Kenmore 11068702890, 11068202790, 11067832790, 11067732790, 11066852690 Owner’s Manual

...

_.__/A/R-_ owner's Manual

29-Inch Wide

ELECTRIC DRYERS

\l

IMPORTANT:

Read and follow all safety

instructions and operating

instructions before first use

of this product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 IJ.S.A.

PART NO. 3405585 PRINTED IN U.S.A.

BEFORE USING YOUR NEW DRYER

SEARS ELECTRIC DRYER WARRANTY

IMPORTANT SAFETY INSTRUCTIONS

INSTALLATION INSTRUCTIONS

OPERATING YOUR DRYER

CARING FOR YOUR DRYER

TROUBLESHOOTING

SEARS MAINTENANCE AGREEMENT

REQUESTING ASSISTANCE OR SERVICE!

Please read this manual. It will help you

install and operate your new electric dryer

in the safest and most economical way.

For information about the care and

operation of Sears appliances call your

nearest Sears store. You will need the

complete model and serial numbers

when requesting information. Your dryer's

model and serial numbers are located

on the Model and Serial Number Plate.

20

22

25

27

28

Use the ,,;pace below to record the

model number and serial number of

your new electric dryer.

Model No.

Serial Nc.

Date of Purchase

Keep this book and your sales

check (receipt) in a safe place for

future reference.

2

90-DAY WARRANTY ON MECHANICAL.

AND ELECTRICAL PARTS

For ninety days from the date of purchase,

when the dryer is installed and operated

according to the instructions in the Owner's

Manual, Sears will repair or replace any

mechanical or electrical parts in this dryer,

if defective in material or workmanship.

WARRANTY SERVICE IS AVAILABLE

BY CONTACTING THE NEAREST

SEARS SERVICE CENTER IN THE

UNITED STATES.

YOUR SAFETY IS IMPORTANT TO US.

WARNING: To reduce the risk of fire,

electric shock, or injury to persons when

using your dryer, follow basic precautions,

including the following:

• Read all instructions before using

the dryer.

• Do not dry articles that have been pre-

viously cleaned in, washed in, soaked

in, or spotted with gasoline, dry-cleaning

solvents, other flammable or explosive

substances as they give off vapors that

could ignite or explode.

• Do not allow children to play on or in

the dryer. Close supervision of children

is necessary when the dryer is used

near children.

• Before the dryer is removed from service

or discarded, remove the door to the

drying compartment.

• Do not reach into the dryer if the drum

is moving.

• Do not install or store this dryer where

it will be exposed to the weather.

• Do not tamper with controls.

• Do not repair or replace any part of the

dryer or attempt any servicing unless

specifically recommended in the user-

maintenance instructions or in published

user-repair instructions that you under-

stand and have the skills to carry out.

This warrartty applies only while this

product is in use in the United States.

This warrarty gives you specific legal

rights, and you may also have other

rights which vary from state to state.

Sears Roebuck and Co., Dept. 817WA,

Hoffman I-states, IL 60179.

NOTE: Exhausting your dryer with plastic

duct may not be covered by your manu-

fa(;turer's warranty. Pages 16-19 of this

Owner's Manual describe the complete

exhaust requirements for this dryer.

• Do not use fabric softeners or products

to eliminatE, static unless; recommended

by the manufacturer of the fabric softener

or product.

• Do not use heat to dry articles containing

foam rubL_eror similarly textured rubber-

like materials.

• Clean lint screen before or after each load.

• Keep area around the exhaust opening

and adjacent surrounding areas free from

the accumulation of lint, dust, and dirt.

• The interior of the machine and exhaust

duct should be cleaned periodically by

qualified se'vice personnel.

This guide contains safety statements

under warning symbols. Please pay

special attention to the warning boxes

similar to the one below and follow

any instructions given.

The inforrnation in this box will

alert you l:o such dangers as fire,

electrical shock, burns and

personal injury.

