Page 1

Use & Care Guide

Manual de uso y cuidado

Guide d'utilisation et d'entretien

English / Espafiol / Fran_ais

Models/Modelos/Mod_les: 106.5478% 106.5479 _

I(enmore Elite

@ @ @

,,:,::,:color number, n@nero de colo_, le num@o de la couleur

P/N W10305237A

Sears Brands Management Corporation

Hoffman Estates, IL, U.S.A. 60179

www.kenmore.com

www.sears.com

Sears Canada Inc.

Toronto, Ontario, Canada M5B 2C3

www.sears.ca

Page 2

TABLE OF CONTENTS

PROTECTION AGREEMENTS ........................................................ 2

WARRANTY .................................................................................. 3

REFRIGERATOR SAFETY .............................................................. 4

Proper Disposal of Your Old Refrigerator ......................................... 4

INSTALLATION INSTRUCTIONS ................................................... 5

Unpack the Refrigerator ....................................................................... 5

Location Requirements ........................................................................... 5

Electrical Requirements ......................................................................... 6

Water Supply Requirements ................................................................ 6

Refrigerator Doors .................................................................................. 7

Connect Water Supply .......................................................................... 9

Prepare the Water System .................................................................. 10

Normal Sounds ....................................................................................... 10

REFRIGERATOR USE .................................................................... 11

Ensuring Proper Air Circulation ............................................................ 11

Using the Controls .................................................................................. 11

Water and Ice Dispensers ................................................................... 12

Water Filter Status Light ...................................................................... 14

Water Filtration System ....................................................................... 14

Ice Maker and Storage Bin .................................................................. 15

REFRIGERATOR FEATURES ......................................................... 16

Refrigerator Shelves .............................................................................. 16

Dell Drawer ............................................................................................. 16

Convertible Vegetable/Meat Drawer, Crisper and Covers .......... 17

Convertible Vegetable/Meat Drawer Temperature Control ........17

Crisper Humidity Control ..................................................................... 17

Wine or Can/Bottle Rack ................................................................... 18

Utility Bin................................................................................................. 18

FREEZER FEATURES ..................................................................... 18

Freezer Shelf .......................................................................................... 18

Freezer Basket or Bin ............................................................................ 18

DOOR FEATURES ......................................................................... 19

Door Bins................................................................................................. 19

Door Rails or Bins .................................................................................. 19

Tilt-out Freezer Door Bin ...................................................................... 19

Chilled Door Bin .................................................................................... 19

Tilt-out Fruit Bin ..................................................................................... 20

REFRIGERATOR CARE ................................................................ 20

Cleaning .................................................................................................. 20

Changing the Light Bulbs ...................................................................... 21

Power Interruptions ............................................................................... 22

Vacation and Moving Care ................................................................ 22

TROUBLESHOOTING .................................................................. 23

Refrigerator Operation ........................................................................ 23

Temperature and Moisture .................................................................. 24

Ice and Water ....................................................................................... 24

ACCESSORI ES............................................................................. 25

WATER FILTER CERTIFICATIONS ............................................... 26

PERFORMANCE DATA SHEET .................................................... 27

SERVICE NUMBERS .................................................. BACK COVER

PROTECTION AGREEMENTS

Master Protection Agreements

Congratulations on making a smart purchase. Your new Kenmore ®

product is designed and manufactured for years of dependable

operation. But like all products, it may require preventive

maintenance or repair from time to time. That's when having a

Master Protection Agreement can save you money and

aggravation.

The Master Protection Agreement also helps extend the life of your

new product. Here's what the Agreement ¢ includes:

I#' Parts and labor needed to help keep products operating

properly under normal use, not just defects. Our coverage goes

well beyond the product warranty. No deductibles, no

functional failure excluded from coverage-- real protection.

I/Expert service by a force of more than 10,000 authorized Sears

service technicians, which means someone you can trust will be

working on your product.

I/Unlimited service calls and nationwide service, as often as you

want us, whenever you want us.

I/"No-lemon" guarantee - replacement of your covered product

if four or more product failures occur within twelve months.

I/Product replacement if your covered product can't be fixed.

I/Annual Preventive Maintenance Check at your request - no

extra charge.

JNDICE ......................................................................................... 31

TABLE DES MATII:RES ................................................................. 62

I/Fast help by phone - we call it Rapid Resolution - phone

support from a Sears representative on all products. Think of us

as a "talking owner's manual."

I/Power surge protection against electrical damage due to power

fluctuations.

I/$250 Food Loss Protection annually for any food spoilage that

is the result of mechanical failure of any covered refrigerator or

freezer.

I/Rental reimbursement if repair of your covered product takes

longer than promised.

I/10% discount off the regular price of any non-covered repair

service and related installed parts.

Once you purchase the Agreement, a simple phone call is all that it

takes for you to schedule service. You can call anytime day or

night, or schedule a service appointment online.

The Master Protection Agreement is a risk free purchase. If you

cancel for any reason during the product warranty period, we will

provide a full refund. Or, a prorated refund anytime after the

product warranty period expires. Purchase your Master Protection

Agreement today!

Some limitations and exclusions apply. For prices and additional

information in the U.S.A. call 1-800-827-6655.

'_Coverage in Canada varies on some items. For full details call

Sears Canada at 1-800-361-6665.

2

Page 3

Sears Installation Service

For Sears professional installation of home appliances, garage

door openers, water heaters, and other major home items, in the

U.S.A. or Canada call 1-800-4-MY-HOME ®.

KENMORE LIMITED WARRANTY

When installed, operated and maintained according to all

instructions supplied with the product, if any non-consumable part

of this appliance other than the sealed refrigerant system fails due

to a defect in material and workmanship within one year from the

date of purchase, call 1-800-4-MY-HOME ® to arrange for free

repair. This coverage applies for only 90 days from the date of

purchase if this appliance is ever used for other than private family

purposes.

If the sealed refrigerant system is defective within five years from

the purchase date, call 1-800-4-MY-HOME ® to arrange for free

repair. This coverage applies for only one year from the date of

purchase if this appliance is ever used for other than private family

purposes.

This warranty covers only defects in material and workmanship.

Sears will NOT pay for:

1. Expendable items that can wear out from normal use, including

but not limited to filters, belts, light bulbs, and bags.

2. A service technician to instruct the user in correct product

installation, operation or maintenance.

3. A service technician to clean or maintain this product.

4. Damage to or failure of this product if it is not installed,

operated or maintained according to the all instructions

supplied with the product.

5. Damage to or failure of this product resulting from accident,

abuse, misuse or use for other than its intended purpose.

6. Damage to or failure of this product caused by the use of

detergents, cleaners, chemicals or utensils other than those

recommended in all instructions supplied with the product.

7. Damage to or failure of parts or systems resulting from

unauthorized modifications made to this product.

Disclaimer of implied warranties; limitation of remedies

Customer's sole and exclusive remedy under this limited warranty

shall be product repair as provided herein. Implied warranties,

including warranties of merchantability or fitness for a particular

purpose, are limited to one year or the shortest period allowed by

law. Sears shall not be liable for incidental or consequential

damages. Some states and provinces do not allow the exclusion or

limitation of incidental or consequential damages, or limitation on

the duration of implied warranties of merchantability or fitness, so

these exclusions or limitations may not apply to you.

This warranty applies only while this appliance is used in the United

States or Canada.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Sears Brands Management Corporation

Hoffman Estates, IL 60179

Sears Canada Inc.

Toronto, Ontario, Canada M5B 2C3

PRODUCT RECORD

Record your complete model number, serial number, and purchase

date. You can find this information on the model and serial number

label located on the product.

Have this information available to help you obtain assistance or

service more quickly whenever you contact Sears concerning your

appliance.

Model number

Serial number

Purchase date

Save these instructions and your sales receipt for future reference.

Page 4

REFRIGERATOR SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury when using your refrigerator, follow these basic precautions:

• Plug into a grounded 3 prong outlet.

• Do not remove ground prong.

• Do not use an adapter.

• Do not use an extension cord.

• Disconnect power before servicing.

• Replace all parts and panels before operating.

• Remove doors from your old refrigerator.

SAVE THESE INSTRUCTIONS

• Use nonflammable cleaner.

• Keep flammable materials and vapors, such as gasoline,

away from refrigerator.

• Use two or more people to move and install refrigerator.

• Disconnect power before installing ice maker (on ice maker

kit ready models only).

• Use a sturdy glass when dispensing ice (on some models).

• Do not hit the refrigerator glass doors (on some models).

Proper Disposalof YourOld Refrigerator

Suffocation Hazard

Remove doors from your old refrigerator.

Failure to do so can result in death or brain damage.

IMPORTANT: Child entrapment and suffocation are not problems

of the past. Junked or abandoned refrigerators are still dangerous -

even if they will sit for "just a few days." If you are getting rid of

your old refrigerator, please follow these instructions to help

prevent accidents.

Before You Throw Away Your Old Refrigerator or Freezer-

• Take off the doors.

• Leave the shelves in place so that children may not easily climb

inside.

4

Page 5

INSTALLATION INSTRUCTIONS

Excessive Weight Hazard

Use two or more people to move and install

refrigerator.

Failure to do so can result in back or other injury.

Remove the Packaging

Remove tape and glue residue from surfaces before turning on

the refrigerator. Rub a small amount of liquid dish soap over

the adhesive with your fingers. Wipe with warm water and dry.

Do not use sharp instruments, rubbing alcohol, flammable

fluids, or abrasive cleaners to remove tape or glue. These

products can damage the surface of your refrigerator. For more

information see "Refrigerator Safety."

When Moving Your Refrigerator:

Your refrigerator is heavy. When moving the refrigerator for

cleaning or service, be sure to cover the floor with

cardboard or hardboard to avoid floor damage. Always pull

the refrigerator straight out when moving it. Do not wiggle or

"walk" the refrigerator when trying to move it, as floor

damage could occur.

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from refrigerator.

Failure to do so can result in death, explosion, or fire.

To ensure proper ventilation for your refrigerator, allow for 1/2"

(1.25 cm) of space on each side and at the top. Allow for 1"

(2.54 cm) of space behind the refrigerator. If your refrigerator has

an ice maker, allow extra space at the back for the water line

connections. When installing your refrigerator next to a fixed wall,

leave a 2" (5.08 cm) minimum space on each side (depending on

your model) to allow the doors to swing open.

FqFq

t/2" (1.25 cm)

Clean Before Using

After you remove all of the packaging materials, clean the inside of

your refrigerator before using it. See the cleaning instructions in

"Refrigerator Care."

important information to know about glass shelves

and covers:

Do not clean glass shelves or covers with warm water when

they are cold. Shelves and covers may break if exposed to

sudden temperature changes or impact, such as bumping.

Tempered glass is designed to shatter into many small,

pebble-size pieces. This is normal. Glass shelves and covers

are heavy. Use both hands when removing them to avoid

dropping.

- II -- I

III

- /

ii

2" (5.08 crn)!

NOTES:

It is recommended that you do not install the refrigerator near

an oven, radiator, or other heat source. Do not install in a

location where the temperature will fall below 55°F (13°C).

Normal minimum cabinet cut-out width required for product

installation is 36" (91.44 cm). However, if the product is placed

against an extended wall and the ability to remove the crisper

pans is desired, an additional 18" (45.72 cm) of cabinet width

is required, so a total cabinet opening width of 54" (137.16 cm)

is recommended.

Page 6

_i ec_:s" _ _,t__!eq_,__eme_'_'s_,,

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed here.

TOOLS NEEDED:

• Flat-blade screwdriver • 1/4"Nut driver

• 7,_6" and 1/2" Open-end or two • 1/4" Drill bit

adjustable wrenches

• Cordless drill

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death_

fire_ or electrical shock.

Before you move your refrigerator into its final location, it is

important to make sure you have the proper electrical connection.

