Kenmore 11022996101, 11022994101, 11022994100, 11022992101, 11022992100 Owner’s Manual

...

Owner's Manual and

Installation Instructions

E L I T E

TM

Three-Speed

Automatic Washers

with TRIPLE SMART TM Dispenser

IMPORTANT:

Read and follow all safety

and operating instructions

before first use of this product.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Sears Canada Inc., Toronto, Ontario, Canada M5B 2B8

8526120 PRINTEDIN U.S.A. 1/01

www, sears.com

www, sears,ca

BEFORE USING YOUR NEWWASHER _ __ 2

KENMORE ELITE TM WASHER WARRANTY 3

WASHER SAFETY ............ 4

INSTALLATION REQUIREMENTS

INSTALLATION INSTRUCTIONS

OPERATING YOUR WASH ER

LAUNDRY TIPS ........... 27

CARING FOR YOUR WASHER 29

TROUBLESHOOTING ........ 30

SEARS MAINTENANCE AGREEMENT 34

Please read this manual. It will help

you install and operate your new

Kenmore ELITE TM washer in the most

economical way.

For more information about the care

and operation of Kenmore ELITE TM

appliances call your nearest Sears store.

You will need the complete model and

serial numbers when requesting informa-

tion. Your washer's model and serial num*

bers are located on the Model and Serial

Number Plate.

6

10

14

Use the space below to record the model

number and serial number of your new

Kenmore ELITE TM washer,

Model No.

Serial No.

Date of Purchase

Modeland Serial

Number Plate

Keep this book and your Sears

Sales check (receipt) in a safe

place for future reference.

Limited Lifetime Warranty on

White Porcelain Basket

For the lifetime of the washer from the

date of purchase, Sears will replace the

white porcelain wash basket if it chips

or rusts due to defective material or

workmanship. After the first year, you

will be charged for labor.

Limited 10-Year Warranty on

Plastic Tub*

For the second through tenth year from

the date of purchase, Sears will replace

the plastic tub if it is defective in

material or workmanship, After the first

year, you will be charged for labor.

Limited 5-Year Warranty on

Gearcase Parts*

For the second through fifth year from

the date of purchase, Sears will replace

any gearcase parts that are defective in

material or workmanship, After the first

year, you will be charged for labor.

Full 1-Year Warranty on

Mechanical and Electrical parts

For one year from the date of pur-

chase, when this washer is installed

and operated according to the instruc-

tions that come with it, Sears will repair

or replace any of its mechanical or

electrical parts if they are defective in

material or workmanship.

Warranty Restriction

If this washer is operated for any pur-

pose other than private family use, all

warranty coverage is restricted to 90

days from the date of purchase.

Warranty Service

Warranty service is available by

contacting your nearest Sears Service

Center in the United States or Canada.

This warranty applies only while this

washer is used in the United States or

Canada.

This warranty gives you specific legal

rights and you may also have other

rights that vary from state to state or

province to province.

Sears, Roebuck and Co.,

Dept. 817WA,

Hoffman Estates, IL 60179

Sears Canada Inc.,

Toronto, Ontario,

Canada M5B 2B8

* In Canada a different warranty may apply.

In the U.S. for Sears warranty information or

to contact a Sears Service Center, call

1-80O-4-MY-HQME ® (1-890-469-4663).

in Canada, call 1-877-533-6937.

Your safety and the safety of others are very important.

We have provided many important safety messages inthis manual and

on your appliance. Always read and obey all safety messages.

This is the safety alert symbol. This symbol alerts you to

potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol

and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously

injured if you don't immediateb L

follow instructions.

You can be killed or seriously

injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how

to reduce the chance of injury, and tell you what can happen if the

instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons

when using your washer, follow basic precautions, including the following:

• Read all instructions before using

the washer.

• Do not wash articles that have been

previously cleaned in, washed in,

soaked in, or spotted with gasoline,

dry-cleaning solvents, other flammable

or explosive substances as they give

off vapors that could ignite or explode,

• Do not add gasoline, dry-cleaning

solvents, or other flammable or

explosive substances to the wash

water. These substances give off

vapors that could ignite or explode.

• Under certain conditions, hydrogen

gas may be produced ina hot water

system that has not been used for 2

weeks or more. HYDROGEN GAS IS

EXPLOSIVE. If the hot water system

has not been used for such a period,

before using a washing machine, turn

on all hot water faucets and let the

water flow from each for several

minutes. This will release any accumu-

lated hydrogen gas. As the gas is

flammable, do not smoke or use an

open flame during this time.

