinge cover and hinge in the openings on each side.

To fit correctly, the inside door assembly edge is completely

inside the outside door assembly edge.

3. Reassemble the inner and outer door assemblies with the

6 screws.

7. Set the inner door assembly aside.

18

Page 19

4. Use a small flat-blade screwdriver to remove plug strip from

the door opening. Slide the head of the screwdriver under the

top portion of the plug strip, being certain not to scratch the

dryer surface. Lift up. Repeat in the middle and at the bottom.

Remove the plug strip in the door opening and insert in the

opposite side.

Insert a screw in the 2nd opening from the top of the hinge

opening and partially tighten. Hang the door by placing the

top hinge keyhole over the 2nd screw head and tighten the

screw. By putting this screw In first, the door will hang in

place while you insert and tighten the remaining 4 screws.

A. Dryer door

B. Dryer

C. Insert this screw first

6. Close the door and check that it latches securely.

1 Check that all parts are now installed. If there is an extra part,

go back through the steps to see which step was skipped.

Check that you have all of your tools.

Dispose of/recycle all packaging materials.

Check the dryer’s final location. Be sure the vent is not

crushed or kinked.

Check that the dryer is level. See “Level Dryer.”

For power supply cord installation, plug into an outlet. For

direct wire installation, turn on power.

7. Remove the blue protective film on the console and any tape

remaining on the dryer.

8. Read “Dryer Use” in the Dryer User Instructions.

9. Wipe the dryer drum interior thoroughly with a damp cloth to

remove any dust,

10. Set the dryer on a full heat cycle (not an air cycle) for

20 minutes and start the dryer.

If the dryer will not start, check the following:

■ Controls are set in a running or “On” position.

■ Start button has been pushed firmly.

■ Dryer is plugged into an outlet and/or electrical supply

is on.

■ Household fuse is intact and tight, or circuit breaker has

not tripped.

■ Dryer door is closed.

11. When the dryer has been running for 5 minutes, open the

dryer door and feel for heat. If you feel heat, cancel cycle and

close the door.

If you do not feel heat, turn off the dryer and check the

following:

■ There may be 2 household fuses or circuit breakers for

the dryer. Check to make sure both fuses are intact and

tight, or that both circuit breakers have not tripped. If

there is still no heat, contact a qualified technician.

NOTE: You may notice a burning odor when the dryer is first

heated. This odor is common when the heating element is first

used. The odor will go away.

19

Page 20

DRYER USE

I

M

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Do not dry anything that has ever had anything

flammabie on It (even after washing).

Failure to follow these instructions can result in death,

explosion, or fire.

WARNING: To reduce the risk of fire, electric shock, or injury to

persons, read the IMPORTANT SAFETY INSTRUCTIONS before

operating this appliance.

Follow these basic steps to start your dryer. Please refer to

specific sections of this manual for more detailed information.

1. Clean lint screen before each load. See “Cleaning the Lint

Screen.”

2. Place laundry in dryer and shut door.

3. Press the selected cycle pad. The preset settings for Auto Dry

Cycles or Manual Cycles will glow. The estimated or actual

cycle time {in minutes) will show in the display.

To use an Auto Dry Cycle

■ Select an Auto Dry Cycle.

■ Select AUTO DRY LEVEL to adjust how dry you want the

load. As the cycle runs, the control senses the dryness of

the load and adjusts the time automatically for the

selected dryness level.

■ Select the desired Options.

Fire Hazard

No washer can completely remove oil.

Do not dry anything that has ever had any type of oil on

it {including cooking oils).

Items containing foam, rubber, or plastic must be dried

on a clothesline or by using an Air Cycle.

Failure to follow these instructions can result in death

or fire.

To make changes during an Auto Dry Cycle:

■ Adjust Options.

NOTE: Auto Dry Level selections can be made only while

using Auto Dry Cycles. You can select a different dryness

level, depending on your load, by pressing Auto Dry Level

and choosing More or Less. Selecting More or Less

automatically adjusts the sensed time needed.

