Page 1

KENCO ENGINEERING COMPANY

P.O. BOX 470426 TULSA, OK 74147-0426 ● PHONE: (918) 663-4406 FAX: (918) 663-4480

www.kenco-eng.com e-mail: info@kenco-eng.com

SMARTSONIC REMOTE ACOUSTIC WAVE LEVEL / OPEN CHANNEL FLOW TRANSMITTER

INSTALLATION / OPERATION INSTRUCTIONS

TABLE OF CONTENTS

1. GENERAL DESCRIPTION ............................................................. 2

2. PRINCIPLE OF OPERATION ......................................................... 2

3. MODEL DESCRIPTION .................................................................. 2

4. SPECIFICATIONS .......................................................................... 2

5. INSTALLATION .............................................................................. 2

6. DIMENSIONS.................................................................................. 3

7. MOUNTING GUIDELINES .............................................................. 4

8. MOUNTING INSTRUCTIONS ......................................................... 4

9. WIRING ........................................................................................... 5

Wiring Connections....................................................................... 6

10. CALIBRATION................................................................................ 8

Accessing the Main Menu............................................................. 10

11. SETTING THE MAIN MENU OPTIONS .......................................... 11

12. OPEN CHANNEL FLOW MEASUREMENT ................................... 22

13. ADDITIONAL FEATURES .............................................................. 30

Additional Features Program List................................................ 31

14. TROUBLESHOOTING .................................................................... 37

Page 1

Page 2

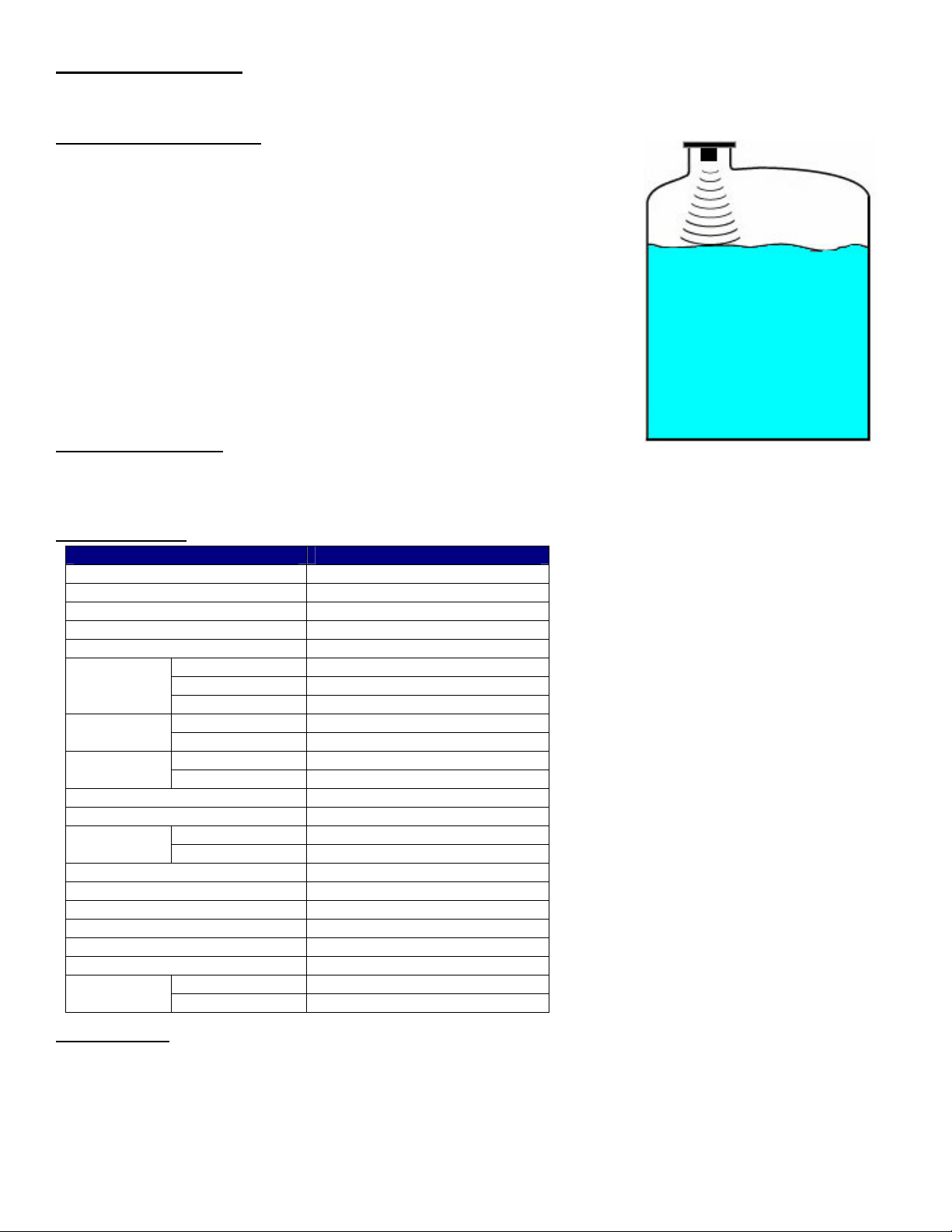

GENERAL DESCRIPTION

Process

Media

Air

Acoustic

The SmartSonic Acoustic Wave Transmitter is designed for high accuracy level measurement of a variety of liquids. The

SmartSonic Integral can also be used for Open Channel Flow Measurement.

PRINCIPLE OF OPERATION

The SmartSonic Transmitters consist of two main components:

• The Electronics

• The Sensor (Transducer)

The transducer contains a piezoelectric crystal that converts an electrical signal

from the electronics, into acoustic (sound) waves. These acoustic waves are

directed through the air toward the process media surface. They are then

reflected off of this surface and returned to the transducer. The piezoelectric

crystal then converts the received waves into an electrical signal which is

analyzed by the electronics.

The time difference between the transmitted wave and the received wave is

proportional to the distance from the face of the transducer to the process media

surface. This distance is used by the electronics to calculate level or open

channel flow in the units selected by the operator.

Waves

MODEL DESCRIPTION

P50-L35V-6N8AE - Remote Transmitter KAWT-xx – Remote Cable (xx = Length in Feet)

PN5-XGB-1-C – 1” NPT Polypropylene Transducer ACC-I – Remote Cable Connector

PN5-XGD-1-C – 1” NPT PVDF (Kynar) Transducer

SPECIFICATIONS

Description Specification

Power Supply 100-230 Vac

Maximum Range 39.4 feet

Minimum Dead Zone 1.3 feet

Maximum Span 38.1 feet

Frequency 50 kHz

Output

Signal

Ratings

Interface

Wave Angle 5º @ 3db

Mounting Connection 1” NPT

Range

Accuracy ±0.2% of max. range

Resolution 0.04” (1 mm)

Enclosure Material ABS + UV

Transducer Housing Material Polypropylene or PVDF

Transducer Material Glass Reinforced Epoxy

Cable Length 328ft. (std.); 656ft. (opt.)

Weight

INSTALLATION

Unpack the transmitter carefully. Inspect all units for damage. Report any damage to carrier immediately. Check the

contents against the packing slip and purchase order. Kenco’s SmartSonic Acoustic Wave Transmitters are

manufactured to the highest quality standards. These instruments use electronic components that can be damaged by

static electricity. Make sure that you are properly grounded before starting installation. Insure that all electrical

connections are properly made, and that there are no “floating” connections.

Analog 4-20mA

Digital RS-422

Discrete (5) SPDT Relays

AC 2A @ 220Vac Relay

DC 2A @ 30Vdc

Display Graphical LCD User

Keypad 4 Button

Ambient -40ºF to 140ºF Temperature

Process -40ºF to 212ºF

Electronics 2.4 lbs

Sensor 1.1 lbs.

Page 2

Page 3

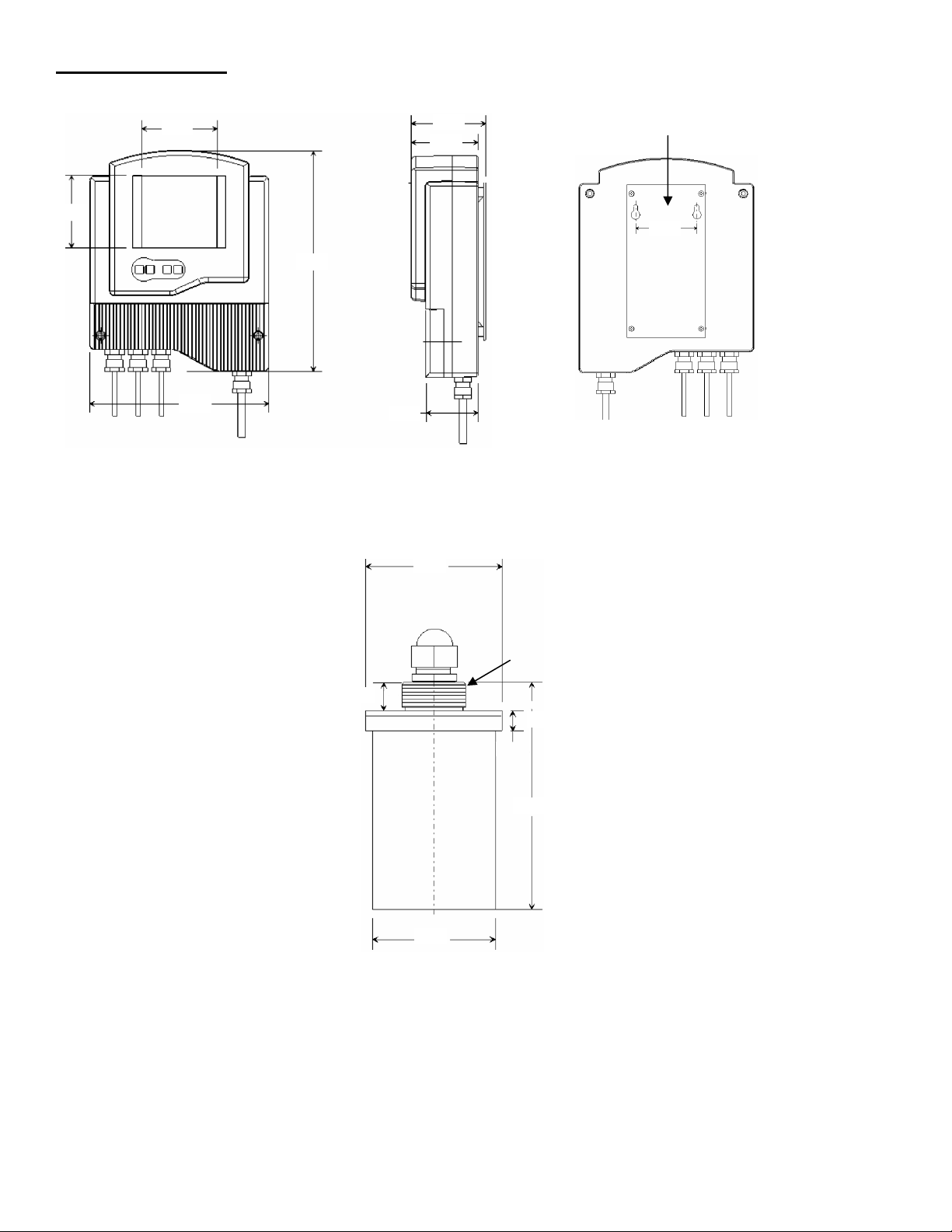

DIMENSIONS - INCHES

3.15

3.31

9.68

3.26

2.87

2.28

2.75

Transducer

(Sensor)

