Page 1

installation instructions

Instrucciones de instalaci6n

instructions pour I'installation

English / Espa_ol / Fran_ais

Table of Contents / {ndice / Table des rnati_res ......2

Modeis/Modeios/Mod_ies: 110.2810 _

I<e

Top°

@rG de

Effi

re

i_iento y carga

o de agua

Gute

con __ation

U C

@fai le

par le essus

$ :coIor number, nOmero de coIor, le num@o de la couJeur

P/N W10550315B

Sears Brands Management Corporation

Hoffrnan Estates, IL 60179 U.S.A.

www.ken rnore.corn

www.sears.corn

rgecent

Sears Canada Inc.

Toronto, Ontario, Canada MSB 2C3

www.sears.ca

Page 2

Table of Contents

Indice

Table des mati_res

WASHER SAFETY .................................... 2

iNSTALLATiON REQUIREMENTS ............. 3

Tools and Parts ....................................... 3

Location Requirements ........................... 4

Drain System .......................................... 5

Electrical Requirements .......................... 6

iNSTALLATiON iNSTRUCTiONS .............. 7

Remove Shipping Moterlols .................... 7

Connect Drain Hose ................................ 7

Connect inlet Hoses ................................ 8

Level Washer ......................................... 10

COMPLETE iNSTALLATiON

CHECKLIST ............................................. 11

INSTALLATION NOTES

Date of purchase:

Date of installation:

installer:

Model number:

Serial number:

SEGURIDAD DE LA LAVADORA ............. 12

REQUISITOS DE INSTALACI6N ............. 13

Herromientos y piezas ............................ 13

Requisitos de ubicaci6n .......................... t4

Sistema de desagUe ............................... 15

Requisitos el_ctricos ............................... 15

INSTRUCCIONES DE INSTALACI6N ..... 16

Quite la base Y el onillo de embolaje ..... 16

Conexi6n de Io monguero de desagUe....|7

Conexi6n de las mangueros de entroda..18

Nivelaci6n de la lavadoro ...................... 19

COMPLETE LA INSTALACI6N ............... 21

NOTAS saBRE LA INSTALACI6N

Fecha de compra:

Fecha de instataci6n:

Instatador:

IxiOmero de modelo:

NOmero de serie:

SECURITE DE LA LAVEUSE .................... 22

EXIGENCES D'INSTALLATION .............. 23

Outillage et pi_ces ................................ 23

Exlgences d'emplacement ..................... 24

Syst_me de vidonge ............................. 24

Specifications _lectriques ...................... 25

iNSTRUCTiONS D'INSTALLATION ........ 26

Retroit de Io bose d'expedition et

de rembollage en anneau ..................... 26

Raccordement du fuyou d'evocuation .... 26

Raccordement des tuyaux de vldange ... 27

Mise 6 niveau de la laveuse .................. 29

LISTE DE V(:RIFICATION

POUR iNSTALLATiON TERMINEE .......... 31

NOTES CONCERNANT L'INSTALLATION

Date d'achat :

Date d'installation :

Instatlateur :

NumSro du modSte :

NumSro de s_rie :

WASHER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't imrnediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Page 3

iMPORTANT SAFETY iNSTRUCTiONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the washer, follow basic precautions,

includingthe following:

[] Read all instructions before using the washer.

[] Do not wash articles that have been previously cleaned

in, washed in, soaked in, or spotted with gasoline,

dry=cbaning solvents, other flammable, or explosive

substances as they give off vapors that could ignite or

explode.

[] Do not add gasoline, dry=cleaning solvents, or other

flammable, or explosive substances to the wash water.

These substances give off vapors that could ignite or

explode.

[] Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been used

for 2 weeks or more. HYDROGEN GAS iS

EXPLOSIVE. If the hot water system has not been

used for such a period, before using the washing

machine, turn on all hot water faucets and let the water

flow from each for several minutes. This will release

any accumulated hydrogen gas. As the gas is

flammable, do not smoke or use an open flame during

this time.

SAVE THESE iNSTRUCTiONS

iNSTALLATiON

[] Do not allow children to play on or in the washer. Close

supervision of children is necessary when the washer is used

near children.

[] Before the washer is removed from service or discarded,

remove the door or lid.

[] Do not reach into the washer if the drum, tub or agitator is

moving.

[] Do not install or store the washer where itwill be exposed to

the weather.

[] Do not tamper with controls.

[] Do not repair or replace any part of the washer or attempt any

servicing unless specificaJly recommended in this manual or in

published user-repair instructions that you understand and

have the skills to carry out.

[] See "Electrical Requirements" located in the installation

instructions for grounding instructions.

REQUIREMENTS

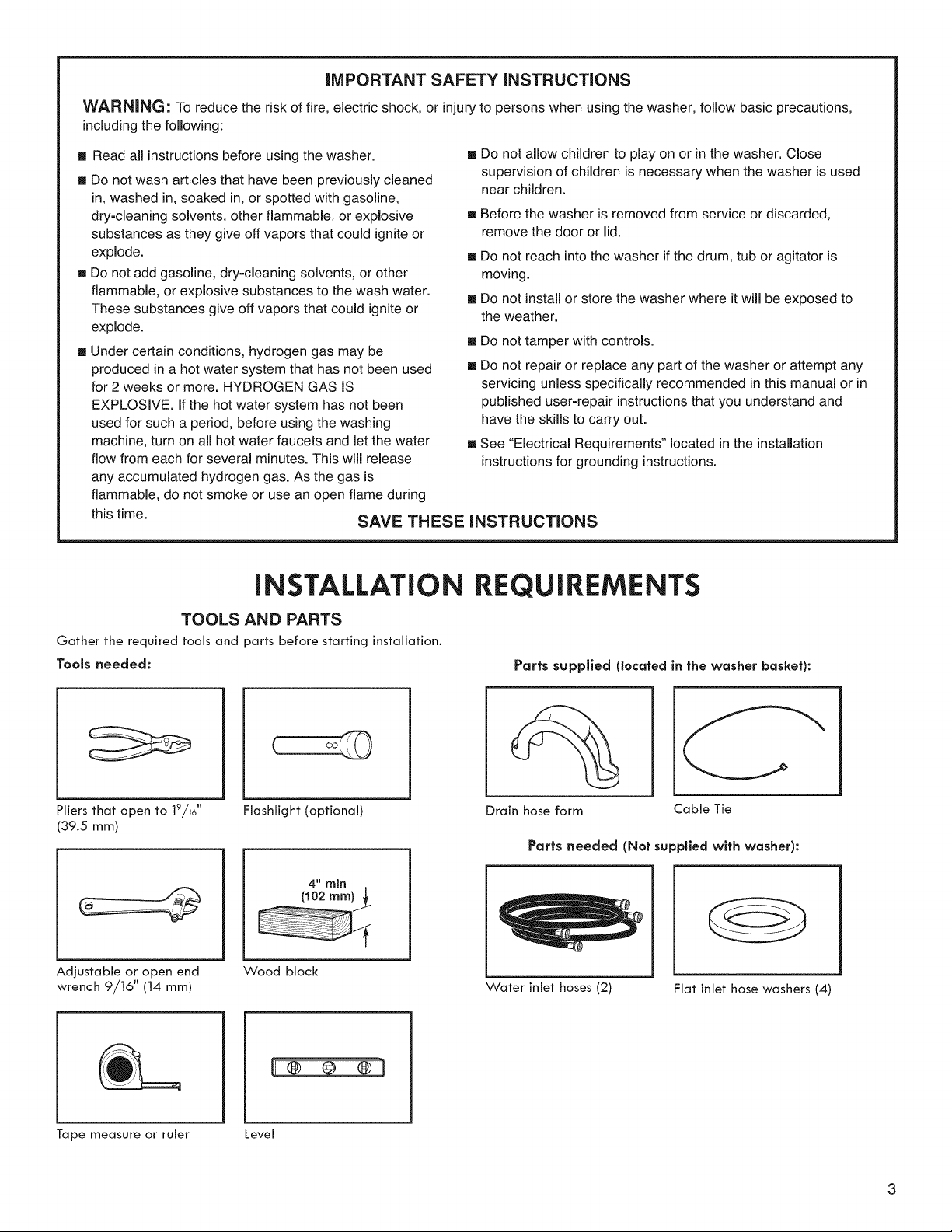

TOOLS AND PARTS

Gather the required tools and parts before starting installation.

Tools needed:

(

Pliers that open to 19/1_''

(39.5 mm)

Adjustable or open end

wrench 9/16" (14 mm)

Flashlight (optional)

4" rain

(102 ram) _

Wood block

Parts supplied (located in the washer basket):

Drain hose form

Parts needed (Nat supplied with washer):

Water inlet hoses (2)

Cable Tie

Flat inlet hose washers (4)

Tape measure or ruler Level

Page 4

To order, please refer to the phone number or website on the

back page of your "Use and Care Guide."

[] 8212656RP

[] 8212641RP

[] 8212646RP

[] 8212545RP

[] 8212487RP

[] 8212638RP

[] 8212637RP

Alternate parts (Nat suppffed wlfh washer):

Your installation may require additional parts. To order, please

refer to the phone number or website on the back page of your

"Use and Care Guide."

if you have:

Laundry tub or

standpipe taller

than 96" (2.4 m)

1" (25 mm)

diameter standpipe

Overhead sewer

10 ft. (3.0 m) Inlet hose, Black EPDM (2 pack)

5 ft. (1.5 m) Inlet hose, Black EPDM (2 pack)

4 ft. (1.2 m) Inlet hose, Black EPDM (2 pack)

5 ft. (1.5 m) Inlet hose, Red and Blue EPDM

(2 pack)

5 ft. (1.5 m) Nylon braided inlet hose (2 pack)

6 ft. (1.8 m) Nylon braided inlet hose, space

saving 90 ° elbow, hypro-blue steel couplings

(2 pack)

6 ft. (1.8 m) Inlet hose, Black EPDM, space

saving 90 ° elbow, hypro-blue steel couplings

(2 pack)

You will need:

Sump pump system (if not already

available)

2" (50 mm) diameter to 1" (25 mm)

diameter Standpipe Adapter Kit,

Part Number 3363920 and

Connector Kit, Part Number 285835

Standard 20 gal. (76 L) 39" (990 mm)

tall drain tub or utility sink, sump

pump, and connectors (available from

local plumbing suppliers)

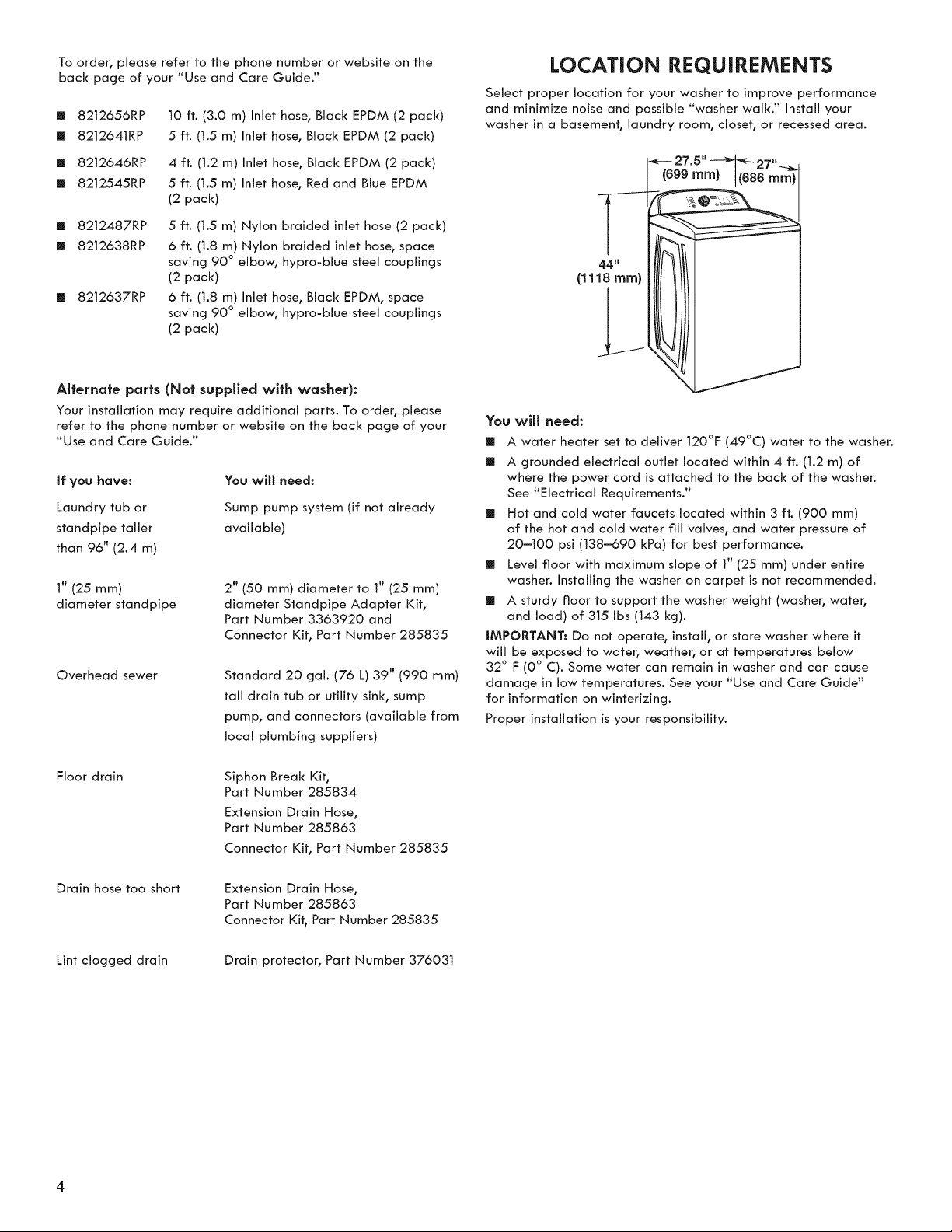

LOCATION REQUIREMENTS

Select proper location for your washer to improve performance

and minimize noise and possible "washer walk." Install your

washer in a basement, laundry room, closet, or recessed area.

