Kenmore 11026842692, 11026842691, 11026834691, 11026832694, 11026832691 Owner’s Manual

...

Owner's Manual and

Installation Instructions

®

Two-Speed

Speed Control

AUTOMATIC WASHERS

_

g

g

IMPORTANT:

Read and follow all safety

and operating instructions

before first use of this product.

Your washer may look different

from the washer shown.

g

g

H

l

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

PART NO. 3950145 Rev. A PRINTED IN U.S.A.

/

BEFORE USING YOUR NEW WASHER

2

SEARS AUTOMATIC WASHER WARRANTY

IMPORTANT SAFETY INSTRUCTIONS 4

INSTALLATION INSTRUCTIONS

OPERATING YOUR WASHER

LAUNDRY TIPS

CARING FOR YOUR WASHER

TROUBLESHOOTING

SEARS MAINTENANCE AGREEMENT

20

30

32

33

37

3

5

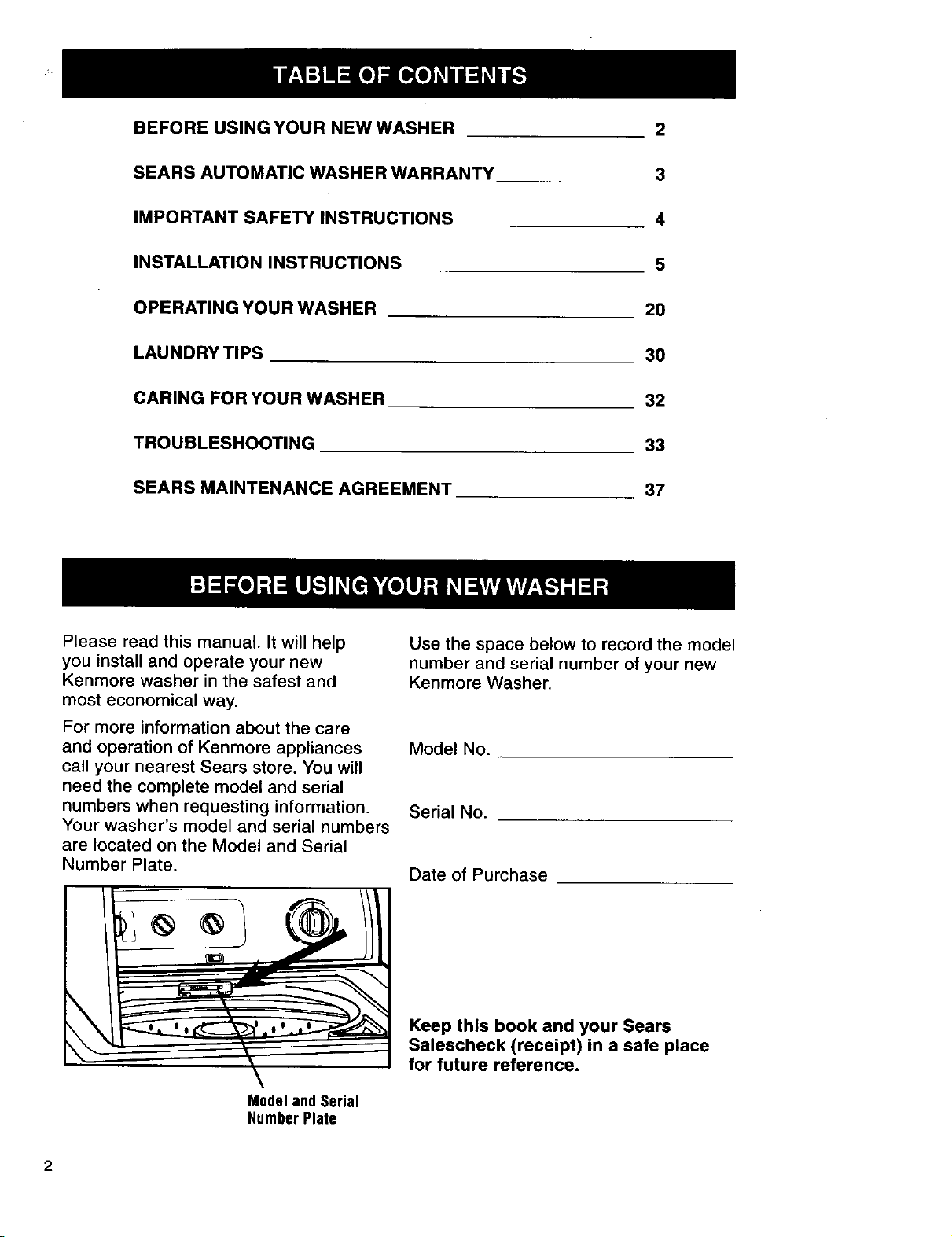

Please read this manual. It will help

you install and operate your new

Kenmore washer in the safest and

most economical way.

For more information about the care

and operation of Kenmore appliances

call your nearest Sears store. You will

need the complete model and serial

numbers when requesting information.

Your washer's model and serial numbers

are located on the Model and Serial

Number Plate.

Model andSerial

NumberPlate

Use the space below to record the model

number and serial number of your new

Kenmore Washer.

Model No.

Serial No.

Date of Purchase

Keep this book and your Sears

Salescheck (receipt) in a safe place

for future reference.

2

FULL 1-YEAR WARRANTY

ON MECHANICAL AND

ELECTRICAL PARTS

For one year from the date of purchase,

when the washer is installed and operated

in accordance with the instructions in

the Owner's Manual, Sears will repair or

replace any mechanical or electrical parts

in this washer, if defective in material or

workmanship.

LIMITED 5-YEAR WARRANTY

ON GEARCASE PARTS

After one year and until five years from

the date of purchase, Sears will furnish

replacement parts for any defective gear-

case parts. You will be charged for labor.

LIMITED 10-YEAR WARRANTY

ON PLASTIC TUB

After one year and until ten years from

date of purchase, Sears will furnish a

replacement plastic tub for any plastic

tub which is defective in material or work-

manship. You will be charged for labor.

If the washer is subjected to other than

private family use, the above warranty

coverage is effective for only 90 days.

WARRANTY SERVICE IS AVAILABLE

BY CONTACTING THE NEAREST

SEARS SERVICE CENTER IN THE

UNITED STATES.

This warranty applies only while this

product is in use in the United States.

This warranty gives you specific legal

rights, and you may also have other

rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA,

Hoffman Estates, IL 60179.

Your safety and the safety of others is very important.

We have provided many important safety messages in this manual

and on your appliance. Always read and obey all safety messages.

This is the safety alert symbol. This symbol alerts

you to hazards that can kill or hurt you and others.

All safety messages will be preceded by the safety

alert symbol and the word "DANGER" or "WARNING:'

These words mean:

You will be killed or seriously

injured if you don't follow

instructions.

You can be killed or seriously

injured if you don't follow

instructions.

All safety messages will identify the hazard, tell you how to reduce the

chance of injury, and tell you what can happen if the instructions are

not followed.

YOUR SAFETY IS IMPORTANTTO US

WARNING: To reduce the risk of fire,

electric shock, or injury to persons

when using your washer, follow basic

precautions, including the following:

• Read all instructions before using

the washer.

• Do not wash articles that have been

previously cleaned in, washed in, soaked

in, or spotted with gasoline, dry-cleaning

solvents, other flammable or explosive

substances as they give off vapors that

could ignite or explode.

• Do not add gasoline, dry-cleaning

solvents, or other flammable or explosive

substances to the wash water. These

substances give off vapors that could

ignite or explode.

• Under certain conditions, hydrogen gas

may be produced in a hot water system

that has not been used for 2 weeks or

more. HYDROGEN GAS IS EXPLOSIVE.

If the hot water system has not been

used for such a period, before using a

washing machine, turn on all hot water

faucets and let the water flow from each

for several minutes. This will release any

accumulated hydrogen gas. As the gas is

flammable, do not smoke or use an open

flame during this time.

• Do not allow children to play on or in

the washer. Close supervision of children

is necessary when the washer is used

near children.

• Before the washer is removed from

service ordiscarded, remove the lid.

• Do not reach into the washer if the tub

or agitator is moving.

• Do not install or store this washer where

it will be exposed to the weather.

• Do not tamper with controls.

• Do not repair or replace any part of the

washer or attempt any servicing unless

specifically recommended in the Owner's

Manual or in published user-repair

instructions that you understand and

have the skills to carry out.

SAVE THESE INSTRUCTIONS

IMPORTANT: Observe all governing codes and ordinances.

4

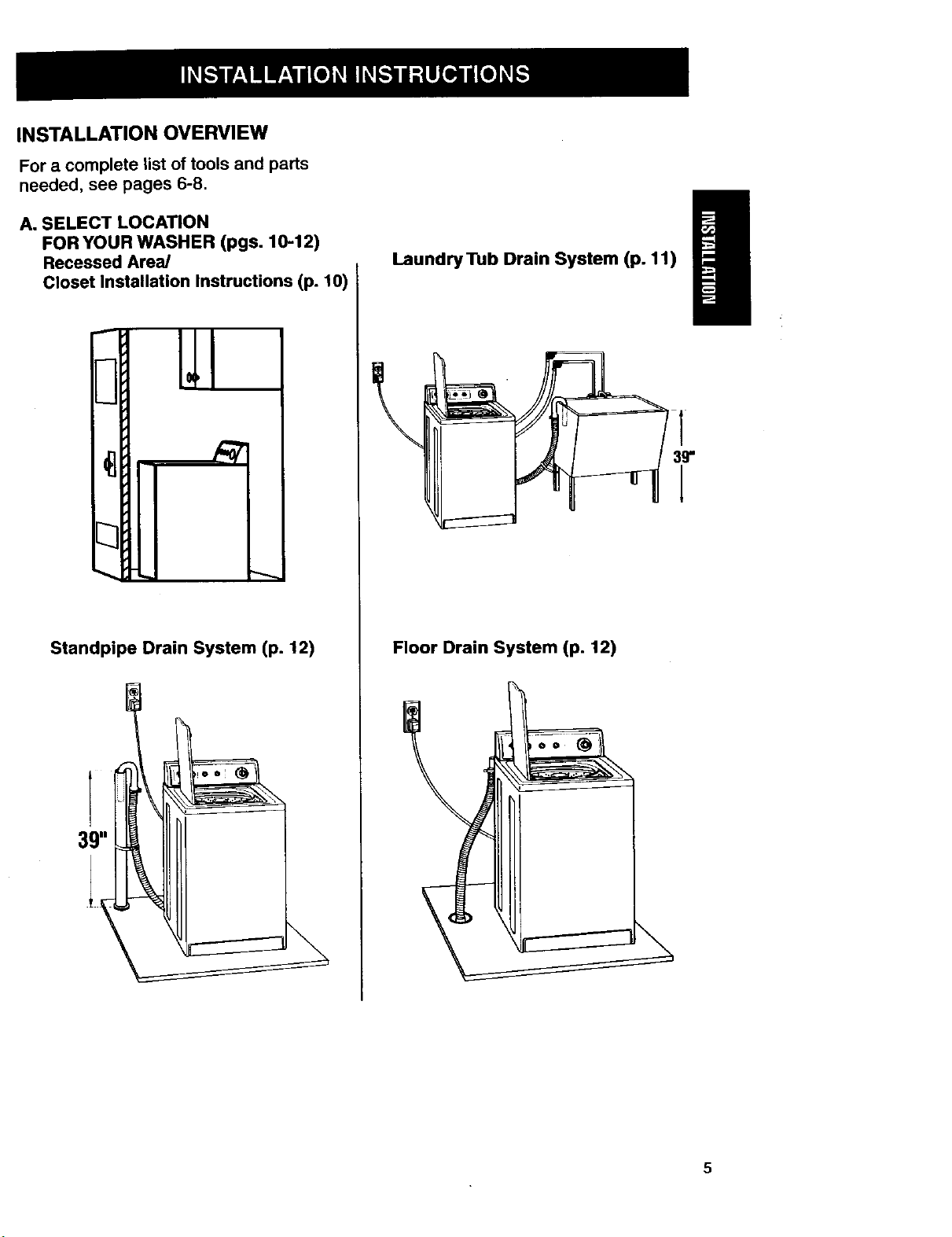

INSTALLATION OVERVIEW

For a complete list of tools and parts

needed, see pages 6-8.