SAVE THESE INSTRUCTIONS 3

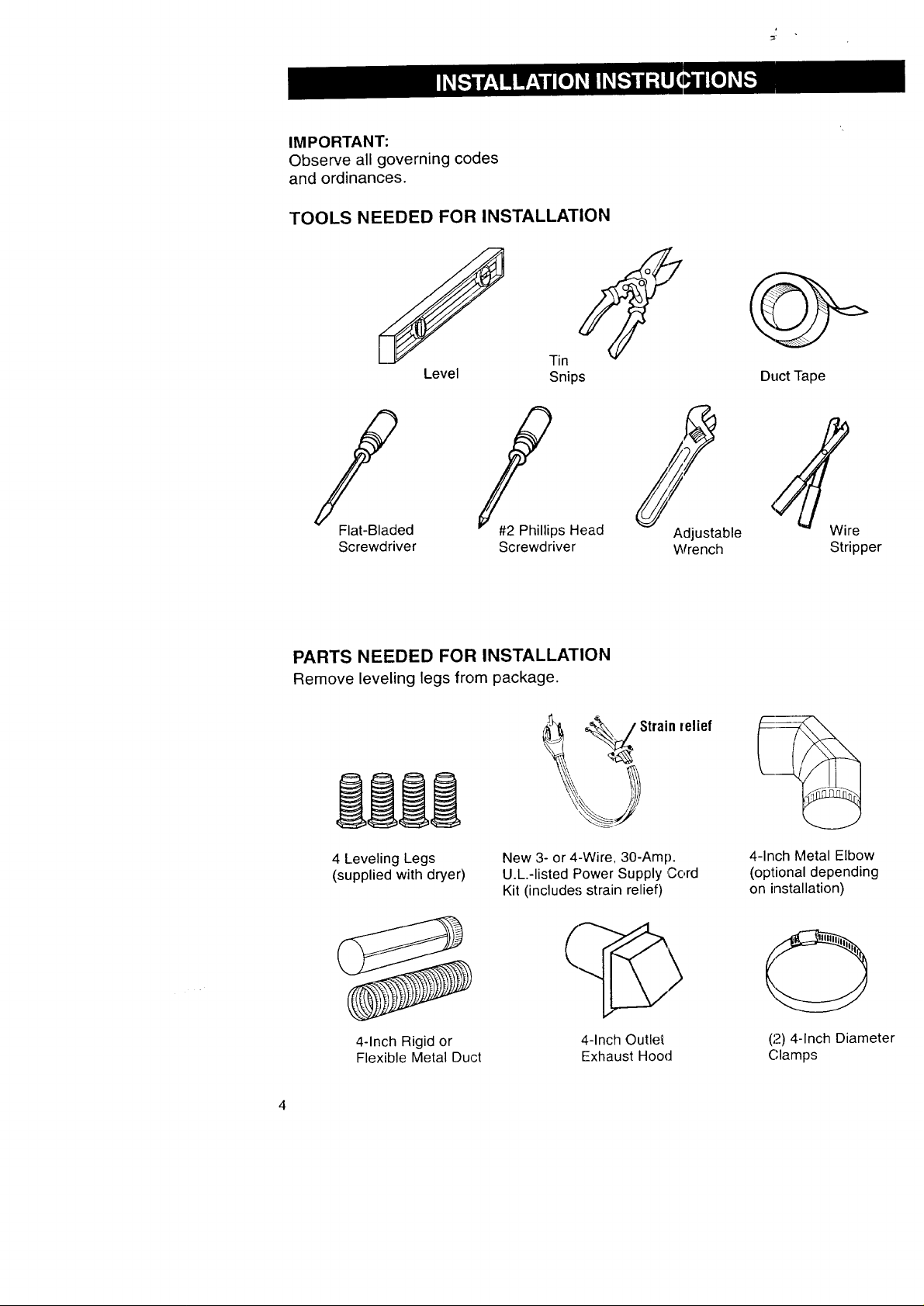

IMPORTANT:

Observe all governing codes

and ordinances.

TOOLS NEEDED FOR INSTALLATION

f

Level

/'

Flat-Bladed

Screwdriver

PARTS NEEDED FOR INSTALLATION

Remove leveling legs from package.

_ps Head

Screwdriver

Tin

Snips

_ Strain

Adjustable

Wrench

felief

Duct rape

Stripper

4 Leveling Legs

(supplied with dryer)

4-Inch Rigid or

Flexible Metal Duct

New 3- or 4-Wire, 30-Amp.

U.L.-listed Power Supply Cord

Kit (include,'; strain relief)

4-Inch Outlet

Exhaust Hood

4-Inch Metal Elbow

(optional depending

on installation)

