Kenmore 11088752799, 11088752792, 11080754006, 11088752798, 11088752791 Owner’s Manual

®

24" (61 cm) Wide

LAUNDRY CENTER

Washer- Electric Dryer

CENTRO DE LAVANDERiA

de 24" (61 cm) de ancho

Lavadora - Secadora el_ctrica

°_.... @U dsdo

Models/Modelos 110. 80754, 88752

\

W10113046C Sears Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.www.sears.com

TABLEOF CONTENTS

PROTECTION AGREEMENTS .................................................... 2

WAR RANTY ................................................................................. 3

WASHER/DRYER SAFETY ......................................................... 3

INSTALLATION INSTRUCTIONS ............................................... 5

Tools and Parts ............................................................................ 5

Alternate Parts .............................................................................. 5

Location Requirements ............................................................... 5

Drain System ................................................................................ 7

Electrical Requirements ................................................................ 7

Electrical Connection ................................................................... 9

Venting Requirements ............................................................... 14

Install Leveling Legs .................................................................. 15

Remove Foam Packing ............................................................. 15

Connect Drain Hose .................................................................. 15

Connect Inlet Hoses .................................................................. 16

Secure Drain Hose .................................................................... 17

Plan Vent System ...................................................................... 17

Install Vent System .................................................................... 18

Connect Vent ............................................................................. 18

Level Laundry Center ................................................................ 18

Complete Installation ................................................................. 19

WASHER USE .............................................................................. 20

Starting Your Washer ................................................................ 20

Cycles ........................................................................................ 21

Rinse and Spin ........................................................................... 21

Drain and Spin ........................................................................... 21

Understanding Washer Cycles .................................................. 22

Normal Sounds .......................................................................... 22

LAUNDRY TIPS ............................................................................ 22

Loading ...................................................................................... 22

DRYER USE ............................................................................... 23

Starting Your Dryer .................................................................... 23

Stopping and Restarting ........................................................... 23

Loading ...................................................................................... 24

Drying, Cycle, and Temperature Tips ........................................ 24

Cycles ........................................................................................ 24

LAUNDRY CENTER CARE .......................................................... 25

Cleaning the Laundry Center Location ..................................... 25

Cleaning Your Washer ............................................................... 25

Water Inlet Hoses ...................................................................... 25

Cleaning the Lint Screen ........................................................... 25

Cleaning the Dryer Interior ......................................................... 26

Removing Accumulated Lint ..................................................... 26

Vacation, Storage, and Moving Care ........................................ 26

TROUBLESHOOTING WASHER ............................................... 27

TROUBLESHOOTING DRYER .................................................. 29

SERVICE NUMBERS ............................................... BACK COVER

PROTECTION AGREEMENTS

Master Protection Agreements

Congratulations on making a smart purchase. Your new

Kenmore _ product is designed and manufactured for years of

dependable operation. But like all products, it may require

preventive maintenance or repair from time to time. That's when

having a Master Protection Agreement can save you money and

aggravation.

The Master Protection Agreement also helps extend the life of

your new product. Here's what the Agreement* includes:

v' Parts and labor needed to help keep products operating

properly under normal use, not just defects. Our coverage

goes well beyond the product warranty. No deductibles, no

functional failure excluded from coverage-- real protection.

v' Expert service by a force of more than 10,000 authorized

Sears service technicians, which means someone you can

trust will be working on your product.

v' Unlimited service calls and nationwide service, as often as

you want us, whenever you want us.

v' - replacement of your covered product if four or more

product failures occur within twelve months.

v' Product replacement ifyour covered product can't be fixed.

v' Annual Preventive Maintenance Check at your request - no

extra charge.

v' Fast help by phone - we call it Rapid Resolution - phone

support from a Sears representative on all products. Think of

us as a "talking owner's manual."

v' Power surge protection against electrical damage due to

power fluctuations.

v' Rental reimbursement if repair of your covered product takes

longer than promised.

v' 10% discount off the regular price of any non-covered repair

service and related installed parts.

Once you purchase the Agreement, a simple phone call is all that

it takes for you to schedule service. You can call anytime day or

night, or schedule a service appointment online.

The Master Protection Agreement is a risk free purchase. If you

cancel for any reason during the product warranty period, we will

provide a full refund. Or, a prorated refund anytime after the

product warranty period expires. Purchase your Master

Protection Agreement today!

Some limitations and exclusions apply. For prices and

additional information in the U.S.A. call 1-800-827-6655.

*Coverage in Canada varies on some items. For full details

call Sears Canada at 1-800-361-6665.

Sears Installation Service

For Sears professional installation of home appliances, garage

door openers, water heaters, and other major home items, in the

U.S.A. or Canada call 1-800-4-MY-HOME ®.

KENMORE APPLIANCE WARRANTY

ONE YEAR LIMITED WARRANTY

When installed, operated and maintained according to all

instructions supplied with the product, if this appliance fails due

to a defect in material or workmanship within one year from the

date of purchase, call 1-800-4-MY-HOME Ceto arrange for free

repair.

This warranty applies for only 90 days from the date of purchase

if this appliance is ever used for other than private family

purposes.

THIS WARRANTY COVERS ONLY DEFECTS IN MATERIAL

AND WORKMANSHIP. SEARS WILL NOT PAY FOR:

1. Expendable items that can wear out from normal use,

including but not limited to filters, belts, light bulbs, and bags.

2. A service technician to instruct the user in correct product

installation, operation or maintenance.

3. A service technician to clean or maintain this product.

4. Damage to or failure of this product if it is not installed,

operated or maintained according to all instructions supplied

with the product.

5. Damage to or failure of this product resulting from accident,

abuse, misuse or use for other than its intended purpose.

6. Damage to or failure of this product caused by the use of

detergents, cleaners, chemicals or utensils other than those

recommended in all instructions supplied with the product.

7. Damage to or failure of parts or systems resulting from

unauthorized modifications made to this product.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATION OF

REMEDIES

Customer's sole and exclusive remedy under this limited

warranty shall be product repair as provided herein. Implied

warranties, including warranties of merchantability or fitness for a

particular purpose, are limited to one year or the shortest period

allowed by law. Sears shall not be liable for incidental or

consequential damages. Some states and provinces do not allow

the exclusion or limitation of incidental or consequential

damages, or limitations on the duration of implied warranties of

merchantability or fitness, so these exclusions or limitations may

not apply to you.

This warranty applies only while this appliance is used in the

United States or Canada.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Sears Brands Management Corporation

Hoffman Estates, IL 60179

Sears Canada Inc.

Toronto, Ontario, Canada M5B 203

PRODUCT RECORD

Record your complete model number, serial number, and

purchase date. You can find this information on the model and

serial number label located on the product.

Have this information available to help you obtain assistance or

service more quickly whenever you contact Sears concerning

your appliance.

Model number ......

Serial number

Purchase date

Save these instructions and your sales receipt for future

reference.

WASHER/DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't foUow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

3

WARN|NG - -.i k ofFifo,,

- Clothes dryer installation must be performed by a qualified insta(ler.

- Install the clothes dryer according to the manufacturer's instructions and local codes.

- Do not insta(I a c(othes dryer with flexible plastic venting materials or flexible metal

(foil type) duct. if flexible meta( duct is insta((ed, it must be of a specific type identified

by the appliance manufacturer as suitable for use with clothes dryers. Flexible venting

materials are known to collapse, be easily crushed, and trap lint. These conditions will

obstruct clothes dryer airflow and increase the risk of fire.

- To reduce the risk of severe injury or death, follow all installation instructions.

- Save these instructions.

IMPORTANT SAFETY iNSTRUCTIONS

WAR NING: To reduce the risk of fire, electric shock, or injury to persons when using the washer/dryer, follow basic

precautions, including the following:

[] Read all instructions before using the washer/dryer.

[] Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to a

chemical reaction that could cause a load to catch fire.

[] Do not wash or dry articles that have been previously

cleaned in, washed in, soaked in, or spotted with gasoline,

dry-cleaning solvents, other flammable, or explosive

substances as they give off vapors that could ignite or

explode.

[] Do not add gasoline, dry-cleaning solvents, or other

flammable, or explosive substances to the wash water.

These substances give off vapors that could ignite or

explode.

[] Do not allow children to play on or in the washer/dryer.

Close supervision of children is necessary when the

washer/dryer is used near children.

[] Before the washer/dryer is removed from service or

discarded, remove the doors to the washer/dryer

compartments.

[] Do not reach into the washer/dryer if the tub, agitator or

drum is moving.

[] Do not install or store the washer/dryer where it will be

exposed to the weather.

[] Do not tamper with controls.

[] Clean dryer lint screen before or after each load.