• MORE

• LESS

AUTO DRY

LEVEL

PRESS & HOLD 3

SECONDS TO LOCK/

UNLOCK CONTROL

20

Page 21

How Auto Dry works

EvenHeat'^'^ improves drying performance with Auto Moisture

Sensing Plus, which advances the cycle as moisture is

extracted from clothing. A thermistor (electronic temperature

sensor) and moisture sensing strips in the dryer drum help

measure the amount of moisture in the clothes as they pass.

An electronic control determines the load type to help save

time, avoid overdrying, and increase the accuracy of the end

dryness level. After the first 5 minutes of an automatic cycle,

the estimated time display will adjust based on the

approximate load size, cycle, dryness level selected and

amount of moisture left in the clothes. When the clothes have

reached approximately 80% of the dryness level selected, the

estimated time display will adjust again, showing the final

drying time. Auto Moisture Sensing Plus takes the guesswork

out of drying time and enhances fabric care.

To use a Manual Cycle

■ Select a Manual Cycle,

■ Press MORE TIME or LESS TIME until the desired drying

time is displayed. Tap MORE TIME or LESS TIME and the

time will change by 1-minute intervals. Press and hold

MORE TIME or LESS TIME and the time will change by

5-minute intervals.

NOTE: The More Time and Less Time features can be

used only with Manual Cycles.

O

LESS TIME

O

■ Press TEMPERATURE until the desired temperature

glows.

NOTE: During a Manuai Cycle, you can change the settings

for Time, Temperature, WRINKLE GUARD® and End of Cycle

Signal. Press PAUSE/CANCEL twice to stop the dryer and

clear the settings. Select another cycle or option.

(OPTIONAL STEP) If desired, select OPTIONS. For more

details, see “Options.”

(OPTIONAL STEP) If desired, set the END of CYCLE SIGNAL.

Select HIGH or LOW to alert you when a cycle ends.

Press and hold START for approximately 3 seconds until

dryer starts. Be sure the door is closed.

■ If you do not press Start within 5 minutes of selecting the

cycle, the dryer automatically shuts off.

■ If you wish to end your drying cycle after pressing Start,

press PAUSE/CANCEL twice.

To stop your dryer at any time

Press PAUSE/CANCEL twice or open the door.

This feature allows you to lock your settings to prevent

unintended use of the dryer. You can aiso use the Control Locked

feature to prevent unintended cycle or option changes during

dryer operation.

To enable the Control Locked feature:

Press and hold AUTO DRY LEVEL for 3 seconds. Control Locked

glows and a single beep tone is heard. To unlock, press and hold

AUTO DRY LEVEL for 3 seconds. The indicator light turns off.

Select the correct cycle and dryness level or temperature for your

load. If an Auto Dry Cycle is running, the display shows the

estimated cycle time when your dryer is automatically sensing

the dryness level of your load. If a Manual Cycle is running, the

display shows the exact number of minutes remaining in the

cycle.

Cool Down tumbles the load without heat during the last few

minutes of all cycles. Cool Down makes the loads easier to

handle and reduces wrinkling. The length of the Cool Down

depends on the load size and dryness level.

Drying tips

■ Follow care label directions when they are available.

■ If desired, add a fabric softener sheet. Foliow package

instructions.

■ To reduce wrinkling, remove the load from the dryer as soon

as tumbling stops. This is especiaily important for permanent

press, knits, and synthetic fabrics.

■ Avoid drying heavy work clothes together with lighter fabrics.

This could cause overdrying of iighter fabrics and lead to

increased shrinkage or wrinkling.

Cycle tips

■ Dry most loads using the preset cycle settings.

■ Refer to the Auto Dry chart or Manual Preset Cycle Settings

chart (in the “Cycles” section) for a guide to drying various

loads.

■ Drying temperature and Auto Dry Level are preset when

you choose an Auto Dry Cycle. You can select a different

dryness level, depending on your load, by pressing Auto

Dry Level and choosing More or Less.

■ If you wish to adjust the cycle length of a Manual Cycle,

press More Time or Less Time. Adjust the temperature of

a Manual Cycle by pressing Temperature until the desired

temperature is selected.