Recommended Grounding Method

A 115 Volt, 60 Hz., AC only, 15- or 20-amp fused, grounded

electrical supply is required. It is recommended that a separate

circuit serving only your refrigerator be provided. Use an outlet that

cannot be turned off by a switch. Do not use an extension cord.

NOTE: Before performing any type of installation, cleaning, or

removing a light bulb, turn the control (Thermostat, Refrigerator or

Freezer Control depending on the model) to OFF and then

disconnect the refrigerator from the electrical source. When you

are finished, reconnect the refrigerator to the electrical source and

reset the control (Thermostat, Refrigerator or Freezer Control

depending on the model) to the desired setting. See "Using the

Controls."

NOTE: Your refrigerator dealer has a kit available with a 1/4"

(6.35 ram) saddle-type shutoff valve, a union, and copper tubing.

Before purchasing, make sure a saddle-type valve complies with

your local plumbing codes. Do not use a piercing-type or 3_6"

(4.76 ram) saddle valve which reduces water flow and clogs more

easily.

IMPORTANT:

• All installations must meet local plumbing code requirements.

• Use copper tubing and check for leaks. Install copper tubing

only in areas where the household temperatures will remain

above freezing.

Water Pressure

A cold water supply with water pressure of between 30 and 120 psi

(207 and 827 kPa) is required to operate the water dispenser and

ice maker. If you have questions about your water pressure, call a

licensed, qualified plumber.

Reverse Osmosis Water Supply

IMPORTANT: The pressure of the water supply coming out of a

reverse osmosis system going to the water inlet valve of the

refrigerator needs to be between 30 and 120 psi (207 and

827 kPa).

If a reverse osmosis water filtration system is connected to your

cold water supply, the water pressure to the reverse osmosis system

needs to be a minimum of 40 to 60 psi (276 to 414 kPa).

If the water pressure to the reverse osmosis system is less than 40 to

60 psi (276 to 414 kPa):

• Check to see whether the sediment filter in the reverse osmosis

system is blocked. Replace the filter if necessary.

Allow the storage tank on the reverse osmosis system to refill

after heavy usage.

If your refrigerator has a water filter, it may further reduce the

water pressure when used in conjunction with a reverse osmosis

system. Remove the water filter. See "Water Filtration System."

If you have questions about your water pressure, call a licensed,

qualified plumber.

6

Page 7

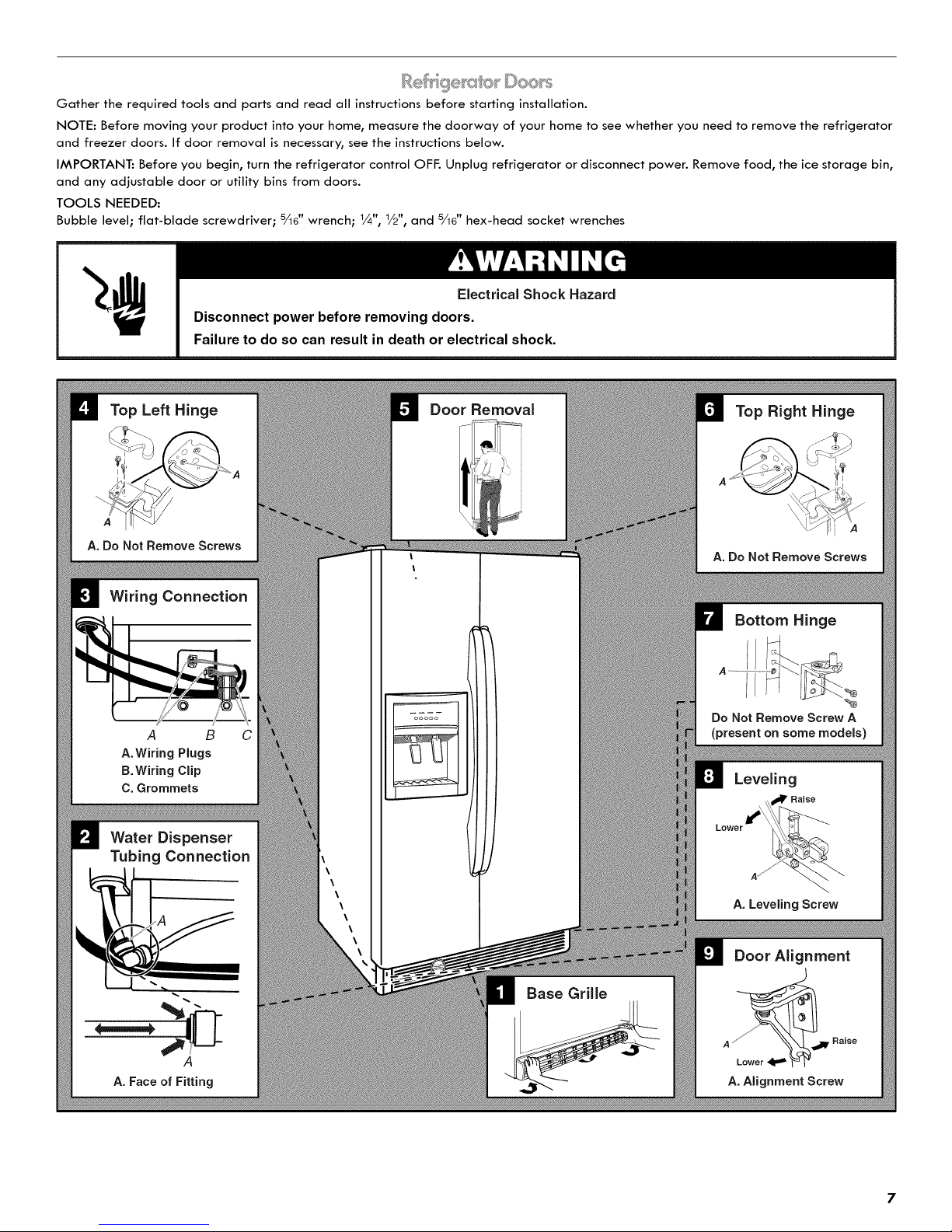

Gather the required tools and parts and read all instructions before starting installation.

NOTE: Before moving your product into your home, measure the doorway of your home to see whether you need to remove the refrigerator

and freezer doors. If door removal is necessary, see the instructions below.

IMPORTANT: Before you begin, turn the refrigerator control OFF. Unplug refrigerator or disconnect power. Remove food, the ice storage bin,

and any adjustable door or utility bins from doors.

TOOLS NEEDED:

Bubble level; flat-blade screwdriver; 5_6" wrench; 1,_,, 1/2-, and 5_6" hex-head socket wrenches

Electrical Shock Hazard

Disconnect power before removing doors.

Failure to do so can result in death or electrical shock.

Top Left Hinge

A. Do Not Remove Screws

Wiring Connection

A B C

A. Wiring Plugs

B.Wiring Clip

C. Grommets

Water Dispenser

Tubing Connection

Door Removal

Top Right Hinge

A. Do Not Remove Screws

Bottom Hinge

Do Not Remove Screw A

(present on some models)

Leveling

r Raise

A

A. Face of Fitting

Base Grille

A. Leveling Screw

Door Alignment

,j,,

A "__ Raise

Lower _ "_ 1_

A. Alignment Screw

Page 8

Remove the Doors

Electrical Shock Hazard

Disconnect power before removing doors.

Failure to do so can result in death or electrical shock.

1.

Unplug refrigerator or disconnect power.

2.

Open both refrigerator doors. Remove the base grille by

pulling up on the bottom outside corners. See Graphic 1.

3.

Disconnect the water dispenser tubing located behind the base

grille on the freezer door side. The dispenser tubing runs

through the door hinge, and must be disconnected in order to

remove the door. See Graphic 2.

• Press blue outer ring against the face of fitting and pull the

dispenser tubing free.

NOTE: Keep the water tubing connector attached to the

tube that runs underneath the freezer. The door cannot be

removed if the connector is still attached to the tube that

runs through the door hinge.

4.

Disconnect the wiring located behind the base grille on the

freezer door side. See Graphic 3.

• Remove the wiring cllp using a 1/4,,hex-head socket wrench.

• Disconnect wiring plugs.

5. Close both doors and keep them closed until you are ready to

lift them free from the cabinet.

6. Use a 5,_6"hex-head socket wrench to remove the top left hinge

screw and cover as shown. See Graphic 4.

Z Remove remaining left hinge screws and hinge as shown. See

Graphic 4.

IMPORTANT: Do not remove either screw A.

8. Lift freezer door straight up off bottom hinge. See Graphic 5.

The water dispenser tubing and wiring remain attached to the

freezer door and pull through the bottom left hinge. Be sure to

avoid damaging the dispenser tubing and wiring.

9. Remove top right hinge cover and screws as shown. See

Graphic 6.

IMPORTANT: Do not remove either screw A.

10. Lift the refrigerator door straight up off bottom hinge.

11. It may not be necessary to remove the bottom hinges to move

the refrigerator through a doorway. Both bottom hinges have

similar construction.

If necessary, disassemble the hinges as shown. See

Graphic 7.

IMPORTANT: To aid in door alignment and closing, there is

a shim located between the hinge and the cabinet. When

the hinge is removed, the shim may fall out of place. If this

occurs, set the shim aside so it can be put back in place

when the hinge is reconnected later.

Replace the Doors and Hinges

1. Replace both bottom hinges, if removed. Make sure the shim is

between the hinge and cabinet. Tighten screws.

2. Before replacing the freezer door on the bottom left hinge,

feed the wiring with the yellow plug and the water dispenser

tubing through the hinge. Assistance may be needed.

NOTE: Provide additional support for the doors while the top

hinges are being replaced. Do not depend on the door magnets to

hold the doors in place while you are working.

3. Align and replace the top left hinge as shown. See Graphic 4.

Tighten screws.

4. Replace left hinge cover and screws.

5. Reconnect water dispenser tubing and wiring.

IMPORTANT: Do not intertwine the water tubing and wiring

bundles when reconnecting them.

• Push tubing into fitting until it stops and the black mark

touches the face of fitting. See Graphic 2.

• Reconnect wiring plugs. Reinstall the wiring clip over the

grommets. Tighten screw. See Graphic 3.

6. Replace the refrigerator door by lifting the door onto the

bottom right hinge.

7. Align and replace the top right hinge as shown. See Graphic 6.

Tighten screws.

8. Replace hinge cover and screws. Tighten screws.

9. Plug into a grounded 3 prong outlet.

Leveling and Door Closing

Your refrigerator has two front adjustable rollers --one on the right

and one on the left. If your refrigerator seems unsteady or if you

want the doors to close more easily, adjust the refrigerator's tilt

using the instructions below:

1. Move the refrigerator into its final location.

2. The two leveling screws are part of the front roller assemblies

which are at the base of the refrigerator on either side. See

Graphic 8.

NOTE: Having someone push against the top of the refrigerator

takes some weight off the leveling screws and rollers. This makes it

easier to adjust the screws.

3. Use a 1/2" hex-head socket wrench to adjust the leveling screws.

Turn the leveling screw to the right to raise that side of the

refrigerator or turn the leveling screw to the left to lower that

side. It may take several turns of the leveling screws to adjust

the tilt of the refrigerator. See Graphic 8.

4. Open both doors again and check that they close as easily as

you like. If not, tilt the refrigerator slightly more to the rear by

turning both leveling screws to the right. It may take several

more turns, and you should turn both leveling screws the same

amount.

5. Use a bubble level to check the leveling of the refrigerator.

Page 9

Door Alignment

A refrigerator that is not level from side-to-side may appear to

have doors that are not properly aligned. If the doors appear this

way, use the instructions in the previous section to check the

leveling.

