Kenmore 11063956101, 11063954101, 11063952101, 11063952100, 11063942101 Owner’s Manual

...

Owner's Manual and

Installation Instructions

27-Inch Wide

ELECTRIC DRYERS

im rmm

IMPORTANT:

Read and follow all safety

and operating instructions

before first use of this product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

www.sears.com

3979091A PRINTED IN U.S.A. 1/01

BEFORE USING YOUR NEW DRYER 2

KENMORE ELECTRIC DRYER WARRANTY 3

DRYER SAFETY ...... 4

INSTALLATION INSTRUCTIONS 6

OPERATING YOUR DRYER 2O

LAUNDRY TIPS ...... 27

CARING FOR YOUR DRYER 29

TROUBLESHOOTING ..... 33

WE SERVICE WHAT WE SELL 35

Please read this manual. It will help

you install and operate your new

Kenmore dryer in the most economical

way.

If you need more information about the

care and operation of Kenmore appliances

call your nearest Sears store. You will

need the complete model and serial

numbers when requesting information.

Your dryer's model and serial numbers are

located on the Model and Sedal Number

Plate.

ModelNo.and

SerialNo. Plate

Use the space below to record the model

number and serial number of your new

Kenmore dryer.

Model No.

Serial No.....

Date of Purchase

Keep this book and your Sears

Salescheck (receipt) in a safe

place for future reference.

Full One Year Warranty on

Mechanical and Electrical Parts

For one year from the date of purchase,

if this dryer is installed and operated

according to the instructions in this manu-

al, Sears will repair or replace any of its

mechanical or electrical parts if they are

defective in material or workmanship.

NOTE: Exhausting your dryer with

a plastic vent may void this warranty,

See "Installation Instructions" for the

complete exhaust requirements for this

dryer.

Warranty Restriction

Ifthe dryer is subjected to other than

private family use, all warranty coverage is

effective for only 90 days.

Warranty Service

Warranty service is available by contacting

your nearest Sears Service Center in the

United States.

This warranty applies only while this dryer

is in use in the United States.

This warranty gives you specific legal

rights, and you may also have other rights

which vary from state to state,

Sears, Roebuck and Co., Dept. 817WA,

Hoffman Estates, IL 60179.

For Sears Warranty information or to contact a

Sears Service Center, please reference the service

numbers located on the back page of this manual

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and

on your appliance. Always read and obey all safety messages.

This is the safety alert symbol. This symbol alerts you to

potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol

and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously

injured if you don't immediately

follow instructions.

You can be killed or seriously

injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how

to reduce the chance of injury, and tell you what can happen if the

instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Toreducetheriskof fire,electricshock,orinjurytopersons

when using the dryer, follow basic precautions, including the following:

• Read all instructions before using • Do not repair or replace any part of

the dryer.

• Do not place items exposed to cook-

ing oils in your dryer. Items contami_

nated with cooking oils may contribute

to a chemical reaction that could

cause a load to catch fire.

• Do not dry articles that have been pre-

viously cleaned in, washed in, soaked

in, or spotted with gasoline, dry_

cleaning solvents, other flammable, or

explosive substances as they give off

vapors that could ignite or explode,

• Do not allow children to play on or in

the dryer, Close supervision of

children is necessary when the dryer

is used near children.

• Before the dryer is removed from

service or discarded, remove the door

to the drying compartment,

• Do not reach into the dryer if the drum

is moving.

• Do not install or store the dryer where

it will be exposed to the weather.

• Do not tamper with controls.

the dryer or attempt any servicing

unless specifically recommended in

this Owner _ Manual or in

published user-repair instructions

that you understand and have the

skills to carry out.

• Do not use fabric softeners or

products to eliminate static unless

recommended by the manufacturer

of the fabric softener or product.

• Do not use heat to dry articles

containing foam rubber or similarly

textured rubber-like materials.

• Clean lint screen before or after

each load.

• Keep area around the exhaust

opening and adjacent surrounding

areas free from the accumulation

of lint, dust, and dirt.

• The interior of the dryer and

exhaust vent should be cleaned

periodically by qualified service

personnel.

• See the "INSTALLATION

INSTRUCTIONS" section for

grounding requirements.

SAVE THESE INSTRUCTIONS

Tools and Parts

Check that you have everything neces-

sary for correct installation, Proper

installation is your responsibility.

• flat*blade screwdriver

• adjustable wrench that opens to 1 in.

or hex_head socket wrench (for

adjusting dryer feet)

• level

• wire stripper (direct wire installations)

• #2 Phillips screwdriver

• safety glasses

• duct tape

• caulking gun and compound (for

installing new exhaust vent)

• gloves

• tin snips (new vent installations)

Parts supplied:

Remove parts package from dryer drum.

Check that all parts were included.

4_veling legs

Parts needed:

Check local codes, check existing

electrical supply and venting and see

"Electrical Requirements" and "Venting

Requirements" before purchasing parts.

Mobile home installations require:

• Metal exhaust system hardware

available for purchase from your local

Sears store or Sears Service Center.

Location Requirements

Explosion Hazard

Keep flammable materials and vapors,

such as gasoline, away from dryer.

Place dryer at least 18 inches (46 cm)

above the floor for a garage

installation.

Failure to do so can result in death,

explosion, or fire.

You will need

• A location that allows for proper

exhaust installation. See "Venting

Requirements."

• A separate 30 amp circuit.

• A grounded electrical outlet located

within 2 ft (61 cm) of either side of the

dryer, See "Electrical Requirements,"

• A sturdy floor to support the total dryer

weight of 200 Ibs (90.7 kg).

• A level floor with a maximum slope of 1

in. (2.5 cm) under entire dryer. (If slope

is greater than 1 in, [2.5 cm], install

Extended Dryer Feet kit, Part No,

279810.) Clothes may not tumble prop-

erly and models with automatic sensor

cycles may not operate correctly if

dryer is not level.

Do not operate your dryer at tempera-

tures below 45°F (7°C). At lower temper-

atures, the dryer might not shut off at the

end of an automatic cycle. Drying times

can be extended.

Install the dryer where it is protected from

water and/or weather.

Check code requirements. Some codes

limit, or do not permit, installation of the

dryer in garages, closets, mobile homes,

or sleeping quarters. Contact your local

building inspector.

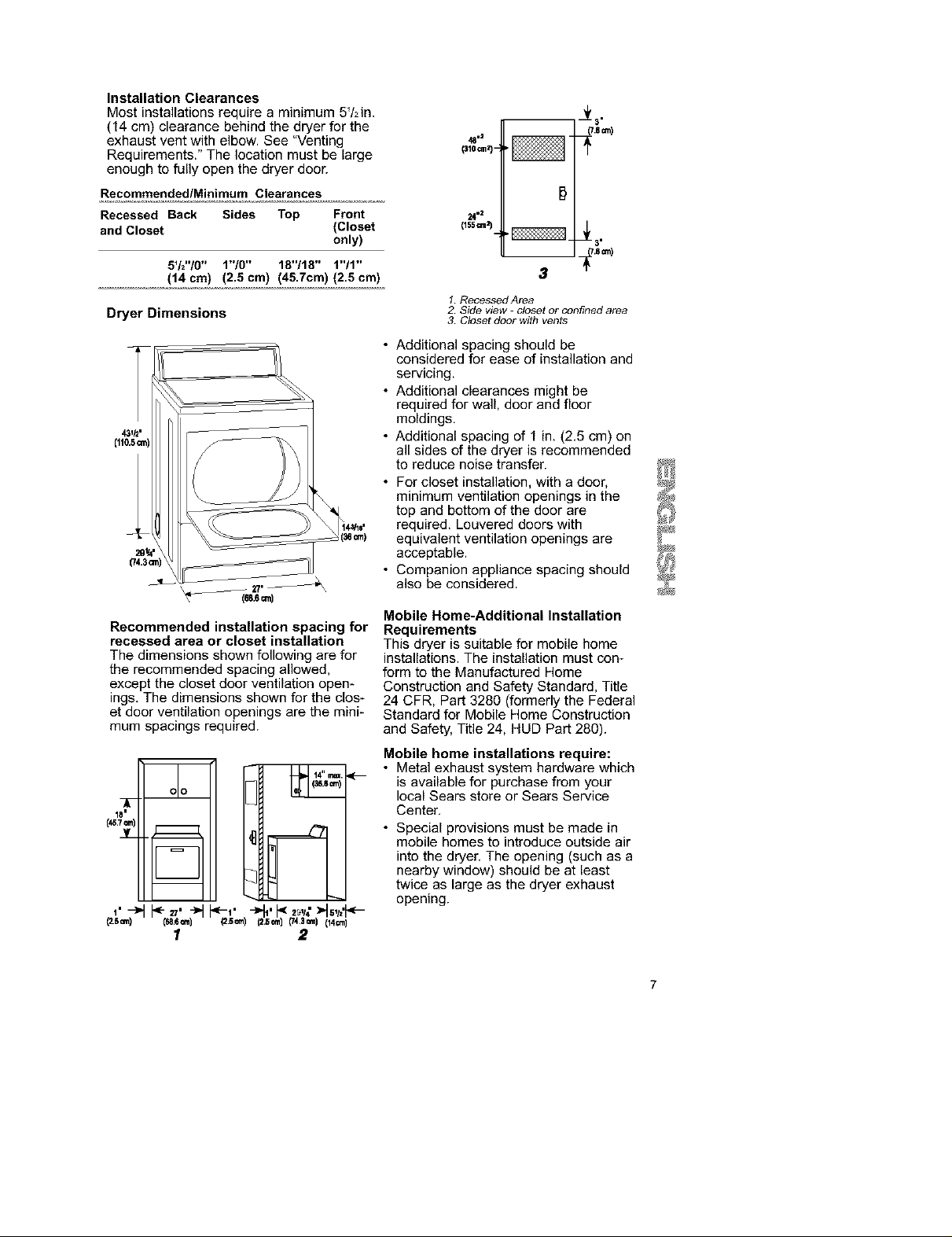

Installation Clearances

Most installations require a minimum 5/2in.