NOTE: You cannot choose an Auto Dry Level with Manual

Cycles.

To pause the dryer at any time

Open the door or press PAUSE/CANCEL once.

To restart the dryer

Close the door. Press and hold START until dryer starts.

NOTE: Dry! ng will continue from where the cycle was interrupted

if you close the door and press Start within 5 minutes. If the cycle

is Interrupted for more than 5 minutes, the dryer will shut off.

Select new cycle settings before restarting the dryer.

21

Page 22

Follow the progress of your dryer with the drying Status indicator

lights.

Wet»

Damp •

COOL DOWN •

Clothes Dry •

Wrinkle Guard •

Check Lint Screen •

Control Locked •

Select the drying cycle that matches the type of load you are

drying. See Auto Dry chart or Manual Preset Cycle Settings chart.

Wet

The Wet light glows at the beginning of Auto Dry or Manual

cycles if a wet item Is detected.

■ In an Auto Dry Cycle, if a wet item is not detected after

5 minutes, the dryer goes directly into Cool Down and the

Cool Down and WRINKLE GUARD® indicators glow, if

selected.

■ In a Manual Cycle, if a wet item is not detected, the dryer will

continue to run for the length of time selected, but the Wet

light will not glow.

Damp

The Damp light glows in an Auto Dry Cycle when the laundry Is

approximately 80% dry. Damp Dry Signal beeps, if selected. See

“Options.”

Cool Down

The Cool Down light glows during the cool down part of the

cycle. Laundry cools for ease in handling.

Clothes Dry

The Clothes Dry light glows when the drying cycle is finished.

This indicator stays on during WRINKLE GUARD®.

WRINKLE GUARD®

The WRINKLE GUARD® light glows when this option is selected.

This indicator stays on with Clothes Dry.

Check Lint Screen

The Check Lint Screen light reminds you to check the lint screen.

The light giows when the user seiects a cycle. It goes out when

the door is opened, Start is pressed, or after 5 minutes elapses.

Auto Dry Cycles allow you to match the cycle to the load you are

drying. See the following Auto Dry Preset Cycle Settings chart.

Each cycle dries certain fabrics at the recommended

temperature. A sensor detects the moisture in the load and

automatically adjusts the drying time for optimal drying.

Heavy Duty

Use this cycle to get high heat for heavy fabrics such as cotton

towels or bedspreads.

Bulky/Bedding

Use this cycle to get medium heat for drying large items that

require long drying times, such as jackets, comforters and

pillows. Rearrange the load when the Damp Dry Signal sounds.

This will aid in the drying process. The Damp Dry Signal is preset

to ON. See “Options.”

Jeans

Use this cycle to get medium high heat for drying denims.

Normal

Use this cycle to get medium heat for drying sturdy fabrics such

as work clothes.

Casual

Use this cycle to get low heat for drying no-iron fabrics, such as

sport shirts, casual business clothes and permanent press

blends.

Delicate

Use this cycle to get extra-low heat to gently dry items such as

lingerie, blouses, or washable knit fabrics.

Control Locked

The Control Locked light glows when this option is enabled.

Indicator lights

Other indicator lights show Cycle, Options, Modifiers and End of

Cycle settings selected. The display shows the estimated or

actual time remaining.

22

Page 23

Auto Dry Preset Cycle Settings Manual Preset Cycle Settings

Auto Dry Cycles

Load Type

HEAVY DUTY

Temperature Time*

(Minutes)

High 44

Heavyweight, towels

BULKY/BEDDING

Medium 64

Jackets, comforters,

pillows

JEANS

Medium High 54

Denim jeans, jackets

NORMAL

Medium 41

Corduroys, work clothes

CASUAL

Low 36

Permanent press,

synthetics

DELICATE

Extra Low 22

Lingerie, blouses,

washable knit fabrics

'Estimated Time with Auto Dry Level (Normai) setting. Time will

vary depending on load type and load size.