You wilN need:

[] A water heater set to deliver 120°F (49°C) water to the washer.

[] A grounded electrical outlet located within 4 ft. (1.2 m) of

where the power cord is attached to the back of the washer.

See "Electrical Requirements."

[] Hot and cold water faucets located within 3 ft. (900 ram)

of the hot and cold water fill valves, and water pressure of

20-100 psi (138-690 kPa) for best performance.

[] Level floor with maximum slope of 1" (25 mm) under entire

washer. Installing the washer on carpet is not recommended.

[] A sturdy floor to support the washer weight (washer, water,

and load) of 315 Ibs (143 kg).

iMPORTANT: Do not operate, install, or store washer where it

will be exposed to water, weather, or at temperatures below

32 ° F (0 ° C). Some water can remain in washer and can cause

damage in low temperatures. See your "Use and Care Guide"

for information on winterizing.

Proper installation is your responsibility.

Floor drain

Drain hose too short

Lint dogged drain Drain protector, Part Number 376031

Siphon Break Kit,

Part Number 285834

Extension Drain Hose,

Part Number 285863

Connector Kit, Part Number 285835

Extension Drain Hose,

Part Number 285863

Connector Kit, Part Number 285835

4

Page 5

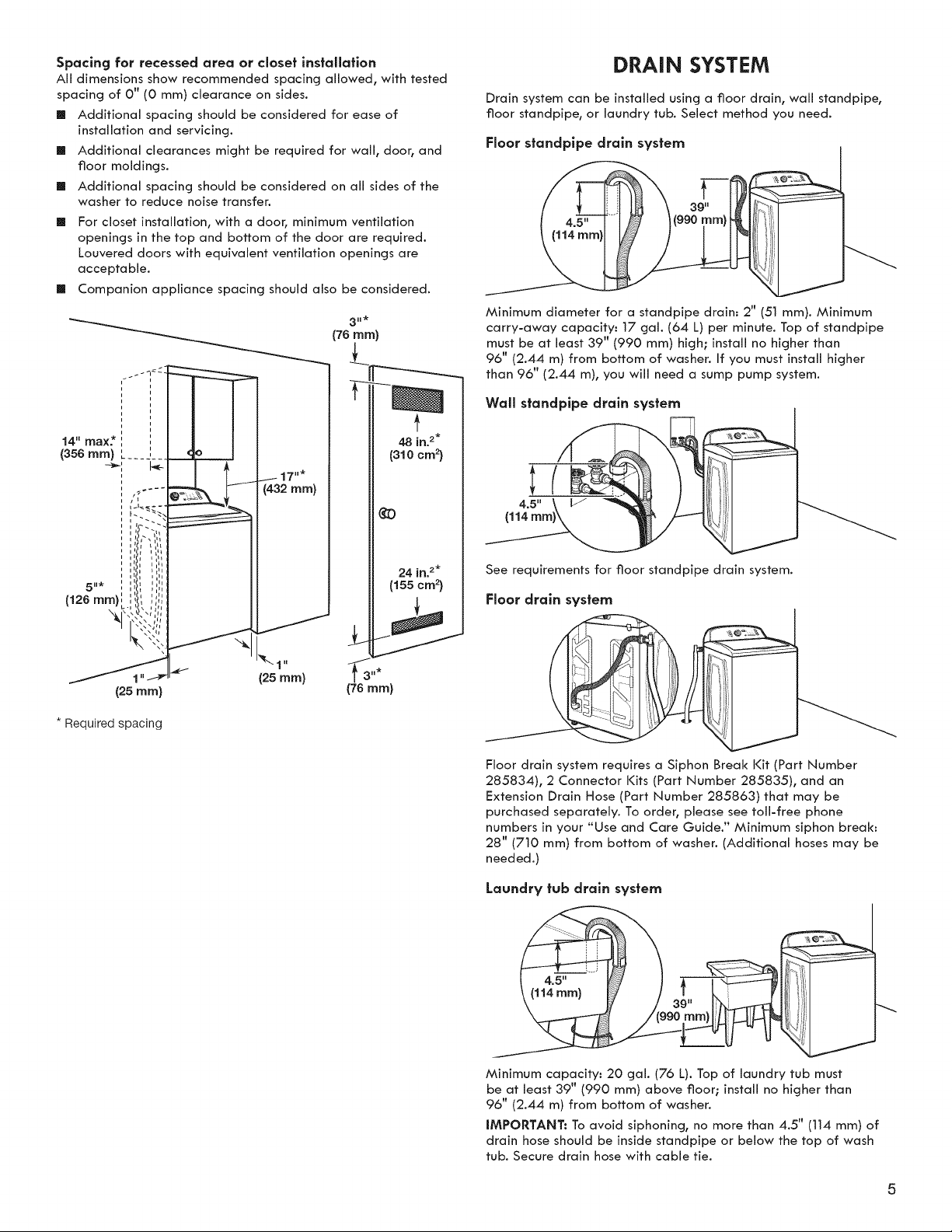

Spacing for recessed area or closet installation

All dimensions show recommended spacing allowed, with tested

spacing of 0" (0 mm) clearance on sides.

[] Additional spacing should be considered for ease of

installation and servicing.

[] Additional clearances might be required for waii, door, and

floor moldings.

[] Additional spacing should be considered on all sides of the

washer to reduce noise transfer.

[] For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

[] Companion appliance spacing should also be considered.

3ran

(76 ram)

n I

I n

I I

n I

I i

I

I I

i

i

14=.max.* ::

(356 turn)

-_ I<-

17"*

48 in.2.

(310 cm 2)

(432 mm)

DRAIN SYSTEM

Drain system can be installed using a floor drain, wall standpipe,

floor standpipe, or laundry tub. Select method you need.

Floor standpipe drain system

Minimum diameter for a standpipe drain.. 2" (51 mm). Minimum

carry-away capacity: 17 gal. (64 L) per minute. Top of standpipe

must be at least 39" (990 ram) high; install no higher than

96" (2.44 m) from bottom of washer. If you must install higher

than 96" (2.44 m), you will need a sump pump system.

Wall standpipe drain system

5"* ::::

(126 m , ,,,,

i

i , \t jh

_\jh

(25 ram)

* Required spacing

(25 ram)

(76 ram)

24 in.2.

(15scm_)

See requirements for floor standpipe drain system.

Floor drain system

Floor drain system requires a Siphon Break Kit (Part Number

285834), 2 Connector Kits (Part Number 285835), and an

Extension Drain Hose (Part Number 285863) that may be

purchased separately. To order, please see toil-free phone

numbers in your "Use and Care Guide." Minimum siphon break:

28" (7]0 mm) from bottom of washer. (Additional hoses may be

needed.)

Laundry tub drain system

Minimum capacity; 20 gal. (76 L). Top of laundry tub must

be at least 39" (990 ram) above floor; install no higher than

96" (2.44 m) from bottom of washer.

IMPORTANT: To avoid siphoning, no more than 4.5" (114 mm) of

drain hose should be inside standpipe or below the top of wash

tub. Secure drain hose with cable tie.

Page 6

ELECTRICAL REQUIREMENTS

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

[] A 120 volt, 60 Hz., AC only, 15- or 20-amp, fused electrical

supply is required. A time-delay fuse or circuit breaker on a

separate circuit serving only this washer is recommended.

[] This washer is equipped with a power supply cord having a

3-prong grounding plug.

[] To minimize possible shock hazard, the cord must be plugged

into a mating, 3-prong, grounding-type outlet, grounded in

accordance with local codes and ordinances. If a mating outlet

is not available, it is the personal responsibility and obligation

of the customer to have the properly grounded outlet installed

by a qualified electrician.

[] If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

[] Do not ground to a gas pipe.

[] Check with a qualified electrician if you are not sure the

washer is properly grounded.

[] Do not have a fuse in the neutral or ground circuit.

GROUNDING iNSTRUCTiONS

For a grounded, cord=connected washer:

This washer must be grounded. In the event of a malfunction

or breakdown, grounding will reduce the risk of electrical

shock by providing a path of least resistance for electric

current. This washer is equipped with a cord having an

equipment-grounding conductor and a grounding plug.

The plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local

codes and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or serviceman if you are

in doubt as to whether the appliance is properly grounded.

Do not modify the plug provided with the appliance - if it will

not fit the outlet, have a proper outlet installed by a qualified

electrician.

For a permanently connected washer:

This washer must be connected to a grounded metal,

permanent wiring system, or an equipment grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead

on the appliance.

6

Page 7

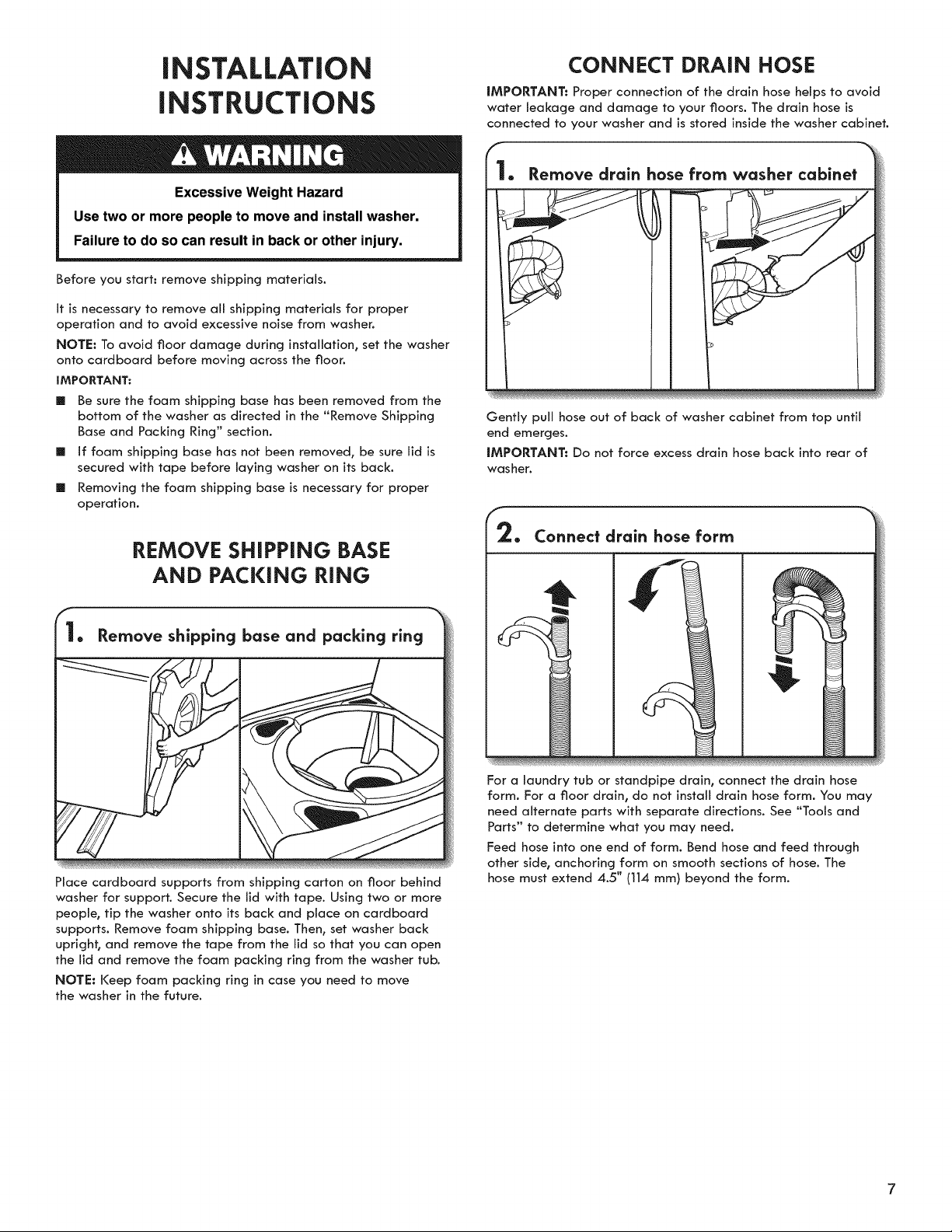

iNSTALLATiON

iNSTRUCTiONS

Excessive Weight Hazard

Use two or more people to move and install washer.