(14 cm) clearance behind the dryer for the

exhaust vent with elbow. See "Venting

Requirements." The location must be large

enough to fully open the dryer door.

Recommended/Minimum Clearances

Recessed Back Sides Top Front

and Closet (Closet

5V2"/0" 1"/0" 18"/18" 1"/1"

(14 cm) (2.5 cm) (45.7cm) (2.5 cm)

only)

Dryer Dimensions

1_m)

_i_,

(743ore)

48 "l

($10Qazj- _1_

24 "2

3

1. Recessed Area

2. Side view - closet or confined area

3. Closet door with vents

_t.ecm)

_.s a'nI

• Additional spacing should be

considered for ease of installation and

servicing.

• Additional clearances might be

required for wall, door and floor

moldings.

• Additional spacing of 1 in. (2.5 cm) on

all sides of the dryer is recommended

to reduce noise transfer.

• For closet installation, with a door,

minimum ventilation openings in the

top and bottom of the door are

required. Louvered doors with

equivalent ventilation openings are

acceptable.

• Companion appliance spacing should

also be considered.

Recommended installation spacing for

recessed area or closet installation

The dimensions shown following are for

the recommended spacing allowed,

except the closet door ventilation open-

ings. The dimensions shown for the clos-

et door ventilation openings are the mini-

mum spacings required.

14 rt_(.

_1 (_.8 _) _--

olo

(_,7=.)

3[_

1,-)

Cs=n)

I 2

Mobile Home-Additional Installation

Requirements

This dryer is suitable for mobile home

installations. The installation must con-

form to the Manufactured Home

Construction and Safety Standard, Title

24 CFR, Part 3280 (formerly the Federal

Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280).

Mobile home installations require:

• Metal exhaust system hardware which

is available for purchase from your

local Sears store or Sears Service

Center.

• Special provisions must be made in

mobile homes to introduce outside air

into the dryer, The opening (such as a

nearby window) should be at least

twice as large as the dryer exhaust

opening.

Electrical Requirements

It is your responsibility:

• To contact a qualified electrical

installer.

• To be sure that the electrical connec*

tion is adequate and in conformance

with the National Electrical Code,

ANSI/NFPA 70-latest edition and all

local codes and ordinances,

A copy of the above code standards

can be obtained from: National Fire

Protection Association, Batterymarch

Park, Quincy, MA 02269.

• To supply the required 3 or 4 wire, sin-

gle phase, 120/240-volt, 60-Hz., AC-

only electrical supply (or 3 or 4 wire,

120/208-volt electrical supply, if speci-

fied on the serial/rating plate) on a

separate 30-amp circuit, fused on both

sides of the line. A time-delay fuse or

circuit breaker is recommended.

Connect to an individual branch circuit.

Do not have a fuse in the neutral or

grounding circuit.

• Do not use an extension cord.

• If codes permit and a separate ground

wire is used, it is recommended that a

qualified electrician determine that the

ground path is adequate.

Electrical Connection

To properly install your dryer, you must

determine the type of electrical connec-

tion you will be using and follow the

instructions provided for it here.

• If local codes do not permit the con-

nection of a cabinet ground connector

to the neutral wire, see "Direct Wire or

Power Supply Cord."

• This dryer is manufactured with a 3-

wire, cabinet-ground conductor con-

nected to the NEUTRAL (white or cen-

ter wire) of the wiring harness at the

terminal block.

• Use a 4-wire conductor cord when the

dryer is installed in a mobile home or

an area where local codes do not per-

mit grounding through the neutral.

If using a power supply cord:

Dryer power supply cord must be:

• ULqisted

• 120/240 volt minimum

• 30 amp

• Type SRD or SRDT

• At least 4 ft (122 cm) long

The wires that connect to the dryer must

end in ring terminals or spade terminals

with upturned ends,

If your outlet looks like this:

©

4-wire receptacle (14-30R)

Then choose a 4-wire power supply cord

with ring or spade terminals and UL

approved strain relief. The 4-wire power

supply cord, at least 4 ft (122 cm) long,

must have 4, 10 gauge solid copper

wires and match a 4-wire receptacle of

NEMA Type 14-30R. The ground wire

(ground conductor) may be either green

or bare. The neutral conductor must be

identified by a white cover.

If your outlet looks like this:

©

3-wire receptacle (10-30R)

Then choose a 3-wire power supply cord

with ring or spade terminals and UL

approved strain relief. The 3-wire power

supply cord, at least 4 ft (122 cm) long,

must have 3, No.*10 copper wires and

match a 3-wire receptacle of NEMA Type

10-30R.

If connecting by direct wire:

Power supply cable must match

power supply (4-wire or 3-wire) and

be:

• Flexible armored or non-metallic

sheathed copper cable (with ground

wire). All current-carrying wires

must be insulated.

• 10 gauge solid copper wire (do not

use aluminum).

• At least 4 ft (122 cm) long.

GROUNDING INSTRUCTIONS

• For a grounded, cord-connected dryer:

This dryer must be grounded. In the

event of malfunction or breakdown,

grounding will reduce the risk of e]ectric

shock by providing a path of least resis-

tance for electric current. This dryer

uses a cord having an equipment-

grounding conductor and a grounding

plug. The plug must be plugged into an

appropriate outlet that is properly

installed and grounded in accordance

with all local codes and ordinances.

• For a permanently connected dryer:

This dryer must be connected to a

grounded metal, permanent wiring

system, or an equipment-grounding

conductor must be run with the circuit

conductors and connected to the

equipment-grounding terminal or lead

on the dryer.

WARNING: Improper connection

of the equipment-grounding conductor

can result in a risk of electric shock.