2.83

0.59

4.88

2.56

0.55

1” NPT

7.87

Mounting Plate

Page 3

Page 4

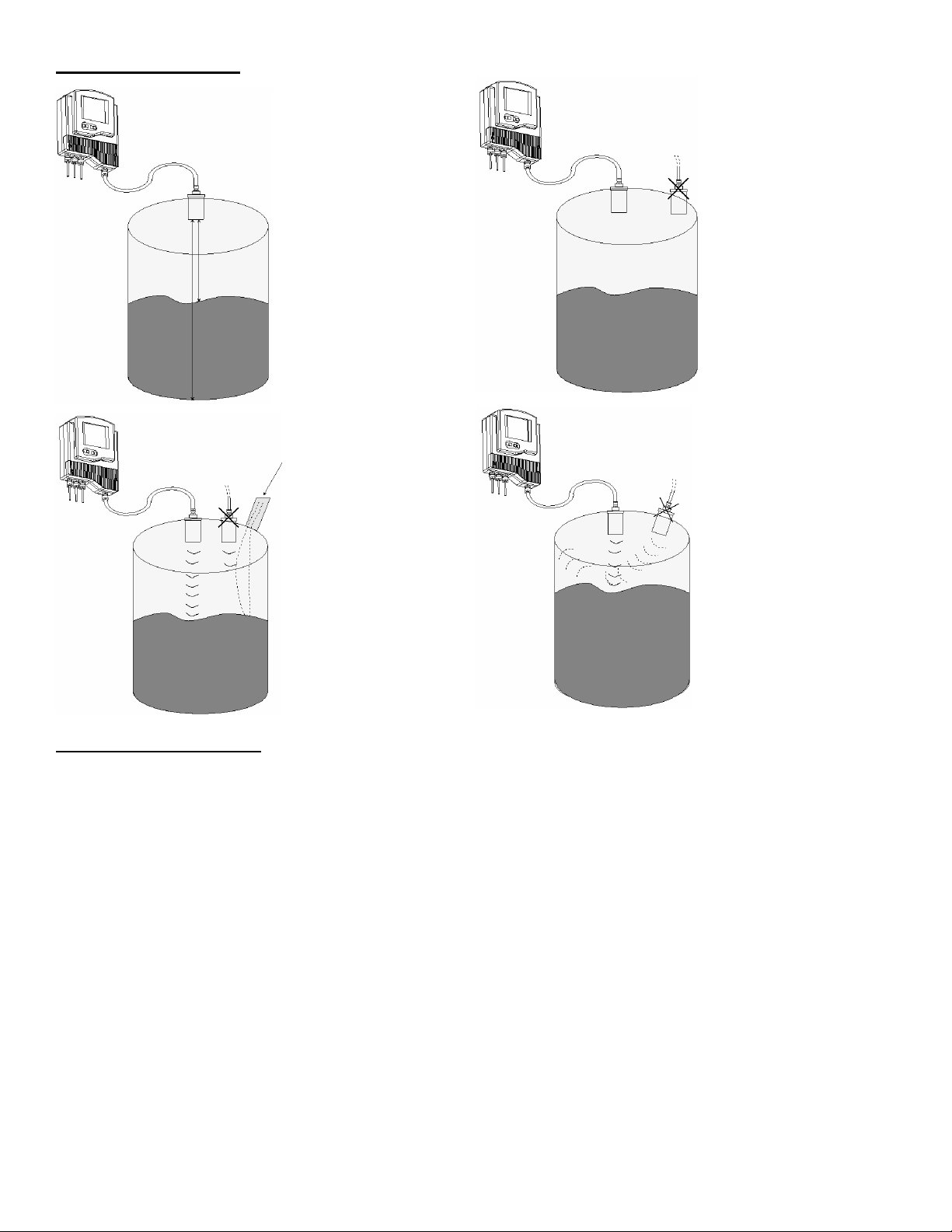

MOUNTING GUIDELINES

MOUNTING INSTRUCTIONS

Precautions:

• Ensure that the sensor is mounted in an area that meets the stated temperature, pressure and technical

specifications.

The transmitter must

be mounted in such a

way, as to avoid the

process fluid level from

entering the Dead

Zone.

If the level enters the

Dead Zone, an error

will occur, and the

transmitter will not

measure the fluid level

The sensor needs to

be mounted as far

away as possible from

processes that can

interfere with the

Acoustic Wave. This

example shows a fluid

filling inlet.

While the narrow wave

diameter of the Kenco

Acoustic Wave

Transmitters allows

you to mount the

sensor closer to the

vessel wall, than other

Ultrasonic transmitters,

it is recommended to

mount the sensor at

least 1.64 feet away

from the wall.

The sensor must be

mounted perpendicular

with the process fluid

level. Even the

slightest mounting off

perpendicular will affect

the measurement.

Anything over 4º will

usually result in a loss

of echo or at the very

least, an inaccurate

reading

• Ensure that high voltage (ac) sources or cables are at least 1 yard away from the sensor and its cable.

• Installation and Operation of this transmitter must conform to the National Electric Code and any applicable local

codes.

Direct Mounting of the Sensor to the Tank

1.) Open the top of the tank

2.) Feed the free end of the sensor cable from the inside of the tank, through the 1” NPT coupling attached to the top

of the tank (customer supplied).

3.) Keep feeding the cable until the sensor threads are touching the coupling. Screw the sensor threads into the

coupling.

Page 4

Page 5

Mounting the Sensor to a Flange

2

1

JP1

1.) Feed the free end of the sensor cable through the 1” NPT threaded connection on the flange. Feed the cable from

the process side of the flange

2.) Keep feeding the cable until the sensor threads are touching the inside of the flange. Screw the sensor threads into

the 1” NPT threaded connection on the flange.

3.) Bolt the flange to the top of the tank. Use a soft gasket.

Mounting the Transmitter (Electronics)

1.) Drill (2) holes, 2.75” apart, onto the desired mounting surface. Install (2) screws into these holes.

2.) Attach the mounting plate to the SmartSonic, using the (4) screws provided.

3.) Mount the SmartSonic onto the desired mounting surface, using the slotted holes on the mounting plate and the (2)

screws on the desired mounting surface from Step #1.

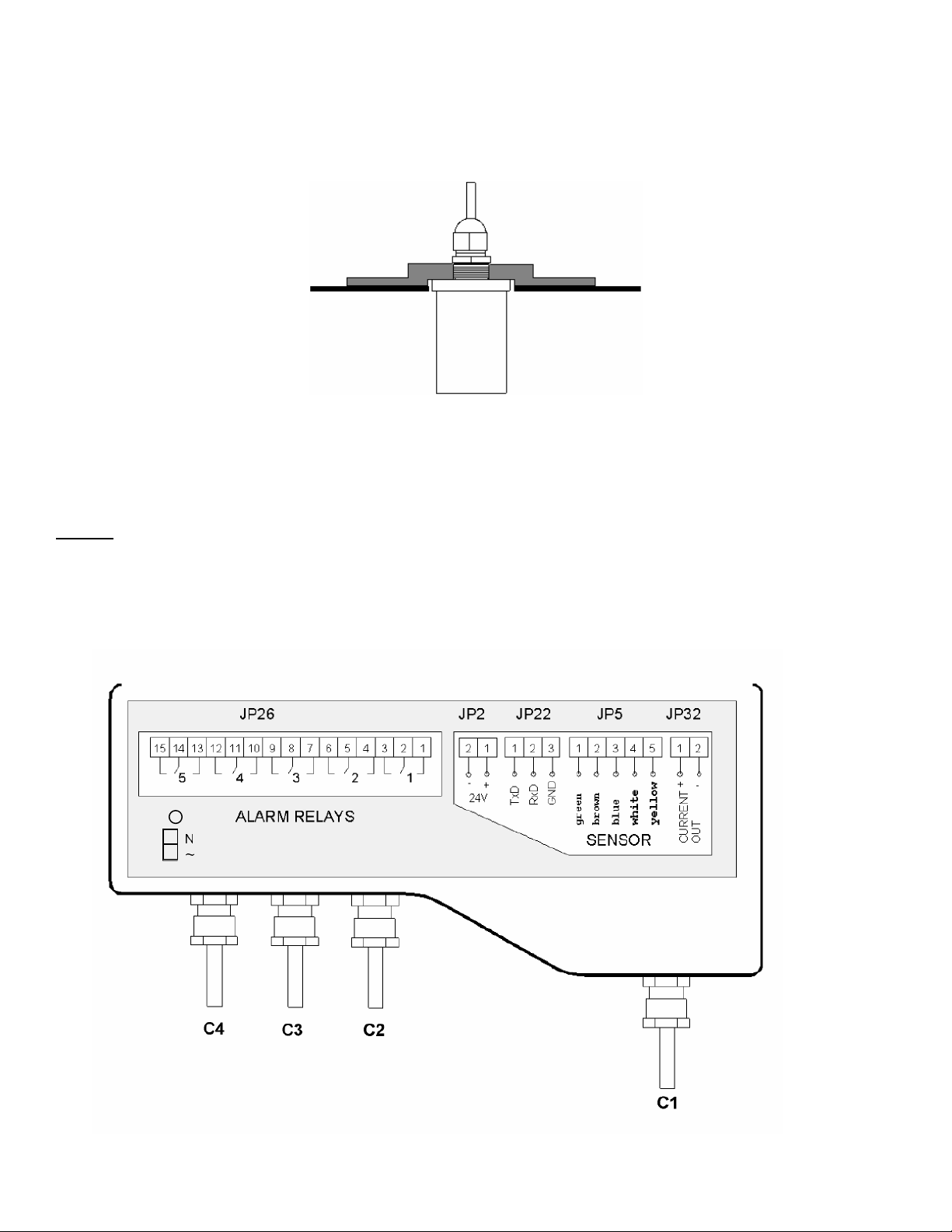

WIRING

It is recommended that conduit be installed onto the ½” NPT connections (C1 thru C4) on the electronics

housing. Seal drain fittings should be used to prevent moisture from entering the transmitter. In high humidity

areas, use breather drains to minimize moisture intrusion.

All wiring, conduit, and fittings must conform to local electrical codes for the location selected. If the transmitter is to be

used in a Hazardous Area, the applicable sections of the National Electric Code must be followed as well.

GND

Page 5

Page 6

Sensor cable side

Wiring Connections

In order to connect the wiring, remove the ribbed faceplate on the front of the electronics, using a 7/64” (3mm) Allen

wrench. Ensure that the cover is reinstalled, with the gasket in place, after completing the wiring. Refer to the drawing on

the previous page for the location of the wiring connections and cable entries.

NOTE: Power must be off when wiring the electronics. Damage and/or injury may occur if power is applied

during wiring.