The doors are designed to be slightly different heights when the

refrigerator is empty, in order to account for the weight of food

that will be placed on the doors. If the doors are still not aligned

after checking the leveling and loading the refrigerator with food,

follow the steps below to adjust the door alignment.

1. Locate the alignment screw on the bottom hinge of the

refrigerator door. See Graphic 9.

2. Use a 5,_6" wrench to turn the screw. To raise the refrigerator

door, turn the screw to the right. To lower the door, turn the

screw to the left.

3. Check that the doors are even at the top and bottom. If

necessary, continue to turn the alignment screw until the doors

are aligned.

4. Replace the base grille.

NOTE: Be sure to refasten the Tech Sheet behind the base grille.

Read all directions before you begin.

IMPORTANT.- If you turn the refrigerator on before the water line is

connected, turn the ice maker OFF.

Connect to Water Line

1. Unplug refrigerator or disconnect power.

2. Turn OFF main water supply. Turn ON nearest faucet long

enough to clear line of water.

3. Locate a 1/2" (1.27 cm) to 11/4'' (3.18 cm) vertical cold water pipe

near the refrigerator.

IMPORTANT:

• Make sure it is a cold water pipe.

• Horizontal pipe will work, but drill on the top side of the

pipe, not the bottom. This will help keep water away from

the drill and normal sediment from collecting in the valve.

4. Determine the length of copper tubing you need. Measure from

the connection on the lower rear corner of refrigerator to the

water pipe. Add 7 ft (2.1 m) to allow for cleaning. Use 1¼,,

(6.35 ram) O.D. (outside diameter) copper tubing. Be sure both

ends of copper tubing are cut square.

5. Using a cordless drill, drill a 1/4" (6.35 ram) hole in the cold

water pipe you have selected.

6. Fasten the shutoff valve to the cold water pipe with the pipe

clamp. Be sure the outlet end is solidly in the 1/4" (6.35 mm)

drilled hole in the water pipe and that the washer is under the

pipe clamp. Tighten the packing nut. Tighten the pipe clamp

screws slowly and evenly so the washer makes a watertight

seal. Do not overtighten, or you may crush the copper tubing.

7. Slip the compression sleeve and compression nut on the copper

tubing as shown. Insert the end of the tubing into the outlet end

squarely as far as it will go. Screw the compression nut onto

outlet end with adjustable wrench. Do not overtighten.

8. Place the free end of the tubing in a container or sink, and turn

ON the main water supply. Flush the tubing until water is clear.

Turn OFF the shutoff valve on the water pipe. Coil the copper

tubing.

Connect to Refrigerator

Style 1

I. Unplug refrigeratorordisconnect power.

2.

Remove and discard the plastic part that is attached to the

inlet of the water valve.

3.

Attach the copper tube to the valve inlet using a compression

nut and sleeve as shown. Tighten the compression nut. Do not

overtig hten.

4.

Use the tube clamp on the back of the refrigerator to secure

the tubing to the refrigerator as shown. This will help avoid

damage to the tubing when the refrigerator is pushed back

against the wall.

5.

Turn shutoff valve ON.

6.

Check for leaks. Tighten any connections (including connections

at the valve) or nuts that leak.

A

.............B

.................... C

D

E

A. Tube clamp

B, Tube clamp screw

C, Copper tubing

7.

The ice maker is equipped with a built-in water strainer. If your

water conditions require a second water strainer, install it in the

1/4" (6.35 mm) water line at either tube connection. Obtain a

water strainer from your nearest appliance dealer.

D. Compression nut

E. Valve inlet

A. Cold water pipe

B. Pipe clamp

C, Copper tubing

D, Compression nut

E. Compression sleeve

F, Shutoff valve

G, Packing nut

Style 2

1. Unplug refrigerator or disconnect power.

2. Remove and discard the black nylon plug from the gray water

tube on the rear of the refrigerator.

3. If the gray water tube supplied with the refrigerator is not long

enough, a 1/4" x 1/4" (6.35 mm x 6.35 mm) coupling is needed in

order to connect the water tubing to an existing household

water line. Thread the provided nut onto the coupling on the

end of the copper tubing.

Page 10

NOTE: Tighten the nut by hand. Then tighten it with a wrench

two more turns. Do not overtighten.

A B C

A. Refrigerator water tubing

B, Nut (provided]

C.Bulb

D. Coupling (purchased)

4.

Turn shutoff valve ON.

5.

Check for leaks. Tighten any nuts or connections (including

connections at the valve) that leak.

D E F G

E.Ferrule (purchased]

F, Nut (purchased)

G, Household water line

9 epc_e _he W_e_ _Sys_e_'_

Please read before using the water system.

Immediately after installation, follow the steps below to make sure

that the water system is properly cleaned.

1. Open the freezer door and turn off the ice maker. The On/Off

switch is located on the top right side of the freezer

compartment. Move the switch to the OFF (right) setting as

shown.

Style 3

1. Unplug refrigerator or disconnect power.

2. Remove and discard the cap from the gray water tube.

A B

A. Cap

B.In/et

3.

Using a compression nut and sleeve, attach the copper tube to

the water inlet.

4.

Once secured, tighten the compression nut. Do not overtighten.

5.

Check the connection by pulling on the copper tubing. Turn on

water supply to refrigerator. Check for leaks. Tighten any nuts

or connections that leak.

Complete the Installation

NOTE: Make sure the base grille filter is properly installed and the

cap is in the horizontal position.

Do not use with water that is microbiologically unsafe or

of unknown quality without adequate disinfection before

or after the system. Systems certified for cyst reduction

may be used on disinfected waters that may contain

filterable cysts.

2. Flush the water system. Use a sturdy container to depress and

hold the water dispenser lever for 5 seconds, then release it for

5 seconds. Repeat until water begins to flow. Once water

begins to flow, continue depressing and releasing the dispenser

lever (5 seconds on, 5 seconds off) until a total of 3 gal. (12 L)

has been dispensed. This will flush air from the filter and water

dispensing system, and prepare the water filter for use.

Additional flushing may be required in some households. As air

is cleared from the system, water may spurt out of the

dispenser.

3. Open the freezer door and turn on the ice maker. Move the

switch to the ON (left) position. Please refer to the "Ice Maker

and Storage Bin" section for further instructions on the

operation of your ice maker.

• Allow 24 hours to produce the first batch of ice.

• Discard the first three batches of ice produced.

• Depending on your model, you may want to select the

maximum ice feature to increase the production of ice.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

1. Plug into a grounded 3 prong outlet.

2. Flush the water system. See "Prepare the Water System" or

"Water and Ice Dispensers."

NOTE: Allow 24 hours to produce the first batch of ice. Allow

3 days to completely fill ice container.

10

Your new refrigerator may make sounds that your old one didn't

make. Because the sounds are new to you, you might be concerned

about them. Most of the new sounds are normal. Hard surfaces,

such as the floor, walls, and cabinets, can make the sounds seem

louder. The following describes the kinds of sounds and what may

be making them.

• If your refrigerator is equipped with an ice maker, you will hear

a buzzing sound when the water valve opens to fill the ice

maker for each cycle.

Page 11

Your refrigerator is designed to run more efficiently to keep

your food items at the desired temperatures and to minimize

energy usage. The high efficiency compressor and fans may

cause your refrigerator to run longer than your old one. You

may also hear a pulsating or high-pitched sound from the

compressor or fans adjusting to optimize performance.

You may hear the evaporator fan motor circulating air through

the refrigerator and freezer compartments. The fan speed may

increase as you open the doors or add warm food.

Rattling noises may come from the flow of refrigerant, the

water line, or items stored on top of the refrigerator.

Water dripping on the defrost heater during a defrost cycle

may cause a sizzling sound.

As each cycle ends, you may hear a gurgling sound due to the

refrigerant flowing in your refrigerator.

Contraction and expansion of the inside walls may cause a

popping noise.

You may hear air being forced over the condenser by the

condenser fan.

You may hear water running into the drain pan during the

defrost cycle.

REFRIGERATOR USE

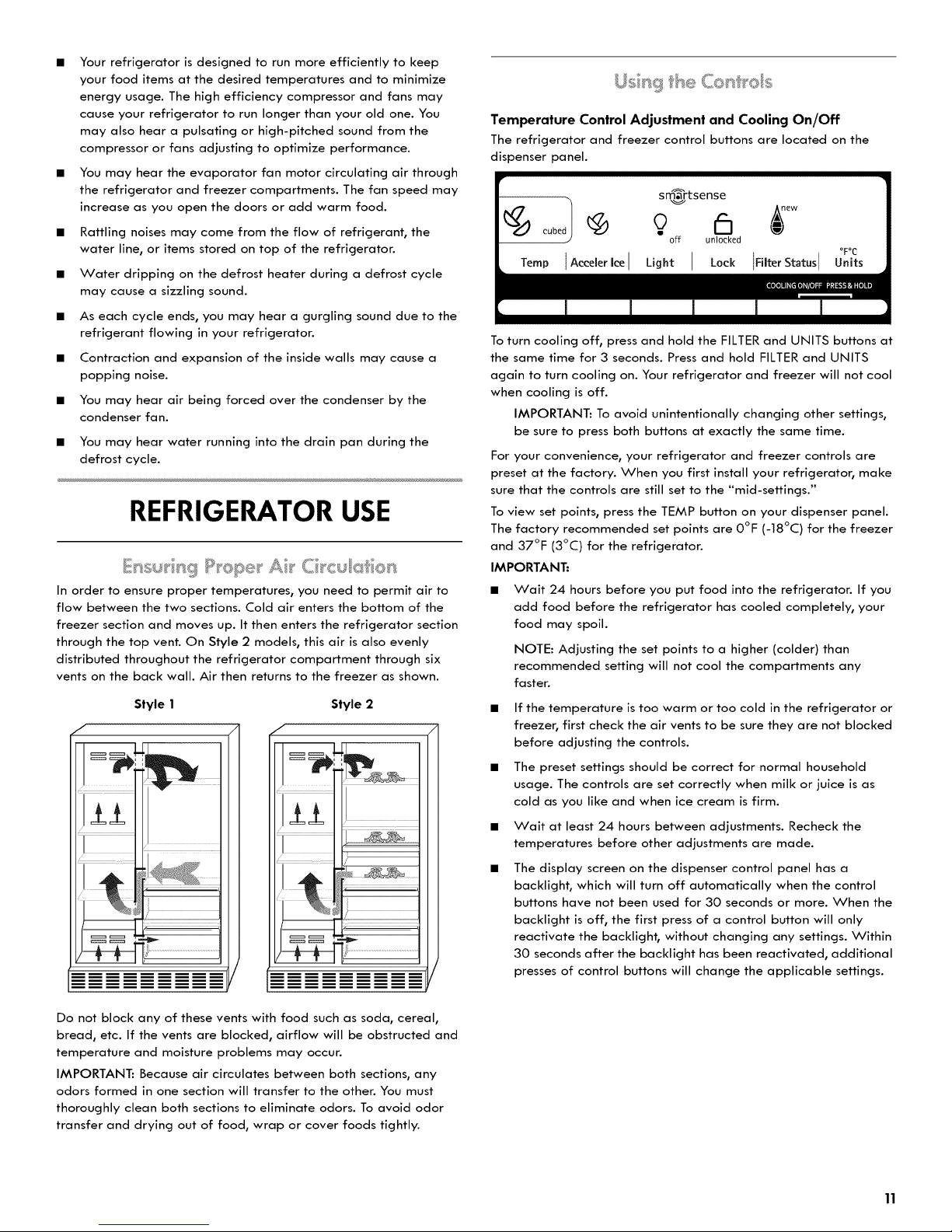

In order to ensure proper temperatures, you need to permit air to

flow between the two sections. Cold air enters the bottom of the

freezer section and moves up. It then enters the refrigerator section

through the top vent. On Style 2 models, this air is also evenly

distributed throughout the refrigerator compartment through six

vents on the back wall. Air then returns to the freezer as shown.