Check with a qualified electrician or ser-

vice representative or personnel if you

are in doubt as to whether the appli-

ance is properly grounded. De not mod-

ify the plug on the power supply cord. If

it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

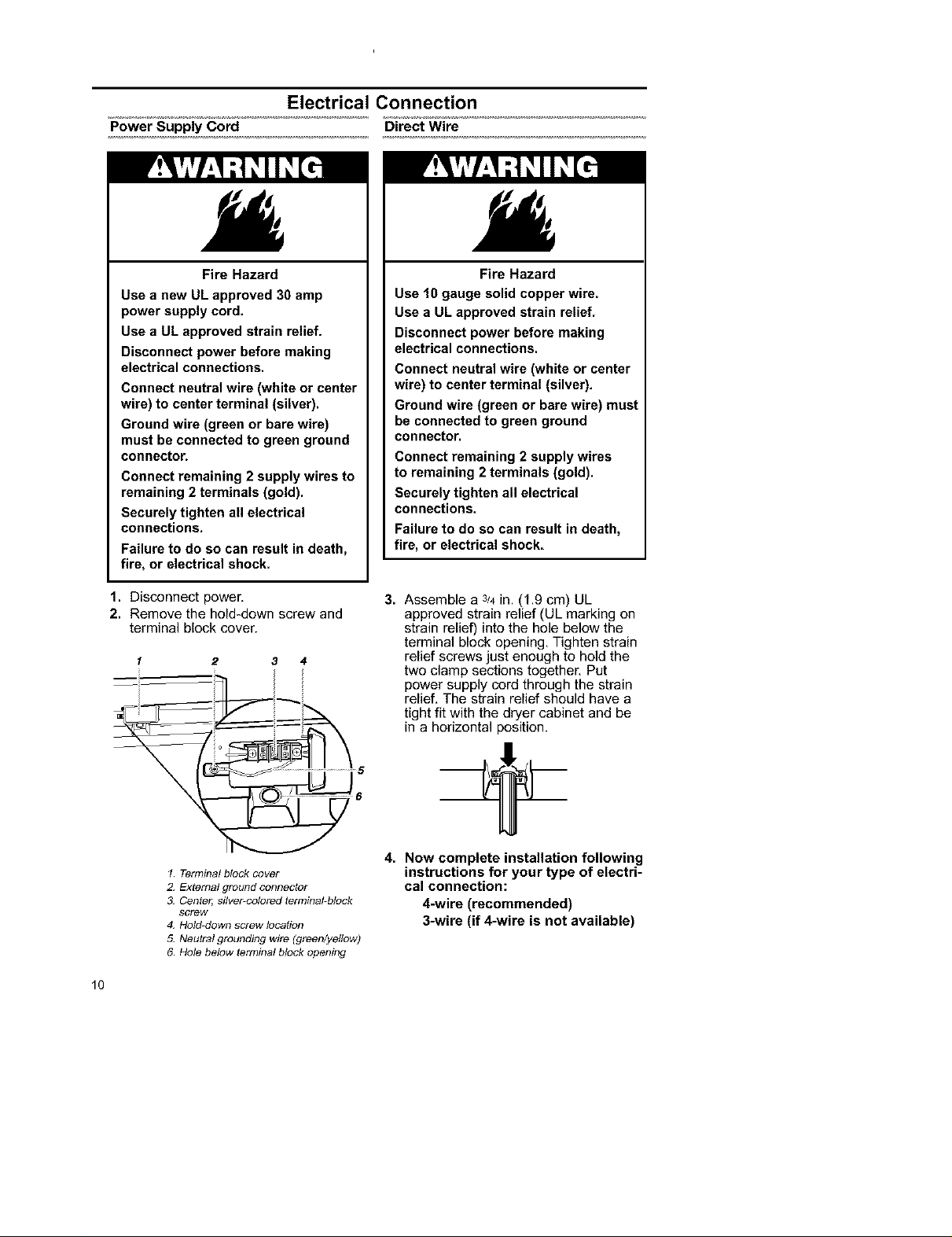

Power Supply Cord

Electrical Connection

Direct Wire

Fire Hazard

Use a new UL approved 30 amp

power supply cord.

Use a UL approved strain relief.

Disconnect power before making

electrical connections.

Connect neutral wire (white or center

wire) to center terminal (silver).

Ground wire (green or bare wire)

must be connected to green ground

connector.

Connect remaining 2 supply wires to

remaining 2 terminals (gold).

Securely tighten all electrical

connections.

Failure to do so can result in death,

fire, or electrical shock.

1. Disconnect power,

2. Remove the hold-down screw and

terminal block cover.

1 2 3 4

Fire Hazard

Use 10 gauge solid copper wire.

Use a UL approved strain relief.

Disconnect power before making

electrical connections.

Connect neutral wire (white or center

wire) to center terminal (silver).

Ground wire (green or bare wire) must

be connected to green ground

connector.

Connect remaining 2 supply wires

to remaining 2 terminals (gold).

Securely tighten all electrical

connections.

Failure to do so can result in death,

fire, or electrical shock.

3.

Assemble a 3_4in, (1,9 cm) UL

approved strain relief (UL marking on

strain relief) into the hole below the

terminal block opening, Tighten strain

relief screws just enough to hold the

two clamp sections together, Put

power supply cord through the strain

relief, The strain relief should have a

tight fit with the dryer cabinet and be

in a horizontal position.

1 Terminal block cover

2. Extemal ground connector

3. Center', silver-colored terminal-block

screw

4. Hold-down screw location

5. Neutral grounding wire (green/yellow)

6 Hole below terminal block opening

10

instructions for your type of electri-

cal connection:

4-wire (recommended)

3-wire (if 4-wire is not available)

4. Now complete installation following

Electrical Connection Options

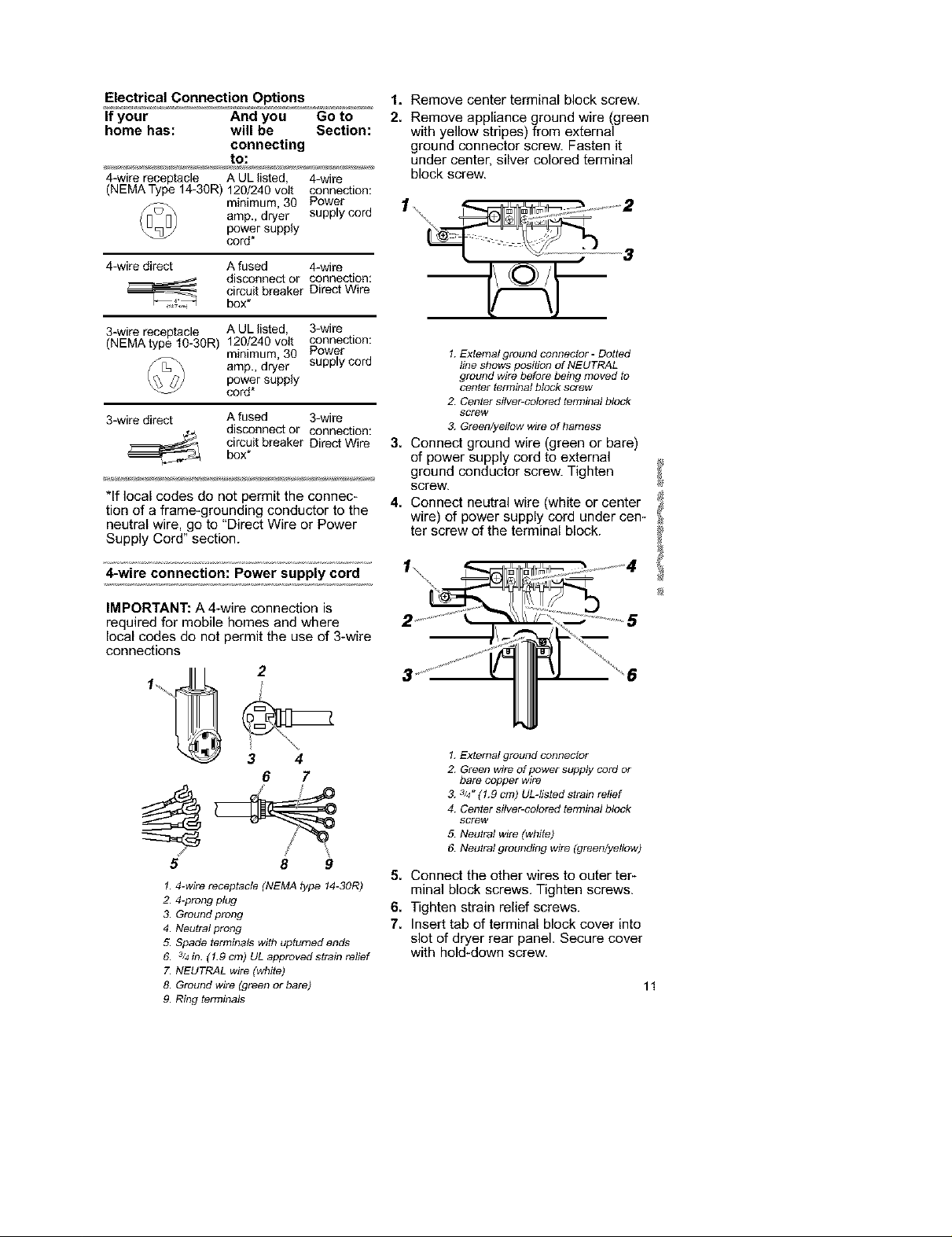

If your And you Go to

home has: will be Section:

connecting

to:

4-wire receptacle A ULlisted, 4-wire

(NEMAType 14-30R)120/240volt connection:

minimum,30 Power

amp.,dryer supply cord

powersupply

cord*

4-wire direct A fused 4-wire

3-wire receptacle A UL listed, 3-wire

(NEMAtype 10-30R) 120/240 volt connection:

3-wire direct 3-wire

disconnect or connection:

circuit breaker Direct Wire

box*

minimum, 30 Power

amp., dryer supply cord

power supply

cord*

A fused

disconnect or

circuit breaker

box*

connection:

Direct Wire

*If local codes do not permit the connec-

tion of a frame-grounding conductor to the

neutral wire, go to "Direct Wire or Power

Supply Cord" section.

1. Remove center terminal block screw.

2. Remove appliance ground wire (green

with yellow stripes) from external

ground connector screw. Fasten it

under center, silver colored terminal

block screw.

1\

3

1. External ground connector - Dotted

line shows position of NEUTRAL

ground wire before being moved to

center terminal block screw

2 Center silver-colored terminal block

SCreW

& Green/yellow wire of harness

3. Connect ground wire (green or bare)

of power supply cord to external

ground conductor screw. Tighten

screw.