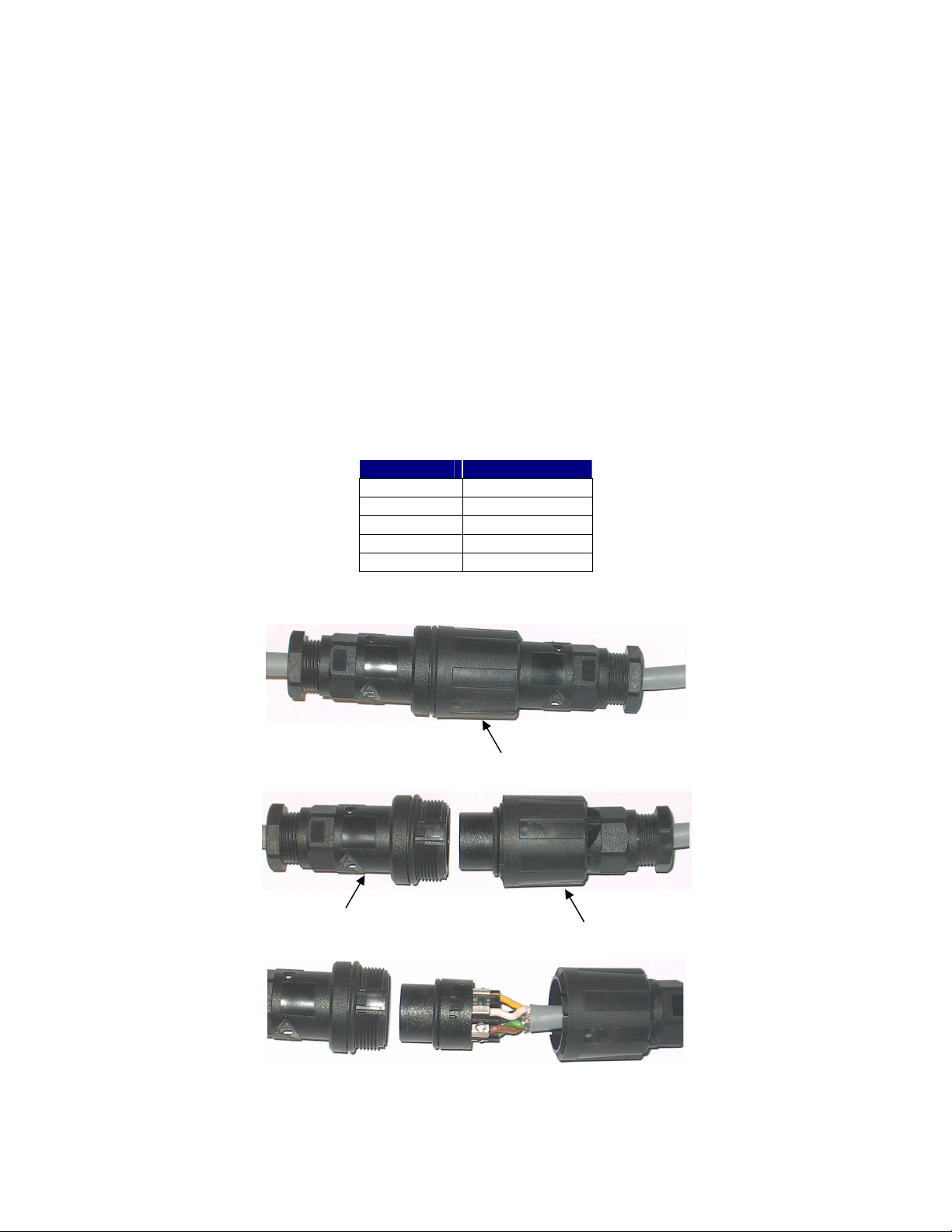

Wiring the Sensor Connections

The sensor uses a custom 5-conductor cable between the sensor and electronics. The cable comes with a cable

connector, which can be used to extend the length of the cable. Make sure that you use Helukabel p/n 16028. Use of

any other cable may damage the sensor, or interfere with the signal.

If you are only using the standard 16.4 ft. of cable supplied attached to the sensor, or the non-connector end of an

extended cable:

1.) Remove the cable connector from the sensor-side of the cable (the male plug). Skip this step if you are using the

non-connector end of an extended cable.

2.) Thread the cable through aperture (C1 – see wiring drawing on page 5) located on the right side of the SmartSonic

electronics base.

3.) Connect each wire by color, to the appropriate screw terminal on connector JP5. If the cable contains multiple black

wires, connect as follows:

JP5 Post Color

1 Green (Black 1)

2 Brown (Black 2)

3 Blue (Shield)

4 White (Black 3)

5 Yellow

If you are using the cable connector, follow these directions:

Nut

1.) Unscrew the nut holding the cable connector together.

Loose cable side

2.) Disassemble the “loose cable side” of the connector.

3.) Disconnect the “dummy cable” wires from the connector, and connect the wires from the extended cable (supplied

separately). The blue wire is connected to the cable shield. Make sure that the wires match exactly. If you aren’t

sure, disassemble the “Sensor cable side” connector and match up the pins to the wire color. If you have any

questions, please contact Kenco. Do not apply power unless the connector is wired correctly.

Page 6

Page 7

Wiring the Digital and Analog Communication Cables

SmartSonic data can be monitored on a PC or PLC via RS-485 (MODBUS RTU) digital communications, when connected

to JP22. You can also monitor a 4-20mA output by connecting to JP32 (the 4mA and 20mA settings are discussed in the

CALIBRATION section).

1.) Thread the connection wires through aperture C2.

2.) Connect each wire to the appropriate screw terminal at connection block JP22 (MODBUS) and / or JP32 (4-20mA).

JP22 connections are as follows:

JP22 Post Wire

1 B (TxD)

2 A (RxD)

3 Ground

JP32 connections are as follows: Post 1 (+); Post 2 (-).

JP32 Post Wire

1 +

2 -

Wiring the Power Connections

1.) Thread the power wires through aperture C4

2.) If you have 100-230Vac power, connect each wire to the appropriate screw terminal on JP1 as follows:

JP1 Post Wire

1 Neutral

2 Hot

GND Ground

NOTE: If you are using 100-230Vac leave the red and black wires connected to JP2.

3.) If you have a 24Vdc power source, disconnect the red and black wires from JP2, and connect your power wires:

JP2 Post Wire

1 +

2 -

NOTE: Use either JP1 or JP2. Do not connect external power to both.

Wiring the Relays

1.) Thread the power wires through aperture C2 (DC Power) or C4 (AC Power). C3 may not be available when using

conduit.

2.) Connect each wire to the appropriate screw terminal (see wiring drawing on page 5).

Page 7

Page 8

CALIBRATION

This section explains how to set up and calibrate the SmartSonic for accurate measurement monitoring using the basic

menu options. SmartSonic is supplied with preprogrammed default settings, making it ready for immediate operation.

Measurement readings are displayed on the default screen as soon as the unit is powered on. It is recommended that

you replace the default tank height value with the actual tank height, as described later in this section.

