Kendo 100, 200, 300, 400, 500 User Manual

...

KONDO

SEWII^

TABLE

0 F

CONTENTS

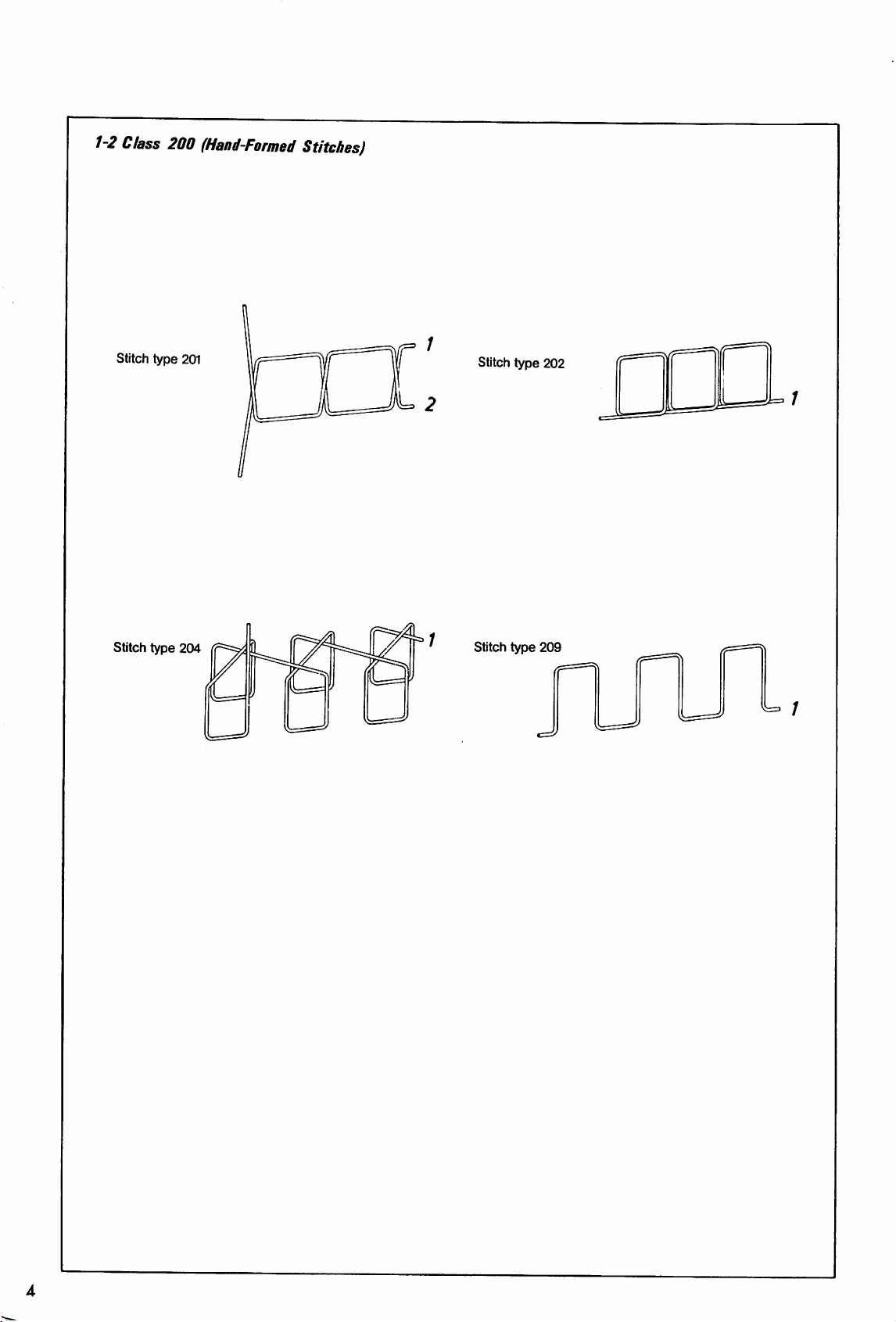

- 1

- 2

- 3

- 4

- 5

- 6

- 7

2.

2-1

2 — 2

2-3

General

Class

Class

Class

Class

Class

Class

Seam

Technical

Specification

List

list

Specifications

100

200

300

400

500

600

and

of

of

Chain

Hand—Formed

Lockstitches

Double Locked

Overedging

^

Flat

Stitching

Tables

Main

Folders

Spare

for

Stitches

Stitches

) —————————

Stitches

and

)

------

) —— ——————

Stitches

Stitches

Seam

of

and

and

Stitches

— — — — — — — — — — — — — —

Yamato

Adjustment

Parts

Sewing

- —— —

— — — — — — — .

Guides

) - - ———

)

———————

)

Machine

Seams

4

8

14

16

18

58

92

2 — 4

2—5

2—6

3,

3-1

3 —2

3—3

4«

4—1

4-2

Information

Product

Machines

Mechanical

Specification

Threading

Oil

Lublication

Construction

Comparison

Needle

Sizes

Needle Systems

of

Devices

classified

Informations

Chart

——————— ————— ———

— — —— — — — — .

by

Codes

Stitch

of

——————

Type

Yamato

Sewing

——•

Machine

Systems ——————————————— 128

of Machines —————————————— 138

Tables

————————————————————

-------------------

95

105

108

ii6

l43

l44

4 —3 Needle Distance ——————————————————— l46

Stitches

Thread

Per

Number

Inch

——————————————————

Systems ———————————————— l46

l46

1.

Genera! Specificatiens fer Stitches and Seams

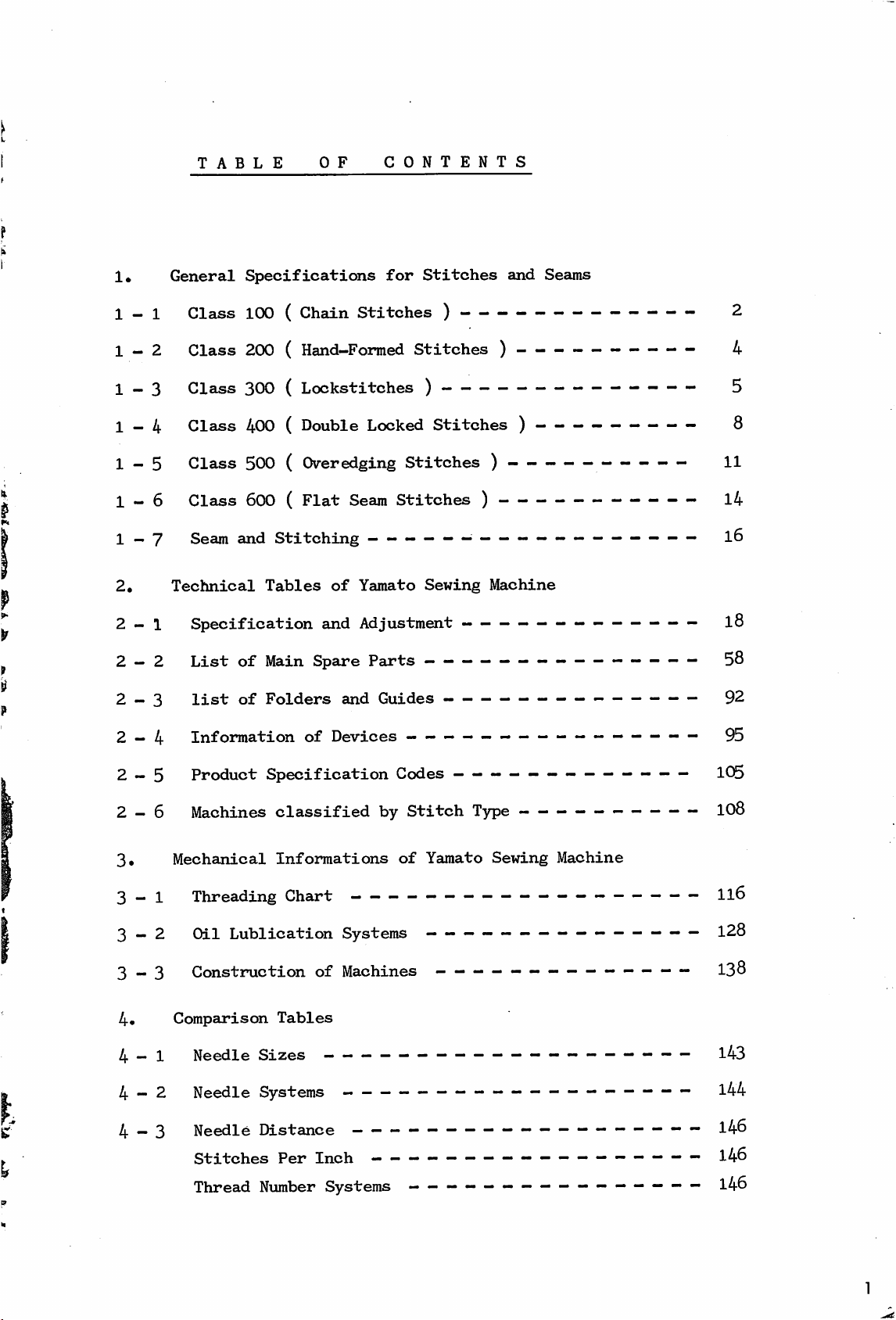

1-1

Class

100

(Chain

Stitches)

stitch

type

101

Stitch

type

104

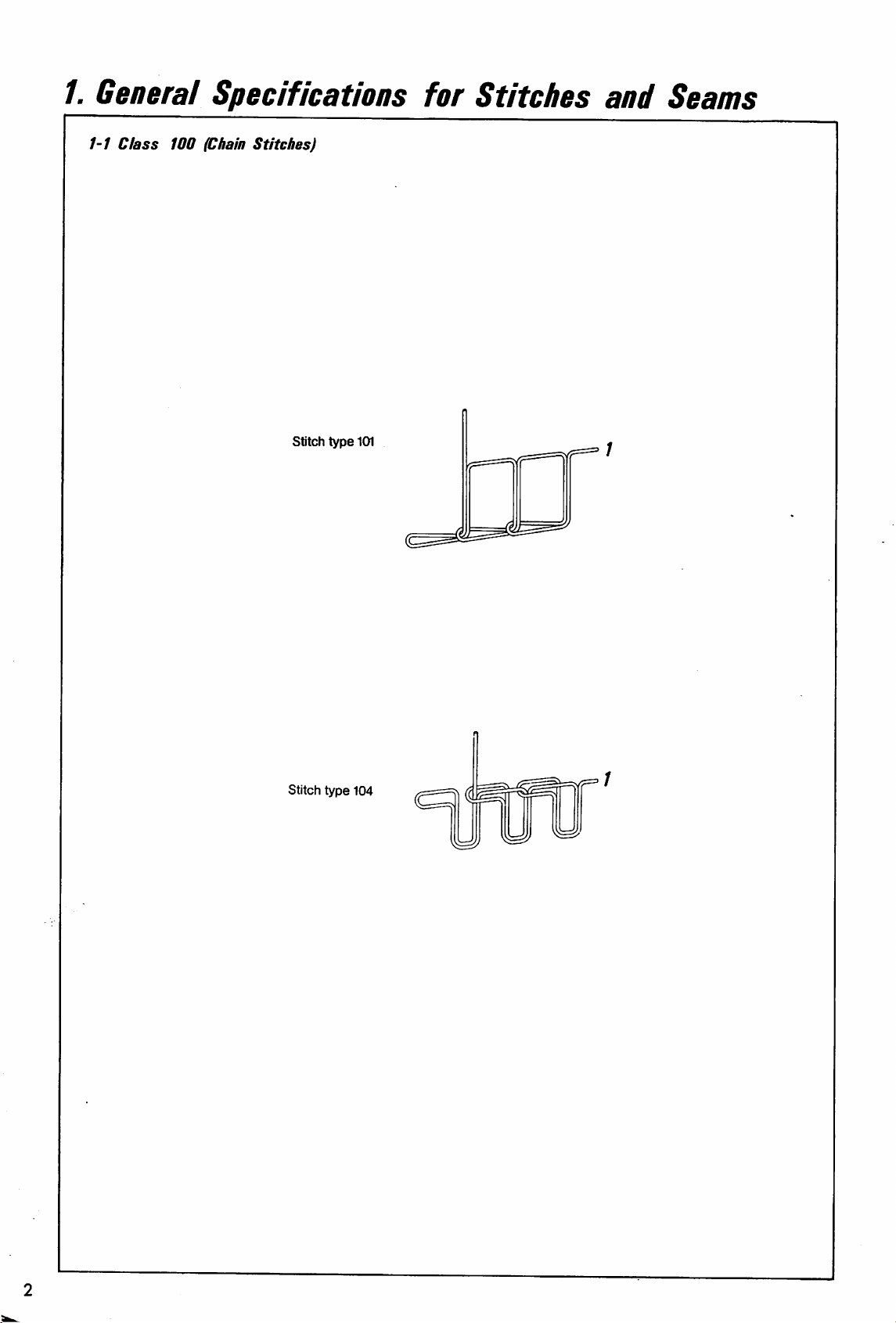

Formation

lOweST

POINTOFNEEOIE

of

a Single Thread Chainsfitch (Stitch

STROKE

NEEDIE

BAR RISE

Type

101)

-

Needleis at lowest point of stroke

Feedmovesmaterial to next stitch position

Needle rises to form loop

Needle

descends

through

previous

loop

Loopis enlareed

lowesi

POINT OF

NEEDLE

stroke

Needleis at lowest point of stroke

NEEDLE

BAR

RISE

Needle rises to form loop

Loopis enlarged

Feed moves material to next stitch position

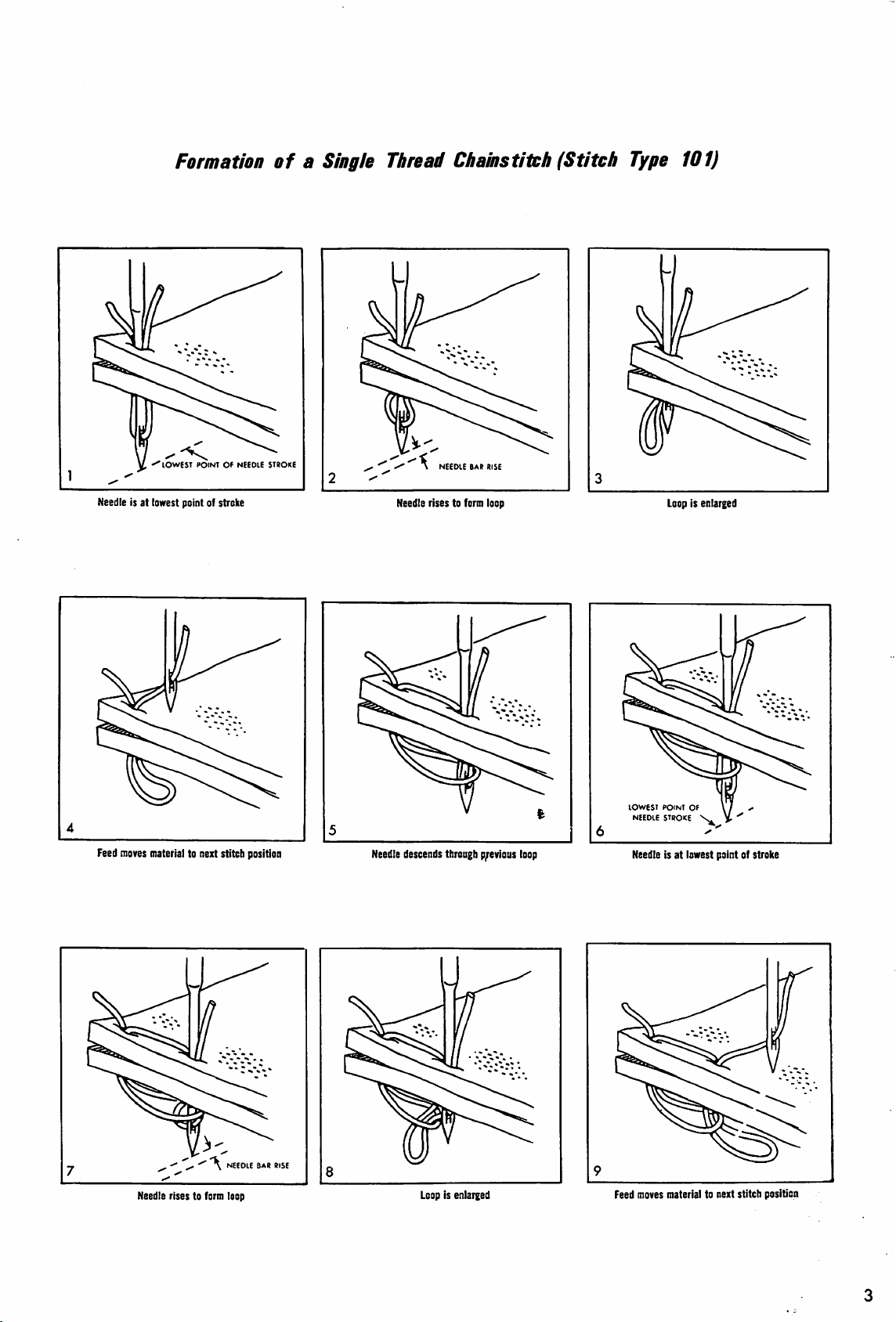

1-2

Class

200

(Hand-Formed

Stitches)