4. Connect neutral wire (white or center /_

wire) of power supply cord under cen-

ter screw of the terminal block.

4-wire connection: Power supply cord

IMPORTANT: A 4-wire connection is

required for mobile homes and where

local codes do not permit the use of 3-wire

connections

2

3 4

6 7

5 8 9

1. 4-wire receptacle (NEMA type 14-30R)

2. 4-prong plug

3. Ground prong

4. Neutral prong

5. Spade terminals with upturned ends

6. 3/4in. (1.9 cm) UL approved strain relief

7. NEUTRAL wire (white)

8. Ground wire (green or bare)

9. Ring terminals

1. External ground connector

2 Green wire of power supply cord or

bare copper wire

& 3/4"(1.9 cm) ULdisted strain relief

4 Center silver-colored terminal block

screw

5. Neutral wire (white)

6. Neutral grounding wire (green/yellow)

5. Connect the other wires to outer ter-

minal block screws, Tighten screws.

6. Tighten strain relief screws.

7. Insert tab of terminal block cover into

slot of dryer rear panel. Secure cover

with hold-down screw.

11

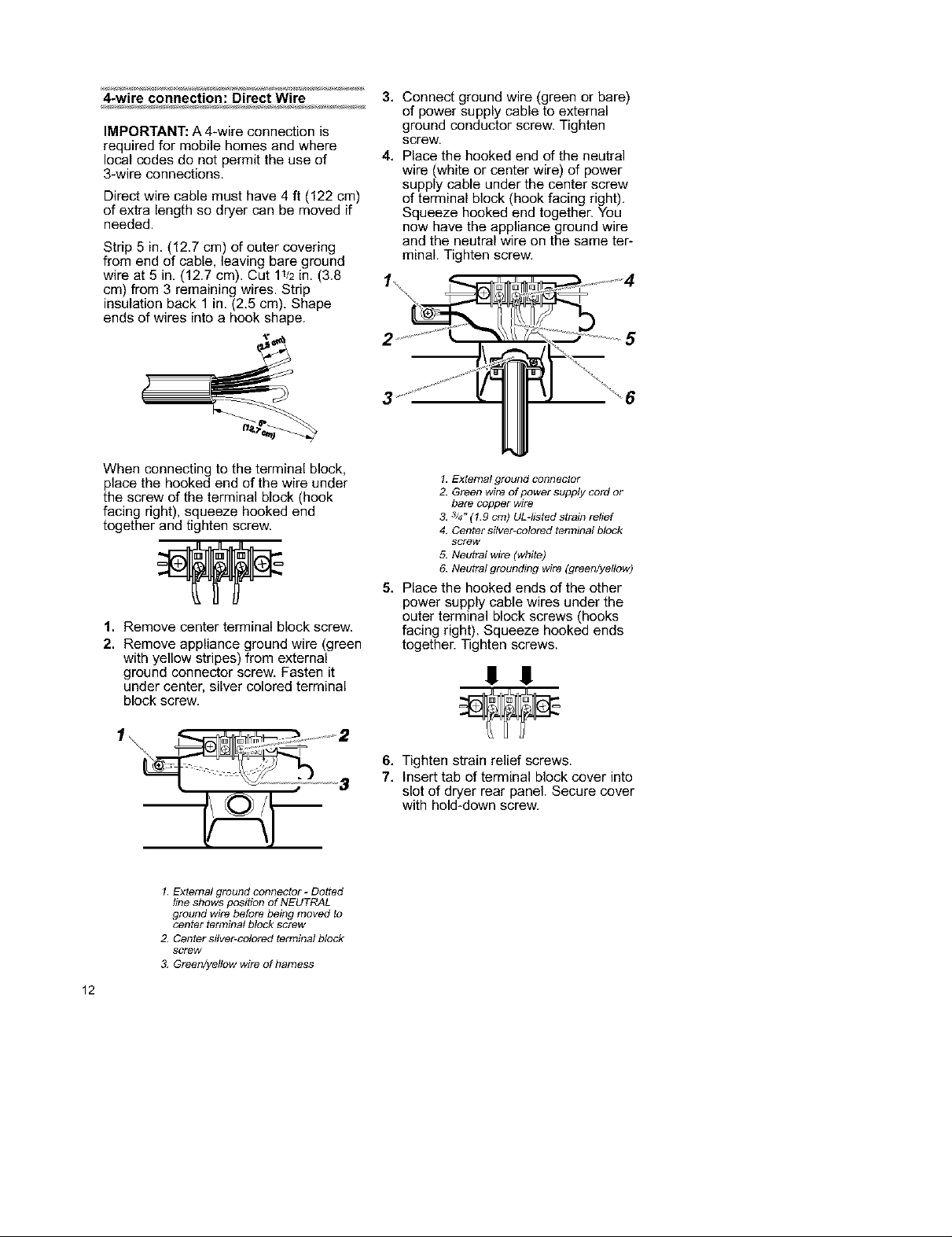

4-wire connection: Direct Wire

IMPORTANT: A 4-wire connection is

required for mobile homes and where

local codes do not permit the use of

3-wire connections.

Direct wire cable must have 4 ft (122 cm)

of extra length so dryer can be moved if

needed.

Strip 5 in. (12.7 cm) of outer covering

from end of cable, leaving bare ground

wire at 5 in, (12.7 cm). Cut 11_2in. (3.8

cm) from 3 remaining wires. Strip

insulation back 1 in, (2,5 cm), Shape

ends of wires into a hook shape.

3,

Connect ground wire (green or bare)

of power supply cable to external

ground conductor screw. Tighten

screw,

4,

Place the hooked end of the neutral

wire (white or center wire) of power

supply cable under the center screw

of terminal block (hook facing right),

Squeeze hooked end together. You

now have the appliance ground wire

and the neutral wire on the same ter-

minal. Tighten screw.

2

5

When connecting to the terminal block,

place the hooked end of the wire under

the screw of the terminal block (hook

facing right), squeeze hooked end

together and tighten screw.

1. Remove center terminal block screw.

2. Remove appliance ground wire (green

with yellow stripes) from external

ground connector screw, Fasten it

under center, silver colored terminal

block screw.

1 External ground connector - Dotted

line shows position of NEUTRAL

ground wire before being moved to

center terminal block screw

2. Center silver-colored terminal block

screw

& Green/yellow wire of harness

12

_3

I. External ground connector

2. Green wire of power supply cord or

bare copper wire

3. 3/4" (1.9 cm) UL-listed strain relief

4. Center silver-colored terminal block

sGrew

5. Neuh_l wire (white)

6. Neuh_l grounding wire (green/yellow)

5, Place the hooked ends of the other

power supply cable wires under the

outer terminal block screws (hooks

facing right). Squeeze hooked ends

together. Tighten screws.

11 11

6. Tighten strain relief screws.

7, Insert tab of terminal block cover into

slot of dryer rear panel. Secure cover

with hold-down screw.

3-wire connection: Power supply cord

Use where local codes permit con-

necting cabinet-ground conductor to

neutral wire:

2

4 5

3

7 6

1. 3-wire receptacle (NEMA type 10-30R)

2. 3-wire plug

3. Neutral prong

4. Spade terminals with up turned ends

5. 3/4"(1.9 cm) UL approved strain relief

6. Ring terminals

7. Neutral (white or center wire)

1, Loosen or remove center terminal

block screw.

2, Connect neutral wire (white or center

wire) of power supply cord to the cen-

ter, silver colored terminal screw of

the terminal block, Tighten screw.

3-wire connection: Direct Wire

Use where local codes permit con-

necting cabinet-ground conductor to

neutral wire.

Direct wire cable must have 4 ft (122 cm)

of extra length so dryer can be moved if

needed.

Strip 31J2in. (8.9 cm) of outer covering

from end of cable. Strip insulation back 1

in. (2.5 cm), If using 3-wire cable with

ground wire, cut bare wire even with

outer covering. Shape ends of wires into

a hook shape.

,gcm_

When connecting to the terminal block,

place the hooked end of the wire under

the screw of the terminal block (hook fac-

ing right), squeeze hooked end together

and tighten screw.

1, Loosen or remove center terminal

block screw,

2. Place the hooked end of the neutral

wire (white or center wire) of power

supply cable under the center screw

of terminal block (hook facing right).

Squeeze hooked end together.

Tighten screw.

1. External ground connector

2. Neutral grounding wire (green/yellow)

3. Center silver-colored terminal block

sGrew

4. Neutral wire (white)

5. 3/4"(1.9 cm) ULdisted strain relief

3, Connect the other wires to outer ter-

minal block screws. Tighten screws.

4. Tighten strain relief screws.

5, Insert tab of terminal block cover into

slot of dryer rear panel. Secure cover

with hold-down screw.