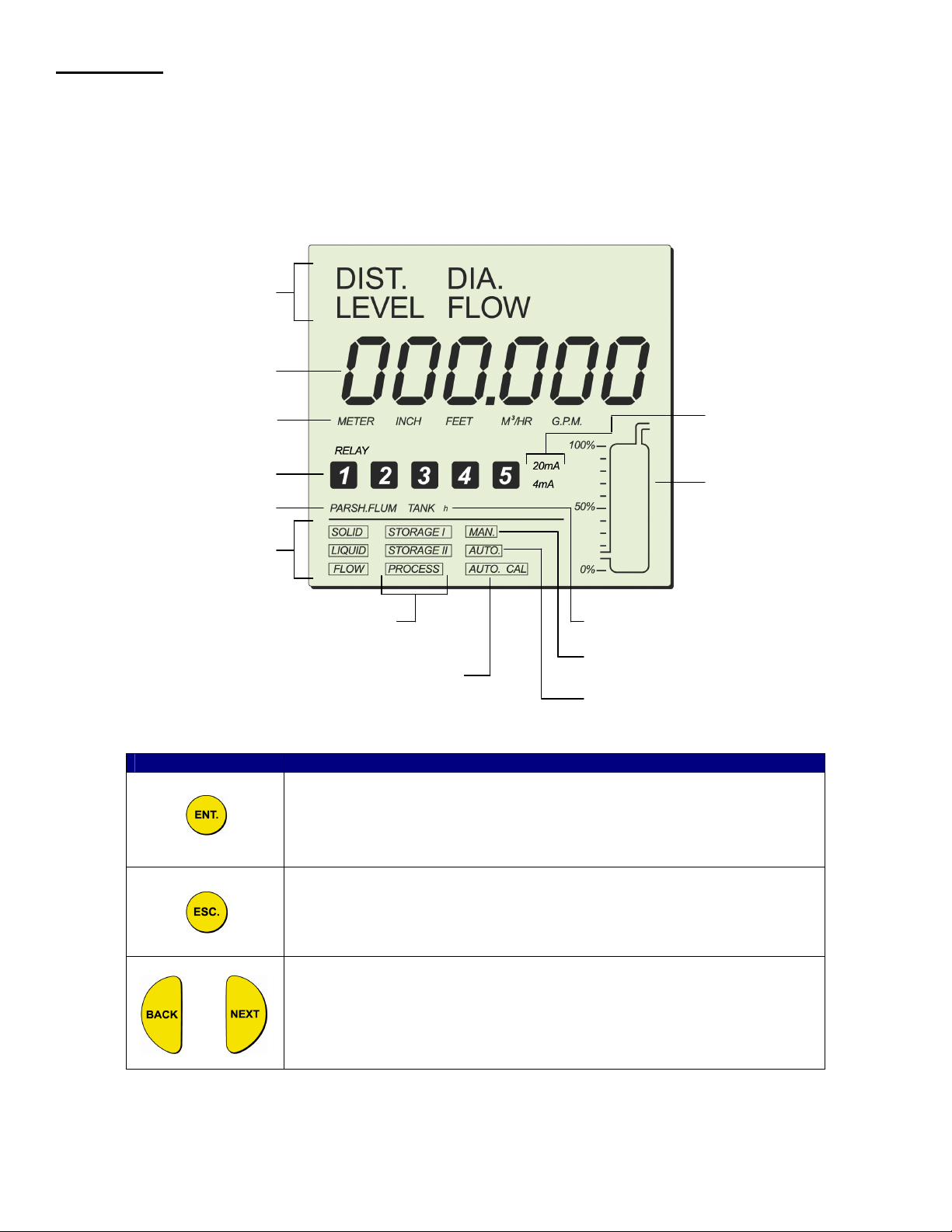

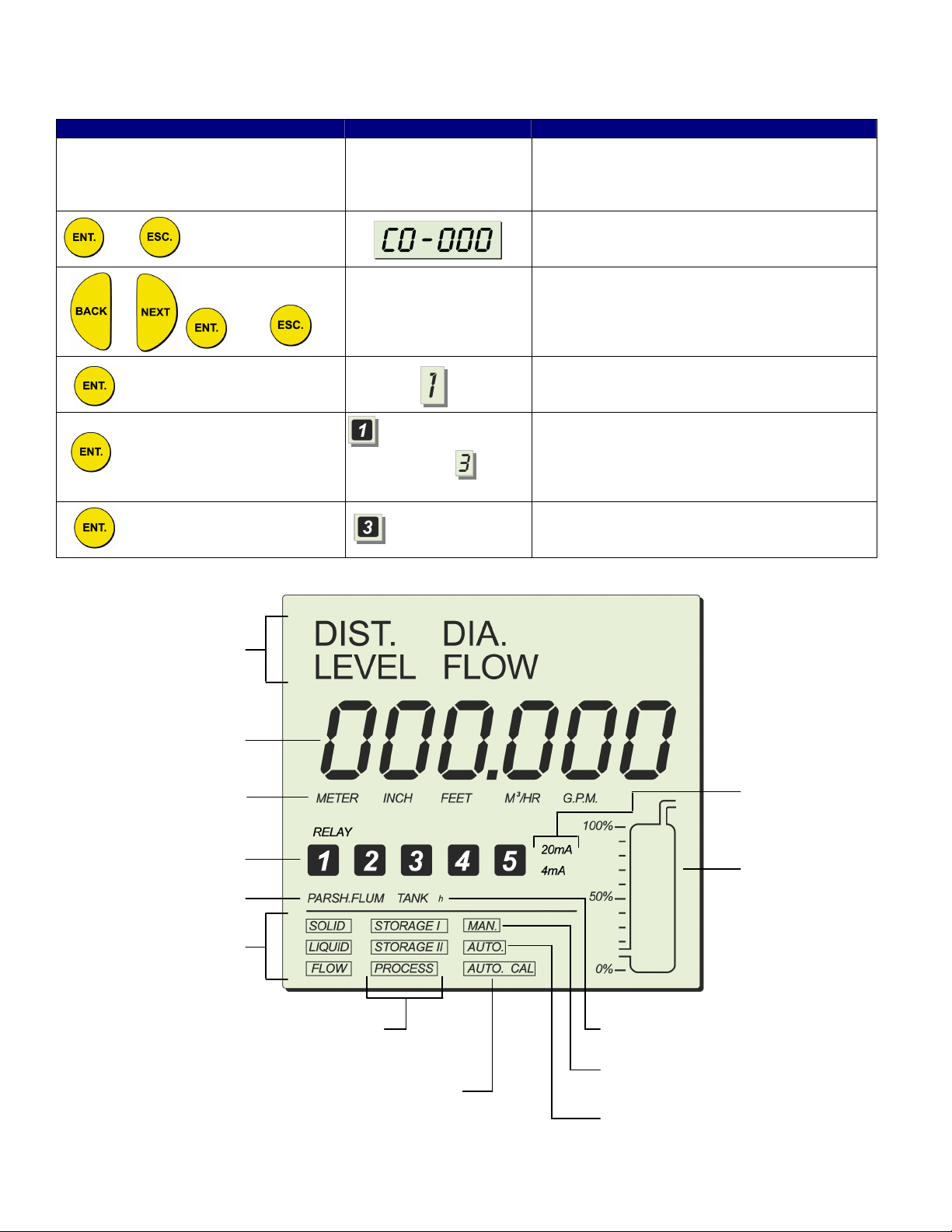

Display / Keypad

The LCD display screen functioning in “Normal” mode provides continuously updated measurement readings. This

display is also used to view the program menus, options, settings, and data values. These are accessed by using the

keypad. The picture below shows the display of the SmartSonic:

The keypad buttons are used to perform various operations, summarized in the following table

Indication modes

Numerical area

Measurement

units

Relays

Flow

measurements

Application types

Button Uses Include:

or

20 mA/4 mA

levels

Tank graphic

Operation

modes

Scan distance

Tank height

Sensor offset

mode indicator

Clear scan distance

• Accessing the program menu (when pressed simultaneously with “ESC.”

• Accessing a function within a menu, enabling you to make modifications

• Moving from left to right between displayed digits.

• Saving changes to data.

• Accessing the program menu (when pressed simultaneously with “ENT.”

• Moving from right to left between displayed digits.

• Returns you to the previous function (without saving changes), or back to

the default screen

• Moving to the next/previous function within a menu.

• Scrolling through or back data values in programs.

NOTE: Within some programs, the digits in the display can be individually modified. This is indicated by a flashing digit.

In this case the ENT and ESC buttons are used to move between digits. The BACK and NEXT buttons are used to

change the value of the flashing digit.

Page 8

Page 9

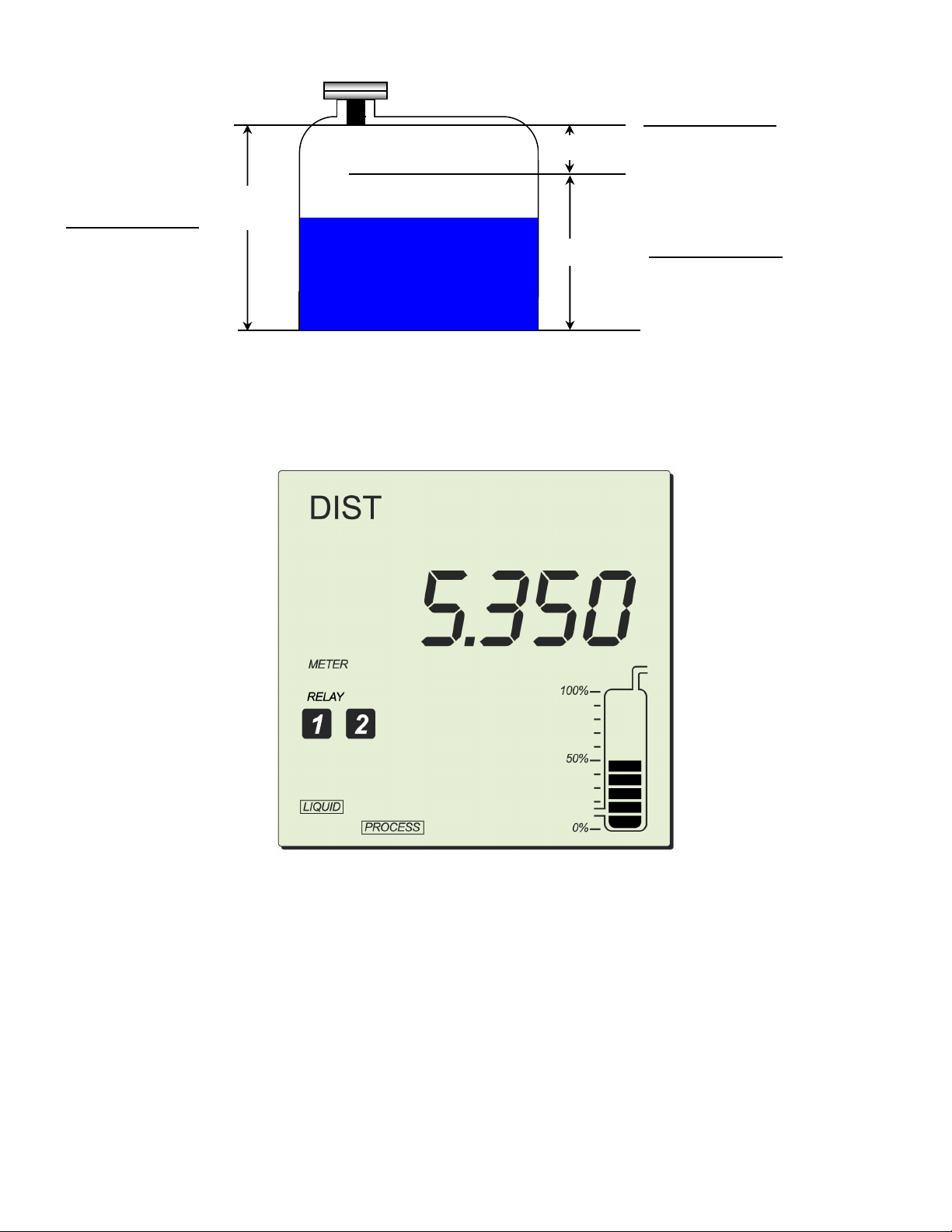

Tank Terminology

Process

Media

r

Tank

Span

Dead Zone

Ai

Dead Zone

SmartSonic Remote

● Minimum 1.3 feet

Tank Height

SmartSonic Remote

● Maximum 39.4 feet

Height

Span Range

(4mA to 20mA)

SmartSonic Remote

● Maximum 38.1 feet

Default Screen

As soon as SmartSonic is fully installed and powered on, the LCD displays the default screen. The default screen

provides continuously updated measurement readings and displays the current settings for some functions (either the

default settings or the settings selected from the main menu). The relay number is displayed for each activated relay. You

can toggle between display indication types, such as: level, distance, volume and others, by using the SmartScan Main

Menu.

The tank graphic in the default screen gives an approximate visual indication of the current level of the tank contents,

while the numerical area gives the exact reading. If the level enters the dead zone, the numerical area displays FF FFF. If

the tank is empty, the numerical area displays the tank height. 000000 may be displayed temporarily while SmartSonic is

taking a reading. You can refresh the reading by pressing the ENT and BACK buttons simultaneously.

NOTE: By default, the displayed value is in meters, and gives the distance measurement, meaning from the sensor face

to the level of the fluid. The measurement indication mode and measurement unit can be changed, as described in Setting

Main Menu Options

Page 9

Page 10

Accessing the Main Menu

and

This section describes the procedure for accessing the SmartSonic Main Menu. The main screen (see Page #7) is

accessed as follows:

Press / Action Display Description

The SmartSonic takes several seconds to

Connect SmartSonic to power supply See Wiring Section

and simultaneously

Flashes for 5

Flashes for 5

seconds, then is

displayed

seconds

warm-up. During this time various characters

will turn on and off, and the Tank Graphic will

cycle

This is the password display

Use to enter the password (716) in place of

(000). BACK and NEXT will change the vlue of

the digit (0-9). ENT steps to the next digit; ESC

steps to the previous digit.

Single Sensor (only available option).

Press ENT.

The main screen (Page #7) is now displayed.