[] Under certain conditions, hydrogen gas may be produced in

a hot water system that has not been used for 2 weeks or

more. HYDROGEN GAS IS EXPLOSIVE. If the hot water

system has not been used for such a period, before using

the washing machine, turn on all hot water faucets and let

the water flow from each for several minutes. This will

release any accumulated hydrogen gas. As the gas is

flammable, do not smoke or use an open flame during this

time.

[] Do not repair or replace any part of the washer/dryer or

attempt any servicing unless specifically recommended in

this Use and Care Guide or in published user-repair

instructions that you understand and have the skills to carry

out.

[] Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

[] Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials.

[] Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint, dust,

and dirt.

[] The interior of the machine and dryer exhaust vent should

be cleaned periodically by qualified service personnel.

[] See "Electrical Requirements" section for grounding

instructions.

SAVE THESE INSTRUCTIONS

State of California Proposition 65 Warnings:

WARNING: This product contains one or more chemicals known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals known to the State of California to cause birth defects or other

reproductive harm.

4

INSTALLATIONINSTRUCTIONS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed:

#2 Phillips and flat-blade

screwdriver

Adjustable wrench that

opens to 1" (25 mm) or

9/16" open-end wrench

(for adjusting dryer feet)

Wire stripper (direct wire

installations)

1/4" nut driver or socket

wrench (recommended)

Tin snips (for new vent

installations)

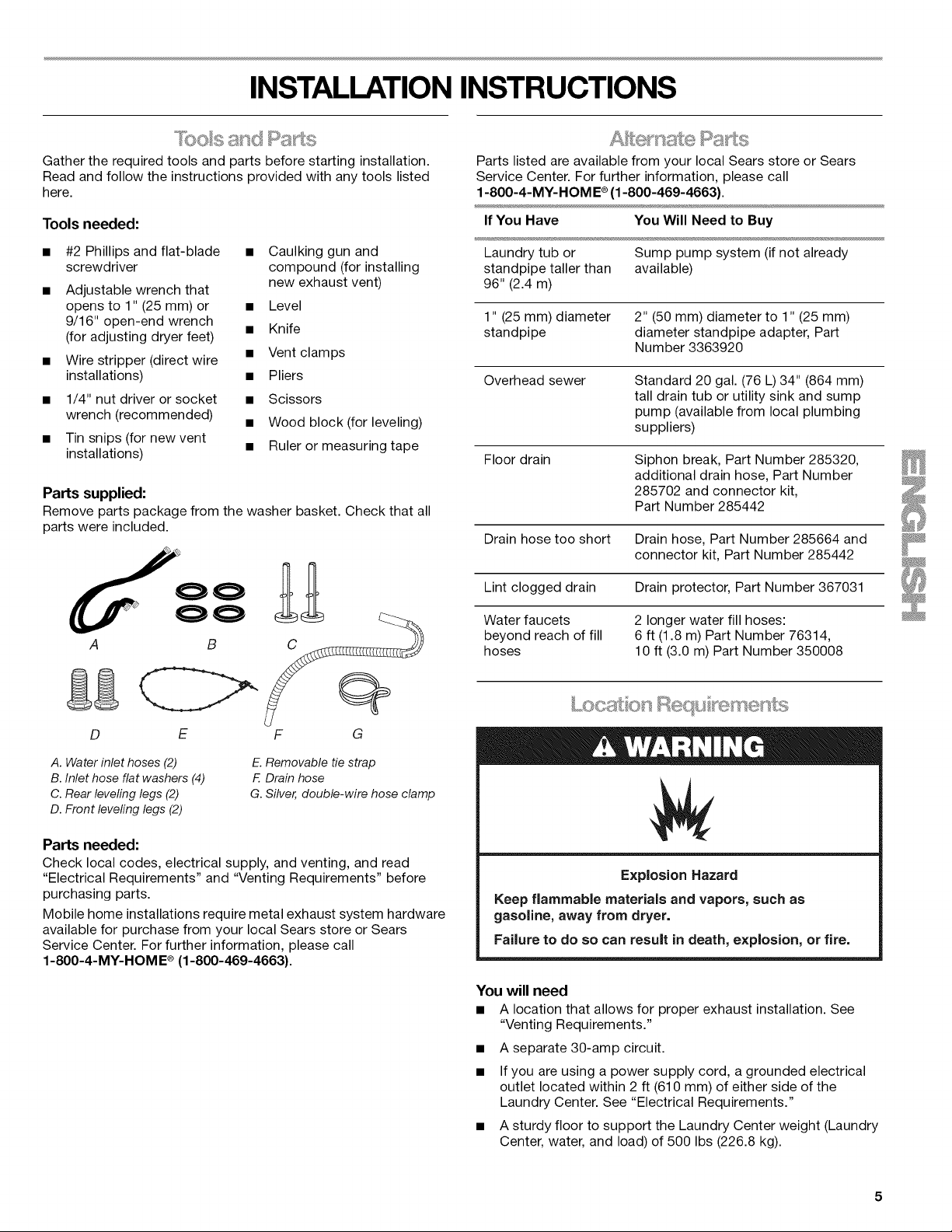

Parts supplied:

Remove parts package from the washer basket. Check that all

parts were included.

• Caulking gun and

compound (for installing

new exhaust vent)

• Level

• Knife

• Vent clamps

• Pliers

• Scissors

• Wood block (for leveling)

• Ruler or measuring tape

Parts listed are available from your local Sears store or Sears

Service Center. For further information, please call

1-800-4-MY- HOM E®(1-800-469-4663).

If You Have

Laundry tub or Sump pump system (if not already

standpipe taller than available)

96" (2.4 m)

1" (25 mm) diameter 2" (50 mm) diameter to 1" (25 mm)

standpipe diameter standpipe adapter, Part

Overhead sewer

Floor drain

Drain hose too short Drain hose, Part Number 285664 and

Lint clogged drain Drain protector, Part Number 367031

You Will Need to Buy

Number 3363920

Standard 20 gal. (76 L) 34" (864 mm)

tall drain tub or utility sink and sump

pump (available from local plumbing

suppliers)

Siphon break, Part Number 285320,

additional drain hose, Part Number

285702 and connector kit,

Part Number 285442

connector kit, Part Number 285442

A B

D E F G

A. Water inlet hoses (2)

B. Inlet hose flat washers (4)

C. Rear leveling legs (2)

D. Front leveling legs (2)

Parts needed:

Check local codes, electrical supply, and venting, and read

"Electrical Requirements" and "Venting Requirements" before

purchasing parts.

Mobile home installations require metal exhaust system hardware

available for purchase from your local Sears store or Sears

Service Center. For further information, please call

1-800-4-MY-HOME ®(1-800-469-4663).

E.Removable tie strap

F. Drain hose

G. Silver, double-wire hose clamp

Water faucets 2 longer water fill hoses:

beyond reach of fill 6 ft (1.8 m) Part Number 76314,

hoses 10 ft (3.0 m) Part Number 350008

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Failure to do so can result in death, e×plosion, or fire.

You will need

• A location that allows for proper exhaust installation. See

"Venting Requirements."

• A separate 30-amp circuit.

• If you are using a power supply cord, a grounded electrical

outlet located within 2 ft (610 mm) of either side of the

Laundry Center. See "Electrical Requirements."

• A sturdy floor to support the Laundry Center weight (Laundry

Center, water, and load) of 500 Ibs (226.8 kg).

5

Alevelfloorwithamaximumslopeof1"(25mm)underentire

LaundryCenter.Clothesmaynottumbleproperlyand

automaticsensorcyclesmaynotoperatecorrectlyifLaundry

Centerisnotlevel.Installingoncarpetisnotrecommended.

Awaterheatersettodeliver120°F(49°C)watertothe

washer.

Hotandcoldwaterfaucetslocatedwithin4ft(1.2m)ofthe

hotandcoldwaterfillvalves,andwaterpressureof5-100psi

(34.5-689.6kPa).

TheLaundryCentermustnotbeinstalledorstoredinanarea

whereitwillbeexposedtowaterand/orweather.

Donotoperateyourwasherintemperaturesatorbelow

32°F(0°C).Somewatercanremaininthewasherandcan

causedamageinlowtemperatures.See"Vacation,Storage,

andMovingCare"forwinterizinginformation.

Donotoperateyourdryerattemperaturesbelow45°F(7°C).At

lowertemperatures,thedryermightnotshutoffattheendofan

automaticcycle.Thiscanresultinlongerdryingtimes.

Checkcoderequirements.Somecodeslimit,ordonotpermit,

installationoftheLaundryCenteringarages,closets,mobile

homes,orsleepingquarters.Contactyourlocalbuilding

inspector.

