Page 1

Dryer Installation instructions

Instrucciones de instalaci6n de la secadora

English / EspaSol

Table of Contents / {ndice ......2

P/N W10562377A

Sears Brands Management Corporation

Hoffman Estates, IL 60179 U.S.A.

www.kenmore.com

www.sears.com

Sears Canada inc.

Toronto, Ontario, Canada M5B 2C3

www.sears.ca

®

Page 2

Table of Contents indite

DRYER SAFETY .................................................................................... 2

iNSTALLATiON REQUIREMENTS ......................................................... 4

Tools and Parts ................................................................................ 4

LOCATION REQUIREMENTS ................................................................. 5

ELECTRICAL REQUIREMENTS .............................................................. 6

iNSTALL LEVELING LEGS ..................................................................... 7

ELECTRICAL CONNECTION ................................................................ 8

VENTING ........................................................................................... 13

Venting Requirements ..................................................................... 13

Plan Vent System ............................................................................ 14

install Vent System ......................................................................... 16

CONNECT iNLET HOSES .................................................................... 16

CONNECT VENT ................................................................................ 18

LEVEL DRYER ..................................................................................... 18

COMPLETE iNSTALLATiON CHECKLIST .............................................. 19

REVERSE DOOR SWING ..................................................................... 19

INSTALLATION NOTES

Date of purchase:

Date of instaffation:

Installer:

Model number:

Serial number:

SEGURIDAD DE LA SECADORA .......................................................... 21

REQUISITOS DE INSTALACI6N .......................................................... 22

Herram_entas y plezcls .................................................................... 22

REQUISITOS DE UBICACK)N ............................................................. 23

REQUISITOS ELECTREOS ................................................................. 24

INSTALACION DE LAS PATAS NIVELADORAS ................................... 26

CONEXION ELECTRICA .................................................................... 26

VENTILACI6N .................................................................................... 32

Requlsltos de ventilaci6n ................................................................. 32

Planiflcac_6n del s_stema de ventilac_6n .......................................... 33

Instalaci6n del slstema de venfilaci6n ............................................. 35

CONEXION DE LAS MANGUERAS DE ENTRADA ............................... 35

CONEXION DEL DUCTO DE ESCAPE ................................................. 37

NIVELACION DE LA SECADORA ....................................................... 37

LISTA DE CONTROL DE LA INSTALACI6N TERMINADA ................... 38

CAMBIO DEL SENTIDO DE ABERTURA DE LA PUERTA ....................... 38

NOTAS saBRE LA INSTALACI6N

Fecha de compra:

Fecha de instalaci6n:

Instaladar:

N_mero de madelo:

NOmero de serie:

2

Page 3

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

WARNING - ...i.kofFi,o..

- Clothes dryer installation must be performed by a qualified installer.

- Install the clothes dryer according to the manufacturer's instructions and local codes.

- Do not install a clothes dryer with flexible plastic venting materials or flexible metal

{foil type} duct. If flexible metal duct is installed, it must be of a specific type identified

by the appliance manufacturer as suitable for use with clothes dryers. Flexible venting

materials are known to collapse, be easily crushed, and trap lint. These conditions will

obstruct clothes dryer airflow and increase the risk of fire,

- To reduce the risk of severe injury or death, follow all installation instructions.

- Save these instructions.

State of California Proposition 65 Warnings:

WARNING: This product contains one or more chemicals known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals known to the State of California to cause birth defects or other

reproductive harm.

Page 4

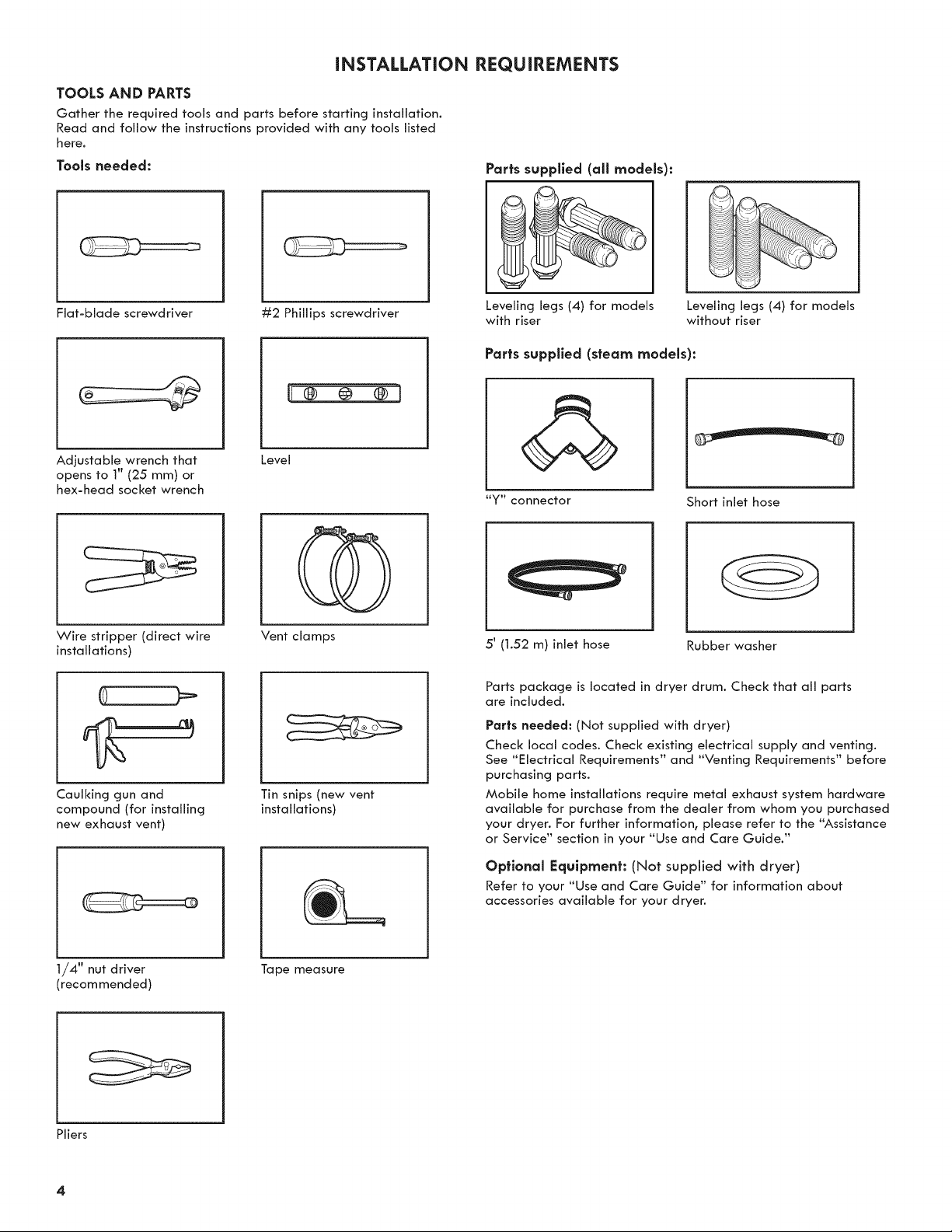

iNSTALLATiON REQUIREMENTS

TOOLS AND PARTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed:

Parts supplied (all models):

Flat-blade screwdriver

Adjustable wrench that

opens to 1" (25 mm) or

hex-head socket wrench

Wire stripper (direct wire

installations)

Caulking gun and

compound (for installing

new exhaust vent)

#2 Phillips screwdriver

{i® @ ®]

Level

(D

Vent clamps

Tin snips (new vent

installations)

Leveling legs (4) for models

with riser

Parts supplied (steam models):

5' (1.52 m) inlet hose Rubber washer

Parts package is located in dryer drum. Check that all parts

are included.

Parts needed: (Not supplied with dryer)

Check local codes. Check existing electrical supply and venting.

See "Electrical Requirements" and "Venting Requirements" before

purchasing parts.

Mobile home installations require metal exhaust system hardware

available for purchase from the dealer from whom you purchased

your dryer. For further information, please refer to the "Assistance

or Service" section in your "Use and Care Guide."

Leveling legs (4) for models

without riser

Short inlet hose

/4" nut driver Tape measure

recommended)

Pliers

4

Optional Equipment: (Not supplied with dryer)

Refer to your "Use and Care Guide" for information about

accessories available for your dryer.

Page 5

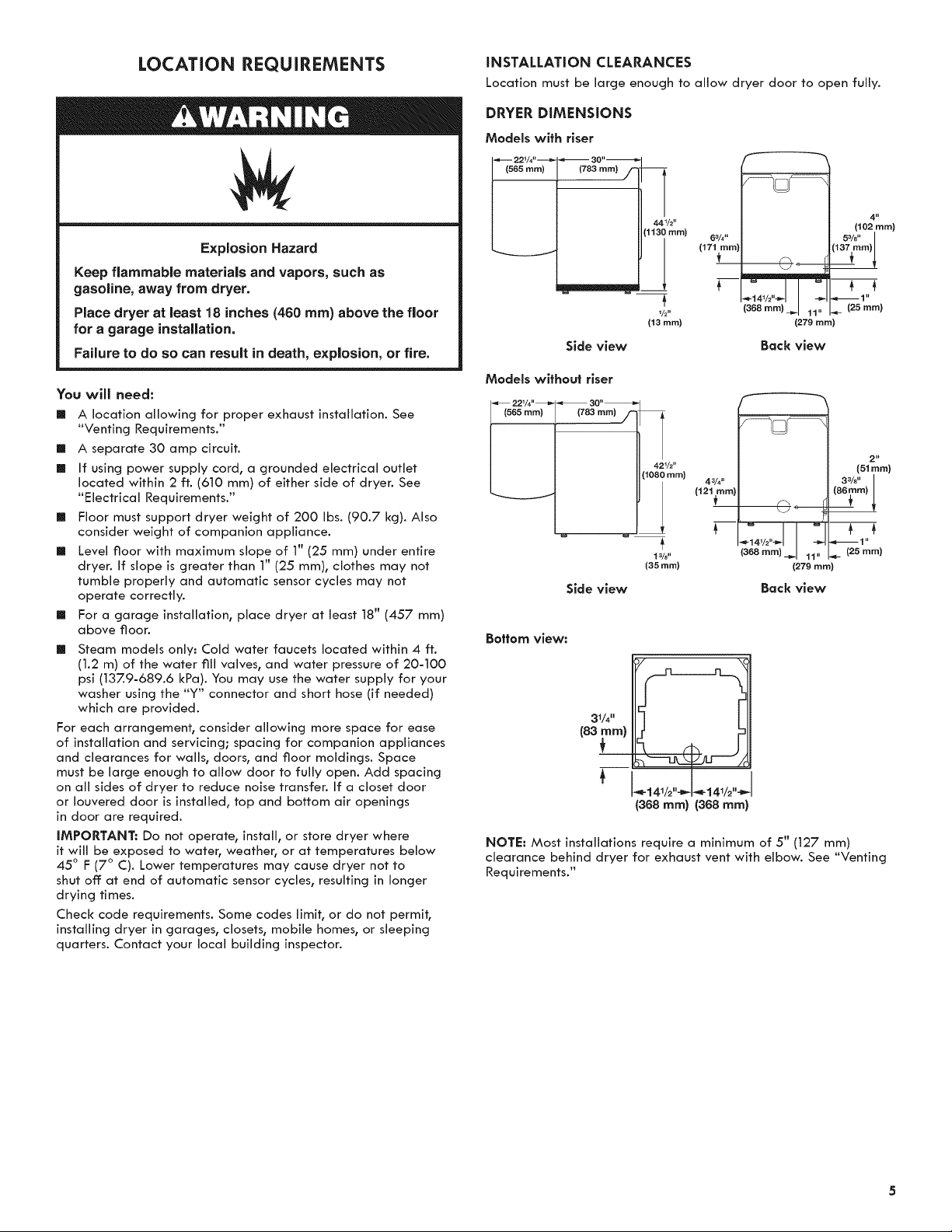

LOCATION REQUIREMENTS

iNSTALLATiON CLEARANCES

Location must be large enough to allow dryer door to open fully.