SAVE THESE INSTRUCTIONS

• Do not allow children to play on or

in the washer. Close supervision of

children is necessary when the

washer is used near children.

• Before the washer is removed from

service or discarded, remove the

door or Iid.

• Do not reach into the washer if the

drum, tub or agitator is moving.

• Do not install or store this washer

where it will beexposed to the

weather,

• Do not tamper with controls.

• Do not repair or replace any part of

the washer or attempt any servicing

unless specifically recommended in

the Owner's Manual or in published

user-repair instructions that you

understand and have the skills to

carry out.

• See the "Installation instructions"

section for grounding requirements.

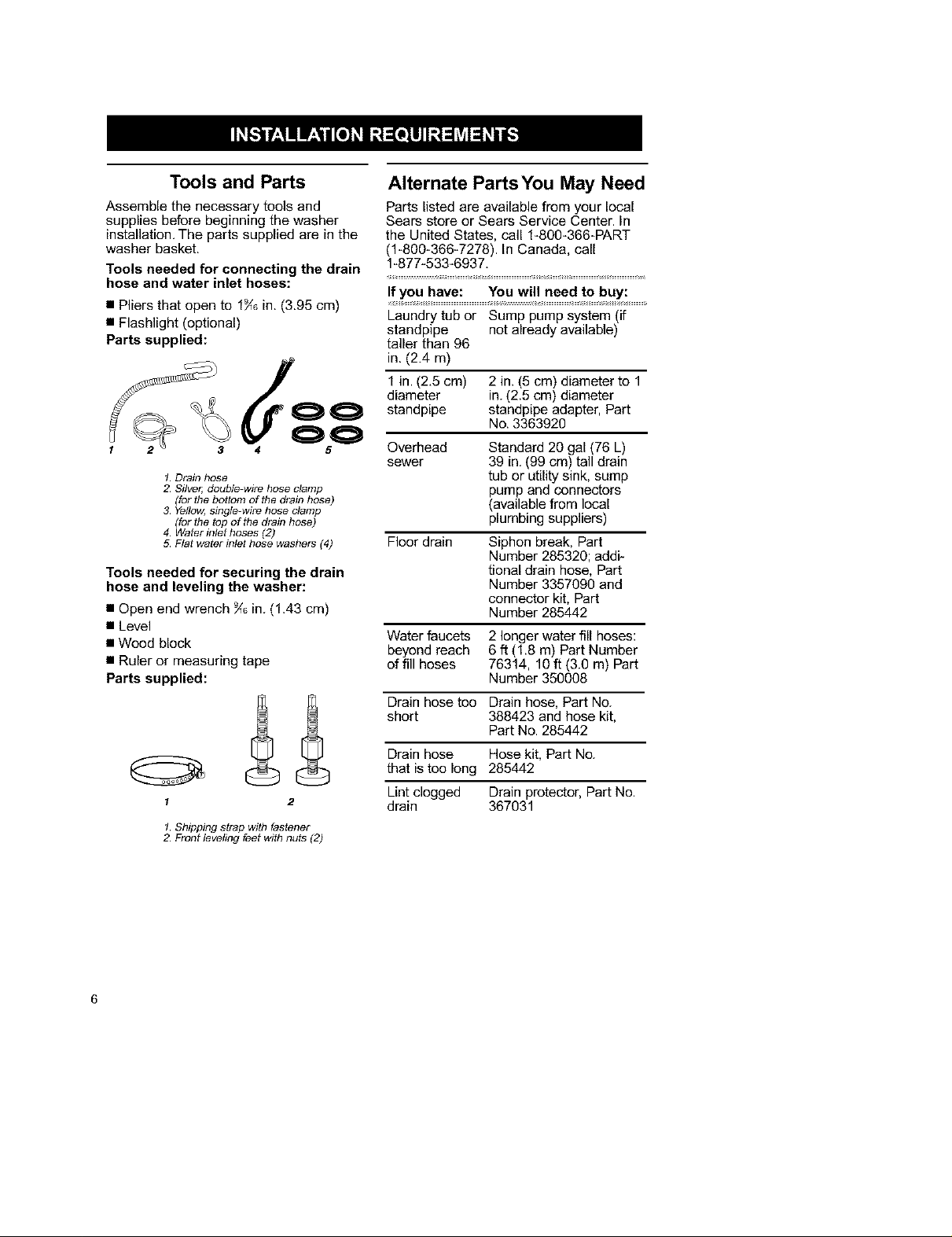

Tools and Parts

Assemble the necessary tools and

supplies before beginning the washer

installation. The parts supplied are in the

washer basket.