Manual Cycles Temperature Default Time

Load Type

(Minutes)

TIMED DRY High 40

Heavyweight, bulk,

bedspreads, work clothes

EXPRESS DRY™

High 27

Small loads

TOUCH UP

Medium High 20

Remove wrinkles

You can customize your cycles by selecting options.

DAMP DRY SIGNAL

(Al'TO Cycles Oftr)

WFWKLE GUARD

Use Manual Cycles to select a specific amount of drying time and

a drying temperature. When a Manual Cycle is selected, the

Estimated Time Remaining display shows the actual time

remaining in your cycle. You can change the actual time in the

cycle by pressing More Time or Less Time. See “Changing

Cycles, Options and Modifiers.”

Timed Dry

Use this cycle to complete drying if items are still damp after an

Auto Dry Cycle. Timed Dry is also useful for drying heavyweight

and bulky items, such as bedspreads and work clothes.

Lightweight garments, such as exercise wear, can be dried using

Timed Dry on a low temperature setting.

EXPRESS DRY™

Use this cycle for drying small

loads or loads that need a short

drying time.

Touch Up

Use this cycle to help smooth out wrinkles from items, such as

clothes packed in a suitcase or items wrinkled from being left in

the dryer too long.

Damp Dry Signal

Select the Damp Dry Signal to alert you that your clothes are

approximately 80% dry. This is useful when you want to remove

lightweight items in a mixed load to avoid overdrying or remove

partially dry items that may need ironing.

The Damp Dry Signal is useful when drying bedsheets/linens in a

mixed load or large items in the “Bulky/Bedding” cycle. When the

signal goes off, open the door to stop the dryer, rearrange the

load Inside the dryer, close the door and restart the dryer to finish

the drying cycle. Rearranging the load will aid in the drying

process.

For the “Bulky/Bedding” cycle, the Damp Dry Signal is preset to

ON.

NOTE: The Damp Dry Signal is available only with the Auto Dry

Cycles.

WRINKLE GUARD®

WRINKLE GUARD® helps smooth out wrinkles that form when

you cannot unload the dryer promptly at the end of a cycle.

During this option, the dryer stops tumbling and then tumbles

again for a brief period.

■ Press WRINKLE GUARD® to get up to 2V2 hours of heat-free,

periodic tumbling at the end of a cycle.

■ Stop WRINKLE GUARD® at any time by pressing WRINKLE

GUARD® or opening the dryer door.

■ For the Casual Auto Dry Cycle, WRINKLE GUARD® Is preset

to ON. The other Auto Dry Cycles will retain the WRINKLE

GUARD® setting. For example, if you select WRINKLE

GUARD® in the Normal cycle, WRINKLE GUARD® will be on

the next time you select the Normal cycle.

NOTE: If you do not select WRINKLE GUARD®, the dryer stops

after cool down.

23

Page 24

Use Modifiers to select temperatures for the Manual Cycles.

Press Temperature until the desired temperature setting glows.

Temperature modifiers cannot be used with the Auto Dry Cycles.

• HIGH

m MEDIUM HIGH

m MEDIUM

• Low

• EXTRA Low

• Air Dry

O

TEMPERATURE

(MANUAL CYCLES ONLY)

Air Dry

Use the Air Dry Modifier for items that require drying without heat

such as rubber, plastic and heat-sensitive fabrics. This table

shows examples of items that can be dried using Air Dry.

Type of Load Time*

(Minutes)

Foam rubber - pillows, padded bras, stuffed toys 20-30

Plastic - Shower curtains, tablecloths 20-30

Changing Options and Modifiers after pressing Start

You can change an Option or Modifier anytime before the

selected Option or Modifier begins.

1. Press PAUSE/CANCEL once.

2. Select the new Option and/or Modifiers.

3. Press and hold START to continue the cycle.

NOTE; If you happen to press PAUSE/CANCEL twice, the

program clears and your dryer shuts down. Restart the selection

process.

- .V. :.V./ ^

End of Cycie Signai

The End of Cycle Signal produces an audible sound when the

drying cycle is finished. Promptly removing clothes at the end of

the cycle reduces wrinkling.

• moH

« Off

End of Cycle Signal

Press END of CYCLE SIGNAL to adjust the sound level or turn off

the signal.

