Page 1

KENCO ENGINEERING COMPANY

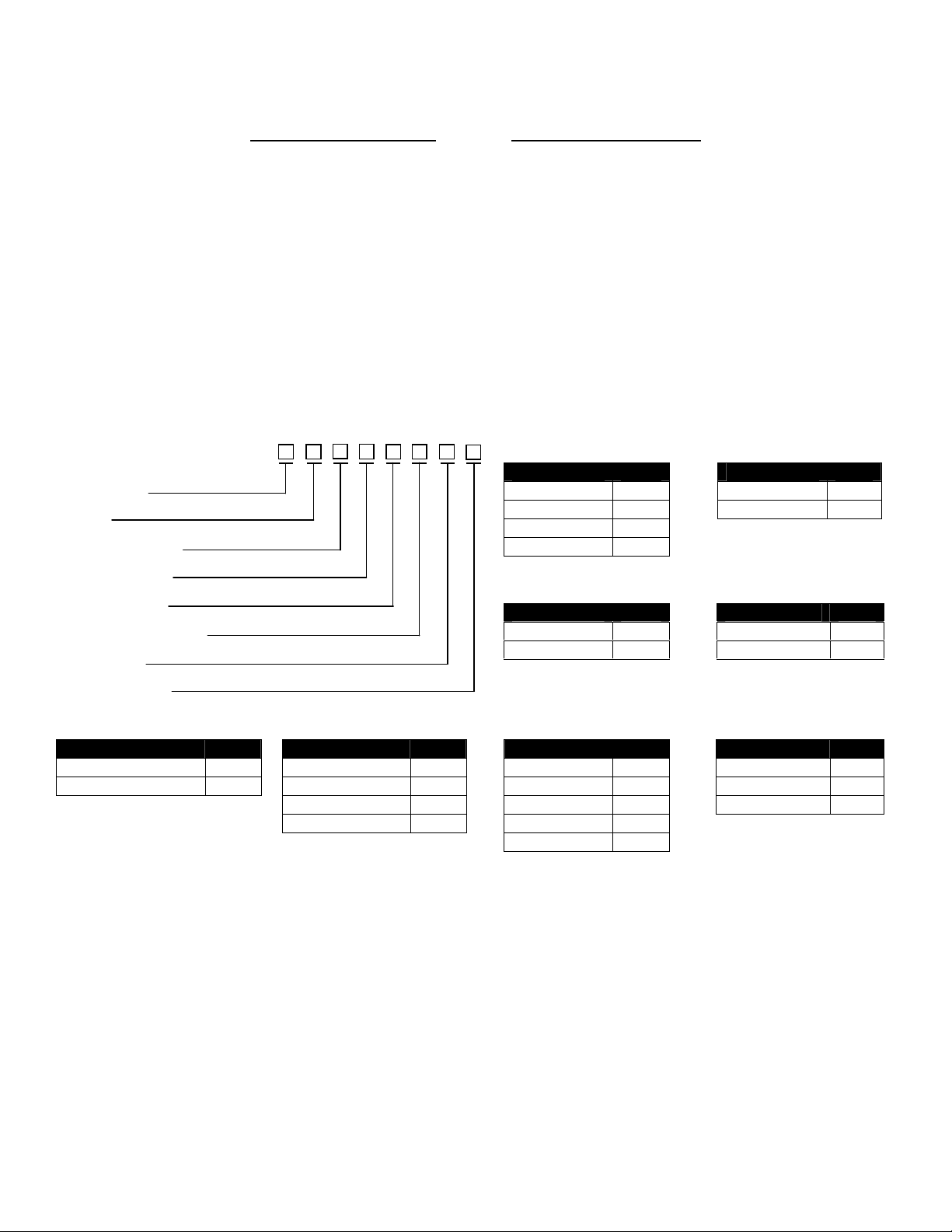

Sensor Length

Process Connection

Flange Size

Flange Material

Input Power

Output

P.O. BOX 470426 TULSA, OK 74147-0426 ● PHONE: (918) 663-4406 FAX: (918) 663-4406

www.kenco-eng.com e-mail: info@kenco-eng.com

MODEL KUST ULTRASONIC SWITCH

INSTALLATION / OPERATION INSTRUCTIONS

GENERAL DESCRIPTION

The KUST Series Ultrasonic Level Switches are ideal, low cost solutions for many liquid level control applications. They

operate in a wide variety of services.

PRINCIPLE OF OPERATION

Ultrasonic switches use piezoelectric crystals to transform electrical energy into mechanical motion (sound). The

Transmit Crystal sends a pulse of sound through the space between the crystals, to the Receive Crystal. If the space is

filled with air, gas, or vacuum, the Receive Crystal does not detect the sound pulse. However, if the space is filled with

liquid, any liquid, the pulse is detected by the Receive Crystal, and the switch output changes.