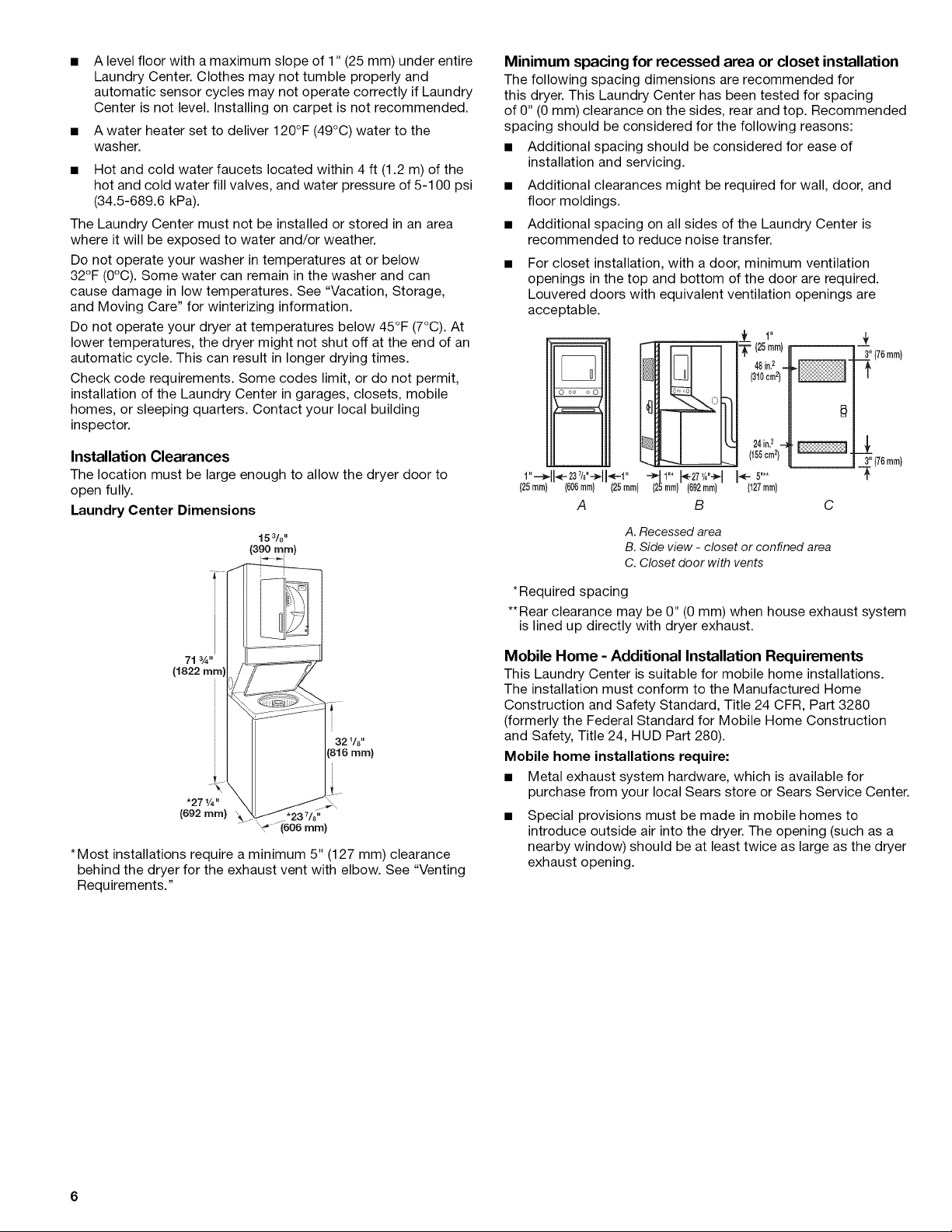

Installation Clearances

The location must be large enough to allow the dryer door to

open fully.

Laundry Center Dimensions

15 3/8"

(390 ram)

Minimum spacing for recessed area or closet installation

The following spacing dimensions are recommended for

this dryer. This Laundry Center has been tested for spacing

of 0" (0 mm) clearance on the sides, rear and top. Recommended

spacing should be considered for the following reasons:

• Additional spacing should be considered for ease of

installation and servicing.

• Additional clearances might be required for wall, door, and

floor moldings.

• Additional spacing on all sides of the Laundry Center is

recommended to reduce noise transfer.

For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

(25turn)

46in,2

(310crn2)

o oo o_O

,A

(76rnrn)

o

24in.2 -

m

1"--_(1_-23'/,"-N1÷_"

(25turn) (606rnm) (26ram)

A

A. Recessed area

B. Side view - closet or confined area

C. Closet door with vents

-H1"*1_27,/,"+1

(26ram) (692mm)

B

(155cm2)

_e. 6"**

(127mm)

i___' (76mm}

(1822 mini

321/8"

(816 ram)

*271/4"

(692mm) ,,_.

* Most installations require a minimum 5" (127 mm) clearance

behind the dryer for the exhaust vent with elbow. See "Venting

Requirements."

"_- --{606 mm)

*Required spacing

**Rear clearance may be 0" (0 mm) when house exhaust system

is lined up directly with dryer exhaust.

Mobile Home - Additional Installation Requirements

This Laundry Center is suitable for mobile home installations.

The installation must conform to the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280).

Mobile home installations require:

• Metal exhaust system hardware, which is available for

purchase from your local Sears store or Sears Service Center.

• Special provisions must be made in mobile homes to

introduce outside air into the dryer. The opening (such as a

nearby window) should be at least twice as large as the dryer

exhaust opening.

TheLaundryCentercanbeinstalledusingthestandpipedrain

system(floororwall),thelaundrytubdrainsystem,orthefloor

drainsystem.Selectthedrainhoseinstallationmethodyouneed.

See"AlternateParts."

Standpipe drain system - wall or floor (views A & B)

The standpipe drain requires a minimum diameter standpipe

of 2" (50 mm). The minimum carry-away capacity can be

no less than 17 gal. (64 L) per minute. A 2" (50 mm) diameter

to 1" (25 mm) diameter standpipe adapter kit is available. See

"Alternate Parts."

The top of the standpipe must be at least 39" (990 mm) high and

no higher than 96" (2.4 m) from the bottom of the washer.

39" [

(990

B

Laundry tub drain system (view C)

The laundry tub needs a minimum 20 gal. (76 L) capacity. The top

of the laundry tub must be at least 34" (864 mm) above the floor

and no higher than 96" (2.4 m) from the bottom of the washer.

Floor drain system (view D)

The floor drain system requires a siphon break that may be

purchased separately. See "Alternate Parts."

The siphon break must be a minimum of 28" (710 mm) from

the bottom of the washer. Additional hoses might be needed.

C D

It is your responsibility

• To contact a qualified electrical installer.

• To be sure that the electrical connection is adequate and in

conformance with the National Electrical Code, ANSl/NFPA

70-latest edition and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association, One Batterymarch Park,

Quincy, MA 02269.

Tosupply the required 3 or 4 wire, single phase, 120/240 volt,

60 Hz., AC only electrical supply (or 3 or 4 wire, 120/208 volt

electrical supply, if specified on the serial/rating plate) on a

separate 30-amp circuit, fused on both sides of the line. A

time-delay fuse or circuit breaker is recommended. Connect

to an individual branch circuit. Do not have a fuse in the

neutral or grounding circuit.

Do not use an extension cord.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

Electrical Connection

To properly install your Laundry Center, you must determine the

type of electrical connection you will be using and follow the

instructions provided for it here.

• This dryer is manufactured ready to install with a 3-wire

electrical supply connection. The neutral ground wire is

permanently connected to the neutral conductor (white wire)

within the dryer. If the dryer is installed with a 4-wire electrical

supply connection, the neutral ground wire must be removed

from the internal ground connector (green screw), and

secured under the neutral terminal (center or white wire) of

the terminal block. When the neutral ground wire is secured

under the neutral terminal (center or white wire) of the

terminal block, the dryer cabinet is isolated from the neutral

conductor.

• If local codes do not permit the connection of a neutral

ground wire to the neutral wire, see "Optional 3-wire

connection" in "Electrical Connection" section.

• Use a 4-wire conductor cord when the dryer is installed in

a mobile home or an area where local codes do not permit

grounding through the neutral.

If using a power supply cord:

• Use a UL listed power supply cord kit marked for use with

clothes dryers. The kit should contain:

• A UL listed 30-amp power supply cord, rated 120/240 volt

minimum. The cord should be type SRD or SRDT and be at

least 4 ft (1.22 m) long. The wires that connect to the dryer

must end in ring terminals or spade terminals with upturned

ends.

• A UL listed strain relief.