Tools needed for connecting the drain

hose and water inlet hoses:

• Pliers that open to 1?'6in. (3.95 cm)

• Flashlight (optional)

Parts supplied:

4 5

1. Drain hose

2. Silver, double-wire hose clamp

(for the bottom of the drain hose)

3. Yellow, single-wire hose clamp

(for the top of the drain hose)

4. Water inlet hoses (2)

5. Flat water inlet hose washers (4)

Tools needed for securing the drain

hose and leveling the washer:

• Open end wrench ?'6in. (1.43 cm)

• Level

• Wood block

• Ruler or measuring tape

Parts supplied:

1 2

1. Shipping strap with fastener

Z Front leveling feet with nuts (2)

Alternate PartsYou May Need

Parts listed are available from your local

Sears store or Sears Service Center. In

the United States, call 1-800-366-PART

(1-800-366-7278). In Canada, call

1-877-533_6937.

If you have: You will need to buy:

Laundry tub or Sump pump system (if

standpipe not already available)

taller than 96

in. (2.4 m)

1 in. (2.5 cm) 2 in. (5 cm) diameter to 1

diameter in.(2.5 cm) diameter

standpipe standpipe adapter, Part

No. 3363920

Overhead Standard 20 gal (76 L)

sewer 39 in. (99 cm) tall drain

tub or utility sink, sump

pump and connectors

(available from local

plumbing suppliers)

Floor drain Siphon break, Part

Number 285320; addi*

tional drain hose, Part

Number 3357090 and

connector kit, Part

Number 285442

Water faucets 2 longer water fill hoses:

beyond reach 6 ft (1.8 m) Part Number

of fill hoses 76314, 10 ft (3.0 m) Part

Number 350008

Drain hose too Drain hose, Part No.

short 388423 and hose kit,

Part No. 285442

Drain hose Hose kit, Part No.

that is too long 285442

Lint clogged Drain protector, Part No.

drain 367031

Location Requirements

Selecting the proper location for your

washer improves performance and mini-

mizes noise and possible washer "walk,"

Your washer can be installed in a base-

ment, laundry room, closet, or recessed

area. (See "Drain System.")

Proper installation is your responsibility.

You will need:

• A water heater set to deliver 120T

(49_C) water to the washer.

• A grounded electrical outlet located with-

in 4 ft (1.2 m) of where the power cord is

attached to the back of the washer. (See

"Electrical Requirements.")

• Hot and cold water faucets located with-

in 4 ft (1.2 m) of the hot and cold water

fill valves, and water pressure of 5-100

psi (34.5-689.6 kPa). Washers with triple

dispensers require 20-100 psi (138.0-

689.6 kPa) for best performance.

• A level floor with a maximum slope of

1 in. (2.5 cm) under entire washer.

Installing the washer on carpeting is not

recommended.

• A sturdy floor to support the washer

weight (washer, water and load) of 315

Ibs (143 kgs).

Do not store or operate your washer in

temperatures at or below 32°F (0°C).

Some water can remain in the washer and

can cause damage in low temperatures.

See "Washer Care" for winterizing infor-

mation.

Recessed area or closet installation

The dimensions shown are for the rec-

ommended spacing allowed, except the

closet door ventilation openings, The

dimensions shown for the closet door

ventilation openings are the minimum

required.

m

1 2

-- _r 3.

24,,2

3

1.Front view

2. Side view

3. Closet door with vents

• Additional spacing should be consid-

ered for ease of installation and ser-

vicing.

• Additional clearances may be required

for wall, door and floor moldings.

• Additional spacing of 1 in. (2.5 cm) on

all sides of the washer is recommend-

ed to reduce noise transfer.

• If a closet door is installed, the mini-

mum air openings in the top and bot-

tom of the door are required. Louvered

doors with air openings in the top and

bottom are acceptable.

• Companion appliance spacing should

also be considered.