2

1. External ground connector

2. Neutral grounding wire (green/yellow)

3. Center silver-colored terminal block

screw

4. Neutral wire (white)

5. 3/4" (1.9 cm) UL-listed strain relief

13

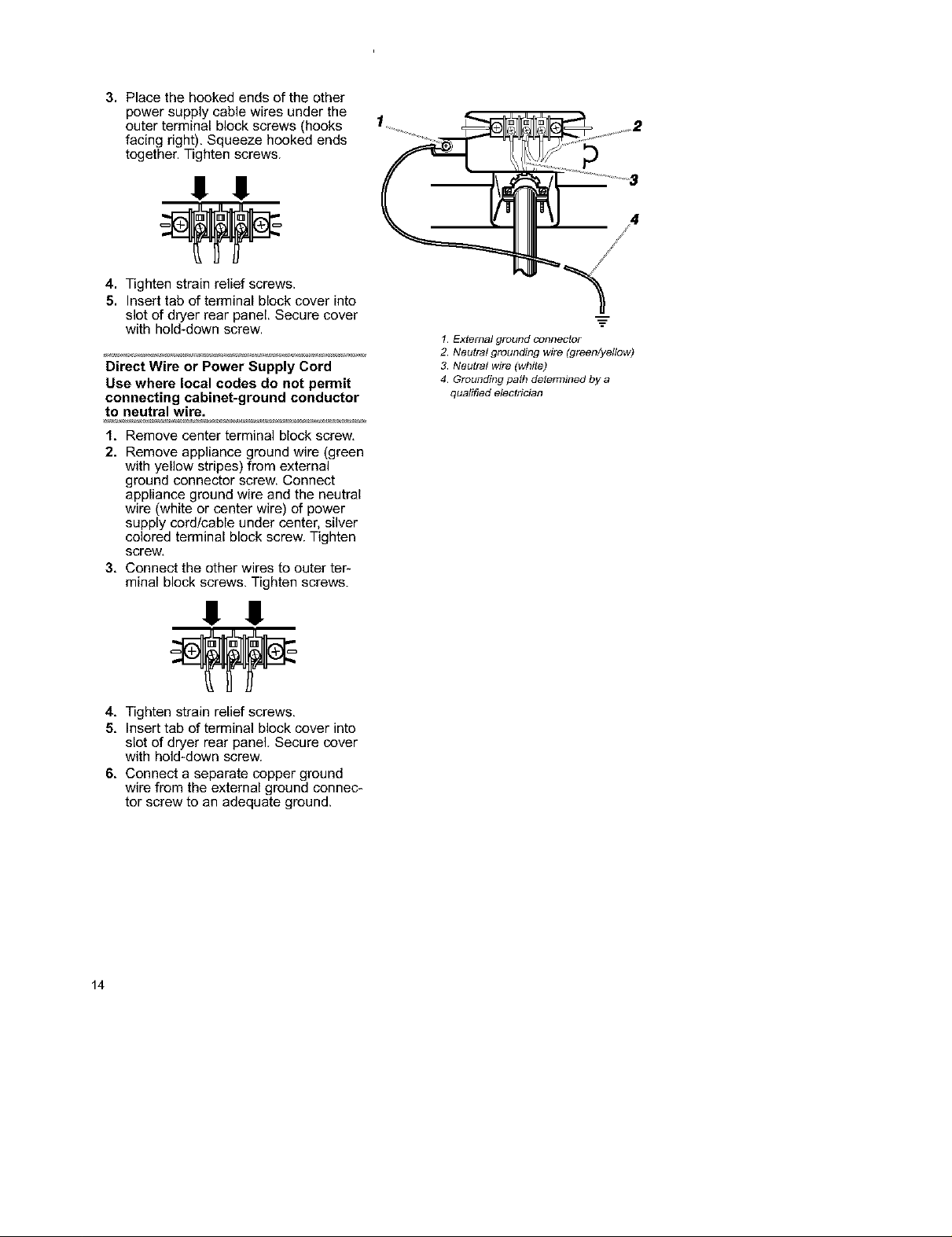

3. Place the hooked ends of the other

power supply cable wires under the

outer terminal block screws (hooks

facing right), Squeeze hooked ends

together. Tighten screws.

1!!!

4. Tighten strain relief screws.

5. Insert tab of terminal block cover into

slot of dryer rear panel. Secure cover

with hold-down screw.

Direct Wire or Power Supply Cord

Use where local codes do not permit

connecting cabinet-ground conductor

to neutral wire.

1, Remove center terminal block screw,

2. Remove appliance ground wire (green

with yellow stripes) from external

ground connector screw. Connect

appliance ground wire and the neutral

wire (white or center wire) of power

supply cord/cable under center, silver

colored terminal block screw. Tighten

screw,

3, Connect the other wires to outer ter-

minal block screws. Tighten screws.

/

/

1. External ground connector

2. Neutral grounding wire (green/yellow)

3. Neutral wire (white)

4. Grounding pafi7 determined by a

qualified electrician

!!!!

4, Tighten strain relief screws,

5, Insert tab of terminal block cover into

slot of dryer rear panel. Secure cover

with hold-down screw.

6, Connect a separate copper ground

wire from the external ground connec-

tor screw to an adequate ground.

14

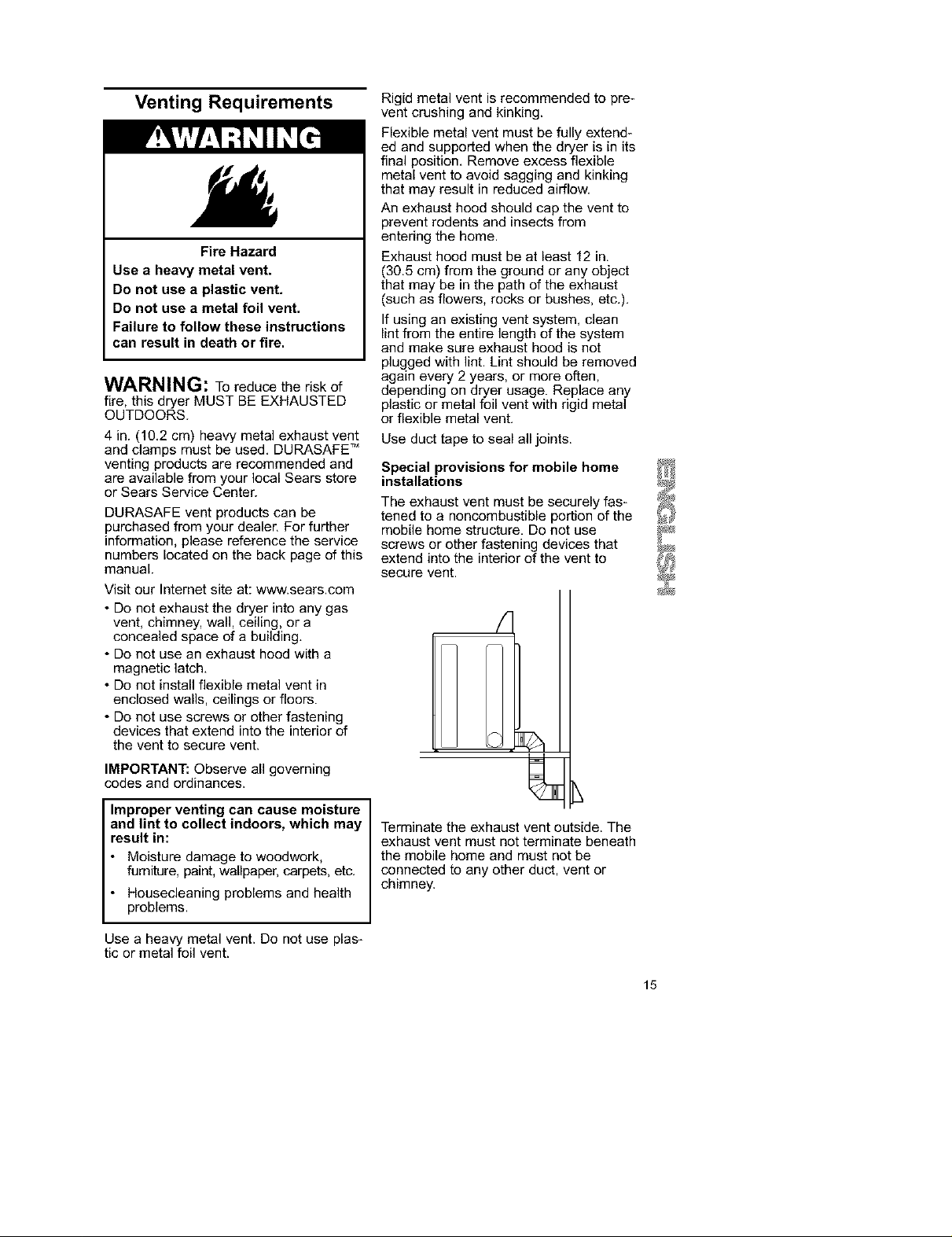

Venting Requirements

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions

can result in death or fire.