7

Ifyouroutletlookslikethis:

4-wire receptacle (14-30R)

Then choose a 4-wire power supply cord with ring or spade

terminals and UL listed strain relief. The 4-wire power supply

cord, at least 4 ft (1.22 m) long, must have four 10-gauge copper

wires and match a 4-wire receptacle of NEMA Type 14-30R. The

ground wire (ground conductor) may be either green or bare. The

neutral conductor must be identified by a white cover.

If your outlet looks like this:

3-wire receptacle (10-30R)

Then choose a 3-wire power supply cord with ring or spade

terminals and UL listed strain relief. The 3-wire power supply

cord, at least 4 ft (1.22 m) long, must have three 10-gauge copper

wires and match a 3-wire receptacle of NEMA Type 10-30R.

If connecting by direct wire:

Power supply cable must match power supply (4-wire or 3-wire)

and be:

• Flexible armored cable or nonmetallic sheathed copper cable

(with ground wire), protected with flexible metallic conduit.

All current-carrying wires must be insulated.

• 10-gauge solid copper wire. (Do not use aluminum.)

• At least 5 ft (1.52 m) long.

GROUNDING INSTRUCTIONS

[] For a grounded, cord-connected washer/dryer:

This washer/dryer must be grounded, in the event of

malfunction or breakdown, grounding will reduce the risk of

electric shock by providing a path of least resistance for

electric current. This washer/dryer uses a cord having an

equipment-grounding conductor and a grounding plug. The

plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local

codes and ordinances.

[] For a permanently connected washer/dryer:

This washer/dryer must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the washer/dryer.

WARNING: improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative or

personnel if you are in doubt as to whether the washer/dryer

is properly grounded. Do not modify the plug on the power

supply cord: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

Eec 1,'ca ©on ect

Power Supply Cord

Fire Hazard

Use a new UL listed 30 amp power supply cord.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal.

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

Direct Wire

Fire Hazard

Use 10 gauge copper wire.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal.

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

1. Disconnect power.

2. Remove the hold-down screw and terminal block cover.

A

B

\

C

I1 n

A. Center terminal block screw

B. Hold-down screw

C. Terminal block cover

D. Internal ground conductor screw

3. Install strain relief.

Style 1: Power supply cord strain relief

Remove the screws from a 3/4" (19 mm) UL listed strain relief

(UL marking on strain relief). Put the tabs of the two clamp

sections into the hole below the terminal block opening so

that one tab is pointing up and the other is pointing down,

and hold in place. Tighten strain relief screws just enough to

hold the two clamp sections together.

"-.... ;.....................................D

A. Strain relief tab pointing up

B. Hole below terminal block opening

C. Clamp section

D. Strain relief tab pointing down

9

Put power supply cord through the strain relief. Be sure that

the wire insulation on the power supply cord is inside the

strain relief. The strain relief should have a tight fit with the

dryer cabinet and be in a horizontal position. Do not further

tighten strain relief screws at this point.

4. Now complete installation following instructions for your type

of electrical connection:

4-wire (recommended)

3-wire (if 4-wire is not available)

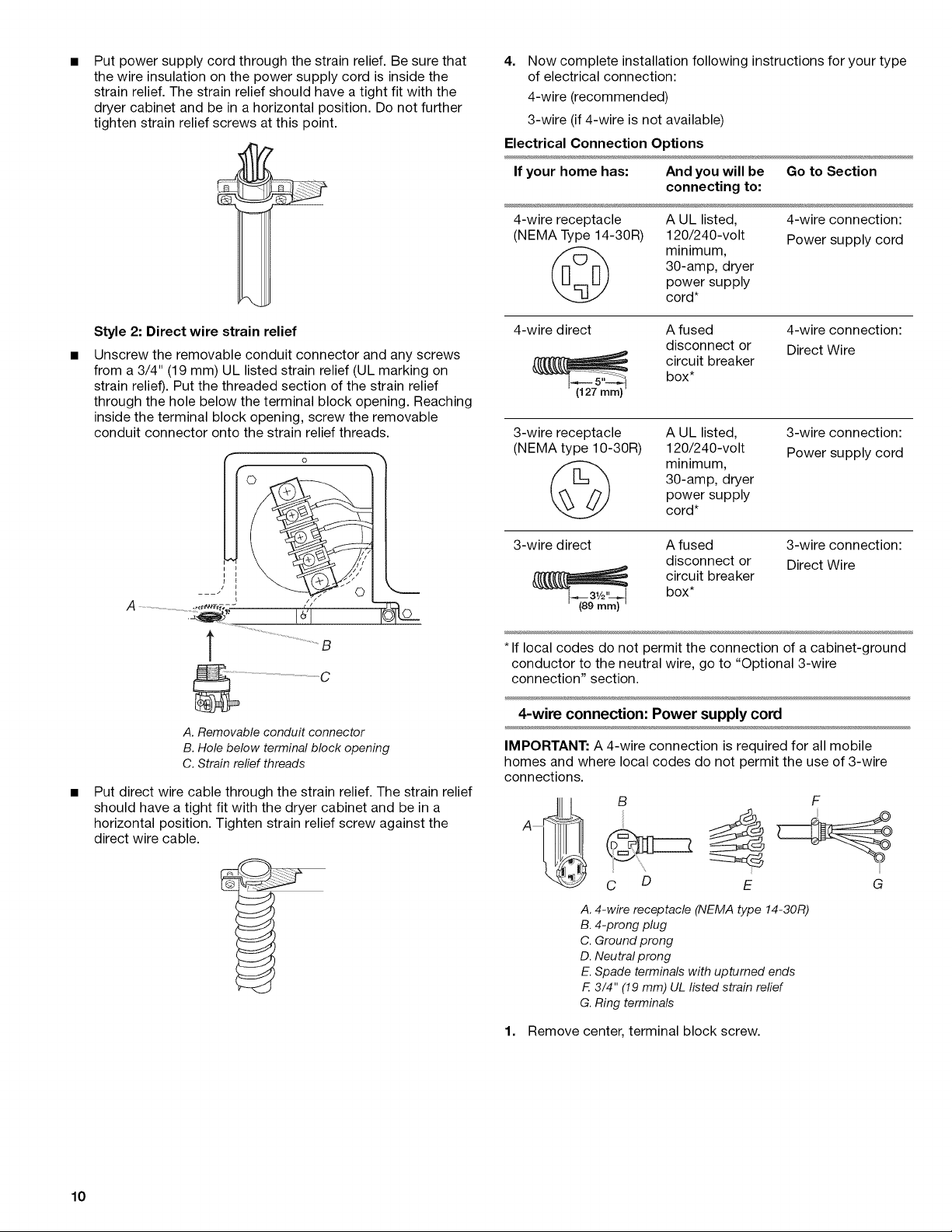

Electrical Connection Options

If your home has: And you will be Go to Section

connecting to:

4-wire receptacle A UL listed, 4-wire connection:

(NEMA Type 14-30R) 120/240-volt Power supply cord

30-amp, dryer

power supply

minimum,

cord*

Style 2: Direct wire strain relief

Unscrew the removable conduit connector and any screws

from a 3/4" (19 mm) UL listed strain relief (UL marking on

strain relief). Put the threaded section of the strain relief

through the hole below the terminal block opening. Reaching

inside the terminal block opening, screw the removable

conduit connector onto the strain relief threads.

r

l

o

/

A ...............................................+,,.,,,,,,_,-- /,

T ................g

_ ............................. C

A. Removable conduit connector

B. Hole below terminal block opening

C. Strain relief threads

Put direct wire cable through the strain relief. The strain relief

should have a tight fit with the dryer cabinet and be in a

horizontal position. Tighten strain relief screw against the

direct wire cable.

4-wire direct A fused 4-wire connection:

disconnect or Direct Wire

box*

circuit breaker

3-wire receptacle A UL listed,

(NEMA type 10-30R) 120/240-volt

3-wire connection:

Power supply cord

30-amp, dryer

power supply

minimum,

cord*

3-wire direct A fused 3-wire connection:

disconnect or Direct Wire

box*

(89 mm_

circuit breaker

* If local codes do not permit the connection of a cabinet-ground

conductor to the neutral wire, go to "Optional 3-wire

connection" section.

4-wire connection: Power supply cord

IMPORTANT: A 4-wire connection is required for all mobile

homes and where local codes do not permit the use of 3-wire

connections.

10

C D E G

A. 4-wire receptacle (NEMA type 14-30R)

B. 4-prong plug

C. Ground prong

D. Neutral prong

E. Spade terminals with upturned ends

F. 3/4" (19 mm) UL listed strain relief

G. Ring terminals

1. Remove center, terminal block screw.

2=

Remove neutral ground wire from internal ground conductor

screw. Connect neutral ground wire and the neutral wire

(white or center wire) of power supply cord under center,

terminal block screw. Tighten screw.