Main Screen Functions

Indication modes

Numerical area

Measurement

units

Relays

Flow

measurements

Application types

20 mA/4 mA

levels

Tank graphic

Operation

modes

Scan distance

mode indicator

Tank height

Sensor offset

Clear scan distance

Page 10

Page 11

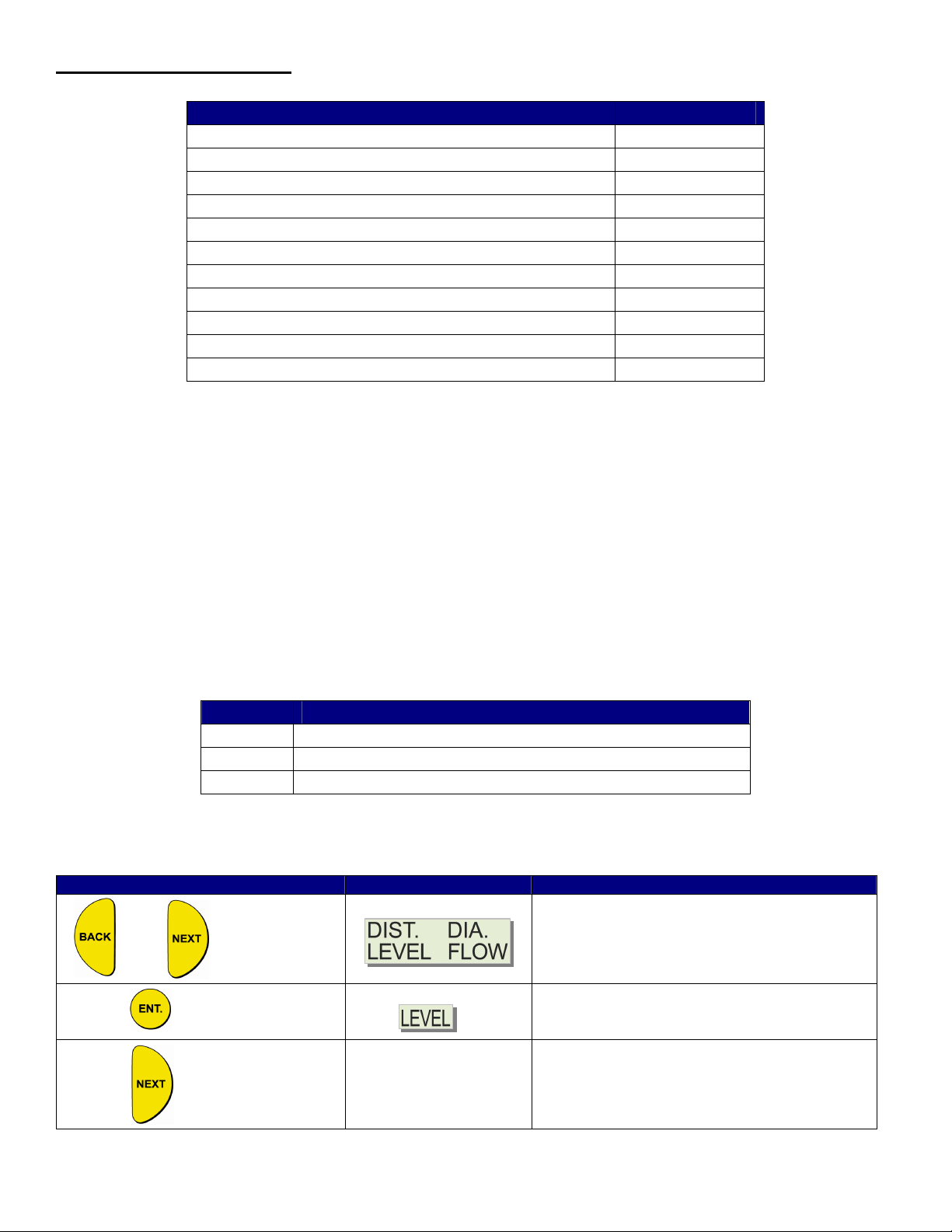

SETTING MAIN MENU OPTIONS

The following functions are available in the SmartSonic Main Menu:

Functions Page

Setting the Indication Mode 11

Setting the Measurement Units 12

Setting the Relay Values 12

Setting The 20mA and 4mA Values 17

Setting the Open Channel Flow Measurements 17

Setting the Tank Height 17

Setting the Application Type 18

Setting the Operation Modes 18

Setting the Sensor Offset 19

Setting the Scan Distance Values 20

Clearing the Scan Distance Values 21

NOTES: After you select any option the “Tank Graphic” will cycle a few times. Wait until one of the

options starts to blink before proceeding to the next step.

When you change an option, a flashing “Ar. 5” may appear. This is just to remind you that the option

you just selected may affect the Relay or 4-20mA Settings, and that you need to review these settings.

Setting the Indication Mode

The first function in the Main Menu is the Indication Mode. This sets the type of measurement. The options are:

• DIST: The displayed reading represents the distance from the sensor face to the process media.

• LEVEL: The displayed reading represents the level of the process media measured from the bottom of the vessel.

• FLOW: The displayed reading represents the flow rate through the configured Flume or Weir.

• DIA: DO NOT USE

Setting an Indication Mode enables you to toggle between other indication types as well, using the BACK and NEXT

buttons as described in the table below: For example, if the unit is configured for Level, the BACK and NEXT buttons will

toggle between Level and Distance.

Indication Toggle Selections (BACK / NEXT Buttons)

Distance Distance / Level

Level Level / Distance

Flow Flow / Level / Distance / Totalization (High) / Totalization (Low)

Totalization indicates the total accumulative flow. It is expressed in 10 digits. The first 5 digits (High) are shown as

H00000, and the second 5 digits (Low) are shown as L00000. This function will be described later in this manual

(Additional Features).

Press / Action Display Description

and

Move between the available options. DIA

(Diameter) is no longer available.

For Example

Select the desired option. This will show on the

display for a few moments, then return to the

Main Menu

Go to the next function (Measurement Mode)

Page 11

Page 12

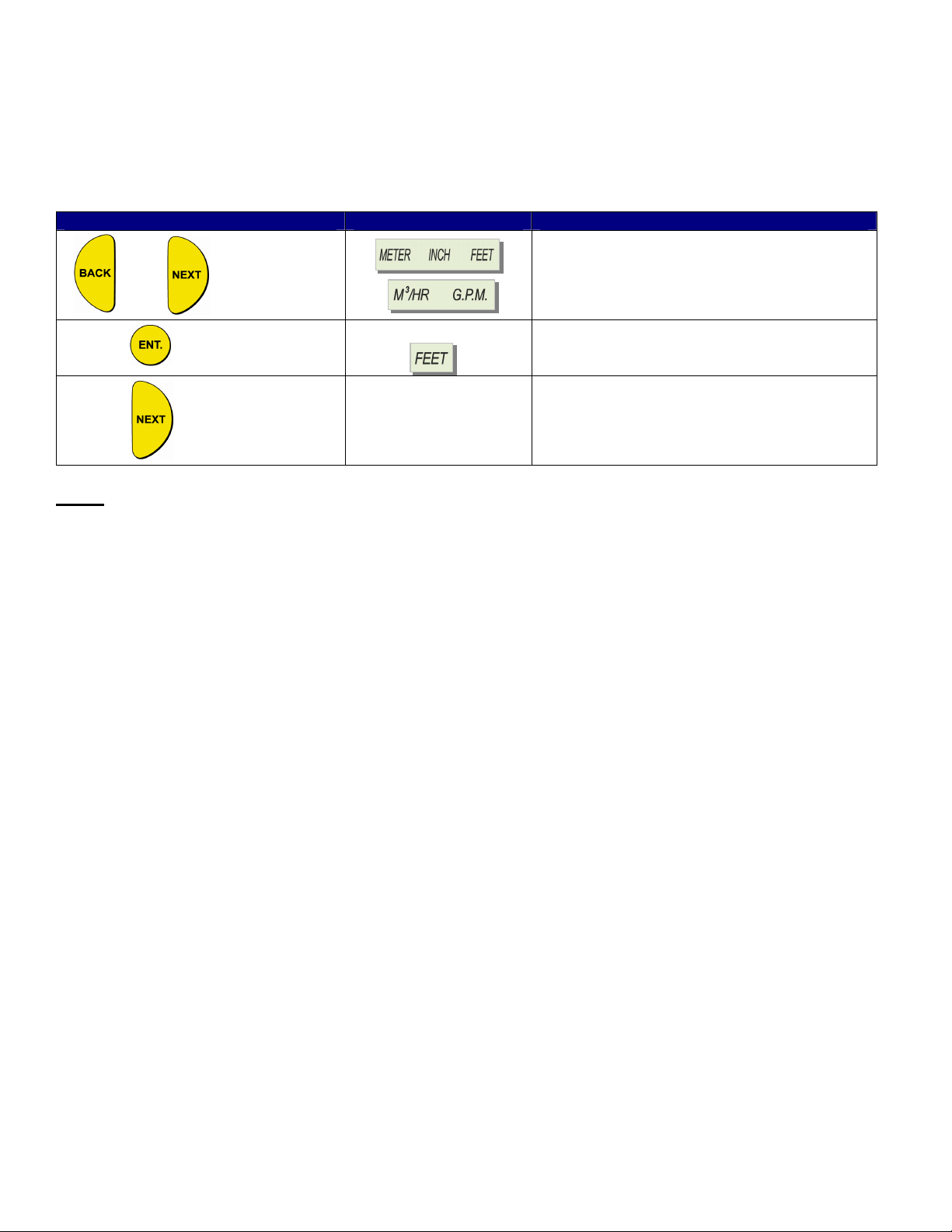

Setting the Measurement Mode

This function is used to select the units used for the display. The following measurement options are available:

• METER (default), INCH, or FEET: Select one of these options for Level or Distance measurements

• M3/HR or G.P.M.: Select one of these for Flow measurements

After setting the measurement unit, the selected unit flashes on the display whenever you enter numerical values during

the setup procedure. The values for functions, such as Relay, will be displayed in the selected measurement unit.

Press / Action Display Description

Move between the available options.

and

For Example

Select the desired option. This will show on the

display for a few moments, then return to the

Main Menu

Go to the next function (Relay Values)

NOTE: If you select METER any relevant flow measurement will be in metric units (M3/HR). The opposite also applies,

so that if you select M3/HR, any relevant distance or level measurements will be in meters. If you select INCH or FEET,

the flow measurements will be in G.P.M.. If you select G.P.M., any relevant distance or level measurements will be in

inches.

If you select METER when using a FLOW unit configured to show G.P.M., the METER sign will flash rapidly for a few

seconds. If you approve the selection by pressing ENT, the flow unit will change to M3/HR.

Setting the Relay Values

The relays in the SmartSonic Remote are SPDT (Single Pole, Double-throw). This means that each relay has (3)

connections:

• Normally Closed (NC)

• Common (C)

• Normally Open (NO)

In the SmartSonic, the term CLOSED means that the relay is de-energized. In this state the NC and C terminals are

closed (connected), and the NO and C terminals are open (disconnected).

The term OPEN means that the relay is energized. In this state the NC and C terminals are open (disconnected), and the

NO and C terminals are closed (connected).

In the event of power loss to the SmartSonic, the relays automatically go to the CLOSED state (NC & C are connected;

NO & C are disconnected). Make sure that any auxiliary equipment connected to the SmartSonic relays, will be in a safe

condition upon loss of power to the SmartSonic.

You can set the relays to (5) different indication modes:

• Level

• Distance

• Flow

• Volume

• Totalization

Page 12

Page 13

Volume and Totalization should only be configured after setting the Volume/Totalization options in the Additional Features

Section later in this manual. The following are the relay setup options:

Indication Mode Relay Mode

Distance Distance / Level

Level Level / Distance

Volume Volume

Flow Flow / Distance / Level

Totalization Flow / Totalization

For example, if the SmartSonic is set to FLOW Indication Mode, the relay can be set to Flow, Distance or Level values.

Each of the (5) relays in the SmartSonic allows you to define OPEN and CLOSED values, enabling its use for functions

such as triggering an alarm or controlling pumps. As an alternate, Relay #4 can be configured to report error messages,

and Relay #5 can be configured for a Flow Totalization pulse (see instructions later in this section).

The relay values function as follows:

• OPEN: The relay energizes if the level measured in the vessel is higher than the programmed OPEN value.

• CLOSED: The relay de-energizes if the level measured in the vessel is lower than the programmed CLOSED

value.

The default value for the OPEN and CLOSED functions is 0. The indication mode default value is LEVEL.