A. SELECT LOCATION

FOR YOUR WASHER (pgs. 10-12)

Recessed Area/

Closet Installation Instructions (p. 10)

LaundryTub Drain System (p, 11)

39"

1

Standpipe Drain System (p. 12)

Floor Drain System (p. 12)

5

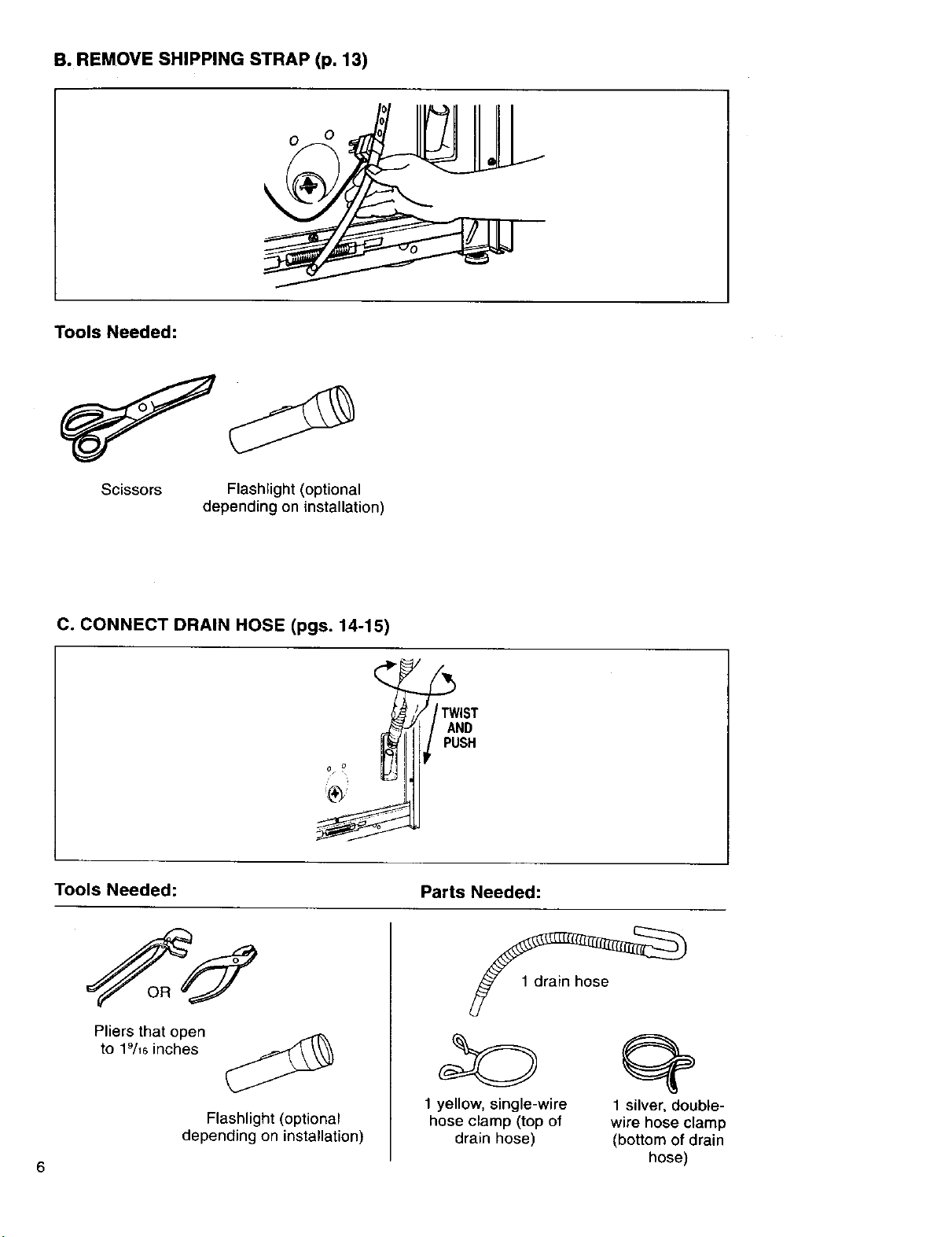

B. REMOVE SHIPPING STRAP (p. 13)

O

Tools Needed:

Scissors Flashlight (optional

depending on installation)

C. CONNECT DRAIN HOSE (pgs. 14-15)

Tools Needed: Parts Needed:

Pliers that open

to 19/_8inches

Flashlight (optional

depending on installation)

1 yellow, single-wire

hose clamp (top of

drain hose)

1 silver, double-

wire hose clamp

(bottom of drain

hose)

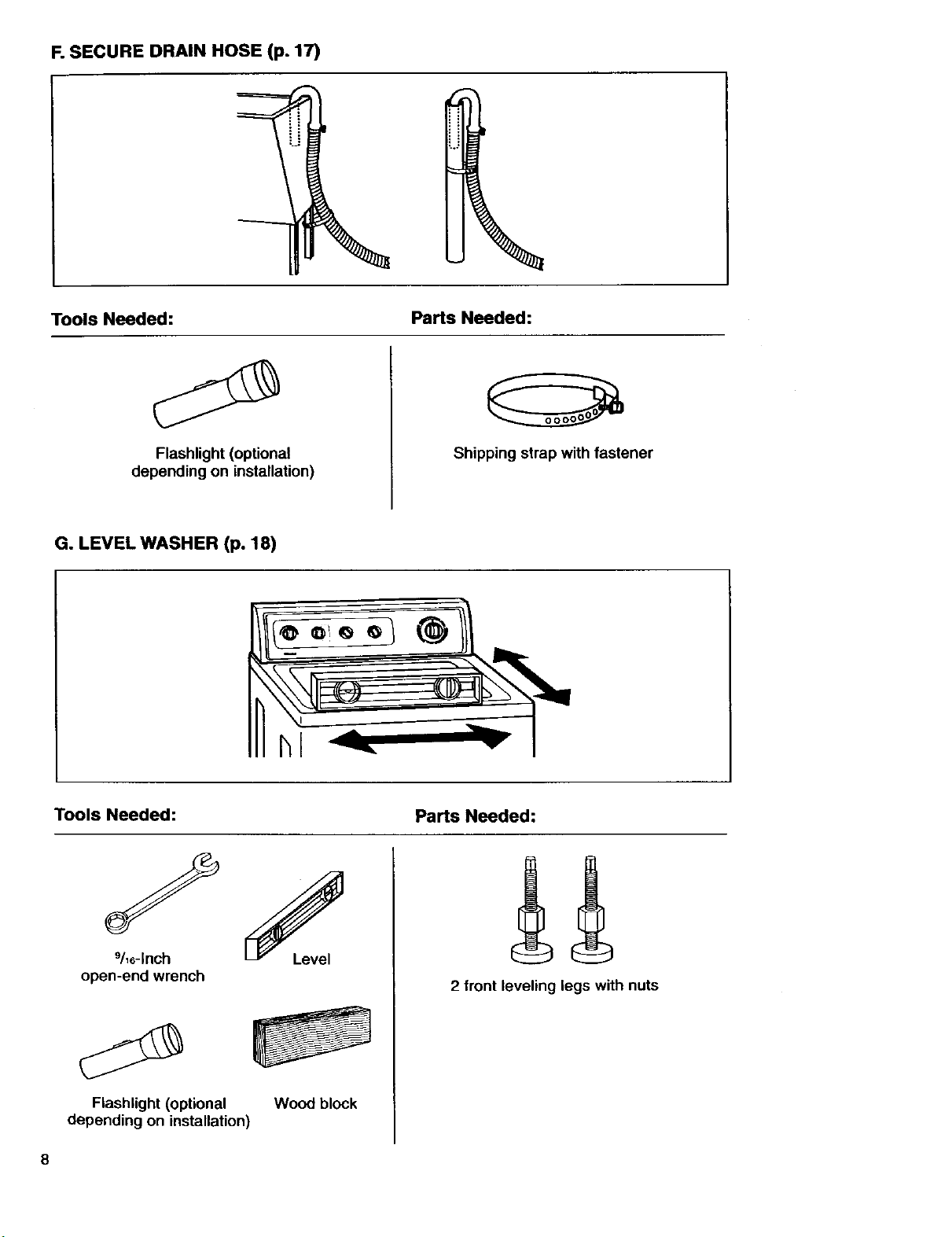

D. CONNECT INLET HOSES TO WASHER (pgs. 15-16)

Tools Needed: Parts Needed:

Pliers that open

to lg/_sinches

hoses

Flashlight (optional

depending on installation)

4 flat water inlet hose washers

E. CONNECT INLET HOSESTO WATER FAUCETS (p. 16)

Tools Needed: Parts Needed:

Pliers that open to 19/_6inches

2 water inlet hoses

depending on

installation)

Flashlight (optional

depending on installation)