Stitch type 201

Stitch

type

204

Stitch

Stitch

type

type

202

209

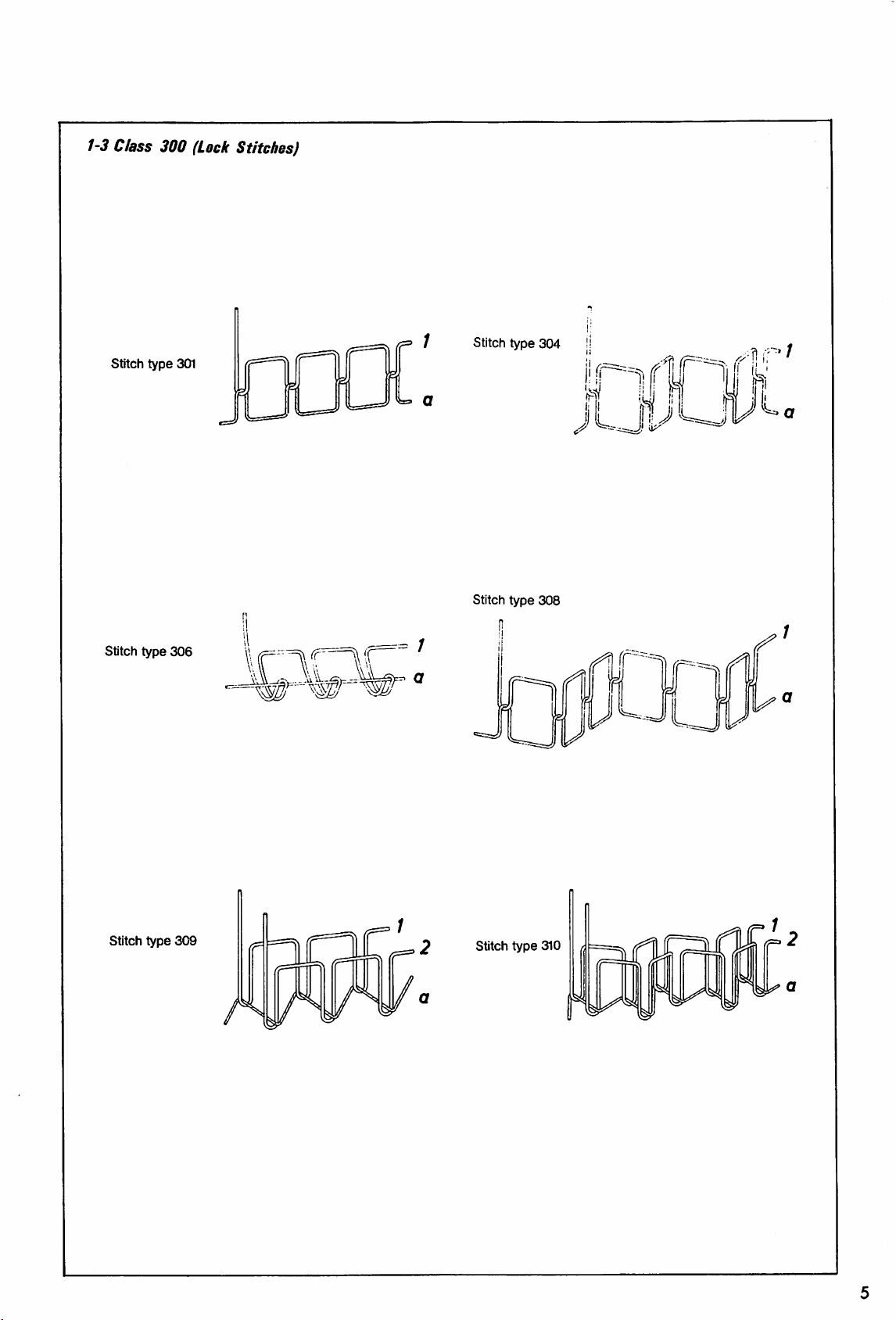

1-3Class 300

(Lock

Stitches)

Stitch

Stitch

type

type

301

306

Stitch type

Stitch

type

304

Ik-'

ll

JLjiLj

308

Stitch

type

309

Stitch

type

310

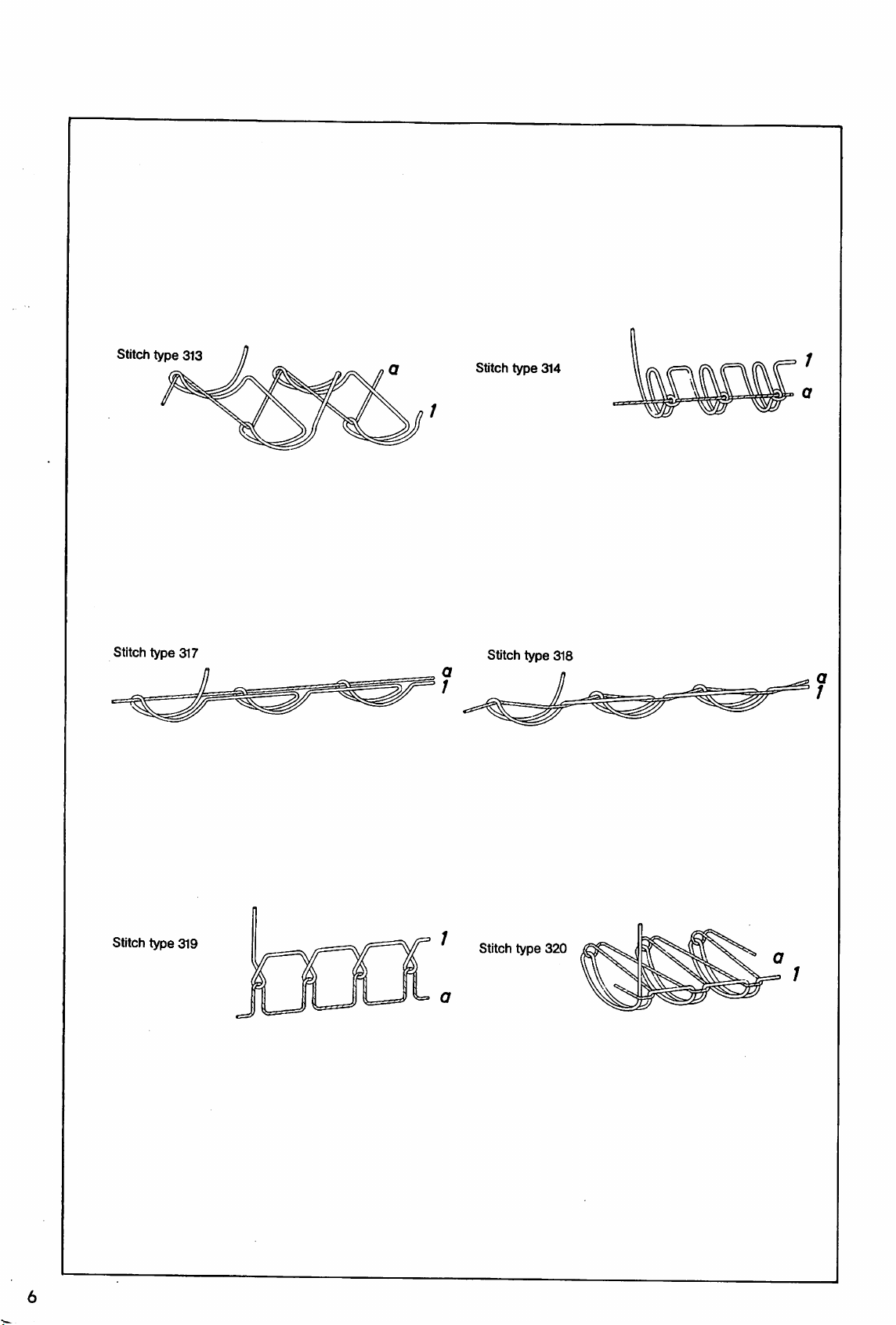

stitch type 313

Stitch

type

317

Stitch

type

Stitch type 318

314

type

Stitch

319

Stitch

type

320

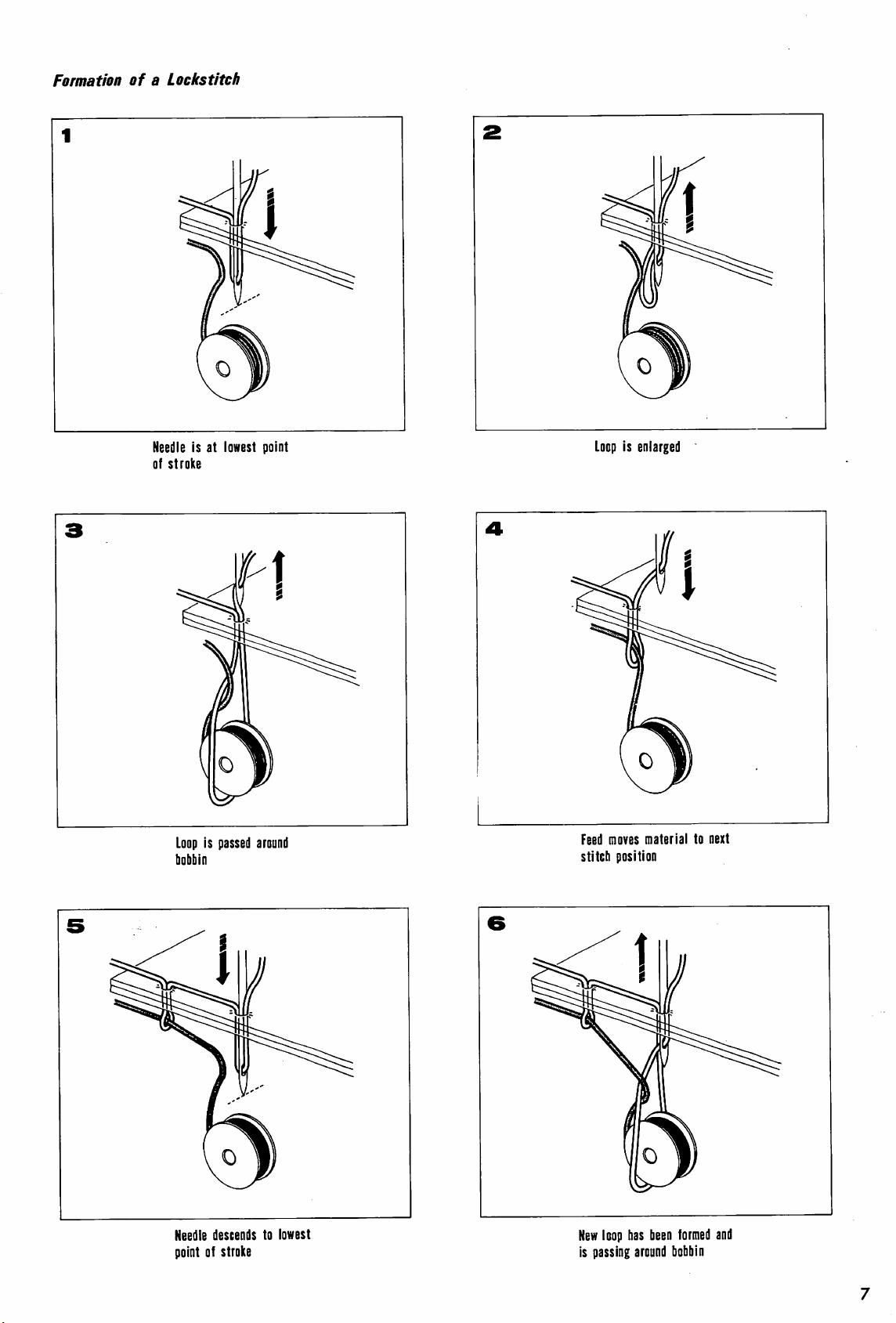

Formationofa

Lockstitch

Needle

Is at lowest point

of

stroke

Loopispassed

bobbin

around

Loopisenlarged

Feed

moves material to next

stitch

position

New

loop

has

Needle descends to lowest

pointofstroke

is

passing

been

around

formed

bobbin

and

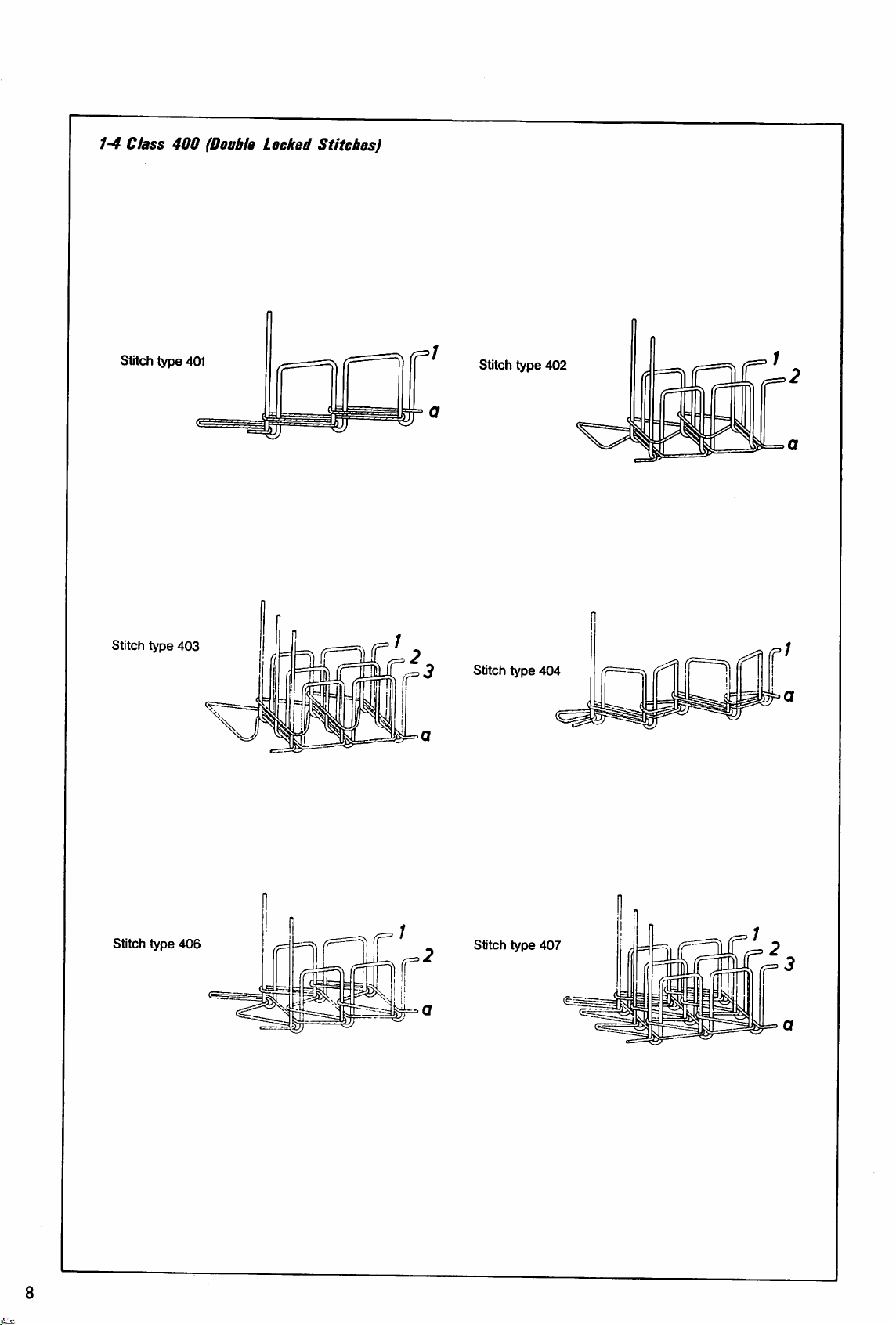

1-4 Class

Stitch

type

400

401

(Double

Locked Stitches)