NOTE: The CLOSE value must be at lease 1 inch lower than the OPEN value. An error (Err. 3 or Err. 10) will appear if

this is not the case. If a relay value greater than the tank height is entered error (Err. 7) will appear

Page 13

Page 14

and

mode

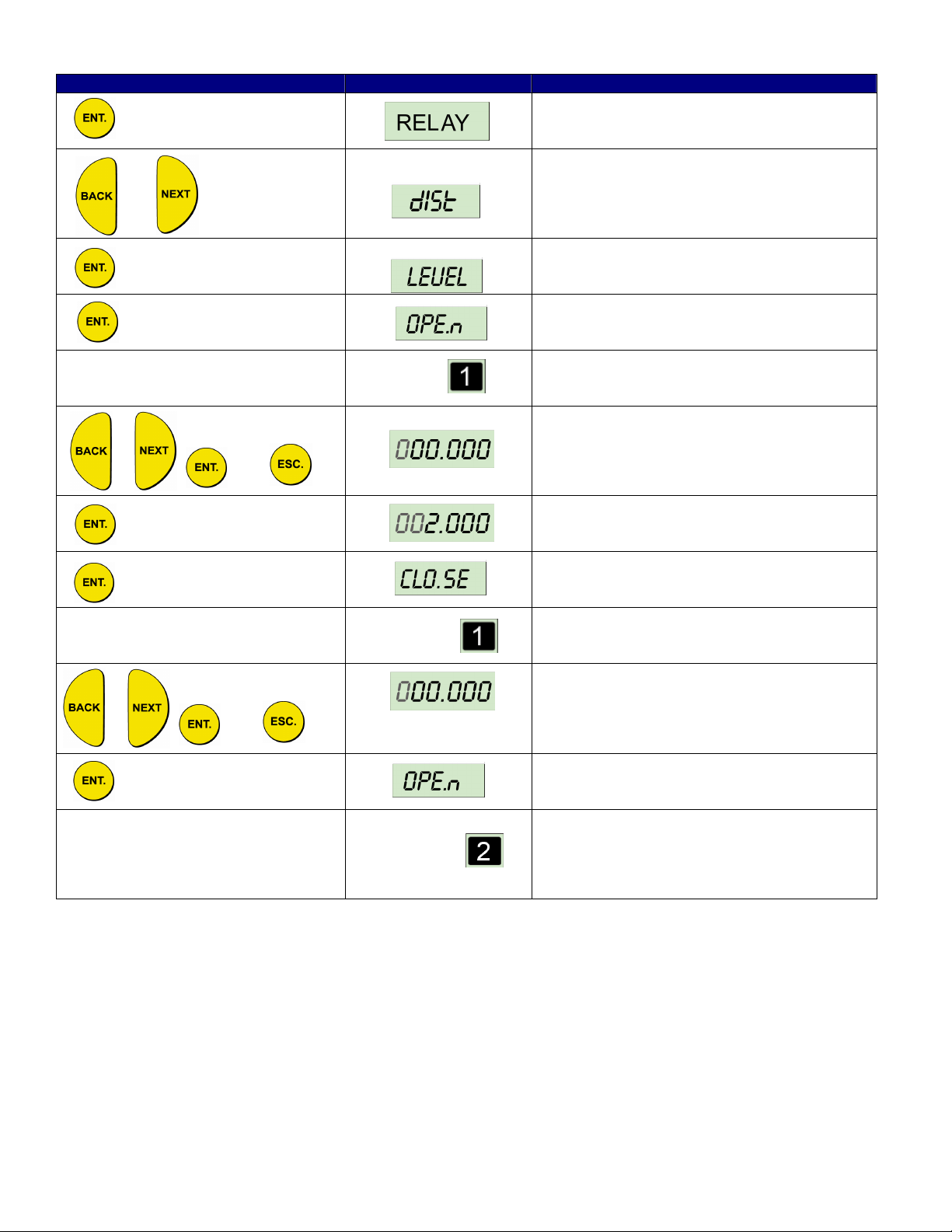

Press / Action Display Description

Press ENT when “Relay” is flashing to enter

relay setup

or

For Example:

For example:

and

Cycle between Level, Distance, Flow (see next

table), Volume, Totalization (Relay #5 only).

Press ENT to select the desired option

Press ENT to enter the OPEN function

The appropriate relay number flashes

throughout the process of defining the values

for the relay

Select the desired value for the OPEN

condition of this relay

Enter the value from the previous step

Press ENT to enter the CLOSED function

and

Relay values can be configured with an alternate method when set to Flow, Volume or Totalization modes (see Additional

Features Section for information on Volume or Totalization Modes).

Use the following procedure to set the relay values for FLOW:

and

and

The appropriate relay number flashes

throughout the process of defining the values

for the relay

Select the desired value for the CLOSED

condition of this relay. Must be 1 inch (3cm)

less than the OPEN Value.

Press ENT to enter the OPEN function

Repeat the previous steps to set an OPEN and

CLOSED value for each relay to be used. If

you do not want to set a value for every relay,

use the ESC button to exit the relay setup

Page 14

Page 15

Press / Action Display Description

Press ENT when “Relay” is flashing to enter

relay setup

or

or then

and

and

For example:

and

Cycle between options until it displays FLOW

Press ENT to select the FLOW option

Select the relay number you wish to configure,

then press ENT.

The appropriate relay number (Relay #1 in this

example), flashes throughout the process of

defining the values for the relay

This screen allows you to enter up to (4) digits

of High numbers of flow values.

This screen allows you to enter up to (5) digits

of Low numbers of flow values.

In the example above, the relay values were configured in the following way:

• 00001 was entered in the High numbers (H = 1)

• 20000 was entered in the Low numbers (L = 20,000)

This would mean that the OPEN value was set at 120.000 (G.P.M. or M3/HR)

NOTE: The same procedure is used for the Volume and Totalization Modes. The units for the Totalization Mode are

Gallons when the selected Measurement Unit is G.P.M. The units for the Volume Mode are the same used when entering

the Volume Strapping Table (see Additional Features Section later in this manual).

Setting Relay #4 to Report Errors

This allows you to use Relay #4 as a trigger to set an alarm if the unit has a “Lost Echo”, indicates a level higher than the

Tank Height, or when the level moves into the “Dead Zone”. Once the error mode is enabled, and an error occurs, the

relay will de-energize and the error message will show on the display. The following are the error displays:

• EE EEE: Loss of Echo, or measurement value is greater than the Tank Height.

• FF FFF: Process media is in the “Dead Zone”.

The relay will be energized as long as the unit is functioning properly.

Repeat the previous steps to set a CLOSED

value for the relay.

Page 15

Page 16

Press / Action Display Description

or and

Setting Relay #5 for Flow Totalization Pulse

You can choose to set Relay #5 for flow totalization pulse or to remain in normal set-up mode. This option enables you to

reserve the accumulated value gathered by the unit, by using an external counter. In this way the total value will be

reserved even if the unit will be replaced. Once set for this option, the relay will generate a pulse per Xm^3 or Gallons of

flow depend on the value that you have selected from the following list of optional values (you can define the X value): 1,

10, 100, 1000, 10000, 100000. An electrical pulse will be generated whenever the relay total flow value will be larger than

the value selected from the list. You can also choose a pulse width between 20 to 2000 milliseconds with a resolution of

10 milliseconds to match your equipment requirements. For example, the relay will generate a pulse with a duration of

1000ms and each time the value of flow will reach 10,000 M^3 (provided that this value was selected from the optional list

of values).

Move to Relay #4, then press ENT.

Choose Err En to enable error alert;

Choose Err dS to disable error alert.

NOTES: Prior to setting Relay #5 for pulse indication, you should configure the SmartScan for Totalization (see

Additional Features Section later in this manual).

To configure Relays #4 and #5 to work in a normal setup, select OPEN or CLOSE mode and enter the required

parameters. When configuring Relay #5 as tOt En (Totalize Enable), the active options are tOt En and tOt dS

(Totalize Disable). To go back to normal work press tOt dS.

The result of the totalization amount is updated every 30 seconds.

Press / Action Display Description

or and

Move to Relay #4, then press ENT.

Choose tOt En to enable Totalization Pulse;

Choose tOt dS to disable Totalization Pulse.

If the selected Measurement Unit is M3/HR, then in the example above a pulse with a duration of 1000milli-seconds

(msec), will occur every 10,000m3. If the elected Measurement Unit is G.P.M., then a pulse with a duration of 1000msec,

will occur every 10,000 Gallons.

Page 16

Select a pulse value from the list of optional

values. Use the BACK and NEXT buttons to

highlight the option. Press ENT to select.

Select a pulse width from the list of optional

values. Use the BACK and NEXT buttons to

highlight the option. Press ENT to select.

Page 17

Setting the 20mA and 4mA Values

Process

Media

r

Tank

Span

Dead Zone

SmartSonic enables you to set Distance, Level, Volume or Flow values to be used as 20mA and 4mA settings. The

default value for 20mA is the Tank Height (or the maximum Volume value), and the default value for 4mA is 0 (or the

minimum Volume value).

NOTES: The values for 20 mA and 4 mA must be different, otherwise an Err. 4 message is displayed. Both must also be

less than the tank height value, otherwise an Err. 7 message is displayed.

In both distance and level measurement modes, the dead-zone area affects the maximum values that can be

used for 20 mA/4 mA levels. The maximum 20 mA/4 mA value is tank height minus 0.4 m/1.3 ft.

Press / Action Display Description

or and

Move to 20mA (flashing). Press ENT.

Displays the default value, or the previously

entered value.

and

then

Used to select the desired value. Press ENT

when finished.

This puts you in the 4mA Mode. Repeat the

previous two steps. Then press NEXT to go to

Flow Measurements.

Setting the Open Channel Flow Measurements

The PARSH.FLUME function enables you to set flume/weir types and measurements for the SmartSonic. See the section

titled “Open Channel Flow Measurement” later in this manual for further information.

Setting the Tank Height

You can enter the height of your tank using the TANK h function. The default value is 39.4 feet. If you enter a value that

exceeds this maximum value, an Err. 8 error message is displayed.

Dead Zone

● Minimum – 1.3ft.

Measurement Range

● Maximum Span –

38.1ft.

Tank Height

● Maximum – 39.4ft.

Ai

Height

Page 17

Page 18

NOTES: Whenever the tank height is required, you should enter the distance from the face of the sensor to the bottom of

the tank. In order to obtain accurate measurement results it is most recommended to perform this operation

when the tank is empty. For flow measurement, enter the precise flume height.

If the entered tank height value is less than a value previously entered for the 4 mA, 20 mA or Relay functions,

the value for that function will automatically revert to the default value.

Press / Action Display Description

or

Move to TANK h (flashing).

Displays the default value, or the previously

entered value.

and

Setting the Application Type

This displays the application function of the transmitter. Either Liquid (Level / Distance mode) or Flow (Flow Mode).

Setting the Operation Mode

The Operation Mode function enables you to set SmartSonic Remote to compensate for environmental conditions that

affect the measurement readings.

For liquid applications, each mode determines the reaction time required for SmartSonic Remote to recalibrate when there

is a change in the environmental conditions. Depending on the specific requirements for your application, you can select a

mode that provides faster readings but with less precision (by performing a smaller number of calculations per cycle), or

slower readings with a greater degree of accuracy (by performing a larger number of calculations per cycle).