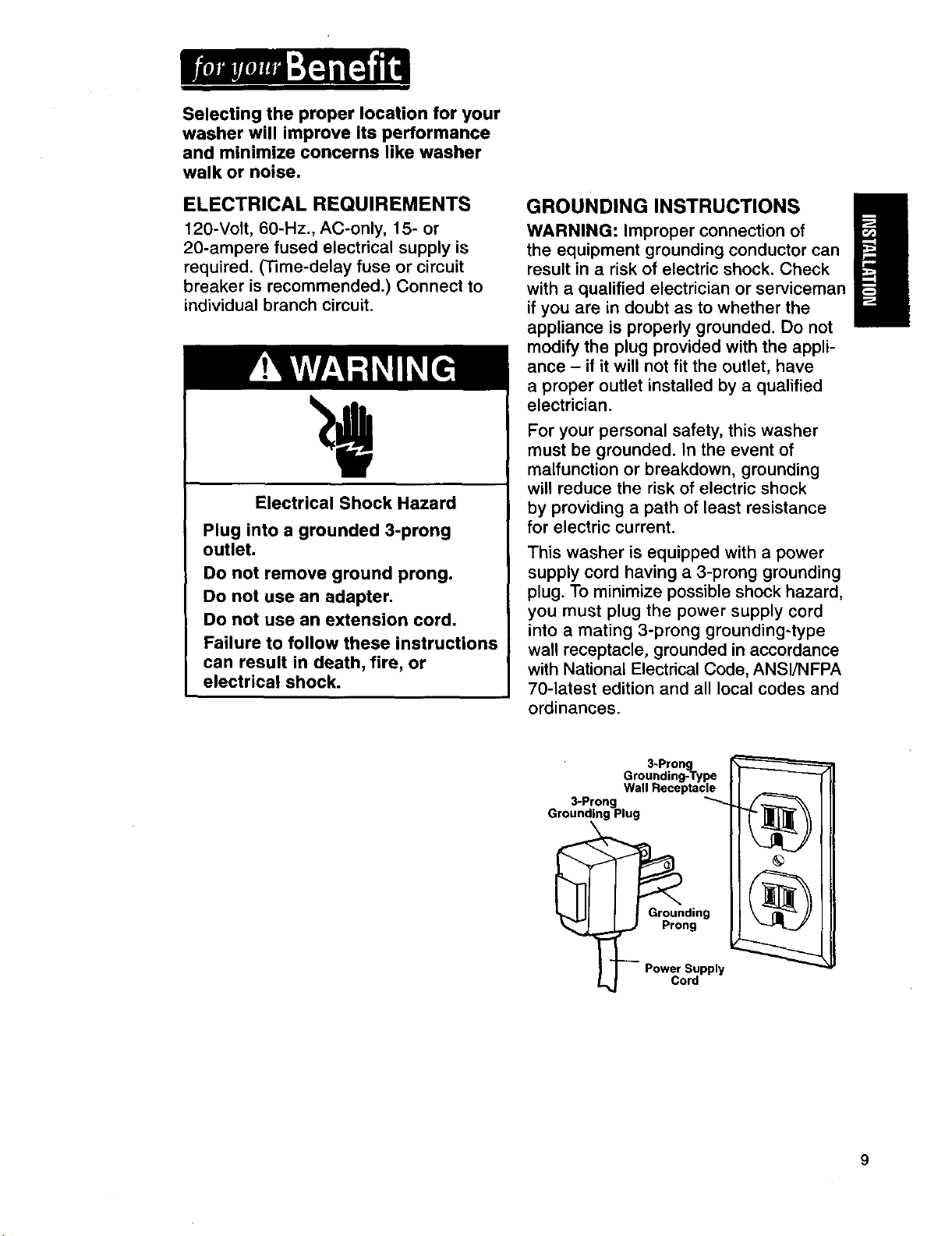

F. SECURE DRAIN HOSE (p. 17)

Tools Needed: Parts Needed:

Flashlight (optional

depending on installation)

G. LEVEL WASHER (p. 18)

Shipping strap with fastener

h

Tools Needed: Parts Needed:

9/_6-1nch

open-end wrench

Flashlight (optional

depending on installation)

2 front leveling legs with nuts

Wood block

Selecting the proper location for your

washer will improve its performance

and minimize concerns like washer

walk or noise.

ELECTRICAL REQUIREMENTS

120-Volt, 60-Hz., AC-only, 15- or

20-ampere fused electrical supply is

required. (Time-delay fuse or circuit

breaker is recommended.) Connect to

individual branch circuit.

Electrical Shock Hazard

Plug into a grounded 3-prong

outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions

can result in death, fire, or

electrical shock.

GROUNDING INSTRUCTIONS

WARNING: Improper connection of

the equipment grounding conductor can

result in a risk of electric shock. Check

with a qualified electrician or serviceman

if you are in doubt as to whether the

appliance is properly grounded. Do not

modify the plug provided with the appli-

ance - if it will not fit the outlet, have

a proper outlet installed by a qualified

electrician.

For your personal safety, this washer

must be grounded. In the event of

malfunction or breakdown, grounding

will reduce the risk of electric shock

by providing a path of least resistance

for electric current.

This washer is equipped with a power

supply cord having a 3-prong grounding

plug. To minimize possible shock hazard,

you must plug the power supply cord

into a mating 3-prong grounding-type

wall receptacle, grounded in accordance

with National Electrical Code, ANSI/NFPA

70-latest edition and all local codes and

ordinances.

m

B

3-Prong

Grounding-Type

Wall Receptacle

3-Prong

Grounding Plug

_o ing

©

ng

Supply

rd

9

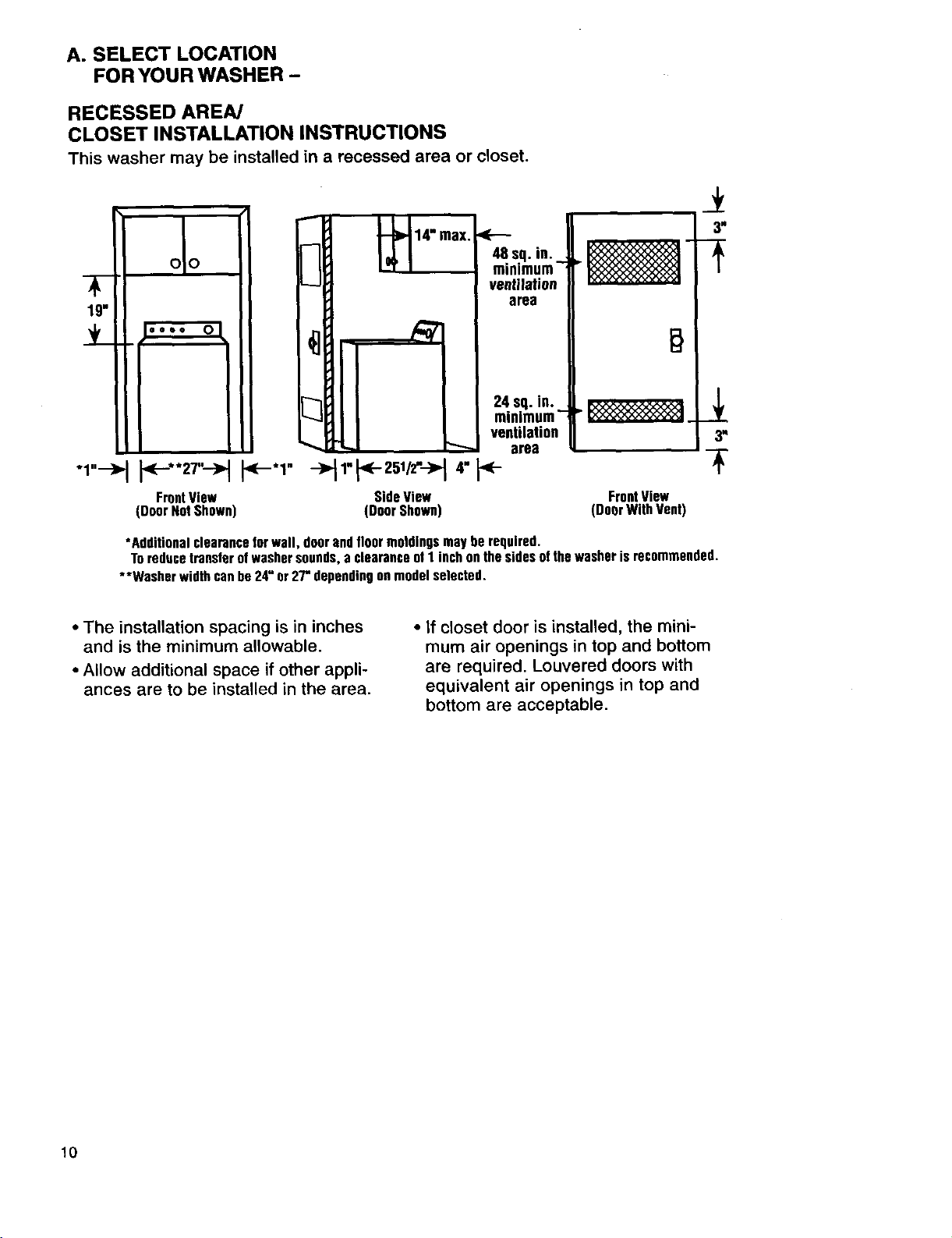

A. SELECT LOCATION

FOR YOUR WASHER -

RECESSED AREA/

CLOSET INSTALLATION INSTRUCTIONS

This washer may be installed in a recessed area or closet.

4('_'1"

FrontView

(Door NotShown)

*Additionalclearanceforwall,doorandfloormoldingsmayherequired.

Toreducetransferofwashersounds,a clearanceolI inchonthesidesofthewasheris recommended.

**Washerwidthcanbe24"or27"dependingonmodelselected.

• The installation spacing is in inches

and is the minimum allowable.

• Allow additional space if other appli-

ances are to be installed in the area.

SideView FrontView

(DoorShown) (DoorWithVent)

• If closet door is installed, the mini-

mum air openings in top and bottom

are required. Louvered doors with

equivalent air openings in top and

bottom are acceptable.

10

LAUNDRY TUB DRAIN SYSTEM

Check location where washer will be

installed. This washer can be installed

using one of three systems:

• Laundry tub drain system (below)

• Standpipe drain system (p. 12)

• Floor drain system (p. 12)

Grounded receptacle: Must

be within 4 feet ofwhere the

power cord is attached tOthe

back of the washer.

Hot and cold water faucets:

Must provide water pressure

between 5-100 psi and be

within 4 feet ofthe hot and

cold water fill valves attached

to the back of the washer.

Do not store or operate washer at or

below 32°F (some water may remain in

washer). See page 32 for Winterizing

Information.

Proper installation is your responsibility.

Make sure you have everything necessary

for correct installation including the

following points:

Laundry tub drain system:

Needs a minimum 20-gallon

laundry tub.

Support: Floor must be sturdy

enough to support a total weight

of 315 pounds (including washer,

water, and load weight).

Level floor: Maximum

allowable slope under entire

washer - 1 inch.

Top of tub must be at

least 39 inches above

floor and no higher

than 96 inches from

bottom of washer.