(2) 4-.Inch Diameter

(;lamps

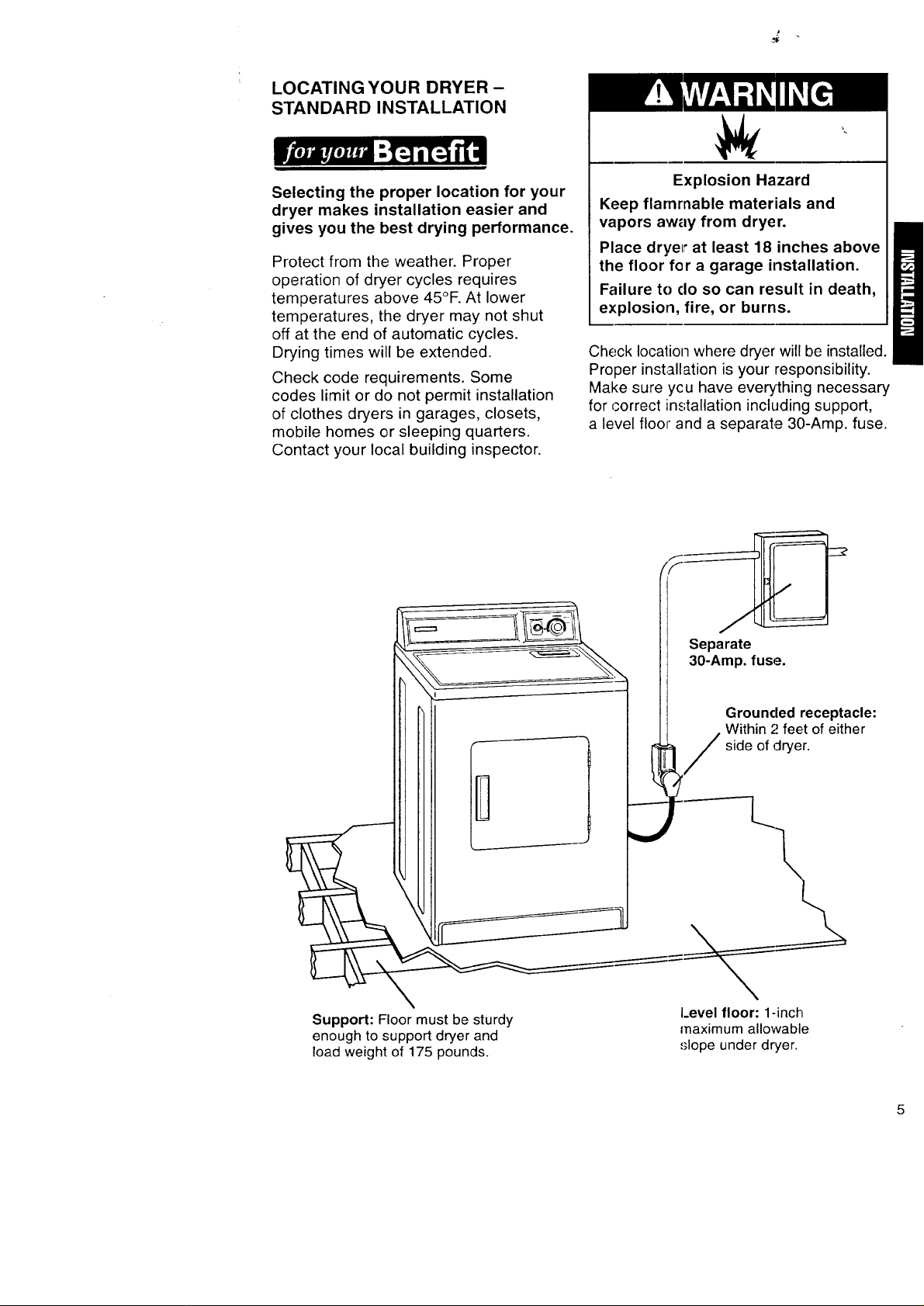

LOCATING YOUR DRYER -

STANDARD INSTALLATION

|

Selecting the proper location for your

dryer makes installation easier and

gives you the best drying performance.

Protect from the weather. Proper

operation of dryer cycles requires

temperatures above 45°F. At lower

temperatures, the dryer may not shut

off at the end of automatic cycles.

Drying times will be extended.

Check code requirements. Some

codes limit or do not permit installation

of clothes dryers in garages, closets,

mobile homes or sleeping quarters.

Contact your local building inspector.

Explosion Hazard

Keep flammable materials and

vapors away from dryer.

Place dryest at least 18 inches above

the floor for a garage installation.

Failure to ¢1oso can result in death,

explosion, fire, or burns.

Check Iocalion where dryer will be installed.

Proper inst;_llation is your responsibility.

Make sure ycu have everything necessary

for correct installation including support,

a level floor and a separate 30-Amp. fuse.

_--_._',. I Separate

___ I 30"A_ilfu_il_ d receptacle:

I' II'l __ =__/ siW_lhionf;; feert,of either

Support: Floor must be sturdy Level floor: 1-inch

enough to support dryer and maximum allowable

load weight of 175 pounds, slope under dryer.