Stitch

type

402

i^==

Cf

Stitch

Stitch

type

type

403

406

Stitch

Stitch

type

type

404

407

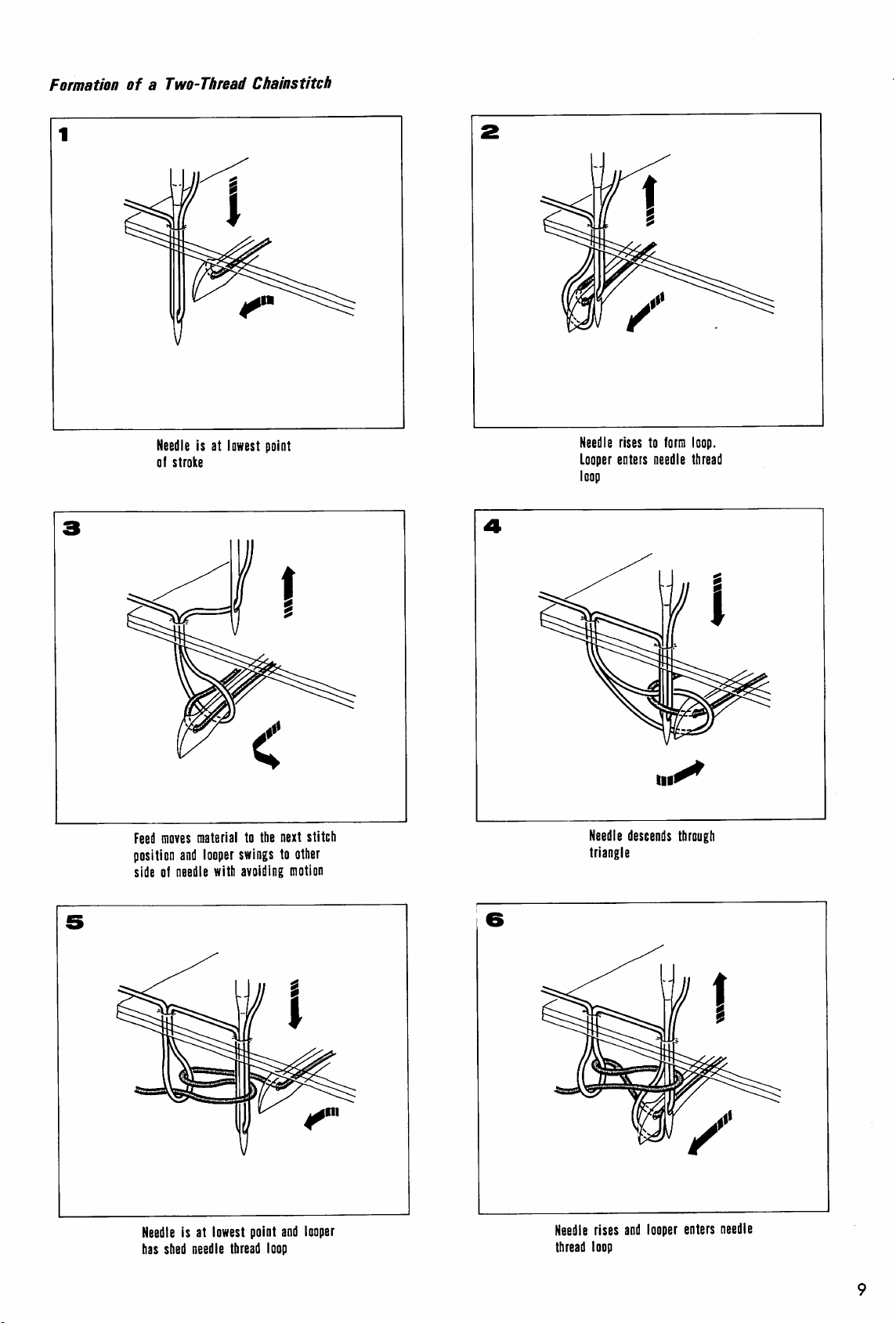

Formationofa Two-Thread

Needle

is at

lowest

of stroke

Chainstitch

point

Needle

Looper

loop

rises to

enters

form

needle

loop.

thread

Feed

moves

material

position

and

looper

side of

needle

with

Needle

is at lowest point

has shed needle thread

to the next stitch

swingstoother

avoiding

loop

motion

and

looper

Needle

triangle

Needle

rises

thread loop

descends

and

looper

through

enters

needle

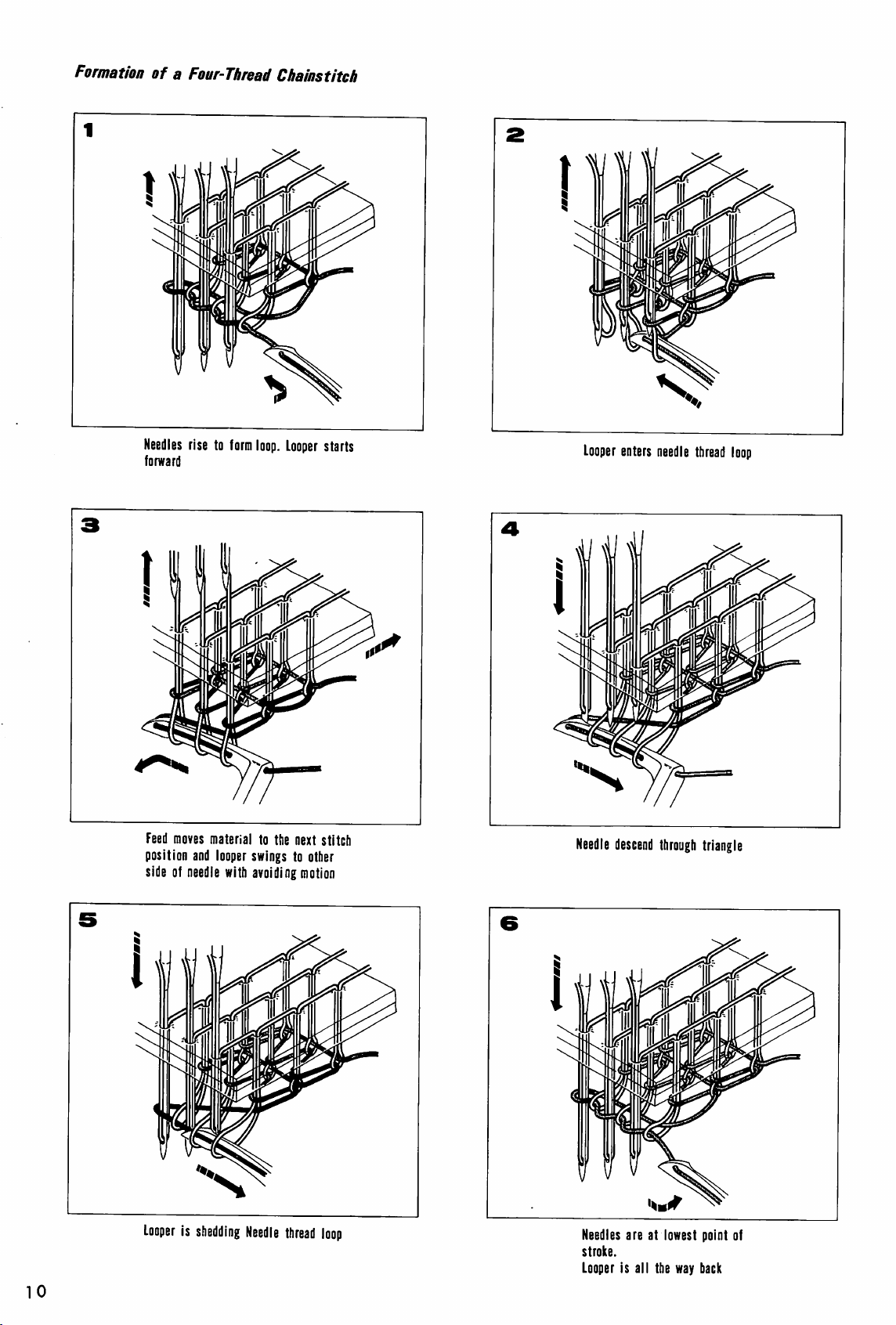

Formationofa

Needles

forward

Four-Thread

risetoform

loop.

Chainstitch

Looper

starts

Looper

enters

needle

thread

loop

Feed

moves

10

material to the next stitch

position

and

looper

side of

needle

with

Looperisshedding

swingstoother

avoiding

Needle

motion

thread

loop

Needle

Needles

stroke.

Looper

descend

are at lowest point of

is all the

through

way

triangle

back

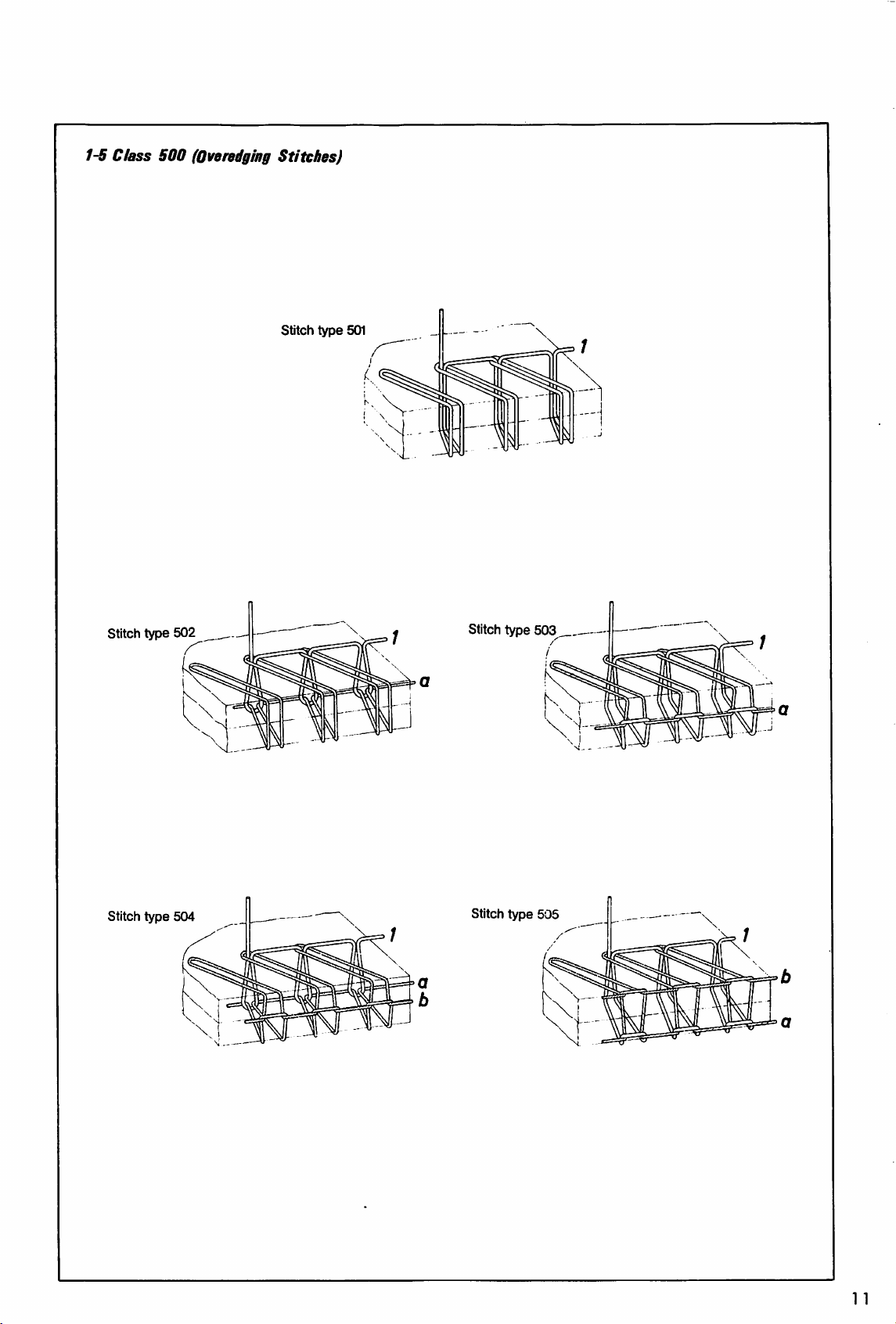

1-5

Class

500

(Overedgmg

Stitches)