Style I Style 2

/

I

Usir g s

Temperature Control Adjustment and Cooling On/Off

The refrigerator and freezer control buttons are located on the

dispenser panel.

smartsense

9 6

off unlocked

Light I Lock

To turn cooling off, press and hold the FILTER and UNITS buttons at

the same time for 3 seconds. Press and hold FILTER and UNITS

again to turn cooling on. Your refrigerator and freezer will not cool

when cooling is off.

IMPORTANT: To avoid unintentionally changing other settings,

be sure to press both buttons at exactly the same time.

For your convenience, your refrigerator and freezer controls are

preset at the factory. When you first install your refrigerator, make

sure that the controls are still set to the "mid-settings."

To view set points, press the TEMP button on your dispenser panel.

The factory recommended set points are 0°F (-18°C) for the freezer

and 37°F (3°C) for the refrigerator.

IMPORTANT:

• Wait 24 hours before you put food into the refrigerator. If you

add food before the refrigerator has cooled completely, your

food may spoil.

NOTE: Adjusting the set points to a higher (colder) than

recommended setting will not cool the compartments any

faster.

If the temperature is too warm or too cold in the refrigerator or

freezer, first check the air vents to be sure they are not blocked

before adjusting the controls.

The preset settings should be correct for normal household

usage. The controls are set correctly when milk or juice is as

cold as you like and when ice cream is firm.

Wait at least 24 hours between adjustments. Recheck the

temperatures before other adjustments are made.

The display screen on the dispenser control panel has a

backlight, which will turn off automatically when the control

buttons have not been used for 30 seconds or more. When the

backlight is off, the first press of a control button will only

reactivate the backlight, without changing any settings. Within

30 seconds after the backlight has been reactivated, additional

presses of control buttons will change the applicable settings.

Units

Do not block any of these vents with food such as soda, cerea b

bread, etc. If the vents are blocked, airflow will be obstructed and

temperature and moisture problems may occur.

IMPORTANT: Because air circulates between both sections, any

odors formed in one section will transfer to the other. You must

thoroughly clean both sections to eliminate odors. To avoid odor

transfer and drying out of food, wrap or cover foods tightly.

11

Page 12

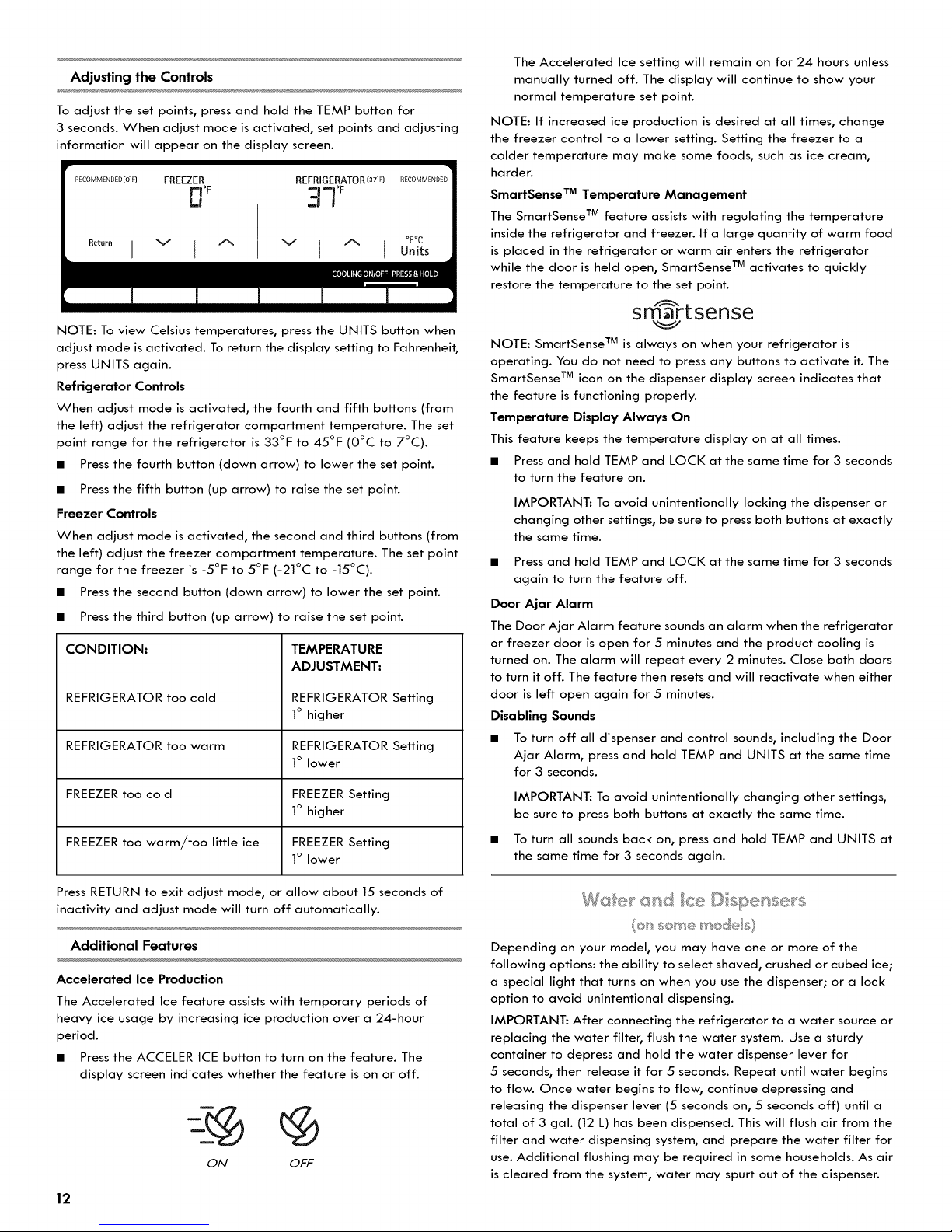

AdjustingtheControls

To adjust the set points, press and hold the TEMP button for

3 seconds. When adjust mode is activated, set points and adjusting

information will appear on the display screen.

RECOMMENDED[dF] FREEZER REFRIGERATOR[37_F) RECOMMENDED

I v I ^

NOTE: To view Celsius temperatures, press the UNITS button when

adjust mode is activated. To return the display setting to Fahrenheit,

press UNITS again.

Refrigerator Controls

When adjust mode is activated, the fourth and fifth buttons (from

the left) adjust the refrigerator compartment temperature. The set

point range for the refrigerator is 33°F to 45°F (0°C to 7°C).

• Press the fourth button (down arrow) to lower the set point.

• Press the fifth button (up arrow) to raise the set point.

Freezer Controls

When adjust mode is activated, the second and third buttons (from

the left) adjust the freezer compartment temperature. The set point

range for the freezer is -5°F to 5°F (-21°C to -15°C).

• Press the second button (down arrow) to lower the set point.

• Press the third button (up arrow) to raise the set point.

CONDITION: TEMPERATURE

REFRIGERATOR too cold REFRIGERATOR Setting

REFRIGERATOR too warm REFRIGERATOR Setting

FREEZER too cold FREEZER Setting

FREEZER too warm/too little ice FREEZER Setting

rl°F -I -| °F

u =| I

v I ^ I u°its

ADJUSTMENT:

1° higher

1° lower

1° higher

1° lower

OFOC

The Accelerated Ice setting will remain on for 24 hours unless

manually turned off. The display will continue to show your

normal temperature set point.

NOTE: If increased ice production is desired at all times, change

the freezer control to a lower setting. Setting the freezer to a

colder temperature may make some foods, such as ice cream,

harder.

SmartSense TM Temperature Management

The SmartSense TM feature assists with regulating the temperature

inside the refrigerator and freezer. If a large quantity of warm food

is placed in the refrigerator or warm air enters the refrigerator

while the door is held open, SmartSense TM activates to quickly

restore the temperature to the set point.

smartsense

NOTE: SmartSense TM is always on when your refrigerator is

operating. You do not need to press any buttons to activate it. The

SmartSense TM icon on the dispenser display screen indicates that

the feature is functioning properly.

Temperature Display Always On

This feature keeps the temperature display on at all times.

• Press and hold TEMP and LOCI( at the same time for 3 seconds

to turn the feature on.

IMPORTANT: To avoid unintentionally locking the dispenser or

changing other settings, be sure to press both buttons at exactly

the same time.

• Press and hold TEMP and LOCI( at the same time for 3 seconds

again to turn the feature off.

Door Ajar Alarm

The Door Ajar Alarm feature sounds an alarm when the refrigerator

or freezer door is open for 5 minutes and the product cooling is

turned on. The alarm will repeat every 2 minutes. Close both doors

to turn it off. The feature then resets and will reactivate when either

door is left open again for 5 minutes.

Disabling Sounds

• To turn off all dispenser and control sounds, including the Door

Ajar Alarm, press and hold TEMP and UNITS at the same time

for 3 seconds.

IMPORTANT: To avoid unintentionally changing other settings,

be sure to press both buttons at exactly the same time.

To turn all sounds back on, press and hold TEMP and UNITS at

the same time for 3 seconds again.

Press RETURN to exit adjust mode, or allow about 15 seconds of

inactivity and adjust mode will turn off automatically.

Additional Features

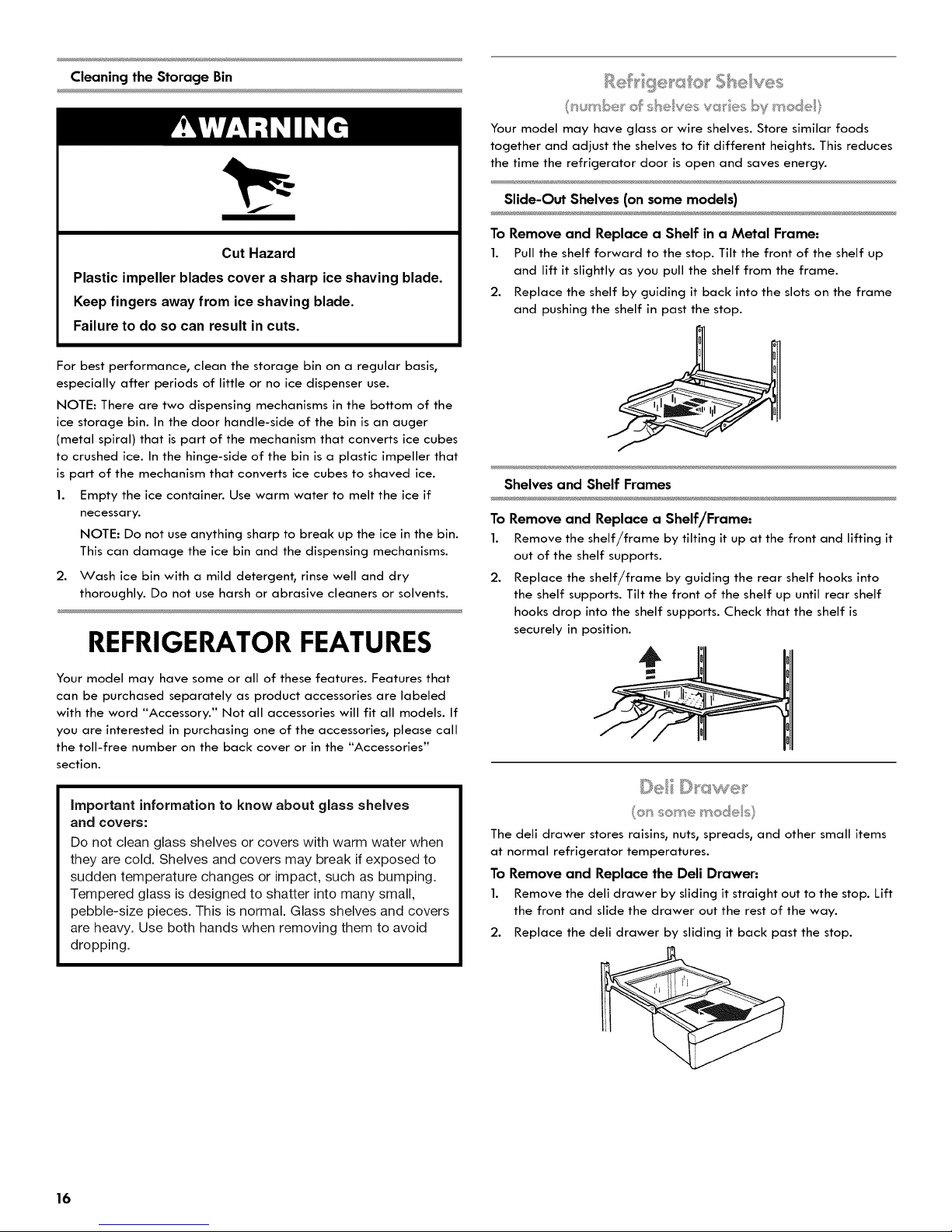

Accelerated Ice Production

The Accelerated Ice feature assists with temporary periods of

heavy ice usage by increasing ice production over a 24-hour

period.