Three modes are available for SmartSonic Remote. Each mode is recommended for use as follows:

F : Recommended in the following conditions:

v Level/Distance Change: 0 – 0.65 ft/sec

v Wavy surfaces

v Slow filling/emptying rate

v Applications where the sensor is installed near the tank wall

Used to select the desired value. Press ENT

when finished.

v Level/Distance Change: 0 – 1.3 ft/sec

v Wavy surfaces

v Slow filling/emptying rate

v Applications where the sensor is installed near the tank wall

F : This mode is suitable for applications where a fast reading is more important than

precision. A reading will be displayed within a short time, even if the signal processing

procedure was not completed.

F

Recommended in the following conditions:

v Level/Distance Rate Change: 0 – 3.3 ft/sec

v Foamy top surface

v Presence of agitation

v Presence of vapor

v Applications requiring very fast readings

: (Twice as fast as STORAGE I): Recommended in the following conditions:

Page 18

Page 19

NOTE: STORAGE I and STORAGE II are not suitable for measuring liquids containing foam, since these

modes cannot perform signal processing.

The operation modes are not relevant for flow applications. If one of the STORAGE I, STORAGE II or

PROCESS options is selected when SmartScan is in FLOW application mode, an warning

message is displayed and SmartScan reverts to distance mode. You must then reset the unit to flow

mode.

Press / Action Display Description

or

Move to STORAGE I (flashing). Select one of

the three modes: (STORAGE I, STORAGE II,

PROCESS)

Setting the Sensor Offset

SmartSonic Remote takes measurements from the tip of the sensor. However, when the sensor is located at a point that

is above or below the true height of the tank, you can use the MAN function to enter the difference. This may be required,

for example, if the sensor is installed at the top of an external pipe, or at the base of an internal pipe in the tank.

When the sensor is located above the tank height, the difference must be subtracted from the actual measurements, so

the offset distance is entered as a negative value and vise versa. The maximum permitted offset value is 2.0 m and the

minimum permitted value is -2.0 m. Values can be entered in meter units only.

Press / Action Display Description

or

Displays the desired value (flashing). Press

ENT to select.

Move to MAN (flashing).

Displays the default value, or the previously

entered value.

or

and

Or

Toggle the first digit between Positive (0) or

Negative (-)

Press ENT to select the value from the

previous step

Continue to enter new values for the five

remaining digits.

Page 19

Page 20

Setting the Scan Distance Values (False Targets)

Up to eight interfering signals (false echoes) can be located by SmartSonic Remote and stored in its memory. The false

echoes, which may be caused by obstructions such as a tank agitator or a side wall, can generate false readings and so

interfere with the true scanning of the tank contents. Defining interfering signals is done while the tank is empty.

Each scan distance reading is stored as an interfering signal until a reading is achieved that indicates the true echo. If

eight interfering signals are already stored and a ninth reading is received, the first value stored is deleted and the new

one saved.

The scan distance function is accessed from the default screen. AUTO. CAL is displayed at the base of the display

screen during the scan distance operation, indicating that you are working in scan distance mode.

NOTE: The reading of the actual target height may not be exact; for example, a target height of 6 feet may give a

reading of 5.998.

Page 20

Page 21

Press / Action Display Description

or

Move to AUTO CAL (flashing).

and simultaneously

Displays while the SmartSonic Remote

searches for a False Target

For Example:

Displays the first target. If this is not the

distance to the process fluid, or bottom of the

tank, press NEXT

Wait a few seconds

For Example:

Displays the next target. If this is the distance

to the process fluid, or bottom of the tank,

press ENT

Saves the true level (echo) value, and

completes the Scan Distance Function (AUTO

CAL)

NOTE: Pressing the NEXT button saves the false target distance. Pressing the ENT button saves the true target (level)

value and exits the AUTO CAL function

Clearing Scan Distance Values

The AUTO function allows you to clear all of the false targets set using the AUTO CAL function (last section)

Press / Action Display Description

Move to AUTO

or

Clears the False Targets from memory

Page 21

Page 22

OPEN CHANNEL FLOW MEASUREMENT

and

This section describes how to set the flow measurement parameters for Open Channel Flow measurement. It also covers

the flume/weir codes used when selecting the flume or weir of your application.

The PARSH.FLUM function in the main menu enables you to select one of the preset flumes/weirs settings for flow

measurements.

When setting flow-measurement parameters, the flume/weir type value (X) is entered first, followed by the letter (U) or (E)

as an indication for American or European open channel flow standard and followed by the code value (FF) that

represents the appropriate flume/weir dimensions, in the following format: . The default is European standard. The

open channel types and codes are described in later in this section.

If you wish to insert custom flume measurements, you must enter 0.E (or U) 01 for this function. This entry will

automatically initiate an additional menu function (Pr 1), enabling manual insertion of custom flume values in an

accordance table, as described in the section titled Additional Features.

Change from European to U.S. Flume Styles

The default setting for Flumes and Weirs is European. To use the U.S. style Flumes and Weirs, perform the following

procedure:

Press / Action Display Description

and simultaneously

Flashes for 5

and simultaneously

Flashes for 5

seconds, then is

displayed

seconds

000.000

This is the password display

Use to enter the password (716) in place of

(000). BACK and NEXT will change the value

of the digit (0-9). ENT steps to the next digit;

ESC steps to the previous digit.

Single Sensor (only available option).

Press ENT.

The main screen (Page #7) is now displayed.

DISTRIBUTOR MODE

and

and

000.001

600.001

Change display to 000.001. Press ENT

Change display to 600.001. Press ENT then

Press ESC. You are now set to select U.S.

style Flumes & Weirs. Follow the directions in

the following section.

Page 22

Page 23

The flume/weir type code methodology used when setting up open channels is based on three digits: X .(E/U) FF

Where:

X refers to the particular flume/weir type

E/U refers to European or American standard

FF refers to the specific flume/weir dimensions

Press / Action Display Description

or

0.U01

Move to PARSH.FLUM (flashing).

Displays the default value, or the previously

entered value.

and

Code

(X)

1

Rectangular Suppressed Sharp-Crested Weir (24) Rectangular Suppressed Sharp-Crested Weir (27)

2

Rectangular Contracted Sharp-Crested Weir (24) Rectangular Contracted Sharp-Crested Weir (27)

3

Trapezoidal (Cipolletti) Sharp-Crested Weir (24) Trapezoidal (Cipolletti) Sharp-Crested Weir (27)

4

V-notch (Triangular) Sharp-Crested Weir (25) V-notch (Triangular) Sharp-Crested Weir (28)

5

Parshall Flume (25) Khafagi-Venturi Flume (28)

6

Palmer-Bowlus Flume (25) Parshall Flume (28)

7

H-Flume (26) Palmer-Bowlus Flume (29)

8

Leopold-Lagco Flume (26) H-Flume (29)

9

NONE Neyrpic-Venturi Flume / Long Base Weir (29)

U.S Standard (Page #) European (Page #)

Used to select the desired value. See table

below to find the desired flow device. Press

ENT when finished.

Page 23

Page 24

Flumes / Weirs – U.S. Standard (dimensions are in inches unless otherwise indicated)

Type 1 (X) – Rectangular Suppressed Sharp-Crested Weir

Type 2 (X) – Rectangular Contracted Sharp-Crested Weir

Type 3 (X) – Trapezoidal (Cipolletti) Sharp-Crested Weir

Code (FF) Crest Length

01 12.00

02 18.00

03 24.00

04 30.00

05 36.00

06 48.00

07 60.00

08 72.00

09 96.00

Code (FF) Crest Length

01 12.00

02 18.00

03 24.00

04 30.00

05 36.00

06 48.00

07 60.00

08 72.00

09 96.00

Code (FF) Crest Length

01 12.00

02 18.00

03 24.00

04 30.00

05 36.00

06 48.00

07 60.00

08 72.00

09 96.00

Page 24

Page 25

Type 4 (X) – V-notch (Triangular) Sharp-Crested Weir

Type 5 (X) - Parshall Flume

Code (FF)

01 1 09 30

02 2 10 36

03 3 11 48

04 6 12 60

05 9 13 72

06 12 14 96

07 18 15 120

08 24 16 144

Type 6 (X) – Palmer-Bowlus Flume

Code (FF) V-notch Angle

01 90º

02 60º

03 45º

04 30º

05 22.5º

Throat

Width

Code (FF)

Throat

Width

Code (FF)

Conduit

Diameter

Code (FF)

Throat

Width

01 4 09 24

02 6 10 27

03 8 11 30

04 10 12 36

05 12 13 42

06 15 14 48

07 18 15 60

08 21 16 72

Page 25

Page 26

Type 7 (X) – H-Flume

Type 8 (X) – Leopold-Lagco Flume

Code (FF)

Flume

Size

Measurement

01 6 1.96

02 9 2.75

03 12 3.54

04 18 5.51

05 24 7.08

06 30 9.05

07 36 11.02

08 54 16.14

Code (FF)

Crest

Length

Code (FF)

01 4 10 30

02 6 11 36

03 8 12 42

04 10 13 48

05 12 14 54

06 15 15 60

07 18 16 66

08 21 17 72

09 24

Point

Crest

Length

Page 26

Page 27

Flumes / Weirs – European (dimensions are in centimeters unless otherwise indicated)

Type 1 (X) – Rectangular Suppressed Sharp-Crested Weir

Code (FF) Crest Length

01 20

02 40

03 60

04 80

05 100

06 150

07 200

08 300

Type 2 (X) – Rectangular Contracted Sharp-Crested Weir

Code (FF) Crest Length

01 20

02 30

03 40

04 50

05 60

06 80

07 100

08 150

09 200

10 300

Type 3 (X) – Trapezoidal (Cipolletti) Sharp-Crested Weir

Code (FF) Crest Length

01 30

02 45

03 60

04 80

05 100

06 150

07 200

08 300

Page 27

Page 28

Type 4 (X) – V-notch (Triangular) Sharp-Crested Weir

Type 5 (X) – Khafagi-Venturi Flume

Type 6 (X) – Parshall Flume

Code (FF) V-notch Angle

01 90º

02 60º

03 53.8º

04 45º

05 30º

06 28.4º

07 22.5º

British Standard

08 90º

09 45º

10 22.5º

Code (FF)

01 QV 302 12

02 QV 303 30

03 QV 304 40

04 QV 305 50

05 QV 306 60

06 QV 308 80

07 QV 310 100

08 QV 313 130

09 QV 316 160

Flume

Type

b0

Code (FF)

01 1 09 36

02 2 10 48

03 3 11 60

04 6 12 72

05 9 13 96

06 12 14 120

07 18 15 144

08 24

Page 28

Throat

Width (in)

Code (FF)

Throat

Width (in)

Page 29

Type 7 (X) – Palmer-Bowlus Flume

Type 8 (X) – H-Flume

Type 9 (X) – Neyrpic-Venturi Flume / Long Base Weir

Code (FF)

Code (FF)

01 1253AX 06 1253C

02 1253AY 07 1253D

03 1253AZ 08 1253E

04 1253A 09 1253F

05 1253B

Code (FF)

Conduit

Diameter (in)

01 6

02 8

03 10

04 12

05 15

06 18

07 21

08 24

09 27

10 30

Code (FF)

01 6 5

02

03

04

05

06

07

08 54 41

Flume

Type

Long Base Weir

10 1245A

11 1245B

12 1245C

13 1245D

Code (FF)

Conduit

Diameter (in)

Flume

Size (in)

9

12

18

24

30

36

Measurement

Point (cm)

7

9

14

18

23

28

Flume

Type

Page 29

Page 30

ADDITIONAL FEATURES

and

This section describes the functions available in SmartSonic Remote's additional menu. The additional menu functions

enable you to calibrate SmartScan to perform the following tasks:

• Display Values in volume format.