11

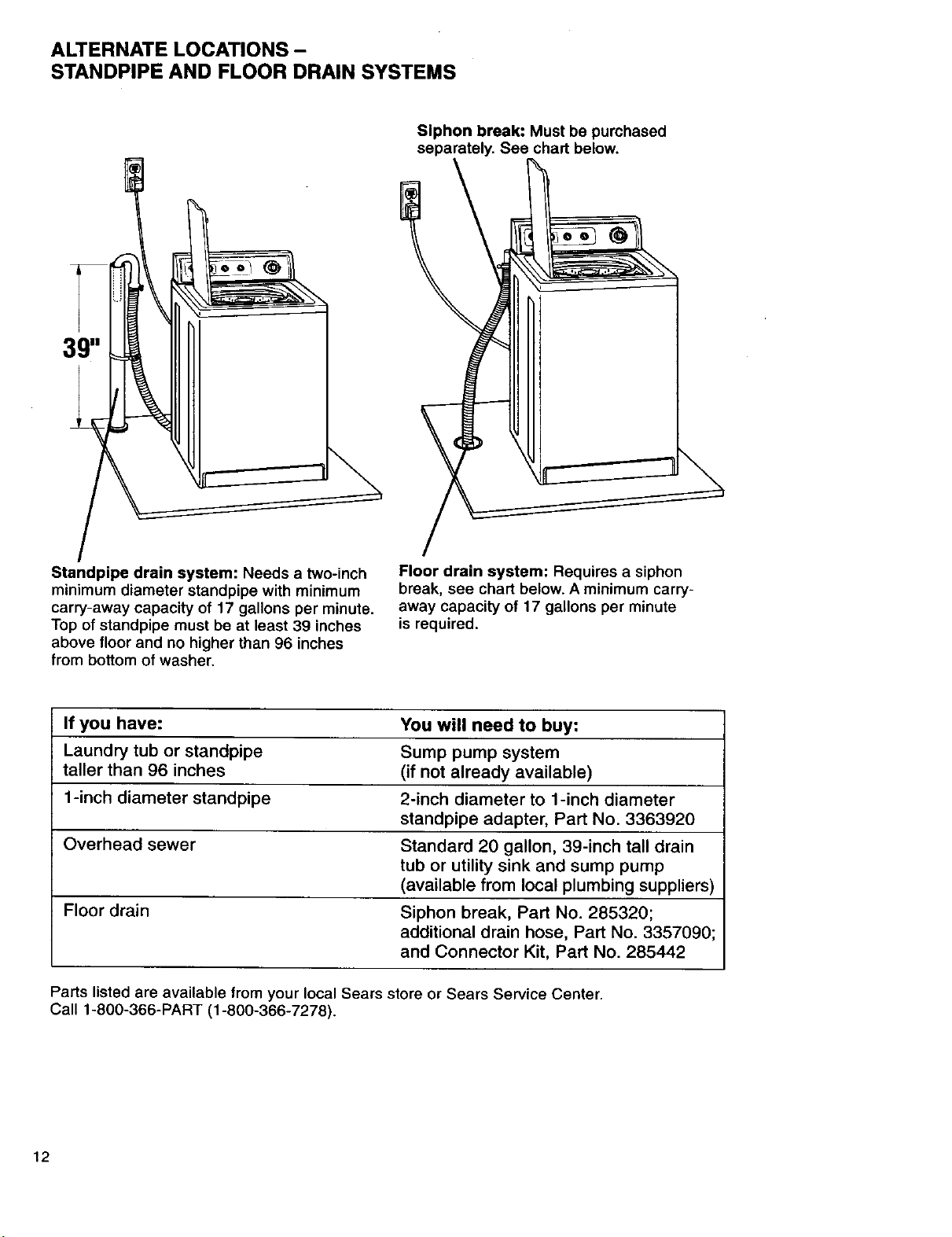

ALTERNATE LOCATIONS -

STANDPIPE AND FLOOR DRAIN SYSTEMS

Siphon break: Must be purchased

separately. See chart below.

Standpipe drain system: Needs a two-inch

minimum diameter standpipe with minimum

carry-away capacity of 17 gallons per minute.

Top of standpipe must be at least 39 inches

above floor and no higher than 96 inches

from bottom of washer.

If you have: You will need to buy:

Laundry tub or standpipe Sump pump system

taller than 96 inches (if not already available)

1-inch diameter standpipe 2-inch diameter to 1-inch diameter

Overhead sewer Standard 20 gallon, 39-inch tall drain

Floor drain Siphon break, Part No. 285320;

Parts listed are available from your local Sears store or Sears Service Center.

Call 1-800-366-PART (1-800-366-7278).

Floor drain system: Requires a siphon

break, see chart below. A minimum carry-

away capacity of 17 gallons per minute

is required.

standpipe adapter, Part No. 3363920

tub or utility sink and sump pump

(available from local plumbing suppliers)

additional drain hose, Part No. 3357090

and Connector Kit, Part No. 285442

12

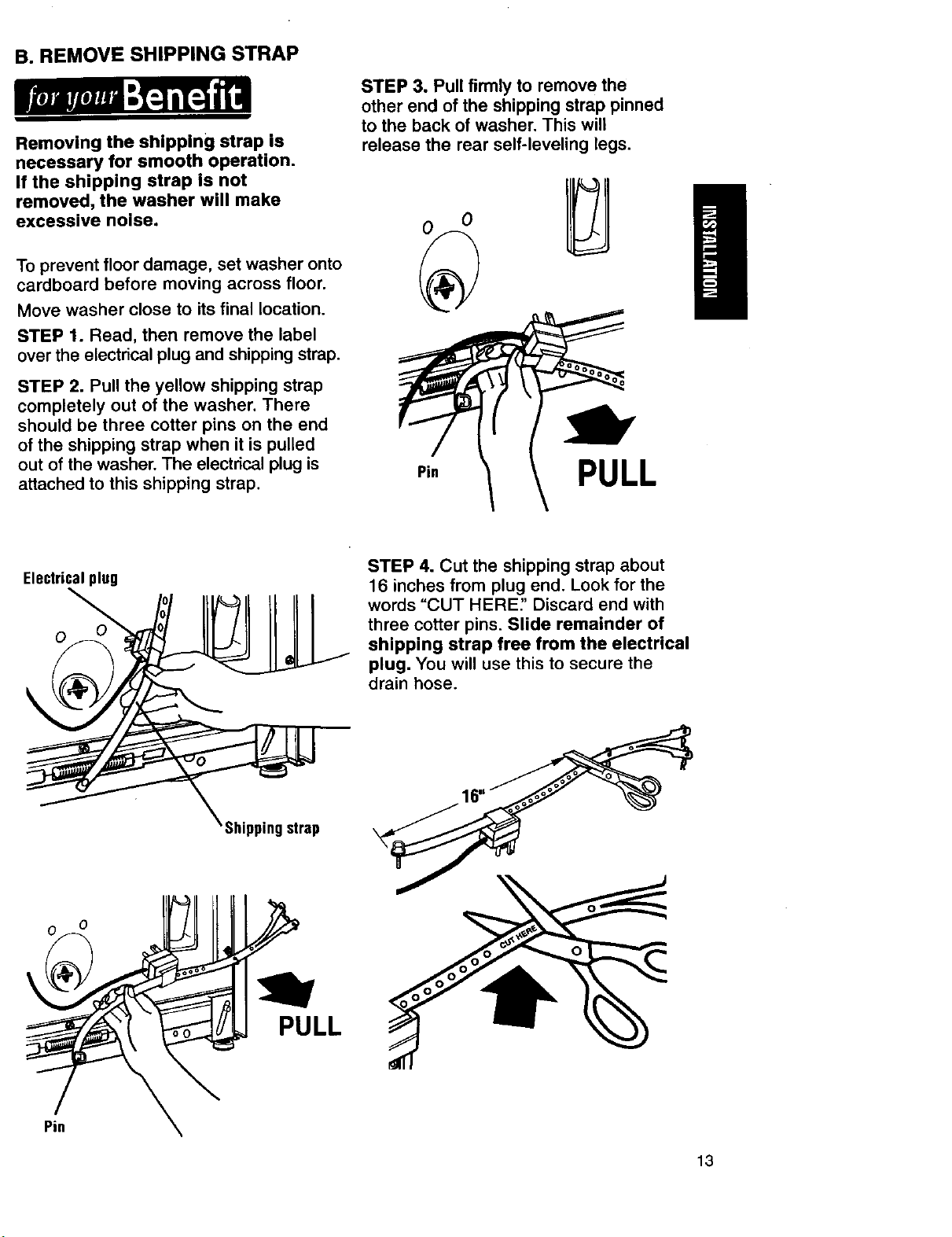

B. REMOVE SHIPPING STRAP

Removing the shipping strap is

necessary for smooth operation.

If the shipping strap is not

removed, the washer will make

excessive noise.

To prevent floor damage, set washer onto

cardboard before moving across floor.

Move washer close to its final location.

STEP 1. Read, then remove the label

over the electrical plug and shipping strap.

STEP 2. Pull the yellow shipping strap

completely out of the washer. There

should be three cotter pins on the end

of the shipping strap when it is pulled

out of the washer. The electrical plug is

attached to this shipping strap.

STEP 3. Pull firmly to remove the

other end of the shipping strap pinned

to the back of washer. This will

release the rear self-leveling legs.

.in PULL

Electricalplug

o

o

STEP 4. Cut the shipping strap about

16 inches from plug end. Look for the

words "CUT HERE" Discard end with

three cotter pins. Slide remainder of

shipping strap free from the electrical

plug. You will use this to secure the

drain hose.

Shippingstrap

Pin

PULL

13

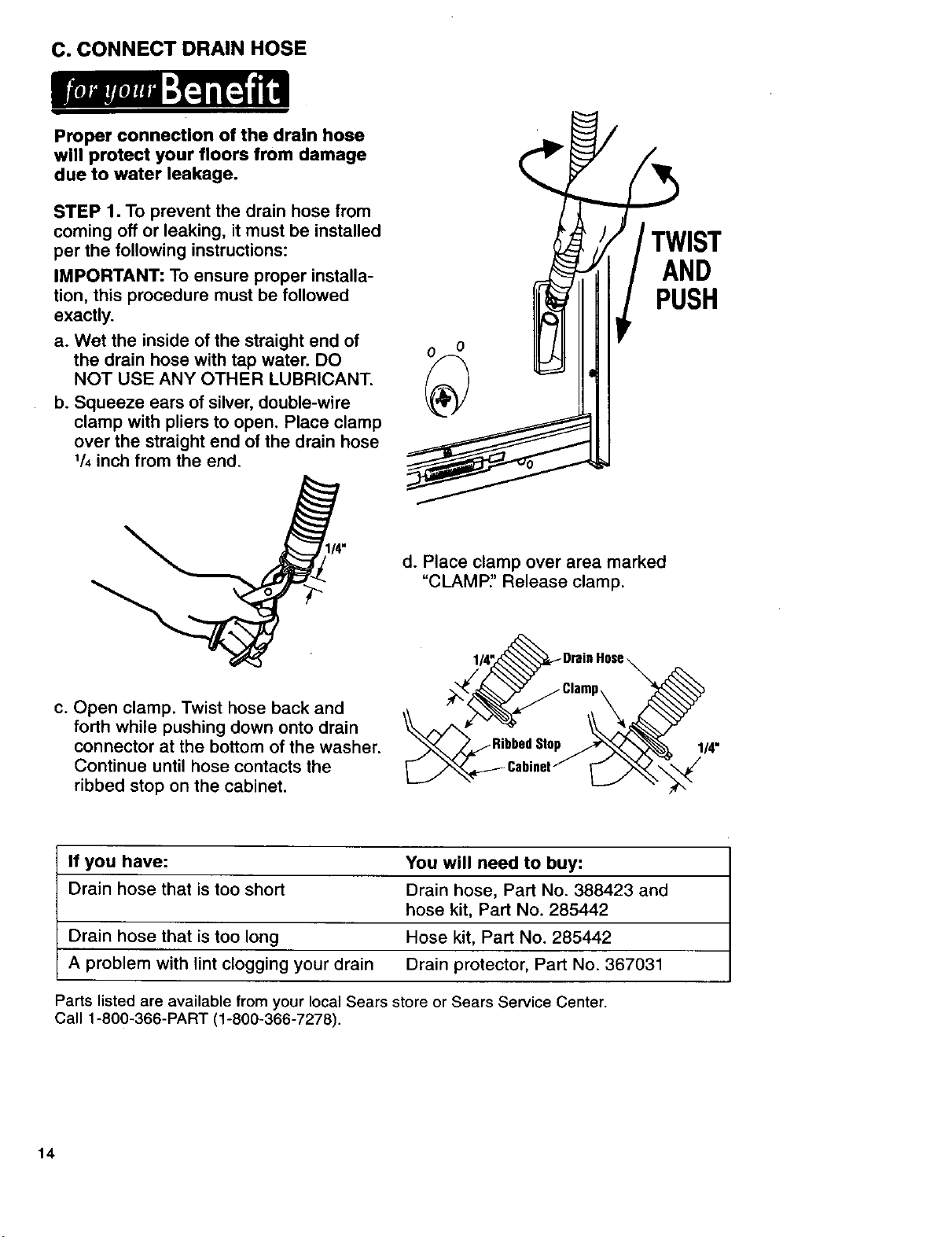

C. CONNECTDRAINHOSE

Proper connection of the drain hose

will protect your floors from damage

due to water leakage.