MODEL DESCRIPTION

Input Power

Output

Switch Mounting

Sensor Material

Sensor Length

Process Connection

Flange Size

KUST - - - - - - - -

Flange Material

Description Code Description Code Description Code Description Code

Standard (2.25”) 00 ¾” NPT 1 None None

*Inches (3” – 120”) xxx 150# Flange F 1-1/2” 0 Carbon Steel A

*316SS Sensor Only 300# Flange H 1 1 316SS S

Sanitary Flange S 2 2

3 3

INSTALLATION

Unpack the switch carefully. Inspect all units for damage. Report any damage to carrier immediately. Check the

contents against the packing slip and purchase order.

Kenco’s Ultrasonic Switches are manufactured to the highest quality standards. These switches use electronic

components that can be damaged by static electricity. Make sure that you are properly grounded before starting

installation. Insure that all electrical connections are properly made, and that there are no “floating” connections.

Description Code Description Code

115Vac 1 10A DPDT 1

230Vac 2 Two-wire 2

24Vdc 3

12Vdc 4

Switch Mounting Sensor Material

Description Code Description Code

Integral 1 316SS S

*Remote 2 Tefzel® T

*Remote 10ft. (std.)

100ft. (max)

Page 2

Operational Check

DO NOT

vertical allowing

Vessel Wall

Before installing the switch a simple operational check should be performed, as follows:

1. Fill a container with water

2. Open the electronics housing cover and connect power (see section on “Wiring”).

3. Set the Fail Safe jumper to the LLFS position (lower two pins).

4. Apply power

5. Place the sensor gap into the water.

a. Relay Version -- The relay will energize (the contacts between (NC) and (C) should open).

b. 2-wire Version -- The current in the Positive lead will be 20.0mA.

6. Remove the sensor from the liquid.

a. Relay Version – The relay will de-energize (the contacts between (NC) and (C) should close).

b. 2-wire Version – The current in the Positive lead will be 4.0mA.