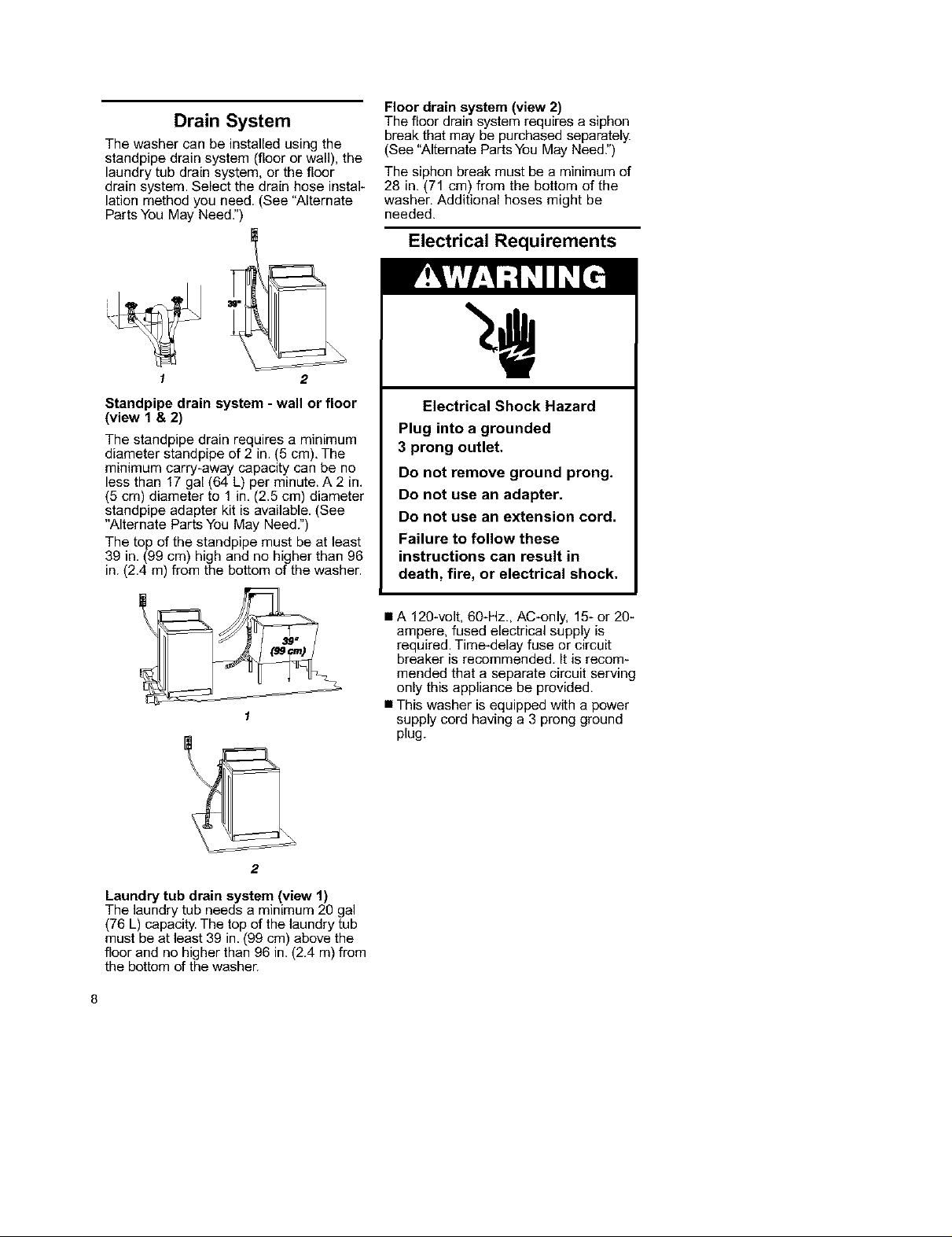

Drain System

The washer can be installed using the

standpipe drain system (floor or wall), the

laundry tub drain system, or the floor

drain system. Select the drain hose instal-

lation method you need. (See "Alternate

Parts You May Need.")

1 2

Standpipe drain system - wall or floor

(view 1 & 2)

The standpipe drain requires a minimum

diameter standpipe of 2 in. (5 cm). The

minimum carry-away capacity can be no

less than 17 gal (64 L) per minute. A 2 in.

(5 cm) diameter to 1 in. (2.5 cm) diameter

standpipe adapter kit is available. (See

"Alternate Parts You May Need.")

The top of the standpipe must be at least

39 in. (99 cm) high and no higher than 96

in. (2.4 m) from the bottom of the washer.