A

/

B

L

©

4-wire connection: Direct Wire

IMPORTANT: A 4-wire connection is required for mobile homes

and where local codes do not permit the use of 3-wire

connections.

Direct wire cable must have 5 ft (1.52 m) of extra length so

Laundry Center can be moved if needed.

Strip 5" (127 mm) of outer covering from end of cable, leaving

bare ground wire at 5" (127 mm). Cut 11/2"(38 mm) from

3 remaining wires. Strip insulation back 1" (25 mm). Shape ends

of wires into a hook shape.

_,,

ED

A. Center terminal block screw

B. Neutral ground wire

C. Internal ground conductor screw - Dotted line shows

position of NEUTRAL ground wire before being

moved to center terminal block screw.

D. Neutral wire (white or center wire)

E.3/4" (19 mm) UL fisted strain relief

3=

Move the green painted screw from the internal to the

external ground conductor location. Connect ground wire

(green or bare) of power supply cord to external ground

conductor screw. Tighten screw.

C

B

/

A ....... ,........C

(127

When connecting to the terminal block, place the hooked end of

the wire under the screw of the terminal block (hook facing right),

squeeze hooked end together and tighten screw. See example

below.

1=

Remove center, terminal block screw.

2.

Remove neutral ground wire from internal ground conductor

screw. Connect neutral ground wire and place the hooked

end (hook facing right) of the neutral wire (white or center

wire) of direct wire cable under the center screw of the

terminal block. Squeeze hooked ends together. Tighten

screw.

A

A. Neutral wire (white or center wire)

B. Center terminal block screw

C. Neutral ground wire

D. External ground conductor screw

E. Ground wire (green or bare) of power supply cord

E Internal ground conductor location

G. 3/4" (19 mm) UL listed, strain relief

4. Connect the other wires to outer terminal block screws.

Tighten screws.

5. Tighten strain relief screws.

6. Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

7. You have completed your electrical connection. Now go to

"Venting Requirements."

UoL

E D C

A. Center terminal block screw

B. Neutral ground wire

C. Internal ground conductor screw - Dotted line shows

position of NEUTRAL ground wire before being

moved to center terminal block screw.

D. Neutral wire (white or center wire)

E.3/4" (19 mm) UL listed strain relief

11

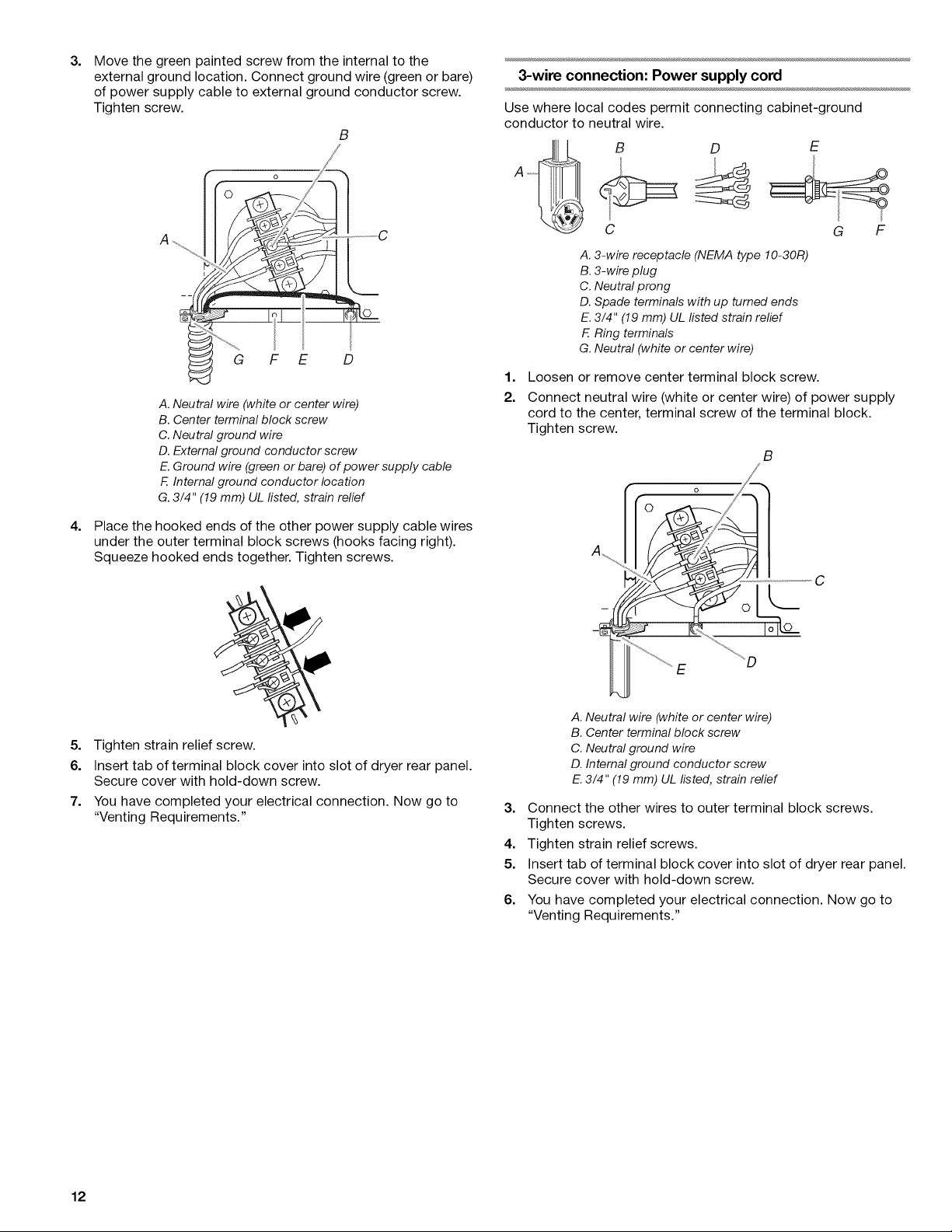

3=

Move the green painted screw from the internal to the

external ground location. Connect ground wire (green or bare)

of power supply cable to external ground conductor screw.

Tighten screw.

B

©

3-wire connection: Power supply cord

Use where local codes permit connecting cabinet-ground

conductor to neutral wire.

D E

A ...... i

G F E D

A. Neutral wire (white or center wire)

B. Center terminal block screw

C. Neutral ground wire

D. External ground conductor screw

E. Ground wire (green or bare) of power supply cable

E Internal ground conductor location

G. 3/4" (19 mm) UL fisted, strain relief

4=

Place the hooked ends of the other power supply cable wires

under the outer terminal block screws (hooks facing right).

Squeeze hooked ends together. Tighten screws.

C

A. 3-wire receptacle (NEMA type 10-30R)

B. 3-wire plug

C. Neutral prong

D. Spade terminals with up turned ends

E. 3/4" (19 mm) UL fisted strain relief

E Ring terminals

G. Neutral (white or center wire)

1=

Loosen or remove center terminal block screw.

2.

Connect neutral wire (white or center wire) of power supply

cord to the center, terminal screw of the terminal block.

Tighten screw.

B

/

G F

5. Tighten strain relief screw.

6. Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

7. You have completed your electrical connection. Now go to

"Venting Requirements."

A. Neutral wire (white or center wire)

B. Center terminal block screw

C. Neutral ground wire

D. Internal ground conductor screw

E. 3/4" (19 mm) UL listed, strain relief

3. Connect the other wires to outer terminal block screws.

Tighten screws.

4. Tighten strain relief screws.

5. Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

6. You have completed your electrical connection. Now go to

"Venting Requirements."

12

3-wire connection: Direct Wire

Use where local codes permit connecting cabinet-ground

conductor to neutral wire.

Direct wire cable must have 5 ft (1.52 m) of extra length so

Laundry Center can be moved if needed.

Strip 31/2"(89 mm) of outer covering from end of cable. Strip

insulation back 1" (25 mm). If using 3-wire cable with ground

wire, cut bare wire even with outer covering. Shape ends of wires

into a hook shape.

3. Place the hooked ends of the other power supply cable wires

under the outer terminal block screws (hooks facing right).

Squeeze hooked ends together. Tighten screws.

4. Tighten strain relief screw.

5. Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

6. You have completed your electrical connection. Now go to

"Venting Requirements."

When connecting to the terminal block, place the hooked end of

the wire under the screw of the terminal block (hook facing right),

squeeze hooked end together and tighten screw.

1=

Loosen or remove center, terminal block screw.

2.