DRYER DIMENSIONS

Models with riser

_---22V4"--_

(556ram)

30"_

(783 mrn_/"

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches (460 ram) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

You wlll need:

[] A location allowing for proper exhaust installation. See

"Venting Requirements."

[] A separate 30 amp circuit.

[] If using power supply cord, a grounded electrical outlet

located within 2 ft. (610 ram) of either side of dryer. See

"Electrical Requirements."

[] Floor must support dryer weight of 200 Ibs. (90.7 kg). Also

consider weight of companion appliance.

[] Level floor with maximum slope of 1" (25 ram) under entire

dryer, if slope is greater than 1" (25 ram), clothes may not

tumble properly and automatic sensor cycles may not

operate correctly.

[] For a garage installation, place dryer at least 18" (457 ram)

above floor.

[] Steam models only.. Cold water faucets located within 4 ft.

(1.2 m) of the water fill valves, and water pressure of 20-100

psi (137.9-689.6 kPa). You may use the water supply for your

washer using the "Y" connector and short hose (if needed)

which are provided.

For each arrangement, consider allowing more space for ease

of installation and servicing; spacing for companion appliances

and clearances for walls, doors, and floor moldings. Space

must be large enough to allow door to fully open. Add spacing

on all sides of dryer to reduce noise transfer. If a closet door

or Iouvered door is installed, top and bottom air openings

in door are required.

iMPORTANT: Do not operate, install, or store dryer where

it will be exposed to water, weather, or at temperatures below

45 ° F(7 ° C). Lower temperatures may cause dryer not to

shut off at end of automatic sensor cycles, resulting in longer

drying times.

Check code requirements. Some codes limit, or do not permit,

installing dryer in garages, closets, mobile homes, or sleeping

quarters. Contact your local building inspector.

441/2"

(1t30 rnm)

_-_j

(102 turn)

53/8" I

(137_mm) 1

t

1/2,L

(!3 turn)

Side view

(279 ram)

Back view

Models without riser

(565 ram}

-_ 30"_

Side view

42V2"

(1080 ram)

1_/8"

(35 ram)

43/4-

(121 ram)

(368 )--_1 11" "=-(25turn)

(279 rnrn)

Back view

Bottom view:

/ x

_-14V2"-=,,.--._-14V2"-_-

(368 mm) (368 ram)

NOTE: Most installations require a minimum of 5" (127 ram)

clearance behind dryer for exhaust vent with elbow. See "Venting

Requirements."

(25 mm)

(51mm)

33/8" I

4"

2"

Page 6

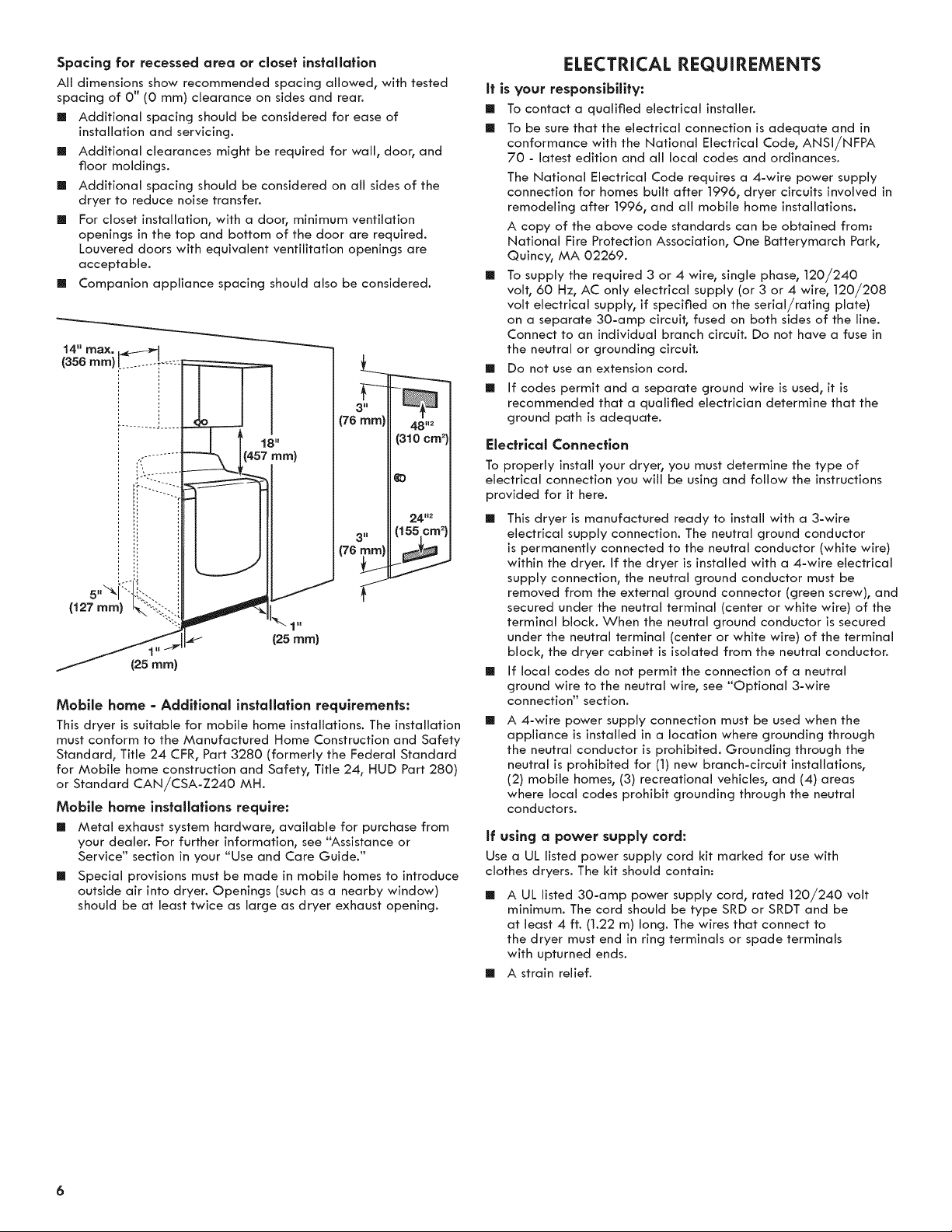

Spacing for recessed area or closet insfallatlon

All dimensions show recommended spacing allowed, with tested

spacing of 0" (0 mm) clearance on sides and rear.

[] Additional spacing should be considered for ease of

installation and servicing.

[] Additional clearances might be required for wall, door, and

floor moldings.

[] Additional spacing should be considered on all sides of the

dryer to reduce noise transfer.

[] For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilitation openings are

acceptable.

[] Companion appliance spacing should also be considered.

14" max,

(356 rnm)

a

(76

i.\ .........

a

(76

(127 ram)

(25 ram)

(25 rnrn)

Mobile home - Addltlonal installation requirements:

This dryer is suitable for mobile home installations. The installation

must conform to the Manufactured Home Construction and Safety

Standard, Title 24 CFR, Part 3280 (formerly the Federal Standard

for Mobile home construction and Safety, Title 24, HUD Part 280)

or Standard CAN/CSA-Z240 MH.

Moblle home installations require:

[] Metal exhaust system hardware, available for purchase from

your dealer. For further information, see "Assistance or

Service" section in your "Use and Care Guide."

[] Special provisions must be made in mobile homes to introduce

outside air into dryer. Openings (such as a nearby window)

should be at least twice as large as dryer exhaust opening.

ELECTRICAL REQUIREMENTS

It is your responsibility:

[] To contact a qualified electrical installer.

[] To be sure that the electrical connection is adequate and in

conformance with the National Electrical Code, ANSI/NFPA

70 - latest edition and all local codes and ordinances.

The National Electrical Code requires a 4-wire power supply

connection for homes built after 1996, dryer circuits involved in

remodeling after 1996, and all mobile home installations.

A copy of the above code standards can be obtained from:

National Fire Protection Association, One Batterymarch Park,

Quincy, MA 02269.

[]

To supply the required 3 or 4 wire, single phase, 120/240

volt, 60 Hz, AC only electrical supply (or 3 or 4 wire, 120/208

volt electrical supply, if specified on the serial/rating plate)

on a separate 30-amp circuit, fused on both sides of the line.

Connect to an individual branch circuit. Do not have a fuse in

the neutral or grounding circuit.

[]

Do not use an extension cord.

[]

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

Elecfrlcal Connection

To properly install your dryer, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

[] This dryer is manufactured ready to install with a 3-wire

electrical supply connection. The neutral ground conductor

is permanently connected to the neutral conductor (white wire)

within the dryer. If the dryer is installed with a 4-wire electrical

supply connection, the neutral ground conductor must be

removed from the external ground connector (green screw), and

secured under the neutral terminal (center or white wire) of the

terminal block. When the neutral ground conductor is secured

under the neutral terminal (center or white wire) of the terminal

block, the dryer cabinet is isolated from the neutral conductor.

[] If local codes do not permit the connection of a neutral

ground wire to the neutral wire, see "Optional 3-wire

connection" section.

[] A 4-wire power supply connection must be used when the

appliance is installed in a location where grounding through

the neutral conductor is prohibited. Grounding through the

neutral is prohibited for (1) new branch-circuit installations,

(2) mobile homes, (3) recreational vehicles, and (4) areas

where local codes prohibit grounding through the neutral

conductors.

if using a power supply cord:

Use a UL listed power supply cord kit marked for use with

clothes dryers. The kit should contain:

[] A UL listed 30-amp power supply cord, rated 120/240 volt

minimum. The cord should be type SRD or SRDT and be

at least 4 ft. (1.22 m) long. The wires that connect to

the dryer must end in ring terminals or spade terminals

with upturned ends.

[] A strain relief.

6

Page 7

if your outlet looks llke this:

Then choose a 4-wire power supply cord with

ring or spade terminals and strain relief. The

4-wire power supply cord, at least 4 ft. (1.22 m)

long, must have 4 10-gauge solid copper wires

and match a 4-wire receptacle of NEMA Type

14-30 R. The ground wire (ground conductor)

4-wire

receptacle

(14-30R)

may be either green or bare. The neutral

conductor must be identified by a white cover.

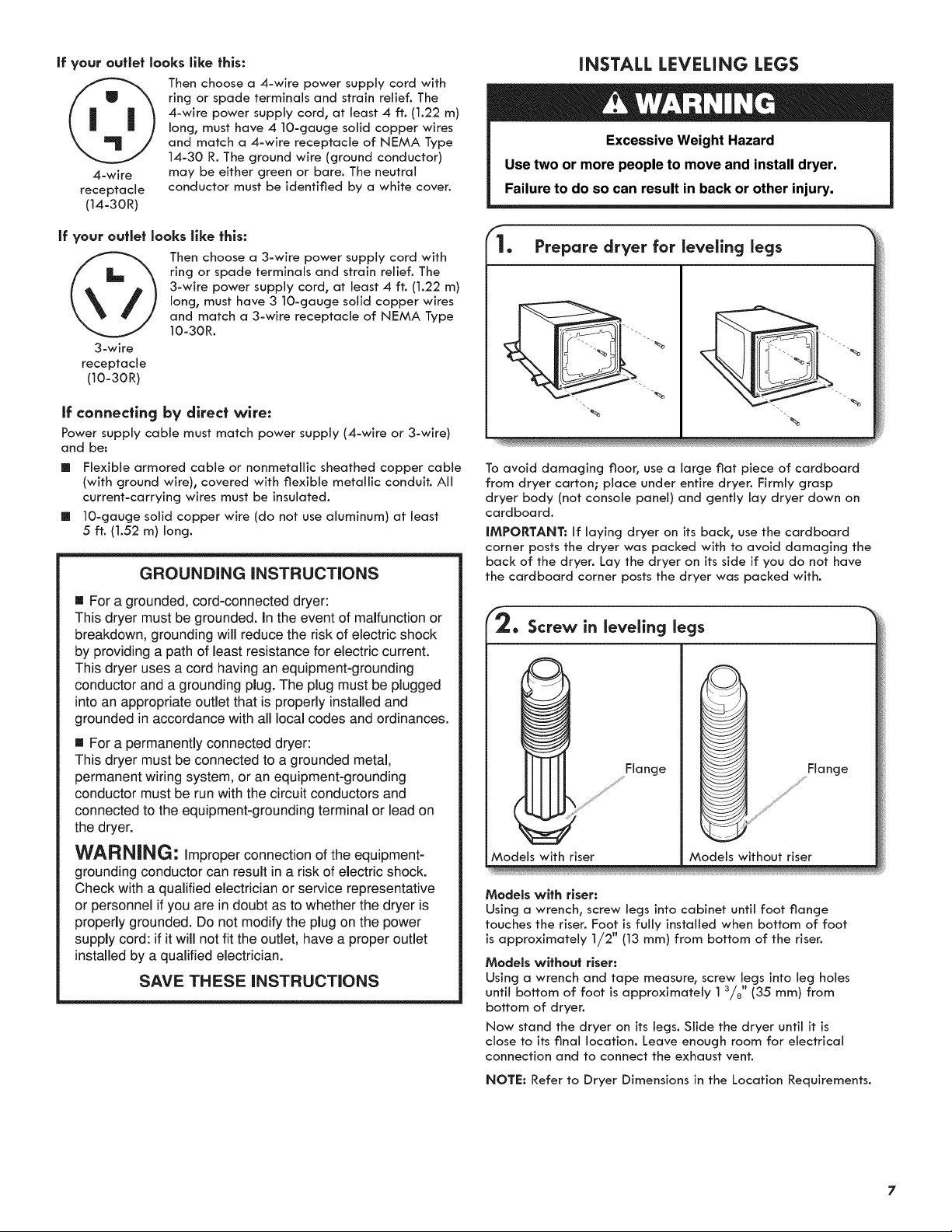

iNSTALL LEVELING LEGS

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

if your outlet looks llke this:

Then choose a 3-wire power supply cord with

ring or spade terminals and strain relief. The

3-wire power supply cord, at least 4 ft. (1.22 m)

iong_ must have 3 10-gauge solid copper wires

and match a 3-wire receptacle of NEMA Type

10-30R.

3-wire

receptacle

(I0-30R)

If connecting by direct wire:

Power supply cable must match power supply (4-wire or 3-wire)

and be:

[] Flexible armored cable or nonmetallic sheathed copper cable

(with ground wire), covered with flexible metallic conduit. All

current-carrying wires must be insulated.

[] 10-gauge solid copper wire (do not use aluminum) at least

5 ft. (1.52 m) long.

GROUNDING iNSTRUCTiONS

[] For a grounded, cord-connected dryer:

This dryer must be grounded, in the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer uses a cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

[] For a permanently connected dryer:

This dryer must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the dryer.

WARNING: improper connection of the equipment-

grounding conductor can result in a risk of ebctric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug on the power

supply cord: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE iNSTRUCTiONS

1. Prepare dryer for levelincj legs

To avoid damaging floor, use a large fiat piece of cardboard

from dryer carton; place under entire dryer. Firmly grasp

dryer body (not console panel) and gently lay dryer down on

cardboard.

iMPORTANT: if laying dryer on its back, use the cardboard

corner posts the dryer was packed with to avoid damaging the

back of the dryer. Lay the dryer on its side if you do not have

the cardboard corner posts the dryer was packed with.

f2. Screw in levelincj lecjs

Flange Flange

Models with riser

Models with riser:

Using a wrench, screw legs into cabinet until foot flange

touches the riser. Foot is fully installed when bottom of foot

is approximately I/2" (13 mm) from bottom of the riser.

Models without riser:

Using a wrench and tape measure, screw legs into leg holes

until bottom of foot is approximately 1 3/8" (35 mm) from

bottom of dryer.

Now stand the dryer on its legs. Slide the dryer until it is

close to its final location. Leave enough room for electrical

connection and to connect the exhaust vent.

NOTE: Refer to Dryer Dimensions in the Location Requirements.

Models without riser

Page 8

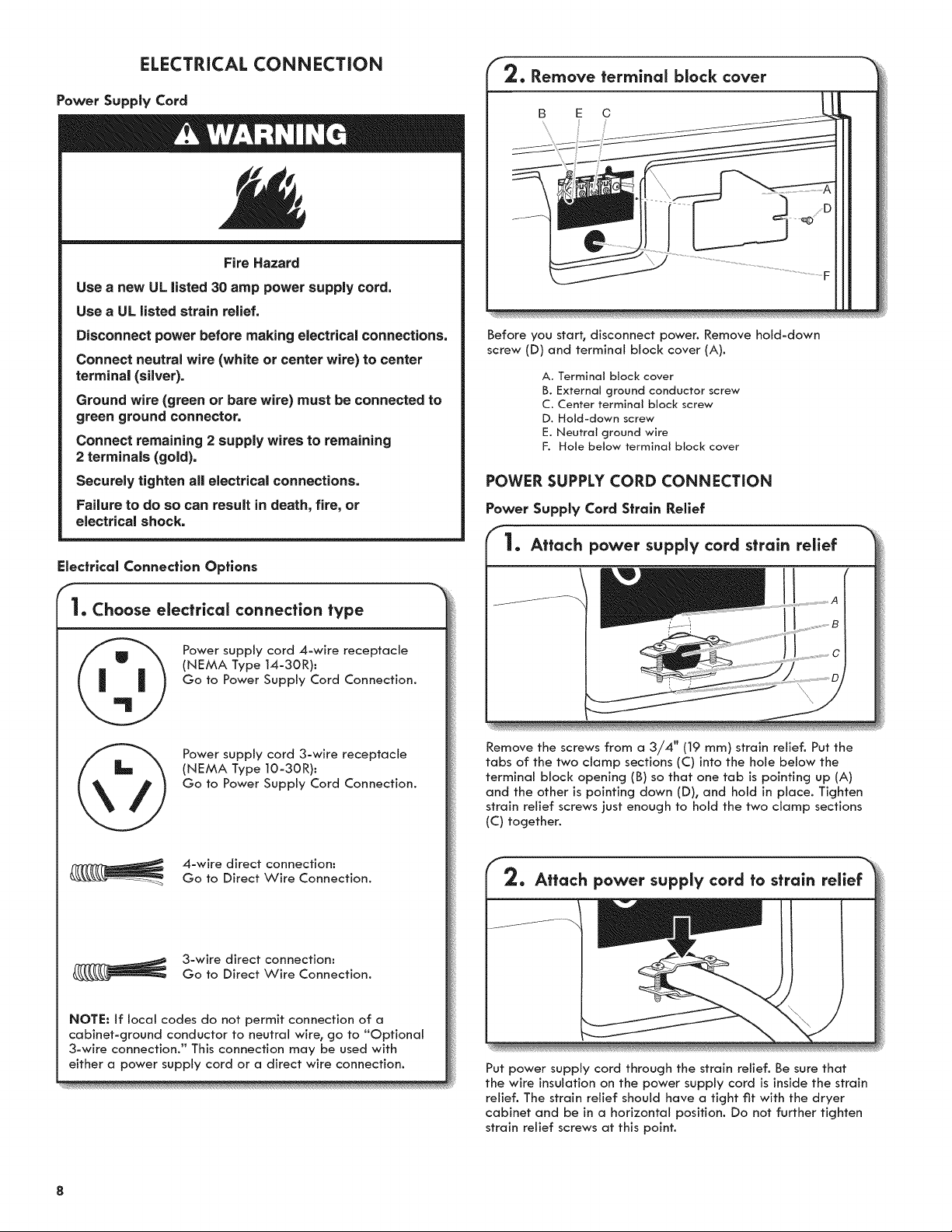

ELECTRICAL CONNECTION

Power Supply Cord

Fire Hazard

Use a new UL listed 30 amp power supply cord.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrica| connections.

Failure to do so can result in death, fire, or

electrical shock.

Electrical Connection Options

B E C

Before you start_ disconnect power. Remove hold=down

screw (D) and terminal block cover (A).

A. Terminal block cover

B. External ground conductor screw

C. Center terminal block screw

D. Hold-down screw

E. Neutral ground wire

F. Hole below terminal block cover

POWER SUPPLY CORD CONNECTION

Power Supply Cord Straln Rellef

]. Attach power supply cord strain relief

1. Choose electrical connection type

Power supply cord 4-wire receptacle

(NEMA Type 14-30R):

Go to Power Supply Cord Connection.

Power supply cord 3-wire receptacle

(NEMA Type 10-30R):

Go to Power Supply Cord Connection.

4-wire direct connection:

Go to Direct Wire Connection.

3-wire direct connection:

Go to Direct Wire Connection.

NOTE: If local codes do not permit connection of a

cabinet-ground conductor to neutral wire, go to "Optional

3-wire connection." This connection may be used with

either a power supply cord or a direct wire connection.

Remove the screws from a 3/4" (19 mm) strain relief. Put the

tabs of the two clamp sections (C) into the hole below the

terminal block opening (B) so that one tab is pointing up (A)

and the other is pointing down (D), and hold in place. Tighten

strain relief screws just enough to hold the two clamp sections

(C) together.

Put power supply cord through the strain relief. Be sure that

the wire insulation on the power supply cord is inside the strain

relief. The strain relief should have a tight fit with the dryer

cabinet and be in a horizontal position. Do not further tighten

strain relief screws at this point.

8

Page 9

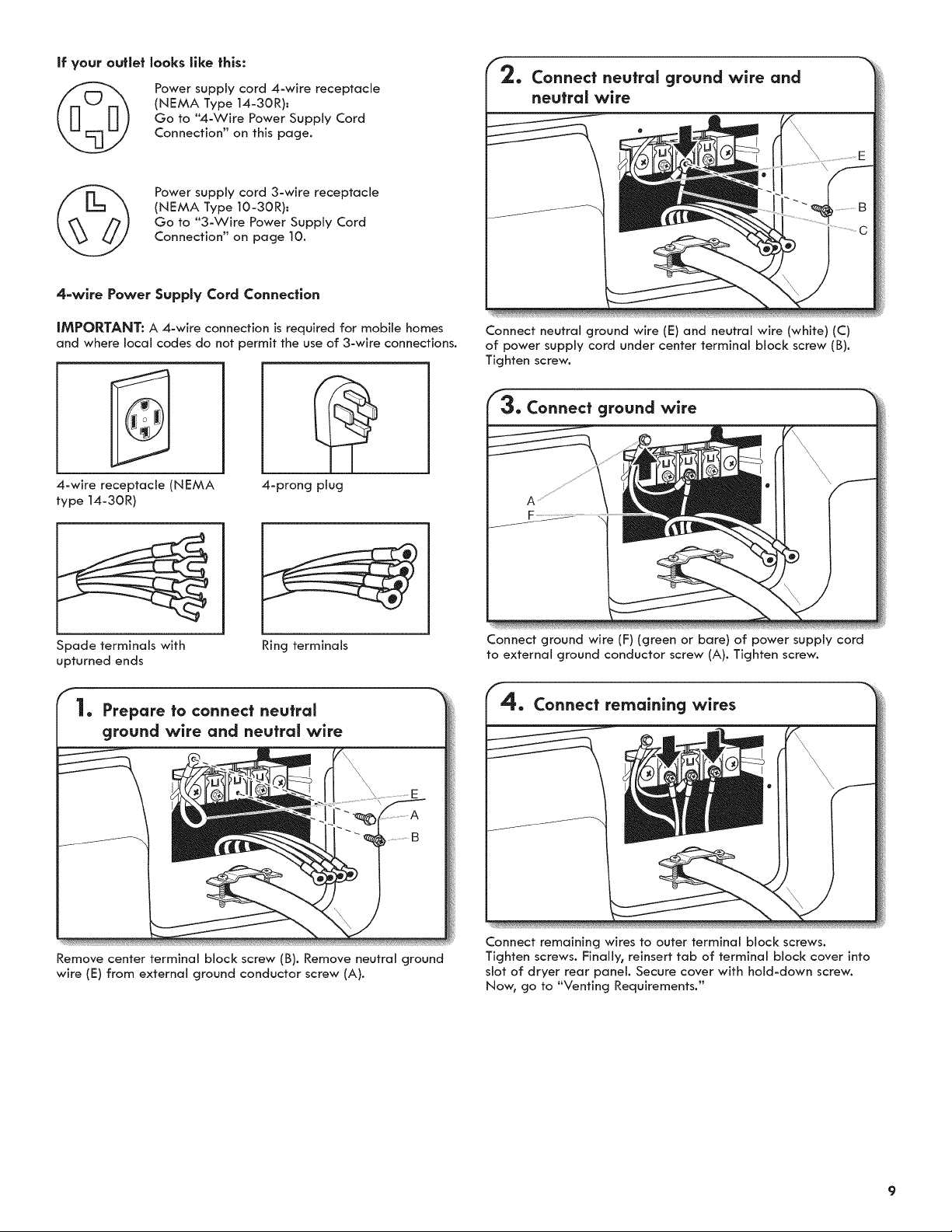

if your outlet looks like this:

Power supply cord 4-wire receptacle

(NEMA Type 14-30R):

Go to "4-Wire Power Supply Cord

Connection" on this page.