WARNING: To reduce the risk of

fire, this dryer MUST BE EXHAUSTED

OUTDOORS.

4 in. (10.2 cm) heavy metal exhaust vent

and clamps must be used. DURASAFE TM

venting products are recommended and

are available from your local Sears store

or Sears Service Center.

DURASAFE vent products can be

purchased from your dealer. For further

information, please reference the service

numbers located on the back page of this

manual.

Visit our Internet site at: www.sears.com

• Do not exhaust the dryer into any gas

vent, chimney, wall, ceiling, or a

concealed space of a building.

• Do not use an exhaust hood with a

magnetic latch.

• Do not install flexible metal vent in

enclosed walls, ceilings or floors.

• Do not use screws or other fastening

devices that extend into the interior of

the vent to secure vent.

IMPORTANT: Observe all governing

codes and ordinances.

Rigid metal vent is recommended to pre-

vent crushing and kinking.

Flexible metal vent must be fully extend-

ed and supported when the dryer is in its

final position. Remove excess flexible

metal vent to avoid sagging and kinking

that may result in reduced airflow.

An exhaust hood should cap the vent to

prevent rodents and insects from

entering the home.

Exhaust hood must be at least 12 in.

(30.5 cm) from the ground or any object

that may be in the path of the exhaust

(such as flowers, rocks or bushes, etc.).

If using an existing vent system, clean

lint from the entire length of the system

and make sure exhaust hood is not

plugged with lint. Lint should be removed

again every 2 years, or more often,

depending on dryer usage. Replace any

plastic or metal foil vent with rigid metal

or flexible metal vent.

Use duct tape to seal all joints.

Special provisions for mobile home

installations

The exhaust vent must be securely fas-

tened to a noncombustible portion of the

mobile home structure. Do not use

screws or other fastening devices that

extend into the interior of the vent to

secure vent.

Improper venting can cause moisture

and lint to collect indoors, which may

result in:

• Moisture damage to woodwork,

furniture, paint, wallpaper, carpets, etc.

• Housecleaning problems and health

problems.

Use a heavy metal vent. Do not use plas-

tic or metal foil vent.

Terminate the exhaust vent outside. The

exhaust vent must not terminate beneath

the mobile home and must not be

connected to any other duct, vent or

chimney.

15

Determine Vent Length

Typical installations vent the dryer from

the rear of the dryer. Other installations

are possible.

When using elbows or making turns,

allow as much room as possible, Bend

vent gradually to avoid kinking. Avoid 90°

turns.

2

I

!

Determine vent length

The maximum length of the exhaust sys_

tem depends upon:

• The type of vent (rigid metal or flexible

metal).

• The number of elbows used.

1. Dryer

2 Elbow

3. Wall

4. Exhaust hood

5. Duct tape and clamps

6. Rigid metal or flexible metal vent _ _

7. Vent length necessary to connect elbows

8. Exhaust outlet

Standard exhaust installations with 1

rigid metal or flexible metal vent

Recommended hood styles are shown

here.

1 2

3

1. Standard rear offset exhaust instaflation

2 Left or right side exhaust installation

3. Bottom exhaust installation

1. Select the route that will provide the

straightest and most direct path out-

doors, Plan the installation to use the

fewest number of elbows and turns.

16

1. Louvered hood style

2. Box hood style

The angled hood style (shown following)

is acceptable.

2. See the exhaust vent length chart that

matches your hood type for the maxi-

mum vent lengths you can use.

Do not use vent runs longer than those

specified in Vent Length Chart.

Exhaust systems longer than those speci-

fied will:

• Shorten the life of the dryer.

• Reduce performance, resulting in longer

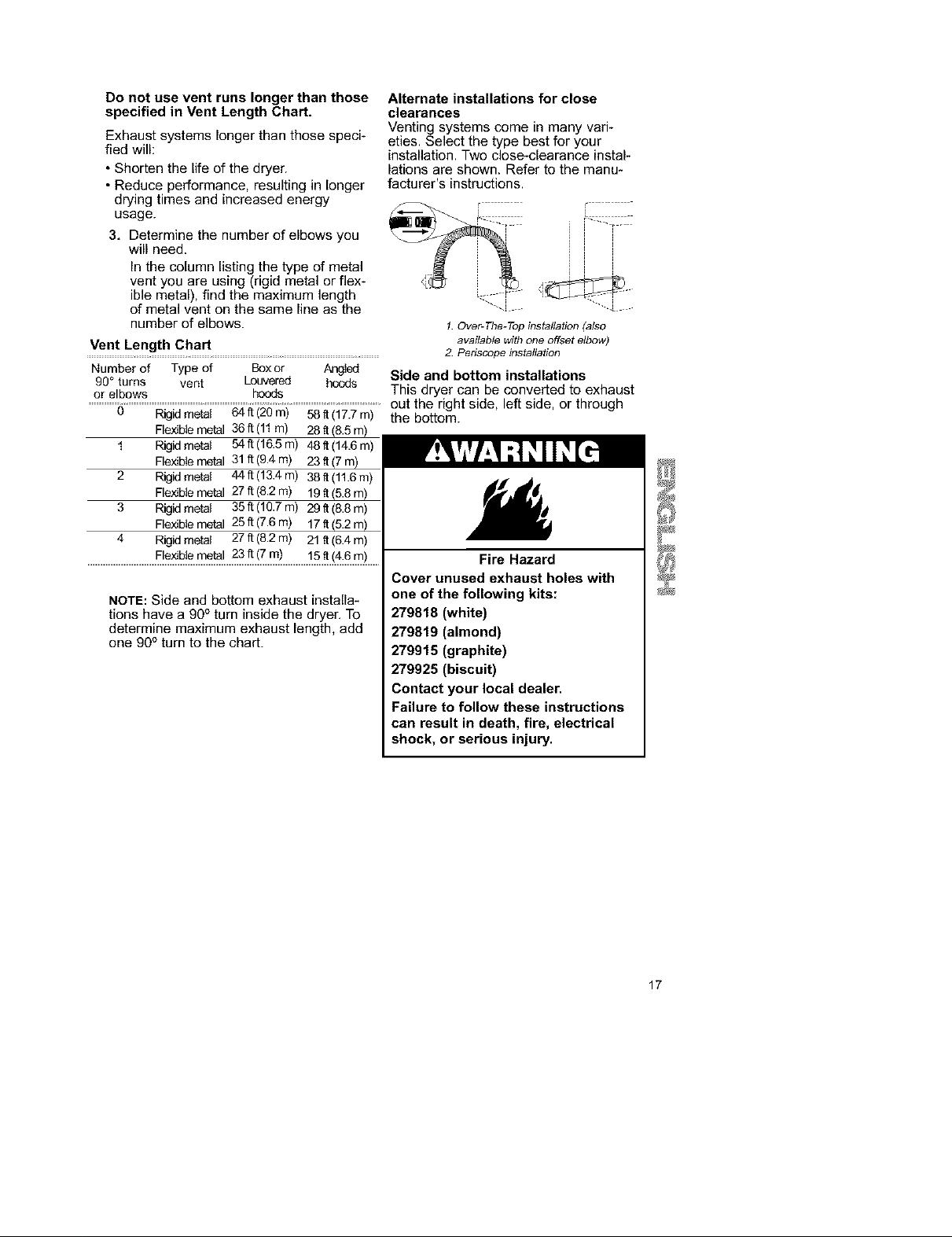

Alternate installations for close

clearances

Venting systems come in many vari-

eties. Select the type best for your

installation. Two close-clearance instal-

lations are shown. Refer to the manu*

facturer's instructions.

drying times and increased energy

usage.

3, Determine the number of elbows you

will need.

in the column listing the type of metal

vent you are using (rigid metal or flex-

ible metal), find the maximum length

of metal vent on the same line as the

number of elbows.

Vent Length Chart

Numberof Type of Boxor Angled

90° turns vent Louvered hoods

or elbows hoods

.............................................................................................................................................................................................................................................out the right side, left side, or through

0 Rigidmetal 64ft(20m) 58It(17.7m) the bottom.

Side and bottom installations

This dryer can be converted to exhaust

1.Over-The-Top installation (also

available with one offset elbow)

2. Periscope installation

Flexiblemetal 36ft (11m) 28ft

1 Rigidmetal 54ft(16.5m) 48It(14.6m)

Flexiblemetal 31ft (9.4m) 23It(7m)

2 Rigidmetal 44ft(13.4m) 38It(11.6m)

Flexiblemetal 27ft(8.2m) 19ft(5.8m)

3 Rigidmetal 35ft(10.7m) 29_(8.8 m)

Flexiblemetal 25ft (7.6m) 17It(5.2m)

4 Rigidmetal 27ft(8.2m) 21ff(6.4m)

Flexiblemetal 23ft (7m) 15ft(4.6 m)

Fire Hazard

Cover unused exhaust holes with

NOTE: Side and bottom exhaust installa-

tions have a 90° turn inside the dryer, To

determine maximum exhaust length, add

one 90° turn to the chart.

one of the following kits:

279818 (white)

279819 (almond)

279915 (graphite)

279925 (biscuit)

Contact your local dealer.