Floor drain system (view 2)

The floor drain system requires a siphon

break that may be purchased separately.

(See "Alternate PartsYeu May Need,")

The siphon break must be a minimum of

28 in. (71 cm) from the bottom of the

washer. Additional hoses might be

needed.

Electrical Requirements

Electrical Shock Hazard

Plug into a grounded

3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these

instructions can result in

death, fire, or electrical shock.

Laundry tub drain system (view 1)

The laundry tub needs a minimum 20 gal

(76 L) capacity. The top of the laundry tub

must be at least 39 in. (99 cm) above the

floor and no higher than 96 in. (2.4 m) from

the bottom of the washer.

• A 120-volt, 60-Hz., AC-only, 15- or 20-

ampere, fused electrical supply is

required. Time-delay fuse or circuit

breaker is recommended, It is recom-

mended that a separate circuit serving

only this appliance be provided,

• This washer is equipped with a power

supply cord having a 3 prong ground

plug.

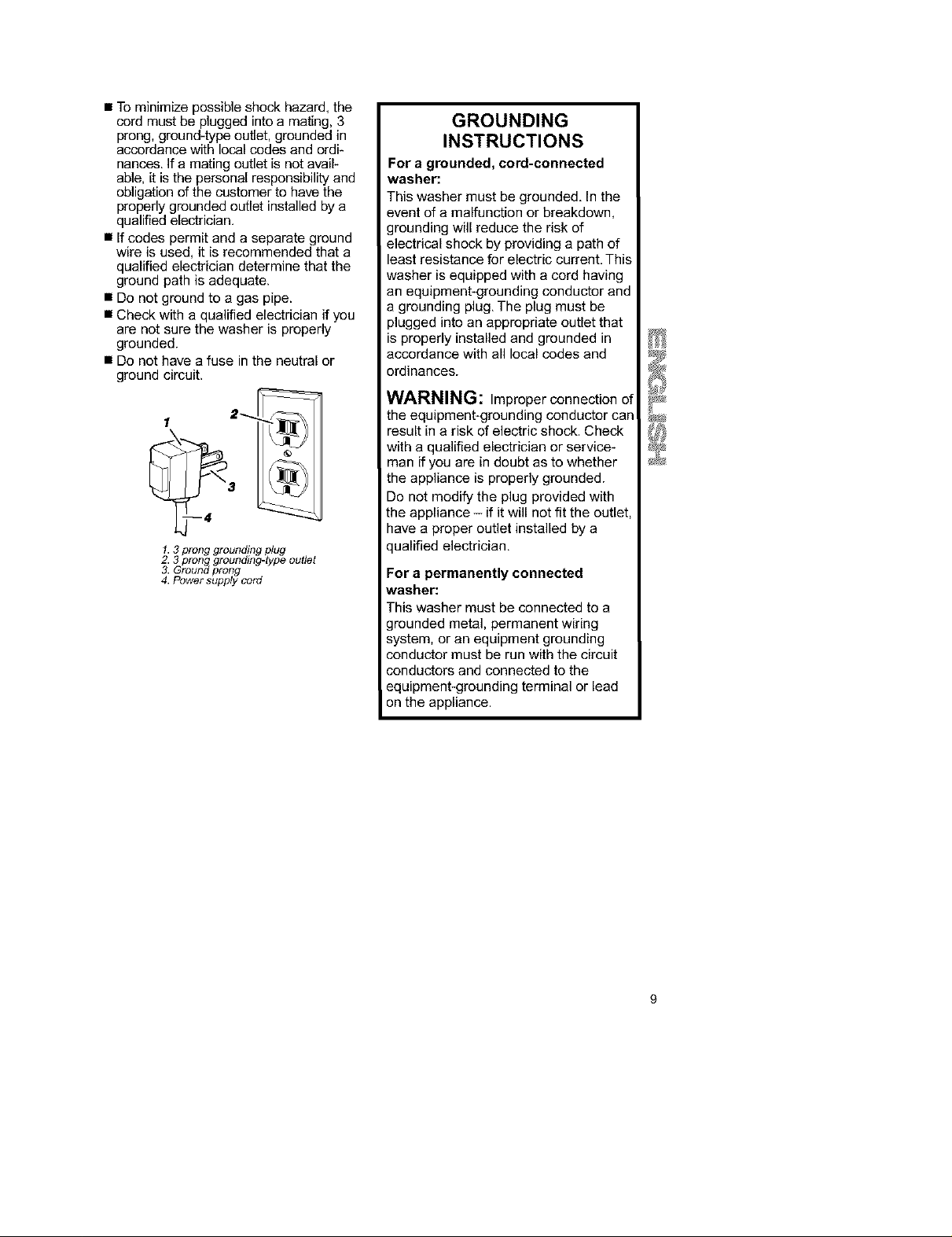

• Tominimizepossibleshockhazard,the

cordmustbepluggedintoamating,3

prong,ground-typeoutlet,groundedin

accordancewithlocalcodesandordF

nances.Ifamatingoutletisnotavail-

able,itisthepersonalresponsibilityand

obligationofthecustomertohavethe

properlygroundedoutletinstalledbya

qualifiedelectrician,

• Ifcodespermitanda separate ground

wire is used, it is recommended that a

qualified electrician determine that the

ground path is adequate.

• Do not ground to a gas pipe.

• Check with a qualified electrician if you