• Press the ACCELER ICE button to turn on the feature. The

display screen indicates whether the feature is on or off.

ON OFF

12

W{_te_" _;_ndce D spense_s

(o/_ss,_i;_memodes}

Depending on your model, you may have one or more of the

following options: the ability to select shaved, crushed or cubed ice;

a special light that turns on when you use the dispenser; or a lock

option to avoid unintentional dispensing.

IMPORTANT: After connecting the refrigerator to a water source or

replacing the water filter, flush the water system. Use a sturdy

container to depress and hold the water dispenser lever for

5 seconds, then release it for 5 seconds. Repeat until water begins

to flow. Once water begins to flow, continue depressing and

releasing the dispenser lever (5 seconds on, 5 seconds off) until a

total of 3 gal. (12 L) has been dispensed. This will flush air from the

filter and water dispensing system, and prepare the water filter for

use. Additional flushing may be required in some households. As air

is cleared from the system, water may spurt out of the dispenser.

Page 13

NOTES:

• The dispensing system will not operate when the freezer door is

open.

• Allow 24 hours for the refrigerator to cool down and chill

water.

Allow 24 hours to produce the first batch of ice. Discard the

first three batches of ice produced.

The display screen on the dispenser control panel has a

backlight, which will turn off automatically when the control

buttons have not been used for 30 seconds or more. When the

backlight is off, the first press of a control button will only

reactivate the backlight, without changing any settings. Within

30 seconds after the backlight has been reactivated, additional

presses of control buttons will change the applicable settings.

The Water Dispenser

IMPORTANT: Dispense at least 1 qt (1 L) of water every week to

maintain a fresh supply.

To Dispense Water:

1. Press a sturdy glass against the water dispenser pad OR place

the glass below the water dispenser and press the water

dispenser button.

@

2. Remove the glass OR release the button to stop dispensing.

IMPORTANT: Depending on your model, the small removable tray

at the bottom of the dispenser is designed to catch small spills and

allow for easy cleaning. There is no drain in the tray. The tray can

be removed from the dispenser and carried to the sink to be

emptied or cleaned.

The Ice Dispenser

Ice dispenses from the ice maker storage bin in the freezer when

the dispenser pad is pressed. The dispensing system will not operate

when the freezer door is open. To turn off the ice maker, see "Ice

Maker and Storage Bin."

Your ice maker can produce shaved, crushed and cubed ice. Before

dispensing ice, select which type of ice you prefer by pressing the

ICE SELECT button.

To Dispense Ice:

1. Press the button to select the desired type of ice.

Cut Hazard

Use a sturdy glass when dispensing ice.

Failure to do so can result in cuts.

2.

Press a sturdy glass against the ice dispenser pad OR place

the glass below the ice dispenser and press the ice dispenser

button.

@

Hold the glass close to the dispenser opening so ice does not

fall outside of the glass.

IMPORTANT: You do not need to apply a lot of pressure to the

pad or button in order to activate the ice dispenser. Pressing

hard will not make the ice dispense faster or in greater

quantities.

3.

Remove the glass OR release the button to stop dispensing.

NOTE: Ice may continue to dispense for several seconds after

removing the glass from the pad or releasing the button. The

dispenser may continue to make noise for a few seconds after

dispensing.

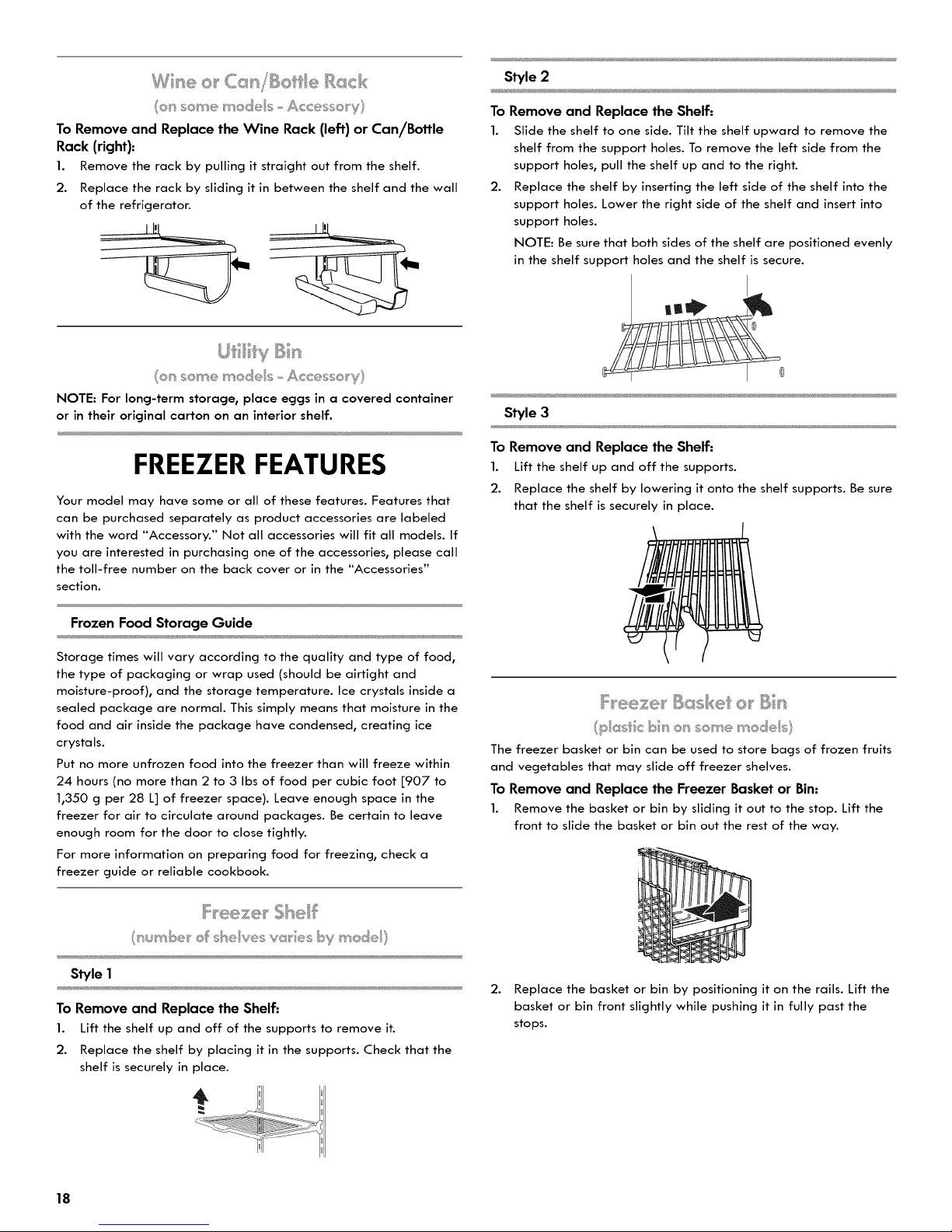

The Dispenser Light (on some models)

When you use the dispenser, the light will automatically turn on.

If you want the light to be on continuously, you may choose either

ON or AUTO. The display screen indicates which mode is selected.

!

g g w

on auto off

ON A UTO OFF

The display screen indicates which type of ice is selected.

"°. o

SHAVED CRUSHED CUBED

For shaved or crushed ice, cubes are shaved/crushed before being

dispensed. This may cause a slight delay when dispensing shaved

or crushed ice. Noise from the ice crusher is normal_ and pieces of

ice may vary in size. When changing from crushed to cubed, a few

ounces of crushed ice will be dispensed along with the first cubes.

ON: Press LIGHT to turn the dispenser light on.

AUTO: Press LIGHT a second time to select AUTO mode. The

dispenser light will automatically adjust to become brighter as the

room brightens, and dimmer as the room darkens.

OFF: Press LIGHT a third time to turn the dispenser light off.

The dispenser lights are LEDs that cannot be changed. If it appears

that your dispenser lights are not working, see "Troubleshooting" for

more information.

13

Page 14

The Dispenser Lock (on some models)

The dispenser can be turned off for easy cleaning or to avoid

unintentional dispensing by small children and pets.

NOTE: The lock feature does not shut off power to the refrigerator,

to the ice maker, or to the dispenser light. It simply deactivates the

dispenser controls and levers. To turn off the ice maker, see "Ice

Maker and Storage Bin."

• Press and hold LOCI( for 3 seconds to lock the dispenser.

• Press and hold LOCI( a second time to unlock the dispenser.

The display screen indicates when the dispenser is locked.

db @

locked unlocked

LOCKED UNL OCKED

The water filter status light will help you know when to change your

water filter. When the water filter status display changes from

"GOOD" to "ORDER," this tells you that it is almost time to change

the water filter cartridge. Replace the water filter cartridge when

the water filter status display changes to "REPLACE." If water flow

to your water dispenser or ice maker decreases noticeably, change

the filter sooner. The filter should be replaced at least every

6 months depending on your water quality and usage. To change

the filter, see "Water Filtration System."

IN DICATOR: STATUS:

Do not use with water that is microbiologically unsafe or

of unknown quality without adequate disinfection before

or after the system. Systems certified for cyst reduction

may be used on disinfected waters that may contain

filterable cysts.

Changing the Water Filter

The water filter is located in the base grille below the freezer

compartment door. It is not necessary to remove the base grille to

remove the filter.

1. Remove the filter by pressing the eject button and pulling

straight out on the filter cap.

NOTES:

• Avoid twisting the cap when removing the filter because

this could cause the cap to come off. If this occurs, replace

the cap and pull the filter straight out.

• There will be water in the filter. Some spilling may occur.

NEW or GOOD (green) New filter installed

ORDER (yellow) Order filter

REPLACE (red) OR Replace water filter

when water flow decreases

After changing the water filter, reset the status light by pressing

and holding the FILTER button for 3 seconds. The status light will

change from Replace (red) to New/Good (green) when the system

is reset.

Style I Style 2

ew GOOD

good

order ORDER

ki.) replace REPLACE

PRESS & HOLD

TO RESET Filter Status

A, Eject button

B, Filter cap

2.

Remove the cap by turning it counterclockwise until it stops.

IMPORTANT: Do not discard the cap. It is part of your

refrigerator. Keep the cap to use with the replacement filter.

3.

Take the new cartridge out of its packaging and remove the

covers from O-rings.

A. Cover

B. O-ring

14

Page 15

4.

Place the cap (removed in Step 2) on the new filter. Align the

ridge on the cap with the arrow on the filter. Turn the cap

clockwise until it snaps into place.