Failure to follow these instructions

can result in death, fire, electrical

shock, or serious injury.

17

Install Vent System

1. (Optional) Put on safety glasses and

gloves.

2, Install exhaust hood. Use caulking

compound to seal exterior wall open_

ing around exhaust hood.

3. Connect vent to exhaust hood. Vent

must fit inside exhaust hood. Secure

vent to exhaust hood with 4 in.

(10.2 cm) clamp.

4. Run vent to dryer location. Use the

straightest path possible. See

"Determine Vent Length." Avoid 90°

turns. Use duct tape to seal all joints.

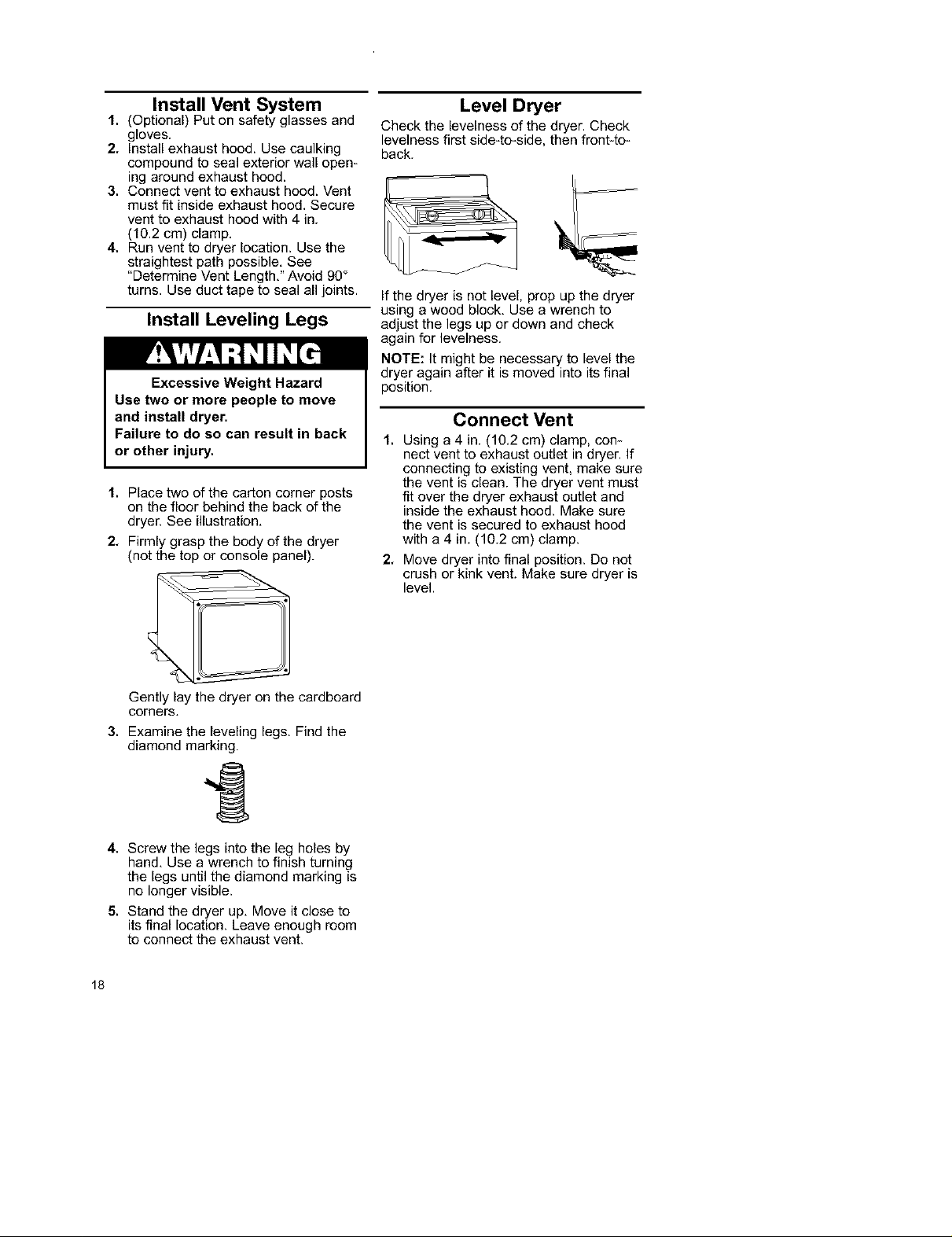

Install Leveling Legs

Excessive Weight Hazard

Use two or more people to move

and install dryer.

Failure to do so can result in back

or other injury.

1. Place two of the carton corner posts

on the floor behind the back of the

dryer. See illustration,

2, Firmly grasp the body of the dryer

(not the top or console panel).

Level Dryer

Check the levelness of the dryer. Check

levelness first side-to-side, then front-to-

back.

If the dryer is not level, prop up the dryer

using a wood block, Use a wrench to

adjust the legs up or down and check

again for levelness.

NOTE: It might be necessary to level the

dryer again after it is moved into its final

position.

Connect Vent

1. Using a 4 in. (10.2 cm) clamp, con-

nect vent to exhaust outlet in dryer. If

connecting to existing vent, make sure

the vent is clean. The dryer vent must

fit over the dryer exhaust outlet and

inside the exhaust hood. Make sure

the vent is secured to exhaust hood

with a 4 in. (10.2 cm) clamp.

2, Move dryer into final position. Do not

crush or kink vent. Make sure dryer is

level.

Gently lay the dryer on the cardboard

corners,

3. Examine the leveling legs. Find the

diamond marking.

1

4. Screw the legs into the leg holes by

hand, Use a wrench to finish turning

the legs until the diamond marking is

no longer visible.

5. Stand the dryer up. Move it close to

its final location. Leave enough room

to connect the exhaust vent.

18

Complete Installation

1, Check to be sure all parts are now

installed. If there is an extra part, go

back through the steps to see which

step was skipped.

2. Check to be sure you have all of

your tools.

3. Dispose of all packaging materials.

4. Check the dryer's final location. Be

sure the vent is not crushed or

kinked.

5, Check to be sure the dryer is level.

(See "Level Dryer.")

6, Plug into a grounded outlet. Turn

power on,

7, Remove the blue protective film on

the console and any tape remaining

on the dryer.

8. Read "Operating Your Dryer."

9, Wipe the dryer drum interior

thoroughly with a damp cloth to

remove any dust,

10. Set the dryer on a full heat cycle (not

the Air cycle) for 20 minutes, Open

the dryer door after five minutes and

feel for heat, If you do not feel heat,

turn the dryer off and wait five

minutes.

Then check the following:

• Controls are set in a running or "On"

position.

• Start button has been pushed firmly.

Repeat 5-minute test as outlined above.

If dryer still does not operate properly,

check the following:

• Dryer is plugged into a grounded outlet.

• Electrical supply is connected.

• House fuse is intact and tight; or circuit

breaker has not tripped.

• Dryer door is closed.

• If dryer makes an unusual noise, check

that dryer is level.

• You may notice a burning odor. This

odor is common when the heating

element is first used. The odor will go

away.

19

Explosion Hazard

Keep flammable materials and

vapors, such as gasoline, away

from dryer.

Do not dry anything that has ever had

anything flammable on it (even after

washing).

Failure to follow these instructions can

result in death, explosion,

or fire.

To get the best drying results, you must

operate your dryer properly. This section

gives you this important information.

STARTING YOUR DRYER

NOTE: The drawings in this section

show the basic features of all models

covered by this manual. Refer to the

supplied "Feature Sheet" for your dryer's

particular features.

STEP 1. Clean lint screen.

STEP 2. Put laundry into dryer and

shut door.

STEP 3. Set Cycle Selector Control

(Timer)_, (see "Cycle Descriptions").

Fire Hazard

No washer can completely

remove oil.

Do not dry anything that has ever had

any type of oil on it (including cooking

oils).

Items containing foam, rubber,

or plastic must be dried on a

clothesline or by using an Air Cycle.

Failure to follow these instructions can

result in death or fire.

STEP 4. Set FABRiC/Temperature

Control @, (see "FABRiC/Temperature

Control"), Check clothes label for manu-

facturer's recommendations.