stitch

type

501

Stitch

Stitch

type

type

502

504

Stitch type

Stitch

type

503,

505

1 1

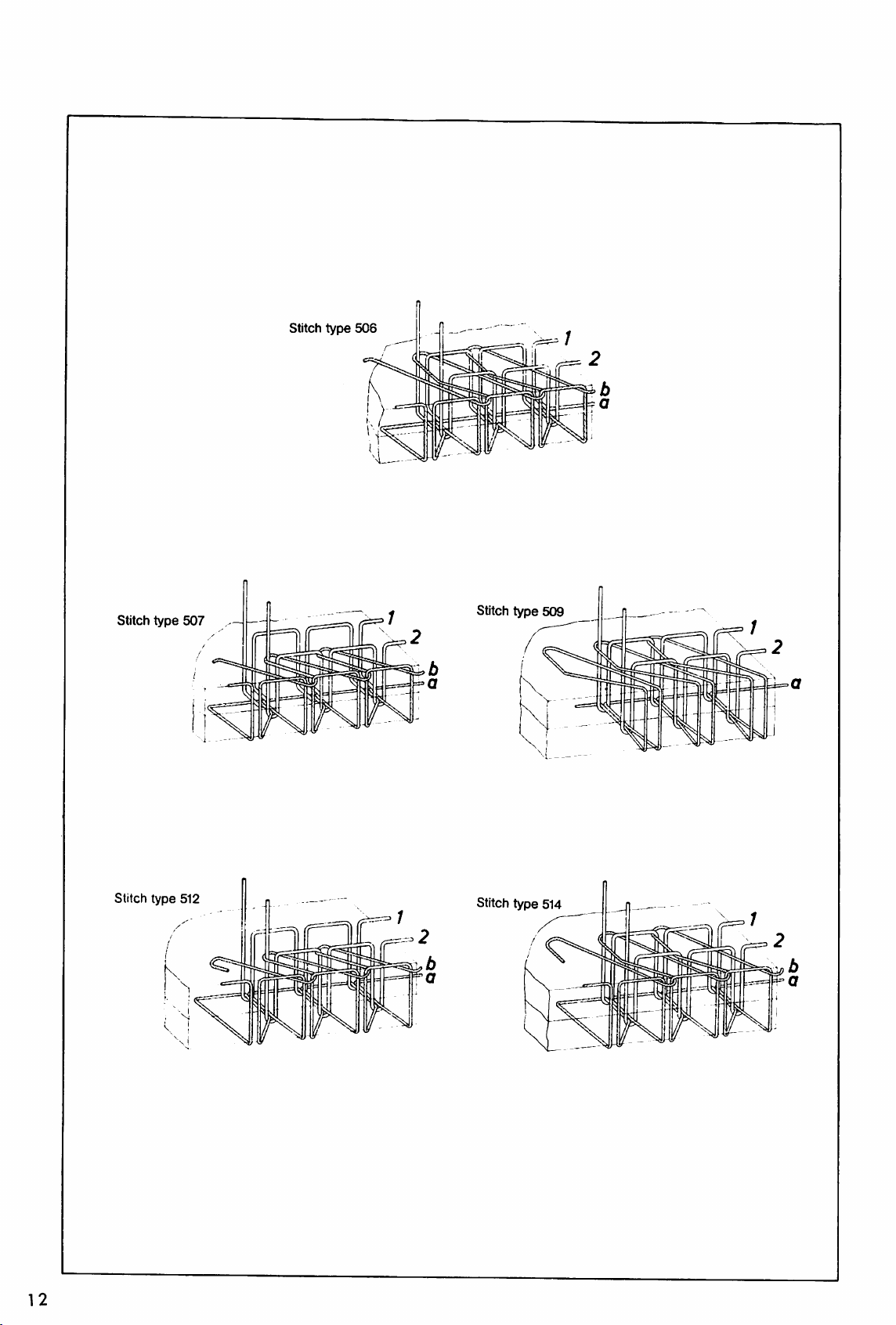

Stitch

type

507

stitch

type

506

Stitch

type

,

509

Stitch

type

512

12

Stitch type 514

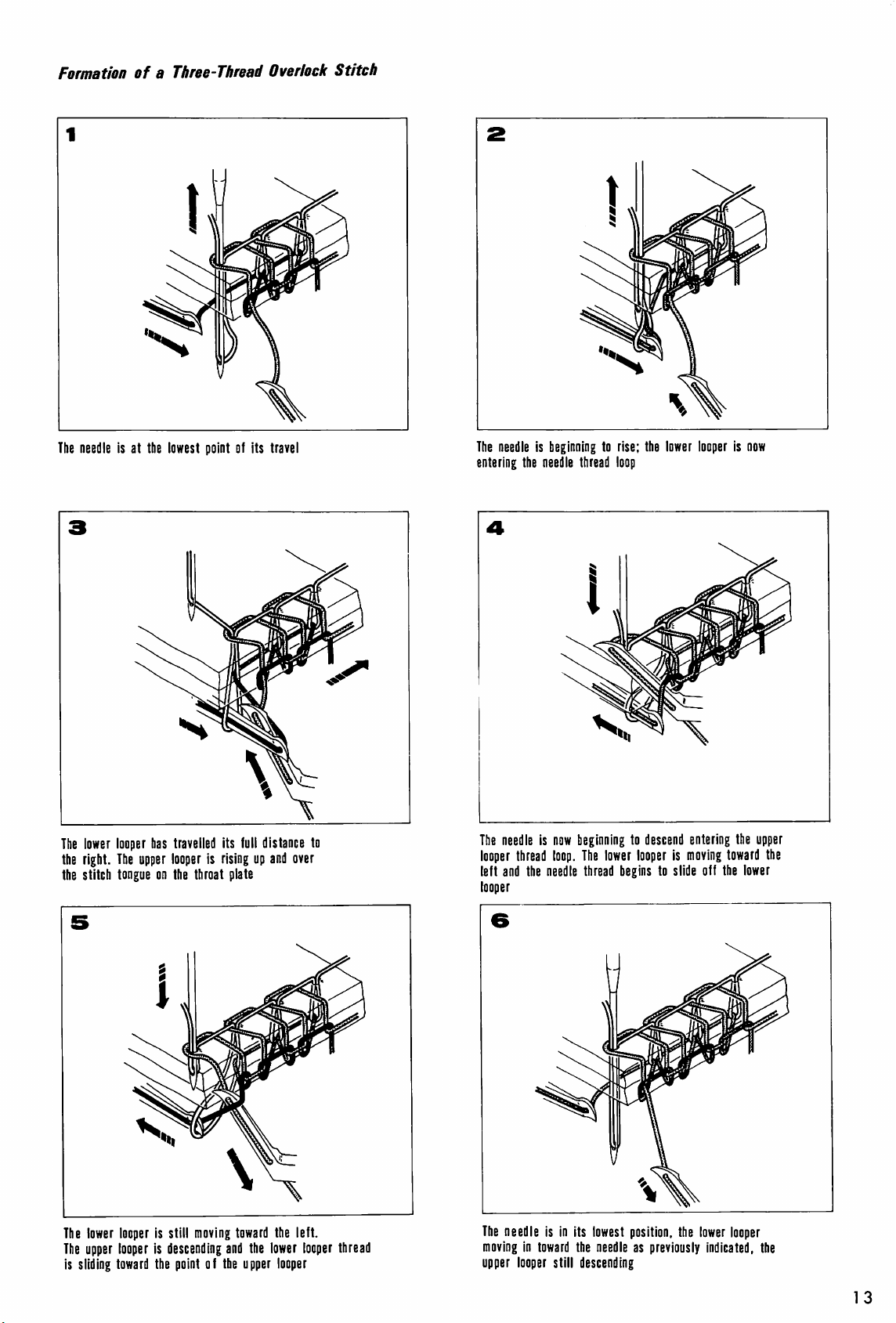

Formationofa Three-Thread Overlook

The

needle

Is at the

lowest

point

of Its travel

Stitch

The

needleIsbeginning

entering

the

needle

to rise; the

thread

loop

lower

looperIsnow

The

lower

the

right.

the stitch

The

lower

The

upper

Is

sliding

looper

has

The

tongueonthe throat

looper

looperIsdescending

toward

travelled

upper

looperIsrisingupand

Is still

moving

the

pointofthe

Its

plate

\

and

full

toward

the

upper

distance

the left.

lower

looper

over

looper

The

to

thread

needleIsnow

looper

thread

left

and

the

looper

The

needleIsIn

movingIntoward

upper

looper

beginningtodescend

loop.

The

needle

still

lower

thread

Its

lowest

the

needleaspreviously

descending

looperIsmoving

beginstoslide

position,

the

entering

off the

lower

Indicated,

the

toward

lower

looper

upper

the

the

13

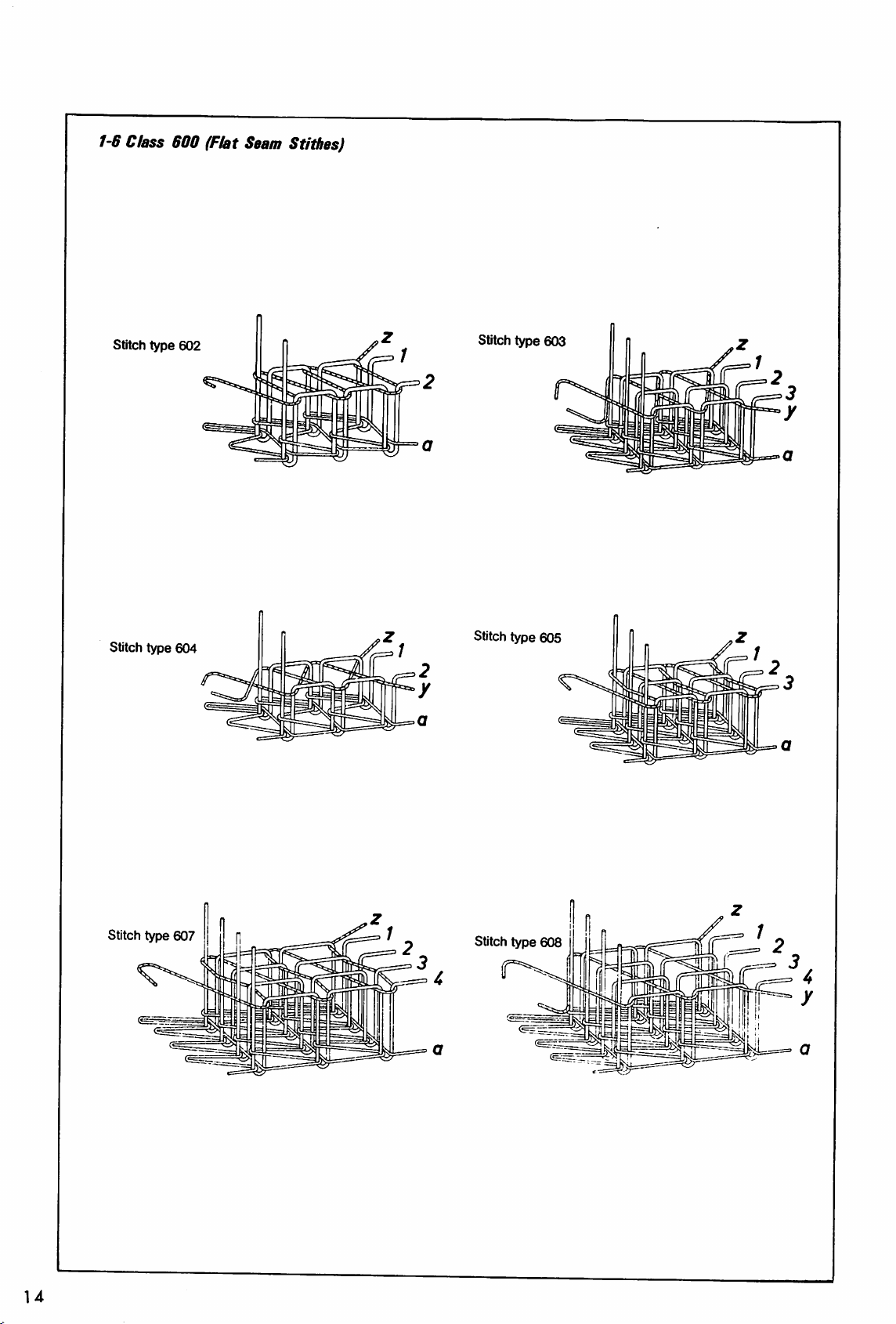

1-6Class 600 (Flat Seam Stitbes)

Stitch

type

602

Stitch

type

603

Stitch type 604

Stitch type 607

Stitch type 605

Stitch type 608

IT^

14

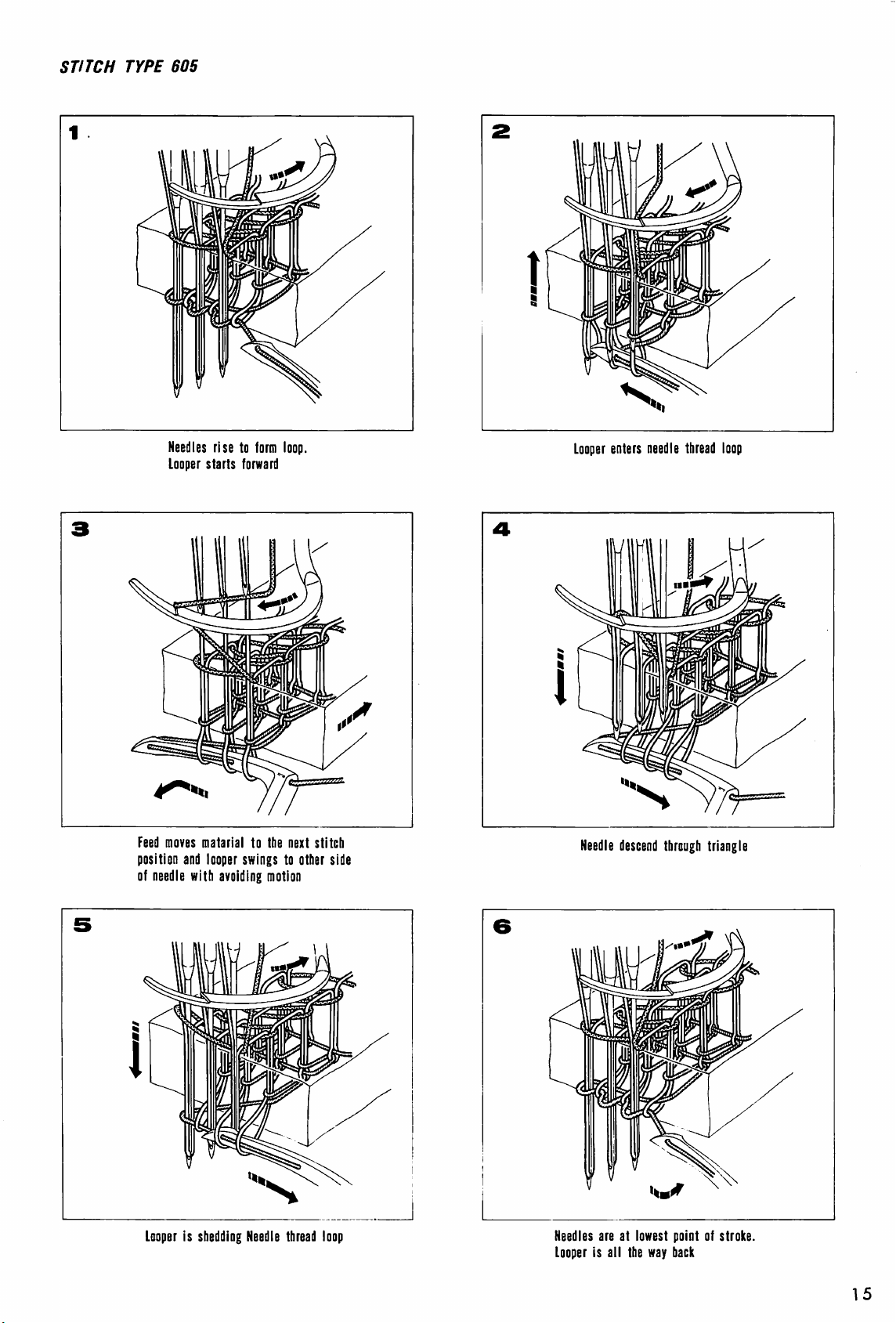

STUCH

TYPE

605

Needles

Looper

rise to

starts

form

forward

loop.

Looper

enters

needle

thread

loop

Feed moves material to the next

position

and

looper

swingstoother

of

needle

with

avoiding

Looperisshedding

motion

Needle

thread

stitch

side

loop

Needle

descend

Needles

are at lowest point of stroke.