Place the hooked end of the neutral wire (white or center wire)

of direct wire cable under the center screw of terminal block

(hook facing right). Squeeze hooked end together. Tighten

screw.

B

C

IL_

E D

Optional 3-wire connection

Use for direct wire or power supply cord where local codes do

not permit connecting cabinet-ground conductor to neutral wire.

1. Remove center, terminal block screw.

2. Remove neutral ground wire from internal ground conductor

screw. Connect neutral ground wire and the neutral wire

(white or center wire) of power supply cord/cable under

center, terminal block screw. Tighten screw.

A

............Io ° "

C

E

A. Neutral wire (white or center wire)

B. Neutral ground wire

C. External ground conductor screw

D. Grounding path determined by a qualified electrician

E. Internal ground conductor location

3. Connect the other wires to outer terminal block screws.

Tighten screws.

A. Neutral wire (white or center wire)

B. Center terminal block screw

C. Neutral ground wire

D. Internal ground conductor screw

E.3/4" (19 mm) UL listed, strain relief

4. Tighten strain relief screws.

5. Move the green painted screw from the internal to the

external ground conductor location. Connect a separate

copper ground wire from the external ground conductor

screw to an adequate ground.

6. Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

13

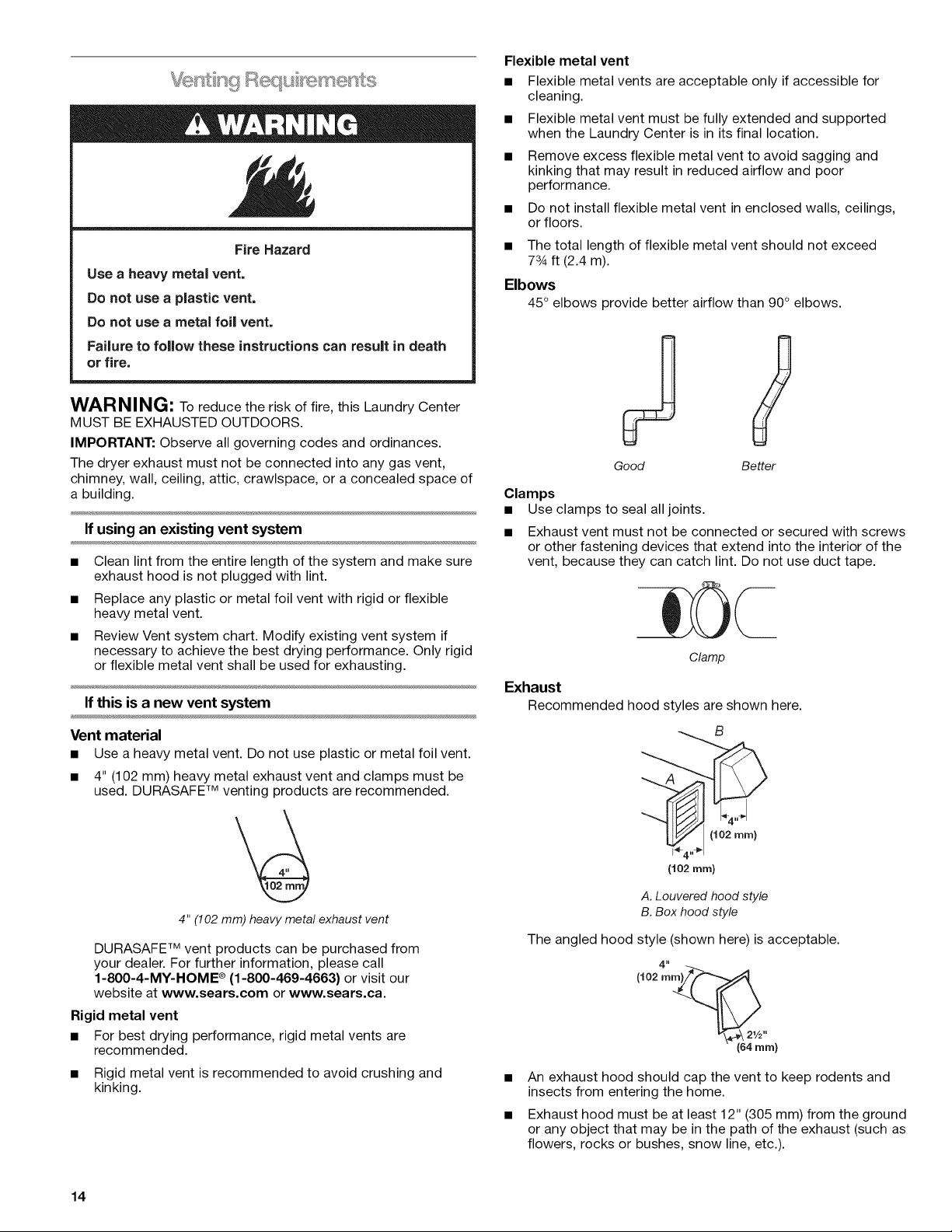

Req ents

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent,

Do not use a metal foil vent.

Fai(ure to follow these instructions can result in death

or fire.

WARNING: To reduce the risk of fire, this Laundry Center

MUST BE EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

The dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space of

a building.

If using an existing vent system

Clean lint from the entire length of the system and make sure

exhaust hood is not plugged with lint.

Replace any plastic or metal foil vent with rigid or flexible

heavy metal vent.

Review Vent system chart. Modify existing vent system if

necessary to achieve the best drying performance. Only rigid

or flexible metal vent shall be used for exhausting.

If this is a new vent system

Flexible metal vent

• Flexible metal vents are acceptable only if accessible for

cleaning.

Flexible metal vent must be fully extended and supported

when the Laundry Center is in its final location.

Remove excess flexible metal vent to avoid sagging and

kinking that may result in reduced airflow and poor

performance.

Do not install flexible metal vent in enclosed walls, ceilings,

or floors.

• The total length of flexible metal vent should not exceed

73Aft (2.4 m).

Elbows

45° elbows provide better airflow than 90° elbows.

Good Better

Clamps

• Use clamps to seal all joints.

• Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into the interior of the

vent, because they can catch lint. Do not use duct tape.

Clamp

Exhaust

Recommended hood styles are shown here.

Vent material

• Use a heavy metal vent. Do not use plastic or metal foil vent.

• 4" (102 ram) heavy metal exhaust vent and clamps must be

used. DURASAFE TM venting products are recommended.

4" (102mm) heavy metal exhaust vent

DURASAFE TM vent products can be purchased from

your dealer. For further information, please call

1-800-4-MY-HOME ®(1-800-469-4663) or visit our

website at www.sears.com or www.sears.ca.

Rigid metal vent

• For best drying performance, rigid metal vents are

recommended.

• Rigid metal vent is recommended to avoid crushing and

kinking.

(102 ram}

A. Louvered hood style

B. Box hood style

The angled hood style (shown here) is acceptable.

(102 m m__

I,_ 21/2.

(64 ram)

An exhaust hood should cap the vent to keep rodents and

insects from entering the home.

Exhaust hood must be at least 12" (305 mm) from the ground

or any object that may be in the path of the exhaust (such as

flowers, rocks or bushes, snow line, etc.).

14

• Donotuseanexhausthoodwithamagneticlatch.

improper venting can cause moisture and lint to collect

indoors, which may result in:

Ill Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

Ill Housecleaning problems and health problems.