are not sure the washer is properly

grounded.

• Do not have a fuse in the neutral or

ground circuit.

1.3 prong grounding plug

2. 3 prong grounding-type outlet

3. Ground prong

4. Power supply cord

GROUNDING

INSTRUCTIONS

For a grounded, cord-connected

washer:

This washer must be grounded, In the

event of a malfunction or breakdown,

grounding will reduce the risk of

electrical shock by providing a path of

least resistance for electric current, This

washer is equipped with a cord having

an equipment-grounding conductor and

a grounding plug, The plug must be

plugged into an appropriate outlet that

is properly installed and grounded in

accordance with all local codes and

ordinances.

WARNING: Improper connection of

the equipment-grounding conductor can

result in a risk of electric shock. Check

with a qualified electrician or service-

man ifyou are in doubt as to whether

the appliance is properly grounded.

Do not modify the plug provided with

the appliance - if it will not fit the outlet

have a proper outlet installed by a

qualified electrician,

For a permanently connected

washer:

This washer must be connected to a

grounded metal, permanent wiring

system, or an equipment grounding

conductor must be run with the circuit

conductors and connected to the

equipment-grounding terminal or lead

on the appliance.

Before You Start

• To prevent floor damage, set the

washer onto cardboard before moving

across floor.

• Move the washer to within approximate-

ly 3 feet (90 cm) of the final

location.