Looper

is all the

way

through

back

triangle

15

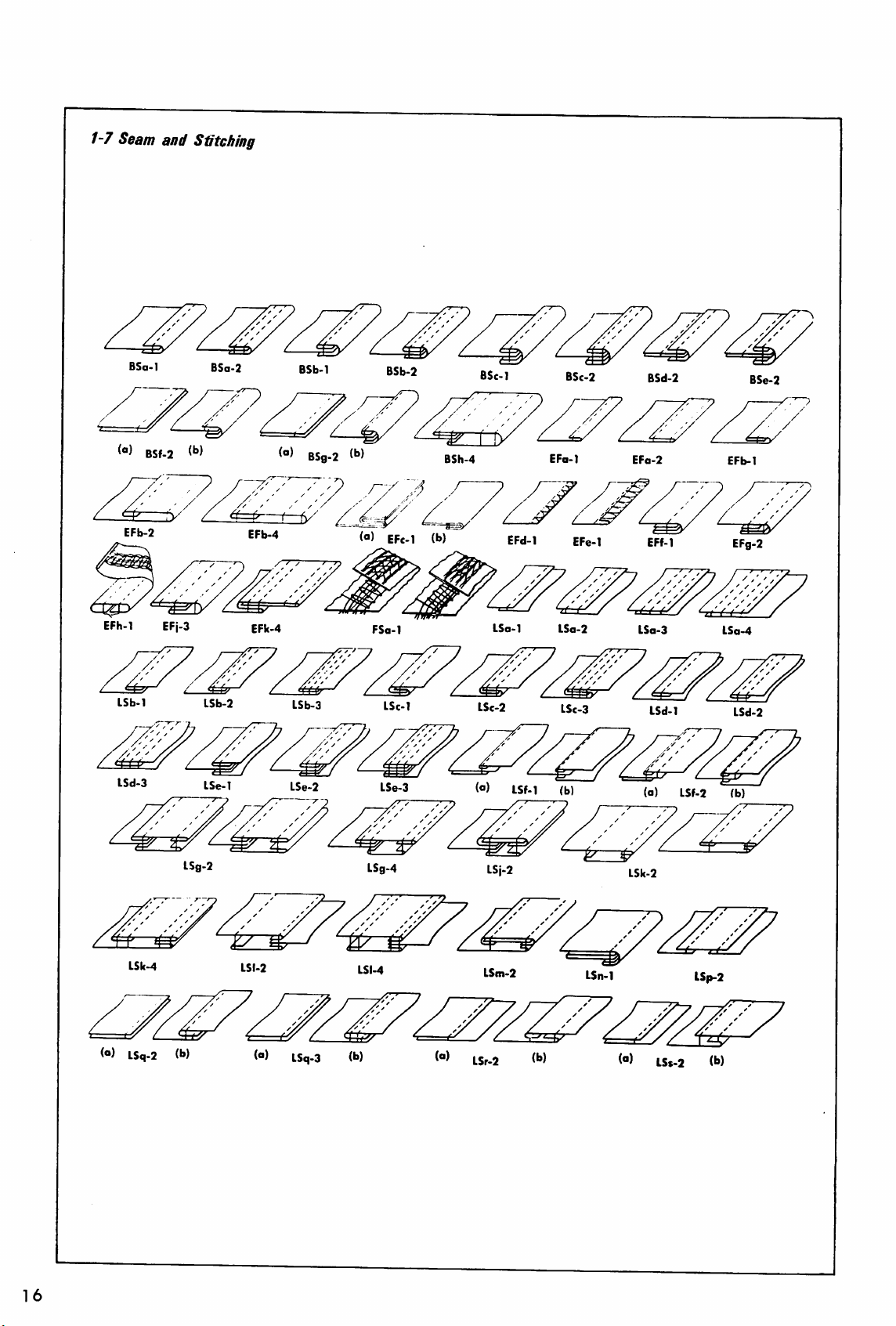

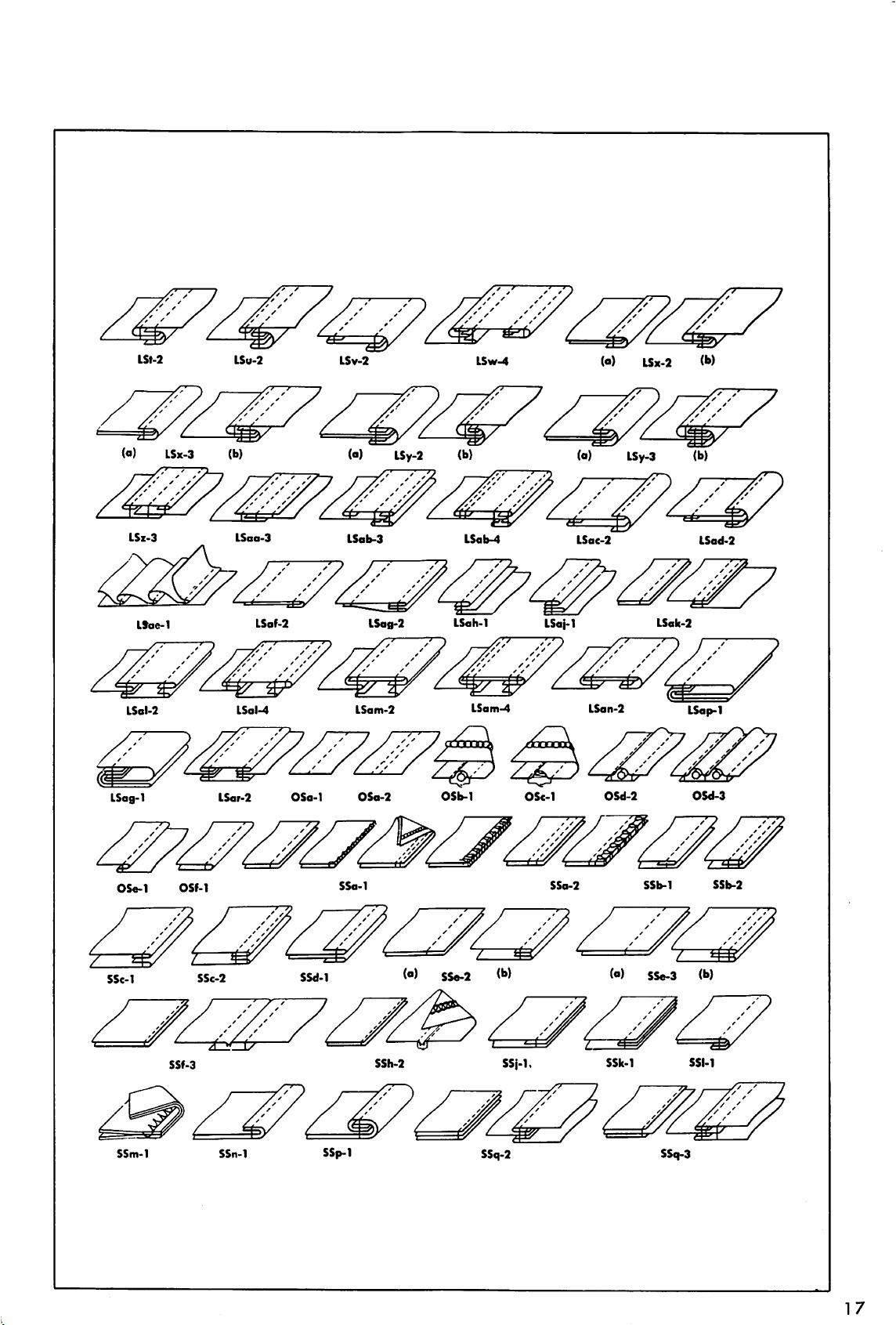

1-7

Seam

and

StftcAing

BSa-1

:'y

EFb-2

EFh-l EFi-3

LSb-1

LSd-3

Z ^

BSa-2

/ ^

LSb-2

EFb.4

EFk-4

BSb-1

LSb-3

LSe-2

BSg-2

f*)

FSa-1

BSb-2

EFc-l

BSh.4

(b)

EFa-I

EFd-1 EFe-1

(«) LSM fb)

EFa-2

LSa-3

BSd-2

EFM

BSe-2

LSa-4

LSd-2

16

(o)

LSq.2

lSg-2

(b)

(a)

LjqO

(b)

LSg-4

LSj-2

LSm-2

(o) (b)

LSk-2

(a)

tj,.,

(b)

LSt.2

LSu-2

LSv-2

LSw-4

(o) LSx-2 (W

(a) LSx-3 (b)

LSz-3

Lxae-i

LSol-2

LSag-l

OSe>1

OSM

LSar-2

LSaa-3

LSa-4

LSaf-2

(<>)

LSab-3

SSa-1

LSag-2

LSam-2

LSy-2

LSah-1

OSb-1

(b)

LSab-4

LSam-4

OSc-1

SSa-2

(o)

LSac-2

LSan-2

OSd-2

LSy-3

SSb-1

LSod-2

LSak-2

SSb-2

i«) SSe.3 (b)

SSk-1

SSm-1

S$f-3

SSc-2

SSn-1

SSp-1

SSh-2

SSj-1.

SSq-2

SSI-1

SSc|-3

17

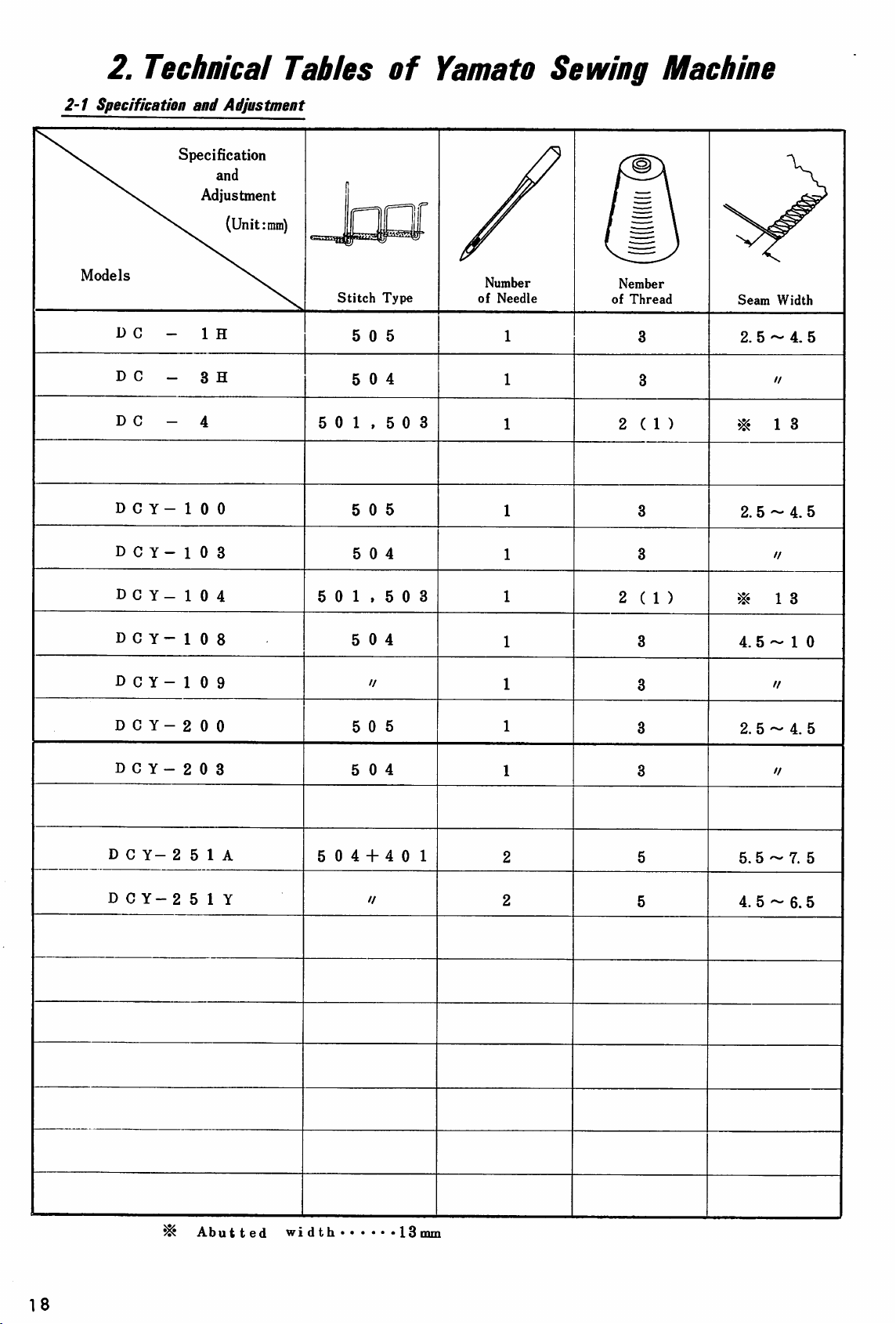

2. Technical Tables

2-1

Specificatien

and

Adjustment

Specification

and

Adjustment

(Unit:

mm)

ef

Yamate Sewing Machine

Models

DC

DC

DC

D C

D C Y - 1 0 3

D C Y - 1 0 4

D C

D C Y - 1 0 9

D C Y - 2 0 0

- 1 H

- 3 H

- 4

Y-

Y-

1 0 0

1 0 8

5 0

5 0

Stitch

5 0 5

5 0 4

1,5

5 0 5

5 0 4

1,5

5 0 4

5 0 5

Type

0 3

0 3

Number

of

Needle

Nember

of

2(1)

2(1)

Thread

Seam

Width

2.

5 -

^ 1 3

2.5~4.

^ 1 3

4.

5 ~ 1 0

2.

5 -

4.

5

5

4.

5

D C Y - 2 0 3

D C

Y-

2 5 1 A

D C

Y-2

5 1 Y

5 0 4

504+401

5.

5 - 7. 5

4.

5 6. 5

^

Abut

ted

width**

18

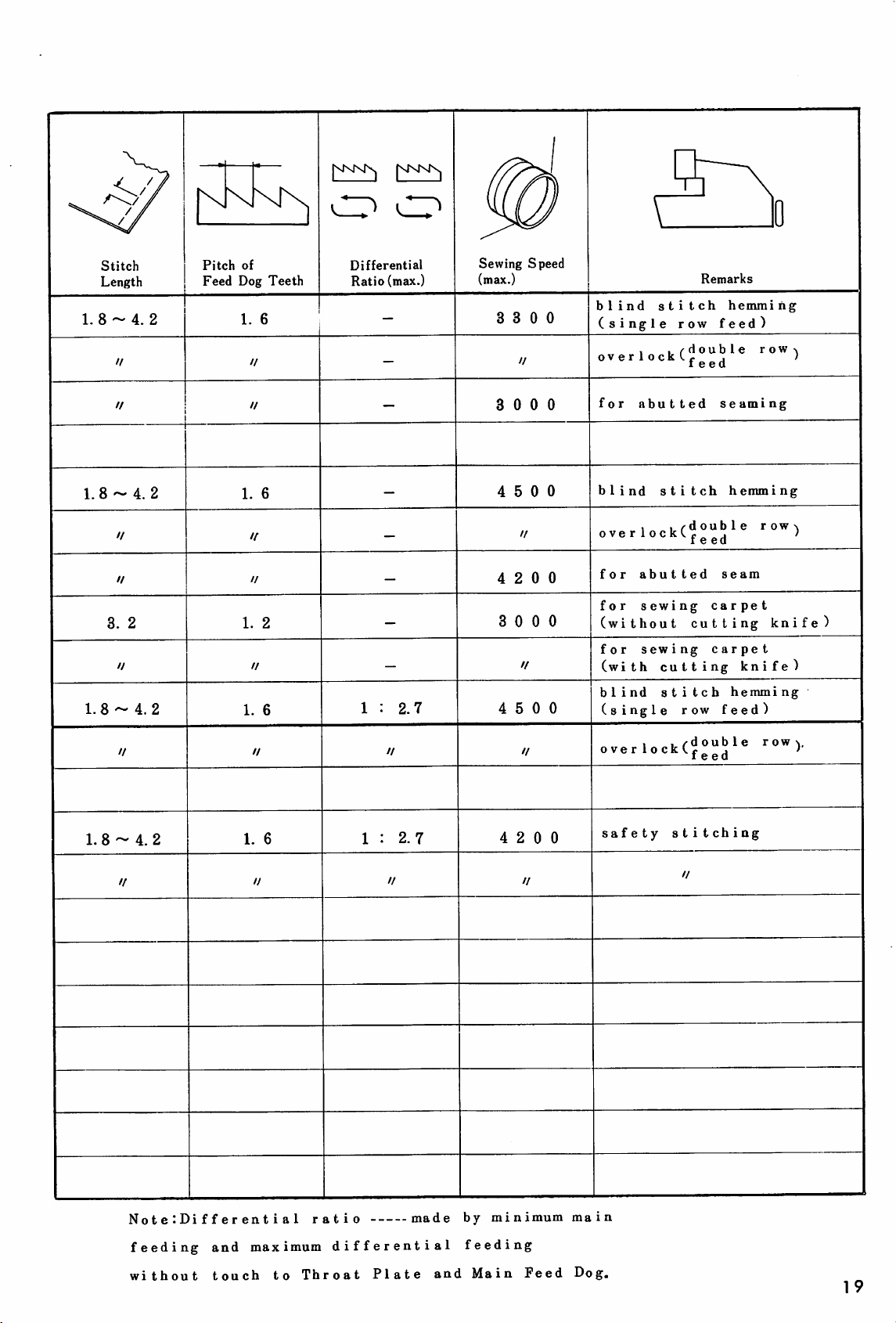

* **

*13

fTiTi

[STsNN^

Stitch

Length

1.