NOTE: When WRINKLE GUARD® is selected and the End of

Cycle Signal is on, a tone sounds every 5 minutes until the

clothes are removed, or WRINKLE GUARD® ends.

Rubber-backed rugs 40-50

Olefin, polypropylene, sheer nylon 10-20

* Reset cycle to complete drying, if needed.

When using Air Dry

■ Check to see that coverings are securely stitched.

■ Shake and fluff pillows by hand periodically during the cycle.

■ Dry item completely. Foam rubber pillows are slow to dry.

NOTE: Air Dry is not available with Auto Dry Cycles.

You can change Auto Dry and Manual Cycles, Options and

Modifiers anytime before pressing Start.

■ Three short tones sound if an unavailable combination is

selected. The last selection will not be accepted.

Changing Cycies after pressing Start

1. Press PAUSE/CANCEL twice.

2. Select the desired cycle and options.

3. Press and hold START. The dryer starts at the beginning of

the new cycle.

NOTE: If you do not press Start within 5 minutes of selecting the

cycle, the dryer automatically shuts off.

The dryer rack is shipped in place in your dryer. Remove and

discard any packing material before use.

Use the TUMBLE FREE"^'^ Pleated Dryer Rack for items that you

do not want to tumble dry, such as sweaters. When you use the

heated dryer rack, the heated air inside the dryer flows in a

concentrated pattern to allow efficient and uniform drying.

Use Timed Dry to select the desired time,

NOTE: Do not use Auto Dry Cycles with the dryer rack.

To use the heated dryer rack:

Do not remove the lint screen.

1. Open dryer door.

2. Place dryer rack over the bottom of the dryer door opening.

Rest the back wire on the dryer back ledge. Push down on

the frame front to secure over lint screen.

24

Page 25

3. Place wet items on top of the rack. Allow space around items

for air to circulate. The rack does not move, but the drum will

rotate. Make sure items do not hang over the edges or

between rack grille.

NOTE: Check the lint screen and remove any lint accumulated

from items dried on the rack.

Suggested Items for Rack

Drying

Temperature

Setting

Suggested

Time*

(Minutes)

4. Close the door.

5. Select TIMED DRY and MORE TIME or LESS TIME. Reset

time as needed to complete drying. Refer to the following

table.

6. Select the desired temperature setting to match the fabrics in

your load by pressing TEMPERATURE. Items containing

foam, rubber, or plastic must be dried on a clothesline or by

using the Air Dry temperature setting. Refer to the foilowing

table.

7. Start the dryer.

NOTE: You must remove rack for normal tumbling. To remove the

dryer rack, lift it straight up and out of the dryer.

DRYER CARE

Keep dryer area clear and free from items that would obstruct the

flow of combustion and ventilation air.

Washable wool items (block

to shape and lay flat on

rack)

Stuffed toys (cotton or

polyester fiber filling)

Stuffed toys (foam rubber

filled)

Galoshes (rubber) Air Dry 20

Foam rubber pillows Air Dry 50

Tennis shoes Air Dry 20

"Reset time as needed to complete drying.

To clean

1. Pull the lint screen straight up. Roll lint off the screen with

your fingers. Do not rinse or wash screen to remove lint. Wet

lint is hard to remove.

Low 20

Low 20

Air Dry 50

AWARNING

J

Ai/

Explosion Hazard

Keep fiammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches {46 cm) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

Every load cleaning

The lint screen Is located in the door opening of the dryer. The

control panel has an indicator light to remind you to clean the lint

screen before or after each load. A screen blocked by lint can

increase drying time.

2. Push the lint screen firmly back into place.

IMPORTANT:

■ Do not run the dryer with the lint screen loose, damaged,

blocked, or missing. Doing so can cause overheating and

damage to both the dryer and fabrics.

■ If lint falls off the screen into the dryer during removal, check

the exhaust hood and remove the lint. See “Venting

Requirements.”