Power supply cord 3-wire receptacle

(NEMA Type 10-30R):

Go to "3-Wire Power Supply Cord

Connection" on page 10.

4-wlre Power Suppty Cord Connection

neutral wire

iMPORTANT: A 4-wire connection is required for mobile homes

and where local codes do not permit the use of 3-wire connections.

4-wire receptacle (NEMA

type 14-30R)

Spade terminals with

upturned ends

4-prong plug

Ring terminals

1. Prepare to connect neutral

ground wire and neutral wire

Connect neutral ground wire (E) and neutral wire (white) (C)

of power supply cord under center terminal block screw (B),

Tighten screw.

Connect ground wire

Connect ground wire (F) (green or bare) of power supply cord

to external ground conductor screw (A). Tighten screw.

Remove center terminal block screw (B). Remove neutral ground

wire (E) from external ground conductor screw (A).

Connect remaining wires to outer terminal block screws.

Tighten screws. Finally_ reinsert tab of terminal block cover into

slot of dryer rear panel. Secure cover with hold-down screw.

Now, go to "Venting Requirements."

Page 10

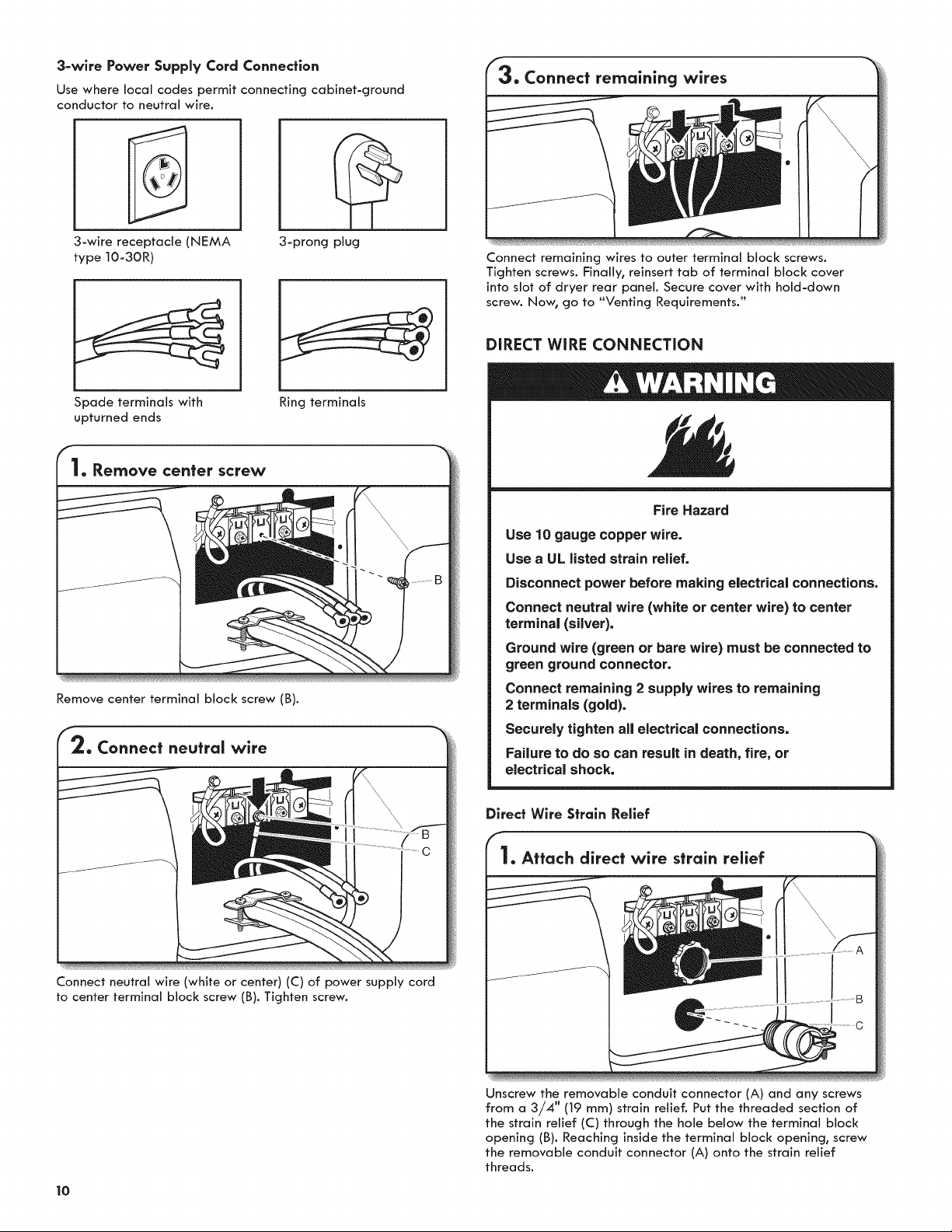

3-wire Power Supply Cord Connection

Use where local codes permit connecting cabinet-ground

conductor to neutralwire,

3-wire receptacle (NEMA

type 10=30R)

Spade terminals with

upturned ends

Remove center terminal block screw (B).

3=prong plug

Ring terminals

Connect remaining wires to outer terminal block screws.

Tighten screws. Finally, reinsert tab of terminal block cover

into slot of dryer rear panel. Secure cover with hold=down

screw. Now, go to "Venting Requirements."

DIRECT WIRE CONNECTION

Fire Hazard

Use 10 gauge copper wire.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock,

Connect neutral wire (white or center) (C) of power supply cord

to center terminal block screw (B). Tighten screw.

I0

Direct Wire Strain Relief

Unscrew the removable conduit connector (A) and any screws

from a 3/4" (19 mm) strain relief. Put the threaded section of

the strain relief (C) through the hole below the terminal block

opening (B). Reaching inside the terminal block opening, screw

the removable conduit connector (A) onto the strain relief

threads.

Page 11

2. Attach direct wire cable to strain relief

Put direct wire cable through the strain relief. The strain relief

should have a fight fit with the dryer cabinet and be in a

horizontal position. Tighten strain relief screw against the direct

wire cable.

If your wiring looks like this:

Go to "4-Wire Direct Connection"

4-wire direct connection:

on this page.

3-wire direct connection:

to

Go "3-Wire Direct Connection"

on page 12.

and neutral wire

Remove center terminal block screw (B). Remove neutral

ground wire (E) from external ground conductor screw (A).

neutral wire

4=wlre Direct Wire Connectlon

IMPORTANT: A 4-wire connection is required for mobile homes

and where local codes do not permit 3-wire connections.

Prepare your 4-wire cable for

direct connection

Direct wire cable must have 5 ft. (1.52 m) of extra length so

dryer may be moved if needed.

Strip 5" (127 mm) of outer covering from end of cable,

leaving bare ground wire at 5" (127 mm). Cut 1 I/2Ww (38 mm)

from remaining 3 wires. Strip insulation back 1" (25 mm).

Shape ends of wires into hooks.

Connect neutral ground wire (E) and place

hooked end (hook facing right) of neutral

wire (white or center wire) (C) of direct wire

cable under center screw of terminal block

(B). Squeeze hooked ends together and

tighten screw.

Connect ground wire (green or bare) (F) of direct wire cable

to external ground conductor screw (A). Tighten screw.

11

Page 12

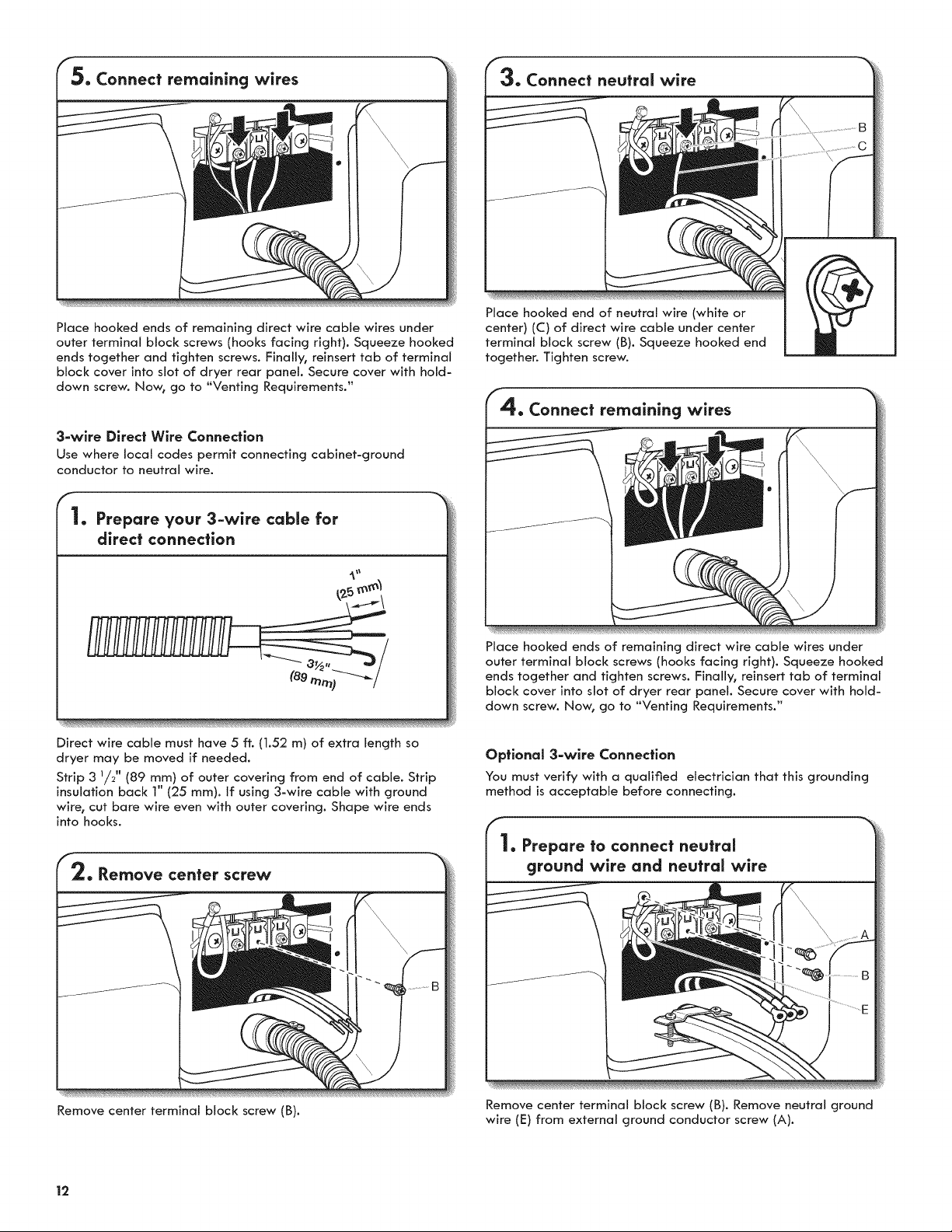

5. Connect remaining wires

Place hooked ends of remaining direct wire cable wires under

outer terminal block screws (hooks facing right). Squeeze hooked

ends together and tighten screws. Finally, reinsert tab of terminal

block cover into slot of dryer rear panel. Secure cover with hold-

down screw. Now, go to "Venting Requirements."

3-wire Direct Wire Connection

Use where local codes permit connecting cabinet-ground

conductor to neutral wire.

Prepare your 3-wire cable for

direct connection

Place hooked end of neutral wire (white or

center) (C) of direct wire cable under center

terminal block screw (B). Squeeze hooked end

together. Tighten screw.