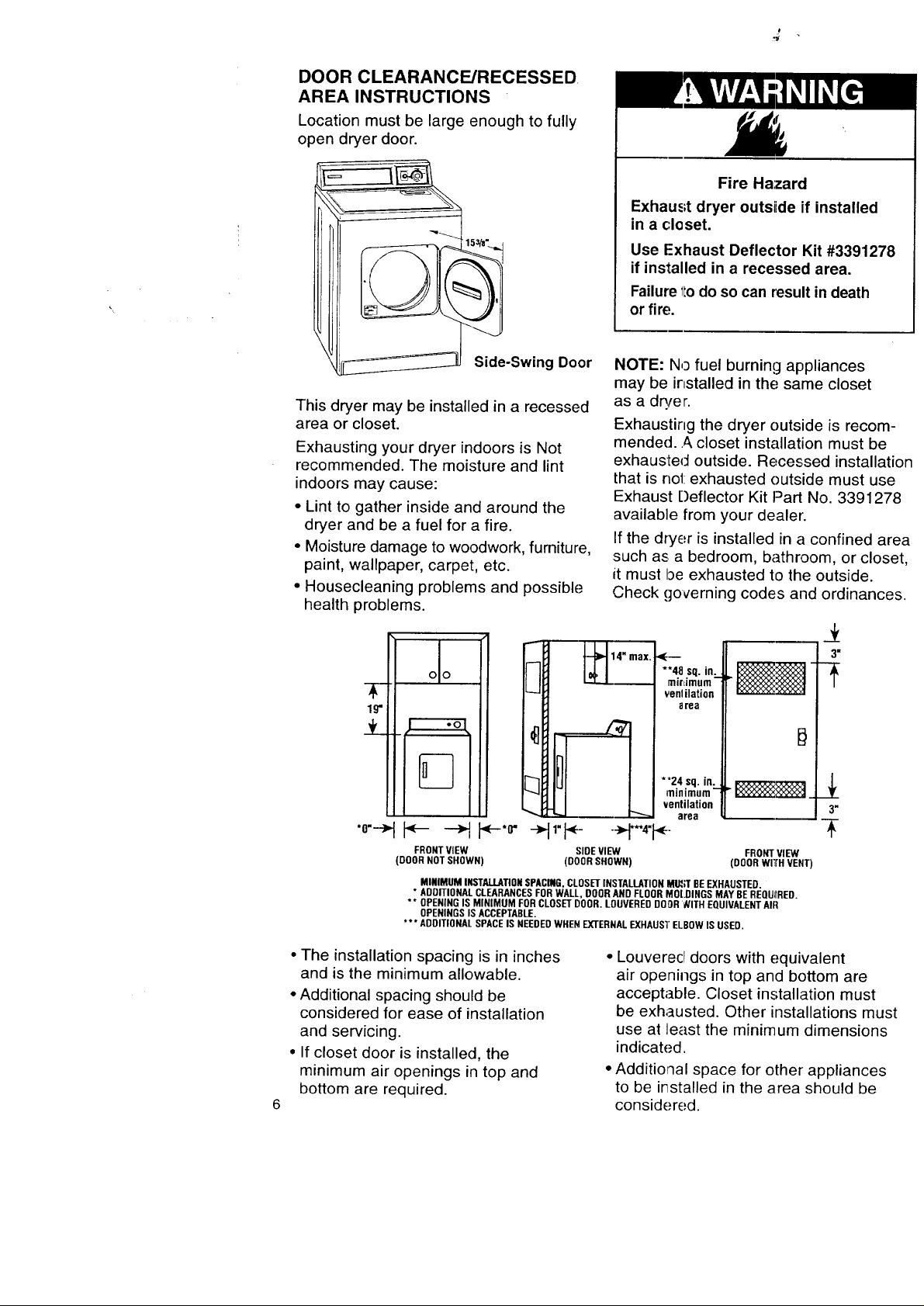

DOOR CLEARANCE/RECESSED

AREA INSTRUCTIONS

Location must be large enough to fully

open dryer door.

Fire Hazard

Exhaust dryer outsiide if installed

in a closet.

Use Exhaust Deflector Kit #3391278

if installed in a recessed area.

Failure 1todo so can result in death

or fire,

Side-Swing Door

This dryer may be installed in a recessed

area or closet.

Exhausting your dryer indoors is Not

recommended. The moisture and lint

indoors may cause:

• Lint to gather inside and around the

dryer and be a fuel for a fire.

• Moisture damage to woodwork, furniture,

paint, wallpaper, carpet, etc.