• Display Values as a total accumulative value for flow.

• Calculate volume for different tank types.

• Calculate flow measurements for custom flumes.

• Calculate results in alternative measurement units.

• Adjust results when there is interference from a conical tank ending.

• Allow compensation of different types of gas.

Press / Action Display Description

The SmartSonic takes several seconds to

Connect SmartSonic to power supply See Wiring Section

and simultaneously

warm-up. During this time various characters

will turn on and off, and the Tank Graphic will

cycle

This is the password display

Use to enter the password (716) in place of

(000). BACK and NEXT will change the vlue of

the digit (0-9). ENT steps to the next digit; ESC

steps to the previous digit.

Single Sensor (only available option).

Flashes for 5

seconds, then is

displayed

Is now displayed

Flashes for 5

seconds

or

NOTE: Press ESC once to return to the Main Menu. Press ESC a second time to return to the normal operating mode.

Pr 0 is now displayed.

Use BACK or NEXT to scroll through the other

menu options (described later in this section)

Page 30

Page 31

Selecting an Indication Mode

Using function Pr 0, you can modify the SmartScan default display to show indications for volume, total flow or diameter

sum. Select the required indication mode, as follows:

F Ind 1: Volume mode: The default screen indicates the volume reading, by means of a value displayed

in the numerical area and the level of the tank graphic.

NOTE: When this mode is selected, you can use Pr 1 or Pr 2 to customize volume measurement

Pr 0 – Selecting an Indication Mode 31

Pr 1 – Manually Inserting Strapping Table Values 32

Pr 2 – Semi-automatic Inserting Strapping Table Values 33

Pr 3 – Entering a Coefficient for Readings 34

Pr 4 – Erasing Strapping Table Values 34

Pr 5 – Configuring Height for a Cone Bottom Tank 35

Pr 6 – Defining the 4-20mA Error Signal (3.7mA or 22mA) 36

(see the next two sections in this manual).

Functions Page

F Ind 2: Totalization for flow mode: The default screen indicates the value for total accumulative flow,

calculated from the point of entering the mode, and updated every 30

seconds.

F The total amount of flow is shown as a nine-digits value in two

separate screens: high and low. The high digits are indicated by an

H, followed by the first five digits of the value; the low digits are

indicated by an L, followed by the last four digits of the value. You

can toggle between the high and low screens using the NEXT and

BACK buttons (there is no level indication in the tank graphic for this

mode.)

F In addition, you can toggle between level, distance and flow values

using the same buttons. There are three options available in this

mode that allows you to, either reset the totalization counter, activate

it or deactivate it. Use the NEXT and BACK buttons to toggle

between options, and ENT. to select the desired option:

• 0: Resets the totalization value

• 1: Activates the totalization mode

• 2: Deactivates the totalization mode

Press / Action Display Description

Indication Mode Program (Pr 0)

or then

Page 31

Displays an Indication Option (Ind. 1 or Ind. 2)

Select Indication Option. DO NOT SELECT

(Ind. 3)

Page 32

Manually Inserting Strapping Table Values

The Pr 1 function enables you to manually create a strapping table of distance points for either volume calculations or

custom flume measurements.

The strapping table is used for manual insertion of distance/volume values when IND 1 was selected as the value for Pr 0,

Manual insertion is applicable when the ratio between the distance and volume of the tank is known or for applications

such as custom-shaped tanks. Up to 24 linear points can be entered in the strapping table, starting from the smallest

distance and largest volume for point 1 (which is the closest point to the sensor). The distance should increase and the

volume decrease with each subsequent entry.

The strapping table automatically enters custom flume mode after .001 is entered as the PARSH.FLUM value in the main

menu. In this mode, the table is used to manually insert up to 24 distance/custom flume measurement values, in the

same way as for distance/volume values. Any custom flume measurement can be entered, as long as the maximal value

entered is the measurement of the distance between the sensor and the flume.

NOTE: You can exit Pr 1 at any time by pressing the ESC button. However, it is recommended that you enter at least 8

points for this function. Values are entered in DISTANCE or LEVEL units.

When working in custom flume mode, exiting Pr 1 returns you to the main menu

Press / Action Display Description

Manually Inserting Strapping Table Values

program

Setup for the first point

and

and

For Example:

DIST or LEVEL

and

Displays 000.000 or previously stored value

Change the digits (000.000) to equal the

desired DIST or LEVEL value.

Displays 000000 (no decimal place)or

previously stored value

Displays 000000 or the previously saved

volume value/custom flume measurement.

Using the buttons as described for the DIST or

LEVEL value (above), enter up to six

pre-decimal point digits to represent the value

that corresponds to the entered distance.

The last three digits entered in the previous

step are displayed before the decimal point.

Using the buttons, you can enter one digit after

the decimal point.

Page 32

Setup for the second point. Repeat the

previous steps to enter at least 8 points. Press

ESC to exit.

Page 33

Semi-automatic Inserting Strapping Table Values

The Pr 2 function enables you to create a strapping table for distance/volume values using distance values measured

automatically by SmartScan, rather than entered manually as described in the previous section. This method enables

more accurate volume indications than the manual method, but entails slower calibration due to the need for additional

instruments, such as a flow meter.

This function should be started when the tank is full, so that point 1 (P 1) is calculated for the smallest distance/highest

volume. The subsequent points are calculated as the tank empties.

NOTE: You can exit Pr 2 at any stage by pressing the ESC button. However, it is recommended that you first enter at

least eight points for the function. The same strapping table is used for functions PR 1 and Pr 2. Any change

made to either of the functions will be applied to the one mutual table. A minimum of (8) strapping points should

be entered into the table to make accurate readings. Maximal number of strapping points to be entered is

twenty-four (24).

Press / Action Display Description

Semi-automatic Inserting Strapping Table

Values program

Setup for the first point

For Example:

and

For Example:

NOTE: 4-20mA parameters in volume mode are identical to the volume values entered in the strapping table.

DIST or LEVEL

and

Displays 000.000 or previously stored value

Displays the current DIST or LEVEL

measurement of the SmartSonic Remote

Displays 000000 (no decimal place)or

previously stored value

Using the buttons as described for the DIST or

LEVEL value (above), enter up to six

pre-decimal point digits to represent the value

that corresponds to the entered distance.

The last three digits entered in the previous

step are displayed before the decimal point.

Using the buttons, you can enter one digit after

the decimal point.

Setup for the second point. Repeat the

previous steps to enter at least 8 points. Press

ESC to exit.

Page 33

Page 34

Entering a Coefficient for Readings

Then

The Pr 3 function enables you to enter a coefficient value, K, which can be used for three different options. For each

option, the entered K value is used by SmartScan in the following formula: Y = K(X)

F The variables represent the following values:

• Y = Result according to the new measurement unit

• K = The factor difference between the previous measurement unit and the current unit

• X = Result according to the previous unit (such as meters, feet or inches)

Press / Action Display Description

Entering a Coefficient for Readings program

Displays the default K value

Use to enter a K value from 0.001 to 99.999

and

Press ENT to select the value you entered from

the previous step.

Erasing Strapping Table Values

The Pr 4 function erases all values entered in the strapping table using functions Pr 1 or Pr 2,

Press / Action Display Description

Erasing Strapping Table Values program

Displays the default K value Then

After the points are erased, the display returns

to Pr 4.

Page 34

Page 35

Configuring Height for a Cone Bottom Tank

The Pr 5 function enables you to enter the cone height for tanks that have a conical base. This may be required if you are

unable to mount the sensor at the center of the tank, or if the cone is causing false echoes and consequently faulty

measurements. The entered cone height value can be from a minimum of 000.000 (the default value) up to a maximum of

half the tank height value.

NOTE: An Err. 1 message is displayed if the cone height (h) is more than halt the Tank Height (H) value.

Press / Action Display Description

Configuring Height for a Cone Bottom Tank

program

and

Displays the default value (shown) or the last

entered value.

Use to enter the cone height value

Page 35

Press ENT to select the value you entered from

the previous step.

Page 36

Defining the 4-20mA Error Signal (3.7mA or 22mA)

The Pr 6 function allows you to define whether the following signal error indications Near Zone and Lost Echo will be

active when the current output reaches 22mA or 3.7mA. The SmartScan default setting enables 22mA analog current and

error messages to appear on its LCD display.

Near Zone - Whenever the level is below the defined Dead Zone message will be displayed on the

SmartSonic Remote's LCD.

Lost Echo - whenever the level falls below the programmed 4mA value, or if the echo is lost, message

will be displayed on the SmartSonic Remote's LCD.

Tank Empty – whenever the tank is empty or when the measured distance is higher than the tank height.

(typically in empty tanks with conic ending), message will be displayed on the SmartSonic Remote's

LCD.

You can choose to enable or disable these error messages and 3.7mA/22mA analog signals as follows:

• 0: Enables 22mA signal error messages

• 1: Enables 3.7mA signal error messages

• 2: Disables signal error messages

Press / Action Display Description

Defining the 4-20mA Error Signal (3.7mA or

22mA) program

and

Displays the default value or the last entered

value.

Use to select between options 0, 1, or 2. Press

ENT to select

Page 36

Page 37

TROUBLESHOOTING

This chapter describes the error messages displayed when an illegal value is entered for a SmartSonic Remote function.

If an illegal value is entered, the appropriate error message is displayed flashing while the level of the tank graphic on the

bottom-right of the screen moves up from 0 to 100%. The numerical area then displays , enabling you to enter a

new value for the function. If an illegal option is selected, an error message is displayed while the tank graphic fills, and

the display then reverts to the menu selection.

The possible error messages are as follows:

If the following information does not lead to a resolution of the problem, contact Kenco for assistance.

Error

Description

The value entered is greater than the

maximum permitted value.

The value entered is less than the

minimum permitted value.

The Close value entered for a relay is

greater than the Open value entered

for the relay.

The value entered for 4 mA is equal

to the value entered for 20 mA.

The selected function/option is not

applicable for the SmartScan model in

use.

The value entered for the 20 mA, 4

mA or Relay function is greater than

the tank height.

The value entered for the tank height

is greater than the maximum value

supported by the SmartScan model in

use.

The measurement unit selected is not

applicable for the SmartScan model in

use.

The Open value entered for the relay

is greater than the Close value

entered for the relay (in Distance

mode).

A strapping table was not entered

under volume mode or a flume/weir

type was not entered under flow

mode.

The value entered for the tank height

is smaller than the actual height, as

measured by SmartScan.

If displayed at the base of the display

screen, this indicates a problem with

the current procedure, for example,

acoustic interference.

Page 37

Loading...

Loading...