4. Connect remaining wires

Direct wire cable must have 5 ft. (1.52 m) of extra length so

dryer may be moved if needed.

Strip 31/2wl (89 mm) of outer covering from end of cable. Strip

insulation back 1" (25 mm). If using 3-wire cable with ground

wire, cut bare wire even with outer covering. Shape wire ends

into hooks.

Place hooked ends of remaining direct wire cable wires under

outer terminal block screws (hooks facing right). Squeeze hooked

ends together and tighten screws. Finally_ reinsert tab of terminal

block cover into slot of dryer rear panel. Secure cover with hold-

down screw. Now, go to "Venting Requirements."

Optlonal 3-wire Connection

You must verify with a qualified electrician that this grounding

method is acceptable before connecting.

ground wire and neutral wire

Remove center terminal block screw (B).

12

Remove center terminal block screw (B). Remove neutral ground

wire (E) from external ground conductor screw (A).

Page 13

VENTING

and neutral wire

Connect neutral ground wire (E) and neutral wire (white or

center wire) (C) of power supply cord or cable under center

terminal block screw (B). Tighten screw.

VENTING REQUIREMENTS

Fire Hazard

Use a heavy metal vent,

Do not use a plastic vent,

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

iMPORTANT: Observe all governing codes and ordinances.

Dryer exhaust must not be connected into any gas vent, chimney,

wall, ceiling, attic, crawlspace, or a concealed space of a building.

Only rigid or flexible metal vent shall be used for exhausting.

[] Only a 4" (102 mm) heavy metal exhaust vent and clamps

may be used.

Place hooked ends of remaining wires under outer terminal

block screws (hooks facing right). Tighten screws.

Connect a separate copper ground wire (G) from the external

ground conductor screw (A) to an adequate ground. Finally,

reinsert tab of terminal block cover into slot of dryer rear

panel Secure cover with hold-down screw. Now, go to "Venting

Requirements."

((),

(102 mm)

t

4" (102 mm) heavy metal exhaust vent

[] Do not use plastic or metal foil vent.

Rigid metal vent:

[] Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to clean)

[] Must be fully extended and supported in final dryer location.

[] Remove excess to avoid sagging and kinking that may

result in reduced airflow and poor performance.

[] Do not install in enclosed walls, ceilings, or floors.

[] The total length should not exceed 7 3/4 ft. (2.4 m).

NOTE: If using an existing vent system_ clean lint from entire length

of the system and make sure exhaust hood is not piugged with

lint. Replace piastic or metal foii vents with rigid metai or fiexibie

metal vents. Review Vent System Chart and if necessary, modify

existing vent system to achieve best drying performance.

13

Page 14

Exhaust hoods:

[] Must be at least 12" (305 mm) from ground or any object that

may obstruct exhaust (such as flowers, rocks, bushes, or snow).

Recommended Styles:

PLAN VENT SYSTEM

Recommended exhaust insfaHaflons

Typical installations vent the dryer from the rear of the dryer.

Other installations are possible.

C

A ...........................

Louvered Hood

Acceptable Style:

Angled Hood

Elbows:

[]

45 ° elbows provide better airflow than 90 ° elbows.

Box Hood

Recommended Styles:

Be

Clamps:

[] Use clamps to seal all joints.

[] Exhaust vent must not be connected or secured with screws or

other fastening devices that extend into interior of duct and

catch lint. Do not use duct tape.

H

A. Dryer E. Clamps

B. Elbow F. Rigid metal or flexible metal vent

C. Wall G. Vent length necessary to connect

D. Exhaust hood elbows

H. Exhaust outlet

Optional exhaust installations:

Fire Hazard

Use a heavy metaJ vent,

Do not use a plastic vent.

Do not use a metal foil vent,

Failure to follow these instructions can result in death

or fire.

[] Exhaust Cover Kit (to cover unused exhaust holes):

Part Number W10186596 - all models

[] Bottom Exhaust Kit- Part Number 8212503

Improper venting can cause moisture and lint to collect

indoors, which may result in:

[] Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

[] Housecleaning problems and health problems.

14

Page 15

If you prefer, dryer may be converted to exhaust through

the bottom. You must contact your local dealer to have

dryer converted.

A

A. Standard rear offset exhaust installation

B. Bottom exhaust installation

Special provisions for mobile homes:

Exhaust vent must be securely fastened to a noncombustible

portion of mobile home and must not terminate beneath the

mobile home. Terminate exhaust vent outside.

________/

Alternate installations for close clearances

Venting systems come in many varieties. Select the type best

for your installation. Two close-clearance installations are shown.

Refer to the manufacturer's instructions.

A. Over-the-top installation

(also available with one offset elbow)

B. Periscope installation

NOTE: The following kits for close clearance alternate installations

are available for purchase. Contact your local dealer.

[] Over-the-Top Installation,.

Part Number 4396028

[] Periscope Installation (For use with dryer vent to wall vent

mismatch),.

Part Number 4396037 - 0" (0 mm) to 18" (460 mm) mismatch

Part Number 4396011 - 18" (460 mm) to 29" (737 mm)

mismatch

Part Number 4396014 - 29" (737 mm) to 50" (1270 mm)

mismatch

Moblie Home Exhaust installation

Determine vent path:

[] Select route that will provide straightest and most direct

path outdoors.

[] Plan installation to use fewest number of elbows and turns.

[] When using elbows or making turns, allow as much room

as possible.

[] Bend vent gradually to avoid kinking.

[] Use as few 90 ° turns as possible.

Determine vent length and elbows needed for best drying

performance:

[] Use following Vent System Chart to determine type of vent

material and hood combinations acceptable to use.

NOTE: Do not use vent runs longer than those specified

in Vent System Chart. Exhaust systems longer than those

specified wJJJ,.

[] Shorten life of dryer.

[] Reduce performance, resulting in longer drying times

and increased energy usage.

The Vent System Charts provide venting requirements that will

help achieve best drying performance.

f

Kenmore Vent System Chart

Number of Type Box/Iouvered Angled

90 ° elbows of vent hoods hoods

0

1

4

NOTE: Bottom exhaust installations have a 90 ° turn inside the

dryer. To determine maximum exhaust length, add one 90 ° turn to

the charts.

Rigldmetal

Rigldmetal

Rigldmetal

Rigldmetal

Rigldmetal

64 ft. (20 m) 58 ft. (17.7 m)

54 ft. (16.5 m) 48 ft. (14.6 m)

44 ft. (13.4 m) 38 ft. (11.6 m)

35 ft. (10.7 m) 29 ft. (8.8 m)

27 ft. (8.2 m) 21 ft. (6.4 m)

15

Page 16

INSTALL VENT SYSTEM

1. Install exhaust hood

12" rain.

(305 ram)

CONNECT iNLET HOSES

For non=steam models, skip to "Connect Vent."

The dryer must be connected to the cold water faucet using the

new inlet hoses. Do not use old hoses.

1. Turn cold water off, remove and

replace rubber washer

®

®

install exhaust hood and use caulking compound to seal

exterior wall opening around exhaust hood.

2. Connect vent to exhaust hood

Vent must fit over the exhaust hood. Secure vent to exhaust

hood with 4" (102 mm) clamp. Run vent to dryer location using

straightest path possible. Avoid 90 ° turns. Use clamps to seal all

ioints. Do not use duct tape, screws, or other fastening devices

that extend into interior of vent to secure vent, because they

can catch lint.

®

Turn cold water faucet off and remove washer inlet hose.

Check and see if rubber washer is in the "Y" connector. Remove

old rubber washer from inlet hose and replace with new rubber

washer provided.

If space permits, attach the female end of the "Y" connector

to the cold water faucet. See figure A.

If "Y" connector cannot be attached directly to the cold water

faucet, the short hose must be used. See figure B. Attach short

hose to cold water faucet. Screw on coupling by hand until

it is seated on faucet. Then attach "Y" connector to male end

of the short hose. Screw on coupling by hand until it is seated

on connector.

16

Tighten couplings

Using pliers, tighten the couplings with additional two=thirds turn.

NOTE: Do not overfighten. Damage to the coupling can result.

Page 17

tighten couplings

6. Turn on cold water faucet

Check that the water faucets are turned on.

One end of the long hose has a wire mesh strainer inside the

coupling. Attach this end to the _Y" connector. Attach washer

cold inlet hose to other side of _Y" connector. Screw on coupling

by hand until it is seated on connector. Using pliers, tighten the

couplings an additional two-thirds turn.

NOTE: Do not overfighten. Damage to the coupling can result.

5. Attach long hose to dryer fill valve

tighten coupling

Attach other end of long hose

to fill valve at bottom of dryer

back panel. Screw on coupling

by hand until it is seated on fill

valve connector. Using pliers, tighten

the coupling an additional two-

thirds turn.

NOTE: Do not overtJghten. Damage

to the coupling can result.

f 7. Check for leaks

Check for leaks around _"Y" connector, faucets, and hoses.

17

Page 18

CONNECT VENT

LEVEL DRYER

Connect vent to exhaust outlet

Using a 4" (102 ram) clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure vent is clean.

Dryer vent must fit over dryer exhaust outlet and inside exhaust

hood. Check that vent is secured to exhaust hood with a 4" (102

mm) clamp.

Move dryer to final location

1. Level dryer

Place

level _

Place

level here

Check levelness of dryer from side to side. Repeat from

front to back.

NOTE: The dryer must be level for the moisture sensing system

to operate correctly.

Move dryer to final location. Avoid crushing or kinking vent.

After dryer is in place, remove cardboard from under dryer.

Not Level LEVEL Not Level

2. Adjust leveling legs

if dryer is not level, prop up using a wood block, use wrench

to adiust legs by backing out the foot as needed, then checking

again for levelness. Once legs are level, make sure all four legs

are snug against the floor.

18

Page 19

COMPLETE iNSTALLATiON CHECKLIST

[_ Check that all parts are now installed. If there is an extra

part, go back through steps to see what was skipped.

[_ Check that you have all of your tools.

[_ Dispose of/recycle all packaging materials.

[_ Check dryer's final location. Be sure vent is not crushed

or kinked.

[_ Check that dryer is level. See "Level Dryer."

[_ Remove film on console and any tape remaining on dryer.

[_ Wipe dryer drum interior thoroughly with a damp cloth to

remove any dust.

[_ Read "Dryer Use" in your "Use and Care Guide."

[_ For power supply cord installation, plug into a grounded

outlet. For direct wire installation, turn on Power.

Steam models only:

[_ Be sure the water faucets are on.

[_ Check for leaks around "Y" connector, faucet, and hoses.

[_ If you live in a hard water area, use of a water softener is

recommended to control the buildup of scale through the

water system in the dryer. Over time, the buildup of lime

scale may clog different parts of the water system, which

will reduce product performance. Excessive scale buildup

may lead to the need for certain part replacement or repair.

All Models:

[_ Select a Timed Dry heated cycle, and start dryer. Do not select

Air Only Temperature setting.

If dryer will not start, check the following:

" Controls are set in a running or "On" position.

" Start button has been pushed firmly.

" Dryer is plugged into an outlet and/or electrical supply.

" Household fuse is intact and tight, or circuit breaker has

not tripped.

" Dryer door is closed.

This dryer automatically runs an installation diagnostic routine

at the start of its first cycle.

If you receive an L2 code, there may be a problem with your

home power supply keeping the dryer's heater from turning on.

See "Troubleshooting."

If your Airflow screen reads °_Check Vent", your dryer vent may

be crushed or blocked. See _Troubleshooting."

NOTE: You may notice an odor when dryer is first heated. This

odor is common when heating element is first used. The odor will

go away.

REVERSE DOOR SWING

You can change your door swing from a right-side opening to a

left-side opening, if desired.

L Place a towel or soft cloth on top of dryer or work space to

avoid damaging the surface.

Remove the door assembly

1. Open the dryer door.

2. Remove the bottom screw (B) from each of the two hinges

that attach dryer door to front panel of dryer.

3. Loosen the top screw (A) from each of the two hinges

in Step 2.

A

B

A

B

A. Top screw

B. Bottom screw

4. Remove the dryer door and the hinges by lifting upward

on the door. Lay the door on a flah covered surface° with

the inside of the door facing up. Remove remaining two

loose screws from dryer front panel.