STEP 5. Press PUSH TO START

Button _. Be sure door is closed.

STOPPING/RESTARTING

YOUR DRYER

• To stop the dryer at any time, open

dryer door.

• To restart, press PUSH TO START

Button _. Be sure door is closed.

• If you wish to end your drying cycle,

turn Cycle Selector Control (Timer)

to OFR

u i_us411_ IITJ._lr

20

CYCLE DESCRIPTIONS

The automatic cycles save you time by

providing the best drying results in the

shortest time. This can help you save

money on utility bills and reduce the

risk of fabric damage.

AUTO MOISTURE SENSING/

EVENHEAT TM with AUTO MOISTURE

SENSING PLUS cycles

Depending on your model, your dryer's

automatic cycle is AUTO MOISTURE

SENSING or EVENHEAT TM with AUTO

MOISTURE SENSING PLUS. Use this

cycle for most loads. Drying time varies

according to type of fabric, size of load,

and dryness setting.

• Set the Cycle Selector Control (Timer)

to NORMAL DRY(*) which is good for

most fabrics.

• At the end of the cycle, feel the dried

clothes. If they are damp, select MORE

DRY the next time you do a similar load.

If they are overdried, select LESS DRY

or DAMP DRY (depending on model)

the next time you do a similar load.

• Dryness is determined by an electronic

sensor that "feels" the amount of

moisture in clothes as they pass over it.

When the dryness selected is reached,

the dryer goes into a Cool Down period

of up to 10 minutes.

• The End of Cycle SIGNAL sounds (if

selected) once the cycle is completed.

• If you do not unload the dryer, it goes

into WRINKLE GUARD ® (see "USING

WRINKLE GUARD®").

NOTE: On some models, WRINKLE

GUARD ®is selected by an option

switch.

TIMED DRY CYCLE

Use this cycle to get up to 80 or 90

minutes (depending on model) of heated

drying time.

• The heating cycle is followed by a 10-

minute (approx.) Cool Down period.

• The End of Cycle SIGNAL sounds (if

selected) once the cycle is completed.

NOTE: Dryers with a WRINKLE GUARD ®

Option control will go into WRINKLE

GUARD ®immediately following this cycle

if it is selected.

TOUCH UP CYCLE

Use this cycle to smooth synthetic and

permanent press clothes that are clean

but wrinkled from being crowded in a

closet or suitcase.

• This setting provides about 15 minutes

of heated tumbling followed by a 10-

minute (approx.) Cool Down period.

• Remove clothes immediately when

tumbling stops.

AUTO

MOIS'IIJRE

SENSING

LES$ DRY

OR

"RMED DRY

TIMED DRY

40 SO

21

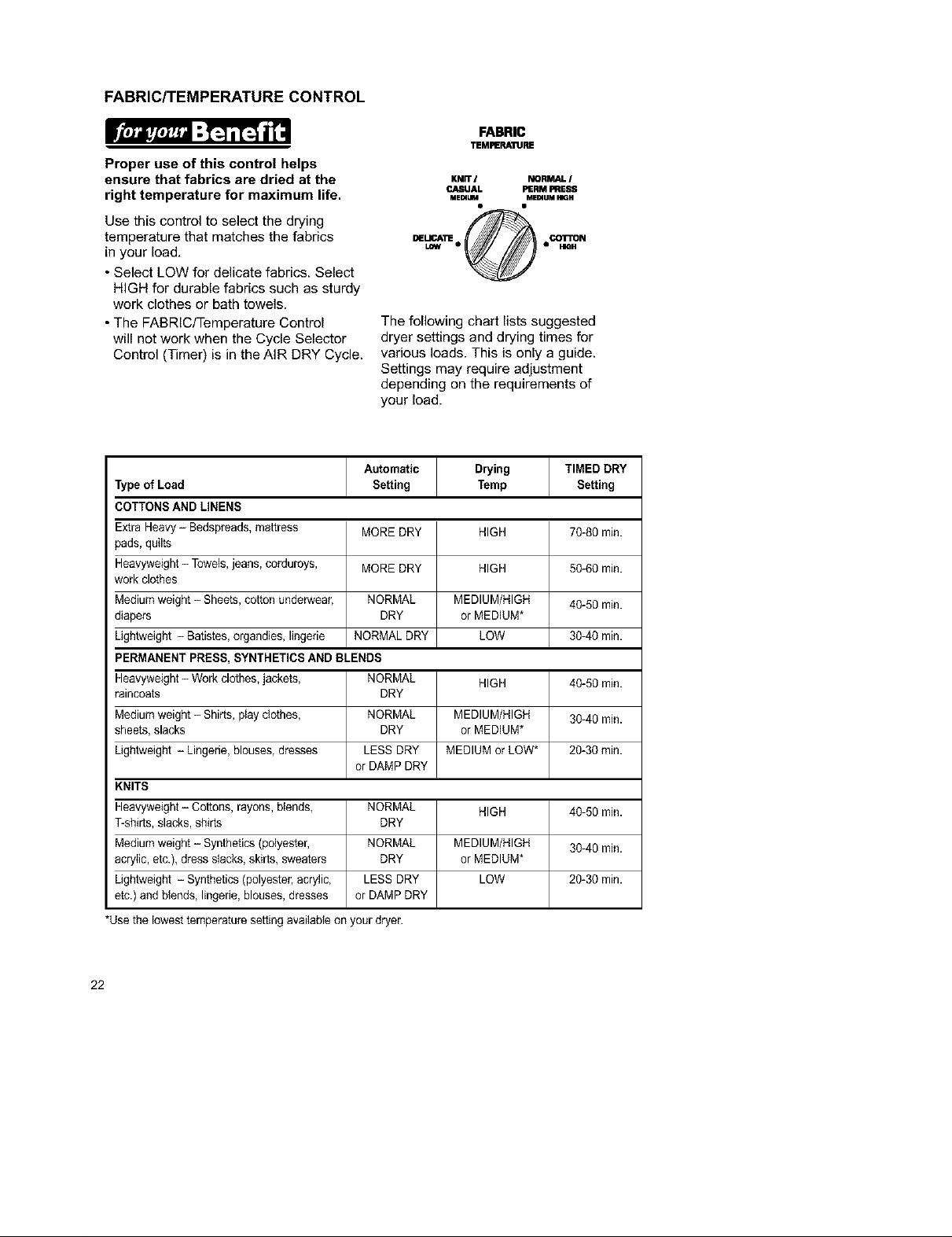

FABRIC/TEMPERATURE CONTROL

FABRIC

TEMFERAIURE

Proper use of this control helps

ensure that fabrics are dried at the

right temperature for maximum life.

Use this control to select the drying

temperature that matches the fabrics

in your load.

• Select LOW for delicate fabrics. Select

HIGH for durable fabrics such as sturdy

work clothes or bath towels.

• The FABRiC/Temperature Control

will not work when the Cycle Selector

Control (Timer) is in the AIR DRY Cycle.

The following chart lists suggested

dryer settings and drying times for

various loads. This is only a guide.

Settings may require adjustment

depending on the requirements of

your load.

Automatic Drying TIMED DRY

Type of Load Setting Temp Setting

COTTONS AND LINENS

Extra Heavy- Bedspreads, mattress MORE DRY HIGH 70-80 min.

pads, quilts

Heavyweight -Towels, jeans, corduroys, MORE DRY HIGH 50-60 min.

work clothes

Medium weight - Sheets, cotton underwear, NORMAL MEDIUM/HIGH 40-50 min.

diapers DRY or MEDIUM*

Lightweight - Batistes, organdies, lingerie NORMAL DRY LOW 30-40 min.

PERMANENT PRESS, SYNTHETICS AND BLENDS

Heavyweight - Work clothes, jackets, NORMAL HIGH 40-50 min.

raincoats DRY

Medium weight - Shirts, play clothes, NORMAL MEDIUM/HIGH 30-40 min.

sheets,slacks DRY or MEDIUM*

Lightweight - Lingerie, blouses, dresses LESS DRY MEDIUM or LOW* 20-30 rain.

KNITS

Heavyweight- Cottons, rayons, blends, NORMAL HIGH 40-50 min.

T-shirts, slacks, shirts DRY

Medium weight - Synthetics (polyester, NORMAL MEDIUM/HIGH 30-40 min.

acrylic, etc.), dress slacks, skirts, sweaters DRY or MEDIUM*

Lightweight - Synthetics (polyester, acrylic, LESS DRY LOW 20-30 min.

etc.)and blends, lingerie, blouses, dresses or DAMP DRY

*Use the lowest temperature setting available on your dryer.

or DAMP DRY

KNiT I NORMAL /

P..JLSUAL PERM PRESS

MEmLIM MEmUM HIGH

DELICA_ _• • CO1"rON

LOW e_ • HIG H

22

Loading...

Loading...