STEP 1. To prevent the drain hose from

coming off or leaking, it must be installed

per the following instructions:

IMPORTANT: To ensure proper installa-

tion, this procedure must be followed

exactly.

a. Wet the inside of the straight end of

the drain hose with tap water. DO

NOT USE ANY OTHER LUBRICANT.

b. Squeeze ears of silver, double-wire

clamp with pliers to open, Place clamp

over the straight end of the drain hose

1/4inch from the end.

AND

PUSH

1/4"

d. Place clamp over area marked

"CLAMP." Release clamp.

c. Open clamp. Twist hose back and

forth while pushing down onto drain

connector at the bottom of the washer.

Continue until hose contacts the

ribbed stop on the cabinet.

If you have: You will need to buy:

Drain hose that is too short Drain hose, Part No. 388423 and

hose kit, Part No. 285442

Drain hose that is too long Hose kit, Part No. 285442

A problem with lint clogging your drain Drain protector, Part No. 367031

Parts listed are available from your local Sears store or Sears Service Center.

Call 1-800-366-PART (1-800-366-7278).

1/4"

14

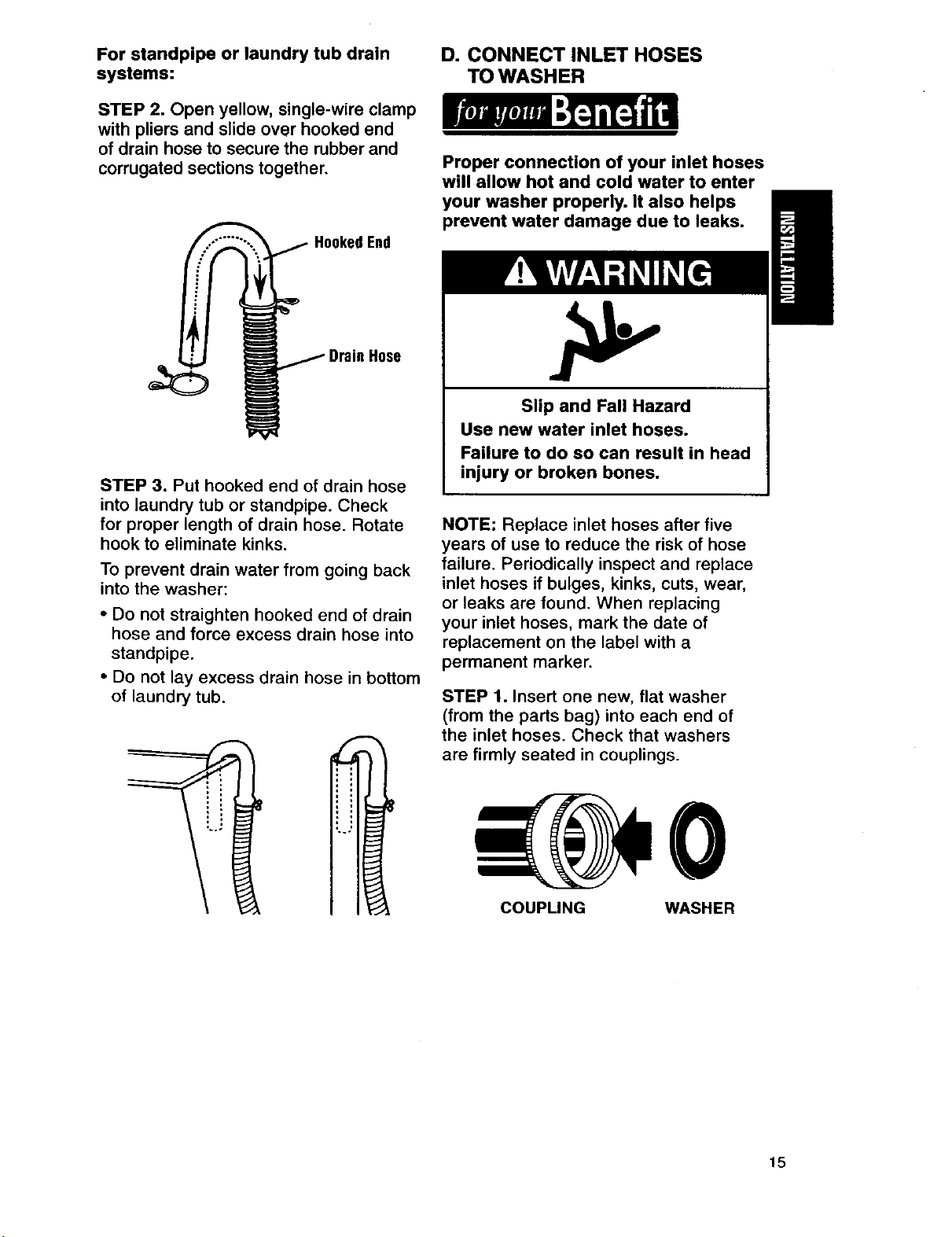

For standpipe or laundry tub drain

systems:

STEP 2. Open yellow, single-wire clamp

with pliers and slide over hooked end

of drain hose to secure the rubber and

corrugated sections together.

HookedEnd

STEP 3. Put hooked end of drain hose

into laundry tub or standpipe. Check

for proper length of drain hose. Rotate

hook to eliminate kinks.

To prevent drain water from going back

into the washer:

• Do not straighten hooked end of drain

hose and force excess drain hose into

standpipe.

• Do not lay excess drain hose in bottom

of laundry tub.

D. CONNECT INLET HOSES

TO WASHER

Proper connection of your inlet hoses

will allow hot and cold water to enter

your washer properly. It also helps

prevent water damage due to leaks.

Slip and Fall Hazard

Use new water inlet hoses.

Failure to do so can result in head

injury or broken bones.

NOTE: Replace inlet hoses after five

years of use to reduce the risk of hose

failure. Periodically inspect and replace

inlet hoses if bulges, kinks, cuts, wear,

or leaks are found. When replacing

your inlet hoses, mark the date of

replacement on the label with a

permanent marker.

STEP 1. Insert one new, flat washer

(from the parts bag) into each end of

the inlet hoses, Check that washers

are firmly seated in couplings.

0

COUPLING WASHER

15

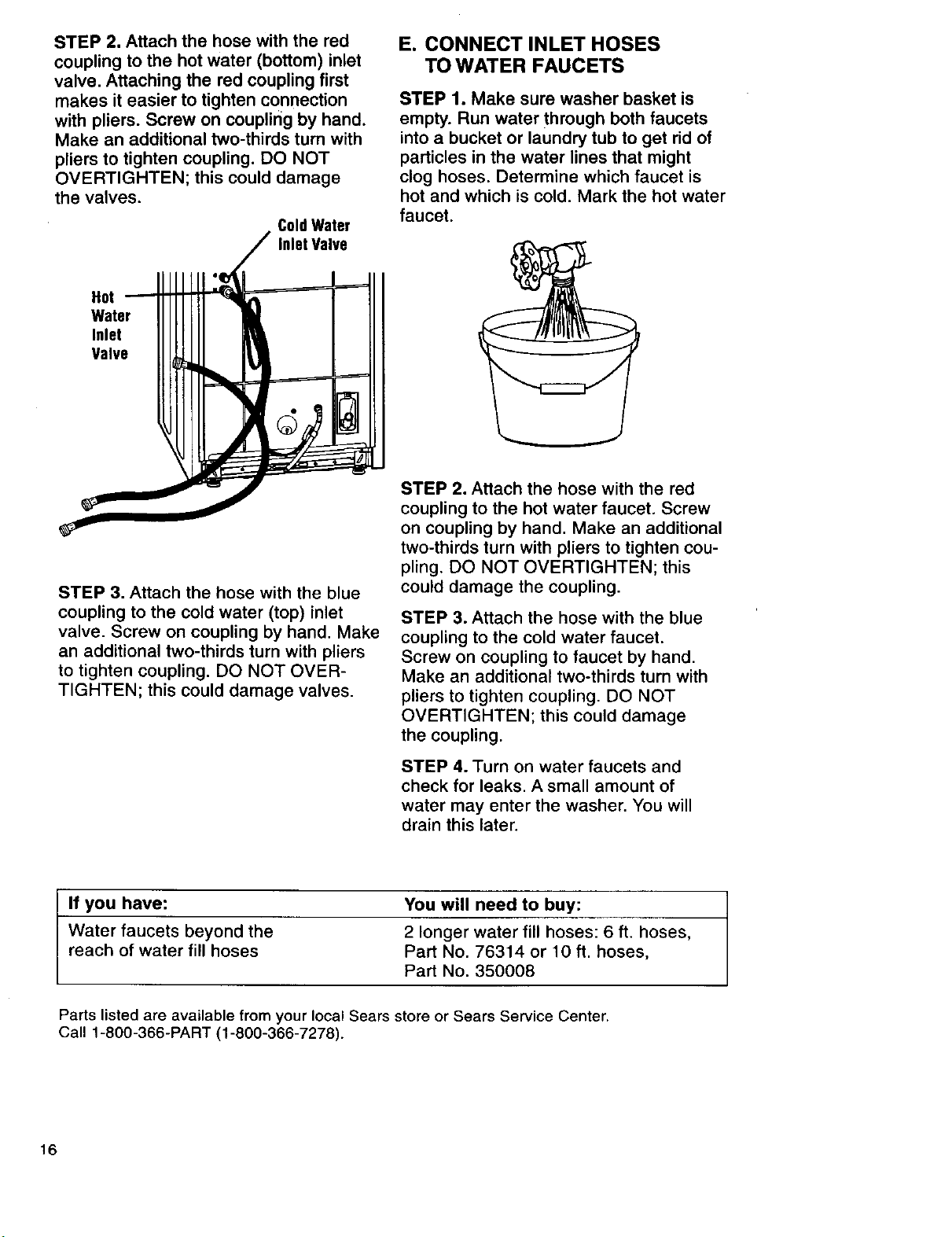

STEP 2, Attach the hose with the red

coupling to the hot water (bottom) inlet

valve. Attaching the red coupling first

makes it easier to tighten connection

with pliers. Screw on coupling by hand.

Make an additional two-thirds turn with

pliers to tighten coupling. DO NOT

OVERTIGHTEN; this could damage

the valves.