Failure to do so can result in back or other injury.

Before you start: remove shipping materials.

It is necessary to remove all shipping materials for proper

operation and to avoid excessive noise from washer.

NOTE: To avoid floor damage during installation° set the washer

onto cardboard before moving across the floor.

IMPORTANT:

[] Be sure the foam shipping base has been removed from the

bottom of the washer as directed in the "Remove Shipping

Base and Packing Ring" section.

[] If foam shipping base has not been removed, be sure lid is

secured with tape before laying washer on its back.

[] Removing the foam shipping base is necessary for proper

operation.

CONNECT DRAIN HOSE

IMPORTANT: Proper connection of the drain hose helps to avoid

water leakage and damage to your floors. The drain hose is

connected to your washer and is stored inside the washer cabinet.

Remove drain hose from washer cabinet

Gently pull hose out of back of washer cabinet from top until

end emerges.

iMPORTANT: Do not force excess drain hose back into rear of

washer.

REMOVE SHiPPiNG BASE

AND PACKING RiNG

Remove shipping base and packing ring

Place cardboard supports from shipping carton on floor behind

washer for support. Secure the lid with tape. Using two or more

people° tip the washer onto its back and place on cardboard

supports. Remove foam shipping base. Then, set washer back

upright, and remove the tape from the lid so that you can open

the lid and remove the foam packing ring from the washer tub.

NOTE: Keep foam packing ring in case you need to move

the washer in the future.

Connect drain hose form

For a laundry tub or standpipe drain, connect the drain hose

form. For a floor drain, do not install drain hose form. You may

need alternate parts with separate directions. See "Tools and

Parts" to determine what you may need.

Feed hose into one end of form. Bend hose and feed through

other side, anchoring form on smooth sections of hose. The

hose must extend 4.5" (114 mm) beyond the form.

Page 8

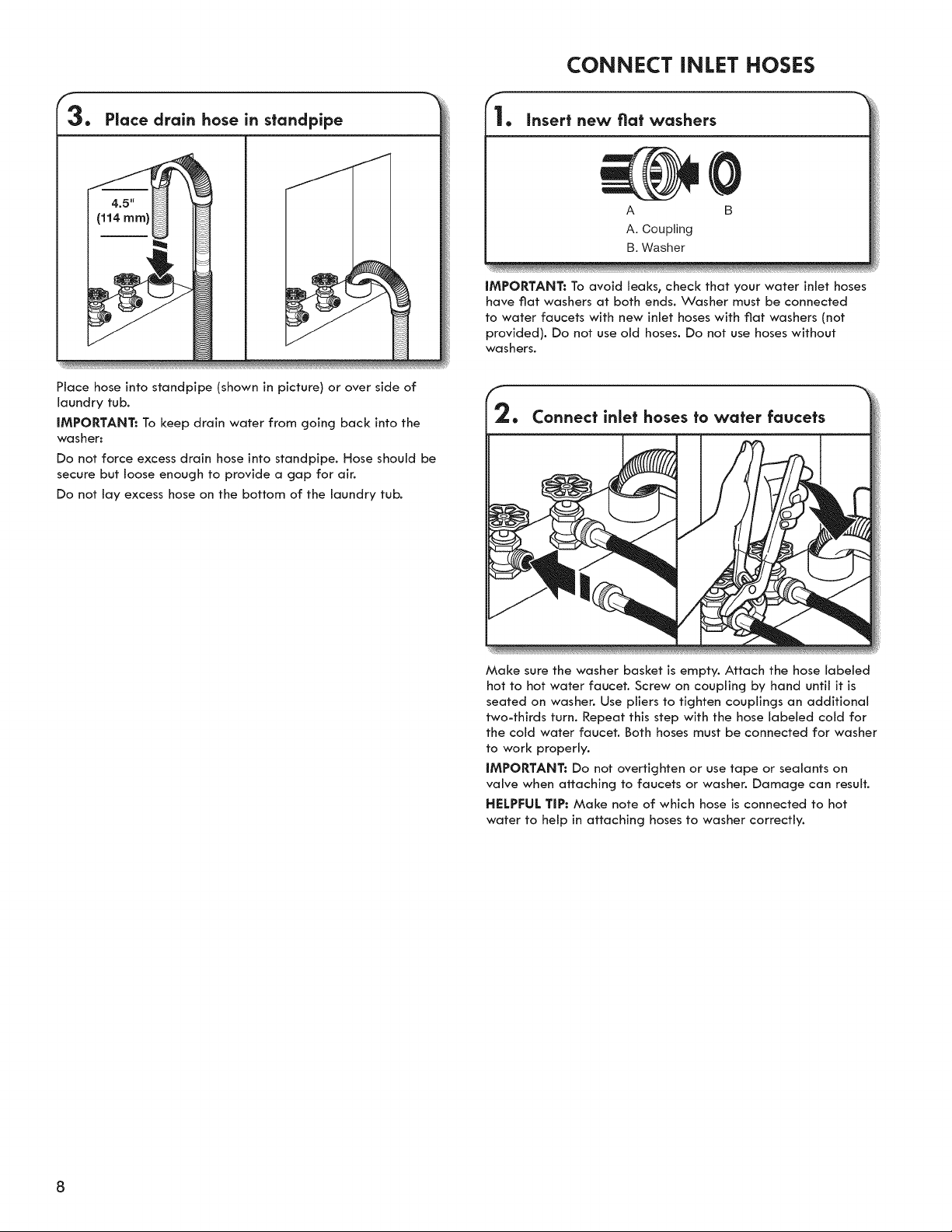

CONNECT iNLET HOSES

Place drain hose in standpipe

Place hose into standpipe (shown in picture) or over side of

laundry tub.

IMPORTANT: To keep drain water from going back into the

washer..

Do not force excess drain hose into standpipe. Hose should be

secure but loose enough to provide a gap for air.

Do not lay excess hose on the bottom of the laundry tub.

insert new nat washers

A

A. Coupling

B. Washer

iMPORTANT: To avoid leaks, check that your water inlet hoses

have fiat washers at both ends. Washer must be connected

to water faucets with new inlet hoses with fiat washers (not

provided). Do not use old hoses. Do not use hoses without

washers.

Connect inlet hoses to water faucets

Make sure the washer basket is empty. Attach the hose labeled

hot to hot water faucet. Screw on coupling by hand until it is

seated on washer. Use pliers to tighten couplings an additional

two-thirds turn. Repeat this step with the hose labeled cold for

the cold water faucet. Both hoses must be connected for washer

to work properly.

iMPORTANT" Do not overfighten or use tape or sealants on

valve when attaching to faucets or washer. Damage can result.

HELPFUL TIP: Make note of which hose is connected to hot

water to help in attaching hoses to washer correctly.

8

Page 9

f

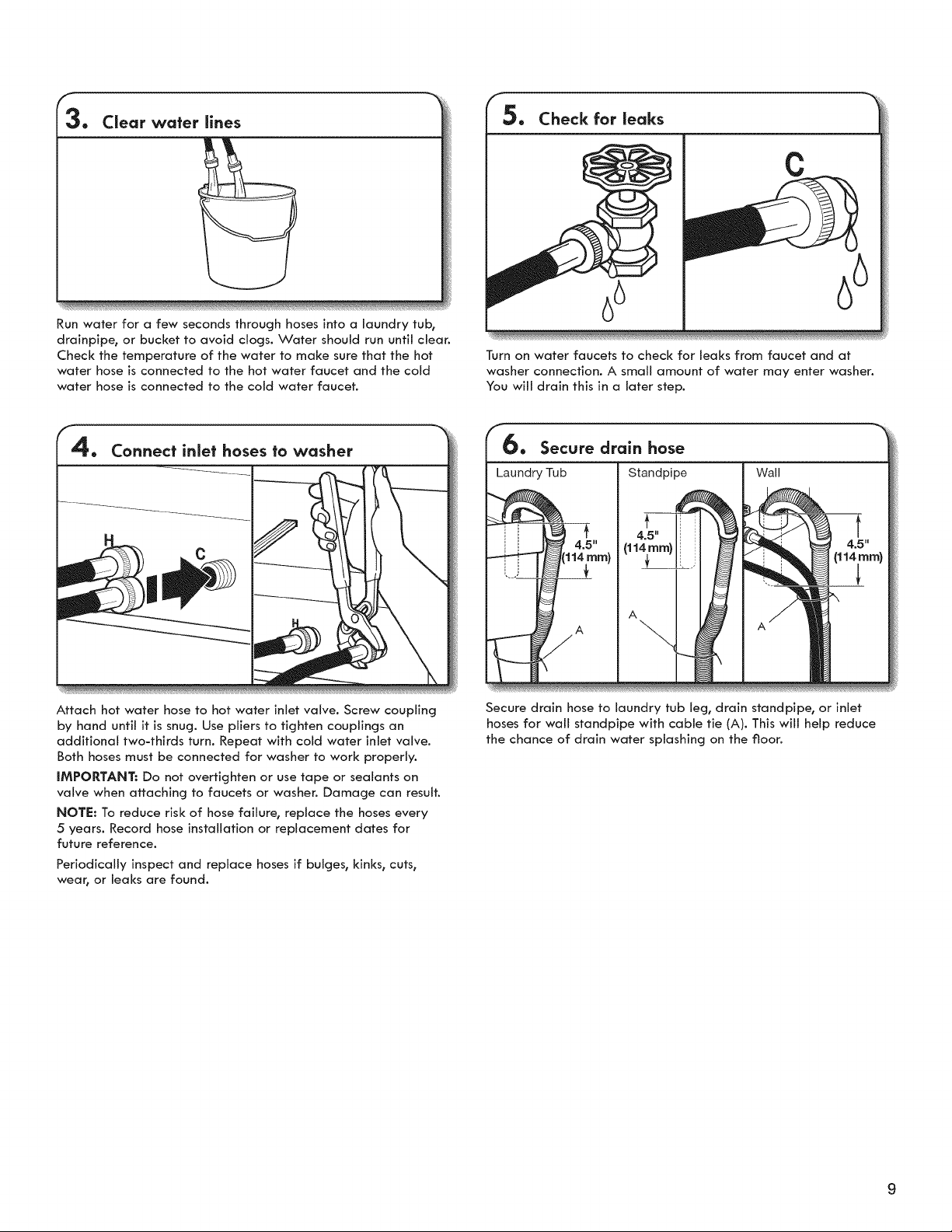

3. Clear water lines

Run water for a few seconds through hoses into a laundry tub,

drainpipe, or bucket to avoid clogs. Water should run until clear.

Check the temperature of the water to make sure that the hot

water hose is connected to the hot water faucet and the cold

water hose is connected to the cold water faucet.

f

4. Connect inlet hoses to washer

Check for leaks

C

Turn on water faucets to check for leaks from faucet and at

washer connection. A small amount of water may enter washer.

You will drain this in a later step.

Secure drain hose

Laundry Tub

Standpipe

Wall

Attach hot water hose to hot water inlet valve. Screw coupling

by hand until it is snug. Use pliers to tighten couplings an

additional two-thirds turn. Repeat with cold water inlet valve.

Both hoses must be connected for washer to work properly.

iMPORTANT: Do not overtighten or use tape or sealants on

valve when attaching to faucets or washer. Damage can result.