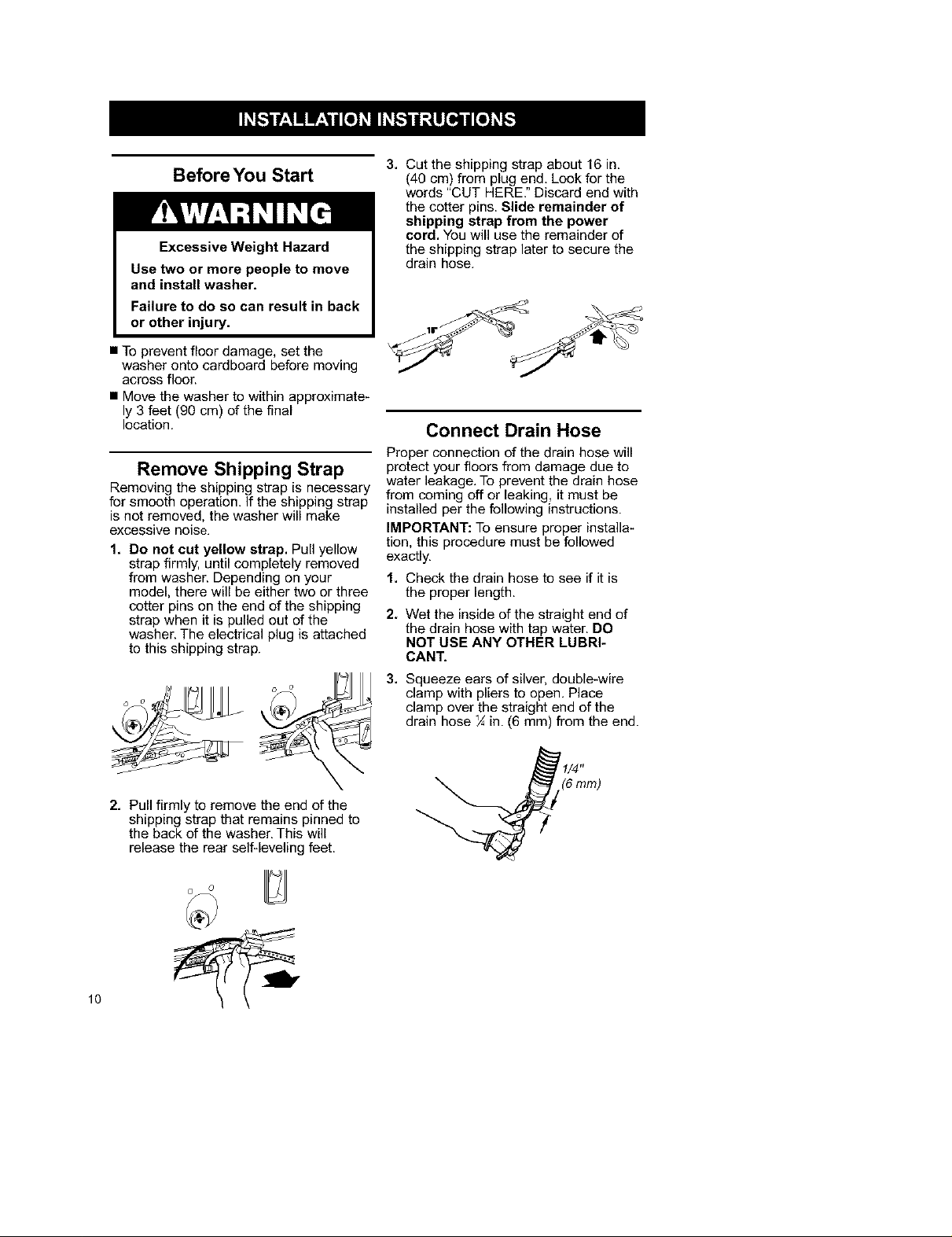

Remove Shipping Strap

Removing the shipping strap is necessary

for smooth operation. If the shipping strap

is not removed, the washer will make

excessive noise.

1, Do not cut yellow strap. Pull yellow

strap firmly, until completely removed

from washer. Depending on your

model, there will be either two or three

cotter pins on the end of the shipping

strap when it is pulled out of the

washer. The electrical plug is attached

to this shipping strap.

3. Cut the shipping strap about 16 in.

(40 cm) from plug end, Look for the

words "CUT HERE." Discard end with

the cotter pins. Slide remainder of

shipping strap from the power

cord. You will use the remainder of

the shipping strap later to secure the

drain hose.

Connect Drain Hose

Proper connection of the drain hose will

protect your floors from damage due to

water leakage, To prevent the drain hose

from coming off or leaking, it must be

installed per the following instructions.

IMPORTANT: To ensure proper installa-

tion, this procedure must be followed

exactly,

1. Check the drain hose to see if it is

the proper length.

2.

Wettheinsideofthestraightend

thed_inhose withtap water. DO

NOT USE ANY OTHER LUBRI-

CAN_

3.

Squeeze ears of silver, double-wire

clamp with pliers to open, Place

clamp over the straight end of the

drain hose _ in. (6 mm) from the end.

2, Pull firmly to remove the end of the

shipping strap that remains pinned to

the back of the washer, This will

release the rear selfqeveling feet.

10

_ !/4"

___ Z_ (6mm)

4. Open clamp. Twist hose back and

forth while pushing down onto drain

connector at the bottom of the wash-

er. Continue until hose contacts the

ribbed stop on the cabinet.