5. Remove the 4 plastic plugs located outside the dryer door

opening.

6. Install 4 plastic plugs into screw holes in the dryer left

where the hinges were removed in Step 4.

19

Page 20

Reverse the strike

1. Remove the door strike from the dryer door opening.

2. Remove the cosmetic screw opposite the door strike.

A

A. Door strike

B. Cosmetic screw

3. Reinstall the door strike and cosmetic screw on the

opposite side of dryer door opening from where they were

removed,

NOTE: Door strike and plugs must be on the same side of

the dryer door opening.

Relnsfall the door

1. Remove the 4 screws and two hinges from the dryer door.

5. Install screws in top hinge holes in the front panel of the

dryer. Do not tighten screws. Leave approximately 1/4" (5

mm) of screw exposed.

6. Hang door by placing screw heads into top slotted holes

of hinges and slide door down. Align bottom screw holes

in hinge and door. Install two bottom screws. Tighten all

hinge screws.

I

2. Replace the 4 screws in the same holes

3. Remove the 4 screws from the opposite side of the door.

4. Install the two hinges to the door using 4 screws. Use the

non-slotted side to attach the hinge to the door.

¢m

¢m

7. Close door to engage door strike.

2O

]

in- ,_ _

Page 21

SEGURIDAD DE LA SECADORA

Su seguridad y la seguridad de los demos es rnuy irnportante.

Hemos incluido muchos mensajes importantes de seguridad en este manual yen su electrodom6stico. Lea y obedezca siempre

todos los mensajes de seguridad.

Este es el simbolo de advertencia de seguridad.

Este simbolo le llama la atenci6n sobre peligros potenciales que pueden ocasionar la muerte o una lesi6n a

usted y a los dem#,s.

Todos los mensajes de seguridad irb,n a continuaci6n del simbolo de advertencia de seguridad y de la palabra

"PELIGRO" o "ADVERTENClA". Estas palabras significan:

Si no sigue las instrucciones de inmediato, usted puede

motif o sufrir una lesi6n grave.

Si no sigue las instrueciones, usted puede motif o sufrir

una lesi6n grave.

Todos los mensajes de seguridad le diran el peligro potencial, le dirAn c6mo reducir las posibilidades de sufrir una lesi6n y Io que

puede suceder si no se siguen las instrucciones.

ADVERTENCIA - ,,.io.godo .co°dio,,

- La instalaci6n de la secadora de ropa debe estar a cargo de un instalador cornpetente.

- Instale la secadora de ropa seg_n las instrucciones del fabricante y los c6digos locales.

- No instale una secadora de ropa con rnateriales de ventilacibn de pl_stico flexible o un

conducto de metal flexible (de hoja de metal). Si se usa un conducto de metal flexible,

_ste deber_ set de un tipo especifico, que est_ identificado pot el fabricante de

electrodorn_sticos corno apto para set usado con secadoras de ropa. Es sabido que

los rnateriales de ventilaci6n flexible se derrurnban, se aplastan con facilidad y atrapan

pelusa. Estas condiciones obstruir&n el flujo de aire de la secadora de ropa y

aurnentar_n el riesgo de incendio.

- Para reducir el riesgo de lesiones severas o la rnuerte, siga todas las instrucciones

de instalaci6n.

- Guarde estas instrucciones.

Advertencias de la Proposici6n 65 del estado de California:

ADVERTENClA: Este producto contiene una o m&s sustancias quimicas identificadas pot el estado de California como

causantes de cb,ncer.

ADVERTENCIA: Este producto contiene una o m_.s sustancias quimicas identificadas pot el estado de California como

causantes de defectos congenitos o algt3n otto tipo de dafios en la funci6n reproductora.

21

Page 22

REQUISITOS DE INSTALACION

HERRAMIENTAS Y PIEZAS

ReOna las herramientas y piezas necesarias antes

de comenzar ia instalacJ6n. Lea y siga las JnstruccJones

provistas con cualquiera de las herramientas enlistadas aquf.

Herramientas necesarias:

Destornillador de hoja plana

Llave ajustable que se abra

a 1" (25 mm) o ilave de

cubo de cabeza hexagonai

Destornillador Phillips N° 2

Nivel

Piezas sumlnls|radas (_odos los modelos):

Paras niveiadoras (4) para Patas niveladoras (4) para

modelos con una contrahuella modelos sin una contrahuella

Piezas surnlnlstradas (modelos con vapor):

Conector en "Y"

Manguera de entrada

corta

Pelacables (instalacJones

de cabieado directo)

Pistola y masHla para

calafateo (para instaiar

el nuevo ducto de escape)

Aprietatuercas de 1/4"

(se recomienda)

Abrazaderas para ducto

Tiieras de lata

(instalaciones del nuevo

ducto de escape)

Cinta de medir

Manguera de entrada

Arandela de goma

de 5 pies (1,52 m)

El paquete con piezas est6 ubicado en el tambor de la secadora.

Verifique que estSn todas las piezas.

Piezas necesarlas: (No se provee con la secadora)

Verifique los c6digos locales. Verifique el suministro el_ctrico

y la ventilaci6n exJstentes. Vea "Requisitos el6ctricos"

y "Requisitos de ventilaci6n" antes de comprar las piezas.

Las instaiaciones en casas rodantes requieren piezas para

ducto de escape de metal que est6n disponibies en la fienda

al por menor donde usted compr6 su secadora. Para obtener m6s

informaci6n, sfrvase leer la secci6n "Ayuda o servicio t_cnico" en

el "Manual de uso y cuidado'.

i:::qu_po op|_|Ivo: (No se provee con la secadora)

Consulte su "Manual de uso y cuidado" para obtener

informaci6n acerca de los accesorios disponibles para

su secadora.

Pinzas

22

Page 23

REQUISITOS DE UBICACION

ESPACIOSLIBRES PARA LA INSTALACI6N

El lucjar debe ser Io suficientemente grande para permitir

que la puerta de la secadora se abra completamente.

DIMENSIONES DE LA SECADORA

Modelos con una contrahuelia

221/4 "-_'_ _ 30"-_

Peligro de Explosi6n

Mantenga los rnateriales y vapores inflarnables, como

la gasolina, lejos de la secadora.

Coloque la secadora a un minimo de 460 mm sobre

el piso para la instalaci6n en un garaje.

No seguir estas instrucciones puede ocasionar

la muerte, expiosi6n o incendio.

Usfed neceslfarc_:

[] Una ubicaci6n que permita una instalaci6n adecuada

del ducto de escape. Vea "Requisitos de ventilaci6n'.

[] Un circuito separado de 30 amperios.

[] Si est6 usando un cable de suministro de enercjfa, un contacto

con conexi6n a tierra ubicado a no m6s de 2 pies (610 mm)

de cualquiera de los lados de la secadora. Vea "Requisitos

el6ctricos''.

[]

Un piso que soporte el peso de la secadora de 200 lb. (90,7

kg). Tencja en cuenta tambi_n el peso de otro electrodomSstico

que le acompa_e.

[]

Un piso nivelado con un declive m6ximo de 1" (25 mm) debajo

de la secadora completa. Si el declive es mayor

que 1" (25 mm), la ropa quiz6s no cjire adecuadamente

y los ciclos con sensor autom6tico posiblemente no funcionen

como es debido.

[] Para realizar una instalaci6n en el garage, coloque la secadora

por Io menos a 18" (457 mm) por encima del piso.

[] Modelos con vapor Onicamente: Grifos de acjua frfa ubicados

a una distancia de no m6s de 4 pies (1,2 m) de las v61vulas de

Ilenado de acjua y una presi6n de agua de 20 a 100 Ib/pulcj 2

(137,9 a 689,6 kPa). Puede usar el suministro de agua para su

lavadora usando el conector en "Y" y la mancjuera corta

(si se requiere), los cuales est6n provistos.

Para cada disposici6n, considere dejar m6s espacio para

facilitar la instalaci6n y el servicio t_cnico, asf como espacio para

electrodomSsticos que le acompa_en y espacios libres para las

molduras de la pared, de la puerta y del piso. El espacio debe ser

Io suficientemente cjrande para permJfir que la puerta se abra por

completo. Agrecjue espacio en todos los lados de la secadora para

reducir la transferencia de ruido. Si se instala una puerta de cl6set

o tipo persiana, es necesario que tencja aberturas para el aire en

la parte superior e inferior de la puerta.

IMPORTANTE: No utilice, instale ni guarde la secadora en donde

estar6 expuesta al acjua, a la intemperie o a temperaturas por

debajo de 45 °F (7 °C). Las temperaturas m_s bajas pueden hacer

que la secadora no se apacjue al final de los ciclos autom6ticos

con sensor, Io que resultar_ en tiempos de secado m_s larcjos.

Verifique los requisitos de los c6digos. Algunos c6digos limitan,

o no permiten, la instalaci6n de la secadora en cjarajes, cl6sets,

casas rodantes o en dormitorios. P6ncjase en contacto con el

inspector de construcciones de su Iocalidad.

(565 mini (783 mini /-

(102 mm

5s/8" I

(25i33nq)

4"

Vista lateral

44V2"

(1130 ram)

/

/

(13 ram)

63/4"

(171 mini

f

(368

t/2"

rt_m)

(279 ram)

Vista posterior

Modelos sin una contrahuella

30"_

(565 ram)

(783 ram} /-"

Vista lateral

421/2"

(1080 ram)

13/8"

(35 ram)

43/4"

(121 ram)

c

" "'{368mm)--_1 11 ",=-

(279 rnm}

Vista posterior

33/8" I

4.=_1"

(51 ram)

(25 ram)

2"

Vista inferior:

31/4"

(83_m)

_,-14V2".._ _,-14V2".-_

(368 ram) (368 ram)

NOTA: La mayoria de las instalaciones requieren un espacio libre

minimo de 5" (127 mm) detr6s de la secadora para acomodar el

ducto de escape con codo. Vea "Requisitos de ventilaci6n'.

23

Page 24

Espacloparala instalaci6nen un lugar empotrado

o en un cl6set

Todas las dimensiones muestran el espacio recomendado, probado

con un espacio de 0" (0 ram) en los lados y la parte posterior.

[] Debe considerarse espacio adicional para facilitar la

instalaci6n y el servicio t_cnico.

[] Se podrfan necesitar espacios libres adicionales para las

molduras de la pared, de la puerta y del piso.

[] Se debe considerar agregar espacio adicional en todos los

lados de la secadora para reducir la transferencia de ruido.

[] Para la instalaci6n en un cl6set, con una puerta, se requieren

aberturas de ventilacJ6n mfnimas en la parte superior e inferior

de la puerta. Se aceptan puertas tipo persianas con aberturas

de ventilaci6n equivalentes.

[] Tambi6n se debe considerar espacio adicional para otto

electrodom_stico que le acompa_e.

REQUlSITOS ELI:CTRICOS

Usfed es responsable de:

[] Ponerse en contacto con un instalador el6ctrico calificado.

[] Asegurarse de que la conexi6n el_ctrJca sea adecuada

y de conformidad con el National Electrical Code (C6digo

Nacional EI6ctrico), ANSI/NFPA 70 - Oltima edici6n y con

todos los c6digos y ordenanzas locales.

El C6digo National EI6ctrico requiere una conexi6n de

sumJnistro de energfa elSctrica de 4 hilos para aquellos

hogares construidos despuSs de 1996, para los circuitos

de secadora que se hayan reformado despu6s de 1996

y todas las instalaciones de casas rodantes.

Usted puede obtener una copia de las normas de los

c6digos arriba indicadas en: National Fire Protection

Association, One Batterymarch Park, Quincy, MA 02269.

[]

Proveer el suministro el6ctrico requerido de 3 o 4 alambres,

monof6sico, de 120/240 volfios, 60 Hz, CA solamente (o un

suministro el6ctrico de 3 o 4 alambres, de 120/208 voltios,

si se especifica en la placa indicadora de clasificaci6n/de

la serie) en un circuito separado de 30 amps, protegido con

fusibles en ambos lados de la linea. Con6ctelo a un circuito

derivado individual. No tenga un fusible en el circuito neutro

o de conexi6n a tierra.

[]

No use un cable el6ctrico de extensi6n.