Cold Water

Inlet Valve

Hot

Water

Inlet

Valve

STEP 3. Attach the hose with the blue

coupling to the cold water (top) inlet

valve. Screw on coupling by hand. Make

an additional two-thirds turn with pliers

to tighten coupling. DO NOT OVER-

TIGHTEN; this could damage valves.

E. CONNECTINLETHOSES

TOWATER FAUCETS

STEP 1, Make sure washer basket is

empty. Run water through both faucets

into a bucket or laundry tub to get rid of

particles in the water lines that might

clog hoses. Determine which faucet is

hot and which is cold. Mark the hot water

faucet.

STEP 2. Attach the hose with the red

coupling to the hot water faucet. Screw

on coupling by hand. Make an additional

two-thirds turn with pliers to tighten cou-

pling. DO NOT OVERTIGHTEN; this

could damage the coupling.

STEP 3. Attach the hose with the blue

coupling to the cold water faucet.

Screw on coupling to faucet by hand.

Make an additional two-thirds turn with

pliers to tighten coupling. DO NOT

OVERTIGHTEN; this could damage

the coupling.

STEP 4. Turn on water faucets and

check for leaks. A small amount of

water may enter the washer. You will

drain this later.

If you have: You will need to buy:

Water faucets beyond the 2 longer water fill hoses: 6 ft. hoses,

reach of water fill hoses Part No. 76314 or 10 ft. hoses,

Part No. 350008

Parts listed are available from your local Sears store or Sears Service Center.

Call 1-800-366-PART (1-800-366-7278).

16

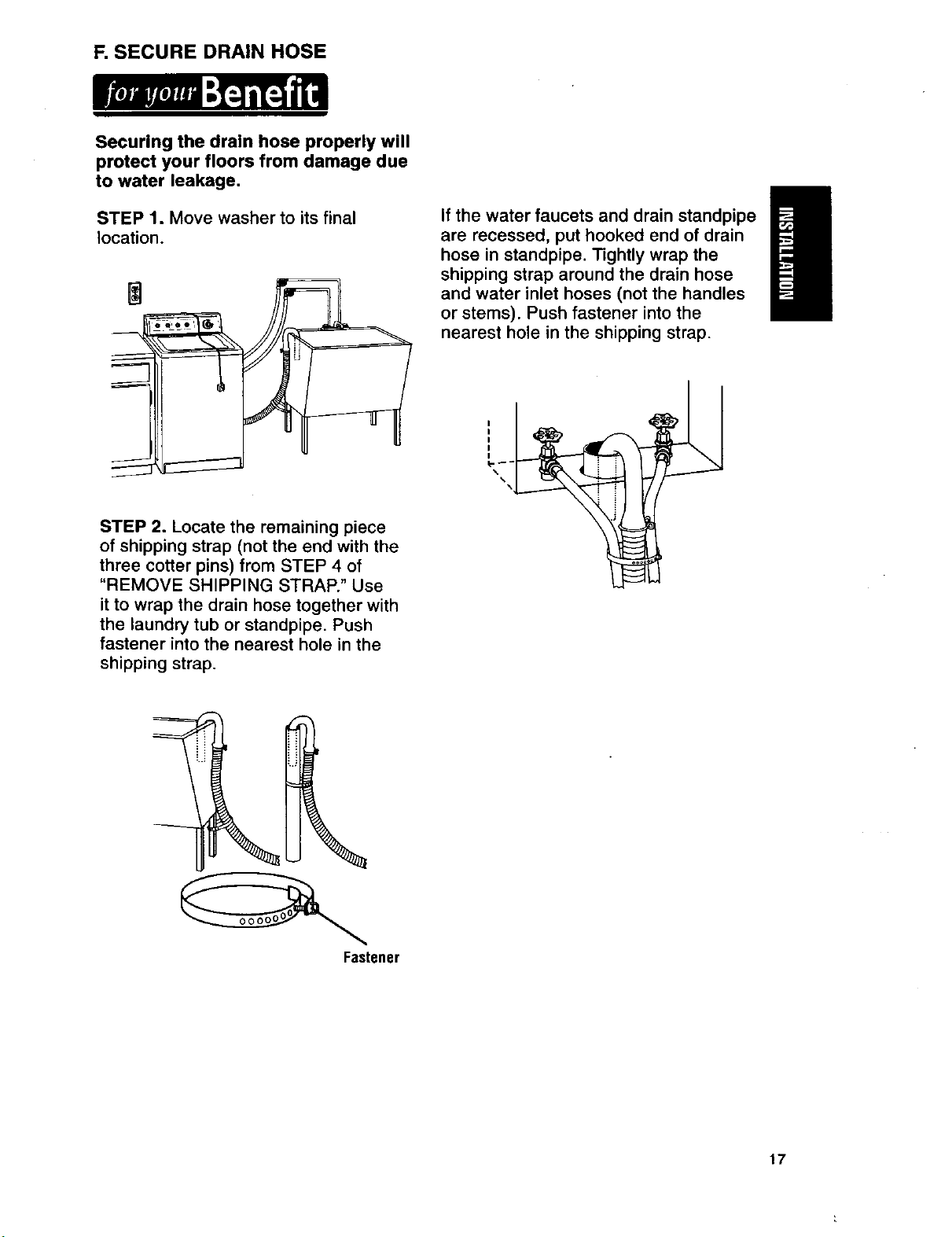

F. SECURE DRAIN HOSE

Securing the drain hose properly will

protect your floors from damage due

to water leakage,

STEP 1. Move washer to its final

location.

J

If the water faucets and drain standpipe

are recessed, put hooked end of drain

hose in standpipe. Tightly wrap the

shipping strap around the drain hose

and water inlet hoses (not the handles

or stems). Push fastener into the

nearest hole in the shipping strap.

I

m

m

STEP 2. Locate the remaining piece

of shipping strap (not the end with the

three cotter pins) from STEP 4 of

"REMOVE SHIPPING STRAP." Use

it to wrap the drain hose together with

the laundry tub or standpipe. Push

fastener into the nearest hole in the

shipping strap.

Fastener

17

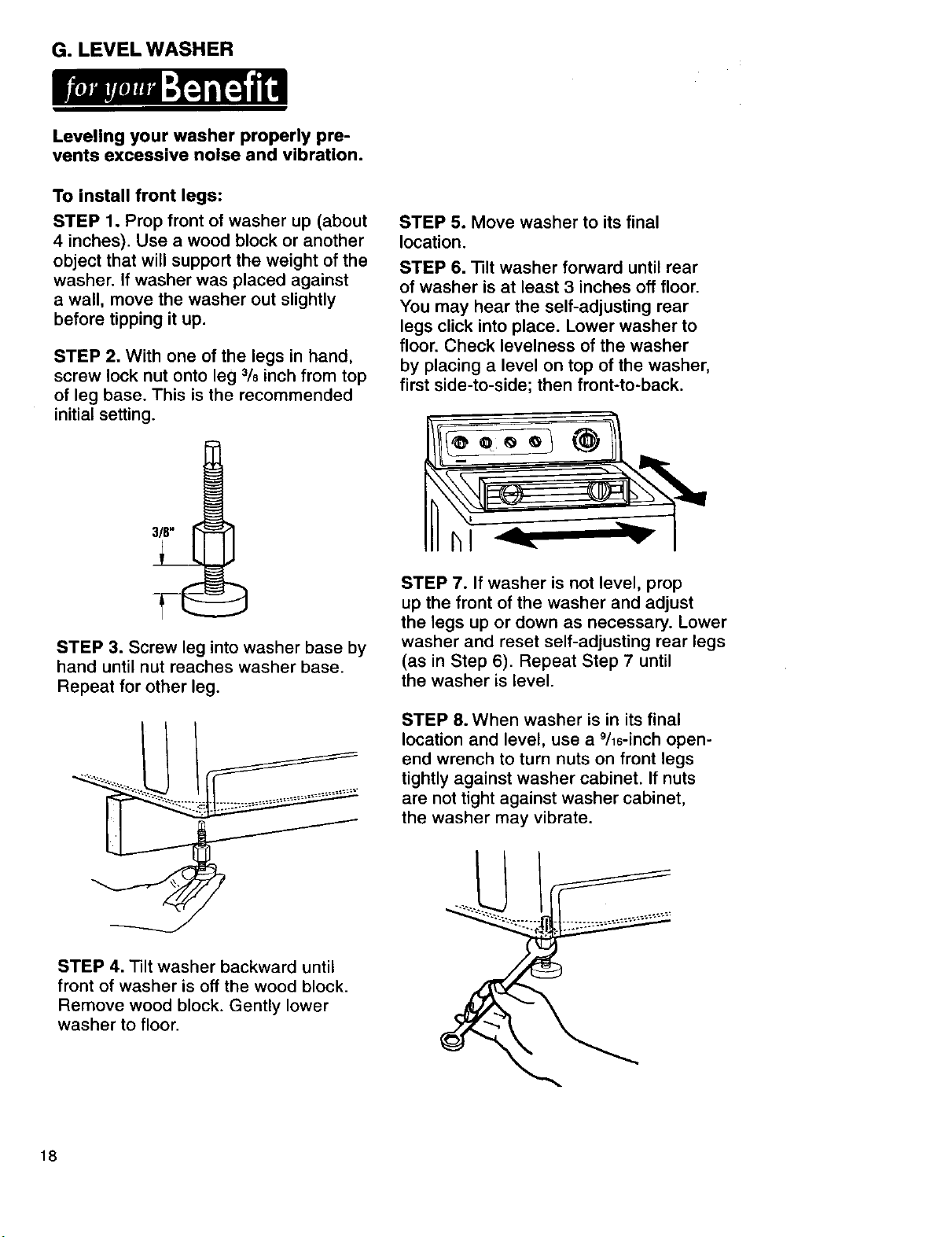

G. LEVELWASHER

Leveling your washer properly pre-

vents excessive noise and vibration.

To install front legs:

STEP 1. Prop front of washer up (about

4 inches). Use a wood block or another

object that will support the weight of the

washer, if washer was placed against

a wall, move the washer out slightly

before tipping it up.

STEP 2. With one of the legs in hand,

screw lock nut onto leg 3/8inch from top

of leg base. This is the recommended

initial setting.

STEP 5. Move washer to its final

location.

STEP 6. Tilt washer forward until rear

of washer is at least 3 inches off floor.

You may hear the self-adjusting rear

legs click into place. Lower washer to

floor. Check levelness of the washer

by placing a level on top of the washer,

first side-to-side; then front-to-back.

STEP 3. Screw leg into washer base by

hand until nut reaches washer base.

Repeat for other leg.

STEP 4. Tilt washer backward until

front of washer is off the wood block.

Remove wood block. Gently lower

washer to floor.

hi v

STEP 7. If washer is not level, prop

up the front of the washer and adjust

the legs up or down as necessary. Lower

washer and reset self-adjusting rear legs

(as in Step 6). Repeat Step 7 until

the washer is level.

STEP 8. When washer is in its final

location and level, use a 9/1s-inch open-

end wrench to turn nuts on front legs

tightly against washer cabinet. If nuts

are not tight against washer cabinet,

the washer may vibrate.

18

REVIEW INSTALLATION

Take a few minutes to complete

this checklist. It will help assure you

that you have a proper installation

and increase your satisfaction with

your Kenmore washer.