Y

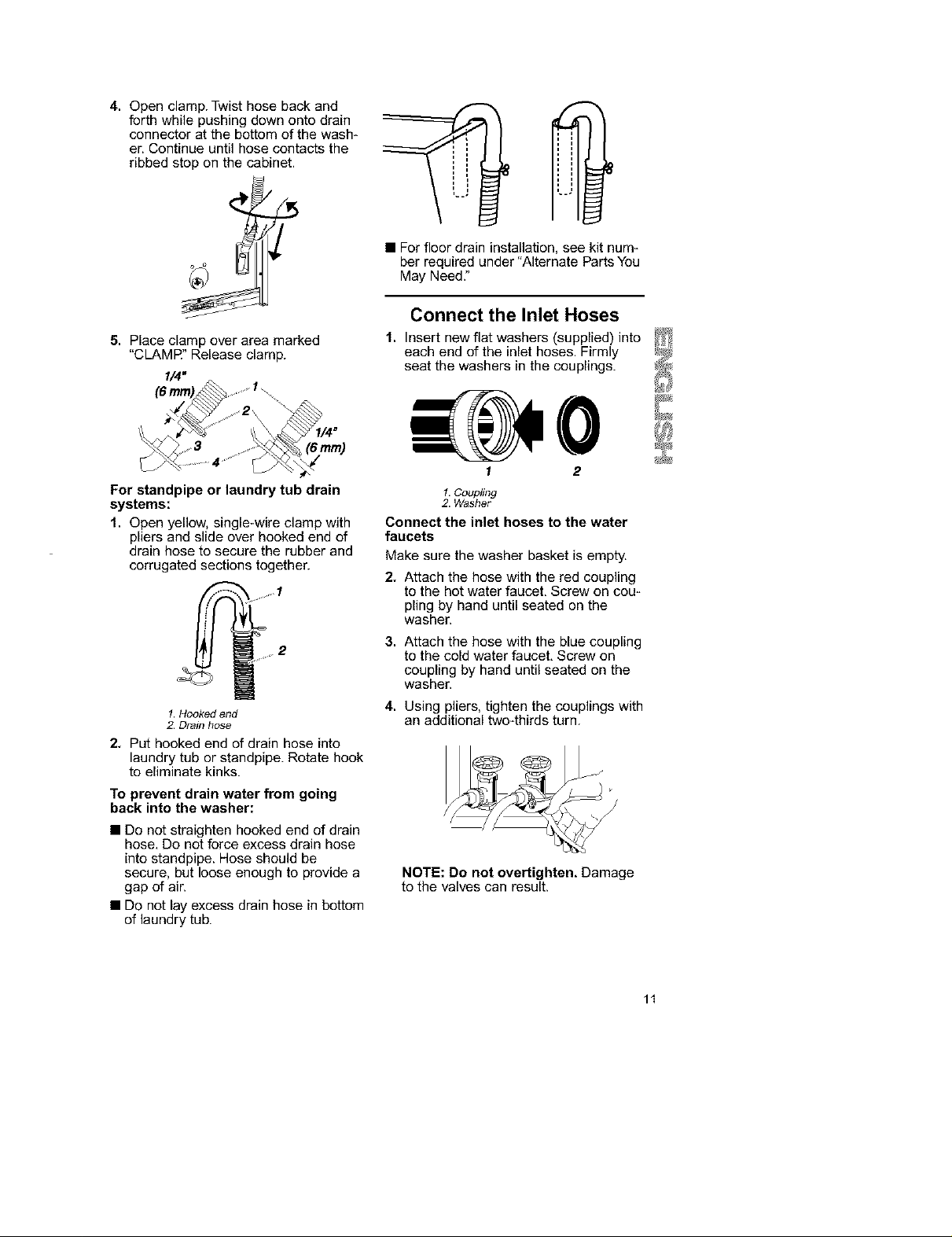

5. Place clamp over area marked

"CLAMP." Release clamp.

1/4"

rnm)

For standpipe or laundry tub drain

systems:

1. Open yellow, single-wire clamp with

pliers and slide over hooked end of

drain hose to secure the rubber and

corrugated sections together.

1.Hooked end

2. Drain hose

2. Put hooked end of drain hose into

laundry tub or standpipe. Rotate hook

to eliminate kinks.

To prevent drain water from going

back into the washer:

• Do not straighten hooked end of drain

hose, Do not force excess drain hose

into standpipe. Hose should be

secure, but loose enough to provide a

gap of air.

• Do not lay excess drain hose in bottom

of laundry tub.

• For floor drain installation, see kit num-

ber required under "Alternate Parts You

May Need."

Connect the Inlet Hoses

1.

Insert new flat washers (supplied) into

each end of the inlet hoses. Firmly

seat the washers in the couplings.

1 2

1. Coupling

2. Washer

Connect the inlet hoses to the water

faucets

Make sure the washer basket is empty.

2. Attach the hose with the red coupling

to the hot water faucet, Screw on cou-

pling by hand until seated on the

washer.

3. Attach the hose with the blue coupling

to the cold water faucet, Screw on

coupling by hand until seated on the

washer.

4. Using pliers, tighten the couplings with

an additional two4hirds turn.

NOTE: Do not overtighten, Damage

to the valves can result.

11

Loading...

Loading...