• Housecleaning problems and possible

health problems.

• I I --H"'i

FRONTVIEW SIDEVIEW FRONTVIEW

(DOORNOTSHOWN) (DOORSHOWN) (ODORwITrHVENT)

MINIMUM INSTALLATIONSPACING,CLOSETINSTALLATIONM_R BEEXHAUSTED.

* ADDITIONALCLEARANCESFORWALL, DOORANDFLOORMOLDINGSMAYBEREQUIIRED.

** OPENINGIS MINIMUM FORCLOSETDOOR.LOUVEREDDOOR_ITH EQUIVALENTAIR

OPENINGSIS ACCEPTABLE.

*** ADDITIONALSPACEIS NEEDEDWHENEXTERNALEXHAUS'I"ELBOWISUSED.

NOTE: No fuel burning appliances

may be installed in the; same closet

as a dryer.

Exhausting the dryer outside is recom-

mended.._, closet installation must be

exhausted outside. Recessed installation

that is no1:exhausted outside must use

Exhaust Deflector Kit Part No. 3391278

available from your dealer.

If the dryer is installed in a confined area

such as a bedroom, bathroom, or closet,

it must be exhausted to the outside.

Check governing codes and ordinances.

3"

**4.8 .sq. in:..

mlrdmum

venlilation

area

*'24 sq. in.

minimum- _:_,_:_:_1

ventilation 3"

area

._x_

• The installation spacing is in inches

and is the minimum allowable.

• Additional spacing should be

considered for ease of installation

and servicing.

• If closet door is installed, the

minimum air openings in top and

bottom are required.

• Louverecl doors with equivalent

air openings in top and bottom are

acceptable. Closet installation must

be exhausted. Other installations must

use at least the minimum dimensions

indicated.

• Additional space for other appliances

to be irTstalled in the area should be

considered.