[]

Check electrical requirements.

Be sure you have correct electrical

supply and recommended grounding

method.

[]

Check that you have:

• All the tools you started with.

• Removed all packaging materials.

• Removed shipping strap with

three cotter pins.

• Installed all parts listed on

pages 6-8.

FINAL STEPS

[] Plug power supply cord into

grounded outlet.

[] Remove the blue protective film on

the console and any tape remaining

on washer.

[] Check that:

• The washer is level.

• The nuts on the front legs are tight.

[] Check that the water faucets are

turned on.

[] Take a few minutes and read the

Operating Instructions (pages 20-29)

to fully understand your new washer.

Then, start the washer and allow it

to complete the ULTRA CLEAN or

NORMAL Cycle.

19

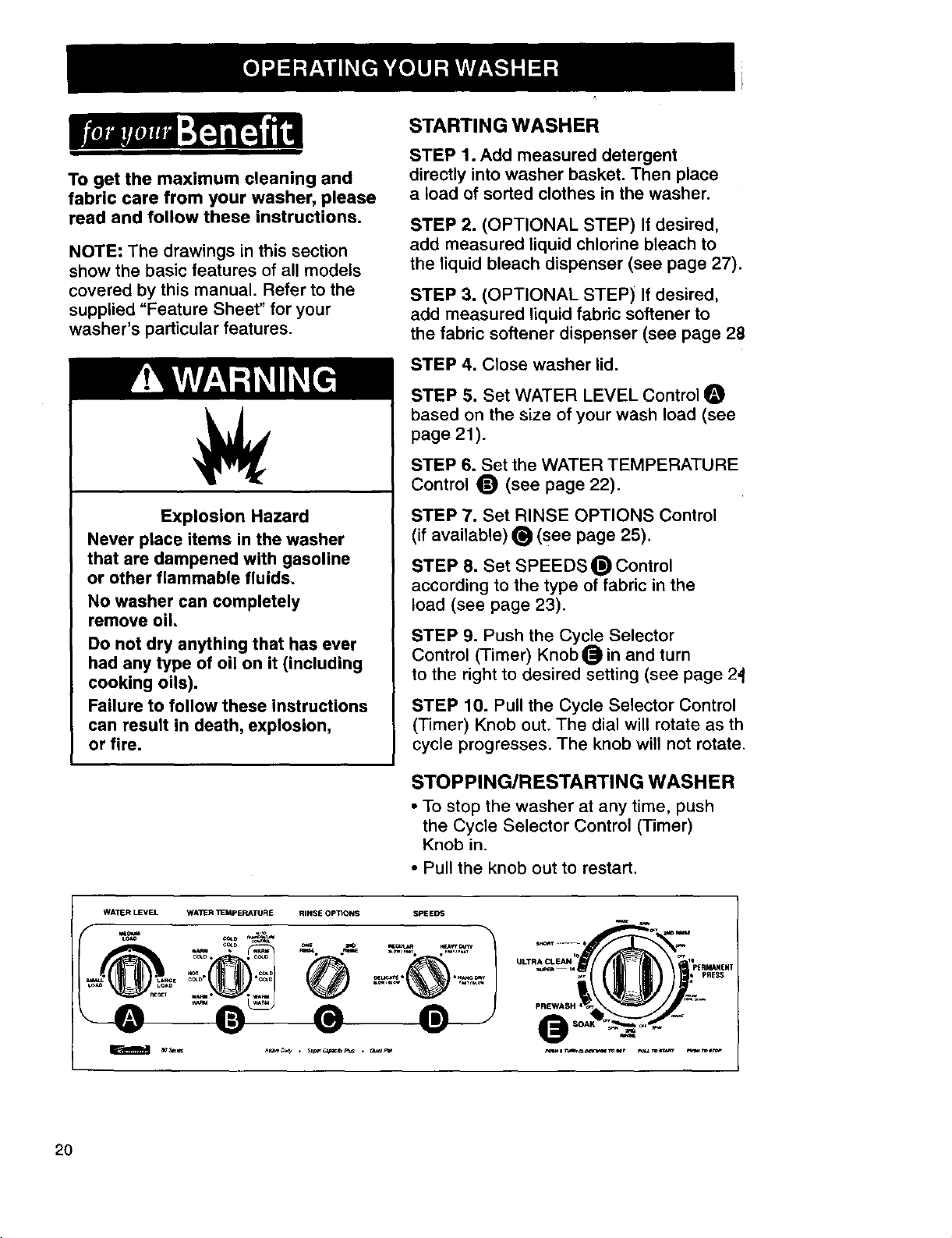

To get the maximum cleaning and

fabric care from your washer, please

read and follow these instructions.

NOTE: The drawings in this section

show the basic features of all models

covered by this manual. Refer to the

supplied "Feature Sheet" for your

washer's particular features.

STARTING WASHER

STEP 1. Add measured detergent

directly into washer basket. Then place

a load of sorted clothes in the washer.

STEP 2. (OPTIONAL STEP) If desired,

add measured liquid chlorine bleach to

the liquid bleach dispenser (see page 27).

STEP 3. (OPTIONAL STEP) If desired,

add measured liquid fabric softener to

the fabric softener dispenser (see page 28

STEP 4. Close washer lid.

STEP 5, Set WATER LEVEL Control O

based on the size of your wash load (see

page 21 ).

STEP 6. Set the WATER TEMPERATURE

Control O (see page 22).

Explosion Hazard

Never place items in the washer

that are dampened with gasoline

or other flammable fluids.

No washer can completely

remove oil.

Do not dry anything that has ever

had any type of oil on it (including

cooking oils).

Failure to follow these instructions

can result in death, explosion,

or fire.

STEP 7. Set RINSE OPTIONS Control

(if available) _ (see page 25).

STEP 8, Set SPEEDS_Control

according to the type of fabric in the

load (see page 23).

STEP 9. Push the Cycle Selector

Control (Timer) Knob _) in and turn

to the right to desired setting (see page 24

STEP 10. Pull the Cycle Selector Control

(Timer) Knob out. The dial will rotate as th

cycle progresses. The knob will not rotate.

STOPPING/RESTARTING WASHER

• To stop the washer at any time, push

the Cycle Selector Control (Timer)

Knob in.

• Pull the knob out to restart,

2O

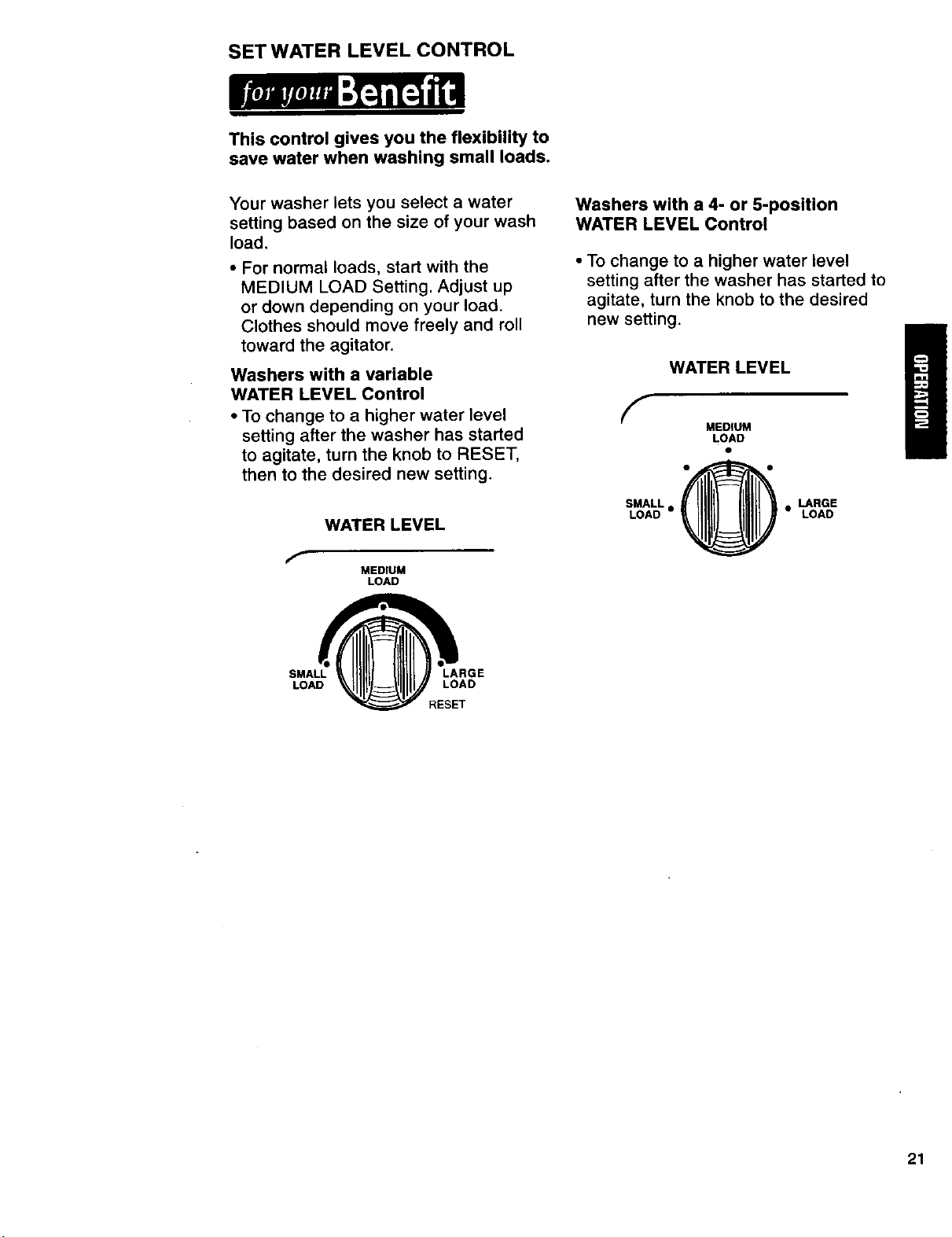

SET WATER LEVEL CONTROL

This control gives you the flexibility to

save water when washing small loads.

Your washer lets you select a water

setting based on the size of your wash

load.

• For normal loads, start with the

MEDIUM LOAD Setting. Adjust up

or down depending on your load.

Clothes should move freely and roll

toward the agitator.

Washers with a variable

WATER LEVEL Control

• To change to a higher water level

setting after the washer has started

to agitate, turn the knob to RESET,

then to the desired new setting.

WATER LEVEL

f

MEDIUM

LOAD

Washers with a 4- or 5-position

WATER LEVEL Control

• To change to a higher water level

setting after the washer has starLed to

agitate, turn the knob to the desired

new setting.