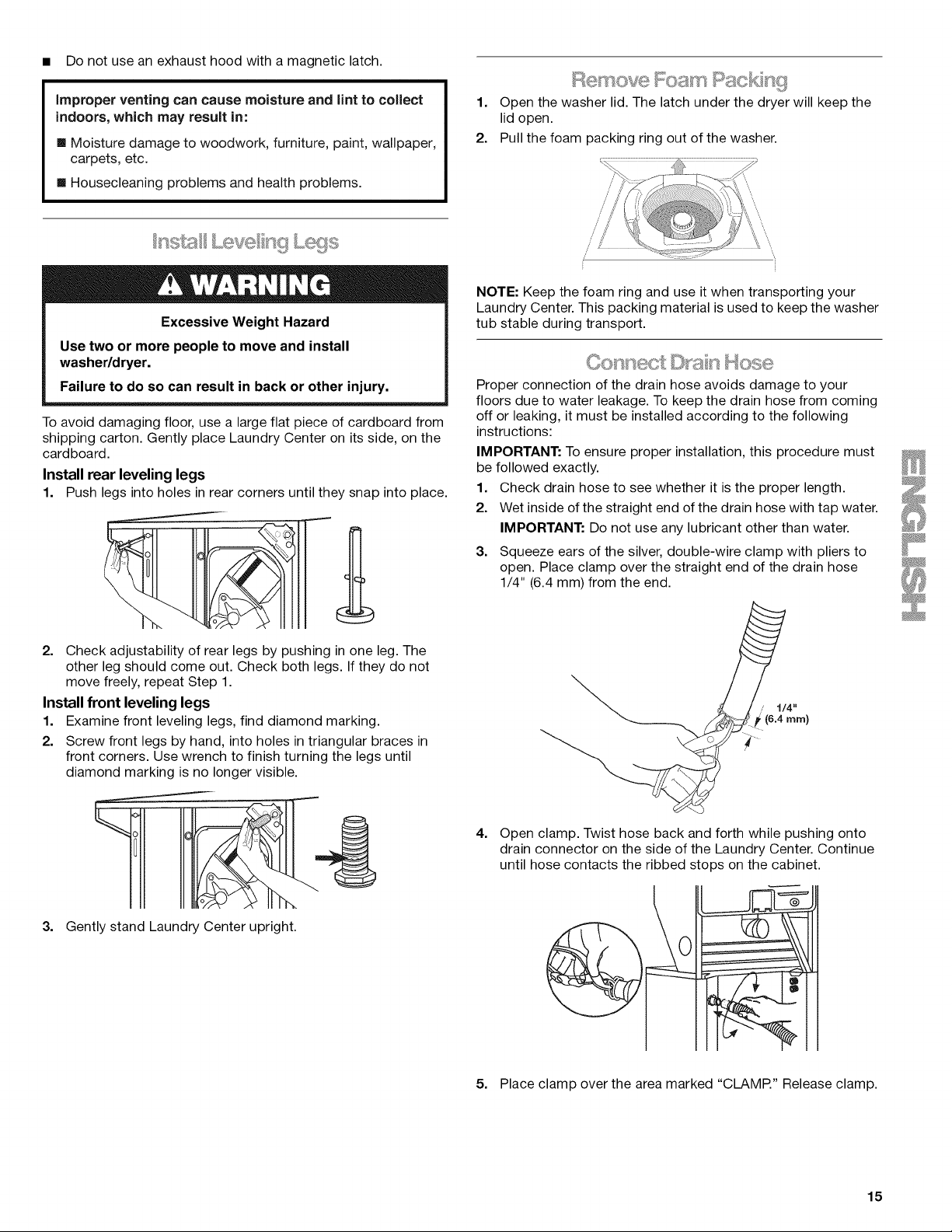

Excessive Weight Hazard

Use two or more people to move and install

washer/dryer.

Failure to do so can result in back or other injury.

To avoid damaging floor, use a large flat piece of cardboard from

shipping carton. Gently place Laundry Center on its side, on the

cardboard.

Install rear leveling legs

1. Push legs into holes in rear corners until they snap into place.

@VOd@ _;; "'

1. Open the washer lid. The latch under the dryer will keep the

lid open.

2. Pull the foam packing ring out of the washer.

NOTE: Keep the foam ring and use it when transporting your

Laundry Center. This packing material is used to keep the washer

tub stable during transport.

earn Psck g

Oonn Hose

Proper connection of the drain hose avoids damage to your

floors due to water leakage. To keep the drain hose from coming

off or leaking, it must be installed according to the following

instructions:

IMPORTANT: To ensure proper installation, this procedure must

be followed exactly.

1. Check drain hose to see whether it is the proper length.

2. Wet inside of the straight end of the drain hose with tap water.

IMPORTANT: Do not use any lubricant other than water.

3. Squeeze ears of the silver, double-wire clamp with pliers to

open. Place clamp over the straight end of the drain hose

1/4" (6.4 mm) from the end.

2. Check adjustability of rear legs by pushing in one leg. The

other leg should come out. Check both legs. If they do not

move freely, repeat Step 1.

Install front leveling legs

1. Examine front leveling legs, find diamond marking.

2. Screw front legs by hand, into holes in triangular braces in

front corners. Use wrench to finish turning the legs until

diamond marking is no longer visible.

3. Gently stand Laundry Center upright.

4. Open clamp. Twist hose back and forth while pushing onto

drain connector on the side of the Laundry Center. Continue

until hose contacts the ribbed stops on the cabinet.

@

5. Place clamp over the area marked "CLAMR" Release clamp.

15

For laundry tub or standpipe drain systems

1. Make sure drain hose form is in correct position.

....................................

A.Drain hoseform

2. Put the hooked end of drain hose into laundry tub or

standpipe. Rotate hook to eliminate kinks.

To keep drain water from going back into the washer:

• Do not force excess drain hose into standpipe. Hose should

be secure but loose enough to provide a gap for air.

• Do not lay excess hose on the bottom of the laundry tub.

Connect inlet hoses to washer

1. Attach the hot water hose to the bottom inlet valve. Attaching

the hot water hose first makes it easier to tighten connection

with pliers.

2. Screw on coupling by hand until it is seated on the washer.

3. Using pliers, tighten the couplings with an additional two-

thirds turn.

NOTE: Do not overtighten or use tape or sealants on the valve.

Damage to the valves can result.

=¸¸%%=¸.............S

For use with floor drain

Do not install the drain hose form on to the corrugated drain

hose. You may need additional parts. See Floor drain under

"Tools and Parts."

1. Insert a new flat washer into each end of the inlet hoses.

Firmly seat the washers in the couplings.

A B

A.Coupling

B. Washer

Connect inlet hoses to water faucets

Make sure the washer basket is empty.

1. Attach hose to the hot water faucet. Screw on coupling

by hand until it is seated on the washer.

2. Attach hose to the cold water faucet. Screw on coupling

by hand until it is seated on the washer.

3. Using pliers, tighten the couplings with an additional

two-thirds turn.

€

NOTE: Do not overtighten or use tape or sealants on the valve.

Damage to the valves can result.

Clear water lines

• Run water through both faucets and inlet hoses, into a

laundry tub, drainpipe, or bucket to get rid of particles in the

water lines that might clog the inlet valve screens.

• Check the temperature of the water to make sure that the hot

water hose is connected to the hot water faucet and that the

cold water hose is connected to the cold water faucet.

A.Cold water inlet valve (top)

B. Hotwater inlet valve(bottom)

4. Attach the cold water hose to the top inlet valve.

5. Screw on coupling by hand until it is seated on the washer.

6. Using pliers, tighten the couplings with an additional

two-thirds turn.

NOTE: Do not overtighten or use tape or sealants on the valve.

Damage to the valves can result.

If you are working in a closet or recessed area

Move the Laundry Center into its final location and remove

cardboard from under Laundry Center. Remove the access panel

by removing 3 Phillips-head screws and one bumper, located at

the top of the access panel. Set panel, screws, and bumper

aside. Complete hookup of water hoses and (on gas models) the

flexible gas connector through the access area. Replace access

panel upon completion of Laundry Center installation.

Check for leaks

• Turn on the water faucets and check for leaks. A small

amount of water might enter the washer. You will drain this

later.

NOTE: Replace inlet hoses after 5 years of use to reduce the risk

of hose failure. Record hose installation or replacement dates for

future reference.

• If you connect only one water hose, you must cap off the

remaining water inlet port.

• Periodically inspect and replace hoses if bulges, kinks, cuts,

wear, or leaks are found.

• The apparatus must be connected to the water faucets using

the new hoses. Do not use old hoses.

16

1. MoveLaundryCentertoitsfinallocationandremoveany

cardboardusedtomoveLaundryCenter.

2. Locateremovabletiestrapincludedinpartspackage.

(2Z>

Removabletie strap

3. Wrap the drain hose to the laundry tub leg or standpipe with

the removable tie strap (A or B below) and secure.

A B C

If the water faucets and the drain standpipe are recessed, put

the hooked end of the drain hose in the standpipe. Tightly

wrap the removable tie strap around the water inlet hoses

and the drain hose (C above).

Optional exhaust installations

This Laundry Center can be converted to exhaust out the right

or left side. To convert the Laundry Center, use Side Exhaust Kit

Part Number 279823. If your Laundry Center was previously

exhausted from the right or left side, it can be converted to rear

exhaust by using standard offset connections. To cover the hole

in the side, one of the following plugs can be added:

692790 (white)

3979370 (graphite)

3977784 (biscuit)

Follow the instructions in the kit to install. Kits are available from

your local Sears store or Sears Service Center.

,%£L [

A B C

A. Standard rear offset exhaust installation

B. Rear exhaust for offset close clearance connection

C. Left or right side exhaust installation

Choose your exhaust installation type

Recommended exhaust installations

Typical installations vent the dryer from the rear of the Laundry

Center. Other installations are possible.