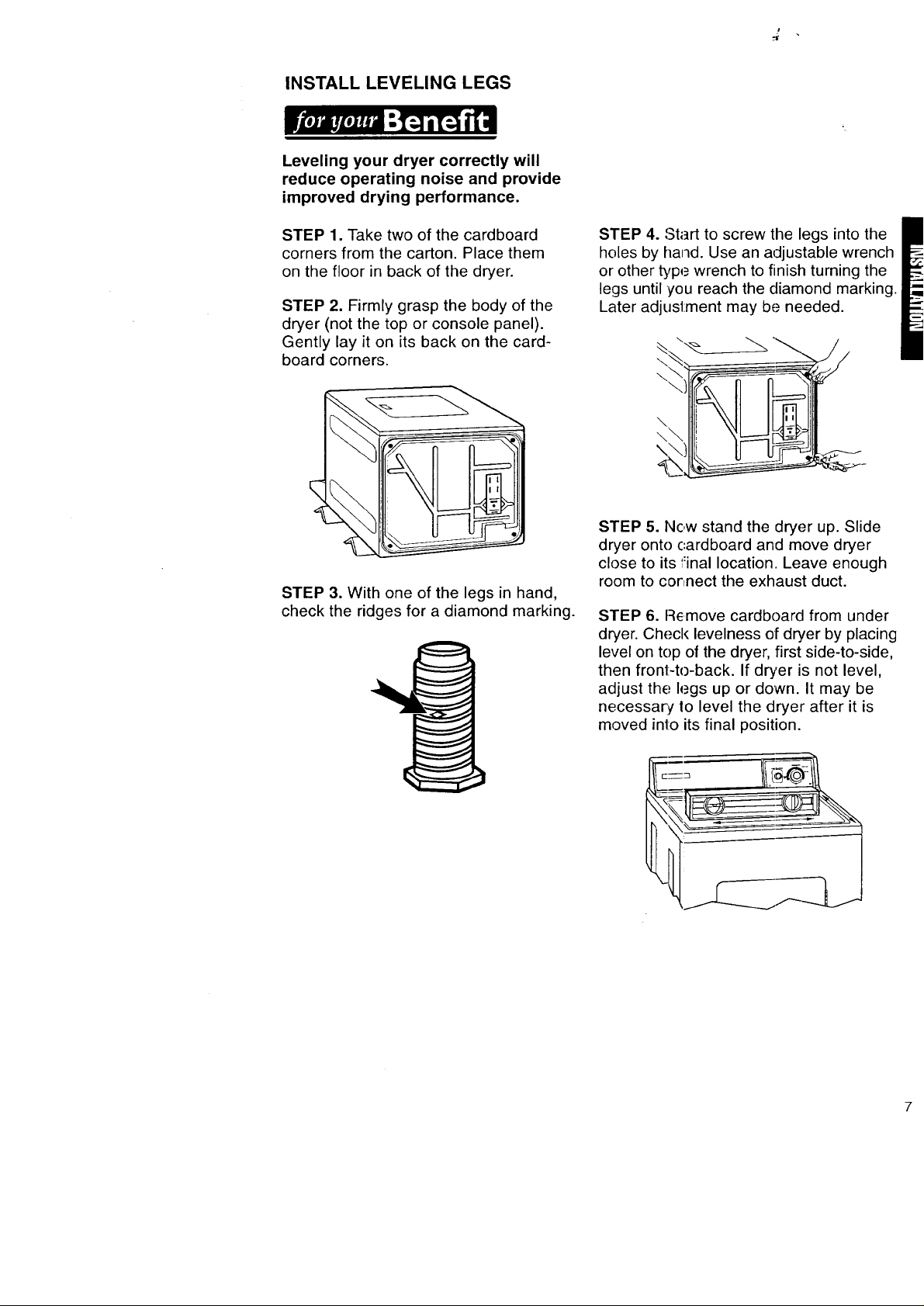

INSTALL LEVELING LEGS

Leveling your dryer correctly will

reduce operating noise and provide

improved drying performance.

STEP 1. Take two of the cardboard

corners from the carton. Place them

on the floor in back of the dryer.

STEP 2. Firmly grasp the body of the

dryer (not the top or console panel).

Gently lay it on its back on the card-

board corners.

STEP 3. With one of the legs in hand,

check the ridges for a diamond marking.

STEP 4. Start to screw the legs into the

holes by hand. Use an adjustable wrench

or other type wrench to finish turning the

legs until you reach the diamond marking.

Later adjustment may be needed.

\

\

\

\\

\

STEP 5. Now stand the dryer up. Slide

dryer onto cardboard and move dryer

close to its final location. Leave enough

room to connect the exhaust duct.

STEP 6. Remove cardboarcl from under

dryer. Check levelness of dryer by placing

level on top of the dryer, first side-to-side,

then front-to-back. If dryer is not level,

adjust thE: legs up or down. It may be

necessary, Io level the dryer after it is

moved into its final position.