WATER LEVEL

F

MEDIUM

LOAD

SMALL • • LARGE

LOAD LOAD

LOAD LOAD

LARGE

RESET

21

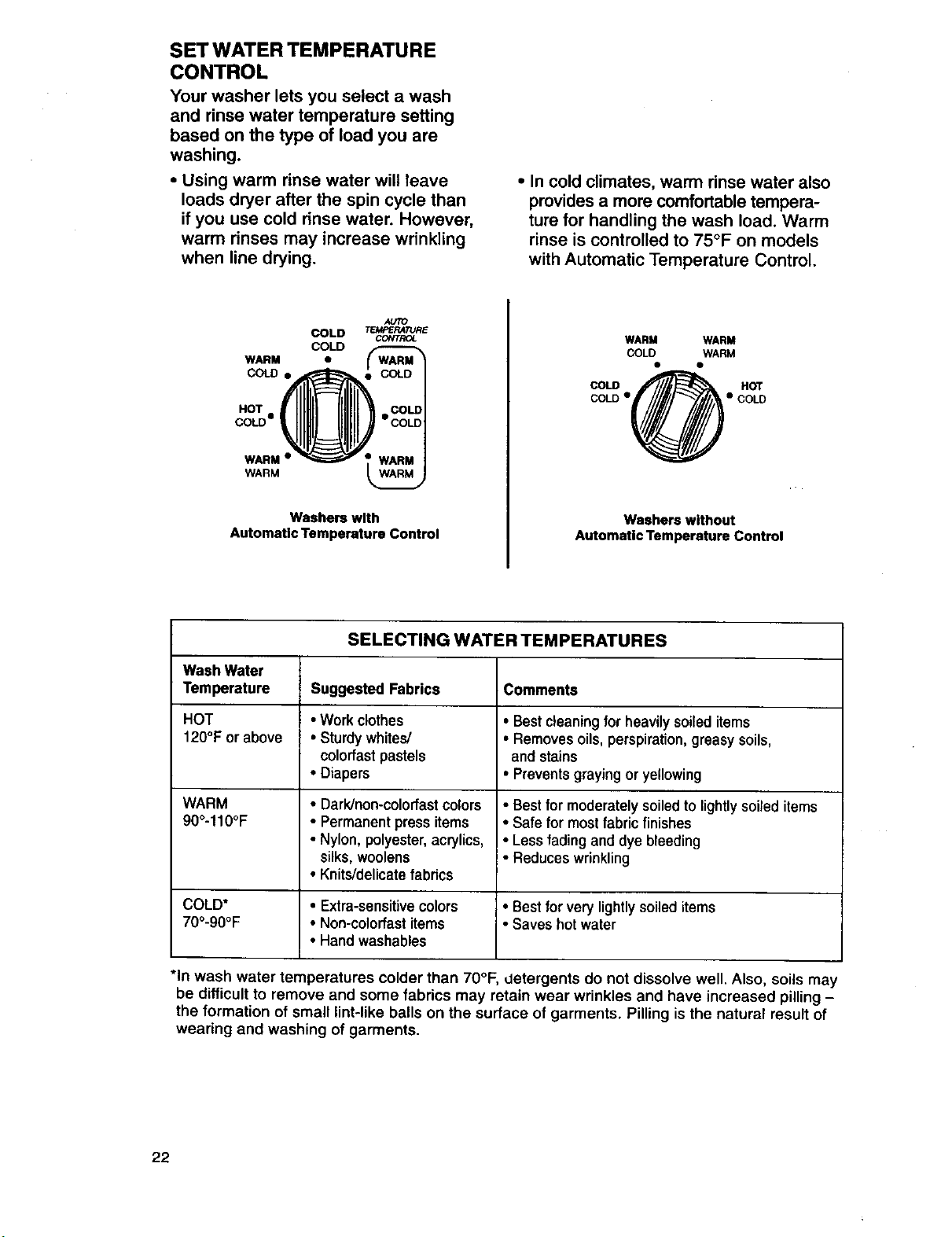

SET WATER TEMPERATURE

CONTROL

Your washer lets you select a wash

and rinse water temperature setting

based on the type of load you are

washing.

• Using warm rinse water will leave

loads dryer after the spin cycle than

if you use cold rinse water. However,

warm rinses may increase wrinkling

when line drying.

• In cold climates, warm rinse water also

provides a more comfortable tempera-

ture for handling the wash load. Warm

rinse is controlled to 75°F on models

with Automatic Temperature Control.

COLD T_,mERATURE

WARM •

COLD •

HOT

COLD• I

WARM •

WARM

Automatic Temperature Control

COLD

Washers with

AUTO

CONTRC(

WARM WARM

COLD WARM

Washers without

Automatic Temperature Control

SELECTING WATER TEMPERATURES

Wash Water

Temperature Suggested Fabrics Comments

HOT • Work clothes • Bestcleaningforheavilysoileditems

120°F or above • Sturdywhites/ • Removesoils,perspiration,greasysoils,

colorfastpastels and stains

• Diapers , Preventsgrayingor yellowing

WARM • Dark/non-colorfastcolors • Bestfor moderatelysoiledto lightlysoileditems

90°-110°F • Permanentpressitems • Safe for mostfabricfinishes

• Nylon, polyester,acrylics, ° Lessfadingand dye bleeding

silks,woolens • Reduceswrinkling

• Knits/delicatefabrics

COLD* • Extra-sensitivecolors • Bestfor verylightlysoileditems

70°-90°F • Non-colorfastitems • Saves hot water

• Hand washables

*in wash water temperatures colder than 70°F, detergents do not dissolve well. Also, soils may

be difficult to remove and some fabrics may retain wear wrinkles and have increased pilling -

the formation of small lint-like balls on the surface of garments. Pilling is the natural result of

wearing and washing of garments.

22

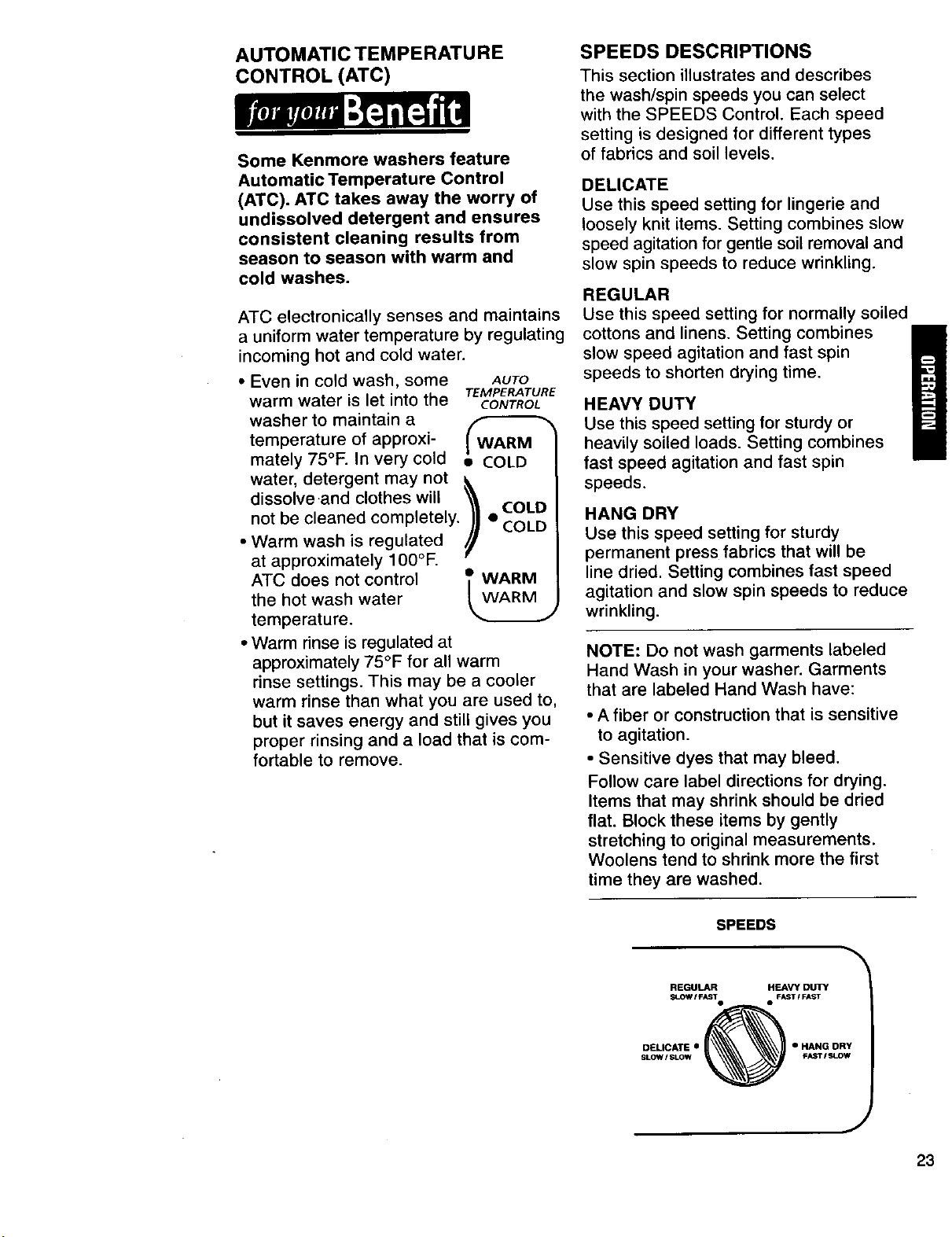

AUTOMATIC TEMPERATURE

CONTROL (ATC)

Some Kenmore washers feature

Automatic Temperature Control

(ATC). ATC takes away the worry of

undissolved detergent and ensures

consistent cleaning results from

season to season with warm and

cold washes.

ATC electronically senses and maintains

a uniform water temperature by regulating

incoming hot and cold water.

• Even in cold wash, some AUTO

warm water is let into the CONTROL

washer to maintain a

temperature of approxi-

mately 75°F. In very cold • COLD

water, detergent may not k

dissolve .and clothes will

not be cleaned completely.

• Warm wash is regulated

at approximately 100°E

ATC does not control

the hot wash water

temperature.

• Warm rinse is regulated at

approximately 75°F for all warm

rinse settings. This may be a cooler

warm rinse than what you are used to,

but it saves energy and still gives you

proper rinsing and a load that is com-

fortable to remove.

TEMPERATURE

)

SPEEDS DESCRIPTIONS

This section illustrates and describes

the wash/spin speeds you can select

with the SPEEDS Control. Each speed

setting is designed for different types

of fabrics and soil levels.

DELICATE

Use this speed setting for lingerie and

loosely knit items. Setting combines slow

speed agitation for gentle soil removal and

slow spin speeds to reduce wrinkling.

REGULAR

Use this speed setting for normally soiled

cottons and linens. Setting combines

slow speed agitation and fast spin

speeds to shorten drying time.

HEAVY DUTY

Use this speed setting for sturdy or

heavily soiled loads. Setting combines

fast speed agitation and fast spin

speeds.

HANG DRY

Use this speed setting for sturdy

permanent press fabrics that will be

line dried. Setting combines fast speed

agitation and slow spin speeds to reduce

wrinkling.

NOTE: Do not wash garments labeled

Hand Wash in your washer. Garments

that are labeled Hand Wash have:

• A fiber or construction that is sensitive

to agitation.

• Sensitive dyes that may bleed.

Follow care label directions for drying.

Items that may shrink should be dried

flat. Block these items by gently

stretching to original measurements.

Woolens tend to shrink more the first

time they are washed.

SPEEDS

REGULAR HEAVY DUI_

SLOW I FASI" FAS3" t FAST

DELICATE • • • • HANG DRY

SLOW I SLOW _ FASt" I SLOW

Loading...

Loading...