7. Disconnect the wiring.

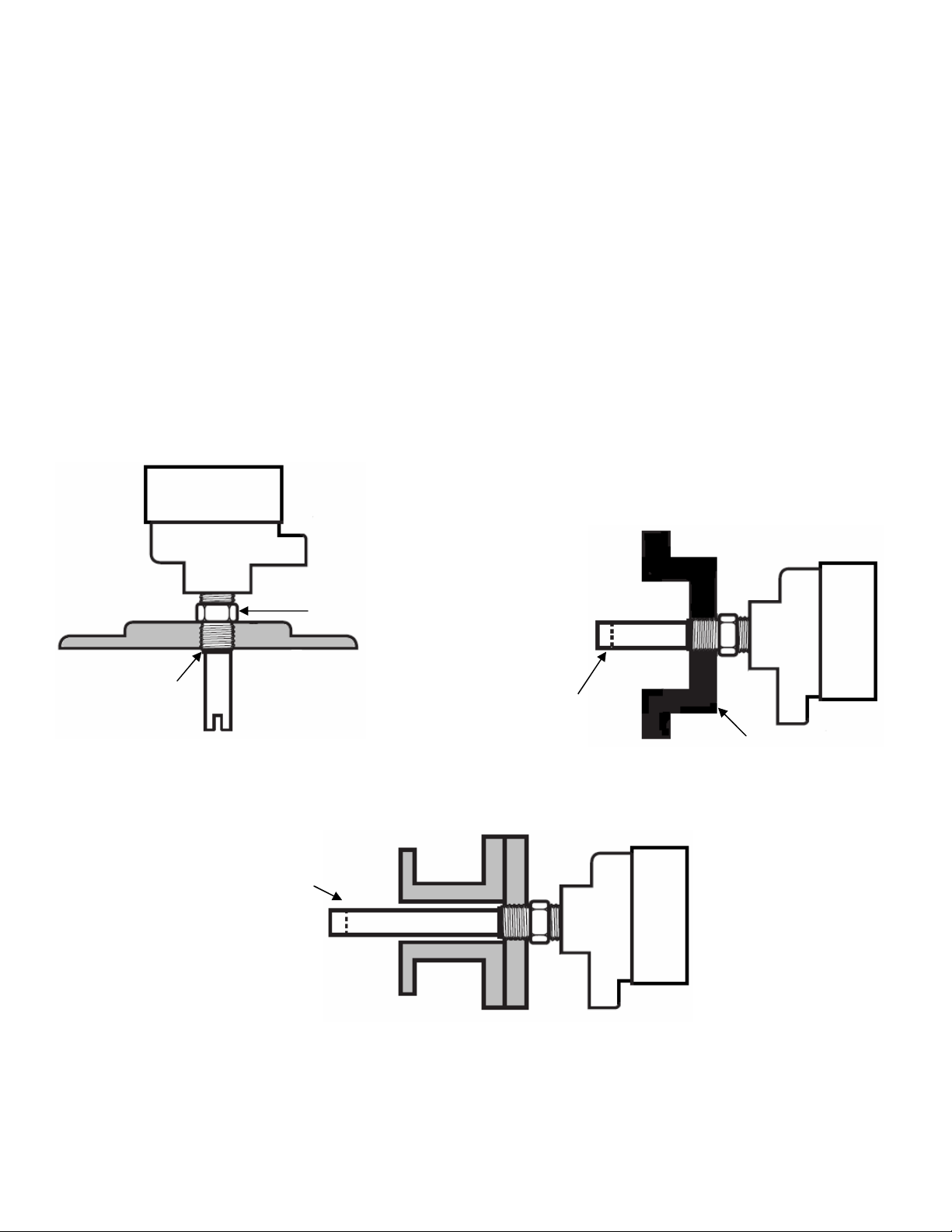

Mounting

For threaded process connections, screw sensor into the opening using a wrench on the sensor mounting nut flats. Use

thread tape or suitable pipe compound on the threads. If flanged, bolt the sensor to the mating flange with the proper

gasket.

The sensor gap must protrude into the vessel / pipe being measured. The sensor will not function properly if the detection

tip is in a nozzle. See the following drawings for mounting guidelines:

housing to

tighten sensor

use

Use wrench here

¾” NPT

Turn slot

media to fall

through

Slot must

extend at least

1” (25mm)

beyond end of

nozzle

Wiring

It is recommended that conduit be installed onto the ¾” NPT connection on the electronics housing. A seal drain fitting

should be used to prevent moisture from entering the switch. All wiring, conduit, and electrical fittings must conform to

local electrical codes for the location selected. If the switch is to be used in a Hazardous Area, the applicable codes of the

National Electrical Code must be followed as well.

Page 3

Relay Version

1. Connect power wiring

a. AC – Hot (L2), Neutral (L2),

and Ground (G)

b. DC – Positive (L1), Negative (G)

2. Connect relay wiring (see diagram)

3. Adjust failsafe jumper

a. HLFS – top (2) pins

b. LLFS – bottom (2) pins

2-Wire Version

1. Connect the power wires as shown in the diagram.

2. Measure the current in the positive lead

a. Dry = 4.0mA

b. Wet = 20.0mA

Specifications

Description Specification

Input Power

Output

Temperature Range

Pressure Range

Sensitivity (Signal-to-noise Ratio) 500:1

Repeatability ±2mm

Response Time (on Alarm) 0.5 sec. non-adjustable

Jumper

High Level Failsafe

(HLFS)

Low Level Failsafe

(LLFS)

Coaxial Cable

To Sensor

Coaxial Cable

To Sensor

{

AC 115Vac or 230Vac; 50/60Hz

DC 12 or 24Vdc

DC (Two-Wire) 9-30Vdc

Relay 10A DPDT

Two-wire (Isolated) 4mA = Dry; 20mA = Wet

Switch -20°F to 170°F

Sensor -40°F to 300°F

316SS Vacuum to 1000psig

Tefzel® Vacuum to 100psig

{

Level

Setpoint

Setpoint

4 or 20mA

- +

GL2L1NCCNONCCNO

+

12 or 24Vdc

}

-

115Vac or 230Vac

}

50/60 Hz

Fail Safe

Setting

HLFS De-Energized Closed Open Above

LLFS Energized Open Closed

HLFS Energized Open Closed Below

LLFS De-Energized Closed Open

Condition

9-30Vdc

}

Relay

Relay Terminals Media

NC to C NO to C

Page 4

TROUBLESHOOTING

Entity Parameters:

NOTES:

Problem Solution

No output change with level change

The output is “chattering”

INTRINSICALLY SAFE CONTROL DRAWING

Check wiring; verify that the correct input

voltage is applied

Verify that liquid is filling the sensor gap

Check for dense foam or dried product in

the gap. Switch may not function properly

if either condition exists.

Check sensor phono plugs for a good

connection. Unplug and Re-plug each

connection.

Check for excessive aeration in process

fluid. This is particularly important in

viscous fluids.

Check wiring; verify that the correct input

voltage is applied

Check for turbulence. Relocate switch or

isolate from turbulence

Check for excessive aeration in process

fluid. This is particularly important in

viscous fluids.

Vmax = 36Vdc

Imax = 150mA

Ci = 0µF

Li = 54µH

1) Vmax > Voc; Imax > Isc; Ci + Ccable < Ca; Li + Lcable < La

2) Dust-tight conduit seal must be used when installed in Class II and Class III environments.

3) Control equipment connected to barrier must not use or generate more than 250V.

4) Installation should be in accordance with the CEC, Part 1.

5) No revision to drawing without prior CSA approval.

6) Associated equipment must be CSA Certified.

7) Associated equipment manufacturer’s installation drawing must be followed when installing this equipment.

8) For wiring refer to installation / operation manual.

Loading...

Loading...