[]

Si los c6digos Io permiten y se emplea un alambre

de conexi6n a tJerra separado, se recomienda que

un electricJsta competente determine si la trayectoria

de conexi6n a tierra es adecuada.

(127 mm)

(25 ram)

(25 ram)

Requlsltos de insfalaci6n adlclonales para las casas

rodanfes:

Esta secadora es apropiada para instalaciones en casas rodantes.

La instalaci6n debe realizarse de acuerdo al Est6ndar de

seguridad y construcci6n de casas fabricadas (Manufactured

Home Construction and Safety Standard), Tffulo 24 CFR, Parte

3280 (anteriormente conocido como Est6ndar federal para la

seguridad y construccJ6n de casas rodantes - Federal Standard for

Mobile home Construction and Safety, Tffulo 24, HUD Parte 280) o

al Est_ndar CAN/CSA-Z240 MH.

Las insfalaclones en casas rodantes necesltan:

[] Piezas para el sistema de escape de metal, que est6n

disponibies con su distribuidor. Para obtener m6s informaci6n,

vea la secci6n "Ayuda o servicio t_cnico"

en el "Manual de uso y cuidado'.

[] Se deben tomar medidas especiales en el caso de casas

rodantes para introducir el aire del exterior a la secadora.

Las aberturas (como la de una ventana adyacente) deber_n

ser por Io menos del doble de tamaSo que la abertura de

ventilaci6n de la secadora.

Conexi6n el6ctrlca

Para instalar su secadora adecuadamente, usted debe determinar

el tipo de conexi6n el6ctrica que va a usar

y seguir las instrucciones que aqui se proveen para el caso.

[] Esta secadora ha sido manufacturada lista para ser

instalada con una conexi6n de suministro de energia

el6ctrica de 3 hilos. El conductor de puesta a tierra neutro

est6 permanentemente conectado al conductor neutro

(cable blanco), dentro de la secadora. Si la secadora est6

instalada con una conexi6n de suministro el6ctrico de

4 hilos, el conductor neutro de puesta a tierra se debe

quitar del conector de puesta a tierra exterior (tornillo verde)

y se debe ajustar debajo de la terminal neutra (cable central

o blanco) del bloque de terminal. Cuando el conductor

neutro de puesta a tierra est6 ajustado debajo de la terminal

neutra (cable central o blanco) del bloque de terminal, la

carcasa de la secadora queda aislada del conductor neutro.

[] Si los c6digos locales no permiten la conexi6n de un conductor

neutro conectado a tierra al alambre neutro, vea la secci6n

"Conexi6n opcional de 3 hilos".

[] Deber_ usarse una conexi6n con suministro de energia

de 4 hilos cuando el aparato est8 instalado en una ubicaci6n

en la cual est6 prohibida la conexi6n a fierra a tray, s del

conductor neutro. Est6 prohibido hacer la puesta a tierra a

travSs del conductor neutro para (1) las nuevas instalaciones de

circuito derivado, (2) casas rodantes, (3) vehiculos de recreaci6n

y (4) areas donde los c6digos locales prohiben la conexi6n a

tierra a tray, s de conductores neutros.

24

Page 25

$iemplea un cable de sumlnlstra el&clrlce:

Use un juego de cable de suministro de energfa que est_ en la lista

de UL, para ser usado con secadoras de ropa. El juego deber_

incluir:

[]

Un cable de suministro de energfa de 30 amperios que est8

en la lista de UL, de 120/240 voltios coma mfnimo. El cable

deber_ ser del ripe SRD o SRDT y tener par Io menos 4 pies

(1,22 m) de largo. Los alambres que Io conectan a la secadora

deben acabar en terminales de anillo o de horquilla con los

extremes hacia arriba.

[] Un protector de cables.

Si hate la conexi6n con cableado dlrecto:

El cable de suministro el6ctrico debe ser igual al suministro

el_ctrico (de 4 alambres o de 3 aiambres) y debe sen

[] Cable blindado flexible o cable de cobre forrado no met(]lice

(con aJambre de puesta a tierra), cubierto con un conducto

met_lico flexible. Todos los alambres conductores de corriente

deben estar aislados.

[] Hilos de cobre s61ido de calibre 10 (no use alurninio) de par

Io menos 5 pies (1,52 rn) de largo.

INSTRUCCIONES PARA LA CONEXI6N A TIERRA

SI el canlacla de pared luce coma &sle:

Ententes elija un cable de suministro

elSctrico de 4 alambres con terminales

de anillo o de horquilla y con protector de

cables. El cable de suministro de energfa de 4

hilos, de par Io menos 4 pies (1,22 rn) de largo,

debe tener 4 hilos de cobre s61ido de calibre 10

Contacto

de 4 alambres

(14=30R)

Si el conlacla de pared luce coma &sle:

(_ Entonces elija un cable de suministro el_ctrico

Contacto tomacorriente para 3 hilos tipo NEMA de lO-

de3alambres 3OR.

(IO=30R)

y encaiar en un tomacorriente para 4 hilos tipo

NEMA de 14-30R. El cable de puesta a tierra

(conductor a tierra) puede ser verde o desnudo.

El conductor neutro debe ser identiflcado con

una cubierta blanca.

de 3 alambres con terminales de anillo o de

horquilla y con protector de cables. El cable

de suministro el_ctrico de 3 hilos, de par Io

menos 4 pies (1,22 rn) de largo, debe tener 3

hilos de cobre de calibre 10 y encajar en un

[] Para la c0nexi6n de una secadora mediante cable

el6ctrico conectado a tierra:

Esta secadora debe estar conectada a tierra. En el caso de

funcionamiento defectuoso o averia, la conexi6n a tierra

reducir#, el riesgo de choque el6ctrJco al proporcionar una

via de menor resistencia para la corriente el6ctrica. Esta

secadora usa un cable que cuenta con un conductor para la

conexi6n a tierra del equipo y un enchufe de conexi6n a

tierra. El enchufe debe conectarse en un contacto

apropiado, que est6 debidamente instalado y conectado a

tierra de acuerdo con todos los c6digos y ordenanzas

locales.

[] Para la conexi6n permanente de una secadora:

Esta secadora debe estar conectada a un sistema de

cableado de metal permanente, conectado a tierra, o se

debe tender un conducto para la conexi6n a tierra del

equipo con los conductores de circuito y conectado al

terminal de tierra del equipo o al conductor de suministro de

la secadora.

ADVERTENClA: La conexi6n indebida del

conductor para la conexi6n a tierra del equipo puede

ocasionar un riesgo de choque electrico. Verifique con un

electricista, representante o personal de servicio tecnico

calificado para asegurarse de que la conexi6n a tierra de la

secadora sea apropiada. No modifique el enchufe que viene

con el cable el6ctrico. Si no encaja en el contacto, contrate

un electricista calificado para que instale un contacto

adecuado.

GUARDE ESTAS INSTRUCCIONES

25

Page 26

INSTALACION DE LAS PATAS NIVELADORAS

Peligro de Peso Excesivo

Use dos o m_s personas para mover e instalar

la secadora,

No seguir esta instrucci6n puede ocasionar una

lesi6n en la espalda u otto tipo de lesiones.

CONEXION EL_:CTRICA

CabJe de surnlnls|ro de energia

3 "

. Prepare la secadora para las paras

niveladoras

% %

Para evitar da_os en el piso0 use un pedazo de cart6n grande y

piano de la caia de la secadora; coJ6quelo debaio de todo el

borde posterior de la secadora. Suiete con firmeza el cuerpo de

la secadora (no el panel de Ja consoJa) y coloque la secadora

suavemente sobre el cart6n.

IMPORTANTE: Si se apoya la secadora sobre la parte posterior,

utJJJce los postes esquJnales de cart6n que venfan con Ja secadora

para evJtar da_ar esa parte de la secadora. Si no tiene los postes

esquinales de cart6n con los que fue empacada Ja secadora,

col6quela de costado.

f

_. Atornille las paras niveladoras

Peligro de Incendio

Use un cable de suministro el6ctrico nuevo de

30 amperios que est6 en la lista de UL.

Use un protector de cables que est6 en la lista de UL.

Desconecte el suministro el6ctrico antes de hacer las

conexiones el_ctricas.

Conecte el alambre neutro (el blanco o el del eentro)

a la terminal central (plateada).

El alambre de tierra (el verde o el no aislado) se debe

conectar con el conector verde de tierra.

Conecte los 2 alambres de suministro restantes con

las 2 terminales restantes (las doradas).

Apriete firmemente todas las eonexiones el6ctricas.

No seguir estas instrucciones puede causar la muerte,

incendio, o cheque el6ctrico.

Opclones para ia conexi6n ei6ctrlca

1. Seieccione el tipo de conexi6n

el_ctrica

Contacto de 4 hilos (Tipo NEMA 14-30R)

para cable de suministro de energfa:

Vaya a ConexJ6n del cable de suministro

el_ctrico.

Reborde

Modelos con una contrahuella

Modeios con una contrahueiia:

Atornille las patas en la carcasa con una Ilave de tuercas, hasta

que el reborde toque la contrahuella. La pata estar6 instalada

correctamente cuando la parte inferior est8 a aproximadamente

1/2" (13 mm) de la parte inferior de ia contrahuella.

Modelos sin una contrahueila:

Con una Ilave de tuercas y cinta m_trica, atornJJle las patas en sus

orJficJos hasta que Ja parte inferior est_ a aproximadamente 13/8"

(35 mm) de la parte inferior de la secadora.

Ahora coloque la secadora en posici6n vertical. Deslice la

secadora cerca de su ubicaci6n final. Deje suficiente espacio para

la conexi6n el_ctrica y para conectar el ducto de escape.

NOTA: Consulte Dimensiones de ia secadora en ia secci6n

Requisitos de ubicaci6n.

Modelos sin una contrahuella

Reborde

26

Contacto de 3 hilos (Tipo NEMA 10-30R)

para cable de suministro de energfa:

Vaya a ConexJ6n del cable de suministro

el_ctrico.

Conexi6n directa de 4 hilos:

Vaya a Conexi6n de cable directo.

Conexi6n directa de 3 hilos,

Vaya a ConexJ6n de cable directo.

NOTA: Si los c6digos locales no permiten ia conexi6n

de un conductor para conexi6n a tierra de la carcasa al

alambre neutro, prosiga a "Conexi6n opcional de 3 hilos'.

Esta conexi6n se puede utilizar con una conexi6n por cable

de suministro de energfa o por cable directo.

Page 27

Desconecte ei suministro de energfa antes de comenzar, Quite

el tornillo de sujecJ6n (D) y la tapa del bJoque de terminal (A).

A. Tapa deJ bloque de terminal

B. Tornillo del conductor de tierra externo

C. Tornillo central del bloque de terminal

D. Tornillo de sujeci6n

E. Hito neutro de puesta a tierra

F. Orificio debajo de la tapa del bloque de terminal

CONEXION POR CABLE DE SUMINISTRO ENERGJA

al protector de cables

Haga pasar eJ cable de suministro de energfa a trav6s del

protector de cables, AsegOrese de que el aislamiento de

cables del cable de suministro de energfa est_ dentro del

protector de cables. El protector de cables deber8 encajar

bJen con la carcasa de la secadora y estar en posJcJ6n

horizontal, No ajuste mSs los torniiios del protector de

cables en este momento.

Si eJ contacto de pared Iuce como _s|e:

Contacto de 4 hilos (Tipo NEMA 14-30R)

para cable de suministro de energfa:

Vaya a "ConexJ6n del cable de sumJnJstro

el_ctrJco de 4 hJlos" en esta p6gina.

Protector de cables del cable de surninistro de energia

1, Sujete el protector de cables del cable

de suministro de energJa

Quite los tornillos de un protector de cables de 3/4" (19 mm),

CoJoque Jas JengLietas de Jas dos seccJones de la abrazadera

(C) en el orificio que estc] debajo de Ja abertura del bioque de

terminal (B) de manera que una JengLieta est_ apuntando hacia

arriba (A) y Ja otra est_ apuntando hacia abajo (D), y suj_teias

en su Jugar. AprJete los tornillos del protector de cables s61o Io

suflcJente para mantener Jas dos secciones

de la abrazadera (C) juntas.