NOTE: To reduce risk of hose failure, replace the hoses every

5 years. Record hose installation or replacement dates for

future reference.

Periodically inspect and replace hoses if bulges, kinks, cuts,

wear, or leaks are found.

IE ....

m)

4.5" i

1114rnm)li

A

\

Secure drain hose to laundry tub leg, drain standpipe, or inlet

hoses for wall standpipe with cable tie (A). This wJJJhelp reduce

the chance of drain water splashing on the floor.

Page 10

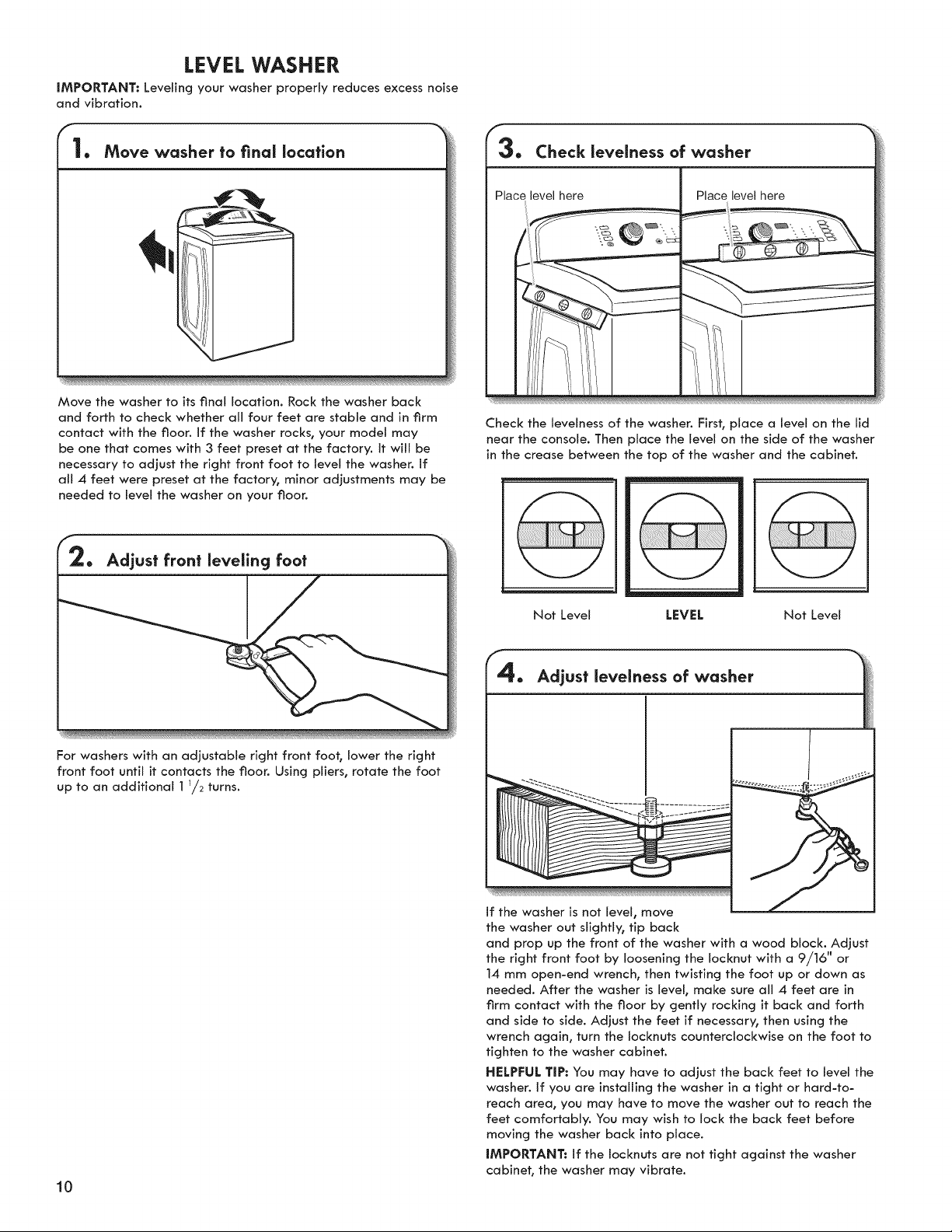

LEVELWASHER

iMPORTANT: Leveling your washer properly reduces excess noise

and vibration.

1. Move washer to final location

Move the washer to its final location. Rock the washer back

and forth to check whether all four feet are stable and in firm

contact with the floor. If the washer rocks, your model may

be one that comes with 3 feet preset at the factory. It wJH be

necessary to adjust the right front foot to level the washer. If

all 4 feet were preset at the factory, minor adjustments may be

needed to level the washer on your floor.

2. Adjust front levelincj foot

Check levelness of washer

Place level here

Check the levelness of the washer. First, place a level on the lid

near the console. Then place the level on the side of the washer

in the crease between the top of the washer and the cabinet.

For washers with an adjustable right front foot, lower the right

front foot until it contacts the floor. Using pliers, rotate the foot

up to an additional 1 ]/2 turns.

10

Not Level LEVEL Not Level

Adjust levelness of washer

If the washer is not level, move

the washer out slightly, tip back

and prop up the front of the washer with a wood block. Adjust

the right front foot by loosening the Iocknut with a 9/16" or

14 mm open-end wrench, then twisting the foot up or down as

needed. After the washer is level, make sure all 4 feet are in

firm contact with the floor by gently rocking it back and forth

and side to side. Adjust the feet if necessary_ then using the

wrench again, turn the Iocknuts counterclockwise on the foot to

tighten to the washer cabinet.

HELPFUL TiP: You may have to adjust the back feet to level the

washer. If you are installing the washer in a tight or hard-to-

reach area, you may have to move the washer out to reach the

feet comfortably. You may wish to lock the back feet before

moving the washer back into place.

IMPORTANT_ If the Iocknuts are not tight against the washer

cabinet, the washer may vibrate.

Page 11

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

5. Plug into a grounded 3 prong outlet

COMPLETE iNSTALLATiON

CHECKLIST

[] Check electrical requirements. Be sure you have correct

electrical supply and recommended grounding method.

See "Electrical Requirements."

[] Check that all parts are now installed, if there is an extra part,

go back through steps to see what was skipped.

[] Check that you have all of your tools.

[] Keep the foam packing ring from the washer tub for future

relocation of the washer. Dispose of/recycle all packaging

materials.

[] Check that both water faucets are on.

[] Check for leaks around faucets and inlet hoses.

[] Remove film from console and any tape remaining

on washer.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

[]

Check that washer is plugged into a grounded 3-prong outlet.

[]

Read "Washer Use" in your "Use and Care Guide."

[]

To test and clean your washer, measure 1/2 of normal

recommended amount of High Efficiency (HE) powdered

or liquid detergent for a medium-size load and pour it into

detergent dispenser. Close lid. Press POWER. Select a normal

cycle and press START. Allow it to complete

one whole cycle.

11

Page 12

SEGURIDAD DE LA LAVADORA

Su seguridad y la seguridad de los demos es rnuy importante,

Hemos incluido muchos mensajes importantes de seguridad en este manual y en su electrodomestico. Lea y obedezca siempre

todos los mensajes de seguridad.

Este es el simbolo de advertencia de seguridad.

Este simbolo le llama la atenci6n sobre peligros potenciales que pueden ocasionar la muerte o una lesi6n a

usted y a los dem&s.

Todos los mensajes de seguridad iran a continuaci6n del simbolo de advertencia de seguridad y de la palabra

"PELIGRO" o "ADVERTENClA'. Estas palabras significan:

Si no sigue las instrucciones de inmediato, usted puede

morir o sufrir una lesi6n grave.

Si no sigue las instrucciones, usted puede morir o sufrir

una lesi6n grave.

Todos los mensajes de seguridad le dirb,n el peligro potencial, le dir_n c6mo reducir las posibilidades de sufrir una lesi6n y Io que

puede suceder si no se siguen las instrucciones.

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

ADVERTENCIA: Para reducir el riesgo de incendio, choque el6ctdco o lesiones a personas al usar su lavadora, siga las

precauciones b&sicas, incluyendo las siguientes:

[] Lea todas las instrucciones antes de usar la

lavadora.

[] No lave articulos que hayan sido previamente

limpiados, lavados, remojados o humedecidos con

gasolina, solventes para lavar en seco, u otras

sustancias inflamables o explosivas ya que 6stas

emanan vapores que podrian encenderse o causar

una explosi6n.

[] No agregue gasolina, solventes para lavar en seco,

u otras sustancias inflamables o explosivas al agua

de lavado. Estas sustancias emanan vapores que

podrian encenderse o causar una explosi6n.

[] En ciertas condiciones, puede generarse gas

hidr6geno en un sistema de agua caliente que no se

haya usado por dos semanas o un periodo mayor.

EL GAS HIDROGENO ES EXPLOSlVO. Si no se ha

usado el agua caliente durante dicho periodo, antes

de usar la lavadora, abra todos los grifos de agua

caliente y deje que corra el agua por varios minutos.

Esto liberar& todo el gas hidr6geno que se haya

acumulado. Debido a la inflamabilidad de dicho gas,

no fume ni use una llama abierta durante este lapso.

GUARDE ESTAS INSTRUCCIONES

[] No permita que los nidos jueguen encima o dentro de la

lavadora. Es necesario una supervisi6n cuidadosa de los

ni5os toda vez que se use la lavadora cerca de ellos.

[] Antes de poner la lavadora fuera de servicio o desechada,

quitele la puerta o la tapa.

[] No introduzca las manos en la lavadora si el tambor, la

tina, o el agitador estb,n funcionando.

[] No instale ni almacene esta lavadora donde pudiese estar

sometida a la intemperie.

[] No trate de forzar los controles.

[] No repare ni cambie pieza alguna de la lavadora ni intente

realizar tarea alguna de servicio t6cnico, excepto cuando

asi se le indique especificamente en este manual o en

instrucciones de reparaci6n para el usuario publicadas,

que usted entienda y para cuya ejecuci6n cuente con la

habilidad necesaria.

[] Para obtener informaci6n respecto alas instrucciones de

conexi6n a tierra, consulte "Requisitos electricos" en las

instrucciones de instalaci6n.

12

Page 13

REQUISITOS DE

Herramientas y Piezas

ReOna las herramientas y piezas necesarias antes de comenzar la

instaiaci6n.

Herrarnlen|as necesarlas:

INSTALACION

Piezas surnlnlstradas (Iocalizada en la canasta de la lavadara):

Pinzas que se abran a

1%" (39,5 mm)

Llave de tuercas ajustable

o de extremo abierto

de 9/16" (14 mm)

Regia o cinta para medir Nivel

Para hacer un pedido, consulte los nOmeros gratuitos en la

contraportada del "Manual de usa y cuidado'.

[] 8212656RP

[] 8212641RP

[] 8212646RP

[] 8212545RP

[] 8212487RP

[] 8212638RP

[] 8212637RP

Manguera de entrada de 10 pies (3,0 m) de

caucho de etiieno propileno negro (EPDM)

(paquete de 2)

Manguera de entrada de 5 pies (1,5 m) de

caucho de etiieno propileno negro (EPDM)

(paquete de 2)

Manguera de entrada de 4 pies (1,2 m) de

caucho de etiieno propileno negro (EPDM)

(paquete de 2)

Manguera de entrada de 5 pies (1,5 m) de

caucho de etileno propileno rojo y azul (EPDM)

(paquete de 2)

Manguera de entrada de 5 pies (1,5 m) de

nylon trenzado (paquete de 2)

Manguera de entrada de nylon trenzado de

6 pies (1,8 m), coda de 90 ° para ahorrar

espacio, acopiamientos de acero "hypro-blue"

(paquete de 2)

Manguera de entrada de 6 pies (1,8 m) de

caucho de etiieno propileno negro (EPDM), coda

de 90 ° para ahorrar espacio, acopiamientos de

acero "hypro-blue" (paquete de 2)

Linterna (optional)

4" nlin

(102 mm)_.

Bloque de madera

Molde de la manguera

de desagOe

Piezas necesarlas (No se proveen con la lavaclora):

Mangueras de entrada

de agua (2)

Piezas alternatlvas (No se praveen can la lavadara):

Su instalaci6n puede requerir piezas suplementarias. Para hacer

un pedido, consulte los nOmeros gratuitos en la contraportada del

"Manual de usa y cuidado'.