A. Eject button

B, Arrow on filter

C. Ridge on cap

5. Push the new filter into the opening in the base grille. As the

filter is inserted, the eject button will depress. The eject button

will pop back out when the filter is fully engaged.

6. Pull gently on the cap to check that the filter is securely in

place.

7. Flush the water system. See "Water and Ice Dispensers."

Using the Dispenser Without the Water Filter Cartridge

You can run the dispenser without a water filter cartridge. Your

water will not be filtered.

1. Remove the filter by pressing the eject button and pulling on

the cap. See "Changing the Water Filter" earlier in this section.

2. Remove the cap by turning it counterclockwise until it stops.

IMPORTANT: Do not discard the cap. It is part of your

refrigerator. Keep the cap to use with the replacement filter.

3. With the cap in a horizontal position, insert the cap into the

base grille until it stops.

Turning the Ice Maker On/Off

The On/Off switch is located on the top right side of the freezer

compartment.

• To turn on the ice maker, slide the control to the ON (left)

position.

• To manually turn off the ice maker, slide the control to the OFF

(right) position.

NOTE: Your ice maker has an automatic shutoff. The ice maker

sensor passes a beam from one freezer wall to the other,

automatically stopping ice production when the storage bin is full.

The control will remain in the ON (left) position.

REMEMBER:

• Allow 24 hours to produce the first batch of ice. Allow 3 days

to completely fill ice container.

• Discard the first three batches of ice produced to avoid

impurities that may be flushed out of the system.

• The quality of your ice will be only as good as the quality of the

water supplied to your ice maker.

Avoid connecting the ice maker to a softened water supply.

Water softener chemicals (such as salt) can damage parts of

the ice maker and lead to poor quality ice. If a softened water

supply cannot be avoided, make sure the water softener is

operating properly and is well maintained.

• It is normal for the ice cubes to be attached at the corners.

They will break apart easily.

• Do not store anything on top of the ice maker or in the storage

bin.

4.

Turn the cap counterclockwise until the cap slips into the

attachment slot. Then, turn the cap clockwise until it is in a

horizontal position.

NOTE: The cap will not be even with the base grille.

Removing and Replacing the Storage Bin

1.

Hold the base of the storage bin with both hands and press the

release button to lift the storage bin up and out.

NOTE: It is not necessary to turn the ice maker control to the

OFF (right) position when removing the storage bin. The sensor

cover ("flipper door") on the left wall of the freezer stops the

ice maker from producing ice if the door is open or the storage

bin is removed.

2.

Replace the storage bin on the door and push down to make

sure it is securely in place.

/

15

Page 16

CleaningtheStorageBin

CutHazard

Plasticimpellerbladescoverasharpiceshavingblade.

Keepfingers away from ice shaving blade.

Failure to do so can result in cuts.

For best performance, clean the storage bin on a regular basis,

especially after periods of little or no ice dispenser use.

NOTE: There are two dispensing mechanisms in the bottom of the

ice storage bin. In the door handle-side of the bin is an auger

(metal spiral) that is part of the mechanism that converts ice cubes

to crushed ice. In the hinge-side of the bin is a plastic impeller that

is part of the mechanism that converts ice cubes to shaved ice.

1. Empty the ice container. Use warm water to melt the ice if

necessary.

NOTE: Do not use anything sharp to break up the ice in the bin.

This can damage the ice bin and the dispensing mechanisms.

2. Wash ice bin with a mild detergent, rinse well and dry

thoroughly. Do not use harsh or abrasive cleaners or solvents.

REFRIGERATOR FEATURES

Your model may have some or all of these features. Features that

can be purchased separately as product accessories are labeled

with the word "Accessory." Not all accessories will fit all models. If

you are interested in purchasing one of the accessories, please call

the toll-free number on the back cover or in the "Accessories"

section.

Your model may have glass or wire shelves. Store similar foods

together and adjust the shelves to fit different heights. This reduces

the time the refrigerator door is open and saves energy.

Slide-Out Shelves (on some models)

To Remove and Replace a Shelf in a Metal Frame:

1. Pull the shelf forward to the stop. Tilt the front of the shelf up

and lift it slightly as you pull the shelf from the frame.

2. Replace the shelf by guiding it back into the slots on the frame

and pushing the shelf in past the stop.

Shelves and Shelf Frames

To Remove and Replace a Shelf/Frame:

1. Remove the shelf/frame by tilting it up at the front and lifting it

out of the shelf supports.

2. Replace the shelf/frame by guiding the rear shelf hooks into

the shelf supports. Tilt the front of the shelf up until rear shelf

hooks drop into the shelf supports. Check that the shelf is

securely in position.

4

Important information to know about glass shelves

and covers:

Do not clean glass shelves or covers with warm water when

they are cold. Shelves and covers may break if exposed to

sudden temperature changes or impact, such as bumping.

Tempered glass is designed to shatter into many small,

pebble-size pieces. This is normal. Glass shelves and covers

are heavy. Use both hands when removing them to avoid

dropping.

16

The deli drawer stores raisins, nuts, spreads, and other small items

at normal refrigerator temperatures.

To Remove and Replace the Deli Drawer:

1. Remove the dell drawer by sliding it straight out to the stop. Lift

the front and slide the drawer out the rest of the way.

2. Replace the dell drawer by sliding it back past the stop.

Page 17

(on s_ss_<_'sen'_odes}

Crisper and Convertible Vegetable/Meat Drawers

To Remove and Replace Drawers=

1. Slide crisper or meat drawer straight out to the stop. Lift the

front of drawer with one hand while supporting the bottom of

drawer with the other hand and slide the drawer out the rest of

the way.

2. Replace the crisper or meat drawer by sliding it back in fully

past the drawer stop.

To store vegetables: Set the control to VEG (all the way to the left)

to store vegetables at their optimal storage temperatures (which

need to be warmer than those for meat).

IMPORTANT: If food starts to freeze, move the control to the left

(less cold). Remember to wait 24 hours between adjustments. Doing

so gives the temperature of the food time to change.

Meat Storage Guide

Crisper or Vegetable/Meat Drawer Covers

To Remove and Replace Covers=

1. Remove the crisper and meat drawer. Press up in center of

crisper glass insert until it rises above the plastic frame. Holding

the crisper glass firmly, slowly slide the glass insert forward to

remove. Lift crisper cover frame and remove. Repeat steps to

remove the meat drawer cover.

2.

Replace back of meat drawer cover frame into supports or

slides on side walls of the refrigerator and lower or slide the

front of the cover frame into place. Slide rear of glass insert

into cover frame and lower front into place. Repeat steps to

replace the crisper cover.

+4 " ®M'/

The convertible vegetable/meat drawer can be adjusted to

properly chill meats or vegetables. The air inside the pan is cooled

to avoid "spot" freezing and can be set to keep meats at the

National Livestock and Meat Board recommended storage

temperatures of 28 ° to 32°F (-2 ° to 0°C).

IMPORTANT: To extend freshness, wrap meats in airtight, moisture-

proof materials before storing. Always store meat as

recommended.

Adjusting the Control:

The convertible control comes preset at the lowest meat setting.

To change a control setting: Move the control to the right (colder)

or to the left (less cold) as desired.

Store most meat in original wrapping as long as it is airtight and

moisture-proof. Rewrap if necessary. See the following chart for

storage times. When storing meat longer than the times given,

freeze the meat.

Fresh fish or shellfish ............................... use same day as purchased

Chicken, ground beef, variety meat (liver, etc.) .................... 1-2 days

Cold cuts, steaks/roasts ............................................................ 3-5 days

Cured meats ............................................................................ 7-10 days

Leftovers - Cover leftovers with plastic wrap, aluminum foil, or

plastic containers with tight lids.

(o_ so_sx_en-_ode/s)

You can control the amount of humidity in the moisture-sealed

crisper. Humidity Control is located on the crisper drawer. Adjust

the control to any setting between LOW and HIGH.

E/E

LOW (open) lets moist air out of the crisper for best storage of

fruits and vegetables with skins.

• Fruit: Wash, let dry and store in refrigerator in plastic bag

or crisper. Do not wash or hull berries until they are ready

to use. Sort and keep berries in original container in crisper,

or store in a loosely closed paper bag on a refrigerator

shelf.

• Vegetables with skins: Place in plastic bag or plastic

container and store in crisper.

HIGH (closed) keeps moist air in the crisper for best storage of

fresh, leafy vegetables.

• Leafy vegetables: Wash in cold water, drain and trim or

tear off bruised and discolored areas. Place in plastic bag

or plastic container and store in crisper.

17

Page 18

Style 2

(e_ se_'_e _s'_odes _,_Access® y

To Remove and Replace the Wine Rack (left) or Can/Bottle

Rack (right):

1. Remove the rack by pulling it straight out from the shelf.

2. Replace the rack by sliding it in between the shelf and the wall

of the refrigerator.

NOTE: For long-term storage, place eggs in a covered container

or in their original carton on an interior shelf.

FREEZER FEATURES

Your model may have some or all of these features. Features that

can be purchased separately as product accessories are labeled

with the word "Accessory." Not all accessories will fit all models. If

you are interested in purchasing one of the accessories, please call

the toll-free number on the back cover or in the "Accessories"

section.

To Remove and Replace the Shelf:

1. Slide the shelf to one side. Tilt the shelf upward to remove the

shelf from the support holes. To remove the left side from the

support holes, pull the shelf up and to the right.

2. Replace the shelf by inserting the left side of the shelf into the

support holes. Lower the right side of the shelf and insert into

support holes.

NOTE: Be sure that both sides of the shelf are positioned evenly

in the shelf support holes and the shelf is secure.

Style 3

To Remove and Replace the Shelf:

1. Lift the shelf up and off the supports.

2. Replace the shelf by lowering it onto the shelf supports. Be sure

that the shelf is securely in place.

Frozen Food Storage Guide

Storage times will vary according to the quality and type of food,

the type of packaging or wrap used (should be airtight and

moisture-proof), and the storage temperature. Ice crystals inside a

sealed package are normal. This simply means that moisture in the

food and air inside the package have condensed, creating ice

crystals.

Put no more unfrozen food into the freezer than will freeze within

24 hours (no more than 2 to 3 Ibs of food per cubic foot [907 to

1,350 g per 28 L] of freezer space). Leave enough space in the

freezer for air to circulate around packages. Be certain to leave

enough room for the door to close tightly.

For more information on preparing food for freezing, check a

freezer guide or reliable cookbook.

su_'_u_be_'of she yes va®s b_!r_ode

Style I

To Remove and Replace the Shelf:

1. Lift the shelf up and off of the supports to remove it.

2. Replace the shelf by placing it in the supports. Check that the

shelf is securely in place.

F eez÷ ,"B ssk® Bir

p as_c b_ o_ss@_'s'sen'tode s

The freezer basket or bin can be used to store bags of frozen fruits

and vegetables that may slide off freezer shelves.

To Remove and Replace the Freezer Basket or Bin:

1. Remove the basket or bin by sliding it out to the stop. Lift the

front to slide the basket or bin out the rest of the way.

2. Replace the basket or bin by positioning it on the rails. Lift the

basket or bin front slightly while pushing it in fully past the

stops.

18

Page 19

DOOR FEATURES

Your model may have some or all of these features. Features that

can be purchased separately as product accessories are labeled

with the word "Accessory." Not all accessories will fit all models. If

you are interested in purchasing one of the accessories, please call

the toll-free number on the back cover or in the "Accessories"

section.