8 -

1.8

1.8-4.2

Pitch

of

Feed

Dog

Teeth

1.

4.

2

4.

2

3.

2

6

1.

6

1.

2

1.

6

Differential

Ratio

(max.)

1 :

2.7

Sewing

(max.)

Speed

3 3 0 0

3 0 0 0

4 5 0 0

4 2 0 0

3 0 0 0

4 5 0 0

blind

(single

, ,

overlockl.f

for

abutted

blind

for

abutted

for

(without

for

(with

blind

(single

stitch

stitch

sewing

sewing

cutting

stitch

Remarks

row

/double

feed

cutting

r ow

hemming

feed)

row^

. )

seaming

hemming

seam

carpet

carpet

knife)

hemming

feed)

knife)

lock(^®"'^^® row).

1 :

1.

1.

8 -

4.

2

6

2.7

4 2 0 0

safety

feed

stitching

Note:Differentia

feeding

without

and

touch

1

maximum

to

Throat

ratio

differential

Plate

made

and

by

minimum

feeding

Main

Feed

main

Dog.

19

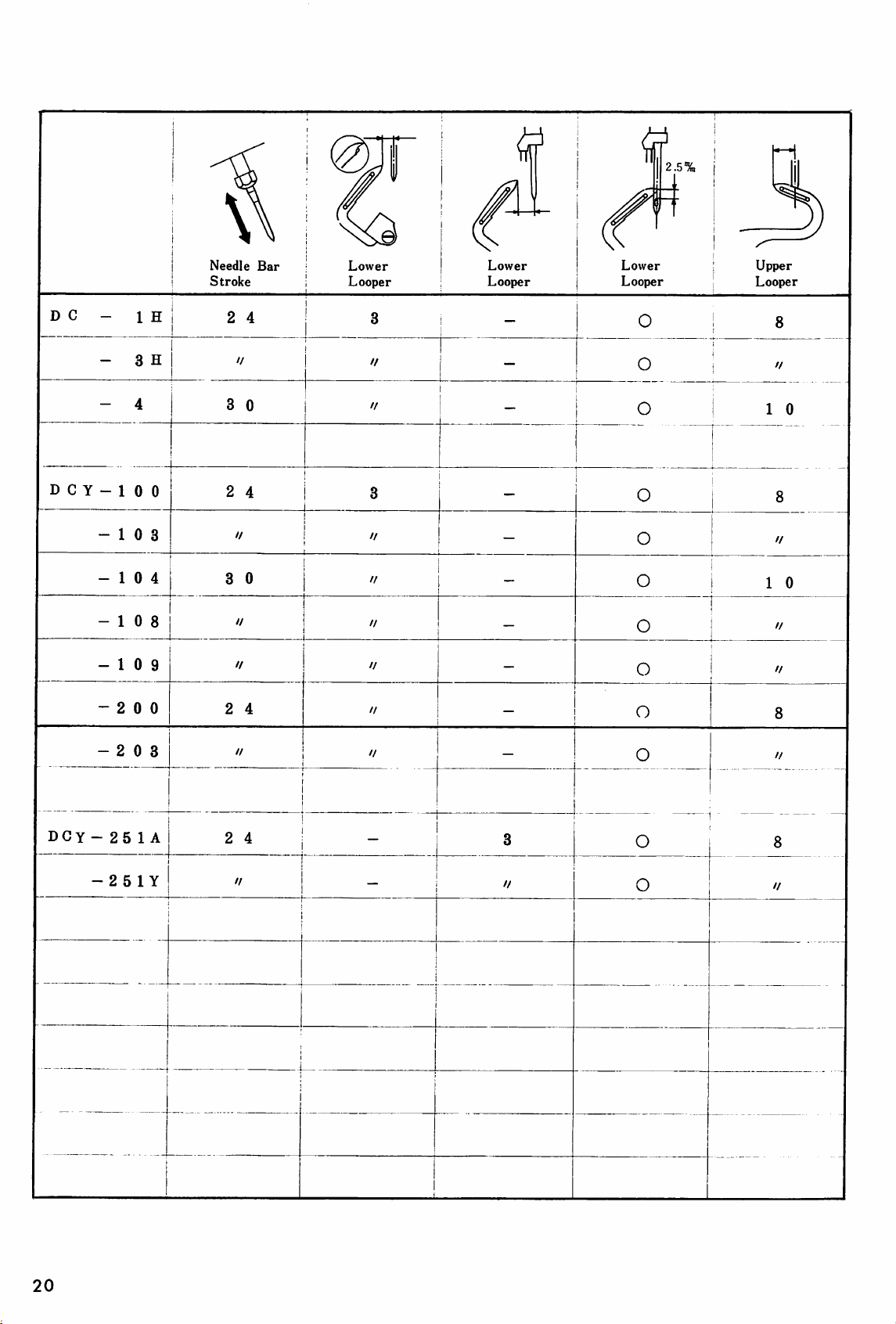

DC

- 1 H

- 3 H

2 4

1 '!

i

- 4 3 0

D C Y - 1 0 0 2 4

- 1 0 3

- 1 0 4

- 1 0 8

//

3 0

u

i

!

i n

\

1 "

1

1 3

1

j

1

I n

\

\

1

1

1

3

—

1

1

1

i ^

0

o

! 8

I

f

!

i 1 0

1

—

—

-

—

o

o

i

o

1 1 0

8

//

!

o

1 //

1

DCy

- 1 0 9

- 2 0 0

- 2 0 3

-

25

1 A

- 2 5 1 Y

// //

2 4 //

//

2 4

n

1

1

1

I

1 i !

\

i

i

1

i

j

1

-

-

—

0

O 8

o

o

//

o

'f

//

8

//

1 i

1

i

1

20

>

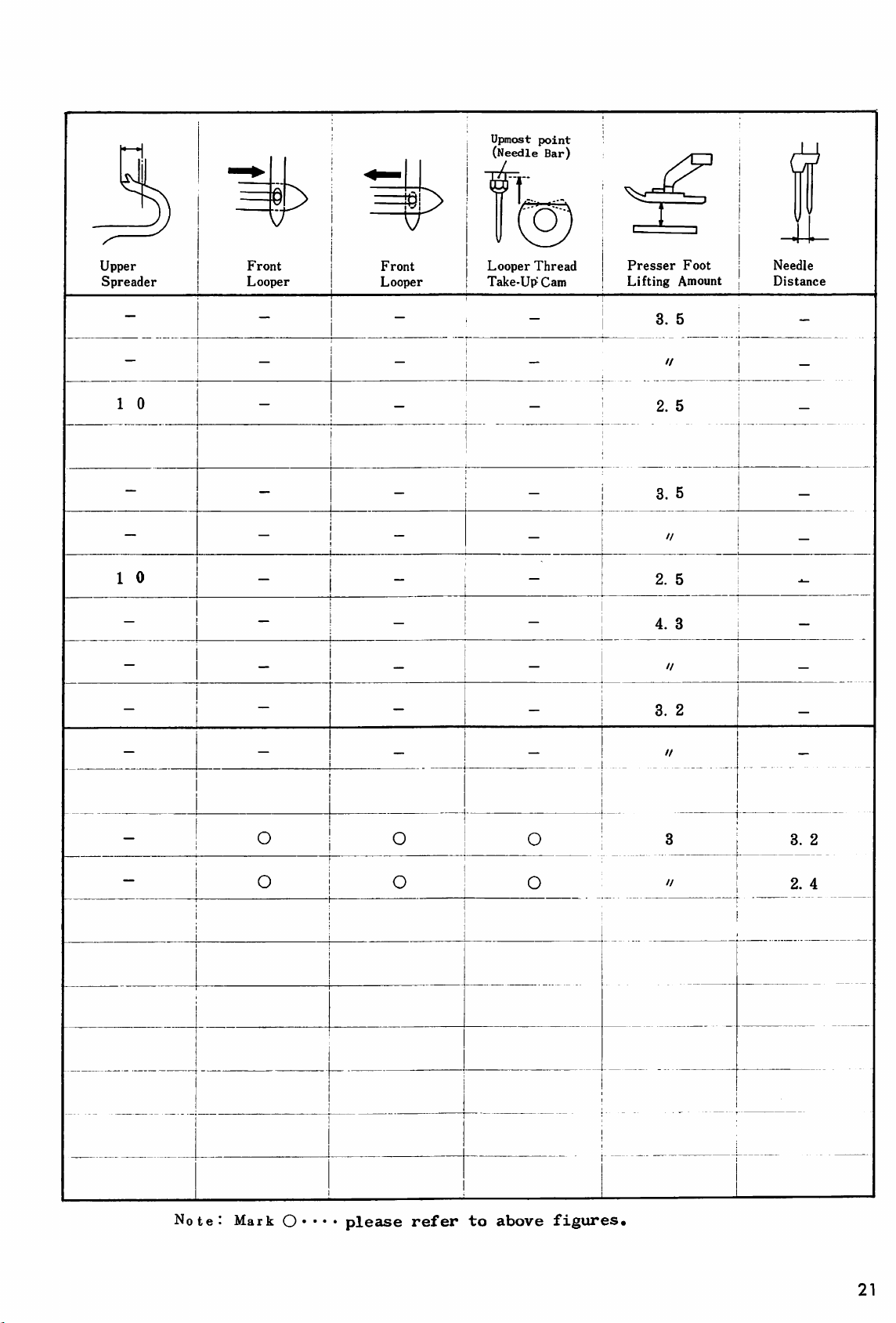

Upmost

point

(Needle Bar)

cy

Upper

Spreader

1 0

1 0

Front

Lcoper

Front

Looper

Looper

Take-Up

Thread

Cam

Presser

Lifting

3.

2.

8.

2.

4.

3.

Foot

Amount

5

5

5

5

3

2

Needle

Distance

Note:

O

O

Mark

O'

•••please

O

o

refer

to

above

o

o

figures,

3.

2

2.

4

21

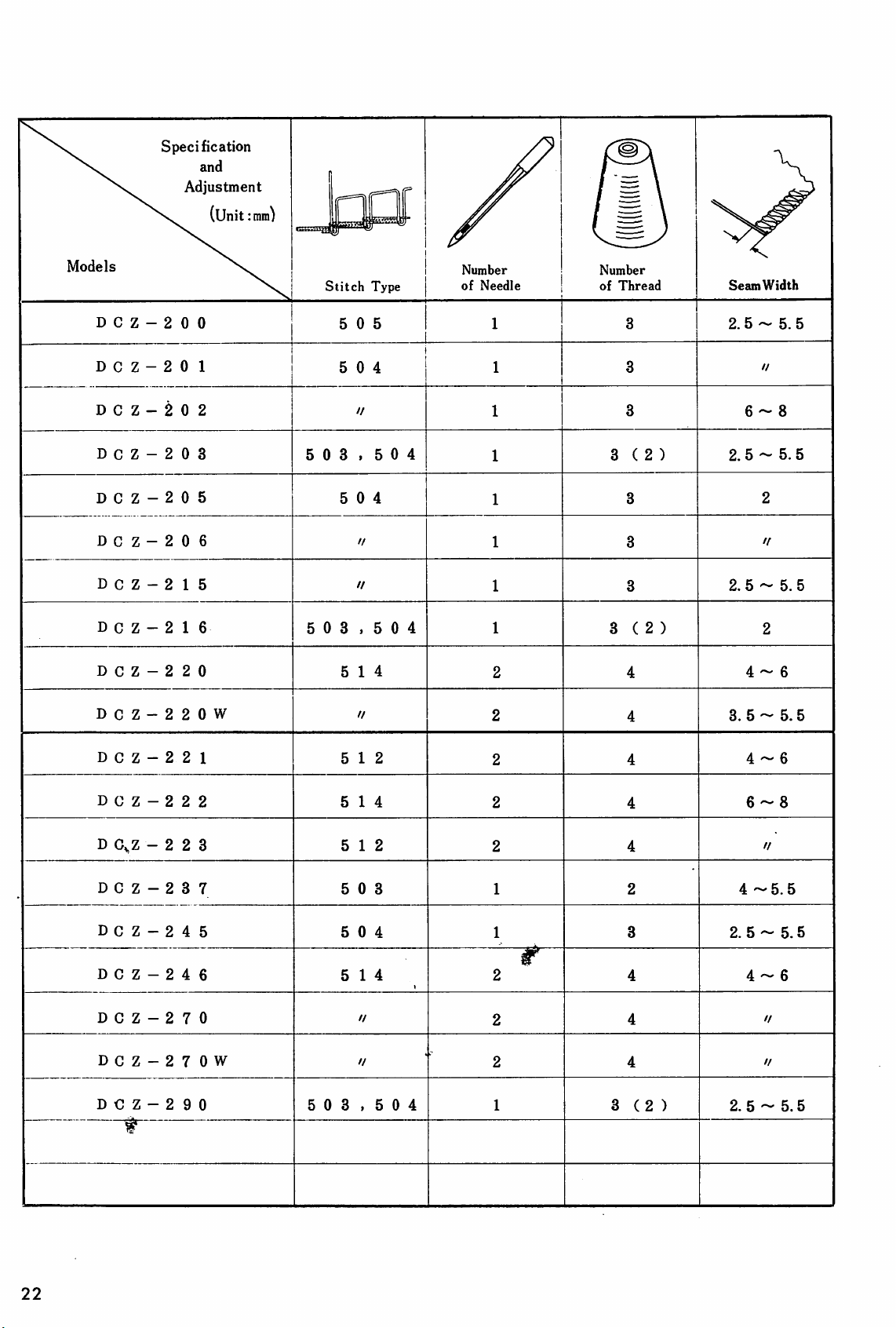

Specification

and

Adjustment

(Unit:

mm)

Models

D C Z - 2 0 0

D C Z - 2 0 1

D C Z - 2 0 2

D C Z - 2 0 3

D C Z - 2 0 5

D C Z - 2 0 6

D c Z - 2 1 5

D C Z - 2 1 6

D c Z - 2 2 0

DCZ-220W

5 0

5 0

Stitch

5 0 5

5 0 4

3,5

5 0 4

3.5

5 1 4

Type

0 4

0 4

Number

of

Needle

Number

of

Thread

3(2)

3(2)

Seam

2.

5 -

6-8

2. 5 -

2.

5 -

4-6

3.

5 -

Width

5.

5.

5.

5.

5

5

5

5

D C Z - 2 2 1

D C Z - 2 2 2

D C^Z - 2 2 3

D C Z - 2 3 7

D C Z - 2 4 5

D C Z - 2 4 6

D C Z - 2 7 0

DCZ-270W

D C Z - 2 9 0

f

5 0

5 1 2

5

14

5 1 2

5 0 3

5 0 4

5 1 4

3,5

0 4

3(2)

2.

2.

4-6

6-8

4-5.5

5 -

4-6

5 -

5.

5

5.