Si tiene: Usted necesitar6:

Tina de iavanderfa

o tuba vertical de

m_s de 96" (2,4 m)

de altura

Tuba vertical de

1" (25 mm) de di_metro

Una alcantarilla

suspendida

DesagOe par el piso

Una manguera de

desagOe corta

DesagOe obstruido

par pelusa

Atadura de cables

Arandeias pianas para

ia manguera de entrada (4)

Sistema de bomba de sumidero

(si no est_ disponible aOn)

Juego de adaptador de tuba vertical

de 2" (51 mm) de di_metro a 1"

(25 mm) de di_metro,

pieza nOmero 3363920

Juego de conectores,

pieza nOmero 285835

Tina de desagOe est_ndar de 20

galones (76 L) 39" (990 mm) de altura

o lavadero utilitario, bomba de

sumidero y conectores (disponible

con proveedores locales)

Interruptor de efecto de sif6n,

pieza n6mero 285834

Juego de extensi6n de desagOe,

pieza nOmero 285863

Juego de conectores,

pieza nOmero 285835

Juego de extensi6n de

pieza nOmero 285863

Juego de conectores,

pieza nOmero 285835

Protector del desagOe,

pieza nOmero 376031

desagOe,

13

Page 14

REQUISITOS DE UBICACI6N

Seleccione una ubicaci6n apropiada para su lavadora, para

realzar el rendimiento y reducir al mfnimo el ruido y la posible

"¢aminata" de la lavadora. Instale su lavadora en un s6tano,

¢uarto para lavar, d6set o un lugar empotrado.

(699 mm_ 1(686 ram)

Usfed neceslfarc_:

[] Un ¢alentador de agua fi]ado en ]20°F (49°C).

[] Un contacto con conexi6n a tierra ubicado a no mc_s de 4 pies

(],2 m) del cable el6ctrico en la parte posterior de la lavadora.

Vea "Requisitos el_ctricos'.

[] Grifos de agua caliente y de agua frfa ubicados a una

distancia de no mc_sde 3 pies (0,9 m) de las vc_lvulas de

Ilenado del agua caliente y frfa en la lavadora y una presi6n

de agua de 20-]00 Ib/pulg 2 (]38--690 kPa) para un meior

rendimiento.

[] Un piso nivelado con un dedive mc_ximo de 1" (25 mm) deba]o

de la lavadora ¢ompleta. No se recomienda la instalaci6n

sobre una alfombra.

[] El piso debe sostener el peso total de la lavadora (con el agua

y la ¢arga) de 315 Ib (143 kg).

IMPORTANTE: No instale, guarde ni utilice la lavadora en donde

estar_ expuesta a la intemperie o en temperaturas por debajo de

32°F (0°C). El agua que queda en la lavadora despu6s del uso

puede causar daSos en temperaturas baias. Vea "Cuidado de la

lavadora" en el "Manual de uso y cuidado', para saber ¢6mo

acondicionada para el invierno.

La instalaci6n ¢orrecta es su responsabilidad.

Insfalaci6n en zona empotrada o en el cl6set

Se recomiendan las siguientes dimensiones de espacio para esta

lavadora. Esta lavadora fue puesta a prueba para la instalaci6n

con un espacio de 0" (0 mm) en ambos lados.

[] Debe considerarse espacio adicional para facilitar la

instalaci6n y el servicio t_cnico.

[] Se podrian necesitar espacios libres adicionales para las

molduras de la pared, de la puerta y del pJso.

[] Se debe considerar agregar espacio adicional en todos los

lados de la lavadora para reducir la transferencia de ruidos.

[] Para la instalaci6n en cl6set, con una puerta, se requieren

aberturas de ventilaci6n minimas en la parte superior e inferior

de la puerta. Se aceptan puertas tipo persiana con aberturas

de ventilaci6n equivalentes.

[] Tambi6n se debe considerar espacio adicional para otro

electrodom_stico que le acompaSe.

3"*

(76 ram)

i

14" ma×.* '

(356 mm} .... , _.

i

t

48 in.2.

(310 cm _}

17"*

(432 mm)

j _h

i i_h

24 in?*

(_sscm_

(126 m , ,,,,

(25 ram)

(25 ram)

Espacio necesario

3ll _

(76 ram)

14

Page 15

SISTEMA DE DESAGOE Si temadede,agUedeti.adelavadero

El sistema de desag0e de la lavadora se puede instalar utilizando

un desag0e de piso, un tubo vertical de pared_ un tubo vertical de

piso o una tina de lavadero. Seleccione el mStodo que necesita.

Sistema de desagUe de tuba vertical de pisa

Di_metro mfnimo para el desag0e de tubo vertical: 2" (51 ram).

Capacidad de desplazamiento mfnima= 17 gal. (64 L) por minuto.

La parte superior del tubo vertical debe estar a 39" (991 ram) de

altura como mfnimo; inst_lela a no m_s de 96" (2,4 m) de la base

de la lavadora. Si la instala a m_s de 96" (2,4 m), necesitar_ un

sistema de bomba de sumidero.

Sisterna de desagUe de tuba vertical de pared

Capacidad mfnima= 20 gal. (76 L). La parte superior de la tina

de lavadero debe estar a 39" (990 mm) del piso como mfnimo;

inst_lela a no m_s de 96" (2,4 m) de la base de la lavadora.

IMPORTANTE: Para evitar el efecto de sif6n, no debe haber

m_s de 4,5" (114 ram) de manguera de desagOe dentro del tubo

vertical o debajo de la parte superior de la tina de lavado.

Siempre ajuste la manguera de desag0e con una atadura de

cables.

REQUISITOS ELECTRICOS

Vea los requisitos para el sistema de desagOe de tubo vertical

de piso.

Sistema de desagUe de pisa

Un sistema de desagOe por el piso requiere de un juego de

desviaci6n de sif6n (pieza nOmero 285834), 2 iuegos de

conectores (pieza nOmero 285835) y extensi6n de manguera de

desag0e (pieza nOmero 285863), la cual puede comprarse por

separado. Para ordenar, sfrvase ¢onsultar los nOmeros gratuitos

en el "Manual de uso y cuidado'. Desviaci6n de sif6n mfnima:

28" (710 mm) de la base de la lavadora. (Se pueden necesitar

mangueras adicionales.)

Peligro de Choque EI6ctrico

Conecte a un contacto de pared de cone×i6n a tierra de

3 terminales.

No quite la terminal de conexi6n a tierra.

No use un adaptador.

No use un cable el6ctrico de extensibn.

No seguir estas instrucciones puede ocasionar

la muerte, incendio o choque el6ctrico.

[] Se necesita un suministro el_ctrico de 120 voltios, 60 hertzios,

CA solamente, de 15 6 20 amperios y protegido con fusible.

Se recomienda un fusible retardador o un cortacircuitos, en

un circuito independiente que preste servicio Onicamente

a este aparato.

[] Esta lavadora viene equipada con un cable el_ctrico dotado

de un enchufe de 3 terminales con conexi6n a tierra.

[] Para reducir al minimo el peligro de posibles choques

el_ctricos, el cable debe ser enchufado en un contacto

apropiado de pared de 3 terminales, conectado a tierra de

acuerdo con los c6digos y normas locales. Si no hay disponible

una salida equivalente, es responsabilidad y obligaci6n

personal del cliente de tener un contacto apropiado con

conexi6n a tierra instalado por un electricista calificado.

[] Si los c6digos Io permiten y se emplea un alambre de

conexi6n a tierra separado, es recomendable que un

electricista calificado determine si la trayectoria de

conexi6n a tierra es adecuada.

[] No conecte a tierra usando una tuberia de gas.

[] Si no est_ seguro de que la conexi6n a tierra de la lavadora

sea la adecuada, verifiquela con un electricista competente.

[] No instale un fusible en el circuito neutral o de tierra.

15

Page 16

INSTRUCCIONES PARA LA CONEXION

A TIERRA

Para una lavadora conectada a tierra con cable

el6ctrico:

Esta lavadora debe conectarse a tierra. En caso de

funcionamiento defectuoso o averia, la conexi6n a tierra

reducir& el riesgo de choque el6ctrico al proporcionar una

via de menor resistencia para la corriente el6ctrica. Esta

lavadora viene equipada con un cable el6ctrico que tiene

un conductor de conexi6n a tierra del equipo y un enchufe

con conexi6n a tierra. El enchufe debe conectarse en un

contacto de pared apropiado que haya sido debidamente

instalado y conectado a tierra de conformidad con todos

los c6digos y ordenanzas locales.

ADVERTENCIA: La conexi6n incorrecta de la terminal

de conexi6n a tierra del equipo puede ocasionar un riesgo

de choque el6ctrico. Consulte con un electricista o t6cnico

en reparaciones calificado si tiene duda alguna en cuanto

a la conexi6n a tierra correcta del electrodom6stico.

No modifique el enchufe provisto con el electrodom6stico.

Si 6ste no encaja en el contacto de pared, pida a un

electricista calificado que le instale un contacto de pared

apropiado.

Para una lavadora con contacto el6ctrico permanente:

Esta lavadora debe estar conectada a un sistema de

cableado de metal permanente, conectado a tierra, o

se debe tender un conducto para la conexi6n a tierra del

equipo con los conductores de circuito y conectado a la

terminal de tierra del equipo o al conductor de suministro

del electrodom6stico.

INSTRUCCIONES DE INSTALACION

Peligro de Peso Excesivo

Use dos o m&s personas para mover e instalar

la lavadora.

No seguir esta instrucci6n puede ocasionar una lesi6n

en la espalda u otro tipo de lesiones.

Antes de comenzar: Quite los materJales de transporte.

Es necesario quitar todos materiales de transporte para

obtener un funcJonamiento adecuado y para evitar ruido

excesJvo de la lavadora.

NOTA: Para evitar daSos en el pJso, coloque la lavadora sobre

un cart6n antes de moverla.

IMPORTANTE:

[] Asegl)rese de que se ha quJtado la base de embalaje de

espuma de la parte inferior de la lavadora como se indica

en la secci6n '"Quite la base y el anJllo de embalaje'.

[] Si no se ha quitado la base de embalaje de espuma, asegOrese

de que la tapa est_ aiustada con cinta adhesiva antes de

colocar la lavadora sobre su parte posterior.

[] Para un funcionamiento adecuado es necesario quitar la base

de embalaje de espuma.

QUITE LA BASE Y ELANILLO

DE EMBALAJE

16

Coloque los soportes de cart6n del embalaje sobre el piso detr_s

de la lavadora para soporte. Asegure la tapa con cinta adhesiva.

Con la ayuda de 2 o m_s personas, incline la lavadora sobre su

parte posterior y col6queia sobre los soportes de cart6n. Quite

la base de embalaje de espuma. A confinuaci6n, coloque la

lavadora nuevamente en posici6n vertical y quite la cinta adhesiva

de la tapa para poder abriria; quite el anillo de embalaje de

espuma de la tina de la lavadora.

NOTA= Conserve el anillo de embalaje de espuma en caso de que

necesite mover la lavadora en el futuro.

Page 17

CONEXION DE LA MANGUERA

DE DESAGUE

IMPORTANTE" Para proteger sus pisos de los da_os ocasionados

pot las fugas de agua, conecte correctamente la manguera de

desag(ie. La manguera de desagiJe est6 conectada a su lavadora

y est6 guardada dentro de la carcasa de la mJsma.

1. Quite la rnanguera de desagUe

de la carcasa de la lavadora

Jale cuidadosamente la manguera fuera de la parte

posterior de la carcasa de la lavadora, desde la parte

de arriba, hasta que salga el extremo.

IMPORTANTE: No fuerce el exceso de la manguera

de desagge nuevamente dentro de ia parte posterior

de la iavadora.

en el tubo vertical

Coloque la manguera dentro del tubo vertical (se muestra

en la ilustraci6n) o sobre el iado de ia tina de lavadero.

IMPORTANTE: Para evitar que el agua de desag0e vuelva

a su iavadora:

No fuerce el exceso de la manguera de desag0e dentro

del tubo vertical. La manguera debe estar asegurada pero

a la vez io suficientemente floja que permita un espacio

para el aire.

No tienda el exceso de la manguera en el fondo de ia tina

del lavadero.

i

Para un desag_ie a travSs de la tJna de lavadero o pot tubo

vertical, conecte el molde de la manguera de desag_ie. Para

un desag_ie pot el piso, no instale el molde de ia manguera

de desag(ie. Puede set que necesite piezas alternativas con

instrucciones pot separado. Vea "Herramientas y piezas" para

determinar io que pueda necesitar.

Haga pasar la manguera dentro de un extremo del molde.

Doble la manguera e ins_rtela a trav_s del otto lado,

asegur6ndola en las secciones lisas de la misma. La manguera

deber6 extenderse 4,5" (114 mm) m6s all6 dei moide.