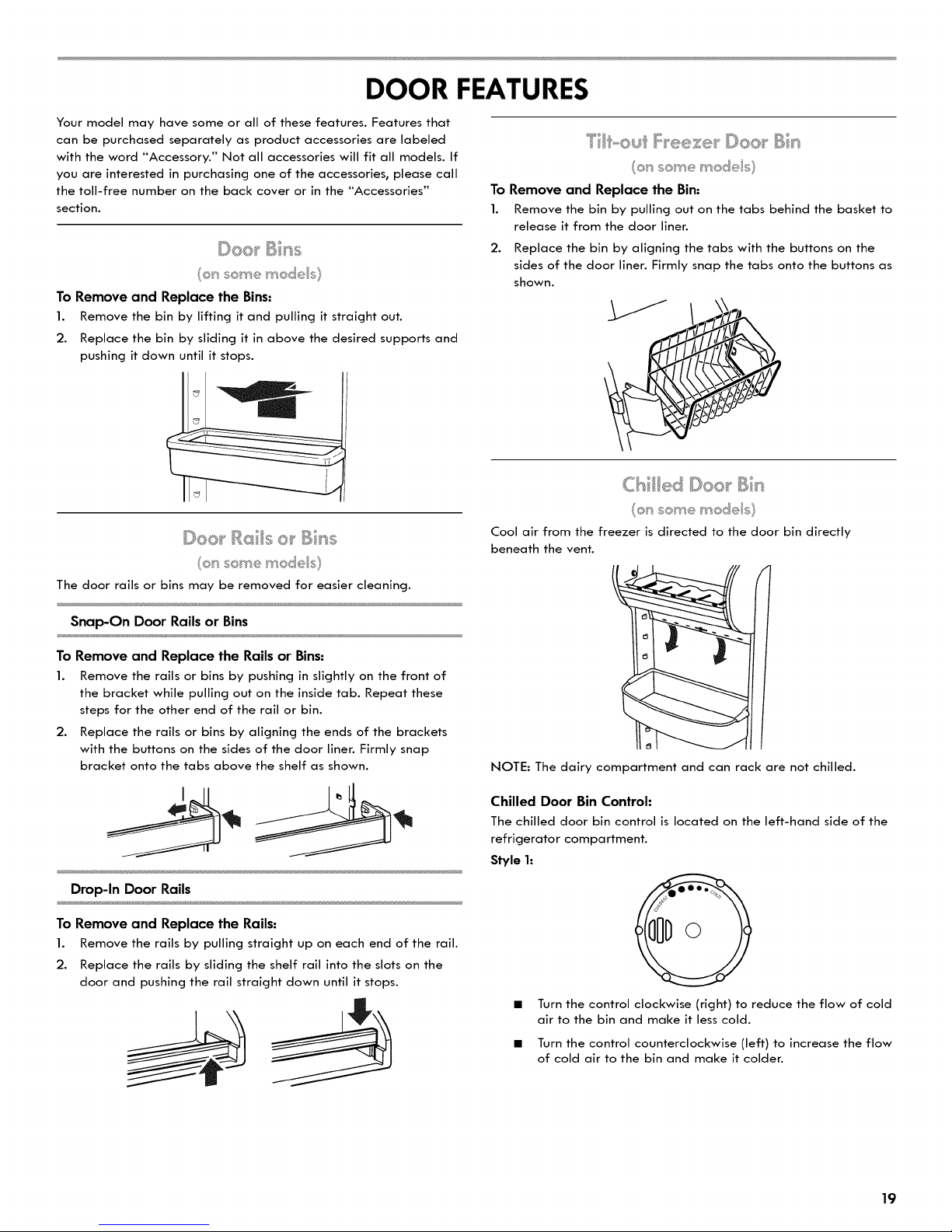

To Remove and Replace the Bins=

1. Remove the bin by lifting it and pulling it straight out.

2. Replace the bin by sliding it in above the desired supports and

pushing it down until it stops.

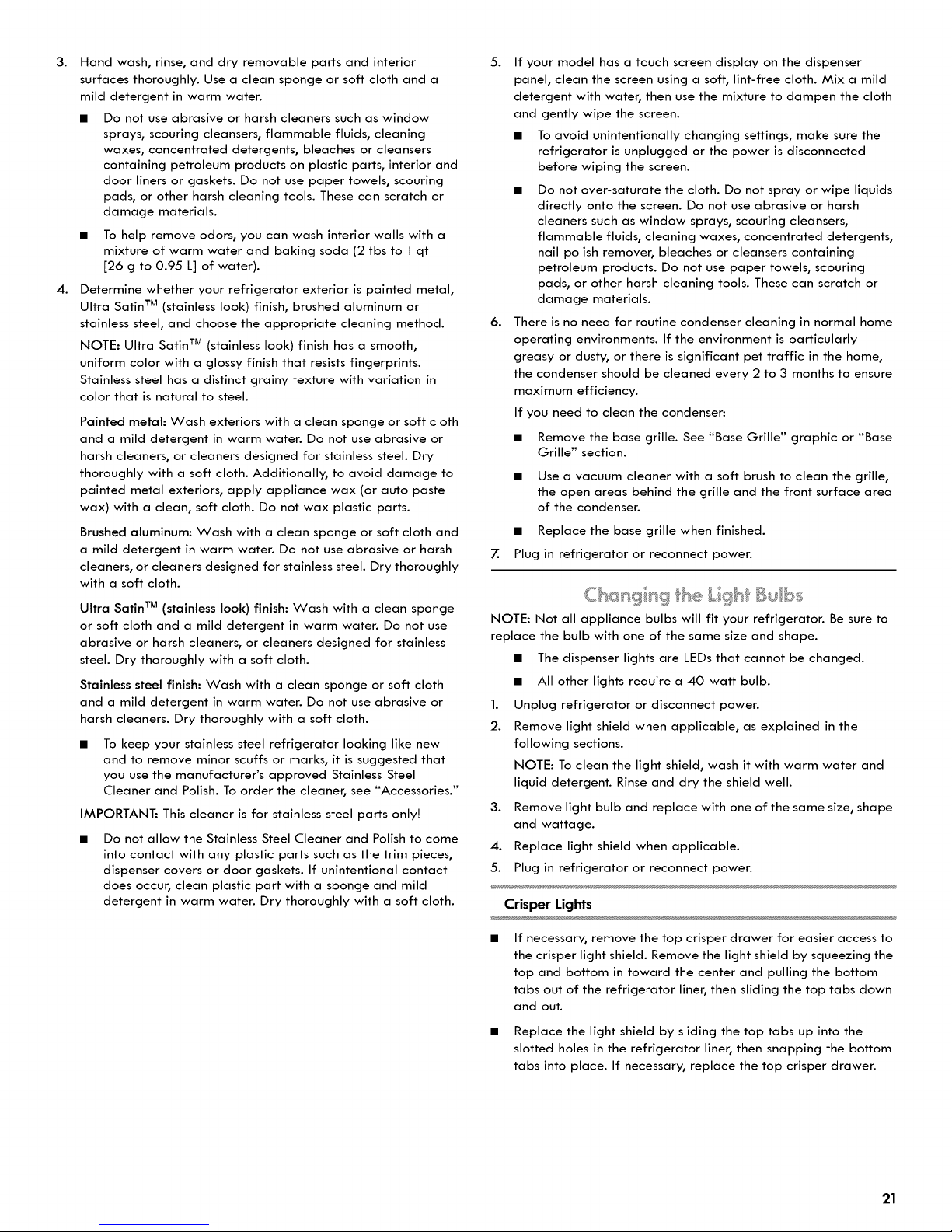

To Remove and Replace the Bin:

1. Remove the bin by pulling out on the tabs behind the basket to

release it from the door liner.

2. Replace the bin by aligning the tabs with the buttons on the

sides of the door liner. Firmly snap the tabs onto the buttons as

shown.

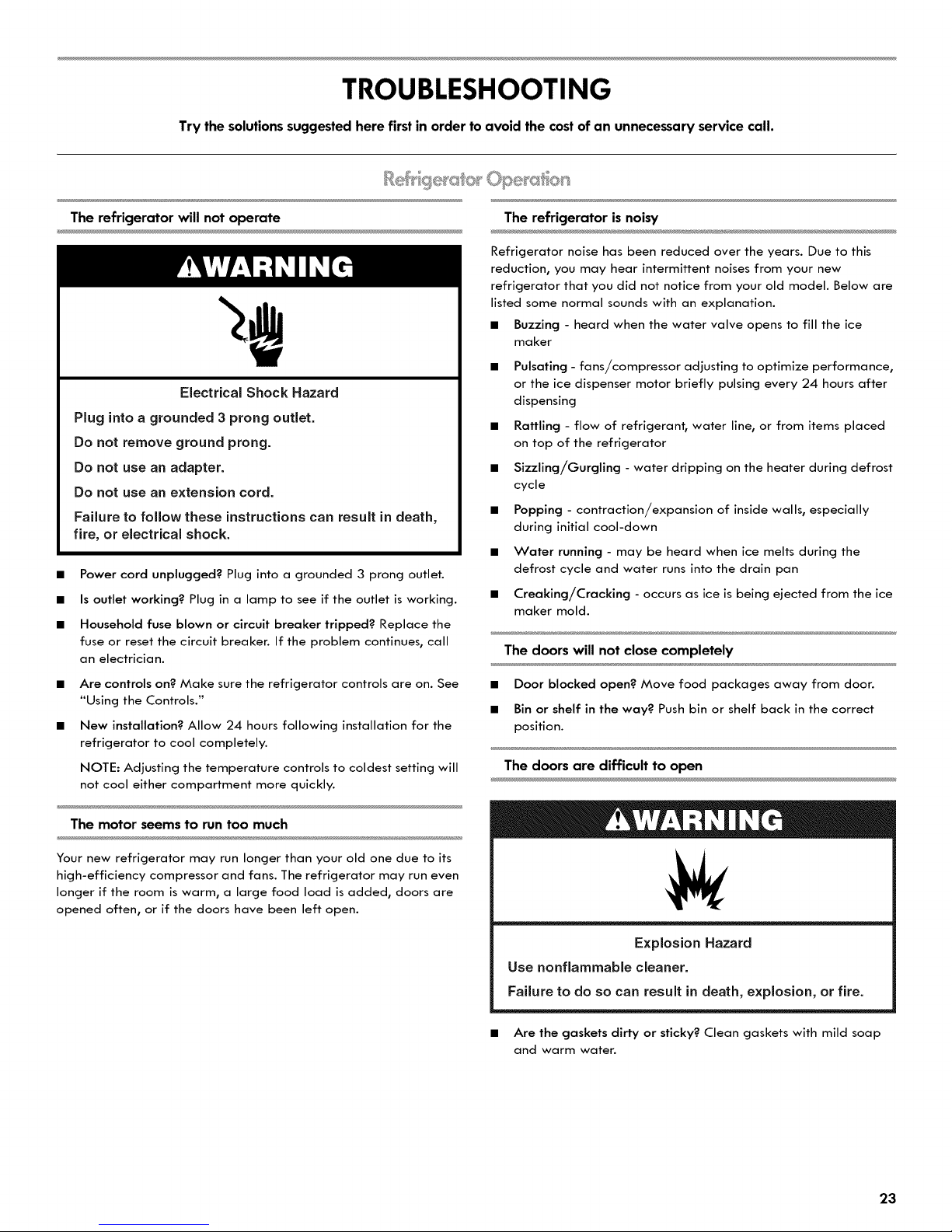

Cool air from the freezer is directed to the door bin directly

beneath the vent.

The door rails or bins may be removed for easier cleaning.

Snap-On Door Rails or Bins

To Remove and Replace the Rails or Bins=

I. Remove the rails or bins by pushing in slightly on the front of

the bracket while pulling out on the inside tab. Repeat these

steps for the other end of the rail or bin.

2. Replace the rails or bins by aligning the ends of the brackets

with the buttons on the sides of the door liner. Firmly snap

bracket onto the tabs above the shelf as shown.