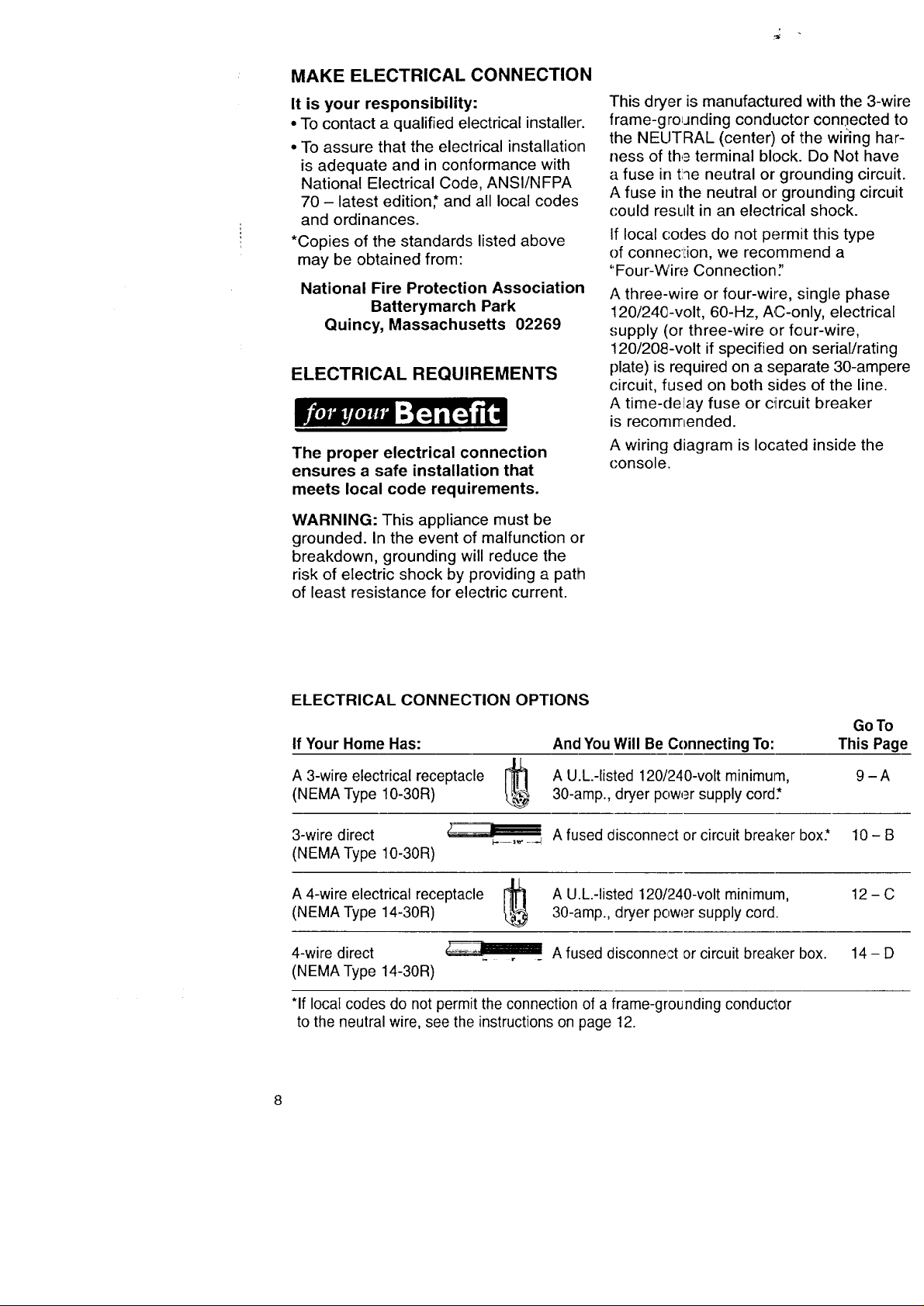

MAKE ELECTRICAL CONNECTION

It is your responsibility:

• To contact a qualified electrical installer.

• To assure that the electrical installation

is adequate and in conformance with

National Electrical Code, ANSI/NFPA

70 - latest edition* and all local codes

and ordinances.

*Copies of the standards listed above

may be obtained from:

National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

ELECTRICAL REQUIREMENTS

The proper electrical connection

ensures a safe installation that

meets local code requirements.

WARNING: This appliance must be

grounded. In the event of malfunction or

breakdown, grounding will reduce the

risk of electric shock by providing a path

of least resistance for electric current.

This dryer is manufactured with the 3-wire

frame-grounding conductor conaected to

the NEUTRAL (center) of the wiring har-

ness of the terminal block. Do Not have

a fuse in tlqe neutral or grounding circuit.

A fuse in the neutral or grounding circuit

could result in an electrical shock.

If local codes do not permit this type

of conneciion, we recommend a

"Four-Wire Connection;'

A three-wire or four-wire, .,;ingle phase

120/240-volt, 60-Hz, AC-only, electrical

supply (or three-wire or four-wire,

120/208-volt if specified on serial/rating

plate) is required on a separate 30-ampere

circuit, fused on both sides of the line.

A time-delay fuse or c_ircuit breaker

is recommended.

A wiring diagram is located inside the

console.

ELECTRICAL CONNECTION OPTIONS

If Your Home Has:

A 3-wire electrical receptacle

(NEMA Type 10-30R)

3-wire direct

(NEMA Type 10-30R)

IL

A 4-wire electrical receptacle r_l

(NEMA Type 14-30R)

4-wire direct

(NEMA Type 14-30R)

*If local codes do not permit the connection of a frame-grounding conductor

to the neutral wire, see the instructions on page 12.

And You Will Be Connecting To:

A U.L.-listed 120/240-volt minimurn,

30-amp., dryer power supply cord*

A fused disconnect or circuit breaker box.* 10- B

A U.L.-listed 120/240-volt minimum,

30-amp., dryer power supply cord.