17

Page 18

CONEXION DE LAS MANGUERAS

DE ENTRADA

I. Inserte nuevas arandelas planas

A B

A. Acoplamiento

B. Arandela

IMPORTANTE: Para evitar los escapes, verifique que las

mangueras de entrada de agua tengan arandelas pianas

en ambos extremos. La lavadora debe estar conectada

a los grifos de agua con mangueras de entrada nuevas y

arandelas planas (no provistas). No use mangueras viejas.

No use las mangueras sin las arandelas.

de entrada a los cjrifos del acjua

3. Despeje las lineas de acjua

Deje correr agua por aigunos segundos por las mangueras, a una

tina de lavadero, tubo de desag0e o cubeta para evitar que se

obstruya. El agua debe cotter hasta que salga limpia. Verifique

la temperatura del agua para asegurarse de que la manguera de

agua caliente est_ conectada al grifo de agua caliente y que la

manguera de agua fda est8 conectada al grifo de agua fda.

f

4. Conecte las mangueras

de entrada a la lavadora

AsegOrese de que la canasta de la lavadora est_ vacfa. Conecte

la manguera con la etiqueta "hot" (caiiente) al grifo de agua

caiiente. Atornille el acopiamiento con la mano hasta que

se asiente en la arandela. Apriete los acoplamientos con los

aiicates, gir6ndoios dos tercios de vuelta adicional. Repita este

paso con la manguera marcada con la etiqueta "cold" (if[a)

para el grifo de agua fr[a. Deben conectarse ambas mangueras

para que la lavadora funcione correctamente.

iMPORTANTE: No apriete en exceso ni use cinta o selladores en

la v6ivula cuando la sujete a los grifos o a la lavadora. Puede

resultar en daSos.

CONSEJO 0TiL: Tome nota de cu6l de las mangueras est6

conectada ai agua caliente, para ayudar a conectar las

mangueras a la iavadora correctamente.

Sujete la manguera de agua caliente a la vc]lvula de entrada

del agua caliente. Atornille el acoplamiento a mano hasta que

quede apretado. Use pinzas para apretar los acoplamientos

dos tercios de vuelta adicional. Repffalo con la v_lvula de

entrada del agua frfa. Deben conectarse ambas mangueras

para que ia lavadora funcione correctamente.

IMPORTANTE: No apriete en exceso ni use cinta o selladores

en la vc]lvula cuando la sujete a los grifos o a la lavadora.

Puede resultar en da_os.

BIOTA: Para reducir el riesgo de que las mangueras fallen,

reempk]celas cada 5 a_os. Para consulta en el futuro, anote en

las mangueras ia fecha de instalaci6n o la fecha de reposici6n

de las mismas.

[] Inspeccione peri6dicamente y reempiace las mangueras

si aparecen bultos, torceduras, cortaduras, desgaste o

filtraciones de agua.

18

Page 19

NIVELACION DE LA LAVADORA

IMPORTANTE: El nJveJar adecuadamente su Javadora reduce eJ

ruido y la vibraci6n en exceso.

1. Mueva la lavadora a su ubicaci6n final

Abra los grifos del agua para revisar si hay fugas de agua en el

grifo yen la conexi6n a la lavadora. Una peque_a cantidad de

agua podrfa entrar en ia iavadora. Esta se desaguar6 m6s tarde.

%. Asegure la manguera de desagUe

Tina de lavadero I Tubo vertical I Pared

i n

rim)

Asegure la manguera de desagLie a la pata del lavadero,

al tubo vertical o a las mangueras de entrada para el tubo

vertical de pared, utilizando la atadura de cables (A).

Esto contribuirc] a reducir ia posibiiidad de que se salpique

agua dei desagLie en el piso.

Mueva la lavadora a su ubicaci6n final. Balancee la lavadora

hacia atrd_s y hacia deiante para ver si las cuatro patas est6n

estables y en contacto firme con el piso. Si la lavadora se

balancea, es posibie que su modelo sea uno que viene con

3 patas aiustadas previamente de fc]brica. Set6 necesario

ajustar Ja pata frontal derecha para nivelar Ja lavadora. Si Jas

4 patas fueron aiustadas previamente de f6brica, es posible

que se necesite hacer peque_os aiustes para nivelar la lavadora

en el piso de su casa.

Para las lavadoras con una pata frontal derecha regulable,

baje la pata frontal derecha hasta que haga contacto con

el piso. Con las pinzas, gire la pata hacia arriba I 1/2giro

adicional.

19

Page 20

Coloque el nivel aqui

Verifique el grado de nivelaci6n de la lavadora. Primero

coloque un nivel sobre la tapa cerca de la consola. Despu6s

coloque el nivel al costado de la lavadora, en la plegadura

que est6 entre la parte superior de la lavadora y la carcasa.

No est6 nivelada NIVELADA No est6 nivelada

Si la lavadora no est(_ nivelada,

mu6vala levemente hacia afuera, inclfnela hacia atr_s y

apuntale el frente de la lavadora con un bloque de madera.

Regule la pata frontal derecha aflojando la contratuerca

con una Ilave de boca de 9/16" o 14 mm; despu6s gire

la pata hacia arriba o hacia abajo, segOn sea necesario.

Despu6s de que la lavadora se haya nivelado, asegOrese de

que las cuatro patas est6n estables yen contacto firme con

el piso, balanceando suavemente la lavadora de adelante

hacia atrc_s, de lado a lado y diagonalmente. Regule las

patas si es necesario; luego gire las contratuercas hacJa

la izquierda sobre la pata usando nuevamente la Ilave de

tuercas, para apretarlas a la carcasa de la lavadora.

Tal vez tenga que regular las patas posteriores para nivelar

la lavadora. Si usted va a instalar la lavadora en un _rea

apretada o diffcil de acceder, tal vez necesite mover la

lavadora hacia fuera para poder alcanzar las patas con

comodidad. Tal vez desee trabar las paras posteriores antes

de mover la lavadora nuevamente en su lugar.

Si las contratuercas no estc_n apretadas contra la carcasa de

la lavadora, la misma podrfa vibrar.

2O

Page 21

Peligro de Choque EI6ctrico

Conecte a un contacto de pared de conexi6n a tierra de

3 terminales.

No quite la terminal de conexibn a tierra.

No use un adaptador.

No use un cable ei6ctrico de extensibn.

No seguir estas instrucciones puede ocasionar

la muerte, incendio o choque el6ctrieo.

5. Conecte a un contacto de pared de

conexi6n a tierra de 3 terrninales

COMPLETE

[]

Revise los requisitos el_ctricos. AsegOrese de ¢ontar con la

fuente de electricidad correcta y el m_todo recomendado de

conexJ6n a tJerra. Vea "Requisitos el_ctricos".

[] Verifique que todas las piezas est_n ahora instaladas. Si hay

alguna pieza extra° vuelva a revisar todos los pasos para vet

qu_ se omiti6.

[] Verifique que tenga todas las herramientas.

[] Guarde el anillo de embalaje de espuma que vino en la tJna

de la lavadora para poder cambiar de lugar la lavadora en

el futuro. Desh6gase de todos los materiales de embalaje o

recfclelos.

[] Verifique que los ambos grifos de agua est_n abiertos.

[] Verifique sJ hay fugas alrededor de los grifos y de las

mangueras de entrada.

[] Quite la peifcuia de la consoia y la cinta que quede en la

lavadora.

LA INSTALACION

Peligro de Choque El_ctrico

Conecte a un contacto de pared de conexi6n a tierra de

3 terminales.

No quite la terminal de conexi6n a tierra.

No use un adaptador.

No use un cable el6ctrico de extensi6n.

No seguir estas instrucciones puede ocasionar

la muerte, incendio o choque el6ctrieo.

[]

Revise que la lavadora est_ conectada en un contacto

de 3 terminales con conexi6n a tierra.

[]

Lea _'Uso de la lavadora" en las Manual de uso y cuidado

de la lavadora.

[]

Para probar y IJmpiar su lavadora0 mida de la cantidad

de detergente de alto rendimJento (HE) en polvo o Ifquido

recomendada pot el fabricante para una carga mediana

y vJ_rtalo en el dep6sito de detergente, Cierre la tapa.

Oprima POWER (Encendido). Seleccione un ciclo normal

y oprima START (Puesta en marcha). Deje que la lavadora

fun¢ione durante el ciclo completo.

21

Page 22

SECURITE DE LA LAVEUSE

Votre s_curit_ et celle des autres est tr_s importante.

Nous donnons de nombreux messages de s6curit6 importants dans ce manuel et sur votre appareil m6nager. Assurez-vous de

toujours life tous les messages de s6curit6 et de vous y conformer.

Voici le symbole d'alerte de securite.

Ce symbole d'alerte de s6curit_ vous signale les dangers potentiels de d6c_s et de blessures graves &vous

eta d'autres.

Tousles messages de s_curit6 suivront le symbole d'alerte de s6curit6 et le mot "DANGER" ou

"AVERTISSEMENT". Ces mots signifient :

Risque possible de d_c_s ou de blessure grave si vous ne

suivez pas imm_diatement les instructions.

Risque possible de d_ces ou de blessure grave si vous

ne suivez pas les instructions.

Tous les messages de s_curit6 vous diront quel est le danger potentiel et vous disent comment reduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

IMPORTANTES iNSTRUCTiONS DE SECURITE

AVERTISSEMENT : Pour r6duire les risques d'incendie, de choc electrique ou de blessures Iors de I'utilisation de la

laveuse, suivre les pr6cautions fondamentales dont les suivantes :

[] Lire toutes les instructions avant d'utiliser la laveuse.

[] Ne pas laver des articles qui ont et6 nettoyes ou

laves avec de I'essence ou imbibes d'essence,

solvants de nettoyage & sec, ou autres substances

inflammables ou explosives; ces substances

peuvent emettre des vapeurs susceptibles de

s'enflammer ou d'exploser.

[] Ne pas ajouter d'essence, solvant de nettoyage &

sec ou autre produit inflammable ou explosif dans

I'eau de lavage. Ces substances peuvent emettre

des vapeurs susceptibles de s'enflammer ou

d'exploser.

[] Dans certaines conditions, de I'hydrogene gazeux

peut se former dans un circuit d'eau chaude qui n'a

pas et6 utilise pendant 2 semaines ou plus. LE GAZ

HYDROGENE EST EXPLOSIBLE. Si le circuit d'eau

chaude n'a pas et6 utilise pendant une telle periode,

avant d'utiliser la laveuse, ouvrir tous les robinets

d'eau chaude et laisser I'eau s'ecouler pendant

plusieurs minutes par chaque robinet. Ceci

permettra I'evacuation de I'hydrogene gazeux

accumule. Comme ce gaz est inflammable, ne pas

ruiner ou utiliser une flamme nue au cours de cette

periode.

CONSERVEZ CES iNSTRUCTiONS

[] Ne pas laisser des enfants jouer sur ou & rint6rieur de la

laveuse. Bien surveiller les enfants Iorsque la laveuse est

utilisee & proximite d'enfants.

[] Avant de mettre la laveuse au rebut ou hors de service,

enlever la porte ou le couvercle.

[] Ne pas tenter d'atteindre un article & I'int6rieur de la cuve de

la laveuse Iorsque le tambour, la cuve ou I'agitateur est en

mouvement.

[] Ne pas installer ou remiser cette laveuse & un endroit oQ elle

serait expos6e aux intemp6ries.

[] Ne pas modifier les organes de commande.

[] Ne pas r6parer ou remplacer un composant quelconque de

la laveuse, ni entreprendre une operation de service, si ce

n'est sp6cifiquement recommand6 dans ce manuel ou dans

un manuel d'instructions de reparations destin6 & rutilisateur;

il est alors essentiel que la personne concernee comprenne

ces instructions et soit comp6tente pour les ex6cuter.

[] Pour les instructions de liaison #,la terre, voir "Sp6cifications

electriques" dans les instructions d'installation.

22

Page 23

E×IGENCES

D'INSTALLATION

OUTILLAGE ET PIECES

Rassembler les outils et composants n_cessaires avant

d'entreprendre rinstailation.

OufiHage n_cessalre :

Pince - ouverture iusqu'_

1%" (39,5 ram)

C18 plate ou c18 6 molette

de 9/16" (14 mm)

Lampe de poche

(facuitative)

4" 131it1

(102 rn rn)_

Cale en bois

Pour commander, consulter les numSros d'appel sans frais figurant

sur la couverture arriSre des "Instructions d'utilisation" de la

laveuse.