Drop-ln Door Rails

To Remove and Replace the Rails=

1. Remove the rails by pulling straight up on each end of the rail.

2. Replace the rails by sliding the shelf rail into the slots on the

door and pushing the rail straight down until it stops.

NOTE: The dairy compartment and can rack are not chilled.

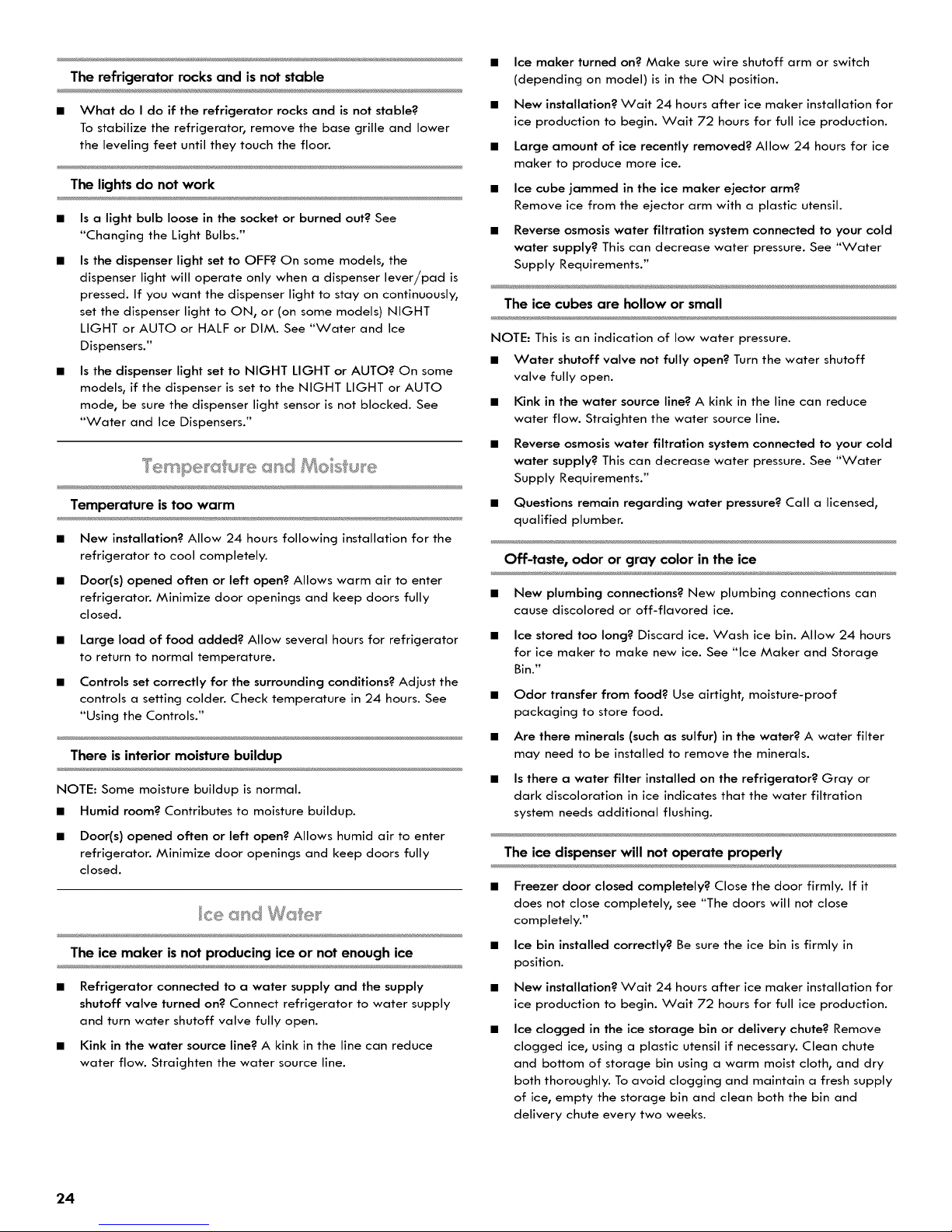

Chilled Door Bin Control:

The chilled door bin control is located on the left-hand side of the

refrigerator compartment.

Style 1"

Turn the control clockwise (right) to reduce the flow of cold

air to the bin and make it less cold.

Turn the control counterclockwise (left) to increase the flow

of cold air to the bin and make it colder.

19

Page 20

Style 2: • Clean the parts as instructed in the "Cleaning" section.

A .......

A. Chi/led door bin eontro/

Slide the control to the left to reduce the flow of cold air to

the bin and make it less cold.

Slide the control to the right to increase the flow of cold air

to the bin and make it colder.

To Remove and Replace the Bin:

1. Remove the bin by lifting it and pulling it straight out.

2. Replace the bin by sliding it in above the desired supports and

pushing it down until it stops.

I

To Remove and Replace the Bin Parts:

1. Press either release button to open the tilt-out portion of the bin.

A

A. Curved/ever

3. Reinstall the tilt-out portion of the bin. Be sure it is properly

seated in the bottom of the bin before inserting the curved

levers into position.

4. Replace the interior parts of the bin.

C

A. Strainer basket

B. Dividers

C, Strainer mat

REFRIGERATOR CARE

A. Release buttons

2.

To remove the tilt-out portion of the bin, press in on the curved

levers on each side of the bin. Pull up and out.

NOTES:

• The bin cannot be removed if it is tilted out all the way. Tilt

it only part of the way before pressing the curved levers to

remove it.

2O

Explosion Hazard

Use nonflammable cleaner.

Failure to do so can result in death, explosion, or fire.

Both the refrigerator and freezer sections defrost automatically.

However, clean both compartments about once a month to avoid

buildup of odors. Wipe up spills immediately.

To Clean Your Refrigerator:

1. Unplug refrigerator or disconnect power.

2. Remove all removable parts from inside, such as shelves,

crispers, etc.

Page 21

3.

Hand wash, rinse, and dry removable parts and interior

surfaces thoroughly. Use a clean sponge or soft cloth and a

mild detergent in warm water.

• Do not use abrasive or harsh cleaners such as window

sprays, scouring cleansers, flammable fluids, cleaning

waxes, concentrated detergents, bleaches or cleansers

containing petroleum products on plastic parts, interior and

door liners or gaskets. Do not use paper towels, scouring

pads, or other harsh cleaning tools. These can scratch or

damage materials.

To help remove odors, you can wash interior walls with a

mixture of warm water and baking soda (2 tbs to 1 qt

[26 g to 0.95 L] of water).

4.

Determine whether your refrigerator exterior is painted metal,

Ultra Satin TM (stainless look) finish, brushed aluminum or

stainless steel, and choose the appropriate cleaning method.

NOTE: Ultra Satin TM (stainless look) finish has a smooth,

uniform color with a glossy finish that resists fingerprints.

Stainless steel has a distinct grainy texture with variation in

color that is natural to steel.

Painted metal: Wash exteriors with a clean sponge or soft cloth

and a mild detergent in warm water. Do not use abrasive or

harsh cleaners, or cleaners designed for stainless steel. Dry

thoroughly with a soft cloth. Additionally, to avoid damage to

painted metal exteriors, apply appliance wax (or auto paste

wax) with a clean, soft cloth. Do not wax plastic parts.

Brushed aluminum: Wash with a clean sponge or soft cloth and

a mild detergent in warm water. Do not use abrasive or harsh

cleaners, or cleaners designed for stainless steel. Dry thoroughly

with a soft cloth.

Ultra Satin TM (stainless look) finish: Wash with a clean sponge

or soft cloth and a mild detergent in warm water. Do not use

abrasive or harsh cleaners, or cleaners designed for stainless

steel. Dry thoroughly with a soft cloth.

Stainless steel finish: Wash with a clean sponge or soft cloth

and a mild detergent in warm water. Do not use abrasive or

harsh cleaners. Dry thoroughly with a soft cloth.

To keep your stainless steel refrigerator looking like new

and to remove minor scuffs or marks, it is suggested that

you use the manufacturer's approved Stainless Steel

Cleaner and Polish. To order the cleaner, see '*Accessories."

IMPORTANT: This cleaner is for stainless steel parts only!

Do not allow the Stainless Steel Cleaner and Polish to come

into contact with any plastic parts such as the trim pieces,

dispenser covers or door gaskets. If unintentional contact

does occur, clean plastic part with a sponge and mild

detergent in warm water. Dry thoroughly with a soft cloth.

5. If your model has a touch screen display on the dispenser

panel, clean the screen using a soft, lint-free cloth. Mix a mild

detergent with water, then use the mixture to dampen the cloth

and gently wipe the screen.

• To avoid unintentionally changing settings, make sure the

refrigerator is unplugged or the power is disconnected

before wiping the screen.

• Do not over-saturate the cloth. Do not spray or wipe liquids

directly onto the screen. Do not use abrasive or harsh

cleaners such as window sprays, scouring cleansers,

flammable fluids, cleaning waxes, concentrated detergents,

nail polish remover, bleaches or cleansers containing

petroleum products. Do not use paper towels, scouring

pads, or other harsh cleaning tools. These can scratch or

damage materials.

6. There is no need for routine condenser cleaning in normal home

operating environments. If the environment is particularly

greasy or dusty, or there is significant pet traffic in the home,

the condenser should be cleaned every 2 to 3 months to ensure

maximum efficiency.

If you need to clean the condenser:

• Remove the base grille. See "Base Grille" graphic or "Base

Grille" section.

• Use a vacuum cleaner with a soft brush to clean the grille,

the open areas behind the grille and the front surface area

of the condenser.

• Replace the base grille when finished.

7.

Plug in refrigerator or reconnect power.

'4 _ • _ _

NOTE: Not all appliance bulbs will fit your refrigerator. Be sure to

replace the bulb with one of the same size and shape.

• The dispenser lights are LEDs that cannot be changed.

• All other lights require a 40-watt bulb.

1. Unplug refrigerator or disconnect power.

2. Remove light shield when applicable, as explained in the

following sections.

NOTE: To clean the light shield, wash it with warm water and

liquid detergent. Rinse and dry the shield well.

3. Remove light bulb and replace with one of the same size, shape

and wattage.

4. Replace light shield when applicable.

5. Plug in refrigerator or reconnect power.

Crisper Lights

If necessary, remove the top crisper drawer for easier access to

the crisper light shield. Remove the light shield by squeezing the

top and bottom in toward the center and pulling the bottom

tabs out of the refrigerator liner, then sliding the top tabs down

and out.

• Replace the light shield by sliding the top tabs up into the

slotted holes in the refrigerator liner, then snapping the bottom

tabs into place. If necessary, replace the top crisper drawer.

21

Page 22

UpperFreezerLight

• Remove the light shield by squeezing the sides of the light

shield in toward the center while pulling the shield forward as

shown.

• Replace the light shield by fitting the tabs into the slotted holes

in the freezer liner. Push in the shield until it snaps into place.

Lower Freezer Light Behind Top Freezer Basket

(on some models)

Depending on your model, remove the top freezer basket or

top freezer basket shelf. Remove light shield by removing the

Phillips screw on the top of the shield. Gently rotate the shield

until the left tab can be gently pulled from the freezer wall.

• Replace the light shield by inserting the left tab into the freezer

wall. Align top tab with screw hole and replace screw.

Vacations

If You Choose to Leave the Refrigerator On

While You Are Away:

1. Use up any perishables and freeze other items.

2. If your refrigerator has an automatic ice maker:

• Raise wire shutoff arm to OFF (up) position or move the

switch to the OFF (right) setting.

• Shut off water supply to the ice maker.

3. Empty the ice bin.

If You Choose to Turn the Refrigerator Off Before You Leave:

1. Remove all food from the refrigerator.

2. If your refrigerator has an automatic ice maker:

• Turn off the water supply to the ice maker at least one day

ahead of time.