5

22

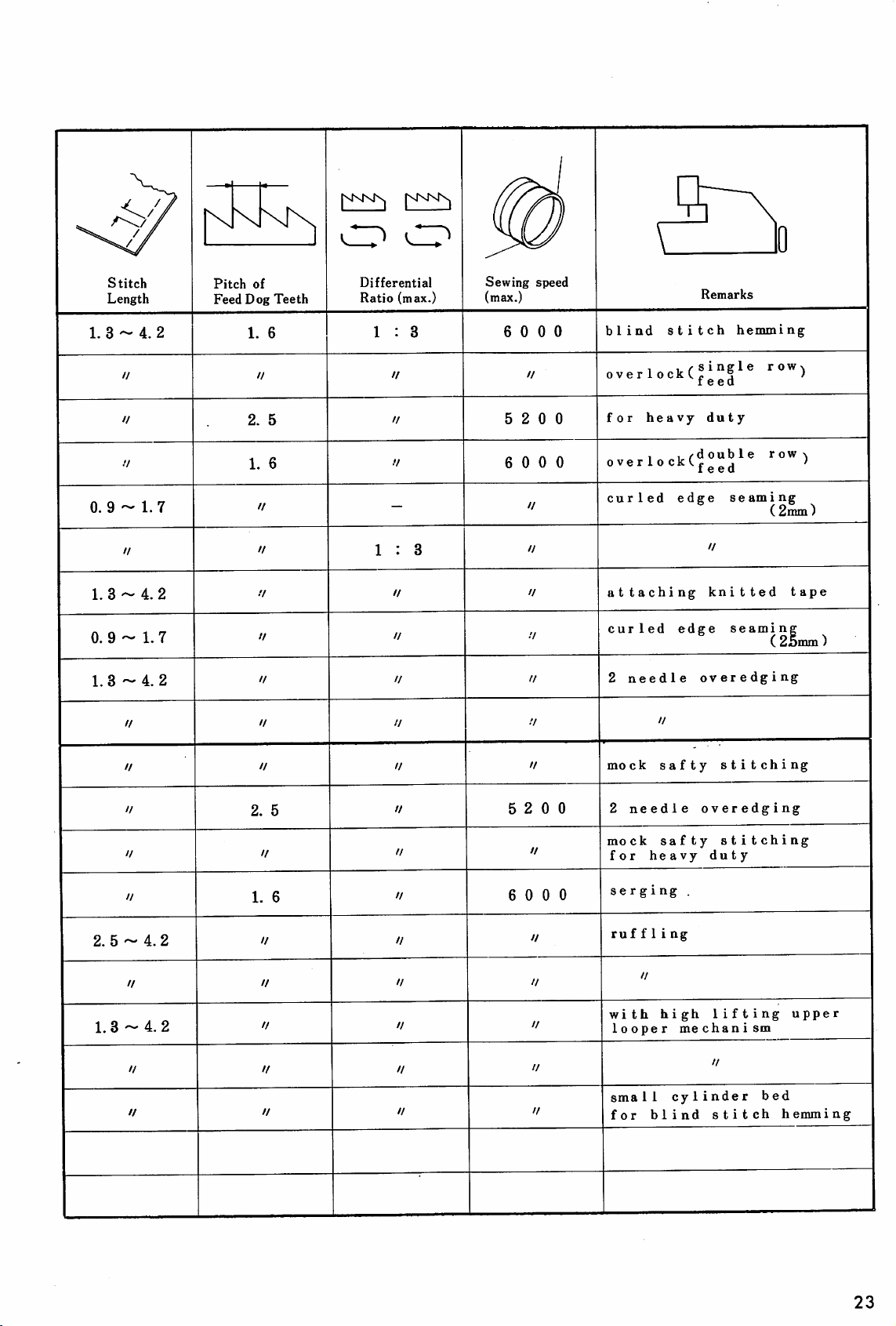

[sfsfsjs^

[SWsN^

Stitch

Length

1. 3 -

0.

9

1.

3 -

0.

9 -

1. 3 -

Pitch

of

Feed

Dog

Teeth

4.

2

1.

7

4.

2

1.

7

4.

2

1.

6

2.

5

1.

6

Differential

Ratio

(max.)

1 : 3

1 : 3

Sewing

(max.)

speed

6 0 0 0

5 2 0 0

6 0 0 0

Remarks

blind

for

overlockCj^^j

curled

attaching

curled

2

heavy

, ,

needle

stitch

duty

/double

edge

knitted

edge

overedging

hemming

seaming

seamin

row\

(

2mm)

)

tape

2.

5 ~4.2

1. 3 -

mock

2.

5

5 2 0 0

2

mock

for

1.

6

6 0 0 0

s e r

ruff1i

with

4.

2

small

for

needle

looper

heavy

g1ng

blind

safty

safty

ng

high

mechanism

cylinder

stitching

overedging

stitching

duty

lifting

stitch

upper

bed

hemming

23

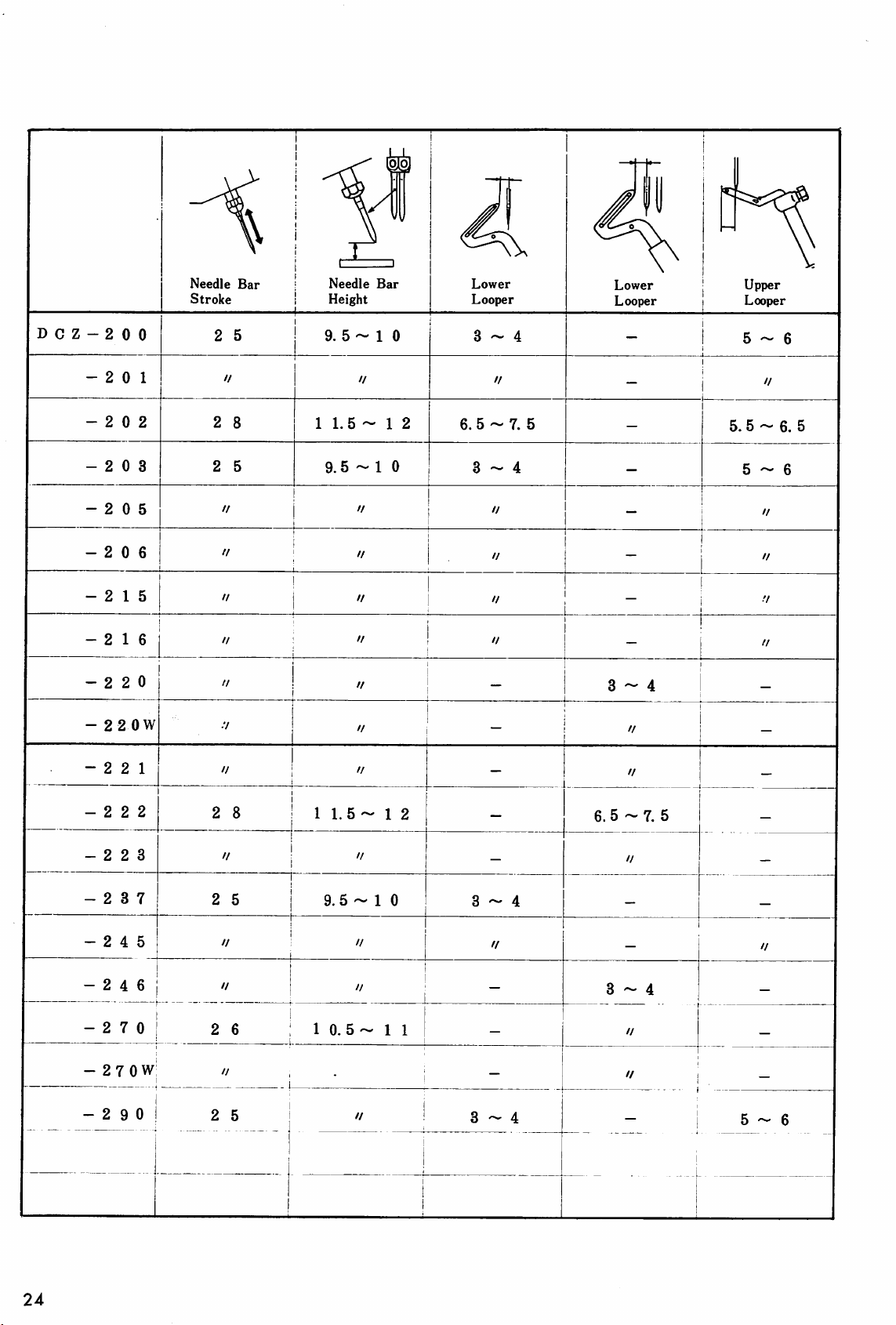

Needle

Stroke

Bar

Needle

Height

Bar

Lower

Looper

Lower

Looper

Upper

Looper

D C Z - 2 0 0

-201

-202

-203

-205

-206

-215

-216

-220

- 2 2

OW

-221

2 5

2 8

2 5

9. 5 ~ 1 0

1

1.5

- 1 2

9.5

~ 1 0

6.

5 ~7.5

3-4

I

3-4

-222

-223

-237

-245

-246

-270

2 7

290 I

ow:

2 8

2 5

2 6

I

2 5

1

1.5

- 1 2

9.5

- 1 0

1 0. 5 - 1 1

6. 5 - 7. 5

3-4

3 — 4

3-4

24

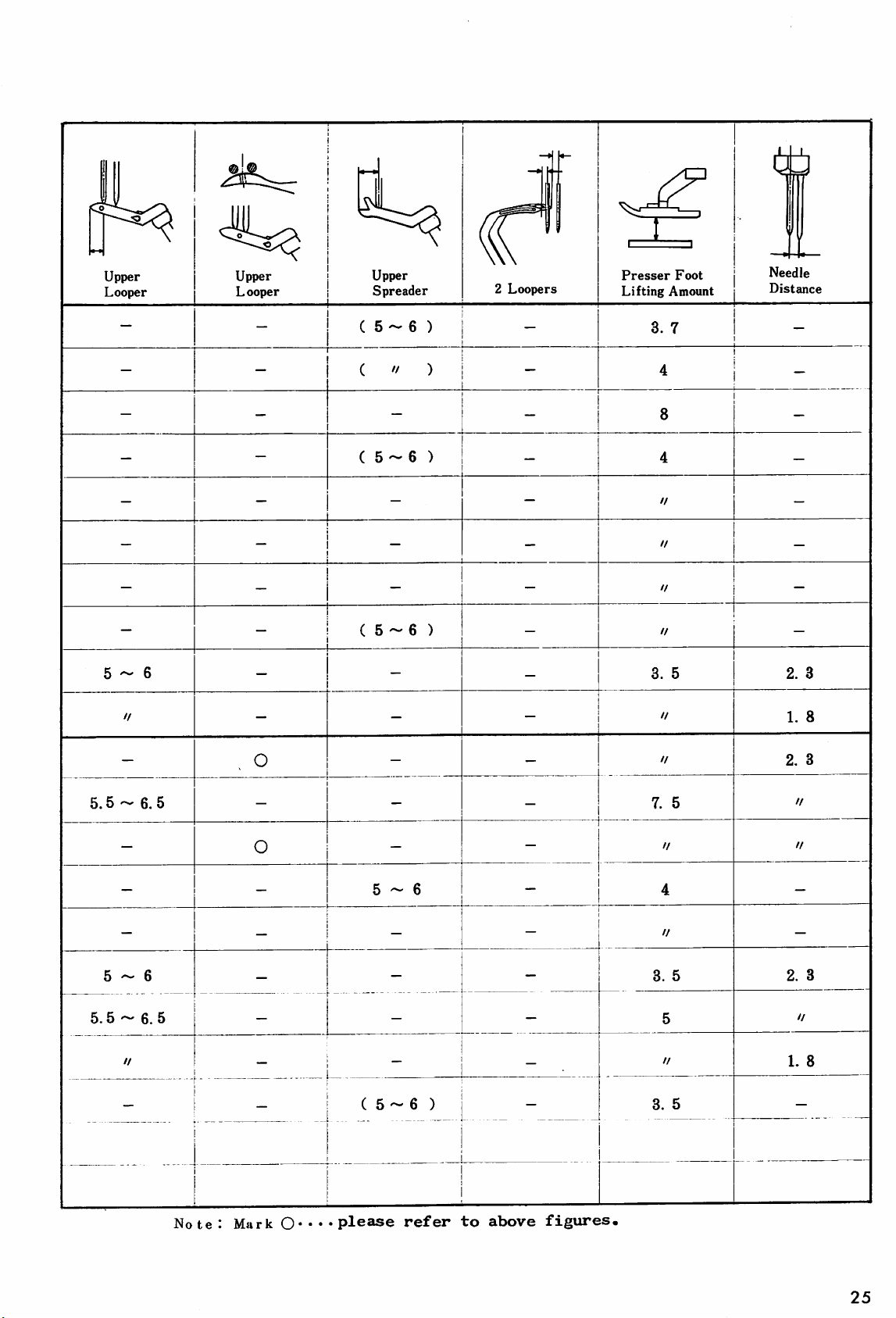

Upper

Looper

Upper

Looper

Upper

Spreader

2

Loopers

Presser

Lifting

Foot

Amount

Needle

Distance

5.5

- 6. 5

Note:

Murk

O • • • •

refer

to

above

figures,

25

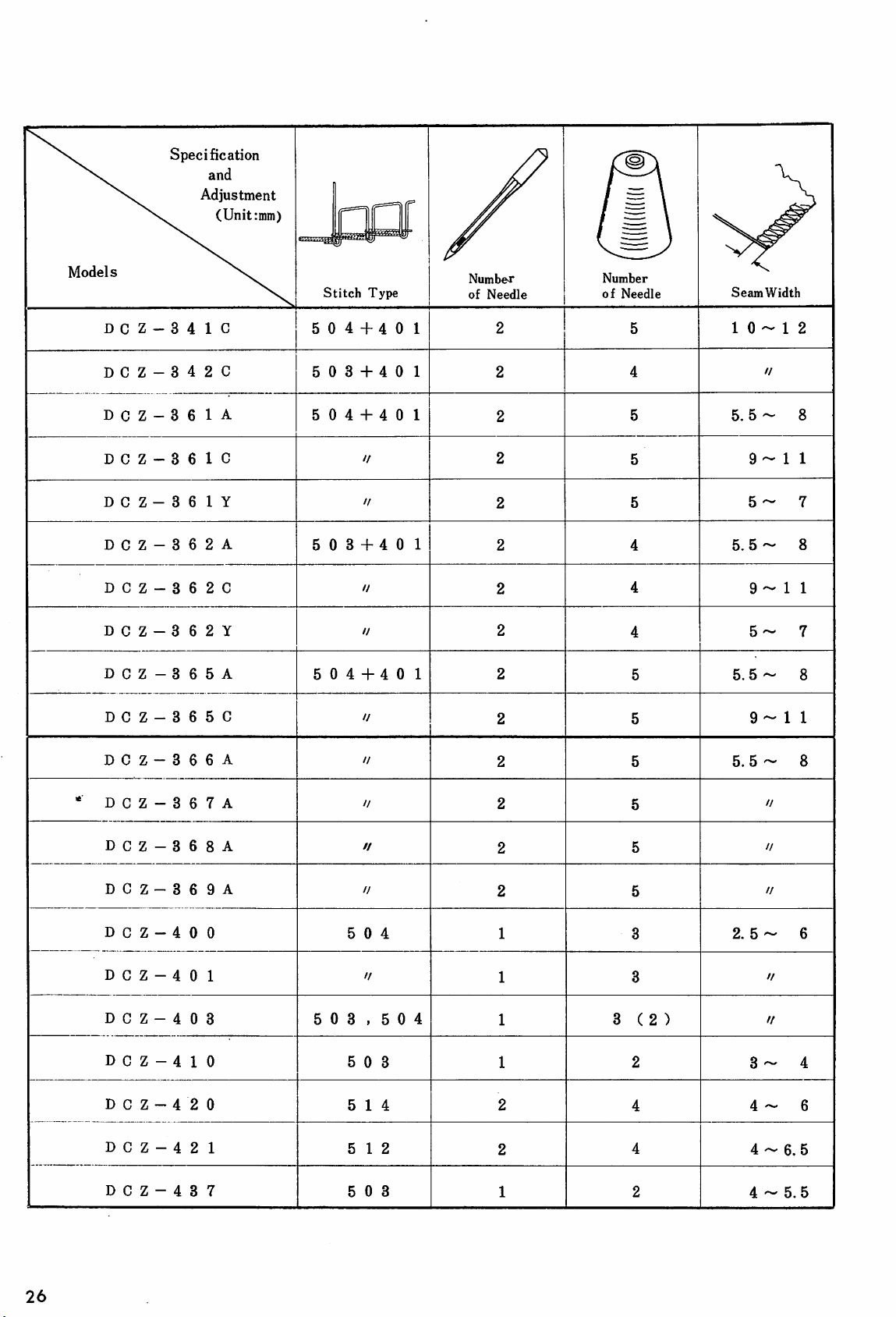

Specification

and

Adjustment

(Unit:mm)

Models

DCZ-341C

DCZ-342C

DCZ-36

DCZ-361C

DCZ-36

DCZ-362A

DCZ-362C

DCZ-362Y

DCZ-3

DCZ-365C

65A

lA

lY

Stitch

504+401

503+401

504+401

503+401

504+401

Type

Number

of

Needle

Number

of

Needle

SeamWidth

10-12

5.5

- 8

9-11

5.5

- 8

9-11

5.5

- 8

9-11

DCZ-366A

DCZ-367A

DCZ-368A

DCZ-369A

D 0 Z - 4 0 0

D C Z - 4 0 1

D C Z - 4 0 3

D C Z - 4 1 0

D C Z - 4 2 0

D C Z - 4 2 1

D C Z - 4 3 7

5 0

5 0 4

3,5

5 0 3

5

14

5 1 2

5 0 3

0 4

3(2)

5.5

2.