[] 8212656RP Tuyau d'arrivSe d'eau de 10 pi (3 m), EPDM

noirs (lot de 2)

[] 8212641RP Tuyau d'arrivSe d'eau de 5 pi (1,5 m), EPDM

noirs (lot de 2)

[] 8212646RP Tuyau d'arriv6e d'eau de 4 pi (1,2 m), EPDM

noirs (lot de 2)

[] 8212545RP Tuyau d'arrivSe d'eau de 5 pi (1,5 m), EPDM

rouge et bleu (lot de 2)

[] 8212487RP Tuyau d'arrivSe en nylon tress_ de 5 pi (1,5 m)

(lot de 2)

[] 8212638RP Tuyau d'arrivSe en nylon tress_ de 6 pi (1,8 m),

coude compact de 90 °, raccords hypro-blue

en acier (lot de 2)

[] 8212637RP Tuyau d'arriv6e de 6 pi (1,8 m), EPDM noir,

coude compact de 90 °, raccords hypro-blue

en acier (lot de 2)

Aufres pi_ces : (Non fournies avec la I_veuse)

II se peut que I'installation n6cessite des pisces supplSmentaires.

Pour commander, consulter le numSro de t_16phone sans frais ou le

site Web sur la page arri_re du "Guide d'utilisation et d'entretien".

MStre-ruban ou rSgle Niveau

Pi_ces fournles (darts le partier de la laveuse) :

Bride de retenue pour

tuyau de vidange

Attache-c_ble

Pi_ces n_cessalres (Non fournies avec la laveuse) :

Tuyaux d'admission

d'eau (2)

Rondelles plates pour

tuyau d'arrivSe d'eau (4)

Si VOUS avez :

Evier de buanderie

ou tuyau de reiet

6 rSgout plus

haut que 96" (2,4 m)

Tuyau de rejet

6 1'6gout de 1" (25 mm)

de diam_tre

Egout sur_lev_

Egout au plancher

Un tuyau de vidange

trop court

II vous faudra :

Syst_me de pompe de puisard

(si non d_i6 disponible)

Ensemble pour adaptateur de

2" (50 mm) 6 1" (25 mm) de diamStre

pour tuyau de rejet 6 I'_gout; pour

tuyau de rejet 6 I'_gout, piece

num6ro 3363920 et ensemble

de connexion, piece num6ro 285835

Tuyau rigide d'_vacuation standard

de 20 gal. (76 L) de 39" (990 mm)

de haut ou 6vier de d6charge, pompe

de puisard et connecteurs (disponibles

chez les vendeurs de mat6riel

de plomberie Iocaux)

Ensemble de brise-siphon, piSce

num6ro 285834; Tuyau de vidange

supplSmentaire, piSce num6ro

285863; Ensemble de raccord,

piSce numSro 285835

Tuyau de vidange suppl6mentaire,

piSce num6ro 285863

Ensemble de connection,

pi@ce nurn6ro 285835

SystSme d'6vacuation

obstru6 par de la

charpie

Protecteur de canalisation,

piece num_ro 376031

23

Page 24

EXIGENCES D'EMPLACEMENT

Le choix d'un emplacement appropri6 pour la hveuse en am61iore

le rendement et r6duit au minimum le bruit et le "d_phcement"

possible de la hveuse. La hveuse peut 6tre install6e dans un

sous-sol, une salle de buanderie, un placard ou un encastrement.

44"

(1118 ram)

L

17"*

(432 ram)

II vous foudro :

[] Un chau_e=eau r_gl6 pour fournir de I'eau _ 120°F (49°C)

la laveuse.

[] Une prise electrique reliee (_ la terre situee a 4 pi (1,2 m)

maximum de remplacement de la prise du cordon _lectrJque

se trouvant _ I'arriere de la laveuse. Voir "Specifications

_lectrJques'.

[] Des robinets d'eau chaude et d'eau froide situ6s

3 pi (900 mm) maximum des valves de remplissage

d'eau chaude et d'eau froide, et une pression d'eau de

20-100 Ib-po 2 (138-690 kPa) pour une performance

optimale.

[] Un plancher de niveau avec une pente maximale de

1" (25 mm) sous I'ensemble de la laveuse. L'installafion

de la hveuse sur de la moquette ou un topis n'est pas

recommand6e.

[] Un phncher robuste pour supporter la laveuse avec

un poids total (laveuse, eau et charge) de 315 Ib (143 kg).

IMPORTANT : Ne pas installer, remiser ou fake foncfionner

la laveuse 6 un emplacement oO elle sera expos_e 6 de

I'eau, des intemp6ries ou 6 des temp6ratures inf6rieures

6 32 ° F (0 ° C). Une certaine quanfit6 d'eau peut rester

dans la hveuse et causer des dommages 6 des temp6ratures

basses. Consulter le "Guide d'utilisation et d'entretien" pour

plus d'informations sur rhiv_risation.

C'est 6 I'ufilisateur qu'incombe la responsabilit8 de rSaliser une

installation correcte.

Espocement pour une installation dons un encastrement

ou dons un placard

Toutes les dimensions Jndiquent le d_gagement autorJs_, avec

un dSgagement test8 de 0" (0 ram) de chaque c6t8.

[] PrSvoir davantage d'espace pour faciliter I'installation et

I'entretien.

[] Des espaces suppl6mentaires peuvent 8tre requis pour les

moulures de porte et de plancher et pour les plinthes.

[] Un espace suppl6mentaire doit 8tre envisag6 de tousles c6tSs

de la laveuse afin de rSduire le transfert de bruit.

[] Pour une installation dans un placard avec porte, on dolt

pr6voir des ouvertures minimums d'entrSe d'air en haut et en

bas de la porte. Les portes 6 claire-vole offrant des ouvertures

8quivalentes de passage de I'air sont acceptables.

[] II faut aussi prendre en compte I'espace requis entre

les appareils voisins.

(25 ram)

*Espacement requis

SYSTJ ME DE VIDANGE

Le syst$me de vidange de la laveuse peut 8tre install_ 6 I'aide

d'un conduit d'SvacuatJon au plancher, un tuyau de rejet 6 I'_gout

au plancher ou mural ou un _vier de buanderie. S_lectionner la

mSthode 6 utiliser.

Syst_me de vidange ave(: tuyou de reje_ _ I'_gout

ou ploncher

DiamStre minimal pour un tuyau de rejet 6 1'Sgout : 2" (51 ram).

Capacit8 minimale d'acheminement : 17 gal. (64 L) par minute.

Le sommet du tuyau de rejet 6 I'_gout doit avoJr une hauteur d'au

moins 39" (990 ram); ne pas rinstaller 6 plus de 96" (2,44 m) du fond

de la laveuse. Si on doit Hnstaller 6 plus de 96" (2,44 m) de hauteur,

un syst_me de pompe de puisard est nScessaire.

Voir les exigences pour le syst@rne de vidange avec tuyau de rejet _ l'_gout

au plancher.

24

Page 25

Syst_me de vidange au plancher []

/

Le syst_me de vidange au plancher n_cessite un ensemble

de brise-siphon (piece num_ro 285834), deux ensembles de []

connection (piSce numSro 285835), et un tuyau de vidange

suppl_mentaire (piece num_ro 285863) qui peuvent 6tre achet_s []

s6par6ment. Pour commander, consulter les numSros d'appel sans

frais figurant dans les "Instructions d'utilisation" de la laveuse. []

Dimension minimale pour le brise-siphon ..28" (710 mm) 6 partir

du fond de la laveuse. (Des tuyaux suppl_mentaires peuvent &tre

requis).

Syst_me de vidange dans un _vier de buanderie

Capacit6 minimale : 20 gal. (76 L). Le sommet de I'_vier de

buanderie doit se trouver 6 au moins 39" (990 ram) du plancher;

ne pas I'installer 6 plus de 96" (2,44 m) du fond de la laveuse.

iMPORTANT : Pour 6viter un effet de siphon, ne pas introduire plus

de 4,5" (114 ram) de tuyau de vidange 6 Iqnt&rieur du tuyau de

rejet 6 F_gout ou sous la partie sup_rieure d'_vier de buanderie.

Immobiliser le tuyau de vidange avec un attache-c_ble.

SPECIFICATIONS ELECTRIQUES

Risque de choc 61ectrique

Brancher sur une prise _ 3 alv6oles reli6e & la terre.

Ne pas enlever la broche de liaison & la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un c_ble de rallonge.

Le non-respect de ces instructions peut causer

un d6c_s, un incendie ou un choc 61ectrique.

Pour minimiser les risques de choc 61ectrique, on doit

brancher le cordon sur une prise de courant de configuration

correspondante, 6 3 alv6oles, reli6e 6 la terre et install_e

conformSment aux codes et rSglements Iocaux. Si une prise de

courant de configuration correspondante n'est pas disponible,

le client a la responsabilit6 et Fobligation de faire installer par

un _lectricien qualifi6 une prise de courant correctement reli6e

6 la terre.

[]

Si les codes le permettent et si Fon utilise un conducteur distinct

de liaison 6 la terre, il est recommand_ qu'un 81ectricien

qualifi6 vSrifie la qualit8 de la liaison 6 la terre.

Ne pas utiliser une tuyauterie de gaz pour le raccordement

la terre.

En cas de doute quant 6 la qualit8 de la liaison 6 la terre

de la laveuse, consulter un 81ectricien qualifi&

Ne pas installer un fusible dans le conducteur neutre ou le

circuit de liaison 6 la terre.

iNSTRUCTiONS DE LiAiSON A LA TERRE

Pour une laveuse reli6e & la terre et connect6e par

un cordon :

Cette laveuse dolt 6tre reli6e &la terre. En cas d'anomalie

de fonctionnement ou de panne, la liaison & la terre r6duira

le risque de choc electrique en offrant au courant electrique

un itineraire d'evacuation de moindre r6sistance. Cette

laveuse est alimentee par un cordon 61ectrique comportant

un conducteur reli6 &la terre et une fiche de branchement

munie d'une broche de liaison & la terre. La fiche dolt 6tre

branch6e sur une prise de courant appropriee qui est bien

install6e et reli6e &la terre conformement & tousles codes

et r_glements Iocaux.

AVERTISSEMENT : Le raccordement incorrect de cet

appareil au conducteur de liaison & la terre peut susciter un

risque de choc 61ectrique. En cas de doute quant & la qualit6

de la liaison &la terre de I'appareil, consulter un 61ectricien

ou technicien d'entretien qualifi6.

Ne pas modifier la fiche de branchement fournie avec

I'appareil - si la fiche ne correspond pas & la configuration

de la prise de courant, demander & un electricien qualifi6

d'installer une prise de courant convenable.

Pour une laveuse raccord6e en permanence :

Cette laveuse dolt 6tre raccordee & un systeme de c&blage

permanent en metal relie #,la terre ou un conducteur reli6 &

la terre dolt 6tre en fonction avec les conducteurs de circuit

et raccordes & la borne de liaison & la terre ou la borne sur

I'appareil menager.

[] Une alimentation de 120 volts, 60 Hz, CA seulement, de

15 ou 20 ampSres, protSgSe par un fusible est requise. On

recommande d'utiliser un fusible ou un disjoncteur temporis_

ainsi qu'un circuit distinct pour cette laveuse.

[] Cette laveuse comporte un cordon d'alimentation 81ectrique

6 trois broches pour liaison 6 la terre.

25

Page 26

iNSTRUCTiONS

D'iNSTALLATJON

Risque du poids excessif

Utiliser deux ou plus de personnes pour d6placer et

installer la laveuse.

Le non=respect de cette instruction peut causer une

blessure au dos ou d'autre bJessure,

Avant de commencer : Retirer le materiel d_exp_dition.

II est n6cessaire de retirer tout le materiel d'exp_dJtion pour un

fonctionnement correct et pour _viter que la laveuse ne fasse trop

de bruit.

RI:MARQUI: : Pour 6viter d'endommager Je plancher durant

I'installation0 installer la laveuse sur un carton avant de la

d_piacer sur le sol.

iMPORTANT :

[] V_rifier que la base d'exp_ditJon en mousse a 6t6 retir6e

de la partie inf_rieure de la laveuse tel qu'indiqu_ dans

°'Retrait de la base d_exp_dition et de I'emballage en anneau'.

[] Si la base d_exp_dition en mousse n'a pas 6t_ retir6e0 v6rifier

que le couvercle est bien immobiiis6 avec du ruban adh_sif

avant de faire reposer la laveuse sur sa partie arri6re.