As needed cleaning

Laundry detergent and fabric softener residue can build up on the

lint screen. This buildup can cause longer drying times for your

clothes, or cause the dryer to stop before your load is completely

dry. The screen is probably clogged if lint falls off while the screen

is in the dryer.

Clean the lint screen with a nylon brush every 6 months, or more

frequently, if it becomes clogged due to a residue buildup.

To wash

1. Roll lint off the screen with your fingers.

2. Wet both sides of lint screen with hot water.

25

Page 26

3. Wet a nylon brush with hot water and liquid detergent. Scrub

lint screen with the brush to remove residue buildup.

3. Use masking tape to secure dryer door.

4. Rinse screen with hot water.

5. Thoroughly dry lint screen with a clean towel. Replace screen

in dryer.

liryisr' ktimm

To clean dryer drum

1. Make a paste with powdered laundry detergent and very

warm water.

2. Apply paste to a soft cloth.

OR

Apply a liquid, nonflammable household cleaner to the

stained area and rub with a soft cloth until all excess dye and

stains are removed.

3. Wipe drum thoroughly with a damp cloth.

4. Tumble a load of clean cloths or towels to dry drum.

NOTE: Garments which contain unstable dyes, such as denim

blue jeans or brightly colored cotton items, may discolor the

dryer interior. These stains are not harmful to your dryer and will

not stain future loads of clothes. Dry unstable dye items inside

out to avoid dye transfer.

. T. ;::T- :-:■ : :T; f T

From Inside the Dryer Cabinet

Lint should be removed every 2 years or more often, depending

on dryer usage. Cleaning should be done by a qualified person.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

For direct-wired dryers:

1. Disconnect power.

2. Disconnect wiring.

3. Make sure leveling legs are secure in dryer base.

4. Use masking tape to secure dryer door.

The dryer light automatically turns on inside the dryer drum when

you open the door.

To change the drum light

1. Unplug dryer or disconnect power.

2. Open the dryer door. Locate the light bulb cover on the back

wall of the dryer. Remove the screw located in the lower right

corner of the cover. Remove the cover.

From the Exhaust Vent

Lint should be removed every 2 years, or more often, depending

on dryer usage.

Vacation care

Operate your dryer only when you are at home. If you will be on

vacation or not using your dryer for an extended period of time,

you should:

1. Unplug dryer or disconnect power.

2. Clean lint screen. See “Cleaning the Lint Screen.”

Moving care

For power supply cord-connected dryers:

1. Unplug the power supply cord.

2. Make sure leveling legs are secure in dryer base.

3. Turn bulb counterclockwise. Replace the bulb with a 10-watt

appliance bulb only. Replace the cover and secure with the

screw.

4. Plug in dryer or reconnect power.

26

Page 27

TROUBLESHOOTING

First try the solutions suggested here and possibly avoid the cost of a service call..

Dryer will not run

Has a fuse blown, or has a circuit breaker tripped?

There may be 2 fuses or circuit breakers for the dryer. Check

to make sure both fuses are intact and tight, or that both

circuit breakers have not tripped. Replace the fuse or reset

the circuit breaker. If a problem continues, call an electrician.

Is the correct power supply available?

Electric dryers require 240 volt power supply. Check with a

qualified electrician.

Was a regular fuse used?

Use a time-delay fuse.

Is the dryer door firmly closed?

Was the Start button firmly pressed?

Large loads may require pressing and holding the Start

button for 2-5 seconds.

No heat

Has a fuse blown, or has a circuit breaker tripped?

The drum may be turning, but you may not have heat. Electric

dryers use 2 fuses or circuit breakers. Replace the fuse or

reset the circuit breaker. If a problem continues, call an

electrician.

Unusuai sounds

Has the dryer had a period of non-use?

If the dryer hasn’t been used for a while, there may be a

thumping sound during the first few minutes of operation.

Is a coin, button, or paper clip caught between the drum

and front or rear of the dryer?

Check the front and rear edges of the drum for small objects.

Clean out pockets before laundering.

Are the four legs installed, and is the dryer level front to

back and side to side?

The dryer may vibrate if not properly installed. See the

Installation Instruotions.

Is the clothing knotted or balled up?