.......................D

A

C ................. _ H

A. Dryer

B. Rigid metal or flexible metal vent

C. Clamps

D. Waft

E. Elbow

F. Clamps

G. Elbow

H. Exhaust hood

Alternate installations for close clearances

Venting systems come in many varieties. Select the type best for

your installation. Three close-clearance installations are shown.

Refer to the manufacturer's instructions provided with the vent

system.

, ,, ,,,,

A B C

A. Loop system with standard elbows

B. Loop system with one offset and one standard elbow

C. Vent system with one periscope (2" [50 mm]

clearance)

NOTE: The following kits for close clearance alternate

installations are available for purchase. To order, please call

1-800-4-MY-HOM E®(1-800-469-4663).

17

Over-the-TopInstallation:

PartNumber26-49900

PeriscopeInstallation(Forusewithdryerventtowallvent

mismatch):

PartNumber26-49901-Lessthan5"(127mm)mismatch

PartNumber26-49908-5"(127mm)to18"(457mm)

mismatch

PartNumber26-49904-18"(457mm)to29"(737mm)

mismatch

PartNumber26-49905-29"(737mm)to50"(1270mm)

mismatch

Specialprovisionsfor mobile home installations

The exhaust vent must be securely fastened to a noncombustible

portion of the mobile home structure and must not terminate

beneath the mobile home. Terminate the exhaust vent outside.

Vent system chart

NOTE: Side exhaust installations add a 90° turn inside the

Laundry Center. To determine maximum exhaust length, add one

90° turn to the chart.

Number of Type of Vent Box or Angled

90° turns Louvered hoods

or elbows hoods

0 Rigid metal 43 ft (13.1 m) 36 ft (11.0 m)

1 Rigid metal 33 ft (10.1 m) 26 ft (7.9 m)

2 Rigid metal 24 ft (7.3 m) 16 ft (4.9 m)

1=

Install exhaust hood. Use caulking compound to seal exterior

wall opening around exhaust hood.

2.

Connect vent to exhaust hood. Vent must fit inside exhaust

hood. Secure vent to exhaust hood with 4" (102 mm) clamp.

3.

Run vent to dryer location. Use the straightest path possible.

See "Determine vent path" in "Plan Vent System." Avoid 90°

turns. Use clamps to seal all joints. Do not use duct tape,

screws or other fastening devices that extend into the interior

of the vent to secure vent. Items sticking through the vent can

catch lint.

Determine vent path

• Select the route that will provide the straightest and most

direct path outdoors.

• Plan the installation to use the fewest number of elbows and

turns.

• When using elbows or making turns, allow as much room as

possible.

• Bend vent gradually to avoid kinking.

• Use the fewest 90° turns possible.

Determine vent length and elbows needed for best

drying performance

• Use the Vent system chart below to determine type of vent

material and hood combinations acceptable to use.

NOTE: Do not use vent runs longer than those specified in

the Vent system chart. Exhaust systems longer than those

specified will:

• Shorten the life of the dryer.

• Reduce performance, resulting in longer drying times and

increased energy usage.

The Vent system chart provides venting requirements that will

help to achieve the best drying performance.

Oo_x_ec¢ st

1. Using a 4" (102 mm) clamp, connect vent to exhaust outlet in

Laundry Center. If connecting to existing vent, make sure the

vent is clean. Dryer vent must fit over dryer exhaust outlet

and inside exhaust hood. Check that vent is secured to

exhaust hood with a 4" (102 mm) clamp.

2. Move Laundry Center to its final location. Avoid crushing or

kinking vent.

Le/e/Lau s@'y Cest@

Properly leveling your Laundry Center avoids excessive noise

and vibration.

1. Check levelness of Laundry Center by placing a level on the

top edge of washer, first side to side, then front to back.

2.

If Laundry Center is not level, prop up front with a wood block

and adjust feet up or down as necessary. Remove wood

block and lower Laundry Center. Repeat this step until

Laundry Center is level.

18

1. Checkthatallpartsarenowinstalled.Ifthereisanextrapart,

gobackthroughthestepstoseewhatwasskipped.

2. Checkthatyouhaveallofyourtools.

3. Disposeof/recycleallpackagingmaterials.Keeptheplastic

foamforuseifLaundryCentershouldbetransported.

4. CheckLaundryCenter'sfinallocation.Besureventisnot

crushedorkinked.

5. CheckthatLaundryCenterislevelandfrontlevelingfeetare

tight.See"LevelLaundryCenter."

6. Forpowersupplycordinstallation,plugintoanoutlet.For

directwireinstallation,turnonpower.

7. Checkthatthewaterfaucetsareon.

8. Checkforleaksaroundfaucetsandinlethoses.

9. Removefilmontheconsoleandanytaperemainingon

LaundryCenter.

10.Read"WasherUse"and"DryerUse."

11.Wipedryerdruminteriorthoroughlywithadampclothto

removeanydust.

12.Totestthewasher,measure1/2thenormalrecommended

amountofdetergentandpouritintothewasher.Closethelid.

SelectHEAVYDUTYandpullouttheCYCLECONTROL

knob.Allowthewashertocompleteonewholecycle.

13.Totestthedryer,setthedryeronafullheatcycle(notanair

cycle)for20minutesandstartthedryer.

Ifthedryerwillnotstart,checkthefollowing:

• Controlsaresetinarunningor"On"position.

• PUSHTOSTARTDRYERbuttonhasbeenfirmlypushed.

• LaundryCenterispluggedintoanoutletand/orelectrical

supplyison.

• Householdfuseisintactandtight,orcircuitbreakerhas

nottripped.

• Dryerdoorisclosed.

14.Whenthedryerhasbeenrunningfor5minutes,openthe

dryerdoorandfeelforheat.Ifyoufeelheat,cancelcycle

andclosethedoor.

Ifyoudonotfeelheat,turnthedryeroffandcheckthe

following:

• There may be 2 household fuses or circuit breakers for

the dryer. Check that both fuses are intact and tight, or

that both circuit breakers have not tripped. If there is still

no heat, contact a qualified technician.

NOTE: You may notice an odor when dryer is first heated. This

odor is common when the heating element is first used. The

odor will go away.

19

WASHER USE

HEAVYDUTY

RINSE

SPIN

REGULAR

GENTLE

SHORT

PERMANENT

PRESS

SHORT S --

REGULAR1R-

SUPER 12 -

PREWAI

SPIN

KNIT/DELICATE

SOAK_

Fire Hazard

Never place items in the washer that are dampened

with gasoline or other flammable fluids.

No washer can completely remove oil.

Do not dry anything that has ever had any type of oil on

it (including cooking oils).

Doing so can result in death, explosion, or fire.

WATER TEIVIP WATER LEVEL

WARM WARM LOAD

MEDIUM

COLD.WARM.

COL_ COLD RESET

• Choose a load size that allows the load to move freely for

best fabric care. See "Loading."

• You may change the load size selection after the washer

has started filling by turning the selector to a different

setting.

5.

Set the WATER TEMP selector to the correct setting for the

type of fabric and soils being washed.

Use the warmest water safe for the fabric. Follow garment

label instructions.

Water Temp Use For

WATER TEMP

WARM WARM

COLD WARM

C0LO • • HOT

COL00 C__LO

WARNING: To reduce the risk of fire, electric shock, or injuryto

persons, read the IMPORTANT SAFETY INSTRUCTIONS before

operating this washer.

The following is a guide to starting your washer. Periodic

references to other sections of this manual provide more detailed

information.

1. Pour measured powdered or liquid detergent into the washer.

If desired, add powdered or liquid color safe bleach.

2. Place a load of sorted clothes in the washer.

• Load evenly to maintain washer balance. Mix large and

small items. See "Loading."

• Items should move easily through the wash water. Tightly

packed loads may cause poor cleaning.

3. Close the washer lid.

4. Turn the WATER LEVEL selector knob to the correct setting

for your wash load and the type of fabric being washed.

WATER LEVEL

MEDIUM

LOAB

SMALL LARGE

RESET

LOA_e e LOAO

20

Hot Whites and pastels

Heavy soils

Warm Bright colors

Moderate to light soils

Cold Colors that bleed or fade

Light soils

NOTE: In wash water temperatures colder than 60°F (15.6°C),

detergents do not dissolve well. Soils can be difficult to

remove. Some fabrics can retain wear wrinkles and have

increased pilling (the formation of small lint-like balls on the

surface of garments).

6.

Push in the CYCLE CONTROL knob and turn it clockwise to

wash cycle you want. Pull out the CYCLE CONTROL knob to

start washer.

To stop or restart your washer:

• To stop washer at any time, push in CYCLE CONTROL

knob.

• To restart washer, close the lid (if open) and pull out

CYCLE CONTROL knob.

Loading...

Loading...