5

4 —6.5

4-5.5

- 8

26

[NNNN,

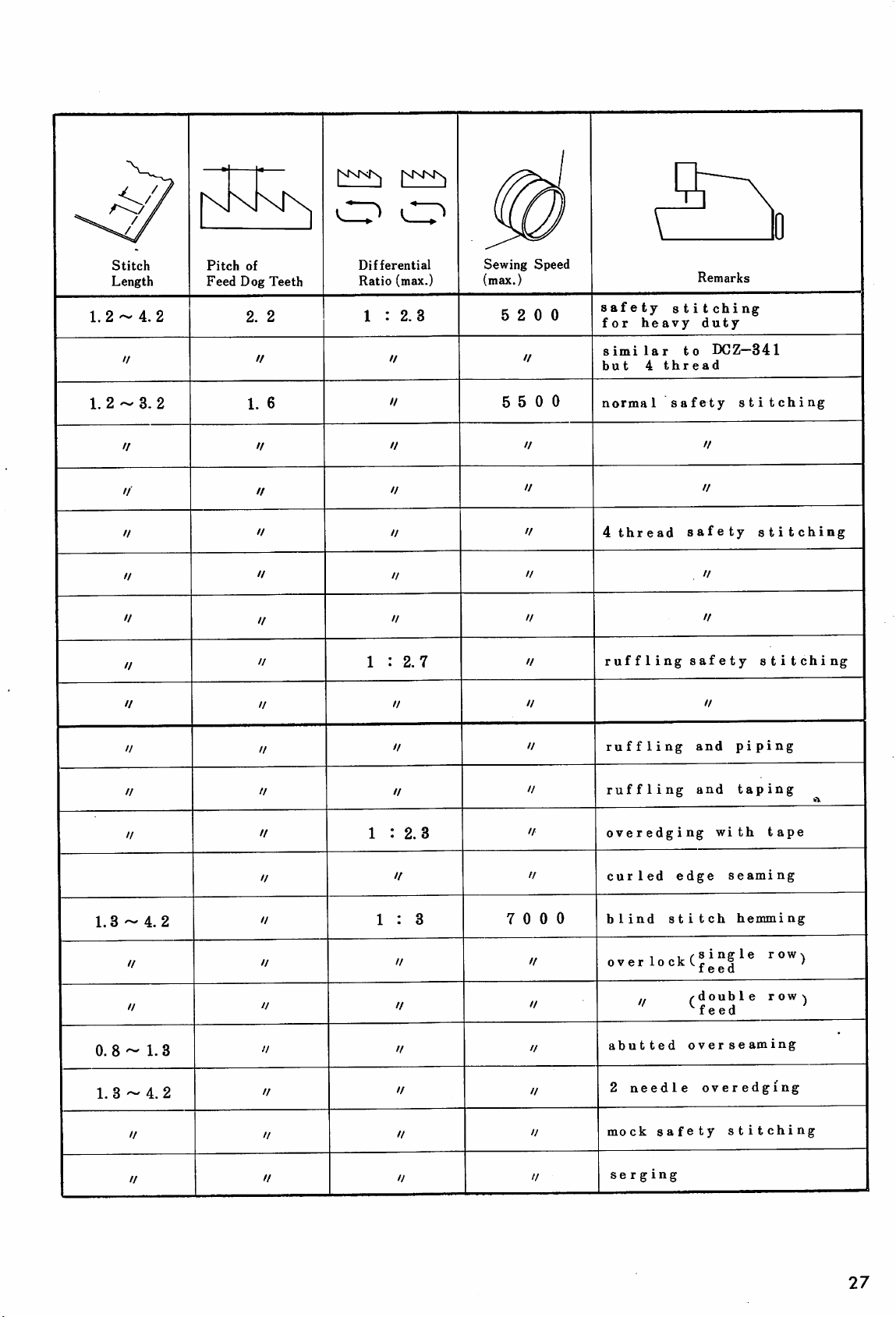

Stitch

Length

1. 2 -

1.

2 ~3.2

Pitch

of

Feed

Dog

Teeth

4.

2

2.

2

Differential

Ratio

(max.)

1 : 2. 3

1 :

2.7

Sewing

(max.)

Speed

5 2 0 0

5 5 0 0

safety

for

heavy

similar

but

4

thread

normal

safety

4thread

ruff1ingsafety

Remarks

stitchi

to

safety

ng

duty

DGZ—341

stitching

stitching

stitching

1.

3 ~4.2

0. 8 ~1.3

1.

3 -

4.

ruffling

ruffling

1 :2.3

overedging

curled

1 : 3

2

7 0 0 0

blind

abutted

2

needle

mock

serging

edge

stitch

safety

and

piping

and

taping

with

seaming

hemming

double

feed

overseaming

overedging

stitching

tape

row

27

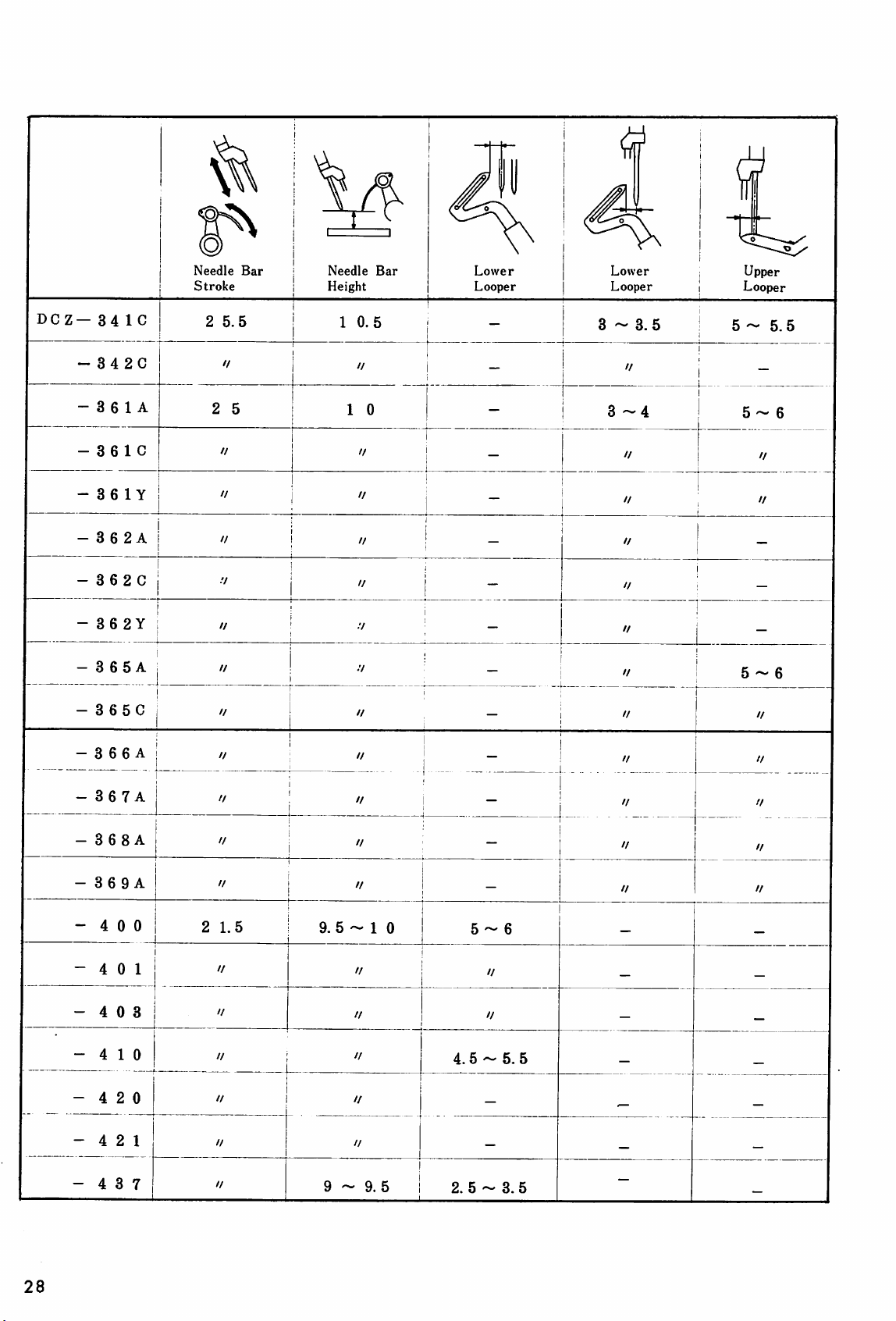

DC

Z—

341C

- 3 4

- 3 6 1 A

-3610

- 3 6 1 Y

- 3 6 2 A

- 3 6 2 0

- 3 6

- 3 6 5 A

- 3 6 5 0

- 3 6 6 A

- 3 6 7 A

- 3 6 8 A

20

2Y

Needle

Stroke

2

2 5

i

i //

1

j

i

//

//

//

//

.7

//

//

//

5.5

//

Bar

Needle

Height

1

1 10.5

i

1

1

\

i "

\

! "

1 "

i

! "

i

i

!

1

\

\

1 0

"

-7

"

"

"

Bar

Lower

Looper

I -

1

j

i

1

1

X

Lower

00

1

—

i

! //

1

-

1 ""

i

1

-

-

—

—

—

-

i "

\

1

Looper

3 -

3.

5

! 5 - 5. 5

1

1

1

//

"

//

//

I —

1

1 —

u

1

u

//

//

//

Upper

Looper

5-6

n

n

5-6

//

n

//

//

- 3 6 9 A

- 4 0 0

- 4 0 1

- 4 0 3

- 4 1 0

- 4 2 0

- 4 2 1

U

1 1

2

1.5

u

u

//

//

//

9. 5 - 1 0

'f 1

//

//

" 1

4.5

5-6

—

//

//

-

5.

5

—

—

ft

—

!

- 4 3 7

//

9-9.5

1

2.

5 -

3.

i

5

—

28

//

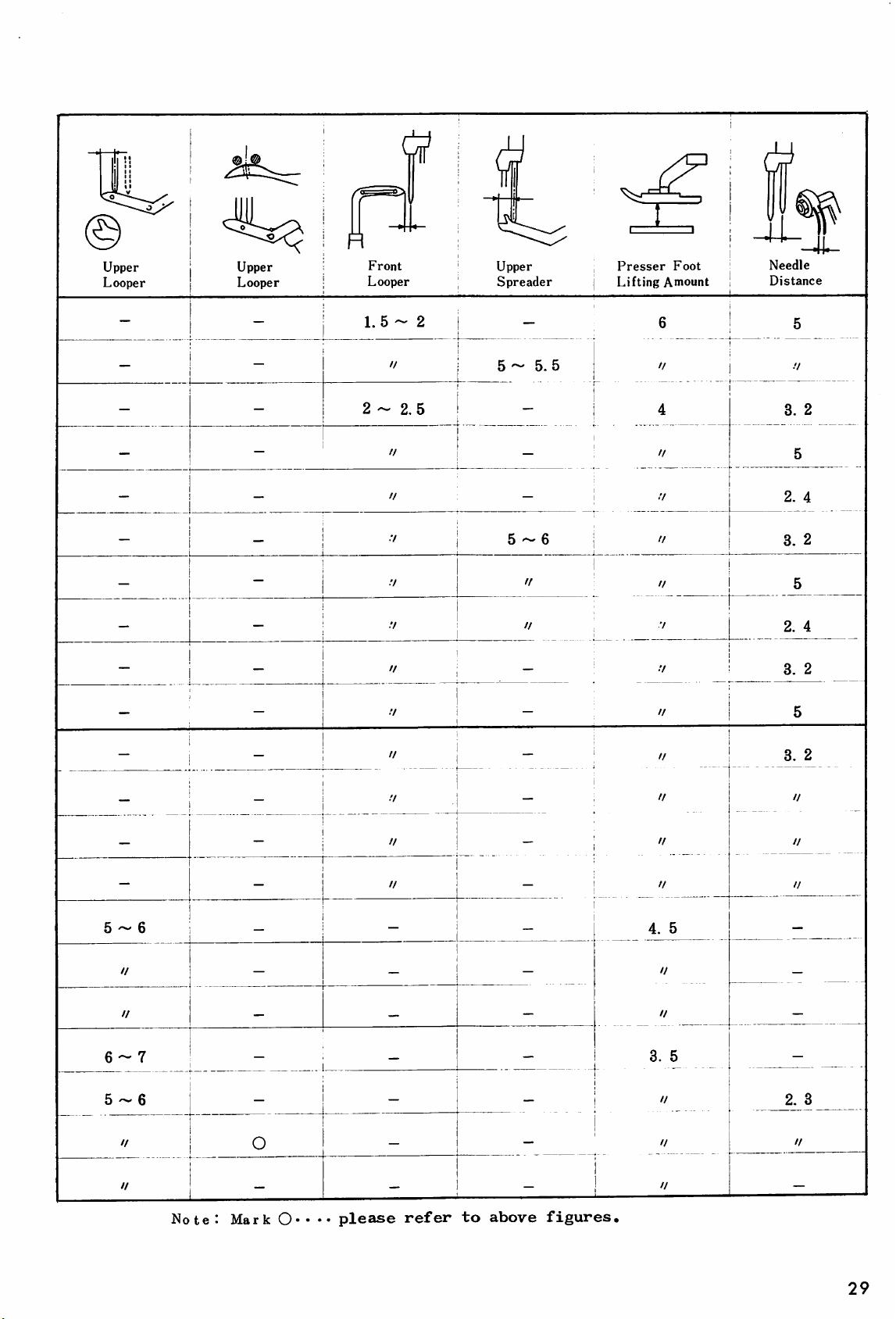

Upper

Looper

Upper

Looper

n

Front

Looper

1.5-2

Upper

Spreader

5-5.5

Presser

Lifting

Foot

Amount

41-

Needle

Distance

4-

2.5

5-6

3.

2

5

2.

4

8.

2

2.

4

3.

2

3.

2

4--

5-6

6-7

5-6

Note:

O

Mark

O**••please

refer

to

above

figures.

4.

5

3.

5

2.

3

29

Loading...

Loading...