[] Le retrait de la base d_exp6dition en mousse est n6cessaire

au bon fonctionnement de rappareil.

RETRAIT DE LA BASE D'EXPI'-:DITION ET

DE L'EMBALLAGE EN ANNEAU

RACCORDEMENT DU TUYAU

D'EVACUATION

iMPORTANT : Un bon raccordement du tuyau d'6vacuation

permet d'6viter les fuites d'eau et ies dommages au plancher.

Le tuyau de vidange est connect_ 6 la laveuse etest remis6 6

rint6rJeur de Ja caisse de Ja Javeuse.

(_|_=.Lib6rer le tuyau de vidange

de la caisse de la laveuse

Lib6rer le tuyau de vidange de la caisse de la laveuse.

iMPORTANT : Ne pas forcer rexc6dent du tuyau de vidange

dans I'arri6re de la laveuse.

Raccordement de la bride

de retenue pour tuyau de

e

et de I'embaiiage en anneau

Placer des supports de carton de la bo?te d'emballage en

carton sur le sol derri6re la laveuse. Fixer le couvercle avec

du ruban adh6sif. ,_, I'aide de deux personnes ou plus, incliner

la laveuse sur sa pattie arri6re et la placer sur les supports de

carton. Oter la base d'exp6dition en mousse. Remettre ensuite

la laveuse debout et refirer le ruban adh_sif du couvercle de

fason 6 pouvoir ouvrir le couvercle et retirer remballage en

anneau de la cuve de la iaveuse.

REMARQUE : Conserver ranneau de I'emballage en mousse en

cas de d6placement uit6rieur de ia laveuse.

Pour un syst6me d'6vacuafion par r6vier de buanderie ou le

tuyau rigide de rejet 6 i'6gout, fixer le support de fixation pour

tuyau d'_vacuation. Pour un syst6me d'6vacuation au piancher0

ne pas installer le support de fixation pour tuyau d'6vacuation.

Des pi6ces suppi6mentaires avec des directives distinctes seront

peut-_tre n6cessaires. Voir _'Outiis et pi6ces" pour d6terminer

les outils n6cessaires.

Introduire le tuyau d_6vacuation dans rune des extr_mit_s du

support. Replier le tuyau et rintroduire dans I'autre c6t_ en

fixant le support sur les parties IJsses du tuyau. Le tuyau dolt

_tre _tir_ de 4,5" (114 mm) au=del6 du support.

26

Page 27

le tuyau de rejet _ P_gout

Placer le tuyau dans le tuyau de rejet 6 r_gout (illustr_ 6

rimage) ou par-dessus le c&t_ de I'_vier de buanderJe.

IMPORTANT : Pour emp@cher Peau de vidange de refluer

dans la laveuse :

[] Fie pas forcer I'exc_dent du tuyau de vJdange dans le

tuyau rigide de rejet 6 r6gout. Le tuyau doit _tre bien

JmmobJJJs_,tout en permettant Je passage d'air.

[] Ne pas mettre rexc_dent du tuyau de vidange dans le

fond de I'_vier de buanderie.

RACCORDEMENT DES TUYAUX

DE VIDANGE

1. insurer les rondelles plates neuves

A

A. Raccord

B. Rondelle

IMPORTANT : Pour _viter des fuites, v_rifier que les tuyaux

d'arriv_e d'eau ont les rondelles plates aux deux extr_mit_s.

La laveuse dolt _tre raccord6e aux robinets d'eau 6 I'aide des

nouveaux tuyaux d'arriv6e d'eau avec les rondeiles plates (non

fournis). Ne pas utiiiser de tuyaux usag6s. Ne pas utiliser de

tuyaux sans rondelles.

aux robinets

S'assurer que le panier de la laveuse est vide. Fixer le tuyau

dont r_tiquette porte la mention "hot" (chaud) au robinet

d'eau chaude. Visser le raccord 6 la main pour qu'il repose

sur la rondelle. Serrer les raccords de deux tiers de tour

suppl_mentaires 6 I'aide d'une pince. R_p_ter cette _tape avec

le tuyau portant la mention "cold" (froide) pour le robinet d'eau

froide. Les deux tuyaux doivent 8tre raccord_s pour que la

laveuse fonctionne correctement.

IMPORTANT : Ne pas setter excessivement ni utiliser de ruban

adh_sif ou de dispositifs d'_tanch_it_ Iors de la fixation des

robinets ou de la laveuse. Cela pourrait entratner des dommages.

CONSEIL UTILE : Rep_rer quel tuyau est raccord_ 6 I'eau chaude

pour permettre une fixation correcte des tuyaux 6 la laveuse.

27

Page 28

Faire couler de I'eau dans les tuyaux de I'_vier de buanderie,

le tuyau rigide de rejet 6 rSgout ou le seau pendant quelques

secondes pour 8viter toute obstruction° On doit laisser couler

I'eau jusqu'6 ce qu'elle soit limpide. V_rifier la tempSrature de

I'eau pour s'assurer que le tuyau d"eau chaude est connect8 au

robinet d'eau chaude et que le tuyau d'eau ffoide est connect8

au robinet d'eau ffoide,

¢

Ouvrir les deux robinets pour v_rifier rabsence de fuite au

niveau du robinet et du raccordement des rondelles. Une petite

quanfit_ d'eau peut entrer dans la laveuse. Vous effectuerez une

vidange lots d'une _tape ult_rJeure.

Fixer le tuyau d'eau chaude au robinet d'arriv_e d'eau chaude.

VJsser le raccord 6 la main ]usqu'6 ce qu'Jl soit bien serr_. Serrer

les raccords de deux tiers de tour suppl_mentaires 6 I'aide

d'une pince. R_p_ter pour le robinet d'eau froide. Les deux

tuyaux doivent _tre raccord_s pour que la laveuse foncfionne

correctement.

IMPORTANT : Ne pas serrer excessivement ni utilJser de

ruban adh_sif ou de dispositifs d'_tanch$it_ iors de la fixation

des robJnets ou de ia laveuse° Ceia pourrait entra_ner des

dommages.

REMARQUE : Pour r_duire le risque de d_faiHance des

tuyaux, remplacer Jestuyaux tous Jes 5 ans. Inscrire la date

d'installafion ou de remplacement des tuyaux pour r_f_rence

uit_rieure.

[] Jnspecter p_riodJquement Jes tuyaux et ies rempJacer en ¢as

de renfiement s de dSformatJon, de ¢oupure, d'usure ou si une

fuite se manifeste.

Tuyau rigide

A

Fixer le tuyau d'Svacuation au pied de 1'Svier de buanderie0 au

tuyau rigide de rejet 6 I'_gout ou aux tuyaux d'arriv_e d'eau pour

ie tuyau de rejet 6 i'Sgout mural avec I'attache-c_ble (A). Ceci

aidera 6 r_duire ie risque d'Sclaboussement d'eau sur ie plancher0

i Mur de rejet &1'6gout

A

4,5"

28

Page 29

MISE A NIVEAU DE LA LAVEUSE

iMPORTANT : L'_tablissement correct de l'aplomb de la laveuse

permet de r6duJre un niveau sonore et des vibrations excessJfs.

f"_ D_pJacer Ja Javeuse _ son

®

emplacement final

D6placer la iaveuse 6 son emplacement final. Pousser la iaveuse

d'avant en artiste pour v6rifler que Jes quatre pieds sont stabies

et en contact ferme avec le plancher. Si la laveuse bascule, ce

module de laveuse correspond peut-_tre 6 celui qui est livr_

avec 3 pieds pr6r6gJ6s _ i'usine. On dolt alors r_gler le pied

avant droit pour 6tabiir i'aplomb de la iaveuse. Si les 4 pieds

sont pr_r_gi6s _ i'usine, de petits r_giages seront peut-_tre

n6cessaJres pour mettre ia iaveuse d'aplomb sur ie piancher.

Placer le niveau & cet endroit

VSrifier le bon aplomb de la laveuse. Placer d'abord un niveau

sur le couvercle pros de la console. Puis, placer le niveau sur le

c6t_ de la laveuse dans I'espace situ_ entre la partie sup_rieure

de la laveuse et la caJsse.

_. Ajuster les pieds de nivellement avant

Pour las laveuses avec un pied avant droit r_glabie, abaisser

ie pied avant droit jusqu'6 ce qu'il soit en contact avec ie

piancher. ,_,raide d'une pince, faire pivoter ie pied vers ie haut

d'un tour et demi supplSmentaire.

Pas d'aplomb D'APLOMB Pas d'aplomb

2g

Page 30

Si la laveuse n'est pus d'aplomb_ d_placer

I_g_rement la laveuse pour la d_gager_

Iqncliner vers rarri_re et soulever ravant

de la Javeuse avec une cale de bois. R_gler le pied avant en

desserrant I'_crou de bJocage _ J'aide d'une ci_ plate de 9/16"

ou 14 mm puis faire tourner le pied vers le haut ou vers le bus

selon le besoin.

Une lois la laveuse d_apiomb_ s'assurer que les 4 pieds sont en

contact ferme avec le plancher en la faisant doucement pivoter

d'avant en artiste et d'un c6t8 8 rautre. RSgler les pieds de

niveilement si nScessaire puis utiliser _ nouveau la cl_ et tourner

les 8crous de blocage duns le sens antihoraire sur les pieds pour

serrer les pieds contre la cuisse de la laveuse.

CONSEIL UTILE : 11faudra peut-Stre rSgler les pieds arriSre pour

8tablir I_aplomb de la laveuse. Si I_on installe la laveuse duns un

endroit exigu ou difficile d'accSs, il faudra peut=Stre d6gager la

laveuse de rempiacement pour pouvoir avoir pleinement accSs

aux pieds. 11peut 8tre utile de bloquer les pieds artiste avant de

rSinstaller la laveuse duns son emplacement.

iMPORTANT : Si les 8crous de blocage ne sont pus bien serrSs

contre la cuisse de la laveuse_ la laveuse peut vibrer.

Risque de choc 61ectrique

Brancher sur une prise _ 3 alv6oles reii6e & la terre.

Ne pas enlever la broche de liaison _ la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un c_ble de rallonge.

Le non-respect de ces instructions peut causer

un d6c_s, un incendie ou un choc 61ectrique.

Brancher I'appareil sur une prise

3 alv_oles reli_e _ la terre

3O

Page 31

LISTE DE VERiFiCATiON POUR

iNSTALLATiON TERMINEE

[] Consulter les spScifications 81ectriques. S'assurer de disposer

d_une source d'61ectricit6 appropriSe, et d'une liaison 6 la terre

conforme 6 la mSthode recommandSe. Voir "Specifications

_lectriques'.

[] VSrifier que toutes les pisces sont maintenant install_es. S'il

reste une piSce, passer en revue les difl:_rentes 8tapes pour

dScouvrir laquelle aurait 8t8 oubli_e.

[] V_rifier la prSsence de tousles outils.

[] Conserver I'anneau de I'emballage en mousse de la cuve en

cas de rSinstallation ultSrieure de la laveuse, l_:liminer/recycler

tousles matSriaux d'emballage.

[] VSrifier que les robinets d'eau sont tous les deux ouverts.

[] V6rifier qu'il n'y a pas de fuite autour des robinets et des

tuyaux d'arrivSe d'eau.

[] (_)ter la pellicule protectrice de la console et tout ruban

adhSsif rest8 sur la laveuse.

Risque de choc 61ectrique

Brancher sur une prise b 3 aIv6oles reli6e b la terre.

Ne pas enlever la broche de liaison b la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un c_ble de rallonge.

Le non=respect de ces instructions peut causer

un d6cbs, un incendie ou un choc 61ectrique.

[]

VSrifier que la laveuse est branchSe sur une prise de courant

6 3 alvSoles reli_e 6 la terre.

[]

Lire la section "UtiJisation de la laveuse" dans le "Guide

d'utilisation et d'entretien ".

[]

Pour tester et nettoyer votre laveuse, mesurer la moiti_ de

la quantit6 normale recommandSe de d_tergent Haute

Efficacit6 (HE) en poudre ou liquide pour une charge de

taille moyenne et la verser dans le distributeur de dStergent.

Fermer le couvercJe. Appuyer sur POWER (mise sous tension).

S61ectionner un programme normal et appuyer sur START

(mise en marche). Laisser un programme complet s'efl:ectuer.

31

Page 32

Your Home

For troubleshooting, product manuals and expert advice:

managemylife

www.managemylife.com

For repair - in your home - of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner's manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME ® (1-800-469-4663)

Call anytime, day or night (U.S.A. and Canada)

www.sears.com www.sears.ca

Our Home