A fused disconnect or circuit breaker box. 14 - D

GoTo

This Page

9-A

12-C

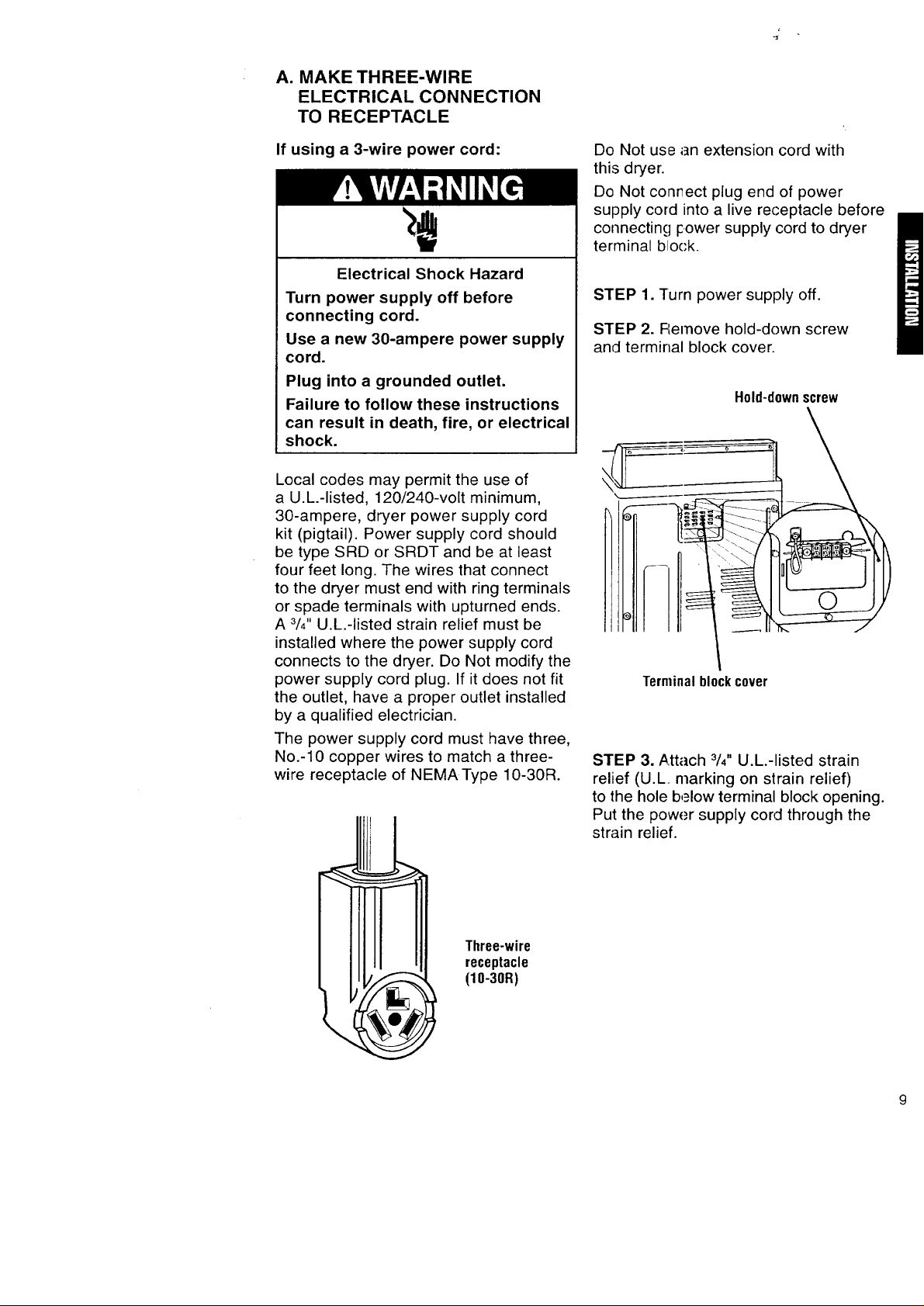

A. MAKE THREE-WIRE

ELECTRICAL CONNECTION

TO RECEPTACLE

If using a 3-wire power cord:

Electrical Shock Hazard

Turn power supply off before

connecting cord.

Use a new 30-ampere power supply

cord.

Plug into a grounded outlet.

Failure to follow these instructions

can result in death, fire, or electrical

shock.

Local codes may permit the use of

a U.L.-listed, 120/240-volt minimum,

30-ampere, dryer power supply cord

kit (pigtail). Power supply cord should

be type SRD or SRDT and be at least

four feet long. The wires that connect

to the dryer must end with ring terminals

or spade terminals with upturned ends.

A 3/4"U.L.-listed strain relief must be

installed where the power supply cord

connects to the dryer. Do Not modify the

power supply cord plug. If it does not fit

the outlet, have a proper outlet installed

by a qualified electrician.

The power supply cord must have three,

No.-10 copper wires to match a three-

wire receptacle of NEMAType 10-30R.

Do Not use an extension cord with

this dryer.

Do Not conr_ect plug end of power

supply cord into a live receptacle before

connecting icower supply cord to dryer

terminal block.

STEP 1. Turn power supply off.

STEP 2. FLemove hold-down screw

and terminal block cover.

Hold-downscrew

Terminalblockcover

STEP 3. ,_.ttach 3/4"U.L.-listed strain

relief (U.L. marking on strain relief)

to the hole b,_low terminal block opening.

Put the power supply cord through the

strain relief.

Three-wire

receptacle

(10-30R)

Loading...

Loading...