Contacto de 3 hilos (Tipo NEMA 10-30R)

para cable de suministro de energ[a:

Vaya a "ConexJ6n del cable de sumJnJstro

de energfa de 3 hJlos" en la p6gina 28.

Conexi6n con cable de suministro de energJa de 4 hiios

IMPORTANTE: Se necesita una conexi6n de 4 hiios para las

casas rodantes y donde los c6digos locales no permJtan ei uso

de conexJones de 3 hilos.

Contacto de 4 hilos

(Tipo NEMA 14-30R)

Enchufe de 4 terminales

Terminales de horquitla con

extremos hacia arriba

Terminales de anillo

27

Page 28

. Prep6rese para conectar el cable

neutro a tierra V el alarnbre neutro

Quite el tornillo central del bloque de terminal (B), Saque

el hJlo neutro de puesta a tJerra (E) del torniilo conductor

a tierra externo (A).

Conecte el hilo neutro a tierra

V el hilo neutro

Conecte el hilo neutro de puesta a tierra (E) y el hilo neutro

(hilo blanco) (C) del cable de suministro de energfa debajo del

torniilo central del bloque de terminal (B). Apriete el torniilo.

Conecte los hJlos restantes a los tornillos externos del bloque

de terminal. AprJete los tornillos. Pot Oltimo vuelva a insertar

la lengOeta de la tapa del bloque de terminal dentro de la

ranura del panel posterior de la secadora. Asegure Ja tapa

con un tornillo de sujeci6n. Ahora vaya a "Requisitos de

ventiiaci6n'.

Conexi6n con cabJe de sumlnls|ro de energia de 3 hilos

Uselo donde los c6digos locales permitan la conexi6n del

conductor de tierra de la carcasa al hHo neutro.

Contacto de 3 hilos

(Tipo NEMA 10-30R)

Terminaies de horquilla con

extremos hacia arriba

Enchufe de 3 terminales

Terminales de anillo

Conecte el hilo a tierra (F) (verde o desnudo) del cable de

suministro de energfa al tornillo conductor a tierra externo (A).

Apriete el tornillo.

28

Quite el tornillo central del bloque de terminal (B).

Page 29

Conecte el hilo neutro (hilo blanco o central) (C) del cable de

suministro de energia al tornillo central del bloque de terminal (B).

Apriete eJtornillo.

Protectordecablesparacabledlrecto

para cable directo

Desatornille el conector de conducto removJble (A) y cualquier

tornillo del protector de cables de 3/4" (19 mm). Haga pasar

la secci6n trenzada del protector de cables (C) a trav6s del

orificJo que estc] debajo de la abertura del bloque de terminal

(B). Busque dentro de la abertura del bloque de terminal y

atornille el conector de conducto removible (A) sobre las roscas

del protector de cables.

Conecte los hilos restantes a los tornillos externos del

bloque de terminal. Apt;ere los tornillos. Pot OltJmo vuelva

a insertar la lengOeta de la tapa del bioque de terminal

dentro de la ranura deJ panel posterior de Jasecadora.

Asegure la tapa con un tornillo de sujeci6n. Ahora vaya

a "Requisitos de ventiiaci6n".

CONEXION POR CABLEDIRECTO

Peligro de Incendio

Utilice alarnbres de cobre s61ido de ancho 10.

Use un protector de cables que est6 en la lista de UL.

Desconecte eJsuministro el6ctrico antes de hacer las

conexiones el6ctricas,

Conecte el alarnbre neutro (el blanco o el del centro)

a la terminal central (plateada).

El alarnbre de tierra (el verde o el no aislado) se debe

conectar con el conector verde de tierra.

Conecte los 2 alambres de suministro restantes con

las 2 terrninales restantes (las doradas).

Apriete firmemente todas las conexiones el6ctricas,

No seguir estas instrucciones puede causar la muerte,

incendio o choque el6ctrico.

de cables

Haga pasar el cable dJrecto a trav_s del protector de cables.

EI protector de cables deberc] encajar bJen con la carcasa de

la secadora y estar en posici6n horizontal. Apriete el torniilo

del protector de cables contra el cable directo.

Siel cableado luce como _ste:

___ ___=_ Conexi6n directa de 4 hilos:

Vaya a _'Conexi6n de cable directo

de 4 hiios" en la p_gina 30.

ConexJ6n directa de 3 hJlos:

Vaya a par

de 3 hiJos" en la p_gina 31.

_'Conexi6n cable directo

29

Page 30

Conexi6n pot cable dlrecto de 4 hiios

IMPORTANTE: Se necesita una conexi6n de 4 hilos para las

casas rodantes y donde los c6digos locales no permJtan las

conexJones de 3 hiios.

1. Prepare el cable de 4 hilos

para la conexi6n directa

y el hilo neutro

(127

Ei cable del hilo directo deber6 tener 5 pies (1,52 m) de largo

adicional, para poder mover la secadora si es necesario.

Pele 5" (127 ram) de la cubJerta exterior del extremo del cable,

dejando el cable a fierra desnudo a 5" (127 ram). Corte 1 1/2"

(38 ram) de los 3 hilos restantes. Pele el aislamiento 1" (25 ram).

D8 forma de gancho a los extremos de los alambres.

a tierra y el alarnbre neutro

Conecte el hilo neutro de puesta a tierra (E)

y coloque el extremo en forma de gancho

(gancho mirando hacia la derecha) del hilo

neutro (blanco o central) (C) del cable de

conexi6n directa debajo del tornillo central

del bioque de terminal (B). Apriete los extremos en forma

de gancho y apriete el tornillo.

Conecte el hiio de fierra (verde o desnudo) (F) del cable directo

al torniJJo conductor de tJerra externo (A). Apriete el torniJJo.

Quite el tornillo central del bloque de terminal (B). Saque

ei hJlo neutro de puesta a tierra (E) dei tornilio conductor

a tierra externo (A).

3O

5. Conecte los hilos restantes

Coloque los extremos en forma de gancho de los hilos restantes

del cable de conexi6n directa debajo de los tornillos exteriores

del bloque de terminal (con los ganchos mirando hacia la

derecha). Apriete los extremos en forma de gancho y apriete los

tornillos. Pot Oltimo vueiva a insertar la lengLieta de la tapa del

bloque de terminal dentro de la ranura del panel posterior de

la secadora. Asegure la tapa con un tornillo de sujeci6n. Ahora

vaya a "Requisitos de ventilaci6n'.

Page 31

Conexi6n par cable dlrecto de 3 hilos

0selo donde los c6digos locales permitan la conexi6n del

conductor de fierra de la carcasa al hiio neutro.

1. Prepare el cable de 3 hilos

para la conexi6n directa

El cable del hilo directo deber_ tener 5 pies (1,52 m) de largo

adicJonal0 para poder mover la secadora si es necesarJo.

Pele 3 1/2" (89 mm) de la cubJerta exterior dei extremo del

cable. Pele el aislamiento 1" (25 mm)° Si va a usar el cable de

3 hiios con hiio a fierra, corte ei hilo desnudo aiineado con la

cubierta exterior° D_ forma de gancho a los extremos de los

aiambres.

4. Conecte los hilos restantes

Coloque los extremos en forma de gancho de los hiios restantes

del cable de conexi6n directa debajo de los tornillos exterJores del

bioque de terminal (con los ganchos mirando hacia la derecha).

AprJete los extremos en forma de gancho y apriete los torniiios.

Pot 6ltimo vueiva a insertar la leng0eta de la tapa dei bJoque de

terminal dentro de la ranura del panel posterior de la secadora.

Asegure la tapa con un tornJllo de sujecJ6n. Ahora vaya a

"RequJsJtos de ventilaci6n'.

Conexi6n opclonal de 3 hilos

Antes de hater la conexi6n, usted deberc] verificar con un

eiectrJcista competente que este m_todo de conexJ6n a fierra

sea aceptabie.

Quite el tornillo central del bloque de terminal (B).

a tierra y el alarnbre neutro

Quite el tornillo central del bloque de terminal (B). Saque el

hJJoneutro de puesta a fierra (E) del tornillo conductor a tierra

externo (A).

neutro

Coloque el extremo en forma de ganeho

del hilo neutro (hilo blanco o central) (C)

del cable directo debajo del tornillo central

(B) dei bloque de terminal. Apriete y junte

el extremo en forma de gancho. AprJete el tornillo.

Conecte ei hilo neutro de puesta a tierra (E) y el hilo neutro

(hiio blanco o central) (C) dei cable de sumJnistro de energfa

debajo del tornillo central del bloque de terminal (B). Apriete

el tornillo.

31

Page 32

3. Conecte los hilos restantes

o

Coloque los extremos en forma de gancho de los hiios restantes

debaio de los torniilos exteriores del bloque de terminal (con

los ganchos mirando hacia ia derecha). Apriete los tornillos.

VENTILACION

REQUISITOS DE VENTILACI6N

Peligro de Incendio

Use un ducto de escape de metal pesado,

No use un ducto de escape de pl_stico.

No use un ducto de escape de aluminio,

No seguir estas instrucciortes puede ocasionar

la rnuerte o incendio.

ADVERTENCIA: Para reducir el riesgo de incendio,

esta secadora DEBE VENTILARSE HACiA EL EXTERIOR.

IMPORTANTE: Observe todos los c6digos y ordenanzas

apiicables. EI ducto de escape de la secadora no debe conectarse

en ning0n ducto de gas, chimenea, pared, techo, desv6n, espacio

angosto o el espacio ocuito de un ediflcio. Deber6 usarse

solamente un ducto de metal rfgido o flexible

para la ventilaci6n.

Conecte un hilo a tJerra de cobre separado (G) desde el

torniiio conductor a tierra externo (A) a una conexi6n a fierra

adecuada. Pot 01timo vuelva a insertar la lengLieta de la tapa

dei bioque de terminal dentro de la ranura del panel posterior

de la secadora. Asegure la tapa con un tornillo de suieci6n.

Ahora vaya a _'Requisitos de ventiiaci6n'.

f102 rnrn)

4"

Ducto de escape de metal pesado

de 4" (102 mm)

[] S6io puede usarse un ducto de escape de metal pesado

de 4" (102 mm) y abrazaderas.

[] No utilice un ducto de escape de pi6stico ni de aluminio.

Ducto de escape de metal rigido:

[] Se recomienda para un mejor desempefio en el secado

y para evitar que se apiaste o se tuerza.

Ducto de escape de metal flexible: (EsaceptabJe s61o

si esaccesible para la limpieza)

[] Deber6 extenderse pot completo y tenet soporte en la

ubicaci6n final de la secadora.

[] Quite el exceso del mJsmo para evitar que se doble y se tuerza,

Io cual podrfa dar lugar a una reducci6n del flujo de aire y a

un rendimiento insuficiente.

[] No instale un ducto de escape de metal flexible en paredes,

techos o pJsos encerrados.

[] La iongitud total no deber6 exceder los 7 3,_ pies (2,4 m).

biOTA: Si se usa un sistema de ventilaci6n existente, limpie la

pelusa de toda la Iongitud del sistema y asegl)rese de que la

capota de ventilaci6n no est8 obstruida con peiusa. Reemplace los

ductos de escape de pl6stico o de hoia de metal pot ductos de

metal rfgido o de metal flexible. Revise el "Cuadro del sistema de

ventilaci6n" y, si es necesario, modiflque el sistema de ventilaci6n

existente para iograr el mejor desempefio de secado.

32

Page 33

Capatas de ventilaci6n:

[] Deberc_n estar a por Io menos 12" (305 ram) desde el piso o

cualquier ob]eto que pueda obstruir la salida (tales como flores,

rocas, arbustos o nieve).

Estilas recomendadas:

Capota tipo persiana

Capota tipo caja

Estila aceptable:

PLANIFICACION DEL SISTEMA DE VENTILACION

Instalaclanes recernendadas de ventilaci6n

Las instalaciones fipicas tienen la ventilaci6n de la secadora en

la parte posterior de la misma. Otras instalaciones son posibles.

B

C

A ....

.....F

.... e

...............g

H

Capota angular

Codas:

[] Los codos de 45 ° proveen un me]or flujo de aire que los codos

de 90 °.

Estilas recamendadas:

M"

Abrazaderas:

[] UtiNce abrazaderas para sellar todas las juntas.